A

B

C

A

C

A

A

B

B

H

INGE SIDE

Z

-BAR

TOP Z-BAR OR DRIP CAP

E

XPANDER AND

V

INYL SWEEP

L

ATCH SIDE

Z-BAR

P

INCH

PINCH

PINCH

PINCH

PINCH

PINCH

CAUTION

INSTALLATION

QUESTIONS?

MISSING PARTS?

PLEASE CALL

1-888-483-3768

OR VISIT

www.larsondoors.com

202220566

EASYVENT LM 10/04

™

EasyVent

Storm/Screen Doors

INSTALLATION INSTRUCTIONS

Congratulations on your new storm door. Your satisfaction is Larson’s number one priority. If you need

assistance or parts, please call the Lar

READ BEFORE BEGINNING INSTALLATION

• Read installation instructions thoroughly.

• Use two people when lifting and installing the door.

• Children should not be allowed to play with the door.

• Homeowners should be aware of pinch points.

• Failure to install door properly could result in an injury.

• Do not operate the storm door without closer(s) installed

and adjusted to prevent door slamming.

• Eye protection must be used during the installation to

prevent injury from flying particles.

• Do not modify or alter the installation and specified use

of the door.

• After installation, clean door with mild soap and water to

remove any oil or dirt residue.

• Larson Manufacturing is not responsible for accidents

and injury resulting from the use or installation of this

product.

son hotline or visit our website.

TOOLS NEEDED:

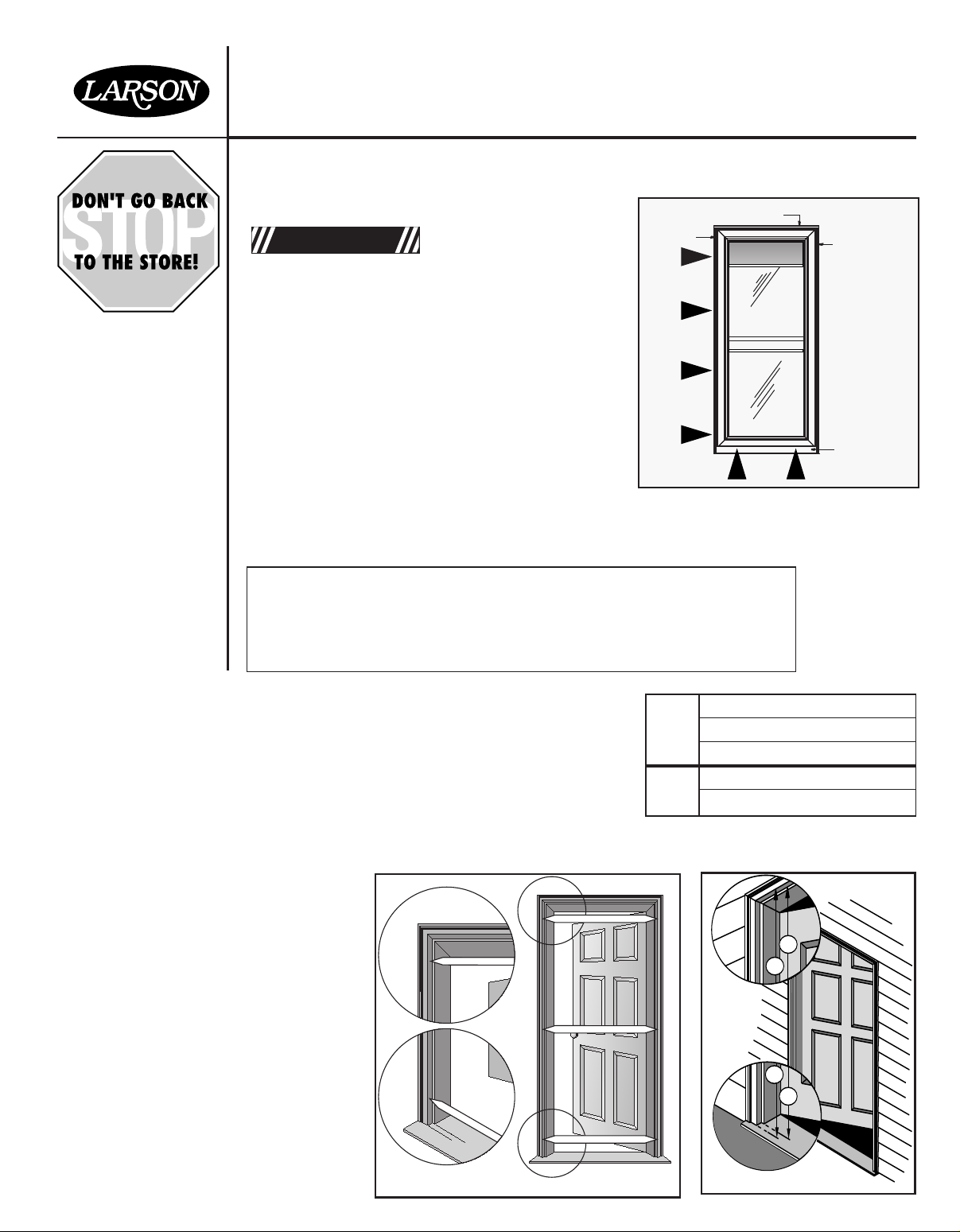

STEP 1

Record Opening

Measurements

Power drill with assorted bits

Phillips head screwdriver

Regular screwdriver

Hacksaw

Caulking gun with caulking

Tape measure

Hammer

Pencil

Pliers

Before starting, measure the opening width and height and

record measurements. Verify minimum and maximum width

allowance shown on box label to ensure you have purchased

the correct size storm door.

NOTE: Measure height from the top of the door opening

(underside of the trim board) down to the bottom threshold.

o measurements as sho

e tw

ak

T

wn in Figure 2 to determine

the threshold angle. You will need this information as you

install the hinge z-bar.

Saw horses

Small wood chisel

1

2

Width A

Width B

Width C

Height A

Height B

FIGURE

FIGURE

FIGURE 1

FIGURE 2

L

EFT HAND HINGE

RIGHT HAND HINGE

#8H/10B x 1/2" Flathead U.C.

TOP OF DOOR

INSIDE FACE OF DOOR UP

INSTALLED

POSITION

ROTATE

START

SCREWDRIVER

WITH

LONG SHAFT

INSIDE LIP

HINGE LEAF

TURNED UP

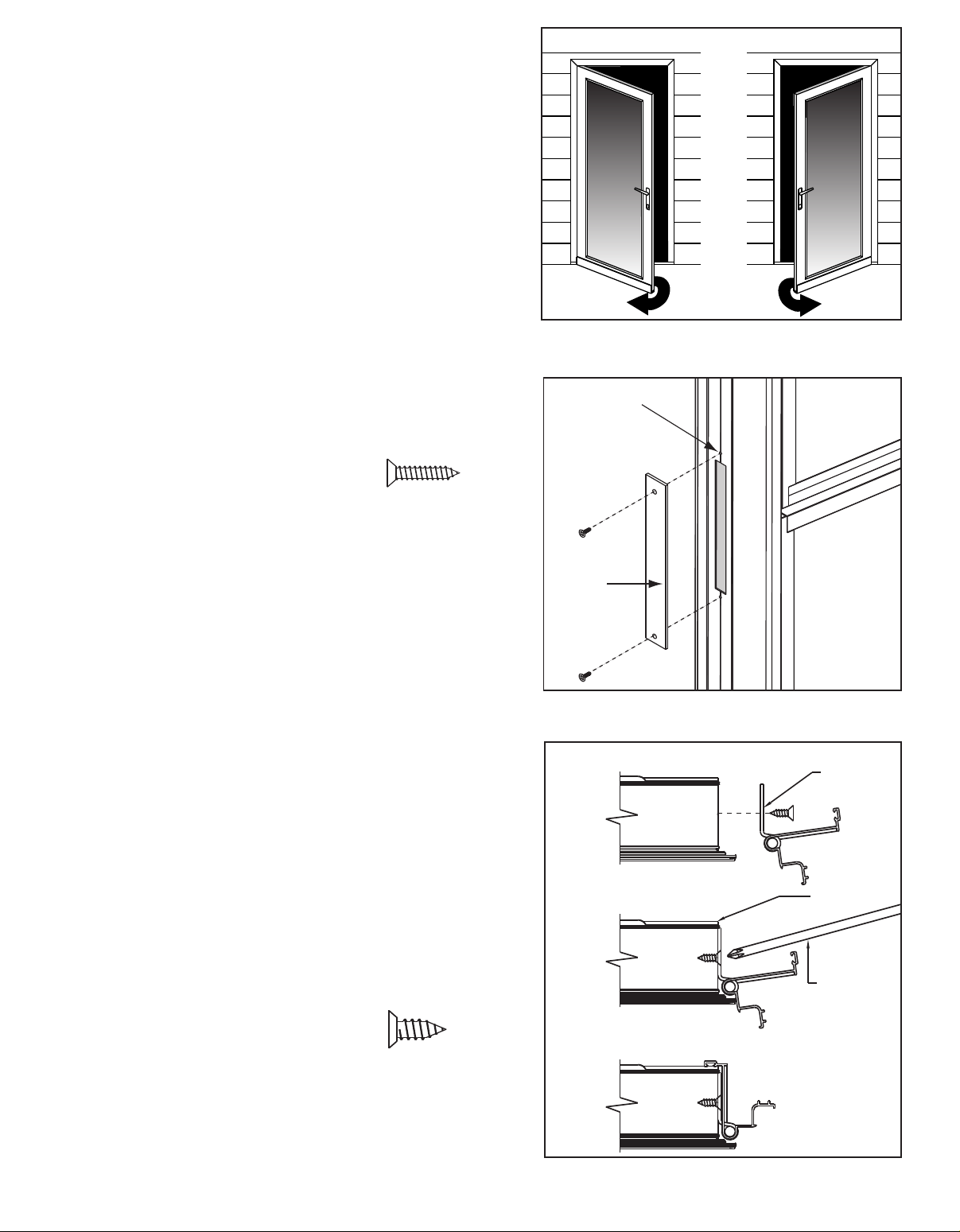

STEP 2

MORTISE

HOLE

COVER

3/32" PILOT HOLE @2

#6 x 5/8" FLATHEAD SCREW

Determine Left

or Right Hinge

Side

STEP 2a

Install Mor

Hole Cover

tise

Your Larson storm door is REVERSA-HINGE

meaning that the door is designed for either right

hand or left hand hinge installation. Looking at your

door opening from the outside, determine which

side you want the hinge attached. The hinge can be

mounted to either side of the door (Figure 3).

IMPORTANT NOTICE: If you choose to have the

storm door handle on the same side as your

prime door hardware, you MUST verify that

there will be NO interference between the two

handles or hardware.

Your storm door handle will be 39" down from the

top of the opening. If the prime door hardware is at

this height, it is likely to interfere with the storm door

hardware. If this is the case, we recommend you

hinge your storm door opposite your prime door.

FIGURE 3

Install Mortise Hole Cover to the hinge-side of your

door frame (Figure 4) using #6 x 5/8" flathead

screws. The opposite side will be left open for

handle installation in Step 12.

Install Hinge

STEP 3

on Door

The hinged z-bar assembly identified in Figure 6 is

packaged unattached. It can be mounted to either

side of the door.

Lay door flat on saw horses with outside face down.

Place the hinge z-bar assembly on the edge of the

door as shown with each hinge leaf turned up

(Figure 5). Check to see that the aluminum z-bar is

orientated as shown in figure 6 (next page), taking

into consideration if you want left or right hinging.

IMPORTANT: Move hinge z-bar assembly until

the top of the z-bar hangs over the top edge of

the door 1/4"

(Figure 7). Align the edge of the top

hinge against the lip on the inside edge of the door

(Figure 5). Mark hole and drill a 1/8" pilot hole.

Fasten with one screw using a #8h/10b x 1/2" flat

head screw.

with a long shaft due to the difficult angle of the

z-bar or door will not operate properly

Note: You must use a screwdriver

.

Repeat this procedure for the remaining hinges

making sure edge of hinge is lined up against the

inside lip (Figure 5). Drill pilot holes for remaining

holes and insert the screws.

NOTE: Hinged z-bar must swing freely (no

binding) after securing hinges to the door

.

FIGURE 4

2 EASY VENT 202220566

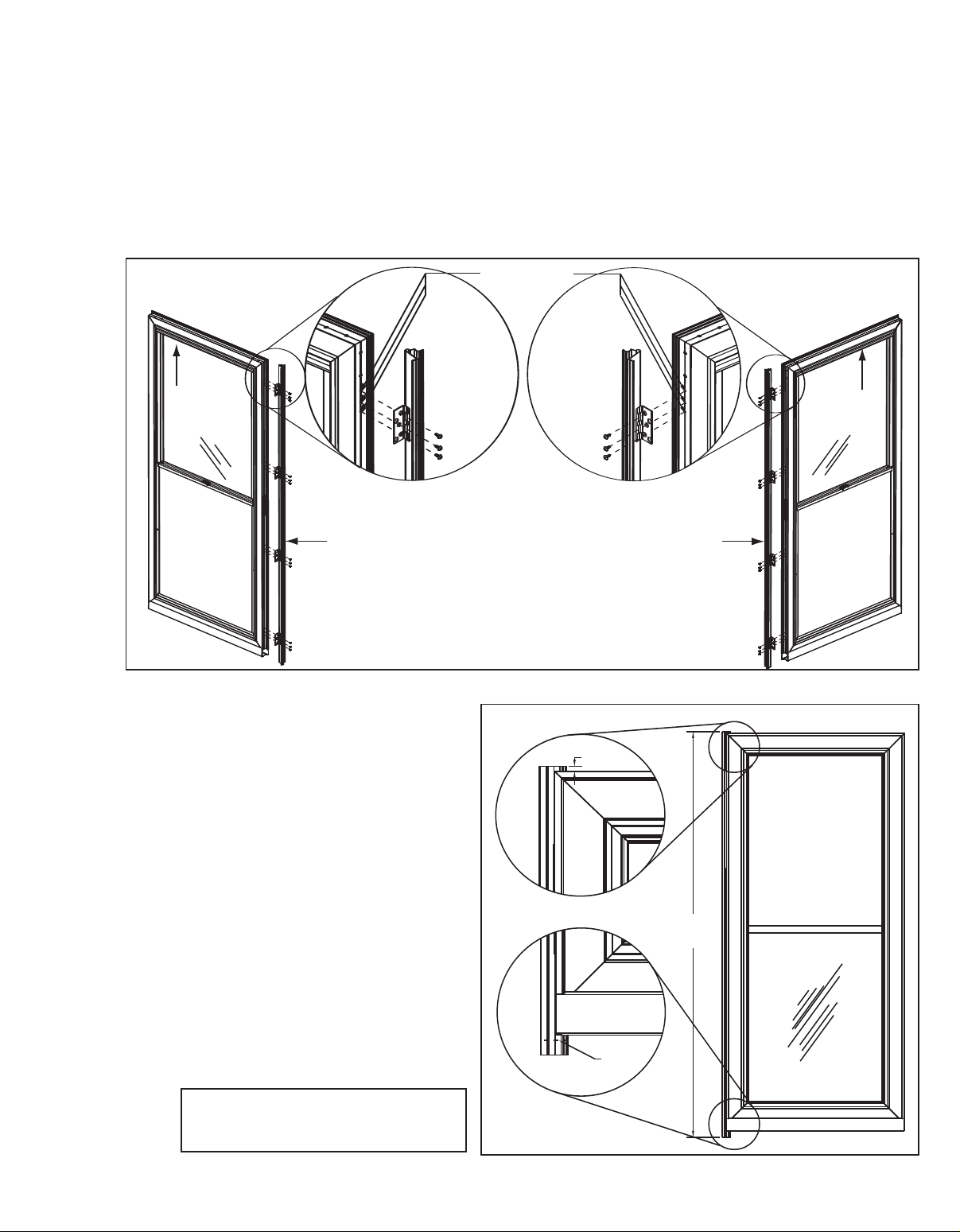

FIGURE 5

INSIDE FACE

RIGHT HINGE INSTALLATION

1/8" PILOT HOLES

REQUIRED

HINGED

Z-BAR

Make sure cassette that houses screen

is at the top of door

SCREEN

CASSETTE

TOP OF DOOR

LEFT HINGE INST

ALLATION

HINGED

Z-BAR

SCREEN

CASSETTE

INSIDE FACE

INSIDE

OF

DOOR

SHOWN

INSIDE

OF

DOOR

SHOWN

CUT

LINE

OPENING

HEIGHT

1/4"

OVERHANG

FRONT

OF

DOOR

STEP 4

Cut Hinge-Side

Z-bar to Length

The top of the Z-bar should be installed at the correct

position—a minimum of 1/4" above the door

. The bottom of

the Z-bar must be cut to the correct length (opening height),

taking into account the angle of the threshold. Refer to Figure

2.

• Using the measurements taken in Step 1, determine the

angle to cut the Z-bar. Transfer this measurement to the Zbar. Do NOT cut on the mark.

• Make the cut 1/16" less than your measurement to allow

room for the top drip cap. Save the z-bar cut-of

f scrap for

securing door to opening (step 6).

HINT: Measure twice.

Cut once!

FIGURE 6

FIGURE 7

202220566 EASY VENT 3

#8 x 1" FLATHEAD SCREW

#8 x 1" PANHEAD SCREW

R

UBBER SWEEP

OUTER FACE OF DOOR

CRIMP INNER LEG

EXPANDER

INSTALLED POSITION

WOOD

SPACER

SPACER MAY BE

REQUIRED IF DISTANCE

IS GREATER THAN 1/4"

1/8" IS IDEAL

SCRAP Z-BAR

INSERT STILES

STORM DOOR

MASTERFRAME STILE

BRICKMOLD

TOP VIEW:

HORIZONTAL SECTION

APPROX. ALIGNED

STEP 5

#8 x 1" PANHEAD SCREW

Install Expander

Sweep

STEP 6

Secure Door to

Opening

To install sweep, thread the sweep into the channel of the

expander (Figure 8). With the sweep installed, crimp both

ends of the expander channel with pliers.

NOTE: For best

results crimp the inner leg of the channel – only at both

ends of the expander

. You must bend the rubber sweep

out of the way while crimping. Install expander on door.

Do NOT fasten at this point. Adjust and fasten the expander

after the door is completely installed (Step 11).

• Place the door in the opening with the hinge-side Z-bar

tight against the door brickmold. Install just two of the

painted #8x1" pan head screws on the front of the hingeside Z-bar. Install one screw next to the top hinge and one

next to the bottom hinge. Be sure not to over tighten the

screws and crush down the Z-bar.

• To ensure proper clearance, set the cut-off scrap piece of

Z-bar in place between the door and up against the wood

trim on the latch side of the door (Figure 10).

• From the outside of the house with the door closed, check

the distance between the side of your Larson storm door

and the scrap Z-bar. If this distance is greater than 1/4",

a wood spacer can be placed between the hinge or latchside Z-bar and the wood jamb (Figure 9).

FIGURE 8

STEP 7

Secure

Hinge-Side

Z-Bar

• If a wood spacer is needed, remove the door, add the

spacer and reinstall. Spacer thickness should NOT

exceed 1/4" and longer screws should be used to properly

secure the door to the jamb. (A wood spacer can also be

used on the latch side Z-bar.)

NOTE: Wood spacers and

longer screws are not included.

FIGURE 9

ith the door properly fit in the opening, open the door to

W

•

expose the hinges. You will see two (2) pre-punched

holes at each hinge plate.

• Using eight (8) #8x1"

hinge plate to the wood jamb. Screw heads must be

flush with the hinge surface.

• Install the remaining #8x1" painted

the outside of the hinge-side Z-bar

FLAT head screws, attach each

PAN head screws in

.

FIGURE 10

4 EASY VENT 202220566

TOP Z-BAR (DRIP CAP)

INSTALLED POSITION

HINGE

Z-BAR

SHOWN

HINGE Z-BAR

VINYL SCREW COVER

LATCH

Z-BAR

SCREW

COVER

O

PENING HEIGHT

(

UNDERSIDE OF

D

RIP CAP TO

TOP OF SILL)

TOP OF DOOR CUT AWAY VIEW

TOP OF FRAMED OPENING

DOOR WILL NOT OPEN IF

THIS IS LESS THAN 1/4"

M

ASTERFRAME

H

EAD

D

RIP CAP

C

AULK

STEP 8

Install the

Drip Cap

The drip cap goes above the door and z-bars. Place the

top drip cap into position as shown in Figure 11. Close the

door. The drip cap and z-bar should nest together for a

good fit. Make sure door closes freely without hitting the

dripcap, but also makes good contact with the

weatherstripping.

pan head screws provided.

OF DRIPCAP

Attach the drip cap with #8x1" painted

CAULK ALONG TOP EDGE

.

STEP 9

Latch-Side

STEP 10

Install Screw

Cap Covers

Install

Z-Bar

Determine Top:

First, determine which end of the Zbar is the top and mark it with a

piece of tape.

Bottom Cut:

Cut the Z-bar to length, using the

same procedure used to cut the

hinge side Z-bar in Step 4. Allow

1/16" for top drip cap (Figure 12).

Installation: Set the Z-bar in place

between the door and the wood

jamb. Allow a 1/8"-3/16" gap

between the door and the latch-side

Z-bar. Make sure the door closes

freely without hitting the Z-bar, but

also makes good contact with the

weatherstripping. See Figure #10

for approximate z-bar to edge-ofdoor alignment. Fasten Z-bar using

#8x1" painted pan head screws

through pre-drilled holes provided in

Z-bar.

• After the door is installed, apply

the drip cap screw cover. Attach

this part per Figure 13. Start at

one end, snap the cover on

working your way towards the

other end.

NOTE: Be sure to

insert the edge toward the door

first, then snap in outer edge.

• Cut the latch and hinge z-bar

screw covers to length—matching

the z-bar lengths respectively.

NOTE: Cut covers using a

scissors or a tin snips.

FIGURE 11

FIGURE 12

• Attach the latch and hinge z-bar

screw covers per Figure 12 as

described above.

FIGURE 13

202220566 EASY VENT 5

#

6 x 3/8" PANHEAD STAINLESS

STEP 11

#

6 x 5/8" FLATHEAD SCREW

Remove

otective Tape

Pr

and

Adjust Bottom

Expander

STEP 12

Install Latch and

Strike Hardware

Some door models have a protective tape over the

door frame on both outside and the inside surface.

Remove this tape now.

Adjust the bottom expander so that the vinyl sweeps

touch the door threshold.

expander should be located on the inside of the door.

Centrally locate the two #6 x 3/8" pan head screws in

the slot to allow for future adjustments.

Drill 3/32" diameter pilot holes for the screws, being

careful not to drill all the way through to the front face

of the door.

screws will break!

Refer to separate instructions packaged in the

hardware box.

NOTE: Pilot holes must be drilled or

The slotted holes in the

STEP 13

Glass Sash/

Screen

Operation

This door has a retractable screen located in the

masterframe head.

• To ventilate make sure sash lock is unlocked, then

pull down on top insert.

• To close, push up on the insert.

• If the screen comes out of the track, it should be

pushed back in place before retracting or simply

close the insert and the screen will reposition itself.

• Use the sash lock to secure the top insert in place.

NOTE: Slow, steady operation should be used to

open and close screen.

6 EASY VENT 202220566

#10 X 5/8" SCREW

SHORT PIN

LONG PIN

#10 x 1-1/2" ROUND HEAD

HINGE SIDE JAMB

#10 X 1 1/2" SCREWS

SHORT CONNECTING

PIN

BOTTOM CLOSER

SASH LOCK

LONG CONNECTION PIN

TYP.

1"

DOOR BRACKET

TOP CLOSURE

SIDE JAMB BRACKET

1/4" FROM DOOR

C

LOSER

FLANGE

E

XTEND ROD 1/4" OUT

“

HOLD OPEN” WASHER

1/4"

EasyVent Series Storm/Screen Door

CLOSER INSTRUCTIONS

NOTE: Be sure door opens and closes freely

before installing the closer.

STEP 1

Closer

Installation

CLOSER ASSEMBLY PREPARATION

• Slide hold-open washer onto closer rod as shown.

Pull rod out of closer so that there is approximately

a 1/4" gap per Figure 1 (insert small screwdriver in

rod hole to provide pulling grip). Position washer

behind flanges and against the closer.

screwdriver.

This will give proper tension for

installation. (Do not change until installation is

complete.) See Figure 1.

• Attach brackets to closer as shown in Figure 2.

Attach

front hole in closer to door bracket (long

connecting pin). Attach closer rod to side jamb

bracket (

short connecting pin) with open side of

jamb bracket toward storm door (see arrow on

bracket).

Your closer assembly is now ready to

be attached to inside of door.

• Close and latch door.

FIGURE 2

Remove

FIGURE 1

202220566 EASY VENT 7

FRONT HOLE

REAR HOLE

ADJUSTING SCREW

CLOSER

SILL DETAIL

CLOSER BRACKET

CAUTION:

TO AVOID SCREEN DAMAGE,

DO NOT ATTACH BRACKET IN THIS AREA!!!

CLOSER BRACKET

TOP OF

WOOD

FRAMING

SCREEN

TUBE

SILL

DRIP

CAP

BRASS

EXPANDER

INTERIOR

HEAD DETAIL: TOP CUTAWAY

SILL DETAIL: BOTTOM CUTAWAY

EXTERIOR

STEP 2

#10 X 5/8" SCREW

SHORT PIN

LONG PIN

#10 x 1-1/2" ROUND HEAD

Closer

Assembly

Installation

• To install the top closer, position door bracket as

shown in Figure 2 and Figure 3. Slide closer over

until jamb bracket is 1/4" back from storm door.

Mark jamb bracket holes and two holes in door

bracket.

• Fasten jamb bracket to jamb with four #10x1-1/2"

screws. The

should be toward the storm door (

bracket

Close and latch the door. Hold the closer and

•

open side of the jamb bracket

see arrow on

).

door bracket level and mark the location for the

insertion of the door bracket screws. Drill 1/8"

starter holes.

the outside of door.

CAUTION: Do not drill through

Install two #10 x 5/8"

screws in bracket.

• To install bottom closer, refer to Figure 2 and

Figure 3 for placement and repeat steps used to

install top closer.

NOTE: Bottom closer may need

to be applied over the door expander in some

cases.

Do not fasten door bracket to kick plate

on mid-view models. Bracket must be in

position as shown in Figure 3.

• To hold the door open: Open door. Slide holdopen washer over flanges toward cylinder on

closer.

FIGURE 3

STEP 3

Controlled

Latching Power

Feature

the FRONT hole of closer, the door will accelerate

its closing speed in the last few inches of travel.

This attachment position is recommended when the

glass storm panel is in place.

If a smoother, quieter closing action is desired, hold

door open about 8" with hold-open washer. Move in

from door bracket and relocate in closer REAR

Installed as directed, with door bracket connected to

hole.

Adjust each closer individually (with the other

closer disconnected from the door) to the closing

speed suf

for each closer should be the same.

ficient to latch the door

The closing speed

.

FIGURE 4

To change closing speed, turn screw on

the end of closer tube clockwise for

slower and counter clockwise for faster

See Troubleshooting, Symptom D for

more adjustment information.

8 EASY VENT 202220566

Storm Door General Care and Maintenance

Keep this document along with your Installation Instructions for future reference.

Glass W

Door Finish Aluminum Skin—Non-abrasive paste wax may be used on your door’s outer surface to help keep the

Hinges/Hardware Hinges and door hardware may require occasional lubrication. A silicone spray lubricant is recommended.

Brass-tone Expander Wash expander using a warm water/mild detergent mixture, and a soft cloth. Do not use a brass cleaner

(Anodized) or steel w

ash glass using a household glass cleaner, or a warm water/mild detergent mixture, and a soft cloth or

wel.

paper to

finish looking new.

ool.

(Follow directions on the product’s label.)

Brass Products (Finish)

Select Larson storm door models incorporate high quality “real" brass component parts. As with all brass products, tarnishing will

occur. Without proper care, brass can become heavily stained, and in extreme cases of neglect, pitting can occur. Larson locksets and

deadbolts have a clear coat finish to protect against tarnishing. If the clear coat finish is damaged, tarnishing will occur. Larson brass,

inlaid in the glass, does not have a clear coat finish. It requires periodic cleaning and polishing to maintain the shiny brass

appearance. Should tarnishing occur in either case, the shiny brass finish can be restored as follows:

Brass Locksets, Deadbolts, Name Plates

• Cleaning

1. Wash brass hardware using a warm water/mild detergent mixture, and a soft cloth. Do not use abrasive cleaners or cloths as

they may damage the clear coat finish.

2. Apply non-abrasive paste wax on the brass hardware to help restore it’s bright finish.

• Refinishing (if clear coat is damaged and tarnishing has occurred)

1. Remove the tarnished hardware from the door.

2. Remove damaged clear coat. This can be done by using a paint stripper, or by lightly rubbing the hardware using #0000

steel wool. Follow the manufacturer’s instructions when using a stripper. Note: If refinishing keyed hardware, cover the

key opening with masking tape to keep out stripper or steel wool particles.

3.Once the clear coat is removed, continue to lightly rub with #0000 steel wool over tarnished areas until the bright brass

finish returns.

4. Clean the brass using a brass cleaner (i.e. Brasso, Tarni-Shield) per the manufacturer’s directions.

5. Apply a “new” clear coat finish. For best results, a clear lacquer spray is recommended. The lacquer can be purchased

at most hardware stores and should be applied per label directions. Note: If refinishing keyed hardware, cover the key

opening with masking tape when applying the lacquer finish (protecting the locking mechanism from gumming up).

6. Reinstall the hardware on the door.

Questions? Call the Larson Homeowner Helpline at 1-888-483-3768.

Larson EasyVent Warranty

EASYVENT Larson Manuf

Limited Lifetime Warranty during the life of the door.

RETRACTABLE

SCREEN

1-Year Warranty

HARDWARE

1-Year Warranty

NOTE: WARRANTY APPLIES TO ORIGINAL OWNER - ONLY. PROOF OF PURCHASE REQUIRED.

STORM DOOR WARRANTY LIMITATIONS: Modification of door will void warranty. Screen damage, glass breakage, or wind damage is not covered under

warranty. In order to obtain performance under these warranties, the original owner shall do the following: 1. Send in the warranty registration card within 30 days

following purchase; 2. Contact us at 1-888-483-3768 with registration number and proof of purchase.

Retractable screen warranty is one year, covering workmanship, mechanical parts and factory defects.

Screen damage or tearing is not covered under warranty.

Hardware warranty is 1 year, covering workmanship and mechanical parts (brass finish is not

covered under the warranty). Brass is like fine silver, it needs occasional maintenance. To

maintain your brass finish, refer to the “General Care and Maintenance" above.

acturing will warranty all manufacturer's defects at no charge to the original owner

202220566 EASY VENT 9

EASYVENT TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE SOLUTION

Screen catches when pulled down

Unit won't retract—screen bunches

up or becomes baggy

Sash Balance protruding from insert

Door does not close properly

Door squeaking when opening

Screen roll may have come out of

the brackets.

Screen roll may be too tight which

can cause binding. Should be

1/8" of play side to side.

Screen may have shifted to one

side.

Torsion Spring may be broken.

Balance not seated correctly.

Hinge may have been attached

too close to the front edge of the

.

door

Jamb screws may be too tight,

causing hinge to bind.

Door opening out of square.

Expander dragging on threshold.

Hinge Z-bar is bent.

Unpainted portion of closer rod

extended beyond 1/16".

Closer speed improperly adjusted.

Air pressure between prime door

and storm door (back pressure

being created).

Hinge to jamb screws too tight.

Door opening out of square.

New hinges are tight.

Remove cover (page 7–see figure 3 in Closer Instructions)

Make sure screen roll is seated properly

Remove cover (page 7–see figure 4 in Closer Instructions)

Push brackets toward outside of door until 1/8" of play is

acquired.

Center screen in opening

Replacement kit needs to be ordered.

Using needle nosed pliers, pull down on balance

approximately two (2) inches and slowly allow balance to

slide into insert and reposition itself.

Reposition hinge closer to inside edge of door masterframe

(see instructions).

Loosen jamb screws to relax tension.

Square up opening.

Raise expander so that bottom of sweeps only touch top of

threshold.

Replace Z-Bar.

Readjust door bracket to allow only 1/16" or less of the

unpainted portion of closer rod to show (see closer

instructions).

Recheck instruction manual for proper closer installation.

Proceed by removing the closer adjusting screw from the

closer. Fully open door and allow it to close (door should

slam shut). Reinstall closer adjusting screw allowing only 1

or 2 threads of the screw to be turned in. Fully open door

and allow the door to close. Adjust the screw 1/4 to 1/2 turn

to achieve the desired closing speed sufficient to latch door.

NOTE: On two closer models adjust each closer individually

(with the other closer being disconnected from the door); the

closing speed should be the same for each closer). If more

latching force is desired, the jamb bracket may be moved up

to 1" away from the door (rather than the recommended

1/4"). NOTE: moving the jamb bracket further from the door

reduces the door opening.

Raise expander or leave window open to allow air to escape.

Back off screws 1/4 of a turn.

Square up opening.

Lubricate with 3-in-1 oil, cooking oil or silicon spray lubricant.

.

Hinges rubbing against wood

jamb.

Door leaking

e the surf

Aluminum doors must ha

ScotchBrite pad to remo

Apply an epoxy primer. Top coat with a premium grade acrylic lacquer or solvent-based

oils.

enamel paint. For best results, have it painted at a professional body shop.

Only paint f

10 EASY VENT 202220566

inishes applied by Larson Manuf

v

e the sheen (gloss), then cleaned with a solv

v

Drainage holes blocked with dirt

or debris.

ace scrubbed with steel w

acturing are co

ool, sand paper (v

ered under the compan

v

ery fine grit), or a

ent to remove any grease or

Chisel wood out from under each hinge.

Inspect drainage holes—located on bottom side of frame.

arranty.

y's w

Loading...

Loading...