Larcan MXD5U Users Manual

TECHNICAL SERVICE MANUAL

MXD5U AMPLIFIER

LARCAN INC.

228 AMBASSADOR DRIVE

MISSISSAUGA, ONTARIO

CANADA L5T 2J2

PHONE: (905) 564-9222

FAX: (905) 564-9244

EMAIL: techservices@larcan.com

PUB09-03 Rev 0

16 April, 2009

MXD5U OPERATIONS AND MAINTENANCE

CONTENTS

1 AMPLIFIER ......................................................................................................................................................................1

2 CONTROLLER.................................................................................................................................................................2

2.1 CONTROL BOARD ASSEMBLY AND JUMPER SETTINGS ..................................................................................................2

2.2 REMOTE CONTROLS AND THE MXD5U FRONT PANEL ON/OFF BUTTON....................................................................4

2.3 EXTERNAL REMOTE CONTROL CONNECTIONS..............................................................................................................6

2.3.1 Remote Command Inputs.....................................................................................................................................6

2.3.2 Remote Telemetry Outputs...................................................................................................................................6

2.3.3 Remote Status Outputs......................................................................................................................................... 7

2.3.4 External1 Interlock..............................................................................................................................................7

2.4 EXTERNAL TRANSMITTER IN TERLOCK .........................................................................................................................8

3 AMPLIFIER INSTALLATION AND STARTUP..........................................................................................................9

3.1 BEFORE APPLYING AC TO THE UNIT ............................................................................................................................9

3.2 APPLYING AC TO THE UNIT..........................................................................................................................................9

3.3 BEFORE TURNING THE AMPLIFIER ON .........................................................................................................................9

3.4 AMPLIFIER ON SEQUENCE..........................................................................................................................................10

3.4.1 Tur ning ON the Amplifier.................................................................................................................................10

4 TEST AND TROUBLESHOOTING .............................................................................................................................11

4.1 BENCH TEST PROCEDURES .........................................................................................................................................11

4.1.1 Front-End Module Bench Test Procedure.........................................................................................................11

4.1.2 IPA1 Bench Test Procedure...............................................................................................................................11

4.1.3 Pallet 21B1751 Bench Test Procedure..............................................................................................................11

4.2 BASIC TROUBLESHOOTING TECHNIQUES ....................................................................................................................12

4.2.1 Amplifier Completely OFF.................................................................................................................................12

4.2.2 No RF Output.....................................................................................................................................................12

4.2.3 Output Reduced to 25%.....................................................................................................................................12

5 MAINTENANCE.............................................................................................................................................................13

5.1 DAILY.........................................................................................................................................................................13

5.2 MONTHLY...................................................................................................................................................................13

5.3 SEMI-ANNUALLY AND ANNUALLY .............................................................................................................................13

5.4 TRANSMITTER COOLING SYSTEM ...............................................................................................................................13

6 TEST EQUIPMENT SETUP..........................................................................................................................................14

7 SPECIFICATIONS .........................................................................................................................................................15

7.1 ELECTRICAL ...............................................................................................................................................................15

7.2 ENVIRONMENTAL.......................................................................................................................................................15

7.3 COOLING ....................................................................................................................................................................15

7.4 DIMENSIONS ...............................................................................................................................................................15

7.5 SHIPPING WEIGHT ......................................................................................................................................................15

FIGURES

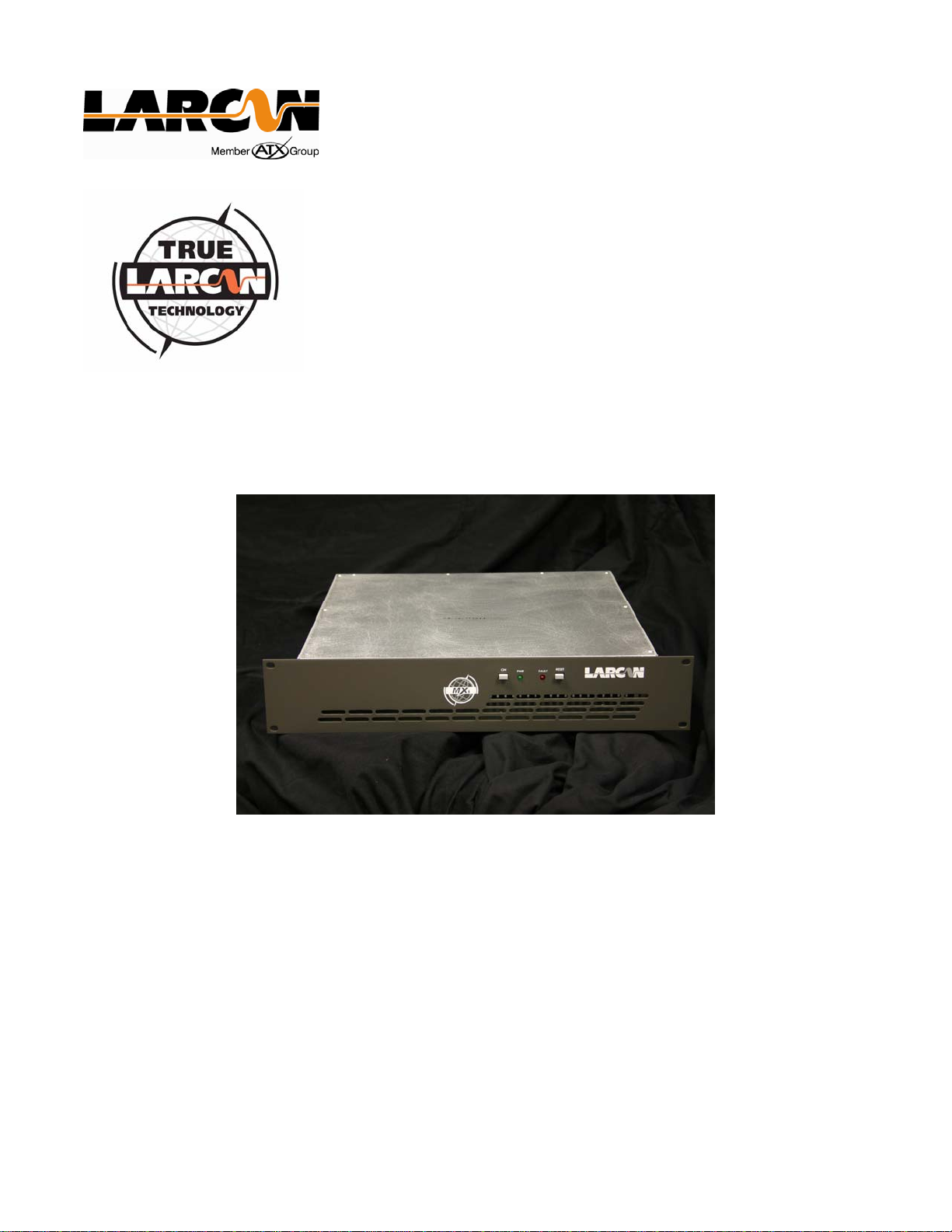

FIGURE 1 MXD5U AMPLIFIER HEATSINK ASSEMBLY..................................................................................................................1

FIGURE 2 CONTROLLER BOARD....................................................................................................................................................2

FIGURE 3 FRONT PANEL ...............................................................................................................................................................2

FIGURE 4 REMOTE COMMAND INPUTS..........................................................................................................................................6

FIGURE 5 REMOTE TELEMETRY OUTPUTS ....................................................................................................................................6

FIGURE 6 REMOTE STATUS OUTPUTS ...........................................................................................................................................7

FIGURE 7 REAR PANEL SHOWING INTERLOCK TERMINAL BOARD................................................................................................9

PUB09-03 Rev 0 April 16, 2009 09-03-i MXi005U Operations and Maintenance

MXD5U OPERATIONS AND MAINTENANCE

FIGURE 8 TEST EQUIPMENT SETUP.............................................................................................................................................14

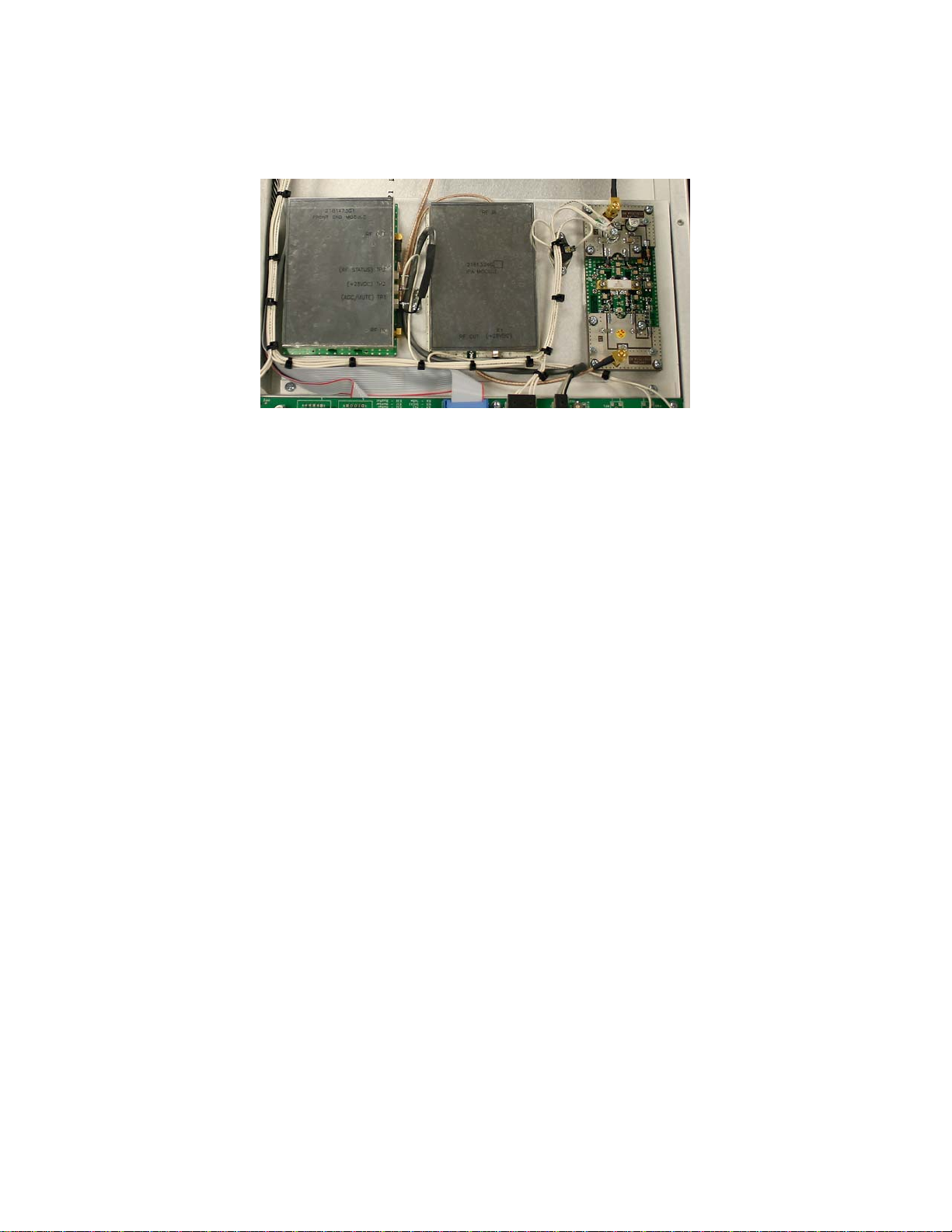

FIGURE 9 - FRONT END AMPLIFIER, MXD5U.............................................................................................................................16

FIGURE 10 - IPA ASSEMBLY, MXD5U.......................................................................................................................................17

FIGURE 11 - AMPLIFIER PALLET, MXD5U.................................................................................................................................18

FIGURE 12 MXD5U CONTROL BOARD ASSEMBLY ....................................................................................................................19

PUB09-03 Rev 0 April 16, 2009 09-03-ii MXi005U Operations and Maintenance

MXD5U OPERATIONS AND MAINTENANCE

1 AMPLIFIER

The RF section of the MXD5U Amplifier consists of a heatsink assembly that includes three cascaded broadband

amplifier modules and a directional coupler.

Figure 1 MXD5U Amplifier Heatsink Assembly

Also mounted on the heatsink is a thermal switch that protects the amplifier from over temperature conditions.

Figure 1 shows the layout of this assembly.

PUB09-03 Rev 0 April 16, 2009 09-03-1 MXD5U Operations and Maintenance

MXD5U OPERATIONS AND MAINTENANCE

2 CONTROLLER

The control board (Assembly 31C1971) is a single-circuit assembly that provides all of the control functions

required for the transmitter on a single circuit board. This board can be configured for a number of different

transmitter types, power levels, transmission standards and options.

Figure 2 Controller Board

The control board provides local front panel interface via ON/OFF and RESET buttons. The board implements

controls/status/telemetry for remote control through a rear panel connector that will interface to a typical remote

control systems (such as Moseley or Gentner). An RS232 serial port is also provided to allow the operator to

access the transmitter through an external computer (with the appropriate software). The control board has RF

detectors for forward and reflected power and all the circuitry to support AGC/VSWR/Cutback functions. Circuitry

to control and monitor the +28V power supply is also included on this board.

Figure 3 Front Panel

2.1 CONTROL BOARD ASSEMBLY AND JUMPER SETTINGS

Figure 9 shows the assembly diagram for the control board (Part No 31C1897A2) that performs all the control,

monitoring, RF detection and communication functions.

There are a number of jumpers on this board that are factory set and should not be altered in the field without

consulting Larcan Technical Services first. Changing the jumper settings may result in improper operation of the

transmitter.

The factory jumper settings are given here in the case that either a jumper is dislodged during shipping or has

been removed for any other reason.

Note: This circuit board is used for a number of transmitter models and a number of components and jumpers are

not installed or used for this transmitter model. We will only detail the jumpers that are used in the MXD5U.

E1 BDM Enable

Allows connection of the BDM program cable to the board

Setting = NORM for all MXD5U transmitters

PUB09-03 Rev 0 April 16, 2009 09-03-2 MXD5U Operations and Maintenance

MXD5U OPERATIONS AND MAINTENANCE

E2 Not used in the MXD5U transmitter

Setting = no jumper installed

E3 Not used in the MXD5U transmitter

Setting = no jumper installed

E4 Not installed in this assembly

E5 Front Panel ON/OFF button Mode

This jumper determines the function of the Front Panel ON/OFF button

If E5 is in the ‘INT’ position, Remote ON/OFF Controls are disabled, Local Controls Only

If E5 is in the ‘EXT’ position, Remote ON/OFF Controls are enabled, Local OFF Control Only

More detail on this function is given in Section XX of this manual

Setting = EXT for all MXD5U transmitters

E6 Transmitter Switching Interlock

This may have either a two pin header or may be permanently jumpered with bus wire

If there is a two pin header, then it requires a shorting jumper

If this is not shorted, then the transmitter will not turn ON.

Setting = Jumper installed

E7 Not used in the MXD5U transmitter

Setting = no jumper installed

E8 Not installed in this assembly

E9 Not installed in this assembly

E10 Not installed in this assembly

E11 Forward Power Sample Gain

Sets either High or Low gain from the DC sample received from the RF coupler

Set to obtain a voltage between 4.5 and 8V at TP2 for full power RF output

Can be either in the HI or LO position depending on channel and RF coupler

Typical Setting = LO for most MXD5U transmitters

E12 Not installed in this assembly

E13 Not installed in this assembly

E14 Not installed in this assembly

E15 Reflected Power Sample Gain

Sets either High or Low gain from the DC sample received from the RF coupler

Set to obtain a voltage between 4.5 and 8.0V at TP4 for 10% reflected power

Can be either in the HI or LO position depending on channel and RF coupler

Typical Setting = HI for most MXD5U transmitters

E16 AGC Disable

This jumper disables the AGC circuitry

DO not install this jumper. It is meant for factory setup

Setting = not Installed for all MXD5U transmitters

PUB09-03 Rev 0 April 16, 2009 09-03-3 MXD5U Operations and Maintenance

MXD5U OPERATIONS AND MAINTENANCE

E18 Direct Vswr Relay reset from the Remote Reset Command

This jumper allows the Remote Reset Command to directly clear the VSWR trip relay

Setting = Installed for all MXD5U transmitters

E19 Forward Power Detection Type

Setting = PK for all MXD5U transmitters

2.2 POWER CALIBRATION, AGC AND CUTBACK SETUP

HIGH VOLTAGE

RISK OF EXPOSURE TO VOLTAGES UP TO 260VAC

Use particular caution near the power supply’s transformer terminals.

The following setup is for the overall assembly of the MXD5U transmitter. It assumes that all individual

components in the assembly have been tested and biased, including the Control Board, the Amplifier Boards and

the Directional Coupler.

Note that the tests below are factory specific and therefore do not include the use of an Output Mask Filter. If one

is available, it can be inserted and setup performed as described in the procedure, with the following exceptions.

- perform power calibration at the filter output calibrating to a 5W level

- installation and alterations of test loads are done at the filter output, not transmitter RF Output.

PLEASE NOTE SAFETY WARNING ABOVE.

Connect a jumper wire across the terminals of the INT’K (External Interlock) terminal block at the rear panel. This

is temporary and must be removed when tests are completed.

Confirm Amplifier Bias

Terminate RF Out with 50R (min 20W rating). Apply no rf drive.

Turn ON Amplifier at front panel. Check for 28VDC at Amplifiers.

Check Amplifier Bias Currents: Front End Amplifier: 0.2-0.3A, IPA:1A, Amplifier Pallet: 1.0A

Power Calibration

Set R105 completely CCW. Ensure J8 is connected.

Remove all Control board jumpers except;

- E7 and E8 IN

- E2 to RS232

Monitor TP1. Adjust R39 for 0.02VDC.

Apply signal to get full power + filter losses at output. Approx 6W.

Check out-of-band shoulder levels at 6W for the broadcast channel before proceeding.

Set E5 to get 4-8V at TP1. Monitor TP2; adjust R46 for 4.00V.

Adjust R79 for 100% meter reading.

Increase Power to get 110%. Remove E7 and set R73 to get 4.0V on TP3. Meter should again read 100%.

PUB09-03 Rev 0 April 16, 2009 09-03-4 MXD5U Operations and Maintenance

Loading...

Loading...