Page 1

Model HVM100

Human Vibration Meter

Manual

Page 2

Larson Davis HVM100

Manual

IHVM100.01 Rev K

Page 3

Copyright

Copyright 2006-2015 by PCB Piezotronics, Inc. This manual is copyrighted, with all rights reserved.

The manual may not be copied in whole or in part for any use without prior written consent of PCB

Piezotronics, Inc.

®

is a registered trademark of PCB Group, Inc. Blaze® is a registered trademark of PCB

ICP

Piezotronics, Inc. Switchcraft

trademark of LEMO SA. LEMO USA

®

is a registered trademark of Switchcraft, Inc. LEMO® is a registered

®

is a registered trademark of INTERLEMO HOLDING USA.

All other trademarks are property of their respective owners.

Disclaimer

The following paragraph does not apply in any state or country where such statements are not

agreeable with local law:

Even though PCB Piezotronics, Inc. has reviewed its documentation, PCB Piezotronics Inc. makes no

warranty or representation, either expressed or implied, with respect to this instrument and

documentation, its quality, performance, merchantability, or fitness for a particular purpose. This

documentation is subject to change without notice, and should not be construed as a commitment or

representation by PCB Piezotronics, Inc.

This publication may contain inaccuracies or typographical errors. PCB Piezotronics, Inc. will

periodically update the material for inclusion in new editions. Changes and improvements to the

information described in this manual may be made at any time.

Record of Serial Number and Purchase Date

HVM100 Purchase Date________ Serial Number: ___________

Recycling

PCB Piezotronics, Inc. is an environmentally friendly organization and encourages our customers to

be environmentally conscious. When this product reaches its end of life, please recycle the product

through a local recycling center or return the product to:

PCB Piezotronics, Inc.

Attn: Recycling Coordinator

1681 West 820 North

Provo, Utah, USA 84601-1341

where it will be accepted for disposal

Product Warranty

For warranty information, refer to our Terms and Conditions of Sale on our website at

www.larsondavis.com/TermsConditions.aspx.

Page 4

Table of Contents

Chapter 1 Introduction 1-1

About This Manual.................................................................................................1-1

Accessories .............................................................................................................1-3

Standard Accessories .........................................................................................1-3

Optional Accessories..........................................................................................1-3

Transducers ...................................................................................................1-3

Calibrator.......................................................................................................1-3

Cables............................................................................................................1-3

Adaptors........................................................................................................1-4

Cases..............................................................................................................1-4

Power Supply ................................................................................................1-4

Software ........................................................................................................1-4

Selecting the Proper Transducer...................... .................................. .....................1-5

Triaxial Accelerometers................................................................................1-7

Single Axis Accelerometers..........................................................................1-9

Modes of Operation..............................................................................................1-10

Frequency Weighting Selections ..........................................................................1-10

Band Limiting Filters.......................................................................................1-11

Chapter 2 Getting Started 2-1

Switching HVM100 On..........................................................................................2-1

Menu Navigation ....................................................................................................2-1

Alpha Numeric Menu Function .........................................................................2-2

Indexed Menu Function.....................................................................................2-3

Key Board Functions ..............................................................................................2-4

Setup Key................................................................................................................2-4

Mode Selection ..................................................................................................2-5

Averaging Time .................................................................................................2-5

Time History Settings....................................................................................2-6

Store Time..........................................................................................................2-7

Auto Store ..........................................................................................................2-7

2nd History.................................................. .......................................................2-8

Vibration Mode Weighting.....................................................................................2-8

Hand Arm Mode Weighting ...................................................................................2-9

Whole Body Weighting Mode........................................ ........................................2-9

HVM100 Manual ii-i

Page 5

Chapter 3 Tools Menu 3-1

Tools Key................................................................................................................3-1

Accelerometer....................................................................................................3-1

Display Units......................................................................................................3-2

Integration..........................................................................................................3-3

Sum Factor X,Y, Z.............................................................................................3-4

AC/DC Output ...................................................................................................3-4

AC/DC Output Settings.................................................................................3-7

Baud Rate...........................................................................................................3-8

Handshaking..................................................................................................3-8

Print History Selection.................................................... ...................................3-8

Erase All Files........................................... .................................. .......................3-9

Erase Setups............................. ........................................................................3-10

Header 1,2,3............................................................ .........................................3-11

Language..........................................................................................................3-12

Date and Time..................................................................................................3-13

Chapter 4 Range Menu 4-1

Range Key...............................................................................................................4-1

Auto Range ........................................................................................................4-1

Gain X, Y, Z.......................................................................................................4-2

Cal Level............................................................................................................4-2

Calibrate X, Y, Z................................................................................................4-3

Sensitivity X, Y, Z .............................................................................................4-4

Reference Acceleration......................................................................................4-5

Hand Arm Exposure Action Value ....................................................................4-5

Chapter 5 Printing 5-1

Printing to a Windows Hyperterminal....................................................................5-1

Chapter 6 Storing and Recalling Data Files and Setups 6-1

STORE Key............................................................................................................6-1

Storing a Setup...................................................................................................6-1

Storing a File......................................................................................................6-3

Temporary Data Storage - File Register 00 .......................................................6-4

Data Storage - File Registers 01 thru 99............................................................6-5

Preserving the File Counter At Power-Off ........................................................6-5

Recall Key...............................................................................................................6-6

Recalling a Setup ...............................................................................................6-6

ii-ii HVM100 Manual

Page 6

Recalling Setup Register S0 at Power-On .........................................................6-7

Recalling a File ..................................................................................................6-8

Chapter 7 Taking Measurements/ Viewing Data on the HVM100 7-1

Run/Stop Key..........................................................................................................7-1

Overload Detection ............................................................................................7-1

Under-Range Indicator (?) .................................................................................7-2

Run-Interrupted Indicator (!) .............................................................................7-2

History Key............................................................ .................................................7-3

Viewing Time History with 2nd History turned on ...........................................7-5

Data Key .................................................................................................................7-6

Chapter 8 Powering the HVM100 8-1

Checking the Remaining Battery Voltage .........................................................8-1

Installing New Batteries..........................................................................................8-1

Using External Power.............................. .................................. .............................8-4

Chapter 9 Connections on the HVM100 9-1

Serial Interface Port ................................................................................................9-2

Pinout.................................................................................................................9-2

Cables Used........................................................................................................9-3

Transducer Connection...........................................................................................9-4

Pinout.................................................................................................................9-4

External Power Connection ....................................................................................9-5

Pinout.................................................................................................................9-5

Larson Davis Adapter ........................................................................................9-5

AC/DC Output Connector..................................................................................9-6

Pinout.................................................................................................................9-7

Chapter 10 Chapter 10 Adaptor Resonances 10-1

Conclusion ............................................................................................................10-1

Mechanical............................................................................................................10-1

Measurements.......................................................................................................10-3

Frequency Response Measurements................................................................10-3

ADP080A + SEN041.......................................................................................10-3

ADP081A + SEN041.......................................................................................10-5

ADP082A + SEN041.......................................................................................10-6

HVM100 Manual ii-iii

Page 7

Appendix A Specifications A-1

General Characteristics..........................................................................................A-1

Type Precision..............................................................................................A-1

Effects of Temperature.................................................................................A-2

Effects of Humidity................................... ...................................................A-2

Limits of Temperature and Humidity...........................................................A-2

Effects of Magnetic Fields ..................................................... ......................A-2

Effects of Mechanical Vibrations.................................................................A-2

Stabilization Time........................................................................................A-2

Data Storage.................................................................................................A-3

Data Communications..................................................................................A-3

Digital Display .............................................................................................A-3

Real-time Clock/Calendar............................................................................A-3

Run-time Clock............................................................................................A-3

Power Supply ...............................................................................................A-3

Dimensions/Weight......................................................................................A-3

Declaration of Conformity................................................................................A-4

Outputs..............................................................................................................A-5

Transducer Electrical Impedance......................................................................A-5

Direct Input ..................................................................................................A-5

®

Input....................................................................................................A-5

ICP

Charge Input.................................................................................................A-6

Functions Measured..........................................................................................A-6

Reference Acceleration..................................................................................... A-6

Reference Calibration Frequency......................................................................A-7

Reference Calibration Vibration.......................................................................A-7

Frequency Weighting Curves ................................................................................A-8

Fa (Flat 0.4 Hz to 100 Hz)............................................................................A-8

Fb (Flat 0.4 Hz to 1260 Hz) Frequency Weighting......................................A-9

Fc (Flat 6.3 Hz to 1260 Hz), Wh, and Ws Frequency Weighting..............A-12

Wm, Wc, and Wd Frequency Weightings..................................................A-13

We, Wj, and Wk Frequency Weighting.....................................................A-15

Wg Frequency Weighting (Defined in BS6841:1987)...............................A-17

Wm (Whole Body) Frequency Weighting.................................................A-18

Typical Measurements Ranges ..................................................... ..................A-20

Vibration - Fa.............................................................................................A-20

Vibration - Fb, Fc, Ws................................................................................A-21

Hand Arm - Wh............................................................. .............................A-22

ii-iv HVM100 Manual

Page 8

Whole Body - Wm .....................................................................................A-23

Whole Body - Wc.................................................. ................................. ....A-24

Whole Body - Wd, We....................................... .................................. ......A-25

Whole Body - Wg ................................ ......................................................A-26

Whole Body - Wb, Wj, Wk.......................... ..............................................A-27

Appendix B Glossary B-1

Table of equations..................................................................................................B-1

RMS Acceleration............................................................................. ...........B-1

RMS Acceleration in Decibels.....................................................................B-1

Allowed Exposure Time...............................................................................B-2

Energy Equivalent RMS Acceleration.........................................................B-2

Running RMS Acceleration LINEAR..........................................................B-2

Running RMS Acceleration EXPONENTIAL ............................................B-3

Vibration Dose Value...................................................................................B-3

Maximum Transient Vibration Value..........................................................B-3

Minimum Transient Vibration Value...........................................................B-3

Long Term Maximum Peak .........................................................................B-3

Short Term Maximum Peak.........................................................................B-4

Long Term Crest Factor...............................................................................B-4

Short Term Crest Factor...............................................................................B-4

Summed Instantaneous Acceleration...........................................................B-4

Appendix C Serial Interface Commands C-1

Setup and Query Commands .................................................................................C-1

Syntax for setup commands................................. .............................................C-1

Syntax for Query commands.............................................................................C-2

System Parameters (Q’s and S’s)...........................................................................C-2

Mode Specific Parameters ................................................................................C-3

Read Data Commands ...........................................................................................C-9

Read Time History Commands............................................................................C-10

Control Commands..............................................................................................C-12

Appendix D Frequency Response Curves D-1

Appendix E Miscellaneous Information E-1

DC Output Calibration ...........................................................................................E-1

AC/DC Outputs......................................................................................................E-3

DC Output.........................................................................................................E-3

AC Output.........................................................................................................E-4

HVM100 Manual ii-v

Page 9

Typical Measurement Ranges for Hand-Arm and Whole Body Measurements ... E-5

®

Accelerometers ........................................................................................ E-5

ICP

Typical Measurement Ranges for General Purpose Vibration Measurements...... E-7

ICP Accelerometers .......................................................................................... E-7

Appendix F Serial Number Backup F-1

Setting Serial Number Backup..........................................................................F-1

Serial Number Reset ......................................................................................... F-1

Failure of Serial Number Reset......................................................................... F-2

ii-vi HVM100 Manual

Page 10

CHAPTER

Introduction

1

About This Manual

Thank you for purchasing the Human Vibration Meter from

Larson Davis. The HVM100 is a powerful but small vibration measurement tool. This Handheld vibration analyzer

will allow a variety of applications to be performed including; Whole Body Vibration analysis, Hand-Arm Vibration

analysis, and general purpose vibration analysis.

This full featured vibration analyzer features 3 input

channels, a sum channel, a variety of frequency weighting

and band limiting settings, single and double integration,

displayed data in a variety of units, and independent AC or

DC outputs for all 3 channels simultaneously.

We invite you to read this manual to obtain the best results

from your HVM100.

This manual has 9 chapters and 5 appendices covering the

following topics:

Chapter 1 - Introduction

In this chapter we will discuss the functionality and

capabilities of your HVM100. We will also go into detail

with regards to frequency weightings and screen and menu

functionality.

Chapter 2 - Getting Started

This chapter will describe in detail the functionality and

selections contained in the Setup menu.

Chapter 3 - The Tools Menu

This chapter will describe in detail the functionality and

selections contained in the Tools menu.

HVM100 Manual Introduction 1-1

Page 11

Chapter 4 - The Range Menu

This chapter will describe in detail the functionality and

selections contained in the Range menu. This includes

calibration of the HVM100.

Chapter 5 - Printing

This chapter will describe how to download data from the

HVM100.

Chapter 6 - Storing and Recalling Data File s and

Setups

This chapter will describe in detail how to store data and

setup information in the HVM100’s on-board memory.

Chapter 7 - Taking Measurements/Viewing Data on

the HVM100

This chapter will describe in detail how to use the Run/Stop

key to take measurements, and how to view that data on the

display of the HVM100.

Chapter 8 - Powering the HVM100

This chapter will describe the two ways in which to power

the HVM100.

Chapter 9 - Connections on the HVM100

This chapter will describe all of the external connectors on

the HVM100.

Chapter 10- Adaptor Resonances

This chapter will describe the frequency response function

data for the ADP08XA Adaptors.

Appendix A - Specifications

Appendix B - Glossary

Appendix C - I/O Commands

Appendix D - Frequency Response Curves

Appendix E - Miscellaneous Information

Appendix F - Serial Number Backup

1-2 HVM100 Manual

Page 12

Accessories

Standard Accessories

Optional Accessories

Selection of the proper accessories for use with your

HVM100 is one of the most important functions you can

perform. The transducer is especially critical to obtaining

good results.

The HVM100 is delivered with the following standard

accessories:

•User Manual

• Batteries, 2 x AA, IEC Type LR6

Transducers • SEN020 to SEN022 (Accel e rometers, 3 axis ICP

• SEN023 to SEN025 (Accel erometers, single axis ICP)

• SEN026 (3 axis ICP, palm accelerometer)

• SEN027 (Accelerometer, seat pad)

• SEN040F (Accelerometer, 3 axis, 2 - 5 kHz, ICP)

• SEN041F (Accelerometer, 3 axis, 2 - 5 kHz, ICP)

Calibrator • 394C06 (Hand-held accelerometer calibrator)

Cables • SEN020-CBL to SEN022-CBL (3 axis accelerometers

including cables)

• SEN023-CBL to SEN025-CBL (single axis

accelerometers including cables)

• SEN026-CBL (3 axis ICP,

cable)

• SEN027-CBL (Cable and seat pad accelerometer)

• SEN040F-CBL (Accelerometers, 3 axis, 2 - 5 kHz, ICP,

including cables)

• SEN041F-CBL (Accelerometers, 3 axis, 2 - 5 kHz, ICP,

including cables)

• CBL006 (Cable, serial computer, DB9S-mDIN08)

palm accelerometer including

)

HVM100 Manual 1-3

Page 13

• CBL120 (Cable, 3 x 10-32 male to 4-pin LEMO

female)

• CBL121 (cable, 3 x BNC male to 4-pin LEMO female)

• CBL124 (Cable, AC/DC Output, 3 X BNC to

Switchcraft

®

)

• CBL125 (Cable, Mini 4-pin to 4-pin LEMO female)

• CBL158 (Cable, 4-pin Microtech to 4-pin LEMO

Adaptors • ADP060 (Adapter, hand accelerometer)

• ADP061 (Adapter, handle accelerometer)

• ADP062 (Adapter, clamp accelerometer)

• ADP063 (Adaptor, palm accelerometer)

• ADP064 (HVM100 adapter kit)

• ADP080A (Adapter, hand accelerometer)

• ADP081A (Adapter, handle accelerometer)

• ADP082A (Adapter, clamp accelerometer)

• ADP084A (Vibration adaptor kit including ADP080A,

ADP081A, ADP082A and ADP063)

• 080A09 (Adapt or, probe tip with 10-32 connector)

• 080A17 (Adapt or, triaxial mounting)

• 080B16 (Adaptor, triaxial mounting, for SEN024 and

SEN025 with 5-40 thread)

®

male)

Cases • CCS020 (HVM100 hard shell carrying case)

• CCS028 (Soft case with belt clip fo r HVM100

Power Supply • PSA027 (Power supply, 90-264 VAC to 12 VDC)

Software • Blaze

®

software (SWW-BLAZE-HVM) for setup,

control and high speed data download

• HVManager software permits both users and

manufacturers of vibrating equipment to create PC-based

vibration data bases containing data measured using an

HVM100 Human Vibration Meter

• DNA (Data, Navigation and Analysis) software for

instrument control, high speed data download, data

streaming with real-time data display on PC, advanced

data graphic presentations and powerful report

generation features

1-4 HVM100 Manual

Page 14

• HVM Programmer software, available from Larson

Davis, can be used to programs the languages and update

the firmware when new versions are available for the

HVM100.

Selecting the Proper Transducer

There are several important considerations when selecting a

transducer to perform your measurements. The first decision

that must be made is what type of transducer to use.

NOTE: The HVM100 has built-in ICP

power supplies and charge amplifiers.

This will allow the HVM100 to interface

directly with ICP or charge transducers,

and eliminates the need for external signal conditioning.

There are two general categories of accelerometers, ICP

and Charge.

®

•ICP

accelerometers are also called “Voltage Mode” or

“Low impedance” and may be known by various other

vendor trade names. ICP is PCB’s registered trademark

which stands for “Integrated Circuit Piezoelectric” and

identifies PCB sensors which incorporate built-in, signal

conditioning electronics. The built-in electronics serve to

convert the high impedance charge signal that is

generated by the piezoelectric sensing element to a

usable low impedance voltage signal which can be

readily transmitted over ordinary 2 wire or coaxial cables

to any voltage readout or recording device. The low

impedance signal can be transmitted over long cable

distances and used in dirty field or factory environments

with little signal degradation.

®

• Charge mode sensors output a high impedance, electrical

charge signal that is generated by the piezoelectric

sensing element. This signal is extremely sensitive to

corruption from environmental influences. To conduct

accurate measurements, it is necessary to condition this

signal to a a low impedance voltage before it can be input

to a readout or recording device. A charge amplifier or

in-line charge converter is generally used for this

purpose.

®

The final way to use the input of the HVM100 is through the

direct input. This would require the use of some kind of

external signal conditioning unit such as an external source

of ICP power, or an external charge amplifier.

HVM100 Manual 1-5

Page 15

The next item to consider is the sensitivity of the transducer.

The sensitivity of the accelerometer will depend on the

application being performed. If the application is a high

vibration level application, a low sensitivity should be

selected. For low vibration level applications a high

sensitivity accelerometer should be used.

NOTE: Transverse sensitivity is also

something to be considered. Transverse

sensitivity is defined as: The unwanted

output signal of a motion sensor when

subjected to motion perpendicular to the

sensitive axis-usually expressed as a percent of the normal axis sensitivity. For

example if you are using a tri-axial

accelerometer and place an input signal

on the Z axis, your X axis could also be

reading a level even though there is

really no x-axis signal present.

The resonant frequency of the transducer should also be

considered. The resonant frequency is defined as the

frequency at which the structure will readily vibrate. For

accelerometers, there is one frequency where the

accelerometer will vibrate much easier than at other

frequencies. At this point, the reading will be very high, and

could overload the input of the HVM100. However, for most

of the recommended accelerometers, the resonant frequency

is well above the upper limit of the HVM100, and will

subsequently be masked out by the low pass filter on the

HVM100. If the resonant frequency becomes an issue, it is

recommended that an external mechanical filter be used.

Frequency range is the next thing to take into consideration.

Most recommended accelerometers will have a frequency

range sufficient for use with the HVM100. See the

frequency response tables (appendix A) and graphs

(appendix D) for more information on the HVM100’s

frequency response.

The last thing to consider is temperature, humidity, and other

physical agents, such as mounting surface, mass and

environment. The mass of the accelerometer should ideally

be no more that 1/50 of the mass of the object being

measured. A ratio of as little as 1/10 is acceptable in extreme

circumstances. The affect of these elements should always

be considered when choosing a transducer. Please also be

aware of the different methods of mounting an

accelerometer and the effects of each of those methods on

the measured data.

The following is a selection from the PCB catalog listing the

characteristics of a transducer. Please note the items that we

have discussed and note where they appear in a transducer

specification

1-6 HVM100 Manual

Page 16

Triaxial Accelerometers .

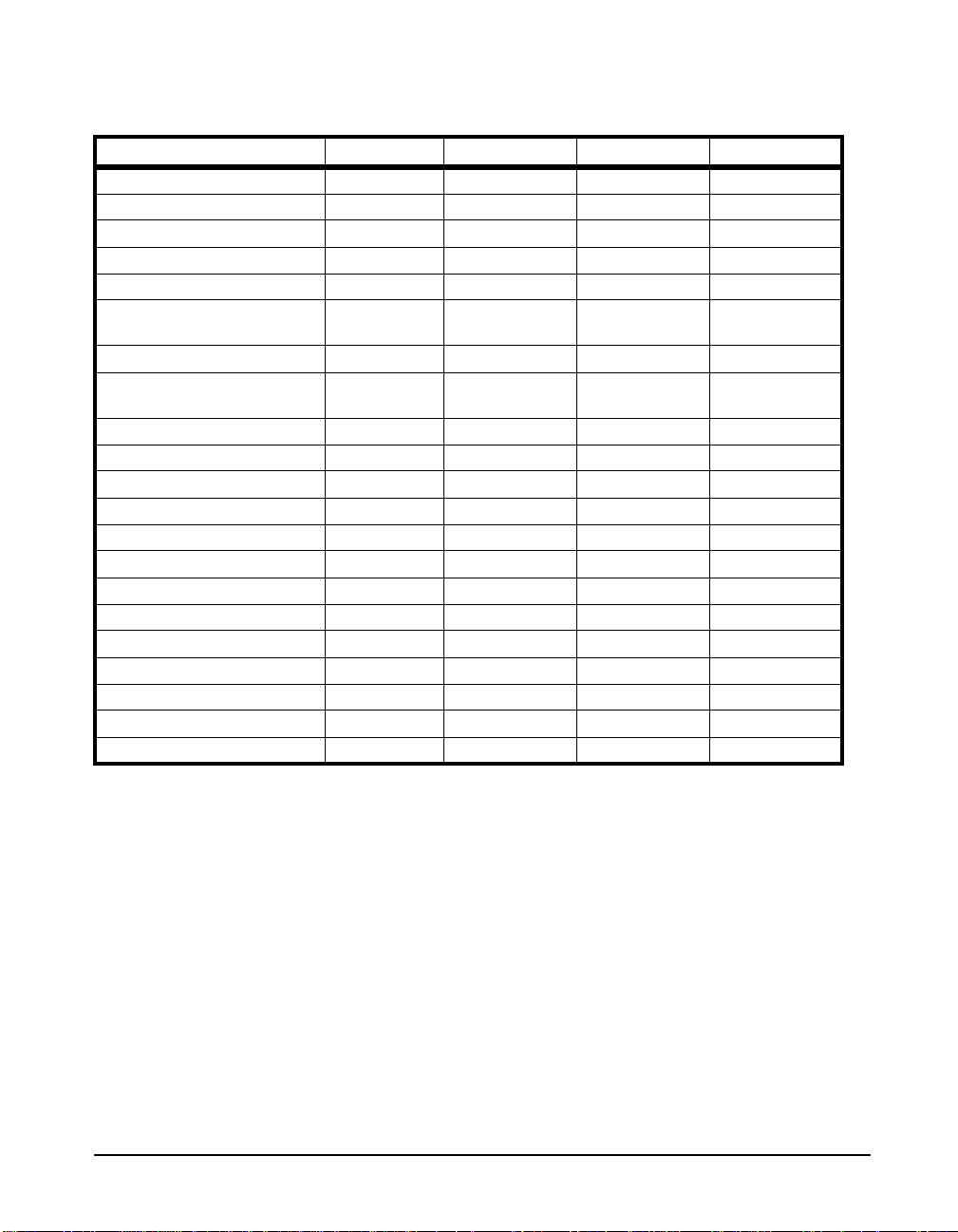

Specification Unit SEN020 SEN21F SEN026

Voltage Sensitivity mV/g 1 10 10

Frequency Range (+/-5%) Hz 0.5 to 5,000 0.5 to 2,500 1 to 9,000

Frequency Range (+/-10%) Hz 0.3 to 6,000 0.5 to 12,000

Mounted Resonant Frequency kHz 25 25 25

Measurement Range +/-g pk 1,500 500 500

Broadband Resolution (1 Hz to 10

kHz)

Shock Limit +/-g pk 7,000 7,000 10,000

Operating Temperature Range

Amplitude Linearity % +/1 +/1 +/1

Transverse Sensitivity % 5 5 5

Strain Sensitivity g/ 0.001 0.001

Excitation Voltage VDC 20 to 30 20 to 30 18 to 30

Constant Current mA 2 to 20 2 to 20 2 to 20

Output Impedance ohms <100 <100 <200

Output Bias VDC 8 to 12 8 to 12 7 to 11

Discharge Time Constant sec 1.0 to 2.0 .4 to 1.2 1.0 to 3.5

Sensing Element Type Ceramic Ceramic Ceramic

Element Configuration Structure Shear Shear Shear

Electrical Connector type/location 4-Pin/side 4-Pin/side 4-Pin/side

Housing material/sealing Titanium/Hermetic Titanium/Hermetic Titanium/Hermetic

Mounting Thread size 10-32 Female 5-40 Male 10-32 Female

g rms 0.005 0.0005 0.0002

o

F [oC] -65 to +250 [-54 to

+121]

-65 to +250 [-54 to

+121]

-65 to +250 [-54 to

+121]

HVM100 Manual 1-7

Page 17

.

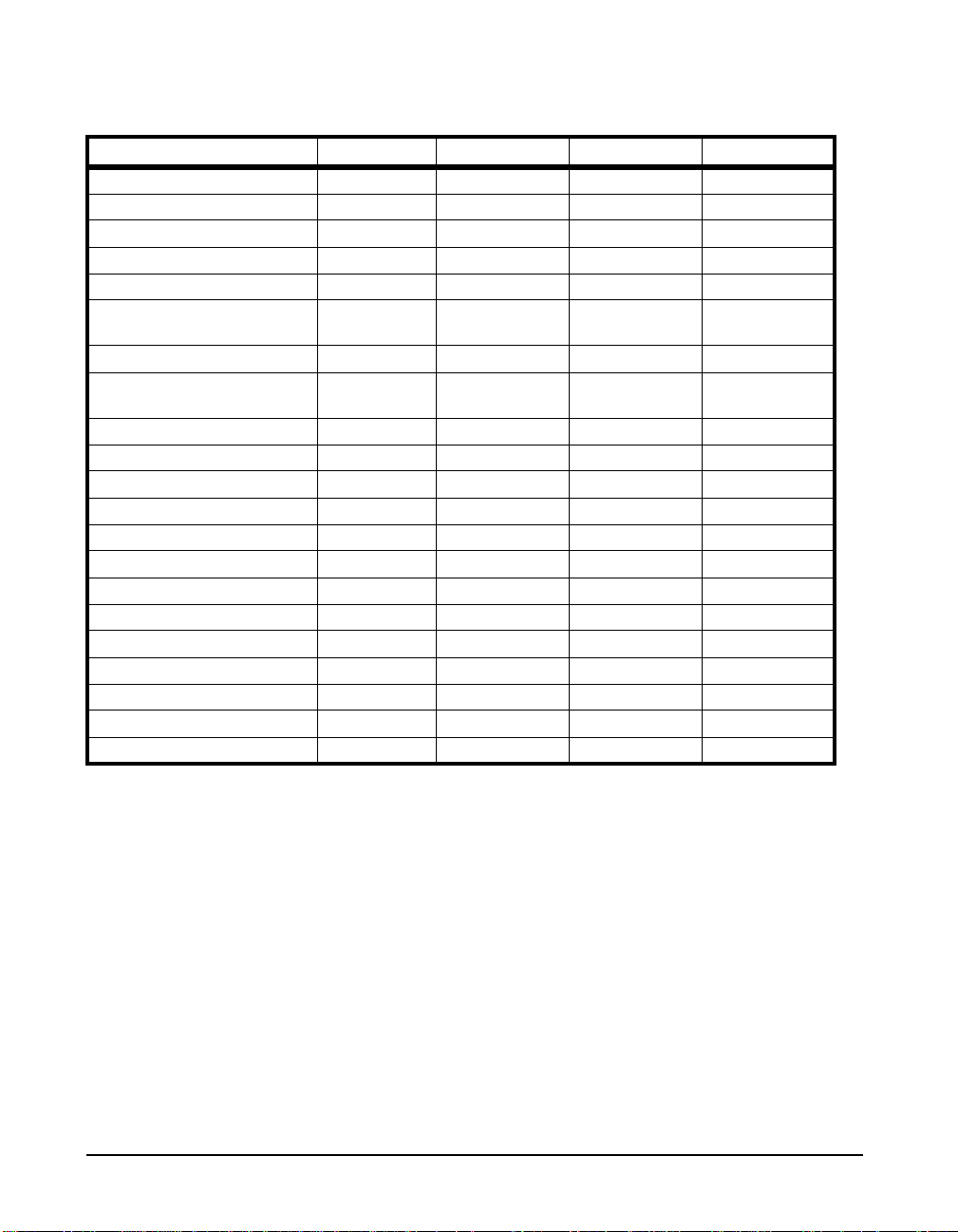

Specification Unit SEN027 SEN040F SEN041F

Voltage Sensitivity mV/g 100 1 10

Frequency Range (+/-5%) Hz 0.5 to 1,000 2 to 4,000 2 to 4,000

Frequency Range (+/-10%) Hz

Mounted Resonant Frequency kHz 27 55 55

Measurement Range +/-g pk 10 5,000 500

Broadband Resolution (1 Hz to 10

kHz)

Shock Limit +/-g pk 2,000 10,000 10,000

Operating Temperature Range

Amplitude Linearity % +/1 +/2.5 +/1

Transverse Sensitivity % 5 5 5

Strain Sensitivity g/

Excitation Voltage VDC 6.5 to 30 18 to 30 18 to 30

Constant Current mA 0.3 to 10 2 to 20 2 to 20

Output Impedance ohms <500 <200 <200

Output Bias VDC 2.8 to 4.5 7 to 11 7 to 11

Discharge Time Constant sec 1.0 to 3.0 1.5 to 3.0 .3 to 1.0

Sensing Element Type Ceramic Ceramic Ceramic

Element Configuration Structure Shear Shear Shear

Electrical Connector type/location Integral cable/side 1/4-28 4-Pin/side 1/4-28 4-Pin/side

Housing material/sealing Titanium/Hermetic Titanium/Hermetic Titanium/Hermetic

Mounting Thread size 10-32 Female 5-40 Female 5-40 Female

g rms 0.002 0.03 0.008

o

F [oC] +14 to +122 [-10 to

+50]

-65 to +250 [-54 to

+121]

-65 to +250 [-54 to

+121]

1-8 HVM100 Manual

Page 18

Single Axis Accelerometers .

Specification Unit SEN022 SEN024 SEN025

Voltage Sensitivity mV/g 100 10 10

Frequency Range (+/-5%) Hz 0.5 to 5,000 1 to12,000 1 to 10,000

Frequency Range (+/-10%) Hz 0.3 to 6,000 0.7 to 18,000 0.3 to 12,000

Mounted Resonant Frequency kHz 25 50 35

Measurement Range +/-g pk 50 500 50

Broadband Resolution (1 Hz to 10

kHz)

Shock Limit +/-g pk 7,000 10,000 5000

Operating Temperature Range

Amplitude Linearity % +/1 +/1 +/1

Transverse Sensitivity % 5 5 5

Strain Sensitivity g/ 0.001 0.006 0.005

Excitation Voltage VDC 20 to 30 1 to 30 1 to 30

Constant Current mA 2 to 20 2 to 20 2 to 20

Output Impedance ohms <200 <100 <300

Output Bias VDC 8 to 12 8 to 12 8 to 12

Discharge Time Constant sec 1 to 3 .4 to 1.2 .4 to 1.2

Sensing Element Type Ceramic Ceramic Ceramic

Element Configuration Structure Shear Shear Shear

Electrical Connector type/location 4-Pin/side 10-32 10-32

Housing material/sealing Aluminum/Epoxy Titanium/Hermetic Titanium/Hermetic

Mounting Thread size 10-32 Male 5-40 Male 5-40 Male

g rms 0.0001 0.0005 .00016

o

F [oC] -65 to +176 [-54 to

+80]

-65 to +250 [-54 to

+121]

-65 to +200 [-54 to

+93]

About the HVM100

The HVM100 is a powerful, all digital, vibration analyzer. It

features simultaneous 3 channel measurements, small

lightweight design, easy to read display, portability utilizing

2 AA batteries, 115.2 kbps RS-232 interface, three modes of

HVM100 Manual 1-9

Page 19

operation: Hand-Arm, Whole Body, and Vibration, and the

capability to display and print text in a variety of languages.

Modes of Operation

The HVM100 is divided into three modes of operation. The

standard mode is the vibration mode. This is the mode

included with the instrument. The other two modes are

optional modes. The Optional modes are Hand-Arm and

Whole Body. Each of these modes feature different

frequency weighting selections as outlined later in this

chapter.

Frequency Weighting Selections

NOTE: The Hand-Arm and Whole body

modes are separately purchased options.

These options and the frequency weightings associated with these options will

not be available unless they are purchased.

Mode Frequency Weighting

Vibration Ws (Severity)

Hand Arm W

Whole Body W

To accommodate the multiple operating modes of the

HVM100, 13 different frequency weighting filters are

available. The following table describes the frequency

weighting options available in each of the operating modes.

To select the frequency w eighting for a particular m ode, see

the section in this manual titled Setup Key.

Fa (0.4 Hz to 100 Hz)

Fb (0.4 Hz to 1250 Hz)

Fc (6.3 Hz to 1250 Hz)

h

m

W

b

W

c

W

d

W

e

W

g

W

j

W

k

The Hand-Arm mode and the Whole body mode frequency

weighting curves are defined in ISO 8041:2005. The W

1-10 HVM100 Manual

g

Page 20

Band Limiting Filters

frequency weighting curve is defined in British Standard

6841:1987.

In addition to defining the frequency weightings for HandArm and Whole Body, ISO 8041:2005 also defines a bandlimiting filter to be used with each of the frequency

weightings. Each band-limiting filter is a combination of a

high-pass and low-pass 2nd order Butterworth filter, 12 dB

per octave attenuation, with - 3 dB corner frequencies at the

frequencies listed in table 3 below. When a frequency

weighting is selected in the HVM100 Hand-Arm mode, or

Whole Body mode, the HVM100 automatically places both

the weighting filter and the appropriate band-limiting filter

in the signal path.

Weighting Band-Limiting Filter

W

h

W

m,Wc, Wd, We, Wj, Wk

, Wg 0.8 to 100 Hz

W

m

6.3 to 1250 Hz

0.4 to 100 Hz

HVM100 Manual 1-11

Page 21

1-12 HVM100 Manual

Page 22

CHAPTER

On Key

Getting Started

2

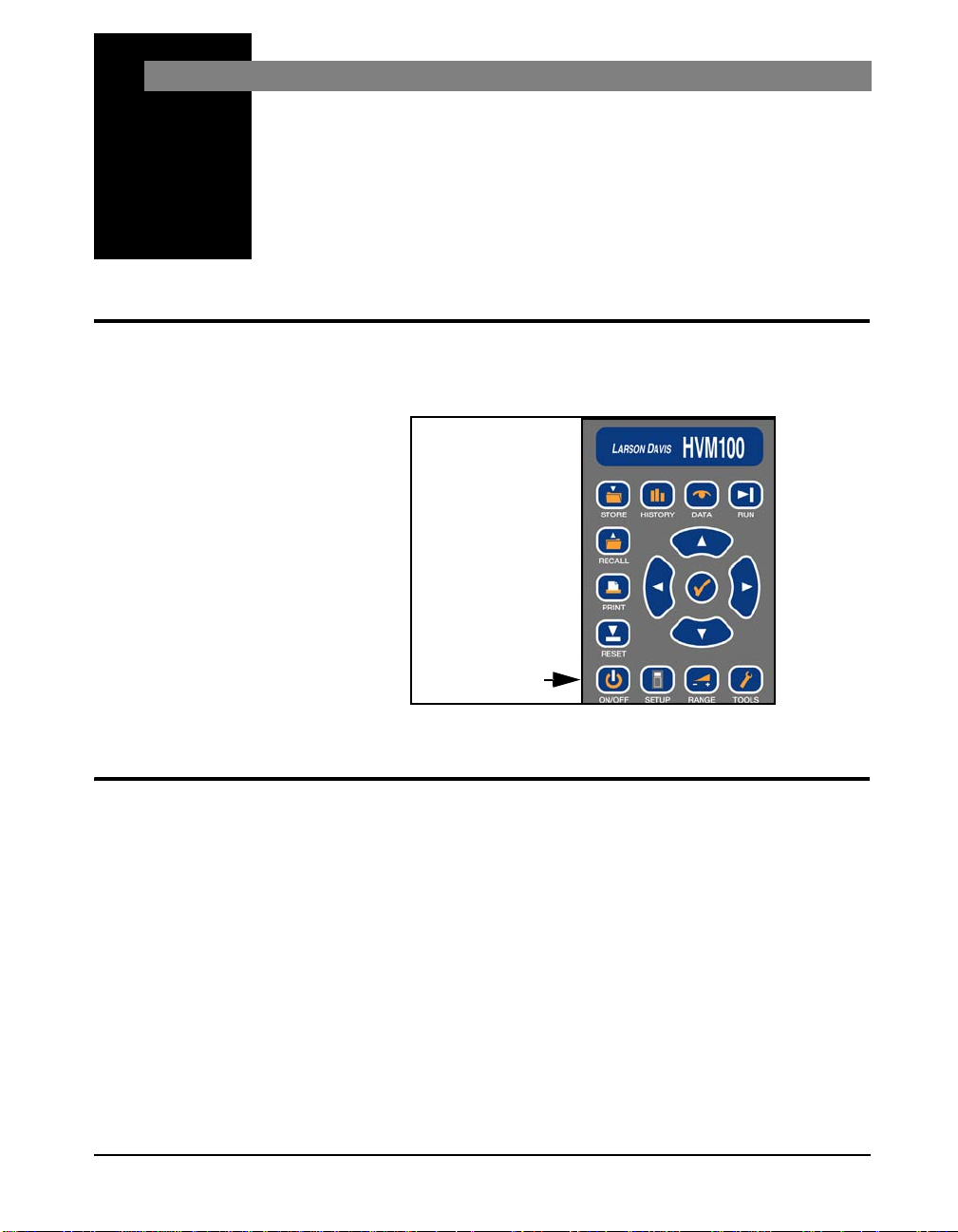

Switching HVM100 On

This section will introduce you to the keypad and

functionality of the HVM100.

If any displays appear during the

boot process which refer to Serial

Number or SN, see section "Serial

Number Backup" on page F-1.

Menu Navigation

To swit ch the HVM100 On, press the On key.

Navigating through the HVM100 menus is similar to

navigating through other Larson Davis instruments. The

menus are arranged in lists. The appropriate menu key is

used to enter the menu, and then the u Up and d Down

arrow keys are used to scroll through the menu. When you

come to a setting you want to change, press the c Check

key to enter the modify section of the menu. You can now

use the r Right and l Left arrow keys to scroll th rough

the options for that item. After the appropriate selection is in

the window, use the c Check key to select that setting. This

will place you back into the main menu where once again

the u Up and d Down arrow keys can be used to

navigate.

HVM100 Manual Getting Started 2-1

Page 23

Alpha Numeric Menu Function

The alpha numeric menu screens include the Header screens

and the Calibrator sensitivity screen. These are settings that

require the user to enter letters of the alphabet or numerals

into the field. To change an alpha numeric menu setting,

Step 1 Go to the menu item you wish to change.

Header 1

Step 2 Press the c key to place the HVM100 into the

modify mode. The selection will begin to blink.

Header 1

Step 3 Use the r and l arrow keys to select a posi-

tion to modify.

Header 1

Step 4 Use the u and d arrow keys to select the char-

acter you want in that position.

Header 1

Wi

Step 5 Use the rand l arrow keys again to move to

the next position. When you move to the next

position, the HVM100 will start you from where

you left off. (i.e. if you entered an ‘F’ in the first

position, when you move to the next position, you

will be starting from the ‘F’ on that position.

Header 1

Wil

Step 6 Hit the c key or move to the next menu item to

accept the change. Anytime you have made a

change, the change will automatically be accepted

2-2 Menu Navigation HVM100 Manual

Page 24

Indexed Menu Function

even if you don’t hit the check key . You can accept

the change just by moving to another section of

the HVM100.

Header 1

Wilson Processin

The following is an example of how to make a change to an

indexed menu item. (An item that has a specific list of

choices.)

Step 1 Go to the setting you wish to change.

Operating Mode

Vibration

Step 2 Press the c key to place the HVM100 in the mod-

ify mode. The selection will begin to blink.

Operating Mode

Vibration

Step 3 Use the l and r arrow keys to scroll through

the selections in the menu.

Operating Mode

Vibration

r

Operating Mode

Hand Arm

r

Operating Mode

whole Body

Step 4 When you come to the selection you desire, stop

scrolling.

Operating Mode

Whole Body

HVM100 Manual Menu Navigation 2-3

Page 25

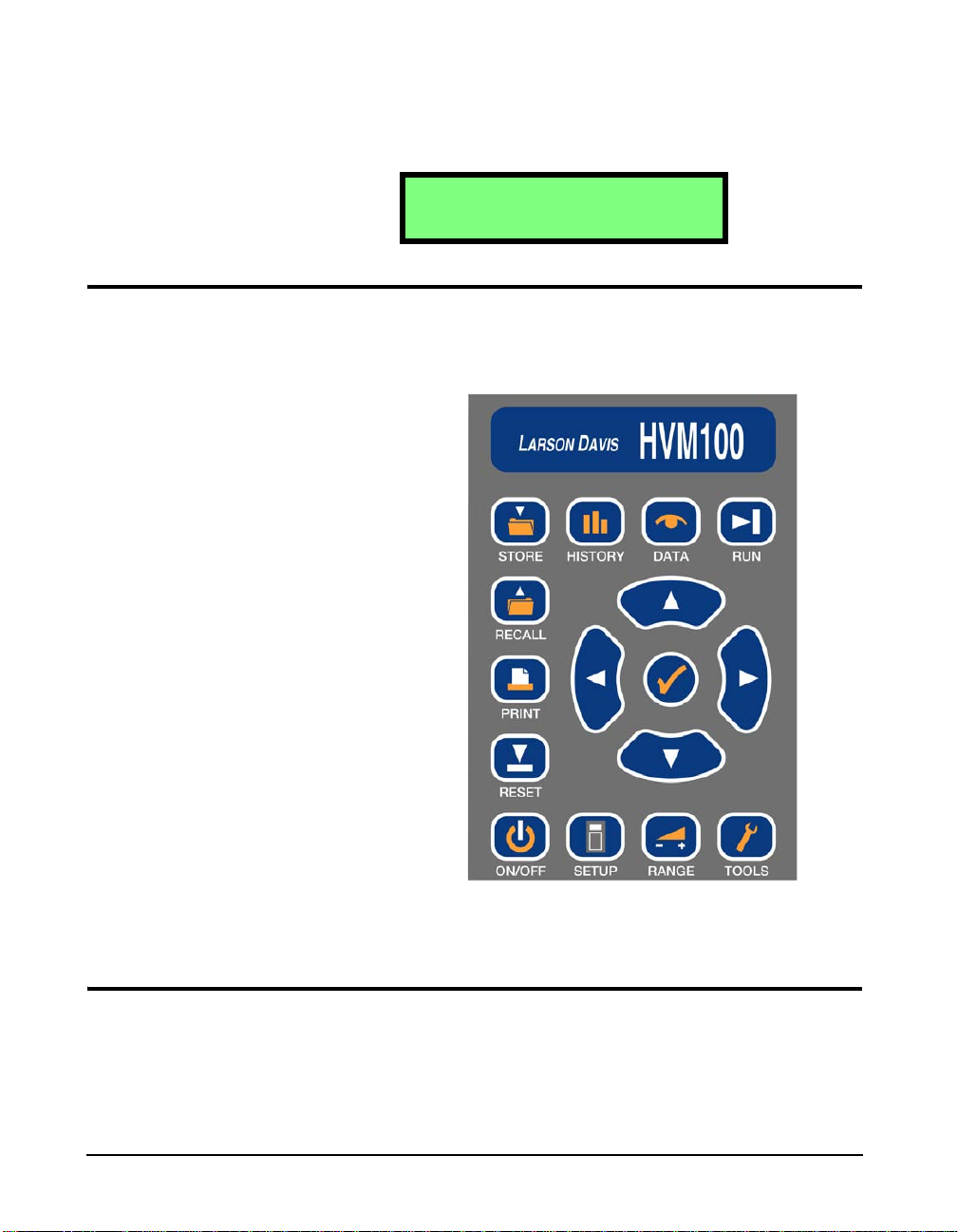

Key Board Functions

Step 5 To accept the change, either hit the c key or move

to the next menu item or to another part of the

HVM100.

Operating Mode

Whole Body

The keyboard on the front of the HVM100 is the main

interface to the instrument. The keyboard consists of 11

dedicated function keys, 4 arrow keys and the check key.

In the following section, we will describe the functionality

and selections associated with each key.

Setup Key

The SETUP key places you into the Setup menu. This menu

is used to set general system parameters such as operating

mode and frequency weighting. The selections available in

the Setup menu are described below. The Setup menu is a

2-4 Key Board Functions HVM100 Manual

Page 26

Mode Selection

Hint: This setting is in the Setup menu. To access the Setup menu press the

SETUP key and then use the u and d arrow keys to navigate

through the menu items.

NOTE: To view each selection, first pr ess

c key, and then press the r or l

the

arrow key to scroll through each selection.

circular menu. You can scroll through and return to the top

by continuously pressing the d or u arrow key.

NOTE: T he Hand-Arm and Whole body

modes are separate purchased options.

These options and the frequency weightings associated with those options will

not be available unless they are purchased.

Averaging Ti me

Hint: This setting is in the Setup menu. To access the Setup menu press the

SETUP key and then use the u and d arrow keys to navigate

through the menu items.

This section is used to set the operating mode. The

selections are Whole body, Hand Arm or Vibration.

Operating Mode

Vibration

Operating Mode

Hand Arm

Operating Mode

Whole Body

HVM100 Manual Setup Key 2-5

Page 27

NOTE: An exponential detector is

defined as a detector that maintains a

moving average of the signal. The only

exponential detector in the HVM100 is

the Slow detector. This detector will

begin by taking a 1 second average. As

time moves, the exponential detector will

discard the first part of the average, as

the next part is collected. A linear detector will take the signal and average over

the averaging time, and then start over.

All previously collected samples are disregar ded in the new linear average.

Time History Settings The Averaging time is also used to determine the rate of

The averaging time refers to the amount of time data is

collected and averaged before a new average is started. The

selections are Slow, 1 sec, 2 sec, 5 sec, 10 sec, 20 sec, 30

sec, and 60 sec. The Slow response is a 1 second exponential

detector, while the others are linear repeat type averages.

The averaging is the same for all Operating modes.

storage for the Time History. The Time History will store the

Arms value along with the Peak value if the user desires, for

the X, Y, Z, and Sum channels. The Time History buffer is

limited to 240 samples, 120 samples if the Peak value is

selected. To setup Time History Peak storage, see the 2nd

History menu section below.

NOTE: T o view each selection, first press

the c key, and then press the r or l

arrow key to scroll through each selection.

The following are the selections you would encounter when

changing the Averaging Time:

Averaging

Slow

Averaging

1 sec

Averaging

2sec

Averaging

5 sec

Averaging

10 sec

Averaging

20 sec

2-6 Setup Key HVM100 Manual

Page 28

Store Time

Averaging

30 sec

Averaging

60 sec

Hint: This setting is in the Setup menu. To access the Setup menu press the

SETUP key and then use the u and d arrow keys to navigate

through the menu items.

NOTE: To change the Store Time parameters, press the

d

arrows to select the desired value,

and then use the r and l arrows

to move to the next position. Once all

positions are set press the

move to any other part of the HVM100 to

accept the entry.

c key, use the u and

c key or

Auto Store

Hint: This setting is in the Setup menu. To access the Setup menu press the

SETUP key and then use the u and d arrow keys to navigate

through the menu items.

NOTE: The data memory in the HVM100

is a non-volatile EEPROM chip. Even if

the batteries go dead for an extended

period of time, the stored setups and data

will be retained.

The Store Time selection works in conjunction with the

Auto Store setting. The Auto Store setting will allow you to

automatically store measurement data at a rate indicated by

the Store Time. The Store Time can be set from 1 minute to

99 hours.

Store Time hh:mm

00:00

The Auto Store function in the HVM100 will allow you to

store data over time. The Store Time is the rate at which the

data will be stored. At the end of the store time the Auto

Store function will store any history data that has been

collected, as well as the overall data from all three channels

and the sum channel. The data will be stored as a file in the

memory. After the data is stored, the instrument is reset

automatically and a new set of data is collected. The

limitation on the memory is 100 files. When the memory

reaches the maximum number of files, it will stop storing

data.

NOTE: To view each selection, first pr ess

the c key, and then press the r or l

arrow key to scroll through each selection.

HVM100 Manual Setup Key 2-7

There are three selections in the Auto Store menu:

Auto Store

Off

Page 29

2nd History

The Auto Store is turned off with this setting.

Auto Store

On

The Auto Store feature will store each time the Store T ime is

reached. This will continue until all file registers are full.

Auto Store

Autostop

The Auto Store-Autostop feature will allow you to take a

fixed length measurement. The Autostop feature will stop

the meter when the Store time is reached, just as if you had

pressed the s key.

Hint: This setting is in the Setup menu. To access the Setup menu press the

SETUP key and then use the u and d arrow keys to navigate

through the menu items.

The 2nd History setting will allow you to store a Peak value

along with the Arms value that is automatically stored in the

Time History buffer. The Peak will be stored for all three

channels and the Sum channel. Turning on the 2nd value

will cut the number of sample storage space from 240

samples to 120 samples.

NOTE: T o view each selection, first press

the c key, and then press the r or l

arrow key to scroll through each selection.

In the 2nd history selection menu you have the choice of

None or Peak.

2nd history

None

2nd History

Peak

Vibration Mode Weighting

Hint: This setting is in the Setup menu. To access the Setup menu press the

SETUP key and then use the u and d arrow keys to navigate

through the menu items.

2-8 Vibration Mode W eighting HVM100 Manual

Page 30

NOTE: To view each selection, first pr ess

the c key, and then press the r or l

arrow key to scroll through each selection.

In the vibration mode you can select from the following

weighting selections. Please see the appendix at the end of

this manual for details on weighting curves. The weighting

selection is independent for all channels. Here we only

depict the X channel data, but the other channels screens

would be the same:

Weighting X

Fa 0.4-100 Hz

Weighting X

Fb 0.4-1250 Hz

Weighting X

Fc 6.3-1250 Hz

Weighting X

Ws Severity

Hand Arm Mode Weighting

As required by ISO 8041:2005 the Hand Arm mode has only

one weighting selection. Please see the appendix at the end

of this manual for details on this weighting curve. The

weighting curve is labeled as Wh. This weighting selection

is for all channels and the sum channel. Because there is

only one selection in the Hand Arm mode, the weighting

selection is not present on the Setup menu.

Whole Body Weighting Mode

Hint: This setting is in the Setup menu. To access the Setup menu press the

SETUP key and then use the u and d arrow keys to navigate

through the menu items.

NOTE: To view each selection, first pr ess

c key, and then press the r or l

the

arrow key to scroll through each selection.

HVM100 Manual Hand Arm Mode Weighting 2-9

In the Whole Body mode you can select from the following

weighting selections as required by ISO8041:2005. Please

see the appendix at the end of this manual for details on the

weighting curves. The weighting selection is independent

Page 31

for all channels. Here we only depict the X channel data, but

the other channels screens would be the same:

Weighting X

Wm

Weighting X

Wb

Weighting X

Wc

Weighting X

Wd

Weighting X

We

NOTE: The Wg frequency weighting

curve is defined in BS 6841:1987.

Weighting X

Wg

Weighting X

Wj

Weighting X

Wk

2-10 Whole Body W eighting Mode HVM100 Manual

Page 32

CHAPTER

3

Tools Key

Accelerometer

Tools Menu

The Tools menu has settings relating to the transducer and

setup information relevant to the instrument. Selections

include communications, printing, headers, etc.

The tools menu functions in exactly the same manner as the

Setup menu and has the following selections:

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow keys to navigate

through the menu items.

NOTE: To view each selection, first pr ess

the c key, and then press the r or l

arrow key to scroll through each selection.

This will allow you to select the type of transducer you wish

to use. The selections are ICP

refer to the type of accelerometer being used.

®

, Direct, and Charge. These

Accelerometer

Direct

The Direct setting is used to input a direct signal from a

transducer. No operational power is provided to the

transducer.

Accelerometer

XDC=10.0V

ICP

®

The ICP

to each of the three input channels, in order to power up to

three accelerometers. This is used with ICP type

accelerometers. The voltage reported on this screen is a

monitoring of the ICP power being provided to the

HVM100 Manual Tools Menu 3-1

setting will pr ovid e a 28 Volt 2mA constant current

Page 33

transducer. When the transducer is not connected, this

voltage will read 25 to 26 volts. If you have a transducer

connected and it is working properly, it should be reading

between 2 and 12 volts depending upon the transducer.

Accelerometers

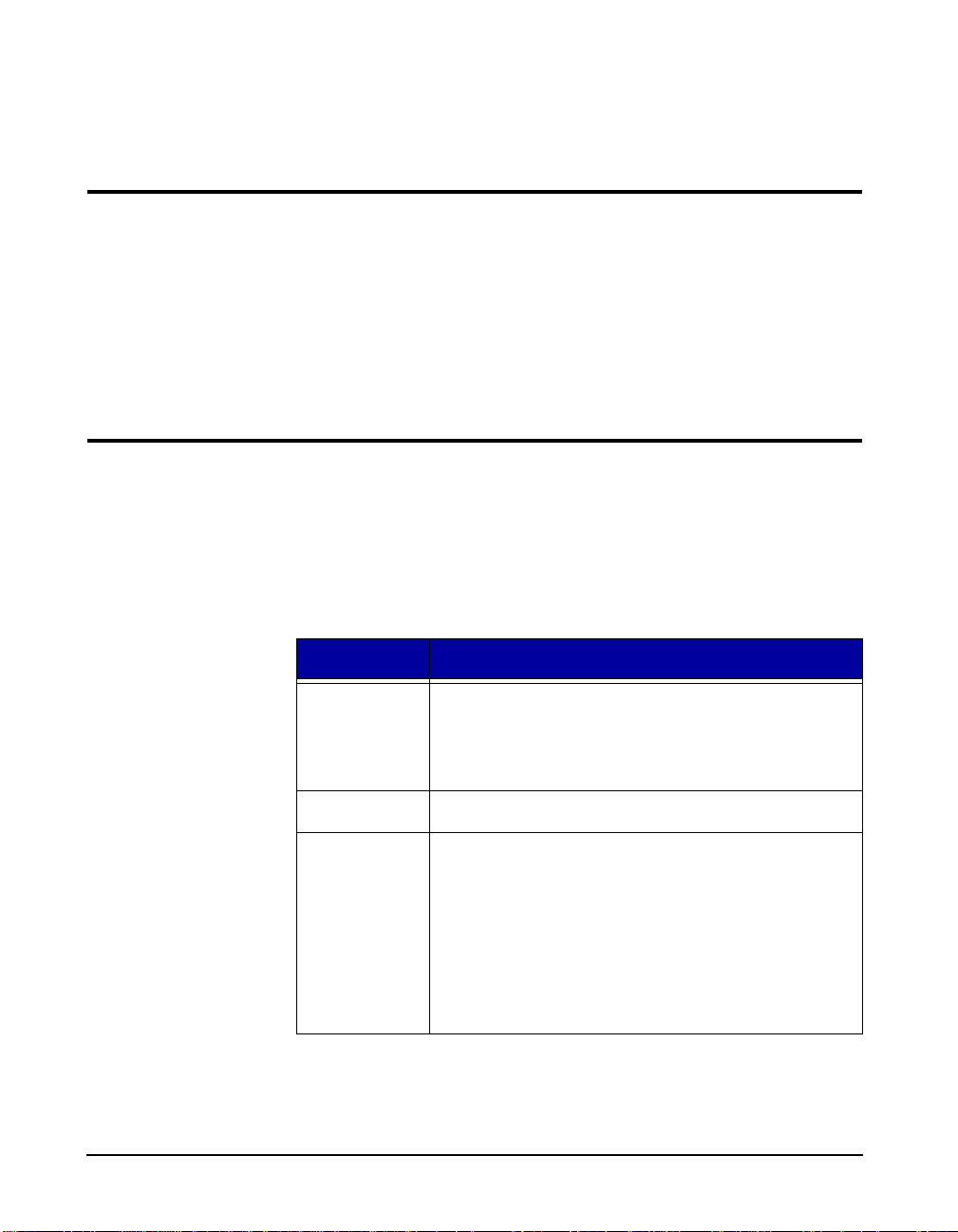

Display Units

The following table shows the typical bias voltage for the

various ICP

®

accelerometers that are normally used with the

HVM100.

Tri-Axial

SEN020

SEN022

Single Axis

Accelerometers

SEN023

SEN024

Palm-Adapter

Accelerometer

SEN026

Seat Pad

Accelerometer

SEN027

SEN025

8-12 volts 8-12 volts 7-11 volts 2-5 volts

®

If the reading is 0, then the ICP

power could be shorted to

ground or have some other problem. Check all connections,

cables, and connectors.

Accelerometer

Charge

This setting would be used to amplify the signal from a

charge type accelerometer.

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow keys to navigate

through the menu items.

NOTE: T o view each selection, first press

the c key, and then press the r or l

arrow key to scroll through each selection.

3-2 Tools Key HVM100 Manual

The Display Units setting controls how data is displayed and

printed by the HVM100. The HVM100 can display data in

six different formats. The selection of the display units will

apply to all three channels and the sum channel. All

channels will have the same units. The choices ar e: m/s

2

, ft/s2, in/s2, g, and dB.

s

2

, cm/

Page 34

NOTE: The HVM100 uses a reference

acceleration of 10-6 m/s2 (velocity reference = 10

= 10

(velocity reference = 10-8 m/s, displacement reference = 10

acceleration, velocity and displacement

in dB units. Please see the section in the

RANGE key for details on changing the

reference acceleration.

-9

m/s, displacement reference

-12

m) or a reference of 10-5 m/s

-11

m) to display

Integration

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow keys to navigate

through the menu items.

Display Units

2

m/s

2

Display Units

cm/s

2

Display Units

ft/s

2

Display Units

in/s

2

Display Units

g

Display Units

dB

NOTE: Integration is a mathematical

process of changing the displayed units

from acceleration to velocity to displacement. Single integration changes the displayed parameter from acceleration to

velocity by dividing the acceleration

2f (i.e. ft/s

by:

tion changes the parameter from acceleration to displacement by dividing the

acceleration by:

meters).

2

to ft/s). Double integra-

2

42f

(i.e. m/s2 to

Integration applies only to the Vibration mode. There is no

integration available in the Hand Arm or Whole Body

Modes. Integration is the process of converting the data

from acceleration, which is the standard method of

displaying the data, into velocity and displacement.

Integration

None

Integration

Single

Integration

Double

HVM100 Manual Tools Key 3-3

Page 35

NOTE: T o view each selection, first press

the c key, and then press the r or l

arrow key to scroll through each selection.

Sum Factor X,Y, Z

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow keys to navigate

through the menu items.

Single integration will express the units in velocity, and

double integration will express the units in displacement.

In the process of calculating the sum quantities (the data

that appears under the

menu) the HVM100 multiplies the

instantaneous acceleration for each channel by a scaler

factor (sometimes called a k-factor). The HVM100 allows

the user to select a different k factor for each channel. The

default setting is 1.00; however; some applications may

require different settings.

Sum Factor X

1.00

NOTE: To change the Sum Factor

parameter, press the c key, use the u

and d

value, and then use the r and l

arrow

Once all positions are set press the

key

HVM100 to accept the entry.

arrows to select the desired

s to move to the next position.

or move to any other part of the

The applications that require the Sum Factor to be altered

are specified in certain ISO standards. If you are not trying

to measure according to any specific standard, the

appropriate setting for this parameter is 1.00.

c

Quantities affected by sum factors ar e A

, Peak, PE and VDV. Individual axis data is not affected.

A

eq

rms

, A

min

, A

max

, Amp,

AC/DC Output

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and thenuse the u and d arrow keys to navigate

through the menu items.

The AC/DC outputs on the HVM100 are independent and

simultaneous for all three channels. First we will discuss the

output in general, and then give the specific settings f or the

AC/DC outputs.

3-4 Tools Key HVM100 Manual

Page 36

NOTE: To view each selection, first pr ess

Example: Chart recorder output, monitoring the

DC output, with an averaging time of 60 seconds.

the c key, and then press the r or l

arrow key to scroll through each selection.

AC output is useful for frequency analysis by an external

analyzer or for recording in a tape recorder. The DC output

is useful for a chart recorder, or to measure the voltage

proportional to the RMS or peak value.

The DC output is updated according to the averaging time.

If the averaging time is set to slow, the signal on the DC

output pin for the selected channel will be updated once p er

second. If the averaging time is set to 60 seconds, the signal

on the DC output pin for the selected channel will be

updated once every 60 seconds.

The AC/DC output connector is a 5 pin Switchcraft

connector located on the bottom edge of the instrument. The

pinout is as follows:

®

HVM100 Manual Tools Key 3-5

Page 37

3

4

1

2

5

Pin # Description

1 Ground

2 X - Axis AC/DC Output

3 Y - Axis AC/DC Output

4 No Connection

5 Z - Axis AC/DC Output

The signal that is output on each pin is selectable for each

channel. The selections are the same for each channel. We

will list the X channel selections, however the available

selections will be the same for all operating modes as well.

3-6 Tools Key HVM100 Manual

The AC output will produce a signal from 0 - 0.5 Volt RMS.

The scale of the DC output is typically 5 mV/dB. The level

Typically varies between 0 Vdc to +1.0 Vdc.

Page 38

AC/DC Output Settings

AC/DC Output X

AC: Weighted

AC/DC Output X

AC: BandLimit

AC/DC Output X

DC: rms

AC/DC Output X

DC: min

AC/DC Output X

DC: max

AC/DC Output X

DC: peak

AC/DC Output X

DC: rms

AC/DC Output X

DC: min

AC/DC Output X

DC: max

AC/DC Output X

DC: peak

The weighting filters work in

conjunction with the band limiting

filters. See page 1-7.

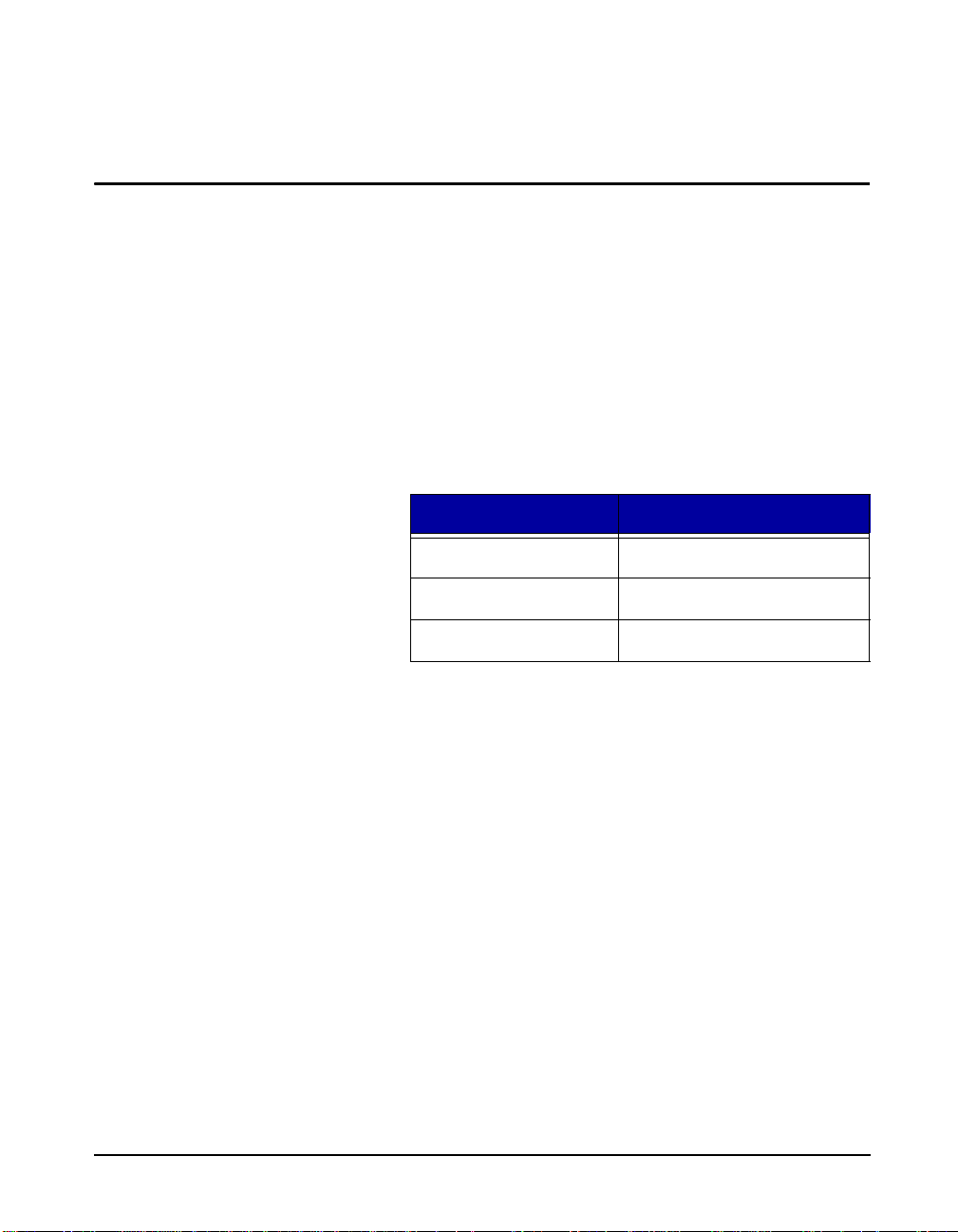

Setting Description

AC:

Weighted

AC: BandLimit

DC: rms

DC: min

DC: max

DC: peak

DC: rms

DC: min

DC: max

DC: peak

This will weight the output pin for the selected

channel according to the weighting selected

for that channel. If Channel X has a weighting

of Ws, then the output pin for Channel X will

produce a Ws weighted AC signal.

This will weight the output pin for the selected

channel according to the Band Limiting filter,

specified in chapter 1, for that channel. For

example if Channel X has a weighting of Wh,

then the output pin for Channel X will produce

a band limited (6.3 to 1250 Hz) AC signal.

This signal will be a DC voltage with a level

proportional to the RMS level displayed on the

HVM100.

This signal will be a DC voltage with a level

proportional to the min level displayed on the

HVM100.

This signal will be a DC voltage with a level

proportional to the max level displayed on the

HVM100.

This signal will be a DC voltage with a level

proportional to the peak level displayed on the

HVM100.

This signal will be a DC voltage with a level

proportional to the RMS sum level displayed

on the HVM100.

This signal will be a DC voltage with a level

proportional to the min sum level displayed on

the HVM100.

This signal will be a DC voltage with a level

proportional to the max sum level displayed on

the HVM100.

This signal will be a DC voltage with a level

proportional to the peak sum level displayed

on the HVM100.

HVM100 Manual Tools Key 3-7

Page 39

Baud Rate

Only one selection can be made for each channel. Channels

Y and Z will have the same selection of settings. The

weighting selected can be independent for each channel.

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow keys to navigate

through the menu items.

The Baud rate selection will allow you to communicate with

the PC or the serial printer. The choices are as follows:

Baud Rate

2400

Baud Rate

9600

Baud Rate

38.4k

Baud Rate

115.2k

NOTE: T o view each selection, first press

c key, and then press the r or l

the

arrow key to scroll through each selection.

Handshaking The handshaking on the HVM10 0 is defaulted to hardware

It is important that the setting on your computer or on the

serial printer match the Baud Rate setting of the HVM100.

(DTR) handshaking.

Print History Selection

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow keys to navigate

through the menu items.

3-8 Tools Key HVM100 Manual

Page 40

The print history selection will determine whether or not the

HVM100 will send the History Buffer information when the

PRINT key is pressed.

Print History

Yes

NOTE: To view each selection, first pr ess

the c key, and then press the r or l

arrow key to scroll through each selection.

Erase All Files

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow keys to navigate

through the menu items.

This selection will cause the HVM100 to send data

contained in the History buffer to the printer.

Print History

No

With this selection, the HVM will only send the overall data

from the 3 input channels and the sum channel.

This allows you to clear the measurement files from the

memory of the HVM100. The memory in the HVM100 is a

non-volatile memory. If the batteries go dead, the

measurement files will not be lost. The only way to clear out

the file registers is to use the Erase All files menu.

This command will not clear the current measurement, or

the current history buffer information. The R Reset key is

used for that purpose. This command will only clear the file

registers.

To clear all files:

NOTE: To view each selection, first pr ess

the c key, and then press the r or l

arrow key to scroll through each selection.

Step 1 Go to the Erase All Files menu item.

Step 2 The following screen will appear. Press the c key.

The ‘No’ will start to flash. Press the r key to

change the screen to ‘Yes’.

Erase All Files

No

HVM100 Manual Tools Key 3-9

Page 41

Erase Setups

Step 3 The following screen will now be showing and

the’Yes’ will be flashing. Press the c key to erase

the files.

Erase All Files

Yes

Step 4 After pressing the c key, the screen will display

the following message. After about 3 seconds the

display will return to the Erase All Files screen.

All Erased

Erase All Files

No

All file registers have now been cleared.

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow keys to navigate

through the menu items.

The HVM100 has the ability to store 10 setups internally in

the memory. This is accomplished, as explained later in the

manual, by pressing the STORE key while in the setup

menu. The Erase Setups command is used to clear all of the

stored setups from the setup registers.

To clear all setups:

NOTE: T o view each selection, first press

the c key, and then press the r or l

arrow key to scroll through each selection.

Step 1 Go to the Erase Setups menu item.

Step 2 The following screen will appear. Press the c key .

The ‘No’ will start to flash. Press the r key to

change the screen to ‘Yes’.

Erase Setups

No

3-10 Tools Key HVM100 Manual

Page 42

Header 1,2,3

Step 3 The following screen will now be showing and the

‘Y es’ will be flashing. Press the c key to erase the

setups.

Erase Setups

Yes

Step 4 After pressing the c key, the screen displays the

following message. The display will return to the

Erase Setups screen after about 3 to 10 seconds.

All Erased

Erase Setups

No

All Setups have now been cleared from the setup registers.

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow to navigate through

the menu items.

The HVM100 has 3 Heading information screens. This will

allow you to enter descriptive information into the

instrument, that will then be printed out with the reports.

The information can be up to 16 characters in length in each

screen.

To enter information in the Header screens, follow these

directions:

NOTE: To change the Header, press the

c key, use the u and d arrows to

select the desired value, and then use the

r and l arrows to move to the

next position. Once all positions are set

press the c key or move to any other

part of the HVM100 to accept the entry.

Step 1 Go to the Header that you wish to change.

Header 1

Step 2 You will have either a blank screen, or a screen

that has previously entered information.

Header 1

HVM100 Manual Tools Key 3-11

Page 43

Header 1

Wilson Processin

Hint: You can use the reset key to erase all of the existing entries in an alpha-

numeric entry. Position the cursor on the Left most position you want

erased. Press the R key, and all positions to the right of the cursor,

including the cursor position will be erased. If the cursor position is all

the way to the left, the entire screen will be erased.

NOTE: The HVM100 will remember the

previously selected character as you

move positions. If you enter a ‘K’ in the

1st position, when you use the r or l

arrow key to move the next position, you

will begin from the ‘K’.

Language

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow keys to navigate

through the menu items.

NOTE: T o view each selection, first press

the c key, and then press the r or l

arrow key to scroll through each selection.

The HVM100 can only store four

different languages at one time.

Contact The HVM Programmer

software can be used to used select

and load these languages.

Step 3 Use the l and r arrow keys to select the posi-

tion you want to change, and use the u and d

arrow keys to change the character in that position.

Step 4 When you have completed all the entries, press the

c key to return to the Tools menu. You can now

move onto the next header (Header 2) by pressing

the arrow key.

The HVM100 has the ability to display and print in several

different languages. The choices are English, Spanish,

Italian, French, German, Portuguese, Czech, and Dutch.

Below is an example of one of the language options:

Language

English

Idioma

Espanol

Idioma

Italiano

Langage

Francais

3-12 Tools Key HVM100 Manual

Page 44

Date and Time

Hint: This setting is in the Tools menu. To access the Tools menu press the

TOOLS key and then use the u and d arrow keys to navigate

through the menu items.

NOTE: To change the Date and Time

parameter, press the c key, use the u

and d

value, and then use the

arrow

Once all positions are set press the c

key

HVM100 to accept the entry.

arrows to select the desired

r and l

s to move to the next position.

or move to any other part of the

The date and time functions can be set in this menu. To set

the date and time, go to this menu item. Press the c key . You

can now make changes just like the alphanumeric menu

items in the Header screens. Once all changes have been

made, press the c key again to confirm the changes.

Date

00:00 01 Jan 99

HVM100 Manual Tools Key 3-13

Page 45

3-14 Tools Key HVM100 Manual

Page 46

CHAPTER

4

Range Key

Auto Range

Range Menu

The RANGE key functi ons are concerned with the level of

input signals coming into the HVM100.

In this menu, Gain is added, Calibration is performed, AutoRanging is enabled, and Accelerometer Sensitivity is

entered.

Hint: This setting is in the Range menu. To access the Range menu press the

RANGE key and then use the u and d arrow keys to navigate

through the menu items.

The Auto-Range function in the HVM100 is designed to

work with a steady state signal, i.e. an object which is

vibrating at or near the level of your test object. Often this is

the object or subject under test. It should be used prior to

starting the actual measurement in order to optimize the

input levels from each of the three axes of the transducer’s

output based on actual vibration levels being produced by

the object or subject under test. It is not meant for use while

taking data. Before enabling this function, the transducer

should be attached to the steady state vibration source to be

measured. Next, find the Auto-Range display, located in the

Range menu. Press the c key to enable auto-ranging. The

HVM100 will use its Auto-Range algorithm to adjust the

gain for all three channels such that the steady state input

signal can be properly measured by the HVM100. (The gain

is adjusted so that the signal falls within the top 20 dB of the

HVM100’s analog to digital converter’s range.)

Auto-Range

X= 0 Y= 0 Z= 0

The selections for the gain will be either 0, 20, 40, or 60 dB.

HVM100 Manual Range Menu 4-1

Page 47

Gain X, Y, Z

Once the gain selection is stable, press the c key to save the

settings. The HVM100 must be stopped and reset before the

Auto-Range function can be used.

Hint: This setting is in the Range menu. To access the Range menu press the

RANGE key and then use the u and d arrow keys to navigate

through the menu items.

A very efficient way to manually set

the gain is to have the transducer

mounted on the subject under test, as

described in the section Auto Range

on page 4-1, and check for

indications of either under-range,

described in the section UnderRange Indicator (?) on page 7-2, or

overload, described in the section

Overload Detection on page 7-1,

and manually adjust the gain as

necessary to avoid both.

NOTE: T o view each selection, first press

c key, and then press the r or l

the

arrow key to scroll through each selection.

The Gain settings in the HVM100 will perform manually

what the Auto-Range setting did automatically.

You can select one channel at a time, and manually assign a

gain setting to that channel. The choices are 0, 20, 40, or 60

dB.

To set the Gain for the X channel, first press the RANGE

key to open the Range menu. Next press the d arrow key

once to view the Gain X parameter. Press the u and d to

enter the change mode, use the r or l arrow keys to

select the desired value, and press the c key again to

confirm the change. The Gain Y and Gain Z displays are

located just below the Gain X display. (From the Gain X

display press the d arrow key once to view the Gain Y

display. Press the d arrow key again to view the Gain Z

display.)

Gain X

40 dB

Cal Level

Hint: This setting is in the Range menu. To access the Range menu press the

RANGE key and then use the u and d arrow keys to navigate

through the menu items.

4-2 Range Key HVM100 Manual

Page 48

NOTE: Calibrators operate at a variety

of frequencies. In order to ensure that the

frequency weighting selection does not

affect the level of the calibration, during

calibration the frequency weighting is

automatically changed to Fc frequency

weighting which applies a bandlimiting

filter from 6.3 Hz to 1250 Hz. This is

indicated by the display of Fc in the

upper right of the display during calibration. This should accommodate most

vibration calibrators.

Calibrate X, Y, Z

The Cal Level screen will allow you to enter the operating

level of your calibrator. The frequency of the calibrator is

also important, please see the adjacent note. To enter a value

for your calibrator, go to the cal level screen, press the c