Larcan MXI201UD User Manual

MXi201U TECHNICAL SERVICE MANUAL

CONTENTS

TSM20-365 MXi201U TECHNICAL SERVICE MANUAL

1 MXi201U AMPLIFIER–INTRODUCTION..................................................................................................................1

2 SAFETY NOTICES..........................................................................................................................................................2

2.1 BERYLLIUM OXIDE WARNING ......................................................................................................................................2

2.2 OTHER TOXIC MATERIALS ...........................................................................................................................................2

2.3 DANGEROUS VOLTAGES...............................................................................................................................................2

2.3.1 Switch to Safety....................................................................................................................................................3

3 LARCAN PARTS, ASSEMBLIES, ASSEMBLY DRAWINGS AND SCHEMATIC NUMBER S...........................5

3.1 VENDOR STANDARD PART NUMBERS...........................................................................................................................5

3.2 LARCAN NUMBERS FOR PARTS, ASSEMBLIES AND DOCUMENTATION .......................................................................5

3.3 LEADED RESISTORS......................................................................................................................................................6

3.4 SURFACE MOUNT RESISTORS 1/4W AND LESS .............................................................................................................6

3.5 SURFACE MOUNT CAPACITORS ....................................................................................................................................7

3.6 PARTS LISTS .................................................................................................................................................................7

3.6.1 Production Changes.............................................................................................................................................7

FIGURES

FIGURE 1 MXI AMPLIFIER HEATSINK ASSEMBLY ........................................................................................................................1

PUB06-78 MXi DUAL PALLET OPERATIONS AND MAINTENANCE

1 MXI DUAL PALLET AMPLIFIER...............................................................................................................................1

2 MXI CONTROLLER.......................................................................................................................................................2

3 AMPLIFIER INSTALLATION AND STARTUP.........................................................................................................4

3.1 BEFORE APPLYING AC TO THE UNIT ............................................................................................................................4

3.2 APPLYING AC TO THE UNIT..........................................................................................................................................4

3.3 BEFORE TURNING THE AMPLIFIER ON .........................................................................................................................5

3.4 AMPLIFIER ON SEQUENCE............................................................................................................................................6

3.4.1 Turning ON MXi Amplifier..................................................................................................................................6

4 TEST AND TROUBLESHOOTING ..............................................................................................................................7

4.1 BENCH TEST PROCEDURES ...........................................................................................................................................7

4.1.1 Front-End Module Bench Test Procedure...........................................................................................................7

4.1.2 IPA1 Bench Test Procedure.................................................................................................................................7

4.1.3 Driver 21B1751 Bench Test Procedure...............................................................................................................8

4.1.4 PA Pallet 11A2142G1 Bench Test Procedure......................................................................................................8

4.2 BASIC TROUBLESHOOTING TECHNIQUES ......................................................................................................................8

4.2.1 Amplifier Completely OFF...................................................................................................................................8

4.2.2 No RF Output.......................................................................................................................................................8

4.2.3 Output Reduced to 25%.......................................................................................................................................8

5 MAINTENANCE..............................................................................................................................................................9

5.1 DAILY...........................................................................................................................................................................9

5.2 MONTHLY.....................................................................................................................................................................9

5.3 SEMI-ANNUALLY AND ANNUALLY ...............................................................................................................................9

5.4 TRANSMITTER COOLING SYSTEM .................................................................................................................................9

6 SERVICE.........................................................................................................................................................................10

TSM20-365 Rev 2 July 17, 2007 ii MXi201U

MXi201U TECHNICAL SERVICE MANUAL

6.1 REMOVING THE FAN ARRAY.......................................................................................................................................10

6.2 REPLACING THE ENTIRE FAN ARRAY .........................................................................................................................11

6.3 REPLACING A SINGLE FAN..........................................................................................................................................11

7 TEST EQUIPMENT SETUP.........................................................................................................................................12

8 SPECIFICATIONS ........................................................................................................................................................13

8.1 ELECTRICAL ...............................................................................................................................................................13

8.2 ENVIRONMENTAL.......................................................................................................................................................13

8.3 COOLING ....................................................................................................................................................................13

8.4 DIMENSIONS ...............................................................................................................................................................13

8.5 SHIPPING WEIGHT ......................................................................................................................................................13

PUB06-79 MXi DUAL PALLET AMPLIFIER CHASSIS

1 MXI DUAL PALLET AMPLIFIER...............................................................................................................................1

PUB06-80 MXi DUAL PALLET POWER AMPLIFIER HEATSINK ASSEMBLY

1

POWER AMPLIFIER HEATSINK ASSEMBLY 40D2052G 1....................................................................................1

2 FRONT END MODULE ASSEMBLY 21B1473G1.......................................................................................................2

3 IPA MODULE 21B1951G1..............................................................................................................................................3

4 DRIVER MODULE 21B1751G1.....................................................................................................................................5

5 PA PALLET ASSEMBLY 11A2142G1 ..........................................................................................................................6

6 TWO-WAY SPLITTER/COMBINER 21B1895............................................................................................................7

7 DIRECTIONAL COUPLER 10A2121G4 ......................................................................................................................8

PUB06-81 MXi 1kW POWER SUPPLY

1 MXI POWER SUPPLY LAR1000-32-P5337.................................................................................................................1

2 POWER SUPPLY DATA SHEET REPRINT ...............................................................................................................3

PUB06-82 Rev2 MXi CONTROLLER BOARD

1

INTRODUCTION ............................................................................................................................................................1

2 GENERAL OPERATIONS.............................................................................................................................................3

2.1 CONNECTOR AND SIGNAL DEFINITIONS........................................................................................................................3

2.1.1 J1 BDM (Background Debug Mode) Connection................................................................................................3

2.1.2 J2 Remote RS232 Connection..............................................................................................................................3

2.1.3 J3 Front Panel LCD and Touchpad.....................................................................................................................3

2.1.4 J4 +32 Volt DC Power Supply.............................................................................................................................3

2.1.5 J5 +32 Volt DC Power Supply Sensing (External)..............................................................................................3

2.1.6 J6 Remote Controls..............................................................................................................................................3

2.1.7 J7 Transmitter Switch Interface...........................................................................................................................4

TSM20-365 Rev 2 July 17, 2007 iii MXi201U

MXi201U TECHNICAL SERVICE MANUAL

2.1.8 J8 Fan Interface...................................................................................................................................................4

2.1.9 J9 External Controls............................................................................................................................................4

2.1.10 J10 AGC Control.................................................................................................................................................4

2.1.11 J11 Aural Detector (Optional).............................................................................................................................4

2.1.12 J12 Forward RF Sample......................................................................................................................................4

2.1.13 J13 Reflected RF Sample .....................................................................................................................................4

2.1.14 J14 Front Panel LCD Power...............................................................................................................................4

2.2 JUMPER OPTIONS..........................................................................................................................................................4

2.2.1 BDM Slide Switch S2...........................................................................................................................................4

2.3 FRONT PANEL AND CONTROL INDICATORS...................................................................................................................7

2.3.1 Default/Normal E5= Ext E7=Out........................................................................................................................7

2.3.2 Manual Override E5= Int E7=Out......................................................................................................................7

2.3.3 Remote Override E5= Ext E7=In........................................................................................................................7

2.3.4 Manual and Remote Override E5= Int E7=In.....................................................................................................7

2.4 RF DETECTOR OPERATION ...........................................................................................................................................8

2.5 AGC, VSWR AND CUTBACK OPERATION ....................................................................................................................9

2.6 INTERLOCKS ...............................................................................................................................................................10

2.6.1 Hard Interlocks..................................................................................................................................................10

2.6.2 Soft Interlocks....................................................................................................................................................11

2.7 EXTERNAL SIGNALS AND REMOTE CONTROL.............................................................................................................11

2.7.1 External #1 Interlock .........................................................................................................................................11

2.7.2 Remote Controls (Individual).............................................................................................................................12

2.7.3 Remote Interface (Serial)...................................................................................................................................12

2.7.4 Transmitter Switching Interface.........................................................................................................................12

2.7.5 External DC Power Supply................................................................................................................................12

3 LCD GUI INTERFACE AND TOUCHPAD................................................................................................................13

3.1 MAIN SCREEN AND TOUCHPAD OPERATIONS .............................................................................................................13

3.1.1 REM...................................................................................................................................................................14

3.1.2 AGC ...................................................................................................................................................................14

3.1.3 ERR....................................................................................................................................................................14

3.1.4 LOG ...................................................................................................................................................................14

3.1.5 AMP...................................................................................................................................................................15

3.1.6 P/S......................................................................................................................................................................15

3.1.7 INTK ..................................................................................................................................................................15

3.1.8 GEN ...................................................................................................................................................................15

3.2 AMPLIFIER SCREEN ....................................................................................................................................................15

3.2.1 TRIP...................................................................................................................................................................17

3.2.2 L/O.....................................................................................................................................................................17

3.2.3 RF ......................................................................................................................................................................17

3.2.4 INTK ..................................................................................................................................................................17

3.2.5 PSOK .................................................................................................................................................................17

3.2.6 FAN1 ..................................................................................................................................................................17

3.2.7 FAN2 ..................................................................................................................................................................18

3.2.8 FAN3 ..................................................................................................................................................................18

3.3 POWER SUPPLY SCREEN .............................................................................................................................................18

3.3.1 OK STAT............................................................................................................................................................19

3.3.2 PS ON ................................................................................................................................................................19

3.3.3 INTK ..................................................................................................................................................................19

3.3.4 FAN....................................................................................................................................................................19

3.4 INTERLOCKS SCREEN..................................................................................................................................................19

3.4.1 TRIP...................................................................................................................................................................20

3.4.2 L/O.....................................................................................................................................................................21

3.4.3 TEMP.................................................................................................................................................................21

3.4.4 PSOK .................................................................................................................................................................21

3.4.5 VOR....................................................................................................................................................................21

3.4.6 CUTB.................................................................................................................................................................21

TSM20-365 Rev 2 July 17, 2007 iv MXi201U

MXi201U TECHNICAL SERVICE MANUAL

3.4.7 FANS ..................................................................................................................................................................21

3.5 REMOTE CONTROLS AND RS232 SERIAL SCREEN.......................................................................................................22

3.5.1 Remote ...............................................................................................................................................................23

3.5.2 NewFmt..............................................................................................................................................................23

3.5.3 ExtCmd ..............................................................................................................................................................23

3.5.4 SerCmd ..............................................................................................................................................................23

3.5.5 Error..................................................................................................................................................................24

3.5.6 Logs Screen........................................................................................................................................................24

3.6 GENERAL SCREEN ......................................................................................................................................................25

4 SETUP PROCEDURES.................................................................................................................................................27

4.1 RF DETECTOR ............................................................................................................................................................27

4.2 AGC AND CUTBACK PROTECTION..............................................................................................................................29

4.2.1 AGC Setup..........................................................................................................................................................29

4.2.2 Cutback Setup....................................................................................................................................................29

4.3 VSWR PROTECTION...................................................................................................................................................29

4.4 REMOTE CONTROL INTERFACE BAUD ........................................................................................................................30

4.5 POWER SUPPLY VOLTAGE AND CURRENT CALIBRATION............................................................................................31

5 REMOTE CONTROL CONNECTIONS MXI TRANSMITTER.............................................................................32

5.1 REMOTE CONTROLS....................................................................................................................................................32

5.1.1 RC_TX_On Remote Transmitter ON Control....................................................................................................33

5.1.2 RC_TX_Off Remote Transmitter OFF Control..................................................................................................33

5.1.3 RC_TX_VOR Remote Transmitter VOR Control...............................................................................................34

5.1.4 RC_RESET Remote RESET Control..................................................................................................................34

5.2 EXT1 SECONDARY EXTERNAL #1 INTERLOCK ...........................................................................................................34

5.2.1 Status Outputs....................................................................................................................................................35

5.3 TELEMETRY OUTPUTS ................................................................................................................................................35

6 CIRCUIT DESCRIPTIONS.......................................................................................................................................... 37

6.1 MC68HC908 MICROPROCESSOR................................................................................................................................37

6.2 POWER SUPPLY VOLTAGE AND CURRENT MONITORING ............................................................................................38

6.3 ON/OFF RELAY K1....................................................................................................................................................40

6.4 AGC, CUTBACK AND VSWR....................................................................................................................................40

6.5 SPI UART..................................................................................................................................................................41

6.6 SPI NVPOT ...............................................................................................................................................................42

6.7 RF DETECTOR ............................................................................................................................................................42

6.7.1 Circuit Description ............................................................................................................................................42

6.8 J12 CHANNEL – VISUAL FORWARD ............................................................................................................................42

6.9 J13 CHANNEL – REFLECTED .......................................................................................................................................43

6.10 J12 CHANNEL – AURAL FORWARD.............................................................................................................................44

7 ADDENDUMS................................................................................................................................................................45

7.1 ADDENDUM 1– CDS51405 DISPLAY CONTROLLER....................................................................................................46

7.2 ADDENDUM 2–DUAL DIGITAL POTENTIOMETER WITH EEPROM .............................................................................49

7.3 ADDENDUM 3–SPI/MICROWIRE-COMPATIBLE UART AND +/-15KV ESD-PROTECTED RS-232 TRANSCEIVERS

INTERNAL CAPACITORS.....................................................................................................................................52

WITH

7.4 ADDENDUM 4–MC68HC908GTXX DATA SHEET .....................................................................................................55

7.5 ADDENDUM 5– CURRENT TRANSDUCER HXS 20-NP.................................................................................................62

TSM20-365 Rev 2 July 17, 2007 v MXi201U

MXi201U TECHNICAL SERVICE MANUAL

1 MXi201U AMPLIFIER–INTRODUCTION

This Technical Service Manual contains publications (PUBs) describing the technical details of the MXi201U

amplifier, as well as the overall operating instructions, including the bench test procedures of the amplifier stages

incorporated in this unit. It also covers the transmitter’s start-up operation, and troubleshooting, as well as basic

transmitter maintenance guidelines.

The RF section of the MXi201U Amplifier consists of a heatsink assembly that includes five cascaded broadband

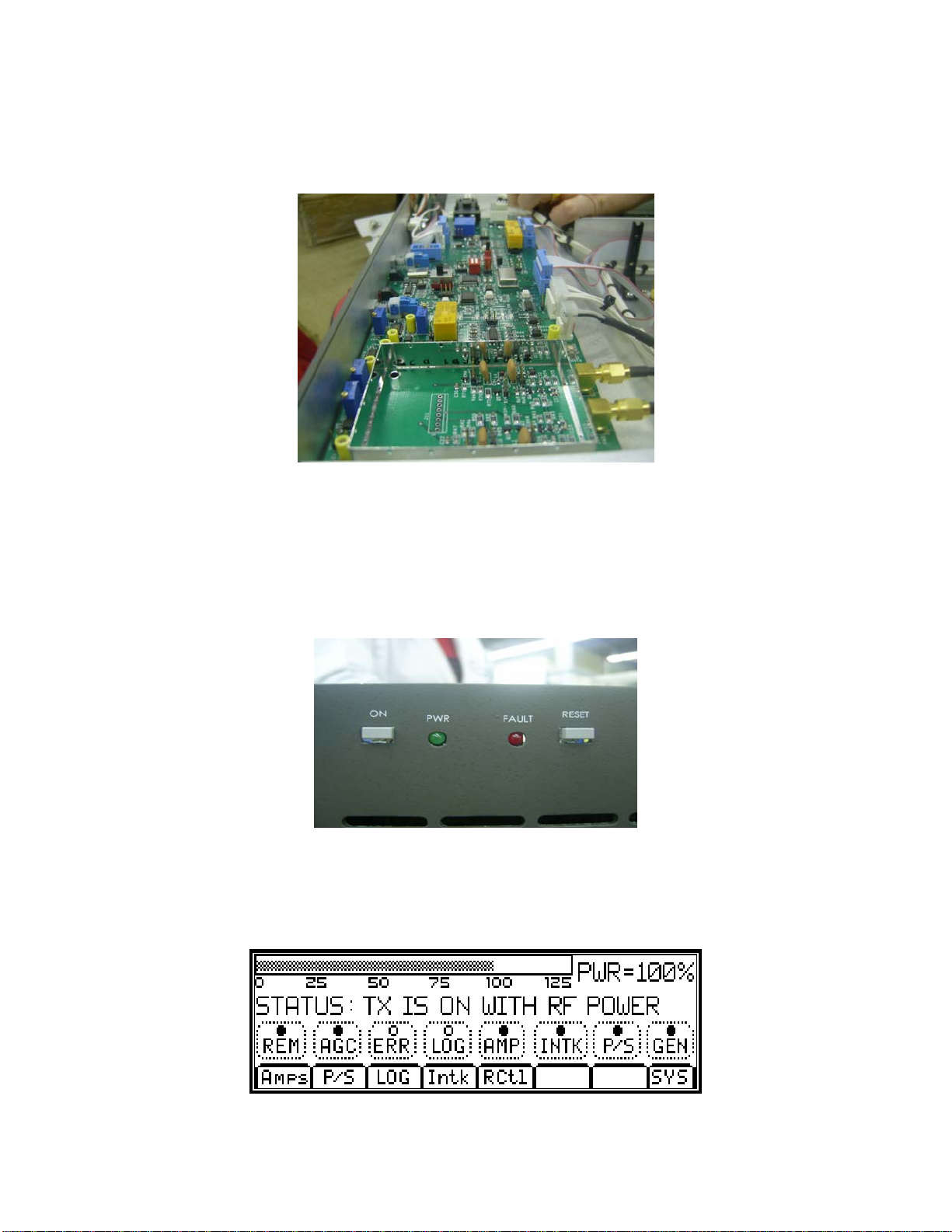

amplifier modules and a splitter and combiner and a directional coupler. Figure 1 shows the layout of this

assembly.

Figure 1 MXi Amplifier Heatsink Assembly

Also mounted on the heatsink is a thermal switch that protects the amplifier from over temperature conditions.

TSM20-365 Rev 2 July 17, 2007 1 MXi201U

MXi201U TECHNICAL SERVICE MANUAL

2 SAFETY NOTICES

This section provides general guidance and information for the operation, maintenance, and service personnel

who are familiar with the hazards of working with high-powered electronic circuits. This manual does not detail all

of the safety precautions which should be observed when servicing this or any other electronic equipment.

Service by inadequately trained or inexperienced personnel can result in personal injury or death and/or

damage to the equipment.

Important: All personnel concerned with the servicing of this equipment should be thoroughly familiar with

standard first aid procedures for the treatment of electrical burns and shock, including cardio-pulmonary

resuscitation (CPR).

Use the “buddy” system, with one person performing the actual service and a colleague observing. The observer

must be familiar with the work being performed and within sight and sound of the person doing the work. The

observer should not be engaged in any other work or be otherwise distracted; he must be available instantly in

case of accident.

Always have the observer with you when you work on the transmitter.

2.1 BERYLLIUM OXIDE WARNING

Internal thermal management in certain RF devices in this equipment is accomplished through the use of

Beryllium Oxide ceramic material. Do not break open any RF power transistors, or otherwise dismantle them.

Beryllium Oxide is a hard white ceramic used as insulation for heatsinking of RF power semiconductors. Beryllium

Oxide is a poison. In case of accidental breakage of devices, do not inhale the resulting beryllium dust and

avoid getting beryllium dust in your mouth. Do not let beryllium into your blood stream through cuts or

open wounds. Seek immediate medical attention if the dust enters your body in any manner. Avoid cuts by

wearing gloves while picking up the broken pieces. Be careful – do not inhale dust while replacing or emptying

vacuum cleaner filter bags and wash your hands thoroughly afterward. Wash your hands thoroughly after

replacing RF power devices. Dispose of defective RF power devices only through approved toxic waste facilities.

Wear gloves when picking up the pieces. Wash your hands thoroughly after replacing devices. Dispose of defective

devices only through approved toxic waste facilities.

When cleaning up after an accidental breakage, remember to wear a respirator mask to avoid inhaling the dust while

replacing or emptying vacuum cleaner filter bags and to wash your hands well after servicing the vacuum cleaner. If

possible, use a wet vacuum, in which the dust gets trapped in water.

2.2 OTHER TOXIC MATERIALS

The non-metallic coverings of some coaxial cables used in this equipment are flammable and can transmit fire

when ignited. Other wire coverings are not capable of supporting combustion but any non-metallic covering when

heated sufficiently can emit dense smoke and acid gases, which can be highly toxic and often corrosive.

Solvents and glues can emit toxic vapors and can be flammable. Read and understand the directions on the

containers and ensure that they are used only in well ventilated locations.

2.3 DANGEROUS VOLTAGES

This equipment has been designed to protect operating personnel from accidental contact with dangerous voltages,

by means of shields and covers. It is extremely important that any protective covering devices be kept in place at all

times.

While all practical safety precautions have been adopted to safeguard personnel from possible injury, both

supervisory and operating personnel are urged to ensure that the safety rules detailed below are followed as an

established routine at all times. The following four Rules are the standard safety guidelines for working with and

around transmitters.

TSM20-365 Rev 2 July 17, 2007 2 MXi201U

MXi201U TECHNICAL SERVICE MANUAL

Rule #1 KILL THE AC POWER BEFORE IT KILLS YOU

Under no circumstances should any person reach within the cabinets for the purpose of servicing or

adjusting the equipment without first disconnecting the AC power or without the immediate presence of

another person capable of rendering aid. The “buddy” system is encouraged for transmitter work.

Rule #2 DO NOT TAMPER WITH INTERLOCKS OR SAFETY SHIELDS

Under normal circumstances, no safety shield should be removed.

Rule #3 REMOVE PERSONAL JEWELRY WHEN WORKING ON THE EQUIPMENT

The mains AC power to this transmitter can deliver high currents capable of melting metallic tools or

personal jewelry, such as watch bands, bracelets, or rings. Accidental short circuits from such metallic

objects can cause an explosive shower of molten metal which can result in serious personal injury.

Rule #4 KNOW FIRST AID AND KEEP FIRST AID SUPPLIES AVAILABLE

Illustrated first aid instructions for the treatment of electrical shock and burns and CPR procedures should

be displayed in a prominent location adjacent to the equipment. In rendering first aid, the timeliness and

effectiveness of the treatment are vitally important to the recovery of the injured person.

Always have a colleague with you when you work on the transmitter and make sure both of you know first

aid, including cardio-pulmonary resuscitation (CPR). This is most important.

Without exception, all personnel should thoroughly familiarize themselves with the procedures involved. One

person, whose normal duties place him or her at the transmitter site often, should be given complete

responsibility and authority to ensure that first aid supplies are kept onsite and maintained. Prominently

display a list of emergency phone numbers. This list should include the numbers of the nearest police,

ambulance, hospital, doctor, fire department, paramedics, poison control center, public works (roads)

department, and the utility (power and phone) companies.

Do not try to work on the transmitter if you are tired or drowsy; you could make a fatal error in judgment.

2.3.1 Switch to Safety

Here are some safety suggestions, based partially on the knowledge of experts familiar with high-powered tubed

equipment, and partially on the procedures used at a typical utility company and at a company which makes and

tests high voltage devices. A few of these suggestions apply primarily to factory environments and require some

modification to be applied in transmitter settings.

Our thanks to the Varian Corporation for sharing its "Electrical Safety Training Program" notes. Our thanks also to

Ontario Hydro for its information booklets dealing with high voltage.

Have in place a comprehensive safety program, with defined procedures. Know First Aid and CPR.

Use the “buddy” system, with one person performing the actual service and a colleague observing. The observer

must be familiar with the work being performed and within sight and sound of the person doing the work. The

observer should not be engaged in any other work or be otherwise distracted; he must be available instantly in

case of accident. Always have the observer with you when you wo rk on the transmitter.

Pay attention to emergency communications requirements. This could even include a voice channel on the STL

so that constant communication with the studio can be maintained. Headset-equipped phones connected on this

voice channel should be installed in locations near hazardous areas or everyone on site should carry fully

charged cell phones. When you are administering CPR, you might not be able to leave your patient for the length

of time it could take to call paramedics, especially if phone service is poor, or lines are down, and/or you are in a

rural area without emergency telephone service (e.g., 911 in North America).

Do not defeat the interlock switches on access doors unless it is absolutely necessary and you know exactly

what you are doing.

Keep the area neat and tidy, free of any interfering conductive material and free of any sharp objects. Remember

that reaction to a shock could cause you to strike nearby objects.

TSM20-365 Rev 2 July 17, 2007 3 MXi201U

MXi201U TECHNICAL SERVICE MANUAL

Avoid wearing loose clothing and personal jewelry such as rings, watches, and chains when working near

energized circuits. Make a habit of removing all jewelry and storing it in a safe place as soon as you enter the

transmitter building.

Before beginning work, shut off all AC to the transmitter power supplies. Tag and lockout the switches.

Your safety routine must ensure that the person placing the tag and locking the switch is the only person who

removes it and reactivates the switch. You might want to include the AC to the remote control as well, if there is

any possibility that a studio worker could unknowingly activate the transmitter while you are working on it. One

way of ensuring that the lockout "placer and remover" are the same person is to issue individual padlocks to each

person on the transmitter technical staff.

You might want to include your tower contractor's rigging crew in the list of people who are allowed to use tags

and padlocks. As an alternative, Dielectric™ makes a transmission line lockout switch that is intended for riggers

to turn off and lock out any RF before climbing over the antenna to replace light bulbs, etc.

Proper grounding is vital. Make ground inspection a part of your maintenance program; someone's life could

depend on it.

TSM20-365 Rev 2 July 17, 2007 4 MXi201U

MXi201U TECHNICAL SERVICE MANUAL

3 LARCAN PARTS, ASSEMBLIES, ASSEMBLY DRAWINGS AND SCHEMATIC

NUMBERS

3.1 VENDOR STANDARD PART NUMBERS

Vendor or original manufacturer part numbers are indicated for most components.

3.2 LARCAN NUMBERS FOR PARTS, ASSEMBLIES AND DOCUMENTATION

An index of LARCAN specified number are used to define and specify the following:

• parts made by a manufacturer to LARCAN specification;

• an assembled unit or “group” such as a PC Board or completed cabinet;

• assembly drawings and schematics;

• standards.

Depending on the application, AutoCAD drawing or Microsoft Word document format is used.

Document numbers have the format YYZXXXXKn Rev m where:

YYZ Prefix denoting drawing size and Product type. Can be 10A, 11A, 20B, 21B, 30C, 31C, 40D, 41D, 50E, 51E

– describes drawing or document size, VHF or UHF application

XXXX Drawing Index number. Between 0000 to 9999.

K Refers to the type of drawing / document:

• “no suffix” for drawing of part (assembly or schematic)

• P = Part

• G = Group of parts

• A = Assembly drawing

• F = PC board fabrication films and

• S = Schematic

n Index number for drawing type. Part, group, assembly drawing or schematic next number and may be

one or more digits

Rev Revision (sometimes denoted as R or R–)

m Revision number and may be one digit or more. May contain a decimal (e.g., Revision 3.2)

Drawings may consist of one or more sheets. Generally multiple sheets are used if one sheet is not enough to

show all necessary information. Sometimes, especially with older drawings, multiple sheets are used to show

more than one part or assembly.

TSM20-365 Rev 2 July 17, 2007 5 MXi201U

MXi201U TECHNICAL SERVICE MANUAL

3.3 LEADED RESISTORS

Generic carbon composition resistors with leads are numbered as follows:

nnnx

3R

P

- or -

nnx

Power Rating Resistance Value * Tolerance

152 = 1/4W nn - first digits of K =10%

77 = 1/2W resistance (5, 10% tol.) J =5%

78 = 1W nnn - first digits of H =1%

79 = 2W resistance (1% tol.)

x - x10 multiplier

For values between 1Ω and 10Ω, a letter “R” will appear in the resistance value to indicate the decimal place.

For vendor leaded resistors a generic drawing describing basic specifications, but having many “parts”, will often

be used.

“3R152P5R6J” is 5.6Ω, 1/4W, ±5%

“3R152P470K” is 47Ω, 1/4W, ±10%

“3R152P1022H” is 10.2kΩ, 1/4W, ±1%

“3R152P102J” is 1kΩ, 1/4W, ±5%

3.4 SURFACE MOUNT RESISTORS 1/4W AND LESS

There is no specified recommended supplier of these parts. The Philips numbering system is employed with the

following parameters/designations (example follows):

9C

SIZE LxW POWER

nn=first 2 digits

x=multiplier

nnnx tolerance<5%

nnn=first 3 digits

nRnx or nnRnx or nRnnx

R inserted as decimal point

0000 - four zeros for jumper

RATING

0603=1.6x08mm 1 = 1/16W

0805=2x1.25mm 2 = 1/10W

1206=3.2x1.6mm 2 = 1/8W

(1% tol.)

3 =1/4W

(5% tol.)

A nnnx

RESISTANCE VALUE

nnx tolerance>=5%

x=multiplier

where required

TOLERANCE TEMP COEF

D=0.5% C=50ppm/°C

F=1% K=100ppm/°C

J=5% L=200ppm/°C

M=300ppm/°C

The pairs of parameters enclosed in boxes are normally mutually selected; for example, a resistor having 1%

tolerance normally is selected as having a temperature coefficient of 100ppm/°C.

TSM20-365 Rev 2 July 17, 2007 6 MXi201U

MXi201U TECHNICAL SERVICE MANUAL

Example: 9C08052A1001F K

(Size 0805, Power Rating 1/10W, Resistance 1kohm, Tolerance 1%, Temperature

Coefficient 100ppm/°C)

3.5 SURFACE MOUNT CAPACITORS

There is no specifically recommended supplier of these parts. The part numbering system being used is based on

a Philips (now Yageo/Phycomp) numbering system with the following parameters/designations (example follows):

SIZE LxW DIELECTRIC

MATERIAL

0603=1.6x08mm CG = NPO nn =first 2 digits B=0.10pF 7=16VDC B=Ni/Sn

0805=2x1.25mm 2R = X7R

1206=3.2x1.6mm 2F = Y5V * x =multiplier as

9=x0.1

0=x1

1=x10

2=x100

3=x1000

4=x10000

5=x100000

* (infrequent use)

2E = Z5U *

shown below

8=x0.01

Nnx

CAPACITANCE

VALUE

(in Pico farads)

C=0.25pF 8=25VDC

D=0.50pF 9=50 VDC

F=1% 0=100VDC

G=2% B=200VDC

J=5% D=500VDC

K=10%

M=20%

TOLERANCE

VOLTAGE

RATING

TERMINATION

A=Ag/Pd

C=Ni/Sn-Pb

e.g., 0805CG102J9B

SIZE =0805

DIELECTRIC MATERIAL =NPO

VALUE =1000pF

TOLERANCE =5%

VOLTAGE RATING =50V

TERMINATION =Ni/Sn

PACKAGING =Not Specified

MARKING =None

Note that “u” appears in most cases instead of the correct symbol “μ” whenever a “micro” is required. Electronic

parts list data, when imported by our PC publication program, allows us to substitute the correct “μ” when

checking and editing.

3.6 PARTS LISTS

Parts lists for all assemblies in the transmitter are provided on CD-ROM, in PDF format. The CD-ROM is packed

inside the transmitter cabinet for shipping.

Parts lists are generated in a hierarchical structure, beginning with major assemblies, then the subassemblies of

each major assembly, and so forth.

3.6.1 Production Changes

From time to time, it may become necessary to make changes in the equipment described in this manual. Such

changes are usually made either to provide improved performance or to accommodate component substitutions.

TSM20-365 Rev 2 July 17, 2007 7 MXi201U

MXi201U TECHNICAL SERVICE MANUAL

A revision letter or number may follow the model or group number marked on the nameplate, chassis, or circuit

board; or on the parts list (where it is an "R" followed by a dash and a number). Whenever a revision letter or

number appears, it should be quoted in any communication regarding the equipment.

TSM20-365 Rev 2 July 17, 2007 8 MXi201U

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

CONTENTS

1 MXi DUAL PALLET AMPLIFIER.................................................................................................................................1

2 MXi CONTROLLER ........................................................................................................................................................2

3 AMPLIFIER INSTALLATION AND STARTUP..........................................................................................................4

3.1 BEFORE APPLYING AC TO THE UNIT ............................................................................................................................4

3.2 APPLYING AC TO THE UNIT..........................................................................................................................................4

3.3 BEFORE TURNING THE AMPLIFIER ON .........................................................................................................................5

3.4 AMPLIFIER ON SEQUENCE............................................................................................................................................6

3.4.1 Turning ON MXi Amplifier..................................................................................................................................6

4 TEST AND TROUBLESHOOTING ...............................................................................................................................6

4.1 BENCH TEST PROCEDURES ...........................................................................................................................................7

4.1.1 Front-End Module Bench Test Procedure...........................................................................................................7

4.1.2 IPA1 Bench Test Procedure.................................................................................................................................7

4.1.3 Driver 21B1751 Bench Test Procedure...............................................................................................................7

4.1.4 PA Pallet 11A2142G1 Bench Test Procedure......................................................................................................8

4.2 BASIC TROUBLESHOOTING TECHNIQUES ......................................................................................................................8

4.2.1 Amplifier Completely OFF...................................................................................................................................8

4.2.2 No RF Output.......................................................................................................................................................8

4.2.3 Output Reduced to 25%.......................................................................................................................................8

5 MAINTENANCE...............................................................................................................................................................9

5.1 DAILY...........................................................................................................................................................................9

5.2 MONTHLY.....................................................................................................................................................................9

5.3 SEMI-ANNUALLY AND ANNUALLY...............................................................................................................................9

5.4 TRANSMITTER COOLING SYSTEM .................................................................................................................................9

6 SERVICE..........................................................................................................................................................................10

6.1 REMOVING THE FAN ARRAY.......................................................................................................................................10

6.2 REPLACING THE ENTIRE FAN ARRAY .........................................................................................................................11

6.3 REPLACING A SINGLE FAN..........................................................................................................................................11

7 TEST EQUIPMENT SETUP..........................................................................................................................................12

8 SPECIFICATIONS .........................................................................................................................................................13

8.1 ELECTRICAL ...............................................................................................................................................................13

8.2 ENVIRONMENTAL.......................................................................................................................................................13

8.3 COOLING ....................................................................................................................................................................13

8.4 DIMENSIONS...............................................................................................................................................................13

8.5 SHIPPING WEIGHT ......................................................................................................................................................13

FIGURES

FIGURE 1 MXI AMPLIFIER HEATSINK ASSEMBLY ........................................................................................................................1

FIGURE 2 MXI CONTROLLER........................................................................................................................................................2

FIGURE 3 MXI FRONT PANEL .......................................................................................................................................................2

FIGURE 4 MAIN MENU SCREEN ....................................................................................................................................................2

FIGURE 5 AMPLIFIER (AMP) SUBMENU ....................................................................................................................................... 3

FIGURE 6 POWER SUPPLY (P/S) SUBMENU SCREEN......................................................................................................................3

FIGURE 7 REAR PANEL SHOWING INTERLOCK TERMINAL BOARD................................................................................................4

FIGURE 8 MAIN MENU..................................................................................................................................................................5

FIGURE 9 INTERLOCKS STATUS ....................................................................................................................................................5

FIGURE 10 AGC OFF...................................................................................................................................................................5

PUB06-78 Rev 1 July 17, 2007 06-78-i MXi Dual Pallet Operations and Maintenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

FIGURE 11 TRANSMITTER ON ......................................................................................................................................................6

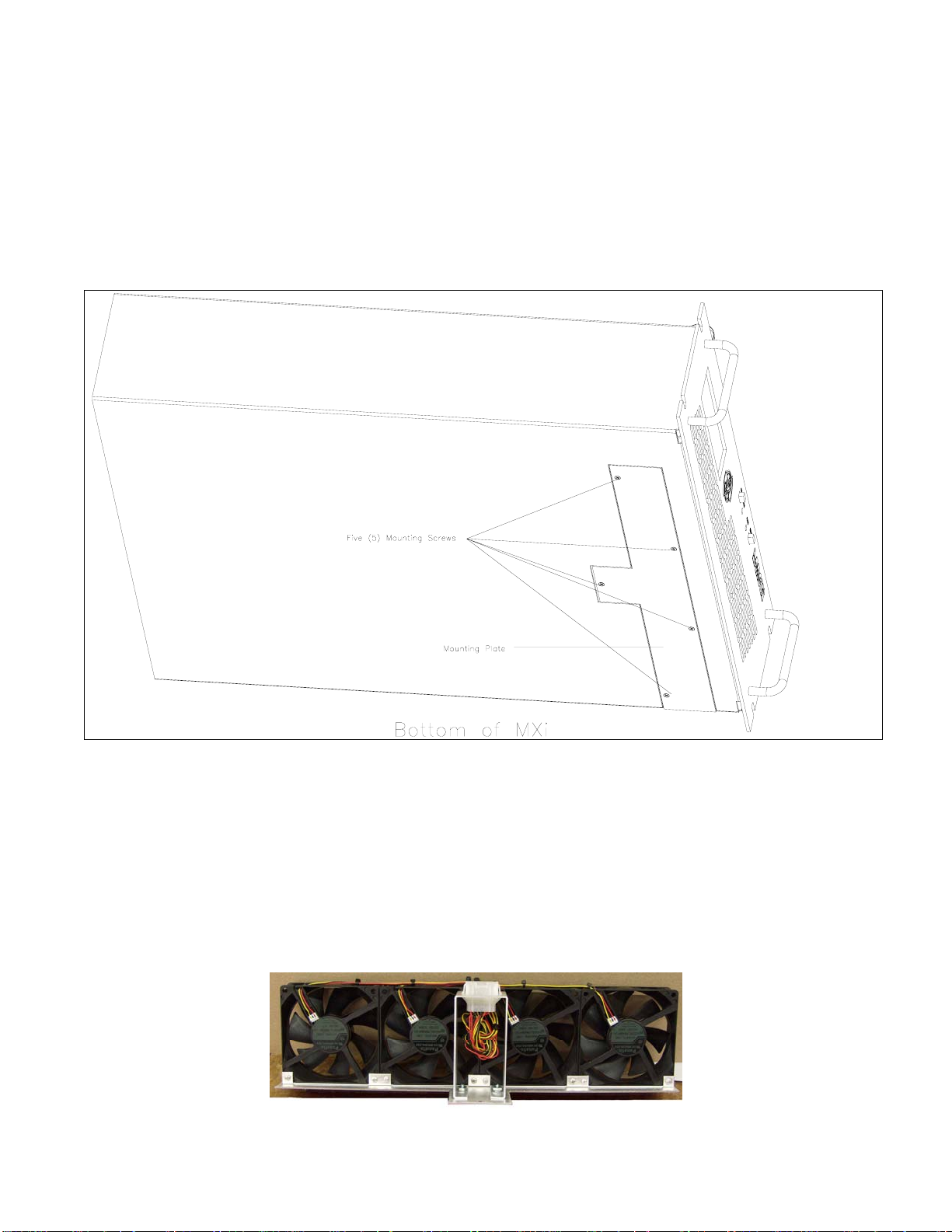

FIGURE 12 BOTTOM VIEW OF MXI.............................................................................................................................................10

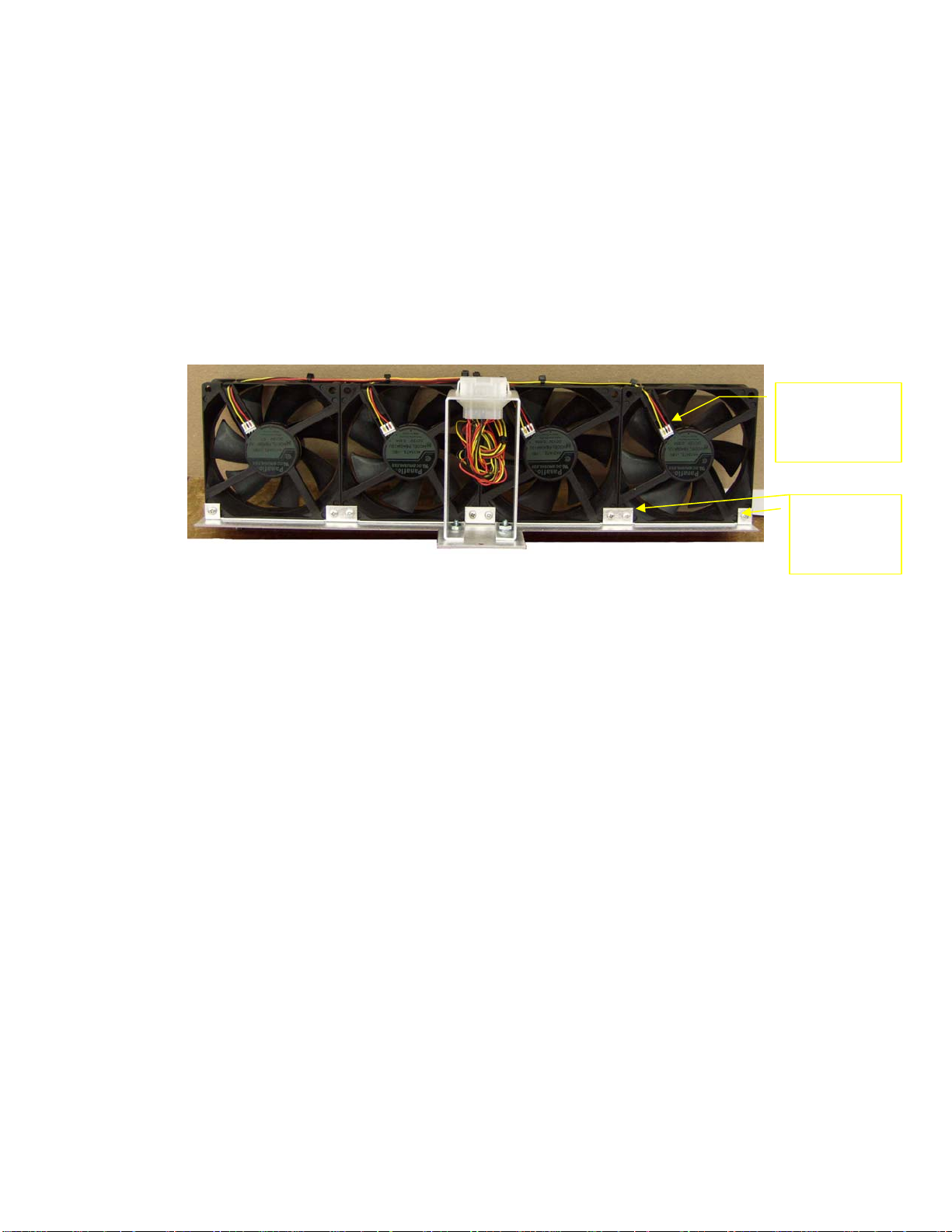

FIGURE 13 FAN ARRAY ..............................................................................................................................................................10

FIGURE 14 FAN ATTACHMENT TO MOUNTING PLATE.................................................................................................................11

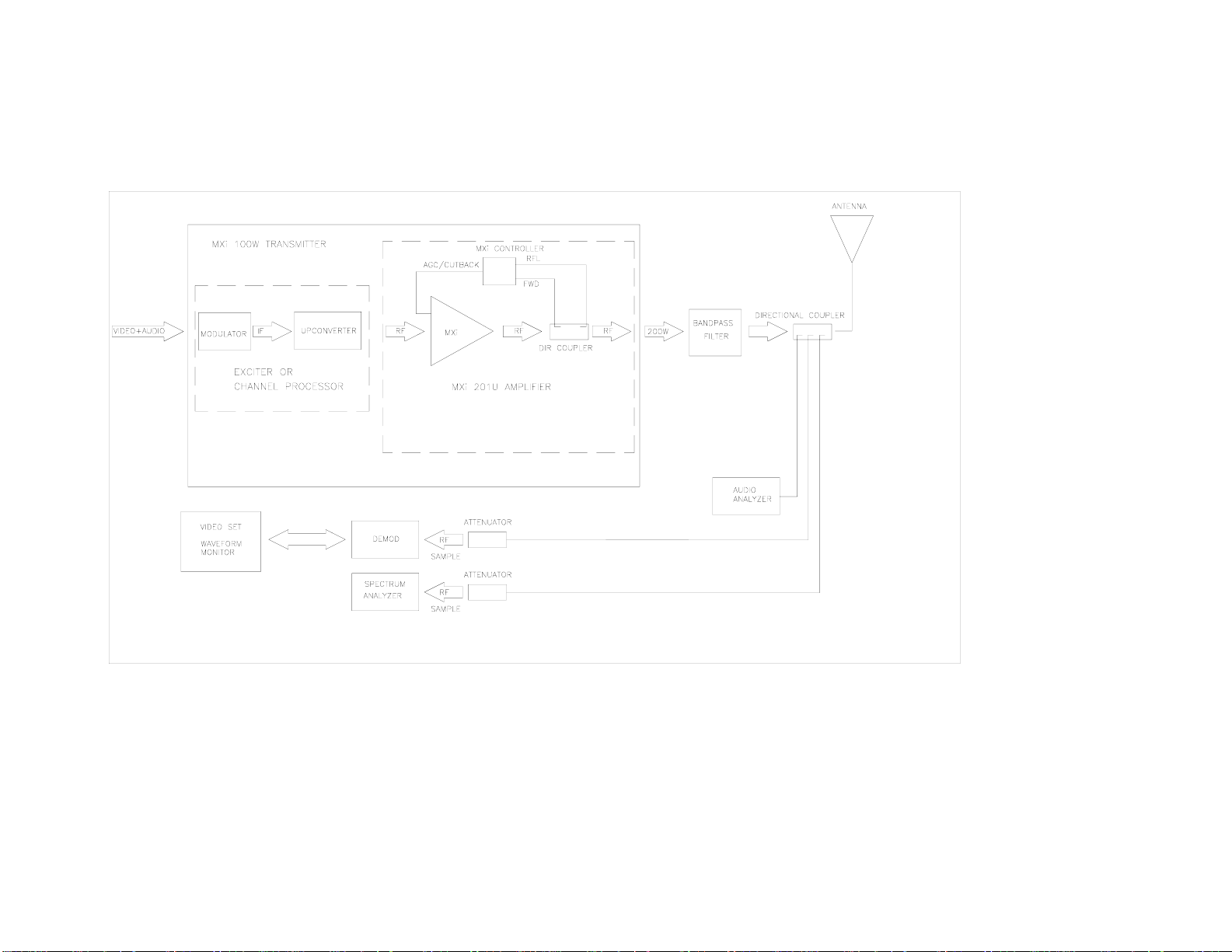

FIGURE 15 TEST EQUIPMENT SETUP ...........................................................................................................................................12

PUB06-78 Rev 1 July 17, 2007 06-78-ii MXi Dual Pallet Operations and Maintenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

1 MXi DUAL PALLET AMPLIFIER

The RF section of the MXi Dual Pallet Amplifier consists of a heatsink assembly that includes five cascaded

broadband amplifier modules and a splitter and combiner and a directional coupler. Figure 1 shows the layout of

this assembly.

Figure 1 MXi Amplifier Heatsink Assembly

Also mounted on the heatsink is a thermal switch that protects the amplifier from over temperature conditions.

PUB06-78 Rev 1 July 17, 2007 06-78-1 MXi Dual Pallet Operations and Mai ntenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

2 MXi CONTROLLER

The MXi control board (Assembly 31C1897) is a single-circuit assembly that provides all of the control functions

required for the MXi series of transmitters on a single circuit board. This board can be configured for a number of

different transmitter types, power levels, transmission standards and options.

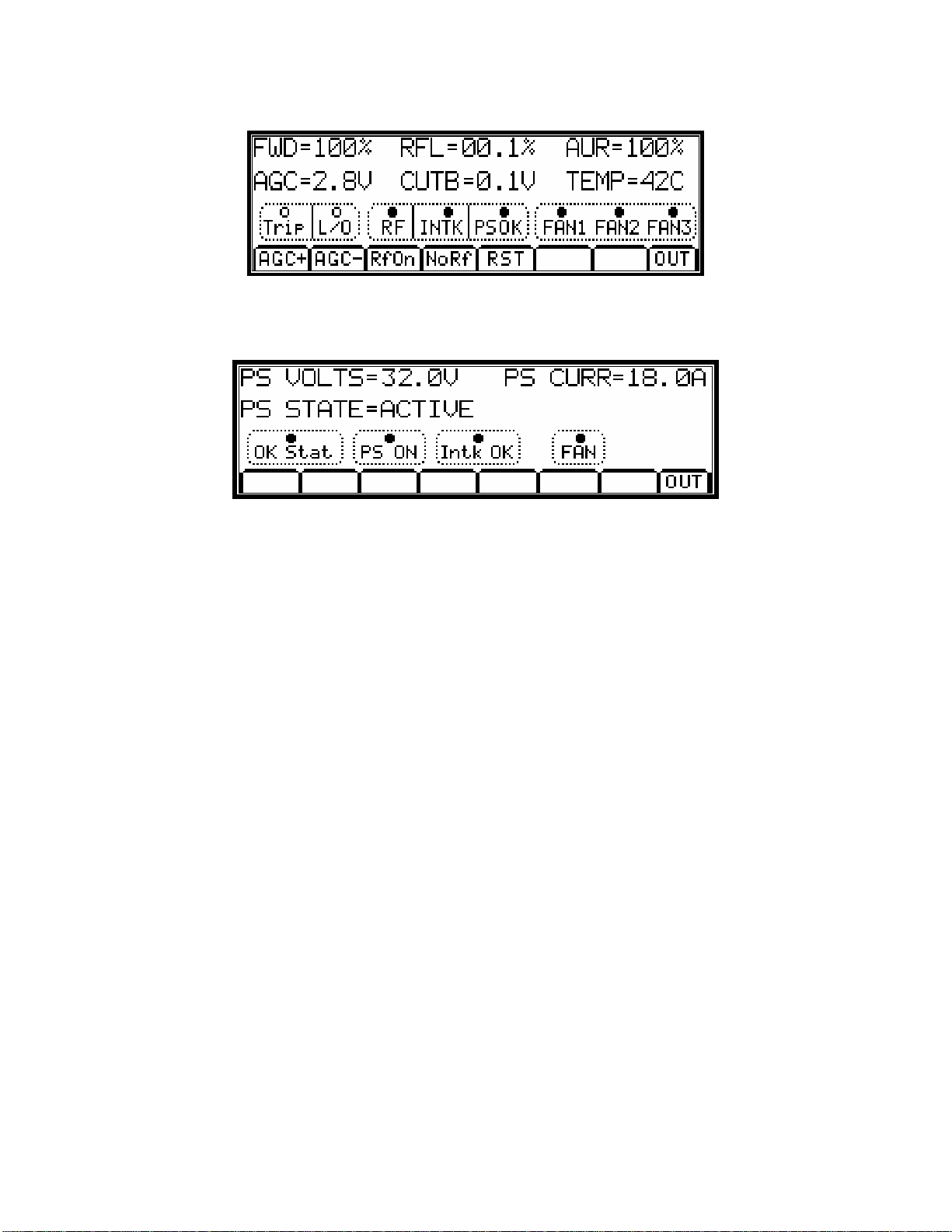

Figure 2 MXi Controller

The MXi control board provides local front panel interface via ON/OFF and RESET buttons as well as a graphical

user interface through a front panel LCD assembly with touchpad for user commands. The board implements

controls/status/telemetry for remote control through a rear panel connector that will interface to a typical remote

control systems (such as Moseley or Gentner). An RS232 serial port is also provided to allow the operator to

access the MXi through an external computer (with the appropriate software). The MXi control board has RF

detectors for forward and reflected power and all the circuitry to support AGC/VSWR/Cutback functions. Circuitry

to control and monitor the +32V power supply is also included on this board.

Figure 3 MXi Front Panel

The user interface to the amplifier is accomplished with the front panel LCD that incorporates a touchpad as an

integral part of the unit. The LCD has the capability of displaying a variety of screens, which are selected by the

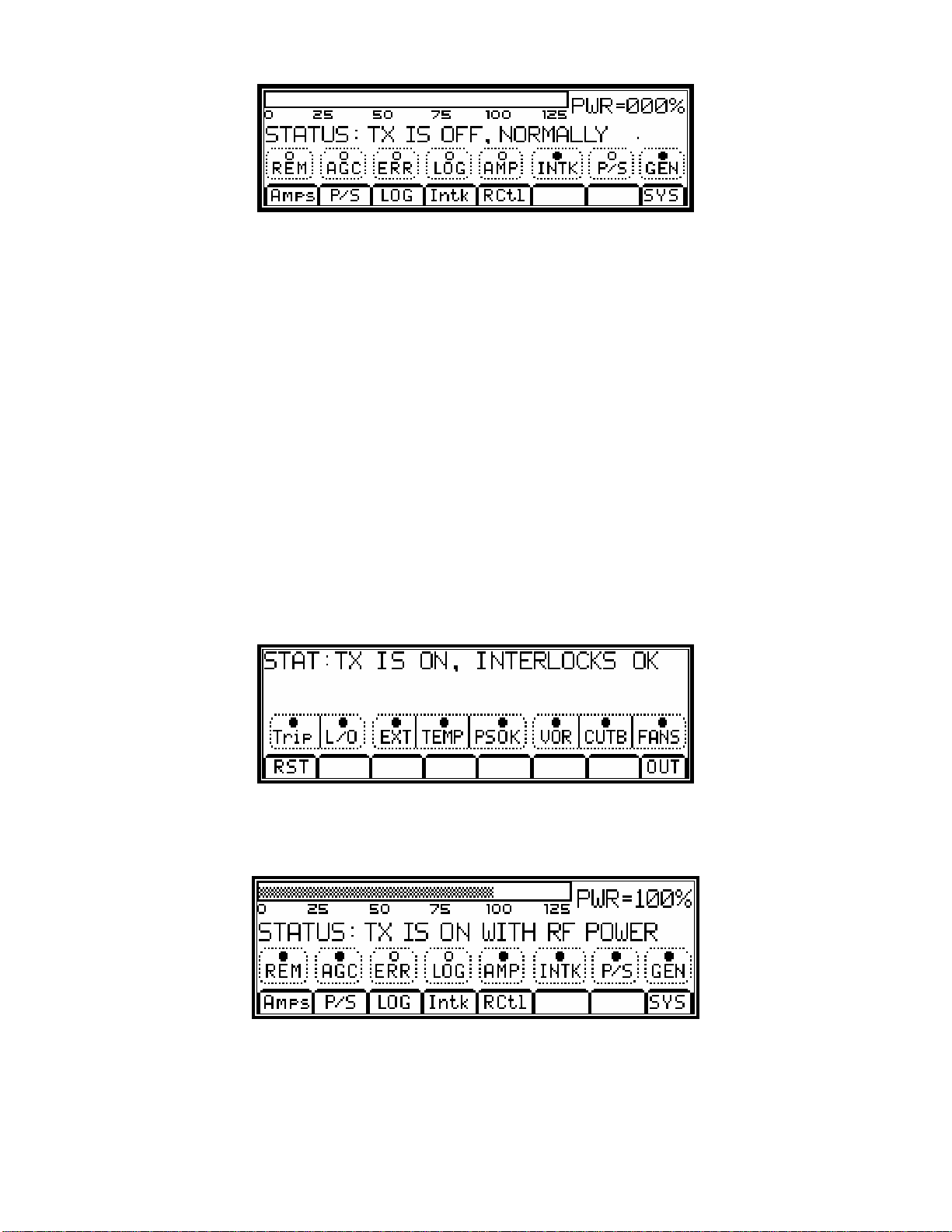

user via the touchpad. Figure 4 shows the LCD main menu, which shows the present status of the amplifier along

with the selections of submenus.

Figure 4 Main Menu Screen

PUB06-78 Rev 1 July 17, 2007 06-78-2 MXi Dual Pallet Operations and Mai ntenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

Forward (FWD) and Reflected power (RFL), AURal power, AGC and CUTBack (VSWR) control voltage, as well

as the heatsink TEMPerature (Optional) can be displayed by selecting the AMP submenu as shown in Figure 5.

Figure 5 Amplifier (AMP) Submenu

Pressing the power supply P/S submenu from the Main Menu displays the power supply voltage and current

consumption as well as its status.

Figure 6 Power Supply (P/S) Submenu Screen

For complete documentation regarding the Controller, see the publication MXi Controller Board.

PUB06-78 Rev 1 July 17, 2007 06-78-3 MXi Dual Pallet Operations and Mai ntenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

3 AMPLIFIER INSTALLATION AND STARTUP

The MXi Amplifier was fully tested at LARCAN before it was delivered. Under normal circumstances, the

transmitter can be fully operational with minimal setup when turned ON. However, a good practice is to take the

“start from scratch” approach, which means that you should take precautionary measures before the amplifier is

allowed to run at full rated power. These important steps will avoid any catastrophic failures at start-up. The

procedure described is essentially the same approach taken at the factory with a new and untested transmitter.

This also applies if there is a need to completely replace a major sub-assembly in the transmitter.

3.1 BEFORE APPLYING AC TO THE UNIT

Pay careful attention to items 1 to 3 before applying AC to the amplifier. These are initial steps that must be

observed and followed for proper and safe operation of the amplifier.

1. Termination

• Ensure that the amplifier is properly terminated with a suitable load. This can be into a dummy load or into

the transmitter output system. A 50 Ohm, 100W load with at least –20dB return loss (1.2 VSWR) is

recommended. Preferably, directional couplers with known coupling levels at the frequency of interest

should be connected at the input and output of the band-pass filter. These points are very useful in

determining absolute power levels and losses and for use as an RF sample for monitoring purposes. See

Figure 15 for a typical transmitter test equipment setup.

2. Interlocks

Interlocks must be connected to the amplifier to avoid damage to the equipment and to the output section.

Interlock is provided at the INTERLOCK terminal board located on the rear panel. If this interlock is open, the

B+ to the amplifier will shut down, including the cooling fans. DO NOT replace this interlock with a jumper.

Figure 7 Rear Panel Showing Interlock Terminal Board

3. Power At Minimum

• Initially, the Exciter or Channel Processor’s RF output should be at minimum level. Adjust the OUTPUT

LEVEL control for a minimum output.

3.2 APPLYING AC TO THE UNIT

• Check that the AC voltage available to the amplifier ranges from 90-264VAC. If so, proceed to applying

the power to the AC INPUT of the amplifier

• Once the AC is applied to the unit, the Control Power Supply turns ON and applies +12V to the MXi

Controller.

• Observe that the Power-Up screen is displayed on the LCD, followed by the Main Menu.

PUB06-78 Rev 1 July 17, 2007 06-78-4 MXi Dual Pallet Operations and Mai ntenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

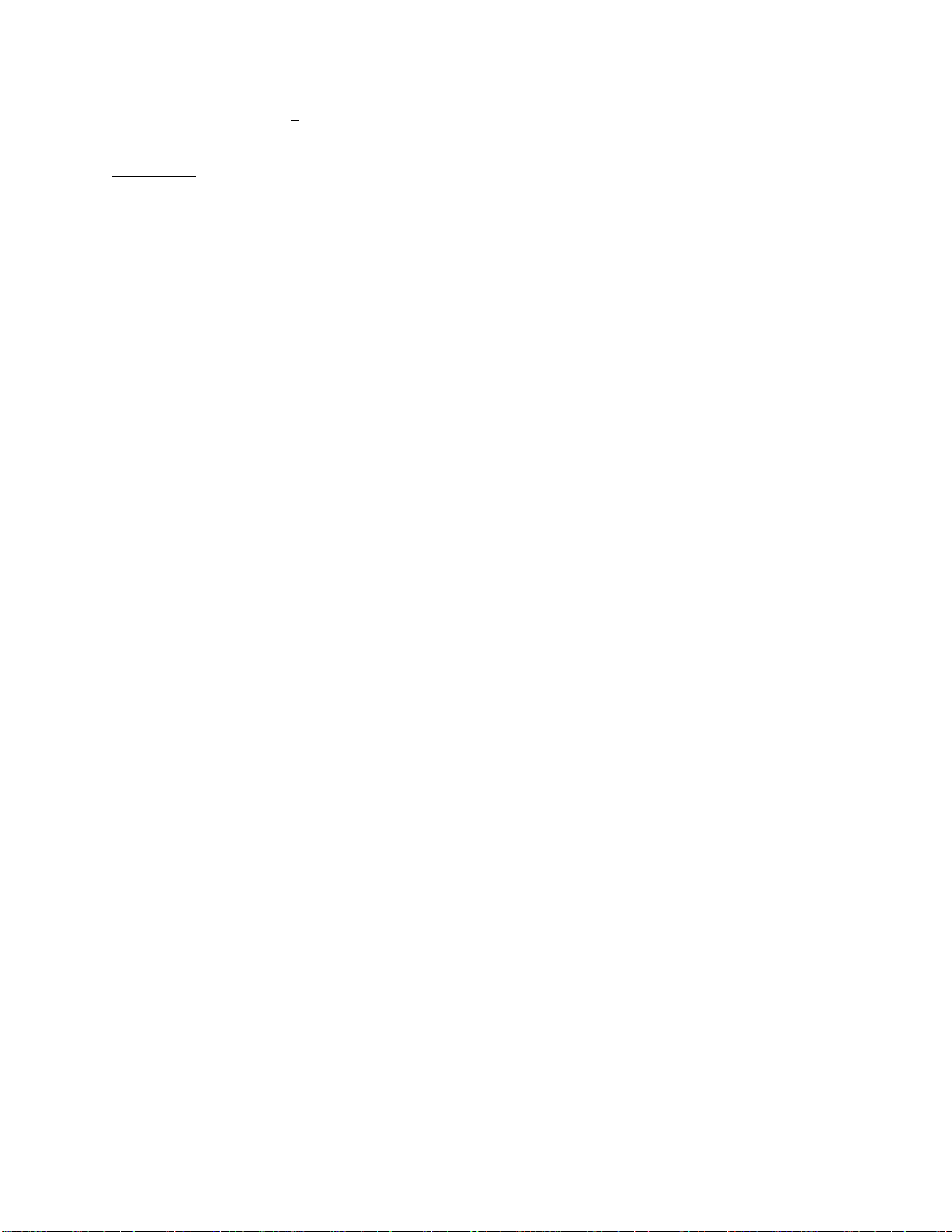

Figure 8 Main Menu

3.3 BEFORE TURNING THE AMPLIFIER ON

From the Main Menu, the status of the amplifier is displayed and shows if the amplifier is ready for operation.

Status legends, when lit, such as the INTK (INTERLCOK), usually signify OK conditions and that the transmitter is

ready to be turned ON.

Check that all of the following conditions are met:

1. EXCITER or Channel Processor is Ready.

• Usually in the application of AC, the Exciter goes through its warm-up sequence. Ensure that it has done

so.

4. POWER METERING is at Zero.

• On the LCD (see Main Menu display in Figure 8), the PWR should be at 000% and the STATUS should

be TX IS OFF, NORMALLY.

5. MXi CONTROLLER is ready.

• If there were prior faults, clear them by pushing the RESET button.

6. INTERLOCKS are closed or OK.

• Interlocks and Status are OK.

Figure 9 Interlocks Status

7. AGC control is DISABLED at this time.

• Push the AGC button on the touchpad so that it is NOT selected.

Figure 10 AGC OFF

8. The Amplifier is in LOCAL mode.

• Push the REM button so that it is NOT lit.

9. The TX is OFF.

PUB06-78 Rev 1 July 17, 2007 06-78-5 MXi Dual Pallet Operations and Mai ntenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

• Push the Front Panel ON/OFF button so that it is NOT pushed in.

3.4 AMPLIFIER ON SEQUENCE

Upon depressing the ON button, the fans start and at the same time the +32V power supply is enabled, thus

applying B+ to the MXi Amplifier. Since the Exciter or Channel Processor is on hot standby (RF is always

applied), the amplifier normally produces output power immediately.

3.4.1 Turning ON MXi Amplifier

10. Enable amplifier LOCAL operation by pressing the REM touch button such that the REM legend is NOT lit.

• Push the front panel ON button.

• The MXi Amplifier should now be ON.

Figure 11 Transmitter ON

11. Monitor the +32V power supply voltage and current on the LCD. Check that the power supply is operating by

pressing the P/S touch button. The voltage reading should be about 32V and the current should be about

5.3A under Static condition (no RF drive).

ALLOW THE AMPLIFIER SOME WARM-UP TIME!

Only after the transmitter has been ON for approximately 15 minutes should you perform the fine

adjustments. The amplifier must be allowed to reach its operating temperature for stable and consistent

operation. The Power Amplifier in the MXi transmitter is equipped with thermal compensation circuits, which

reduce the output power when the temperature rises. Therefore, the operating temperature must be reached

before adjusting the RF level to its proper level. The amplifier is also equipped with Automatic Gain Control,

primarily designed to prevent the transmitter from overpower or overdrive condition.

12. Increase the RF output by slowly turning the Exciter or Channel Processor output level control.

Stop at about 50% output power indicated on the LCD. At this level, the current should not be more than 10

Amps.

13. If the current is not abnormally high, increase the power to 100%. Again, make note of the PS current reading.

This should not be more than 32 Amps.

14. AGC SETTING: With the AGC still disabled, increase the output power to 110%, using the output level control

in the Exciter or Channel processor. Enable the AGC by pressing the AGC touch button until it lights. Use the

LOWER button to set the power to 100%.

15. With the amplifier fully functional and adjusted to its final setting, record keeping becomes very important.

Record the current, voltage, power, etc. This data can be used as a very valuable troubleshooting tool later.

Below is typical test data pertaining to the MXi amplifier at 100% output power.

TYPICAL DATA read on the LCD

FWD 100% CUTB 0.1V

RFL 00.1% PS VOLTS 32.0V

AGC 1.0V PS CURR 28.0A

AUR 100% (Only if running as a analog)

PUB06-78 Rev 1 July 17, 2007 06-78-6 MXi Dual Pallet Operations and Mai ntenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

4 TEST AND TROUBLESHOOTING

4.1 BENCH TEST PROCEDURES

The following procedures are test instructions for the amplifier modules comprising the MXi amplifier.

4.1.1 Front-End Module Bench Test Procedure

• Connect a +32V (1A current limit) power supply to TP2.

• Apply a 0dBm (1mW) RF input to the amplifier.

• Turn RV2 fully clockwise. The front-end should have a gain of 13dB. Adjusting RV2 from one extreme to

the other should vary the gain by a minimum of 20dB. Set RV2 fully clockwise.

• RF Mute Check: Connect a variable supply to TP1. Gradually increase the voltage until the gain drops by

20dB or more. The applied voltage should be approximately 7 volts.

• Telemetry: Monitor TP3. Note voltage decrease to 0V DC when RF output has been muted.

4.1.2 IPA1 Bench Test Procedure

This amplifier must be mounted on a properly sized heatsink for testing.

• Connect a suitable load to the output of the Pre Amplifier.

• On the unit under test, set RV200 fully clockwise and set RV110 fully counter-clockwise.

• Set variable power supply to 32.0 volts and set its current limit to 1 ampere.

• Apply the +32V to the feedthrough capacitor of the pre-amp shield box.

• Adjust RV3 to achieve 6.5 ±0.2 volts at the junction of R5 and RV100.

• Adjust RV200 to achieve total current draw of 500 ±20 mA.

• Check that the junction of R100 and CR100 measures between 3.5 and 5.5 volts.

• Adjust RV110 to raise total current draw to 1000 ±50 mA.

• Check that the junction of R110 and CR110 measures between 3.5 and 5.5 volts.

• Increase the power supply current limiting to 2.2 Amps.

• Increase RV3 clockwise slowly and check that the maximum current limits itself at 1.6 ±0.1 Amp but do

not allow current to go above 2 amps while performing this test.

• Reset RV3 to achieve 6.5 ±0.2 volts measured at the junction of R5 and RV100.

• Check balance of the two transistors with a voltmeter connected between the hot sides of C105 and

C115; the difference in voltage should be less than 3mV.

• Apply RF drive (max. +18 from a pre-amp) and adjust C101, C103, C111, and C113 for minimum

frequency response ripple and flat response. Gain should be a minimum of 15dB with maximum variation

less than 0.5dB over the frequency range 470MHz through 860MHz (Note: output will then be about

+33dBm or 2 Watts for an input of +18dBm, so make sure you properly protect your test equipment).

• If roll off at the higher frequencies prevents meeting this gain-bandwidth specification, it may be

necessary to replace either C103 or C113 or both with a higher value; use variable capacitor made by

Johanson, part # 16E2320-2, which is 2.5 to 10pF.

4.1.3 Driver 21B1751 Bench Test Procedure

• BIAS SETTING: Connect a 50-Ohm load to the output of the pallet.

• Before applying +32V to the module, adjust R12 fully clockwise. Limit the power supply current to 3.0A.

PUB06-78 Rev 1 July 17, 2007 06-78-7 MXi Dual Pallet Operations and Mai ntenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

• Apply +32V to the B+ terminal. Monitor the current and adjust R12 counter clockwise (CCW) for a total

current of about 2.5A +

• Proceed to the next step if a network analyzer or similar equipment is available.

0.1A.

• RF SWEEP

470MHz to 860MHz should be 15 to 16dB.

: Adjust C7 for best frequency response. With the bias set at 2.5A, the gain in the range of

4.1.4 PA Pallet 11A2142G1 Bench Test Procedure

• BIAS SETTING: Connect a 50-Ohm load to the output of the pallet.

• Before applying +32V to the module, adjust R11 fully counter-clockwise. Limit the power supply current to

3.0A.

• Apply +32V to the B+ terminal. Monitor the current and adjust R11 clockwise (CW) for a total current of

2.0A + or – 0.2A.

• Proceed to the next step if a network analyzer or similar equipment is available.

• RF SWEEP

between 15 to 16dB.

: Adjust C4 for best frequency response. The gain, in the range of 470MHz to 860MHz, should be

4.2 BASIC TROUBLESHOOTING TECHNIQUES

One of the best tools in troubleshooting is knowing what the nominal figures or typical values of the MXi amplifier

when it is at its normal performance. If a fault condition occurs, then you can compare the data taken previously

with the present conditions and come up with a reasonable conclusion about what is at faul t.

The following describes some fault conditions and possible solutions.

4.2.1 Amplifier Completely OFF

The MXi amplifier is equipped with a fused AC line filter. Although it rarely happens, abnormal conditions such as

power surges may cause the fuse to blow. A blown AC fuse will completely shutdown the amplifier, including a

complete loss of information on the LCD touchpad. In this case, replacing the fuse will rectify the problem.

4.2.2 No RF Output

• Check for proper power supply voltage.

• Check for potential connector problems causing either no drive to a module pallet (input connector) or VSWR

(output connector) problems.

4.2.3 Output Reduced to 25%

If the output is approximately 25%, a possible cause is a failure of one of the devices in the IPA or the PA

amplifier module. These stages have dual devices so that if one fails the output of that stage will be reduced to

quarter power (25%). A measurement of the current drawn by the amplifier will determine if this condition exists.

The IPA usually draws 1A. If the current is 0.5, then this is the case. Similarly, the PA pallet draws 2.0A with no

drive condition. If it reads 1.0A, then this is also the case.

PUB06-78 Rev 1 July 17, 2007 06-78-8 MXi Dual Pallet Operations and Mai ntenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

5 MAINTENANCE

Equipment which is regularly and carefully maintained is far less likely to be subject to sudden failure than that

which is operated without regard to basic maintenance requirements. A detailed preventive maintenance program

should be established to ensure that the original efficiency and picture quality is maintained throughout the life of

the equipment. Given reasonable care and attention, the transmitter will provide efficient and reliable service for

many years.

Preventive maintenance techniques do not necessarily involve extensive dismantling of the various assemblies;

on the contrary, this practice is to be discouraged unless a valid reason exists for doing so. Preventive

maintenance is more directed at detailed physical inspection and the general observation of the equipment during

and after operation, to detect the presence of any abnormality, which, if not corrected, might result in operational

failure.

In preparing any maintenance program, the frequency and scope of the inspections must be determined and to a

great degree will be influenced by site location and the station's market parameters and consequently its hours of

operation, equipment configuration, and technical personnel deployment. For example, is the station on the air for

24 hours-a-day? Are there main/standby transmitters and are they attended or unattended?

In general, the following routines should form the basis of any maintenance program.

5.1 DAILY

At an attended site, the operator is afforded the opportunity to make frequent checks on the equipment and

thereby increase his/her familiarity with its operation. The transmitter log entries made during these checks would

include all meter readings, also any irregularity in performance or in picture quality, for later analysis. An

unattended site where equipment is operated by remote control and monitored by telemetry and a high quality offair receiver or demodulator can also be continuously checked for performance by studio technical personnel.

5.2 MONTHLY

In addition to the normal operational tests, thorough physical inspection of every piece of equipment should be

made, with all power turned off. All surfaces should be dusted off or wiped down, terminal boards checked for

loose connections, and all components examined for any evidence of overheating. Air filter media should be

inspected and replaced if necessary. High-pressure air, not over 20psi, can be used with discretion to dislodge

dust from inaccessible places.

5.3 SEMI-ANNUALLY AND ANNUALLY

Check all external RF connections for tightness, looking specifically for any discoloration, which might indicate a

loose inner connector, flange or sleeve coupling. Test the passive RF system with a transmission test set or

network analyzer, if one is available, to identify any potential problems with the antenna or line. Inspect and clean

contacts on all switches and contactors; carefully redress contact surfaces if pitted.

Check the operation of all interlocks including patch panel, dummy load, air and thermal switches and emergency

interlocks (if applicable).

5.4 TRANSMITTER COOLING SYSTEM

The air filter supplied with the transmitter is a pleated filter with a medium ASHREA efficiency rating. These filters

have special polyester coatings, designed to attract and hold very fine particles that may be in the airflow. This

filter should be inspected every month or more often, and replaced when dirty. Frequency of inspection and

replacement depends on the particular local environmental conditions.

All cooling fans in the transmitter are fitted with sealed bearings requiring no lubrication during the lifetime of the

motor. Access to the blower assembly is via the top of the transmitter.

PUB06-78 Rev 1 July 17, 2007 06-78-9 MXi Dual Pallet Operations and Mai ntenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

6 SERVICE

The MXi contains few user-serviceable parts; the modular surface-mount design makes module replacement

and/or factory repair the most efficient repair method.

The service most likely to be performed by users is the replacement of the fan array.

6.1 REMOVING THE FAN ARRAY

The MXi fan array consists of four 4” muffin-type fans which are attached to the mounting plate. The mounting

plate is secured to the bottom of the MXi chassis with five Phillips head screws.

Figure 12 Bottom View of MXi

1. Turn the MXi OFF.

2. Disconnect the AC power from the MXi.

3. Slide the MXi partially out from the mounting rack. Important: Ensure that the weight of the MXi is fully

supported.

4. With a Phillips screwdriver, remove the five mounting screws on the underside of the MXi. When

removing the last screw, be sure to hold the mounting plate in place.

5. Remove the mounting plate. The fan array is attached to the mounting plate and comes out with the plate.

Figure 13 Fan Array

PUB06-78 Rev 1 July 17, 2007 06-78-10 MXi Dual Pallet Operations and Maintenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

6.2 REPLACING THE ENTIRE FAN ARRAY

In the event of a fan failure, LARCAN recommends replacing the entire array, as all fans have a similar lifespan.

1. Remove the fan array as described in Section 6.1.

2. Slide the new fan array into the MXi. The power connection is aligned so that it connects when the

mounting plate is fully in place.

3. Insert and tighten the five mounting screws. Note: Screws only need to be snug; do not overtighten.

6.3 REPLACING A SINGLE FAN

1. Remove the fan array as described in Section 6.1.

2. Each of the four fans is attached to the mounting plate via two screw-and-nut assemblies. Remove the

screws and nuts and set aside.

Three-pin

wiring harness

connector

Screw-andnut

assemblies

Figure 14 Fan Attachment to Mounting Plate

3. Disconnect the three-pin wiring harness connection by gently sliding it back with a fingernail or small

plastic tool.

4. If necessary, carefully cut and remove the zip tie holding the wires to the fan frame.

5. Remove the defective fan and replace with a known good fan of exactly the same dimensions and

specifications.

6. Re-connect the three-pin wiring harness co nnection.

7. Re-fasten the two screw-and-nut assemblies holding the fan to the mounting plate.

8. If necessary, replace the zip tie holding the wires to the fan frame.

9. Replace fan array into MXi as described in Section 6.1.

PUB06-78 Rev 1 July 17, 2007 06-78-11 MXi Dual Pallet Operations and Maintenance

7 TEST EQUIPMENT SETUP

MXi201U OPERATIONS AND MAINTENANCE

Figure 15 Test Equipment Setup

PUB06-78 Rev 1 July 17, 2007 06-78-12 MXi Dual P allet Operations and Maintenance

MXi DUAL PALLET OPERATIONS AND MAINTENANCE

8 SPECIFICATIONS

Specifications are subject to change without notice.

8.1 ELECTRICAL

AC Line Input .....................................................................................................................90 to 264VAC, 50 to 60Hz

Power Consumption, black picture + 10% aural .................................................................................500VA (typical)

8.2 ENVIRONMENTAL

Ambient Temperature .....................................................................................................0°C to +45°C (0°F to 113°F)

Humidity .....................................................................................................................................................0% to 90%

Altitude .............................................................................................................................................2286 m (7500 ft.)

8.3 COOLING

Four 4” muffin fans push air through the heatsink and through the rear panel perforations.

8.4 DIMENSIONS

The Amplifier and Channel Processor chassis are standard 19" rack wide units.

Height