Larcan DTR10SC User Manual

PUBLICATION TSM 20-399

TECHNICAL MANUAL

10 WATT VHF AMPLIFIER

FOR FRONTIER SERIES

DIGITAL TV TRANSMITTER/TRANSLATOR

LARCAN INC.

228 AMBASSADOR DRIVE

MISSISSAUGA, ONTARIO

CANADA L5T 2J2

PHONE: (905) 564-9222

FAX: (905) 564-9244

Rev 0 Feb 2014

CONTENTS

1 GENERAL .......................................................................................................................................................................... 3

1.1 SAFETY NOTICES .......................................................................................................................................................... 3

1.1.1 Beryllium Oxide Warning .................................................................................................................................... 3

1.1.2 Other Toxic Materials .......................................................................................................................................... 3

1.1.3 Dangerous Voltages ............................................................................................................................................. 3

1.1.4 Switch to Safety .................................................................................................................................................... 4

1.2 STATIC AWARENESS ..................................................................................................................................................... 5

1.3 TRADEMARK INFORMATION .......................................................................................................................................... 6

1.4 PRODUCTION CHANGES ................................................................................................................................................ 6

2 INTRODUCTION.............................................................................................................................................................. 7

2.1 AMPLIFIER CHAIN ......................................................................................................................................................... 7

3 MASK FILTER AND OUPTPUT .................................................................................................................................... 8

3.1 HELICAL RESONATOR BANDPASS FILTER ...................................................................................................................... 8

3.2 LOW POWER FILTER FOR HIGH BAND ........................................................................................................................... 9

3.3 LOW PASS AND NOTCH FILTER FOR LOW BAND ............................................................................................................ 9

3.4 RF DIRECTIONAL COUPLER ......................................................................................................................................... 10

4 RF POWER AMPLIFIER AND HEATSINK ASSEMBLY ........................................................................................ 18

4.1 PREAMPLIFIER ............................................................................................................................................................. 18

4.2 OUTPUT AMPLIFIER ..................................................................................................................................................... 18

5 METERING AND CONTROL ....................................................................................................................................... 24

5.1 SYSTEM ...................................................................................................................................................................... 24

5.2 RF DETECTORS ........................................................................................................................................................... 24

5.3 RF METERING BOARD CALIBRATION .......................................................................................................................... 24

5.3.1 Forward Power Meter Calibration - Zero Adjust .............................................................................................. 24

5.3.2 Reflected Power Meter Calibration - Zero Adjust ............................................................................................. 24

5.3.3 Forward Power Calibration .............................................................................................................................. 25

5.3.4 Reflected Power Calibration ................................................................................................ .............................. 25

TSM 20-399 Rev 0, Feb 2014 1 10W VHF Amplifier

LIST OF FIGURES

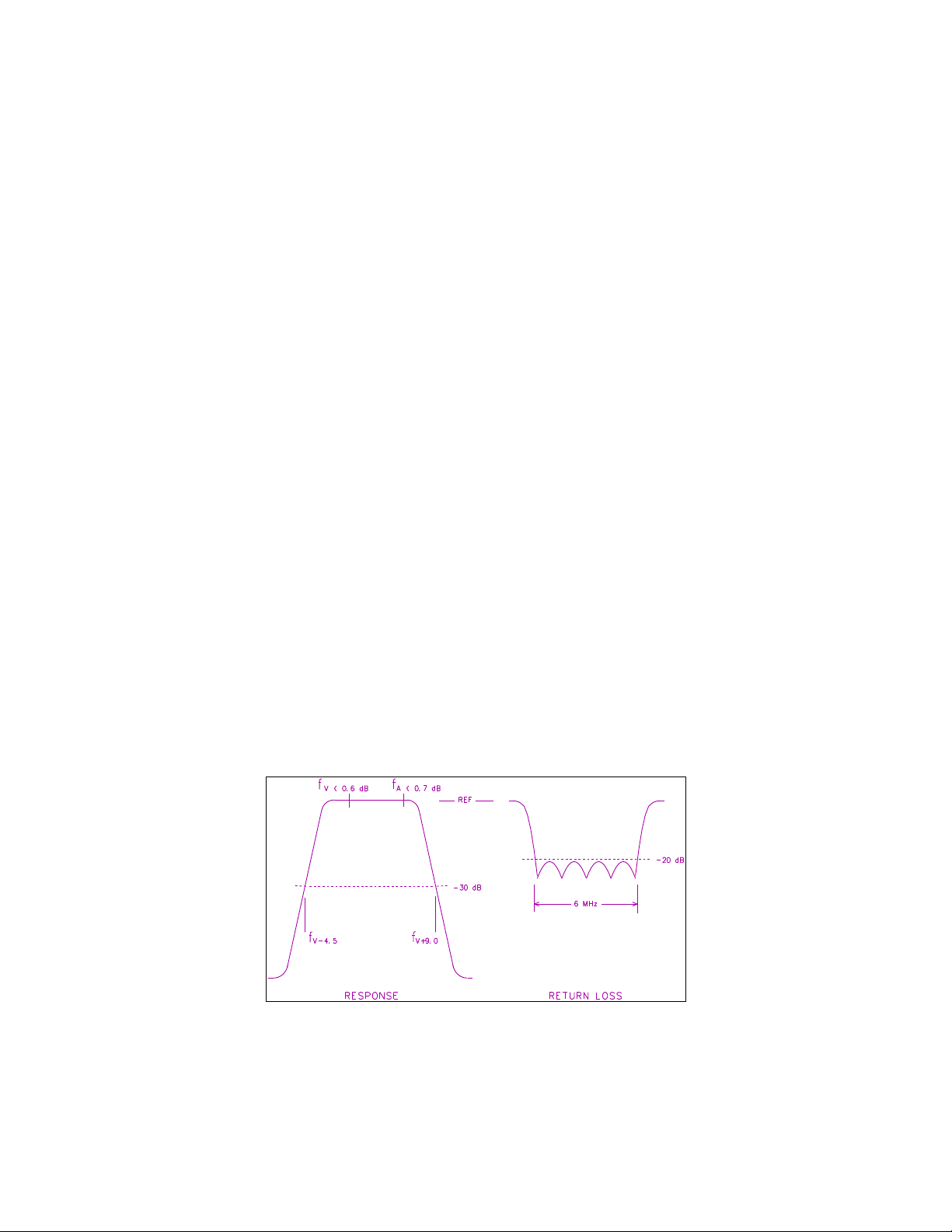

Figure 1 Bandpass Filter Response ...........................................................................................................................8

Figure 2 Bandpass Filter Schematic ...........................................................................................................................9

Figure 3 RF Directional Coupler Schematic .............................................................................................................11

Figure 4 Generic Helical Resonator Bandpass Filter Assembly ..............................................................................12

Figure 5: Filter Schematic .........................................................................................................................................13

Figure 6 Low Band Bandpass and Notch Filter Assembly ........................................................................................14

Figure 7 Low Band Bandpass and Notch Filter Schematic .....................................................................................15

Figure 8 RF Directional Coupler ...............................................................................................................................16

Figure 9 Low Band Coupler PC Board Assembly .....................................................................................................17

Figure 10: Preamplifier Assembly .............................................................................................................................19

Figure 11: Preamplifier Schematic............................................................................................................................20

Figure 12: Final Amplifier Assembly (sht 1) ..............................................................................................................21

Figure 13: Final Amplifier Assembly (sht 2) ..............................................................................................................22

Figure 14: Final Amplifier Schematic ........................................................................................................................23

Figure 15: System Block Diagram ............................................................................................................................26

Figure 16:Metering Board Assembly.........................................................................................................................27

Figure 17: Metering Board Schematic ......................................................................................................................28

TSM 20-399 Rev 0, Feb 2014 2 10W VHF Amplifier

1 GENERAL

1.1 SAFETY NOTICES

This section has been written to provide general guidance and information for the operation, maintenance, and service

personnel who are familiar with the hazards of working with high-powered and high-voltage electronic circuits. This

manual does not detail all of the safety precautions which should be observed when servicing this or any other

electronic equipment. Service by inadequately trained or inexperienced personnel can result in personal injury

or death and/or damage to the equipment.

Important: All personnel concerned with the servicing of equipment should be thoroughly familiar with standard first

aid procedures for the treatment of electrical burns and shock, including cardio-pulmonary resuscitation (CPR).

Use the “buddy” system, with one person performing the actual service and a colleague observing. The observer must

be familiar with the work being performed and within sight and sound of the person doing the work. The observer

should not be engaged in any other work or be otherwise distracted; he must be available instantly in case of

accident.

Always have the observer with you when you work on the transmitter.

1.1.1 Beryllium Oxide Warning

Internal thermal management in certain RF devices in this equipment is accomplished through the use of Beryllium

Oxide ceramic material. Beryllium Oxide is a hard white ceramic used as insulation for heatsinking of RF power

semiconductors. It is used between the silicon die of the device and the case, or flange, to both insulate and to conduct

heat to the heatsink through the flange of the transistor. Beryllium Oxide is a poison. Do not break open any RF power

transistors or otherwise dismantle them. In case of accidental breakage of devices, do not inhale the resulting

beryllium dust and avoid getting beryllium dust in your mouth. Do not let beryllium into your blood stream

through cuts or open wounds. Seek immediate medical attention if the dust enters your body in any manner. Avoid

cuts by wearing gloves while picking up the broken pieces. Be careful – do not inhale dust while replacing or emptying

vacuum cleaner filter bags and wash your hands thoroughly afterward. Wash your hands thoroughly after replacing RF

power devices. Dispose of defective RF power devices only through approved toxic waste facilities. Wear gloves when

picking up the pieces. Wash your hands thoroughly after replacing devices. Dispose of defective devices only through

approved toxic waste facilities.

Note: the ceramic cap that makes up the visible part of an RF device is not made from Beryllium Oxide. Beryllium Oxide

is only used internally to the device. While a broken ceramic cap can be sharp and cause cuts and abrasions and it is

therefore wise to handle it with care, the Beryllium Oxide is the substance used between the die of the device and the

internal case or flange.

When cleaning up after an accidental breakage, remember to wear a respirator mask to avoid inhaling the dust while

replacing or emptying vacuum cleaner filter bags, and to wash your hands well after servicing the vacuum cleaner. If

possible, use a wet vacuum, in which the dust gets trapped in water.

1.1.2 Other Toxic Materials

The non-metallic coverings of some coaxial cables used in this equipment are flammable and can transmit fire when

ignited. Other wire coverings are not capable of supporting combustion but any non-metallic covering when heated

sufficiently can emit dense smoke and acid gases, which can be highly toxic and often corrosive.

Solvents and glues can emit toxic vapors and can be flammable. Read and understand the directions on the containers

and ensure that they are used only in well ventilated locations.

1.1.3 Dangerous Voltages

LARCAN equipment has been designed to protect operating personnel from accidental contact with dangerous voltages,

by means of shields and covers. It is extremely important that any protective covering devices be kept in place at all times.

TSM 20-399 Rev 0, Feb 2014 3 10W VHF Amplifier

While all practical safety precautions have been adopted to safeguard personnel from possible injury, both supervisory

and operating personnel are urged to ensure that the safety rules detailed below are followed as an established routine at

all times. The following four Rules are the standard safety guidelines for working with and around transmitters:

Rule #1 KILL THE AC POWER BEFORE IT KILLS YOU

Under no circumstances should any person reach within the cabinets for the purpose of servicing or adjusting the

equipment without first disconnecting the AC power or without the immediate presence of another person

capable of rendering aid. The “buddy” system is encouraged for transmitter work.

Rule #2 DO NOT TAMPER WITH INTERLOCKS OR SAFETY SHIELDS

Under normal circumstances, no safety shield should be removed.

Rule #3 REMOVE PERSONAL JEWELRY WHEN WORKING ON THE EQUIPMENT

The mains AC power to this transmitter can deliver high currents capable of melting metallic tools or personal

jewelry, such as watch bands, bracelets, or rings. Accidental short circuits from such metallic objects can cause

an explosive shower of molten metal which can result in serious personal injury.

Rule #4 KNOW FIRST AID AND KEEP FIRST AID SUPPLIES AVAILABLE

Illustrated first aid instructions for the treatment of electrical shock and burns and CPR procedures should be

displayed in a prominent location adjacent to the equipment. In rendering first aid, the timeliness and

effectiveness of the treatment are vitally important to the recovery of the injured person.

Always have a colleague with you when you work on the transmitter and make sure both of you know first aid,

including cardio-pulmonary resuscitation (CPR). This is most important.

Without exception, all personnel should thoroughly familiarize themselves with the procedures involved. One person,

whose normal duties place him or her at the transmitter site often, should be given complete responsibility and authority to

ensure that first aid supplies are kept on site and maintained. Prominently display a list of emergency phone numbers.

This list should include the numbers of the nearest police, ambulance, hospital, doctor, fire department, paramedics,

poison control center, public works (roads) department, and the utility (power and phone) companies.

Do not try to work on the transmitter if you are tired or drowsy; you could make a fatal error in judgment. Antihistamines

and decongestants for colds or allergies, and some prescription medications, can make you drowsy; ask your pharmacist

if you do not know for sure. Avoid alcohol, even in moderate amounts, before working on the transmitter.

1.1.4 Switch to Safety

Here are some safety suggestions, based partially on the knowledge of experts familiar with high-powered tubed

equipment, and partially on the procedures used at a typical utility company and at a company which makes and tests

high voltage devices. A few of these suggestions apply primarily to factory environments and require some modification

to be applied in transmitter settings.

Our thanks to the Varian Corporation for sharing its "Electrical Safety Training Program" notes. Our thanks also to

Ontario Hydro for its information booklets dealing with high voltage.

MAKE SURE YOU HAVE IN PLACE A COMPREHENSIVE SAFETY PROGRAM AND HAVE DEFINED

PROCEDURES FOR EVERY ACTIVITY IN IT. KNOW FIRST AID AND CPR.

Use the “buddy” system, with one person performing the actual service and a colleague observing. The observer must

be familiar with the work being performed and within sight and sound of the person doing the work. The observer

should not be engaged in any other work or be otherwise distracted; he must be available instantly in case of

accident. Always have the observer with you when you work on the transmitter.

Keep the area neat and tidy, free of any interfering conductive material and free of any sharp objects. Remember that

reaction to a shock could cause you to strike nearby objects.

Avoid wearing loose clothing and personal jewelry such as rings, watches, and chains when working near energized

TSM 20-399 Rev 0, Feb 2014 4 10W VHF Amplifier

circuits. Make a habit of removing all jewelry and storing it in a safe place as soon as you enter the transmitter building.

Before beginning work, shut off all AC to the transmitter power supplies. Tag and lockout the switches. Your

safety routine must ensure that the person placing the tag and locking the switch is be the only person who removes it

and reactivates the switch. You might want to include the AC to the remote control as well, if there is any possibility that

a studio worker could unknowingly activate the transmitter while you are working on it. One way of ensuring that the

lockout "placer and remover" are the same person is to issue individual padlocks to each person on the transmitter

technical staff.

You might want to include your tower contractor's rigging crew in the list of people who are allowed to use tags and

padlocks. As an alternative, Dielectric™ makes a transmission line lockout switch intended for riggers to turn off and

lock out any RF before climbing over the antenna to replace light bulbs, etc.

Proper grounding is vital. Make ground inspection a part of your maintenance program; someone's life could depend

on it!

1.2 STATIC AWARENESS

Care must be taken at all times because this equipment contains static-sensitive MOS and FET devices. The following

information on static is particularly pertinent to CMOS and other MOS device handling.

1. It is important to avoid surroundings or situations in which static can be generated. The building floor should have

grounded conductive floor coverings or a grounded conductive mat placed on the floor in front of the bench. The

bench itself should also have a grounded conductive mat on which the equipment is placed. Anybody working on

the equipment should wear either a grounded wrist strap (preferable) or conductive overshoes. Vacuum cleaner

tools should all be conductive and grounded to avoid static from air motion. (Vacuum cleaners made for computer

servicing would be suitable). Soldering iron tips must be grounded. Use properly maintained soldering equipment

that has a three-wire grounding plug, verifying low path resistance between ground and the tip with an ohmmeter

every time this equipment is used.

2. The average person wearing rubber-soled shoes and walking across a woolen or synthetic carpet or untreated

vinyl tiled floor is able to generate voltages in excess of 15 to 20kV. Most MOS devices will suffer puncture of the

oxide insulating their gates, at 20 to 40V. Many CMOS devices are fabricated with built-in Zeners which will clamp

foreign voltages, but the amount of energy that must be dissipated can easily exceed the rating of this protection.

You should therefore assume that little or no static protection exists in a CMOS device and that you must provide

your own.

3. A typical unprotected gate of a CMOS logic IC has an input capacitance of about 5pF and can self-immolate at

20V, so the energy to destroy the IC is given by the expression W = CV2/2, where W is in watt-seconds, C is in

farads, and V is in volts. One watt-second is also known as a Joule. Substituting numeric quantities results in W =

-12

5 x 10

human body charged to 15kV, becomes W = 100 x 10

x 20 x 20 ¸ 2 = 1 x 10-9 Joule per gate. Stored energy in the approximately 100pF capacitance of the

-12

x 15000 x 15000 /2 = 11.25 x 10-3 Joule. Eleven and a

quarter million times more energy than is needed to destroy one gate input!

4. To avoid destroying CMOS devices, the human body must be grounded first. This is the reason for all the

"grounded surroundings" suggested in paragraph 1. Always ground yourself first, then the board.

5. Avoidance of static exposure of circuits and CMOS devices is easier. Ensure that board assemblies are always

kept in conductive bags or boxes when not in place in the equipment, and that spare CMOS ICs and devices are in

conductive chip carriers or plugged into conductive foam. Be careful about this point; many plastic foams can be

colored black, but may still be an insulator. Use an ohmmeter to be sure.

6. Identical statements to those made in the above paragraphs apply to RF power MOSFETs and although the gates

of these devices might appear to be considerably more robust than those of the average CMOS logic device, this

is due only to the much greater gate area and consequently greater input capacitance. The same order of

magnitude of gate oxide breakdown voltage exists for RF power FETs as for small CMOS devices, therefore use

the same care in handling.

TSM 20-399 Rev 0, Feb 2014 5 10W VHF Amplifier

1.3 TRADEMARK INFORMATION

All material in this manual is copyright LARCAN INC. and reproduction in whole or in part in any form for any purpose

other than exclusive use of the equipment owner, without prior written authorization from LARCAN INC., is prohibited.

Trademarks used in this document are the property of their respective owners and are mentioned in the text for

discussion purposes; any such mention is not necessarily an endorsement of the trademark or its owner.

Although the following pages contain as much information as is reasonably possible to provide, these instructions do

not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met. It is

assumed that fully competent technical personnel will be responsible for the maintenance and repair of the equipment

that is described in this manual. If more information is required, contact:

LARCAN INC.

228 Ambassador Drive,

Mississauga, Ontario, Canada L5T-2J2.

Telephone (905) 564-9222, FAX (905) 564-9244

www.larcan.com

1.4 PRODUCTION CHANGES

From time to time, it becomes necessary to make changes to the equipment described in this manual. Such changes are

usually made either to provide improved performance or to accommodate component substitutions necessitated by

vendor product availability. A revision number might follow the model or group number marked on the nameplate, chassis,

or circuit board; or on a parts list. In a parts list, an "R" a number indicates the parts list revision status. This revision

number should be quoted whenever contacting LARCAN Customer Service, especially if renewal parts are needed.

TSM 20-399 Rev 0, Feb 2014 6 10W VHF Amplifier

2 INTRODUCTION

This manual describes the LARCAN 10 Watt VHF amplifier designed for ATSC channels 2 through 13. Model part

number 21B2935G2 is for channels 7 through 13, 21B2935G1 for channels 2 through 6. These amplifiers are used in

the LARCAN MXi FRONTIER series transmitters and translators.

LARCAN all-solid-state 10W VHF amplifier were designed to operate conservatively at 10W average digital ATSC

power with superb performance, reliability and operating economy. This amplifier accepts an on-channel ATSC 8VSB

driving signal of about 1mW, as input to its RF chain.

The 10W amplifier and transcoder chassis are designed to fit in a single 19" customer-provided cabinet rack, and

require 8.75" (5RU) of vertical panel space for a complete transmitter or translator system.

The RF amplifier is entirely convection cooled. The simplicity of design, the deployment of all modular and other

subassemblies, and the use of standard readily available components, also enhance serviceability.

Forward power is displayed on an LCD readout on the front panel of the unit.

2.1 AMPLIFIER CHAIN

The RF output of the transcoder/modulator is fed to a conservatively designed broadband solid-state amplifier. This

amplifier requires no tuning or adjustment. Simplicity of operation, reduced maintenance costs and increased reliability

are a few of the major benefits derived from this amplifier.

The amplifier chain consists of two stages of amplification.

The preamplifier uses high gain, broadband, integrated circuit amplifier(s) operating Class A.

The PA stage consists of a pair of push-pull FETs, operating in Class AB as a linear amplifier. This amplifier is capable

of providing 10W of digital ATSC power at the output of the system Mask Filter.

The amplifier output is fed through a directional coupler, which provides a small sample of forward and reflected

output power for AGC, over drive and VSWR supervisory functions. The transmitter output then passes to the

bandpass filter and then the antenna system.

TSM 20-399 Rev 0, Feb 2014 7 10W VHF Amplifier

3 MASK FILTER AND OUPTPUT

3.1 HELICAL RESONATOR BANDPASS FILTER

LARCAN bandpass filter implementations generally consist of a cascaded series of coupled resonators. Some use

helical resonators; essentially a self supporting high Q coil (the helix) mounted inside a metallic shield enclosure. One

end of the coil is solidly connected to the shield enclosure and the other end is open circuited except for a small

trimmer capacitance to ground. The dimensions of the coil are critical to the frequency of operation; the assembly

behaves as though it were a quarter wave coaxial transmission line resonator. Several sizes of coils and enclosures

are necessary to cover the desired frequency ranges.

Figure 4 indicates the generic assembly of a coupled helical resonator bandpass filter.

The referenced drawing in Figure 4 is a low band filter. The high band unit is laid out identically and appears almost the

same, except the high band helixes have fewer turns of coarser winding pitch and their shield enclosure dimensions

are somewhat smaller.

The desired response shape is presented as Figure 1 below, and the filter electrical equivalents are presented on the

next page as Figure 2. When we examine the assembly, and take capacitances into account, the equivalent circuit of a

helical resonator becomes simply a parallel resonant LC tank circuit having low (trimmer) capacitance and relatively

high inductance. Adjustment of the trimmer produces a change of capacitance and the trimmer's moveable slug is

shaped to appear as a shorted turn, which alters the inductance of the helix.

Matching from and to 50 ohm transmission lines is accomplished with taps on the input and output helixes.

Coupling between sections is electrically a bridged T network of capacitors and is made up of the small capacitance

between the free ends of the coils, controllable by the amount of capacitance to ground that is introduced by the

coupling adjustment screws; the coupling is maximum when the screws are backed out fully from the enclosure.

Shielding partitions placed inside the enclosure between helixes, produce fixed area apertures which affect the

coupling capacitance between helixes. Helix #3 in the Figure 4 drawing has taller partitions on both sides of it, giving

lower capacitance and less coupling than the others.

For system use, the tuning and coupling is adjusted for a flat topped response with steep sides, and the desired shape

is such that fV - 4.5 MHz and fV + 9.0 MHz are both 30 dB down, but the carriers must be fV < 0.6 dB and fA < 0.7 dB

departure from flatness. Input and output return loss must be 20dB or better over the full 6 MHz bandwidth. These

sweep curves are shown below as Figure 1.

Figure 1 Bandpass Filter Response

There are nine screw adjustments and two I/O matching (with soldering iron) adjustments that need to be made

simultaneously, and all of them interact with each other. To make these adjustments properly, a network analyzer is

mandatory, and because this is an expensive piece of test equipment not likely to be available in the field, for this

reason we say the unit is not user-adjustable.

Our recommendation is to not adjust the filters at all.

TSM 20-399 Rev 0, Feb 2014 8 10W VHF Amplifier

Loading...

Loading...