HogNose

Building instructions.

March 19, 2018

Version 1.1

lasercutplanes.co.uk

THANKYOU FOR PURCHASING THE HOGNOSE FROM

"LASERCUTPLANES.CO.UK"

PLEASE READ THE MANUAL BEFORE STARTING TO FAMILIARISE

YOURSELF WITH THE BUILD PROCEDURE.

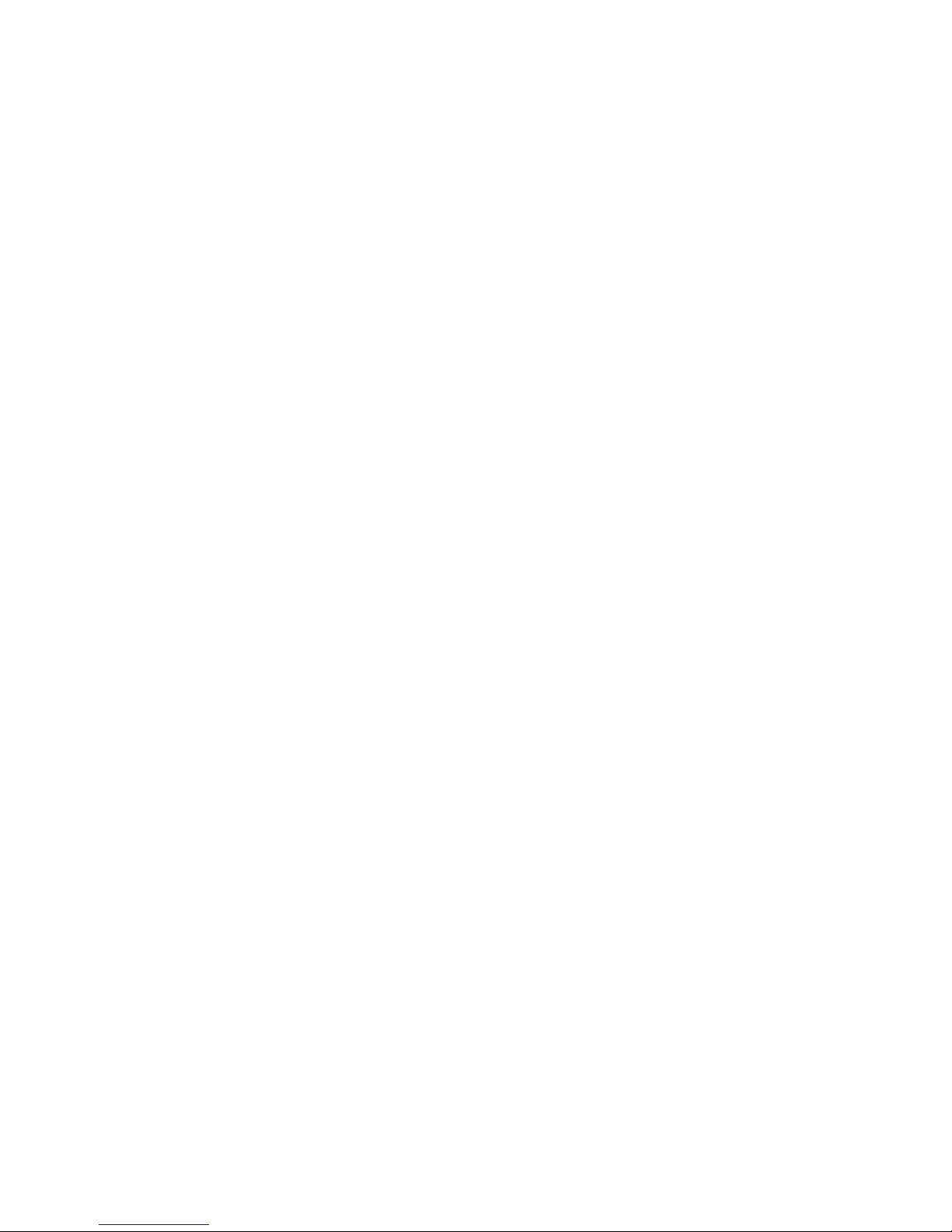

1:-The kit is supplied in 6 laser cut sheets. Sheets 1 to 5 are 1/16th

balsa. Sheet 6 is 1mm ply. There is also a bag of accessories

containing push rods, undercarriage wire, wheels etc.

2:- The items are held in place on the sheets by small tabs. These tabs

need to be cut through carefully in order to remove the items. Also due

to the varying density of the balsa there may be the odd place that the

laser has not cut fully through and any areas like this also need to be

cut through. A scalpel with a no11 blade is ideal for this.

3:- We find it best to leave the items on the sheets until they are

needed for the build. This way any small items are less likely to get lost

.

4:- The instructions which follow assume you are using the motor,

gearbox and receiver which can be bought as optional extras to the kit.

If you are NOT using these items then certain modifications will need to

be made to facilitate the fitting of any alternative parts.

5:- The plane is designed for indoor flying or for outdoor in flat calm

conditions.

Specification.

Wing span = 490mm

Overall length = 400mm

Flying weight, (Including battery) = < 58 grms.

General Comments.

Please read before starting.

March 19, 2018

Version 1.1

WARRANTY

Lasercutplanes guarantee this kit to be free from defects in both material and workmanship at the

date of purchase. This warranty does not cover any component parts damaged by use or modification.

In no case shall Lasercutplanes liability exceed the original cost of the purchased kit. Further,

Lasercutplanes reserves the right to change or modify this warranty without notice.

LIABILITY RELEASE

In that Lasercutplanes has no control over the final assembly or material used for final assembly,

no liability shall be assumed nor accepted for any damage resulting from use by the user. By the act of

using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is

advised to return this kit immediately in new and unused condition when a full refund minus postage costs will be

given.

THIS PRODUCT IS NOT SUITABLE FOR CHILDREN 12 YEARS OF AGE OR YOUNGER.

WARNING: The use of CA glue is advised for the kit assembly. Adhere strictly to the health and safety procedures

recommended by the manufacturers of the glue being used.

PRODUCT SUPPORT

This product has been engineered to function properly and perform as advertised, with the suggested

power system and supporting electronics as outlined within this product manual. Product support

cannot be provided, nor can Lasercutplanes assist in determining the suitability or use of

electronics, hardware, or power systems not explicitly recommended by Lasercutplanes.

For product assembly support, replacement parts, hardware, and electronics to complete this model,

please contact info@Lasercutplanes.co.uk

Lasercutplanes

Contact :- Info@lasercutplanes.co.uk

Sales :- sales@lasercutplanes.co.uk

Suggested Items needed to Complete this Model

Many of the suggested items listed below are available at your local hobby shop. For your convenience,

lasercutplanes stock most the power system components and some of the building supplies required

to complete this kit. If you have difficulties sourcing any of these items locally, please visit our website,

lasercutplanes.co.uk to purchase the items necessary to complete your model.

Suggested Electronics

☐ RC transmitter DSM2/DSMX with at least 3 channels

☐ Receiver/ESC/Servo brick (AR6410 or equivalent)

☐ Motor/Gearbox (PKZ3624)

☐ Propeller, 130mm x 70mm (EFL9051)

☐ LiPo battery, 120 - 160 mAh 3.7V

This assumes the use of Spektrum electronics. Other systems may be used.

Covering Film Requirements

Any high-quality covering film may be used to finish this model, superior results will be achieved by

using the lightest covering film possible. (Solite currently available to purchase with the kit).

☐ 1 - Pack of Solite sufficient to cover complete plane

Available in Transparent Red, Blue and Green. (other colours available to order).

We recommend the use of Acrylic paint to finish the bare wood parts of the model. This may be either brushed or

airbrushed on.

Required Building Supplies and Tools

☐ CA glue, medium,

☐ CA glue, thin,

☐ CA glue accelerator

☐ Hobby knife with supply of #11 blades

☐ Sanding block with 400 and 600 grit paper

Building Supplies and Tools

☐ Covering iron and heat gun

☐ Needle nose pliers, small

☐ Clear tape, 1/2 in.

☐ Velcro for mounting battery

☐ Masking tape

☐ Solite covering film

Optional Building Supplies and Tools

☐ Balsa filler (HCAR3401)

☐ Modeling clay (ballast)

☐ CA glue de-bonder (PAAPT16)

☐ Required Building Supplies

KIT INVENTORY.

5 X 1/16th BALSA SHEETS OF LASERCUT PARTS.

1 X 1mm PLYWOOD SHEET OF LASERCUT PARTS.

NOSE CONE IN 2 PARTS IN 1/8th BALSA.

2 X CARBON FIBRE PUSHRODS.

4 X PUSH ROD ENDS.

HEAT SHRINK TUBING.

PLASTIC RECEIVER CLIP.

PREFORMED UNDERCARRAIGE WIRE.

2 X WHEELS.

SUGGESTED OPTIONAL EXTRAS.

1 X AR6410 or EQUIVALENT, DSM2/DSMX 6 CHANNEL RECEIVER WITH LINEAR SERVOS AND

BRUSHED ESC.

1 X PARKZONE P51 MOTOR AND GEARBOX. (PKZ3624)

1 X E-Flite Micro 4-Site PROPELLER with SPINNER. (EFL9051)

1 X SOLITE COVERING FILM (TRANSPARENT BLUE, RED OR GREEN).

REQUIRED TO FINISH.

DSM2 OR DSMX COMPATIBLE TRANSMITTER.

LIPO BATTERY, SINGLE CELL 130-160 mAH

These suggestions are for Spektrum systems, When using other systems the electronic

requirements will, of course be different.

INVENTORY

March 19, 2018

HogNose building instructions

6

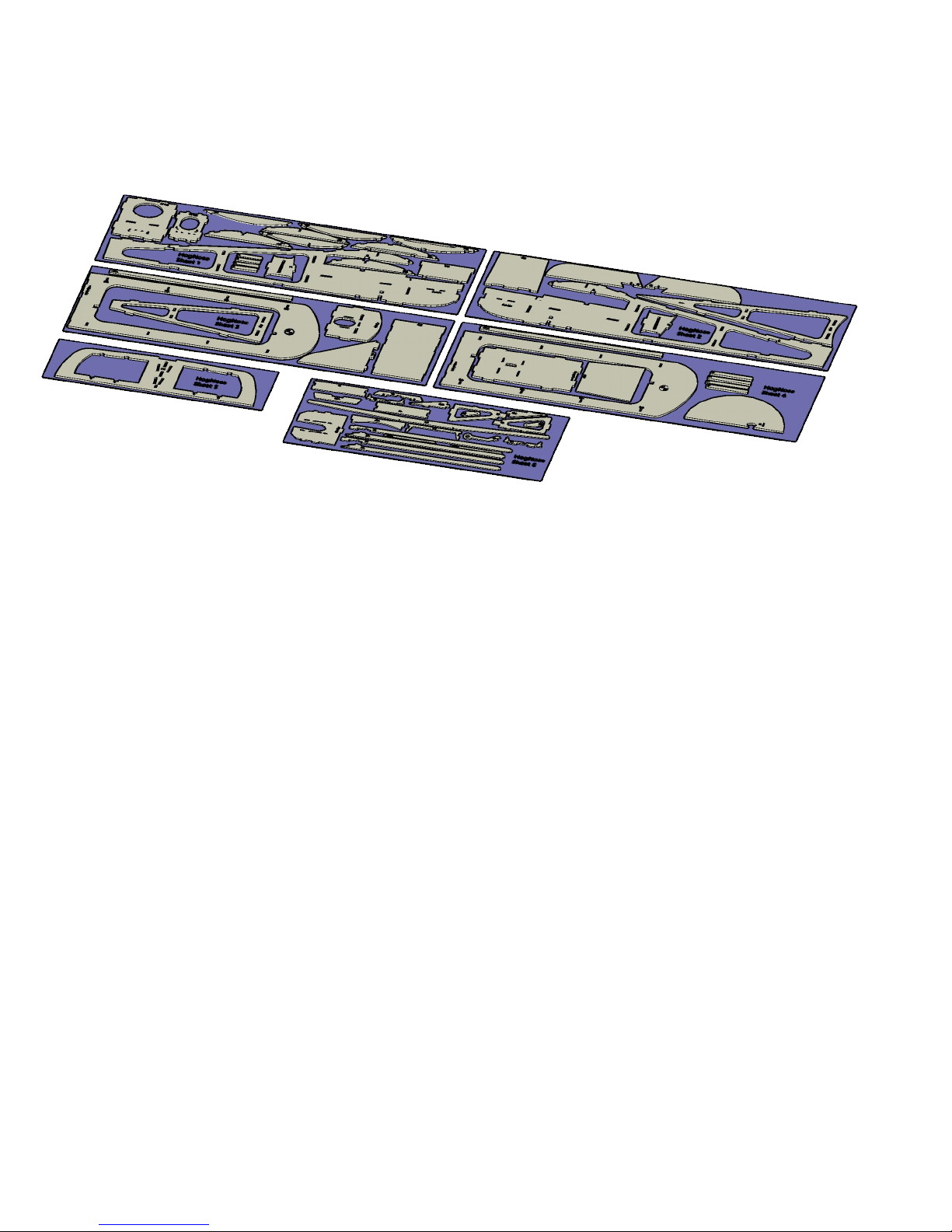

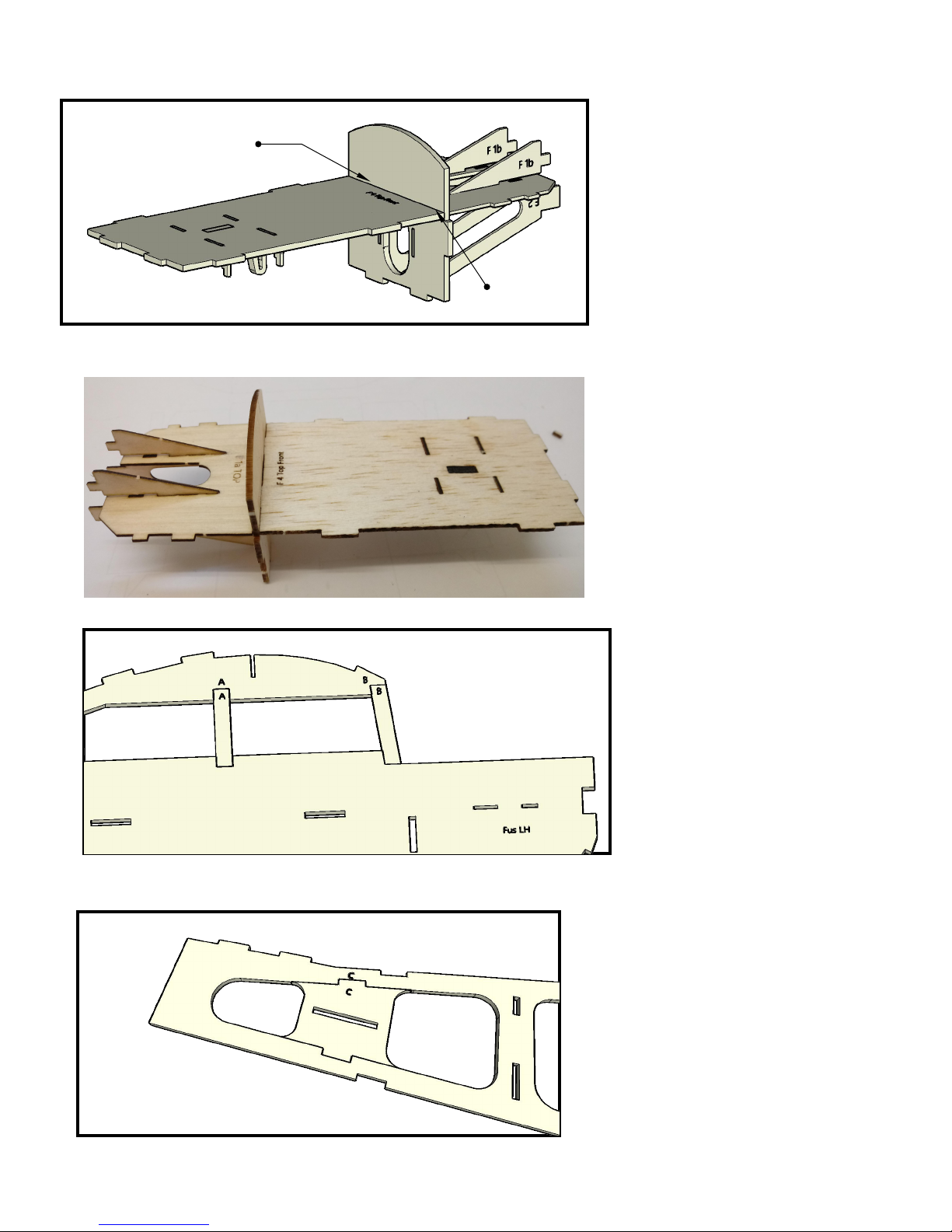

Step 1

Take item "F1a" (sheet 6) and place it on

a flat surface with the markings

uppermost.

Note that the recess for the motor is

intentionally angled to give the model

right thrust.

Glue the 2 items "F1b" (sheet 6) into the

slots in the TOP of "F1a" using 1 spot of

CA where shown.

Ensure no glue enters the slot at the front

of "F1a". This is where the motor will slide

into position.

Step 3

Step 2

Glue item "F3" (sheet 3) to the

back of the assembly made in

Step 1.

Note that 2 of the slots in "F3" are

left empty. These are used later.

1 spot of CA

Ensure no glue enters this slot.

Turn "F1a" over and glue the 2

items "F2" (sheet 6) into the slots in

"F1a"

Ensure no glue enters the slots

between "F1a" and "F1b".

No glue in these 2 slots

Motor

recess.

No glue in this slot

March 19, 2018

HogNose building instructions

7

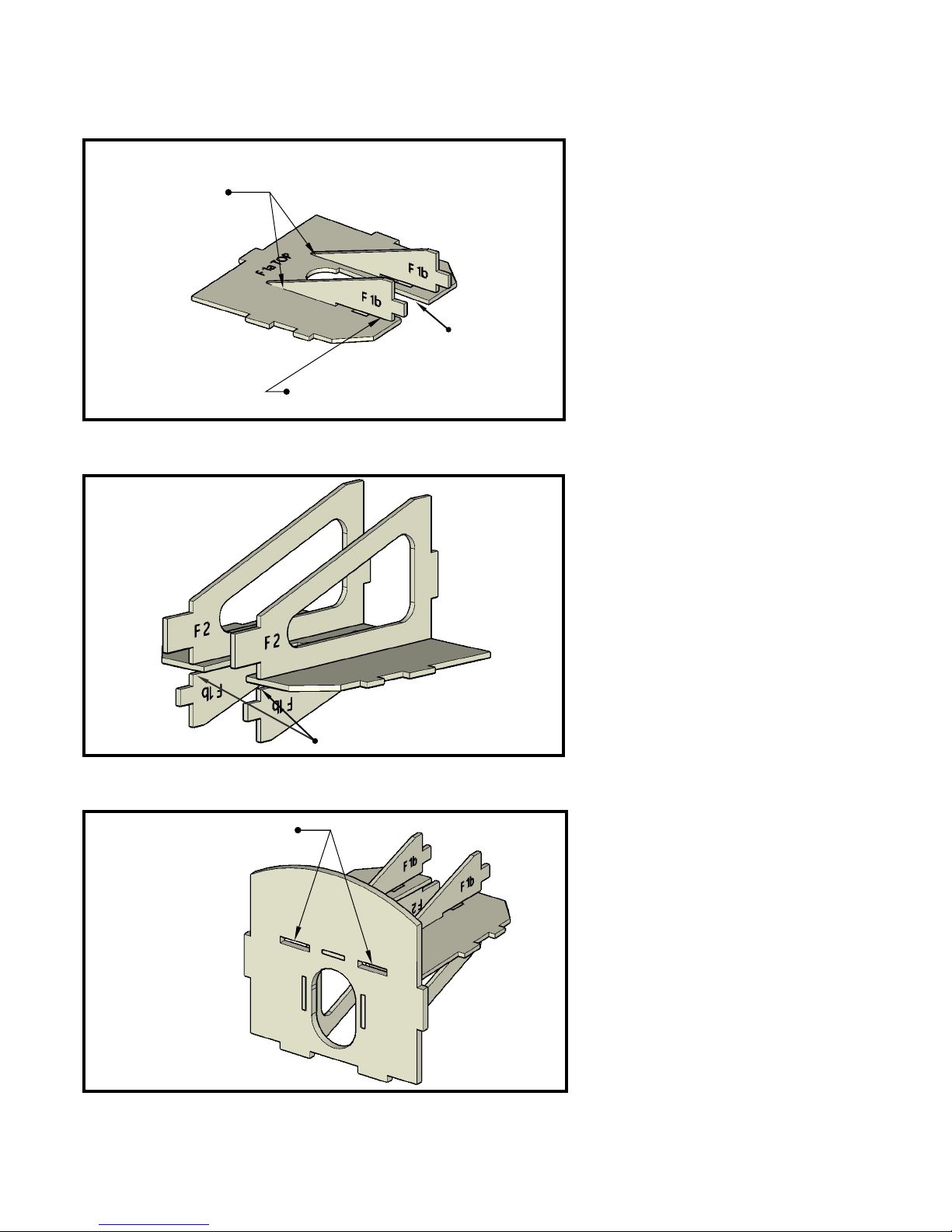

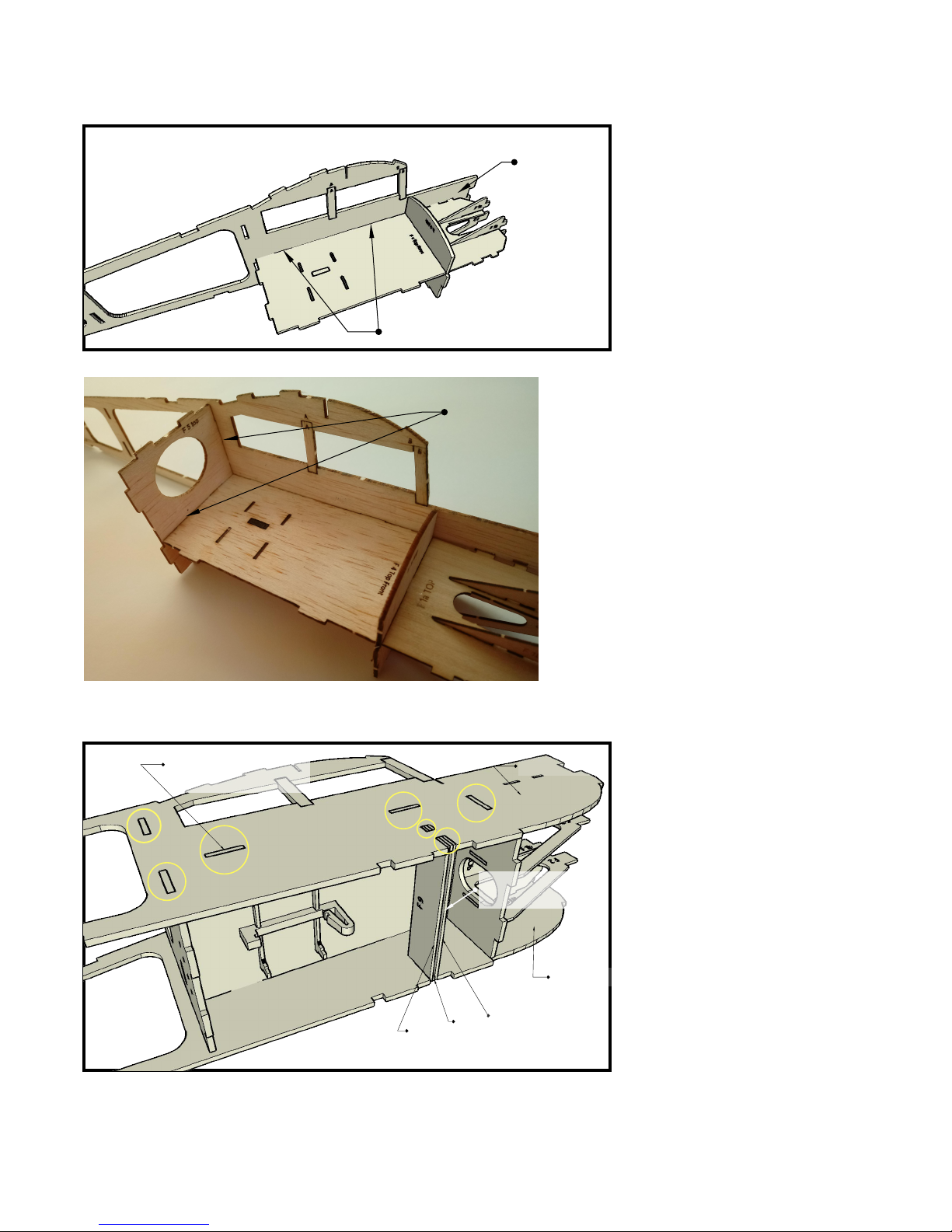

Step 5

Step 4

Locate the plastic receiver

clip (in bag of accessories)

and glue this into the slots

in "F4" and the 2 "RT's".

Photo of the completed assembly.

Note the slot for the motor is

completely clear. If this is not the case

use a small file or blade to clean it out.

Be careful not to enlarge it as the

motor mount needs to be a snug fit.

Set this assembly aside.

THIS STEP ONLY APPLIES IF YOU ARE

USING THE OPTIONAL RECEIVER SUPPLIED

WITH THE KIT. Otherwise you'll need a tray

to fit the receiver being used.

Take item "F4" (SHEET 4) and place it TOP

DOWN on the work surface.

Working on the UNDERSIDE:Locate the 2 plywood items "RT" (sheet 6).

Glue these into the slots provided in "F4".

Note they only fit one way around.

This slot must be clear

March 19, 2018

HogNose building instructions

8

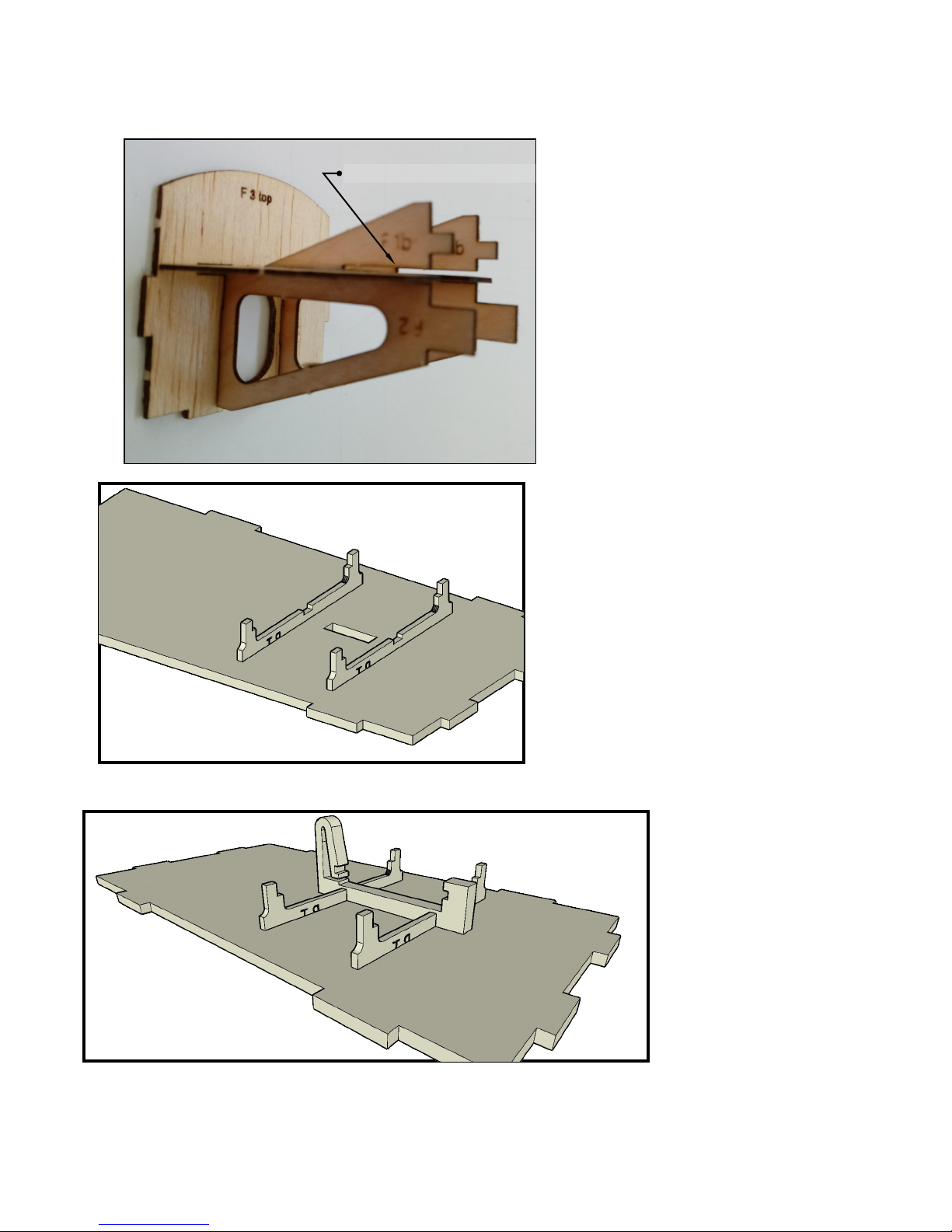

This shows the completed

assembly.

Step 6

Step 8

Locate the small item "C" (sheet 1)

and glue this into place in the slots

provide at the rear of the fuselage

side. The slot in this item is for the

pushrod to pass through. (Elevator

or rudder).

Repeat this step on the RH Fus.

Keep all markings on the inside so

they don't show on the finished

model.

Photo of assembly.

Glue "F4" into the back of the

"F3" assembly from step 3,

ensuring a 90 degree joint

between the two. Ensure the top

of "F4" is uppermost.

(You can use one of the fuselage

sides to hold the items in the

correct position until the glue has

set but don't glue the assembly

to the fuselage yet).

Step 7

Glue

90 degrees

Take "Fus LH" and the items "A"

and "B" (sheet 1).

Glue "A" and "B" into their

corresponding positions in "Fus

LH".

Repeat this step on "Fus RH".

Keep all markings to one side.

That way they don't show on the

finished model.

March 19, 2018

HogNose building instructions

9

Step 9

FOLLOW THIS STEP CLOSELY.

Fit the "Fus RH" in place but DO

NOT GLUE.

Manoeuver "F7" "F8" and "F9"

(sheet 6) into place. ("F8" is

sandwiched between "F7" and

"F9" to form the slot for the

undercarriage to fit into).

You need to let the RH fuselage

side move out to achieve this.

When everything is correctly

seated, apply glue to the 7 tenons

(shown circled) on BOTH

FUSELAGE SIDES to hold

everything in place.

DO NOT allow any glue to enter

the undercarriage slot.

Step 10

Step 11

Take the assembly completed in

"Step 6" and glue it into the slots

in the "LH Fus". Note that there

will be a gap forward of "F3",

DON'T Glue this yet.

DO NOT GLUE THE OTHER

FUSELAGE SIDE TO THIS

ASSEMBLY.

Fit and glue "F5" (sheet 1) to

the fuselage LH side and also

to rear of "F4".

Ensure the markings on "F5"

are facing forward.

gap

Glue Glue Fus LH

Fus RH

F7F8F9

Glue the tenons

only

Undercarriage

slot

March 19, 2018

HogNose building instructions

10

Step 12

Step 15

Manoeuver item "F12"

(sheet 3) into position and

when correctly seated glue

just the 4 places where

shown. (DON'T glue to the

fuselage sides yet).

Turn the fuselage over.

Manoeuver item F13 (sheet 2)

into place and when correctly

seated glue just the 4 places

shown. DON'T glue to the

fuselage sides yet.

Step 13

Ensure a tight fit then apply glue

to all joints around "F4".

You can now pinch together the

front of the fuselage sides until

they are tight along the edge of

"F1a" and then glue in place.

Step 14

Fit "F6" (sheet 1) into the slots

in fuselage sides and pinch the

tail ends together. DO NOT

GLUE.

Ensure the markings on "F6"

are facing forward.

Hold the tail together with a

small piece of masking tape or

similar.

Glue Pinch and glue

Hold together with tape

F6

Glue Glue

F12

F13

March 19, 2018

HogNose building instructions

11

Remove the tape that was

holding the tail together and

check for perfect alignment.

This is very important because

if these are misaligned the

horizontal stabiliser will not fit

correctly.

When perfectly aligned, glue

the tail ends of the fuselage

together.

Step 18

The fuselage sides can

now be glued to "F12"

and "F13". Start at the

position shown and work

your way back to the tail

ensuring a good fit all

along.

Fit item "F15" and glue in place.

ENSURE that the undercarriage slot

is free from obstruction. DON'T

allow glue to enter the slot.

Step 16

Photo of "F13" in place. Note

the sides not glued.

Step 17

Sides not glued

Just the tabs glued

Perfect Alignment

Glue

Start here

Ensure good fit all

along.

"F13"

"F12"

Start here

"F15"

Don't allow

glue in slot

March 19, 2018

HogNose building instructions

12

Fit "NC1" (nose cone one 1/8th

balsa).

Squeeze the fuselage sides in to

make a tight joint and glue into

place around the edges and

around the tenons.

Ensure no glue enters the motor

slot.

Step 19

Step 20

Fit "NC2" and glue into place.

(fit with the markings

innermost. Shown this way for

clarity).

Ensure a good tight fit between

"NC1 and "NC2".

Ensure no glue enters the

motor slot.

Locate "F14" (sheet 6). and glue

into place at the front of the

receiver bay.

DO NOT allow any glue to enter

the undercarriage slot.

Test fit "F19" (sheet 4) under

the nose. Adjust if required by

lightly sanding the ends.

When happy with the fit, glue it

into place.

Step 22

Step 21

Check the fit at each end

Tight joint

Glue No glue in slot

Glue

Tightly together and

glue

NO GLUE in this slot.

"F14"

Keep slot clear

March 19, 2018

HogNose building instructions

13

Fit "F20" (sheet 3) noting that it

only fits one way. The edges

only go half way across the

fuselage side thickness, leaving

a small step to accept the wings.

Glue into place FROM THE

INSIDE to avoid glue entering

the step for the wings.

Step 23

Sand the nose cone into a pleasing shape.

Also lightly sand the whole of the fuselage rounding off

all sharp corners and removing any glue residue.

This completes the fuselage.

Set aside.

Step 24

Fit "F19" (sheet 4) with its' front edge flush with

the front of the nose cone. There should be a

small gap at the back of "F19" to accept the

windscreen. (fitted later).

Don't worry if there is an overlap at the sides,

this will be sanded off later.

Glue into place.

NOTE:If you are going to paint the inside of the cockpit,

then this is best done now before the next step.

Step 25

Flush

Small gap

Don't get

glue in this corner

F20

March 19, 2018

HogNose building instructions

14

Take the 2 "W4" wing ribs (sheet

1) and position them as shown.

Position a "W4a" (sheet 6) on

each rib and align it with the

markings on the rib.

The bottom edges must be flush.

Glue into place.

This strengthens the ribs at this

point and creates small pockets

to accept the wing stays later.

Step 26

Step 29

Take "W2" (sheet 1) and fit it

in the slot labelled "W2" on the

underside of the wing. Ensure

the correct way around and

that the rear edge is flush with

the wing edge.

Also make sure the rib is at 90

degrees to the wing.

The rib markings go next to

the wing markings. IE "W2"

next to "W2".

Glue only at the point shown.

Bend the wing around "W2" to

engage the tenon at the

leading edge. Glue just the

tenon into place.

Repeat steps 28 and 29 on the

other wing.

Step 27

Place "W1 LH" (sheet 4) on the

work surface with the markings

uppermost.

Fit "W1a" (sheet 4) into the slots

and glue in place.

Repeat this step on "W1 RH".

(sheet 3)

Step 28

Glue Glue this point only

these edges

level.

Glue here

only.

Pocket for wing stay

W2

March 19, 2018

HogNose building instructions

15

Fit "W3" (sheet 1) and "W4" (from step

27) to the wing, engaging the rib tabs into

their respective wing slots.

Ensure that you use the correct "W4"

assembly (from Step 27) so that the

pockets are facing inwards. i.e. The

reinforcing strip is on the outside.

Step 30

Photo of finished wings.

Turn the wing over and set on a flat

surface.

Glue only the tenons as shown. This should

ensure that the wing is flat and not twisted.

Check again by sighting along the ribs.

When happy, glue all ribs fully in place.

Ensure NO GLUE enters the slots for the

wing spar shown in picture for Step 31.

Repeat Step 31 and 32 on the other wing.

This completes the wings.

Set them aside.

Step 31

Repeat steps 28 and 29 for

the fitting of "W5" (sheet 1)

at the outer end of the wing.

Sight along the wings to

check they are not twisted.

Repeat on the other wing.

Step 32

Pockets facing inward.

Slots for wing spar.

W3W4.

Glue Glue

March 19, 2018

HogNose building instructions

16

Locate the 2 items "E2" (sheet 2)

and item "E1" (sheet 6)

Fit them together as shown on a flat

surface, (all markings on underside).

Note that "E1" is slightly thinner

than "E2".

The front edge MUST be in a straight

line so set this against a straight

edge and glue "E1" into place.

Ensure no glue enters the slots for

the elevator control horn.

Set aside.

Step 33

Step 36

Locate items "SA" and "SB", 2

of each. (sheet 6). These are

the wings stays.

Fit each pair together as shown

on a flat surface, Glue the

joints.

Ensure a strong joint.

Set aside.

Locate "VS" and "R". vertical

stabiliser (sheet 3) and rudder.

(sheet 4)

Lightly sand and round off the

edges shown. The joining edges

should be left square.

Step 34

Locate "HS" (sheet 5), and the 4

ribs marked "D" and "E". (sheet 4).

Fit he ribs into "HS" as shown and

on a flat surface, glue into place.

Set aside.

Step 35

Round off

Round off

Square

Square

E2E2E1

This edge MUST be straight

No glue in slots

March 19, 2018

HogNose building instructions

17

Locate "E3" (sheet 6).

Take the elevator assembly from "Step 33" and

place it on a flat surface with the markings

uppermost, as shown.

Insert "E3" into the slot shown. i.e. the right

hand slot when viewing from the straight edge.

It should be at 90 degrees to the elevator and

the small hole should be approximately

vertically over the edge of the elevator.

Glue into place.

Step 37

The model now ready for covering/painting.

PAINTING

Paint the following areas.

The receiver bay under the fuselage which takes the

receiver and the battery.

The underside of both wings.

Both wing stays from "Step 35"

The wing spar "WS" sheet 4.

The rudder assembly from "Step 37". BOTH SIDE AT

THE SAME TIME TO AVOID WARPING.

The elevator assembly form "Step 38". BOTH SIDES AT

THE SAME TIME.

Item "TS", (tail skid), sheet 4.

The horizontal stabiliser assembly from "Step 33".

BOTH SIDES AT THE SAME TIME.

The vertical stabiliser. BOTH SIDES AT THE SAME.

The nose cone can either be painted or covered with

film.

Step 38

Locate "R2" (Sheet 6), and fit it into the slot in

the rudder. This MUST be fitted from the side

of the rudder marked "R", also it must be at 90

degrees to the rudder and positioned so that

the small hole is approximately vertically over

the rudder edge.

Glue into place.

Step 39

Keep the horizontal stabiliser, vertical stabiliser, elevator

and rudder flat until fully dry.

March 19, 2018

HogNose building instructions

18

The uncovered area is required to allow for

the installation of the push rods.

This area will be covered after the receiver

and pushrods have been installed and tested.

Cover the following items.

The roof of the cockpit is best covered after

the wings have been fitted. This way the

joint can be covered and it looks neater.

If using a transparent covering film, don't

remove the film that covers the side cockpit

windows.

If using a solid colour covering, the

openings may be cut out and clear acetate

sheet attached to form the windows.

Remove all covering from along the wing

joint.

Underside of covered fuselage

Covered fuselage

Don't cover, access

required for installing

pushrods.

Don't cover

until after

wings are

fitted

No covering

along wing joint.

Cover side windows

The top surface ONLY of both wings.

The top surface ONLY of the horizontal stabiliser.

The whole of the fuselage except for the cockpit

roof and the underside of "F13".

This Photo shows the covered horizontal

stabiliser. NOTE:- This is only covered on the

upper side.

Is this photo the stabiliser has just been test

fitted and it is not glued at this stage.

Upper surface only

is covered with

film.

COVERING

March 19, 2018

HogNose building instructions

19

Top rear of fuselage

Remove all covering from along the

horizontal stabiliser joint.

Remove the covering from the pushrod

slots on both sides of the fuselage.

Step 40.

Locate "WS" (sheet 6).

Remove the covering from the

slots just under the cockpit

roof. Feed "WS" through the

slots.

Ensure that "WS" is the

correct way up. I.E. the tips

are higher than the centre.

There are marks to position

"WS" centrally but if these

have been obscured by the

painting, measure each side

to get it exactly central.

Then turn the model over to

gain access to the joint

through the windscreen hole

and run glue along the joint

as shown.

Remove covering

from pushrod slots.

Both sides

Tenons for horizontal

stabiliser must be free

from covering

Remover covering

from these notches

Slit the covering

to allow undercarriage

to fit.

Remove the covering from the notches for

the wing stays.

Slit the covering to allow the undercarriage

wire to enter its slot.

Measure from fuselage

to tip of "WS" to get

both sides equal.

VERY

IMPORTANT.

"WS" MUST

BE CENTRAL

Glue along

this joint

Remove covering

from slots

Positioning marks

March 19, 2018

HogNose building instructions

20

Step 41

Photo of the fuselage with "WS" fitted.

PUSHRODS.

Locate the 2 lengths of carbon

fibre, the 2 SMALLER diameter

push rod ends and cut 2 x

10mm lengths of the heat

shrink tube.

(bag of accessories)

Photo.

Step 42

Put the heat shrink tube over the

one end of the carbon rod, insert

a push rod end into the heat

shrink tube as shown.

Using a heat gun shrink the tube

onto the carbon rod and the

metal push rod end.

Repeat with the other items to

make two push rods.

Secure the tube onto the rods

with a drop of CA glue.

Fit the two pushrods to the receiver

linear servos as shown using the centre

hole on esch servo tab.

Ensure that the push rod ends are fully

engaged, the last bend should be

pointing upward.

Step 43

Small diameter metal push rod end

Heat shrink tube

Carbon rod

Drop of CA

Centre hole

Pointing up

Elevator pushrod

Rudder pushrod

March 19, 2018

HogNose building instructions

21

Step 45

With the receiver still attached and the correct

way up:Feed the other ends of the rods through the holes

in "F5" and "F6" which are marked "E" for the

elevator rod and "R" for the rudder rod.

It's the outer 2 holes in "F5" and the upper 2 holes

in "F6". (This view is of the underside).

The other holes are not used but may help if

fitting your own receiver.

And finally out through the slots in the

fuselage sides through piece "C".

These rod have been pre-cut to length

and should not require further

trimming.

Now fit the receiver into the receiver

tray and check it is fully located in the

small notches in the plastic receiver

clip. (SEE BELOW).

Step 44

E R Slot in "C" fuselage side.

Elevator pushrod

Rudder pushrod

Nose

Fit the receiver

to this slot first

Gently push

until the receiver

clicks into position

Note:- Push rods not shown in

this view for clarity.

To fit the receiver into the receiver

tray.

Locate the "V7" lettering on the

receiver and engage this part of

the receiver into the rear notch of

the plastic receiver clip.

Then gently push the front of the

receiver down until it engages in

the front clip.

"V7"

Fitting the receiver into the tray.

Tail

March 19, 2018

HogNose building instructions

22

Fit the horizontal stabiliser to the top rear of the

fuselage, covered side uppermost, making sure

to engage the 4 tenons into their slots. MAKE

SURE the horizontal stabiliser is at 90 degrees to

the fuselage.

Turn the fuselage over and glue the stabiliser

into place.

IT IS VERY IMPORTANT that the stabiliser is at

90 degrees to the fuselage.

Step 46

Step 49

Remove the covering form the top

centre portion of the horizontal

stabiliser as shown.

Fit the vertical stabiliser, ensure that all 3

tenons are fully engaged into their slots and

glue this in place.

IT IS VERY IMPORTANT that the vertical

stabiliser is at 90 degrees to the horizontal

stabiliser.

Step 47

Test the setup at this point.

Bind the receiver to your transmitter.

Test the operation of both elevator and

rudder.

If everything is running smoothly continue

with next step.

Step 48

Uncovered

face of stabiliser

Glue along

this joint ,both

sides

Remove covering

Glue along

this joint

both sides

March 19, 2018

HogNose building instructions

23

Step 50.

Take 2 pieces of adhesive tape, 1 at 50 x

12mm and the other 20 x 12mm.

Attach them to the rudder as shown. i.e. to the

side that does NOT have the control horn

attached.

Then attach the rudder to the

vertical stabiliser leaving a small

gap (1mm approx.) between the

two.

The rudder should have

approximately 30 degrees of

movement side to side.

Take 2 pieces of adhesive tape

55 x 12mm.

Attach them as shown to the

TOP of the elevator, i.e. to the

side that does not have the

control horn attached.

Step 51

Adhesive tape

Then attach the elevator to the horizontal stabiliser leaving

a small gap (1mm approx.), between the two.

The elevator should have approximately 30 degrees of

movement up and down.

Adhesive tape

1mm parallel gap.

1mm parallel

gap.

March 19, 2018

HogNose building instructions

24

Step 52

Repeat the above procedure with the

rudder.

The rudder must be straight before

shrinking the tube. Use DIRECT HEAT

as a heat gun WILL damage the

covering.

Power up the transmitter and receiver

and check that both rudder and

elevator operate correctly.

If all is well, the underside of F13 can

now be covered with film.

Cut a short length, (approx. 15mm) of

the heat shrink tubing supplied. Slide

this over the end of the elevator

pushrod.

Take one of the larger diameter push

rod ends. Fit the "Z bend" to the

elevator control horn ensuring that it is

correctly seated with the end pointing

away from the elevator, then slide the

other end into the heat shrink tube.

Note that the end is bent to bring the

wire parallel to the pushrod. This bend

may need adjusting.

Position the elevator so it is IN LINE with

the horizontal stabiliser and then apply

heat to the tube to shrink it onto the

pushrod and end.

Use DIRECT HEAT for this because a

heat gun WILL damage the covering.

Make sure the end is held in place BUT

DON'T GLUE. This will be done after

trimming the aircraft.

Step 53

Heat shrink tube

Push rod end

Elevator control horn

Heat shrink tube

Push rod end

Rudder control horn

F13

March 19, 2018

HogNose building instructions

25

Cut a piece of covering film about 8mm

wider than the cockpit roof. Cover the

cockpit roof overlapping the joints with

the film.

Step 54

Step 57

With the model upside down, locate the

wing stays, ("SA + SB" step 35).

These MUST be fitted the correct way

around, with the longer arm "SB" to the rear

of the plane.

Fit the joined end into the slot in the

fuselage side and "SB" into the rear pocket

in "W4/W4a". Glue the stay in place at these

two points ONLY. (see photo).

Now bend the wing slightly to engage the

end of "SA" into its' pocket in "W4/W4a".

Glue this into place.

When you view the wing end on, it will be

twisted with its' front edge lower at the tip.

This is called "washout" and enables the

plane to fly slower without stalling.

Fit the stay on the other wing in the same

way.

Step 55

Take a wing and carefully slide it along

the wing spar until it meets the

fuselage side. The spar fits through the

slots in "W2" and "W3".

When a good fit is achieved glue all

areas shown.

Repeat with other wing.

Step 56

Glue along this joint

Glue along length

of spar.

Glue spar to ribs

Overlap this joint

with film

SBSAGlue

Glue

Manipulate wing to engage

here, then glue into place

SB

SA

March 19, 2018

HogNose building instructions

26

Fit the wheels onto the wire and

then shrink another short length

of tube outside the wheel.

Ensure that the wheels turn

freely, then trim off the excess

wire.

Step 58

Slit the covering (if not previously done) from

over the undercarriage slot and insert the

undercarriage wire.

Then fit "LG1" (Sheet 6), into the slot

...........

.... and push it right in so that

the it grips the undercarraige

wire fully.

Ensure that the undercarriage is

central.

Apply glue to the places shown

to secure the undercarriage into

position.

Carefully bend the wire if

necessary to get the plane level

when on its' wheels.

Step 59

Locate the undercarriage wire.

Cut 2 short lengths, (about

3mm long) of heat shrink tube

and shrink them onto the wire

as shown.

Step 60

Short length of tube

2nd piece of heat shrink tube

Trim the wire here

Slit the covering

Push "LG1" into the slot

Glue

March 19, 2018

HogNose building instructions

27

Fit the tail wheel, "TS" (sheet 6)

and glue into place making sure

its at 90 degrees to the fuselage.

Step 61

Step 63

Locate the acetate sheet

windscreen and fit it into the

slots in the fuselage side. Trim

it to size if necessary and then

glue into place.

Take the motor and gearbox and cut off the

4 spikes from the holder as shown.

Remove the covering from the

tail wheel slot on the underside

as shown.

Step 62

Remove covering

Glue

Slot

Glue Cut off 4 spikes

March 19, 2018

HogNose building instructions

28

Feed the motor power wires through the nose and

into the receiver bay.

Insert the motor and gearbox into the slots in the

nose cone as shown with the larger gear for the

propeller uppermost ..........

Step 64

........ then push it fully into the nose. The large

gear should be just inside the nose cone.

The motor is held in place by friction alone, if

however you find the motor isn't held tight

enough, it may be glued in place.

Hot glue or any wood glue is fine for this.

DON'T GET GLUE ON ANY OF THE MOVING

PARTS.

NOTE The motor and propeller shaft will not be in

line with the fuselage. they will be pointing

approximately 3 degrees to the right when

viewed from above.

This is required to compensate for the rotation of

the motor.

Step 65

Attach the propeller as it's

easier to do at this stage.

Step 66

UP

Carefully remove a logo from the

black vinyl sheet and fix it as shown to

the fuselage side.

Repeat on the other side of the

fuselage.

March 19, 2018

HogNose building instructions

29

Step 68

Connect the motor power wires

to the "esc" output of the

receiver.

There are 2 pins on the motor

plug but 3 sockets in the

receiver ESC.

The motor plug MUST be fitted

into the correct sockets and also

the correct way around in order

for the motor to work correctly

and in the correct rotation.

Fit the plug as shown in the

photo.

Attach a piece of "Velcro" to

the side of the receiver bay as

shown to support the battery.

Power up your transmitter and

the receiver and test that the

motor is working correctly in

the correct direction.

Step 67

Step 69

Velcro

Battery

FRONT

Glue the spinner onto the

propeller.

White wire

Black wire

No connection

March 19, 2018

HogNose building instructions

30

Congratulations the

plane is complete

and ready for flight

tests.

The plane is designed for indoor flying. (Can be flown outdoors in flat calm conditions).

Before flying the model, check that the rudder and elevator and in the neutral position. i.e. straight.

Check that the centre of gravity is correct by supporting the plane on two fingers resting on the C of G

spots on the underside of either wing.

Check that both rudder and elevator and operating in the correct direction. 20 degrees of movement in

each direction is usually enough.

As the plane does not have ailerons, you may prefer to set up a mix on your transmitter to make the

right stick control both elevation and direction. This is optional.

Test fly the plane and then manually adjust the rudder and elevator positions to give a straight and

level flight with "hands free" from the transmitter.

When happy with the flight, apply a spot of glue to the heat shrink tubing holding the rudder and

elevator push rod ends to secure them into position.

We hope you enjoy flying the HogNose.

If you have any comments regarding the HogNose or this instruction manual please email us at

:- Info@lasercutplanes.co.uk.

Complete

Loading...

Loading...