Larius GHIBLI 24:1 DE Operating And Maintenance Instruction Manual

11 - 11

004

Ed.

PNEUMATIC PUMP FOR EXTRUSION

P A I N T S P R A Y I N G E Q U I P M E N T

OPERATING AND

OPERATING AND

MAINTENANCE INSTRUCTION

MAINTENANCE INSTRUCTION

ENGLISH

Due to a constant product improvement programme, the factory reserves the right to modify technical

details mentioned in this manual without prior notice.

This manual is to be considered as an English language translation of the original manual in Italian.

The manufacturer shall bear no responsibility for any damages or inconveniences that may arise due

to the incorrect translation of the instructions contained within the original manual in Italian.

PNEUMATIC PUMP FOR EXTRUSION

PNEUMATIC PUMP FOR EXTRUSION

INTRODUCTION

WORKING PRINCIPLE ......................................p.2

A

TECHNICAL DATA .............................................p.2

B

DESCRIPTION OF THE EQUIPMENT ..............p.4

C

TRANSPORT AND UNPACKING ......................p.5

D

SAFETY RULES .................................................p.5

E

TYPICAL INSTALLATION ...................................p.6

F

SETTING-UP ...................................................... p.7

G

WORKING ..........................................................p.7

H

CLEANING AT THE END OF THE WORK .........p.8

I

.......................................................p.1

GHIBLI 24:1 DE

J

ROUTINE MAINTENANCE ................................p.8

K

PROBLEMS AND SOLUTIONS .........................p.9

L

MANUAL RESET OF THE PNEUMATIC

MOTOR ..............................................................p.10

M

DISASSEMBLY OF THE PNEUMATIC MOTOR .p.10

DISASSEMBLY OF THE PUMPING GROUP ..... p.11

N

EXPLODED VIEW OF PNEUMATIC MOTOR .... p.14

O

P

EXPLODED VIEW OF PUMPING

STANDARD GROUP .......................................... p.16

ACCESSORIES ..................................................p.18

Q

English

Read this operator’s

manual carefully before

using the equipment. An

improper use of this machine can cause injuries

to people or things.

It indicates an accident risk or serious

damage to equip-

ment if this warning

is not followed.

WE ADVISE THE USE OF THIS EQUIPMENT ONLY BY PROFESSIONAL OPERATORS.

ONLY USE THIS MACHINE FOR USAGE SPECIFICALLY MENTIONED IN THIS MANUAL.

Thank you for choosing a LARIUS S.R.L. product. As well as the product purchased,

you will receive a range of support services enabling you to achieve the results desired,

It indicates a fire

or explosion risk if

this warning is not

followed.

quickly and professionally.

It indicates wound and

finger squashing risk

due to movable parts in

the equipment.

It is obligatory to wear suitable

clothing as gloves, goggles and

face shield.

tant recommenda-

process of products

in accordance with

the environmental

1

It indicates impor-

tions about dispo-

sal andrecycling

regulations.

A

WORKING PRINCIPLE

GHIBLI 24:1 DE

English

GHIBLI 24:1 DE is a high pressure pneumatic pump used for

extrusion and transferring of high viscosity products.

The pump is essentially constituted of an air motor and of a structure

called "material pumping group" or simply "pumping group".

In the pneumatic motor, compressed air causes the vertical reciprocating movement of the motor piston; this movement is transmitted

through a connecting rod to the material pumping piston ending

with a shovel plate alowing to suck very viscous products.

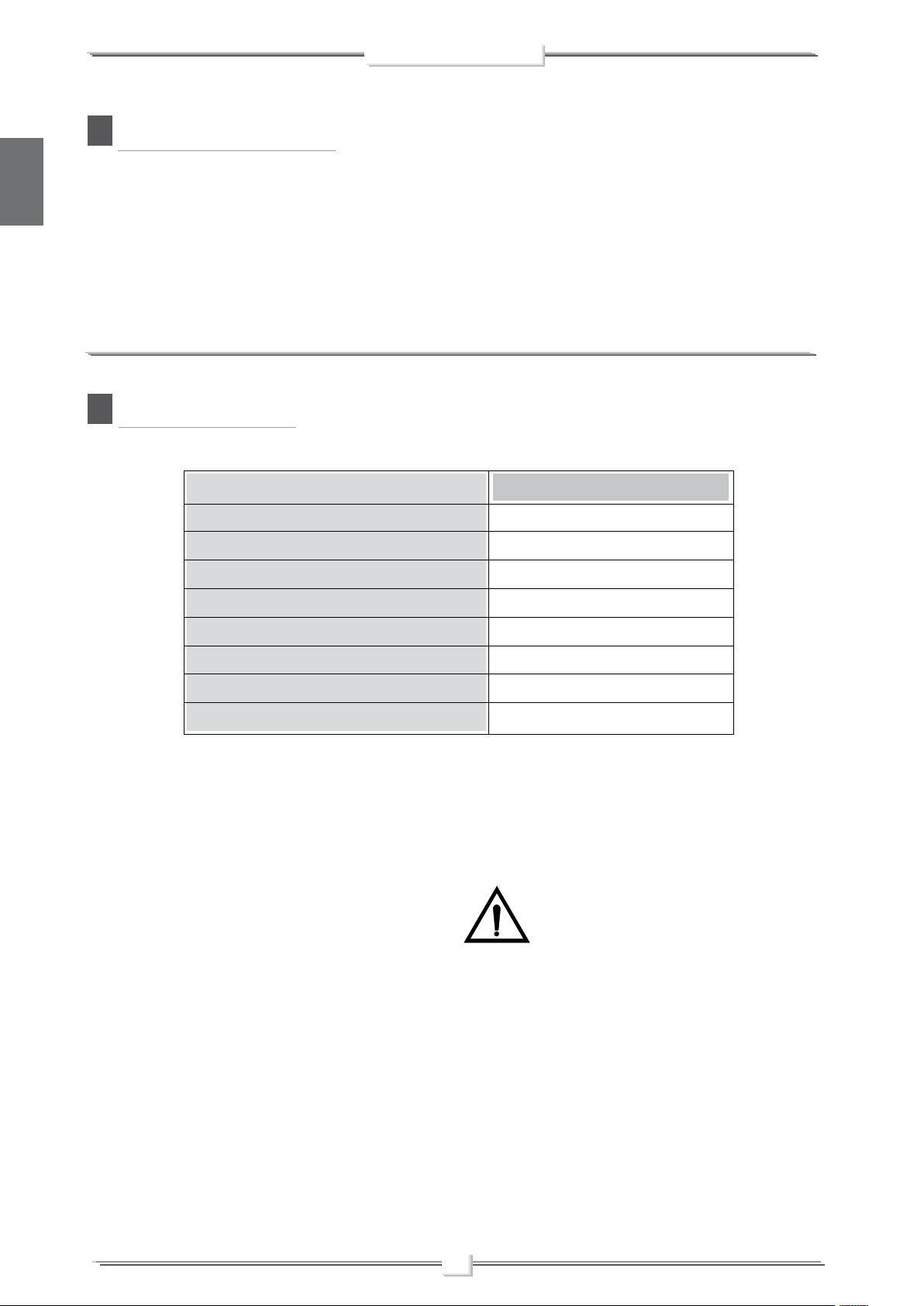

B

TECHNICAL DATA

PUMP FEED AIR PRESSURE

MAXIMUM PRESSURE OF THE PRODUCT

*FEED AIR INLET

MAXIMUM DELIVERY

The ratio 24:1 means that the outlet pressure of material is 24

times higher than the pump feed air pressure.

GHIBLI 24:1 DE

3-7 bar

168 bar

1/2" GAS (F)

4 l/min (6,4 cpm)

CYCLES PER LITRE

MAXIMUM CYCLES PER MINUTE

MATERIAL OUTLET [CONICAL GAS (F)]

NOISE PRESSURE LEVEL

*N.B. The pump is supplied with a bayonet connection.

Parts of the pump in contact with the material

Pumping group: galvanized carbon steel

Sealing balls: stainless steel AISI 420B

Gaskets: Teflon, Viton

Other parts of the pump

Motor casing and motor piston: aluminium

15

60

3/4" GAS CON. (F)

<80 dB (A)

Always observe these instructions carefully

when evaluating the product compatibility and

in case of disposal of some parts of the pump no

more usable, in order to meet the environmental

regulations on recycling process.

2

GHIBLI 24:1 DE

0 0,2 0,4 0,6 0,8 1

0 1 2 3 4

PUMP DELIVERY

CPM

40

35

30

25

20

15

10

5

0

CPM

L/MIN

L/MIN

1000

800

600

400

200

0

AIR CONSUMPTION

69

50

Ø140

Ø10

English

40

80

140

180

Pump

Long

Medium

7 bar (100 psi)

5 bar (70 psi)

3 bar (40 psi)

A

870

1310

640

1080

B

Weight

20 Kg

19 Kg

B

440

137440

194

A

3

GHIBLI 24:1 DE

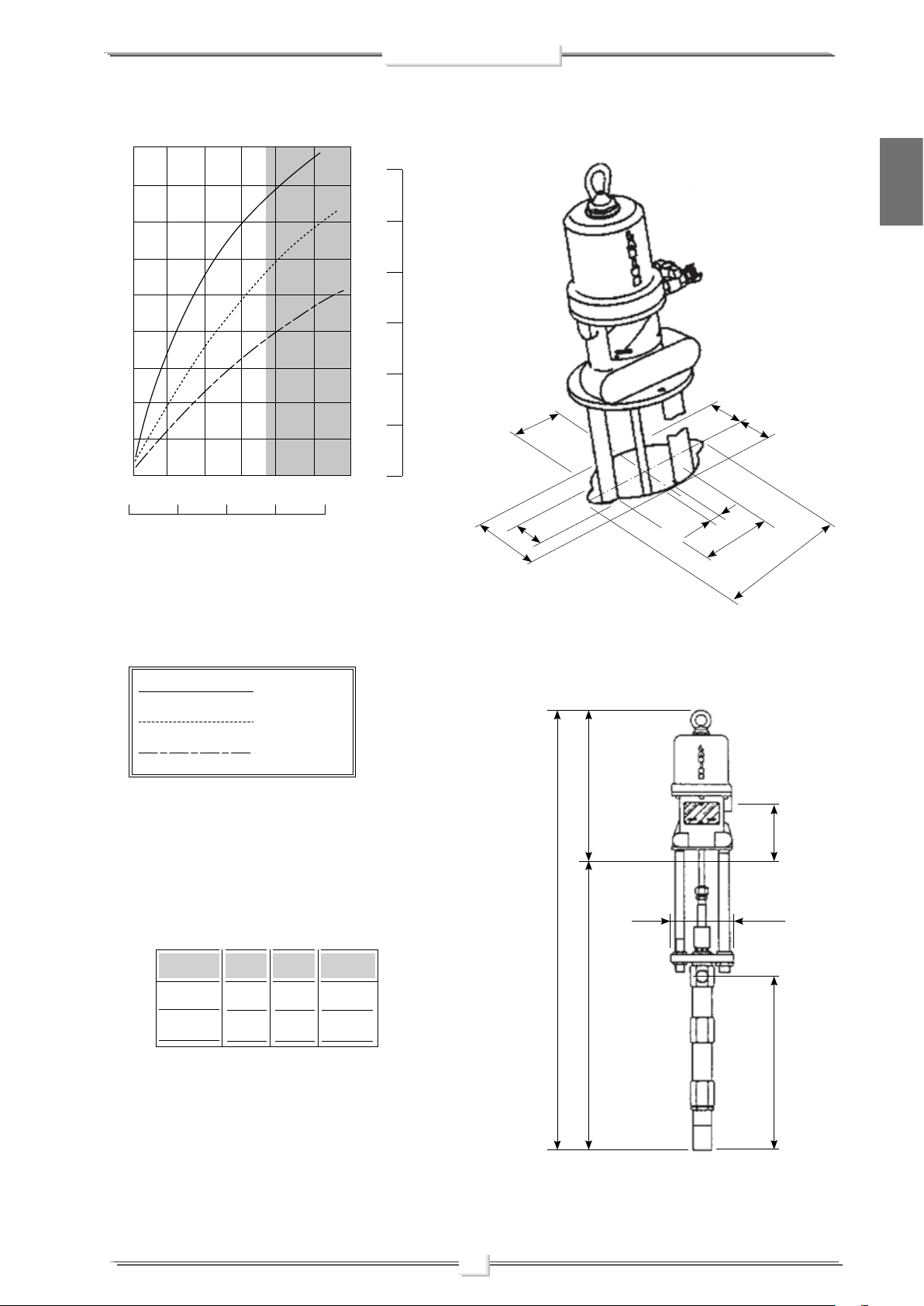

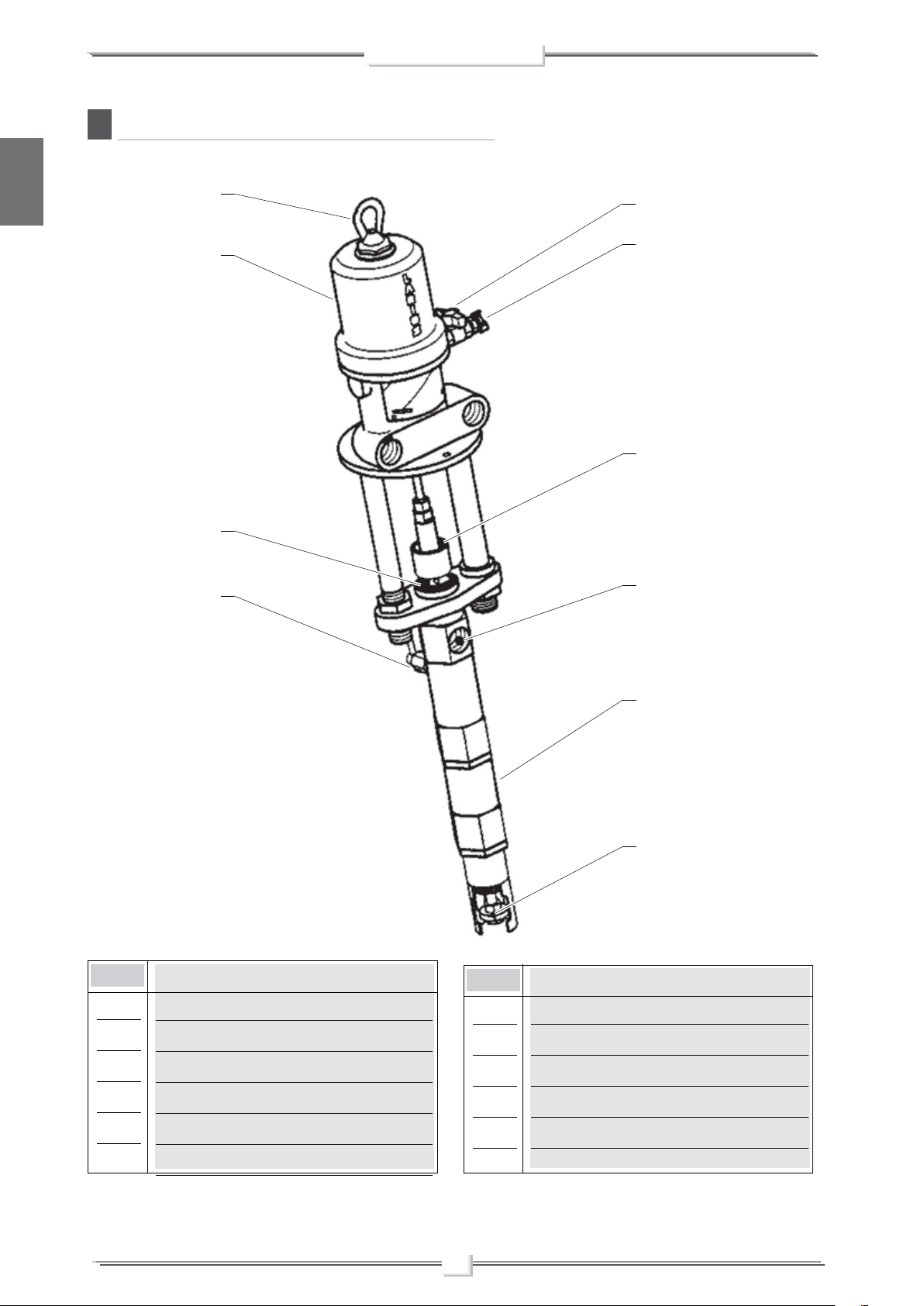

DESCRIPTION OF THE EQUIPMENT

C

English

10

1

9

8

7

2

3

5

POS.

1

2

3

4

5

Description

Opening - Closing valve for air passage

Pump feed air inlet

Wet cup

Material pumping group

Material outlet

POS.

6

7

8

9

10

4

6

Description

Material shovel plate

Bleeder valve

Upper packing nut

Pneumatic motor

Eyebolt to fasten the pump for transport

4

GHIBLI 24:1 DE

TRANSPORT AND

D

UNPACKING

• The packed parts should be handled as indicated in the

symbols and markings on the outside of the packing.

• Before installing the equipment, ensure that the area to

be used is large enough for such purposes, is properly

lit and has a clean, smooth floor surface.

THE BEHAVIOUR OF THE EMPLOYEES SHALL STRICTLY

English

COMPLY WITH THE ACCIDENT PREVENTION AND

ALSO ENVIRONMENTAL REGULATIONS IN FORCE IN

THE COUNTRY WHERE THE PLANT IS INSTALLED AND

USED.

• The user is responsible for the operations of unloading

and handling and should use the maximum care so as

not to damage the individual parts or injure anyone.

To perform the unloading operation, use only qualified

and trained personnel (truck and crane operators, etc.)

and also suitable hoisting equipment for the weight of the

installation or its parts.

Follow carefully all the safety rules.

The personnel must be equipped with the necessary

safety clothing.

• The manufacturer will not be responsible for the unloading

operations and transport to the workplace of the machine.

• Check the packing is undamaged on receipt of the equipment. Unpack the machine and verify if there has been

any damage due to transportation.

In case of damage, call immediately LARIUS and the

Shipping Agent. All the notices about possible damage or

anomalies must arrive timely within 8 days at least from

the date of receipt of the plant through Registered Letter

to the Shipping Agent and to LARIUS.

• The disposal of packaging materials is a customer’s

competence and must be performed in accordance with

the regulations in force in the country where the plant is

installed and used.It is nevertheless sound practice to

recycle packaging materials in an environment-friendly

manner as much as possible.

SAFETY RULES

E

• THE EMPLOYER SHALL TRAIN ITS EMPLOYEES

ABOUT ALL THOSE RISKS STEMMING FROM ACCIDENTS, ABOUT THE USE OF SAFETY DEVICES FOR

THEIR OWN SAFETY AND ABOUT THE GENERAL

RULES FOR ACCIDENT PREVENTION IN COMPLIANCE WITH INTERNATIONAL REGULATIONS AND WITH

THE LAWS OF THE COUNTRY WHERE THE PLANT

IS USED.

Read carefully and entirely the following

instructions before using the product. Please

save these instructions in a safe place.

The unauthorised tampering/replacement of

one or more parts composing the machine,

the use of accessories, tools, expendable

materials other than those recommended by the

Manufacturer can be a danger of accident.

The Manufacturer will be relieved from tort and criminal

liability.

• KEEP YOUR WORK PLACE CLEAN AND TIDY. DISORDER

WHERE YOU ARE WORKING CREATES A POTENTIAL

RISK OF ACCIDENTS.

• ALWAYS KEEP PROPER BALANCE AVOIDING UNUSUAL

STANCE.

• BEFORE USING THE TOOL, ENSURE THERE ARE NOT

DAMAGED PARTS AND THE MACHINE CAN WORK PROPERLY.

• ALWAYS FOLLOW THE INSTRUCTIONS ABOUT SAFETY

AND THE REGULATIONS IN FORCE.

• KEEP THOSE WHO ARE NOT RESPONSIBLE FOR THE

EQUIPMENT OUT OF THE WORK AREA.

• NEVER EXCEED THE MAXIMUM WORKING PRESSURE

INDICATED.

• NEVER POINT THE SPRAY GUN AT YOURSELVES OR AT

OTHER PEOPLE. THE CONTACT WITH THE CASTING CAN

CAUSE SERIOUS INJURIES.

• IN CASE OF INJURIES CAUSED BY THE GUN CASTING,

SEEK IMMEDIATE MEDICAL ADVICE SPECIFYING THE

TYPE OF THE PRODUCT INJECTED. NEVER UNDERVALUE A WOUND CAUSED BY THE INJECTION OF A

FLUID.

• ALWAYS DISCONNECT THE SUPPLY AND RELEASE THE

PRESSURE IN THE CIRCUIT BEFORE PERFORMING ANY

CHECK OR PART REPLACEMENT OF THE EQUIPMENT.

• NEVER MODIFY ANY PART IN THE EQUIPMENT. CHECK

REGULARLY THE COMPONENTS OF THE SYSTEM.

REPLACE THE PARTS DAMAGED OR WORN.

•

TIGHTEN AND CHECK ALL THE FITTINGS FOR

5

Loading...

Loading...