LASDROP Gen.II Installation Instructions Manual

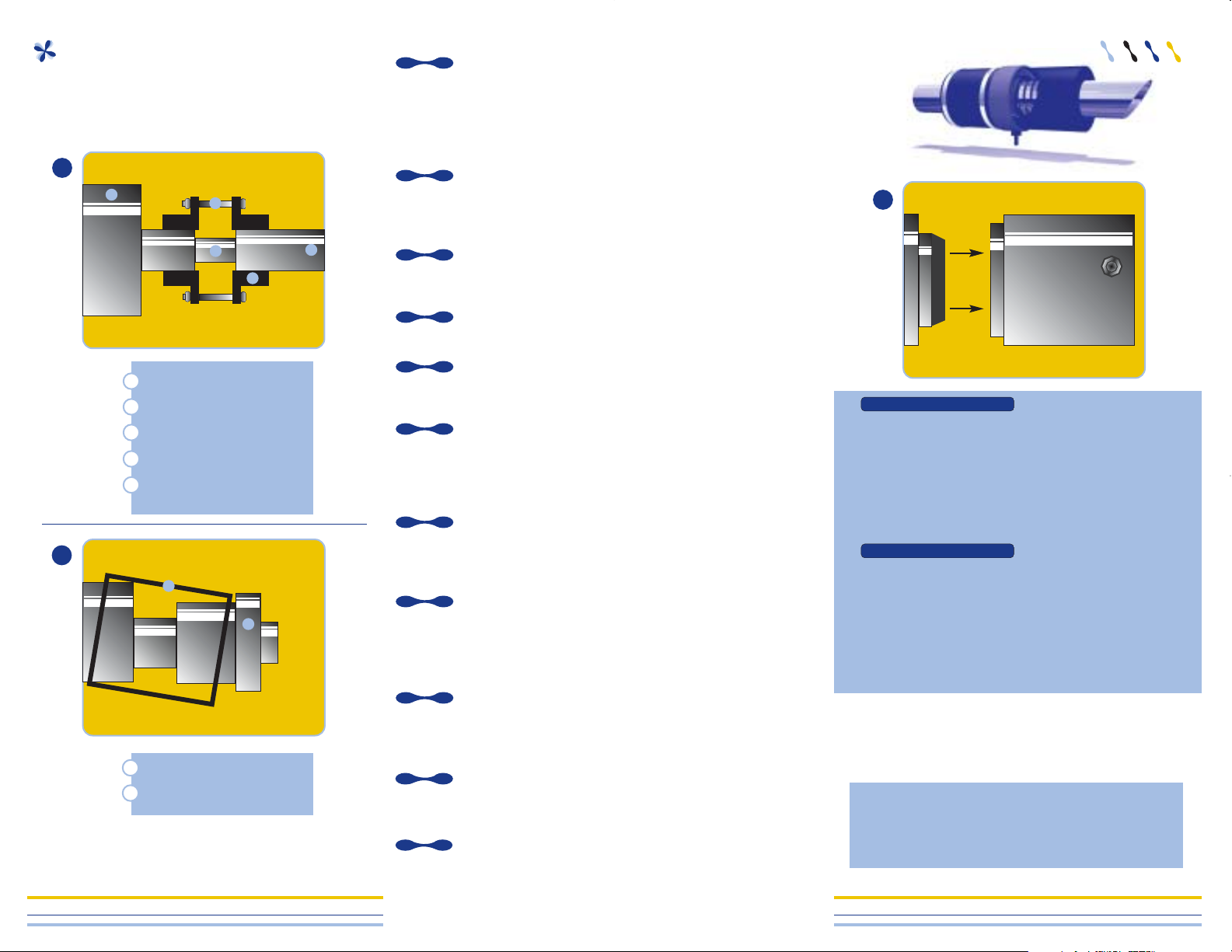

Unbolt the shaft coupling from the engine coupling.Remove the

shaft coupling from the shaft (on most installations the coupling

is held on the shaft by two set screws). Helpful hint: Removing

the shaft coupling may be difficult. The drawing below shows

the use of a spacer as a press between propeller shaft and the

transmission(fig.1)

Insert a spacer (smaller than the shaft diameter) between the

shaft and transmission.Re-tighten the coupling back onto the

transmission. You have now created a press to push the shaft

away from the coupling.

Remove your old stuffing box. (*If your boat is equipped with a

bolt on or rigid type stuffing box, please refer to heading: For

bolt-on or rigid type stuffing boxes.)

Clean shaft as thoroughly as possible with very fine sandpaper

(400 to 600 grit) and remove any sharp edges or burrs.

Slide the Friction Assembly over the shaft and connect it to your

stern tube with the provided stainless hose clamps. An insert

may be necessary for proper fit.

When mounting Friction Assembly, arrange connection hose so

that there is a minimum amount of pressure on the inner alignment bearing (inside the Friction Assembly). This should only

have to be done if shaft is not centralized with the stern tube in

a fairly extreme manner.

Mount connection hose crooked to relieve any major pressure

caused by misalignment. When tightening hose to Friction

Assembly with clamps, DO NOT over tighten. This may cause

Friction Assembly to grab shaft(Fig.2)

If the end of your drive shaft is not tapered, you will need to use

the included installation plug to install the Clamp/Pressure unit

over the shaft. Use liquid soap to lubricate the inner lip seals

then place the installation plug next to the lip seal inside the

unit.

Carefully slide the Assembly onto the shaft. You will need to

push the plug out the back of the Assembly using your finger as

a guide. Re-install the coupling onto the shaft and bolt the

assembly back onto the transmission.

Slide the Clamp/Pressure assembly into contact with the carbon

friction assembly and mark this “neutral” position with a magic

marker(Fig.3)

While using the “neutral” mark on the shaft, compress the

Clamp/Pressure assembly 1/4”. Keeping the assembly onto the

shaft by tightening the two bolts on the housing.

1111

1100

55

66

77

88

99

44

33

11

22

RRee aa dd AAllll IInn sstt rr uucc ttiioonnss tt hhoorr oo uu gghh llyy bbee ffoorree iinn sstt aall ll iinngg

tthh ee LL aa ssddrr oo pp GGeenn.. IIII.. BBee SSuurree nnoott ttoo ddaammaaggee tthh ee

iinnnnee rr ll ii pp ssee aa ll wwhhiillee uu nn pp aa cc kkiinn gg aa nn dd hhaa nn ddlliinngg..

AA

BB

CC

DD

EE

AA

BB

CC

DD

EE

Transmission

Bolt

Spacer

Shaft Coupling

Shaft

AA

BB

AA

BB

Friction Assembly

Mounting Hose

Drawing is exaggerated for demonstration purposes

HHuullllss AABBOOVVEE 1100 KKnnoottss

HHuullllss BBEELLOOWW 1100 KKnnoottss

The Lasdrop Gen.II. requires water for cooling and lubrication.

The system uses a “vent line” that lets air escape from the seal

and stern tube to let water take its place. Simply route the

included hose above the water line. A valve can also be spliced

into the line and used as a safety shut off. Whenever launching

your boat, open the valve and “burp” the system.

High speed hulls must inject water into the seal. The supply to

the after-cooler, a bottom hull scoop or separate water pump are

good sources for cool clean water. It is best that the supply line

is spliced into a fresh water line using a “T” fitting. (Due to the

many different combinations of “T” sizes, this part is not included in the kit.) The exhaust manifolds may also provide water,

but due to the excess heat of some boats and the amount of

floating debris, it is not recommended.

WWaarrnniinngg!!

If engine is located below water line, DO NOT connect water coolant

line into exhaust manifold.This may flood the engine.

11

22

33

IIMMPPOORRTTAANNTT!!

There is, on average, a 20 minute break-in period when the

carbon face is polishing the face of the stainless steel.

During this break-in period there will be a fine black mist

being emitted during operation between the two faces.

IInnssttaallllaattiioonn IInnssttrruuccttiioonnss

GGeenn..IIII

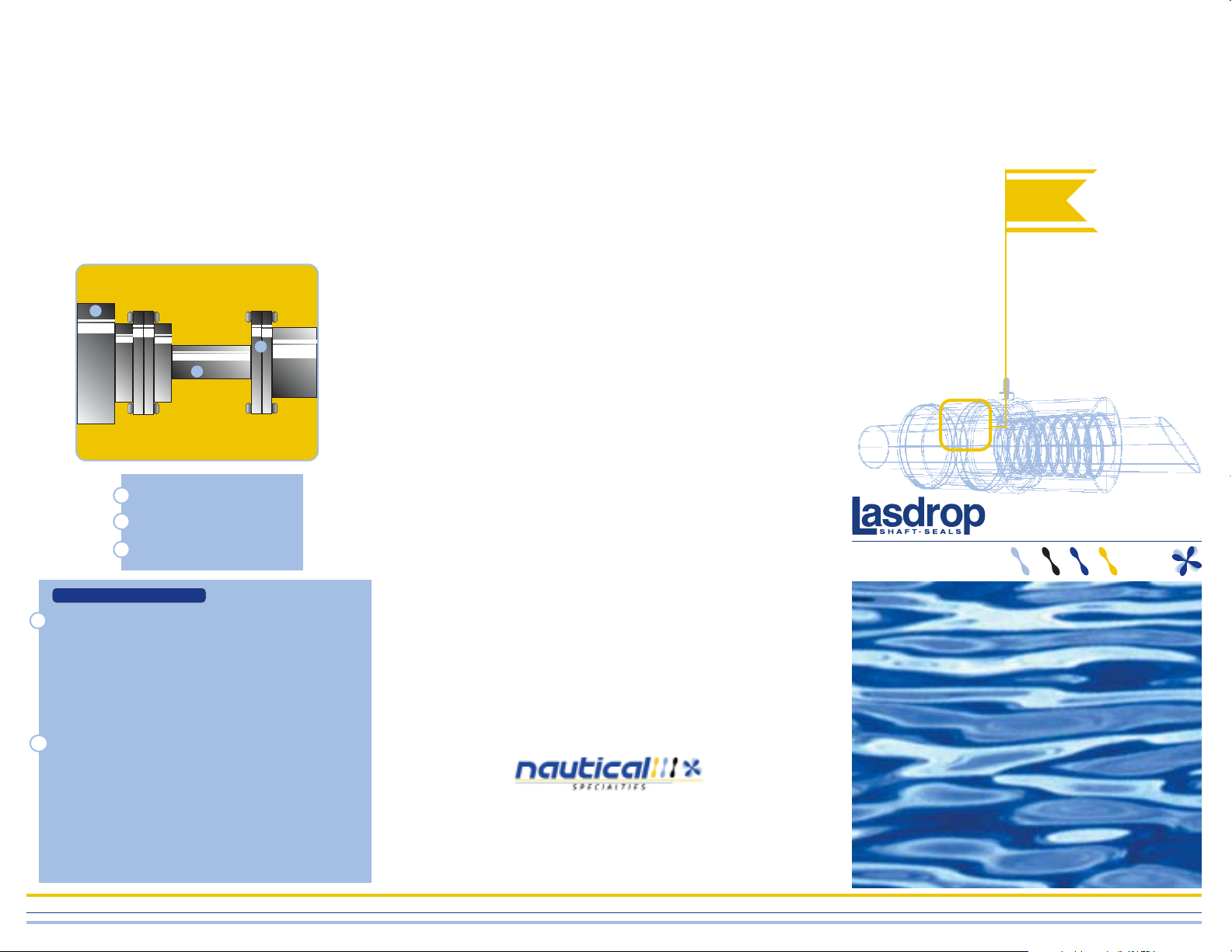

FF OORR BBOO LLTT--OONN OORR RRII GGIIDD SSTTUUFFFF IINNGG BBOO XXEESS::

If your stuffing box is a bolt-on or rigid type you will need to

reverse the plate and tube that are used to compress the

packing. Once reversed, the connection hose can be fitted

over the tube. When re-attaching your reversed plate and

tube, seal the two surfaces so that no water can leak

through. Products such as “Form-a-Gasket” or an automotive type of gasket will work for this application. If your old

stuffing box was threaded on you will need to cover the

threads with a liquid gasket material like “Form-a-gasket” to

prevent the threads from cutting into the connection hose.

AA

Transmission

Shaft

Bolt-on Stuffing box

AA

BB

CC

BB

CC

Every engine, shaft, and motor mounts are different. Because

of this, every installation may be different. If you should experience any spray or “misting” during high speed operation

(after break-in period), add an additional 1/16” compressionto

the Clamp/Pressure assembly and repeat until the spray has

stopped at cruising RPM

The seal is created between the polished faces of the

Stainless steel and the carbon. If the seal leaks when the is

not turning, some foreign material such as grease or transmission fluid may be prohibiting the two faces from seating properly. To clean this foreign material from the two faces, insert a

clean cloth rag between carbon and stainless steel faces and

rotate it around the shaft vigorously. As you do this, water

will flush both faces of any impurities.

TTrroouubblleesshhoooottiinngg

11

22

Spray or “mist” during operation.

Dripping while not operational.

Lasdrop 3-Year Limited Warranty

Nautical Specialties, Inc. hereinafter referred to as NSI,

warrants to the first retail purchase of thisproduct, or a

NSI product, properly incorporated in another venders

products that, for a period of three (3) years from the

date of original purchase, NSI products will be free from

defects in materials and workmanship. NSI makes no

warranty as to merchantability or to fitness of its

products for a particular purpose.

The above warranty does not apply to a product that has

not been installed or maintained in accordance with NSI

instructions, been subject to damage in an accident or

abused during operation, or repaired or modified by persons other than NSI. This warranty is also void when NSI

products are installed at any location which is judged by

NSI to be an inappropriate application which is in NSI

judgement are compatible with the NSI product or

adversely affect its performance or durability.

If any NSI product is used commercially, for such purposes as rental or other income-producing activities,

than this warranty is limited to one (1) year from the date

of original purchase.

NSI’s responsibility in respect to warranty claims is

limited solely to repair or replacement of product found

by NSI to be defective. NSI does not pay for labor

charges connected with removal of a product deemed to

be defective or with installation or replacement of

repaired product, or for any other incidental or

consequential damages resulting from product failure.

To make claim under this warranty, return the product

believed to be defective to Nautical Specialties, Inc.

14081 Timberview Shelby Twp. MI. 48315 along with

proof of purchase. If found to be defective, and if within

the warranty period, NSI will repair or replace the

and return it freight prepaid.

This warranty is and shall be in lieu of all other

warranties, whether expressed or implied by NSI, its

agents, employees, representatives or otherwise with

respect to any sale, service or other transaction on or

subsequent July 20, 1999.

Nautical Specialties Inc.

P.O. Box 223

New Baltimore, MI 48047

USA

toll free - 1 800 940 7325

direct - 586 725 2230

fax - 586 725 2250

Loading...

Loading...