Page 1

Model 824

Precision Sound Level Meter

& Real Time Analyzer

Reference Manual

Page 2

Page 3

Larson Davis

Model 824

Technical Reference Manual

I824.01 Rev P

Page 4

Copyright

Copyright 2006, 2007, 2008, 2009 by PCB Piezotronics, Inc. This manual is copyrighted, with all

rights reserved. The manual may not be copied in whole or in part for any use without prior written

consent of PCB Piezotronics, Inc.

Disclaimer

The following paragraph does not apply in any state or country where such statements are not

agreeable with local law:

Even though PCB Piezotronics, Inc. has reviewed its documentation, PCB Piezotronics Inc. makes no

warranty or representation, either expressed or implied, with respect to this instrument and

documentation, its quality, performance, merchantability, or fitness for a particular purpose. This

documentation is subject to change without notice, and should not be construed as a commitment or

representation by PCB Piezotronics, Inc.

This publication may contain inaccuracies or typographical errors. PCB Piezotronics, Inc. will

periodically update the material for inclusion in new editions. Changes and improvements to the

information described in this manual may be made at any time.

Record of Serial Number and Purchase Date

Model 824 Serial Number: ___________

PRM902 Preamplifier Serial Number: ___________

Microphone Model: _________ Serial Number: ___________

Recycling

PCB Piezotronics, Inc. is an environmentally friendly organization and encourages our customers to

be environmentally conscious. When this product reaches its end of life, please recycle the product

through a local recycling center or return the product to:

PCB Piezotronics, Inc.

Attn: Recycling Coordinator

1681 West 820 North

Provo, Utah, USA 84601-1341

where it will be accepted for disposal

Page 5

824 Reference Manual

Chapter 1 Introduction 1-1

About This Manual .................................................................................................1-1

Special Features of the Electronic Version........................................................1-3

Bookmarks .........................................................................................................1-3

Opening Bookmarks......................................................................................1-3

Closing Bookmarks.......................................................................................1-4

Expanding Bookmarks ..................................................................................1-4

Click to Display Page....................................................................................1-5

Return to Previous View ...............................................................................1-5

Links...................................................................................................................1-5

Click to Display Page....................................................................................1-5

About This Chapter.................................................................................................1-6

Formatting...............................................................................................................1-6

Features...................................................................................................................1-7

Hardware Features: ............................................................................................1-7

System 824 Components..................................................................................1-10

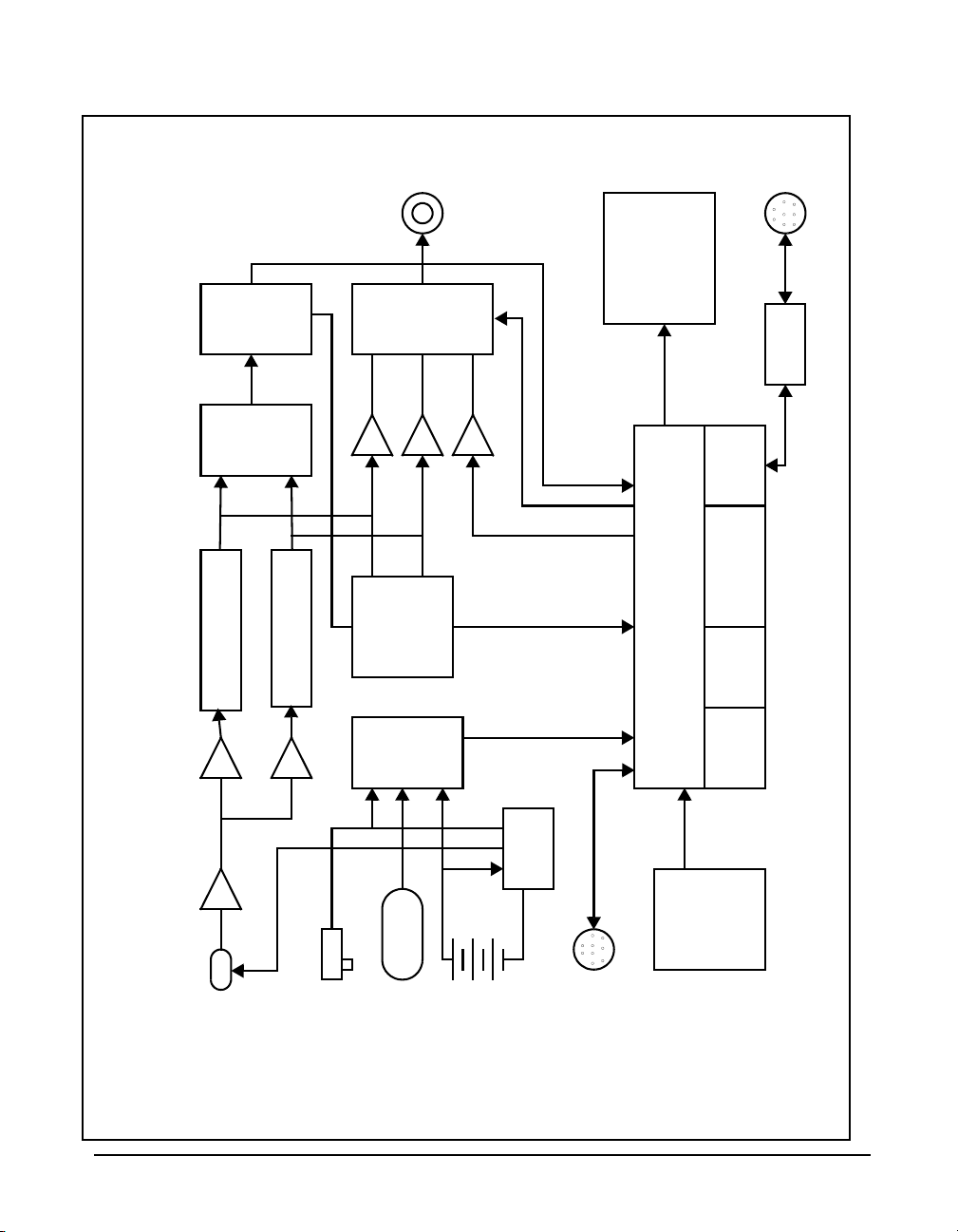

System Diagram...............................................................................................1-13

Getting Started ......................................................................................................1-14

Unpacking and Inspection................................................................................1-14

..........................................................................................................................1-16

Comments concerning the Digital Signal Processor...................................1-16

Accessories and Optional Equipment ..............................................................1-16

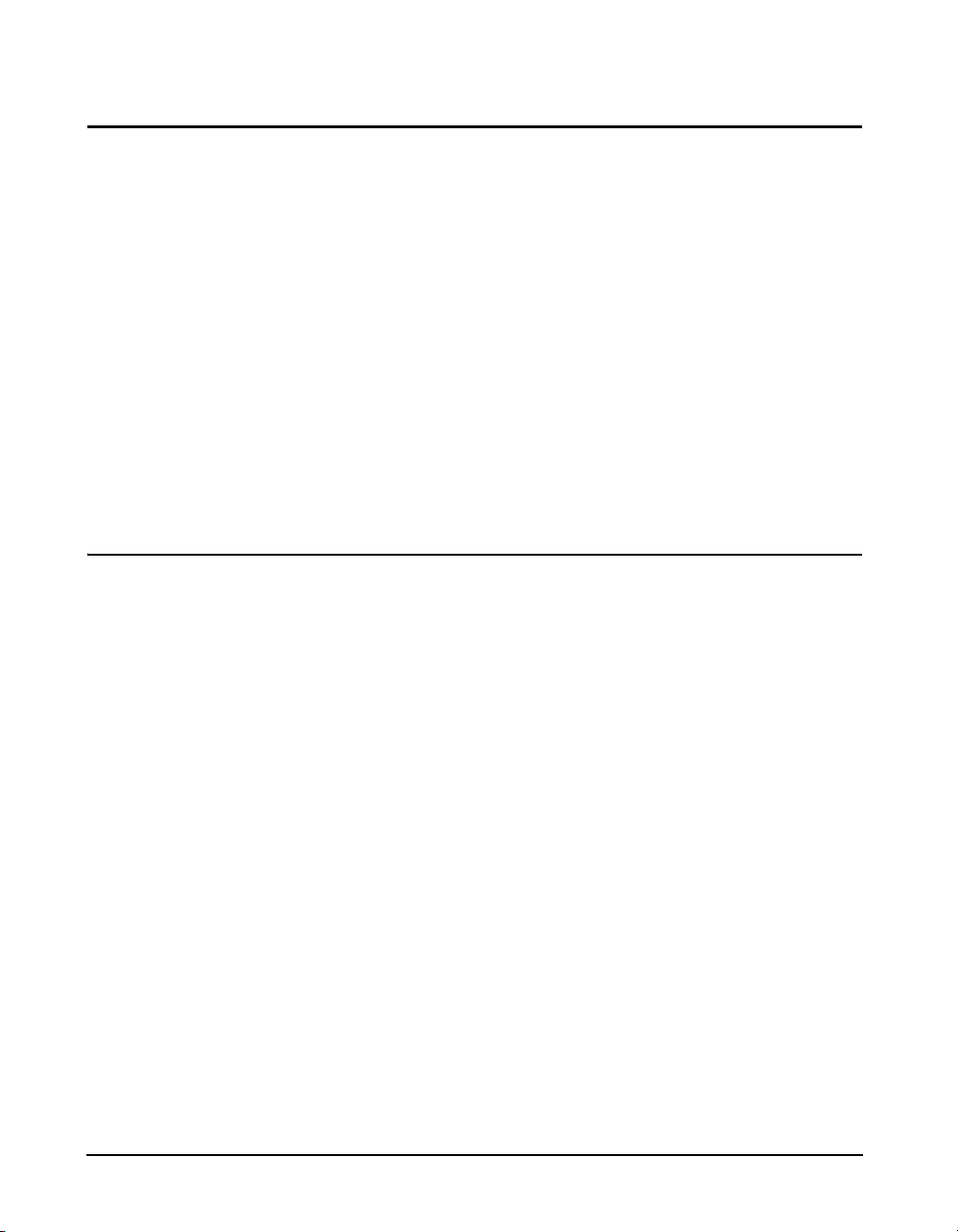

Connecting Internal or External Power............................................................1-18

Using the NiMH Battery Pack ....................................................................1-18

Using Alkaline Batteries or Individual NiMH rechargable cells. ...............1-19

Using the AC Power Adapter......................................................................1-20

Chapter 2 Overview 2-1

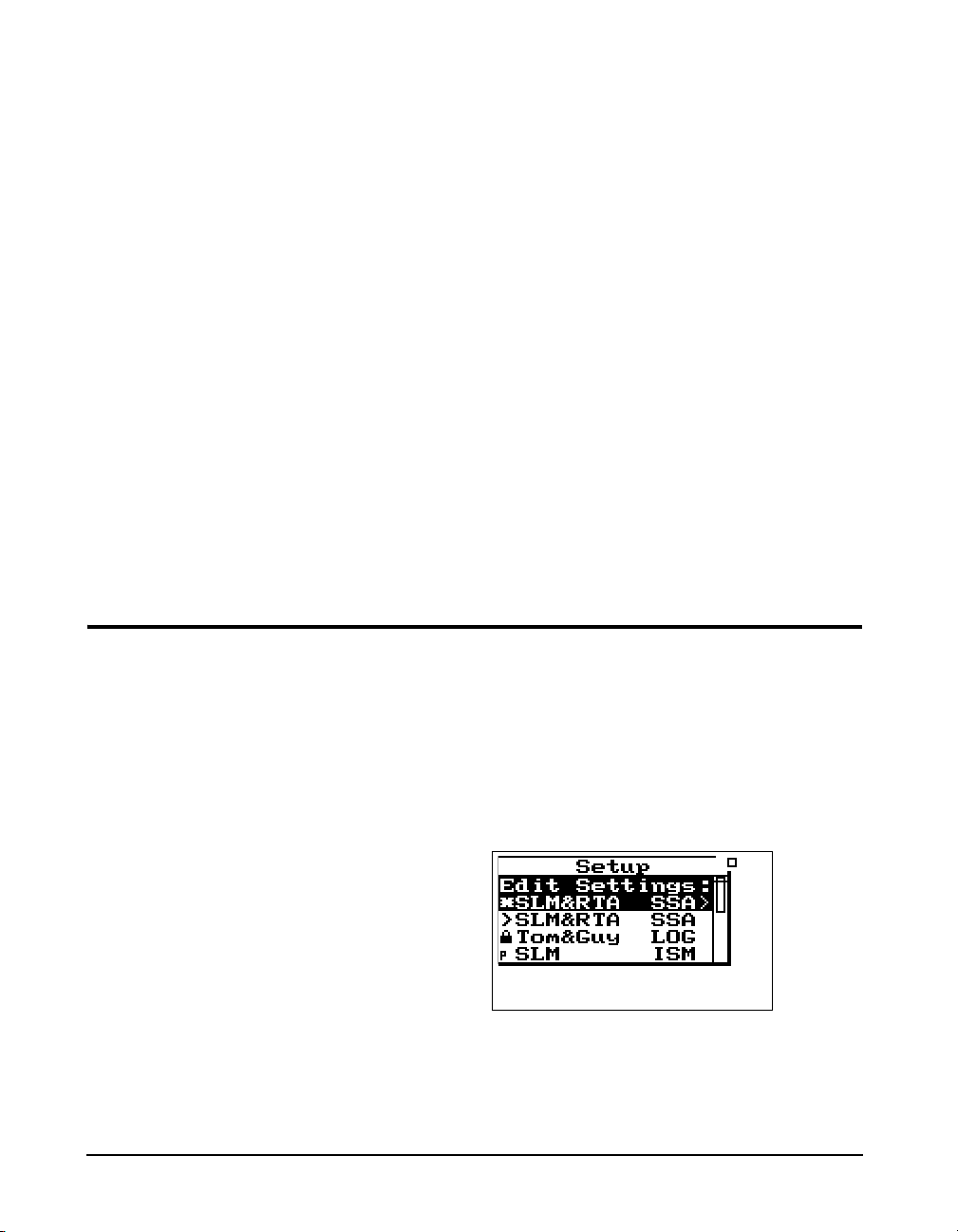

System 824 Setups or Instrument Definitions ........................................................2-1

Instrument Definition (ID) Types ..........................................................................2-2

Write Protect, Delete, Write Enable IDs............................................................2-2

SLM&RTA (SSA) .............................................................................................2-2

SLM (ISM) ........................................................................................................2-4

Logging (LOG) ..................................................................................................2-4

Selecting a Measurement Setup..............................................................................2-6

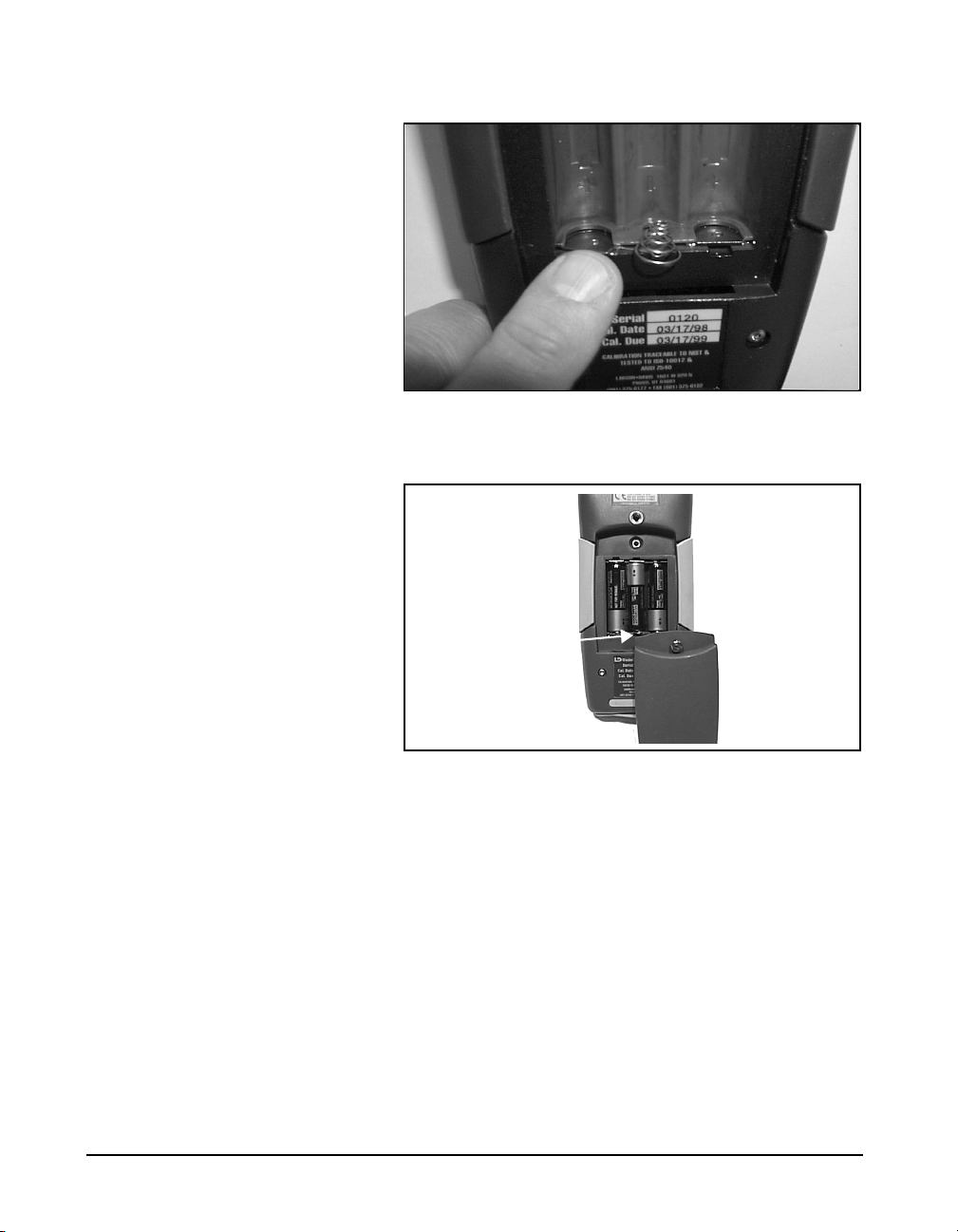

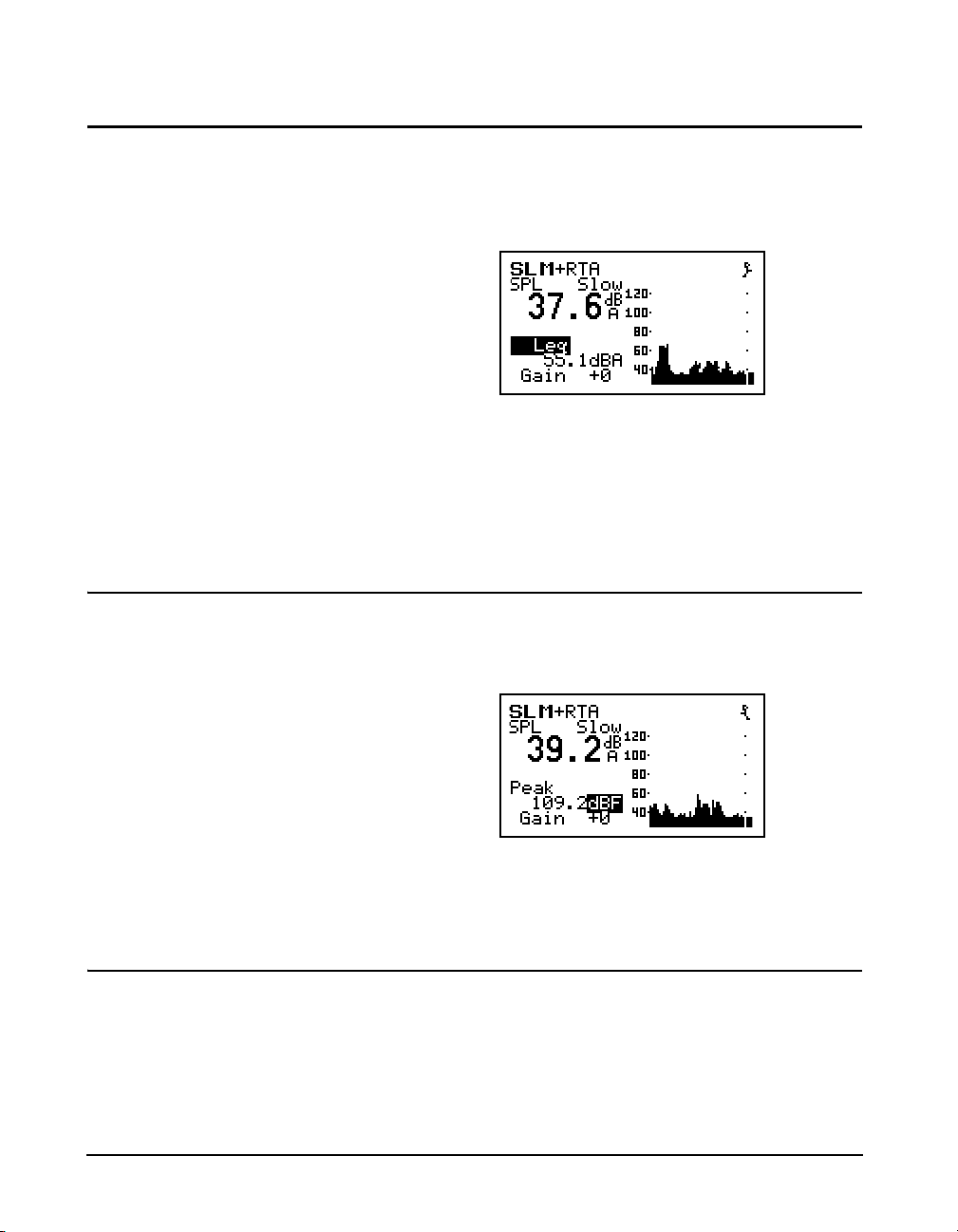

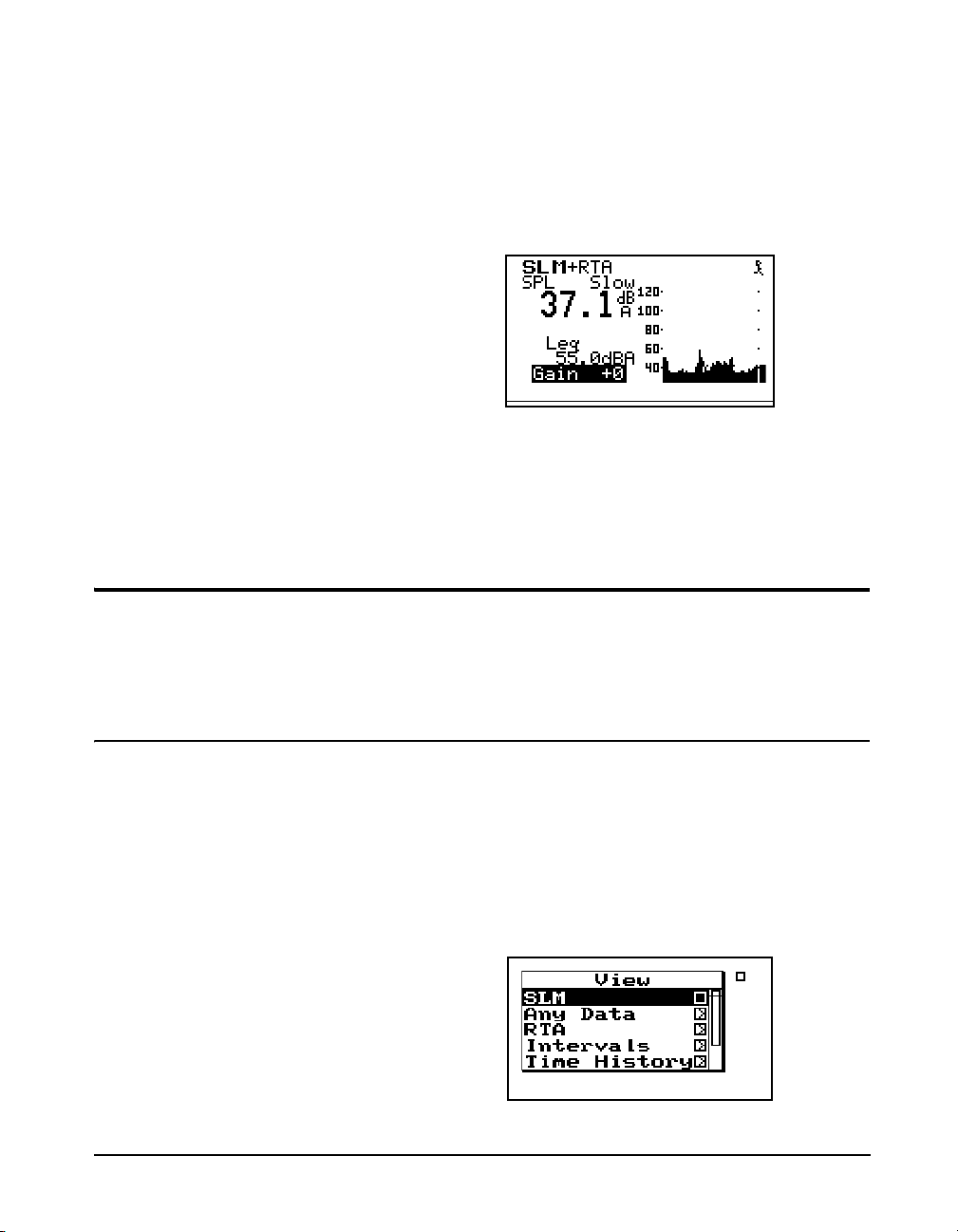

Performing a Measurement; SLM&RTA (SSA) ....................................................2-7

Stop, Pause and Back Erase Functions ..............................................................2-8

Stopping and Starting Measurements............................................................2-8

iii-i

Page 6

824 Reference Manual

Pausing Measurements..................................................................................2-8

Back Erasing .................................................................................................2-8

Changing the detector of the displayed SPL value ............................................2-8

Changing the frequency weighting of the displayed SPL value ........................2-9

Changing the displayed secondary parameter..................................................2-10

Changing the frequency weighting of the displayed Lpeak value ...................2-10

Changing the amplitude range, or input Gain ..................................................2-10

Views ....................................................................................................................2-11

Selecting a VIEW.............................................................................................2-11

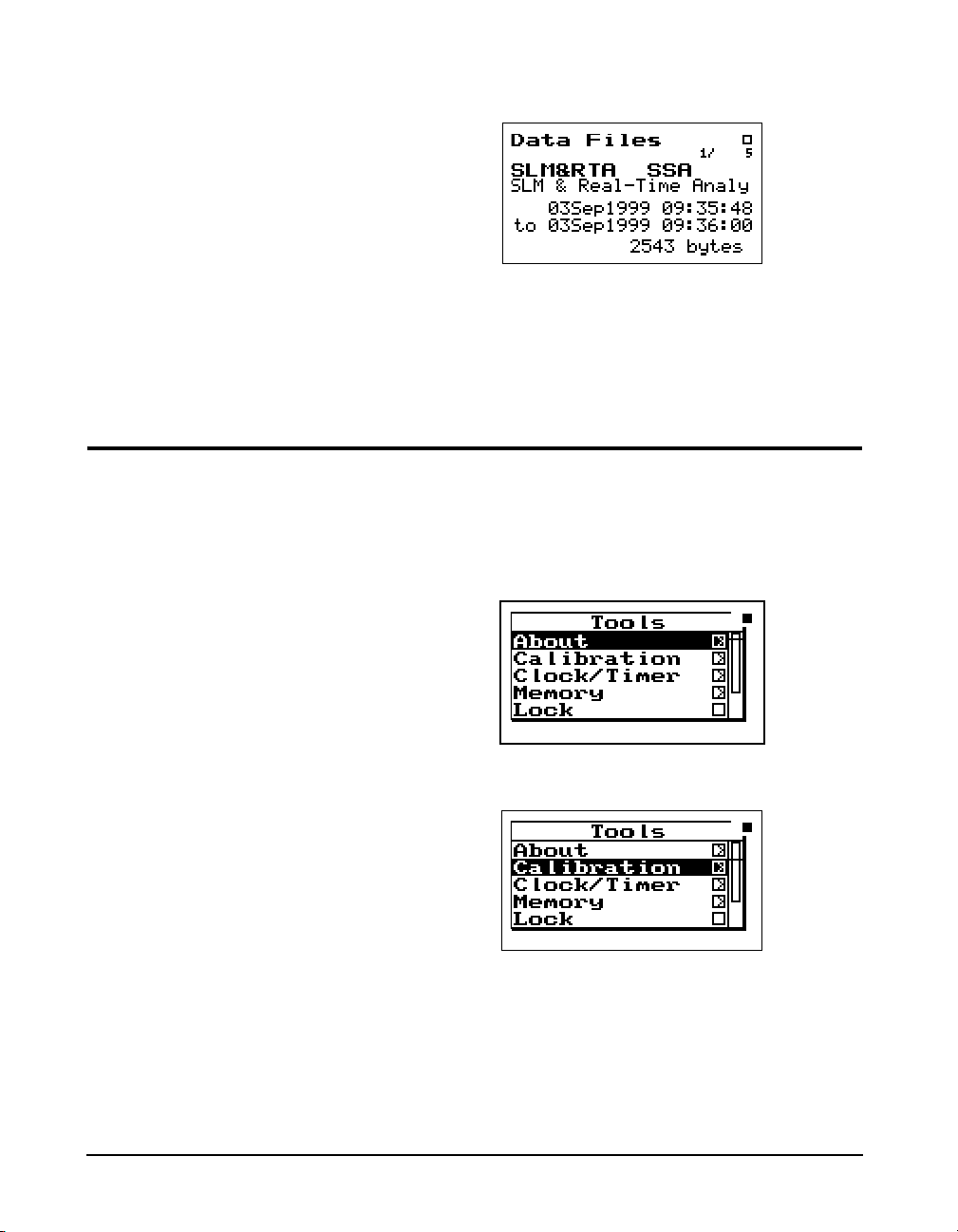

Data Storage and Recall........................................................................................2-13

Storing Data.................................................................................................2-13

Recalling Data.............................................................................................2-13

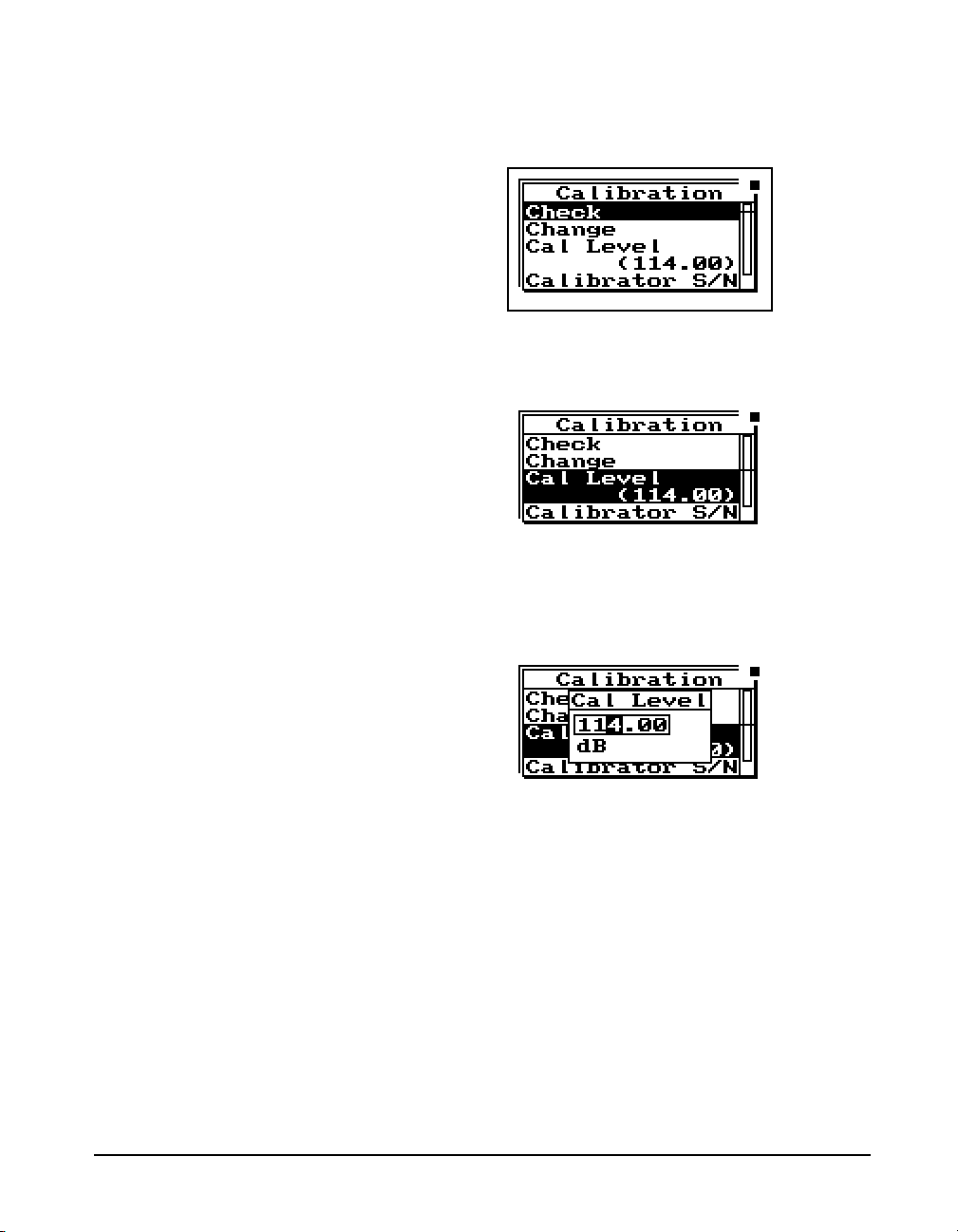

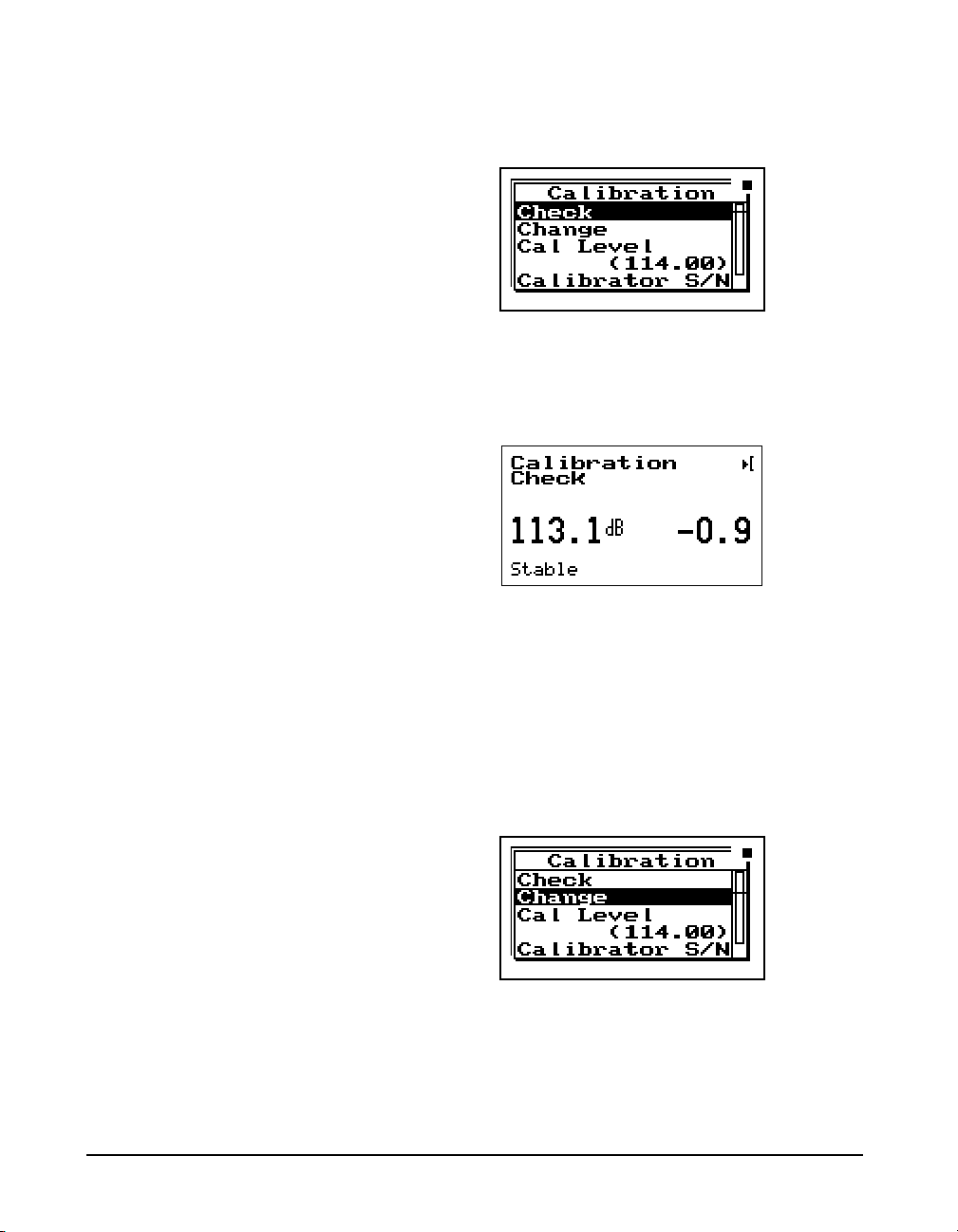

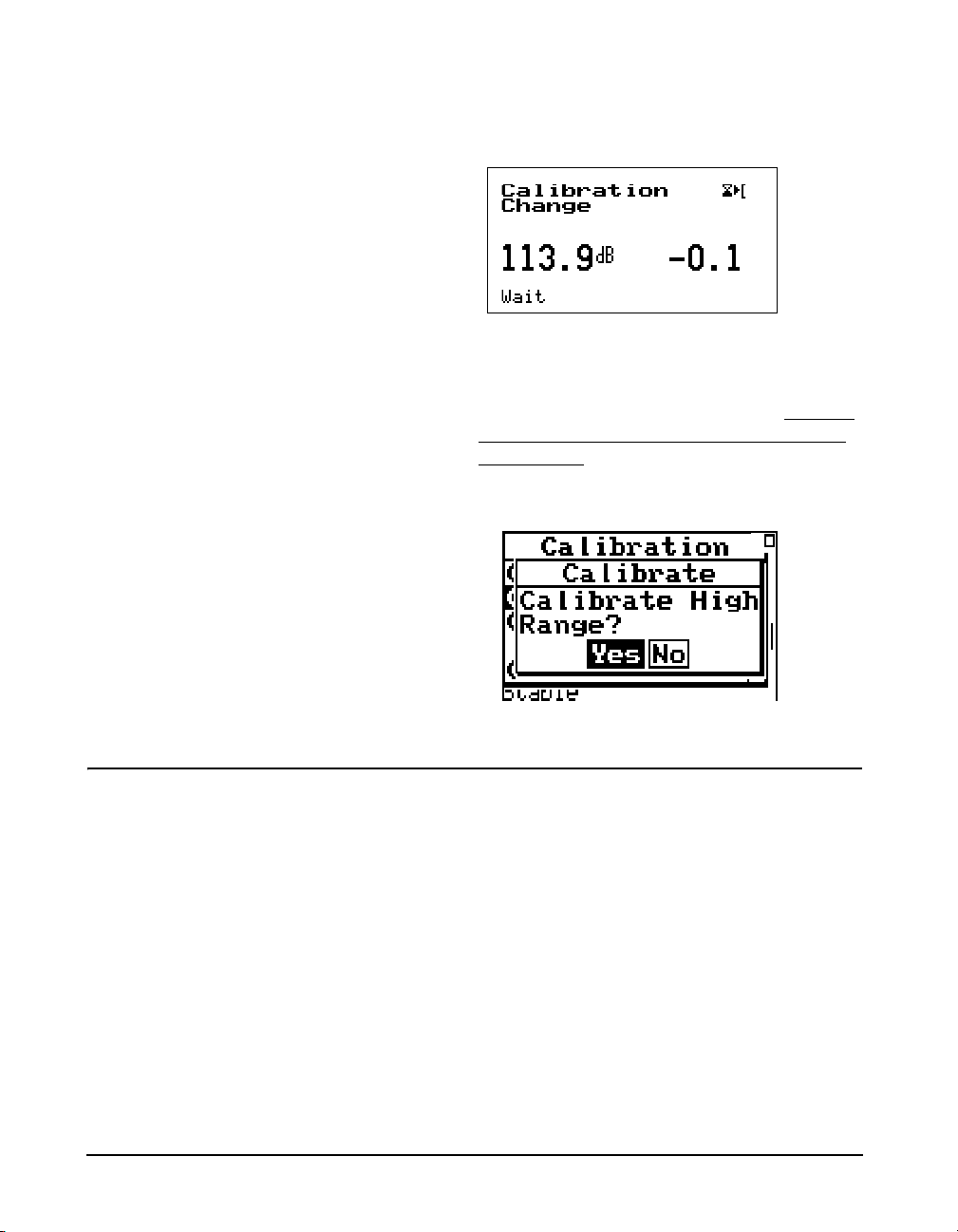

Calibration ............................................................................................................2-14

Correction of Calibrator Output Level.............................................................2-17

Chapter 3 Front Panel Keys; Functions and Menus 3-1

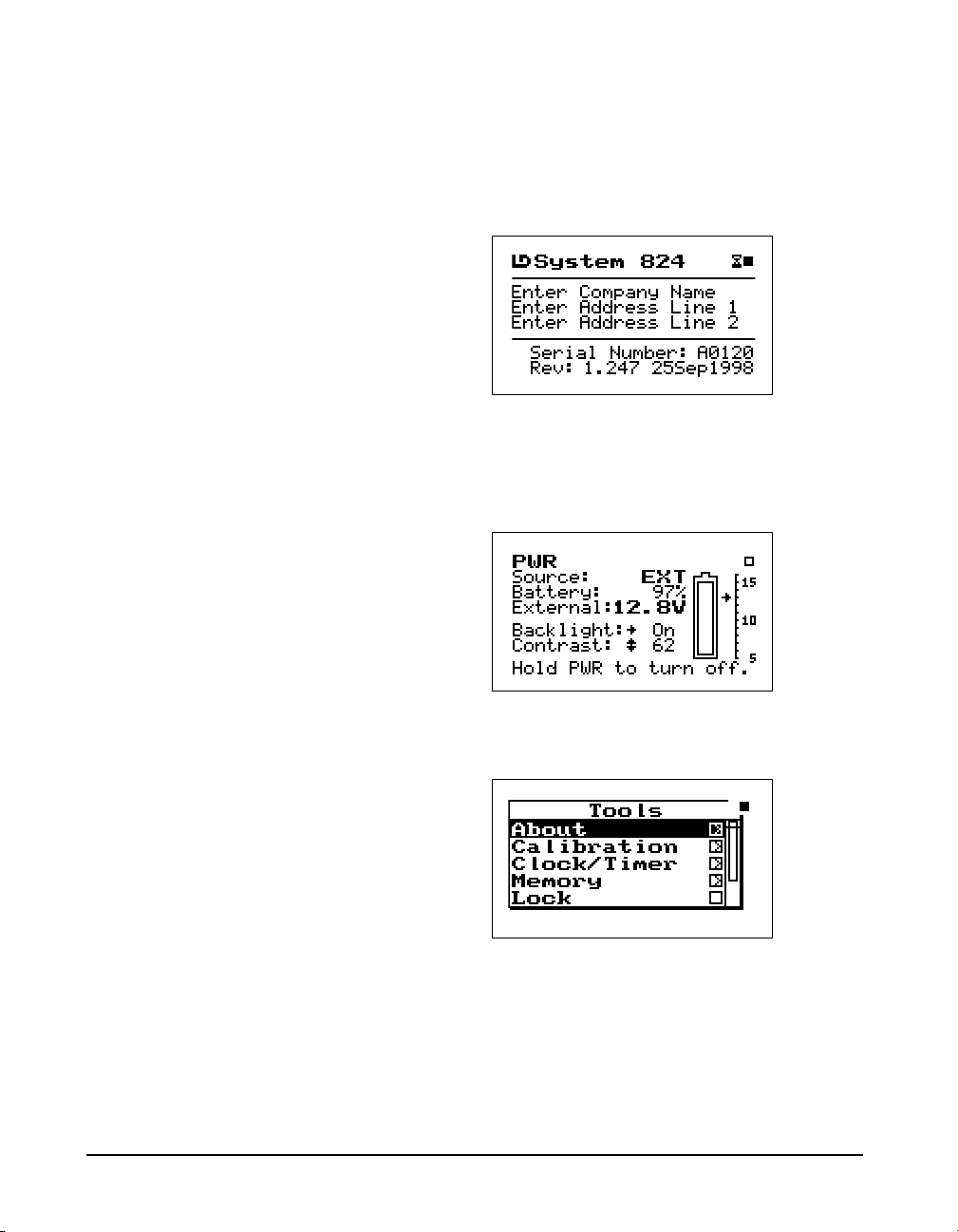

v Power Key .........................................................................................................3-3

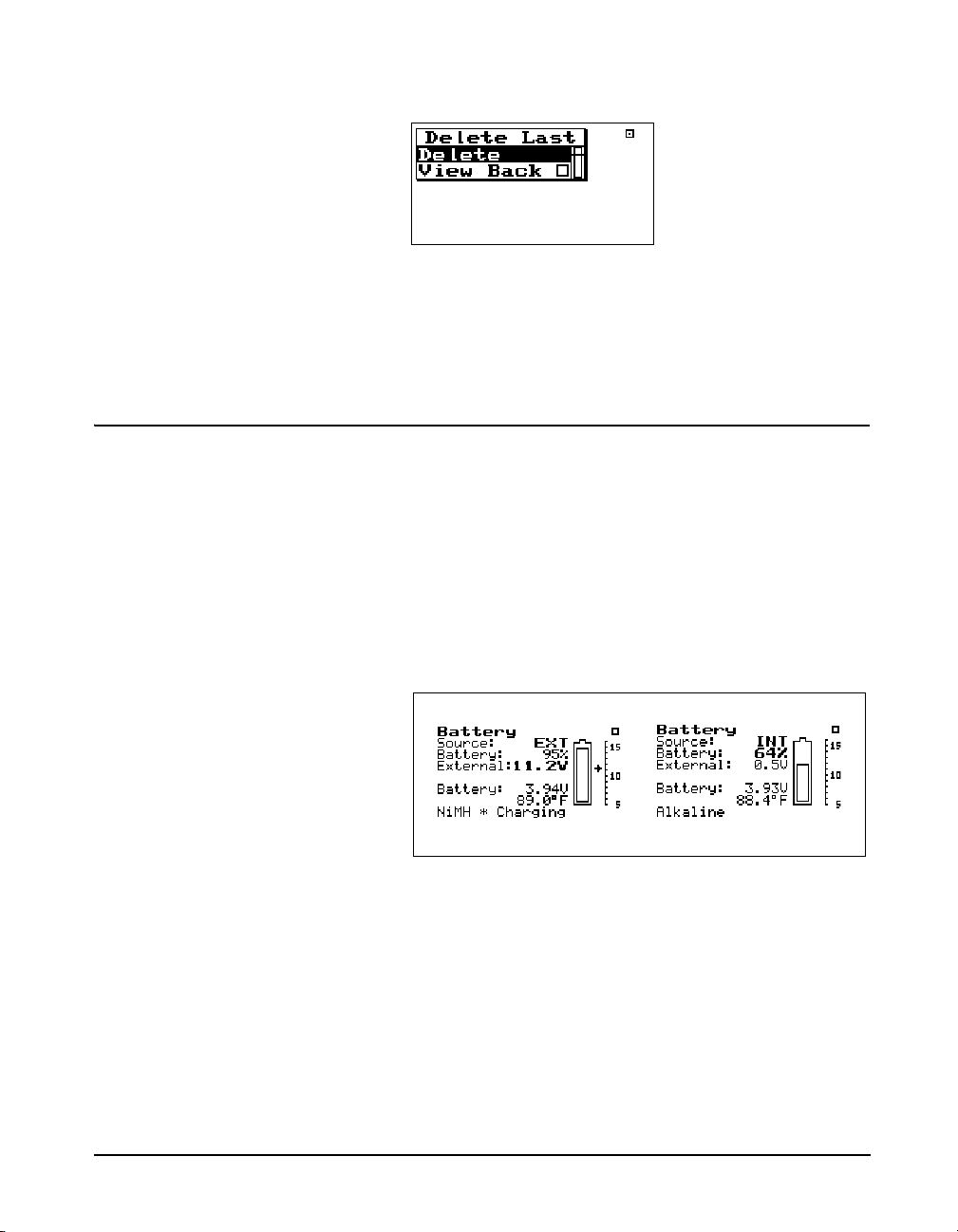

Power-up the Instrument / Viewing PWR Display............................................3-4

Power Settings....................................................................................................3-6

Extra Notes on Power Conservation ..................................................................3-8

s Run/Stop Key ....................................................................................................3-8

R Reset Key ..........................................................................................................3-9

p Pause Key........................................................................................................3-10

Pause............................................................................................................3-10

Pause, Back Erase .......................................................................................3-10

Preview........................................................................................................3-11

lrud Arrow Keys.................................................................................3-11

c Check Key........................................................................................................3-12

V View Key.........................................................................................................3-12

D Data Key..........................................................................................................3-13

S Setup Key ........................................................................................................3-14

Save ID........................................................................................................3-16

Title .............................................................................................................3-16

ID Name ......................................................................................................3-16

Write Protect, Delete, Write Enable IDs..........................................................3-17

TTools Key .........................................................................................................3-18

About................................................................................................................3-20

Calibration........................................................................................................3-22

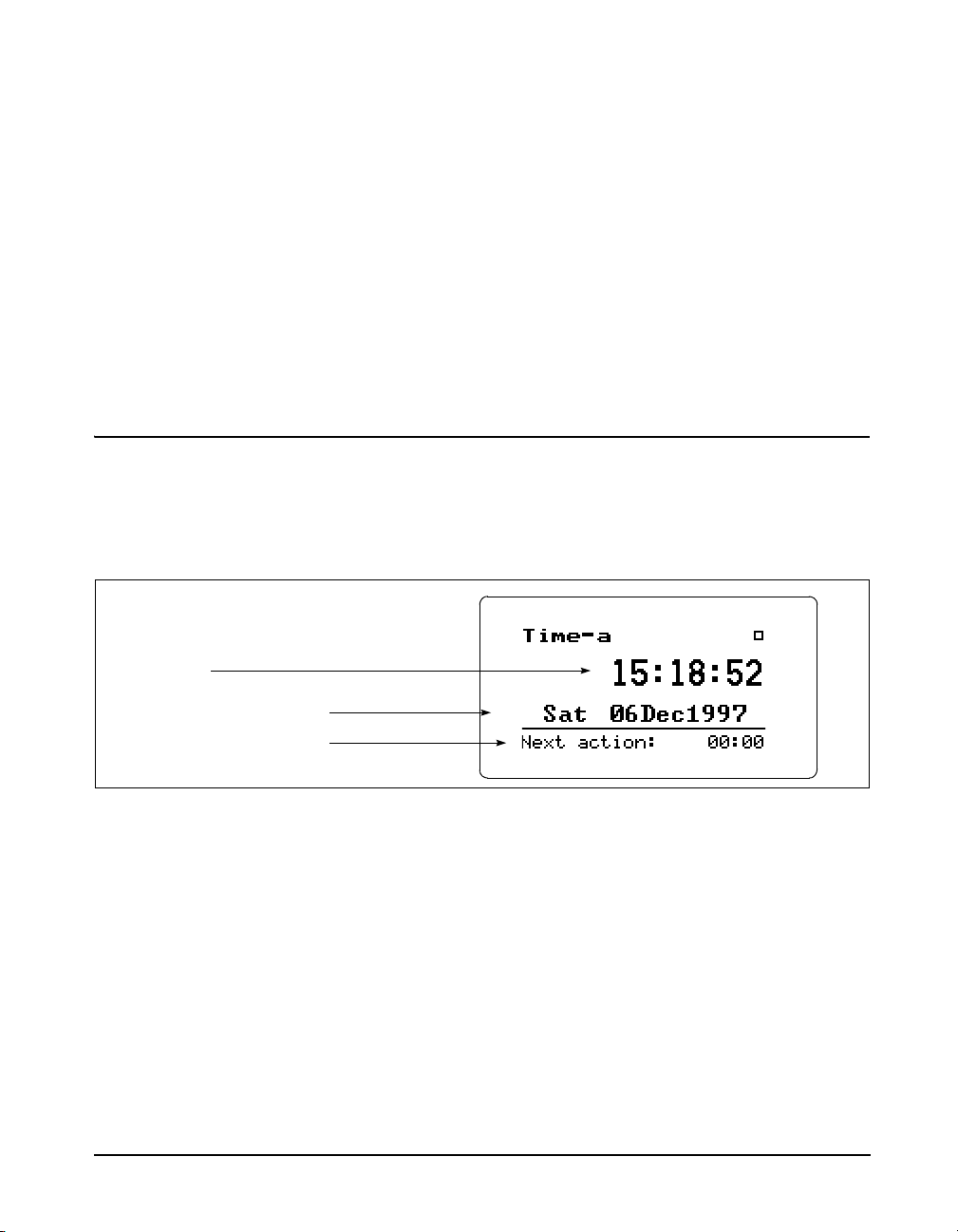

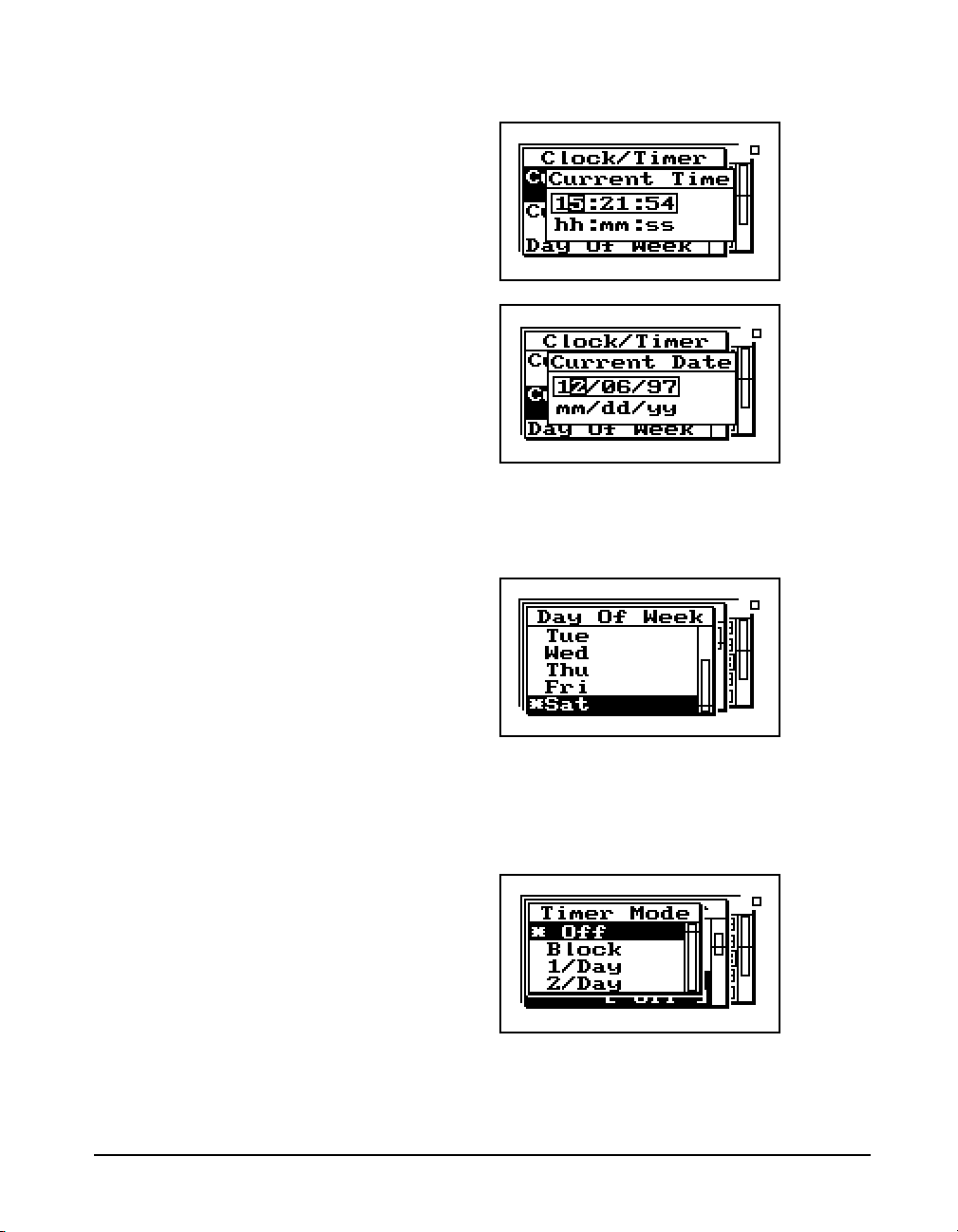

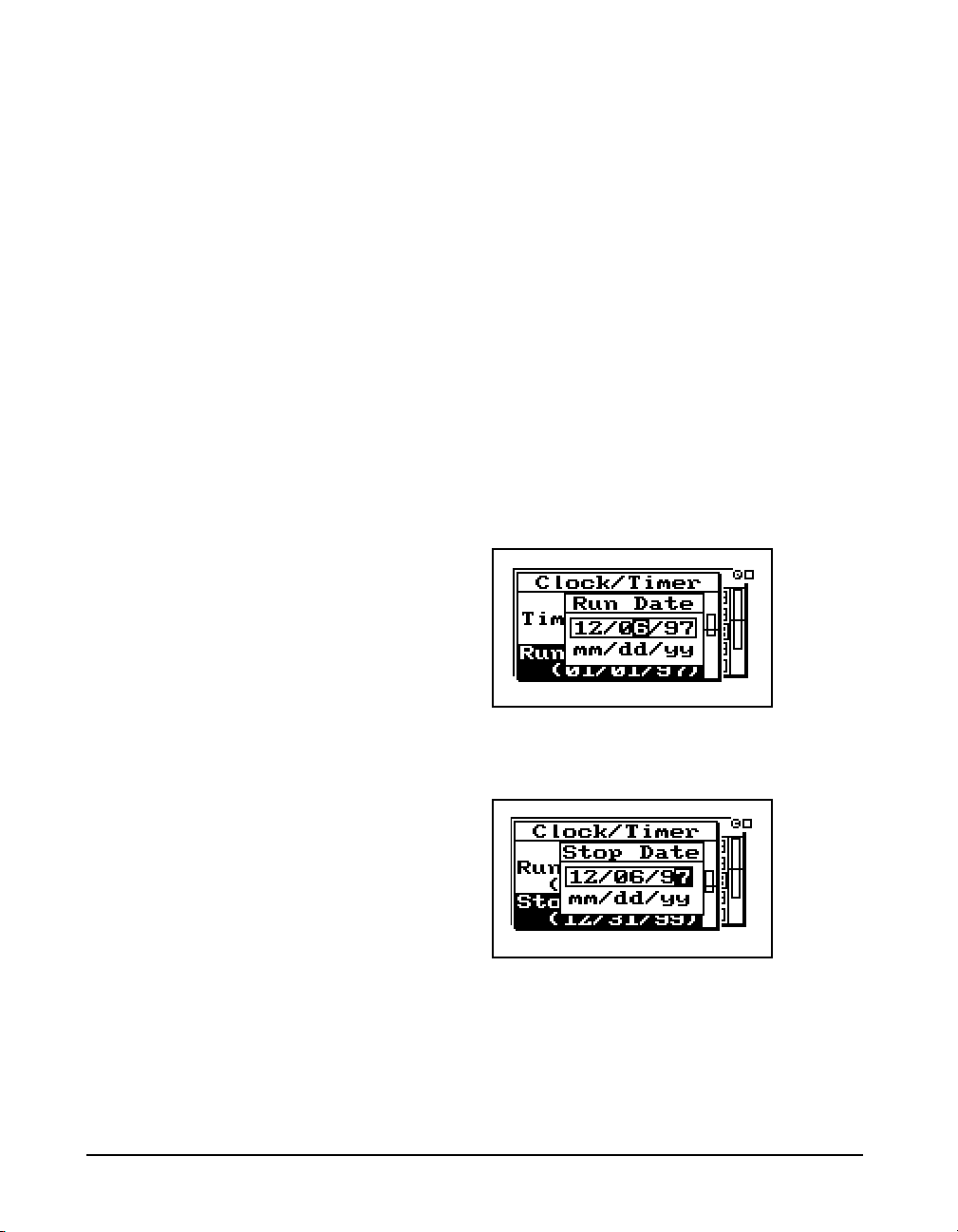

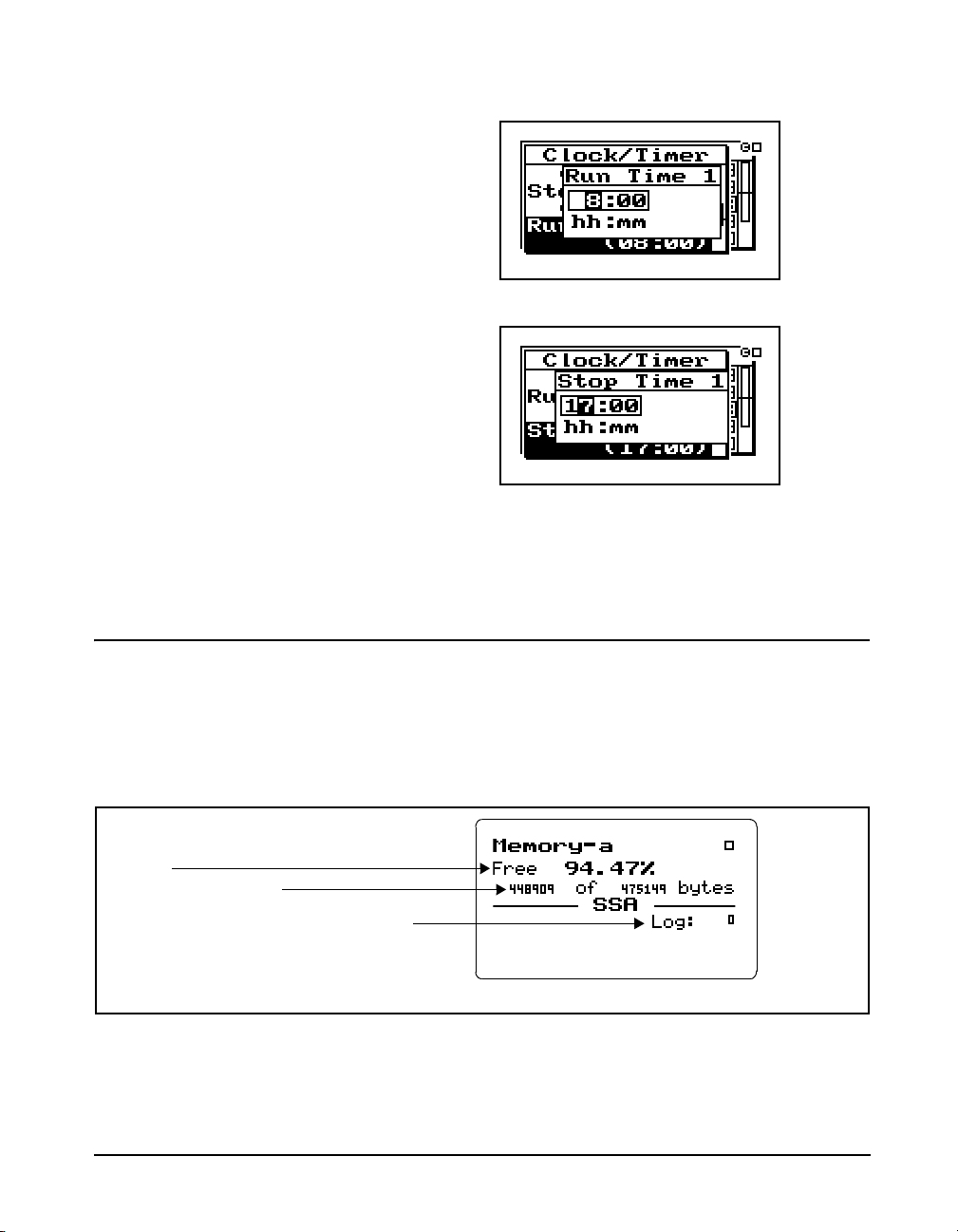

Clock/Timer .....................................................................................................3-23

iii-ii

Page 7

824 Reference Manual

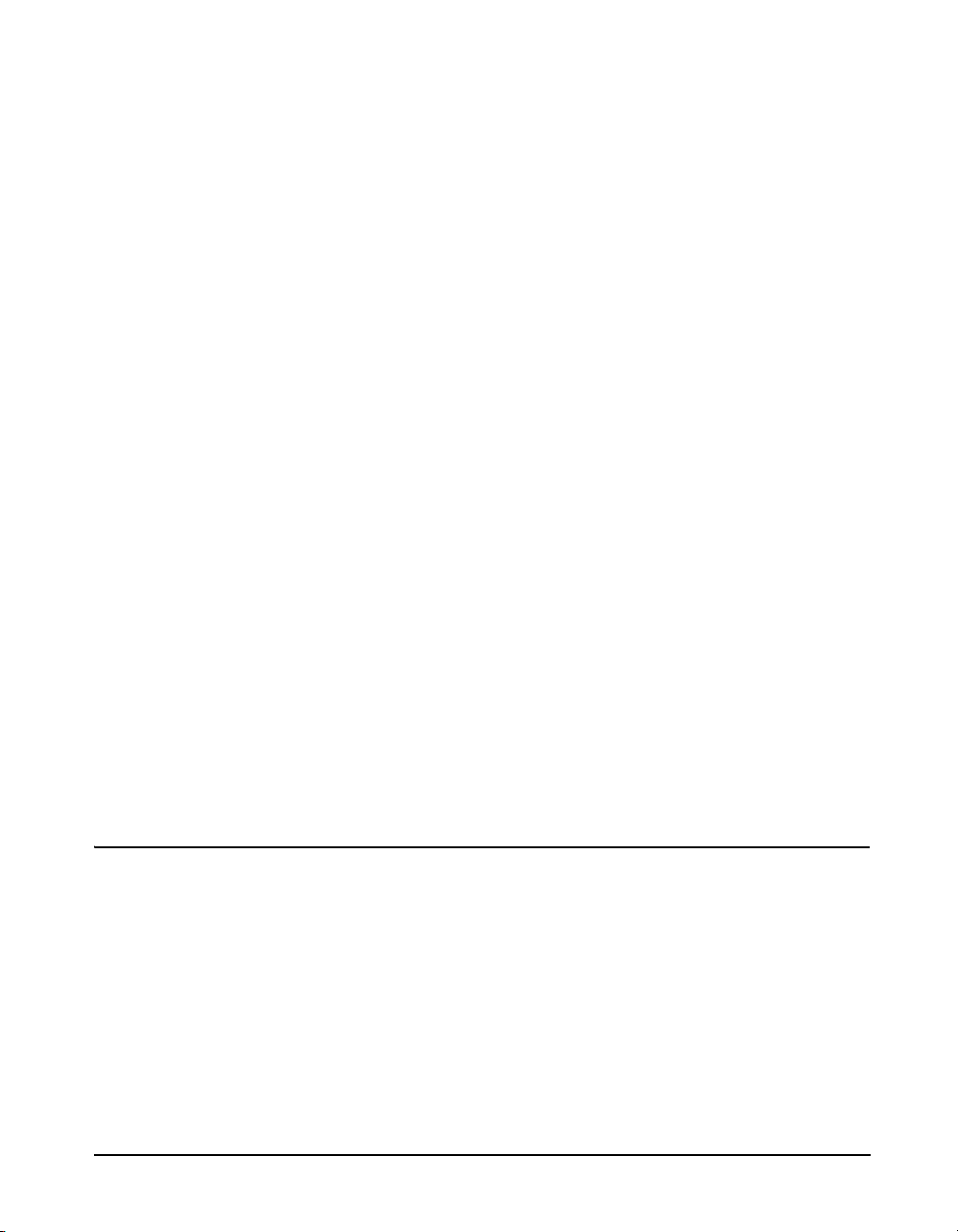

Memory............................................................................................................3-27

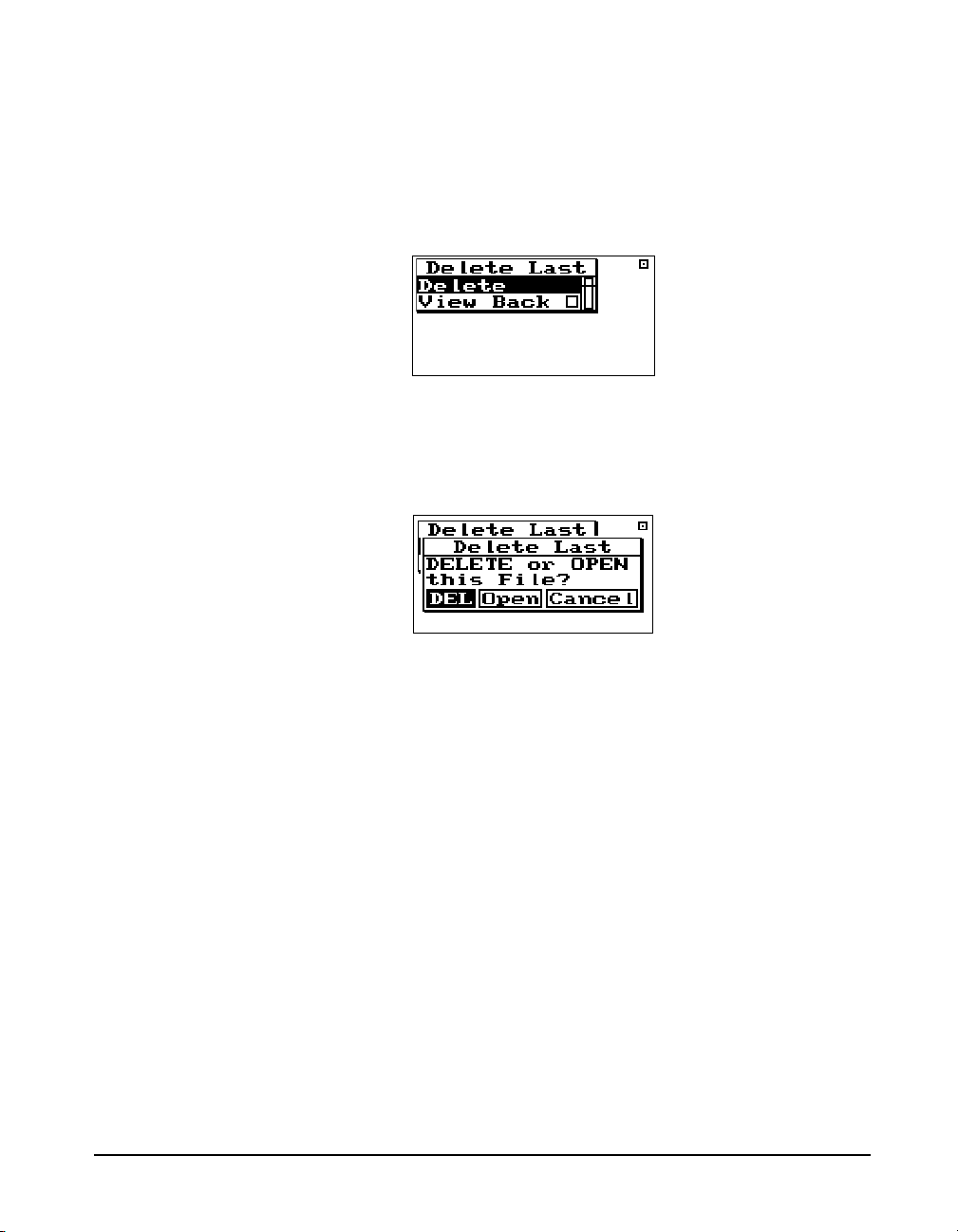

Deleting Stored Data........................................................................................3-29

Delete Last Function ...................................................................................3-29

824 Memory Structure ................................................................................3-29

Deleting the Last Stored Record .................................................................3-30

Deleting Individual Records........................................................................3-31

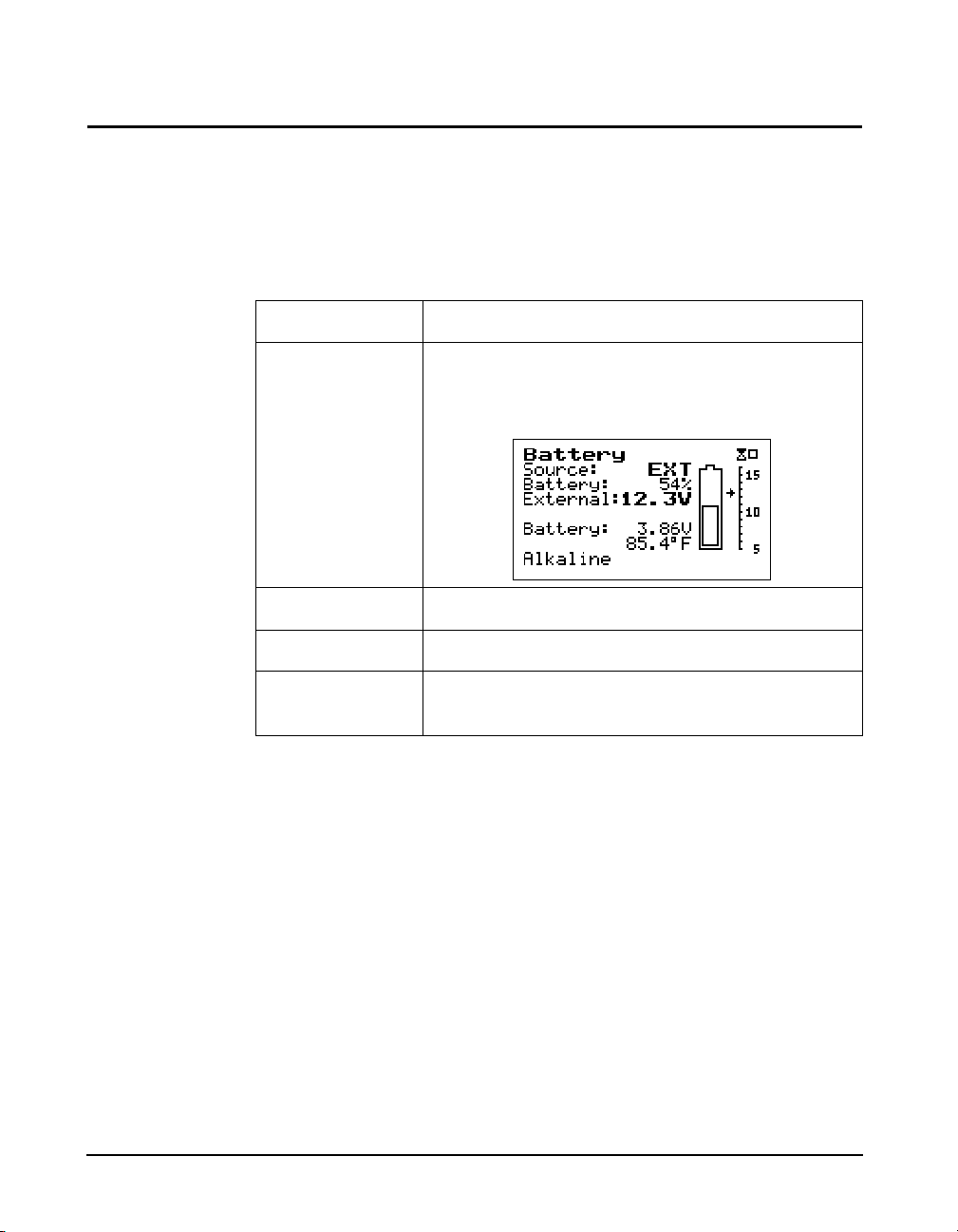

Power Monitor .................................................................................................3-33

Communication................................................................................................3-34

P Print Key..........................................................................................................3-37

Chapter 4 Quick Start 4-1

Turning On and Calibrating the System 824 ..........................................................4-1

High Range Calibration .....................................................................................4-4

Taking Measurements and Storing Data.................................................................4-5

SLM&RTA Measurements................................................................................4-5

Viewing RTA Displays during a Measurement.................................................4-8

Recalling Stored Data ...........................................................................................4-11

Selecting and Modifying Instrument Definitions (IDs) ........................................4-12

The Setup Menu...............................................................................................4-13

The Active ID...................................................................................................4-13

Menu Scrolling.................................................................................................4-15

Permanent IDs..................................................................................................4-15

Write-protected IDs..........................................................................................4-16

Preparing for a Measurement...........................................................................4-16

Selecting a Different ID ...................................................................................4-17

Accessing the Settings Menu ...........................................................................4-17

Accessing the Settings Menu to Initiate Editing or Modification....................4-18

Setting Control in the SLM View ....................................................................4-22

Chapter 5 System 824 Views 5-1

Status Icons and Indicators .....................................................................................5-2

General Views.........................................................................................................5-4

SLM Views ........................................................................................................5-5

Any Data View...................................................................................................5-8

Any Level Format .........................................................................................5-8

Any Impulse Format......................................................................................5-8

Any Time Format..........................................................................................5-9

SSA Specific Views................................................................................................5-9

SSA Displays ...................................................................................................5-11

iii-iii

Page 8

824 Reference Manual

Logging SLM Specific Views ..............................................................................5-23

SSA Displays Including 1/1 or 1/3 Octave Spectral Data...........................5-11

Tabular SSA Views.....................................................................................5-12

Time History Displays ................................................................................5-13

SSA Intervals...............................................................................................5-13

SSA Time History .......................................................................................5-16

Run Log.......................................................................................................5-19

Ln Centiles ..................................................................................................5-19

Current SLM and Overall SLM Views............................................................5-25

Current SLM/Overall SLM Display-a (SPL)..............................................5-26

Current/Overall SLM Display-b (Times)....................................................5-28

Current/Overall SLM Display-c (Min/Max)...............................................5-29

Current/Overall SLM Display-d (Peaks).....................................................5-29

Current/Overall SLM Display-e (TWA).....................................................5-30

Exposure Views ...............................................................................................5-31

Exposure Display-a .....................................................................................5-32

Exposure-b Display.....................................................................................5-33

Exposure-c Display .....................................................................................5-34

Ln Centiles Views............................................................................................5-35

Ln-a Display................................................................................................5-35

Ln-b Display................................................................................................5-36

Stats Views.......................................................................................................5-37

Stats-a Display.............................................................................................5-38

Stats-b Display ............................................................................................5-38

Stats-c Display.............................................................................................5-39

Run Log (LOG & SSA) ...................................................................................5-40

Time History ....................................................................................................5-42

Single Other Level ......................................................................................5-43

Multiple Other Levels .................................................................................5-43

Intervals............................................................................................................5-44

Intervals-a Display ......................................................................................5-44

Intervals-b Display ......................................................................................5-46

Intervals-c Display ......................................................................................5-47

Intervals-d Display ......................................................................................5-48

Intervals-e Display ......................................................................................5-49

Intervals-f Display.......................................................................................5-50

Exceedance History..........................................................................................5-52

Excd-a Display ............................................................................................5-52

iii-iv

Page 9

824 Reference Manual

Excd-b Display............................................................................................5-53

Excd-c Display ............................................................................................5-54

Excd Time History Display.........................................................................5-55

Daily Views......................................................................................................5-58

Daily-a Display ...........................................................................................5-58

Daily-b Display ...........................................................................................5-60

Daily-c Wind Display..................................................................................5-61

Daily-d Windy Percent Display ..................................................................5-62

Hourly Leq Display.....................................................................................5-63

Metrics .............................................................................................................5-65

Metrics-a Display ........................................................................................5-65

Metrics-b Display........................................................................................5-66

PassBy..............................................................................................................5-67

Wind/Tach........................................................................................................5-69

Wind-a Display ...........................................................................................5-69

Wind-b Display ...........................................................................................5-70

Wind-c Percent Display ..............................................................................5-71

Chapter 6 System 824 Virtual Instruments 6-1

System 824 Virtual Instruments .............................................................................6-1

Selecting an Instrument ID .....................................................................................6-3

Sound Spectrum Analyzer (SSA) ...........................................................................6-3

SSA Measuring Ranges .....................................................................................6-4

LN Percentiles (Spectral)...................................................................................6-5

AC/DC Output ...................................................................................................6-5

Logging SLM..........................................................................................................6-7

Time History ......................................................................................................6-7

Interval History ..................................................................................................6-7

Exceedances.......................................................................................................6-8

LN Percentiles (Broadband)...............................................................................6-8

Sound Exposure .................................................................................................6-9

............................................................................................................................6-9

LOG and ISM Measuring Ranges......................................................................6-9

Chapter 7 Using ID Setting Files 7-1

Recalling ID Setting Files.......................................................................................7-1

Customizing Settings ..............................................................................................7-2

Settings Example - SLM&RTA (SSA)..............................................................7-2

Settings Descriptions ..............................................................................................7-4

iii-v

Page 10

824 Reference Manual

Common SLM Settings......................................................................................7-5

Title Setting - (SSA, LOG, ISM) ....................................................................7-5

Detector Setting - (SSA, LOG, ISM) ..............................................................7-5

Weighting Setting - (SSA, LOG, ISM) ...........................................................7-6

Gain Setting - (SSA) ......................................................................................7-6

Range Setting - (LOG, ISM) ..........................................................................7-7

Transducer Setting - (SSA, LOG, ISM)..........................................................7-8

Random Incidence Microphone Correction - (Available to all Instrument

types) .............................................................................................................7-8

Pk Weighting - (SSA, LOG, ISM) ..................................................................7-9

RTA Detector Setting - (SSA) ......................................................................7-9

RTA Weighting - (SSA)...............................................................................7-10

Bandwidth Setting - (SSA)...........................................................................7-10

Common Control Settings................................................................................7-10

Control Settings - (ISM)..............................................................................7-10

Control Settings _(SSA, LOG)....................................................................7-11

AC/DC Output Settings - (SSA, LOG, ISM) ................................................7-12

Logic Input Setting - (SSA, LOG, ISM) .......................................................7-12

Logic Output Setting - (SSA, LOG, ISM) ....................................................7-13

Logic Output Time Setting - (SSA, LOG, ISM) ...........................................7-15

Logic Output #2 ..........................................................................................7-16

Logic Output #2 Time Setting.....................................................................7-16

Heater On ....................................................................................................7-16

E. A. Cal Tone.............................................................................................7-16

Logging SLM TWA Settings...........................................................................7-17

Ovll Exchange - (LOG) ...............................................................................7-17

Ovll Threshold - (LOG)...............................................................................7-18

Ovll Criterion - (LOG) ................................................................................7-18

Criterion Time - (LOG)...............................................................................7-19

Crnt Exchange - (SSA, ISM, LOG) .............................................................7-19

Crnt Threshold (SSA, ISM, LOG)..............................................................7-20

Crnt Criterion (LOG) ..................................................................................7-20

LOG and SSA Ln Settings...............................................................................7-20

Enable Ln ....................................................................................................7-21

Start Level ...................................................................................................7-21

Ln’s .............................................................................................................7-22

Spectral Ln’s (SSA only) ............................................................................7-22

LOG and SSA Triggering Settings ..................................................................7-23

SPL Excd Lvl 1 - (LOG, SSA) .....................................................................7-23

iii-vi

Page 11

824 Reference Manual

SPL Excd Lvl 2 - (LOG, SSA) .....................................................................7-23

PK Excd Lvl 1 - (LOG, SSA).......................................................................7-24

Pk Excd Lvl 2 - (LOG, SSA)........................................................................7-24

Hysteresis - (LOG, SSA) ..............................................................................7-24

LOG and SSA Wind/Tach Settings .................................................................7-25

Setup of Wind/Tach Function .....................................................................7-26

Wind Scale ..................................................................................................7-27

Wind Units ..................................................................................................7-28

Direction Units ............................................................................................7-28

Wind/Tach Enable.......................................................................................7-29

Windy Threshold.........................................................................................7-29

Wind Exceedance Level..............................................................................7-29

Windy Hysteresis ........................................................................................7-29

Wind Pause Enable......................................................................................7-30

Pulse Trigger Voltage..................................................................................7-30

Pulse Source ................................................................................................7-30

LOG and SSA Time History Settings ..............................................................7-30

Hist Enable - (LOG, SSA) ............................................................................7-32

Hist Period (LOG, SSA) ...............................................................................7-33

Period Units - (LOG, SSA)...........................................................................7-33

Other Level - (LOG only)............................................................................7-33

Resolution - (LOG, SSA)..............................................................................7-34

Advanced Time History - (LOG, SSA).......................................................7-35

Marker Text - (LOG, SSA) .........................................................................7-35

LOG and SSA Interval Settings.......................................................................7-36

Intv Enable - (LOG, SSA) ............................................................................7-37

Intv Period - (LOG, SSA) .............................................................................7-37

Intv Time Sync - (LOG, SSA) ......................................................................7-37

Intv Save Ln’s - (LOG, SSA)......................................................................7-38

Intv Auto Stop - (LOG, SSA) .......................................................................7-38

Intv Threshold - (LOG, SSA) .......................................................................7-39

Intv Exchange - (LOG, SSA)........................................................................7-39

Intv Spectrum - (SSA only).........................................................................7-39

Logging SLM Exceedance History Settings....................................................7-40

Triggering - (LOG)......................................................................................7-40

Excd Enable - (LOG)...................................................................................7-40

Min Duration - (LOG) .................................................................................7-40

Excd Time Hist - (LOG)..............................................................................7-41

iii-vii

Page 12

824 Reference Manual

Menu Layout of SSA Settings ..............................................................................7-45

Menu Layout of Integrating SLM (ISM) Settings................................................7-50

Menu Layout of Logging SLM Settings...............................................................7-52

Advanced Menu Layout........................................................................................7-56

Check Menus ........................................................................................................7-59

T.H. Period - (LOG)....................................................................................7-41

Excd Trigger - (LOG)..................................................................................7-41

Excd Time - (LOG) .....................................................................................7-41

Timed Excd Period - (LOG)........................................................................7-41

Daily Enable - (LOG)..................................................................................7-42

Daily Ln’s - (LOG)......................................................................................7-42

Logging SLM Define Report Settings .............................................................7-42

Data Report - (LOG, SSA)............................................................................7-43

Setup Report - (LOG, SSA) ........................................................................7-43

SPL Histogram - (LOG) ..............................................................................7-44

Pk-1 Histogram - (LOG) .............................................................................7-44

Pk-2 Histogram - (LOG) .............................................................................7-44

Intv Report - (LOG, SSA).............................................................................7-44

Hist Report - (LOG, SSA) ............................................................................7-45

Check Menu Example......................................................................................7-60

SLM Check Menu Options (SSA and LOG) ...................................................7-62

Mark Display...............................................................................................7-62

Graph Menu.................................................................................................7-64

Settings........................................................................................................7-65

Controls Settings Menu...............................................................................7-65

Other SSA Check Menus .................................................................................7-65

Any Data Check Menu................................................................................7-65

RTA Check Menu .......................................................................................7-66

Intervals Check Menu .................................................................................7-67

Time History Check Menu..........................................................................7-68

Run Log Check Menu .................................................................................7-69

Ln Centiles Check Menus ...........................................................................7-70

Other Logging (LOG) Check Menus ...............................................................7-73

Any Data Check Menu................................................................................7-73

Current SLM / Overall SLM Check Menu..................................................7-73

Exposure Check Menu ................................................................................7-73

LN Centiles Check Menu............................................................................7-74

Stats Check Menu........................................................................................7-75

iii-viii

Page 13

824 Reference Manual

Run Log Check Menu .................................................................................7-75

Time History Check Menu..........................................................................7-76

Intervals Check Menu .................................................................................7-76

Excd History Check Menu ..........................................................................7-77

Daily History Check Menu .........................................................................7-78

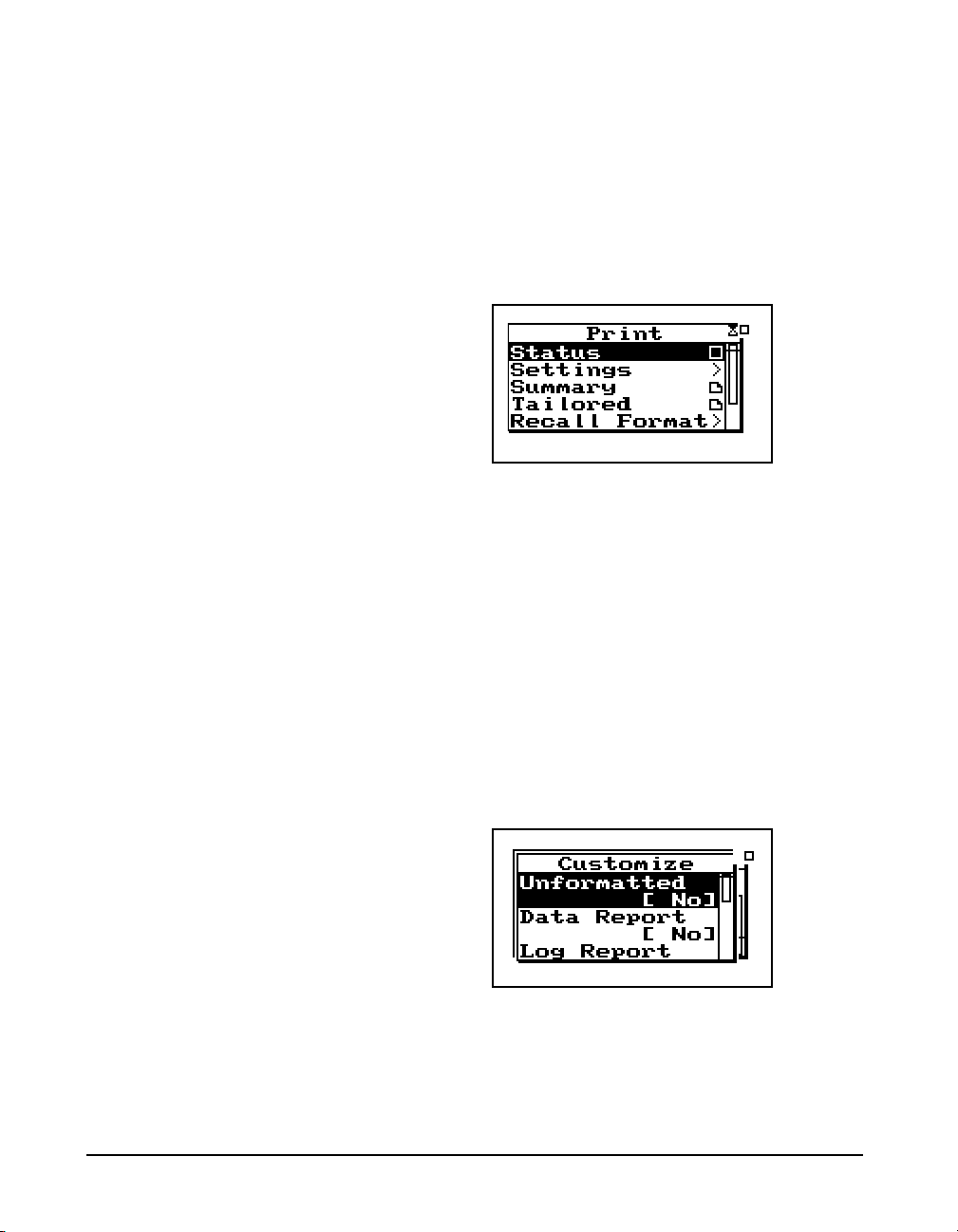

Chapter 8 Printing a Report 8-1

Connecting the 824 to a Serial Printer....................................................................8-1

Printing Reports ......................................................................................................8-2

Defining and Printing Tailored Reports..................................................................8-5

Using the Recall Format (SSA and LOG instruments only)..............................8-7

Default Settings Values for the Recall Format Reports................................8-8

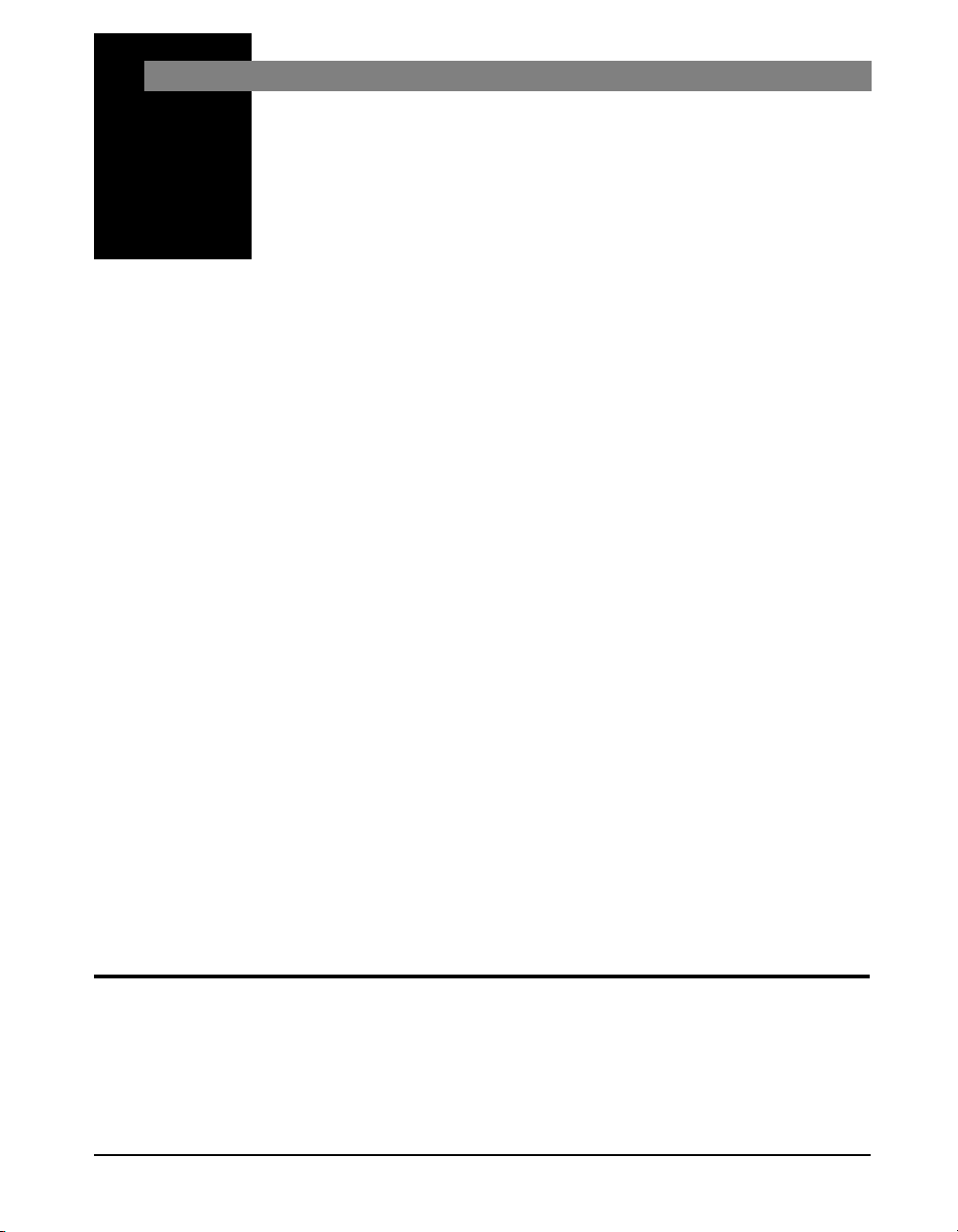

Printing a Custom Report .....................................................................................8-23

Chapter 9 Performing a Sound Level Measurement 9-1

Configuration of the System...................................................................................9-1

Selecting a Measurement Mode..............................................................................9-1

Selecting a Measurement ID..............................................................................9-2

Editing the Microphone Parameters .......................................................................9-3

Calibration ..............................................................................................................9-3

Entering the Noise Floor Values.............................................................................9-4

Editing the Measurement Parameters .....................................................................9-5

Positioning the Meter..............................................................................................9-7

Use of a Windscreen ..........................................................................................9-7

Selecting the SLM Display.....................................................................................9-9

Selecting the Measurement Range..........................................................................9-9

ISM and LOG Modes.........................................................................................9-9

Selecting the Range Setting.........................................................................9-10

SSA Mode........................................................................................................9-10

Performing a Measurement...................................................................................9-11

Averaging Time ...............................................................................................9-12

Linearity Range.....................................................................................................9-13

Overload and Under Range Conditions ................................................................9-14

Overload Condition..........................................................................................9-14

Reset............................................................................................................9-14

Under Range Condition ...................................................................................9-14

Max, Min and Peak Values...................................................................................9-15

Measuring for a Preset Integration Time ..............................................................9-16

Timer Mode......................................................................................................9-16

iii-ix

Page 14

824 Reference Manual

Measuring using User-Selectable Thresholds.......................................................9-17

Chapter 10 Using the 824 Utility Software 10-1

824 Utility Installation ..........................................................................................10-1

Starting the 824 Utility Software..........................................................................10-2

Connecting to Your Computer..............................................................................10-2

824 Utility Tool Bar..............................................................................................10-4

824 Utility Setup Window ....................................................................................10-6

Retrieving setups from the 824 ........................................................................10-7

Modifying and Storing Setups to the 824 ........................................................10-9

Changing System Settings...........................................................................10-9

Manipulating a Setup ................................................................................10-10

Saving Setups to Disk Files ...........................................................................10-12

Opening Setup Disk Files ..............................................................................10-12

Creating a New Setup ....................................................................................10-14

Renaming an Existing Setup..........................................................................10-15

Deleting an Existing Setup.............................................................................10-16

Locking and Unlocking Setups......................................................................10-17

Downloading Measurement Data .......................................................................10-17

Specifying a Destination File.........................................................................10-18

Changing the Download File Name...............................................................10-20

Adding Notes to a download file ...................................................................10-21

Selecting Active Measurements or Data Files ...............................................10-21

Downloading the Measurement .....................................................................10-22

Explanation of files in the 824 Utility Directory ...........................................10-24

Translating Data from a Downloaded Binary File..............................................10-25

Selecting a Data set to view...........................................................................10-27

Printing a Translated File...............................................................................10-29

Viewing a Translated File Within a Spreadsheet Program............................10-31

Additional Features.............................................................................................10-32

Chapter 11 RTA (optional) 11-1

Settings Menu .......................................................................................................11-2

Settings Descriptions ............................................................................................11-6

RTA Settings Menu .........................................................................................11-6

Autostore Settings Menu..................................................................................11-8

Arm Settings Menu ..........................................................................................11-9

Trigger Settings Menu ...................................................................................11-11

End Settings Menu.........................................................................................11-12

iii-x

Page 15

824 Reference Manual

Then Settings Menu .......................................................................................11-14

Trigger Settings Menu (continued)................................................................11-14

RT60 Reverberation Time Settings................................................................11-16

RT60-A and RT60-B Instrument Definition..................................................11-17

Qualifying Background Noise: Rooms [RTA] ID .........................................11-18

Display Views.....................................................................................................11-19

RTA Views ....................................................................................................11-19

Trigger Views ................................................................................................11-23

Autostore Views.............................................................................................11-25

Autostore ByTime Spectral History...............................................................11-29

ByTime Spectrum Check Menu.....................................................................11-30

ByTime Graph Check Menu..........................................................................11-31

RT-60 .............................................................................................................11-33

RT60 Check Menu.........................................................................................11-35

Spatial Avg Views .........................................................................................11-35

Spatial Avg Check Menu ...............................................................................11-37

Avg History Check Menu ..............................................................................11-38

Rooms Views .................................................................................................11-39

Chapter 12 FFT (Optional) 12-1

Features.................................................................................................................12-1

Settings Menu .......................................................................................................12-1

Settings Descriptions ............................................................................................12-3

FFT Display ..........................................................................................................12-6

FFT...................................................................................................................12-6

FFT Check Menu .............................................................................................12-8

THD (Total Harmonic Distortion)........................................................................12-9

THD Check Menu..........................................................................................12-10

Snapshot..............................................................................................................12-11

Snapshot Check Menu ...................................................................................12-12

FFT Calibration...................................................................................................12-13

Calibrating dB to a Different Reference ........................................................12-13

Displaying Amplitude in Linear Units...........................................................12-14

Setup of Linear Units Readout..................................................................12-15

Frequently Asked Questions Concerning FFT...............................................12-17

Chapter 13 AUD (Optional) 13-1

Connecting the Test System .................................................................................13-2

Selecting the 824-AUD Operation Mode .............................................................13-3

iii-xi

Page 16

824 Reference Manual

Microphone Sensitivity Calibration......................................................................13-4

AUD Modes..........................................................................................................13-4

FFT Display ........................................................................................................13-25

View Menu.......................................................................................................13-5

SLM/RTA Submenu ...................................................................................13-5

FFT Submenu..............................................................................................13-5

Pulse/FM Submenu .....................................................................................13-5

Display Sequence.............................................................................................13-6

SLM+RTA Live Display .................................................................................13-6

SLM+RTA Live Check Menu.....................................................................13-7

Any Level -a, -b and -c Displays .....................................................................13-8

Any Level Check Menu ..............................................................................13-9

Linearity RTA Display...................................................................................13-10

Manual Lock .............................................................................................13-12

Automatic Lock.........................................................................................13-12

Linearity RTA Check Menu......................................................................13-13

Linearity FFT Display....................................................................................13-14

Manual Lock .............................................................................................13-16

Automatic Lock.........................................................................................13-16

Linearity FFT Check Menu.......................................................................13-17

Flatness FFT Display .....................................................................................13-18

THD Display..................................................................................................13-19

THD Check Menu .....................................................................................13-21

Pulse/FM Display...........................................................................................13-21

Pulse/FM-a Display...................................................................................13-22

Pulse/FM-b Display...................................................................................13-24

Pulse/FM Check Menu..............................................................................13-24

FFT Check Menu ......................................................................................13-25

Appendix A Serial Port Interface Remote Control A-1

Interface Cables .....................................................................................................A-2

Connection to a computer using CBL006....................................................A-3

‘Daisy Chain Addressing.......................................................................................A-5

824 Network, Addressing Commands ..............................................................A-6

Commands .............................................................................................................A-8

Remote Control Commands (Detailed) .................................................................A-9

Mode Commands ..............................................................................................A-9

“Read” Commands (Reads out data variables)...............................................A-10

“ANY DATA” READ COMMANDS............................................................A-25

iii-xii

Page 17

824 Reference Manual

Other Read Commands ...................................................................................A-28

Group Read Programming ..............................................................................A-29

Setting Commands...............................................................................................A-30

Querying Settings............................................................................................A-31

Ln Query Commands (SSA)...........................................................................A-33

Entering Settings.............................................................................................A-33

Option Settings...........................................................................................A-33

Numeric Settings........................................................................................A-35

Character String Settings............................................................................A-35

Template Settings.......................................................................................A-36

Setting List...........................................................................................................A-37

Histogram Reports ..........................................................................................A-44

Tailored Report ..........................................................................................A-45

Miscellaneous.............................................................................................A-45

Error Checking I/O..........................................................................................A-48

RTA Settings Commands................................................................................A-51

History Records...............................................................................................A-54

Types of History.........................................................................................A-55

Advance......................................................................................................A-55

Backup........................................................................................................A-56

Find.............................................................................................................A-56

History Data Variables.........................................................................................A-57

Exceedance History Variables ........................................................................A-57

Interval History Variables (“I” Commands) ...................................................A-59

Daily History Variables - (D1-D102) ............................................................A-64

Run Log Variables (SSA, ISM, LOG, TAL) ..................................................A-65

Calibration History Variables (LOG) .............................................................A-66

Time History Variables (SSA, LOG, TAL)....................................................A-67

Time History Variables (SSA, LOG, TAL)....................................................A-68

Histogram Table Variables .............................................................................A-68

Print Command....................................................................................................A-69

Error Messages and Warnings .............................................................................A-71

Modem Control Mode (All Instruments).............................................................A-74

Modem Mode..................................................................................................A-74

Dial Out Mode ................................................................................................A-74

Monitor Number .............................................................................................A-75

824 Phone Dialing Procedure .........................................................................A-75

Model 824 Answering Procedure ...................................................................A-76

iii-xiii

Page 18

824 Reference Manual

Unsupported Miscellaneous Commands .............................................................A-78

Data File Commands ...........................................................................................A-79

Keyboard Simulation ...........................................................................................A-80

Operation Notes ...................................................................................................A-81

Appendix B Integrated Level Calculations B-1

Appendix C Technical Specifications C-1

Declaration of Conformity................................................................................ C-2

1/1 and 1/3 Octave Filters ...............................................................................C-20

Frequency Range........................................................................................ C-20

Filter Shapes:..............................................................................................C-20

Frequency Response .......................................................................................C-24

Power/Current Draw of 824 Using External Power........................................ C-49

Appendix D Glossary D-1

Allowed Exposure Time (Ti) .......................................................................D-1

Average Sound Level (Lavg) .......................................................................D-2

Community Noise Equivalent Level (CNEL, Lden)....................................D-2

Criterion Duration (Tc) ................................................................................D-3

Criterion Sound Exposure (CSE) .................................................................D-3

Criterion Sound Level (Lc) ..........................................................................D-3

Daily Personal Noise Exposure (LEP,d)......................................................D-3

Day-Night Average Sound Level (DNL, Ldn).............................................D-3

Decibel (dB) .................................................................................................D-4

Department of Defense Level (LDOD)........................................................D-8

Dose..............................................................................................................D-8

Detector ........................................................................................................D-8

Eight Hour Time-Weighted Average Sound Level (L TWA(8)).................D-8

Energy Equivalent Sound Level (Leq).........................................................D-8

Exchange Rate (Q), Exchange Rate Factor (q), Exposure Factor (k) ..........D-8

Far Field .......................................................................................................D-9

Free Field......................................................................................................D-9

Frequency (Hz, rad/sec) ...............................................................................D-9

Frequency Band Pass Filter........................................................................D-10

Frequency Filter - Weighted ......................................................................D-10

Leq.............................................................................................................. D-12

Level (dB) ..................................................................................................D-12

Measurement Duration (T).........................................................................D-12

iii-xiv

Page 19

824 Reference Manual

Microphone Guidelines..............................................................................D-12

Near Field...................................................................................................D-15

Noise...........................................................................................................D-15

Noise Dose (D)...........................................................................................D-16

Noise Exposure ..........................................................................................D-17

OSHA Level (LOSHA)..............................................................................D-17

Preamplifier................................................................................................D-17

Projected Noise Dose .................................................................................D-17

Single Event Noise Exposure Level (SENEL, LAX) ................................D-17

Sound..........................................................................................................D-17

Sound Exposure (SE) .................................................................................D-18

Sound Exposure Level (SEL, LET) ...........................................................D-18

Sound Pressure ...........................................................................................D-19

Sound Pressure Level (SPL, Lp)................................................................D-20

Sound Power(W)........................................................................................D-21

Sound Power Level (PWL, Lw).................................................................D-21

Sound Speed, (c,) .......................................................................................D-22

Spectrum (Frequency Spectrum)................................................................D-22

Threshold Sound Level (Lt) .......................................................................D-22

Time Weighted Average Sound Level (TWA, LTWA(TC)).....................D-22

Time Weighting..........................................................................................D-23

Vibration..................................................................................................... D-23

Wavelength (l)............................................................................................D-23

Wavenumber (k).........................................................................................D-23

Appendix E Memory Usage E-1

LOG Memory Usage .............................................................................................E-1

Exceedance Records (Exceedance History Enabled)] ...................................... E-1

Interval Records (Intv History Enabled)...........................................................E-2

Daily Records (Daily History Enabled) ............................................................ E-2

Time History Records (Time History Enabled)................................................ E-2

Other Histories and Memory Usage.................................................................. E-2

Estimating Memory Usage: .............................................................................. E-3

824-LOG Memory Usage Worksheet...............................................................E-5

824-SSA Memory Usage ....................................................................................... E-7

Interval Records (Intv History Enabled)...........................................................E-7

Time History Records (Time History Enabled)................................................ E-8

Appendix F SLM Testing to IEC61672-1 F-1

iii-xv

Page 20

824 Reference Manual

Reference Sound Pressure Level:................................................................. F-1

Reference Level Range: ............................................................................... F-1

Microphone Reference Point:....................................................................... F-1

Average Frequency Response Corrections .................................................. F-2

Periodic Testing of A-Weighted Sound Levels............................................ F-4

A-Weighted Sound Levels at Upper and Lower Limits of the Linear Operating

Range............................................................................................................ F-5

Electrical Signal Input Device..................................................................... :F-5

Inherent Noise: ............................................................................................. F-5

Maximum Sound Pressure Level: ................................................................ F-6

Power Supply Voltage Range: ..................................................................... F-6

Display Device ............................................................................................. F-6

Stabilization Time Following Changes of Environmental Conditions: ....... F-6

Electric Field Strength Above 10 V/m:........................................................ F-6

Greatest Radio Frequency Emission Levels: ............................................... F-6

Effect of Electrostatic Discharges................................................................ F-7

Greatest Susceptibility to AC Power and Radio Frequency Fields:............. F-7

...................................................................................................................... F-7

Appendix G Miscellaneous Information G-1

iii-xvi

Page 21

CHAPTER

Introduction

1

About This Manual

Welcome to the Larson Davis LxT. This versatile

instrument, with graphic display, performs the functions of

several instruments. It puts the combined features of a

precision sound level meter and a real-time frequency

analyzer in the palm of your hand.

This manual has 12 chapters and 5 appendices covering the

following topics:

Chapters

• Chapter 1 - Introduction: Orients the user to the

contents of this user manual and the System 824’s

features, functions and measurement capabilities. It also

includes instructions on unpacking the System 824.

• Chapter 2 - Overview: Provides an overview of the

instrument’s capabilities and a description of each key

along with its function and displays. It also includes

instructions on working with menus.

• Chapter 3 - Front Panel Keys; their Functions and

Associated Menus: Explains the functions associated

with each key on the 824.

• Chapter 4 - Quick Start: Guides users in the immediate

use of the System 824 including how to take

measurements, understanding the readings, and storing

data in the System 824.

9/29/09 Introduction 1-1

Page 22

• Chapter 5 - System 824 Instrument Modes: Provides

descriptions of the System 824’s standard instrument

ID’s.

• Chapter 6 - System 824 Views: Gives you a detailed

description of the different display views available and

how to access them.

• Chapter 7- Using ID Setting Files: Describes how to

recall, customize and save IDs.

• Chapter 8 - Printing a Report: Describes how to print

a report of the data collected with the System 824.

• Chapter 9 - Performing a Sound Level

Measurement: Walks the user through the steps

necessary to obtain a sound level measurement whose

accuracy will be optimal for the measurement

conditions.

• Chapter 10 - Using the 824 Utility Software:

Describes how to connect the 824 to a computer, in order

to download, translate and export data.

• Chapter 11 - RTA (Optional): Explains how the RTA

high speed data gathering option enables you to perform

architectural acoustics, impulse event analysis, and

passby event analysis.

• Chapter 12 - FFT (Optional): Describes the features

and functions of the fast fourier analysis option.

• Chapter 13 - AUD (Optional): Explains how the AUD

option can be used to manually test an audiometer by

measuring level, frequency, linearity, THD, pulse,

crosstalk, frequency modulation, narrow band, broad

band, and speech noise.

Appendices

• Appendix A - Integrated Level Calculations: Provides

information on TWA Leq, SEL, dose and projected dose

calculations.

1-2 824 Reference Manual 9/29/09

Page 23

• Appendix B - Serial Port Remote Control Interface:

Explains how to use the Serial Port Interface for Remote

Control of the System 824.

• Appendix C - Technical Specifications: Gives a listing

of acoustic, electronic, environmental, and physical

characteristics of the System 824

• Appendix D - Glossary: Contains Technical Definitions

of key acoustical and vibration terms.

• Appendix E - Memory Usage: Provides details on the

allocation of memory when data are stored. This

information is particularly important for applications

such as noise monitoring where measurements are

performed and stored automatically over a period of days

or weeks.

• Appendix F - SLM Testing to IEC61672-1: Presents

information for testing the sound level meter function of

the System 824 according to IEC61672-1.

• Appendix G - Miscellaneous Information: Contains

additional information about the 824 in the form of

questions and answers

Special Features of the Electronic Version

There are a variety of special techniques for navigating

through pdf documents which can greatly simplify finding

specific items in this manual. Two of these, bookmarks and

links, are discussed below.

Bookmarks

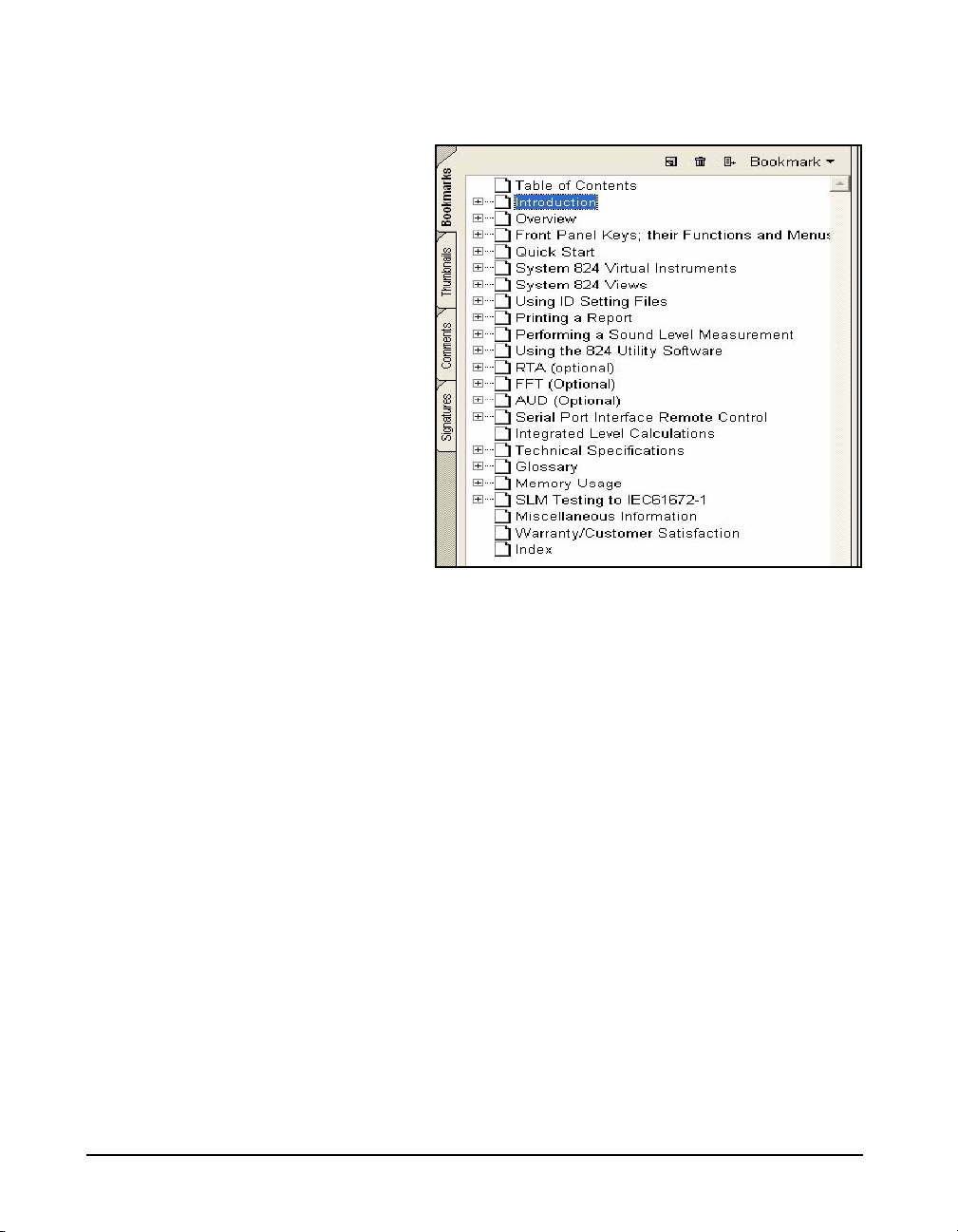

Opening Bookmarks

Bookmarks are clickable navigation tools in pdf files. To

open bookmark, left click the upper Tab on the left of the

9/29/09 Introduction 1-3

Page 24

screen labeled Bookmarks. These will appear as shown

below.

In the unexpanded view, bookmarks lists the names and page

numbers of chapters and appendixes in order of appearance,

as well as the Table of Contents and the Index.

Closing Bookmarks

To close bookmarks, simply left click the tab once more.

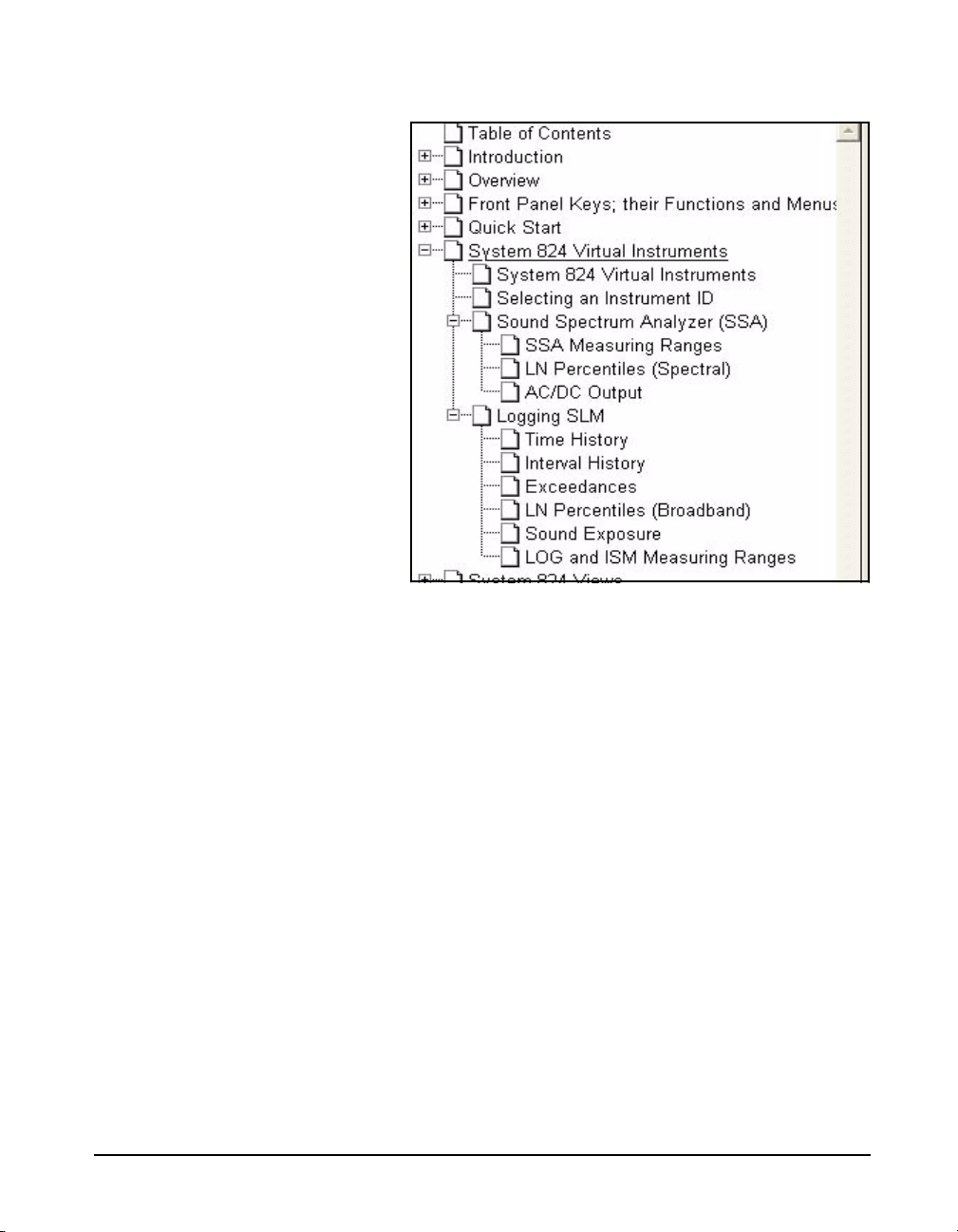

Expanding Bookmarks

For any entry, if there is a + within the rectangle to the left,

there are sub entries which can be displayed upon expanding

the tree by clicking the rectangle. For example, clicking the

+ to the left of any chapter will expand it into major

headings and, by clicking all the + symbols, the complete

tree for that chapter will be shown. In the following figure

we can see the entry System 824 Virtual Instruments

completely expanded.

1-4 824 Reference Manual 9/29/09

Page 25

Click to Display Page

Return to Previous View

Links

Click to Display Page

Left click on any text field (Chapter name, Appendix name,

Table of Contents, Index, or any sub heading) and the page

displayed on the right will jump to the page associated with

that text field.

To return to the page which was displayed previous to

clicking on a bookmark text line, right click on the display

page, then left click on “Go to Previous View”.

The Table of Contents and the Index have a page number

associated with each item. For the Table of Contents, left

click on the text line and that page will be displayed. For the

Index, left click on the page number itself to display the

page associated with that entry. To return to the previous

display, follow the procedure described in "Return to

9/29/09 Introduction 1-5

Page 26

About This Chapter

Press the v key

Detector [Slow]

Formatting

Previous View" on page 1-5

This introductory chapter covers the following topics:

• Formatting Conventions: Provides an explanation of

the fonts and other formatting conventions used in this

manual.

• Features: Gives an overview of the System 824 keypad,

functions and measurement capabilities.

• Getting Started: Provides instructions for unpacking,

inspecting and initially assembling the System 824.

This manual uses the following format conventions:

In step-by-step directions, the process (what you do) is

shown in the right column, and the rationale (why you do it)

with other cautions and comments are shown in the left

column.

1-6 824 Reference Manual 9/29/09

Keys to press on the LxT are shown with the icon

representing the appropriate key. For example:

Items that appear in various on-screen menus (such as

settings) are shown in bold and italicized style. For example:

Page 27

Features

Hardware Features:

The Larson Davis System 824 has the following features:

• Large backlit bitmapped graphic display

• Soft rubber backlit keys

• Pop-up menus with scroll bars

• Pick and choose setup...just click and run!

• File management system (stores multiple measurements)

• Multiple Instruments

SSA: Sound Spectrum Analyzer combining a

sound level meter and real-time spectrum analyzer

(optional)

LOG: Logging SLM (optional)

ISM: Integrating SLM (standard)

RTA: Adds high speed spectral data gathering

(optional)

FFT: Adds Fast Fourier Analysis to the 824

(optional)

AUD: Gives the 824 the ability to certify

audiometers; used in conjunction with the AUDit

software (optional)

TAL: Measures tonality according to DIN 45681

and appraisal of low frequencies according to DIN

45680 (optional)

• Type 1 precision integrating sound level meter: satisfies

IEC61672-1 (tested with 377B41 microphone only), IEC

60651-1993, IEC 60804-1993, and ANSI S1.4 1985)

9/29/09 Introduction 1-7

Page 28

• Simultaneous measurement of sound pressure level using

Fast, Slow, Impulse, Peak, and Leq detectors with A, C,

and Flat weighting (SSA, ISM, LOG, and TAL

instruments)

• Exceptionally large dynamic range (> 93 dB for SSA and

> 115 dB for ISM and LOG)

• Digital filters with real-time rate to 20 kHz satisfying

IEC 1260-1995 Class 1 and ANSI S1.11-1986 Type 1-D

meeting linearity specifications over a range of 85dB:

- 1/1 octave, 16 Hz to 16 kHz (11 filters)

- 1/3 octave, 12.5 Hz to 20 kHz (33 filters)

• Automatic logging of sound level parameters including

Interval data, L

statistics, noise event detection using

n

exceedance history and exceedance time history (LOG

only)

The windspeed (tacho) and wind

direction (throttle position) feature

requires the firmware option 824WND, not included with standard

System 824 configurations.

• Measurement of windspeed (tacho) and wind direction

(throttle position) using external weather transducers

with inclusion of data in Views and Data Displays for

SSA and LOG instruments.

• Real-time 1/3 octave spectrum analysis with rapid

spectrum vs. time autostorage and triggering for sound

decay measurement (RTA)

• Simultaneous operation of sound level meter with

independent frequency and 1/3 octave analyzer function

weighting (SSA)

• Advanced time history feature allows you to store up to

38 different parameters including spectral data with each

time history sample

• Narrow band real-time frequency analysis with 400-line

FFT and Hanning, Flat-Top or Rectangular window (FFT

Mode)

• Standard memory (2 MB) sufficient to store one of the

following:

- 30,000 point 1/3 octave SSA Leq time history

- 20,000 intervals with 1/3 octave Leq spectrum

1-8 824 Reference Manual 9/29/09

Page 29

- 12,300 SSA intervals with Leq & Max 1/3

octave spectra

- 60,000 LOG intervals without Ln

- 35,000 LOG intervals with Ln

- 1,000,000 point time history

- 70,000 RTA 1/1 octave spectra

- 28,000 RTA 1/3 octave spectra

- 2400 FFT 400 line snapshots

• AC/DC output, unweighted, with gain to 50 dB and

attenuation to -20 dB

• Flash memory for in-field firmware upgrades

• Multi-tasking processor: provides simultaneous

measuring, viewing, transferring and printing of data

• RS-422 (RS-232 compatible) interface:

Serial bit rate to 115 kbps

• Direct report printouts

•Windows

TM

-based software included for setup, control,

and high speed data downloading and translation to

ASCII format

9/29/09 Introduction 1-9

Page 30

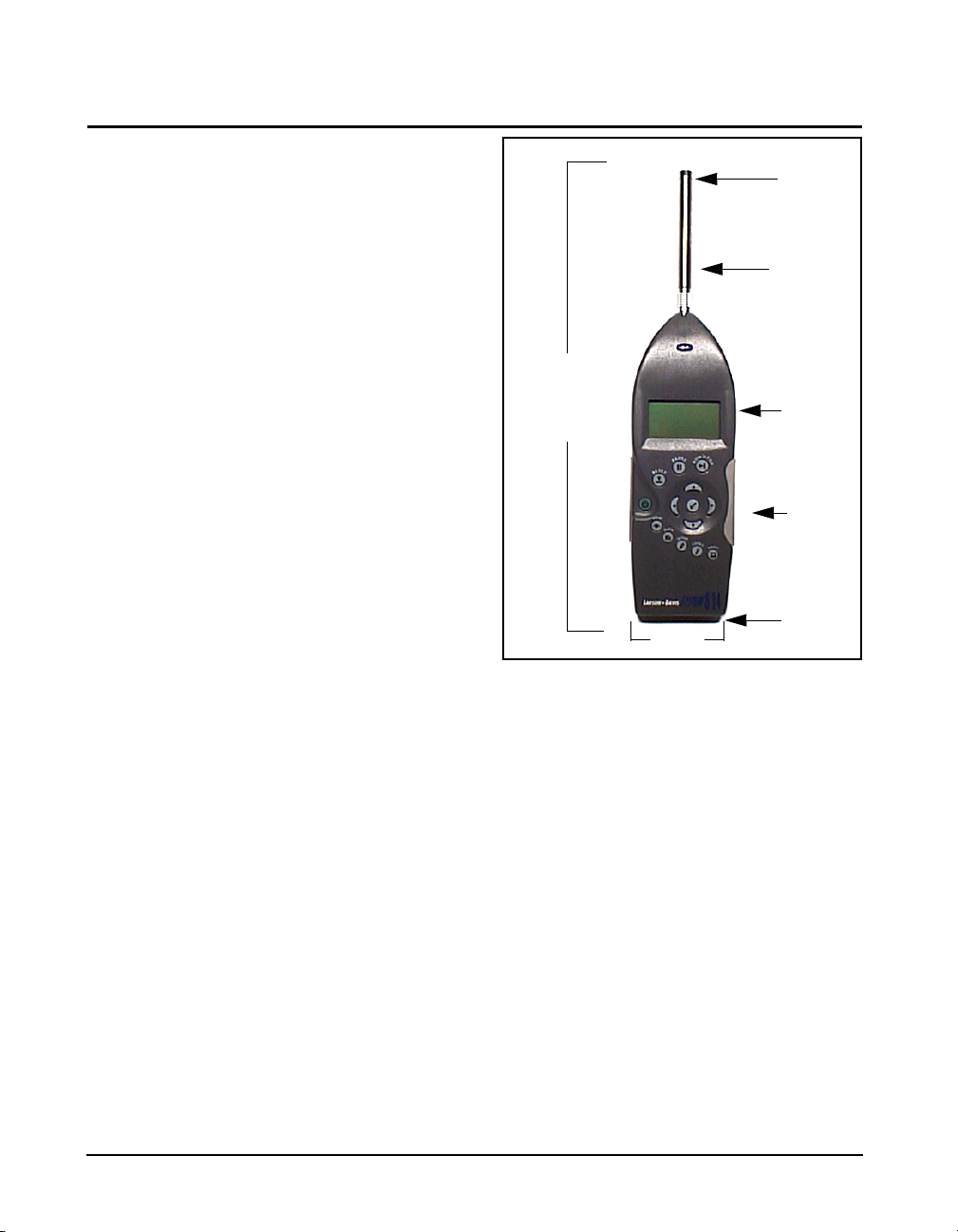

System 824 Components

Condenser

LCD Display

Keypad

Connectors

Microphone

38 cm

(15”)

9 cm

(3.5”)

Preamplifier

Figure 1-1 The System 824 is a convenient hand-held sound

level meter with a simple user interface.

The standard System 824 shown in Figure 1-1 includes the

following:

• 1/2” diameter condenser microphone

• Backlit graphic 64 x 128 pixel LCD display

• 14-key soft rubber backlit keypad

• AC/DC output, control, serial, and external power

connectors (shown in figure Figure 1-2)

• True “hand held” instrument with “sure grip” pads

1-10 824 Reference Manual 9/29/09

Page 31

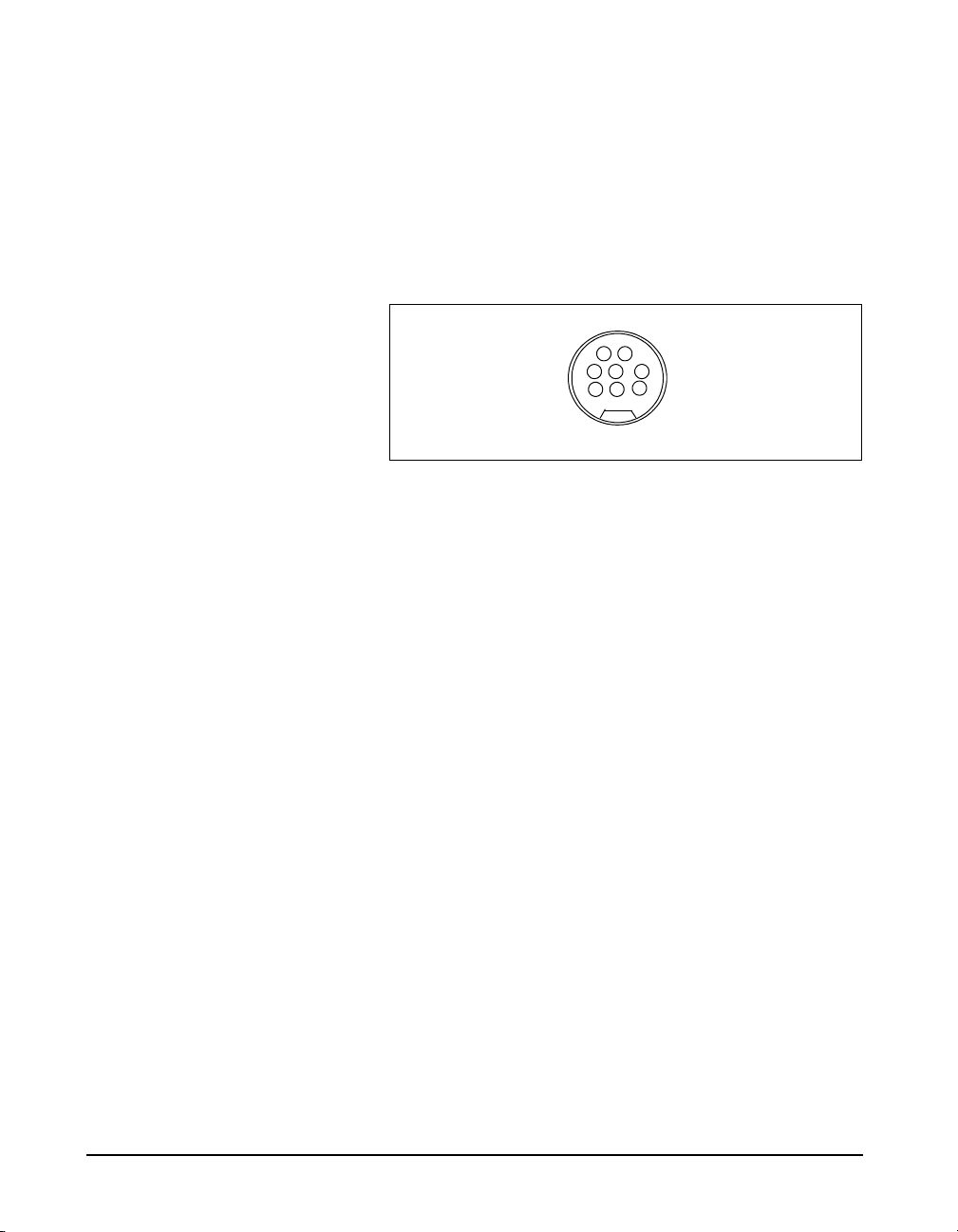

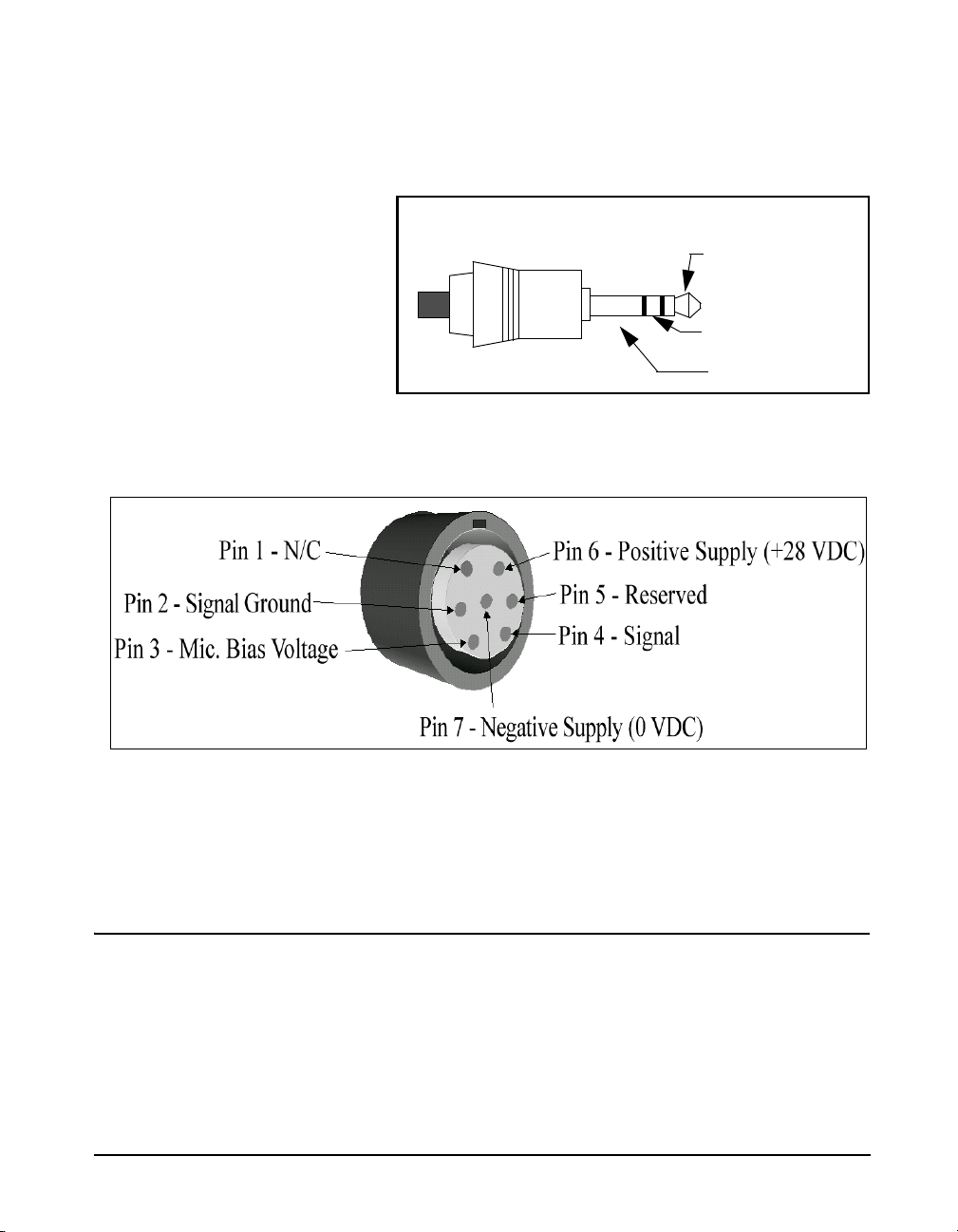

Figure 1-2 The System 824 has a series of connectors located at

Control Connector

AC/DC Output Connector

External DC Power Connector

Serial Interface Connector

12

3