Larius K-2 Operating And Maintenance Instruction Manual

11 - 10

005

Ed.

Airless Line Striper

PAINTING EQUIPMENT

OPERATING AND MAINTENANCE

OPERATING AND MAINTENANCE

INSTRUCTION

INSTRUCTION

ENGLISH

HIGH PRESSURE

HIGH PRESSURE

PAINTING EQUIPMENT

PAINTING EQUIPMENT

INTRODUCTION

WORKING PRINCIPLE ...................................... p.2

A

TECHNICAL DATA .............................................. p.2

B

C

DESCRIPTION OF THE EQUIPMENT ............... p.3

CONTROLS DESCRIPTION .............................. p.4

D

TRANSPORT AND UNPACKING ....................... p.5

E

SAFETY RULES .................................................p.5

F

SETTING-UP ...................................................... p.6

G

H

WORKING .......................................................... p.8

I

CLEANING AT THE END OF THE WORK ......... p.9

J

ROUTINE MAINTENANCE ................................p.9

L

PROBLEMS AND SOLUTIONS .........................p.10

M

CORRECT PROCEDURE OF

....................................................

DECOMPRESSION ............................................p.11

N

REPLACEMENT OF THE PUMPING

GROUP'S GASKETS ......................................... p.12

p.1

O

CHARGING THE BATTERY ............................... p.12

P

CLEANING AND/OR REPLACEMENT OF

THE PRESSURE TRANSMITTER ..................... p.13

Q

COMPLETE PRESSURE CONTROL

DEVICE REF. 16350 ...........................................p.14

R

COMPLETE PUMPING

S

FILTER GROUP ................................................. p.18

T

RECIRCULATING-SAFETY VALVE

REF. 16100

.................... p.16

GROUP REF.16400 ............................................ p.19

U

DRIVE ASSEMBLY ............................................. p.20

V

SUCTION SYSTEM ............................................p.22

W

50L TANK ............................................................p.23

Z

ACCESSORIES ..................................................p.24

English

Read this operator’s

manual carefully

before using the

equipment. An

improper use of this

machine can cause

injuries to people or

things.

It indicates an

accident risk or

serious damage

to equipment if

this warning is not

followed.

WE ADVISE THE USE OF THIS EQUIPMENT ONLY BY PROFESSIONAL OPERATORS.

ONLY USE THIS MACHINE FOR USAGE SPECIFICALLY MENTIONED IN THIS MANUAL.

Thank you for choosing a LARIUS S.R.L. product.

It indicates a fire

or explosion risk if

this warning is not

followed.

As well as the product purchased,

you will receive a range of support services

enabling you to achieve the results desired,

quickly and professionally.

It is obligatory to wear suitable clothing as gloves,

goggles and face shield.

1

It indicates important

recommendations

about disposal

andrecycling process

of products in

accordance with

the environmental

regulations.

A

WORKING PRINCIPLE

The unit LARIUS K-2 is defined “piston pump”. This pump is used

for high pressure painting without air (from this process derives

the term “airless”).

English

The pump is controlled by an motor coupled with a reduction gear.

A cam shaft and a connecting rod allow to obtain the reciprocating

motion necessary to the working of the “pumping group” diaphram.

The piston movement produces a “depression”.

B

DATI TECNICI

MOTOR POWER

TRACTION ENGINE POWER

MAX. WORKING PRESSURE

MAX. DELIVERY

SUPPLY

WEIGHT

The product is sucked, pushed towards the pump outlet and then

sent to the gun through the flexible hose. A mechanical device

allows to adjust and control the pressure of the material coming

out of the pump.

A safety valve avoiding overpressure, guarantees the total reliability

of the equipment.

K-2

1 kW (1,3 Hp)

0,6 kW (0,8 Hp)

200 bar

2 L/min

24 V

185 Kg

WEIGHT WITH BATTERIES

LENGTH

WIDTH

HEIGHT

C

260 Kg

(A) 1800 mm

(B) 1100 mm

(C) 800 mm

B

A

2

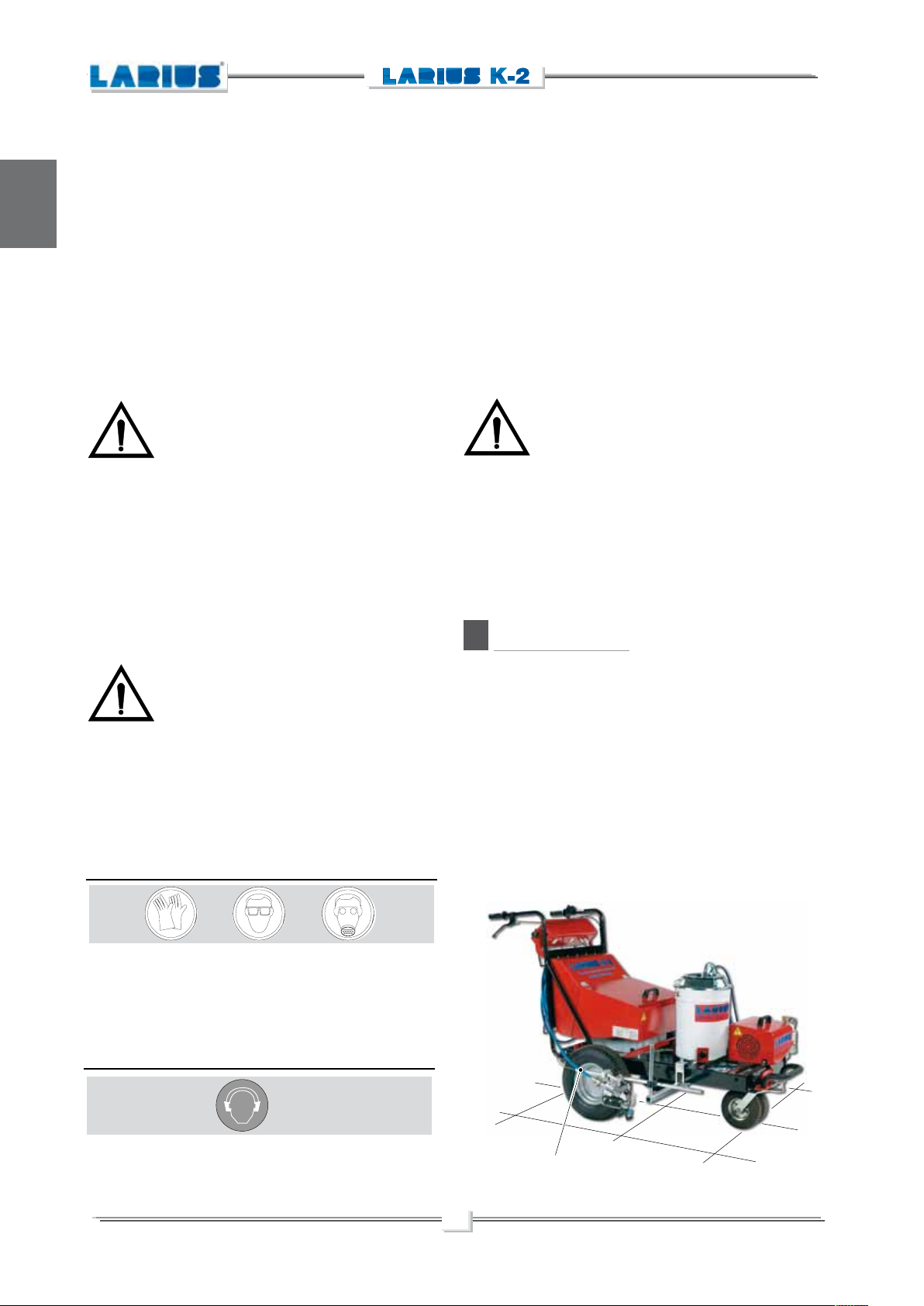

DESCRIPTION OF THE EQUIPMENT

C

4

English

6 8

1

POS.

1

2

5

11

Description

Pressure control knob

Reduction casting

8

2

12

3

713

POS.

8

9

High pressure manometer

Airless manual gun

Description

910

3

Suction Tube

4

High pressure hose

5

Airless gun

6

Product tank

7

Suction filter

10

Trigger safety clamp

11

Battery charger

12

Drain valve

13

Recirculation tube

3

CONTROLS DESCRIPTION

D

D1) Steerage lever.

Pulling the lever the straight only "mode" will be unlocked

English

allowing the machine to run.

D2) Internal gun operating lever.

Pulling the lever the gun placed at the internal side will

spray.

D3) Pull the lever to release the motors brake.

D4) LED

Indicates whether the power to the panel is on or off.

D5) Key-operated selector switch

Used to switch on machine.

D6) Indicator

Indicates the charge in the electrical battery.

D7) Adjustment knob

Used to progressively adjust the machine’s running speed.

D8) Direction selector

Allows the user to select the machine’s advancement direction;

stops the machine’s movement if pressed..

D9) Speed

Steerage lever

AV IND

D1

D6

D7 D4

PUSH

D5

Gun control

lever

D3D2

Motor brake

release

D8

D9

STOP

4

TRANSPORT

E

AND UNPACKING

• The packed parts should be handled as indicated

in the symbols and markings on the outside of the

packing.

• Before installing the equipment, ensure that the area to

be used is large enough for such purposes, is properly

lit and has a clean, smooth floor surface.

• The user is responsible for the operations of unloading

and handling and should use the maximum care so as

not to damage the individual parts or injure anyone.

To perform the unloading operation, use only qualified

and trained personnel (truck and crane operators, etc.)

and also suitable hoisting equipment for the weight of

the installation or its parts.

Follow carefully all the safety rules.

The personnel must be equipped with the necessary

safety clothing.

• The manufacturer will not be responsible for the unloading operations and transport to the workplace of

the machine.

THE BEHAVIOUR OF THE EMPLOYEES SHALL

STRICTLY COMPLY WITH THE ACCIDENT PREVENTION AND ALSO ENVIRONMENTAL REGULATIONS

IN FORCE IN THE COUNTRY WHERE THE PLANT

IS INSTALLED AND USED.

Read carefully and entirely the following in-

structions before using the product. Please

save these instructions in a safe place

The unauthorised tampering/replacement of

one or more parts composing the machine, the

use of accessories, tools, expendable materials

other than those recommended by the manufacturer can be a danger of accident.

The manufacturer will be relieved from tort and criminal

liability.

• KEEP YOUR WORK PLACE CLEAN AND TIDY. DISORDER

WHERE YOU ARE WORKING CREATES A POTENTIAL

RISK OF ACCIDENTS.

English

• Check the packing is undamaged on receipt of the

equipment. Unpack the machine and verify if there

has been any damage due to transportation.

In case of damage, call immediately LARIUS and the

Shipping Agent. All the notices about possible damage

or anomalies must arrive timely within 8 days at least

from the date of receipt of the plant through Registered

Letter to the Shipping Agent and to LARIUS.

• The disposal of packaging materials is a customer’s

competence and must be performed in accordance with

the regulations in force in the country where the plant is

installed and used.It is nevertheless sound practice to

recycle packaging materials in an environment-friendly

manner as much as possible.

SAFETY RULES

F

• THE EMPLOYER SHALL TRAIN ITS EMPLOYEES

ABOUT ALL THOSE RISKS STEMMING FROM ACCIDENTS, ABOUT THE USE OF SAFETY DEVICES FOR

THEIR OWN SAFETY AND ABOUT THE GENERAL

RULES FOR ACCIDENT PREVENTION IN COMPLIANCE WITH INTERNATIONAL REGULATIONS AND WITH

THE LAWS OF THE COUNTRY WHERE THE PLANT

IS USED.

• ALWAYS KEEP PROPER BALANCE AVOIDING UNUSUAL

STANCE.

• BEFORE USING THE TOOL, ENSURE THERE ARE NOT

DAMAGED PARTS AND THE MACHINE CAN WORK PROPERLY.

• ALWAYS FOLLOW THE INSTRUCTIONS ABOUT SAFETY

AND THE REGULATIONS IN FORCE.

• KEEP THOSE WHO ARE NOT RESPONSIBLE FOR THE

EQUIPMENT OUT OF THE WORK AREA.

• NEVER EXCEED THE MAXIMUM WORKING PRESSURE

INDICATED.

• NEVER POINT THE SPRAY GUN AT YOURSELVES OR AT

OTHER PEOPLE. THE CONTACT WITH THE CASTING CAN

CAUSE SERIOUS INJURIES.

• IN CASE OF INJURIES CAUSED BY THE GUN CASTING,

SEEK IMMEDIATE MEDICAL ADVICE SPECIFYING THE

TYPE OF THE PRODUCT INJECTED. NEVER UNDERVALUE A WOUND CAUSED BY THE INJECTION OF A

FLUID.

• ALWAYS DISCONNECT THE SUPPLY AND RELEASE THE

PRESSURE IN THE CIRCUIT BEFORE PERFORMING ANY

CHECK OR PART REPLACEMENT OF THE EQUIPMENT.

• NEVER MODIFY ANY PART IN THE EQUIPMENT. CHECK

REGULARLY THE COMPONENTS OF THE SYSTEM.

REPLACE THE PARTS DAMAGED OR WORN.

5

• TIGHTEN AND CHECK ALL THE FITTINGS FOR CONNECTION BETWEEN PUMP, FLEXIBLE HOSE AND SPRAY GUN

BEFORE USING THE EQUIPMENT.

• ALWAYS USE THE FLEXIBLE HOSE SUPPLIED WITH

STANDARD KIT. THE USE OF ANY ACCESSORIES OR

English

TOOLING OTHER THAN THOSE RECOMMENDED IN

THIS MANUAL, MAY CAUSE DAMAGE OR INJURE THE

OPERATOR.

Electrical safety precautions

• Check the "ON/OFF" switch is on the "OFF" position before

connecting the cable to the mains.

• Never carry a plugged-in equipment.

• Disconnect the equipment before storing it and before performing any maintenance operation or replacing of accessories.

• THE FLUID CONTAINED IN THE FLEXIBLE HOSE CAN

BE VERY DANGEROUS. HANDLE THE FLEXIBLE HOSE

CAREFULLY. DO NOT PULL THE FLEXIBLE HOSE TO

MOVE THE EQUIPMENT. NEVER USE A DAMAGED OR

A REPAIRED FLEXIBLE HOSE.

The high speed of travel of the product in the

hose can create static electricity through di-

scharges and sparks. It is suggested to earth

the equipment.

The pump is earthed through the earth cable of the supply.

The gun is earthed through the high pressure flexible hose.

All the conductors near the work area must be earthed.

• NEVER SPRAY OVER FLAMMABLE PRODUCTS OR SOL-

VENTS IN CLOSED PLACES.

• NEVER USE THE TOOLING IN PRESENCE OF POTEN-

TIALLY EXPLOSIVE GAS.

Always check the product is compatible with

the materials composing the equipment (pump,

spray gun, flexible hose and accessories) with

which it can come into contact. Never use

paints or solvents containing halogen hydrocarbons (as the

methylene chloride).

If these products come into contact with aluminium parts can

provoke dangerous chemical reactions with risk of corrosion

and explosion.

• Do not carry the equipment neither unplug it by pulling the

electric cable.

Protect the cable from heat, oil and sharp edges.

• When the tool is used outdoors, use only an extension cable

suited for outdoor use and so marked.

Never attempt to tamper with the calibre of

instruments.

• Take care when the pumping rod is moving.

Stop the machine whenever someone is within its vicinity.

• Repairs of the electrical equipment should only be carried

out by skilled personnel, otherwise considerabledanger to

the user may result.

SETTING-UP

G

CONNECTION OF THE FLEXIBLE HOSE TO THE GUN

• Connect the high pressure flexible hoses to the pump and the

guns tightening the fittings strongly (the use of two wrenches

is suggested).

NEVER use sealants on fittings threads.

It is ADVISED to mount a high pressure manometer at the

pump outlet (see on page "Accessories") to read the product

pressure.

• It is recommended to use the hose provided with the standard

kit.

NEVER use a damaged or a repaired flexible hose.

IF THE PRODUCT TO BE USED IS TOXIC, AVOID INHALATION

AND CONTACT BY USING PROTECTION GLOVES, GOGGLES

AND PROPER FACE SHIELDS

TAKE PROPER SAFETY MEASURES FOR THE PROTECTION

OF HEARING IN CASE OF WORK NEAR THE PLANT.

High pressure hose

6

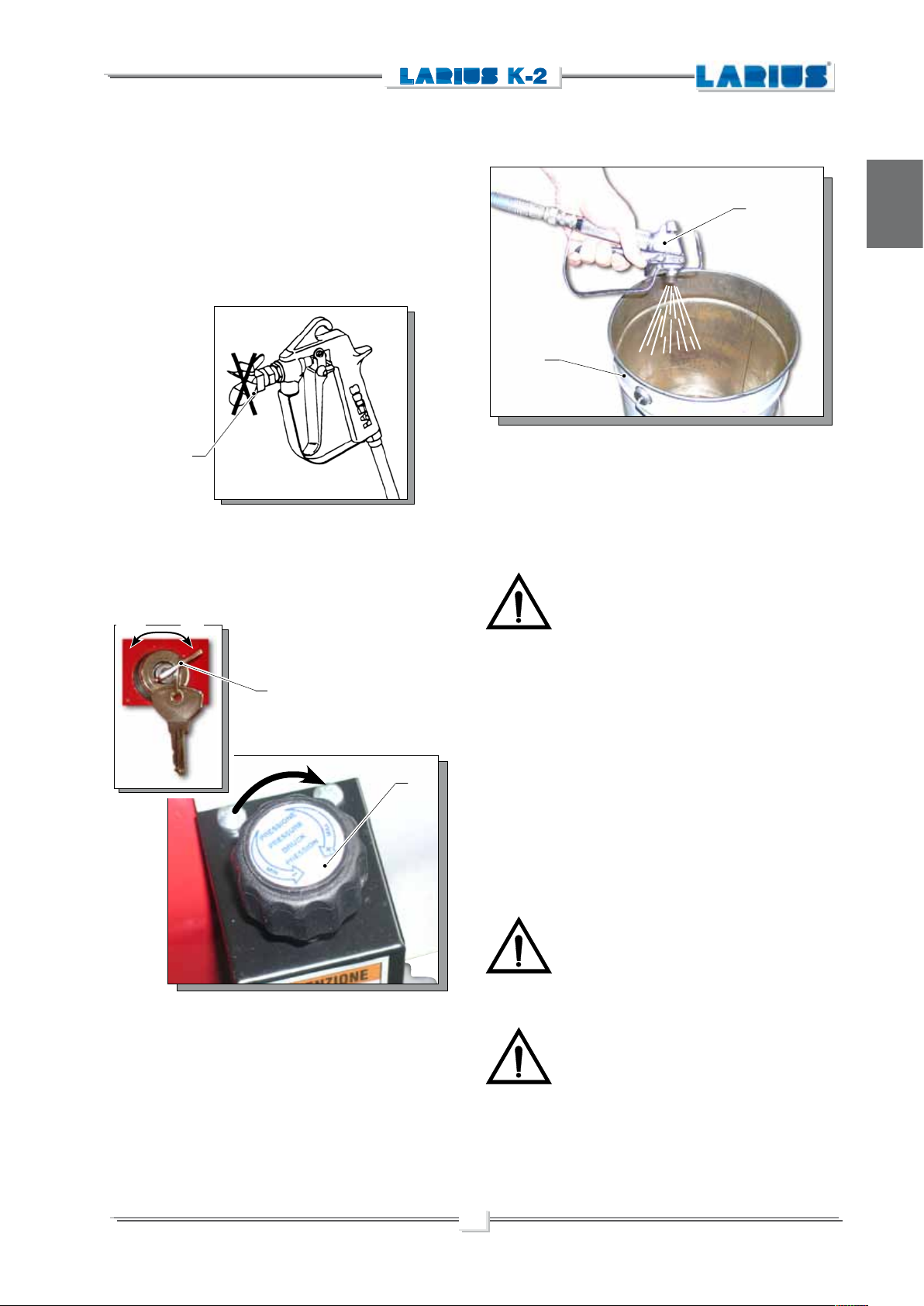

WASHING OF THE NEW EQUIPMENT

• The equipment has already been adjusted at our factory with

light mineral oil left inside the pumping group as protection.

Therefore, wash with diluent before sucking the product.

• Remove the suction pipe and take away the solvent tank.

English

• Lift the suction pipe and dip it into the solvent tank.

• Ensure the gun (G1) is without nozzle.

G1

• Turn the key (G2) of the equipment to the ON (I) position.

• Turn clockwise the pressure control knob (G3) so as the

machine works at idle speed.

ONOFF

G4

G5

• Point the gun at the solvent tank and press the trigger so as

to recover the residual solvent.

• As soon as the pump starts to over-rev turn the key to the

OFF (0) position to switch off the equipment.

Absolutely avoid to spray solvents indoors. In

addition, it is recommended to keep away from

the pump in order to avoid the contact between

the solvent fumes and the electric motor.

G2

G3

• Point the gun (G4) at a container (G5) keeping the trigger

pressed (so as to drain the oil inside) till a clean solvent

comes out. Now, release the trigger.

• Now the machine is ready. Should you use water paints,

besides the solvent wash, a wash with soapy and then clean

water is suggested.

• Insert the gun trigger lock and assemble the nozzle.

PREPARATION OF THE PAINT

• Make sure the product is suitable to be used with a spray

gun.

The use of non-compliant products causes

damage to the machine thus annulling the

guarantee (only use specific filtered paints for

airless applications).

Make sure the product to be used is compatible with

the materials employed for manufacturing the equipment (stainless steel and aluminium). Because of that,

please contact the supplier of the product

.

Never use products containing halogen hydrocarbons (as methylene chloride). If these products come into contact with aluminium

parts of the equipment, can provoke dangerous chemical reactions

with risk of explosion.

7

Loading...

Loading...