LT-2D3D

User Manual v2.12

Edited: August 19, 2016

2 | P a g e

Table of Contents

1.0 Jobsite Setup .................................................................................................................................... 6

1.1 LT-2D3D Setup ............................................................................................................................. 6

1.2 LT-2D3D Jobsite Setup ................................................................................................................ 6

2.0 Using The Laser Templator Software ............................................................................................. 7

2.1 Help ............................................................................................................................................. 7

2.1.1 Check for Updates ..................................................................................................................................7

2.1.2 Import/Export Settings...........................................................................................................................7

2.1.3 Manual ...................................................................................................................................................7

2.1.4 About......................................................................................................................................................7

2.1.5 View Changes .........................................................................................................................................7

2.1.6 Tips .........................................................................................................................................................8

2.1.7 Setup Device ..........................................................................................................................................8

2.2 New ............................................................................................................................................. 8

2.3 Open ............................................................................................................................................ 8

2.3.1 Hard Drive ..............................................................................................................................................8

2.3.2 Drop-In ...................................................................................................................................................8

2.3.3 Auto Save ...............................................................................................................................................8

2.3.4 Other (Advanced) ...................................................................................................................................9

2.3.5 Drive Info ................................................................................................................................................9

2.4 Import/Export ............................................................................................................................. 9

2.4.1 Estimate .................................................................................................................................................9

2.4.2 PDF (Print) ............................................................................................................................................ 10

2.4.3 Shop Sheet ........................................................................................................................................... 11

2.4.4 Email ..................................................................................................................................................... 11

2.4.5 Upload to Job Tracker .......................................................................................................................... 11

2.4.6 Import Job Tracker Data ....................................................................................................................... 12

2.5 Save ........................................................................................................................................... 12

2.6 Save As ...................................................................................................................................... 12

2.6.1 Hard Drive ............................................................................................................................................ 12

2.6.2 Drop-In ................................................................................................................................................. 12

2.6.3 Other (Advanced) ................................................................................................................................. 13

2.6.4 Drive Info .............................................................................................................................................. 13

2.7 Exit ............................................................................................................................................. 13

2.8 Connect To Laser ....................................................................................................................... 13

2.9 Options ...................................................................................................................................... 14

2.9.1 General Settings ................................................................................................................................... 14

Save Settings ...................................................................................................................................................... 14

Print Settings ...................................................................................................................................................... 15

Drawing Display Settings .................................................................................................................................... 15

Job Details Settings ............................................................................................................................................. 15

Miscellaneous Settings ................................ ................................................................ ................................ ....... 16

Job Tracker Settings............................................................................................................................................ 16

2.9.2 Estimate Settings .................................................................................................................................. 16

2.9.3 Quick Actions ....................................................................................................................................... 17

2.9.4 E-Mail Settings ..................................................................................................................................... 17

2.9.5 Advanced.............................................................................................................................................. 19

2.9.6 Shortcuts .............................................................................................................................................. 19

3 | P a g e

2.10 Job Info / Pages ......................................................................................................................... 19

2.10.1 General ............................................................................................................................................ 19

2.10.2 Address ............................................................................................................................................ 19

2.10.3 Dates ............................................................................................................................................... 19

2.10.4 Additional Items .............................................................................................................................. 20

2.10.5 Pages ............................................................................................................................................... 20

2.10.6 Notes ............................................................................................................................................... 21

2.10.7 Agreement ....................................................................................................................................... 21

2.11 Move Circle................................................................................................................................ 21

2.12 Split Line .................................................................................................................................... 21

2.13 Flip / Scale ................................................................................................................................. 22

2.14 Add Photo .................................................................................................................................. 22

2.15 Erase Segment ........................................................................................................................... 22

2.16 Erase All On Page ...................................................................................................................... 23

2.17 Split Object On Point................................................................................................................. 23

2.18 Units .......................................................................................................................................... 23

2.18 Rotate Drawing ......................................................................................................................... 24

2.19 Mirror ........................................................................................................................................ 24

2.20 Object Info ................................................................................................................................. 24

2.21 Circle Diameter.......................................................................................................................... 24

2.22 Display Measured Points .......................................................................................................... 24

2.23 Display Contiguous Breaks ....................................................................................................... 25

2.24 Display Polylines ....................................................................................................................... 25

2.25 Display Color Names ................................................................................................................. 26

2.26 Display Area Legend .................................................................................................................. 26

2.27 Re-Position Laser ....................................................................................................................... 27

2.28 Set Plane .................................................................................................................................... 27

2.29 Offset ......................................................................................................................................... 28

2.29.1 Offset Scribed Wall .......................................................................................................................... 28

2.29.2 Offset Polygon ................................................................................................ ................................ . 28

2.30 Define (0,0) ................................................................................................................................ 28

2.31 Slab Layout ................................................................................................................................ 28

2.32 Backsplash ................................................................................................................................. 30

2.33 Angle .......................................................................................................................................... 30

2.34 Radius ........................................................................................................................................ 30

2.35 Dimensions ................................................................................................................................ 30

2.36 Maximum Dimensions .............................................................................................................. 30

2.37 Text ............................................................................................................................................ 30

2.38 Center Line ................................................................................................................................ 30

4 | P a g e

2.39 Line ............................................................................................................................................ 31

2.40 Arc .............................................................................................................................................. 31

2.41 Circle .......................................................................................................................................... 31

2.42 Circle .......................................................................................................................................... 32

2.43 Ellipse ........................................................................................................................................ 32

2.44 Cross .......................................................................................................................................... 32

2.45 Custom Box ............................................................................................................................... 32

2.46 Menu Bar Functions .................................................................................................................. 33

2.46.1 Laser On ........................................................................................................................................... 33

2.46.2 Start New Line ................................................................................................................................. 33

2.46.3 Laser Off .......................................................................................................................................... 33

2.46.4 Zoom ............................................................................................................................................... 33

2.46.5 Best Fit ............................................................................................................................................. 33

2.47 Laser Mode ................................................................................................................................ 34

2.48 Erase .......................................................................................................................................... 34

2.49 Distance ..................................................................................................................................... 34

2.50 Auto Fillet .................................................................................................................................. 34

2.51 Fillet ........................................................................................................................................... 34

2.52 Offset ......................................................................................................................................... 35

2.53 Rotate ........................................................................................................................................ 35

2.54 Extend ........................................................................................................................................ 36

2.55 Draw Segment ........................................................................................................................... 36

2.56 Dimensions ................................................................................................................................ 36

2.57 Color .......................................................................................................................................... 36

2.58 Drop-In ...................................................................................................................................... 37

2.59 Quick Action .............................................................................................................................. 37

2.60 Undo .......................................................................................................................................... 37

2.61 Redo ................................................................................................................................ 37

3.0 Bluetooth Pairing ................................................................................................................. 38

3.1 Pair Laser to the Tablet PC (Pre-February, 2016) ............................................................... 38

3.2 Setting Comports (Purchased Pre-February, 2016) ............................................................ 39

3.3 Pair Laser to the Tablet PC (Purchased Post-February, 2016) ............................................. 39

3.4 Setting Comports (Purchased Post-February, 2016) ........................................................... 40

4.0 Methods of Use .................................................................................................................... 41

4.1 Tripod Setup / Mounting .................................................................................................. 41

4.2 Jobsite Placement ............................................................................................................ 41

4.3 Targets ....................................................................................................................................... 41

4.3.1 Pin Targets............................................................................................................................................ 41

5 | P a g e

4.3.2 “T” Targets ........................................................................................................................................... 41

4.3.3 Clamp Targets ...................................................................................................................................... 41

4.3.4 Black Shields ......................................................................................................................................... 41

4.4 Causes of Bad Measurements .................................................................................................. 41

4.4.1 Reflection ............................................................................................................................................. 41

4.4.2 Drastic Angles ....................................................................................................................................... 42

4.4.3 Dirty Lens ............................................................................................................................................. 42

4.5 Micro Adjust .............................................................................................................................. 42

4.5.1 Mounting on Tripod ............................................................................................................................. 42

4.5.2 Usage .................................................................................................................................................... 42

4.5.3 Adjusting Tension ................................................................................................................................. 42

4.6 Micro Adjust .............................................................................................................................. 42

5.0 Power Information ........................................................................................................................ 43

5.1 Battery Life ...................................................................................................................... 43

5.2 Battery Indication LEDs (Pre-February, 2016) .................................................................... 43

5.3 Battery Indication LEDs (Purchased Post-February, 2016) .................................................. 43

5.4 Charging at Home and in a Car.......................................................................................... 43

5.5 Normal Power Off Procedure ........................................................................................... 44

6.0 General Information ...................................................................................................................... 45

6.1 Warranty Information............................................................................................................... 45

6.2 Laser Safety Guidelines ............................................................................................................. 45

6.3 Using the Computer with Other Programs .............................................................................. 46

6.4 Cleaning / General Care and Storage ....................................................................................... 46

6.5 LT-2D3D Laser Templator Specifications .................................................................................. 46

6.6 Training Videos ......................................................................................................................... 47

7.0 Technical Information ................................................................................................................... 48

7.1 Accuracy and Distance Specifications ...................................................................................... 48

7.2 Storage and Operating Temperatures ...................................................................................... 48

7.3 Laser Specifications ................................................................................................................... 48

8.0 Contact Information ...................................................................................................................... 49

9.0 Registration ................................................................................................................................... 50

6 | P a g e

1.0 JOBSITE SETUP

1.1 LT-2D3D Setup (Purchased Pre-February, 2016)

1. When you walk into the job site, turn on the tablet and set up the tripod while the tablet is booting.

2. Place the laser on the tripod and make sure it is in plane with the countertops.

3. Plug in the USB cable into the tablet after Windows has fully started.

4. Once the USB cable is connected, press the power button on the side of the laser.

5. After the laser shows a green LED on the side next to Power, start the program by double clicking on it on the

desktop. You should wait at least 5 seconds between turning on the laser and opening the program to allow the

laser enough time to turn on and start the Bluetooth Service.

6. You will be prompted with a window that tells you to make sure the laser is locked before proceeding.

7. You will see in the top bar “LT Connected”

a. If the top bar shows “LT Disconnected”

i. Exit the program.

ii. Unplug the USB cable and plug it back in.

iii. Make sure the laser is on indicated by the green light on the side of the laser next to Power.

iv. Start the program by double clicking on program on the desktop.

v. If it is still not connected, check for any pending Windows Updates that need to be installed.

8. After connected, press Laser On or Start New Line and you can begin templating.

1.2 LT-2D3D Jobsite Setup (Purchased Post-February, 2016, marked R4.1 on the bottom

label)

1. When you walk into the job site, turn on the tablet and set up the tripod while the tablet is booting.

2. Place the laser on the tripod.

3. Plug in the USB cable into the tablet after Windows has fully started.

4. Once the USB cable is connected, press the power button on the side of the laser.

5. After the laser shows a green LED on the side below Power, start the program by double clicking on it on the

desktop. You should wait at least 5 seconds between turning on the laser and opening the program to allow the

laser enough time to turn on and start the Bluetooth Service.

6. You will be prompted with a window that tells you to make sure the laser is locked before proceeding.

7. You will see in the top bar “LT Connected”

a. If the top bar shows “LT Disconnected”

i. Exit the program.

ii. Unplug the USB cable and plug it back in.

iii. Make sure the laser is on indicated by the green light on the side of the laser below Power.

iv. Start the program by double clicking on program on the desktop.

v. If it is still not connected, check for any pending Windows Updates that need to be installed.

8. Set the plane you are going to measure by capture three points.

a. You will be prompted to set a plane before capturing any points with the laser. If you are not going to

template immediately, you can ignore the following steps and use other functions.

b. Points should be at least 12” apart and should not be in a straight line.

c. Clicking the “Show Example” button in the software will bring up an image showing where to position

the three points. The points only need to generally be in a left, right, back/top orientation to one

another

9. After connected, press Laser On or Start New Line and you can begin templating.

7 | P a g e

2.0 USING THE LASER TEMPLATOR SOFTWARE

File Menu

The File menu is where you will find the most basic actions that will be performed when starting a new job, saving a job,

opening previous jobs and adding information of a job.

2.1 Help

The Help menu is where you will find a comprehensive source of information on the Laser Templator software. Please

use this resource if you have any questions about the software. If your question is not answered here, contact us at our

main office. We are open Monday through Friday, 9:00 am through 5pm, Central Standard Time.

Laser Products Industries

1344 Enterprise Dr.

Romeoville, IL 60446

877-679-1300

www.LaserProductsUS.com

2.1.1 Check for Updates

Every time you open our software, if there is an active internet connection, it will check to see if there are updates

available for it. However, if none are found because you have a slower connection, you can also use this function

to check as well.

2.1.2 Import/Export Settings

We allow you to import and export your program settings so easily set up both your tablet and your office

computer (second seat) the same way.

To Export:

1. Click the browse button (…)

2. Type in a file name

3. Choose the location you want to save it to and press Save

4. Press Export

To Import:

1. Click the browse button (…)

2. Select the file you want to import

3. Click Open

4. Click Import

2.1.3 Manual

This is the Manual you are looking at right now. It has been compiled up to version 2.1.

2.1.4 About

Located in the About section, you will be presented with current information about the software version you are

currently running as well as copyright information on our software.

2.1.5 View Changes

This section of the Help menu simply lists what is changed from the previous version. New features, bug

fixes and other general information on new releases are all shown.

8 | P a g e

2.1.6 Tips

This section of the Help menu offers tips for the user of the laser. As tips are submitted by our

customers, they will be added to this menu. If you wish to submit a tip, please email

info@laserproductsus.com with the subject of Tip.

2.1.7 Setup Device

Setup Device allows you to choose what COM port both the Laser and Encoder are communicating to the

tablet PC on. This will not show up on non-Bluetooth versions of the laser and will be already set up

when your laser arrives. If we send you a loaner tablet PC while yours is being repaired, this will need to

be set up. See Section 4.0 Bluetooth Pairing.

2.2 New

Selecting New will give you a blank canvas to start a new job.

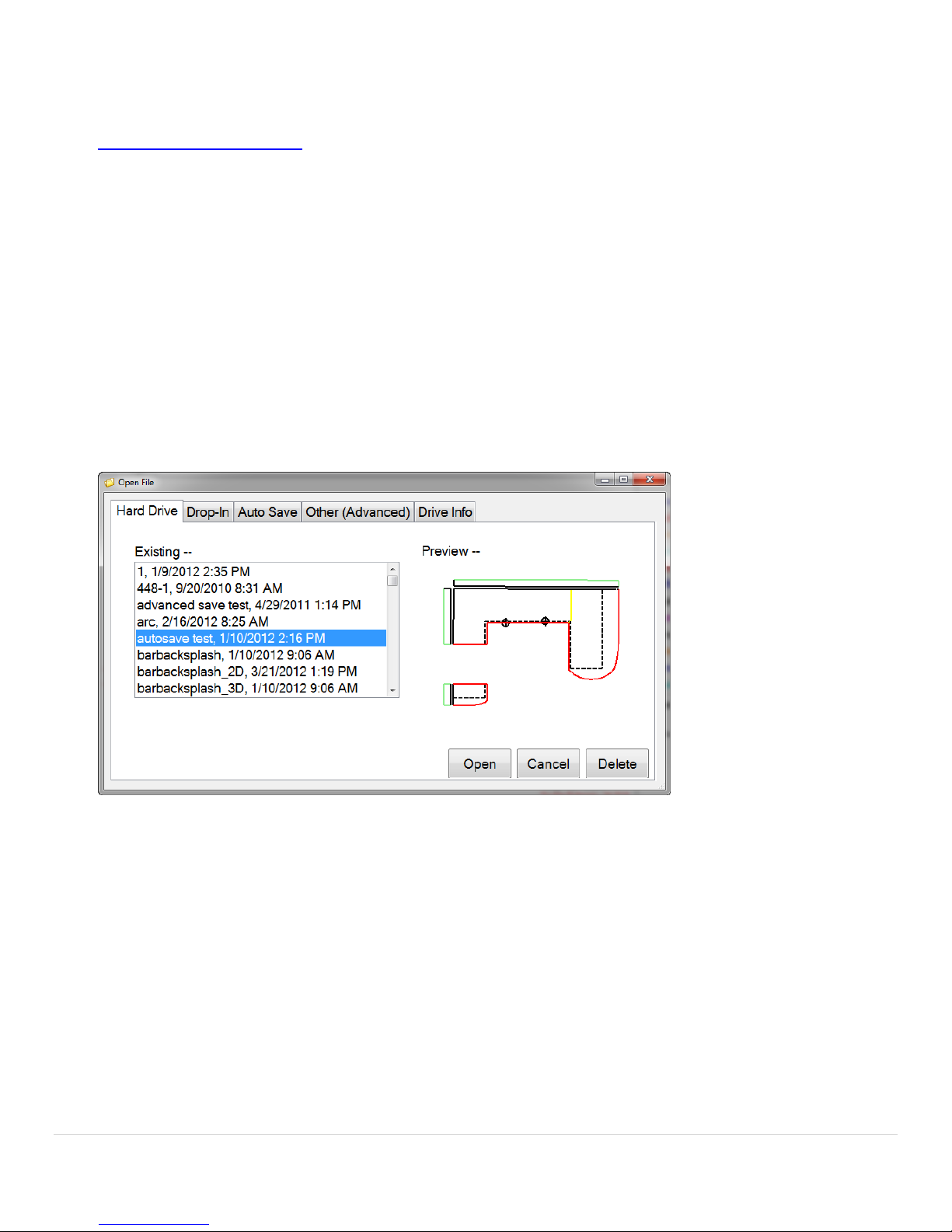

2.3 Open

In the Open section, you will be presented with 4 different options to opening files. You can open files from the Hard

Drive, Drop-Ins, Auto Save files and you can use an Advanced open menu.

2.3.1 Hard Drive

Open Opening files from the 3THard Drive3T will show you all of the templated jobs you have saved on the hard drive

of the tablet/computer. These templates are located in the 3TMy Documents3T folder of the tablet/computer.

2.3.2 Drop-In

If you create a 3TDrop-In3T like a special corner, bump out or a sink bowl and you want to save it for future use, this is

where it will be located. The templates that are located here are the ones you will see when you choose the 3TDrop-

In3T feature.

2.3.3 Auto Save

An 3TAuto Save3T occurs while the tablet is sitting idle and more frequently when being used. This is done as a backup

if you make a mistake and need to go back to a previous version of the template or you forget to save your job. If

you finish a job and forget to save the template, you can look in the 3TAuto Save3T area and open the most recent

one.

9 | P a g e

You should not rely on these files because if you close the program out before an auto save occurs, only the most

recent action made before the previous auto save will be saved and be available. Anything made after the last

auto save will not be recorded.

2.3.4 Other (Advanced)

The 3TOther (Advanced)3T option for opening jobs should be used if you do not save your templates in the 3TMy

Documents3T folder or on your SD memory card. By using this option, you can open up and job files that are located

anywhere on the tablet.

2.3.5 Drive Info

Drive Info simply shows you how much memory is currently being used and is available on your system.

2.4 Import/Export

We offer the ability to import and export data from our software in a multitude of formats.

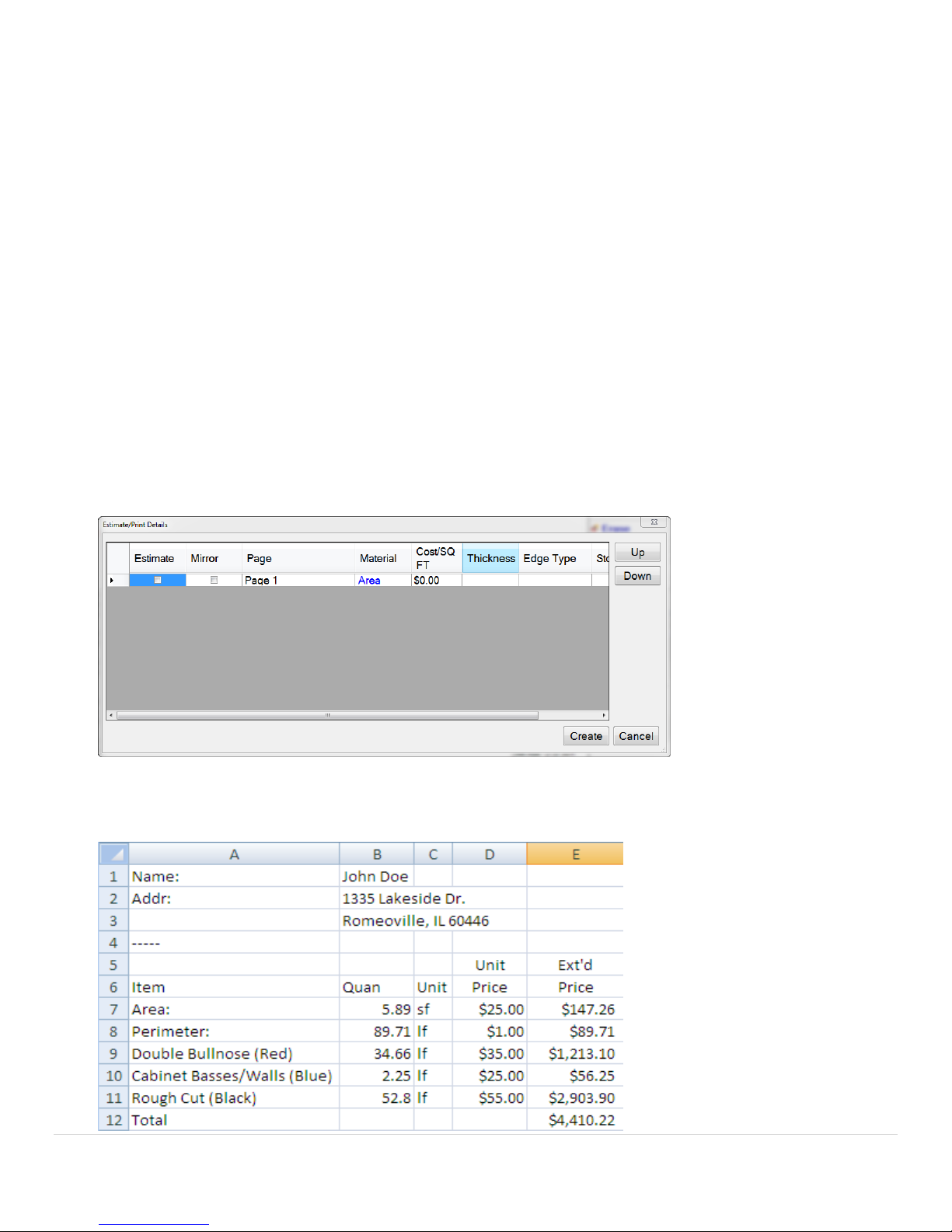

2.4.1 Estimate

Using the Estimate function will open up an Excel based spreadsheet showing you common estimate values like

sq. footage, perimeter, costs based on different edge treatments as well as a total cost of the job. These numbers

can be used for customer quotes or just for internal estimations of cost per job.

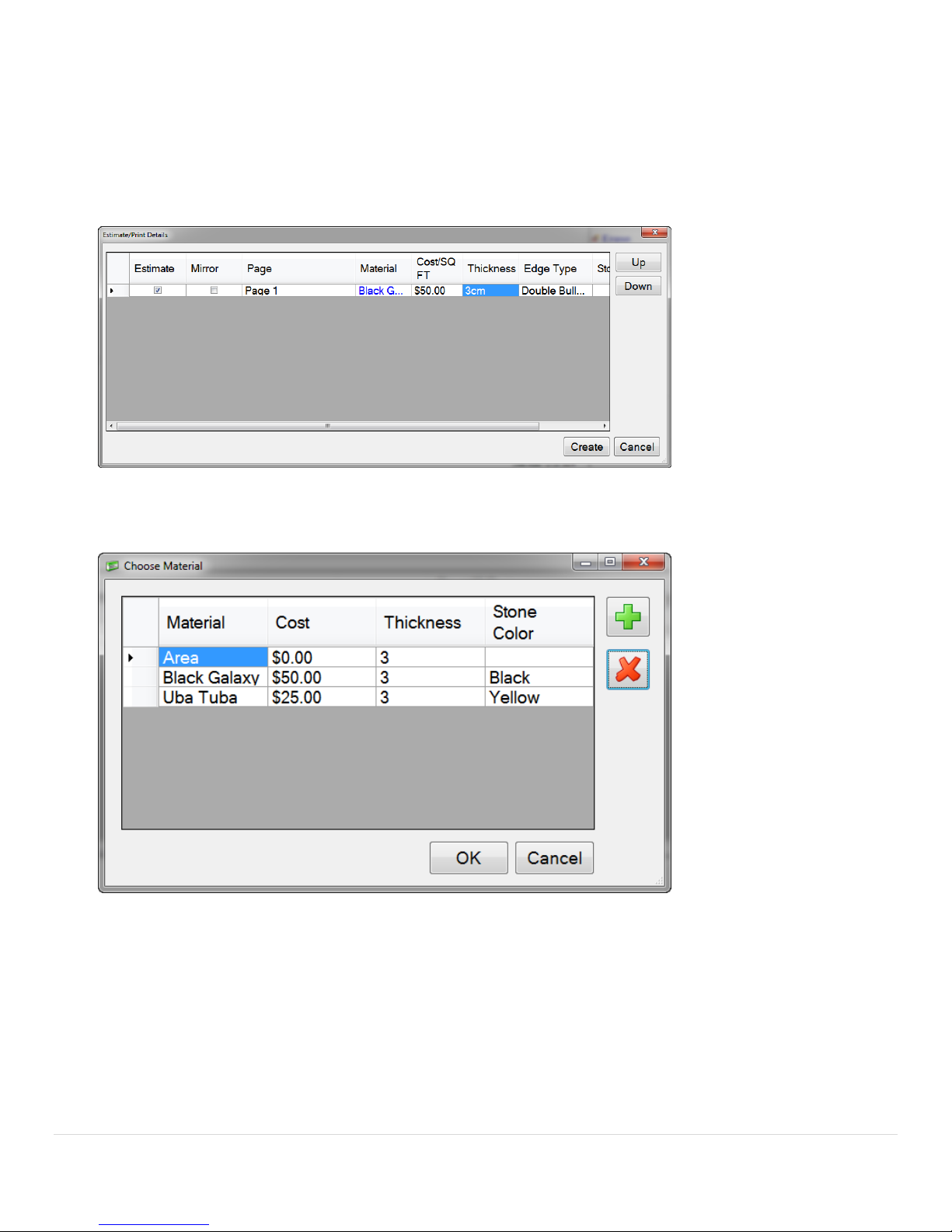

First you will see the Estimate/Print Details page where you can set up your Estimate. You can choose to print the

basic Estimate or you can add the Summary, Estimate and Pages.

10 | P a g e

A .csv estimate file will be saved to the job folder where the templated .dxf file is as well as the photographs of the

job if you choose to use them.

2.4.2 PDF (Print)

You will need to have a printer installed on the tablet or on your computer to print these out. If you do not have a

printer, you can save the .pdf file to later transfer it to a computer that has printing capabilities if you just want to

save the digital file for your records.

If you wish to store a database of material (type of stone) you have in inventory, click on Area. You will be

presented with a window that will allow you to add the material of your choice.

1. To add materials, click the green plus sign.

2. Click in the Material box and type in the name of the material.

3. Click in the Cost box and type in a cost of the material.

4. Add a Thickness and Color.

5. To remove a material, click on the material and click on the red x.

6. To choose your material click on the material name and click OK.

Use the check boxes on the bottom half of the screen and check the boxes if you want this to be included in your

print out. If you uncheck a box, it will not be included.

11 | P a g e

2.4.3 Shop Sheet

The shop sheet is a .pdf file that is created specifically for the fabrication facility in your business. Information on

this form is filled out in the Job Information Center and the individual Page information. One shop sheet is

automatically created for each page in your job.

2.4.4 Email

If you want to E-Mail your job files back to your fabrication shop, you will first need to set up your email settings.

To do so, follow the instructions in section 2.9.4 - E-Mail Settings.

To send an email, enter the address you want to send the job to, the Subject (usually the job name) and any

comments in the Message field. Check the boxes on the right to include whatever files you want. Sending pictures

and PDF’s will slow down the process of sending because of the file sizes. We suggest only sending the L55 and

DXF files when emailing. Photos can be included if needed. All the PDF files can be recreated at the office by

opening the job file and saving it again.

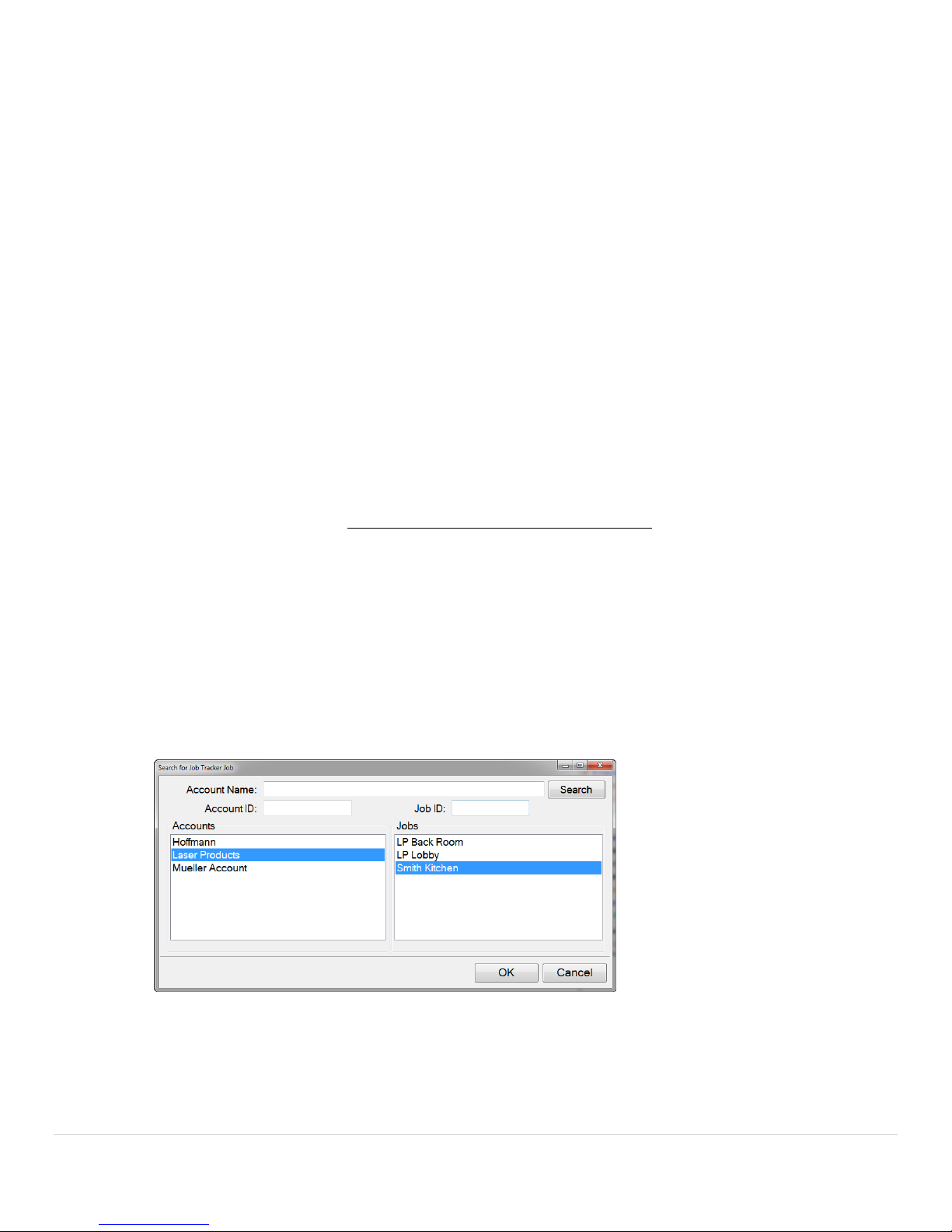

2.4.5 Upload to Job Tracker

In version 2 of the software, we have added Moraware’s Job Tracker integration. You can now import job

information from Job Tracker’s website as well as export/upload the job files created with the laser. To use this

functionality, you will need to first set up your account in our Options menu.

1. Click Edit / Options

2. Scroll to the bottom of the General Setting tab where you will see Job Tracker Settings

3. Enter the API URL (which is https://<xyz>.moraware.net/<xyz>/api.aspx where <xyz> is your own

company information)

4. Enter your User Name

5. Enter your Password

6. Press OK

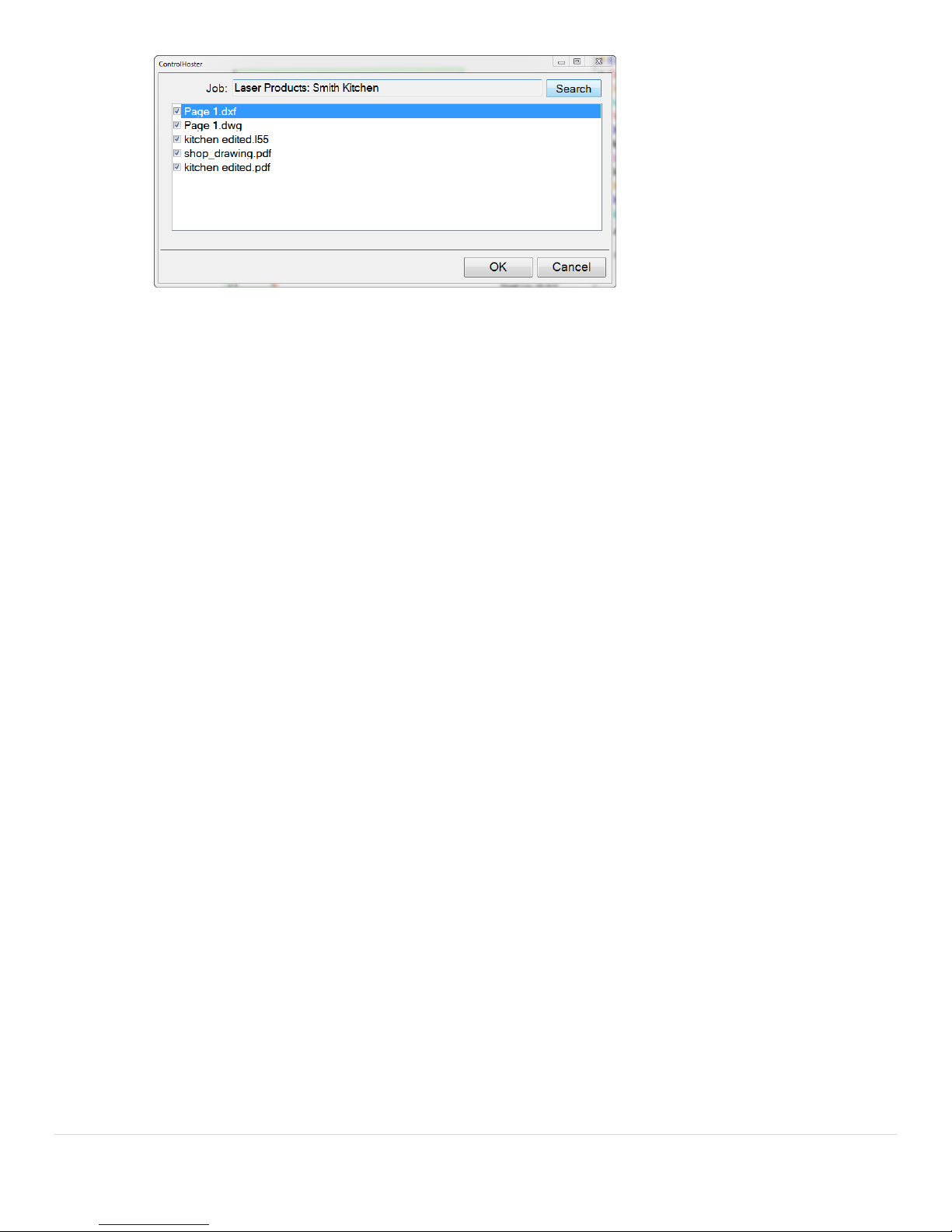

To upload data to Job Tracker

1. Have the job you want to upload open

2. Click File / Import/Export / Upload to Job Tracker

3. Click Search

4. Click on the Account and Job you want to upload the job files to

5. Check the boxes of the files you want to upload

12 | P a g e

6. Click Ok.

2.4.6 Import Job Tracker Data

Now that you have your Job Tracker account settings ready in the program, you can import the job information.

1. Click File / Import/Export / Import Job Tracker Data

2. Select the Account that the job is saved under

3. Select the Job that you want to import the data from

4. Click Ok.

The job’s data will now be visible in the Job Information area of the software.

2.5 Save

Choosing to Save your project should be done frequently. The current version of the job will be saved when you press

3TSave3T. If this is the first time the job is being saved, it will ask you to enter a name for it. Once a name is associated with

the file, choosing save will just overwrite the older version with the current one.

The program saves files with .l55 extensions. This is the file that contains all measurement information and recorded

date. From this file, .dxf, .dwg, .ord, .xml, .csv, .txt, and .pdf files can be recreated. The only files that are not recreated

from the .l55 file are the .jpg files (images).

The .l55 file will have all points flattened to a horizontal 2D plane (if the 'Template Wall' function was used, the points

will be flattened to a vertical 2D plane).

The 'INTERNAL 3D IMAGE.dxf' file located in the same job folder will have all the points saved in 3D space in a point

cluster that can be opened and edited in a separate CAD program.

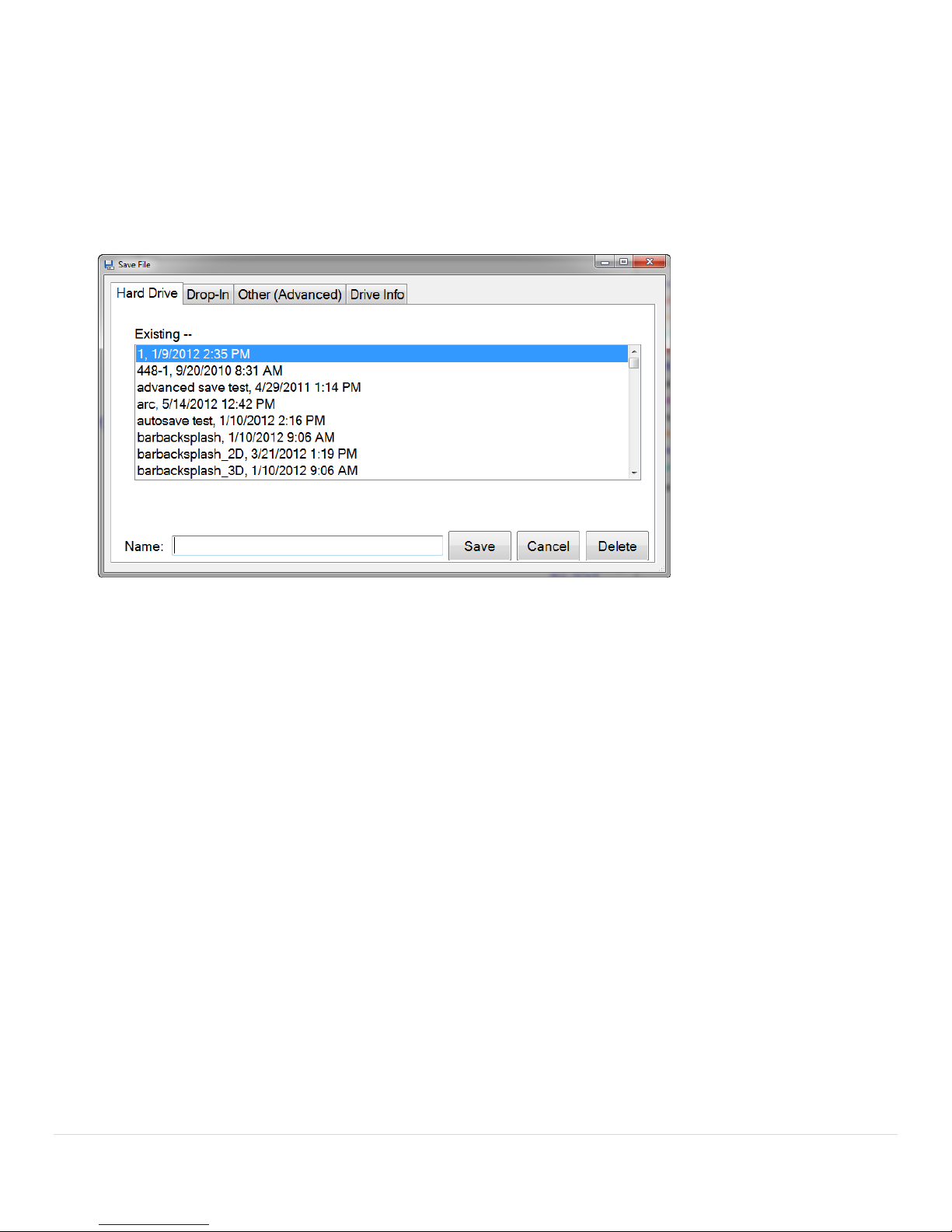

2.6 Save As

The first time you are saving a template, you should choose to Save As. This will bring up a box giving you the option to

save the template on the Hard Drive, as a Drop-In or using the Advanced saving option (Other).

2.6.1 Hard Drive

Saving files to the Hard Drive will place the jobs in the My Documents folder of the tablet.

2.6.2 Drop-In

If you create a Drop-In like a special corner, bump out or a sink bowl and you want to save it for future use, this is

where you will save it to. By saving here, the template will show up when you choose the 3TDrop-In3T feature.

13 | P a g e

2.6.3 Other (Advanced)

The Other (Advanced) method for saving templates should be used if you do not want to save your templates in

the My Documents folder or on your SD memory card. By using this option, you can save .dxf, .l55 (job files) or or

both files anywhere on the tablet that you want to (i.e. the desktop or a projects folder you created).

2.6.4 Drive Info

Drive Info shows the current status of the drives/storage devices on the tablet PC. This includes the hard drive, as

well as any SD cards and removable disk drives (flash drives).

2.7 Exit

Exiting the program will close the program and take you back to the Windows desktop. You should always make sure to

save changes to any job file you were working on before you exit the program.

When Exiting the program in conjunction with using the laser, the laser will shut off on its own if it is a pre-February,

2016 model. If Purchased Post-February, 2016, marked R4.1 on the bottom label, the laser will continue to remain on for

a couple more minutes. It will shut off on its own but if you wish to manually turn it off, hold the power button for 3

seconds.

2.8 Connect To Laser

The only time this will show up is if the tablet is not connected to the laser. If you look in the title bar of the program,

you will see "LT Disconnected" and there will be no interaction between the tablet and the laser.

If the tablet is connected to the laser via the USB cable and the title bar is showing "LT Disconnected" you can select

Connect To Laser. This will then establish a connection between the laser and the tablet. This process of connecting can

take up to 10 seconds.

14 | P a g e

Edit Menu

The Edit menu is where you will find the most basic editing options that will be performed when starting a new job,

saving a job, opening previous jobs and adding information of a job.

2.9 Options

2.9.1 General Settings

Here you can change general settings and functions with the way the program is run. The General Settings are

categorized by their purpose in the software.

Save Settings

HD Save Location is used to change the location job files will be saved on your Tablet PC or computer. Click on

the browse button “…” to the right of the dialogue box and choose the folder you want to save all job files in

by default. Click Clear if you wish to revert back to the default location of My Documents.

Days to keep auto save files simply allows you to change how long auto save files are stored on the hard

drive. These auto saved files are located in C:\Program Files\Laser Products\LT-55XL\auto_save. This defaults

to 10 day but can be changed to however long you wish to save them.

Save with page names, if checked while saving a job the resulting .dxf files that are saved with it will be titled

whatever the page name is for that drawing.

Default DXF Polylines, if checked will default all lines to Polylines instead of Line Segments. Some CNC/CAM

machinery will only work with one or the other. Check with your machinery to see if this should be checked or

unchecked for your specific shop setup.

Export PDF in black/white with edge treatments, if checked will export the drawings to a .pdf file in black and

white with the edge types labeled on them.

Save Template Images, if checked will save a screen shot of the drawing as a .jpg file and can be used as a

reference.

Use Color in DXF Layer, if checked the layer name within the .dxf file will be preceded with the name of the

color. Some CAD/CAM systems need to have this checked.

Export DXF BYLAYER, if checked will export the BYLAYERS if your CNC machinery needs it.

Use DXF on advanced save, if checked will default to saving a .dxf file on the Advanced Save instead of the

default .l55.

Sync DXF files when opening LT55 file, if checked will import any modified .dxf files back into the job file (.l55)

when opening. This is done if you have an employee that modified the files in another CAD program and you

want update the .l55 file.

The line thickness within the exported DXF file is the default line thickness in .dxf files after exported.

Settings Save Location is the default location that settings files are saved to.

DXF File Name Format is the formatting scheme for naming .dxf files once saved.

15 | P a g e

Create DWG files when saving a job is checked when your company wishes to use DWG instead of DXF

Create DXF files when saving a job is checked when your company wishes to use DXF instead of DWG

Print Settings

Print page details, if checked will include each individual page’s details on Estimates.

Prepend to PDF is where you can attached a company estimate sheet (or any other pdf document) in front of

the Print Sheet we create.

Prepend to PDF Description just describes what the file is that is being prepended.

Company Info and the Customer Agreement will be presented on each printout they do. Clicking the Edit

button next to each will open up Windows Notepad. You can either write a customer agreement into the file

or you can write you own and then save it.

Print Logo is the log that will be added to your Print sheet. This needs to be a .jpg image.

Shop Sheet Logo is the logo that will be added to your Shop Sheet. This needs to be a .jpg image.

Drawing Display Settings

Auto Scale Dimensions, if checked will automatically scale the dimensions when printed.

Dimension Font Size is default font size for dimensions and text.

Show Tips at Startup, if checked will present you with a tip when the LT-2D3D software opens.

Display Radii Text, allows you to specify how you want radii to be shown on the screen. The default is the

number for the radius and then “R” but if you want only the number you can delete the “R” after <radius>.

Display Area Legend, allows you to turn on or off the Area Legend in the bottom right corner of the drawing

area.

Ignore mirror when drawing text, if checked will allow text to be read legibly (not mirrored) while you are

drawing in Mirror Mode.

Use black background on drawing, if checked will make the default white screen black on the drawing canvas.

We added this because many CAD/CAM programs use black and we wanted to allow users to have it be the

same as they are used to.

Display Shortcut Text, if checked will show the text in the right menu. If unchecked, it will only show the icons.

Job Details Settings

Install Date Add will allow you to automatically add a set number of days to the Install Date based on the

Template Date.

16 | P a g e

Use Job Name as Email Subject, if checked will automatically fill the job name in the Subject line while selling

an email.

Import Job Mapping File, allows you to specify how you want to import job information into the program

based on what job tracking software you currently use to store customer information.

Set Install Days Automatically, if checked will automatically set the install date based on the Template Date.

Miscellaneous Settings

Drop-In Folder is used if you want to use a specific folder as your drop in folder. This is helpful if you don’t

want to see the sample sinks and marks we have included. Many users of will create a Drop In folder in My

Documents and save them all in there.

Remember Last Drop-in opens the drop-in menu to the last drop-in you used.

Auto shutoff wired LT-55 XL will turn off the laser to save battery after inactivity.

Zip files for Email when checked will zip all emailed files to compress them so sending is faster. When

unchecked, all emailed files will be sent unzipped.

Display Popup Calculator when unchecked will not pop up the number pad. This is mostly done on desktop or

laptops that have a keyboard available all the time.

Display Edge Type instead of Color changes Color in the right drawing menu to Edge Type for those

companies that do not specifically use colors but edge codes instead.

Display Radius Label on Drawing will automatically display all radius measurements when drawn.

Job Tracker Settings

API URL is the web address that is used to log in to Job Tracker on Moraware’s website. The address is

https://xyz.moraware.net/xyz/api.aspx where xyz is your company name.

User Name is your company’s Moraware Job Tracker log in name.

Password is your company’s Moraware Job Tracker password.

2.9.2 Estimate Settings

Here you can change the values used in your estimates. Area and perimeter can be modified based on what

treatment you assign to a specific color.

Group By Page, if checked, will allow the estimate option to group all the pages so that each page has its own

estimated values.

A Materials field has been added if you pass these costs onto the customer. Click the “+” button to add a new

line. Then click on the Material line and type in what you need to add. Similarly, click on the Cost line and

modify the cost to reflect the cost you associate with the material.

17 | P a g e

2.9.3 Quick Actions

Quick Actions are commonly used actions. These include fillets, radii and offsets that are used often.

To create a new action, follow the steps below:

1. Click Add New

2. Select the Action Type, Fillet Type, Unit of Measure, Amount/Font Size and Display Quick Action

Text Color

3. Choose if you want the Quick Action to be displayed in the main Quick Action menu by checking the

box or just in that individual’s action menu by unchecking the box.

To remove a previous created Quick Action, highlight the one you wish to remove and click Remove.

Default Quick Action Text Color allows you to make all the text the same color.

2.9.4 E-Mail Settings

If you choose to email your templated files back to your shop while you are at a jobsite, this is where you will

set up your email configurations.

The email settings are standard settings so please look at your personal email account settings and copy that

information over to these forms. If you are unsure of your email settings, please contact your email/internet

provider to obtain them. There are many email providers out there; we cannot keep track of everyone's

individual settings.

If you have a Gmail account, we made it easy for you. All you have to do is fill in your username (email

address), password and a From Name (your name). Then click on the Web button in the lower left corner and

follow the instructions there to allow our software to send email through your account by enabling POP in the

Gmail settings. The setting in our program will look like this:

Below are the most common email settings.

Gmail

SMTP Server: smtp.gmail.com

SMTP User: your email address

SMTP Password: your password

SMTP Port: 587

18 | P a g e

SMTP Secure: checked

From Address: your email address (same as SMTP User)

From Name: Your Name

You need to Enable POP Email in your GMail account. Instructions to do so can be found here:

https://support.google.com/mail/answer/13273?hl=en

You need to turn on “Less Secure Apps.” On the following page:

http://www.google.com/settings/security/lesssecureapps

Comcast

SMTP Server: smtp.comcast.com

SMTP User: your email address

SMTP Password: your password

SMTP Port: 587

SMTP Secure: checked

From Address: your email address (same as SMTP User)

From Name: Your Name

Hotmail

SMTP Server: smtp.live.com

SMTP User: your email address

SMTP Password: your password

SMTP Port: 587

SMTP Secure: checked

From Address: your email address (same as SMTP User)

From Name: Your Name

Yahoo (Required Yahoo! Plus Account (yearly payment))

SMTP Server: smtp.mail.yahoo.com

SMTP User: your email address

SMTP Password: your password

SMTP Port: 587

SMTP Secure: checked

From Address: your email address (same as SMTP User)

From Name: Your Name

MSN

SMTP Server: smtp.live.com

SMTP User: your email address

SMTP Password: your password

SMTP Port: 587

SMTP Secure: checked

From Address: your email address (same as SMTP User)

From Name: Your Name

AOL

SMTP Server: smtp.aol.com

SMTP User: your email address

SMTP Password: your password

SMTP Port: 587

SMTP Secure: checked

From Address: your email address (same as SMTP User)

19 | P a g e

From Name: Your Name

Network Solutions

SMTP Server: smtp.yourdomain.com

SMTP User: your email address

SMTP Password: your password

SMTP Port: 587

SMTP Secure: checked

From Address: your email address (same as SMTP User)

From Name: Your Name

2.9.5 Advanced

In the Advanced Options tab you can choose between any of the 11 languages we currently offer (English,

Brazilian Portuguese, Chinese, Czech, French, German, Italian, Polish CE, Polish UTF, Russian and Spanish).

Once you choose a new language you will need to restart the software in order to see the changes to the

language.

Associate l55 files with this application is used if when you double click on an .l55 file and it does not open up

in the Precision Laser Templator software. By clicking the “Associate” button, this will fix this.

Associate csv files with Open Office is used if there is ever a problem with opening estimate files in Open

Office.

Backup will save all your job files to another location. This can be done from the hard drive to an external hard

drive or from your SD Card.

2.9.6 Shortcuts

Shortcuts are used to quickly perform actions in the program. This is commonly used in Windows programs

like CTRL + O will bring up the open file function. CTRL + E will activate the Erase function.

2.10 Job Info / Pages

The 3TJob Info3T section is where you will enter information on each specific job that you template. This includes names of

customers, addresses, important dates, additional items used for the job and an agreement for your customers to sign.

2.10.1 General

3TGeneral3T information includes the name of the job you are working on. This can be designated by internal

reference numbers, bar code numbers or something as simple as the customer's last name.

2.10.2 Address

Address is the location of the job site, home or industrial location.

2.10.3 Dates

Template Date is the date which you and the customer decide to template the job (usually the current date).

Draw Date is used if an employee modifies the job file after it is template. If the templator is responsible for

modifying it onsite (adding offsets, radii, drop-ins etc.) this is unnecessary to use. However, if there is another

employee in the workflow, we believe it is important to know who has modified that file for accountability.

20 | P a g e

Approved Date is used to record the date in which the customer has approved the final product which is to be

fabricated. This could be at the customer’s house after the templator has template and modified the .dxf or it

could be at a later time.

Install Date is when you will install the counter tops. This can be used in conjunction with your scheduling

software so you can determine when the shop will be able to produce the counter tops and when your installers

will be able to deliver them to the customer.

Name is the person that preformed the specific job functions associated with the dates.

2.10.4 Additional Items

Additional Items is where you can list the cost of fixtures or other materials you will be charging the

customer. We have also created a Catalog where you can add items that you know will be used in the

future instead of having to enter them in each time.

1. Click Add

2. Type the description of the item

3. Enter the amount of the item

4. Click OK

We also allow you to create a Catalog of items that you use frequently. To use the catalog:

1. Click Catalog

2. Click Add New Item

3. Enter a Description and Amount

4. Click OK

5. Check the box of the items you want to add to this specific job

6. Click OK

2.10.5 Pages

Pages allow you to have multiple digitized templates of the job in their own space. For example if you

have templated a customer's kitchen countertops, and you need to do their bathroom as well, you can

add a new page. When saved, you will have the same job folder but the 2 portions of the jobs will be in

their own separate .dxf files.

21 | P a g e

Pages can be switched back and forth by clicking on the tab at the top of the drawings. Simply click on the Page

you wish to see.

If you click Edit Pages, you will have the option to edit information about each specific page. In the column on

the left, you can choose what page you want to edit.

Page Name allows you to name each page.

Preview will show you what is on each page.

Use DXF Polylines, if checked allows you to specify on a page by page basis if that top needs to be saved in

Polylines. Line Segments are the default.

Save Invisible Colors, if checked will save all geometry in the file even if the color is set to be invisible.

Notes can be added about each page. This is to be more specific than the notes on the main screen.

Sink Info and Cook top Info can be added to each page if they are required.

2.10.6 Notes

In the Notes tab, you can enter notes about the job. These are different from the individual page notes that will

appear on the Shop Sheets. See the Pages section for more information on that.

2.10.7 Agreement

In the Agreement tab, you can attach your own company policy dealing with warranties and liabilities for the

customer to read. Once read and the customer checks the box saying they read and accept the terms, they can

sign their name right below it. Their signature will be presented on every page of the estimate you run.

When you go to print out an estimate with all the job information, you can choose to include the customer’s

signature on all the pages or select specific ones (Estimate, Notes, Images [images of the actual .dxf files] and

Photos)

1. To use a custom agreement, go to My Computer

2. Double click on C:

3. Double click on Program Files

4. Double click on Laser Products

5. Double click on Laser Templator

6. Double click on CustomerAgreement.txt (copy and paste it if you already have it written)

7. Write the agreement you want in this file

8. When finished, save the file

2.11 Move Circle

Move Circle will take any circle you click on and then move it in the direction you click, leaving behind the original one.

This is used commonly for making the faucet and soap dispenser holes.

2.12 Split Line

Split Line is used when you need to finish an edge with two different edges. You will split the line into two based on a

setback amount and then change the color/edge type accordingly.

22 | P a g e

1. Click the line you want to split

2. Enter an amount to split the line from the front edge

3. You will see the line split with a yellow line appearing to show the split and press OK

2.13 Flip / Scale

Flip will allow you to flip a drawing horizontally, vertically or both. This would be sued for when you draw a custom

corner and want to flip it to use it on the opposite edge.

Scale allows you to quickly double or half the size of a drawing. You can also enter a custom percentage to scale it.

2.14 Add Photo

Adding photographs to you job can be a very valuable tool; you can use the built in camera on the tablet to take job site

reference pictures.

To take photographs with the tablet follow these steps:

2. Click Add Photo from the Edit menu

3. Click Start Camera

4. Point the back of the tablet at the area you want to photograph

5. Click Capture

6. To view the captured photographs, click View Images

These photographs will be located in the same folder as the templated .dxf and the estimate file.

2.15 Erase Segment

Erase Segment will erase one line segment. To erase a segment:

1. Click Draw

2. Click Erase Segment

3. Click on one end point of the segment

4. Click on the other end point of the segment

Remember, every line has 2 end points, as well as a midpoint. When a line intersects another line that is not at the

midpoint, it will create new end points and midpoints.

23 | P a g e

2.16 Erase All On Page

Erase All On Page will erase the entire template you currently have on your screen. This is similar to creating a new file,

but if you have saved it, the name will remain associated with the current file. If you Erase All On Page and then

template again followed by a save, the original template will be lost.

2.17 Split Object On Point

Split Object On Point allows you to take an entity and split it into two entities at a snap point where another entity

crosses it.

2.18 Units

Under Units, you can choose if you wish to measure in Imperial (Standard) or Metric and set the denominator or

decimal places.

24 | P a g e

View Menu

The View menu is where you will find the most basic actions that will be performed when starting a new job, saving a

job, opening previous jobs and adding information of a job.

2.18 Rotate Drawing

This allows you to rotate the drawing to any degree.

1. Click Rotate Drawing from the View Menu

2. Enter in the degree you wish to rotate the drawing and click OK

2.19 Mirror

I you Mirror the template you have made, it will flip it along its vertical access. This is used if you are digitizing a

template on the floor. You template it and then Mirror it so production is correct.

2.20 Object Info

Object Info show detailed information on objects you select.

2.21 Circle Diameter

Clicking in the center of any circle will show you the diameter of that circle in millimeters, inches and fractions, an inches

and decimals.

1. Click Circle Diameter from the View Menu

2. Click on a circle

3. The circle diameter will be presented to you.

2.22 Display Measured Points

If you select Display Measured Points, every point that was captured by the laser while templating will be shown on the

template by a black x.

25 | P a g e

A grey crosshair will also appear if the file you are looking at was templated with the and not just drawn. This represents

the location the laser was when the job was being templated.

2.23 Display Contiguous Breaks

By clicking on Display Contiguous Breaks, a box will be shown if there is gap between any 2 lines or arcs that are 1/4"

(.25") or smaller.

To turn on Display Contiguous Breaks:

1. Click View.

2. Click Display Contiguous Breaks.

As you can see in the example above, you can see the break in the lines.

Once the break has been connected, the boxes will disappear. This can be done with the Draw Line, Fillet or Extend

functions.

2.24 Display Polylines

Display Polylines show you what objects are polylines in your job file. Polylines are indicated by a double black border

around line within the drawing. Also if you will notice that there is the area measurement shown in the top left corner of

the polyline.

26 | P a g e

If you have an object that you believe should be a polyline but is not indicated as one, click on Display

Contiguous Breaks. If there is a break in the object, it will not be defined as a polyline.

2.25 Display Color Names

Allows the color names to be viewed and printed on the edges for customers that do not have color printers. This was

originally added for a customer that had a color blind employee that couldn’t see the different colors.

2.26 Display Area Legend

Allows the user to display or hide the area legend.

27 | P a g e

Draw Menu

Draw functions are used once a countertop or surface has been templated. This is primarily used for editing the

templated surface.

2.27 Re-Position Laser

When you encounter a jobsite where you cannot see the entire surface that needs to be templated like a pillar for

example, you can use the Re-Position Laser feature to obtain all the field measurements you need.

Position 1

1. Template the job from the first position as you normally would.

2. Click Draw.

3. Click Re-Position Laser.

4. Template 3 points that will be visible from the second position (position 2) after the laser has been moved.

These should be marked with a target or have a physical blemish that can be distinguished from both locations

and be at least 10 feet apart. As you are templating them, you will see red “x” appear with a number next to it.

This will help when you move to the second position.

Position 2

5. Pick up and move the laser to the second position making sure you can still see the 3 points you just templated.

6. Align laser to first of the three points (red laser hits the target) indicated on the screen by a red “x” and the

number “1”

7. Tap on the digital representation of the first cross on the screen. It will have the number “1” and a red circle

around it now.

8. Pause and make sure the Tablet PC chirps signifying that the measurement was received.

9. Align laser to first of the three points (red laser hits the target) indicated on the screen by a red “x” and the

number “2”

10. Tap on the digital representation of the first cross on the screen. It will have the number “2” and a red circle

around it now.

11. Pause and make sure the Tablet PC chirps signifying that the measurement was received.

12. Align laser to first of the three points (red laser hits the target) indicated on the screen by a red “x” and the

number “3”

13. Tap on the digital representation of the first cross on the screen. It will have the number “3” and a red circle

around it now.

14. You will see a confirmation that the laser has been properly repositioned and you can continue templating. If

not, it will ask you to re template the last three points again.

2.28 Set Plane

When starting a new job or page, LT-2D3D Laser Templator (Post-February, 2016) users will be asked to set the plane

that they will be templating on. Any new pages or jobs can be created without re-engaging the 2D lock. They will

be instructed to template three points on that plane. The plane would be a countertop, wall (backsplash) or

any other surface.

Clicking the “Show Example” button will bring up the following image showing where to position the three points. The

points only need to generally be in a left, right, back/top orientation to one another

28 | P a g e

The three points need to be at least 12” apart from each other and cannot be near to a straight line. If the three points

are set like this, you will see a warning box stating that the measurement’s accuracy will be affected. The user can then

choose to reshoot or accept them as is. We suggest that get the three points in a triangular pattern and have them be as

far apart as possible to the highest level of accuracy.

2.29 Offset

2.29.1 Offset Scribed Wall

To offset a scribed wall:

1. Key in the distance you want to offset the scribed wall and hit OK.

2. Select all parts of the wall you want to offset.

3. Select Done Selecting.

4. Click in the direction you want the wall to be offset just as if you were doing a normal offset.

2.29.2 Offset Polygon

Offset Multiple would be used if you want to offset an entire object outward or inward. This is commonly used in

the situation of a sink reveal. If you are using a under mounted sink and need to reduce the size of the opening in

the countertop because you are going to top mount it (different sink with same dimensions), you would drop in

the sink, select it and then reduce the size of the opening.

1. Key in the distance you want to offset and hit OK.

2. Select all parts of the object you want to offset.

3. Select Done Selecting.

4. Click in the direction you want the wall to be offset just as if you were doing a normal offset.

2.30 Define (0,0)

Define (0,0) is used for when you create a 3TDrop-In3T and need to designate a point where you want it to snap to

when you add it to a template. To 3TDefine (0,0)3T:

1. Click 3TDraw3T.

2. Click 3TDefine (0,0)3T.

3. Click the point you wish to designate (points will snap to end points, midpoints and intersections).

2.31 Slab Layout

When Slab Layout is clicked, you will need to tap on all the lines you want to move or modify.

29 | P a g e

Selecting lines is done one of three ways. You can individually click on each line segment or you can click and drag to

select all lines that inside the selection box. If you have used multiple colors on your job, you can click the drop down

box on, choose the color you want selected and then click the Select button. Only the color you choose will be selected.

Once selected, the selected lines will turn yellow-dashed indicating they have been selected. If you want to deselect all

the lines you have selected, instead of clicking on each line, you can press the Deselect All button. Below the Deselect

All button, you can also click the Erase Selected button which will delete all the selected lines.

From here you can use the Move section to move the selected lines in any of eight directs (up, down, left, right and any

directional at a 45º angle. The selected lines will be moved a set distance every time the Arrow buttons are pressed. This

distance determined below the Arrow buttons. If you wish to change this distance, you can click in the box and then use

the keypad to the right to determine the set distance.

If you want to rotate any selected lines you can either click the -45 or +45 buttons or you can change the angle in the

box below and click the + or – buttons to rotate those lines to that angle. There is also a wheel to the right of the Rotate

section that allows you to set predetermined angles in 45 increments (0 º, 45 º, 90 º, 135 º, 180 º, 225 º, 270 º and 315

º).

If you want to view a portion of the drawing that is off the screen, you can select the Pan check box. Once checked, you

can click on the screen and then drag it in any direction which will then move the drawing around on the screen.

You can move pieces using snap points.

1. Select the pieces you want to move.

2. Click Set Snap Point.

3. Click the point on the selected piece you want to snap to another point.

4. Click the point where you want to move the selected points to.

5. Click Move.

Once you are finished in Slab Layout, click the flashing Done button in the bottom right corner.

30 | P a g e

2.32 Backsplash

To add a backsplash to a countertop:

1. Click Draw.

2. Click Add Backsplash.

3. Enter the Height (or Full Height) and the Offset of the splash.

4. Click Ok.

5. Now click 2 points that will be then ends of the backsplash.

6. Finally click in the direction you want the offset to be. In this case above the line.

2.33 Angle

To add an angle:

1. Click 2 points that will define the ends of the lines.

2. Click the point that will be the vertex where the 2 lines will intersect.

2.34 Radius

Display Radii allows you do display the radius of an arch or circle. To display the radii:

1. Select the arc or circle you wish to have the radius displayed.

2. Click the location you would like that radius to be displayed at.

2.35 Dimensions

To add dimensions to a job:

1. Click Draw.

2. Click Add Dimensions.

3. Click 2 points that you want to use as end points of the dimensions.

4. Click away in the direction you want the dimension to be added to.

2.36 Maximum Dimensions

Maximum Dimension allows you to find the maximum lengths and widths of an object. To figure the maximum

dimension:

1. Select the 2 outer lines that you want to use as the outermost dimensions. Red arrows will show the objects you

selected.

2. Select Done Selecting. The arrows will turn green signifying they have been selected and are ready to be

measured.

Click in the area you want the dimension to be displayed.

2.37 Text

To Add Text:

1. Click 3TDraw3T.

2. Click 3TAdd Text3T.

3. Type in the text you want.

4. Tap on the screen where you want it to appear.

2.38 Center Line

To add a Center Line:

1. Click the line you want to add a Center Line to (this does not need to be the center of the countertops, it can be

the center of a sink, stove or anything else that will be dropped in).

2. Click the direction you want the center line to be based off of.

3. Enter an Offset Distance that will be from the front or right edge.

31 | P a g e

4. Enter a Set Back Distance that will be from the line you clicked on.

5. Press Ok.

6. A cross with dimensions showing the offset dimensions will be shown (you can erase these dimensions if you

want).

2.39 Line

While editing a template, there are 2 types of lines that can be drawn, 2 Point Line and 1 Point Line.

To draw a 2 Point Line:

1. Click Draw.

2. Click Draw Line.

3. Click 2 Point Line.

4. Finally click any 2 points. These can be end points, midpoints or intersections.

To draw a 1 Point Line:

1. Click Draw.

2. Click Draw Line.

3. Click 1 Point Line.

4. Choose the Line Length and Angle of the line you want to draw.

5. Finally click any point. This can be an end point, midpoint or intersection.

2.40 Arc

While editing a template, you can draw an arc by clicking any 3 points. To draw an Arc:

1. Click Draw.

2. Click Draw Arc.

3. Click any 3 points. These can be end points, midpoints or intersections.

2.41 Circle

While editing a template, there are 2 types of circles that can be drawn. 3-Point Circle and 1-Point Circle.

To draw a 1-Point Circle:

1. Click Draw.

2. Click Draw Circle.

3. Select 1-Point and enter a Radius value.

4. Click on the template and that will become the midpoint of the circle.

To draw a 3-Point Circle:

1. Click Draw.

2. Click Draw Circle.

3. Select 3-Point. Radius is not important because you will be selecting 3 points on your template to create the

circle and then it will be automatically figured.

4. Click on any 3 points in the template and a circle will be created running through all 3 selected points.

32 | P a g e

2.42 Circle

While editing a template, there are 2 types of circles that can be drawn. 3-Point Circle and 1-Point Circle.

To draw a 1-Point Circle:

2.43 Ellipse

To draw an ellipse:

1. Click Draw.

2. Click Ellipse.

3. Enter the Horizontal Radius (how wide it is left to right) and Vertical Radius how tall it is (top to bottom).

4. Click anywhere on the template.

2.44 Cross

To draw a Manual Cross:

1. Click Draw.

2. Click Manual Cross.

3. Click anywhere on the template and a cross will be created.

2.45 Custom Box

Adding a custom box is use when you want to insert a standard sized box. Most often when there is an island that you

do not want to template but you have a standard sized shape that needs to be added to a drawing.

33 | P a g e

2.46 Menu Bar Functions

2.46.1 Laser On

If the tablet is connected to the laser, click Laser On and the laser will turn on.

2.46.2 Start New Line

While templating and measuring points, after you have taken 2 points (which will draw a line), click Start New Line

if you wish to start a new surface. This would be used when you have taken 2 points on one side of a cabinet base

and then you move to the front or back of the cabinet base.

If you do not hit Start New Line, a chamfer will be drawn connecting the 3rd and 4th points.

2.46.3 Laser Off

If the tablet is connected to the laser, click Laser Off and the laser will turn off.

2.46.4 Zoom

While you are editing the template, you can Zoom in and out to get into close areas that you need to be enlarged.

This can be done 2 different ways.

+ & -:

1. Click the + button and the drawing will zoom in.

2. You can click and drag the screen around to move to the area you want to.

3. Once finished, you can click the -button and you will zoom out.

2-Point Zoom:

1. Click Zoom.

2. Click 2 points on a diagonal in which you want to be the top and bottom corners.

1. The easiest way to do this is think about top right and bottom left or top left and bottom right

corners.

2.46.5 Best Fit

While you are zoomed in on a specific area while editing, you can click Best Fit and the template will be zoomed in

or out so that the entire drawing is fit within 90% of the window.

34 | P a g e

Templating Menu (Right Sidebar)

This menu is used while you are actually doing the templating and taking measurements.

2.47 Laser Mode

There are 4 drawing modes to use while templating, Line, Arc, Circle and Cross.

Line - This is the default mode that will be set up each time you open our software. Every 2 points measured will create

a line.

Arc - Every 3 points will create an arc.

Circle - There are 2 types of circles that can be drawn, 3-Point and 1-Point.

3-Point - This type of circle is used when there is a column or anything stationary that you have to template and has

to be precisely on. All you need to do is measure 3 points and the software will create a circle based on those 3

measurements.

1-Point - This type of circle is used when you are going to be putting a grommet in. The exact position is not

necessary, only the size of it. Input the radius of the circle and the next measured point will be the center of the

circle. Remember a radius is 1/2 of a circle so if you do a 2-inch radius, the circle will be a 4 inches in diameter.

Cross - Drawing a cross will simply put a cross on the measured point. This is especially useful for drop-ins, marking

center lines, as well as use with the Re-Position Laser (Leap) feature.

2.48 Erase

Clicking Erase will allow you to erase any line segment you have templated or drawn.

2.49 Distance

Using the Distance feature allows you to measure from any one point to any other point.

1. Click Distance.

2. Click 2 points on the template.

2.50 Auto Fillet

Using the Auto Fillet feature allows you to speed up your templating. You no longer need to click Start New Line when

you are moving to a new plane. This is because every third point taken will start a new line.

For example, you will take 2 points on the side of a cabinet base creating a line. The third point will then be taken on the

front of the cabinet base. Once the forth point is taken and you have to lines drawn, those are then automatically

filleted to each other creating a corner.

2.51 Fillet

Fillet allows you to add in special corners to templates. This includes corners that have been drawn in already as well as

corners that have been left open while templating.

There are 3 different types of fillets that you can add (Radii, Chamfers and Sharp Corners).

35 | P a g e

Radius - When you choose to fillet a radius, the software will automatically figure the intersection of the 2 lines and then

back off that many inches and ad the radius edge.