OPERATING AND

MAINTENANCE INSTRUCTIONS

OPERATING AND

MAINTENANCE INSTRUCTIONS

ENGLISH

P A I N T S P R A Y I N G E Q U I P M E N T

II 2 G c IIB T6

AIRLESS PNEUMATIC PUMP

Ed.

007

11 - 11

Due to a constant product improvement programme, the factory reserves the right to modify technical details

mentioned in this manual without prior notice.

This manual is to be considered as an English language translation of the original manual in Italian. The

manufacturer shall bear no responsibility for any damages or inconveniences that may arise due to the incorrect

translation of the instructions contained within the original manual in Italian.

1

NOVA 45:1/60:1

English

S

DESCRIPTION FOR EXPLOSIVE AREAS ........ p.9

DISASSEMBLY OF THE PNEUMATIC MOTOR .p.12

DISASSEMBLY OF THE PUMPING GROUP .....p.17

EXPLODED VIEW FOR STAINLESS STEEL

PUMPING GROUP .............................................p.20

EXPLODED VIEW FOR MOTOR GROUP .........p.22

EXPLODED VIEW FOR CARBON STEEL

PUMPING GROUP .............................................p.24

EXPLODED VIEW FOR HIGH PRESSURE LINE

FILTER

................................................................p.26

COMPLETE HANDTRUCK ................................p.28

AIR GROUP COMPLETE ...................................p.29

ACCESSORIES ..................................................p.30

P

Q

R

INTRODUCTION

....................................................... p.1

WORKING PRINCIPLE ...................................... p.2

TECHNICAL DATA .............................................p.2

DESCRIPTION OF THE EQUIPMENT ..............p.4

TRANSPORT AND UNPACKING ......................p.5

SAFETY RULES .................................................p.5

CONDITIONS OF GUARANTEE ........................p.6

TYPICAL INSTALLATION ...................................p.6

SETTING-UP ...................................................... p.7

WORKING .......................................................... p.7

CLEANING AT THE END OF THE WORK .........p.8

ROUTINE MAINTENANCE ................................p.8

PROBLEMS AND SOLUTIONS .........................p.9

A

B

C

D

E

F

G

H

O

I

L

U

T

AIRLESS PNEUMATIC PUMPS FOR SPRAY PAINTING

AIRLESS PNEUMATIC PUMPS FOR SPRAY PAINTING

Read this operator’s

manual carefully before

using the equipment. An

improper use of this machine can cause injuries

to people or things.

It indicates an accident risk or serious

damage to equip-

ment if this warning

is not followed.

It indicates a fire

or explosion risk if

this warning is not

followed.

It is obligatory to wear suitable

clothing as gloves, goggles and

face shield.

It indicates impor-

tant recommenda-

tions about dispo-

sal andrecycling

process of products

in accordance with

the environmental

regulations.

It indicates wound and

finger squashing risk

due to movable parts in

the equipment.

WE ADVISE THE USE OF THIS EQUIPMENT ONLY BY PROFESSIONAL OPERATORS.

ONLY USE THIS MACHINE FOR USAGE SPECIFICALLY MENTIONED IN THIS MANUAL.

Thank you for choosing a LARIUS S.R.L. product. As well as the product purchased,

you will receive a range of support services enabling you to achieve the results desired,

quickly and professionally.

M

V

Z

N

2

NOVA 45:1/60:1

English

A

B

NOVA 45:1

3-7 bar (40-90 psi)

270 bar (3900 psi)

3/4" GAS (M)

14 l/min (3,7 gpm)

4

60

1" conical GAS (F)

57 kg

<90 dB (A)

1110 mm

PUMP FEED AIR PRESSURE

MAXIMUM PRESSURE OF THE PRODUCT

FEED AIR INLET

MAXIMUM DELIVERY

CYCLES PER LITRE

MAXIMUM CYCLES PER MINUTE

MATERIAL OUTLET

WEIGHT

NOISE PRESSURE LEVEL

TOTAL HEIGHT

3-7 bar (40-90 psi)

360 bar (5200 psi)

3/4" GAS (M)

12 l/min (3,2 gpm)

5

60

1" conical GAS (F)

57 kg

<90 dB (A)

1110 mm

NOVA 60:1

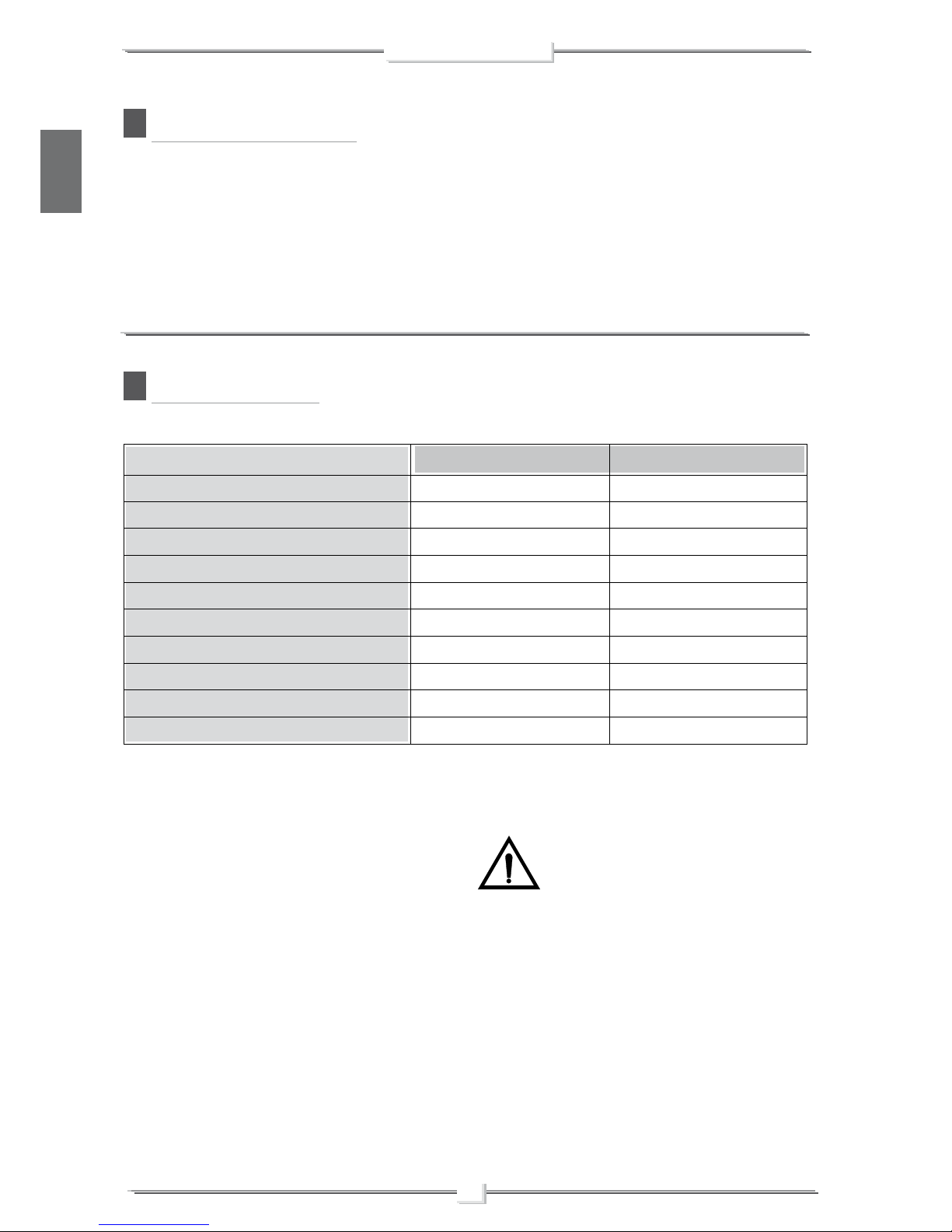

WORKING PRINCIPLE

NOVA pump 45:1 (or 60:1) is a pneumatic pump to be used in

the high pressure painting without air (Airless) or for transferring

of fluids in case of more stations of usage.

NOVA pump is essentially constituted of an air motor and a structure

called «material pumping group» or simply «pumping group».

In the pneumatic motor, compressed air causes the vertical reciprocating movement of the motor piston; this movement is transmitted

through a connecting rod to the material pumping piston.

So doing the pump sucks the fluid and pushes it to the outlet.

The ratio 45:1 (o 60:1) means that the outlet pressure of fluid is

45 (o 60) times higher than the pump feed air pressure.

TECHNICAL DATA

Parts of the pump in contact with the material

Pumping group: galvanized carbon steel and cast iron or stainless

steel AISI 303 and 420B

Sealing balls: stainless steel AISI 420B

Gaskets: teflon or nitrile or delrin or vulkollan

Other parts of the pump

Support and cylinder for pneumatic motor: aluminium

Covering: sheet FE37

Motor piston and roller pushing mount: cast iron

Always observe these instructions carefully

when evaluating the product compatibility

and in case of disposal of some parts of the

pump no more usable, in order to meet the

environmental regulations on recycling process.

3

NOVA 45:1/60:1

English

1110

580530

87

240

0 5 10 15 20 0 5 10 15 20

0 1 2 3 4 5 0 1 2 3 4 5

0

50

100

150

200

250

0

60

120

180

240

300

BAR BAR

500

1000

1500

2000

2500

3000

3500

4000

600

1200

1800

2400

3000

3600

4200

4800

0

800

1600

2400

3200

4000

0

20

40

60

80

100

120

140

160

0

600

1200

1800

2400

3000

0

15

30

45

60

75

90

105

120

7 bar (100 psi)

5 bar (70 psi)

3 bar (40 psi)

PSI

L/MIN

CFMPSI

L/MIN

CFM

GPMGPM

L/MINL/MIN

Black curve: Material outlet pressure

Gery curve: Air consumption

The pump can work in continuity when the delivery is limited to the

white zone. Out of this zone the speed must be intermittent.

PUMP DELIVERY

MATERIAL OUTLET PRESSURE

AIR CONSUMPTION

PUMP DELIVERY

MATERIAL OUTLET PRESSURE

AIR CONSUMPTION

4

NOVA 45:1/60:1

English

C

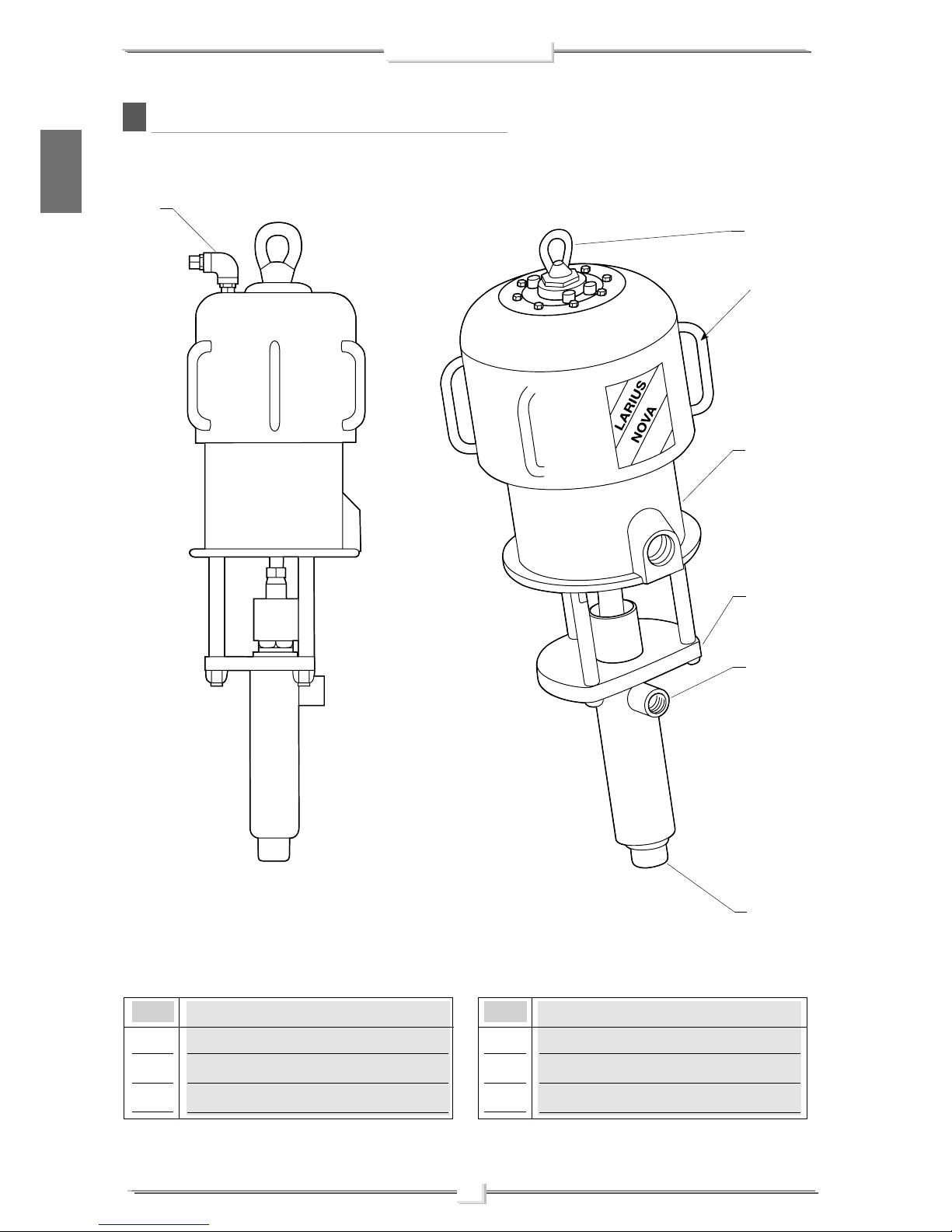

DESCRIPTION OF THE EQUIPMENT

POS.

1

2

3

POS.

4

5

6

Pump feed air inlet

Pneumatic motor

Material outlet

Description

Fluid inlet

Fluid pumping group

Eyebolt for pump transport

Description

ANTI-FREEZE SYSTEM

1

3

2

6

4

5

5

NOVA 45:1/60:1

English

D

E

TRANSPORT AND

UNPACKING

• The packed parts should be handled as indicated in the

symbols and markings on the outside of the packing.

• Before installing the equipment, ensure that the area to

be used is large enough for such purposes, is properly

lit and has a clean, smooth floor surface.

• The user is responsible for the operations of unloading

and handling and should use the maximum care so as

not to damage the individual parts or injure anyone.

To perform the unloading operation, use only qualified

and trained personnel (truck and crane operators, etc.)

and also suitable hoisting equipment for the weight of the

installation or its parts.

Follow carefully all the safety rules.

The personnel must be equipped with the necessary

safety clothing.

• The manufacturer will not be responsible for the unloading

operations and transport to the workplace of the machine.

• Check the packing is undamaged on receipt of the equipment. Unpack the machine and verify if there has been

any damage due to transportation.

In case of damage, call immediately LARIUS and the

Shipping Agent. All the notices about possible damage or

anomalies must arrive timely within 8 days at least from

the date of receipt of the plant through Registered Letter

to the Shipping Agent and to LARIUS.

• The disposal of packaging materials is a customer’s

competence and must be performed in accordance with

the regulations in force in the country where the plant is

installed and used.It is nevertheless sound practice to

recycle packaging materials in an environment-friendly

manner as much as possible.

SAFETY RULES

• THE EMPLOYER SHALL TRAIN ITS EMPLOYEES

ABOUT ALL THOSE RISKS STEMMING FROM ACCIDENTS, ABOUT THE USE OF SAFETY DEVICES FOR

THEIR OWN SAFETY AND ABOUT THE GENERAL

RULES FOR ACCIDENT PREVENTION IN COMPLIANCE WITH INTERNATIONAL REGULATIONS AND WITH

THE LAWS OF THE COUNTRY WHERE THE PLANT

IS USED.

THE BEHAVIOUR OF THE EMPLOYEES SHALL STRICTLY

COMPLY WITH THE ACCIDENT PREVENTION AND

ALSO ENVIRONMENTAL REGULATIONS IN FORCE IN

THE COUNTRY WHERE THE PLANT IS INSTALLED AND

USED.

Read carefully and entirely the following

instructions before using the product. Please

save these instructions in a safe place.

The unauthorised tampering/replacement of

one or more parts composing the machine,

the use of accessories, tools, expendable

materials other than those recommended by

the Manufacturer can be a danger of accident.

The Manufacturer will be relieved from tort and criminal

liability.

• KEEP YOUR WORK PLACE CLEAN AND TIDY. DISORDER

WHERE YOU ARE WORKING CREATES A POTENTIAL

RISK OF ACCIDENTS.

• ALWAYS KEEP PROPER BALANCE AVOIDING UNUSUAL

STANCE.

• BEFORE USING THE TOOL, ENSURE THERE ARE NOT

DAMAGED PARTS AND THE MACHINE CAN WORK PROPERLY.

• ALWAYS FOLLOW THE INSTRUCTIONS ABOUT SAFETY

AND THE REGULATIONS IN FORCE.

• KEEP THOSE WHO ARE NOT RESPONSIBLE FOR THE

EQUIPMENT OUT OF THE WORK AREA.

• NEVER EXCEED THE MAXIMUM WORKING PRESSURE

INDICATED.

• NEVER POINT THE SPRAY GUN AT YOURSELVES OR AT

OTHER PEOPLE. THE CONTACT WITH THE CASTING CAN

CAUSE SERIOUS INJURIES.

• IN CASE OF INJURIES CAUSED BY THE GUN CASTING,

SEEK IMMEDIATE MEDICAL ADVICE SPECIFYING THE

TYPE OF THE PRODUCT INJECTED. NEVER UNDERVALUE A WOUND CAUSED BY THE INJECTION OF A

FLUID.

• ALWAYS DISCONNECT THE SUPPLY AND RELEASE THE

PRESSURE IN THE CIRCUIT BEFORE PERFORMING ANY

CHECK OR PART REPLACEMENT OF THE EQUIPMENT.

• NEVER MODIFY ANY PART IN THE EQUIPMENT. CHECK

REGULARLY THE COMPONENTS OF THE SYSTEM.

REPLACE THE PARTS DAMAGED OR WORN.

•

TIGHTEN AND CHECK ALL THE FITTINGS FOR

6

NOVA 45:1/60:1

English

CONNECTION BETWEEN PUMP, FLEXIBLE HOSE AND

SPRAY GUN BEFORE USING THE EQUIPMENT.

• ALWAYS USE THE FLEXIBLE HOSE SUPPLIED WITH

STANDARD KIT. THE USE OF ANY ACCESSORIES OR

TOOLING OTHER THAN THOSE RECOMMENDED IN

THIS MANUAL, MAY CAUSE DAMAGE OR INJURE THE

OPERATOR.

• THE FLUID CONTAINED IN THE FLEXIBLE HOSE CAN

BE VERY DANGEROUS. HANDLE THE FLEXIBLE HOSE

CAREFULLY. DO NOT PULL THE FLEXIBLE HOSE TO

MOVE THE EQUIPMENT. NEVER USE A DAMAGED OR

A REPAIRED FLEXIBLE HOSE.

The high speed of travel of the product in

the hose can create static electricity through

discharges and sparks. It is suggested to earth

the equipment.

The pump is earthed through the earth cable

of the supply.

The gun is earthed through the high pressure flexible hose.

All the conductors near the work area must be earthed.

• NEVER SPRAY OVER FLAMMABLE PRODUCTS OR

SOLVENTS IN CLOSED PLACES.

• NEVER USE THE TOOLING IN PRESENCE OF POTEN-

TIALLY EXPLOSIVE GAS.

Always check the product is compatible with

the materials composing the equipment (pump,

spray gun, flexible hose and accessories)

with which it can come into contact. Never

use paints or solvents containing Halogen

Hydrocarbons (as the Methylene Chloride).

If these products come into contact with aluminium parts can

provoke dangerous chemical reactions with risk of corrosion

and explosion.

Avoid approaching too much to the pump

piston rod when the pump is working or under

pressure. A sudden movement of the piston rod

can cause wounds or finger squashing.

IF THE PRODUCT TO BE USED IS TOXIC, AVOID INHALATION

AND CONTACT BY USING PROTECTION GLOVES, GOGGLES

AND PROPER FACE SHIELDS.

TAKE PROPER SAFETY MEASURES FOR THE PROTECTION

OF HEARING IN CASE OF WORK NEAR THE PLANT.

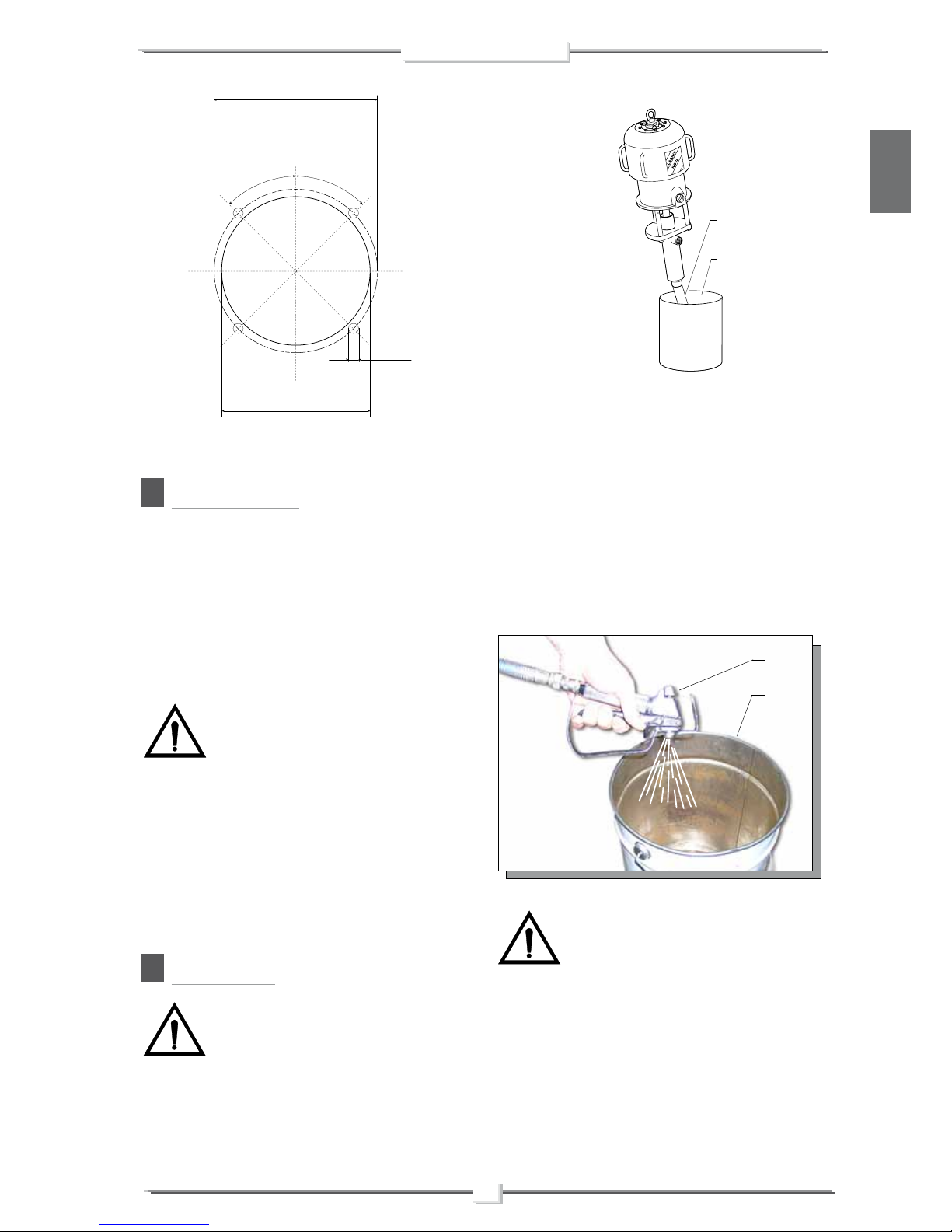

F

TYPICAL INSTALLATION

The NOVA pump is generally supplied on support for wall fastening

or on trolley or on double post ram.

For the correct fastening of the pump on other structures use

the 4 holes placed at the base of the pneumatic motor (see the

illustration for dimensions).

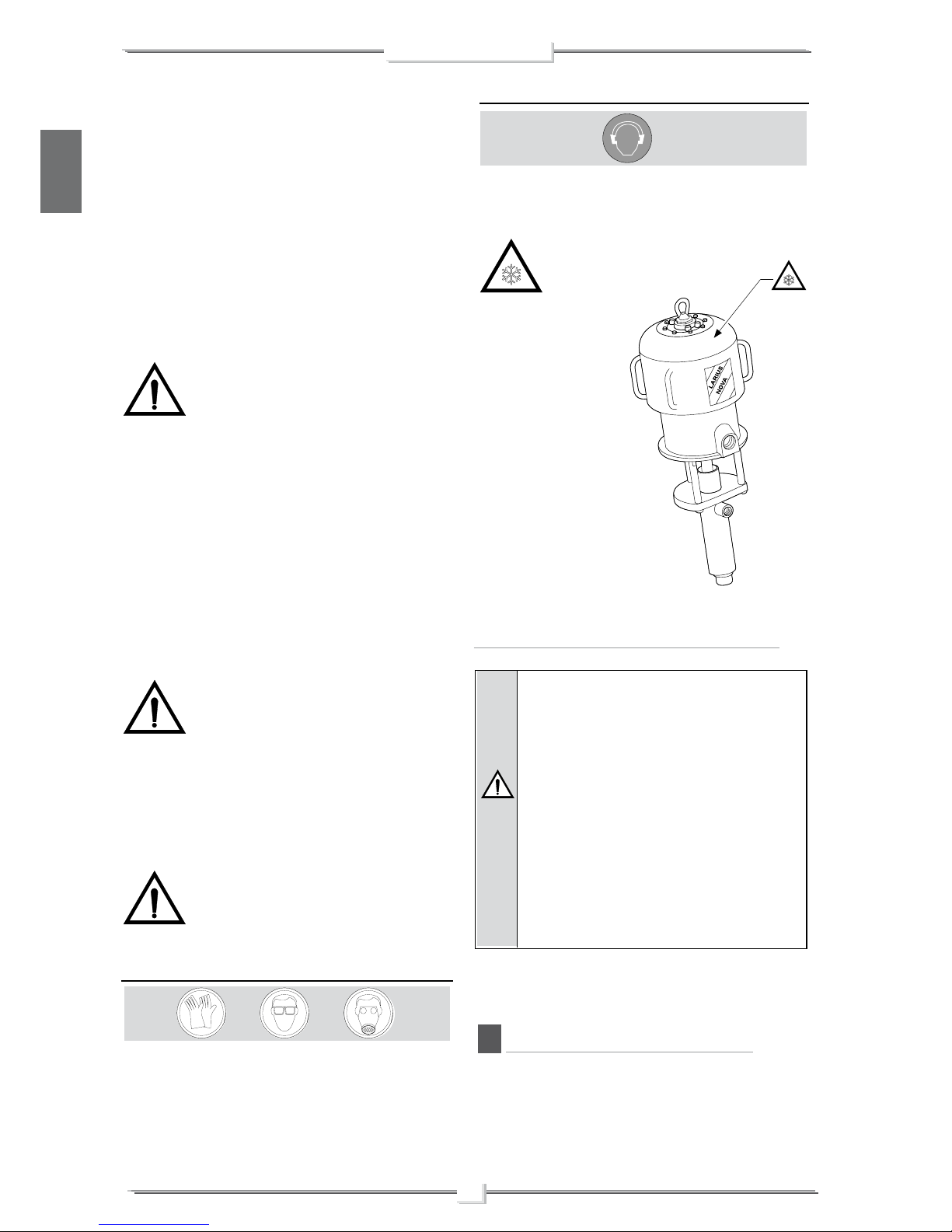

The machine is equipped with

an anti-freeze system

that allows it to

work even at very low temperatures. However, after a few

minutes of operation, the

upper metal outer surface

cools dramatically.

Avoid touching the area

indicated.

Contact of the skin with the

low-temperature area may

cause frostbite. Common working clothes and leather gloves

provide adequate protection.

The conditions of guarantee do not apply in the

following situations:

- improper washing and cleaning of components

causing malfunction, wear or damage to the

equipment or any of its parts;

- improper use of the equipment;

- use that does not conform with applicable national

legislation;

- incorrect or faulty installation;

- modifications, interventions and maintenance that

have not been authorised by the manufacturer;

- use of non-original spare parts or parts that do

not correspond to the specific model;

- total or partial non-compliance with the instructions provided.

CONDITIONS OF GUARANTEE

7

NOVA 45:1/60:1

English

Ø266

Ø11

Ø240

45ϒ

45ϒ

H1

H2

• Make the compressed air flow into the pump. It is advisable to

adjust air pressure to minimum necessary for its continuous

working.

• When the product chamber is full, pump will start working and

stopping. Pump will start working again any time the trigger

of the spray gun is pressed or the delivery valve is open.

• The pump has been adjusted at our factory with light mineral

oil and a part of it could be left inside the pumping element.

Point the spray gun (H3) or the delivery valve at the tank (H4)

and drain the product left inside the pump till the material to

be used has come out.

Always avoid pump idling: this operation could

damage the pneumatic motor and the seals.

• In case of long inactivity during the use with the plant (for

example, all night long at the end of the working day), ensure

the product you are using can be left inside the pump and

the different pipes without drying.

In this case, it is enough to stop the air supply to the pump

and drain the residual pressure in the circuit acting on the

delivery valve or on the pump bleeder valve.

*

*Int. holes

G

SETTING-UP

PUMP FASTENING ON THE HOIST

For the correct fastening of the pump on the ram, follow the

procedure described in the manual for use and maintenance of

the double post ram.

CONNECTION TO THE FEED AIR

For pump feed use a hose with an internal diameter no lower

than 20 mm.

H

WORKING

Install at the pump inlet an air pressure regulator

(it is suggested complete with condensate filter

and lubricator). The outlet pressure of the material

is 45 times (NOVA 45:1) or 60 times (NOVA 60:1)

the inlet pressure of the pump feed air. Therefore, it is extremely important to adjust the value of the feed air pressure.

CONNECTION OF THE MATERIAL OUTLET HOSE

Connect the high pressure hose at the outlet of the pump.

It is recommended to tighten the fittings.

Check all the fittings for connection of the dif-

ferent components (pump, flexible hose, spray

gun, etc.) before using the equipment.

• Dip the material pumping hose (H1) into the product tank

(H2) (if the pump is fixed on the double post ram, follow the

procedure described in the manual of use and maintenance

of the double post ram).

H4

H3

8

NOVA 45:1/60:1

English

I

CLEANING AT THE END OF

THE WORK

By "cleaning at the end of the work" is meant the cleaning to carry

out in case of use with a different product or if a long period of

storage is foreseen.

• Stop the air supply to the pump.

• Dip the material pumping hose into the washing solvent

tank (check its chemical compatibility with the product being

used).

• Make compressed air flow into the pump. It is advisable to

adjust the air pressure to minimum necessary to its continuous

working.

• Point the spray gun or the delivery valve at a container and

drain all the product left inside the pump till a clean solvent

comes out.

• Now, stop the air supply to the pump and drain the residual

pressure.

• In case of long inactivity, the operations of sucking and leaving

light mineral oil inside the pumping element are suggested.

Store possible dangerous fluids in proper containers. Their disposal must be performed in

accordance with the regulations in force about

the industrial waste goods.

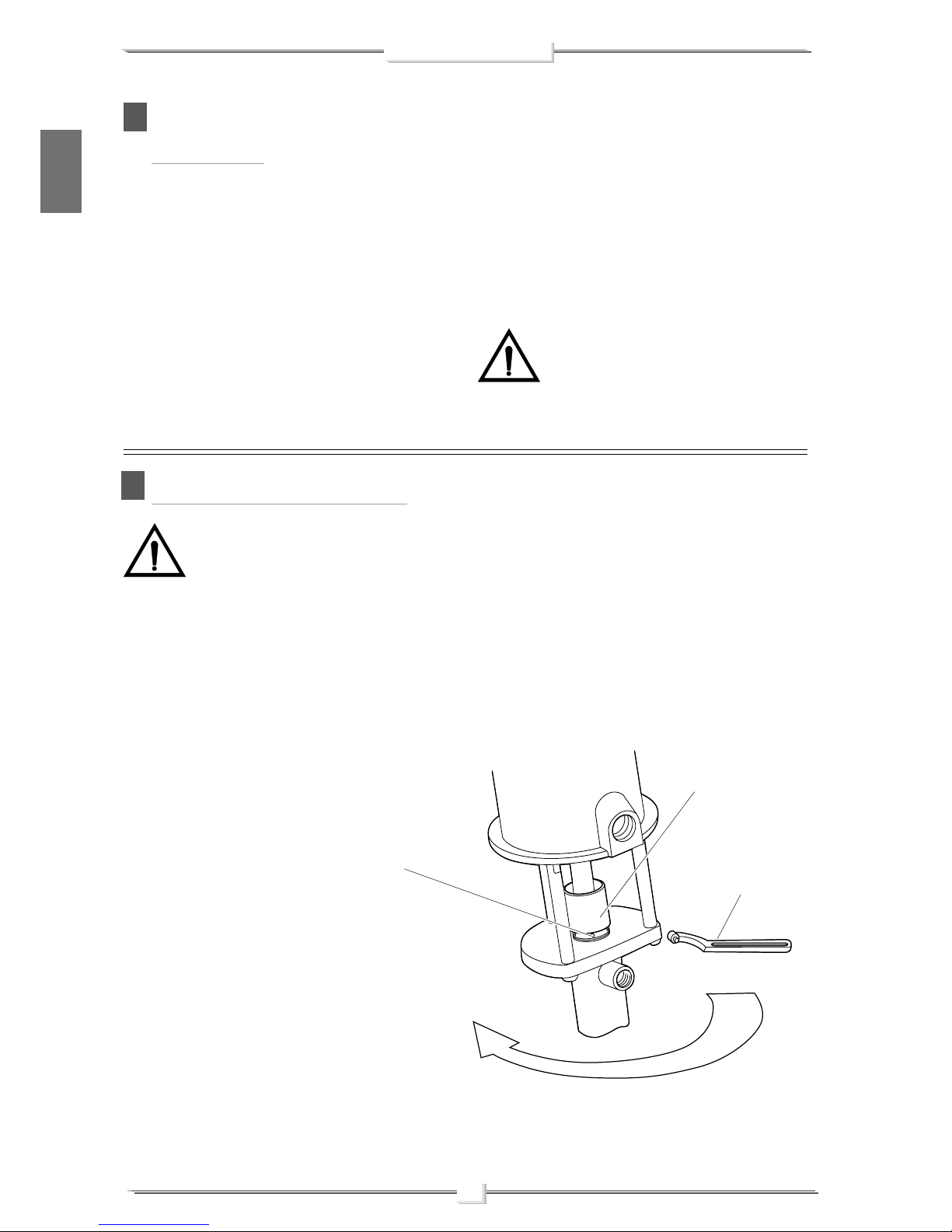

L

ROUTINE MAINTENANCE

Always close the compressed air supply and release the pressure in the plant before performing

any check or maintenance of the pump.

• Check periodically (and each time the pump is operated after

a long storage) the packing nut is not loosened, causing

otherwise the coming out of the product. To tighten the packing

nut, lift the wet cup (see illustration below).

Use the wrench supply (ref. 11504). The packing nut must be

tightened so as to avoid wastes of product, but not excessively

to provoke pumping piston seizure and seals wear. In case

of persistent coming out of product, replace the seals.

• To prevent the product from drying up on the piston rod, refill

the cup with lubricant (compatible with the product used).

• Check periodically the air supply to the pump. Ensure the

air is always clean and lubricated. In case of installation of

a lubricator on the air supply to the pump, it is advisable to

keep its cup full of a mixture of water and antifreeze liquid

(dilution ratio 4:1).

Oil ring

Wet cup

Key

Ref. 11504

9

NOVA 45:1/60:1

English

M

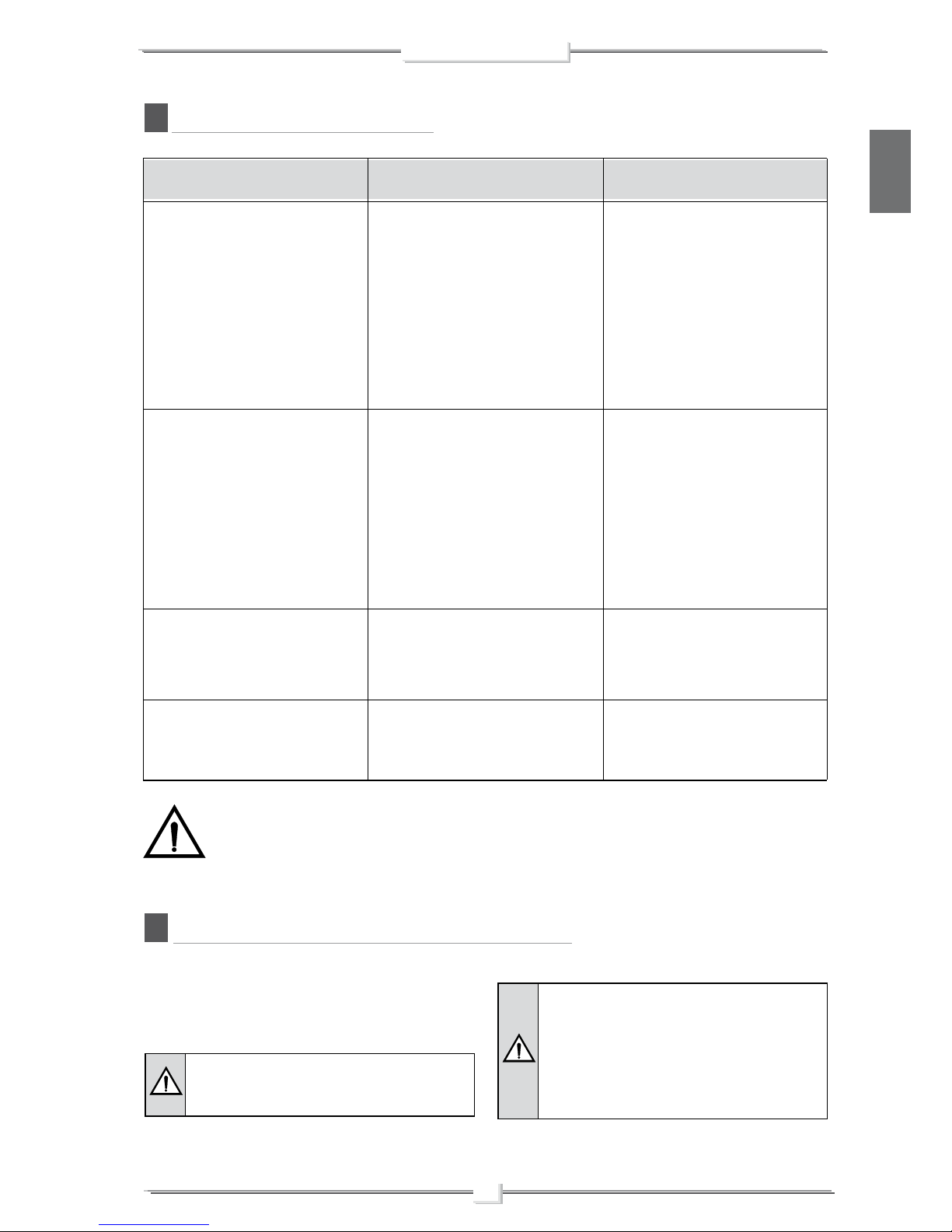

PROBLEMS AND SOLUTIONS

Solution

Cause

Problem

• The pump does not start

• Accelerated working and no pres-

sure of the pump

• The pump works, but not sufficient

flow of product

• Leakage of product from the wet

cup

• Feed air not sufficient;

• Outlet product line clogged;

• Dried product inside the pumping

element;

• Pneumatic motor blocked in the cycle

reversal position;

• Parts failure of the pneumatic motor;

• There is no product;

• The pump sucks air;

• Feed air not sufficient;

• Suction valve worn or partially clogged;

• Outlet valve worn or partially clogged;

• Suction valve worn or partially clogged;

• Outlet product line clogged;

• The feed air pressure is too low;

• Upper gaskets worn.

• Check the air supply. Widen the

diameter of the feed hose;

• Clean. Disconnect the outlet product

pipe. Feed pump at minimum pressure and check if the pump starts

without the outlet pipe;

• Disassemble the pumping group and

clean;

• Turn the plug counterclockwise and

push downwards the valve body. Use

a metal rod and a mallet;

• Disassemble the motor and check;

• Add product;

• Open the bleeder valve. For ram

version, follow the instructions in the

relevant manual;

• Increase the feed air pressure;

• Disassemble the suction valve. Clean

and/or replace if necessary the worn

parts;

• Disassemble the outlet valve. Clean

and/or replace if necessary the worn

parts;

• Disassemble the suction valve. Clean

and/or replace the worn parts;

• Clean. Disconnect the outlet product

pipe. Feed pump at minimum pressure and check if delivery increases

without the outlet pipe;

• Increase air pressure;

• Tighten the packing nut. In case of

persistent waste of product, replace

the upper gaskets of the pumping

element.

Always close the compressed air supply and release the pressure in the plant before performing any check or

replacement of parts of the pump.

N

These safety instructions refer to the installation, use and maintenance procedures for NOVA series LARIUS pneumatic piston

pumps for decanting. These pumps are designed for use in potentially explosive areas where gas or vapours are present.

NOVA series LARIUS pneumatic piston pumps

are group II mechanical devices for use in the

presence of gas in zones classified as IIB (category

2 G). They have been designed and constructed in

accordance with ATEX Directive 94/9/EC and the

European standards: EN 1127-1, EN 13463-1ed

EN 13463-5.

These instructions must be followed in addition to

the warnings given in the user and maintenance

manual.

DESCRIPTION FOR EXPLOSIVE AREAS

10

NOVA 45:1/60:1

English

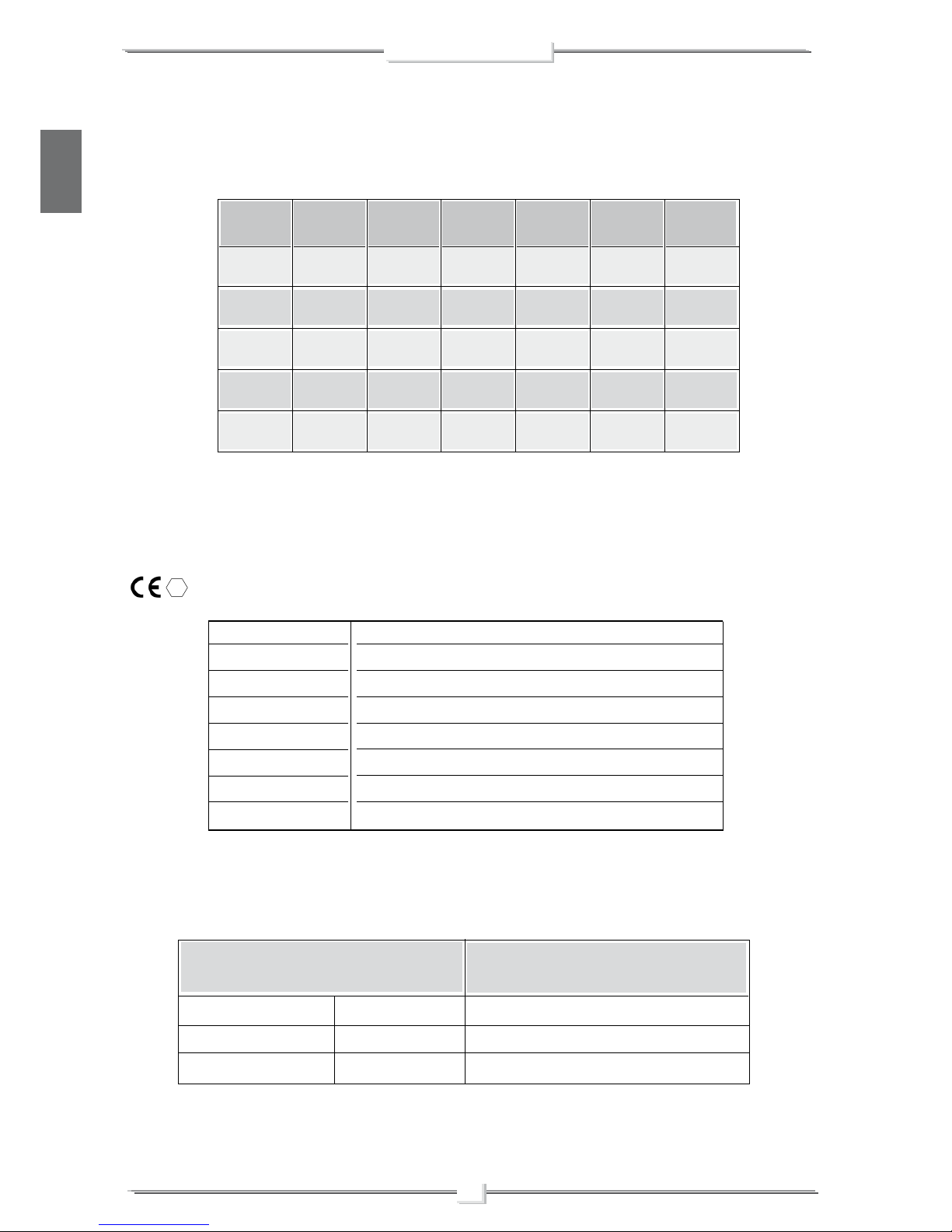

TECHNICAL FEATURES

The main characteristics of NOVA series pneumatic piston pumps

are indicated in the table below:

MARKING

Ratio

Input

pressure

Ø Air

intake

Ø Material

intake

Ø Material

outlet

Ø Max working

pressure

Max capacity

20:1

45:1

55:1

60:1

68:1

3 ÷ 6 bar

3 ÷ 6 bar

3 ÷ 6 bar

3 ÷ 6 bar

3 ÷ 6 bar

CG 3/4"

CG 3/4"

CG 3/4"

CG 3/4"

CG 3/4"

Ball valve

Ball valve

Plate

Ball valve

Ball valve

CG 1. 1/2"

CG 1. 1/2"

CG 1"

CG 1"

CG 3/4"

120 bar

270 bar

330 bar

360 bar

410 bar

32 l/min

14 l/min

12 l/min

12 l/min

11 l/min

Relation between hazardous areas, products and categories

• Environment temperature: -20°C ÷ +60°C • Max. fluid temperature: 60°C • Maximum number of cycles per minute: 60

3

X

II 2 G c IIB T6 • Eanvironment temp.: -20°C ÷ + 60°C • M fluid temperature: 60°C • Tech. File: NOVA/ATX/08

Gas, vapour or fog

Gas, vapour or fog

Gas, vapour or fog

1G

2G or 1G

3G, 2G or 1G

Zone 0

Zone 1

Zone 2

CATEGORIES AS PER RULES

94/9/CE

DANGEROUS AREA

II =

2 =

G =

c =

T6 =

- 20°C ÷ + 60°C

60°C

xxxx/AA

Group II ( surface)

Category 2 (zone 1)

Explosion hazardous environment with presence of gas, fog and vapour

Manufacturing safety "c"

Class of temperature T6

Environment temperature

Maximum fluid temperature

Serial number (xxxx = PROGRESSIVE/ year = AA)

11

NOVA 45:1/60:1

English

SAFETY INSTRUCTIOINS FOR ONSTALLATIONS IN HAZARDOUS AREAS

•

The M.T. cable of the above mentioned pumps must be

grounded by means of an appropriate anti-loosening connection element.

•

The pipes used to connect suction and delivery must be

metallic, or plastic with metallic braid or plastic with fabric

braid with suitable earthing cable.

•

The pumps must be installed upon grounded barrels made

from metallic or anti-static materials.

•

Gas and vapour of flammable liquids must belong to the

group IIB.

•

According with the nature of the operations and products, the

operator must regularly check the presence of deposit, the

cleaning, the wearing and the correct pump’s functioning.

•

The user must periodically clean the filter located upon the

suction unit in order to prevent solids from reaching the

pump’s internal elements. The air feeling the pump needs

to be filtered and originated by a safe area. (SAFE AREA).

Before proceeding with the installation carefully

read the use and service manual. All the service

operations must be carried out as stated in the

manual.

The NOVA series pneumatic piston pumps must

not be made to run without a proper load.

All the operations, installation and service, must

be carried out by qualified operators.

SAMPLE DECLARATION OF CONFORMITY

We Larius S.r.l.

Via Stoppani, 21

23801 Calolziocorte (LC)

declare under our sole responsibility that the product

NOVA series pneumatic piston pumps for decanting

to which this declaration relates complies with the

following Directives:

- Directive 94/9/EC (ATEX)

The conformity are under observance of the following standards or standards documents:

- EN 1127-1

- EN 13463-1

- EN 13463-5

Marking

Technical file: NOVA/ATX /08

Technical file c/o: INERIS (0080)

Calolziocorte- LC Signature (LARIUS)

The diagram illustrates a typical installation example of a LARIUS

pneumatic piston pump for decanting.

EXAMPLE OF INSTALLATION

3

X

II 2 G c IIB T6 • Eanvironment temp.: -20°C ÷ + 60°C

• M. fluid temperature: 60°C • Tech. File: NOVA/ATX/08

12

NOVA 45:1/60:1

English

O DISASSEMBLY OF THE PNEUMATIC MOTOR

Always close the compressed air supply and

release the pressure in the plant before disassembling the pneumatic motor of the pump.

• Unscrew the coupling sleeve so as to disconnect the pumping

group from the motor.

• Disconnect the air feed pipe to the pump.

• Unscrew the fitting (N1) and the sleeve (N2).

• Turn counterclockwise the screws (N3) [take care of the

washers (N4)] and remove the covering (N5).

• Unscrew the two ring nuts (N6) from the mount (N7).

• Turn counterclockwise the screws (N8) [take care of the

washers (N9)] and extract the mount (N7) together with the

rollers (N10) and the pins (N11).

• Extract the spring (N12), the spring guide rod (N13) and the

roller pushing piston (N14). Ensure the spring slides freely

on the guide rod, the guide rod slides into the roller pushing

piston and this last slides into the mount hole. Replace possible

damaged parts.

• Check the roller (N10) and the pin (N11) are undamaged.

Replace them if damaged.

• Remove and check the rubber pad (N15) and the washer

(N16).

N8

N9

N6

N12

N13

N14

N7

N14

N13

N12

N6

N15

N16

N10

N11

N11

N10

N3

N2

N1

N4

N5

Coupling sleeve

13

NOVA 45:1/60:1

English

• Pull upwards the seat (N17) so as to take out the valves

(N18) and the springs (N19) (clean and/or replace the worn

parts).

• Unscrew the lock nut (N20) [take care of the washer (N21)]

by keeping the bush (N22) blocked using a key.

• Extract the seat (N17) from the rod (N23).

• Unscrew the bush (N22) (if necessary, keep the rod (N23)

blocked on the threaded part using pliers with the bits wrapped

in rags to avoid damage to thread).

• Remove the screws (N24) [take care of the washers (N25)],

a manifold (N26) and the gasket (N27).

Handle with care the manifold. The edges of its

plate are very sharp.

Important: do not remove the other manifold if

not necessary (it will facilitate the fastening of

the manifold removed).

• Using a screwdriver, extract the washer (N28) and the rubber

pad (N29).

N18 N19 N17 N19 N18

N24

N25

N26

N27

N28

N29

N20

N21

N17

N22

N23

14

NOVA 45:1/60:1

English

• Turn counterclockwise the trip rod bearing (N30) [take care

of the washer (N31)] and check the seal inside the screw

(N30) is undamaged.

• Take out the screws (N32) [take care of the washers (N33)]

and remove carefully the cylinder (N34) (do not bend it during

extraction in order to avoid that motor piston may damage

the internal surface of the cylinder).

• Extract the motor piston from the motor support (N35).

• Verify the O-ring (N36) is undamaged.

• Tighten the lower edge of the piston rod using pliers (see

illustration) and unscrew the fitting (N37) with a key.

• Remove the motor rod (N38) and check it is undamaged.

• Rub the motor rod (N38) with vaseline grease before inserting

it into the housing of the piston rod.

• Tighten again with pliers the lower edge of the piston rod and

screw the fitting (N37) (application of a sealant on the thread

is advisable).

N30

N31

N32

N33

N34

N36

N35

N38

N37

Warning: tighten here

15

NOVA 45:1/60:1

English

1 mm

• Check the gas ring inside the support (N39) is undama-

ged.

• Check the gasket (N40) is undamaged and correctly positio-

ned.

• Coat the inner walls of the cylinder (N41) with a thin layer of

vaseline grease.

• Insert the motor piston (N42) into the cylinder (N41) careful-

ly.

• Fasten the cylinder (N41) on the support (N39) (respect the

position) and at the same time insert the piston rod into the

support.

• Turn clockwise the screws (N43).

• Insert into the motor rod (N44) the washer (N45).

• Carefully insert the trip rod bearing (N46) into the motor rod

(turn it slowly following the direction of the thread) and screw

it on the cylinder (N41).

• Insert the rubber pad (N47) and the washer (N48) into the

support.

• Screw the bush (N49) on the motor rod (N44). Insert the seat

(N50), the washer (N51) and screw the lock nut (N52).

Adjust bush and lock nut so as the rod (N44)

just out of about 1 mm from the lock nut (see

illustration).

N52

N48

N43

N41

N42

N40

N39

N47

N46

N45

N44

N51

N50

N49

N44

Check gas ring

16

NOVA 45:1/60:1

English

46 mm

0,8 mm 0,8 mm

• Insert the springs (N54) and the valves (N55) into the seat

(N53). Position the seat on the pump support and lay the

manifold (N56) on the seat [do not forget the gasket (N57)].

• Fasten the manifold with screws (do not tighten) ensuring it

is perfectly parallel to the other manifold and the distance

between them is 46 mm (see illustration).

The distance between the walls of the manifold and the edge

of the seat must be about 0,8 mm.

• Rub the rollers (N58) and the pins (N59) with vaseline grease

and insert them into the mount (N60).

• Rub the rubber pad (N61) and the washer (N62) with vaseline

grease and insert them into the mount (N60).

• Grease the roller pushing pistons (N63), the spring guide

rods (N64), the springs (N65) and insert them into the mount

(N60).

• Fasten without tightening the ring nuts (N66) on the mount

(N60).

• Fasten the mount on the manifolds and tighten the screws

(N68) [do not forget of washer (N67)].

• Tighten the ring nuts (N66) and the screws (N69).

• Assemble again the covering and all the fittings of the air

supply line.

N68

N63

N60

N58

N56 N57

N64

N65

N66

N59

N61

N62

N67

N66

N69

N53 N54 N55

N56

N53

17

NOVA 45:1/60:1

English

P DISASSEMBLY OF THE PUMPING GROUP

Always close the compressed air supply and

release the pressure in the plant before disassembling the pumping group. If the product being

used is toxic, it is suggested to follow the cleaning

procedure on page 8 to avoid the contact with the product

during the disassembling of the pumping element.

• Disconnect the suction pipe and the outlet tube of the product

from the pumping group.

• Unscrew the coupling sleeve so as to disconnect the pumping

group from the motor.

• Remove the nuts (O1) and take out the pumping group.

• Remove the wet cup (O2).

O1

O2

Coupling sleeve

18

NOVA 45:1/60:1

English

• Unscrew the suction valve. Clean and/or replace its parts, if

necessary.

• Remove the split pin (O3), loosen the nut (O4) and unscrew

the tie rod from the piston rod.

• Unscrew the packing nut (O5).

O4

O3

O5

Tie rod

19

NOVA 45:1/60:1

English

It is possible to increase the suction valve ball

stroke placing the stop ball pin (O6) on the upper

holes of the suction valve. This modification is

suggested in case of very viscous products. The

same operation can be performed on the piston rod.

• Extract the piston rod from the bottom.

• Disassemble the piston rod and replace the gaskets worn.

• Remove the upper gaskets, if necessary, to be replaced.

• For the correct reassembling see illustration and the exploded

view on page 18.

Suction valve

O6 O6

20

NOVA 45:1/60:1

English

Q

EXPLODED VIEW FOR STAINLESS STEEL PUMPING GROUP

WARNING: always indicate code and quantity for each part required.

1

2

3

4

5

6

8

9A

10

7

7A

7B

7C

9

9

11

12

13

14

16

19

2

17

18

20

9

8

22

24

26

28

15

29

10

9A

21

23

25

27

30

9A

9

9

9A

9

21

NOVA 45:1/60:1

English

Pos. Pos.

Complete pumping group for NOVA

45:1 inox

Bush

Split pin

Sleeve

O-ring

Tie rod

Nut

Cup complete with packing

Cup

O-ring

Packing nut

Female ring

Teflon "V" gasket

Polyethilene gasket

Male ring

Pumping group housing

Filter fitting

Gasket

Sleeve

Bush

Piston rod

Stop ball pin

Elastic ring

Ball Ø7/8"

Packing nut

Piston valve

Ring

Stop ball pin

Ball guide

Ball Ø1-1/4"

O-ring

Suction valve

Reduction M-F

Suction pipe fitting

Elbow M-F 1" GAS"

98200

,

95003

95015

95004

95005

95006

95007

95008

95008/1

95008/3

95008/2

98209

95010

95138

98212

98214

98126

95016

98217

96099

98218

98220

98219

98053

98222

98223

98224

98225

98226

95027

95028

98229

98230

98232

98231

Code Description Code Description

,

1

2*

3

4

5

6

7

7A

7B

7C

8*

9*

9A*

10*

11

12

13

14

15

16

17

18*

19

20

21

22

23

24

25

26*

27

28

29

30

*Pumping group repair kit for stainless steel NOVA 45:1 Ref. 40071

Pos. Pos.

Complete pumping group for NOVA

60:1 inox

Bush

Split pin

Sleeve

O-ring

Tie rod

Nut

Cup complete with packing

Cup

O-ring

Packing nut

Female ring

Teflon "V" gasket

Polyethilene gasket

Male ring

Pumping group housing

Filter fitting

Gasket

Sleeve

Bush

Piston rod

Stop ball pin

Elastic ring

Ball Ø7/8"

Packing nut

Piston valve

Ring

Stop ball pin

Ball guide

Ball Ø1-1/4"

O-ring

Suction valve

Reduction M-F

Suction pipe fitting

Elbow M-F 1" GAS"

98201

,

95003

95015

95004

95005

95006

95007

95502

95008/1

95008/3

95502/1

98203

95504

95514

98204

98210

98126

95016

98208

96099

98202

98205

98219

98053

98206

98207

98224

98225

98226

95027

95028

98229

98230

98232

98231

Code Description Code Description

,

1

2*

3

4

5

6

7

7A

7B

7C

8*

9*

9A*

10*

11

12

13

14

15

16

17

18*

19

20

21

22

23

24

25

26*

27

28

29

30

*Pumping group repair kit for stainless steel NOVA 60:1 Ref. 40076

22

NOVA 45:1/60:1

English

R EXPLODED VIEW FOR MOTOR GROUP

WARNING: always indicate code and quantity for each part required.

4

35

13

1

40

41

42

43

44

45

46A

46B

47

48

49

52

53

46

2

3

34

34

36

37

29

30

5

6

50

7

12

11

9

8

10

14

28

27

38

25

24

15

26

17

16

23

24

26

27

33

32

18

15

14

21

25

28

19

20

22

31

29

30

39

51

54

23

NOVA 45:1/60:1

English

Pos. Pos.

Screw

Washer

Covering

Screw

Washer

Eyebolt

Support

Roller

Pin

Roller piston

Spring guide

Spring

Ring nut

Shock absorber

Washer

Lock nut

Washer

Bush

Rod guide screw

Leather ring

Seal

Copper washer

Valve housing

Spring

O-ring

Travese reverse valve

Manifold plate

Plate gasket

Manifold

Manifold gasket

Washer

Screw

Plug 3/4" conical GAS

Fitting

Elbow 3/4" GAS

Extension

Gas ring

Screw

Motor cylinder

O-ring

Motor piston

Motor rod

Fitting

Gasket

O-ring

Complete motor mount

Gas ring

Leather ring

Washer

Screw

Plug

Plug

Sleeve 3/4" GAS

Tie rod

Nut

Plug

95062

95063

95064

95065

95066

95061

95109

95092

95091

95084

95085

95086

95087

95093

95094

95095

95096

95098

95078

95079

95080

33031

95097

95077

95075

95076

95073

95071

95070

95072

95096

95068

95067

95090

95089

95088

95099

95074

95100

95101

95102

95103

95104

95105

95106

95107

3314

95082

95114

95083

95159

510040

95944

95002

95013

95229

Code Description Code Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20*

21*

22*

23

24

25*

26

27

28

29

30*

31

32

33

34

35

36

37

38

39

40*

41

42

43

44

45

46

46A*

46B*

47

48

49

50

51

52

53

54

*Motor gasket kit for NOVA pump Ref. 40065

24

NOVA 45:1/60:1

English

S EXPLODED VIEW FOR CARBON STEEL PUMPING GROUP

WARNING: always indicate code and quantity for each part required.

1

2

3

4

5

6

8

10

7

7A

7B

7C

15

9

11

12

13

14

16

19

2

17

18

20

9

8

22

24

26

28

30

31

9

9

21

23

25

27

29

10

9

9

9

15

9

25

NOVA 45:1/60:1

English

Pos. Pos.

Complete pumping group for

NOVA 45:1

Bush

Split pin

Sleeve

O-ring

Tie rod

Nut

Cup complete with packing nut

Cup

O-ring

Packing nut

Female ring

Leather "V" gasket

Male ring

Pumping group housing

Filter fitting

Gasket

Sleeve

Teflon "V" gasket

Piston rod

Stop ball pin

Elastic ring

Ball Ø7/8"

Packing nut

Piston valve

Ring

Stop ball pin

Ball guide

Ball Ø1-1/4"

O-ring

Suction valve

Reduction M-F

Elbow M-F

Suction pipe fitting

Bush

95001

,

95003

95015

95004

95005

95006

95007

95008

95008/1

95008/3

95008/2

98209

95011

98212

95014

95126

95016

98217

95010

98218

95020

95019

95021

98222

95023

95024

95025

95026

95027

95028

95029

95030

95031

95032

96099

Code Description Code Description

,

1

2*

3

4

5

6

7

7A

7B

7C

8*

9*

10*

11

12

13

14

15*

16

17

18*

19

20

21

22

23

24

25

26*

27

28

29

30

31

*Pumping group repair kit for carbon steel NOVA 45:1 Ref. 40070

Pos. Pos.

Complete pumping group for

NOVA 60:1

Bush

Split pin

Sleeve

O-ring

Tie rod

Nut

Cup complete with packing nut

Cup

O-ring

Packing nut

Female ring

Leather "V" gasket

Male ring

Pumping group housing

Filter fitting

Gasket

Sleeve

Teflon "V" gasket

Piston rod

Stop ball pin

Elastic ring

Ball Ø7/8"

Packing nut

Piston valve

Ring

Stop ball pin

Ball guide

Ball Ø1-1/4"

O-ring

Suction valve

Reduction M-F

Elbow M-F

Suction pipe fitting

Bush

95500

,

95003

95015

95004

95005

95006

95007

95502

95008/1

95008/3

95502/1

95503

95505

95506

95511

95126

95016

98208

95504

98202

98205

95019

95021

98206

95509

95024

95025

95026

95027

95028

95029

95030

95031

95032

96099

Code Description Code Description

,

1

2*

3

4

5

6

7

7A

7B

7C

8*

9*

10*

11

12

13

14

15*

16

17

18*

19

20

21

22

23

24

25

26*

27

28

29

30

31

*Pumping group repair kit for carbon steel NOVA 60:1 Ref. 40075

26

NOVA 45:1/60:1

English

T

EXPLODED VIEW FOR HIGH PRESSURE FILTER

WARNING: always indicate code and quantity for each part required.

6

5

4

2

15

13

16

12

16

16

16

14

3

1

17

12

15

11

8

9

10

7

27

NOVA 45:1/60:1

English

Version INOX

Nova 45:1/60:1

Pos. Pos.

Complete line filter

Filter base

O-ring

Sieve fitting

Dowel

Sieve support

Filter sieve 30 MESH

Filter sieve 60 MESH

Filter sieve 100 MESH

Filter sieve 200 MESH

Screw

Intermediate fitting

Ring nut

O-ring

Filter container

Fitting 3/8" - 3/8"

Fitting 3/8"" G-M16x1,5

Fitting 3/8" G-M20x2

High pressure ball valve 3/8"

Washer

Plug 3/8" GAS

95200

95201

95202

98303

95204

95205

95218

95219

95220

95221

95206

95207

95208

95209

96115

95230

95231

3387

33034

33010

95214

Code Description Code Description

,

1

2

3

4

5

6

6

6

6

7

8

9

10

11

12

13

14

15

16

17

Pos. Pos.

Stainless steel comp lete li ne

filter

Filter base

O-ring

Sieve fitting

Dowel

Sieve support

Filter sieve 30 MESH

Filter sieve 60 MESH

Filter sieve 100 MESH

Filter sieve 200 MESH

Screw

Intermediate fitting

Ring nut

O-ring

Filter container

Fitting 3/8" - 3/8"

Fitting 3/8"" G-M16x1,5

Fitting 3/8" G-M20x2

High pressure ball valve 3/8"

Washer

Plug 3/8" GAS

98300

,

98301

95202

98303

98304

95205

95218

95219

95220

95221

98306

98307

95208

95209

98090

6149

6148

3385

33037

33010

98385

Code Description Code Description

,

1

2

3

4

5

6

6

6

6

7

8

9

10

11

12

13

14

15

16

17

Nova 45:1/60:1

28

NOVA 45:1/60:1

English

U COMPLETE HANDTRUCK

Pos.

Complete handtruck

Wheels

95150

95154

Code Description

1

2

1

2

29

NOVA 45:1/60:1

English

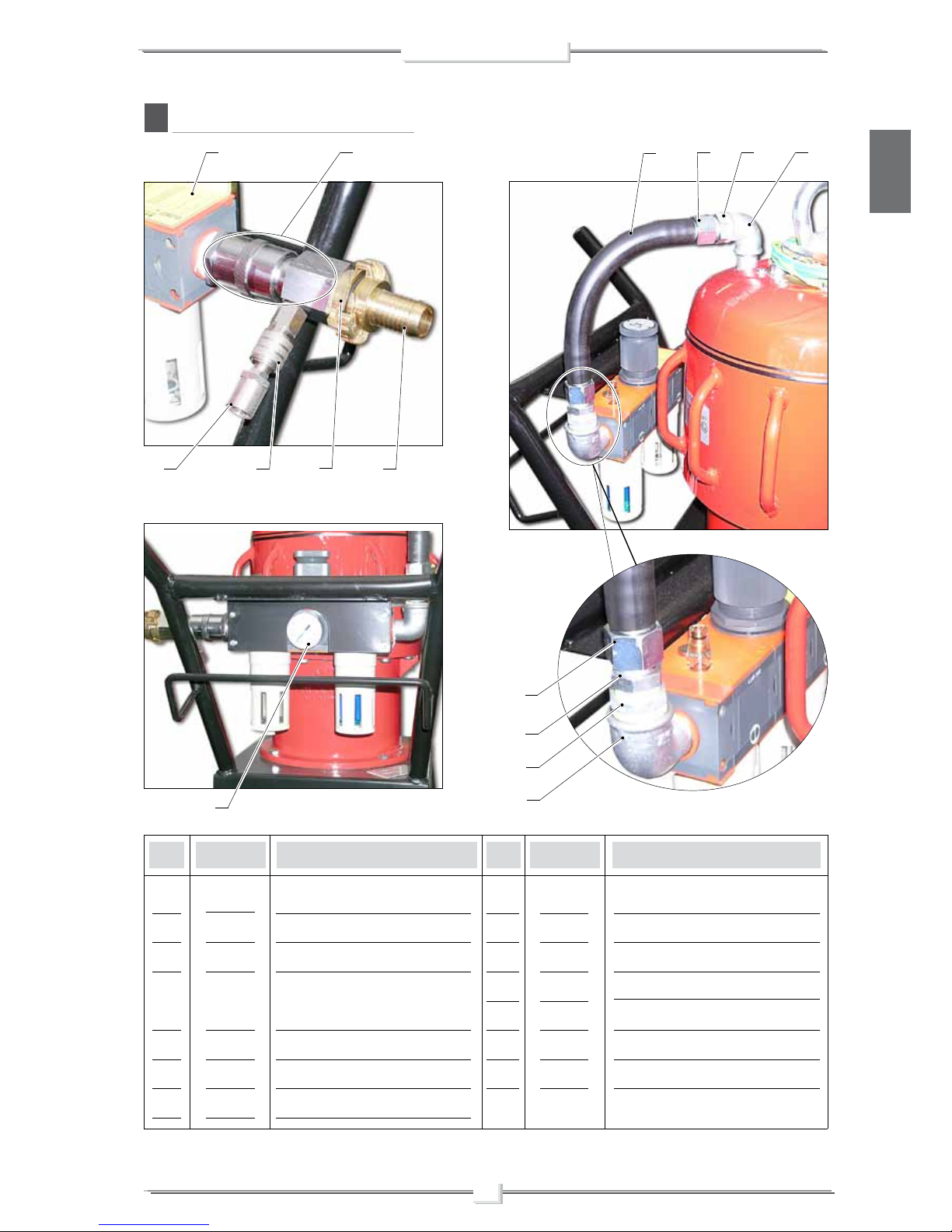

V AIR GROUP COMPLETE

Pos. Pos.

Air group complete

Elbow Male Female 1" -MF92

Adapter 3/4 (NGE 3/4)

Rapid coupling C/for rubber

hose skg 25

Rapid coupling 1"male

Female fitting (FB 3/4X19)

Hose tor/20NL 71N 19x29

Reduction 1" -3/4" Male Female

Rapid coupling 8x17

Rapid coupling male da 1/4"

Valve 1"

Group F.R.L.

Manometer

Elbow F-F 3/4"

95145

95031

95090

95301

,

95302

95308

95309

95313

95318

95319

95323

95350

96259

95089

Code Description Code Description

,

1

2

3

,

4

5

6

7

8

9

10

11

12

13

6

5

2

13

5

2

7

1

10

11

8

9

4

3

12

30

NOVA 45:1/60:1

English

Z ACCESSORIES

Code 11250: AT 250 1/4"

Code 11200: AT 250 M16x1,5

Code 11000: AT 300 1/4"

Code 11090: AT 300 M16x1,5

PISTON GUNSTOCK FILTERS

Code

11039: Green (30M) -

Code

11038: White (60M)

Code

11037: Yellow (100M) -

Code

11019: Red (200M)

Code 11180: L91X 1/4"

Code 11120: L91X M16x1,5

FILTER

Code 95218: SIEVE 30M

Code 95219: SIEVE 60M

Code 95220: SIEVE 100M

Code 95221: SIEVE 200M

FITTING WITH MANOMETER

Code 147: M16x1,5

Code 150: 1/4"

Code

91044: PNEUMATIC MIXER

Code 7030: HP FLOW REGULATOR

Code 6099: HEATER

31

NOVA 45:1/60:1

English

Code 300: FAST-CLEAN base UE 11/16x16

FAST-CLEAN

FAST-CLEAN TIP

Nozzles code

07-20

07-40

09-20

09-40

11-20

11-40

13-20

13-40

13-60

15-20

15-40

15-60

17-20

17-40

17-60

19-20

19-40

19-60

21-20

21-40

21-60

23-20

23-40

23-60

25-20

25-40

25-60

27-20

27-40

27-60

27-80

29-20

29-40

29-60

29-80

31-40

31-60

31-80

33-40

33-60

33-80

39-40

39-60

39-80

43-40

43-60

43-80

51-40

51-60

51-80

Code 18270: SUPER FAST-CLEAN base UE 11/16x16

Code 18280: GASKET

SUPER FAST-CLEAN TIP

SUPER FAST-CLEAN

Nozzles code

SFC07-20

SFC07-40

SFC09-20

SFC09-40

SFC11-20

SFC11-40

SFC13-20

SFC13-40

SFC13-60

SFC15-20

SFC15-40

SFC15-60

SFC17-20

SFC17-40

SFC17-60

SFC19-20

SFC19-40

SFC19-60

SFC21-20

SFC21-40

SFC21-60

SFC23-20

SFC23-40

SFC23-60

SFC25-20

SFC25-40

SFC25-60

SFC27-20

SFC27-40

SFC27-60

SFC27-80

SFC29-20

SFC29-40

SFC29-60

SFC29-80

SFC31-40

SFC31-60

SFC31-80

SFC33-40

SFC33-60

SFC33-80

SFC39-40

SFC39-60

SFC39-80

SFC43-40

SFC43-60

SFC43-80

SFC51-40

SFC51-60

SFC51-80

Code 18280: GASKET

32

NOVA 45:1/60:1

English

Code

95200: LINE FILTER

Code

98300: LINE FILTER inox

HIGH PRESSURE HOSE 3/8" - M16x1,5

Code 18063: 7,5 mt

Code 18064: 10 mt

Code 18065: 15 mt

Code

95055: SUCTION SYSTEM

Code

98055: SUCTION SYSTEM inox

ANTISTATIC HOSE 3/16" - M16x1,5

Code 6164: 5 mt

Code 55050: 7,5 mt

Code 35018: 10 mt

EXTENTION

Code

153: cm 30

Code

154: cm 40

Code

155: cm 60

Code

156: cm 100

PAINT SPRAYING EQUI PMENT

L’innovazione.

Quella vera.

AIRLESS PNEUMATIC PUMPS

23801 CALOLZIOCORTE - LECCO - ITALY - Via Stoppani, 21

Tel . (39 ) 0341/62. 11.52 - Fax (39) 0 341/62.12.43

E-mail: larius@larius.com - Internet http://www.larius.com

MANUFACTURER:

DIRECT LINE

Tel. (39) 0341/621256

Fax (39) 0341/621234

CUSTOMERS TECHNICAL SERVICE

VEGA AIRLESS Art.-Nr. 91500

VEGA MISTLESS Art.-Nr. 91400

SUPERNOVA Rif. 65100

GHIBLI ZINC Rif. 96900

OMEGA ZINC Rif. 7430

OMEGA AIRLESS Art.-Nr. 7300

OMEGA MISTLESS Art.-Nr. 7340

GHIBLI MIX 2K 40:1 INOX: Rif. 24561

GHIBLI 30:1 Art.-Nr. 96000

Loading...

Loading...