LARSEN & TOUBRO LIMITED, MYSORE WORKS ER300P-PRIDE User Manual

1

Electronic Trivector Meter

ER300P-PRIDE

Class 0.2S

For

Neyveli Lignite Corporation

LARSEN & TOUBRO LIMITED, MYSORE WORKS

2

2.1 Theory of Operation

2.1.1 Analog section

2.1.2 Digital processing section

2.1.3 Power supply section

2.2 Hardware

2.2.1 Compact

2.2.2 Efficient

2.2.3 Ruggedness and Safety

2.2.4 Features

2.2.5 Data Safety

2.3 Software

2.3.1 Definitions

2.3.2 Load survey records

2.3.3 Instantaneous Parameters.

2.3.4 Programmable features

2.3.4.1 External CT/PT ratios

2.3.4.2 RTC Setting

2.3.4.3 Communicating Parameter setting

2.3.4.4 Factory Configurable

2.3.4.5 Accuracy Method

2.3.5 Display Details

2.3.6 Communication

2.3.7 Internal Battery Option

3

4. APPENDIX A

Fig 1. Parts/Dimensions

Fig 2 3 Ph 4W connection diagram - with CT

Fig 3 3 Ph 4W connection diagram - with CT & PT

Fig 4 RS 485 connection diagram (top view)

Fig 5 RS 485 connection diagram (front view)

5. APPENDIX B - Technical specifications

6. APPENDIX C - MODBUS details and memory map

7. APPENDIX D – List of errors

4

failure and CT open are also indicated instantaneously.

• 15 minutes Load Survey recorders for 40 days

1. Forward Wh

2. Reverse Wh

3. Forward VArh

4. Reverse VArh

and Tampers are recorded.

• Meter configuration/data collect i on possible t hr ough

- RS485 port using MODBUS protocol.

- Optically isolated serial interface using DCD.

• kWh & kVArh pulse output LEDs available on front

panel.

• LCD Segments for indicating presence of voltages in

each phase separately is available.

• LCD, with back lighting and of extended temperature, to

display various parameters.

• Keys on the front panel to scroll through display

parameters.

• Rugged polycarbonate casing makes it a good insulator

and so no external "EARTHING TERMINAL” is req uired.

• Built in self-supervision.

5

High precision current transformers and voltage transducers

step down input currents and voltages, that are fed to an

Analog to Digital converter

2.1.2. DIGITAL PROCESSING SECTION

A powerful microprocessor controls the analog and digital

sections. The digital samples are processed t o obtain various

metering data that is stored in non-volatile memory. A high

precision real time clock controls all tim e keeping activities.

External interface is through Display, Keyboard, RS485

Communication port and Optical Communicat ion por t .

2.1.3. POWER SUPPLY SECTION

A switched mode power supply supplies power to the meter’s

internal circuitry.

2.2 HARDWARE

The hardware of the meter has been desig ned to make it light

in weight, rugged, reliable and safe for the users.

2.2.1. Compact

The meter is designed using Surf ace Mount Technology, which

makes it light in weight and com pact .

6

meters that use LED displays.

2.2.3. Ruggedness and safety

All components used in the meter are of extended

temperature range, which makes the meter ideal for tropical

climates.

The meter’s top and bottom covers are m ade of polycarbonate,

which is a good insulator. The meter is saf e for the user.

The meter’s casing and t erminal block have been made of nonflammable plastic material.

2.2.4. Features

•

LEDs - LEDs for Wh & VArh. PULSE outputs are

available on front panel.

•

Keys - In closed condition, two keys are provided on

the front panel, f or scrolling through the display.

•

LCD - The meter uses an extended temperature LCD,

with back lighting, which displays various parameters.

•

RS485 port – for communication using MODBUS

protocol

•

Optical port – for serial communication.

2.2.5. Data safety

7

RTC

with battery backup is used for time keeping. It

has a calendar of 100years.

•

Watch dog timer is used to monitor the processing

activities that ensures the reliable operation of the

meter.

•

Power down sensor senses power failur e and shuts

down the system safely.

•

Data security lock is provided for storing metering

data. This makes the metering data immune to

spurious signals on power lines.

•

The meter is designed to conf orm to I EC standards for

EMI/EMC, which makes the system immune to

Electromagnetic Interference.

•

Periodic setup/program data check is carried out

and anomaly is indicated on error occurrence.

8

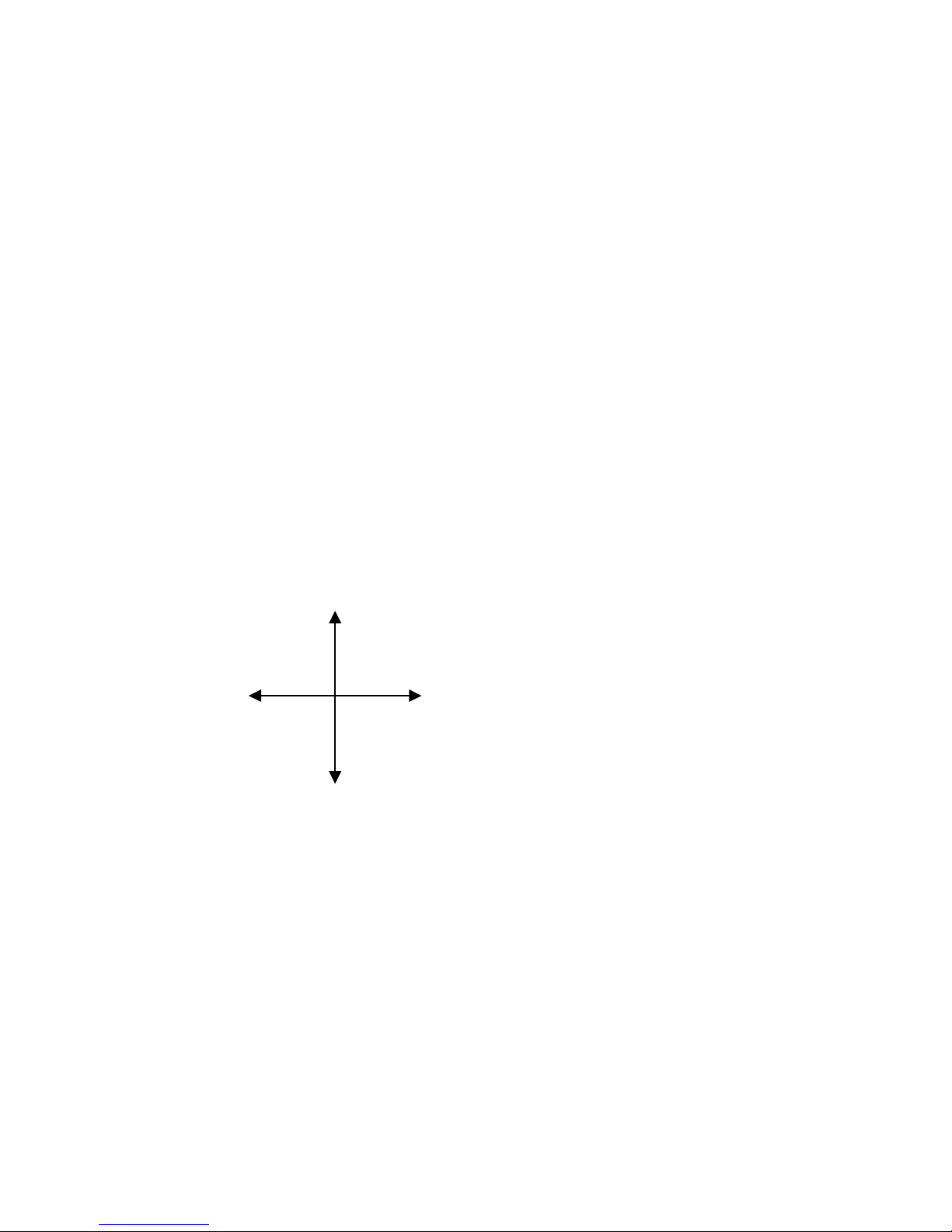

Method of energy computation:

All energies are of fundam ental component only.

Following method is adopted for forward/reverse energy

calculations -

Forward Wh: (W1 + W2)

Reverse Wh: (W3 + W4)

Forward VArh: (R1 + R4)

Reverse VArh: (R2 + R3)

Where W1, W2, W3 & W4 are the absolute active energies & R1,

R2, R3 & R4 are the absolute reactive energies in the four

quadrants.

Note: All energies are of f undamental component only.

0

W2 W1

R2 R1

270 90

W3 W4

R3 R4

180

• Average freq. –

9

minutes time blocks will be contracted by ten seconds each.

• Ret a r d RTC comma nd:

When Retar d RTC command is given, six consequent 15

minutes time blocks shall be elongated by ten seconds each.

2.3.2. LOAD SURVEY RECORDERS

All energies, voltages and currents are of fundamental component

only.

Load survey data at 15 minutes interval for 40days:

1. Forward Wh

2. Reverse Wh

3. Forward VArh

4. Reverse VArh

5. Average frequency

6. Average of 3 phase voltages

7. Tamper details

Resolution (without CT and PT ratios)

Energ y: 2 decimals (xxx.xx Wh/VA rh)

Frequency: 3 decimals (xx.xxx Hz)

Voltage : 2 decimal s (xxx.xx V)

Tamper details:

Voltage failure, CT open, CT or PT setting tampered, Meter

malfunction, Power fail, Advance comm and, Retard

command and RTC set command details are available.

10

b Phase voltages.

c> Phase currents.

d> Active Power.

e> Reactive Power.

f> Apparent Power.

g> Total Power Factor.

h> Average Frequency.

i> Tamper Status.

Format: Bit nos.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

x x x x x x x x s r a x e t c v

where

v = voltage failure (immediate status)

c = CT open (immediate s tatus)

t = CT or PT setting done (of running 15 mins block)

e = Meter mal-function (of running 15 mins block)

a = advance RTC (of running 15 mins bloc k)

r = retard RTC (of running 15 mins block)

s = RTC set (of running 15 mins bl ock)

x = don’t care

(bit is set if event occurred)

j> Time.

k> Cumulative Energies.

l> Anomaly string

2.3.4 PRO GRAMMABLE FEATURES

All the below given features are pr ogrammable through RS485

port & DCD

2.3.4.1. EXTERNAL CT/PT RATI OS

The meter can be program m ed for external CT/PT rat ios.

11

2.3.4.2. RTC SETTING

RTC setting

For RS485, PC software can have password protection.

Password protection on meter for DCD.

No hardware protection.

a> SYNC RTC time setting

(absolute RTC command)

b> Advance RTC command

Contracts six consecutive 15 minutes. Time blocks by

10secs each.

c>

Retard RTC command

Expands six consecutive 15 minutes. time blocks by

10secs each.

Between advance/retard command there will be a lockout period of

7 days. If power fails before com pletion of all time blocks of

advance/retard command, then on power on, the balance correct ion

will be done in the following 15 minutes time blocks. Pending

advance/retard commands are aborted by sync RTC command.

2.3.4.3 COMMUNICATING PARAMETERS SETTING

Meter ID, baud and parity settings used by MODBUS

communication only, can be changed through DCD, with password

protection.

(Default setting of MODBUS: Meter ID =01, baud = 9600, par ity =

none)

DCD to meter optical head, communicat ion parameters are fixed –

i.e. 4800 baud, even parity, 7bit, 1start bit and 1 stop bit.

12

Each meter is given a unique number at factory.

2.3.4.5. ACCURACY METHODS:

• Pulse method - PULSES/Wh: 10 for 5A meter

50 for 1A meter

PULSES/VArh: 10 for 5A meter

50 for 1A meter

• Accuracy check using DCD (MRI) -

Energies are in Watt- hour s.

2.3.5. DISPLAY DETAILS

• LCD-The parameters calculated by the meter are displayed

on a LCD with back Lighting.

• Scroll rate - The scroll rate of the display parameters in

the Auto scroll mode is 3 seconds.

• Display modes-

a> Manual scrolling – Manual scrolling within a display

mode is possible by using UP or DOWN keys.

b> Auto scrolling – The display on the meter changes as

per the sequence given at scroll rate.

• Mode Switching – Switching bet ween Manual and Auto

Scrolling Mode is possible by simultaneously pressing the

UP and DOWN keys.

Loading...

Loading...