ITALIANO

Ediz. 006 - 12/2017

www.larius.eu

INSTRUCTION MANUAL

Sirio

27:1

32:1

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

2

Due to a constant product improvement programme, the factory reserves the right to modify technical

details mentioned in this manual without prior notice.

This manual is to be considered as an English language translation of the original manual in Italian. The

manufacturer shall bear no responsibility for any damages or inconveniences that may arise due to the

incorrect translation of the instructions contained within the original manual in Italian.

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

3

SPARE PARTS

COMPLETE PNEUMATIC MOTOR .................... p.35

PNEUMATIC REGULATOR UNIT ASSEMBLY. ... p.37

PUMPING 155 CC (32:1) ..................................... p.38

PUMPING 180 CC (27:1) ..................................... p.39

FILTER ASSEMBLY ............................................p.40

STANDARD COMPLETE TROLLEY .................... p.41

PAINT SUCTION SYSTEM ................................. P. 42

PUMPING UNIT COUPLING KIT ........................ p.43

ACCESSORIES .................................................. p.44

INDEX ................................................................. P. 3

WARNINGS ........................................................P. 5

WORKING PRINCIPLE ....................................... p. 6

TECHNICAL DATA ............................................. p. 6

DESCRIPTION OF THE EQUIPMENT ............... p. 8

TRANSPORT AND UNPACKING ....................... p.10

SAFETY RULES ................................................. p.11

SETTING-UP ...................................................... p.12

WORKING ......................................................... p.14

CLEANING AT THE END OF THE WORK .......... p.14

ROUTINE MAINTENANCE ................................. p.15

DISASSEMBLY AND REASSEMBLY

OF THE PUMPING UNIT .................................... p.16

RIPRISTINO MANUALE DEL MOTORE

PNEUMATICO ................................................... p.24

DISASSEMBLY AND REASSEMBLY

OF THE PNEUMATIC MOTOR ........................... p.25

PROBLEMS AND SOLUTION ............................ p.33

Q

R

S

N

O

P

A

B

C

D

E

F

G

H

J

K

L

M

I

T

U

V

AIRLESS PNEUMATIC PUMPS FOR SPRAY PAINTING

WE ADVISE THE USE OF THIS EQUIPMENT ONLY BY PROFESSIONAL OPERATORS.

ONLY USE THIS MACHINE FOR USAGE SPECIFICALLY MENTIONED IN THIS MANUAL.

Thank you for choosing a LARIUS S.R.L. product. As well as the product

purchased, you will receive a range of support services

enabling you to achieve the results desired, quickly and professionally.

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

4

White page

intentionally

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

5

Read this operator’s manual carefully before using the equipment.

An improper use of this machine can cause injuries to people or things.

Do not use this machine when under the influence of drugs or alcohol.

Do not modify the equipment under any circumstances.

Use products and solvents that are compatible with the various parts of the equipment, and read the manufacturer’s warnings

carefully.

See the Technical Details for the equipment given in the Manual.

Check the equipment for worn parts once a day. If any worn parts are found, replace them using ONLY original spare parts.

Keep children and animals away from work area.

Comply with all safety standards.

It indicates an accident risk or serious damage to equipment if this warning is not followed.

It indicates important recommendations about disposal and recycling process of products in accordance with the environmental

regulations.

WARNINGS

The table below provides the meaning of the symbols used in this manual in relation to using, earthing,

operating, maintaining, and repairing of this equipment.

It indicates wound and finger squashing risk due to movable parts in the equipment.

Tenersi lontano dalle parti in movimento.

Do not use the equipment without the proper protection.

Before any inspection or maintenance of the equipment, carry out the decompression procedure explained in this manual, and

prevent any risk of the equipment starting unexpectedly.

Report any risk of chemical reaction or explosion if this warning has not been given.

There is a risk of injury or serious lesion related to contact with the jet from the spray gun. If this should occur, IMMEDIATELY

contact a doctor, indicating the type of product injected.

Do not spray before the guard has been placed over the nozzle and the trigger on the spray gun.

Do not put your fingers in the spray gun nozzle.

Once work has been completed, before carrying out any maintenance, complete the decompression procedure explained in

this manual.

This symbol signals the presence of a terminal with a grounding cable.

Use ONLY three-wire extensions and electrical outlets with grounding connections.

Before beginning work, make sure the electrical system is equipped with a grounding connection and that it complies with the safety

regulations.

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin.

To help prevent injection, always:

- Engage trigger lock when not spraying.

- Do not put your hand over the spray tip. Do not stop or deflect leaks with your hand, body or other.

- Do not point gun at anyone or at any part of the body.

- Never spray without tip guard.

- Ensure the trigger is locked at the end of spraying procedure.

- Do pressure relief at the end of spraying procedure and before any service operation.

- NEVER use components whose operating pressure is below the Maximum Working Pressure.

- Never allow children use this unit.

- Pay close attention to the possible recoil during gun triggering.

If high pressure fluid pierces your skin, the injury might look like “just a cut”, but it is a serious wound! Get immediate medical attention.

It is obligatory to wear suitable clothing as gloves, goggles and face shield.

Wear clothing that complies with the safety standards in force in the country in which the equipment is used.

Do not wear bracelets, earrings, rings, chains, or anything else that may hinder the operator’s work.

Do not wear clothing with wide sleeves, scarves, ties, or any other piece of clothing that could get tangled up in moving parts of

the equipment during the work, inspection, or maintenance cycles.

FIRE AND EXPLOSION HAZARD

Solvent and paint fumes in working area can ignite or explode.

To help prevent fire and explosion:

• Use equipment ONLY in well ventilated area.

• Eliminate all ignition sources, such as pilot lights, cigarettes and plastic drop cloths (potential static arc).

• Ground equipment and conductive objects.

• Use only grounded airless conductive hoses.

• Do not use trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such

solvents in pressurized aluminium equipment. Such use can cause serious chemical reaction and explosion.

• Never clean when the electrostatic parts of the gun are ON. Turn on the electrostatic parts of the gun only after having

removed any solvent from the circuit.

• Use cleaning solvents with a flash point as high as possible, preferably higher than ambient temperature

If electrical shocks or discharges are encountered, immediately stop the operation of the equipment.

Keep a fire extinguisher at hand close to the working area.

0

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

6

A

B

Sirio pumps are pneumatic pumps for high pressure painting

without the use of compressed air (AIRLESS). The stainless steel

version is particularly suitable for use with water-based paints.

The Sirio pump is essentially comprised of an air motor and

a structure known as the “Material Pumping Unit”, or simply

the “Pumping Unit”.

In the pneumatic motor, compressed air causes the vertical

reciprocating movement of the motor piston; this movement

is transmitted through a connecting rod to the material pum-

ping piston.

This allows for the material to be aspirated and pushed towards

the outlet. The unit comes complete with a transportation

trolley, a high-pressure material filter, an air supply regulator

for the pump, a material suction tube (complete with filter)

and a recirculation tube.

The ratio (27:1-30:1-32:1-45:1) means that the outlet pressure

of material is (27-30-32-45) times higher than the pump feed

air pressure.

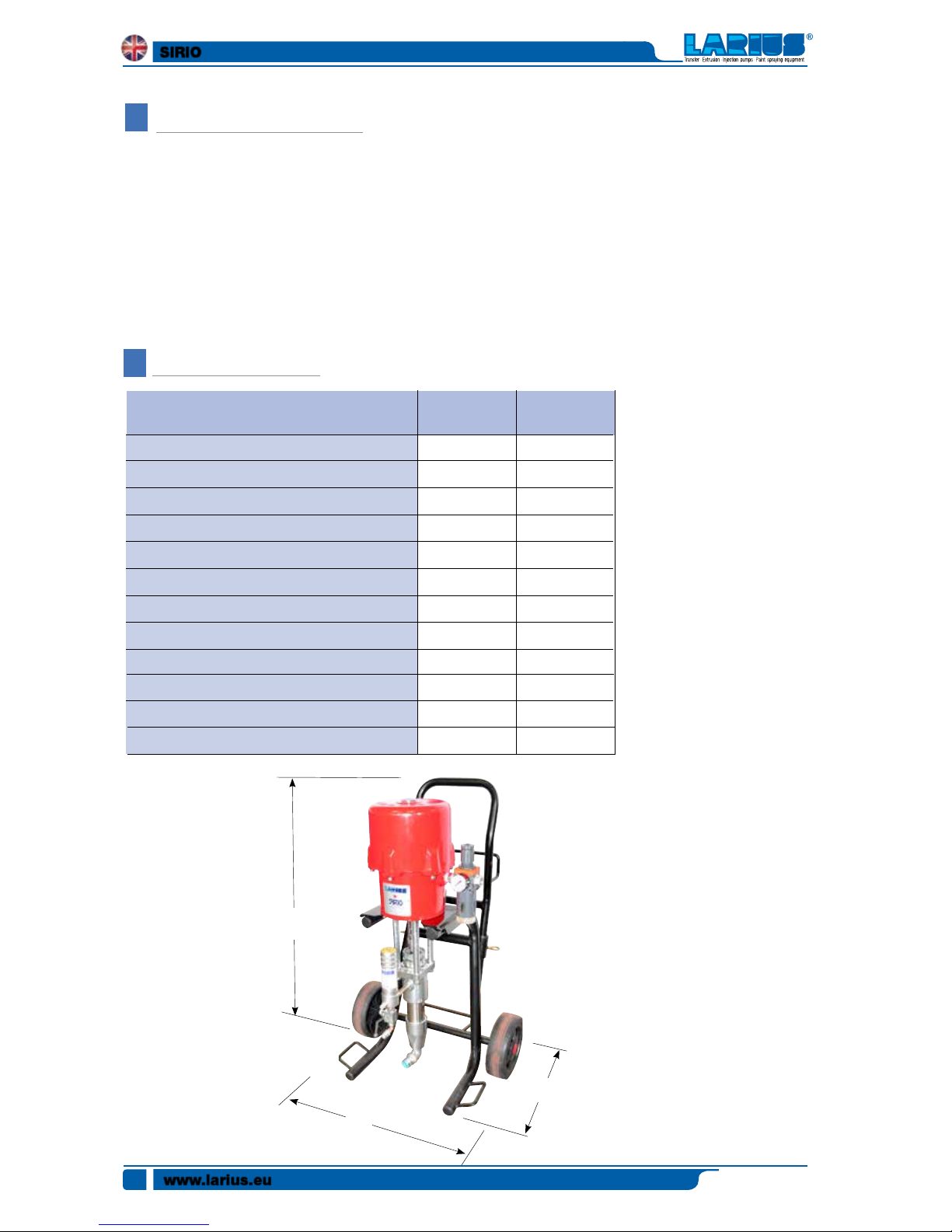

TECHNICAL DATA

27:1

3-7 bar

189 bar

1/2" GAS (F)

3/4" GAS C (M)

3/8" GAS C (F)

9.2 l/min

153

58 Kg

<80 dB (A)

930

450

450

PUMP FEED AIR PRESSUREA

MAXIMUM PRESSURE OF THE PRODUCT

*FEED AIR INLET

MATERIAL ENTRY

MATERIAL EXIT

MAXIMUM DELIVERY

CC/CYCLE

WEIGHT

NOISE PRESSURE LEVEL

DIMENSIONS

A

B

C

32:1

3-7 bar

224 bar

1/2" GAS (F)

3/4" GAS C (M)

3/8" GAS C (F)

8.2 l/min

137

58 Kg

<80 dB (A)

930

450

450

SIRIO

WORKING PRINCIPLE

a

c

b

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

7

Parts of the pump in contact with the material

Pumping group: galvanised carbon steel and aluminium or

stainless steel (based on the versions)

Sealing balls: stainless steel AISI 420B

Gaskets: Teflon

Other parts of the pump

Motor casing and motor piston: aluminium

Pneumatic motor piston rod: stainless steel

Trolley structure: painted sheet metal

Always observe these instructions carefully when evaluating the product compatibility and in case of disposal of some

parts of the pump no more usable, in order

to meet the environmental regulations on

recycling process.

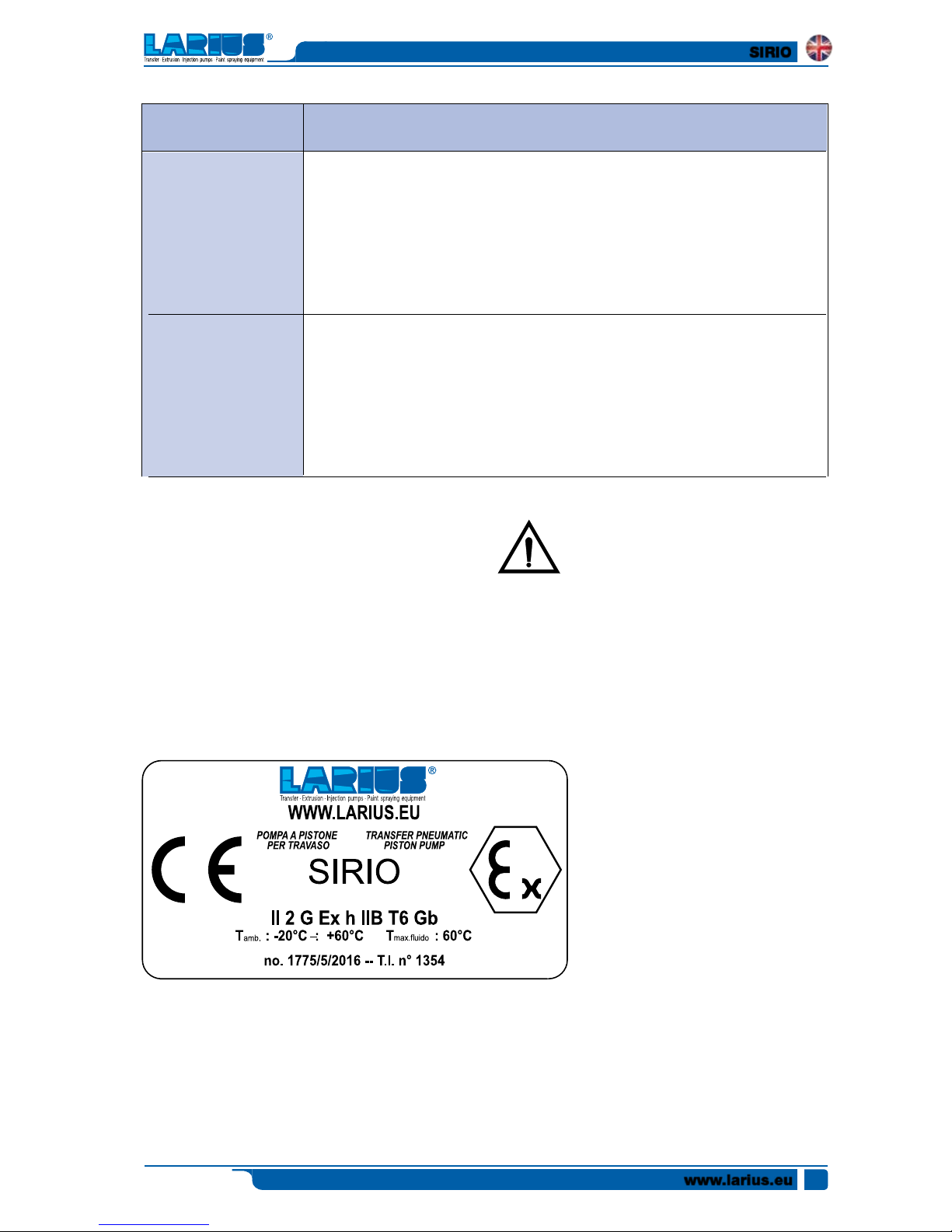

ATEX plate

Code

Sirio 27:1 Stainless steel - Trolley version + accessories

99000 Sirio 27:1 Stainless steel complete with FRL unit, line filter, drain valve,

suction-recirculation system

35014 High pressure hose ø¼” 7.5 m M16x1.5 fitting

11200 AT250 airless spray gun with M16x1.5 revolving fitting

18270 Super Fast Base Clean

SFC Airless nozzle (choice of size)

17200 Toolbox

Sirio 32:1 Stainless steel - Trolley version + accessories

99002 Sirio 32:1 Stainless steel complete with FRL unit, line filter, drain valve,

suction-recirculation system

35014 High pressure hose ø¼” 7.5 m M16x1.5 fitting

11200 AT250 airless spray gun with M16x1.5 revolving fitting

18270 Super Fast Base Clean

SFC Airless nozzle (choice of size)

17200 Toolbox

K99000

K99002

Description

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

8

C

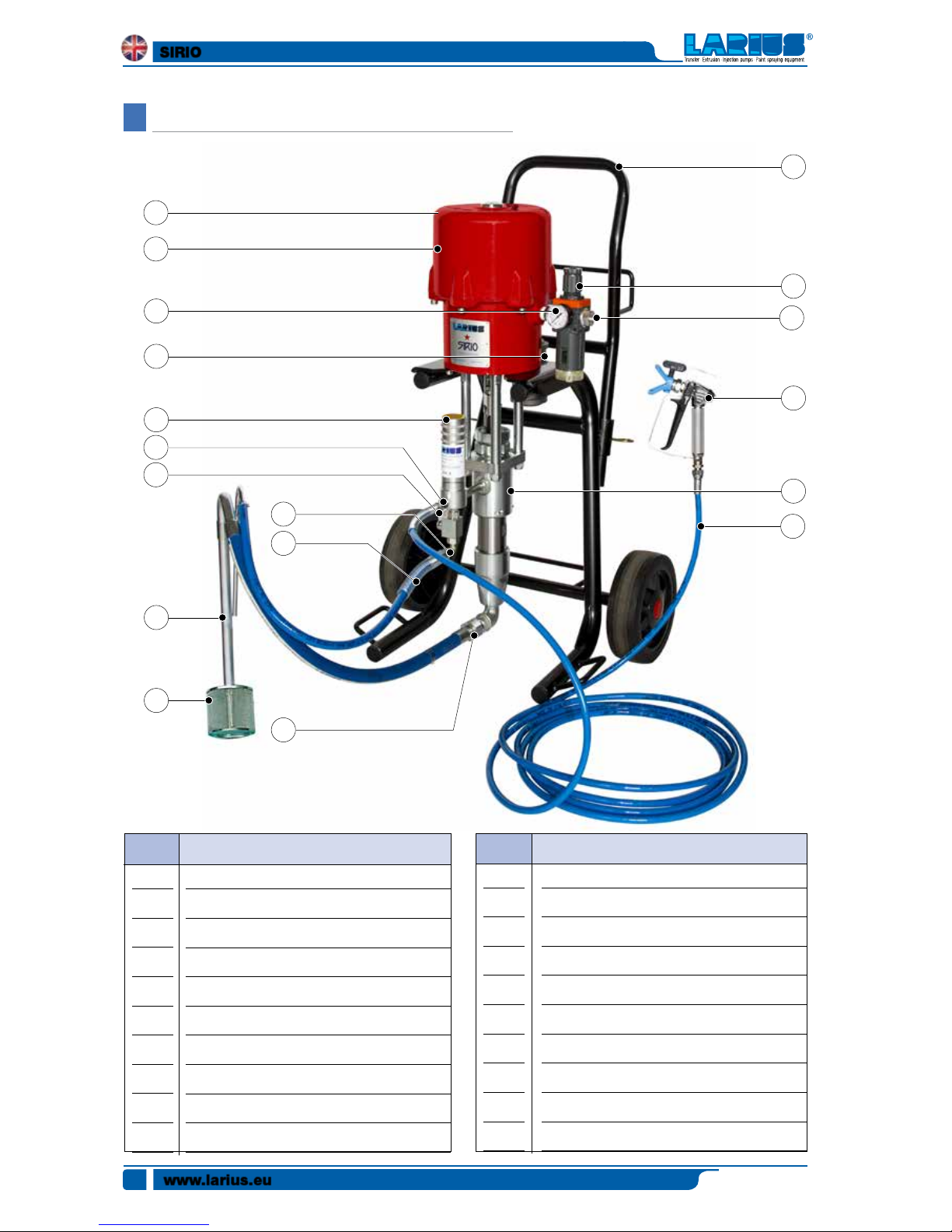

DESCRIPTION OF THE EQUIPMENT

POS.

1

2

3

4

5

6

7

8

9

10

Compressed air inlet

Manometer reading air pressure alim. pump

Feed air pressure regulator. pump

Trolley transport equipment

Sound absorbing filter

Pneumatic motor pump

Filtro alta pressione uscita materiale

High pressure filter out material

Recirculating cock

Recirculation pipe fitting fixing

Description POS. Description

11

12

13

14

15

16

17

18

19

20

Fluid recirculation pipe

Material suction pipe

Material suction filter

Fitting pipe fitting intake

Material pumping group

Material flexible pipe

Spray technology

Cable grounding with gripper

Gun AT250 - OPTIONAL

Gun L91 - OPTIONAL

1

3

2

4

6

7

8

9

10

11

12

13

14

15

16

17

18

5

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

9

18

3

1

9

7

8

10

6

2

air

5

16

13

12

11

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

10

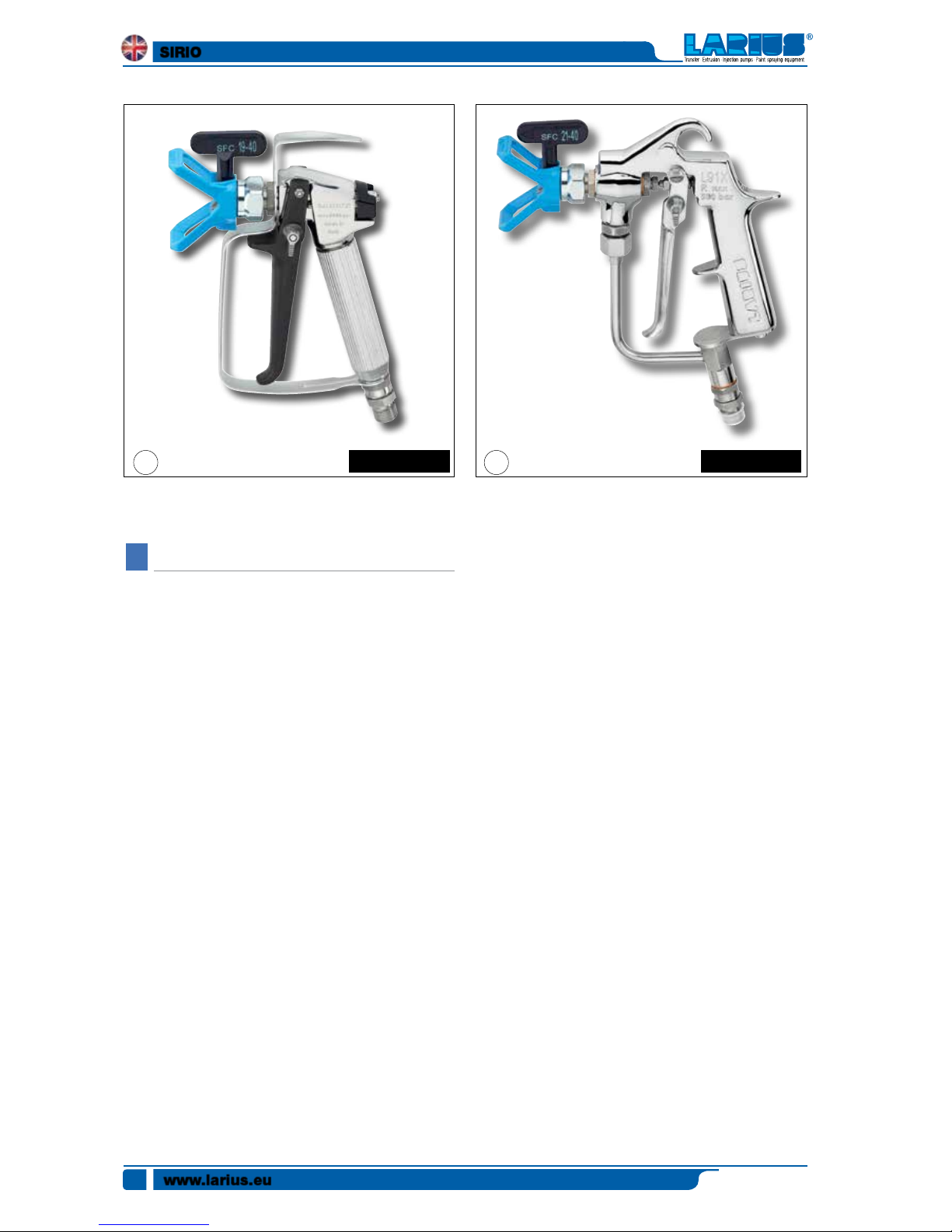

D

19

Gun AT250

20

Gun L91

TRANSPORT AND UNPACKING

• Thepackedpartsshouldbehandledasindicatedinthe

symbols and markings on the outside of the packing.

• Beforeinstallingtheequipment,ensurethattheareato

be used is large enough for such purposes, is properly

lit and has a clean, smooth floor surface.

• Theuserisresponsiblefortheoperationsofunloading

and handling and should use the maximum care so as

not to damage the individual parts or injure anyone.

To perform the unloading operation, use only qualified

and trained personnel (truck and crane operators, etc.)

and also suitable hoisting equipment for the weight of

the installation or its parts.

Follow carefully all the safety rules.

The personnel must be equipped with the necessary

safety clothing.

• The manufacturer will not be responsible for the unlo-

ading operations and transport to the workplace of the

machine.

• Checkthepacking is undamaged on receipt of the

equipment. Unpack the machine and verify if there has

been any damage due to transportation.

In case of damage, call immediately LARIUS and the

Shipping Agent. All the notices about possible damage

or anomalies must arrive timely within 8 days at least

from the date of receipt of the plant through Registered

Letter to the Shipping Agent and to LARIUS.

• Thedisposal ofpackaging materialsisa customer’s

competence and must be performed in accordance with

the regulations in force in the country where the plant is

installed and used.It is nevertheless sound practice to

recycle packaging materials in an environment-friendly

manner as much as possible.

OPTIONAL OPTIONAL

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

11

E

SAFETY RULES

•

THE EMPLOYER SHALL TRAIN ITS EMPLOYEES

ABOUT ALL THOSE RISKS STEMMING FROM ACCI

DENTS, ABOUT THE USE OF SAFETY DEVICES FOR

THEIR OWN SAFETY AND ABOUT THE GENERAL

RULES FOR ACCIDENT PREVENTION IN COMPLIANCE

WITH INTERNATIONAL REGULATIONS AND WITH THE

LAWS OF THE COUNTRY WHERE THE PLANT IS USED.

THE BEHAVIOUR OF THE EMPLOYEES SHALL STRICTLY

COMPLY WITH THE ACCIDENT PREVENTION AND ALSO

ENVIRONMENTAL REGULATIONS IN FORCE IN THE

COUNTRY WHERE THE PLANT IS INSTALLED AND USED.

Read carefully and entirely the following

instructions before using the product. Please

save these instructions in a safe place.

The unauthorised tampering/replacement of

one or more parts composing the machine,

the use of accessories, tools, expendable

materials other than those recommended

by the Manufacturer can be a danger of

accident.

The Manufacturer will be relieved from tort

and criminal liability.

• KEEP YOUR WORK PLACE CLEAN AND TIDY. DISORDER

WHERE YOU ARE WORKING CREATES A POTENTIAL

RISK OF ACCIDENTS.

• ALWAYS KEEP PROPER BALANCE AVOIDING UNUSUAL

STANCE.

• BEFORE USING THE TOOL, ENSURE THERE ARE NOT

DAMAGED PARTS AND THE MACHINE CAN WORK PROPERLY.

• ALWAYS FOLLOW THE INSTRUCTIONS ABOUT SAFETY

AND THE REGULATIONS IN FORCE.

• KEEP THOSE WHO ARE NOT RESPONSIBLE FOR THE

EQUIPMENT OUT OF THE WORK AREA.

• NEVER EXCEED THE MAXIMUM WORKING PRESSURE

INDICATED.

• NEVER POINT THE SPRAY GUN AT YOURSELVES OR

AT OTHER PEOPLE. THE CONTACT WITH THE CASTING

CAN CAUSE SERIOUS INJURIES.

• IN CASE OF INJURIES CAUSED BY THE GUN CASTING,

SEEK IMMEDIATE MEDICAL ADVICE SPECIFYING THE

TYPE OF THE PRODUCT INJECTED. NEVER UNDERVALUE

A WOUND CAUSED BY THE INJECTION OF A FLUID.

• ALWAYS DISCONNECT THE SUPPLY AND RELEASE THE

PRESSURE IN THE CIRCUIT BEFORE PERFORMING

ANY CHECK OR PART REPLACEMENT OF THE EQUIPMENT.

• NEVER MODIFY ANY PART IN THE EQUIPMENT. CHECK

REGULARLY THE COMPONENTS OF THE SYSTEM.

REPLACE THE PARTS DAMAGED OR WORN.

•

TIGHTEN AND CHECK ALL THE FITTINGS FOR

CONNECTION BETWEEN PUMP, FLEXIBLE HOSE

AND SPRAY GUN BEFORE USING THE EQUIPMENT.

• ALWAYS USE THE FLEXIBLE HOSE SUPPLIED WITH

STANDARD KIT.

• THE USE OF ANY ACCESSORIES OR TOOLING OTHER

THAN THOSE RECOMMENDED IN THIS MANUAL, MAY

CAUSE DAMAGE OR INJURE THE OPERATOR.

• THE FLUID CONTAINED IN THE FLEXIBLE HOSE CAN

BE VERY DANGEROUS. HANDLE THE FLEXIBLE HOSE

CAREFULLY. DO NOT PULL THE FLEXIBLE HOSE TO

MOVE THE EQUIPMENT. NEVER USE A DAMAGED OR A

REPAIRED FLEXIBLE HOSE.

The high speed of travel of the product in the

hose can create static electricity through

discharges and sparks. It is suggested to earth

the equipment. The pump is earthed through

the earth cable of the supply.

The gun is earthed through the high pressure flexible hose.

All the conductors near the work area must be earthed.

• NEVER SPRAY OVER FLAMMABLE PRODUCTS OR SOL-

VENTS IN CLOSED PLACES.

• NEVER USE THE TOOLING IN PRESENCE OF POTEN-

TIALLY EXPLOSIVE GAS.

Always check that the product is compatible

with the materials composing the equipment

(pump, spray gun, flexible hose and accessories)

with which it can come into contact. Never

use paints or solvents containing Halogen

Hydrocarbons (as the Methylene Chloride). If these products

come into contact with aluminium parts can provoke

dangerous chemical reactions with risk of corrosion and

explosion.

Avoid approaching too much to the pump pi-

ston rod when the pump is working or under

pressure. A sudden movement of the piston

rod can cause wounds or finger squashing.

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

12

TAKE PROPER SAFETY MEASURES FOR THE PROTECTION

OF HEARING IN CASE OF WORK NEAR THE PLANT.

F

SETTING-UP

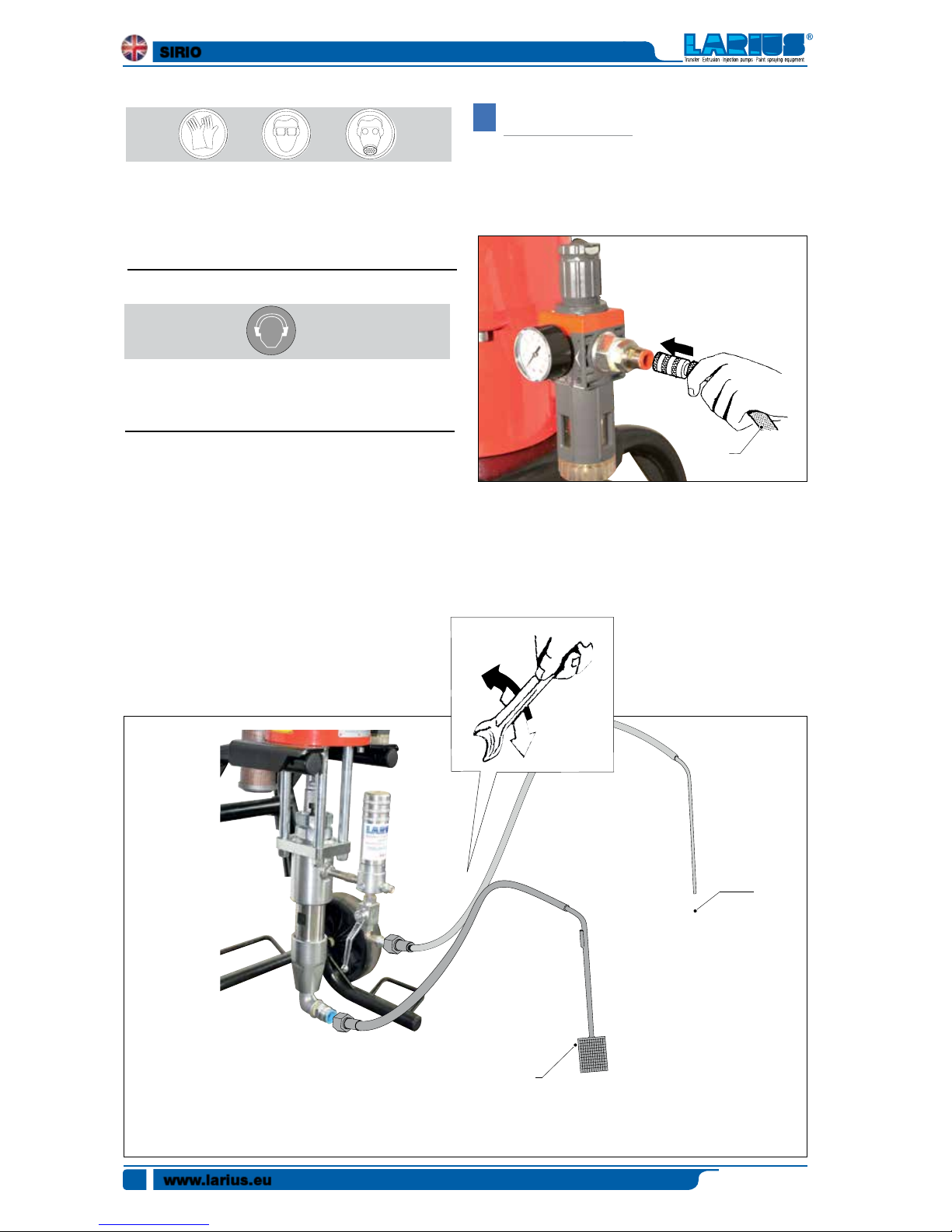

CONNECTION TO THE FEED AIR

For pump feed use a hose (F1) with an internal diameter no

lower than 10 mm.

CONNECTION OF SUCTION AND RECIRCULATING PIPES

•Connect the suction and recirculating pipes to the pump.

The suction hose can be locked finger tight (F1). Use a spanner

to tighten the recirculating pipe (F2). In both cases do not use

sealant agents for fitting threads.

IF THE PRODUCT TO BE USED IS TOXIC, AVOID INHALATION

AND CONTACT BY USING PROTECTION GLOVES, GOGGLES

AND PROPER FACE SHIELDS.

F1

F2

F1

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

13

PREPARATION OF THE PAINT

•Ensure the product is suitable to be used with a spray gun.

•Mix and filter the product before using it. For filtration, the

use of close-mesh (Ref. 214) and large-mesh (Ref. 215) LARIUS

METEX braids is suggested.

Make sure the product to be used is compatible

with the materials employed for manufacturing

the equipment. For this reason, please contact

the supplier of the product.

CONNECTION OF SUCTION AND RECIRCULATING PIPES

AIRLESS version

•Connect the high pressure flexible hose (F3) to the pump

and to the spray gun, paying attention to tighten the fittings

strongly (the use of two spanners is suggested). Do not use

sealant agents for fitting threads.

•Makesurethesprayguniswithouttheatomizationnozzle.

WASHING OF THE BRAND-NEW EQUIPMENT

•The equipment has been tested at our plant with light mineral

oil left inside of the pumping element as protection. Therefore,

before sucking the product, carry out a washing using a diluent.

•Dip the suction hose (F4) into the tank of the washing.

•Insert the recirculating pipe (F5) into a container (a metal

container is suggested).

•Open the recirculating cock (F6).

F5

F4

•Set the pump feed pressure at about 3 bar and open the air

passage valve.

•The pump will start working and will drain oil from the recirculating pipe. Close the recirculating cock (F6) as soon as the

clean solvent has come out.

•Lift the solvent tank’s suction tube.

•Lean the spray gun against the rim of the container (F7) and

drain the residual oil pressing the trigger. Release the trigger

as soon as the clean solvent comes out.

•Point the spray gun at the tank of the solvent and press the

trigger so as to recover the clean solvent left inside the pump.

•As an accelerated working of the pump (the pump “idles”)

appears, close the air passage valve.

F7

F3

F6

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

14

sideways (right-left) when spraying.

• Always paint with regular parallel bands coats.

• Keep a safety and constant distance between the spray

gun and the support to be painted and keep yourselves

perpendicular to it.

Never point the spray gun at your selves or at

other people. The contact with the cating can

cause serious injuries.

H

CLEANING AT THE END OF

THE WORK

• Lift the suction hose from the tank of the product.

• Reduce the pump feed pressure to about 3-4 bar and

open te recirculating cock so as to recover the product

left inside the equipment.

• Close the air passage valve for pump feed.

• Point the spray gun at the tank of the solvent and press

the trigger so as to recover the clean solvent left inside

the pump.

• Remove the nozzle from the spray gun (Do not forget to

clean it using a solvent!).

• Dip the suction hose into the tank of the washing solvent

(ensure it is compatibile with the product being used).

• Insert the recirculating hose into a container (a metal con-

tainer is recommended).

• Open the recirculating cock.

• Open the air passage valve in order to start up the pump.

• Close the recirculating cock as soon as a clean solvent

comes out.

• Lift the solvent tank’s suction tube.

• Point the spray gun at the tank of the solvent and press

the trigger so as to recover the clean solvent left inside

the pump.

• As an accelerated working of the pump (the pump “idles”)

appears, close the air passage valve .

•

In case of long storage, we recommend you to suck and to leave

light mineral oil inside the pumping group and the flexible hose.

• In this case, please follow the washing procedure described

on page 8 before using the tooling.

Store possible dangerous fluids in proper

containers. Their disposal must be performed

in accordance with the regulations in force

about the industrial waste goods.

G

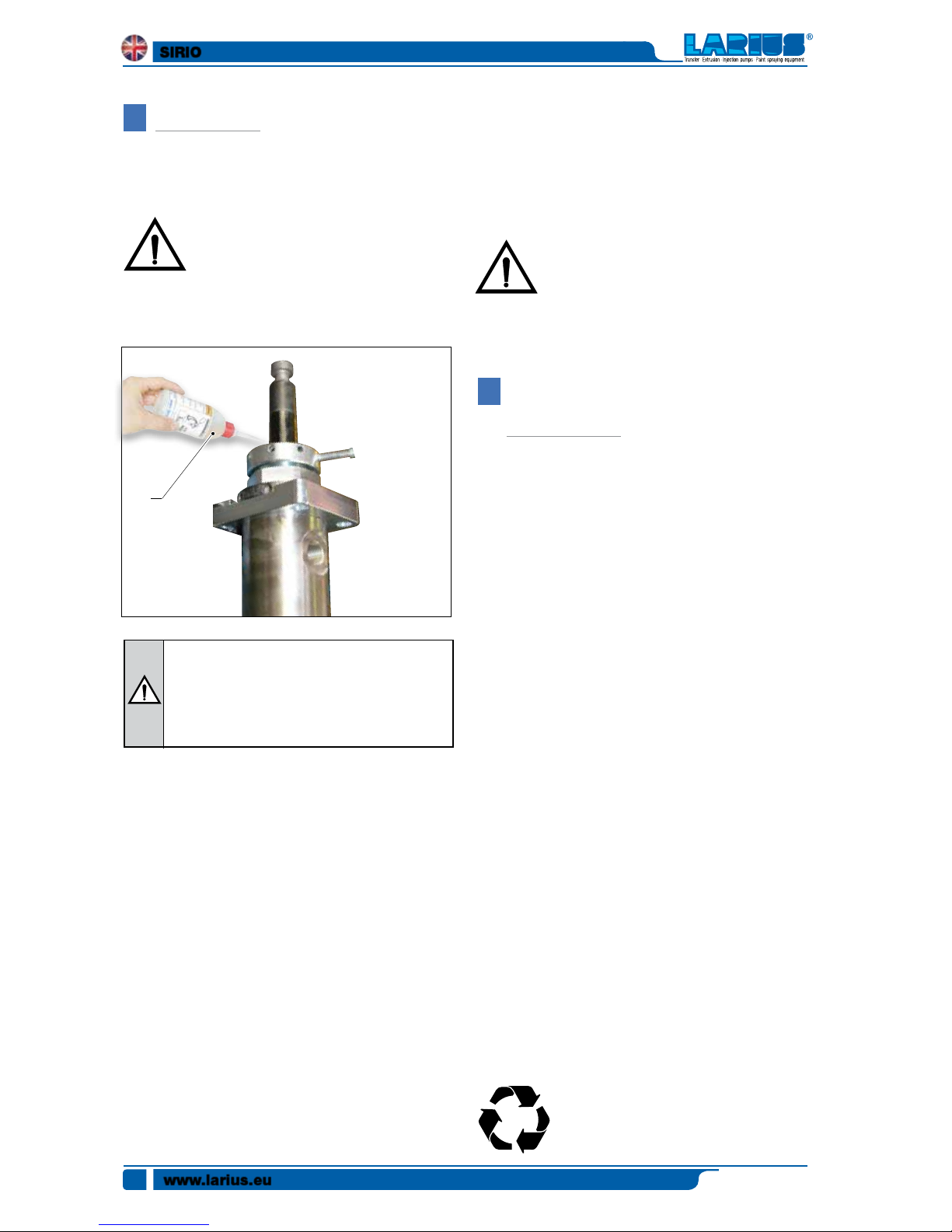

WORKING

• Use the machine after carrying out all the setting-up operations described in the previous paragraph.

Check all the fittings for connection of the

different components (pump, flexible hose,

spray gun, etc.) before using the equipment.

• Use the supplied lubricant (G1 - ref. 16325)

to facilitate the sliding of the piston inside the seal packing

and to interpose the oil within the air.

At the start of each working day, make sure that the

ring nut is filled with hydraulic oil (ref. 16325); the

oil facilitates the sliding of the piston and prevents

any material which may have leaked out of the seals

from drying once the equipment has been shut off.

• Fix the atomization nozzle on the spray gun. Select the

right nozzle according to the characteristics of the material

to be used and to the type of work to be performed.

• Dip the suction and recirculating pipes into the tank of the

product.

• Open the recirculating cock.

• Set the pump feed pressure at about 3-4 bar and open

the air passage valve.

• Allow the product to circulate for a few seconds. Then

close the recirculating cock. The pump will keep on working

until the high pressure flexible hose is full of product up

to the spray gun. Then the pump will stop automatically.

• Increase pump feed pressure so as to reach a pressure

value to guarantee a good atomization of the product.

• An irregular and marked spray on the sides indicates a

low working pressure. On the contrary, a too high pressure

causes a high fog (“overspray”) and waste of product.

• In order to avoid overthick ness of paint, let the gun advance

G1

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

15

I

ROUTINE MAINTENANCE

Always close the compressed air supply and release the pressure in the plant before performing

any check or maintenance of the pump.

RING NUT CHECK

• Check periodically (and every time the pump is operated

after a long storage) the packing nut is not loosened, cau-

sing otherwise the coming out of the product.

To tighten the packing nut (I1) use wrench supplied

(I2). The packing nut must be tightened so as to avoid

wastes of product, but not excessively to avoid the

seizure of the pumping piston and the wear of seals.

In case of persistent coming out of product, replace

the seals.

MATERIAL SUCTION FILTER

• Remove and clean the material suction filter (I3).

HIGH PRESSURE FILTER CLEANING

• Remove and clean the high pressure filter for material

outlet (I4).

• Check periodically the air supply to the pump. Ensure the

air is always clean and lubricated.

At the start of each working day, make sure that the

ring (I1) nut is filled with hydraulic oil (ref. 16340); the

oil facilitates the sliding of the piston and prevents

any material which may have leaked out of the seals

from drying once the equipment has been shut off.

MATERIAL SUCTION FILTER

MATERIAL OUTPUT FILTER

I3

I4

I2

Rif. 16340

I1

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

16

J

DISMANTLING AND REASSEMBLING THE PUMPING UNIT

2a

Necessary tools and equipment

Procedure

1.1 Remove the high pressure filter unit from the pump

Procedure

3.1 Unscrew and remove the

bottom valve body (3a)

1

Necessary tools and equipment

Procedure

2.1 Remove nuts (2a)

2

2a

Necessary tools and equipment

3

3a

3a

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

17

Necessary tools and equipment

Necessary tools and equipment

Necessary tools and equipment

Procedure

4.1 Remove the gasket (4a)

4.2 Remove the components (4b, 4c, 4d)

4.3 Clean and lubricate the gasket housing and replace it with

a spare part

4.4 Reassemble the components (4a,

4b, 4c, 4d)

Procedure

5.1 Loosen the ring nut (5a) without removing it

Procedure

6.1 Unscrew and remove the component (6a)

4

5

6

4b 4c

5a

4d

6a

6a

CLEANER

4a

4a

4b

4d

4c

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

18

Necessary tools and equipment

Procedure

8.1 Using a rubber mallet (8a),

slide off the component (8b)

8

Necessary tools and equipment

Procedure

9.1 Remove the gaskets (9a, 9b) clean and lubricate the gasket housing

and replace them with new spare parts

9

Procedure

7.1 Remove the gasket (7a)

7.2 Clean and lubricate the gasket housing

7.3 Replace the gasket with a spare part

7

8b

9a 9b

Necessary tools and equipment

7a

CLEANER

8a8b

CLEANER

9a 9b

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

19

10

Procedure

10.1 Unscrew and remove the

component (10a)

Procedure

11.1 Remove the complete gasket pack (11a)

11

Procedure

12.1 Remove the component (12a)

12.2 Clean and lubricate the gasket

housing and replace it with the

new one (12b)

12.3 Reassemble the component (12a)

12

12a

10a

10a

Necessary tools and equipment

11a

CLEANER

12b

12a

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

20

Procedure

13.1 Clean and lubricate the gasket housing

and replace it with the new spare

parts (13a)

A: Female STEEL ring

B: PTFE V seal ring

C: POLYPROPYLENE V seal ring

D: Male STEEL ring

E: Gasket housing

Follow the direction of rotation

of gaskets

NOTE

Direction

of assembly

13

Necessary tools and equipment

14

Procedure

14.1 Reassemble the component (14a)

14a

14a

CLEANER

13a

A

B

C

B

C

B

D

E

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

21

Procedure

13.1 Using a 36mm wrench, un

screw and remove the

component (13a)

15

Necessary tools and equipment

Necessary tools and equipment

16

Procedure

14.1 Remove the complete gasket pack (14a)

14.2 Clean and lubricate the gasket housings and replace them

with new spare parts

A: Male STEEL ring

B: PTFE V gasket

C: POLYETHYLENE V gasket

D: Female STEEL ring

E: Ball

F: Piston valve

A: Anello maschio in ACCIAIO

B: guarnizione in PTFE V

C: guarnizione in POLYETHYLENE V

D: Anello femmina in ACCIAIO

E: Sfera

F: Valvola pistone

Direction

of assembly

Direction

of assembly

Follow the direction of

rotation

of gaskets

Follow the direction of

rotation

of gaskets

NOTE NOTE

155 cc 180 cc

13a

CLEANER

14a

A

B

C

B

C

B

C

B

D

E

F

A

B

C

B

C

B

D

E

F

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

22

Procedure

17.1 Clean and lubricate the threaded area

17.2 Using a 36mm wrench,

reassemble the component (17a)

17

Necessary tools and equipment

Procedure

18.1 Reassemble the

component

(18a) as shown

in the figure (18b)

18

Necessary tools and equipment

Procedure

19.1 Insert the component (19a) inside the

component (19b)

19.1 Using a wrench, screw in the component (19a)

19

19b

17a

CLEANER

18a

18b

19a

19a

CLEANER

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

23

Necessary tools and equipment

Procedure

20.1 Tighten the ring nut (20a)

20

Procedure

21.1 Reassemble the bottom valve body (21a)

Necessary tools and equipment

21

Necessary tools and equipment

Procedure

22.1 Reassemble the nuts (22a)

22

20a

21a

21a

CLEANER

22a

22a

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

24

K

MANUAL RESET OF THE PNEUMATIC MOTOR

• The feed air pressure of the pump must never be higher

than the maximum value indicated in the technical data.

Exceed this value can block the valves of the pneumatic

motor in the intermediate position of the cycle reversal.

• Tostartagain ablockedmotor,close theairsupply and

release pressure in the plant. This operation should allow

the recovery of the valves.

• Incasethemotorisblocked,proceedasfollows:

- Close the air supply to the pump and release the residual

pressure in the plant;

- unscrew the motor cap (K1) and pull it upward along

with the guide rod (K2) so as to manually trigger the stroke

inversion unit;

- screw again the plug.

Necessary tools and equipment

Procedure

1.1 Reassemble the high pressure filter unit

on the pump

1

K1

K2

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

25

L

DISMANTLING AND REASSEMBLING THE PNEUMATIC MOTOR

Procedure

1.1 Close the compressed air supply to the pump and release

the residual pressure in the plant.

1.2 Unscrew the motor cap (

1a

) and pull it upwards together

with the guide rod (1b) (1e)

1.3 Hold the guide rod (

1b

) and remove the plug (1a) (using

two wrenches).

1

Necessary tools and equipment

Replace immediately the plug with a usual M8 (1C) nut

before the guide rod (1B) slides into the cylinder (1D).

1e

1a

1a

1b

1c

1a

1b

1b

1c

1c

1d

1c

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

26

2

Necessary tools and equipment

Procedure

2.1 Remove the screws (2a) and the washers (2b). (2c)(2d)

Procedure

3.1 Carefully extract the motor cylinder (3a) fom the pump.

3

3a

2c 2d

2b

2a

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

27

Necessary tools and equipment

Procedure

4.1 Unscrew the nut (4a), holding the guide rod with a 7mm wrench.

Then reassemble the cap (4b).

4

Procedure

5.1 Press at the point (5a) to snap inside the rocker arm stud screw

Procedure

6.1 Unscrew and remove the two screws (6a, 6b) with 2 13mm wrenches as shown in figure (6c)

5

6

Necessary tools and equipment

4a

4b

5a

6a

6b

6c

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

28

Necessary tools and equipment

Necessary tools and equipment

Procedure

8.1 Remove the two valve screws (8a, 8b)

Procedure

9.1 Proceed with disassembly and replace the 6 seal

sleeves (9a) with pliers

8

9

Necessary tools and equipment

Procedure

7.1 Use a screwdriver to lever the

lower part of the stud screw

(7a), keeping a hand over the

cap to accompany it. (7b)

7

7a

7b

8b

8a

9a

9a

9a

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

29

Necessary tools and equipment

Procedure

10.1 Lubricate the springs (10a, 10b).

10

Procedure

12.1 Reassemble the two valve screws

(12a) as shown in the drawing

11

12

Necessary tools and equipment

Necessary tools and equipment

Procedure

11.1 Remove the OR gasket (11a) and replace it if necessary

with a spare part

CLEANER

12a

Follow the direction of rotation

of gaskets

NOTE

10a

10b

11a

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

30

Procedure

12.2 Reassemble the two valve

screws, inserting a 3.5 mm

thickness gauge as shown

in the drawing and adjusting

the exact position of the

stud screw as shown in the

drawing, keeping a tolerance

distance of 3.5 mm

Make adjustments in the same way

on both valve screws

NOTE

Necessary tools and equipment

Procedure

13.1 Unscrew the cap (13a), holding the guide rod with a 7mm wrench.

Then reassemble the nut (13b).

13

3,5 mm

of the stud screw

valve screw

13b

13a

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

31

15

Necessary tools and equipment

Procedure

15.1 Re-screw in the 6 screws (

15a

) and the washers (

15b

). (15c)(15d)

Procedure

14.1 Lubricate the gasket (14a)

14.2

Carefully reassemble the motor cylinder (14b) on the pump.

14

Necessary tools and equipment

14a

14a

15b

15a

15c 15d

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

32

Procedure

16.1

Raise the central guide rod (16b) from inside the cylinder

(16d)

16.2

Remove the nut (16c)

16.3

Re-screw the cap (16a) onto the rod using 2 wrenches

and re-screw in the cap on the cover (16e)

16

Necessary tools and equipment

16a

16b

16c

16a

16b

16c

16c

16d

16c

16e

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

33

M

PROBLEMS AND SOLUTION

Solution

Possible cause

Problem

• The pump does not start

• Accelerate working and no

pressure of the pump

• The pump functions, but doesn’t

stop when the chamber is full (the

pump continues slowly, increasing

and/or decreasing)

• The pressure of the material is

significantly reduced when the

trigger is pressed

• Feed air not sufficient;

• Outlet product line clogged;

• Clogged product intake line;

• Pneumatic motor blocked in the cycle

reversal position;

• Parts failure of the pneumatic motor;

• There is no product;

• The pump sucks air;

• Gaskets of the pumping rod worn;

• Suction valve worn or partially

clogged;

• Suction filter clogged;

• Suction filter too fine;

• Gaskets of the pumping rod worn;

• Suction valve worn or partially

clogged;

• Delivery valve worn or partially obstructed;

• Upper gaskets worn.

• The spray gun’s nozzle is too large

or worn

• Thespraygun’sfilterandthematerial

output filter’s sieve are too fine

• Check on the air supply line. Increase the diameter of the feed hose;

• Open the recirculation tap to

check whether the pump starts up.

Unscrew the high pressure filter

and clean/replace the filter sieve.

Clean/replace the spray gun’s filter.

• Cleanthesuctionfilter;

• Reduce feed air pressure;

• Disassemble the motor and verify;

• Add the product;

• Check the flexible suction tube;

• Replace the lower gaskets;

• Disassemble the suction valve.

Clean and/or replace, if possible,

the parts worn;

• Clean/replace the suction filter’s

two disks;

• Remove the fine disk, leaving only

the larger one inside;

• Replace the lower seals

• Disassemble the suction valve.

Clean and/or replace, if possible,

the parts worn;

• Remove the delivery valve and

clean/replace any worn parts;

• Tighten the packing nut.

• Replace it with a smaller one

• Replace them with filters of a larger

mesh size

Always close the compressed air supply and release the pressure in the plant before performing any check or

replacement of parts of the pump.

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

34

White page

intentionally

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

35

SPARE PARTS

N

Complete pneumatic motor

pag. 36

O

O

Pneumatic regulator

pag. 37

S

Complete trolley

pag. 41

T

U

pag. 42

Pumping unit coupling kit

pag. 43

Pumping 155cc (32:1)

pag. 38

Pumping 180cc (27:1)

pag. 39

Pumping unit: Filter Assembly

pag. 40

P

Q

R

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

36

N

COMPLETE PNEUMATIC MOTOR

Ref. 99100

SCREW VALVE COMPLETA

RIF. 99068

COMPLETE ROCKER ARM

RIF. 99066

BUSH

RIF. 96017

40

39

38

31

29

28

27

37

26

25

24

23

19

18

17

16

15

14

13

4

1

5

7

6

3

2

9

10

NOT INCLUDED

IN THE MOTOR ASSEMBLY

11

12

8

34

33

32

30

22

21

20

35

36

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

37

WARNING: always indicate code and quantity for each part required.

WARNING: always indicate code and quantity for each part

required.

Pos.

Complete motor

Motor base

Washer Ø 10

Screw

Elbow Fitting

Sound Absorbing Filter

Screw

Ground. Plate

Grounding Cable

ivet

Machine Plate

T. Sirio 32:1 Technical Data Plate

T. Sirio 27:1 Technical Data Plate

Shearing Plate

O-ring

O-ring

Seal Ring

Brass Bearing

Guide Bushing

Piston rod

Washer

Piston

Valve Screw

Valve Gasket

Code Description

,

1

2

3

4

5

6

7

8

9

10

11

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Q.ty

-

1

6

6

1

1

1

1

1

12

1

1

1

1

1

1

1

1

1

1

1

1

2

2

99100

96050

33005

16111

99270

99054

96211

96210

5010

34020

99052

99064

99065

99069

99055

99056

96019

96017/1

96017/2

96016

33031

99051

99057

99058

PNEUMATIC REGULATOR UNIT ASSEMBLY Rif. 99291

Pos.

Guide Spring

Screw

O-ring

Seal Bushing

Exchange Spring

Roller

Fork

Rocker lever

Fork pin

Nut

Washer Ø 8

Gasket

Crosspiece

Guide Bushing

Guide Rod

Motor cylinder

O-ring

Cap

ATEX Plate

Code Description Q.ty

2

2

1

6

2

2

2

1

2

4

4

4

1

2

1

1

1

1

1

96011

96025

99059

96009

99061

99060

96007

96008

96024

4108

32024

96111

99062

96112

96010

99053

95075

96001

99041

NOT INCLUDED IN THE MOTOR ASSEMBLY

1

2

3

Pos.

Seal Washer

Nipple

Pneumatic Regulator

Code Description Q.ty

1

1

1

91622

95090

99290

3

2

1

O

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

38

P

PUMPING 155 cc (32:1) Ref. 155050

11

12

4

3

3A

3A

2

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

8

WARNING: always indicate code and quantity for each part required.

Pos. Pos.Code CodeDescription DescriptionQ.ty Q.ty

Complete pumping 155cc (32:1)

Gaskets ring nut

Female ring

Gasket PTFE V

Polyethylene gasket V

Male ring

Gasket holder

O-ring

Pumping group

O-ring

Locking ring nut

Sleeve

Piston rod

Rondella pistone

Ball

Pumping piston

Ball guide

Ball locking pin

Ball

Bottom valve body

1

2

6

4

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

_

1

2

3

3A

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

155050

155011

155012

155007/1

155007/2

155006

155013

155014

155015

155016

155022

155017

155001

155005

35163

155010

155019

155018

20149

155021

PUMPING 155 cc (32:1)

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

39

Q

PUMPING 180 cc (27:1) Ref. 180050

WARNING: always indicate code and quantity for each part required.

Pos. Pos.Code CodeDescription DescriptionQ.ty Q.ty

Complete pumping 180cc (27:1)

Gaskets ring nut

Female ring

Gasket PTFE V

Polyethylene gasket V

Male ring

Gasket holder

O-ring

Pumping group

O-ring

Locking ring nut

Sleeve

Piston rod

Ball

Pumping piston

Ball guide

Ball locking pin

Ball

Bottom valve body

1

2

6

4

2

1

1

1

2

1

1

1

1

1

1

1

1

1

-

1

2

3

3A

4

5

6

7

8

9

10

11

12

13

14

15

16

17

180050

180006

180004

180003/1

180003/2

180002

180007

155014

155015

155016

155022

180009

180001

35163

180005

155019

155018

20149

155021

PUMPING 180 cc (27:1)

11

4

3

3A

3A

2

12

13

14

15

16

17

1

2

3

4

5

6

7

8

9

10

8

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

40

R

FILTER ASSEMBLY Ref. 99250

WARNING: always indicate code and quantity for each part required.

Pos. Code Description Q.ty

Filter assembly

Warning Label

Filter Tank

Filter Sieve

Filter Sieve Support

O-ring

Fitting

Ball valve

Fitting

Cap

Fitting

1

1

1

1

1

1

2

2

1

1

,

1

2

3

4

5

6

7

8

9

10

99250

10107

99252

95218

65078

65099

6148

33037

6149/1

95214

3385

Pos. Code Description Q.ty

Seal Washer

Filter Base

Filter Inlet Fitting

27:1 label

32:1 label

1

1

1

1

1

11

12

13

14

14

33010

99251

99253

99042

99043

FILTER ASSEMBLY Ref 99250

1

2

3

4

6

7

8

9

7

10

8

12

13

11

5

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

41

S

STANDARD COMPLETE TROLLEY Rif. 99150

WARNING: always indicate code and quantity for each part required.

Pos. Code Description Q.ty

Standard complete trolley

Base Trolley

Washer Ø 10

Screw

Tube Cap

Wheel

Wheel Stop Washer

Ø 40 Tube Cap

Wall Support

Heater Holder

Screw

Split pin

Bushing

1

4

4

2

2

2

6

1

1

2

2

2

,

1

2

3

4

5

6

7

8

9

10

11

12

99150

99153

33005

4408

95159

37238

20305

95229

99156

99154

6130

18902

99155

1

2

7

2

9

10

11

12

3

4

5

6

7

7

8

Heater assembly kit (MOD. 6099)

Ref. 99151

Wall support

Ref. 99157

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

42

T

PAINT SUCTION SYSTEM

SPLIT

Ref. 85026

1

2

3

4

WARNING: always indicate code and quantity for each part required.

Pos.

Intake system

Suction pipe complete

Recirculation hose

Locking spring

Intake filter

85026

18097

16613

18096

37216

1

2

3

4

Code Description

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

43

U

PUMPING UNIT COUPLING KIT Ref. 99280

WARNING: always indicate code and quantity for each part required.

Pos. Code Description Q.ty

Complete kit

Tie rod

Nut

Split pin

Or 3050

Joint sleeve

Nut

Pumping shaft connection

4

4

1

1

1

2

1

,

1

2

3

4

5

6

7

99280

99281

95013

3323

96073

99282

99284

99283

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

44

V

ACCESSORIES

Code 11250: AT 250 1/4"

Code 11200: AT 250 M16x1,5

Code 11090: AT 300 1/4"

Code 11000: AT 300 M16x1,5

PISTON GUNSTOCK FILTERS

Code

11039: Green (30M)

Code

11038: White (60M)

Code

11037: Yellow (100M)

Code

11019: Red (200M)

Code 11131: L91X 1/4"

Code 11130: L91X M16x1,5

FILTRO

Code 95218: TAMIS 30M

Code 95219: TAMIS 60M

Code 95220: TAMIS 100M

Code 95221: TAMIS 200M

FITTING WITH MANOMETER

Code 147: M16x1,5

Code 150: 1/4"

Code

91044: PNEUMATIC MIXER

Code 7030: HP FLOW REGULATOR Code 6099: HEATER

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

45

Code 18270: SUPER FAST-CLEAN

base

UE 11/16x16

Code 18280: GASKET

UGELLO SUPER FAST-CLEAN

SUPER FAST-CLEAN

Nozzle code

SFC07-20

SFC07-40

SFC09-20

SFC09-40

SFC11-20

SFC11-40

SFC13-20

SFC13-40

SFC13-60

SFC15-20

SFC15-40

SFC15-60

SFC17-20

SFC17-40

SFC17-60

SFC19-20

SFC19-40

SFC19-60

SFC21-20

SFC21-40

SFC21-60

SFC23-20

SFC23-40

SFC23-60

SFC25-20

SFC25-40

SFC25-60

SFC27-20

SFC27-40

SFC27-60

SFC27-80

SFC29-20

SFC29-40

SFC29-60

SFC29-80

SFC31-40

SFC31-60

SFC31-80

SFC33-40

SFC33-60

SFC33-80

SFC39-40

SFC39-60

SFC39-80

SFC43-40

SFC43-60

SFC43-80

SFC51-40

SFC51-60

SFC51-80

GUN EXTENSION

Code 153: cm 30 -Code 153: cm 40

Code 155: cm 60 - Code 158: cm 80 - Code 156: cm 100

PAINT SPRAYING EQUIPMENT

Innovation.

The real kind.

SIRIO

Ediz. 006 - 12/2017

www.larius.eu

47

NOVA

45:1 - 60:1 - 68:1

GHIBLI ZINC

30:1

SIRIO

27:1 - 32:1

SIRIO

plunger piston

30:1 - 45:1

SUPER NOVA

45:1 - 68:1 - 80:1

OMEGA ZINC

30:1

GHIBLI

30:1 - 40:1

OMEGA

23:1 - 30:1 - 34:1

SUPER OMEGA ZINC

34:1

VEGA

23:1

SUPER OMEGA

23:1 - 34:1 - 40:1

SUPER NOVA ZINC

45:1

AIRLESS PNEUMATIC PUMPS

LARIUS srl

Via Antonio Stoppani 21 - 23801 Calolziocorte (LC) ITALY

TEL. +39 0341 621152 - Fax +39 0341 621243 - larius@larius.com

Made in Italy 1969

www.larius.eu

Loading...

Loading...