www.larius.eu

CH 200 AD

OPERATING AND MAINTENANCE INSTRUCTION

ITALIANO

Ediz. 03 - 06/2019

WE ADVISE THE USE OF THIS EQUIPMENT ONLY BY PROFESSIONAL OPERATORS.

ONLY USE THIS MACHINE FOR USAGE SPECIFICALLY MENTIONED IN THIS MANUAL.

Thank you for choosing a LARIUS S.R.L. product.

As well as the product purchased, you will receive a range of support services

enabling you to achieve the results desired, quickly and professionally.

Due to a constant product improvement programme, the factory reserves the right to modify technical

details mentioned in this manual without prior notice.

This manual is to be considered as an English language translation of the original manual in Italian.

The manufacturer shall bear no responsibility for any damages or inconveniences that may arise due

to the incorrect translation of the instructions contained within the original manual in Italian.

POWDER COATING SYSTEM

POWDER COATING SYSTEM

CH 200 AD

INTRODUCTION .................................................. p.1

WARNINGS .......................................................... p.2

A

PRINCIPLE OF OPERATION ............................... p.3

TECHNICAL DATA ............................................... p.4

B

DESCRIPTION OF THE EQUIPMENT ................. p.5

C

D

TRANSPORT AND UNPACKING ......................... p.6

E

SAFETY REGULATIONS ...................................... p.6

Electrical safety regulations ........................... p.7

Precautions during work ................................. p.7

CONDITIONS OF GUARANTEE .......................... p.6

F

CORRECT USE OF THE SYSTEM ....................... p.8

G

INCORRECT USE OF THE SYSTEM

H

CONTROL PANEL ................................................ p.9

Operating controls

Current output adjustment µa

Connections .................................................... p.11

Operation ......................................................... p.13

Use with CH spray gun (corona effect) .......... p.13

Use with triboelectric spraying gun ............... p.15

I

CYCLICAL ROUTINE MAINTENANCE ................ p.16

J

COLOR CHANGE ................................................. p.18

J

K

PROBLEMS AND SOLUTIONS ........................... p.19

............................................... p.9

.....................p.9

........................... p.11

SPARE PARTS

SHAKING TABLE CH-200-AD ............................. p.24

L

M

FRAME SPARE PARTS CH-200-AD .................... p.24

N

ELECTROPNEUMATIC GENERATOR ................. p.28

O

CH 200 MANUAL GUN REF.9700 ........................ p.30

P

SPARE PARTS FOR AUTOMATIC GUN

CH 200 REF.9705 ................................................. p.32

Q

SPARE PARTS FOR AUTOMATIC AND MANUAL

TRIBO SPRAY GUN ............................................. p.34

CONE JET NOZZLE SPRAY GUN FOR CH 200

R

SPARE PARTS FOR CONE JET NOZZLE WITH

S

EXTENSION FOR CH 200

FAN NOZZLE SPARE PARTS FOR CH 200

T

HIGH PERFORMACE NOZZLE SPARE PARTS

U

FOR CH 200

V

MULTI-DIFFUSION NOZZLE SPARE PARTS

FOR CH 200

Z

POWDER DELIVERY PUMP SPARE PARTS

REF.5505

Y

ACCESSORIES .................................................... p.42

.......................................................... p.39

.......................................................... p.40

............................................................... p.41

...................................... p.37

..... p.36

............ p.38

Edit. 03 - 06/2019

www.larius.eu

1

CH 200 AD

WARNINGS

Carefully read this manual before using the machine.

Improper use may cause damage to persons or property.

Do not use the spray gun if you are under the influence of drugs or alcohol.

Do not modify the spray gun for any reason.

Use products and solvents that are compatible with the different parts of the spray gun, carefully reading the manufacturer's warnings.

Refer to the Technical Data of the spray gun in this manual.

Check the spray gun daily; if worn parts are noted, replace them using ONLY original spare parts.

Keep children and animals away from the work area.

Observe all safety regulations.

This symbol signals the risk of injury or serious damage to the machine if the warning is not heeded.

These symbols signal the risk of chemical reactions and the risk of explosion if the warning is not heeded.

There is a danger of serious injury caused by contact with the spray gun jet, if injury occurs IMMEDIATELY seek

medical care, specifying the type of product injected.

Do not spray without having installed the nozzle guard and the spray gun trigger guard.

Do not place fingers on the spray gun nozzle.

At the end of the work cycle and before performing any maintenance operation, follow the pressure relief procedure

included in this manual.

The meanings of the symbols used in the manual that concern use as well as use, maintenance and

repair operations of this machine are described in the following table.

This symbol signals important instructions and recommendations for the environmentally-friendly disposal or re

cycling of a product.

This symbol signals the risk of electric shock if the warning is not heeded and the presence of electric voltage.

Store in a place with no humidity and do not expose to rain.

Check to make sure the cables are intact.

Switch off the machine and discharge any residual voltage supply before performing cleaning and maintenance

operations.

This symbol signals the presence of a terminal with a grounding cable.

Use ONLY three-wire extensions and electrical outlets with grounding connections.

Before beginning work, make sure the electrical system is equipped with a grounding connection and that it complies

with the safety regulations.

FIRE AND EXPLOSION HAZARD

Flammable fumes, like solvent and paint fumes can ignite and may explode.

To prevent fire or explosion:

- Use the machine ONLY in well-ventilated areas.

Eliminate all possible sources of ignition; such as pilot lights, cigarettes, flashlights, synthetic clothing (potential static

arc), etc.

- Ground the machine and all conductive objects in the work area.

- Only use airless conductive tubes that are grounded.

- Do not use trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such

solvents in aluminium devices that are under pressure. This may cause a dangerous chemical reaction that may

could result in an explosion.

If electric charges or shocks are detected immediately interrupt the operation you are performing with the machine.

Keep a fire extinguisher in the immediate vicinity of the work area.

-

www.larius.eu

2

Edit. 03 - 06/2019

CH 200 AD

DANGER OF HIGH PRESSURE FLUID INJECTION

The high pressure fluid that comes out of the spray gun or from any leaks may penetrate the skin and cause lacerations.

To prevent fire or fluid injection:

- Enable the spray gun's trigger safety lock when not spraying.

- Do not place hands or fingers on the nozzle of the spray gun. Do not try and stop leaks with your hands, body or

other.

- Do not point the spray gun towards yourself or anyone else.

- Do not spray without the special nozzle guard.

-

Discharge the pressure of the system after spraying and before performing any maintenance operations.

- Do not use components whose operating pressure is less than the maximum pressure of the system.

- Do not allow children to use this machine.

- Be careful of the possible backlash when you pull the spray gun trigger.

If the high pressure fluid penetrates the skin, the wound may seem like a "simple

cut" but, in reality, it could

affected area.

These symbols signal the obligation to wear protective gloves, goggles and masks.

Wear clothing that complies with safety regulations in force in the country of the user.

Do not wear bracelets, earrings, rings, chains or other objects that may obstruct the operator's work.

Do not wear clothing with large sleeves, scarves, ties or any other item that can become tangled in the moving parts

of the machine during the operating cycle and inspection and maintenance operations.

be a very serious injury. Immediately provide medical treatment to the

PRINCIPLE OF OPERATION

A

This type of machine constitutes a complete and independent

unit for the application of powder coatings.

LARIUS has created this AD CH 200-TRIBO unit which allows

the use of corona effect spray guns (the powder is charged by

electrodes), and triboelectric spray guns (the charge occurs

via friction).

Therefore the same machine can be used as an electrostatic

generator for CH 200 series spray guns, or as a control unit

for the electrostatic charge for LARIUS TRIBO manual and

automatic spray guns.

The conversion from one system to the other occurs via the

simple touch of a switch.

The AD version is the ideal solution when frequent colour

changes are required. As a matter of fact, the powder is sucked

up directly by the original package. If necessary just replace

the box with the powder and clean the suction tube.

Edit. 03 - 06/2019

www.larius.eu

3

CH 200 AD

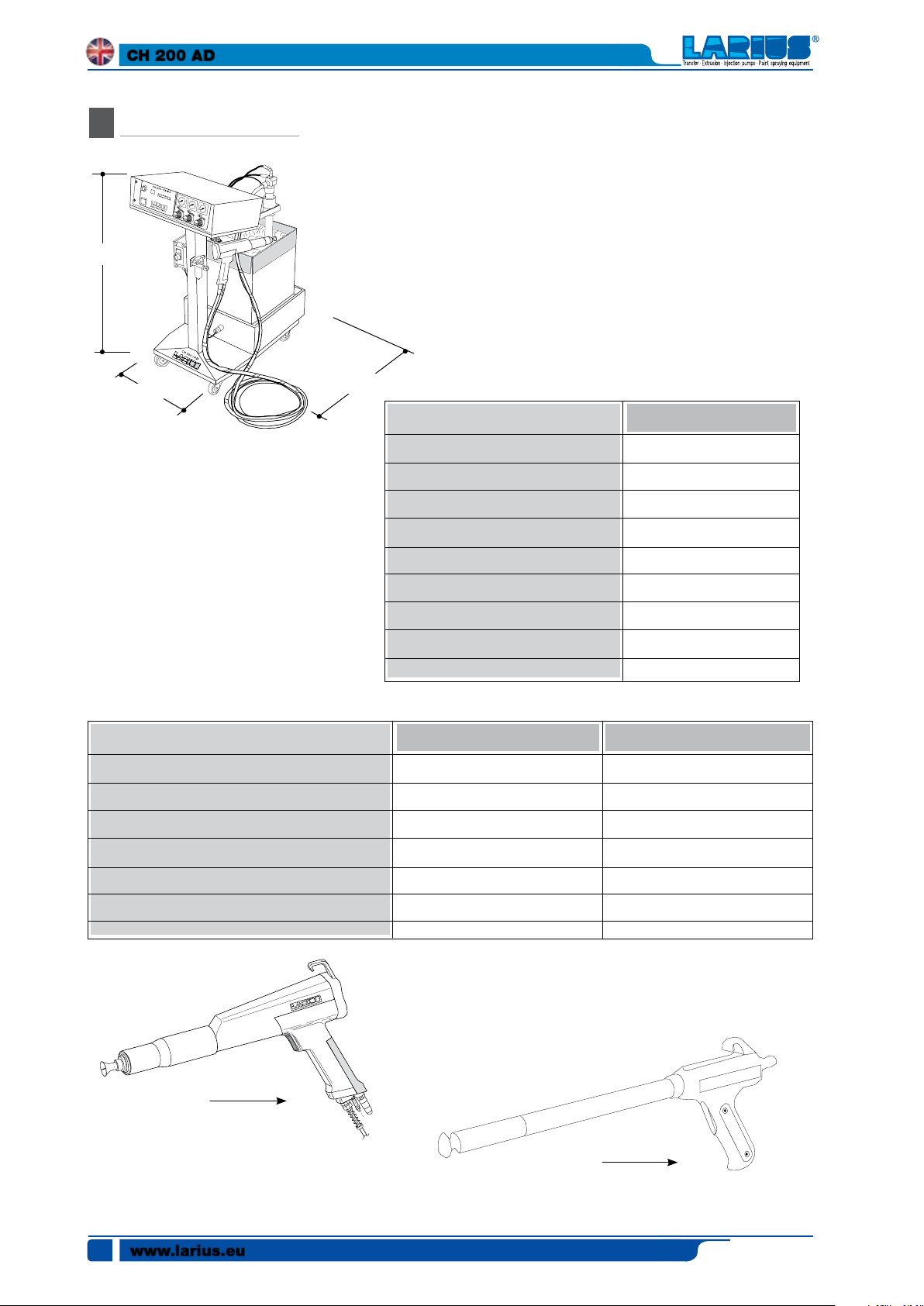

TECHNICAL DATA

B

C

B

SUPPLY VOLTAGE

OUTPUT VOLTAGE

NOMINAL CURRENT

POLARITY

WEIGHT

LENGTH

A

SUPPLY VOLTAGE

INSTALLED POWER

FREQUENCY

POWDER FLOW

WEIGHT

LENGTH

WIDTH

HEIGHT

approx. 12 V

0-120 KV c.c.

µA

0-190

Negative

690 g

360 mm

CH 200 - TRIBO /AD

120-220 Vca

60 W

50 Hz

3-20 kg/h

55 Kg

(A) 490 mm

(B) 800 mm

(C) 1100 mm

SPRAY GUN TRIBOSPRAY GUN CH 200

-

-

-

Positive

590 g

450 mm

www.larius.eu

4

CH 200 Spray gun

TRIBO Spray gun

Edit. 03 - 06/2019

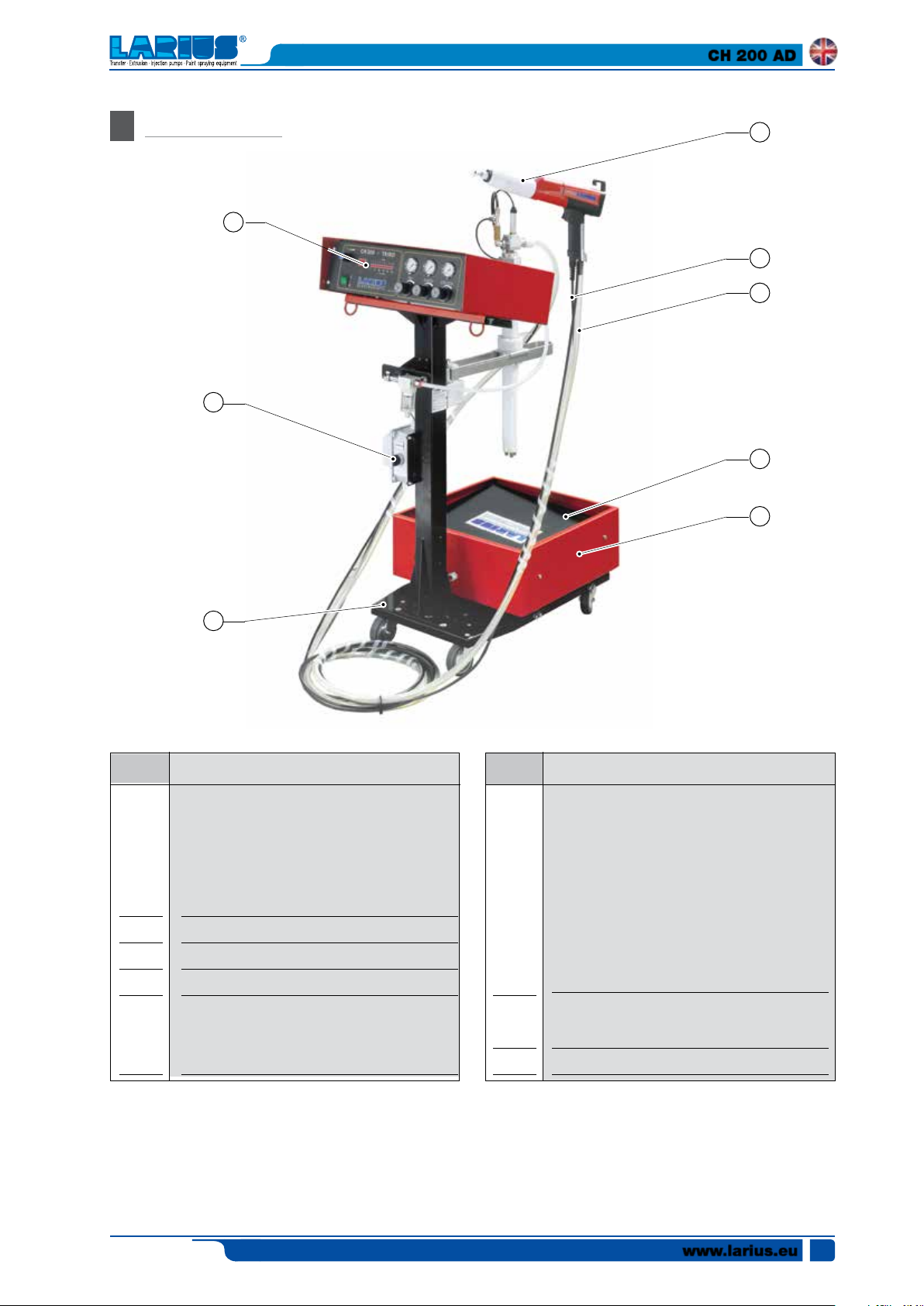

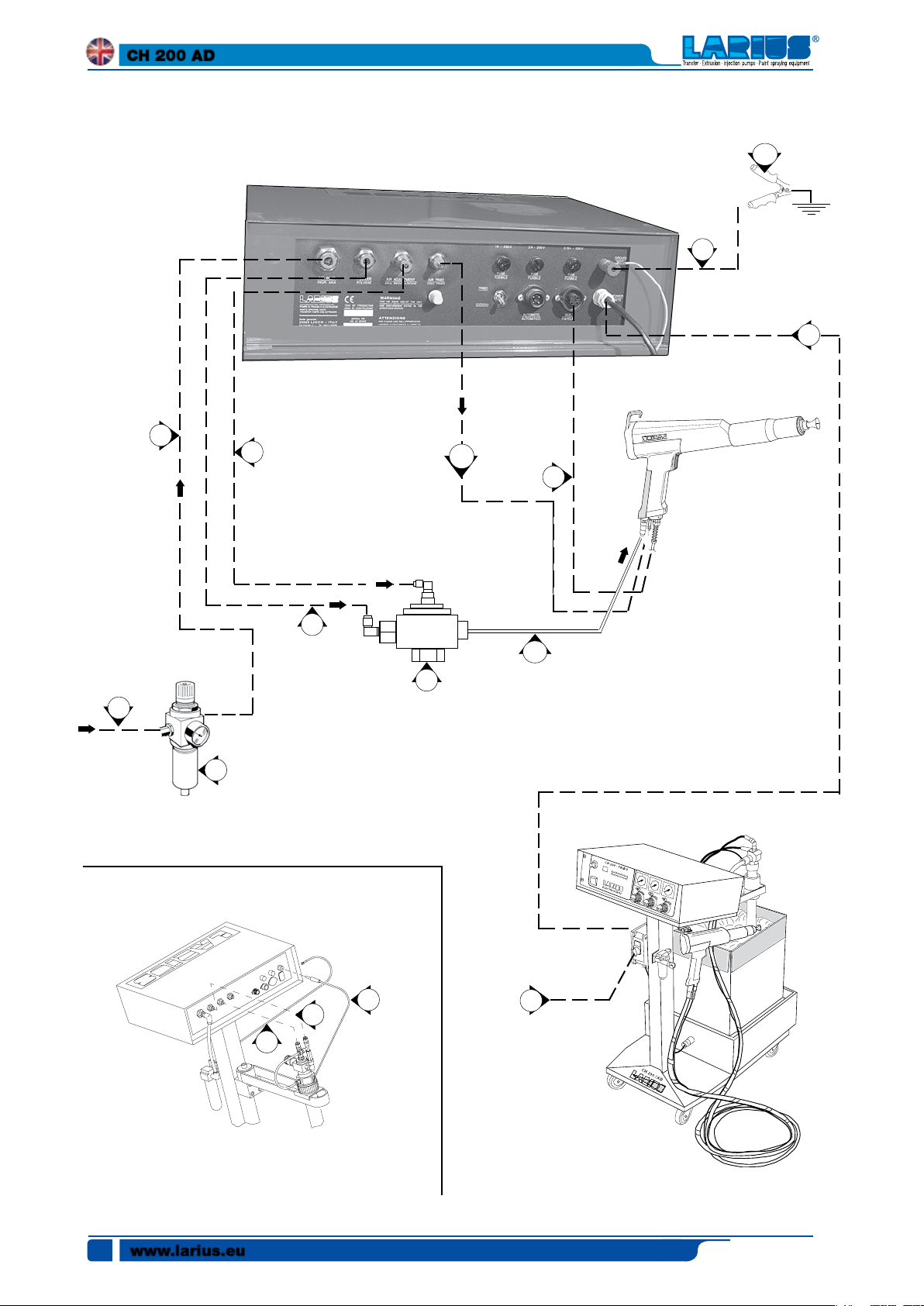

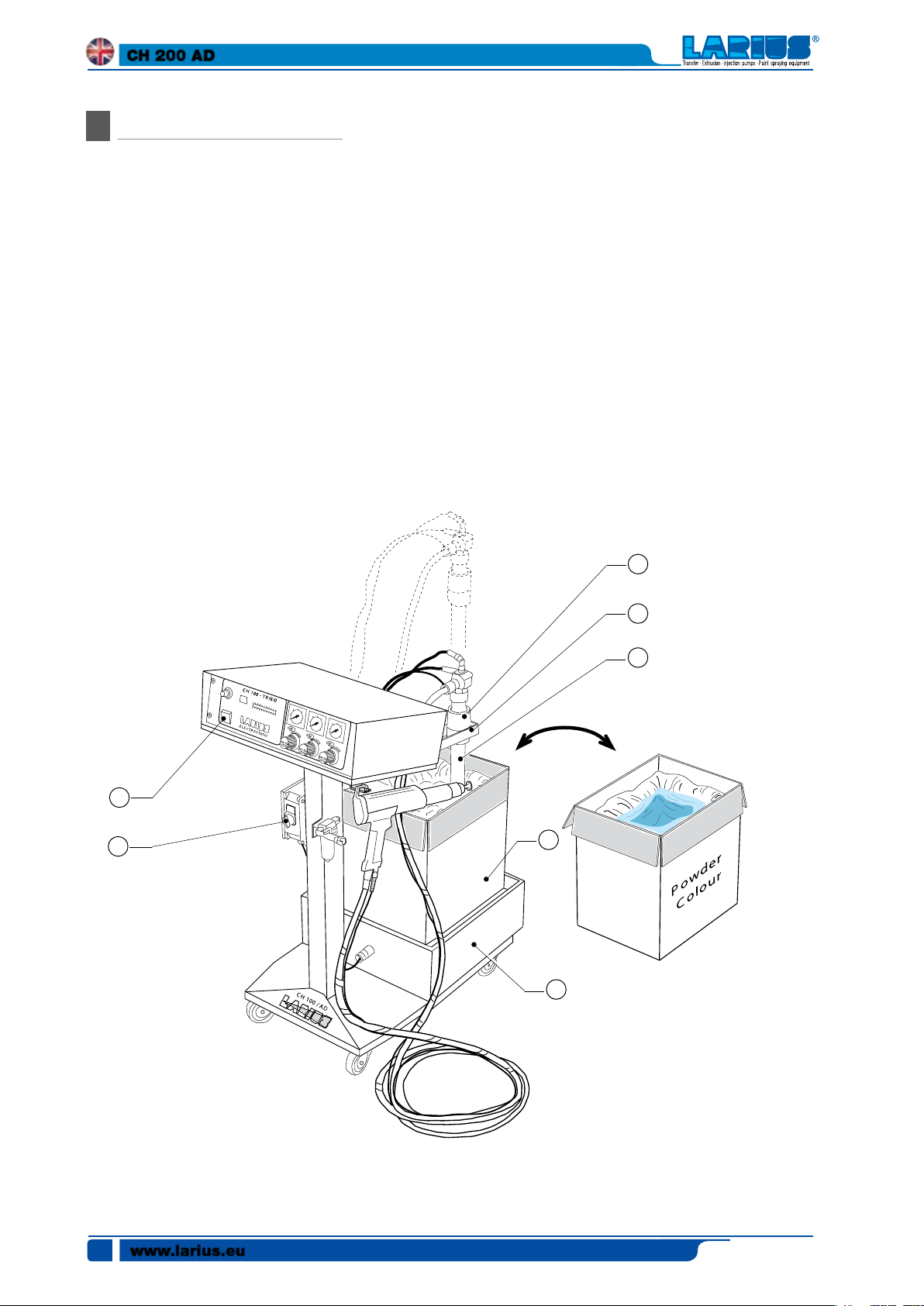

MAIN PARTS

C

8

CH 200 AD

6

1

3

2

7

REP.

1

.

2

3.

4

5

.

4

Description Description

RACK electrostatic generator which en-

closes all the power and control circuits,

both electrical and pneumatic, as well as

the safety systems, and digital display

of operating voltage and current.

Powder supply tube.

Power supply cable for manual spray gun.

Support trolley with rotating wheels.

Interchangeable powder container for

using different colour powders (max.

recommended capacity 25 kg).

REP.

6

.

7

.

8

5

CH200 powder spray gun, composed

of a black of epoxy resin cast under

pressure and treated withresins for total

safety during operation. The voltage

multiplier protected by insulating resins

is housed inside the body of the spray

gun (which can be used with CH 200 -

TRIBO triboelectric spray guns).

Vibrating shaking table with inclined

surface, complete with electric vibrator.

Switch for electric vibrator

Edit. 03 - 06/2019

www.larius.eu

5

CH 200 AD

TRANSPORT AND

D

UNPACKING

• Carefully observe the position of the packaging indicated

on the outside by writing or symbols.

• Before installing the machine, prepare an area that is

suitable in size, has the correct lighting, and a clean

and smooth floor.

All operations of unloading and handling of the

machine are the responsibility of the user, who

must be very careful to avoid causing damage or

injury to persons or the machine.

Only specialised and qualified personnel (forklift

drivers, crane operators, etc.) and suitable lifting

equipment with a capacity that can support the

weight of the packaging and that complies with

safety regulations should be employed for unloading operations.

Personnel must be equipped with the necessary

personal protection equipment.

•

The manufacturer declines all responsibility regarding the

unloading and transport of the machine in the workplace.

• Upon receipt of the machine, verify the packaging is

intact. Remove the machine from its packaging and

check that it has not been damaged during transport.

If damaged components are noted, contact LARIUS

and the shipping agent in a timely manner. Any damage

noted must be communicated within a maximum of 8

days from receipt of the system.

The communication must be made via registered mail

with return receipt, addressed to LARIUS and the

shipping agent.

The disposal of packaging materials, which is the

responsibility of the user, must be carried out in

compliance with laws in force in the country where

the machine is used.

However, it is good practice to recycle the

packaging materials as much as possible in an

environmentally-friendly way.

SAFETY REGULATIONS

E

• THE EMPLOYER MUST EDUCATE PERSONNEL ABOUT

THE RISKS OF INJURIES, OPERATOR SAFETY DEVICES

AND THE GENERAL ACCIDENT PREVENTION RULES

ESTABLISHED BY INTERNATIONAL DIRECTIVES AND

LEGISLATION IN THE COUNTRY WHERE THE MACHINE IS

INSTALLED IN ADDITION TO REGULATIONS CONCERNING

ENVIRONMENTAL POLLUTION.

•

• KEEP THE WORK AREA IN ORDER. DISORDER IN THE

• ALWAYS KEEP YOUR BALANCE, AVOIDING UNSAFE

• BEFORE USE THOROUGHLY CHECK THAT THERE ARE

• ALWAYS OBSERVE SAFETY INSTRUCTIONS AND REGU-

• DO NOT ALLOW PERSONS NOT INVOLED IN THE OP-

• NEVER EXCEED THE MAXIMUM OPERATING PRESSURES

• NEVER POINT THE SPRAY GUN TOWARDS YOURSELF OR

• ALWAYS DISCONNECT THE POWER SUPPLY AND

• NEVER MODIFY ANY COMPONENT OF THE MACHINE.

PERSONNEL MUST CAREFULLY OBSERVE ACCIDENT

PREVENTION REGULATIONS OF THE COUNTRY WHERE

THE MACHINE IS INSTALLED AS WELL AS REGULATIONS

CONCERNING ENVIRONMENTAL POLLUTION.

Carefully read the following instructions in their

entirety before using the machine.

Keep these instructions in a safe place.

The non-authorised tampering with or replacement

of one or more parts that make up the machine, the

use of accessories, tools and consumable materials

that are different from those recommended by the

manufacturer may cause accidents and relieves

the manufacturer from all civil and penal liabilities.

WORKPLACE CAUSES DANGER AND ACCIDENTS.

POSITIONS.

NO DAMAGED PARTS AND THAT THE MACHINE IS ABLE

TO PROPERLY CARRY OUT ITS FUNCTION.

LATIONS IN FORCE.

ERATION OF THE MACHINE TO ACCESS THE WORK

AREA.

INDICATED.

OTHERS. DIRECT CONTACT WITH THE JET MAY CAUSE

SERIOUS INJURY. IN CASE INJURIES ARE CAUSED BY

THE SPRAY GUN JET IMMEDIATELY SEEK MEDICAL

ATTENTION, SPECIFYING THE TYPE OF PRODUCT ABSORBED BY THE SKIN. NEVER UNDERESTIMATE AN

INJURY CAUSED BY FLUID INJECTION.

DISCHARGE THE PRESSURE IN THE CIRCUIT BEFORE

PERFORMING ANY TYPE OF INSPECTION OR REPLACEMENT OF COMPONENTS OF THE MACHINE.

REGULARLY INSPECT THE COMPONENTS OF THE MACHINE. REPLACE DAMAGED OR WORN PARTS.

www.larius.eu

6

Edit. 03 - 06/2019

CH 200 AD

• TIGHTEN AND CHECK ALL THE CONNECTION FITTINGS

BETWEEN THE PUMP, THE FLEXIBLE TUBE AND THE

SPRAY GUN BEFORE USING THIS MACHINE.

• ALWAYS USE THE FLEXIBLE TUBE PROVIDED IN THE

STANDARD WORK KIT. THE USE OF ACCESSORIES OR

EQUIPMENT DIFFERENT THAN THOSE RECOMMENDED

IN THIS MANUAL MAY CAUSE INJURY.

• THE FLUID CONTAINED IN THE FLEXIBLE TUBE MAY BE

VERY DANGEROUS. HANDLE THE FLEXIBLE TUBE WITH

CARE. DO NOT PULL THE FLEXIBLE TUBE TO MOVE THE

MACHINE. NEVER USED A DAMAGED OR REPAIRED

FLEXIBLE TUBE.

If the product flows at high speed through the

flexible tube static electricity may be created,

manifested with small shocks and sparks. The

• To prevent injuries, repairs of electrical parts must only be

machine should be electrically grounded. The

pump is grounded by the grounding wire of the

power cable. The spray gun is grounded via a high

pressure flexible tube. All the conductive objects

that are near the work area must be grounded.

• ABSOLUTELY AVOID SPRAYING FLAMMABLE PRODUCTS

OR SOLVENTS IN CLOSED ENVIRONMENTS.

• ABSOLUTELY AVOID USING THE MACHINE IN ENVIRONMENTS SATURATED WITH POTENTIALLY EXPLOSIVE

GASES

Always verify the compatibility of the product with

the materials that make up the system (pump, spray

gun, flexible tube and accessories) with which it may

come into contact. Do not use paints or solvents

that contain halogenated hydrocarbons (such

as methylene chloride). Products in contact with

aluminium parts of the machine may cause dangerous chemical reactions with risk of explosion.

Electrical safety regulations

Ensure the switch is in the “OFF” position before inserting

•

the power cable plug into the electrical outlet.

• Do not transport the machine if it is connected to the power

supply network.

• Disconnect the plug from the outlet if the machine is not in

use and before performing all maintenance or accessory

replacement operations.

• Do not drag the machine or disconnect the plug by pulling

on the power cable.

• Keep the cable away from heat, mineral oils and sharp

edges.

• If the machine is used outdoors, use a suitable extension

cord, that is intended and marked for outdoor use.

Never tamper with the calibration values of the

instruments.

carried out by qualified personnel.

PRECAUTIONS DURING WORK

• Do not smoke, do not cause open flames.

• Only the spray guns and the vehicles required for trans-

porting the powders must be in the booths: all other the

electrical devices must be outside the booth.

• Ensure that suction capacity in the spray booth is sufficient

and that the powder does not accumulate in any part of

the booth.

• Verify that the frames and all the electrical devices are

properly grounded.

• Ensure the operator is correctly "grounded".

Do not use insulated gloves and plastic shoes. Antistatic

shoes are recommended.

• Do not enter the spray booth when the machine is operating. Before entering, ensure the locking system of the entire

system is working properly.

•

Facial masks and protective suits are recommended, when

you need to work in environments filled with powder.

• Keep the area surrounding the booth clean, for at least 5

metres.

• Keep the lighting lamps clean. Wash hands and face before

eating or drinking.

IF THE PRODUCT TO BE USED IS TOXIC, AVOID

INHALATION AND ONLY HANDLE USING PROTECTIVE GLOVES, PROTECTIVE GOOGLES AND

APPRORPIATE MASKS.

USE APPROPRIATE HEARING PROTECTION EQUIPMENT IF WORKING IN THE IMMEDIATE VICINITY

OF THE MACHINE.

Edit. 03 - 06/2019

HEALTH AND SAFETY

The powders:

• Can cause irritation to the eyes, hands and respiratory

system, after prolonged direct contact.

• Are toxic if inhaled.

• Are not flammable, but they can cause combustion if their

concentration in the air exceeds the allowable limit.

• Can form a conductor wire, that can be be switched on by

"open flames", heat or by electrical sparks.

www.larius.eu

7

CH 200 AD

Powder leakage:

clean with suction tube. Do not sweep.

Fire:

insulate electrical appliances and use foam.

Contact with eyes:

wash with running water and appropriate medicines.

Inhalation:

go outdoors. Put on clean clothes. If case of respiratory difficulty, seek immediate medical attention.

Ingestion:

provide immediate medical care.

• Distance between the electrode and the piece being pro-

The safety device of the LARIUS CH 200 electrostatic

Therefore it would be wrong to get too close to narrow

CONDITIONS OF GUARANTEE

The conditions of guarantee do not apply in the

following situations:

- improper washing and cleaning of components

causing malfunction, wear or damage to the

equipment or any of its parts;

- improper use of the equipment;

- use that does not conform with applicable national legislation;

- incorrect or faulty installation;

- modifications, interventions and maintenance that

have not been authorised by the manufacturer;

- use of non-original spare parts or parts that do

not correspond to the specific model;

- total or partial non-compliance with the instructions provided.

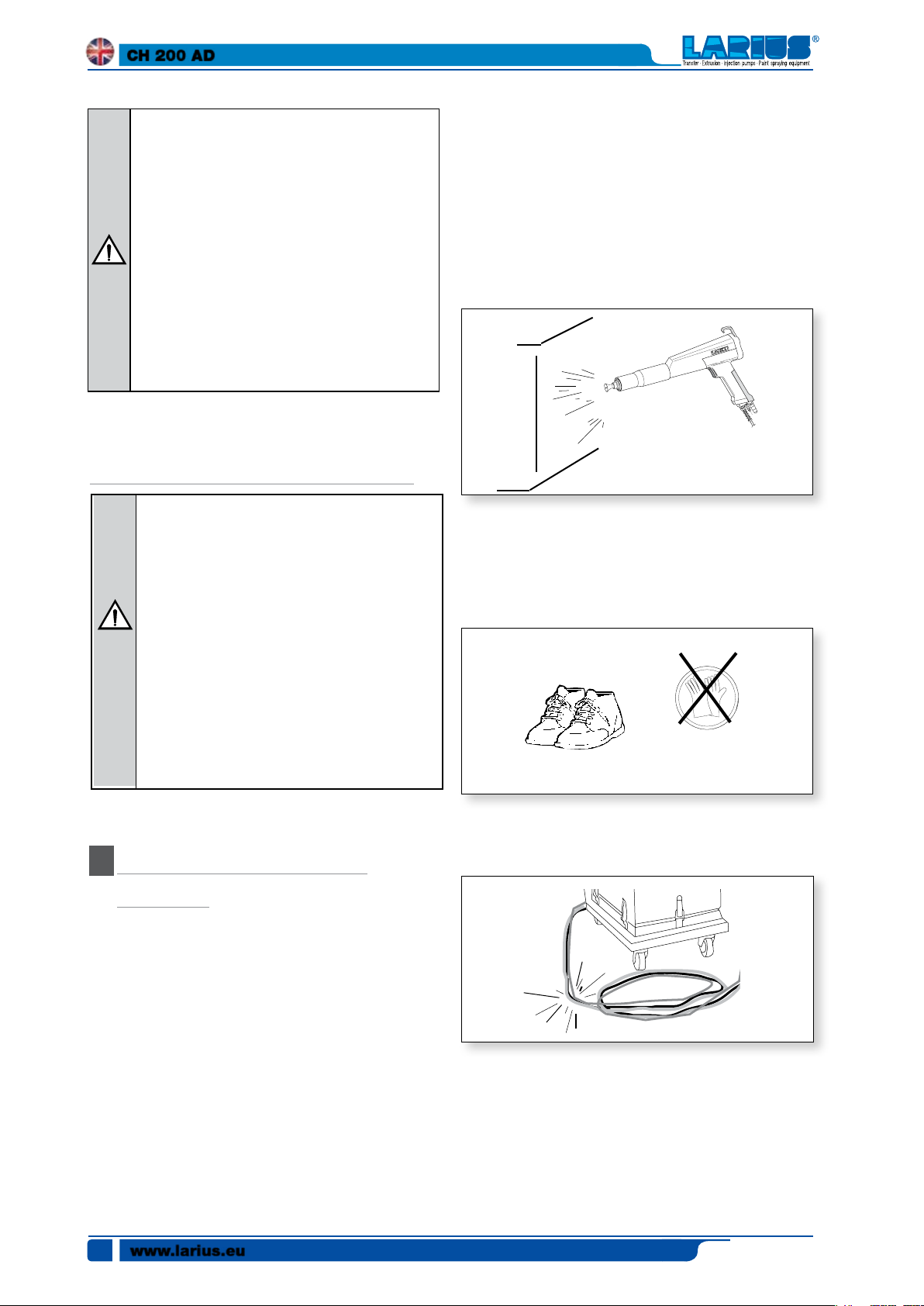

• The operator must wear conductive shoes (leather), no

cessed.

system, when below 20mm, causes a reduction in charging voltage that is so strong that the particles of sprayed

powder are no longer charged.

points in order to obtain better penetration.

gloves, as the operator's ground connection is established

through the metal plate on the handle of the spray gun.

leather

NO

• The powder tube must not be twisted or bent in any way.

CORRECT USE OF THE

F

SYSTEM

The machine described in this manual constitutes a complete

and autonomous unit for the application of powder coatings.

Correct use of the machine allows for the full exploitation of the

performance that is able to provide in conditions of complete

operator safety.

To achieve this, carefully observe the instructions provided below:

• Grounding of all mechanical parts, including the frame of

the machine and, of course, the piece being processed.

www.larius.eu

8

Edit. 03 - 06/2019

CH 200 AD

Follow the instructions included in the use and

maintenance manual.

• Verify the integrity of the components and parts of the

machine.

• Observe the instructions and warnings provided on the

machine, the safety warning labels on the machine must

always be perfectly legible.

• Check the state of preservation (cleaning) and maintenance

of the machine and its main components.

• Check the correct operation of the pneumatic system and

the condition of the pipes and fittings.

• For all operations, always wear suitable clothing, in compliance with workplace safety regulations.

• Report any operating malfunctions (faulty operation, sus-

pected breakage, incorrect movements and noise that exceeds

normal limits) to the department manager and switch off

the machine.

• Observe the maintenance schedule and record, after each

check, any observations concerning the maintenance

operation performed.

• The powder must be stored in a cool and dry place, in sealed

containers that are subject to frequent stock turnover.

• The surfaces of the piece to be treated must be free of any

contaminating agents and correctly pretreated.

The compressed air must not contain water or oil.

•

The piece to be treated must be correctly secured and

•

properly grounded.

• The frames must provide good grounding for the piece.

• The temperature of the furnace must be correct in order

to polymerise perfectly.

• The powder feeders, the spray booth, and the recovery

system must be free of all contaminating agents and free

of any powder that is different than that chosen for use.

• Pre-treatment and firing checks must be carried out periodically during processing.

• All the recycled powder must be sieved and mixed with

new powder observing the recommended proportions.

• Do not use silicones or paints near the machine.

• Use of the machine by personnel who is not adequately

trained.

• Failure to comply with routine maintenance requirements

or maintenance operations performed improperly.

• Use of non-original or unsuitable spare parts.

• Modification or cancellation of safety device settings and/

or tampering with the various equipment.

• Perform inspection, maintenance or repair operations

without having switched off the machine.

• Make temporary repairs or carry out recovery interventions

that do not comply with the instructions.

The company LARIUS is not responsible for mechanical damage to persons caused by incorrect uses as

described above.

In the event the customer must use the machine

with materials different than those cited in the sales

contract or modify the operating parameters, the

customer must contact LARIUS for new operating

parameters and technologies.

It is recommended that the operator in charge of the

machine's operation and the person responsible for

its maintenance, keep the safety and control areas

and the access area to the parts of the hoist, free

of all obstacles and equipment.

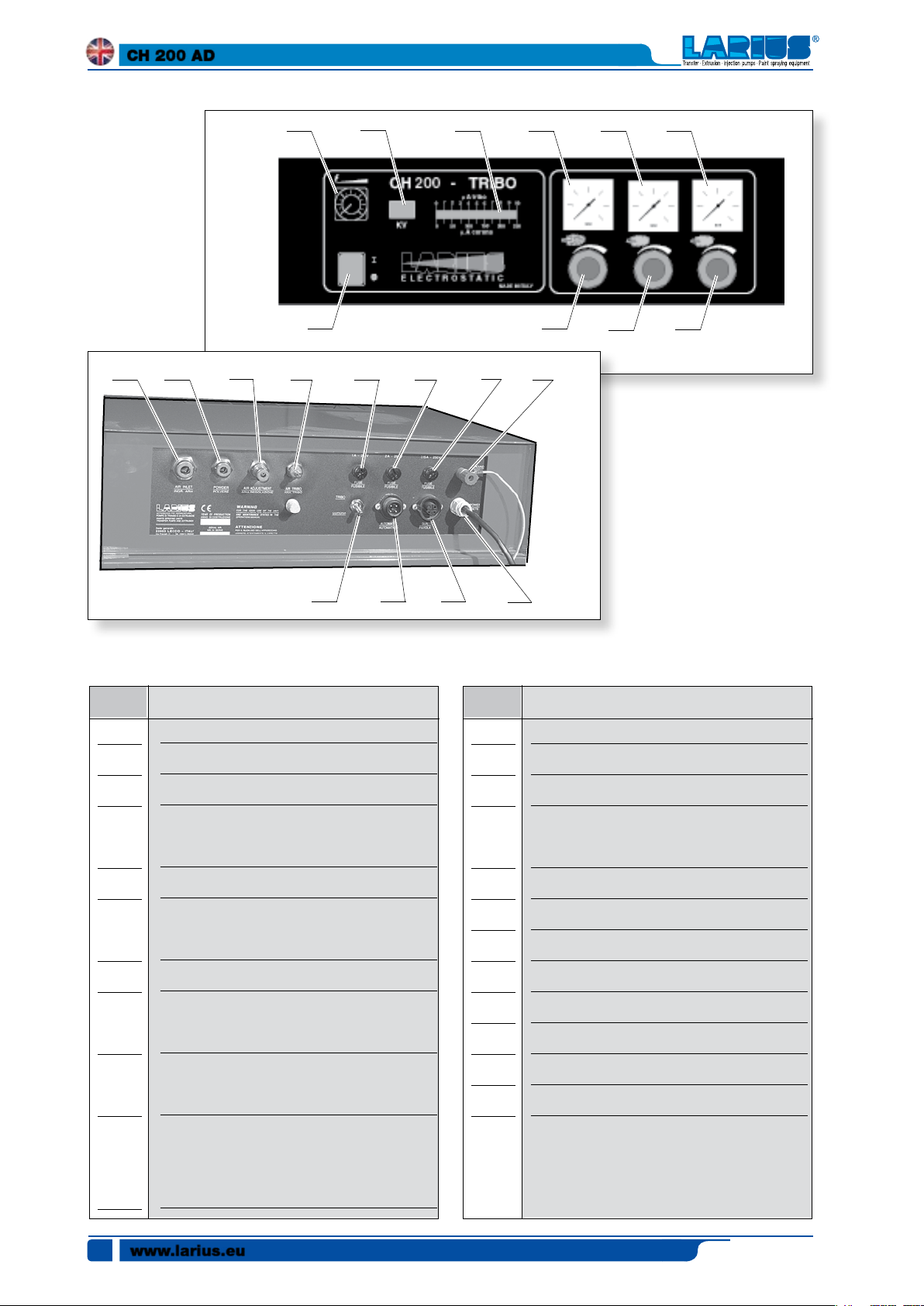

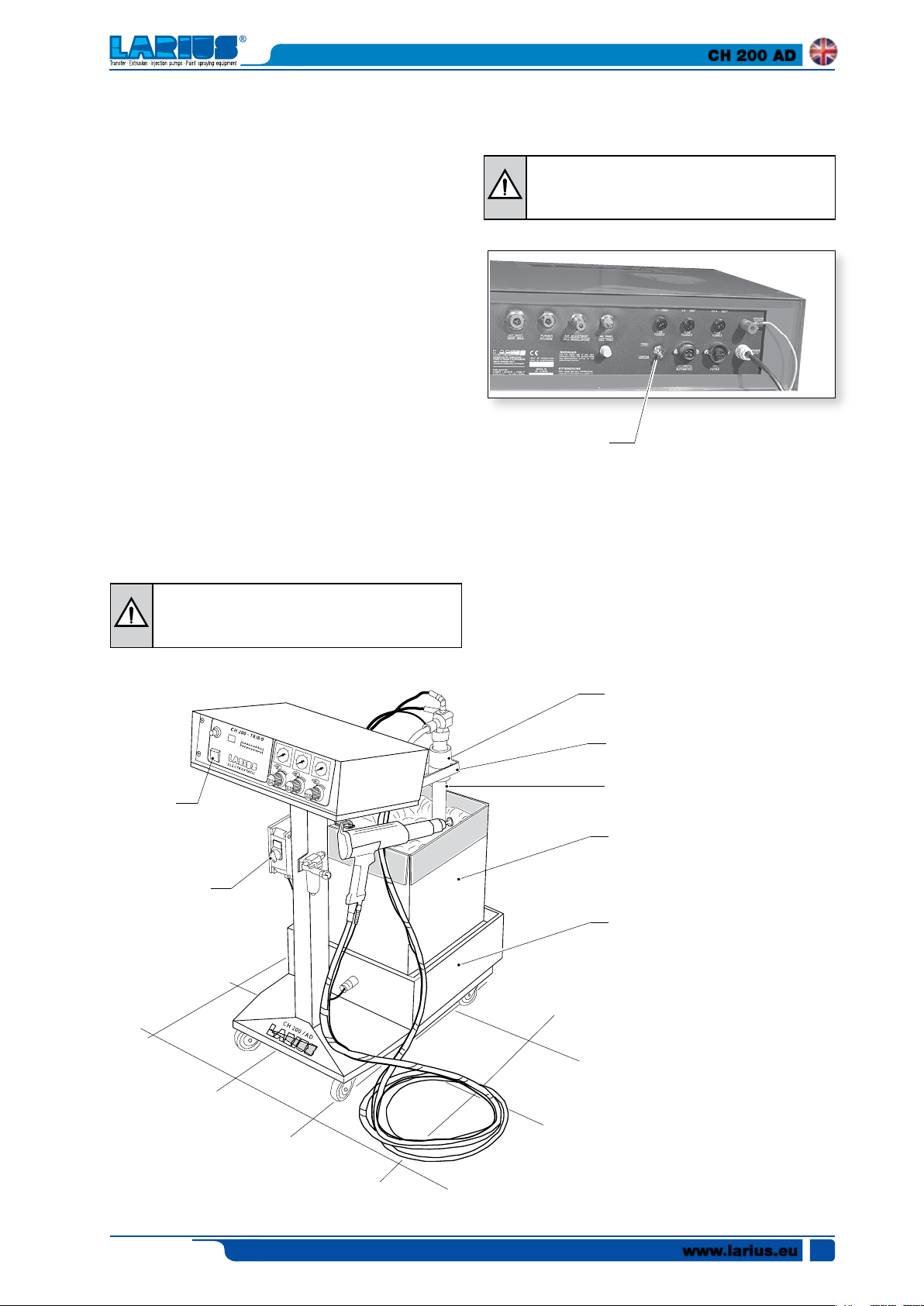

CONTROL PANEL

H

The operation, adjustment, and stoppage of the system, as well

as the instructions concerning correct operation, are managed

by the control panel positioned above.

Install a disconnecting switch with fuses upstream

of the main switch, in order to completely isolate

INCORRECT USE OF THE

G

the machine from the power supply network.

SYSTEM

OPERATING CONTROLS

The company LARIUS considers "incorrect use" of the machine

to be any use that is not described in the previous paragraph and:

• Do not point the spray gun jet at people.

• Use of improper or inadequate energy sources.

If modifications must be made to the machine, you must

contact LARIUS in order to obtain the most up-to-date

technology.

Edit. 03 - 06/2019

Buttons - Switches - Indicator lights - Potentiometers

The operating controls are located on the control panel and are

used directly by the operator during operation and to carry out

every maintenance or testing operation.

www.larius.eu

9

CH 200 AD

1 2 3 4 5 6

7

11 12 13 14 15 16 17 18

19 20 21 22

Pos.

1

2

Description

Kv adjusting potentiometer

Kv Digital indicator

Pos.

11

12

8

9 10

Description

Air inlet tube fixing attachment

Powder delivery air tube fixing connection

3

4

5

6

7

8

9

10

Led indicator µA

Pressure gauge for reading powder delivery air

pressure

.

Pressure gauge for press. additional air reading

Pressure gauge for reading "tribo air" pressure

and additional air pressure for cleaning CH 200

.

Main switch

Knob for adjusting powder delivery air pressure

.

Additional air pressure adjustment knob (to

evenly distribute the jet of powder)

.

Knob for adjusting the "tribo air" (increases the

electric effect) pressure and additional air for

cleaning the CH200 diffuser and rheophore

.

13

14

15

16

17

18

19

20

21

22

Fixing connection for additional air tube

Fixing connection for "tribo air" tube

and additional air tube for cleaning CH200

.

Main fuse (1A)

Solenoid fuse (2A)

Main PCB fuse (3.15 A)

Grounding cable fixing coupling

Selector for corona or electric painting

Outlet for automatic spray gun control cable

Outlet for spray gun supply cable

Power cable

www.larius.eu

10

Edit. 03 - 06/2019

CH 200 AD

CURRENT OUPUT ADJUSTMENT µA

• Connect the machine to the compressed air supply using

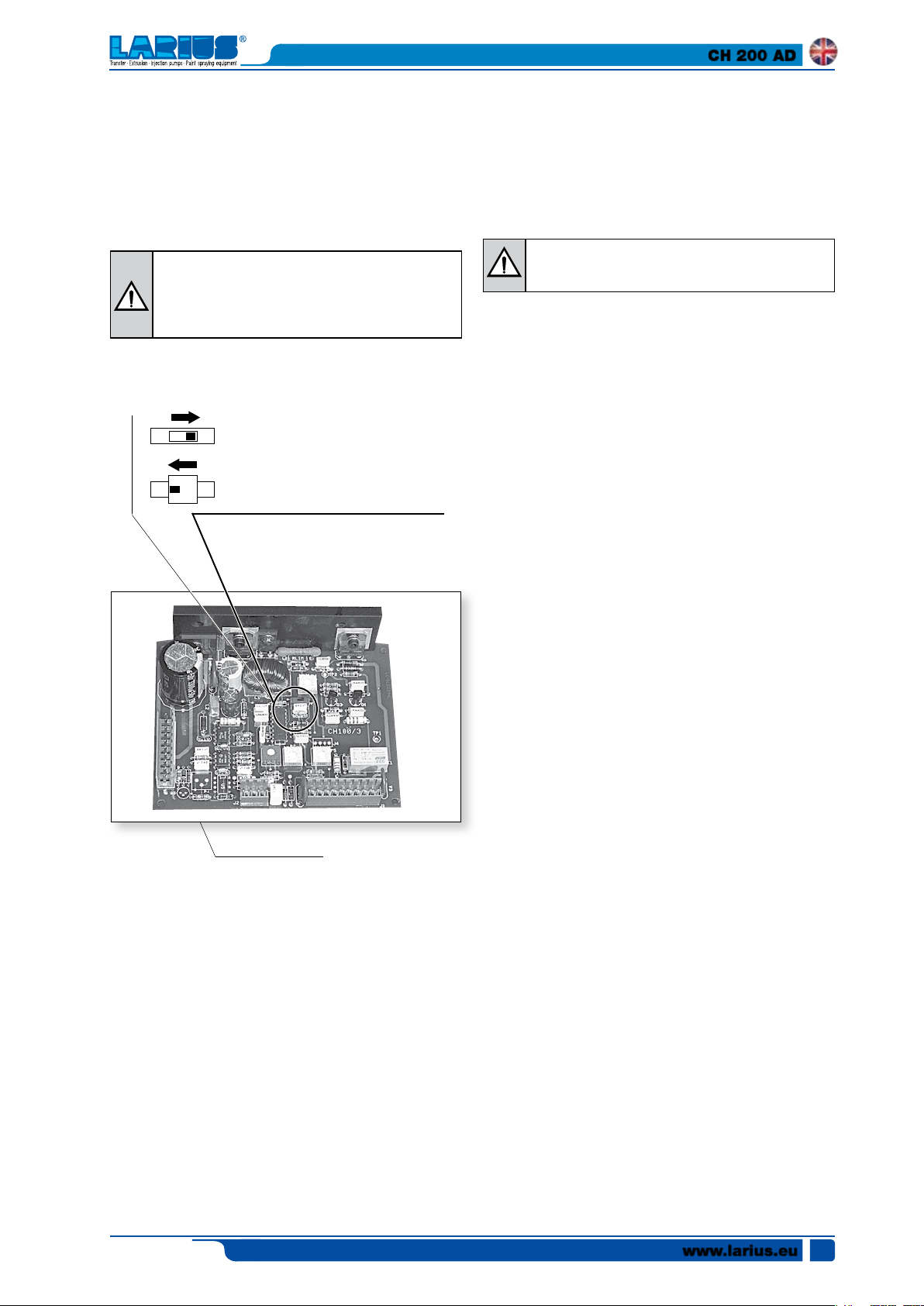

The electronic processing board located inside the generator

is supplied complete with a current limiter device that allows,

if necessary, increasing the current without modifying the set

The tube must be connected to the (H3) filter.

voltage.

Increase the value of current supplied only if necessary. In normal working conditions with manual

spray guns it is recommended that the current

limiter be left enabled.

The humidity of the air must be less than 1 gr. of water p.p.m.

The quantity of air required depends on the operating pressure

(200-600 L/min.).

The compressor that supplies the air must be grounded sepa-

Current limiter excluded

Output current: min.180µA - max 250µA

rately with its own grounding cable.

• Connect the compressed air supply tube (H4) ø 10 mm to

Current limiter enabled

Output current: min.120µA - max.150µA

• Connect the powder supply tube (H6) and the additional air

a suitable type tube (H2), it must have a internal diameter

that is not less than 8 mm and must be able to withstand

a maximum pressure of 10 bar.

It is recommended that a shutter valve (ON-OFF)

be placed on the air supply line.

the rear of the rack's control panel.

tube (H7) to the powder supply pump and to the generator

(H5).

CIRCUIT BOARD

CONNECTIONS

• Make sure the system is equipped with a grounding connection

• Ensure that the mains voltage corresponds to that indicated

on the machine's nameplate.

• Connect the generator to the spray booth using a grounding cable (H8) and clamp (H9).

• Connect the vent tube (H10) to the tank cover and the spray

booth (or to a container).

Electrostatic spray gun

• Connect the power supply cable (H11) to the spray gun

and the generator.

• Connect the powder passage tube (H12) to the spray gun

and the powder delivery pump.

• Connect the additional air passage tube (H13) for clean-

ing the diffuser and rheophore to the spray gun and the

generator.

Triboelectric spray gun

• If spray guns are used which employ the triboelectric paint

system, remove the tribo air outlet cap and connect the

tube (H14) to the tribo spray gun.

• Make sure the switch is in the "0" position

.

• Connect the machine to the mains using the dedicated

cable (H1).

Edit. 03 - 06/2019

www.larius.eu

11

CH 200 AD

H10

H9

H3

H5

H4

H8

For tribo-electric spray gun

CH200 Additional air coupling

H7

H6

H14

H13

H12

110 - 220 V c.a.

Electrostatic spray gun

H2

www.larius.eu

12

H7

H8

H11

H1

110 - 220 V c.a.

Edit. 03 - 06/2019

CH 200 AD

OPERATION

After having carried out all the electrical and pneumatic connections as described in the previous chapter, proceed as follows:

•

Turn the revolving arm (H15) in order to be able to position

the cardboard box (H16) containing the powder on the

vibrating surface (H17) as illustrated in the figure.

•

Lift up the powder suction tube (H18). Loosening the locking ring nut (H19), it is possible to slide the suction tube

along the revolving arm.

•

Turn the revolving arm (H15) and position it above the

powder container.

•

Lower the powder suction tube (H18) inside the container.

•

Open the air supply to the machine.

•

Press the main switch (H20) of the control panel to power

the generator.

•

Turn the switch (H21) of the electric vibrator to the "ON"

position.

The electric vibrator is activated each time the

spray gun trigger is pressed and it automatically

stops every time the trigger is released.

USE WITH CH 200 SPRAY GUN (corona effect)

To use with the CH 200 spray gun (corona effect),

make sure the selector (H17) is in the "CORONA"

position.

H22

• Point the spray gun inside the spray booth and hold down

the trigger to adjust the powder delivery setting.

• Adjust the air pressure delivered to the powder supply

pump (H18), using the regulator (H19) and reading the

value expressed in bar on the pressure gauge H20) (max

recommended values 3-4 bar).

H20

H19

H15

H18

H16

H21

H17

Edit. 03 - 06/2019

www.larius.eu

13

CH 200 AD

H29 H30 H31 H24 H26 H28

H32

• Adjust the powder diffusion range of the spray gun using

H23

• Point the spray gun at the object to be painted (recomthe knob (H21) and reading the value expressed in bar on

the pressure gauge (H22), (recommended values 0.5-2 bar);

however, this value must always be less than the supply

air pressure (pressure gauge H23); once adjustment is

complete, release the spray gun trigger.

• Adjust the flow of the additional air that controls the cleaning of the diffuser and charging rheophore. Using the knob

(H24) and checking the pressure gauge (H25) set the outlet

air pressure to the recommended values between 0.5-1 bar.

Depending on the amount of powder delivered, ensure the

cleaning cone cleans the powder residue from the affected

areas.

• Using the potentiometer (H26) select the desired voltage

value (0 -100 kv) read the set value on the digital display

(H27).

H25 H27

mended distance 15-20 cm) and press the trigger, which

will start to deliver powder, as well as high voltage; the

value of current, expressed in microamperes (max 250 µA)

can be read on the lit indicator (H3).

Protect the spray gun from all violent mechanical

action. Repeated impacts and shocks of considerable intensity, while not altering the outer integrity

of the spray gun, may cause internal damage and

cause the spray gun to become unusable.

www.larius.eu

14

Edit. 03 - 06/2019

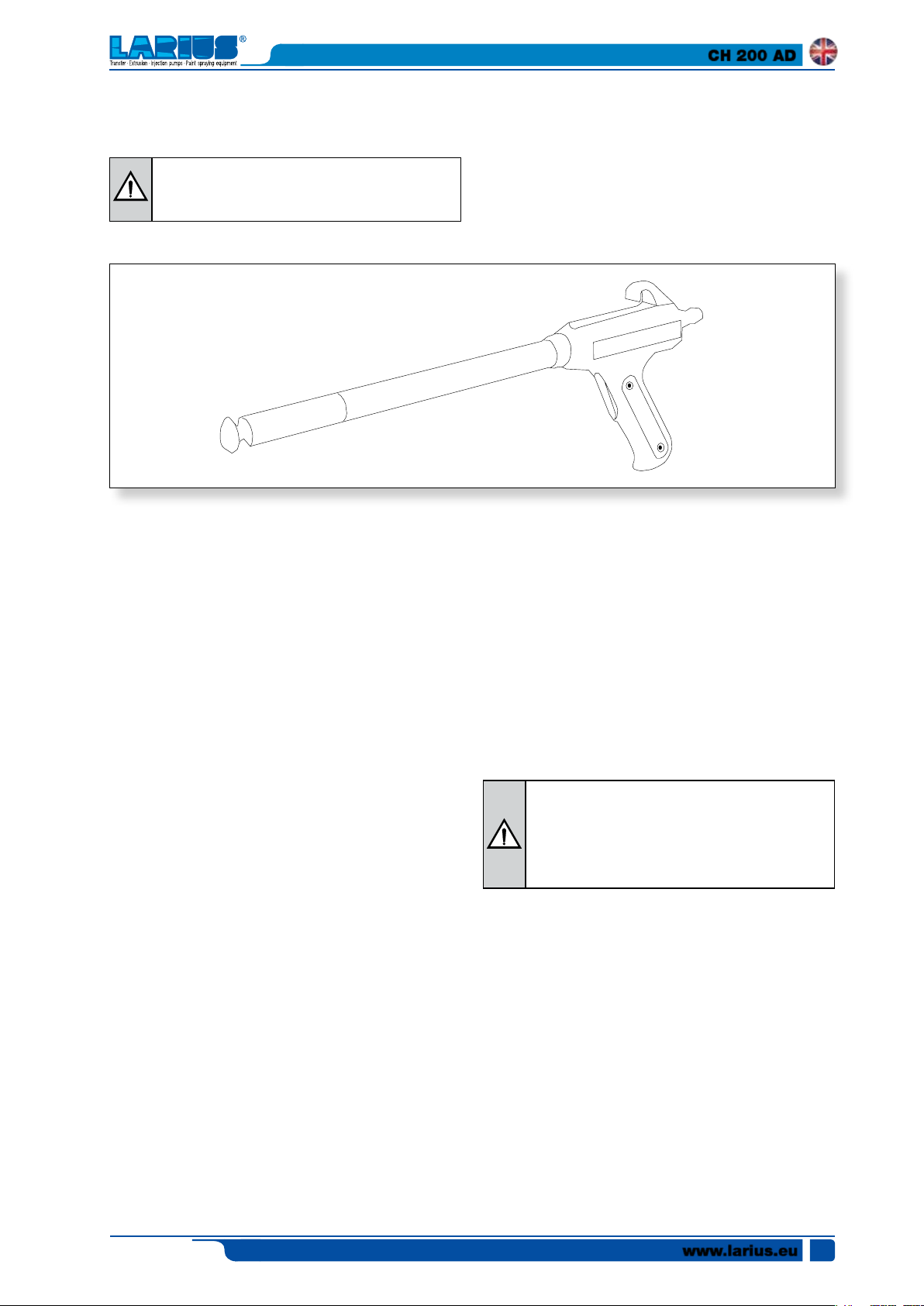

USE WITH THE TRIBOELECTRIC SPRAY GUN

To use with the triboelectric spray gun, make sure

the selector (H22) is in the "TRIBO" position.

CH 200 AD

• Point the spray gun at the object to be painted (recom-

If the pressure is increased, the triboelectric effect is also

mended distance 15-20 cm) and press the trigger, which

will start to deliver powder, as well as high voltage; the

The electrostatic charge value can be read on the luminous

value of current, expressed in microamperes (max 250 µA)

can be read on the lit indicator (H28).

• Adjust the air pressure to the powder supply pump (H29),

by turning the regulator (H30) and reading the value expressed in bar displayed on the pressure gauge (H23)

(recommended max values 3-4 bar).

At this point, release the spray gun trigger.

Point the spray gun at the object to be pained (recommended

distance 10-20 cm) and press the spray gun trigger, which will

start to deliver powder.

The value of the current expressed in µA (max 10 µA) can be

read on the luminous indicator (H28).

• Adjust the powder diffusion range of the spray gun using

the knob (H29) and reading the value expressed in bar on

the pressure gauge (H22), (recommended values 0.5-2 bar);

however, this value must always be less than the supply

air pressure (pressure gauge H23).

• Adjust the "tribo air" pressure using the knob (H24) and

reading the pressure value set on the pressure gauge (H25).

increased.

indicator (H28) located on the generator.

Protect the spray gun from all violent mechanical

action. Repeated impacts and shocks of considerable intensity, while not altering the outer integrity

of the spray gun, may cause internal damage and

cause the spray gun to become unusable.

Edit. 03 - 06/2019

www.larius.eu

15

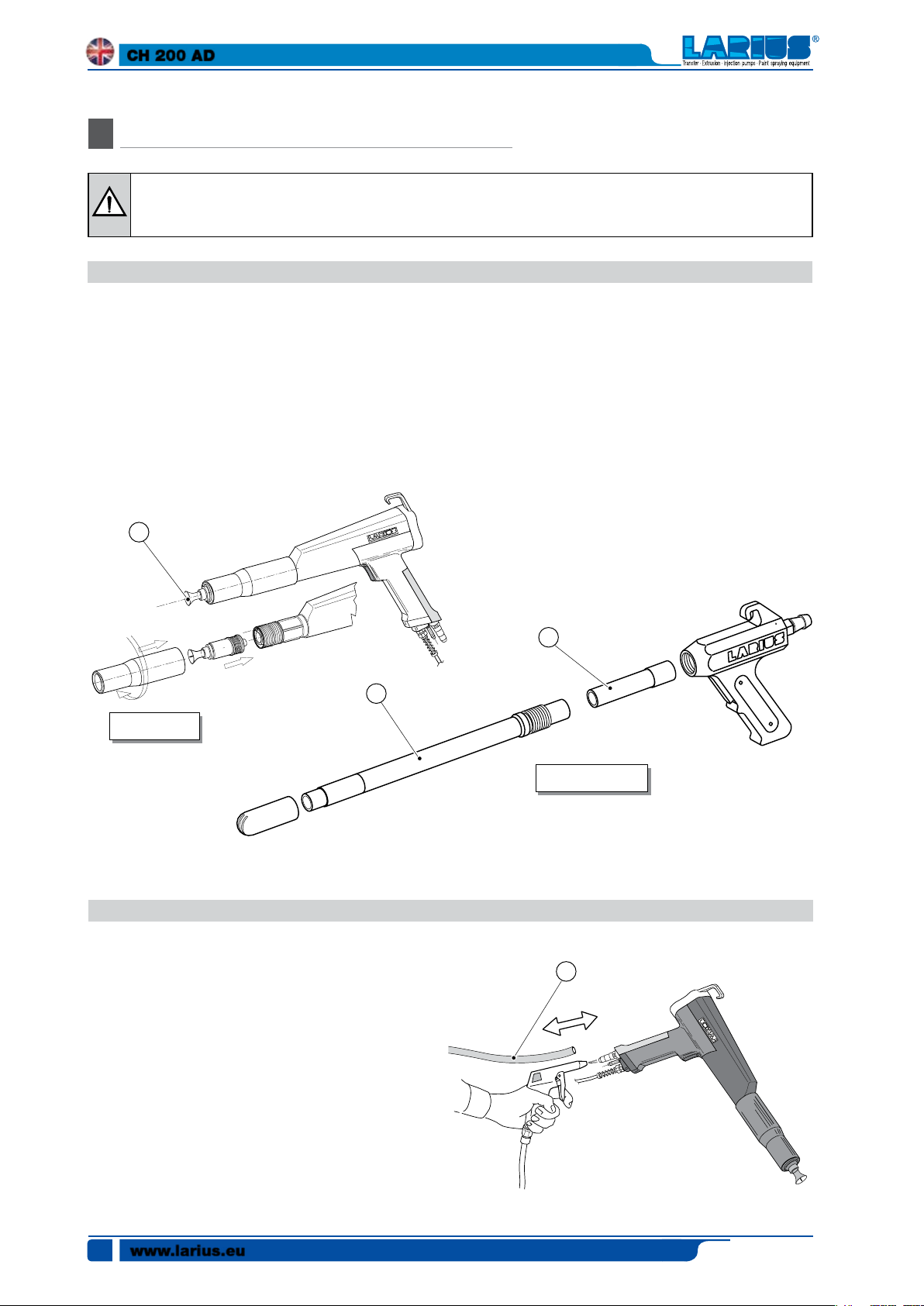

CH 200 AD

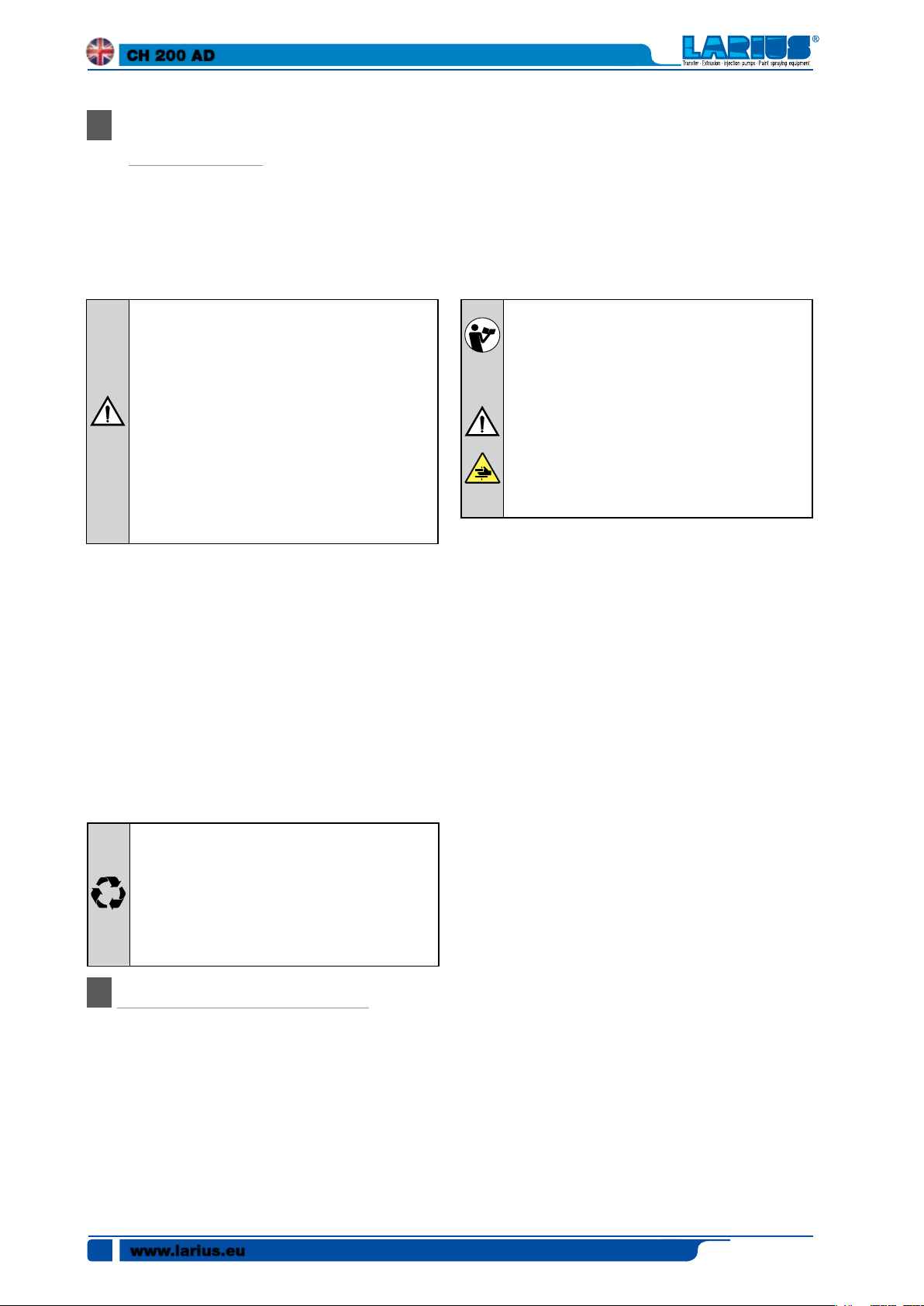

CYCLICAL ROUTINE MAINTENANCE

I

Before performing any maintenance or cleaning operation disconnect the electric and pneumatic power supply.

EVERY 8 HOURS AND/OR AT EVERY COLOUR CHANGE

Cleaning the CH200 spray gun

• Disconnect the powder supply tube and remove the nozzle

(I1) of the spray gun.

• Clean the inner part of the spray gun and nozzle with a jet

of compressed air. If necessary, use the brush supplied to

clean the spray gun.

I1

I2

Gun CH 200

Cleaning the triboelectric spray gun

• Disconnect the powder supply tube and remove the nozzle. Clean the inner part of the spray gun and nozzle with

a jet of compressed air.

• If removing the triboelectric spray gun is necessary

Using your hands, unscrew the charge tube (I2) from the

spray gun body. Using your hands, slip off the diffuser (I3).

Remove the nozzle.

I3

Tribo-electric gun

EVERY 40 - 80 HOURS AND/OR AT EVERY COLOUR CHANGE

Cleaning the powder supply tube

• Disconnect the powder supply tube (I4) from the tank

and spray gun and blow in compressed air to remove any

remaining powder residue.

Ensure the powder passage tube is not cracked, bent or

damaged in any way.

www.larius.eu

16

I4

Edit. 03 - 06/2019

EVERY 40 - 80 HOURS

Check venturi diffuser

• Check the wear of the powder delivery pump's Venturi

diffuser (I5).

A new diffuser hole is 4.8mm; with wear the hole's diameter

CH 200 AD

increases, decreasing the Venturi effect and, when the hole

reaches 8 mm, the diffuser must be replaced.

For highly abrasive materials use tungsten carbide diffus-

ers.

I5

EVERY 40 - 80 HOURS

Cleaning the pressure reducer filter

To ensure proper machine operation, follow these rules:

• Ensure proper operation of the pressure reducer lter.

Ensure there is no condensation build-up inside the cup.

If necessary, periodically discharge the condensation by

unscrewing the bleed screw (I6) under the filter cup; the

pressure inside the cup will cause the expulsion of the

condensation.

• Periodically clean the lter cartridge in order to prevent

system performance losses.

Wash the cup with water and dry with a jet of compressed

air.

Before removing the cup close the compressed

air supply.

Adjusting the pressure

Adjust the pressure by turning the knob located on the upper

part of the reducer.

To increase it turn clockwise (+).

To decrease it turn counter clockwise (-).

Do not power the pneumatic system with compressed air that

is excessively dirty or that contains aggressive liquids.

Edit. 03 - 06/2019

I6

www.larius.eu

17

CH 200 AD

COLOUR CHANGING

J

• Remove the box and replace it with that of the new colour

which you intend to use, correctly placing it on the shaking

table(J5).

The design of the CH 200/AD unit allows for quick colour

changing, directly using the original box containing the powder.

To change the colour, proceed as follows:

• Disconnect the electric and pneumatic mains supply that

powers the machine.

• Turn the revolving arm (J1) in order to remove the cardboard

box (J2).

• Lift up the powder suction tube (J3). Loosening the locking

ring nut (J4) it is possible to slide the suction tube along

the revolving arm.

• Turn the revolving arm (J1) and position it above the powder

container.

• Lower the (J3) powder suction tube inside the container.

• Open the air supply to the machine.

• Press the main switch (J6) of the control panel to power

the generator.

• Turn the switch (J7) of the electric vibrator to the "ON"

position.

J5

J1

J4

J6

J7

www.larius.eu

18

J2

J3

Edit. 03 - 06/2019

PROBLEMS AND SOLUTIONS

K

CH 200 AD

Problem

• Electrical charges between the

spray gun nozzle and the object

to be painted

• The machine does not start up

after the ON-OFF switch has been

pressed

• The rack switches on but the Kv

display is not working

• The kv display lights up but the kv

scale does not increase when the

potentiometer is turned

• Excessive voltage;

• For CH 200 spray gun: excessive

• For CH 200 spray gun: nozzle dam-

• The object to be painted is not prop-

• For CH 200 spray gun the voltage

• No mains voltage;

• Fuse 1A is defective;

• Fuse 3.15A is defective;

• Processing board defective;

• KV control potentiometer defective,

Cause

electric current;

aged;

erly electrically grounded;

multiplier is defective;

processing board defective or display

board defective

Solution

• For CH 200 spray gun: decrease

the voltage using the rack's potentiometer;

• For spray gun: decrease the air

pressure;

• Reset the current limiter switch

located on the processing board ;

• Replace the nozzle;

• With a tester or similar instrument

check the electrical grounding of

the piece holder hooks. If necessary, clean the piece holder hooks;

• Replace the voltage multiplier;

• Check the electric supply line;

• Replace the 1A fuse;

• Replace the 3.15A fuse;

• Replace the processing board;

• Proceed as follows:

- Disconnect the power supply

- Remove the four fixing screws

and slip the rack off the CH

200-tribo machine's protective

cover.

- Remove the connector marked

j3 from the processing board.

- Using a tester (or similar instru-

ment capable of measuring

electrical resistance) check the

integrity of the potentiometer:

connect a tip of the tester to

the central terminal of the potentiometer and the other tip to

one of the two side terminals.

Turning the potentiometer knob,

the resistance value read on the

tester varies from 0 to 1 KΩ, approximately.

- If a negative result is obtained,

replace the potentiometer.

• The machine is working but the

powder does not come out of

the spray gun when the trigger is

pressed.

Edit. 03 - 06/2019

• No powder;

• Powder delivery pump clogged;

• The air pressure is not sufficient to

• Fuse 2 A is defective;

• Spray gun-generator cable incor-

adjust powder delivery;

rectly connected or damaged;

• Add powder;

• Remove the powder delivery pump

and clean the passages;

• Increase the air pressure to adjust

powder delivery;

• Replace the 2 A fuse;

• Check the connections; verify the

continuity of the cable connections

using a tester and, if necessary,

replace it;

www.larius.eu

19

CH 200 AD

Problem

• Rapid wear of Venturi diffuser

• The powder puffs out of the spray

gun

• Insufficient powder flow

Cause

• No mains voltage;

• Worn or partially clogged Venturi;

• The additional air pressure is exces-

sive (rack central regulator) or the

ratio between this and the powder

delivery air pressure is incorrect (left

rack regulator);

• The tank's fluid bed air pressure is

excessive or insufficient;

• The unidirectional valves of the powder pump are partially clogged;

• Powder passage tube too short or

with excessive inner diameter;

• The air pressure for adjusting the

powder delivery is insufficient;

• Use a hard metal Venturi diffuser

• Clean and/or replace the Venturi;

• Decrease the additional air pres-

Important: The additional air pres-

• Adjust the fluid bed air pressure

• Clean and/or replace the unidirec-

• Use the powder passage tube

• Increase the air pressure to adjust

Solution

(code 5296/A);

sure and/or increase the powder

delivery air pressure.

sure must always be lower than the

powder delivery air pressure;

(recommended pressure value:

0.5-1bar);

tional valves;

supplied or a tube with an inner

diameter that is no greater than

12mm and with a length no less

than 5 metres;

powder delivery;

• The powder is not sufficiently

electrostatically charged and/or

does not “cover”

•

The powder "cover" but the µA

scale does not increase

• The powder is too wet and is sucked

up by the powder pump with difficulty;

• Worn or partially clogged Venturi;

• The additional air pressure (central

regulator rack) is excessive;

• The additional nozzle cleaning air

pressure is excessive;

• The piece to be painted is not properly

electrically grounded;

• The powder is not suited for use with

a corona and/or triboelectric system;

• Only for triboelectric spray gun: •

The "tribo" air pressure (central

regulator rack) is excessive;

• For CH 200 spray gun: nozzle damaged and/or dirty;

• For triboelectric spray gun: charge

tube dirty and/or damaged;

• Display board not working;

• Check the compressed air supply

line. Install an air dryer if necessary;

• Clean and/or replace the Venturi;

• Decrease the additional air pres-

sure;

• Decrease the additional air pressure;

• With a tester or similar instrument

check the electrical grounding of

the piece holder hooks. If necessary, clean the piece holder hooks;

• Consult the powder supplier;

• Increase the "tribo" air pressure to

increase the triboelectric effect;

• Clean and/or replace the nozzle;

• Clean and/or replace the charge

tube;

• Replace the display board;

www.larius.eu

20

• For triboelectric spray gun: tribocorona switch set to"corona";

• Move the switch to "tribo";

Edit. 03 - 06/2019

CH 200 AD

Problem

• For triboelectric spray gun: spray

• For triboelectric spray gun: process-

• The powder does not charge and

does not "cover"

• The machine is working but the

powder does not come out of

the spray gun when the trigger is

pressed.

• The powder is not suited for use with

• For CH 200 spray gun: processing

• For CH 200 spray gun: tribo-corona

• For CH 200 spray gun: nozzle elec-

• For CH 200 spray gun: the voltage

• Solenoid valve or processing board

• Spray gun button defective

Cause

• Check the connections; verify the

gun-generator cable not connected

properly or damaged;

• Replace the processing board;

ing board damaged.

• Consult the powder supplier;

a corona and/or triboelectric system;

• Replace the processing board;

board damaged ;

• Move the switch to "corona";

switch on "tribo";

• Correctly secure the nozzle and/or

trodes are broken or nozzle is not

secured correctly to the spray gun;

• Replace the voltage multiplier;

multiplier is defective;

• Replace the solenoid and/or pronot working;

• For triboelectric spray gun:

• For CH 200 spray gun:

Solution

continuity of the cable connections

using a tester and, if necessary,

replace it;

replace the nozzle;

cessing board;

- Disconnect the spray gungenerator connecting cable from

the generator;

- With a tester (or similar instrument capable of measuring

electrical resistance) verify the

electrical continuity between the

terminals marked with a 1 and

the connector when the spray

gun trigger is pressed;

- If the result of the test is negative,

proceed with replacing, in order,

the trigger lever, then the trigger

body, and lastly both parts;

- Disconnect the spray gungenerator connecting cable from

the generator;

- With a tester (or similar instrument capable of measuring

electrical resistance) verify the

electrical continuity between the

terminals marked with a 1 and

the connector when the spray

gun trigger is pressed;

- If the result of the test is negative,

proceed with replacing, in order,

the trigger, then the reed block,

and lastly both parts;

Edit. 03 - 06/2019

www.larius.eu

21

CH 200 AD

Problem

• The machine is working and the

powder comes out of the spray

without the trigger.

• Spray gun button defective

Cause

Solution

• Replace the solenoid and/or processing board;

• For triboelectric spray gun:

- Disconnect the spray gungenerator connecting cable from

the generator;

- With a tester (or similar instrument capable of measuring

electrical resistance) verify the

electrical continuity between the

terminals marked with a 1 and

the connector when the spray

gun trigger is pressed;

- If the result of the test is negative,

proceed with replacing, in order,

the trigger lever, then the trigger

body, and lastly both parts;

• For CH 200 spray gun:

- Disconnect the spray gungenerator connecting cable from

the generator;

- With a tester (or similar instrument capable of measuring

electrical resistance) verify the

electrical continuity between the

terminals marked with a 1 and

the connector when the spray

gun trigger is pressed;

- If the result of the test is negative,

proceed with replacing, in order,

the trigger, then the reed block,

and lastly both parts;

• The machine is working but the

electro-vibrator fails to switch

on when the spray gun trigger is

pressed.

Always disconnect the power supply and discharge the pressure before performing any checks or replacing parts

of the pump (follow the "correct pressure relief procedure").

• Vibrator switch in the “OFF” position;

• Electro-vibrator defective.

• Turn the switch to the “ON” position;

• Replace the electro-vibrator.

www.larius.eu

22

Edit. 03 - 06/2019

SPARE PARTS

CH 200 AD

ELECTRO-PNEUMATIC

O

N

GENERATOR

pag.28

CH200-AD FRAME SPARE

O

M

PARTS

pag.26

POWDER DELIVERY PUMP SPARE PARTS

O

Z

RIF.5505

pag.41

CH 200 MANUAL SPRAY GUN RIF.9700

O

O

pag.30

CH 200 AUTOMATIC SPARY GUN RIF. 9705

O

P

pag.32

AUTOMATIC AND MANUAL TRIBO SPRAY

O

Q

GUN SPARE PARTS

pag.34

CONE JET NOZZLE SPARE PARTS

O

R

FOR CH 200

pag.36

CH200-AD SHAKING TABLE

O

L

SPARE PARTS

pag.24

ACCESSORIES

Y

pag.42

CONE JET NOZZLE WITH EXTENTION

O

S

SPARE PARTS FOR CH 200

pag.37

FAN NOZZLE SPARE PARTS FOR CH 200

O

T

pag.38

HIGH PERFORMANCE NOZZLE SPARE

O

U

PARTS FOR CH 200

pag.39

MULTI-DIFFUSION NOZZLE SPARE PARTS

O

V

FOR CH 200

pag.40

Edit. 03 - 06/2019

www.larius.eu

23

CH 200 AD

CH 200-AD SHAKING TABLE SPARE PARTS

L

WARNING: Always indicate code and quantity for each part required.

www.larius.eu

24

Edit. 03 - 06/2019

CH 200 AD

Pos. Pos.

1

2

3

4

5

6

6

7

8

Code Description Code Description

510425

5877

5725

5726

5728

5723

5757

95063

8042

Screw

Shaking table

Washer

Screw

Vibration damper

Vibrator 220 V

Vibrator 110 V

Washer

Self-locking nut

9

10

11

12

13

14

15

16

17

5727

5878

5729

54003

54004

5583

5738

91026

5582

Screw

Shaking table base

cable gland

Washer

Screw

Screw

Trolley base

Nut

Wheel

Edit. 03 - 06/2019

www.larius.eu

25

CH 200 AD

M FRAME SPARE PARTS CH 200-AD

WARNING: Always indicate code and quantity for each part required.

www.larius.eu

26

Edit. 03 - 06/2019

CH 200 AD

Pos. Pos.

.

1

2

3

4

5

6

7

8

9

10

11

12

13

Code Description Code Description

5710

5875

5591

5778

5583

95063

8042

5746

5747

32029

5876

91154

96030

34008

Complete rack support

Generator cover

Screw

Slotted nut

Screw

Washer

Nut

Screw

Washer

Nut

Generator support

Electric box

Washer

Screw

18

19

20

21

22

23

24

25

26

27

28

29

30

31

5751

5750

5749

5755

5756

34009

7059

5765

5768

5708

5743

5745

11719

5741

Washer

Friction washer di frizione

Block for swivel arm

Screw

Nut

Washer

Screw

Grounding cable

Self-tapping screw

Powder suction complete hose

Upper fitting

Throttling

Automatic fitting

Suction hose

14

15

16

17

5752

5754

5753

5748

Tube locking ring nut

Guiding support

Suction tube guide

Swivel arm

32

33

34

5740

5742

5744

Powder hose

Lower fitting

Filter

Edit. 03 - 06/2019

www.larius.eu

27

CH 200 AD

N

ELECTRO-PNEUMATIC GENERATOR

ATTENZIONE: per ogni particolare richiesto indicare sempre il Code e la quantità.

www.larius.eu

28

Edit. 03 - 06/2019

CH 200 AD

Pos. Code Description

5920

-

Electro-pneumatic generator

preset for CH 200 spray gun and

.

-

.

-

.

1

2

.

.

5101

.

5922

.

5929

5603

.

5925

.

5927

.

Larius Tribo

Electro-pneumatic generator

preset for CH 200 spray gun

Electro-pneumatic generator

preset for Larius Tribo spray gun

Display board

Data processing board for

CH 200

Data processing board for CH

1200 and Tribo

Data processing board for tribo-

electric

Q.ty

Pos. Code Description Q.ty

-

22

23

.-

24

.

25

-

26

.

27

1

28

1

29

.

30

1

.

31

1

.

32

9149

5937

.

4018

5349

5348

5676

5347

22016

5609

.

5649

.

5353

Fuse 1A

Connector for fixing automatic

.

control cable

Silencer

Fitting for tube ø 6

Fitting for tube ø 8

Fitting for tube ø 6

Fitting for tube ø 10

1/4" Fitting for tube ø 8

Solenoid valve complete with coil,

.

connector, fittings

Solenoid valve complete with coil

.

and connector

Solenoid valve

1

1

.

1

1

1

1

1

1

1

.

1

.

1

3

4

5

6

7

9

12

13

14

17

18

19

5931

5932

5933

5346

5341

5787

.

5789

22015

.

22014

.

5566

5158

5934

Potentiometer

Potentiometer knob

ON-OFF switch

1/8" Fitting for tube ø 4

Pressure gauge 0-6 bar

Regulator complete with fittings

.

Air regulator 0-4 bar

1/4" Revolving elbow fitting tube

.

ø 8

1/8" Revolving elbow fitting tube

.

ø 4

Grounding terminal

Fuse 3.15 A

Power supply cable

1

33

1

34

1

35

3

36

3

37

3

38

.

39

3.

40

6

41

42

3

43

.

.1

1

1

5627

5628

510019

4039

5597

5359

8032

5255

4006

510020

5935

Solenoid coil

Solenoid coil connector

1/4" Fitting ø 8

Elbow for tube ø 8

1/4" Fitting ø 10

Elbow for tube ø 10

1/4” fitting

1/4 Elbow fitting

1/4" Fitting for tube ø 8

"T" Fitting for tube ø 8

Tribo-corona switch

1

2

1

1

1

3

1

2

1

1

.

20

21

Edit. 03 - 06/2019

9148

5936

.

gland clamp

Fuse 2 A

Spray gun cable fixing connector

.

1

1

www.larius.eu

29

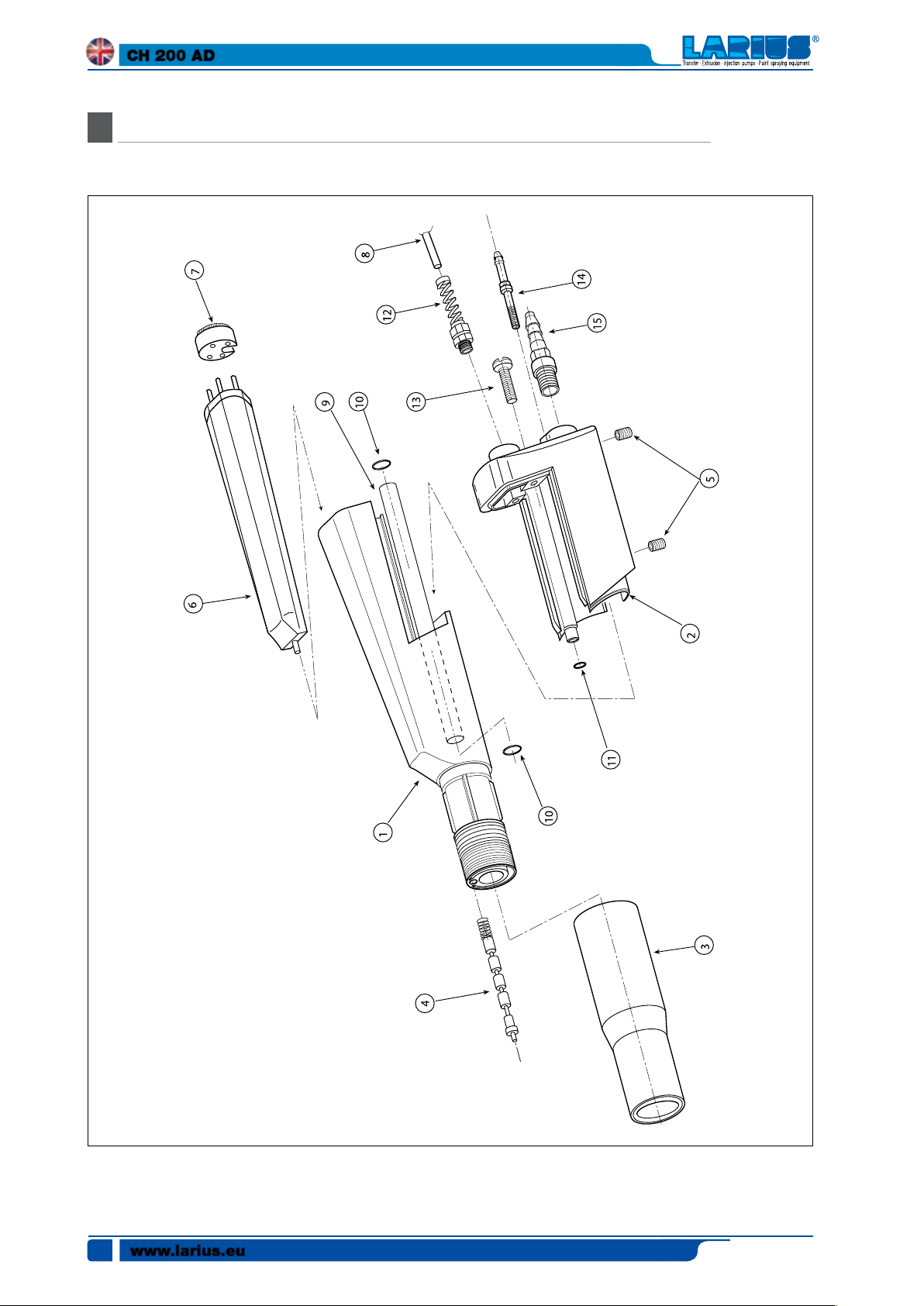

CH 200 AD

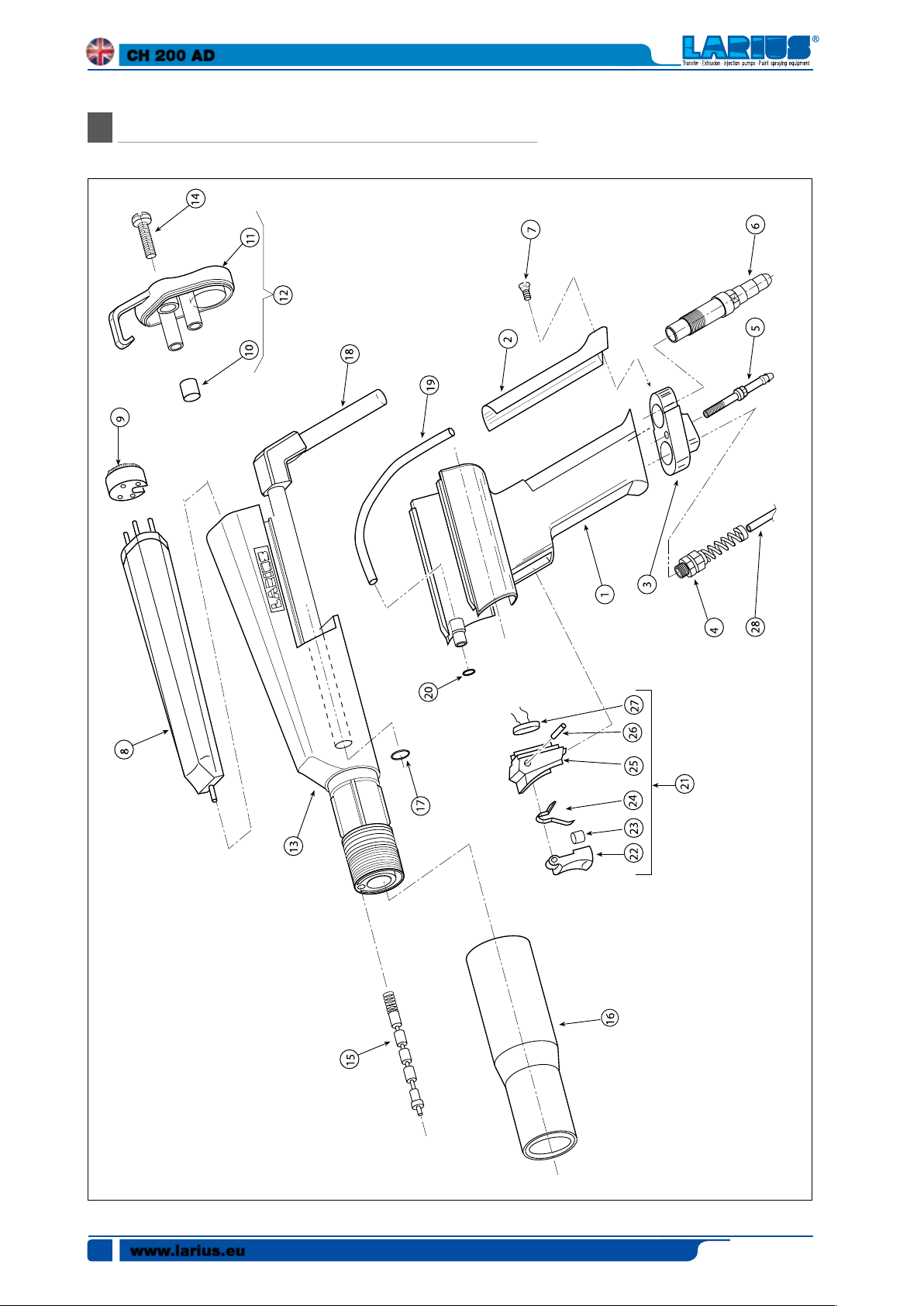

CH 200 MANUAL SPRAY GUN REF.9700

O

ATTENTION: for each part required always indicate the code and quantity.

www.larius.eu

30

Edit. 03 - 06/2019

CH 200 AD

Pos. Code Description

9700

1*

2*

3*

4*

5

6

7*

8

9

10

11

.

9752

9756

9755

9849

9762

.

.

9760

.

.

9819

9820

9832

9754

9753

CH 200 manual Spray Gun

Handgrip

Grounding cover

Terminal block

cable gland

Air passage tube fixing con-

nection

Powder passage tube fixing

connection

Screw

Multiplier

Connector

Check glass

Rear cap

Pos. Code Description Q.ty

Q.ty

1

14

1

15

1

16

1

17

1

18

1

19*

.

20

1

21*

.

22

1

23

1

24

1

25

1

26

1

27

9803

9770

9779

95326

9772

9761

4077

9763

9765

5055

9792

9764

9766

9769

Screw

Electric resistance assembly

Ring nut

O-ring

Powder passage tube

Air tube

O-ring

Complete trigger

Trigger

Magnet

Spring

Trigger support

Trigger pin

Reed sensor

1

1

1

1

1

1

1

1

1

1

1

1

1

1

12

13

9703

9751

Complete rear cap

Complete front body

* Complete handgrip code 9945

1

28*

9900

Cable

1

2

Edit. 03 - 06/2019

www.larius.eu

31

CH 200 AD

SPARE PARTS FOR AUTOMATIC GUN CH 200 REF. 9705

P

ATTENTION: for each part required always indicate the code and quantity.

www.larius.eu

32

Edit. 03 - 06/2019

CH 200 AD

Pos. Code Description

9705

1

2*

3

4

5*

6

7

.

9751

9801

9779

9770

5546

9820

9832

Automatic spray gun

Complete front body

Rear cap

Ring

Electric resistance assembly

Threaded inserts

Multiplier

Connector

* Complete rear cap code 9950

Pos. Code Description Q.ty

Q.ty

-

8*

1

1

10

1

11

4

12*

1

13

1

14

1

15

9900

9802

9

95326

4077

9849

9803

9804

5529

Cable

Powder passage tube

O-ring

O-ring

Cable gland

Screw

Air fitting

Powder inlet fitting

1

2

1

1

2

1

1

1

Edit. 03 - 06/2019

www.larius.eu

33

CH 200 AD

SPARE PARTS FOR AUTOM. AND MANUAL TRIBO SPRAY GUN

Q

ATTENTION: for each part required always indicate the code and quantity.

www.larius.eu

34

Edit. 03 - 06/2019

CH 200 AD

Pos. Code Description

15200

-

15203

-

15211

1

15260

2

15226

3

.

15225

4

.

15268

5

15264

6

15265

7

15220

8

15217

9

Manual triboelectric spray gun

Automatic triboelectric spray gun

Automatic spray gun body

Manual spray gun body

Air passage tube fixing

.

connection

Powder passage tube fixing

.

connection

Grounding plate

Trigger lever

Trigger body

Diffuser

Spacer cone

Pos. Code Description Q.ty

Q.ty

10

11

12

13

14

15

16

17

17

18

18

19

15262

15237

15223

15224

15216

15280

15298

15297

15296

15290

15293

15295

15221

.

Central rod length 400 mm

Tube

Spacer

Tube

Diffuser holder fitting

Complete charging tube

Bush for cone jet nozzle

Diffuser diameter 22mm

Diffuser diameter 26 mm

Flat jet nozzle

30° flat jet nozzle

Nozzle with holes for round jet

Nozzle with 1 flat notch

-

-

1

1

1

.

1

.

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

*

*

*

* Upon request

Edit. 03 - 06/2019

www.larius.eu

35

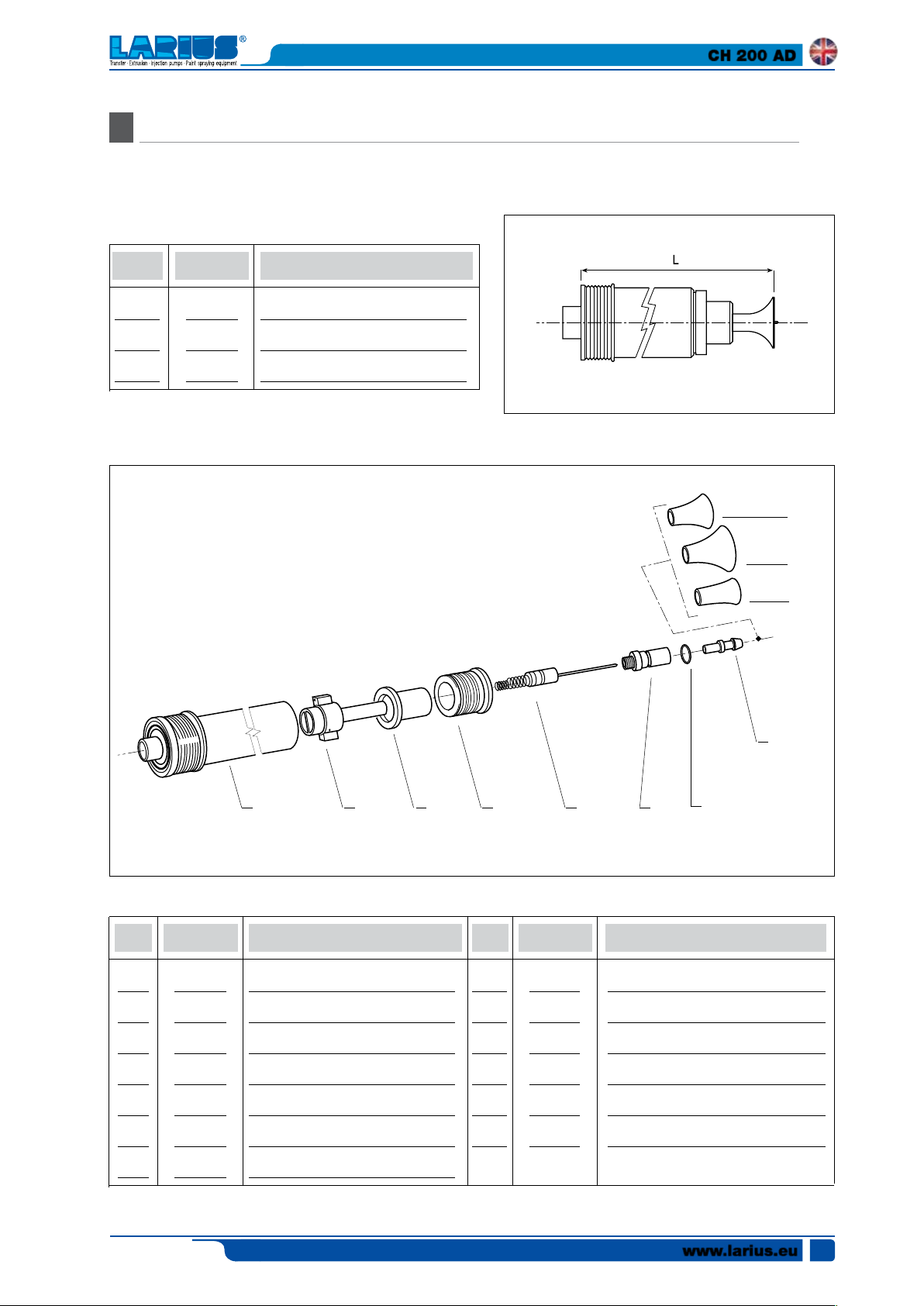

CH 200 AD

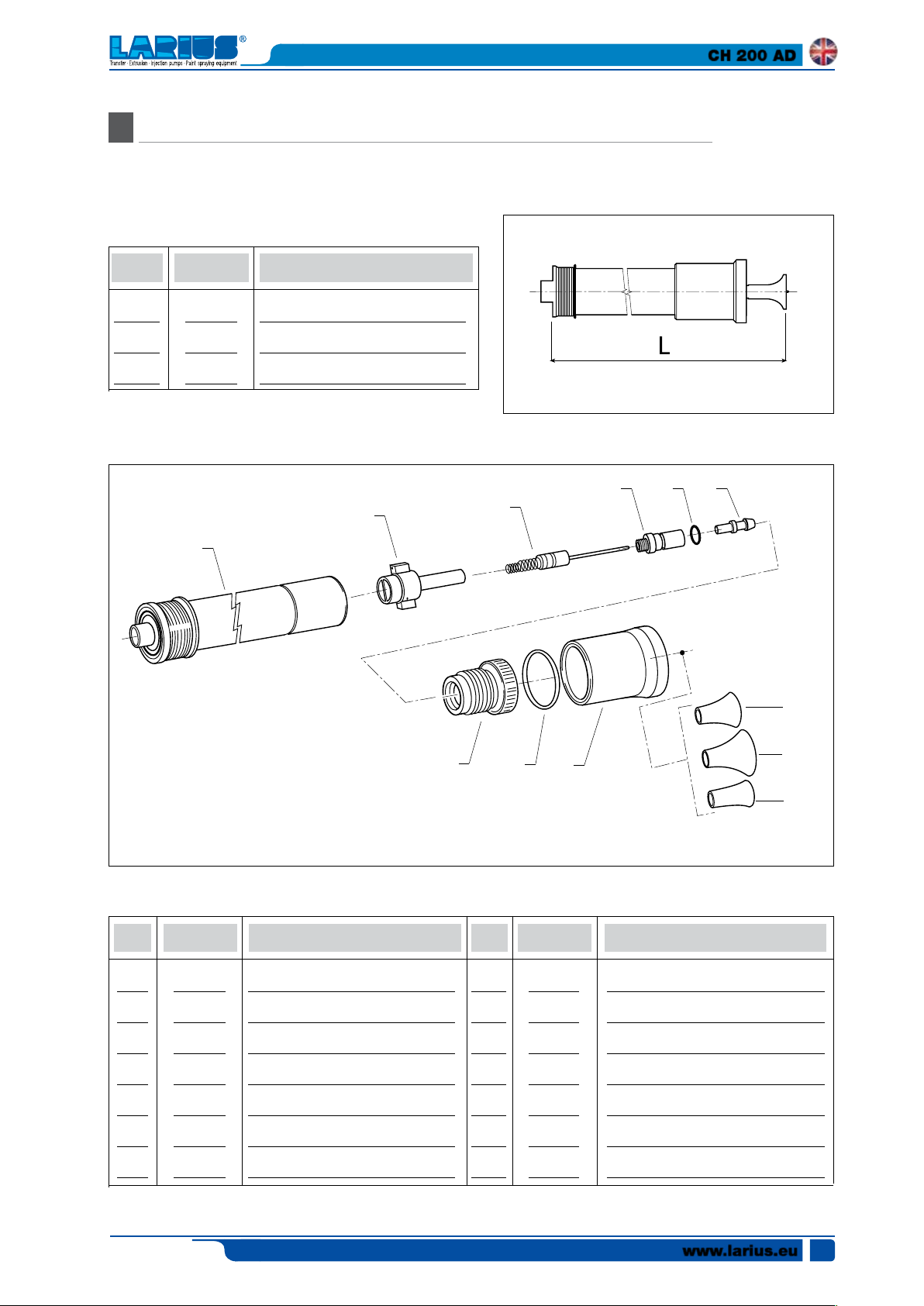

CONE JET NOZZLE SPARE PARTS FOR CH 200

R

L (mm)

Code Description

971590

Standard nozzle

10

11

9

1

Pos. Pos.

1

2

3

4

5

6

36

Code Description Code Description

9865

9866

9861

9862

9855

9856

www.larius.eu

Complete nozzle body (standard)

Complete electrode holder

Bushing

Ring

Complete electrode

Diffuser holder tip

2

3

4

7

8

9

10

11

9895

9857

9858

9859

9860

5

O-ring

Air diffuser

Diffuser ø 16

Diffuser ø 24

Diffuser ø 32

8

6

7

Edit. 03 - 06/2019

CH 200 AD

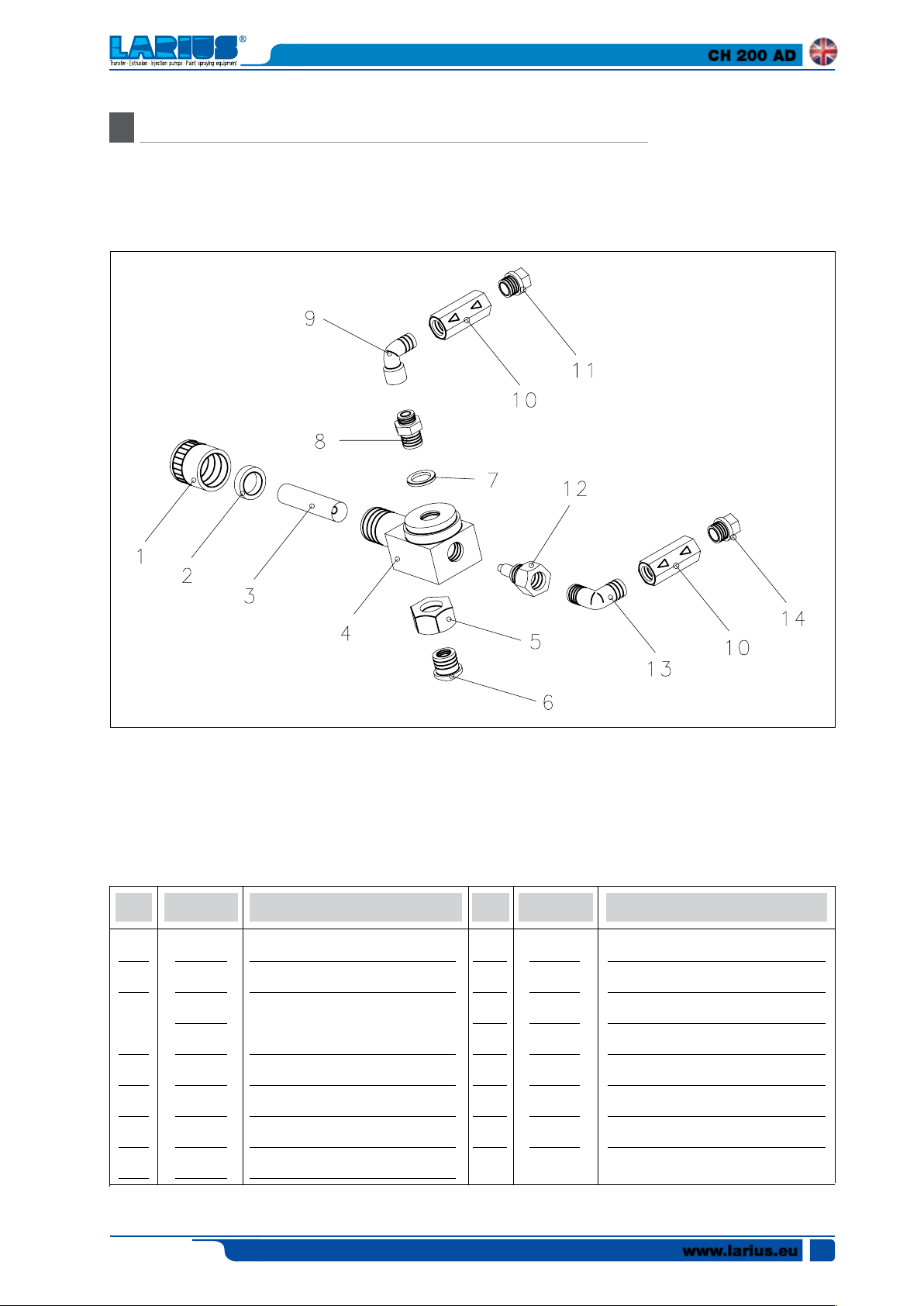

SPARE PARTS FOR CONE JET NOZZLE WITH EXTENSION FOR CH 200

S

L (mm)

160

310

570

Code Description

9720

9725

9730

Medium nozzle

Long nozzle

Extra-long nozzle

9

10

8

1

Pos. Pos.

1

1

1

2

3

4

5

Code Description Code Description

9885

9886

9887

9866

9861

9862

9855

Complete nozzle body (medium)

Complete nozzle body (long)

Complete nozzle body (extra long)

Complete electrode holder

Bushing

Ring nut

Complete electrode

2

3

6

7

8

9

10

11

11

7

9856

9895

9858

9859

9860

9857

5

Diffuser holder tip

O-ring

Diffuser ø 16

Diffuser ø 24

Diffuser ø 32

Air diffuser

4

6

Edit. 03 - 06/2019

www.larius.eu

37

CH 200 AD

FAN NOZZLE SPARE PARTS FOR CH 200

T

L (mm)

90

160

310

570

Code Description

9735

9740

9745

9750

Standard nozzle

Medium nozzle

Long nozzle

Extra-long nozzle

1

Pos. Pos.

1

1

1

1

2

Code Description Code Description

9855

9885

9886

9887

9866

Standard nozzle body

Complete nozzle body (medium)

Complete nozzle body (long)

Complete nozzle body (extra long)

Complete electrode holder

2 3

3

4

5

6

9890

9891

9892

9862

4

Complete electrode

Tip

Fan nozzle

Ring

5

6

www.larius.eu

38

Edit. 03 - 06/2019

HIGH PERFORMANCE NOZZLE SPARE PARTS FOR CH 200

U

CH 200 AD

L (mm)

150

300

560

Code Description

9815

9816

9817

Medium nozzle

Long nozzle

Extra-long nozzle

2

1

4

5 6

3

8

10

Pos. Pos.

1

1

1

2

3

4

5

Code Description Code Description

9920

9921

9922

9923

9855

9856

9895

Complete nozzle body (medium)

Complete nozzle body (long)

Complete nozzle body (extra long)

Complete electrode holder

Complete central electrode

diffuser support

O-ring

6

7

8

9

10

11

12

11

12

9857

9858

9859

9860

9925

11105

5832

9

7

Air diffuser

Diffuser ø 16

Diffuser ø 24

Diffuser ø 32

Rheophore support

O-ring

Jet adjustment bush

Edit. 03 - 06/2019

www.larius.eu

39

CH 200 AD

MULTI-DIFFUSION NOZZLE SPARE PARTS FOR CH 200

V

1

2 3

4

5

6

7

Pos. Pos.

1

1

.

1

.

1

.

40

Code Description Code Description

9930

9936

9937

.

9938

.

9939

.

www.larius.eu

Complete multi-diffusion nozzle

Standard diffuser body 12 pcs.

Diffuser body with a central notch

(upon request)

Diffuser body with two 30° inclined

notches (upon request)

Diffuser body with two 60° inclined

notches (upon request)

2

3

.

4

5

6

7

9934

9935

.

9955

9933

9940

9956

Tube supports

Series of tubes (specify number of

pcs. required)

Complete nozzle body

Conical diffuser

O-ring

Complete nozzle contact

Edit. 03 - 06/2019

POWDER DELIVERY PUMP SPARE PARTS REF. 5505

Z

CH 200 AD

Pos. Pos.

1

2

3

.

4

5

6

7

Edit. 03 - 06/2019

Code Description Code Description

5297

5298

9977

9977

9976

5291

5290

32010

Ring nut

Ring

Venturi tube (Delrin)

Venturi tube (hard metal)

Body

Ring nut

Ogive

Washer

8

9

10

11

12

13

14

5294

5255

9902

5313

5288

3365

5312

Fitting

1/4" Elbow M-F

Unidirectional valve

Fitting for tube ø6

Fitting

1/4" Elbow M-M

Fitting for tube ø 8

www.larius.eu

41

CH 200 AD

ACCESSORIES

Y

Code 5243:

POWDER PASSAGE TUBE (PER METRE)

Code 5518:

BRUSH FOR CLEANING CH 200 SPRAY

GUN

Code 5010:

GROUNDING CABLE

Code 5573:

VENT TUBE (PER METRE)

www.larius.eu

42

Edit. 03 - 06/2019

PAINT SPRAYING EQUIPMENT

L’innovazione.

Quella vera.

Made in Italy 1969

LARIUS srl

Via Antonio Stoppani 21 - 23801 Calolziocorte (LC) ITALY

TEL. +39 0341 621152 - Fax +39 0341 621243 - larius@larius.com

www.larius.eu

Loading...

Loading...