HYDRAULIC TOOLS:

CABLE AND BAR CUTTER

“CC0018”

LARZEP, S.A. LARZEP AUSTRALIA PTY. LTD. LARZEP AUSTRALIA PTY. LTD.

Avenida Urtiaga, 6 139 Wedgewood Road, 49A Sustainable Avenue

48269 MALLABIA, SPAIN HALLAM, VIC. 3803 AUSTRALIA BIBRA LAKE, WA 6163 AUSTRALIA

Tel. +34 943 171200 Tel. +61 (3) 9796 3744 Tel. +61 (8) 9418 4988

Fax. +34 943 174166 Fax. +61 (3) 9796 5964 Fax. +61 (8) 9418 2644

e-mail: sales@larzep.com e-mail: sales@larzep.com.au e-mail: sales@larzep.com.au

www.larzep.com www.larzep.com.au www.larzep.com.au

2

Instruction Manual

Cable and Bar Cutter “CC0018”

INDEX

1. BEFORE USING THE EQUIPMENT --------------------------- 2

2. TECHNICAL FEATURES --------------------------------------- 2-3

3. ESSENTIAL SAFETY REQUIREMENTS --------------------- 3

4. START-UP ------------------------------------------------------------- 4

5. MAINTENANCE ----------------------------------------------------- 4

6. WARRANTY ---------------------------------------------------------- 4

7. DECLARATION OF CONFORMITY --------------------------- 5

ANNEX

GENERAL DRAWING

1. BEFORE USING THE EQUIPMENT.

Remove the tool from its packaging and check for external damage, such as:

o Broken cutting blade.

o Damaged levers.

o Loosed/unscrewed parts.

LARZEP hydraulic tools are designed in accordance with internal quality standards, in compliance with the ISO 9001 regulation.

The tools are designed for the applications described in this manual. Any other use may pose a risk to the equipment and result in hazardous situations for the

operator. Always use the tools in well-lit areas.

The manufacturer accepts no responsibility for damage resulting from the improper use of the tool.

The operator should be fully aware of the risks inherent in the use of high-pressure hydraulic tools, and should act responsibility in accordance with that described in

this manual, ensuring both his/her own safety as well as the safety of others located in the vicinity of the working zone.

The working instructions should be available for the operator at all times. In addition to reading and understanding the instructions manual, the operator should be

trained in the use of the machine and in the standards and regulations governing operations of this kind, such as those pertaining to accident prevention and

environmental protection, for example. All exposed personnel should use appropriate personal protection equipment: boots, helmet, goggles, gloves and protective

clothing.

Boots Helmet Goggles Gloves Clothes

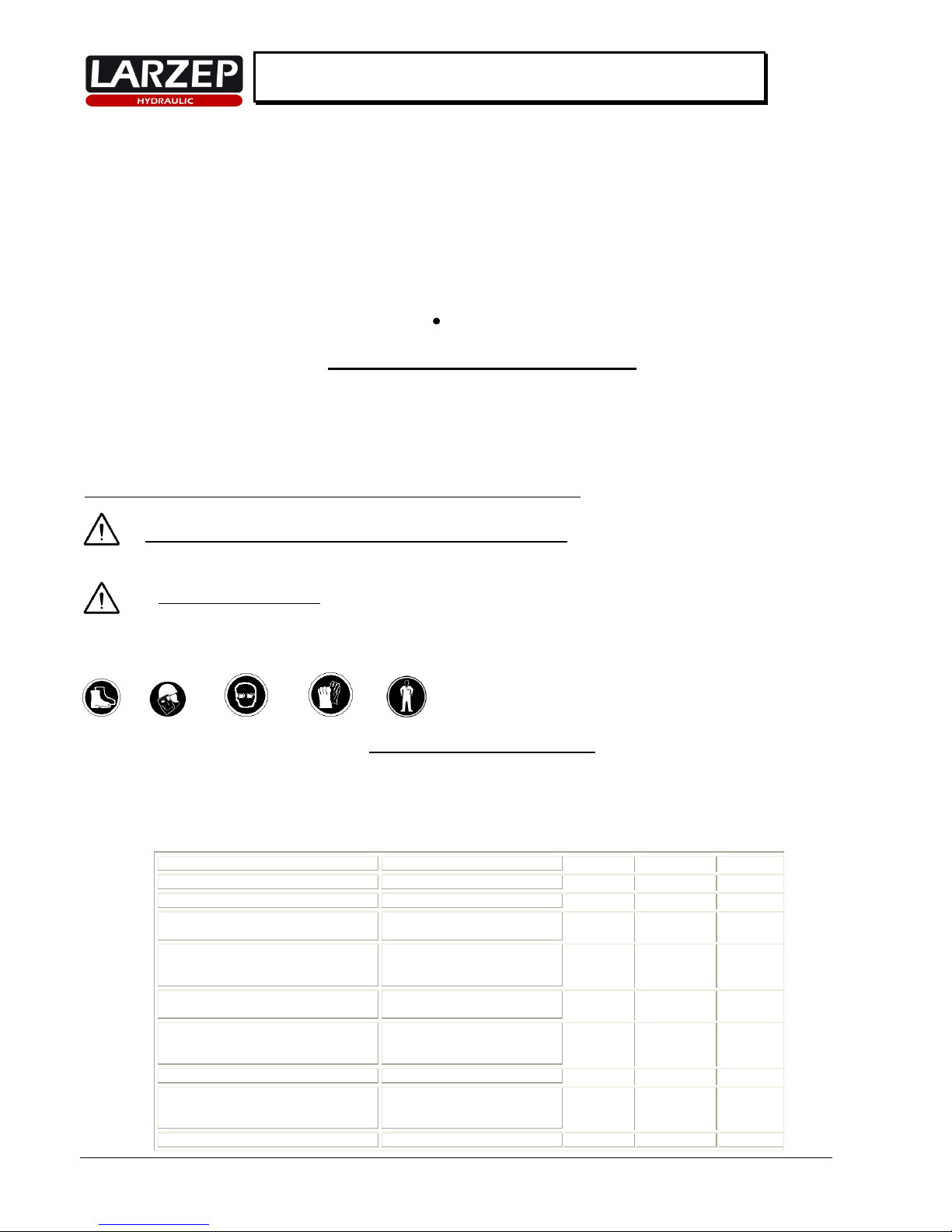

2. TECHNICAL FEATURES.

The tools in the CC cable cutter range are designed to cut cables and bars in accordance with the specifications contained in the table below. Any other use not

included in the said specifications may cause irreparable damage to the cutter and render it unable to carry out the task for which it was designed.

When using the cable cutter, the operator should take steps to prevent the cable from fraying. We recommend that, before commencing the cutting operation, the

cable be attached to either end of the cutting zone, using tape, wire or another similar means.

The operator should take appropriate steps at all times to prevent exposure to flying particles of cable or bar generated during the cutting process (personal

protection equipment, protection screens, etc.).

MODEL

CC0018

CC0040

CC0075

CAPACITY

kN

54 kN

135 kN

70 kN

PRESSURE

bar

550 bar

700 bar

700 bar

WIRE ROPE

STEEL Ext. mm

ALUMMINIUM Ext. mm

18 mm

18 mm

40 mm

40 mm

40 mm

-

CABLE

TELÉPHONE Ext. mm.

LEAD Ext. mm

UNDERGROUND Ext. mm.

18 mm

18 mm

40 mm

40 mm

75 mm

75 mm

75 mm

STEEL ROPE MAX.R = 1800 N/mm

Ext. mm.

WIRE min.mm.

18 mm

1 mm

32 mm

2 mm - -

BAR MAX.R= 400 N/mm

STEEL Ext. mm

COPPER Ext. mm

ALUMMINIUM Ext. mm

12 mm

15 mm

15 mm

20 mm

30 mm

30 mm

-

-

-

BLADE

CRC 18

CRC-35-40

CRC75

DIMENSIONS

A mm

B mm

C mm

385 mm

60 mm

18 mm

490 mm

92 mm

41,5 mm

650 mm

126 mm

77 mm

WEIGHT

kg

2,8 kg

5,6 kg

6,8 kg

Do not loose instruction manual.

Never use hydraulic equipment that is damaged or suspected to be in poor condition.

3

Instruction Manual

Cable and Bar Cutter “CC0018”

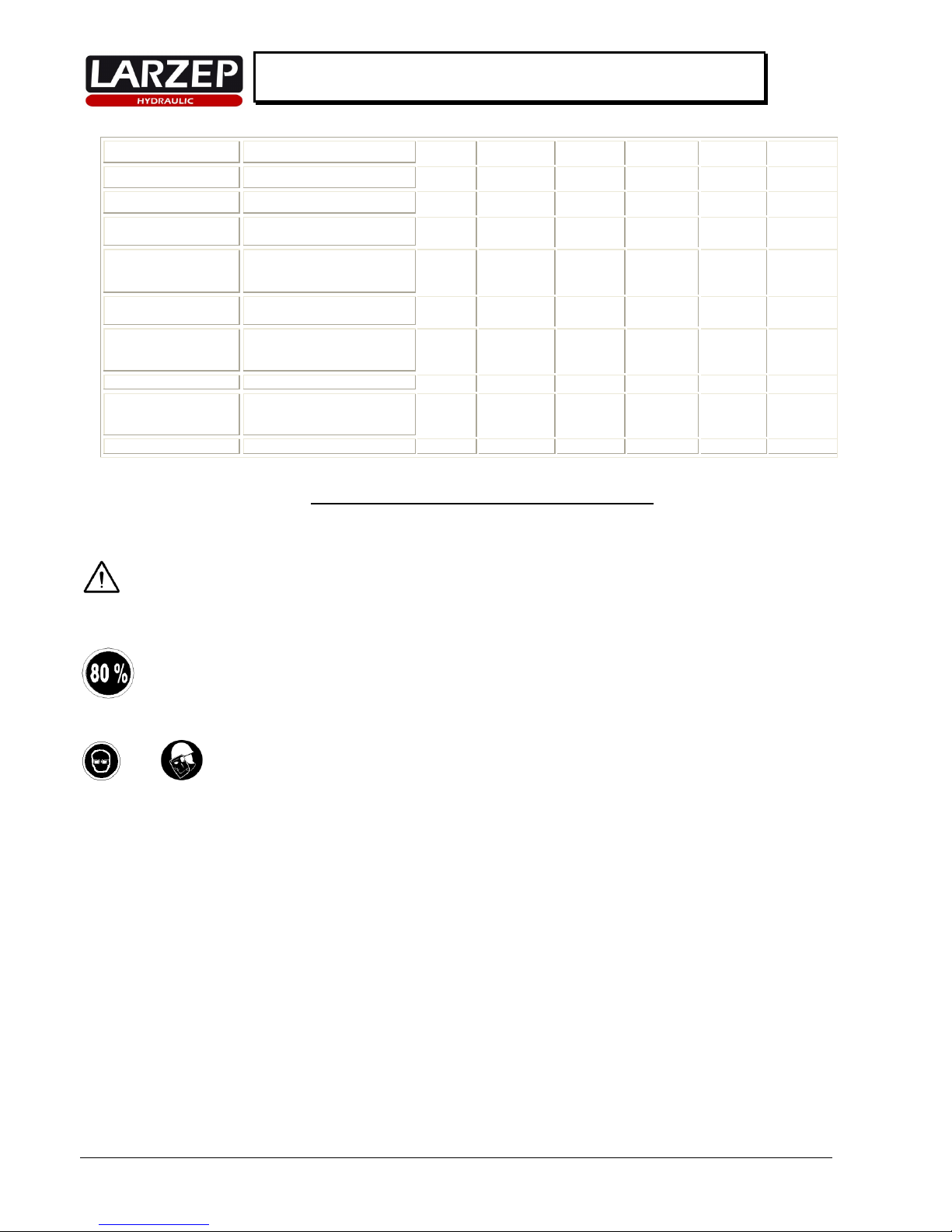

MODELS

CC0118

CC0140

CC0175

CC0190

CC01120

CC0160

CAPACITY

kN

54 kN

135 kN

70 kN

109 kN

109 kN

437 kN

PRESSURE

bar

550 bar

700 bar

700 bar

700 bar

700 bar

700 bar

WIRE ROPE

STEEL Ext. mm

ALUMMINIUM Ext. mm

18 mm

18 mm

40 mm

40 mm

40 mm

-

35 mm

-

35 mm

-

60 mm

60 mm

CABLE

TELÉPHONE Ext. mm

LEAD Ext. mm

UNDERGROUND Ext. mm

18 mm

18 mm

40 mm

40 mm

75 mm

75 mm

75 mm

90 mm

90 mm

90 mm

120 mm

120 mm

120 mm

-

-

-

STEEL ROPE

MAX.R = 1800 N/mm

Ext. mm

WIRE min. mm

18 mm

1 mm

32 mm

2 mm - - - - - -

60 mm

3 mm

BAR MAX.R= 400

N/mm

STEEL Ext. mm

COPPER Ext. mm

ALUMMINIUM Ext. mm

12 mm

15 mm

15 mm

20 mm

30 mm

30 mm

-

-

-

-

-

-

-

-

-

25 mm

35 mm

35 mm

BLADE

CRC 18

CRC-35-40

CRC75

CRC0190

CRC01120

CRC0160

DIMENSIONS

A mm

B mm

C mm

212 mm

60 mm

19 mm

290 mm

92 mm

41,5 mm

451 mm

126 mm

75 mm

535 mm

146 mm

92mm

635 mm

178 mm

122 mm

388 mm

105 mm

64 mm

WEIGHT

kg

2 kg

4,5 kg

5,5 kg

10 kg

11,7 kg

15,6 kg

3. ESSENTIAL SAFETY REQUIREMENTS.

In the event of the improper working of the machine or one of the connected elements, immediately halt all operation, depressurise the system and solve the

problem.

Before beginning operation, make sure that the dangerous area is free of people.

Always use the tools in well-lit areas.

Regardless of whether the cutting tool has a built-in or separate pump, try to establish the most convenient and stable working method for both the tool and the

operator.

When cutting the work piece may project particles and fragments. Therefore, the operator should protect his/her body and (particularly) eyes using appropriate

protective equipment.

Goggles Face Protection.

In the case of tools with a separate pump, the hose enables the operator to move further away from the dangerous area, while in the case of tools with built-in

pumps, if possible, a guard should be positioned between the work piece and the operator.

Do not expose tools to intense heat sources, such as welding equipment, for example.

Depressurise and disconnect the tools before carrying out any maintenance operations.

The controls of both the tools with built-in pumps and the separate pumps themselves should always be activated manually. Do not use hand tools, levers, etc.

to work the controls.

In the case of tools with separate pumps, make sure all the quick plugs are completely clean before connecting.

Make sure that the hydraulic hoses are neither twisted nor unduly tensed.

When working with an electric pump, make sure that the valve is set to its neutral position before connecting the tool.

When working with cable cutters, fraying may occur during the cutting operation. To avoid this, clamp the cable to either end of the cutting blade with tape,

wire or even a bushing.

Clean the quick plugs thoroughly before connecting.

In all cases, the operator should be thoroughly trained in the operation of the tool and should act in accordance with the logical safety criteria associated with

the use of high-pressure equipment.

Allow for a general use at 80% of the tool’s nominal capacity. Do not exceed the tool’s nominal capacity.

In the case of tools with separate pumps, we recommend the use of a pressure indicator, to enable the operator to monitor at all times

the force which the system is subjected.

Check that the machine and accessories have not been damaged in any way during transportation to the plant.

4

Instruction Manual

Cable and Bar Cutter “CC0018”

4. START UP.

MODELS WITH IN-BUILT PUMP.

CC0018,CC0040 AND CC0075

MODELS WITH A SEPARATE PUMP.

CC0118, CC0140, CC0162, CC0175, CC0190 AND C01120.

1- Hold the tool by the thick handle and with the tool in an upright position (head

facing up).

1- Connect the hose’s female quick plug to the tool’s male plug. Make

sure the connection is secure.

2- Pump the lever to check that the blade moves forward.

2- Read and follow the pump instructions.

3- Make sure the deformation zone is free from obstruction, and then continue

pumping until the blade reaches the end of its travel. At this point the lever will

become stiffer and harder to move.

3- Remove the pin and open the tool head.

4-Continue pumping until the safety valve is activated. Check for oil leaks.

4- Place the material to be cut in the cavity of the counter-blade and

close the head, fixing it in place with the pin. Make sure the pin is

properly positioned.

5- Press the unload button and check that the blade returns to its initial position.

5- Pump until the material is cut.

6- Repeat this operation as many times as necessary in order to become familiar

with the operation of the tool.

6- Move the blade back activating the valve of the pump.

7- Remove the pin and open the tool head.

7- Pump until the material is cut.

8- Place the material to be cut in the cavity of the counter-blade and close the

head, fixing it in place with the pin. Make sure the pin is properly positioned.

8- When using electric or air-based pumps, the application is

automated. In such cases, the operator should be specially trained, in

order to avoid the possibility of involuntary actions.

9- Pump until the material is cut.

10- Once cut, press the unload button to move the blade back. Open the head and

remove all traces of waste material before making another cut.

5. MAINTENANCE.

After use, the tool should be cleaned and the area where the blade comes into contact with the heads oiled.

In the event of oil leaks, disassemble the tool and change the seals. The individual blueprint provided for each tool specifies its components and codes.

During this operation, check the condition of the inside of the cylinder. If scratches or snags are detected, then a more thorough repair procedure will be

required. We recommend that this be carried out by specialist personnel.

Check for loose nuts in the head.

In the event of improper functioning in the models with built-in pumps, we recommend that you send the tool to an authorised technical service for

inspection and repair.

CHANGING THE BLADE.

CC0018, CC0118, CC0075, CC0175, CC0190 and CC01120: pump until the piston and blade move out far enough to provide access to the screw (22). Release

the screw and remove the blade. Replace the blade with a new one and attach to the piston by tightening the screw (22) once again.

CC0040, CC0140 and CC0160: You do not need to pump the piston out, since in these models, the screw (22) can be accessed with the blade in its standby

position. Simply remove the screw (22) and replace the blade.

6. WARRANTY.

LARZEP, S.A. guarantees its products against all design and manufacturing defects for the durations of two years from the date of purchase. This guarantee does

not include the ordinary wear of both metal and non-metal parts, abuse, using the equipment beyond its rated capacity and any wear or damage incurred as a result of

using a hydraulic fluid which is not recommended by LARZEP, S.A.

Please note that if the equipment is disassembled or serviced by anyone other than an authorized service dealer or by LARZEP, S.A., this guarantee is rendered null

and void.

In the event of a warranty claim, return the equipment, to LARZEP, S.A. or the authorized dealer which sold you the hydraulic equipment, LARZEP, S.A. will

repair or replace the faulty equipment, whichever is deemed most appropriate. LARZEP, S.A. shall not be held liable for any consequential damages or losses,

which may occur as a result of faulty equipment

5

Instruction Manual

Cable and Bar Cutter “CC0018”

7. DECLARATION OF CONFORMITY.

6

Instruction Manual

Cable and Bar Cutter “CC0018”

7

Instruction Manual

Cable and Bar Cutter “CC0018”

Loading...

Loading...