Page 1

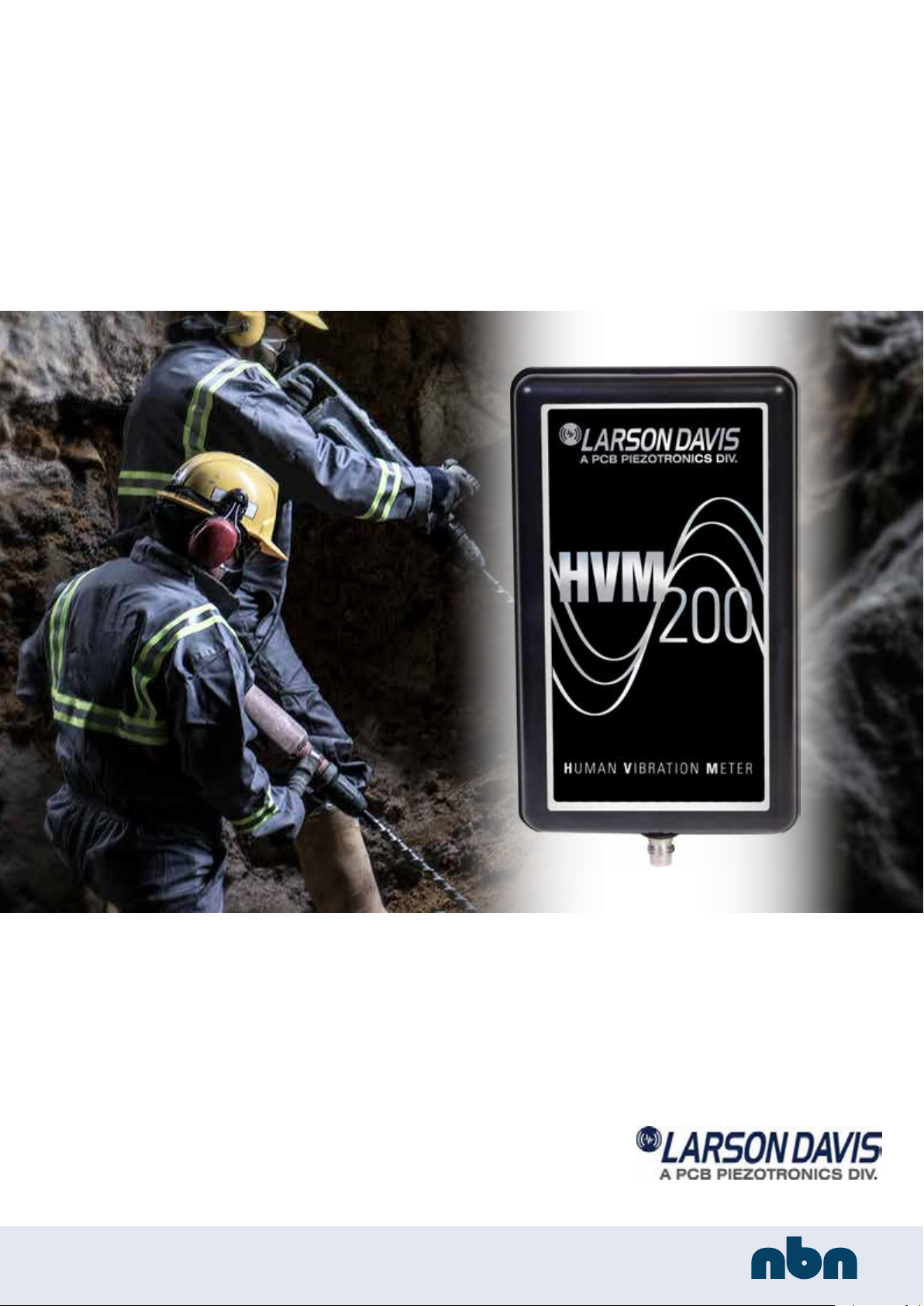

Model HVM200

Human Vibration Meter

Manual

Vertrieb für Österreich :

www.nbn.at

nbn Elektronik Handelsgesellschaft m. b. H.

Riesstraße 146, 8010 Graz | Tel. +43 316 40 28 05 | Fax +43 316 40 25 06

Page 2

Larson Davis

HVM200

Reference Manual

IHVM200.01 Rev C

Page 3

Copyright

Copyright 2016 PCB Piezotronics, Inc. This manual is copyrighted, with all rights reserved. The manual may

not be copied in whole or in part for any use without prior written consent of PCB Piezotronics, Inc.

Trademarks

PCB® is a registered trademark of PCB Group, Inc. Microsoft®, Windows®, and Excel® are either registered

trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

Disclaimer

The following paragraph does not apply in any state or country where such statements are not agreeable with

local law: Even though PCB Piezotronics, Inc. has reviewed its documentation, PCB Piezotronics, Inc.

makes no warranty or representation, either expressed or implied, with respect to this instrument and documentation, its quality, performance, merchantability, or fitness for a particular purpose. This documentation

is subject to change without notice, and should not be construed as a commitment or representation by PCB

Piezotronics, Inc. This publication may contain inaccuracies or typographical errors. PCB Piezotronics, Inc.

will periodically update the material for inclusion in new editions. Changes and improvements to the information described in this manual may be made at any time.

Warranty

For warranty information, refer to our Terms and Conditions of Sale on our website at www.larsondavis.com/

TermsConditions.aspx.

HVM200 Purchase Information

Record the serial number and date of purchase below.

Serial Number:_______________________ Date of Purchase:____________________

Recycling

PCB Piezotronics, Inc. is an environmentally friendly organization and encourages our customers to be environmentally conscious. When this product reaches its end of life, please recycle the product through a local

recycling center or return the product to:

PCB Piezotronics, Inc.

Attn: Recycling Coordinator

1681 West 820 North

Provo, Utah, USA 84601-1341

where it will be accepted for disposal.

Contact Larson Davis

Website: www.larsondavis.com

Worldwide Corporate Headquarters

Larson Davis - a PCB Piezotronics division

Toll-free (in the US):888-258-3222

Phone:716-926-8243

USA fax:716-926-8215

E-mail: sales@larsondavis.com

HVM200 Reference Manual i-2

Page 4

Table of Contents

Module 1 Introduction 1-1

1.1 Overview ..........................................................................................................................1-1

1.2 Features ...........................................................................................................................1-1

1.3 Standard Contents ...........................................................................................................1-1

Module 2 Getting Started 2-1

2.1 Overview ..........................................................................................................................2-1

2.2 Powering the HVM200 .....................................................................................................2-1

2.3 Power Button Operation ...................................................................................................2-3

2.4 Downloading the HVM200 Control App ...........................................................................2-3

2.5 Connecting the HVM200 to a Mobile Device ....... ... .... ... ... ... ... .... ... ... ... ....... ... ... ... .... ... ... ..2-4

2.6 Connecting HVM200 to G4 LD Utility ...............................................................................2-7

2.7 Connecting the Accelerometer .........................................................................................2-9

Module 3 Making Measurements 3-1

3.1 Overview ..........................................................................................................................3-1

3.2 Setting Up the Measurement ...........................................................................................3-1

3.3 Making the Measurement .............. .... ............................................................. ... ... .... ... ... ..3-7

3.4 Downloading Data .......................................... ... ... ... .......................................................3-12

Module 4 Changing Features 4-1

4.1 Overview ..........................................................................................................................4-1

4.2 Setting/Syncing Meter Time and Date .............................................................................4-1

4.3 Turning Off/On WiFi Signal ..................................... .... .....................................................4-3

4.4 Upgrade Firmware and Options .......................................................................................4-5

Appendix A Specifications A-1

A.1 General Characteristics ................................................................................................... A-1

A.2 Physical Characteristics .................................................................................................. A-3

A.3 Operational Characteristics ............................................................................................. A-4

A.4 Electrical Characteristics ................................................................................................. A-5

A.5 Reference Values ............................................................................................................A-7

A.6 Measurement Ranges ..................................................................................................... A-8

A.7 Frequency Weighting Curves ............................................ ... ... .... ...... ... .... ... ... ... ... .... ... ... . A-8

A.8 Frequency Weighting Tables .. ... ... .... ... ...... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ...... .... ... .. A-13

A.9 Integration Weighting Limits .......................................................................................... A-23

A.101/1 & 1/3 Octave Band Filters ...................................................................................... A-29

A.11Standards Met .................................. ............................................................. ... ... .... ... ..A-38

Appendix B Adaptor Resonance & Frequency Response B-1

B.1 Mechanical ...................................................................................................................... B-1

Appendix C Glossary of Terms C-1

Appendix D Regulatory Compliance Statement D-1

HVM200 Reference Manual ii-1

Page 5

Module1 Introduction

1.1 Overview ...............................................................................................................1-1

1.2 Features ................................................................................................. ...............1-1

1.3 Standard Contents ................................................................................................1-1

1.3.1 Optional Kits .............................................................................................1-2

1.3.2 Optional Accessories ...............................................................................1-2

1.1 Overview

This module describes the features and options available on the HVM200.

1.2 Features

The Larson Davis HVM200 Human Vibration Meter is designed for use

in assessing vibration as perceived by human beings.

The HVM200 provides the following features for vibration measurement:

1.3 Standard Contents

The HVM200 package includes the following contents:

TRY THIS Record the meter serial

number and date of purchase in a safe

place where it can be retrieved, in

case you require customer support.

• Whole body, hand-arm, and general vibration applications

• Wireless mobile interface

• Compact design for easy wear and convenient placement

• Mobile application for configuring, measuring, and viewing vibration data on multiple meters

• Connection and control of multiple meters through WiFi access

• Support for optional 1/1 and 1/3 Octave Band Analysis

• Data analysis and visualization using optional G4 LD Utility software

• HVM200 Human Vibration Meter and certificate

• BAT018 Rechargeable Lithium Battery

• PSA035 Power Supply and Adapters

• CBL218 USB Type A to micro-B USB Cable

• CBL217-01 Accelerometer Cable (1/4-28 4-pin connection)

• G4 LD Utility Software CD

HVM200 Reference Manual Overview 1-1

Page 6

1.3.1 Optional Kits

Optional CCS047

Hard Shell Case

• Removable 8 GB SD Memory (in meter)

• Optional license document for HVM support in G4 LD Utility if

purchased

The following HVM200 models provide kits with the following contents:

• HVM200-HA-41F: Standard contents with CCS047 Hard Shell

Case, CCS048-L Hand/Arm Vibration Arm Band, SEN041F

accelerometer, ADP081A Hand Adapter, and SWW-G4-HVM

software license

• HVM200-WB: Standard contents with CCS047 Hard Shell Case,

SEN027 Whole Body Vibration Seat Adapter, and SWW-G4HVM software license

• HVM200-ALL-41F: Standard Contents with CCS047 Hard Shell

Case, CCS048-L Hand/Arm Vibration Arm Band, SEN041F

accelerometer, ADP081A Hand Adapter, and SWW-G4-HVM

software license

1.3.2 Optional Accessories

SWW-G4-HVM

License to enable HVM100 and HVM200 support in G4 LD Utility

HVM200-OB3

1/1 and 1/3 Octave Band Analysis firmware

HVM200-RAW

Record sampled raw data files

SWW-G4-SDK

G4 software development kit

CCS047

Hard Shell Case for transport and protection of HVM200 and accessories

CCS048-L (large) and CCS048-S (small)

Arm Band for wearing the HVM200

SEN026

Accelerometer for ADP063 palm adapter.

SEN040F & SEN041F

Accelerometers for Hand-Arm vibration measurement

SEN020

Accelerometer for Hand-Arm and general vibration measurements

HVM200 Reference Manual Standard Contents 1-2

Page 7

SEN027

Seat Adapter, accelerometer, and adapter for whole-body vibration measurements

LEARN MORE For more informa-

tion on HVM200 accessories, including sensors, see “Adaptor Resonance

& Frequency Response” on page B-1

ADP063, ADP080A, ADP081A, and ADP082A

Adapters for accelerometer placement

CBL217-05, CBL216, and CBL217-01

Cables for connection between accelerometers and HVM200 meter

394C06

Hand-held Shaker for vibrational measurement verification

HVM200 Reference Manual Standard Contents 1-3

Page 8

Module2 Getting Started

2.1 Overview ...............................................................................................................2-1

2.2 Powering the HVM200 ................................................. .... ... ... ... .... ... ..................... 2-1

2.3 Power Button Operation ........................................................................................2-3

2.4 Downloading the HVM200 Control App ................................................................2-3

2.5 Connecting the HVM200 to a Mobile Device ........................................................2-4

2.5.1 Mobile Device Connection Options ..........................................................2-4

2.5.2 Connecting to a Mobile Device via Access Point .....................................2-4

2.5.3 Connecting HVM200 to WiFi Network ......................................................2-5

2.6 Connecting HVM200 to G4 LD Utility ....................................................................2-7

2.6.1 G4 LD Utility Connection Options ............................................................2-7

2.6.2 Connecting the HVM200 meter to G4 LD Utility via USB .........................2-8

2.6.3 Connecting the HVM200 meter to G4 LD Utility via IP Address ..............2-8

2.7 Connecting the Accelerometer ..............................................................................2-9

2.1 Overview

This module provides instructions for setting up and configuring

HVM200 meters for use with the HVM200 Control app and G4 LD Utility.

2.2 Powering the HVM200

Before using your HVM200, charge the battery completely by following

these steps:

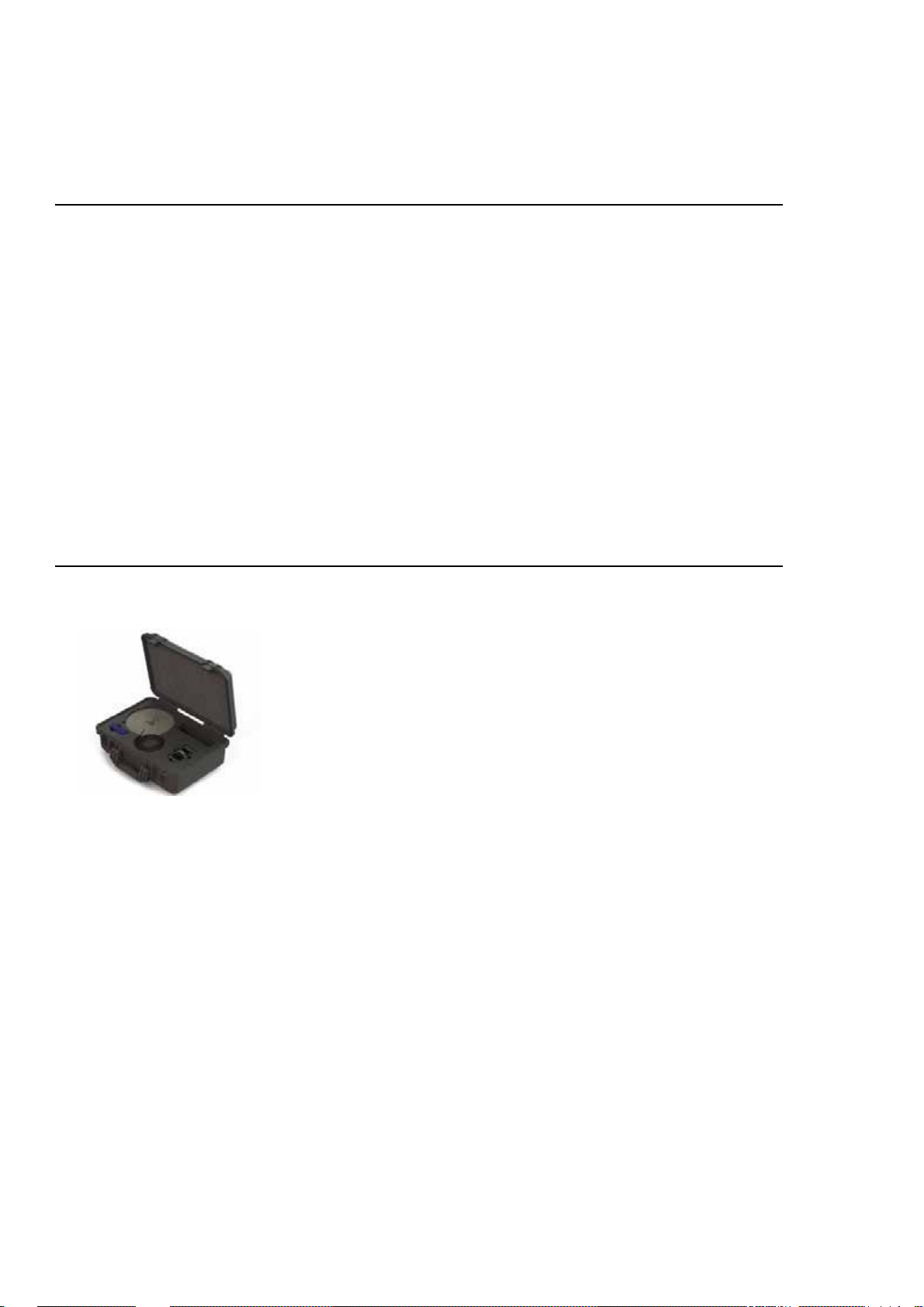

Step 1 Slide and remove the back battery cover from the HVM200

meter.

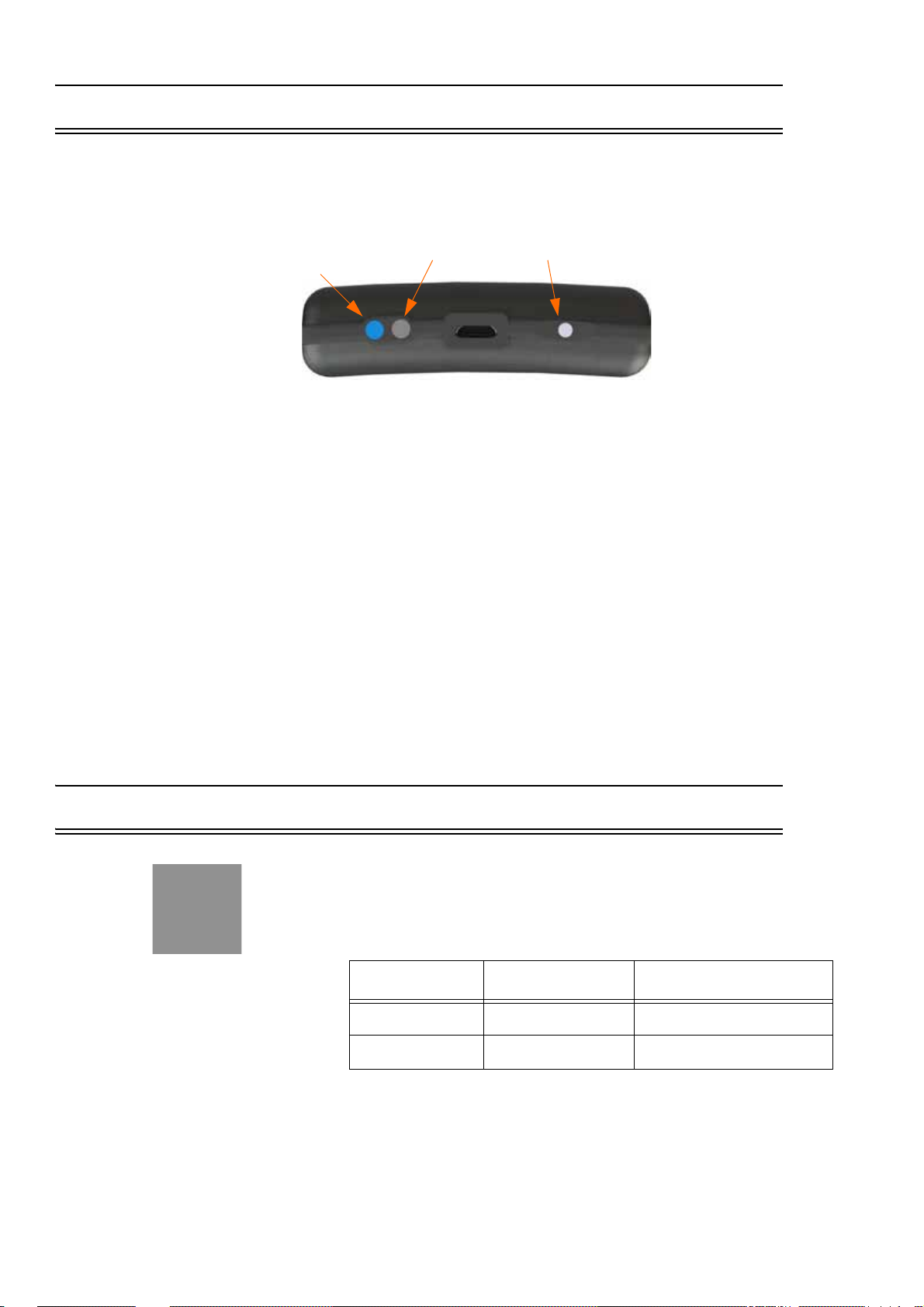

FIGURE 2-1 Remove Battery Cover

HVM200 Reference Manual Overview 2-1

Page 9

Step 2 Insert the supplied battery into the HVM200 by sliding the

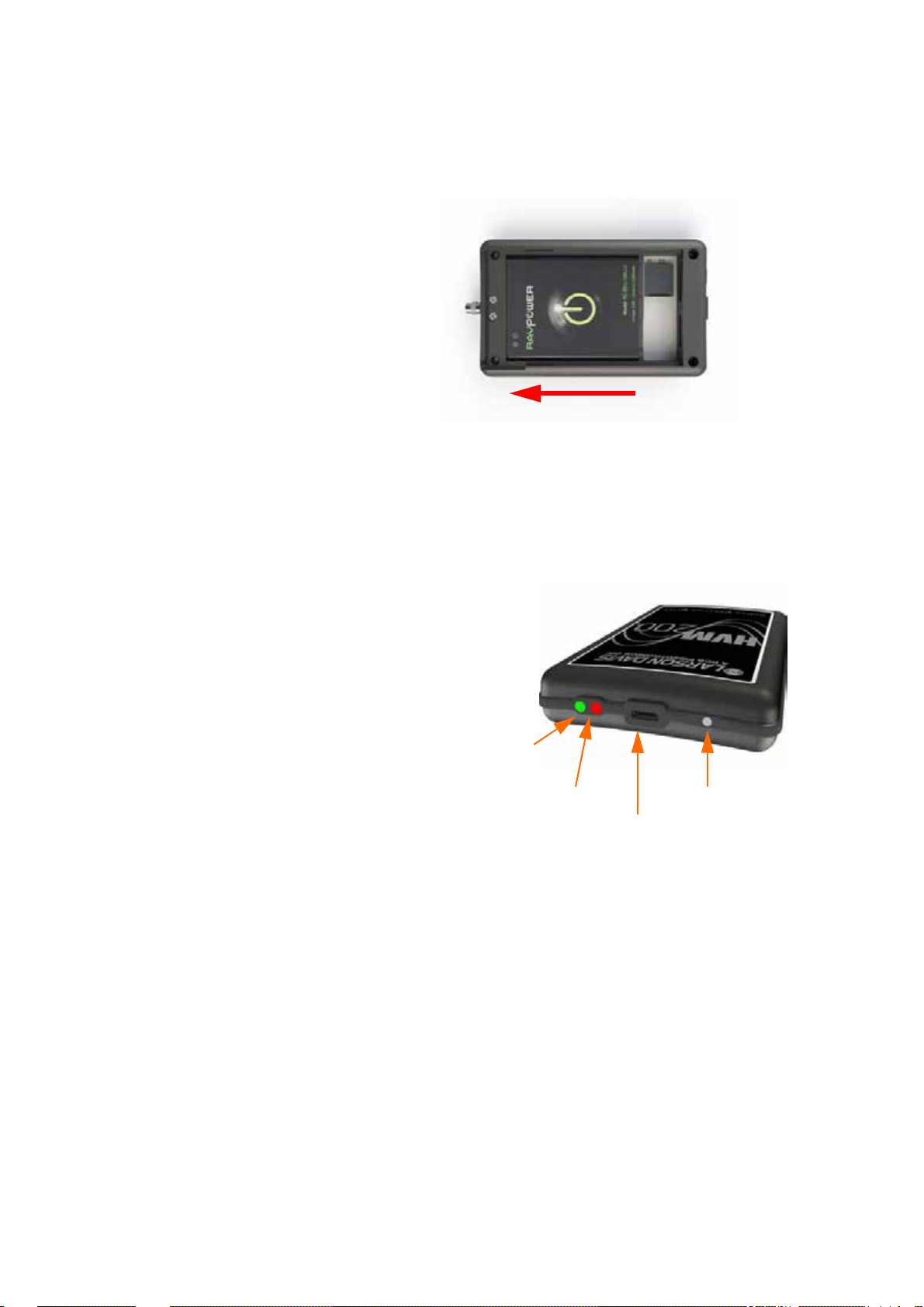

Power LED

Status LED

Power Button

Micro-B USB port

battery contacts against the meter power contacts first and

then lowering the other end of the battery into the tray.

TAKE NOTE Make sure the battery

contacts are fully seated against the

power contacts in the meter and that

the battery lies flat in the tray.

TAKE NOTE The Power LED dis-

plays a yellow color while charging.

TAKE NOTE Avoid leaving the bat-

tery drained for extended periods of

time in order to maximize overall

battery life.

FIGURE 2-2 Insert Battery

Step 3 Slide the back battery cover onto the HVM200.

Step 4 Connect one end of the supplied USB cable to the HVM200

Micro-B USB port and the other end to the PSA035 charger.

FIGURE 2-3 HVM200 Communication

LEARN MORE Refer to the back

label of your HVM200 for a description of each LED indication, or see

see “LED Indications” on page A-4.

Step 5 In order to get an accurate battery reading, the HVM200

must be fully charged prior to use. When fully charged, the

Power LED displays a solid green color. Charging time may

take from 3 to 6 hours.

HVM200 Reference Manual Powering the HVM200 2-2

Page 10

2.3 Power Button Operation

Power Button

Status LED

Power LED

The HVM200 has one button. This power button operates all functions

needed for full operation.

FIGURE 2-4 HVM200 Power Button

Turn Meter On

Press power button until the Power LED shows blue.

Start Measurement

Press power button once and the Status LED will show green. It may flash

to indicate run pending. When the green light stops flashing and periodically winks, this means the meter is working and collecting data.

LEARN MORE For further help with

the LED indicators, refer to the label

on the back of the meter, or see “LED

Indications” on page A-4.

Stop Measurement

Press power button once and the Status LED will show red to indicate that

the measurement has stopped.

Turn Meter Off

Press and hold power button just until the Power LED shows blue, then let

go. Wait until both LEDs go dark, this indicates that the meter is now off.

2.4 Downloading the HVM200 Control App

Use your mobile device to find and download the HVM200 Control app

from Google Play or the Apple App Store

“HVM200”.

Table 2.1 Mobile Requirements

Apple Android

Space 2.5MB 2.8M

®

. To find the app, search for

OS Version 7.0 or later 4.0 and up

HVM200 Reference Manual Power Button Operation 2-3

Page 11

2.5 Connecting the HVM200 to a Mobile Device

With the HVM200 Control app, you can make a direct WiFi connection to the HVM200

from your mobile device.

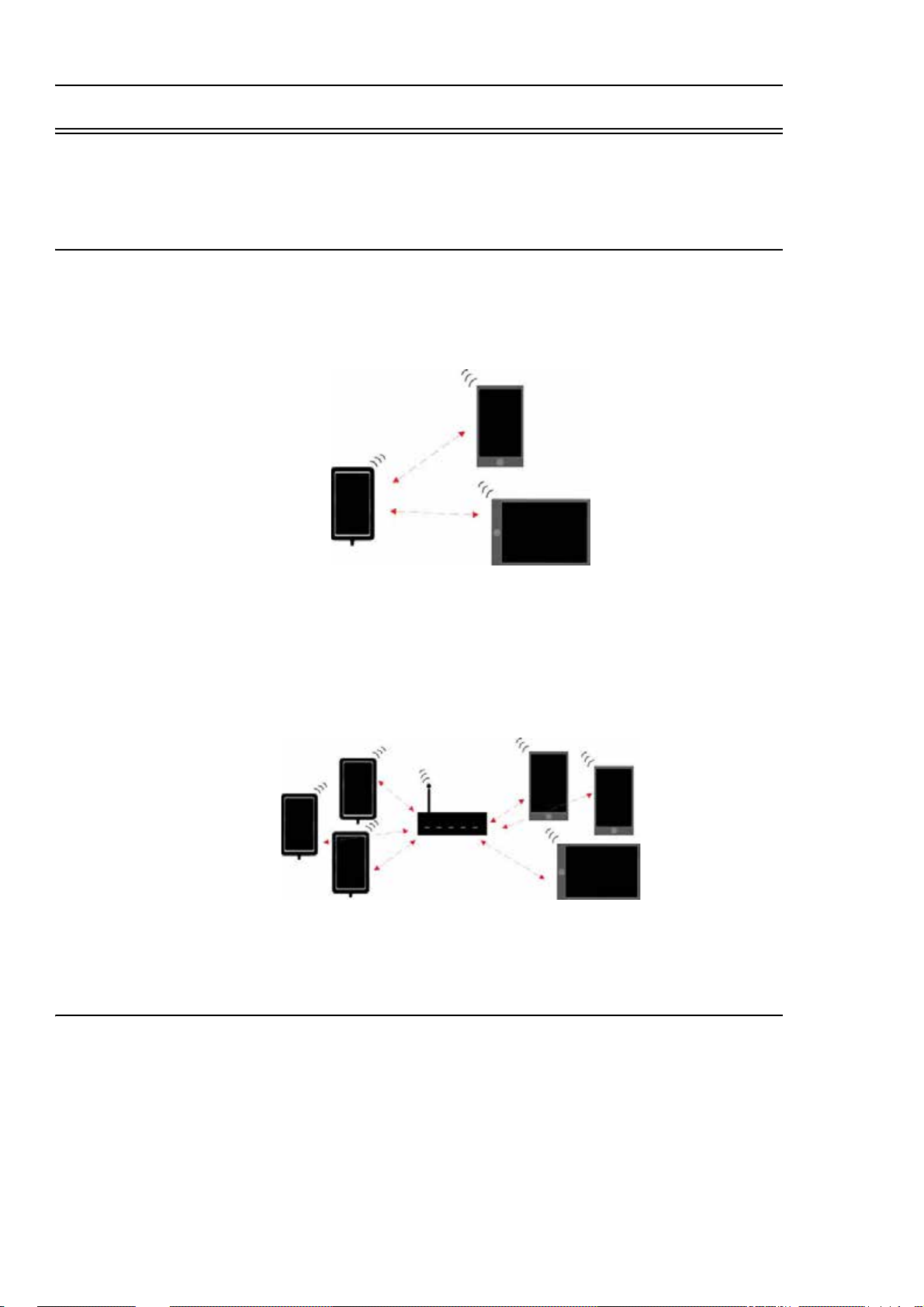

2.5.1 Mobile Device Connection Options

One HVM200 to multiple mobile devices.

FIGURE 2-5 Mobile Connection

Use HVM200 Access Point to connect meter to one or more mobile

devices.

Multiple HVM200 to multiple mobile devices

FIGURE 2-6 Mobile Connections

If a router is within range, connect the HVM200 to the same WiFi network as mobile device(s).

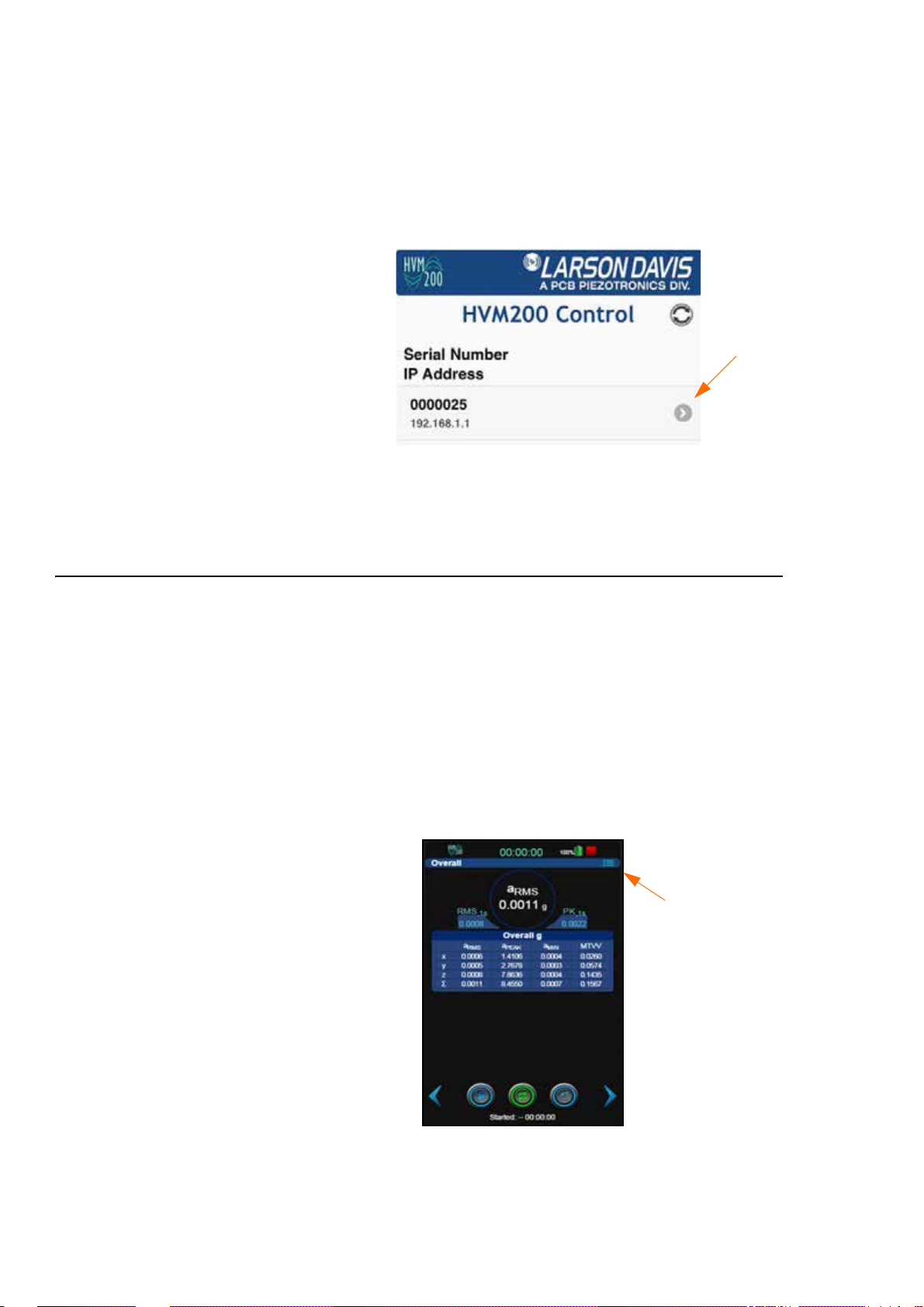

2.5.2 Connecting to a Mobile Device via Access Point

With the HVM200 Control app, you can make a direct WiFi connection to

the HVM200 from your mobile device:

TRY THIS If there is no network

showing, make sure the HVM200 is

turned on.

HVM200 Reference Manual Connecting the HVM200 to a Mobile Device 2-4

Step 1 Open the WiFi settings on your mobile device.

Page 12

TAKE NOTE Depending on your

Tap here

Menu Icon

mobile device, you may need to perform this step each time you want to

connect to the HVM200.

Step 2 Connect to the HVM200 WiFi network displaying the serial

number of your meter.

Step 3 Launch the HVM200 Control app to begin controlling the

meter on your mobile device.

FIGURE 2-7 HVM200 Access Point

Step 4 Connect the HVM200 by selecting the meter with the serial

number displayed for your meter.

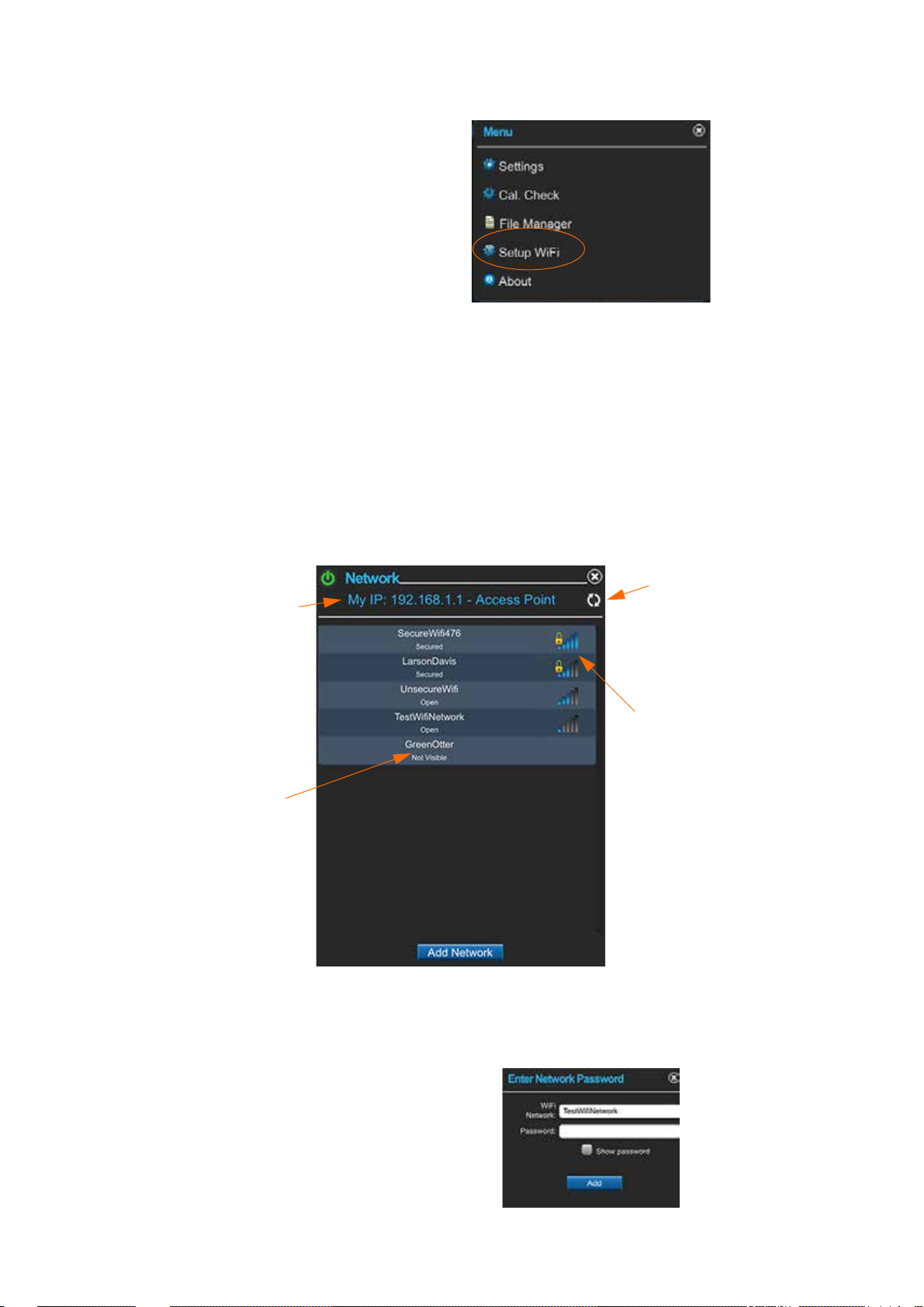

2.5.3 Connecting HVM200 to WiFi Network

The HVM Control App will be able to connect to the HVM200 as long as

the mobile device is connected to the same wireless local network as the

HVM200.

To establish a WiFi connection over a network with the HVM200 meter,

follow these steps:

Step 1 Launch the HVM200 Control app or the G4 Live Stream

view. Select your meter. Click the menu icon.

TAKE NOTE It is best to make the

initial connection to a WiFi network

while also connected to a PC via

USB, if possible.

FIGURE 2-8 HVM200 App

Step 2 On the HVM200 Menu, select Setup WiFi.

HVM200 Reference Manual Connecting the HVM200 to a Mobile Device 2-5

Page 13

FIGURE 2-9 WiFi Setup

Signal strength indicator and Secured

network icon

(requires password)

Not visible net-

works are previously used but not

currently detected.

Refresh

This meter is set as

an Access Point

LEARN MORE Networks are listed

in the order of greatest signal

strength.

TAKE NOTE If you have already

entered a password and saved a network, the HVM200 automatically

connects to the network with the

greatest signal strength.

FIGURE 2-10 Network Settings.

Step 3 Select an available network. If no network appears on the

list, click the refresh button. To connect to a hidden network,

click Add Network and provide network name.

TAKE NOTE The HVM200 supports

WPA and WPA2 WiFi security. Larson Davis recommends using secure

WiFi networks.

Step 4 Enter the network password, if required, and click Add

FIGURE 2-11 Enter Network Password

HVM200 Reference Manual Connecting the HVM200 to a Mobile Device 2-6

Page 14

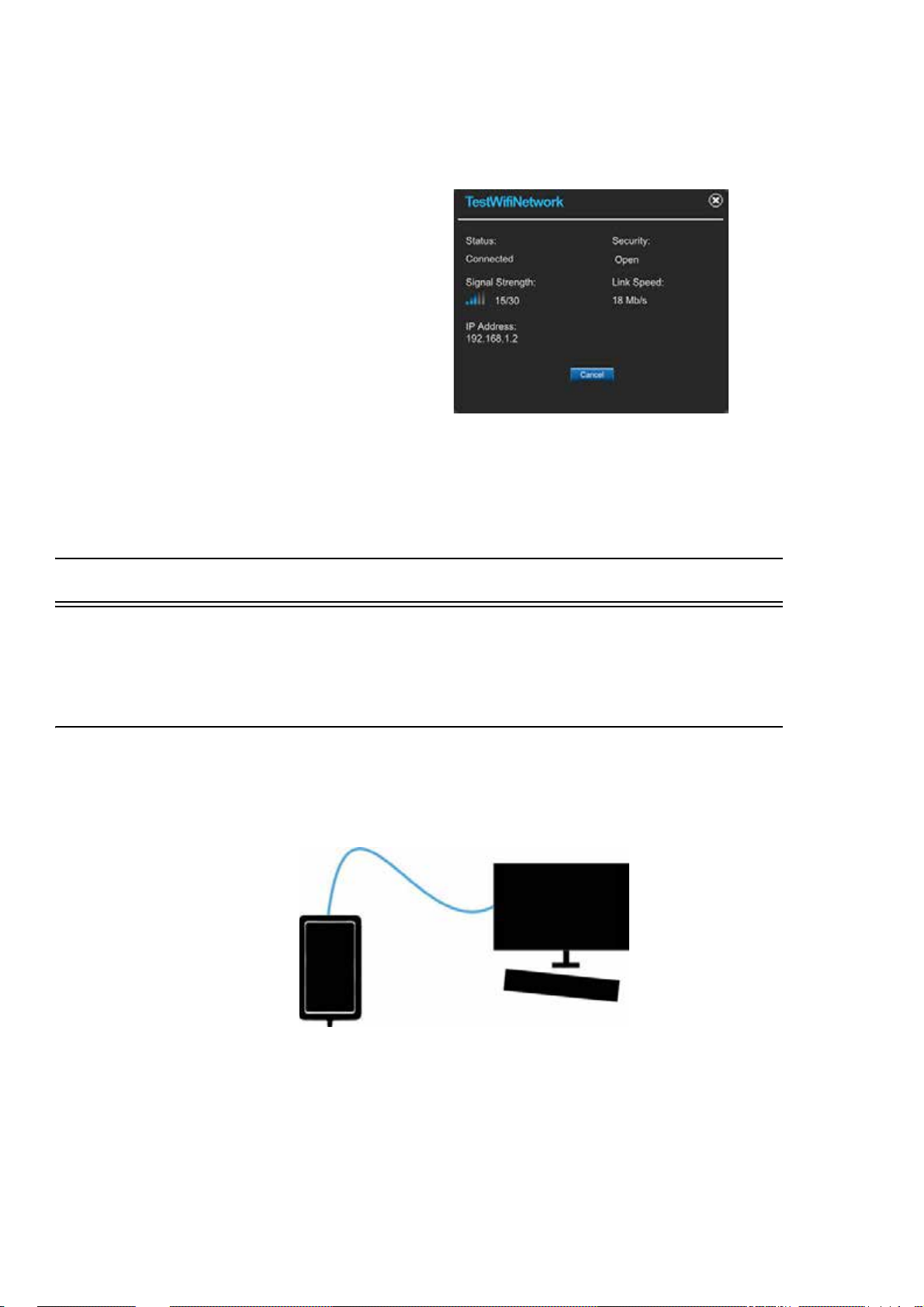

Step 5 Verify your network connection details by clicking the

newly added network from the list.

FIGURE 2-12 Network Connection Details

Step 6 In the connect screen of the HVM Control App, if the

HVM200 and your mobile device are both on the same local

network, you will see it in the list. Select it to connect.

2.6 Connecting HVM200 to G4 LD Utility

TAKE NOTE G4 LD Utility for

HVM software requires a license.

2.6.1 G4 LD Utility Connection Options

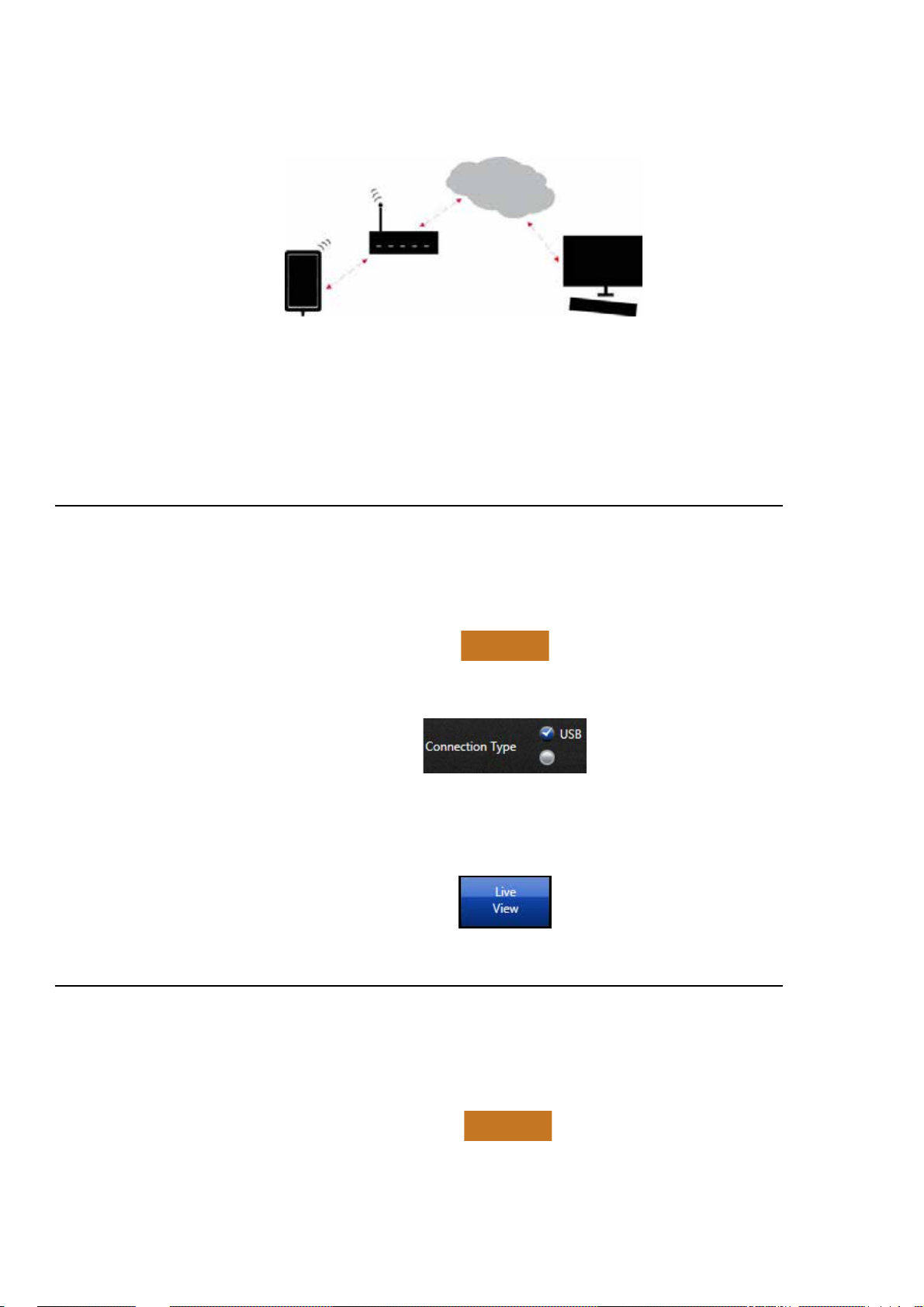

HVM200 to PC via USB Cable

FIGURE 2-13 USB Cable Connection

G4 LD Utility for HVM software provides features for setup, measurement, data download, and data viewing.

Using a Micro B USB cable, you can directly connect your PC to meter

and operate it using G4 LD Utility.

HVM200 Reference Manual Connecting HVM200 to G4 LD Utility 2-7

Page 15

HVM200 to PC via TCP/IP

FIGURE 2-14 TCP/IP Connection

With the meter connected to a WiFi network that has Internet access, a PC

can access the meter as long as it is currently connected to the Internet and

you have the IP address to enter into G4 LD Utility, in addition port forwarding will need to be set up on the gateway or router.

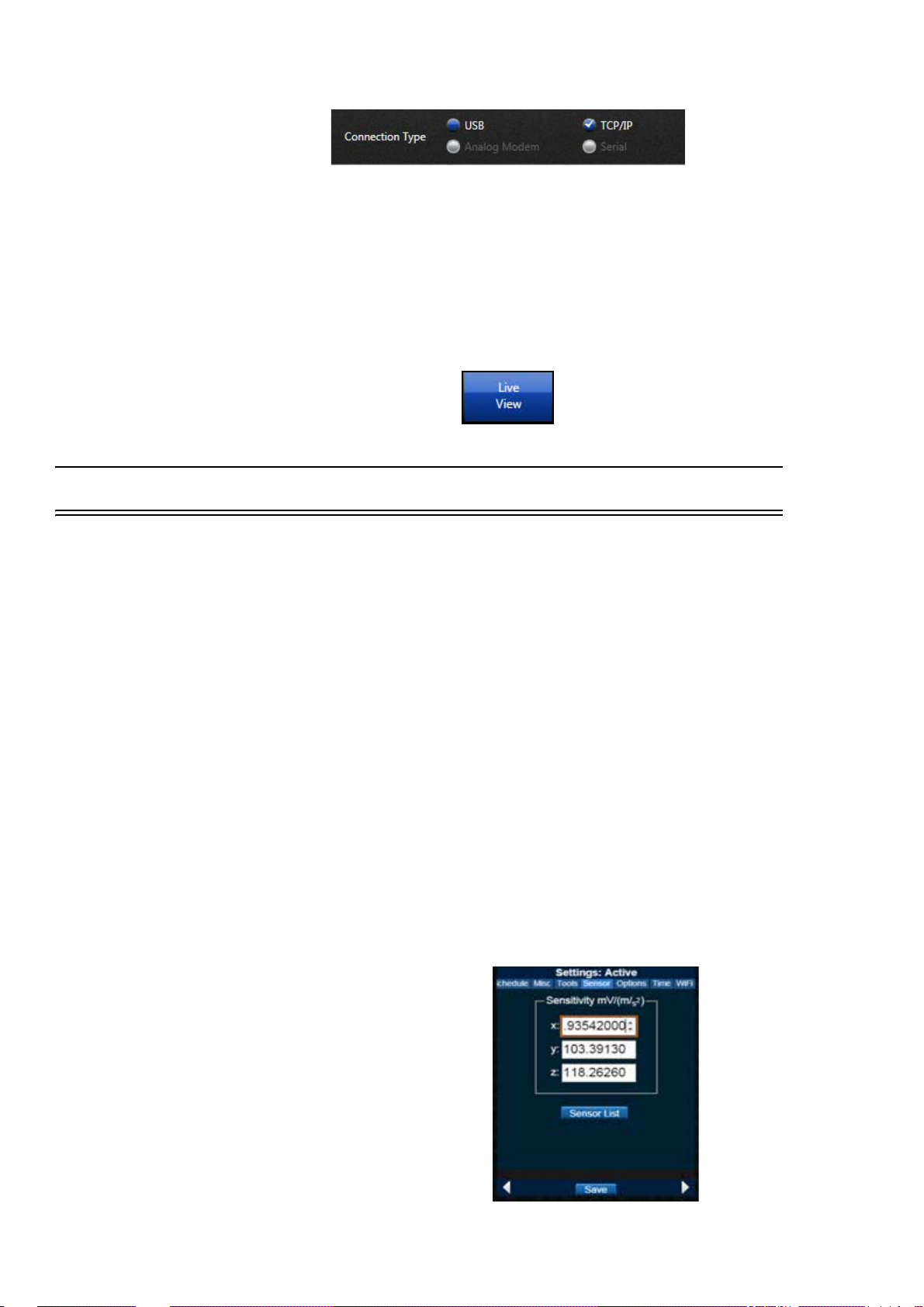

2.6.2 Connecting the HVM200 meter to G4 LD Utility via USB

LEARN MORE For more informa-

tion on working with G4 LD Utility,

refer to the G4 LD Utility Software

Manual.

Step 1 Connect the HVM200 to a PC with the provided USB to

micro-B USB cable. (CBL218).

Step 2 Launch G4 and click Connect.

Step 3 Connect via USB.

Step 4 Click the Live View button. The Live View presents the

same interface as the HVM200 App for working with measurements.

2.6.3 Connecting the HVM200 meter to G4 LD Utility via IP Address

LEARN MORE For more informa-

tion on working with G4, refer to the

G4 LD Utility Software Manual.

Step 1 Using previous instructions, connect meter to a WiFi net-

work with Internet access.

Step 2 Launch G4 and click Connect.

HVM200 Reference Manual Connecting HVM200 to G4 LD Utility 2-8

Page 16

Step 3 Connect via TCP/IP. Click the Add Meter button.

Step 4 Place your cursor in fields and enter the IP address.

Step 5 Once IP address is entered, the Connect button will turn

blue, select it.

TAKE NOTE IP address is the only

required field to add a meter, unless a

password has been created.

Step 6 Click the Live View button. The Live View presents the

same interface as the HVM200 App for working with measurements.

2.7 Connecting the Accelerometer

LEARN MORE Refer to the "Hand-

held Shaker for vibrational measurement verification" in this manual for

information on selecting the proper

accelerometer for the HVM200

meter.

To connect the accelerometer to your HVM200 meter, follow these steps:

Step 1 Insert the accelerometer cable into the 4-pin connector on

the HVM200 and then rotate the nut on the cable until the

connection is tight.

Step 2 Insert the other end of the accelerometer cable into the 4-pin

connector on the accelerometer and tighten the cable nut.

Step 3 If the HVM200 is not already turned on, press the power

button once, the Power LED will turn blue.

Step 4 Connect the HVM200 to G4 via USB.

LEARN MORE For more informa-

tion on working with G4 tabs and settings, refer to the G4 LD Utility

Software Manual.

TAKE NOTE If you are using an

accelerometer with Transducer Electronic Data Sheet (TEDS) capabilities, the sensitivity values will

already be displayed for the x, y, and

z axes of the sensor.

HVM200 Reference Manual Connecting the Accelerometer 2-9

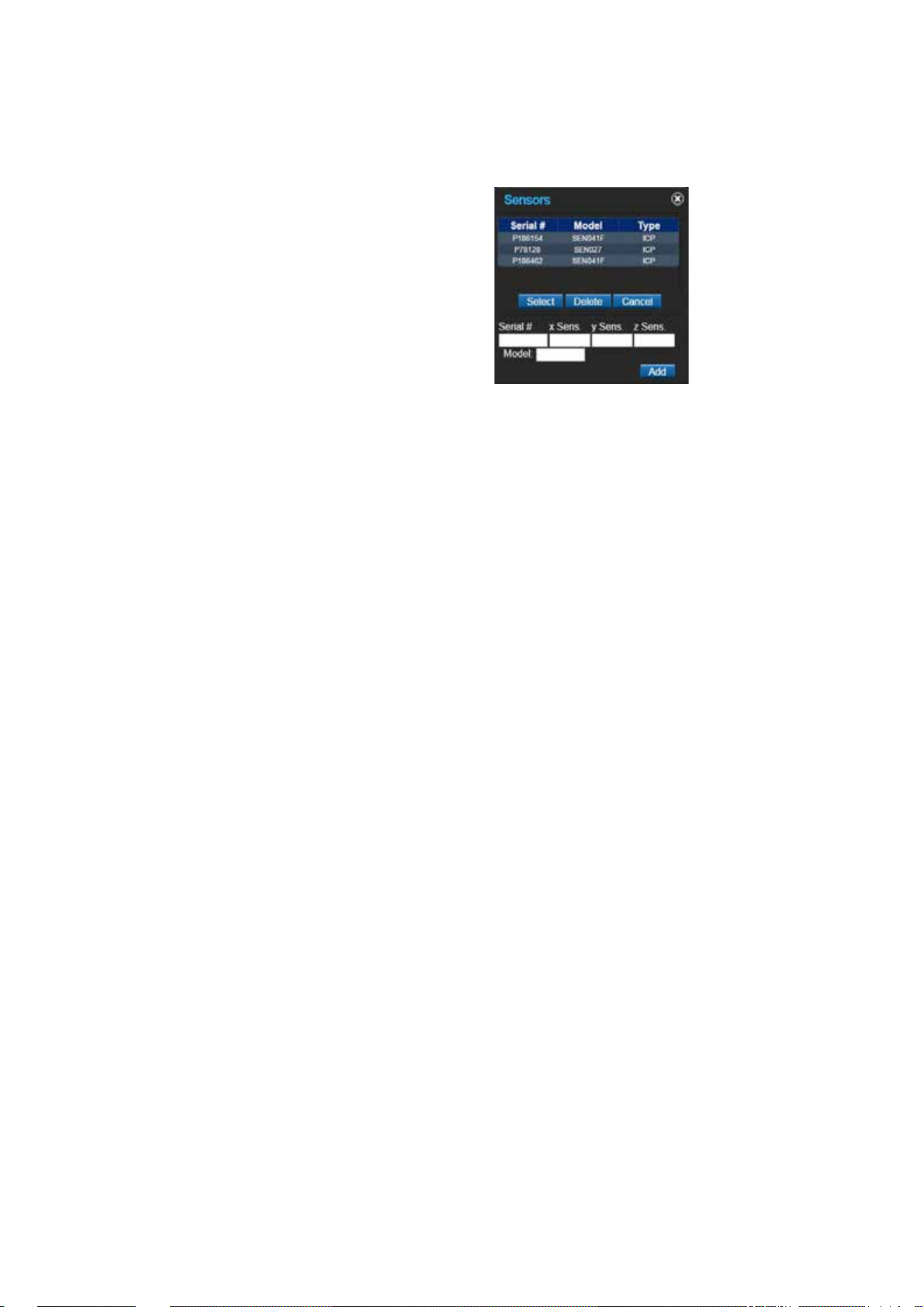

Step 5 Click the Setup Manager tab in G4. Under the meter set-

tings (displaying the meter serial number) click the Sensor

tab.

FIGURE 2-15 Sensor Settings

Page 17

FIGURE 2-16 Sensor Tab

Step 6 Click Sensor List.

TAKE NOTE Sensor information,

including model, serial number, and

sensitivity specifications are usually

listed on the calibration certificate

that comes with an accelerometer.

FIGURE 2-17 Sensor List Identification and Sensitivity

Step 7 In the Sensor List, type the model, serial number of your

accelerometer, and the sensitivity for the x, y, and z axes and

then click Add.

Step 8 Select the accelerometer when it appears in the list and click

Select. The sensitivity values will automatically appear on

the Sensor tab. Click Save. Use the Sensor List to quickly

access and select stored sensors for future measurements.

HVM200 Reference Manual Connecting the Accelerometer 2-10

Page 18

Module

3.1 Overview ...............................................................................................................3-1

3.2 Setting Up the Measurement ................................................................................3-1

3.2.1 Perform a Calibration Check ....................................................................3-1

3.2.2 Selecting a Setup File Using Your Mobile Device ....................................3-3

3.3 Making the Measurement ......................................................................................3-7

3.3.1 Position for Hand/Arm Vibration ............................................................. ..3-7

3.3.2 Position for Whole Body Vibration with Seat Adapter ..............................3-7

3.3.3 Start/Stop the Measurement ....................................................................3-8

3.4 Downloading Data ...............................................................................................3-12

3.4.1 Working with RAW Data Files ................................................................3-12

3 Making Measurements

3.1 Overview

This module provides an example procedure for performing a vibration

measurement with the HVM200 Control app and G4 LD Utility.

The following example demonstrates procedures for measuring vibration,

including:

• Setting Up the Measurement

• Making the Measurement

• Downloading the Measurement Data

3.2 Setting Up the Measurement

To set up the measurement:

1. Perform a calibration check.

2. Specify a setup file on your mobile device.

The following sections describe these steps in more detail.

3.2.1 Perform a Calibration Check

TAKE NOTE A calibration check on

an HVM200 requires a hand held

shaker like the PCB Model 394C06.

HVM200 Reference Manual Overview 3-1

To perform a calibration check, follow these steps:

Step 1 If you have not indicated sensitivity values for the x, y, and z

axes on the Sensor tab, refer to “Connecting the Accelerom-

eter” to specify these settings.

Step 2 Launch G4 or HVM Control app on mobile device, connect

to HVM200, and click Live View.

Page 19

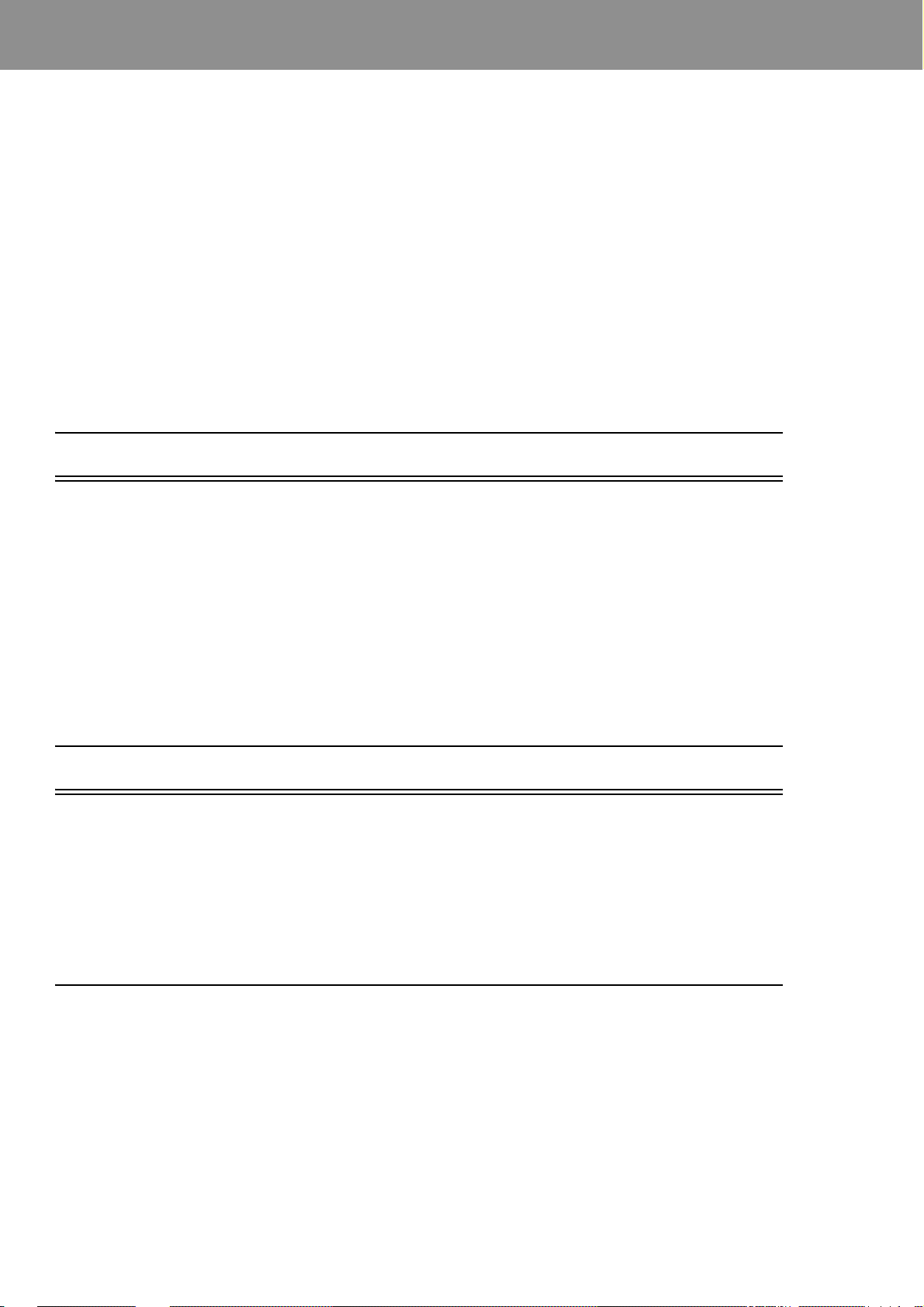

Step 3 Click the Menu icon.

FIGURE 3-1 Menu Icon

TAKE NOTE A calibration can only

be made if the meter is stopped and

currently on Live. Performing a cali-

bration will automatically put the

meter in this state.

Step 4 Click Cal. Check on Menu.

FIGURE 3-2 Cal. Check Option

Step 5 Enter the Reference value for the shaker you will use to per-

form the calibration check and click Set. This value is usu-

ally provided in the shaker reference documentation.

Step 6 Attach the transducer on your shaker so that the axis you

wish to check is oriented properly.

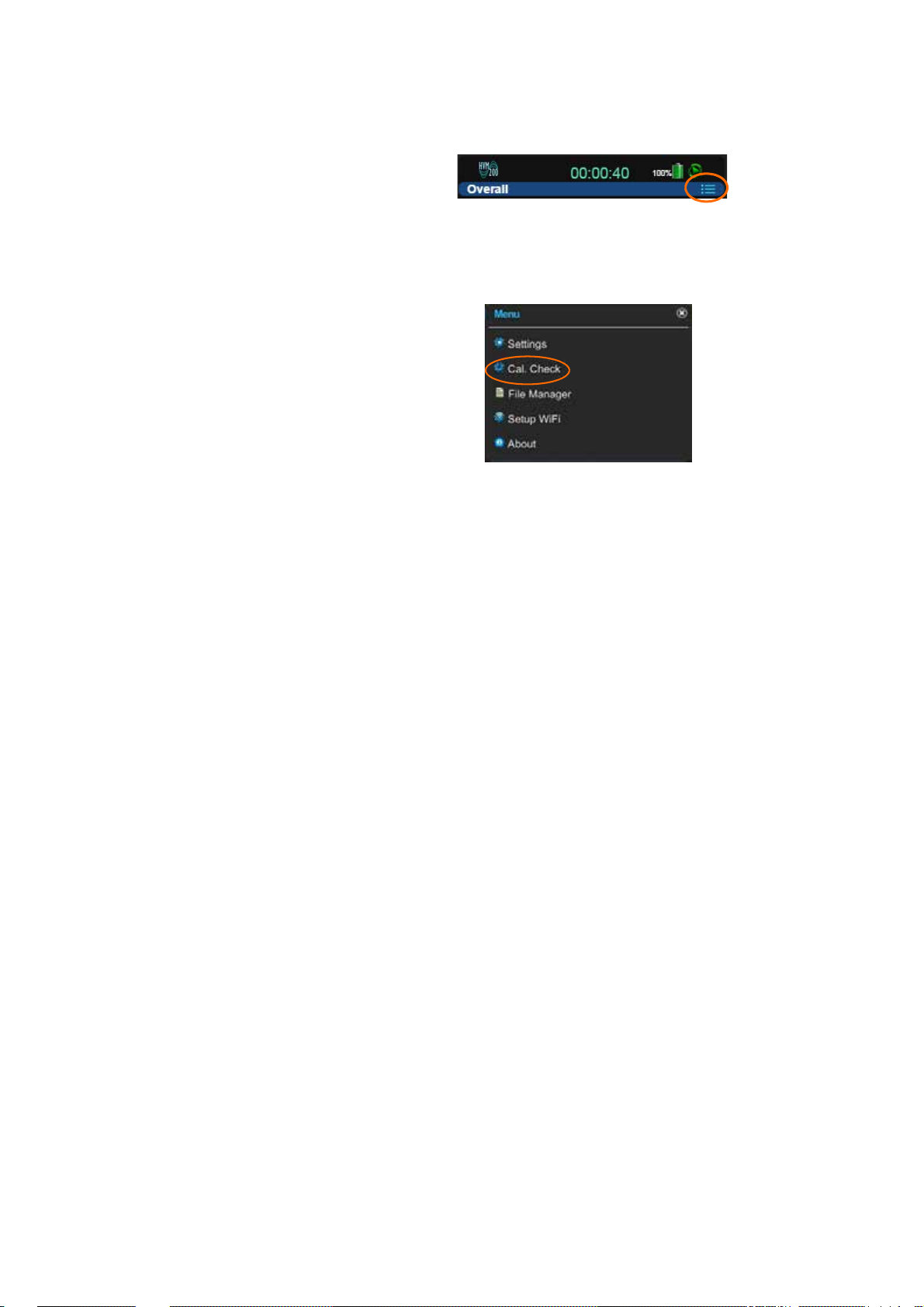

Step 7 Start the shaker and note the a

values for each axis, as

rms

follows:

TAKE NOTE The filter is automati-

cally set to the Fb weighting during

calibration check measurements and

restored when finished.

• Values are gray when level has not been checked.

• Values are white when level is being checked.

• Values are red if the axis measurement is complete and the

level varies from the reference value by more than ± 5%.

• Values are green if the axis measurement is complete and

the level is within ± 5% of the reference value.

Step 8 Repeat the process for each axis on the accelerometer.

HVM200 Reference Manual Setting Up the Measurement 3-2

Page 20

FIGURE 3-3 Calibration Check

Z axis has been

checked and is

within range.

Reference value

from shaker

Shows saved calibration checks

Sensitivity settings

specified in setup

Green indicates values are within range.

LEARN MORE If you are using G4

LD Utility software (optional license

required), the last two saved calibration checks are displayed in measurement spreadsheets. See the G4 LD

Utility Software Manual for more

information.

Step 9 To save the calibration check, close the Calibration Check

dialog box. Saved calibration check information is displayed

at the bottom of the dialog box when it is re-opened.

3.2.2 Selecting a Setup File Using Your Mobile Device

The HVM200 includes nine default setups in its Settings list. These

default setups correspond to settings typically used for different methods

of measurement.

You can also create new setup files on the Settings list. To create a new

setup file, follow these steps:

Name the Setup File

TRY THIS The easiest way to create

a new setup file is to modify an existing default setup and save it with a

different name.

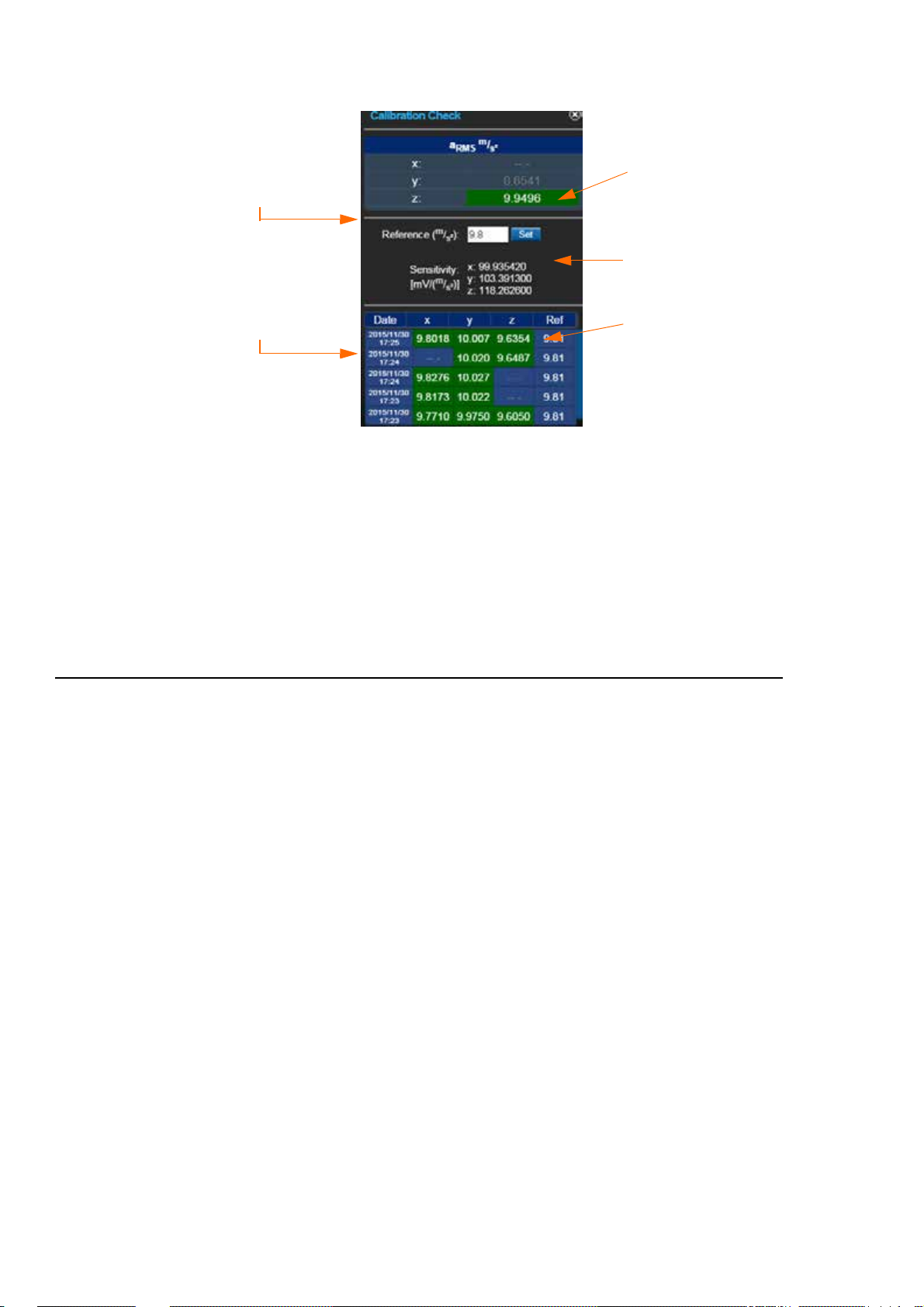

Step 1 Tap the menu icon on the HVM200 app and then tap Set-

tings.

Step 2 Press and hold your finger on a default Setup File in the Set-

tings list. Select Save As and specify the setup name.

HVM200 Reference Manual Setting Up the Measurement 3-3

Page 21

FIGURE 3-4 Name the Setup File

TAKE NOTE If you return to the

Setup Manager tab from a settings

tab, you are prompted to save set-

tings. Click Yes to apply the changes

to the setup.

Step 3 Find and click the setup file you just created by scrolling

down the list. The list now displays a report icon next to

your new setup file.

FIGURE 3-5 Select New Setup File

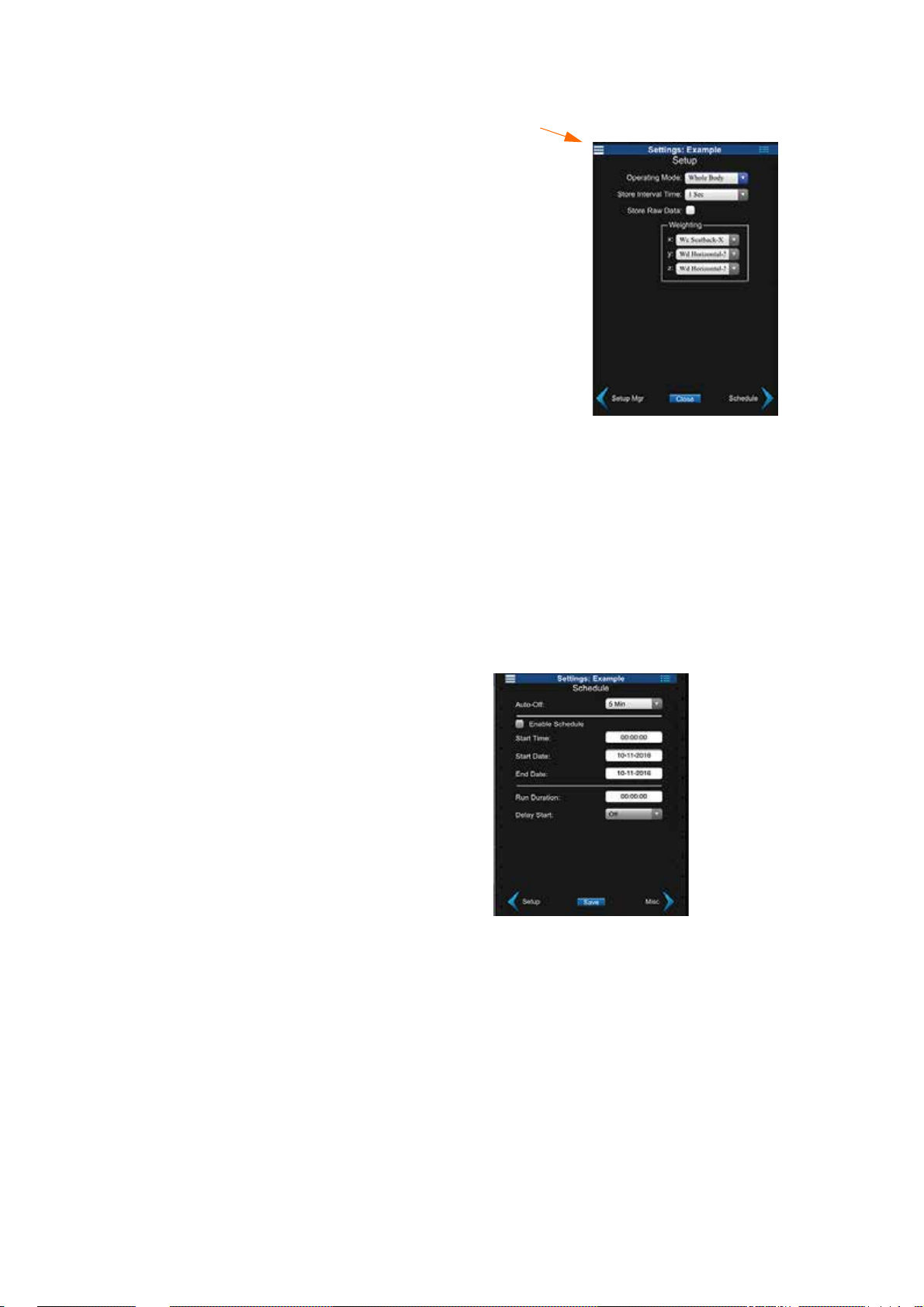

Set Operating Mode, Interval Time, and Weighting

TAKE NOTE The interval time val-

ues represent the span that data is

collected, averaged, and stored

before starting a new sample.

Step 4 Use the bottom right arrow to move to the Setup tab, specify

any changes to your settings and select the Store Raw Data

option if you have it installed and need it for your post-mea-

surement analysis. The Store Raw Data option will greatly

increase the amount of memory required to store the mea-

surement. Click Save.

The supplied HVM200 memory card can store individual file sizes up to 2

GB and more than 6 hours of measurements with the Store Raw Data

option enabled. When not enabled, the card can store approximately 8000

hours of measurements.

HVM200 Reference Manual Setting Up the Measurement 3-4

Page 22

TAKE NOTE The Wh weighting is

This is the Setting

Menu which will

allow you to jump

to any of the settings options at

anytime.

automatically specified for all axes

with the Hand/Arm mode. For more

information on operating mode

options and weighting curves,

“Specifications” on page A-1.

Set Measurement Schedule

FIGURE 3-6 Operation Settings

TAKE NOTE When run duration is

set to 00:00:00 the HVM200 will run

until manually stopped. If the run

duration is set to any other time, the

HVM200 will automatically stop

after acquiring data for the selected

amount of time.

TAKE NOTE If a manual measure-

ment overlaps with the Start Time of

a scheduled measurement, the scheduled measurement will not start until

the manual measurement has stopped

and any specified delay has passed.

Step 5 If needed, schedule the HVM200 to take a measurement

automatically by selecting the Enable Schedule option on

the Schedule tab. Specify the Start Time, Start Date, End

Date, and Duration. Specify a Delay Start, if needed.

FIGURE 3-7 Schedule Settings

TAKE NOTE Auto-Off is the

amount of time the HVM200 will

remain fully powered if it is not taking a measurement. If a measurement

occurs, this time will reset.

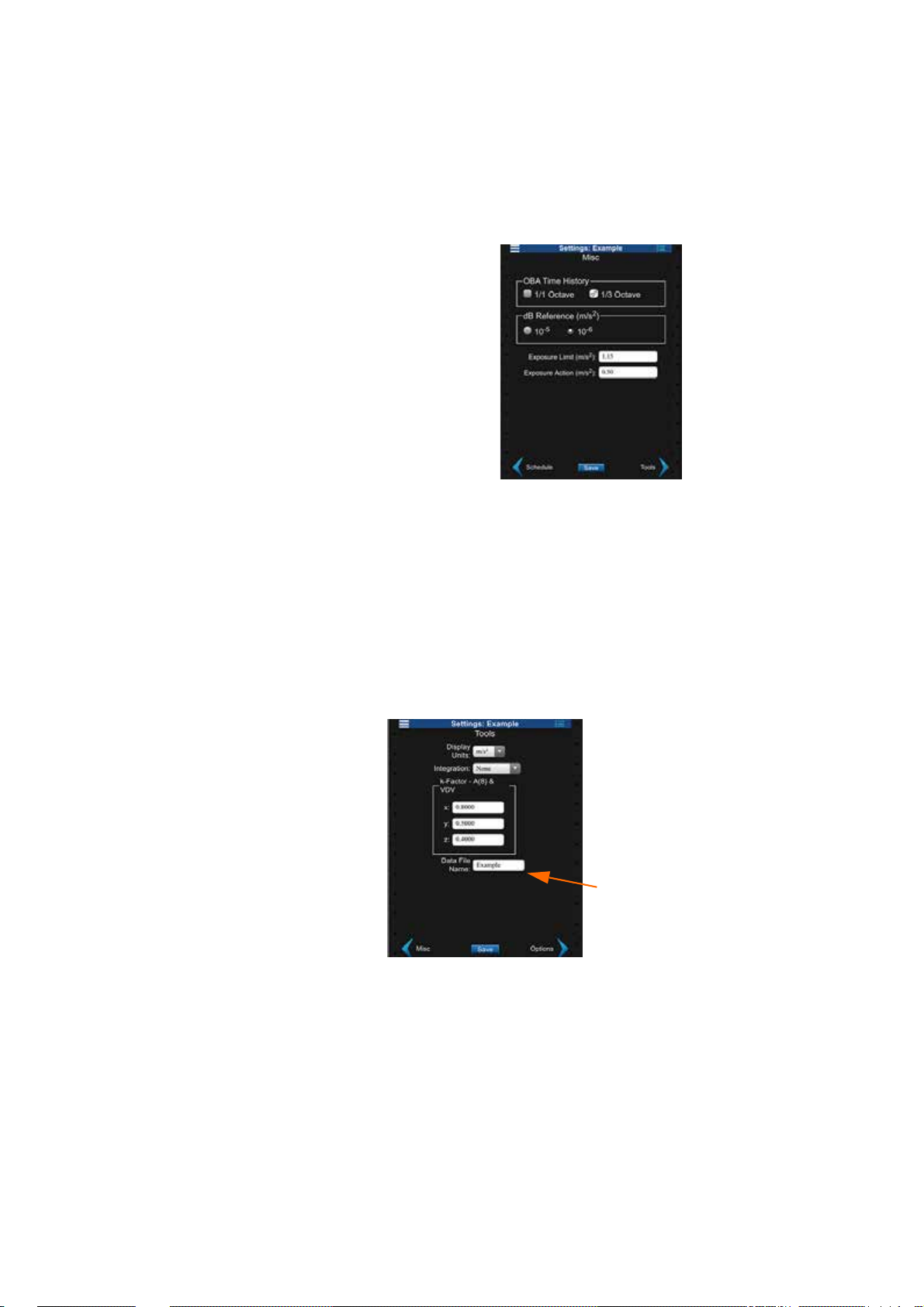

Set OBA Time History, Decibel Reference, and Exposure Settings

Step 6 On the Misc tab, select 1/1 Octave or 1/3 Octave to include

octave band analysis in your measurement data, if you have

the options installed.

HVM200 Reference Manual Setting Up the Measurement 3-5

Page 23

TAKE NOTE Single and double inte-

The data files for this

Setup will be saved with

this name as a pretext

gration are not allowed when display

units are set to dB.

Step 7 If you plan to choose dB reference units as the Display

Units (Tools tab), select 10-5 or 10-6 as the dB Reference on

this tab; otherwise this selection is ignored.

Step 8 Specify the Exposure Limit and Exposu re Action.

TAKE NOTE The exposure settings

show default values according to the

EU Physical Agents Directive (2002/

44/EC) but can be modified according to differing standards or needs.

Choose Tools Settings

TAKE NOTE Single integration cal-

culations convert acceleration values

into velocity values; double integration converts acceleration values into

displacement values.

FIGURE 3-8 Misc. Settings

Step 9 On the Tools tab, choose the Display Units and Integration

method. Specify the k-Factor for each axis and type a Data

File Name. Click Save.

TAKE NOTE For whole body mea-

surements, the HVM200 multiplies

the specified k-Factor by the instan-

taneous acceleration for each axis to

produce the summation (value in

the Overall view of the app. K-factors are ignored for general vibration

and hand/arm measurements. See

“Glossary of Terms” on page C-1.

Verify Sensor Settings

FIGURE 3-9 Tools Settings

If you are using an accelerometer with TEDS capability, the Sensor tab

on the HVM200 settings (displaying serial number) are automatically

specified. If your accelerometer does not have TEDS capability and you

have not already specified the settings, refer to the section “Connecting

the Accelerometer” on page 2-9.

HVM200 Reference Manual Setting Up the Measurement 3-6

Page 24

Verify Installed Options

If you have purchased Octave Band Analysis or Raw Data options, click

the Options tab and verify that they are displayed and selected in the list.

You can deselect this feature temporarily if given measurement does not

require the data.

3.3 Making the Measurement

To make the vibration measurement:

1. Position the HVM200 meter and accelerometer.

2. Start the measurement.

3. Observe data.

4. Stop and annotate the measurement.

The following sections describe these steps in more detail.

3.3.1 Position for Hand/Arm Vibration

For Hand/Arm vibration measurement, follow these steps:

Step 1 Attach the Larson Davis CCS048 Arm Band on the person

being monitored. The end with the transparent cover should

be the farthest from the hand.

Step 2 Insert the HVM200 into the arm band so that the accelerom-

eter connector is nearest the hand.

Step 3 Connect the accelerometer to the HVM200.

TAKE NOTE Refer to see “Mechani-

cal” on page B-1.

Step 4 Attach the accelerometer to an appropriate adapter and place

it so that the vibration that is coupled to the hand can best be

measured.

3.3.2 Position for Whole Body Vibration with Seat Adapter

For whole body vibration measurements using the Larson Davis SEN027

Seat Adapter, follow these steps:

TAKE NOTE The Seat Adapter is

sold with the SEN027 accelerometer

already housed within the adapter

and with the cable already connected

to the accelerometer.

Step 1 Place the seat adapter in the location where the person being

monitored will sit.

Step 2 Connect CBL217-01 to the HVM200 on one end and the

seat adapter cable on the other end.

Step 3 Set the HVM200 meter in a secure location, where it will not

fall from its position.

HVM200 Reference Manual Making the Measurement 3-7

Page 25

3.3.3 Start/Stop the Measurement

Run Stop

Annotate

Running

Stop

Run Live

Start Measurement

TRY THIS You can also start the

measurement manually by pushing

the power button on the HVM200 for

at least one second after it is stable

(or after the Status LED is red), see

“Power Button Operation” on

page 2-3.

Stop Measurement

Click the Run button that appears on the HVM200 Control app or G4 LD

Utility.

FIGURE 3-10 Meter is stopped

Click the Stop button.

FIGURE 3-11 Meter is running measurement

View Live Data

Observe Data

TRY THIS Alternatively, you can

also schedule measurements auto-

matically on the Schedule tab if you

do not need to observe them.

While meter is stopped and not taking a measurement, click the red Stop

button. A green Live button will appear. To return to stop, press Live

again.

FIGURE 3-12 Viewing Live Data & Meter is stopped

The HVM200 Control app provides the following data displays:

•Overall

• Summation

• X-axis

• Y-axis

• Z-axis

To advance from one data display to the next, click the Next Arrow. To

enlarge a data display, click the Zoom button.

HVM200 Reference Manual Making the Measurement 3-8

Page 26

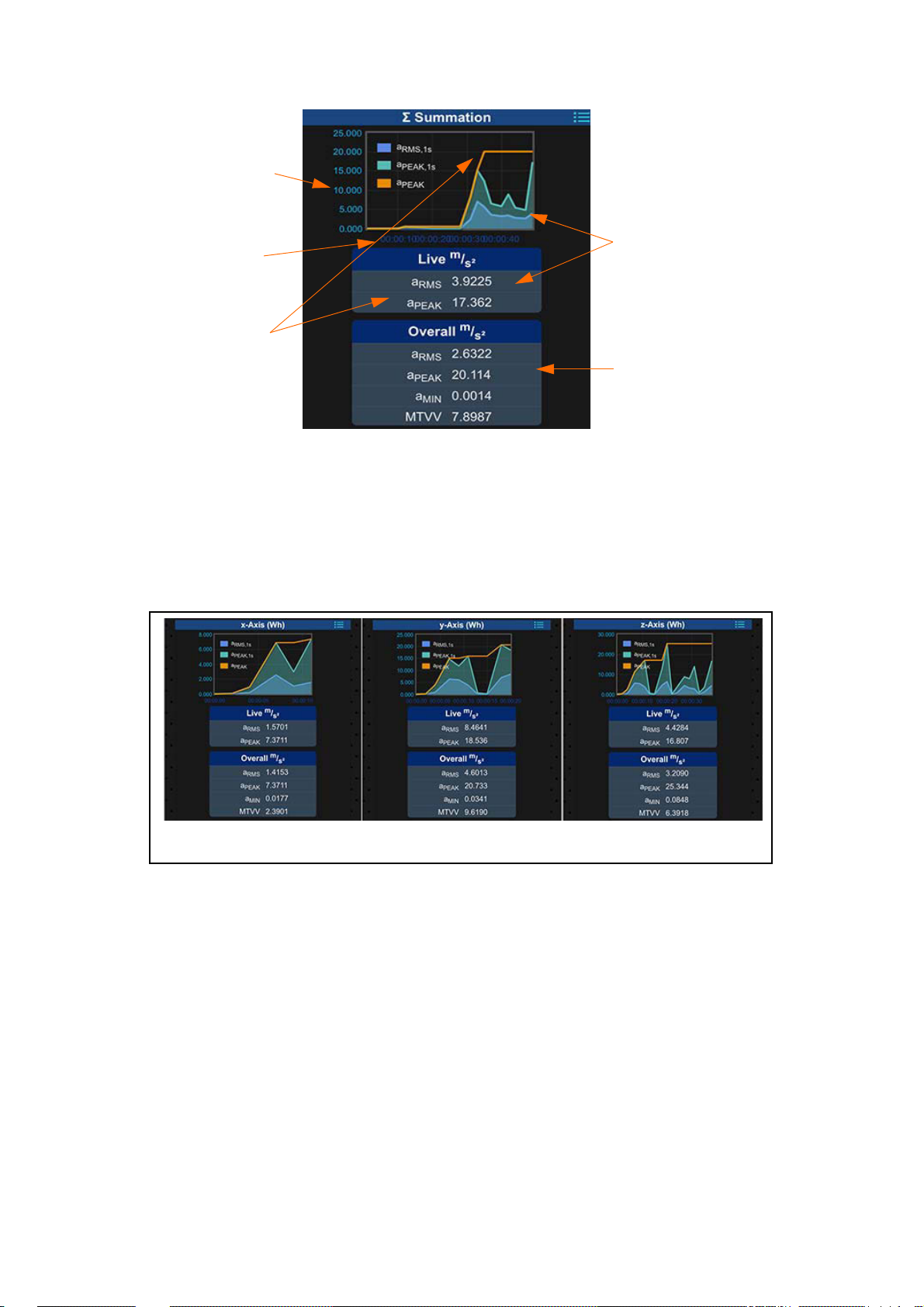

The Overall display shows cumulative data for all three axes and their

Current overall root mean

square (RMS) vibration value

according to specified units.

Measurement

Duration Clock

RMS value from the previous second

Overloaded Indicators

Values for each axis

Summation values

Next data display arrow

Battery

Status

RMS: Root mean

square value

PEAK (PK):

Highest instantaneous value

MIN: Lowest

value

MTVV: Maxi-

mum Transient

Vibration Value

summation for the measurement.

FIGURE 3-13 Overall Data Display

MIN and MTVV are the minimum and maximum whole body and hand/

arm values of the vibration signal with a one second exponential time

weighting. MIN and MAX are the minimum and maximum general

vibration values.

represents the summation of vibration values taken from the X, Y, and Z

axes.

The Summation display provides a real-time graphical representation of

the current summed values from all three axes.

HVM200 Reference Manual Making the Measurement 3-9

Page 27

FIGURE 3-14 Summation Data Display

Vibration values according to specified units

Measurement Time

Current a

RMS

value

Current a

PEAK

value

Overall measurement data

X

Y

Z

For more information on summation values, including Vibration Dose

Value (VDV) and the daily vibration exposure value over eight hours

A(8), see the "Glossary" on page C-1.

The Axes displays provide real-time graphical and tabular representations

of current and overall values for each axis, similar to Figure 3-14.

FIGURE 3-15 X, Y, and Z Axes Data Displays

Overload and Under-range Indicators

Overload

LEARN MORE For information on

overload indications on the Status

LED, see “Operational Characteristics” on page A-4.

An overload occurs when the signal from the accelerometer exceeds the

input range of the meter.

HVM200 Reference Manual Making the Measurement 3-10

Page 28

FIGURE 3-16 Overload Indicators

Indicates an overload has occurred on one or

more axes in current measurement

Red background

shows overload for

each axis.

Gray background

shows under-range

condition for the Y

and Z axes.

Under-range

An under-range occurs when the signal from the accelerometer is below

the input range to the point it cannot be measured accurately.

Annotate the Measurement

FIGURE 3-17 Under-range Indicators

Click the Annotate button and type a note to include with the measurement (you do not need to stop the measurement to annotate).

FIGURE 3-18 Annotate Button

HVM200 Reference Manual Making the Measurement 3-11

Page 29

TAKE NOTE An annotation note

may be made before the measurement is started and will be added as

an overall measurement note; only

one such note may be applied to the

measurement, but it can be overwritten if needed.

FIGURE 3-19 Annotate Measurement

3.4 Downloading Data

Once you have clicked the Stop button and the measurement is com-

pleted, you can download and work with data by using any of the following methods:

TAKE NOTE Refer to the G4 LD

Utility Manual for information on

downloading and viewing data with

G4.

LEARN MORE For tips on working

with raw data, see see “Working with

RAW Data Files” on page 3-12

• Download and view .hvm2 files in G4. The HVM functionality in

G4 requires a license.

• Download raw data files. You also need to specify storing data

with this option on the Setup tab during measurement setup. See

"Selecting a Setup File Using Your Mobile Device" for more

information.

• Use a third-party tool. Because .hvm2 files are stored in JavaS-

cript Object Notation (JSON) format, you can copy the data file

from the removable SD memory card and work with it in any tool

compatible with the format.

3.4.1 Working with RAW Data Files

RAW data files can be created with each measurement, if the Setup File

has checked “Store Raw Data” on the Setup Tab, see “Figure 3-6 Operation Settings” on page 3-5.

While HVM200 is connected to G4, a RAW file can be downloaded from

the Data Manager tab. The file will always be larger than an HVM file.

FIGURE 3-20 Raw Data File

HVM200 Reference Manual Downloading Data 3-12

Page 30

The raw data file is a binary file that contains raw data samples in a float

format for the x, y, and z axes after sensitivity has been applied. Each

sample contains 12 bytes in the following format:

Byte 01234567891011

Definition X Axis Sample Y Axis Sample Z Axis Sample

The byte order within each float is little endian.

TAKE NOTE The resulting data will

be in acceleration, which is the standard method of displaying the data,

and will need to be integrated into

velocity or displacement if needed.

In order to work with a RAW file, you will need MATLAB, GNU Octave,

or similar program. The following script can be used to parse the data.

The file name will need to be adjusted to match the file name of your

RAW file. After parsed, "Weighting Filters for Raw Data" to adjust

weighting filters for hand arm or whole body vibration purposes.

%% Example Matlab / GNU Octave code for parsing HVM200 raw data format

close all; clear all; clc;

%% Number of Samples to read

Sample_Rate = 7161.45833;% Hz (Hard wired sample rate)

Sample_Time = 10; %second

num_samples_to_read = Sample_Rate*Sample_Time;

%% Open file, Read, Close

%% filename = 'HVM_SERIAL_NUMBER_BASENAME_DATESTAMP.00.raw';

filename = 'HVM_0000056_HVMD_151216_180801.00.raw';

rawsavename = 'HVM_0000056';

filteredsavename = 'HVMFilt_0000056';

FID = fopen(filename,'r');

A = fread(FID,[num_samples_to_read*3],'float');

fclose(FID);

%% Build Axis data

axis_counter = 1;

x_axis = zeros(1,floor(num_samples_to_read));

y_axis = zeros(1,floor(num_samples_to_read));

z_axis = zeros(1,floor(num_samples_to_read));

x_axis = A(1:3:end);

y_axis = A(2:3:end);

z_axis = A(3:3:end);

%% Remove DC bias from data (optional)

x_axis = x_axis - mean(x_axis);

y_axis = y_axis - mean(y_axis);

z_axis = z_axis - mean(z_axis);

HVM200 Reference Manual Downloading Data 3-13

Page 31

%% Plot

figure(1);

plot(x_axis,'-b');

hold on;

plot(y_axis, '-r');

plot(z_axis, '-k');

hold off;

legend('x','y','z');

title('HVM200 Data');

save(rawsavename,'x_axis','y_axis','z_axis','Sample_Rate','Sample_Time')

;

%% Further processing through ISO 8041 Wk filter

x_axis_filt = isofilwk(x_axis, Sample_Rate);

y_axis_filt = isofilwk(y_axis, Sample_Rate);

z_axis_filt = isofilwk(z_axis, Sample_Rate);

figure(2);

plot(x_axis_filt,'-b');

hold on;

plot(y_axis_filt, '-r');

plot(z_axis_filt, '-k');

hold off;

title('HVM200 Data with Wk filter');

legend('x','y','z');

save(filteredsavename,'x_axis_filt','y_axis_filt','z_axis_filt','Sample_

Rate','Sample_Time');

Weighting Filters for Raw Data

The "isofilwk()" function comes from sample code taken from the ISO

8041 standard, and can be modified for other weighting filters using the

desired parameters from Table 3-1 'Parameters and transfer functions of

the frequency weightings (source: ISO 8041)'.

Use the following script and table to adjust RAW data file for hand arm or

whole body vibrations.

isofilwk() Sample Code (ISO 8041 standard)

function y = isofilwk(x, fs)

% ISOFILWK

% Filter ISO 8041 Wk

% y = isofilwk(x,fs)

HVM200 Reference Manual Downloading Data 3-14

Page 32

% y output signal, acceleration

% x input signal, acceleration

% fs sampling frequency Hz

% bilinear transformation algorithm is used

f1 = 0.4;

f2 = 100;

f3 = 12.5;

f4 = 12.5;

Q4 = 0.63;

f5 = 2.37;

Q5 = 0.91;

f6 = 3.35;

Q6 = 0.91;

% Note that in the function “butter” the variables Ql and Q2 are

% effectively set to equal to l/sqrt(2), therefore they don't need

% to be explicitly set here.

w3 = 2*pi*f3;

w4 = 2*pi*f4;

w5 = 2*pi*f5;

w6 = 2*pi*f6;

nyq = fs/2; % Nyquist frequency

% determine parameters for band limiting high pass and low pass

[b1,a1] = butter (2,f1/nyq, 'high' ); % High pass

[b2,a2] = butter (2,f2/nyq); % Low pass

% determine parameters for a-v transition

B3 = [1/w3 1];

A3 = [1/w4/w4 1/Q4/w4 1];

[b3,a3] = bilinear (B3, A3, fs);

% determine parameters for upward step

B4 = [1/w5/w5 1/Q5/w5 1]*w5*w5/w6/w6;

A4 = [1/w6/w6 1/Q6/w6 1];

[b4,a4] = bilinear (B4, A4, fs);

% Apply filter to input signal vector x (output to signal vector y)

y = filter (b2, a2, x); % Apply low-pass band limiting

y = filter (b1, a1, y); % Apply high-pass band limiting

y = filter (b3, a3, y); % Apply a-v transition

HVM200 Reference Manual Downloading Data 3-15

Page 33

y = filter (b4, a4, y); % Apply upward step

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

end

Band-limiting a-v-transition Upward step Gain

Weighting

W

b

W

c

W

d

W

e

W

f

W

h

W

j

W

k

W

m

f

Q1

1

f

Q

2

2

f

3

f

4

Q

4

f

5

Q

5

Hz Hz Hz Hz Hz Hz

0,4

0,4

0,4

0,4

0,08

8/

10

10

0,4

0,4

10

0,1

1/

1/

1/

1/

1/

1/

1/

1/

-

1/

100

100

100

100

0,63

31/

10

10

100

100

100

1/

1/

1/

1/

1/

1/

1/

1/

1/

16 16 0,55 2,5 0,9 4 0,95 1,024

8 8 0,63 ∞ 1 ∞ 11

2 2 0,63 ∞ 1 ∞ 11

1 1 0,63 ∞ 1 ∞ 11

∞ 0,25 0,86 0,0625 0,80 0,10 0,80 1

100/(2π) 100/(2π) 0,64 ∞ 1 ∞ 11

∞∞1 3,75 0,91 5,32 0,91 1

12,5 12,5 0,63 2,37 0,91 3,35 0,91 1

1/(0,028 ×

2π)

1/(0,028 ×

2π)

0,5 ∞ 1 ∞ 11

f

Q

6

6

K

NOTE 1 For weighting Wb, Table A.1 of ISO 2631-4:2001 rounds the value of parameter Q

to 2 decimal

1

places. The parameter specified here is the exact value.

NOTE 2 For weighting Wh, Table A.1 of ISO 5349-1:2001 rounds the values of parameters f1, f2, f3 and f

to 5 significant figures and parameter Q

to 2 decimal places. The parameters specified here are the exact

1

values.

Table 3.1 Parameters and transfer functions of the frequency

weightings (source: ISO 8041)

4

HVM200 Reference Manual Downloading Data 3-16

Page 34

Module4 Changing Features

Select Sync PC

and Meter Clocks

4.1 Overview ...............................................................................................................4-1

4.2 Setting/Syncing Meter Time and Date ..................................................................4-1

4.2.1 Setting/Syncing Time via G4 LD Utility ....................................................4-1

4.2.2 Setting/Syncing Time via HVM200 Control app .......................................4-2

4.3 Turning Off/On WiFi Signal ...................................................................................4-3

4.3.1 Turn Off WiFi Signal .................................................................................4-3

4.3.2 Turn Back On WiFi Signal ........................................................................4-4

4.4 Upgrade Firmware and Options ............................. ... ... .... ... ... ....... ... ... ... .... ... ... ... ..4-5

4.1 Overview

This module provides instructions for setting and disabling features, and

upgrading the HVM200.

4.2 Setting/Syncing Meter Time and Date

The HVM200 has a time feature that allows the meter’s internal clock to

be either manually set or synced with your PC or mobile device.

4.2.1 Setting/Syncing Time via G4 LD Utility

Step 1 Ensure the meter is powered on.

Step 2 Launch G4 LD Utility and connect meter either through

USB cable or IP address.

TAKE NOTE If you don’t see the

Time tab, you may be in a different

setting than Active. Only in the

Active setting can you set or sync the

time.

FIGURE 4-1 Maintenance Tab

Step 3 Navigate Meter ManagerMaintenance.

HVM200 Reference Manual Overview 4-1

Page 35

Step 4 Select Set to use the PC clock as the new time for the meter.

If you uncheck this option, you can set the date and time

manually.

FIGURE 4-2 Date and Time

4.2.2 Setting/Syncing Time via HVM200 Control app

Step 1 Make sure the meter is powered on.

LEARN MORE For more informa-

tion on connecting the HVM200 to

mobile app, see “Connecting the

HVM200 to a Mobile Device” on

page 2-4

FIGURE 4-3 HVM200 Menu

TAKE NOTE If you don’t see the

Time tab, you may be in a different

setting than Active. Only in the

Active setting can you set or sync the

time.

Step 2 Launch app and connect the HVM200 meter to your device

using an Access Point or WiFi network.

Step 3 Navigate MenuSettings.

Step 4 In the new HVM screen, select the upper left Menu icon,

then choose Time.

HVM200 Reference Manual Setting/Syncing Meter Time and Date 4-2

Page 36

FIGURE 4-4 HVM200 Time Tab

Menu Icon

Step 5 There are two options:

• Set Time: Tap the inside of the time and data fields, edit by

hand what time you want the meter to be, then select Set

Time.

• Sync Time: Select this button to sync the time on your

meter with the time on your mobile device.

4.3 Turning Off/On WiFi Signal

4.3.1 Turn Off WiFi Signal

To disable WiFi signal completely from the HVM200 meter, follow these

steps:

CAUTION You will only be able to

turn the WiFi signal back on from G4

LD Utility with meter connected via

USB.

Step 1 Launch the HVM200 Control app or the G4 LD Utility Live

Stream view.

Step 2 Click the menu icon.

FIGURE 4-5 HVM200 App

Step 3 On the HVM200 Menu, select Setup WiFi.

HVM200 Reference Manual Turning Off/On WiFi Signal 4-3

Page 37

FIGURE 4-6 WiFi Setup

Power button

Power button

Step 4 Click on the power button.

FIGURE 4-7 Network Settings

Step 5 An Alert will appear. Select Confirm. WiFi is now disabled.

4.3.2 Turn Back On WiFi Signal

To turn the WiFi signal back on from the HVM200 meter, follow these

steps:

Step 1 Connect HVM200 via USB cable to PC, launch G4 LD Util-

Step 2 From the Setup WiFi screen, click the red power symbol in

FIGURE 4-8 Network Settings

ity and connect meter, see “Connecting HVM200 to G4 LD

Utility” on page 2-8.

the upper left side

Step 3 An Alert will appear, click Confirm.

Step 4 A reboot is required to turn the WiFi back on, so you can

select the Reboot button or manually turn off the meter

HVM200 Reference Manual Turning Off/On WiFi Signal 4-4

Page 38

FIGURE 4-9 Reboot Button

Reboot

Button

To disconnect meter, click this ×

Step 5 A dialogue box will appear. Select Confirm.

Step 6 A second alert will appear. Wait 30 seconds.

Step 7 The meter will lose connection to G4 LD Utility.

Step 8 Reestablish connection.

4.4 Upgrade Firmware and Options

To upgrade firmware and install optional firmware, follow these steps:

Step 1 Make sure the meter is powered on.

Step 2 Launch G4 LD Utility and connect the HVM200 meter to

your PC. see “Connecting HVM200 to G4 LD Utility” on

page 2-7

Step 3 If you meter is connected to G4 LD Utility, disconnect by

clicking on the × on the tab of your meter.

FIGURE 4-10 Disconnect Meter

Step 4 From G4, navigate FileUpgrade Firmware or

Options.

Step 5 Choose meter, then select Connect.

Step 6 In this dialogue box you can check Firmware or Options,

then press button for Choose Firmware File (or Choose

Options File if you checked “Options”.

HVM200 Reference Manual Upgrade Firmware and Options 4-5

Page 39

FIGURE 4-11 Upgrade Firmware

Step 7 Open selected file.

Step 8 Press button for Upload Firmware (or Upload Options). A

success message will appear, close out window.

HVM200 Reference Manual Upgrade Firmware and Options 4-6

Page 40

Appendix A Specifications

A.1 General Characteristics ........................................................................................ A-1

A.1.1 Time History (Logging) ........................ ... ... ...... .... ... ... ... .... ... ... ... .... ... ... ... . A-2

A.1.2 Run Modes .............................................................................................. A-2

A.1.3 Clock/Calendar ...... .................... ................ ................... .................... ....... A-2

A.1.4 Effects of Magnetic Fields ....................................................................... A-2

A.1.5 Effec ts of Mechanic al Vibrat ions ......................................... ... ... .............. A-2

A.1.6 Stabilization Time ................... ... ... ... .... ... ... ... ........................................... A-3

A.1.7 Data Storage ........................................................................................... A-3

A.1.8 Transducer Electronic Data Sheets (TEDS) Support .............................. A-3

A.2 Physical Characteristics ......................................................................... .... ... ... ... . A-3

A.2.1 Dimensions/Weight ................................................................................. A-3

A.2.2 Communication Interface .................... ... ... ... ... .... ... ...... .... ... ... ... .... ... ... ... . A-3

A.2.3 Connections ............................................................................................ A-3

A.3 Operational Characteristics .................................................................................. A-4

A.3.1 LED Indications ....................................................................................... A-4

A.4 Electrical Characteristics ...................................................................................... A-5

A.4.1 Power Consumption ............... ... ... ... .... .................................................... A-5

A.4.2 Power Supply ............................................... ... .... ... ................................. A-5

A.4.3 Electrical Testing ..................................................................................... A-6

A.4.4 Input ........................................................................................................ A-6

A.5 Reference Values ................................................................................................. A-7

A.6 Measurement Ranges ...................................................... ... ................................. A-8

A.7 Frequency Weighting Curves ............................................................................... A-8

A.8 Frequency Weighting Tables .............................................................................A-13

A.9 Integration Weighting Limits ................................................................... .... ... ... .. A-23

A.10 1/1 & 1/3 Octave Band Filters ............................................................................ A-29

A.10.1 OBA Compliance ................................................................................... A-29

A.10.2 OBA General Specifications .................................................................. A-30

A.10.3 1/1 OBA Filter Responses ..................................................................... A-30

A.11 Standards Met .................................................................................................... A-38

Specifications are subject to change without notice.

A.1 General Characteristics

• Measurement modes: Hand-arm, Whole-body, Vibration

• Metrics by mode:

HVM200 Reference Manual General Characteristics A-1

Page 41

Vibration

Hand-arm

Whole-body

• Measurement units: m/s2, cm/s2, ft/s2, in/s2, g, dB

RMS, Peak, Min, MTVV, A(8) Act, A(8) Exp, EP VDV (x, y, z & )

RMS, Peak, Min, Max (x, y, z & )

RMS, Peak, Min, MTVV, A(8) (x, y, z & )

A.1.1 Time History (Logging)

• Store interval (user-selected): 1, 2, 5, 10, 20, 30 s; 1, 2, 5, 20, 30 min; 1 hr

• Stored values: RMS and Peak for x, y, and z axes and for .

A.1.2 Run Modes

• Manual: Run/stop with app or meter button

• Timed: Start at time specified in setup

• Delayed: Start after delay specified in setup of 5, 10, 20, 30, or 60 seconds

A.1.3 Clock/Calendar

• 24 hour clock format: hh:mm:ss

• Run-time resolution: 1 second

• 5 minute (typical) clock retention during battery change

Time of Day Drift

Worst case: 6.91 seconds per day (-10 C to + 50 C).

Effects of Temperature and Humidity

• Operating temperature: 14°F to 122°F (-10 °C to 50 °C)

• The RMS level of the HVM200 varies up to 1% when exposed to temperatures of - 10 °C to 50 °C

and relative humidity (RH) 20 to 90% (non-condensing).

• Tested at 159.4 Hz and 9.81 m/s2.

A.1.4 Effects of Magnetic Fields

Complete instrument RMS level varies up to 1.4% when exposed to an 80 A/m, 60 Hz magnetic field

(worst case orientation).The complete instrument is defined as the HVM200 meter, CBL217-01, and

SEN041F.

A.1.5 Effects of Mechanical Vibrations

Complete instrument RMS level varies up to 0.4% when exposed to mechanical vibrations of 30 m/s2 at

79.58 Hz (worst-case orientation).

HVM200 Reference Manual General Characteristics A-2

Page 42

A.1.6 Stabilization Time

• 60 seconds

• Measurements with integration settings require up to one minute additional stabilization time before

initiating (the Power LED may display a solid green color during this additional stabilization time).

A.1.7 Data Storage

• Removable micro SD memory card up to 32 GB.

• 2 GB file size limit. Files are truncated at 2 GB. No limit to number of files or setups.

• Data and settings are stored in non-volatile memory

• Swapping limitation: Device must be off while replacing Micro SD card or battery.

A.1.8 Transducer Electronic Data Sheets (TEDS) Support

• Chips supported by HVM200: DS2430 and DS2431

• Versions supported: 0.9 (only DS2430 chip) and 1.0

• Templates supported: 0 (version 0.9), 25 (version 1.0)

A.2 Physical Characteristics

A.2.1 Dimensions/Weight

• Length: 4.6 inches (11.8 cm)

• Width: 2.6 inches (6.7 cm)

• Depth: 0.7 inches (1.8 cm)

• Weight: 4.6 ounces (130 grams) - including battery

• Ingress Protection Rating: IP42

A.2.2 Communication Interface

• USB 2.0 Hi-Speed

• WiFi 802.11 b/g/n with WPA and WPA2 security

A.2.3 Connections

• Micro-B USB cable (Communication and power)

• 1/4-28 4-pin 3-channel sensor connector

HVM200 Reference Manual Physical Characteristics A-3

Page 43

A.3 Operational Characteristics

Power LED

Status LED

Power Button

G4 Live View

Warning Icon

A.3.1 LED Indications

The following tables shows HVM200 LED indications, states, and additional information.

Power LED

Indication State Additional Information

Click the Warning Icon on the G4 LD Utility Live View. The “About

This Meter” information shows if there is a sensor/cable connection

System

Warning

Battery Low

(Blinking)

Battery

Charging

Battery

Charged

error, battery connection error, or SD memory card error. To avoid

system errors, do not hot swap SD memory cards.

Charge the HVM200 via USB from your computer or from the

PSA035 power supply. If not charged, the HVM200 will shut down

when the remaining battery life approaches the threshold for safe shut

down. If the HVM200 shuts down mid-measurement, the file is trun-

cated and G4 LD Utility may not be able to display summary informa-

tion for the file.

Allow the battery to charge fully to maximize overall battery life.

N/A

Power On is displayed both on start up and shut down. When turning

on the HVM200, press the power button for about one second until

Power On

HVM200 Reference Manual Operational Characteristics A-4

the blue LED is displayed. When shutting down, press the power but-

ton until the blue LED is displayed and the Status LED is dark.

Power On is also displayed when the HVM200 is running on battery

power (not simultaneously charging through USB connection).

Page 44

Status LED

Indication State

Measurement

Stopped

Measurement

Running

Measurement

Run Pending

(Blinking)

Overload

Overloaded

(Blinking)

Power Button Functions

Additional Information

The HVM200 is not running a measurement.

The HVM200 is in the process of taking a measurement.

The HVM200 is stabilizing for an impending measurement, which

may last up to 60 seconds, or is awaiting a delayed start set from the

scheduling tab.

A signal from the accelerometer is currently exceeding the calibrated

input range of the HVM200.

An overload has occurred in this measurement.

Power Button Functions

Action Press Power Button

Turn on power At least one second until Power LED is blue

Turn off power Until Power LED is blue and Status LED is dark

Start or stop toggle for manual measurement After turning on meter, less than three seconds

Shut down (if unresponsive) At least 16 seconds

A.4 Electrical Characteristics

A.4.1 Power Consumption

• USB Power: 130 mA in station mode; 180 mA in access point mode

• Battery run time: 12 hours in station mode; 9 hours in access point mode

A.4.2 Power Supply

• User replaceable rechargeable lithium-ion battery

• Charge time: 3.5 hours with Larson Davis PSA035 power supply

HVM200 Reference Manual Electrical Characteristics A-5

Page 45

• External Power:

Represents one

input for each axis

(x,y, z).

Refer to the “Pinout” diagram

below for more

information on the

1/4-28 input connection.

USB Type A to Micro-B USB cable, 3 ft (1 m)

Larson Davis Power Supply PSA035 (universal 100-240 VAC to 5 V USB power adapter)

A.4.3 Electrical Testing

During electrical testing, the following circuit was used:

Circuit to Inject Electrical Signal into HVM200 ICP® Inputs

A.4.4 Input

• Input type: ICP, IEPE, or CCP

• Excitation current: 2 mA

• Input connector: 1/4-28 4-pin male (the input connection is also the transducer connection)

• Measurement input voltage range: 1.8 to 16 Vdc

• Measurement AC reference bias voltage: 9 Vdc

• Absolute voltage range (min to max): 0 to 28 V

• Bandwidth: 0.4 Hz to 3000 Hz

• Range: Single range

• Sample rate: 7161.45833 Hz

HVM200 Reference Manual Electrical Characteristics A-6

Page 46

Pinout

A1

A2

B2 B1

Pin Signal

A1 GND

A2 X Axis

B1 Y Axis

B2 Z Axis

A.5 Reference Values

The following values represent the primary frequencies and amplitudes at which weighting filters are specified and tested.

Operating

Mode

Vibration Fa (0.4 Hz to 100 Hz)

Frequency W e ighting Reference Frequency

50 rad/s (7.958 Hz)

Fb (0.4 Hz to 1250 Hz)

Fc (6.3 Hz to 1250 Hz)

500 rad/s (79.58 Hz)

500 rad/s (79.58 Hz)

Hand Arm Wh 500 rad/s (79.58 Hz)

Whole Body Wm

100 rad/s (15.915 Hz)

Wb

Wc

Wd

We

Wj

Wk

Reference

Amplitude

10 m/s

10 m/s

10 m/s

10 m/s

1.0 m/s

1.0 m/s

1.0 m/s

1.0 m/s

1.0 m/s

1.0 m/s

1.0 m/s

2

2

2

2

2

2

2

2

2

2

2

Wf (Severity)

2.5 rad/s (0.3979 Hz)

0.1m/s

2

HVM200 Reference Manual Reference Values A-7

Page 47

A.6 Measurement Ranges

The following table shows the HVM200 dynamic and linearity ranges in root-mean square values. (Peak values are 1.414 times higher.)

Frequency

Weighting

Noise Floor

(typical mV)

Lower Limit

(Under-range

mV)

Lower Limit Lin-

earity Range

(typical mV)

Lower Limit

Linearity Range

(maximum mV)

Upper Limit

(Overload V)

Fa 0.028 0.204 0.092 0.178 5.01

Fb 0.046 0.232 0.133 0.176 5.01

Fc 0.041 0.205 0.116 0.152 5.01

Wb 0.016 0.167 0.073 0.137 5.01

Wc 0.021 0.184 0.089 0.150 5.01

Wd 0.014 0.181 0.072 0.175 5.01

We 0.012 0.193 0.073 0.161 5.01

Wf 0.009 0.185 0.100 0.147 5.01

Wh 0.014 0.087 0.042 0.090 5.01

Wj 0.023 0.167 0.077 0.151 5.01

Wk 0.018 0.144 0.073 0.121 5.01

Wm 0.017 0.103 0.060 0.077 5.01

A.7 Frequency Weighting Curves

The following graphs show frequency weighting curves for the HVM200.

HVM200 Reference Manual Measurement Ranges A-8

Page 48

HVM200 Reference Manual Frequency Weighting Curves A-9

Page 49

HVM200 Reference Manual Frequency Weighting Curves A-10

Page 50

HVM200 Reference Manual Frequency Weighting Curves A-11

Page 51

HVM200 Reference Manual Frequency Weighting Curves A-12

Page 52

A.8 Frequency Weighting Tables

The following tables show frequency weighting values for the HVM200.

HVM200 Reference Manual Frequency Weighting Tables A-13

Page 53

Fa (Flat 0.4 Hz to 100 Hz)

Freq ( Hz) Fa Ideal (dB) Fa Typical (dB) Tolerance (dB)

0.1000

0.1259

0.1585

0.1995

0.2512

0.3162

0.3981

0.5012

0.6310

0.7943

1.000

1.259

1.585

1.995

2.512

-24.10

-20.12

-16.19

-12.34

-8.71

-5.51

-3.05

-1.48

-0.65

-0.27

-0.11

-0.04

-0.02

-0.01

0.00

-25.19 +2/-

-21.21 +2/ -

-16.92 +2/ -

-12.95 +2/-

-9.26 +2/-2

-5.84 +2/-2

-3.15 +1/-1

-1.46 +1/-1

-0.57 +1/-1

-0.17 +1/-1

0.06 +1/-1

0.00 +1/-1

-0.02 +1/-1

-0.03 +1/-1

-0.03 +1/-1

3.162

3.981

5.012

6.310

7.943

10.00

12.59

15.85

19.95

25.12

31.62

39.81

50.12

63.10

79.43

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

-0.01

-0.02

-0.04

-0.11

-0.27

-0.64

-1.46

-0.03 +1/-1

-0.02 +1/-1

-0.03 +1/-1

-0.04 +1/-1

0.00 0

-0.01 +1/-1

0.00 +1/-1

0.02 +1/-1

-0.02 +1/-1

-0.05 +1/-1

-0.03 +1/-1

-0.12 +1/-1

-0.27 +1/-1

-0.65 +1/-1

-1.44 +1/-1

100.0

125.9

158.5

199.5

-3.01

-5.46

-8.64

-12.27

-2.99 +1/-1

-5.47 +2/-2

-8.65 +2/-2

-12.32 +2/ -

HVM200 Reference Manual Frequency Weighting Tables A-14

Page 54

Freq ( Hz) Fa Ideal (dB) Fa Typical (dB) Tolerance (dB)

251.2

316.2

398.1

-16.11

-20.04

-24.02

-16.20 +2/ -

-20.16 +2/ -

-24.22 +2/ -

HVM200 Reference Manual Frequency Weighting Tables A-15

Page 55

Fb (Flat 0.4 Hz to 1260 Hz) Frequency Weighting

Freq ( Hz) Fb Ideal (dB) Fb Typical (dB) Tolerance (dB)

0.1000 -24.10 -25.24 +2 / -

0.1259 -20.12 -21.23 +2 / -

0.1585 -16.19 -16.94 +2 / -

0.1995 -12.34 -12.99 +2 / -

0.2512 -8.71 -9.29 +2 / -2

0.3162 -5.51 -5.84 +1 / -1

0.3981 -3.05 -3.18 +1 / -1

0.5012 -1.48 -1.49 +1 / -1

0.6310 -0.65 -0.59 +1 / -1

0.7943 -0.27 -0.21 +1 / -1

1.000 -0.11 -0.08 +1 / -1

1.259 -0.04 -0.05 +1 / -1

1.585 -0.02 -0.04 +1 / -1

1.995 -0.01 -0.04 +1 / -1

2.512 0.00 -0.04 +1 / -1

3.162 0.00 -0.07 +1 / -1

3.981 0.00 -0.05 +1 / -1

5.012 0.00 -0.05 +1 / -1

6.310 0.00 -0.07 +1 / -1

7.943 0.00 -0.06 +1 / -1

10.00 0.00 -0.03 +1 / -1

12.59 0.00 -0.03 +1 / -1

15.85 0.00 -0.01 +1 / -1

19.95 0.00 -0.03 +1 / -1

25.12 0.00 -0.05 +1 / -1

31.62 0.00 -0.02 +1 / -1

39.81 0.00 -0.02 +1 / -1

50.12 0.00 -0.03 +1 / -1

63.10 0.00 -0.03 +1 / -1

79.43 0.00 0.00 0

100.0 0.00 -0.01 +1 / -1

HVM200 Reference Manual Frequency Weighting Tables A-16

Page 56

Freq ( Hz) Fb Ideal (dB) Fb Typical (dB) Tolerance (dB)

125.9 0.00 -0.04 +1 / -1

158.5 0.00 -0.02 +1 / -1

199.5 0.00 -0.05 +1 / -1

251.2 -0.01 -0.06 +1 / -1

316.2 -0.02 -0.05 +1 / -1

398.1 -0.04 -0.10 +1 / -1

501.2 -0.11 -0.15 +1 / -1

631.0 -0.27 -0.31 +1 / -1

794.3 -0.64 -0.63 +1 / -1

1000 -1.46 -1.47 +2 / -2

1259 -3.01 -3.35 +2 / -2

1585 -5.46 -6.86 +2 / -2

1995 -8.64 -12.55 +2 / -2

2512 -12.27 -21.30 +2 / -

3162 -16.11 -39.09 +2 / -

3981 -20.04 -85.43 +2 / -

HVM200 Reference Manual Frequency Weighting Tables A-17

Page 57

Fc (Flat 6.3 Hz to 1260 Hz), Wh, and Wf Frequency Weighting.

Freq

( Hz)

Fc Ideal

(dB)

Fc T yp

(dB)

Wh Ideal

(dB)

Wh T yp

(dB)

Tolerance

(dB)

Wf Ideal

(dB)

Wf T yp

(dB)

Tolerance

(dB)

0.7943 0.7943 -36.06 -36.00 -36.10 +2 / - -32.37 -32.08 +2 / -

1.000 1.000 -32.08 -31.99 -32.08 +2 / - -28.40 -30.95 +2 / -

1.259 1.259 -28.08 -27.99 -28.09 +2 / - -24.41 -26.39 +2 / -

1.585 1.585 -24.08 -23.99 -24.07 +2 / - -20.34 -21.30 +2 / -

1.995 1.995 -20.09 -20.01 -20.08 +2 / - -16.06 -17.28 +2 / -

2.512 2.512 -16.16 -16.05 -16.12 +2 / - -11.45 -12.58 +2 / -2

3.162 3.162 -12.31 -12.18 -12.26 +2 / - -6.86 -7.07 +2 / -2

3.981 3.981 -8.70 -8.51 -8.56 +2 / -2 -3.16 -3.56 +2 / -2

5.012 5.012 -5.50 -5.27 -5.32 +2 / -2 -0.92 -1.13 +4 / -1

6.310 6.310 -3.02 -2.77 -2.83 +2 / -2 0.04 -0.02 +1 / -1

7.943 7.943 -1.52 -1.18 -1.25 +2 / -2 -0.06 -0.12 +1 / -1

10.00 10.00 -0.67 -0.43 -0.46 +1 / -1 -1.41 -1.39 +1 / -1

12.59 12.59 -0.31 -0.38 -0.39 +1 / -1 -4.22 -4.21 +1 / -1

15.85 15.85 -0.12 -0.96 -0.99 +1 / -1 -8.22 -8.22 +1 / -1

19.95 19.95 -0.08 -2.14 -2.17 +1 / -1 -13.05 -12.96 +2 / -2

25.12 25.12 -0.06 -3.78 -3.83 +1 / -1 -18.73 -18.63 +2 / -2

31.62 31.62 -0.02 -5.69 -5.71 +1 / -1 -25.30 -25.22 +2 / -2

39.81 39.81 -0.03 -7.72 -7.75 +1 / -1 -32.57 -32.49 +2 / -

50.12 50.12 -0.03 -9.78 -9.80 +1 / -1 -40.26 -40.20 +2 / -

63.10 63.10 -0.03 -11.83 -11.86 +1 / -1 -48.14 -48.11 +2 / -

79.43 79.43 0.00 -13.88 -13.88 0 -56.11 -55.96 +2 /-

100.0 100.0 -0.01 -15.91 -15.92 +1 / -1

125.9 125.9 -0.04 -17.93 -17.97 +1 / -1

158.5 -0.02 -19.97 +1 / -1

199.5 0.00 -0.05 -19.94 -22.01 +1 / -1

251.2 0.00 -0.06 -21.95 -24.04 +1 / -1

316.2 -0.01 -0.05 -23.96 -26.06 +1 / -1

398.1 -0.02 -0.10 -25.98 -28.13 +1 / -1

501.2 -0.04 -0.15 -28.00 -30.21 +1 / -1

631.0 -0.11 -0.31 -30.07 -32.40 +1 / -1

HVM200 Reference Manual Frequency Weighting Tables A-18

Page 58

Freq

( Hz)

Fc Ideal

(dB)

Fc T yp

(dB)

Wh Ideal

(dB)

Wh T yp

(dB)

Tolerance

(dB)

794.3 -0.27 -0.63 -32.23 -34.70 +1 / -1

1000 -0.64 -1.47 -34.60 -37.41 +2 / -2

1259 -1.46 -3.35 -37.42 -40.97 +2 / -2

1585 -3.01 -6.86 -40.97 -46.21 +2 / -2

1995 -5.46 -12.55 -45.42 -54.40 +2 / -2

2512 -8.64 -21.30 -50.60 -67.23 +2 / -

3162 -12.27 -39.09 -56.23 -92.87 +2 / -

3981 -16.11 -86.14 -62.07 -101.37 +2 / -

Wf Ideal

(dB)

Wf T yp

(dB)

Tolerance

(dB)

HVM200 Reference Manual Frequency Weighting Tables A-19

Page 59

Wm, Wc, and Wd Frequency Weightings

Freq

( Hz)

Wm Ideal

(dB)

WmTyp

(dB)

Wc Ideal

(dB)

Wc Typ

(dB)

Wd Ideal

(dB)

Wd T yp

(dB)

Tolerance

(dB)

0.100 -32.04 -36.81 -24.10 -25.20 -24.09 -25.23 +2 / -

0.1259 -28.20 -32.86 -20.12 -21.23 -20.12 -21.21 +2 / -

0.1585 -23.98 -28.53 -16.19 -16.93 -16.18 -16.96 +2 / -

0.1995 -20.23 -24.53 -12.34 -13.00 -12.32 -13.00 +2 / -

0.2512 -16.71 -20.60 -8.71 -9.30 -8.68 -9.28 +2 / -2

0.3162 -13.51 -16.58 -5.51 -5.88 -5.47 -5.78 +2 / -2

0.3981 -10.98 -12.67 -3.05 -3.17 -2.98 -3.10 +1 / -1

0.5012 -9.53 -9.04 -1.47 -1.50 -1.37 -1.40 +1 / -1

0.6310 -8.71 -5.76 -0.64 -0.60 -0.50 -0.45 +1 / -1

0.7943 -8.38 -3.18 -0.25 -0.23 -0.08 -0.06 +1 / -1

1.00 -8.29 -1.59 -0.08 -0.06 +0.10 0.12 +1 / -1

1.259 -8.27 -0.85 +0.00 -0.01 +0.06 0.06 +1 / -1

1.585 -8.07 -0.61 +0.06 0.02 -0.26 -0.28 +1 / -1

1.995 -7.60 -0.64 +0.10 0.05 -1.00 -1.06 +1 / -1

2.512 -6.13 -0.86 +0.15 0.09 -2.23 -2.30 +1 / -1

3.162 -3.58 -1.24 +0.19 0.12 -3.88 -3.93 +1 / -1

3.981 -1.02 -1.78 +0.21 0.14 -5.78 -5.84 +1 / -1

5.012 0.21 -2.55 +0.11 0.04 -7.78 -7.85 +1 / -1

6.310 0.46 -3.52 -0.23 -0.31 -9.83 -9.92 +1 / -1

7.943 0.21 -4.76 -0.97 -1.06 -11.87 -11.91 0

10.0 -0.23 -6.16 -2.20 -2.25 -13.91 -13.95 +1 / -1

12.59 -0.85 -7.75 -3.84 -3.88 -15.98 +1 / -1

15.85 -1.83 -9.44 -5.74 -5.74 -17.95 +1 / -1

19.95 -3.00 -11.30 -7.75 -7.81 -20.02 +1 / -1

25.12 -4.44 -13.19 -9.80 -9.85 -15.93 -22.04 +1 / -1

31.62 -6.16 -15.12 -11.87 -11.91 -17.95 -24.05 +1 / -1

39.81 -8.11 -17.14 -13.97 -14.00 -19.97 -26.12 +1 / -1

50.12 -10.09 -19.26 -16.15 -16.20 -21.98 -28.28 +1 / -1

63.10 -12.43 -21.62 -18.55 -18.59 -24.01 -30.67 +1 / -1

79.43 -15.34 -24.40 -21.37 -21.39 -26.08 -33.45 +1 / -1

HVM200 Reference Manual Frequency Weighting Tables A-20

Page 60

Freq

( Hz)

Wm Ideal

(dB)

WmTyp

(dB)

Wc Ideal

(dB)

Wc Typ

(dB)

Wd Ideal

(dB)

Wd T yp

(dB)

Tolerance

(dB)

100.0 -18.72 -27.95 -24.94 -24.96 -28.24 -37.02 +1 / -1

125.9 -23.00 -32.43 -29.39 -29.45 -30.62 -41.50 +2 / -2

158.5 -28.56 -37.60 -34.57 -34.63 -33.43 -46.68 +2 / -2

199.5 -34.03 -43.28 -40.20 -40.32 -36.99 -52.36 +2 / -

251.2 -39.69 -49.17 -46.04 -46.21 -41.43 -58.25 +2 / -

316.2 -45.65 -55.16 -51.98 -52.19 -46.62 -64.23 +2 / -

398.1 -51.84 -61.23 -57.95 -58.29 -52.24 -70.30 +2 / -

HVM200 Reference Manual Frequency Weighting Tables A-21

Page 61

We, Wj, and Wk Frequency Weighting

Freq

( Hz)

We Ideal

(dB)

We Typ

(dB)

Wj Ideal

(dB)

Wj Typ

(dB)

Wk Ideal

(dB)

Wk T yp

(dB)

Tolerance dB