ENGLISH

VEGA 23:1VEGA 23:1

PNEUMATIC MIST-LESS PISTON PUMP

II 2 G c IIB T4

A t e x C e r t i f i e d

WALL BRACKET

Version

Version

on TANK

TROLLEY

Version

OPERATING AND

MAINTENANCE INSTRUCTION

OPERATING AND

MAINTENANCE INSTRUCTION

Ed.

003

10 - 11

P A I N T S P R A Y I N G E Q U I P M E N T

WE RECOMMEND THE USE OF THIS EQUIPMENT ONLY BY PROFESSIONAL OPERATORS.

USE THIS MACHINE FOR PURPOSES SPECIFICALLY MENTIONED IN THIS MANUAL, ONLY.

Thank you for choosing a LARIUS S.R.L. product. As well as the purchased product, you

will receive a range of support services enabling you to achieve the results desired in a

quick and professional way.

Due to a constant product improvement programme, the factory reserves the right to modify technical details

mentioned in this manual without prior notice.

This manual is to be considered as an English language translation of the original manual in Italian. The

manufacturer shall bear no responsibility for any damages or inconveniences that may arise due to the incorrect

translation of the instructions contained within the original manual in Italian.

1

VEGA 23:1

English

AA

BBCCDD

EE

FF

GG

HH

II

JJ

KK

NN

OO

PP

QQ

RR

SS

TT

UU

VVWWXX

YYZZAAAA

ABAB

ACAC

ADAD

AEAE

AFAF

LL

MM

INDEX ................................................................... p. 1

WARNINGS .......................................................... p. 2

WORKING PRINCIPLE ........................................ p. 3

TECHNICAL DATA ................................................ p. 4

DESCRIPTION OF THE EQUIPMENT ................. p. 7

CARRIAGE AND UNPACKING ............................ p.10

SAFETY INSTRUCTIONS .................................... p.10

CONNECTIONS ................................................... p.11

Connect the suction and recirculation hoses ... p.11

Connect the gun hose ...................................... p.11

Washing the new equipment ............................ p.12

Preparation of the paint .................................... p.13

OPERATION ......................................................... p.13

Start spraying operations ................................. p.13

Adjusting the spraying jet ................................. p.14

CLEANING AT THE END OF THE WORK ........... p.15

ROUTINE MAINTENANCE .................................. p.16

Lubricating the gaskets ring nut ....................... p.16

Cleaning the suction filter ................................. p.16

Cleaning the product suction filter .................... p.16

REPLACEMENT OF THE PUMPING

UNIT GASKETS ................................................... p.17

CLEANING AND REPAIRING THE

SUCTION VALVE .................................................. p.19

MANUAL SERVICING OF THE

PNEUMATIC MOTOR ........................................... p.19

DISASSEMBLING THE MOTOR .......................... p.20

TROUBLESHOOTING .......................................... p.23

SPARE PARTS

VEGA PUMP 23:1 - RIF. 9100 COMPLETE

PNEUMATIC MOTOR ........................................... p.26

STAINLESS STEEL SPLIT VEGA PUMP 23:1 -

COMPLETE PUMPING UNIT

................................. p.28

VEGA SPLIT PUMP 23:1 COMPLETE

PUMPING UNIT ................................................. p.30

VEGA SPLIT PUMP ON TANK 23:1 COMPLETE

PUMPING UNIT ................................................. p.32

VEGA SPLIT PUMP 23:1 ON TANK

RIF. 91700 ............................................................. p.34

COMPLETE TROLLEY ......................................... p.36

AIRLESS VERSION RIF. 96250 AIR

REGULATION UNIT ............................................. p.37

MISTLESS VERSION RIF. 96262 AIR

REGULATION UNIT ............................................. p.38

PAINT SUCTION SYSTEM .................................. p.39

AT 250 HIGH PRESSURE GUN ........................... p.40

ACCESSORIES .................................................... p.42

VERSIONS ........................................................... p.44

ATEX CERTIFICATION ......................................... p.47

TECHNICAL FEATURES ..................................... p.47

MARKING ............................................................. p.48

SAFETY INSTRUCTIONS .................................... p.48

EXAMPLE OF INSTALLATION ............................. p.49

DECLARATION OF CONFORMTY ...................... p.49

PNEUMATIC PISTON PUMP

PNEUMATIC PISTON PUMP

2

VEGA 23:1

English

Read this operator’s manual carefully before using the equipment.

An improper use of this machine can cause injuries to people or things.

Do not use this machine when under the influence of drugs or alcohol.

Never modify the equipment.

Use products and thinners compatible with the various parts of the equipment and read the manufacturer’s warnings carefully.

Always refer to the equipment technical data reported in the Manual.

Daily check the equipment for worn parts. If any worn parts are found, replace them using ONLY original spare parts.

Keep children and animals away from work area.

Comply with all safety standards.

WARNINGS

The table below provides the meaning of the symbols used in this manual in relation to using, grounding,

operating, maintaining and repairing of this equipment.

0

0 BAR 0 PSI

It indicates a risk for accident or serious damage to equipment if this warning is not followed.

It indicates important warnings and suggestions about disposal and recycling of the product in accordance with the environmental

regulations.

FIRE AND EXPLOSION DANGER

Flammable fumes, such as thinners or painting fumes could ignite or explode.

In order to prevent fire or explosion risks:

- Use the equipment ONLY in a well ventilated area. Keep the working area free from scrap materials.

- Remove all ignition sources such as pilot lights, cigarettes, portable electric lamps and plastic drop cloths (potential static span)

- Ground the equipment and all conductive items located in the work area.

- Use only conductive airless tubes, duly grounded.

- Never use trichloroethane, methylene cloride, any halogenated hydrocarbon thinners or fluids containing such thinners with aluminium

equipment under pressure. This use could cause a dangerous chemical reaction with expolsion risk.

- Do not connect or switch lights on or off if the air contains flammable fumes.

In case of electrical shocks, immediately stop the operation being carried out on the equipment.

Keep a fire extinguisher near the working area.

It indicates the risk of finger injury or crushing due to movable parts in the equipment.

Keep far from movable parts.

Do not use the equipment without the suitable protections.

Before any inspection or maintenance of the equipment, carry out the decompression procedure explained in this manual preventing

any risk of the equipment starting unexpectedly.

They report the risk of chemical reaction or explosion.

There is a risk of injury or serious damage related to contact with the jet from the spray gun. If this should occur, IMMEDIATELY contact

a doctor, indicating the type of product injected.

Do not spray before placing the guard over the nozzle and the trigger on the spray gun.

Do not put your fingers in the spray gun nozzle.

Once work has been completed, before carrying out any maintenance, complete the decompression procedure explained in this manual.

It indicates the presence of a clamp with grounding cable.

Use ONLY 3-wire extension cords and grounded electrical plugs.

Before starting work, make sure that the electrical system is grounded and complying with safety standards.

The high pressure product spraying out of the gun or from any lacks could cause body injury. To prevent any fire or injury risk:

- Use the safety block on the gun trigger when you are not spraying.

- Do not put hands or fingers on the gun nozzle. Never try to stop any lack with your hands or body.

- Do not direct the gun towards yourself or anyone else.

- Never spray without the suitable nozzle protection.

- Decompress the system at the end of the spraying process and before any maintenance operation.

- Do not use any components having an operating pressure lower than the system max pressure.

- Do not let the children use the equipment.

- Pay attention to the possible recoil when you trig the gun.

Should the high pressure fluid penetrate through the skin, the wound could appear similiar to a “simple cut” even if the damage is more

serious. Immediately contact a doctor to medically treat the wound part.

They indicate the obligation to wear suitable clothing as gloves, goggles and face shield.

Wear clothing that complies with the safety standards in force in the country in which the equipment is used.

Do not wear bracelets, earrings, rings, chains, or anything else that may hinder the operator’s work.

Do not wear clothing with wide sleeves, scarves, ties, or any other piece of clothing that could get tangled up in moving parts of the

equipment during the work, inspection, or maintenance cycles.

3

VEGA 23:1

English

AA

Wood

Carpentry

Handcraft

Small and medium industry

for limited productions

Fields of application

Paints for wood in general

Very well ground enamels and rust preventers

Primers

Polyurethan paints

Lakes

Main application products

Degreasers

Detergents

Oils

etc...

WORKING PRINCIPLE

VEGA 23:1 pump is a pneumatic pump for high pressure painting

without the use of compressed air (AIRLESS). The stainless steel

version is particularly suitable for use with water-based paints.

The pump is essentially composed of an air motor and a structure

known as “Product Pumping Unit”, or simply the “Pumping Unit”.

In the pneumatic motor, the compressed air causes the vertical

reciprocating movement of the motor piston; this movement is

transmitted through a connecting rod to the product pumping piston.

This allows the pump to suck the product and to feed it towards

the outlet.

The ratio 23:1 means that the outlet pressure of the product is 23

times higher than the pump feed air pressure.

The unit comes complete with a transportation trolley, a highpressure product filter, an air supply regulator for the pump, a

product suction tube (complete with filter) and a recirculation tube.

Our spray guns are tested and controlled in our factory and are

derivered to the customer in perfect working conditions.

For this rason, in order not to alter the characteristics of these

units, it is advisable to carefully read these instructions and to

follow them accordingly.

Version on tank

Trolley version

Wall bracket version

4

VEGA 23:1

English

BB

VEGA 23:1

MAXIMUM RATE

PUMP FEEDING AIR PRESSURE

AIR CONSUMPTION

AT 3 BAR

AT 5 BAR

AT 7 BAR

AIR INLET

PRODUCT INPUT

PRODUCT OUTPUT

TOTAL LENGHT

PUMPING UNIT LENGHT

WEIGHT

GASKETS

OVERALL DIMENSIONS

Trolley version A HEIGHT

B WIDTH

C DEPTH

OVERALL DIMENSIONS version on tank

D HEIGHT

E DIAMETER

OVERALL DIMENSIONS wall bracket version

F HEIGHT

G WIDTH

H DEPTH

SOUND PRESSURE LEVEL

2,6l/min (0.7 gpm)

3-8 bar (40-120 psi)

180 l/min (6.5 cfm at 40 psi)

380 l/min (13.5 cfm at 70 psi)

550 l/min (19.5 cfm at 100 psi)

3/8” GAS (F)

3/4” GAS (M)

3/8” GAS C (F)

710 mm

410 mm

16 Kg

UPPER.: teflon LOWER.: teflon

930 mm

450 mm

450 mm

780 mm

340 mm

800 mm

250 mm

290 mm

<80 dB (A)

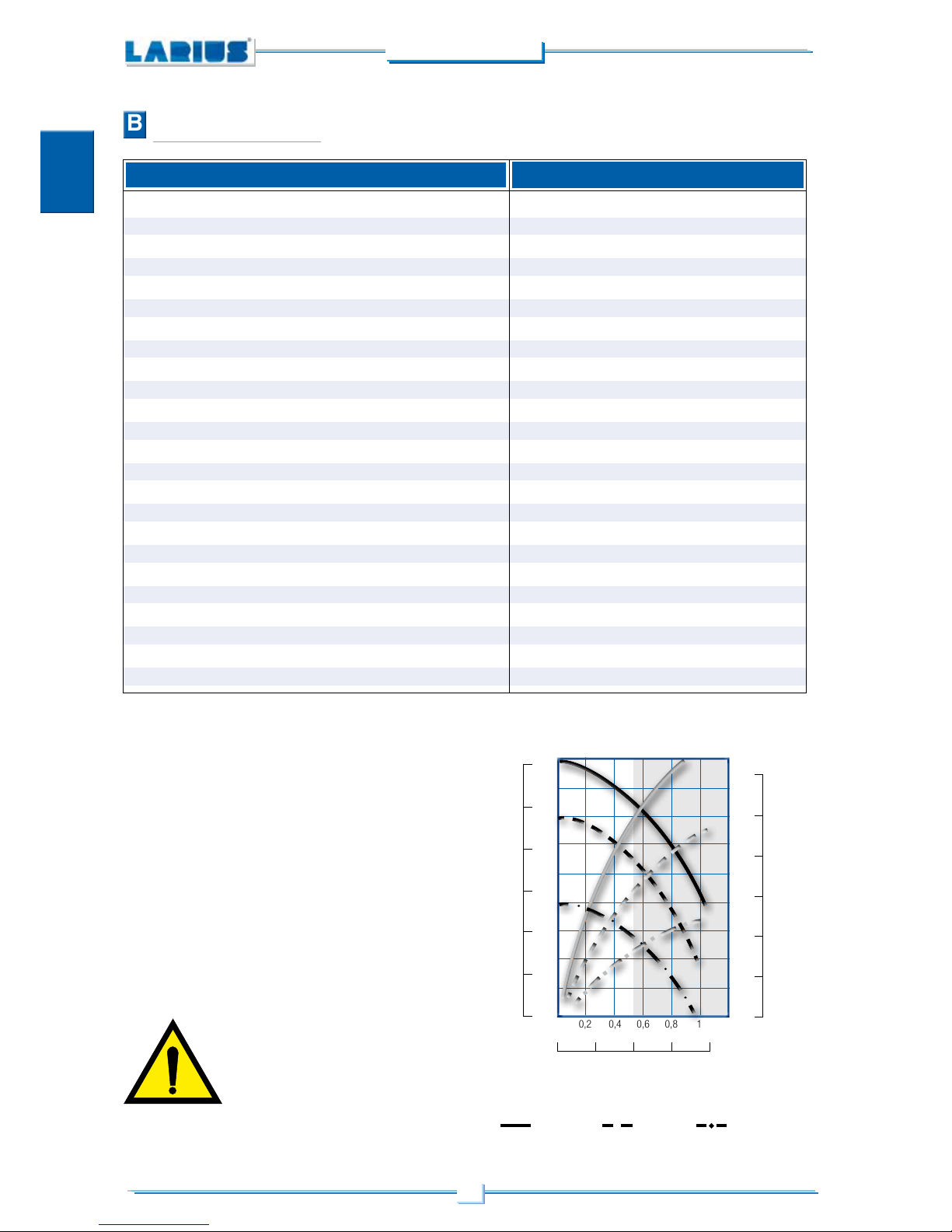

TECHNICAL DATA

Parts of the pumpt in contact with the product

Pumping group: galvanized steel and aluminium or stainless

steel (according to versions)

Sealing balls: stainless steel AISI 420B

Gaskets: Teflon

Other parts of the pump

Motor body and motor piston: aluminium

Pneumatic motor piston rod: stainless steel

Trolley frame: painted metal sheet

These notes shall be kept in consideration in case you need

to evaluate the compatibility of a product

to be used or when you need to dispose

one or more components of the pump,

in order to schedule a suitable reciclying

of the single component according to

environment standards.

Note. The pump is supplied with bayonet coupling.

O 0,2 0,4 0,6 0,8 1 GPM 0

O 1 2 3 4 L/MIN.

PUMP RATE

PRODUCT EXIT PRESSURE

BAR

125

100

75

50

25

0

PSI

2000

1750

1500

1250

1000

750

500

250

AIR CONSUMPTION

L/MIN.

500

400

300

200

100

0

CFM

20

17,5

15

12,5

10

7,5

5

2,5

BLACK CURVE: PRODUCT EXIT PRESSURE

GREY CURVE: AIR CONSUMPTION

7 bar (100 psi) 5 bar (70 psi) 3 bar (40 psi)

The pump can operate in continuous mode when the rate is limited to

the white area. Outside this area, the speed shall be intermittent.

5

VEGA 23:1

English

H

G

F

WALL BRACKET

Version

D

E

ON TANK

Version

TROLLEY

Version

B

C

A

6

VEGA 23:1

English

7

VEGA 23:1

English

CC

POS. Description

1

Motor unit

2

Pumping unit

3

Filter unit

4

Suction hose

5

Recirculation tube

6

High pressure tube

7

Product suction filter

POS. Description

8

Wheels

9

Manual gun

10

Compressed air inlet

11

Pump feeding air pressure gauge

12

Pump feeding air pressure regulator

13

Equipment transport trolley

7

12

10

5

4

1

9

13

3

5

4

6

2

8

DESCRIPTION OF THE EQUIPMENT

11

8

VEGA 23:1

English

18

14

15

17

19

16

21

20

POS. Description

14

Product exit high pressure filter

15

Product exit fitting

16

Recirculation tap

17

Recirculation tube fitting

POS. Description

18

Suction hose fitting

19

Product pumping unit

20

Flexible hose air-product

21

AT250 Gun

9

VEGA 23:1

English

24

23

22

27

26

POS. Description

22

Pump air feeding opening-closing valve

23

Pump pneumatic motor

24

Grounding cable

POS. Description

25

Wall bracket

26

Lifting handle

27

Container

25

10

VEGA 23:1

English

DD

EE

• Strictly respect the orientation of the package indicated

externally by labels or symbols.

• Before installing the equipment, prepare an environment

suitable in terms of space, proper lighting, clean and

smooth floor.

•

The manufacturer declines any liability relevant to the unload

and carriage of the equipment to the workplace.

• Check the integrity of the package upon receipt. Remove

the equipment from the packaging and check that no

damage has occured during transport.

Should any damaged components be found, promptly

contact LARIUS and the shipping agent. The maximum

deadline to notify the damage is 8 days from the date of

equipment receipt. The communication must be made

by registered mail with acknowledgement addressed to

LARIUS and to the carrier.

SAFETY INSTRUCTIONS

•

THE EMPLOYER SHALL PROVIDE TO DULY TRAIN THE

PERSONNEL REGARDING THE RISKS OF ACCIDENTS,

THE SAFETY DEVICES AND THE GENERAL ACCIDENT

PREVENTION GUIDELINES PROVIDED BY THE INTERNATIONAL DIRECTIVES AND BY THE LAW IN FORCE IN THE

COUNTRY WHERE THE UNIT IS INSTALLED, IN ADDITION

TO THE STANDARDS RELEVANT TO ENVIRONMENTAL

POLLUTION.

• PERSONNEL STAFF SHALL CAREFULLY RESPECT THE

ACCIDENT PREVENTION STANDARDS IN FORCE I

N THE

COUNTRY WHERE THE UNIT IS INSTALLED, IN ADDITION

TO THE RULES RELEVANT TO ENVIRONMENTAL POLLUTION.

Carefully read the following instructions before using

the equipment.

Keep these instructions with care.

Tampering or unauthorized replacement of one or

more parts composing the equipment, the use of

accessories, tools, consumables other than those

recommended by the manufacturer, might represent

a risk of injury and raise the manufacturer from any

liability and penalty.

• KEEP THE WORKING AREA IN GOOD ORDER.

FAILURE IN RESPECTING THIS MAY CAUSE

RISK OF ACCIDENTS.

• ALWAYS KEEP A GOOD BALANCE AVOIDING

UNSAFE POSITIONS.

• BEFORE STARTING OPERATION, CAREFULLY CHECK THAT THERE ARE NO DAMAGED

COMPONENTS AND THAT THE EQUIPMENT

IS ABLE TO OPERATE CORRECTLY.

• ALWAYS FOLLOW THE SAFETY INSTRUCTIONS AND REGULATIONS IN FORCE.

• KEEP UNAUTHORIZED PERSONNEL AWAY

FROM THE WORKING AREA.

• NEVER EXCEED THE MAXIMUM OPERATING

PRESSURE

• NEV E R DIRE C T TH E G UN TOWAR D S

YOURSELF OR ANYONE ELSE. GETTING

IN TOUCH WITH THE JET MIGHT CAUSE

SERIOUS WOUNDS. IN CASE OF WOUNDS

DERIVED BY THE GUN JET, IMMEDIATELY

PROVIDE FOR MEDICAL ASSISTANCE SPECIFYING THE PRODUCT YOU WERE USING.

NEVER UNDERESTIMATE THE WOUND CAUSED BY THE INJECTION OF A FLUID.

• ALWAYS DISCONNECT THE POWER SUPPLY

AND DISCHARGE THE PRESSURE IN THE

CIRCUIT BEFORE PERFORMING ANY CONTROL OR REPLACEMENT OF EQUIPMENT

COMPONENTS.

• NEVER MODIFY ANY EQUIPMENT COMPONENT. PERIODICALLY CHECK THE COMPONENTS OF THE SYSTEM. REPLACE DAMAGED

OR WORN COMPONENTS, IF ANY.

• CHECK AND TIGHTEN ALL FITTINGS BETWEEN THE PUMP, THE FLEXIBLE HOSE AND THE

GUN BEFORE USING THE EQUIPMENT.

CARRIAGE AND UNPACKING

All unloading and handling operations of the

equipment are at User’s care who should pay the

utmost attention in order to avoid any damage to

people or things.

The unloading operations shall be carried out by

skilled and trained personnel (truck, crane ope-

rators, etc..) with suitable hoisting means able to

bear the weight of the package and to meet all

safey standards.

The personnel must be equipped with suitable

protective devices.

The disposal of packaging materials, at user’s care,

shall be performed in compliance with applicable regulations in force in the country where the equipment

is installed.

It is however good practise to dispose the packaging

materials in the most environment-friendly way.

11

VEGA 23:1

English

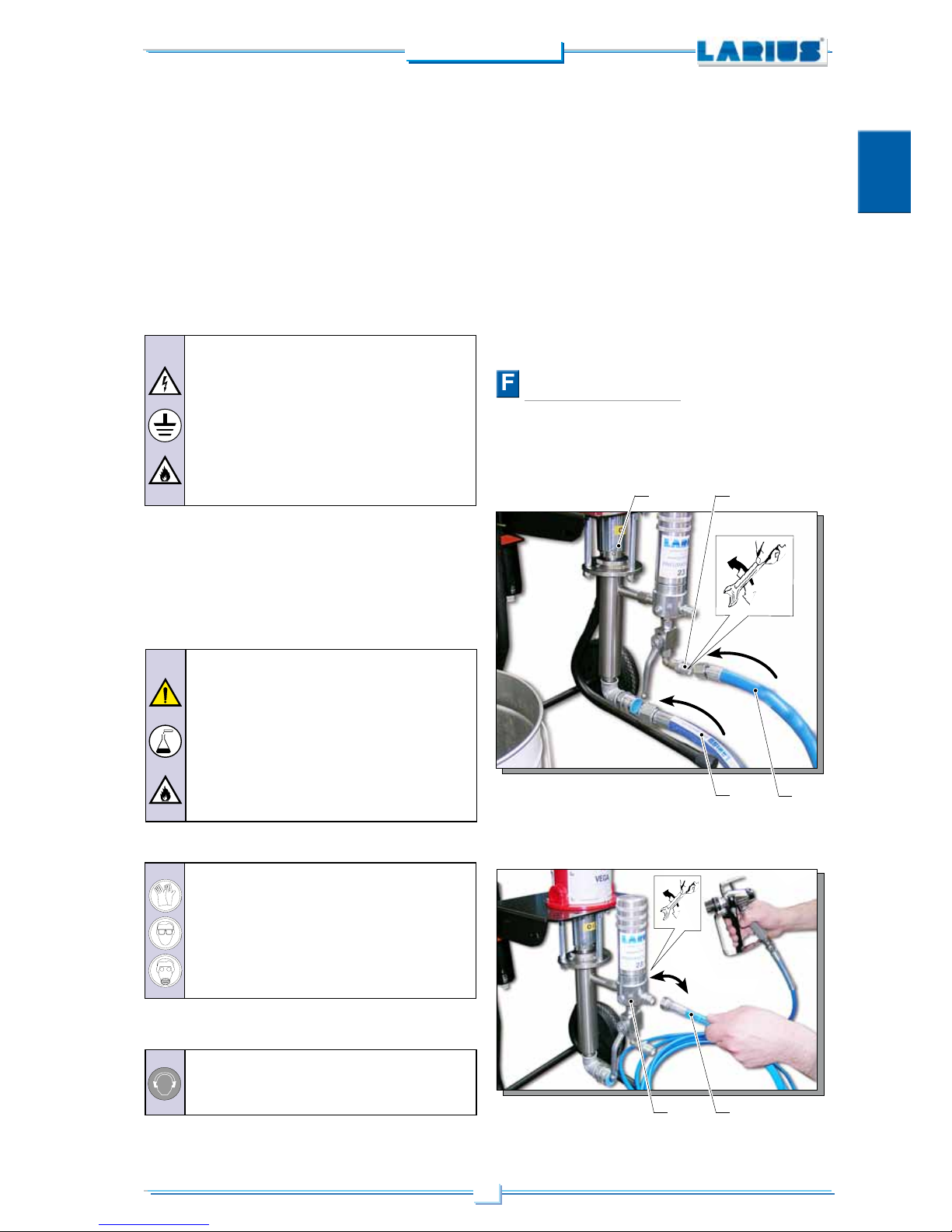

FF

• NEVER SPRAY FLAMMABLE PRODUCTS OR

THINNERS IN CLOSED ROOMS.

• NEVER USE THE EQUIPMENT IN PRESENCE

OF POTENTIALLY EXPLOSIVE GASES.

The high speed of the product flowing in the flexible hose may cause statical electricity showing

short sparks. It is recommended to provide a

suitable grounding for the equipment. The pump

is connected to the ground cable of the electric

supply. The gun is grounded by means of the high

pressure flexible hose. Each conductive parts near

the workplace shall be duly grounded .

Always check the compatibility of the product with

the materials composing the equipment (pump, gun,

hose and accessories) with which it can come into

contact. Do not use paint or thinners containing halogenated hydrocarbon (such as methylene chloride).

These products, when in contact with equipment

aluminum parts, can cause dangerous chemical

reactions thus representing a risk of explosion.

IF THE PRODUCT TO BE USED IS TOXIC

AVOID INHALATION AND CONTACT, BY

USING PROTECTIVE GLOVES, GOGGLES AND SUITABLE FACE SHIELDS.

ADOPT SUITABLE HEARING PROTECTION MEASURES WHEN WORKING NEAR THE EQUIPMENT.

CONNECTIONS

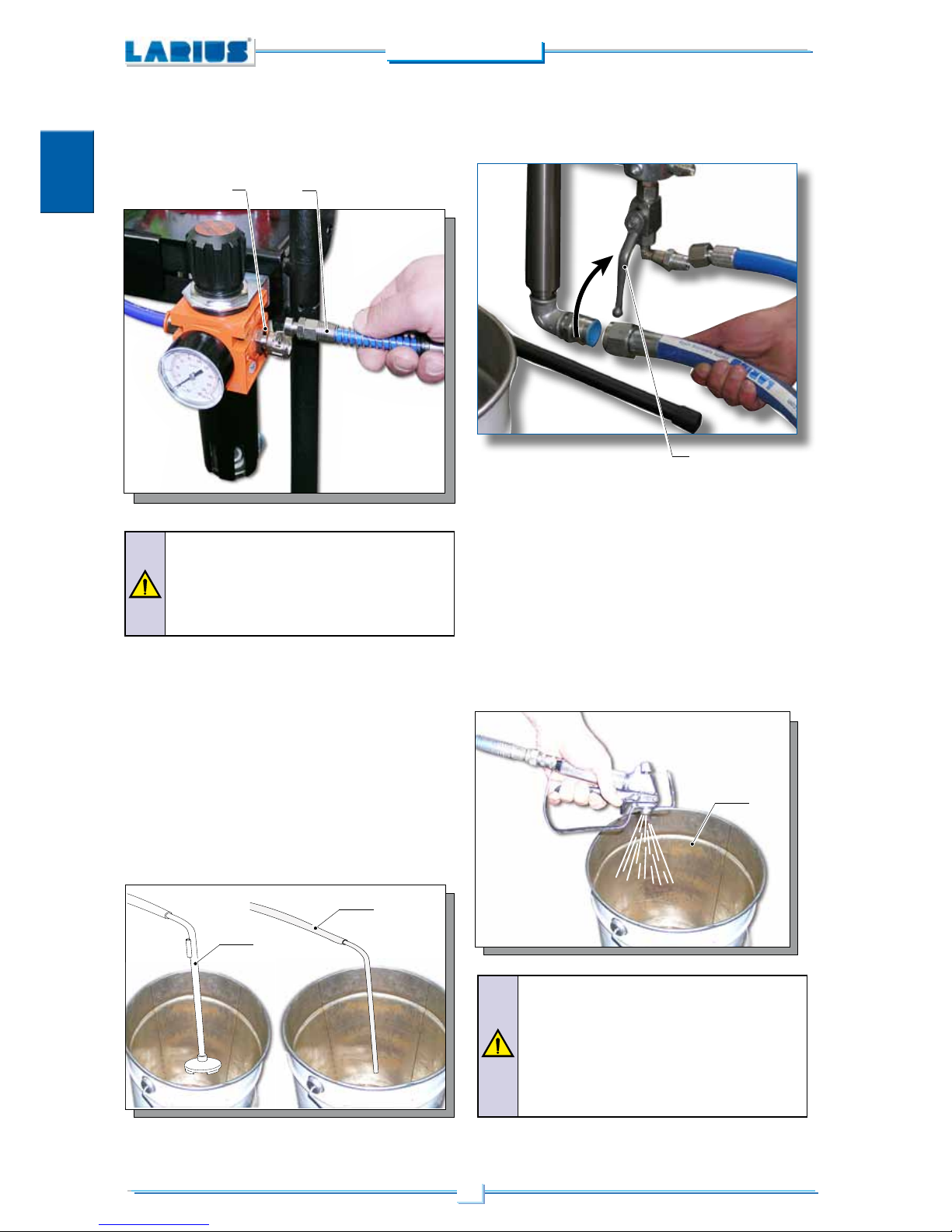

CONNECT THE SUCTION AND RECIRCULATION HOSES

•

Connect the suction (F1) and the recirculation hoses (F2) to

the pumping unit (F3) and to the filter (F4) as indicated in the

picture.

CONNECT THE GUN HOSE

•

Connect the product feeding hose (F5) to the filter unit (F6).

•

MAKE SURE YOU KNOW HOW TO STOP THE EQUIPMENT

WHEN NEEDED. IT IS ALSO RECOMMENDED TO TRAIN

THE USERS ON THE SAFE AND CORRECT USE OF THE

EQUIPMENT BEFORE STARTING OPERATIONS.

• KEEP UNAUTHORIZED PERSONNEL FAR FROM THE

EQUIPMENT, ESPECIALLY IF THE PRODUCT TO BE USED

IS TOXIC .

• IF NECESSARY, USE WARNING SIGNALS TO KEEP ANY

UNAUTHORIZED PERSON AT A SAFE DISTANCE.

• MAKE SURE THAT THERE IS SOMEONE HEARING YOU IN

THE UNLIKELY EVENT OF AN ACCIDENT.

• ALWAYS USE THE HOSE PROVIDED IN THE

STANDARD KIT. USE OF EQUIPMENT OR

ACCESSORIES OTHER THAN THOSE RECOMMENDED IN THIS MANUAL MAY CAUSE

ACCIDENTS.

• THE FLUID CONTAINED IN THE FLEXIBLE

HOSE CAN BE VERY DANGEROUS. HANDLE

THE HOSE WITH CARE. DO NOT PULL THE

HOSE TO MOVE THE EQUIPMENT. NEVER

USE A DAMAGED OR REPAIRED HOSE.

F1

F2

F3

F5F6

F4

12

VEGA 23:1

English

NEVER use thread adhesive products on the fittings.

We recommend the use of the hose included in the

standard kit.

NEVER use a damaged or repaired flexible hose.

CONNECT THE FEEDING AIR HOSE

• Connect the adjustment group (F7) to the compressed air

fitting (F8).

Never operate the pump without the product, in order

to prevent the gaskets to be damaged.

Never spray cleaning liquids in close rooms. It is also

recommented to place yourself far from the pump in

order to avoid the contact with the cleaning liquids

vapours.

WASHING THE NEW EQUIPMENT

• Our equipment has been tested in our factory with a light mineral

oil which is being left inside the unit for protection. Before sucking

the product, it is necessary to duly wash with a thinner.

• Plunge the suction hose (F9) in the container of the washing

thinner.

• Plunge the recirculation hose (F10) in a collector (a metal con-

tainer is recommended).

• Open the recirculation tap (F11).

• Set the pump feeding pressure at about 3 bar and open the

air valve.

F10

F9

F11

• The pump will start and will discharge the oil for the recirculation

hose. Close the recirculation tap as soon as the clean thinner

begins to flow.

• Take the suction hose out of the product container.

• At this point place the gun against the collector (F12) and press

the trigger in order to discharge the residual oil. Release the trigger

as soon as the clean thinner begins to flow.

• Direct the gun against the thinner container and press the trigger

in order to recover the clean thinner left inside the pump.

• As soon as the pump begins to work in an accelerated way

(“vacuum") close the air valve.

F12

F7

F8

13

VEGA 23:1

English

Paints and products without pigments and

charges. Very fine and with low viscosity

paints and lakes, enamels, primers, polyesters, oils, degreasers amd detergents,

polyurethan paints.

Normal lakes or having higher viscosity,

fillers, produts with a coarse grinding, rust

preventers, vinyl produts for coverings, etc.

Same products with a high yield, epossidic

resins, dispersion for the building industry,

applications with high thickness.

NOZZLE Ø

PRODUCT

mm

0,18 ÷ 0,28

inch

0,007” ÷ 0,011”

mm

0,33 ÷ 0,62

inch

0,013” ÷ 0,025”

mm

0,68 ÷ 0,94

inch

0,027” ÷ 0,037”

NOZZLE SIZE

ACCORDING TO THE PRODUCT

• At this point the unit is ready. Should water paints be used,

it is advisable to wash with soap water and then with clean

water, besides the washing with cleaning liquid.

PREPARATION OF THE PAINT

• Make sure that the product is suitable to be sprayed.

• Duly mix and filter the product before use. We recommend the

use of LARIUS METEX filters with fine-mesh (Rif. 214) or large

mesh (Rif. 215).

Make sure that the product is suitable to be

used with the materials employed for the unit

manufacturing. For this purpose, refer to the

product supplier.

• Rotate clockwise the pressure adjustment knob (F10) so that

the pump starts to work.

• When the product has been duly mixed, the product will flow

from the recirculation hose. (F2)

If the product does not flow, this means it is too thick and it

is necessary to dilute it again until a correct flow is achieved.

Let the product flow for a short time. At this point, the machine

is ready to work.

OPERATION

F10

PRODUCT PREPARATION

• Make sure that the product and the thinner are suitable to

be sprayed. Make sure that the thinner is suitable to be used

with the product to be sprayed. Make sure that the product

has been duly filtered and mixed.

NOZZLE AND FILTERS

• The nozzle and the filter shall be suitable for the gun, according to the product to be sprayed and to the operation to be

carried out (refer to the assembly tables and instructions).

• This table is for indication only. The adapatability of a certain

product to a determined nozzle changes according to different

aspects. If previous experiences are lacking, a practical test

is always necessary. A nozzle, which has been duly chosen,

will give as result a neat jet without pulsations and gives a

perfect praying of the product.

• An inconstant spray, slightly marked on the sides, might

indicate a too low pressure. If the maximum pressure has

already been reached, it is then necessary to choose a smaller

nozzle. With the exclusion of some products, which can be

atomized at high pressures only, it is advisable not to exceed

the value of 140-170 Atm (high pressure could cause mist).

• Considering an equal speed of application, a

nozzle with a spraying angle of 20° lays down a

film having a thickness which is averagely double

in respect to the one which can be obtained with

the same nozzle with an angle of 60°.

• An excessive diameter of the angle could result

in an anomalous pressure drop.

• When ordering a nozzle, choose accurately the

reference number on the list of the nozzles.

START SPRAYING OPERATIONS

• Use the equipment only after having completed all the

adjustment operations described in the previous paragraph.

Before using the equipment, check all the

connection fittings on the various components

(pump, flexible hose, gun, etc.)

GG

14

VEGA 23:1

English

• Use the provided lubricant (G1) (rif. 16325) in order to make

the sliding of the piston easier inside the sealing pack and

interpose oil to air.

G1

Daily check that the ring nut is covered with hydraulic oil (rif. 16325); the oil improves the sliding of

the piston and prevent the product, coming out

from sealing gaskets, to dry once the equipment

is stopped.

• Fix the spraying nozzle on the gun, choosing the suitable

nozzle according to the characteristics of the product to be

used and the kind of operation to be performed.

Plunge the suction hose (G1) and the recirculation hose (G2) in the product container (G3).

G1

G2

G3

• Open the recirculation tap.

• When the air tap (G4) is closed, make the air flow from the

compressed air supply.

Check on the pressure gauge (G5) that the pressure does not

exceed 2-3 Atm [adjust it with the knob (G6) of the regulator].

With an empty pump, a higher pressure might

cause a quick and violent movement of the piston,

which could be dangerous. Beside this, starting

with the max pressure (6-8 bar) the pump will not

be able to fill the chamber considering the high

speed of the cycle.

• Open the air tap (G4).

G4

G6

G4

G5

15

VEGA 23:1

English

• Should the cycle speed be too high, decrease the feeding

pressure or slightly close the air tap (G4). Set the minimum

pressure necessary for the operation.

At the end of the work, stop the pump in the lower position

in order to prevent the product to dry on the piston and to

damage the gaskets.

ADJUSTING THE SPRAYING JET

• Slowly turn clockwise the pressure adjustment knob until

the suitable value able to grant a proper atomization of the

product is reached.

• An inconstant spray, slightly marked on the sides, might indicate a too low pressure. On the contrary a too high pressure

might cause mist (overspray) and product dispersion.

• Do not spray without the contemporaneous advancement of

the gun (right-left) in order to avoid an anomalous thickness

of the paint.

• Always proceed with regular and parallel passages.

• Keep a constant distance (25/30 cm) between the nozzle and

the support to be sprayed and keep yourself perpendicular

to it.

• Avoid to work with maximum pressure.

• Let the product flow for a few seconds. Then close the recirculation tap. The pump will continue to work until the product

will fill the high pressure flexible hose up to the gun, then it

will stop.

NEVER direct the gun towards yourself or anyone

else.

Getting in touch with the jet might cause serious

wounds. In case of wounds derived by the gun jet,

immediatly provide for medical assistance specifying the product you were using.

Recirculation-safety valve: during the operation

at the maximum pressure availble, when releasing

the gun trigger, you can assist to brisk pressure

increasings. In this case the recirculation-safety

valve automatically opens, discharging part of the

product from the recirculation hose. It then closes

in oder to set the previous working conditions.

H4

CLEANING AT THE END OF

THE WORK

• Remove the suction (H1) and the recirculation hoses (H2)

from the product container (H3) by going on spraying (H4),

until the pump is completely empty.

H3

H2

H1

• Plunge the suction (H5) and the recirculation hoses (H6)

in the thinner container (H7). Set pressure to the mimimum

and by keeping the nozzle below the thinner level in the

container, spray until the thinner has been recycled during

three or five minutes.

HH

16

VEGA 23:1

English

• By going on spraying, lift the suction (H8) and the recirculation

hoses (H2), in order to drain out all the thinner. Then stop the

pump, by closing the air tap.

H2

H1

H7

H8

• After washing, in case a long period of downtime is foreseen

or if a water-based product has been used, it is advisable

to lubricate the inner parts (pumping group), by sucking the

hydraulic oil with the pump, without discharging it.

Before using the equipment, make sure to follow

the cleaning procedure.

ROUTINE MAINTENANCE

Periodically check the air supply line to the pump.

Make sure that the air is always clean and lubricated.

I1

Before carrying out any control or maintenance

operation on the pump, always close the compressed air supply and discharge the pressure

in the circuit.

Rif. 16325

LUBRICATING THE GASKETS RING NUT

• Periodically check (and in any case each time the pump

is started after a long period of downtime) that the

gaskets ring nut is tight in order to avoid any product

leak.

• Weekly check that the gaskets ring nut (I1) is tight.

To tighten the gaskets ring nut (I1) use the provided

wrench (I2). The ring nut shall be duly tightened so

that to prevent any leak but this shall not be excessive

in order to avoid the blocking of the pumping piston

and the wear of the sealing gaskets. Should the product leak, provide to replace the upper gaskets. This

adjustment shall be carried out after having removed

the air feeding tube and having discharged the pressure.

I2

OIL

II

17

VEGA 23:1

English

PRODUCT SUCTION FILTER

I3

CLEANING THE SUCTION FILTER

• Disassemble and clean the product suction filter (I3).

PRODUCT OUTPUT FILTER

I4

CLEANING THE PRODUCT SUCTION FILTER

• Disassemble and clean the high pressure filter for product

output (I4).

Daily check that the ring nut is covered with hydraulic oil (rif. 16325); the oil improves the sliding of

the piston and prevent the product, coming out

from sealing gaskets, to dry once the equipment

is stopped.

REPLACEMENT OF THE

PUMPING UNIT GASKETS

• Unscrew the filter group (J1) from the pump housing (J2).

•

Unscrew the three self-locking nuts (J3) and remove the

pumping unit (J4), by unscrewing it from the motor piston rod.

J1

J2

J3J4

JJ

18

VEGA 23:1

English

• Remove the split pin (J6).

J6

• Unscrew the gaskets ring nut (J7) form the pump housing.

Unscrew the group of the suction valve (J8) .

When reassembling the seat of the valve (J12) in

the piston (J9) the thread shall be covered with

threads braking adhesive.

• Remove the piston (J9) from the pump housing and replace

the gaskets upper set (J10) or lower set (J11) respecting

the assembly order of the same.

J10

J11

J12

J9

J8

J7

19

VEGA 23:1

English

CLEANING AND REPAIRING

THE SUCTION VALVE

• If the suction valve is seized in the housing of the pump, inject

oil around the thread and knock slightly around the body of

the pump by means of a wooden mallet. Unscrew the valve

from the pump body.

Remove the pin (K1) holding the ball, as well as the ring

stop (K2), the O-ring (K3), the ball (K4). Clean all the parts,

inspect them and reassemble all the parts in the same order,

by screwing the valve in its seat.

MANUAL SERVICING OF THE

PNEUMATIC MOTOR

• The pump feeding air pressure shall never be higher than the

maximum value provided by the technical data sheet. Failure

in respecting this value could cause the blocking of the valves

of the pneumatic motor in the cycle inversion position.

• In order to restart a blocked motor, close the air feeding valve

and release the air pressure in the circuit. This should allow

the return of the valves in the correct position.

• Should the motor be blocked, proceed as follows:

- close the air supply to the pump and discharge the residual

pressure in the circuit;

K1

K2

K3

K4

KK

LL

20

VEGA 23:1

English

L1

L2

DISASSEMBLING THE

MOTOR

• Place the piston to the upper point of its run and unscrew

the plug (M1). Block the guide rod (M2) with clamping pliers

and replace the plug (M1) with a M8 nut (M3).

- unsprew the plug (L1) and pull it upwards together with the

guide rod (L2), by making thus manually trig the run inversion

group.

- screw the plug.

• Remove the screws (M4).

M2

M3

M4

M1

MM

21

VEGA 23:1

English

•

Take out the cylinder (M5) with the utmost care from the piston,

without inclining it in order to avoid damages to the inner walls

of the same.

•

By keeping the hands far from the cross piece (M6), press

on the rocker arm (M7) so that the cross piece (M6) trigs

downwards (drain valves closed).

• Unscrew the two counternuts (M8) which block the valve screws.

• Remove the valve screws (M9) and check the wear condition

of the gaskets (M10).

M5

M6 M7

M8

M8

M10

M9

22

VEGA 23:1

English

A

3,5 mm

•

Block the roller (M11) with the pliers and by pressing on the

spring (M12), remove it from its seat. In this way, it will be

possible to remove all the run inversion group.

•

Check the condition of each piece, in particular of the gaskets

(M13) and the O-ring (M14), (M15) and (M16).

Control that the inner walls of the cylinder are not scratched.

Before reassembling all parts, lubricate them with light and

water proof grease.

•

Adjust then the distance (A) between the gaskets and the

surface of the piston. This adjustment shall be done with the

cross piece (M7) down and it can be better done by using our

special metering device.

After having reassembled all parts, before connecting the

group to the pump, test it by feeding a small quantity of air

(3-4 bar).

• For a correct reassembly, refer to the pumping group detailed

drawing, by following the disassembly instructions in reverse

order.

M11

M13

M12

M13

M16

M15

M14

23

VEGA 23:1

English

TROUBLESHOOTING

• The pump does not work

• The operation of the pump is ac-

celerated and without pressure

• The pump works but it does not

stop when the chamber is full (the

pumping unit slowly moves up

and/or down)

• By pressing the gun trigger, the

pressure of the product highly

decreases

• Feeding air is not sufficient.

• Product outlet line is clogged;

• Product inlet line is clogged;

• Pneumatic motor is blocked in the

position of cycle inversion;

• Some components of the pneumatic

motor are damaged ;

• The product is lacking;

• The pump is sucking air;

• The gaskets of the pumping rod are

worn;

• The suction valve is worn or partially

clogged;

• The suction filter is clogged;

• The suction filter is too thin;

• The gaskets of the pumping shaft are

worn;

• The suction valve is worn or partially

clogged;

• The feeding valve is worn or partially

clogged;

• Upper gaskets are worn;

• Gun nozzle is too big or worn

• Gun filter and the filter sieve for product

outlet are too thin

• Check the air supply line. Increase

the diameter of the feeding air pipe;

• Open the recirculation nozzle and

check that the pump starts. Unscrew

the high pressure filter and clean and/

or replace the filter sieve. Clean and/

or replace the gun filter;

• Clean the suction filter;

• Decrease the feeding pressure;

• Manually service the pneumatic

motor;

• Disassemble the motor and inspect

it;

• Add product;

• Check the flexible suction hose;

• Replace the lower gaskets;

• Disassemble the suction valve. Clean

and/or replace any worn component.

• Clean and/or replace the two discs

of the suction filter;

• Remove the fine-mesh filter disc and

leave only the large-mesh filter disc.

• Replace the lower gaskets

• Disassemble the suction valve and

clean and/or replace any worn detail

• Disassemble the feeding valve and

clean and/or replace any worn detail

• Tighten the gaskets ring nut

• Replace it with a smaller one

• Replace them with larger-mesh filters

Solution

Possible cause

Faults

Before performing any inspection or replacement of the pump components, make always

sure to close the compressed air supply and discharge the residual pressure in the circuit.

NN

24

VEGA 23:1

English

25

VEGA 23:1

English

SPARE PARTS

SPARE PARTS

Complete trolley

page 36

Paints suction system

page 39

Air regulation unit

AIRLESS - MISTLESS

version page 37-38

Complete pneumatic motor Rif. 9100

page 26

Vega stainless steel split

pump complete pumping

unit page 28

Vega split pump complete

pumping unit

page 30

Vega split pump on tank

complete pumping unit

page 32

Vega split pump on tank

page 34

High pressure gun AT 250

page 40

OO

PPQQSS

XX

WWRRTT

U-VU-V

26

VEGA 23:1

English

VEGA PUMP 23:RIF. 9100 COMPLETE PNEUMATIC MOTOR

ATTENTION: always indicate code and quantity of each requested detail

L A R I U S

V E G A

1

2

3

9

9

10

10

11

11

12

13

17

18

4

5

6

7

8

14

15

16

21

22

23

19

24

25

27

32

29

30

26

31

33

34

35

29

28

36

38

37

20B

20

20A

OO

27

VEGA 23:1

English

* Kit 40040: motor gaskets kit

** Kit 40401: cross piece screws kit

Pos.

Complete pneumatic motor

Vega pump 23:1

Plug

O-Ring

Cylinder motor

Roller

Spring

Fork

Fork gudgeon

Rocker lever

M8 Nut **

Washer **

Gasket

Bushing **

Cross piece

O-Ring *

Guide

Rubber valve

M3 screw

Cross piece guide spring

Motor piston

Complete valve screw

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

1

1

2

2

2

2

1

4

4

4

2

1

1

1

2

2

2

1

1

Pos.

20A

20B

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Rubber valve

Valve screw

Washer

Piston rod

Complete washer

O-ring *

O-ring

Motor support

Grounding plate

M6 screw

Felt gasket

M8 screw

Front label

Upper label

M4 screw

Tie rod

M10 Nut

Elbow 3/8”

Ball valve

Quick coupling 3/8” ø 12

1

1

1

1

1

1

1

1

1

1

2

4

1

1

12

3

3

1

1

1

91000

,

96001

95075

91028

96005

96006

96007

96024

96008

4108

32024

96111

96112

91029

91034

91033

96009

91030

91032

91035

96027

96014

96015

91036

91043

96017

91037

91038

91042

96210

96211

96340

34008

91039

91040

96028

91006

96080

96214

91101

96215

Code Description Q.ty Code Description Q.ty

*

**

*

**

*

**

*

**

28

VEGA 23:1

English

STAINLESS STEEL SPLIT VEGA PUMP 23:1

COMPLETE PUMPING UNIT

ATTENTION: always indicate code and quantity of each requested detail.

Complete line filter Complete pumping unit

10

12

14

15

16

17

18

19

20

13

21

22

23

24

25

26

27

28

30

29

32

31

33

34

35

36

11

37

38

15A

23A

1

2

3

4

5

6

7

8

9

10

11

12

13

10

PP

29

VEGA 23:1

English

Pos.

Complete pumping unit

Oil cup

O-ring

Gaskets ring nut

Complete cup

Female V ring

Ptfe gasket

Polyethylene gasket

Male V ring

Pumping unit housing

O-ring

Split pin

Piston rod

Washer

Male V ring

Ptfe gasket

Code Description

,

10

11

12

13

*14

*15

*15A

*16

17

18

*19

20

21

*22

*23

Q.ty

1

1

1

1

1

2

2

1

1

1

1

1

1

1

2

Pos. Code Description Q.ty

*23A

*24

*25

26

27

28

29

*30

*31

32

33

34

35

36

37

38

Polyethilene gasket

Female V ring

Ø5/16* Ball

Pumping unit piston

Ball guide

Ring

Ball locking pin

O-ring

Ø1/2* Ball

Suction valve

Elbow

Suction hose fitting

Bushing

Filter fitting

Gasket

Liner

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

98440

91001/1

3429

98506

91001

98454

91031

91048

98456

98455

91008

3323

98452

98458

98460

91022

91049

98462

96090

98463

98466

98368

98370

96093

96094

98373

98374

98376

96099

98378

96083

91512

* Kit 40045: spare kit

Pos.

Complete line filter

3/8” gas plug

Filter tank

Sieve spring

Filter sieve 200m

Filter sieve 100m

Filter sieve 60m

Sieve support

Code Description

1

2

3

4

5

Q.ty

1

1

1

1

1

1

1

Pos. Code Description Q.ty

6

7

8

9

10

11

12

13

O-ring

1/4” gas-16x1,5 nipple

Filter base

Adapter 1/4” con-cil

Copper gasket 1/4”

Ball valve 1/4”

Elbow MF 1/4”

Adapter 1/4” - M20x2

1

1

1

1

2

1

1

2

98387

98385

98384

96202

95221

95220

95219

96207

96203

98383

98380

3110

32012

98325

98377

96065

30

VEGA 23:1

English

VEGA SPLIT PUMP 23:1 COMPLETE PUMPING UNIT

ATTENTION: always indicate code and quantity of each requested detail.

10

12

14

15

16

17

18

19

20

13

21

22

23

24

25

26

27

28

30

29

32

31

33

34

35

36

11

37

38

15A

23A

1

2

3

4

5

6

7

8

9

10

11

12

13

10

Complete line filter Complete pumping unit

QQ

31

VEGA 23:1

English

Pos.

Complete pumping unit

Oil cup

O-ring

Gaskets ring nut

Complete cup

Female V ring

Teflon gasket

Polyethilene gasket

Male V ring

Pumping unit housing

O-ring

Split pin

Piston rod

Washer

Male V ring

Teflon gasket

Code Description

,

10

11

12

13

*14

*15

*15A

*16

17

18

*19

20

21

*22

*23

Q.ty

1

1

1

1

1

2

2

1

1

1

1

1

1

1

2

Pos. Code Description Q.ty

*23A

*24

*25

26

27

28

29

*30

*31

32

33

34

35

36

37

38

Polyethilene gasket

Female V gasket

Ø5/16* ball

Pumping unit piston

Ball guide

Ring

Ball locking pin

O-ring

Ø1/2* ball

Suction valve

Elbow

Suction hose fitting

Entry liner

Filter fitting

Gasket

Liner

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

91027

91001/1

3429

98506

91001

98454

91031

91048

98456

98455

91008

3323

98452

98458

98460

91022

91049

98462

96090

98463

91714

96092

98370

96093

96094

98373

95089

96098

96099

98378

96083

91512

* Kit 40045: spare kit

Pos.

Complete line filter

3/8” gas plug

Filter tank

Sieve spring

Filter sieve 200m

Filter sieve100m

Filter sieve 60m

Sieve support

Code Description

1

2

3

4

5

Q.ty

1

1

1

1

1

1

1

Pos. Code Description Q.ty

6

7

8

9

10

11

12

13

O-ring

1/4” gas-16x1,5 nipple

Filter base

Adapter 1/4” con-cil

Copper gasket 1/4”

Ball valve 1/4”

Elbow MF 1/4”

Adapter 1/4” - M20x2

1

1

1

1

2

1

1

2

96200

95214

96201

96202

95221

95220

95219

96207

96203

96206

96204

96208

33012

33013

5255

33015

32

VEGA 23:1

English

VEGA SPLIT PUMP ON TANK 23:1 COMPLETE

PUMPING UNIT

L A R I U S

V E G A

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

36

32

33

34

35

32

34

33

31

37

1

2

3

4

5

6

8

7 9

Complete line filter

Complete pumping unit

ATTENTION: always indicate code and quantity of each requested detail.

RR

33

VEGA 23:1

English

Pos. Code Description Q.ty

Complete line filter

3/8” gas plug

Filter tank

Sieve spring

Filter sieve 200m

Filter sieve100m

Filter sieve 60m

Sieve support

O-ring

1/4” gas-16x1,5 nipple

Filter base

1/4” gas plug

,

1

2

3

4

5

6

7

8

9

1

1

1

1

1

1

1

1

1

1

2

96200

95214

96201

96202

95221

95220

95219

96207

96203

96206

96204

96205

Pos.

Complete pumping unit

Filter fitting

Gaskets ring nut

Female V ring

Teflon gasket (standard)

Leather gasket

Male V ring

Pumping unit housing

O-ring

Split pin

Piston rod

Washer

Male V ring

Teflon and glass gasket

(standard)

Pure Teflon gasket

Leather gasket

Code Description

,

10

11

12

*13

13A

14

15

16

*17

18

19

20

*21

21A

21B

Q.ty

1

1

1

4

1

1

1

1

1

1

1

1

4

1

1

Pos. Code Description Q.ty

22

*23

24

25

26

*27

28

*29

30

31

32

33

34

35

36

37

Female V ring

Ø5/16* ball

Pumping unit piston

Ball guide

Ring

O-ring

Ball locking pin

Ø1/2* ball

Suction valve

Fitting

Fitting

Hub

Hub nut

Product tube

Fitting

(3 leather 1 teflon)

Complete pneumatic motor

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

91710

91730

91001/2

91002

91003

91004

91005

91007

91008

3323

91009

91011

91012

91014

91022

91015

91013

96090

91017

91714

96092

96093

96096

96094

91713

91712

91715

91716

91717

91718

91719

91000

* Kit 40045: spare kit

34

VEGA 23:1

English

VEGA SPLIT PUMP 23:1 ON TANK RIF. 91700

L A R I U S

V E G A

14

2

13

8

7

6

4

5

1

15

4

18

17

16

10

9

11

12

19

3

ATTENTION: always indicate code and quantity of each requested detail.

SS

35

VEGA 23:1

English

Pos.

Complete pneumatic motor

Complete line filter

Complete pumping unit

Code Description

1

2

3

Q.ty

1

1

1

91000

96200

91710

Pos.

Complete air regulation unit

3/8” gas C nipple

3/8” gas tap

Pressure regulator

Bajonet coupling

Pressure gauge

Code Description

4

5

6

7

8

Q.ty

2

1

1

1

1

91735

91020

91101

91736

10103

96259

Pos.

Complete tank filter

Filter tank

Fine-mesh filter disc

Large-mesh filter disc

Spring

Code Description

9

10

11

12

Q.ty

1

1

1

1

91725

91726

35006

35007

35008

Pos.

Complete container

Container handle

Split pin

M6 screw

Container cover

Washer

M6 Nut

Container

Code Description

13

14

15

16

17

18

19

Q.ty

1

2

3

1

3

3

1

91740

91741

84007

91062

91742

54003

91026

91743

36

VEGA 23:1

English

COMPLETE TROLLEY

7

2

3

4

5

6

1

6

8

9

Pos.

Complete trolley

Trolley handle

Trolley frame

Trolley plate

Wheel

Feet

Code Description

1.

2

3

4

5

Q.ty

1

1

1

2

2

Pos. Code Description Q.ty

6

7

8

9

10

Wheel washer

Screw

Washer

Nut

Split pin

6

2

2

2

2

96320

16271

16272

16954

91023

37403

91047

8047

95063

91026

84007

10

10

7

8

9

6

4

6

5

ATTENTION: always indicate code and quantity of each requested detail.

TT

37

VEGA 23:1

English

Pos.

Complete unit

3/8 tube Ø 12 quick coupling

FR group

UNI 5588 M6 Nut

Ø 6 washer

Code Description

1.

2

3

4

Q.ty

-

1

1

2

2

Pos. Code Description

5

6

7

8

TCE UNI 5931 M6x22 screw

Bajonet coupling

Pressure gauge

Rilsan tube

2

1

1

1

96250

96015

91107

91026

95063

8047

10103

96259

96217

AIRLESS VERSION Rif. 96250 AIR REGULATION UNIT

Q.ty

ATTENTION: always indicate code and quantity of each requested detail

1

2

3

4

5

6

7

8

UU

38

VEGA 23:1

English

Pos.

Complete unit

3/8 tube Ø 12 quick coupling

Pressure gauge

Group RL 3/8 + bracket

3/8 mm conic adapter

3/8 “T” female fitting

Bajoinet coupling

3/8 1/4 mm CON-CON adapter

Pressure gauge

Code Description

1

2

3

4

5,

6

7,

8

Q.ty

-

1

1

1

1

1

1

1

1

Pos. Code Description Q.ty

9

10

11

12

13

14

15

16

17

Air regulator

1/4 MF adapter

MF 1/4 elbow

1/4 cupper gasket

1/4 mm adapter

Pressure gauge bracket

UNI 5588 M6 nut

Ø 6 washer

TCE UNI5931 M6x22 screw

1

1

1

1

1

1

2

2

2

96262

96216

96259

91107

91020

3379

10103

3560

8167

3344

8055/1

5255

33012

3289

510510

91026

95063

8047

MISTLESS VERSION Rif. 96262 AIR REGULATION UNIT

9

1

2

3

4

5

6

10

7

11

8

12

13

15

16

17

14

17

16

15

ATTENTION: always indicate code and quantity of each requested detail.

VV

39

VEGA 23:1

English

Pos.

Paints suction system with split

suction tubes

Filter assembly

Suction hose complete with filter

with split suction unit

Filter tank

Thin filter disc (80 mesh)

Thick filter disc (25 mesh)

Spring

Split recirculation tube

Code Description

1

2

3

4

5

6

7

Q.ty

1

1

1

1

1

1

1

Pos. Code Description Q.ty

1

2

3

4

5

6

7

Paints suction system with stain-

less steel suction tubes

Asssieme filtro di fondo

Suction hose complete with filter

with split suction unit

Filter tank

Thin filter disc (80 mesh)

Thick filter disc (25 mesh)

Spring

Split recirculation tube

1

1

1

1

1

1

1

16110

35020

16608

35005/1

35006

35007/1

35008

16609

16111

35020

16612

35005/1

35006

35007/1

35008

16613

PAINTS SUCTION SYSTEM

7

2

3

4

5

6

1

ATTENTION: always indicate code and quantity of each requested detail.

WW

40

VEGA 23:1

English

ATTENTION: always indicate code and quantity of each requested detail.

A

1

2

3

4

6

12

5

11

6a

6b

6c

6d

6e

7

8

9

10

13

14

15

6h

6a

6h

6b

6f

6g

6g

6

AT 250 HIGH PRESSURE GUN

XX

41

VEGA 23:1

English

Components Pos. 5 - 11023 - Linkage

11005/3 Ball

11204/1 Ball housing

11205/2 Spring

11205/4 Linkage

11205/5 Sleeve

11205/6 Ring sleeve

11205/7 Bushing

Pos

.

Pos

Nozzle Super Fast Clean

Body Super Fast Clean

Gasket Super Fast Clean

Sleeve

Safety for hand +

3 screws TSP 3x8

Complete linkage

Trigger gun

Safety lever

Brake washer

Trigger

Pin

Pin

Pin

Nut M3

Washer

Gun body

Spinet

Plate

Self-locking nut M5

Copper gasket

Filter

Handgrip

Spring

Copper gasket

Articulated joints M16x1,5

Articulated joints 1/4”

See table*

18270

18280

11004

11006 +

11032

11203

11008

11010

11011

11009

11012

11013

11034/1

11027

11016

11206

11207

11208

11209

11020

-

11018

11017

32010

11015

11155

A

1

2

3

4

5

6

6a

6b

6c

6d

6e

6f

6g

6h

7

8

9

10

11

12

13

14

15

16

Code Description Code Description

42

VEGA 23:1

English

ACCESSORIES

Art. 11250: AT 250 1/4"

Art. 11200: AT 250 M16x1,5

GUN FILTERS

Art.

11039: Green (30M) -

Art.

11038: White (60M)

Art.

11037: Yellow (100M) -

Art.

11019: Red (200M)

FILTER

Art. 95218: SIEVE 30M

Art. 95219: SIEVE 60M

Art. 95220: SIEVE 100M

Art. 95221: SIEVE 200M

FITTING WITH PRESSURE GAUGE

Art.

147: M16x1,5

Art.

150: 1/4"

Art.

18270: SUPER FAST-CLEAN

base

UE 11/16x16

Art.

18280: GASKET

SUPER FAST-CLEAN NOZZLE

SUPER FAST-CLEAN

Nozzles codes

SFC07-20

SFC07-40

SFC09-20

SFC09-40

SFC11-20

SFC11-40

SFC13-20

SFC13-40

SFC13-60

SFC15-20

SFC15-40

SFC15-60

SFC17-20

SFC17-40

SFC17-60

SFC19-20

SFC19-40

SFC19-60

SFC21-20

SFC21-40

SFC21-60

SFC23-20

SFC23-40

SFC23-60

SFC25-20

SFC25-40

SFC25-60

SFC27-20

SFC27-40

SFC27-60

SFC27-80

SFC29-20

SFC29-40

SFC29-60

SFC29-80

SFC31-40

SFC31-60

SFC31-80

SFC33-40

SFC33-60

SFC33-80

SFC39-40

SFC39-60

SFC39-80

SFC43-40

SFC43-60

SFC43-80

SFC51-40

SFC51-60

SFC51-80

YY

43

VEGA 23:1

English

Art. 16610: SUCTION SYSTEM

Art. 16611: SUCTION SYSTEM stainless steel

HIGH PRESSURE TUBE 3/8" - M16x1,5 max pressure 425 bar

Art.

18063: 7,5 mt

Art.

18064: 10 mt

Art.

18065: 15 mt

ANTISTATIC TUBE 3/16" - M16x1,5 max pressure 210 bar

Art.

6164: 5 mt

Art.

55050: 7,5 mt

Art.

35018: 10 mt

ANTI-PULSE TUBE 1/4" - M16x1,5 max pressure 250 bar

Art.

35013: 5 mt

Art.

35014: 7,5 mt

Art.

35017: 10 mt

Art.

18026: 15 mt

Art. 96200: LINE FILTER galvanized

Art. 98387: LINE FILTER stainless steel

GUN EXTENSION

Art. 153: cm 30 -Art. 153: cm 40

Art. 155: cm 60 - Art. 158: cm 80 - Art. 156: cm 100

44

VEGA 23:1

English

Vega 23:1 on trolley

Vega 23:1 stainless steel on trolley

Vega 23:1 on tank

Vega 23:1 on wall bracket

Vega 23:1 stainless steel on wall bracket

Code DESCRIPTION

91500

91504

91700

91900

91905

Vega ratio 23:1 without working kit

Pump complete with line filter, discharge valve,

suction, recirculation system.

Rif. 91700: VERSION ON TANK

Rif. 91500: VERSION ON TROLLEY

Rif. 91900: VERSION ON WALL BRACKET

VERSIONS

ZZ

45

VEGA 23:1

English

High pressure tube Ø 3/16” coupled M16X1,5 mt 7,5

Airless gun AT 250 revolving coupling M16X1,5 including Super fast clean base Rif. 18270

as option: Rif. 11250 airless gun AT250 revolving coupling ¼” including Super fast clean base Rif. 18270

Super fast clean base

“Super fast clean nozzle from 0.007” to 0,051”

Vega 23:1 Version on trolley + accessories complete with FRL and drain valve

Vega with line filter, suction-recirculation system

High pressure tube Ø 3/16” coupled M16X1,5 mt 7,5

Airless gun AT250 revolving coupling m16x1,5

Super fast clean base

Vega 23:1 stainless steel Version on trolley + accessories complete with FRL and drain valve

Vega with line filter, suction-recirculation system

High pressure tube Ø 3/16” coupled M16X1,5 mt 7,5

Airless gun AT250 revolving coupling m16x1,5

Super fast clean base

Vega 23:1 Version on tank + accessories complete with FRL and drain valve

Vega with line filter, suction-recirculation system

High pressure tube Ø 3/16” coupled M16X1,5 mt 7,5

Airless gun AT250 revolving coupling m16x1,5

Super fast clean base

AT 250 Airless gun kit

AT 250 Airless gun filters

AT 250 Trigger kit

Vega 23:1 gaskets kit

Vega 23:1 motor kit

Vega 23:1 bar screws kit

Code

Code

Code

DESCRIPTION

DESCRIPTION

DESCRIPTION

55050

11200

18270

SFC

k91506

91500

55050

11200

18270

K91508

91504

55050

11200

18270

K91510

91700

55050

11200

18270

40005

40400

40026

40045

40040

40401

Working kit

Vega ratio 23:1 complete with working kit. Nozzle not included.

KIT

It is possible to use standard nozzles.

46

VEGA 23:1

English

This safety instructions refer to the installation, use and maintenance of LARIUS piston pneumatic transfer pumps VEGA series for the

use in potentially explosive areas in presence of gas or vapours.

These instructions should be followed in addition to the instructions provided in the use and

maintenance manual.

The main characteristics of piston pneumatic transfer pumps

VEGA serie are indicated in the table below:

LARIUS piston pneumatic transfer pumps VEGA series are

mechanical equipment belonging to group II, for

the use in areas in presence of gas which are

classified as IIB (category 2 G). They have been

designed and manufactured in compliance with

the directive ATEX 94/9/CE, according to european standards

EN 1127-1, EN 13463-1ed EN 13463-5.

Max number of cycles per minute: 60

Room temperature: -20°C÷ +60°C

Fluid max temperature: [°C]: 60°C

SAFETEY INSTRUCTIONS FOR THE USE OF

PISTON PNEUMATIC TRANSFER PUMPS VEGA SERIES

IN POTENTIALLY EXPLOSIVE ENVIRONMENTS

IN PRESENCE OF GAS OR VAPOURS.

91360 91362 5:1 3 ÷ 8 bar GC 3/8" Ball valve GC 3/4" 40 bar 10 l/min

91365 91361 5:1 3 ÷ 8 bar GC 3/8" Ball valve GC 3/4” 40 bar 10 l/min

91368 91363 5:1 3 ÷ 8 bar GC 3/8" Ball valve GC 3/4” 40 bar 10 l/min

91501 91503 23:1 3 ÷ 8 bar GC 3/8" Ball valve GC 3/8" 184 bar 2,6 l/min

91910 - 45:1 3 ÷ 8 bar GC 3/8" Washer GC 3/8" 360 bar 1 l/min

91911 - 45:1 3 ÷ 8 bar GC 3/8" Washer GC 3/8" 360 bar 1 l/min

91912 - 45:1 3 ÷ 8 bar GC 3/8" Washer GC 3/8" 360 bar 1 l/min

Type Ratio Supplied Ø Air Ø product Ø product max operat. max

Standard

St. steel

pressure inlet feeding outlet pressure rate

ATEX CERTIFICATION

ATEX CERTIFICATION

AAAA

DESCRIPTION

ABAB

TECHNICAL FEATURES

47

VEGA 23:1

English

3

X

II 2 G c IIB T6 T

amb

: -20°C ÷ + 60°C T

max.

fluid: 60°C Tech. File: VEGA/ATX/08

II

2

G

c

T6

- 20°C ÷ + 60°C

60°C

xxxxx/AA

Group II ( surface)

Grade 2 (zone 1)

Explosive environment with gas, vapour or mist

Constructive safety "c"

Class of temperature T6

Room temperature

Max temperature of process fluid

Series number or lot number

(xxxxx = PROGRESSIVE / year = AA)

Correspondence between dangerous areas, substances and grade

GRADE ACCORDING TO

DIRECTIVE 94/9/CE

Gas, vapour or mist

Gas, vapour or mist

Gas, vapour or mist

1G

2G or 1G

3G, 2G or 1G

DANGEROUS AREA

Area 0

Area 1

Area 2

Before installation please read carefully the use and main-

tenance manual. All maintenance operations

must be carried out as reported in the manual.

• The grounding cable of these pumps must be connected

by means of suitable electrical connector.

• The feeding and suction hoses should be metal pipes, or

plastic pipes with metal braid or plastic pipes with textile

braid equipped with a suitable grounding conductor.

• Pumps must be installed on containers made of metal or

antistatic material,duly grounded.

• Gas or vapour rising from flammable liquids shall belong

to the group IIB.

• The user must periodically control the presence of foulings, the cleaning and wear conditions and the proper

operation of the pump, according to the type and use of

the product

• The user should periodically clean the suction filter in

order to prevent foreign matters entering into the pump.

The air used to supply power to the pump must be filtered

and come from a safe area (SAFE AREA).

The pneumatic piston pumps VEGA series

must not run dry.

All installation and maintenance operations

must be performed by qualified personnel.

ACAC

MARKING

ADAD

SAFETY INSTRUCTIONS

FOR THE INSTALLATION IN

DANGEROUS AREAS

48

VEGA 23:1

English

The picture shows a typical example of installation of a piston

transfer pneumatic pump.

We Larius S.r.l.

Via Stoppani, 21

23801 Calolziocorte (LC)

declare under our sole responsibility that the product:

Piston transfer pneumatic pumps VEGA series.

,this declaration is referred to, complies to the following directive:

- Directive 94/9/EC (ATEX)

3

X

Compliance has been verified on the basis of the

requirements provided by the following rules and

documents:

- EN 1127-1 - EN 13463-5

- EN 13463-1

Marking

II 2 G c IIB T6 Tamb.: - 20°C ÷ 60°C Tmax. fluid: 60°C

Technical dossier: VEGA/ATX/08

Technical dossier c/o: INERIS (0080)

Calolziocorte- LC, 15/12/2008

Signature (LARIUS)

AEAE

EXAMPLE OF

INSTALLATION

AFAF

DECLARATION OF

CONFORMITY

49

PAINT SPRAYING EQUIPMENT

L’innovazione.

Quella vera.

23801 CALOLZIOCORTE - LECCO - ITALY - Via Antonio Stoppani, 21

Tel. ( 39) 03 41/62 .11.5 2 - Fax (39) 0 341/6 2 .12. 4 3

E-mail: larius@larius.com - Internet http://www.larius.com

DIRECT LINE

Tel. (39) 0341/621256

Fax (39) 0341/621234

CUSTOMERS TECHNICAL SERVICE

AIRLESS PNEUMATIC PUMPS

MANUFACTURER:

GHIBLI 30:1 Art.-Nr. 96000

NOVA Rif. 95040

GHIBLI ZINC Rif. 96900

OMEGA ZINC Rif. 7430

OMEGA AIRLESS Art.-Nr. 7300

OMEGA MISTLESS Art.-Nr. 7340

SUPER NOVA 45:1 Rif. 65100

SUPER NOVA 68:1 Rif. 65102

SUPER NOVA 80:1 Rif. 65104

GHIBLI MIX 2K 40:1 INOX: Rif. 24561

Loading...

Loading...