LAPLACE INSTRUMENTS RF300 Mk II-A User Manual

Laplace Instruments Ltd

LAPLACE INSTRUMENTS LTD

RF300

Large Loop Antenna

(Van Leen Loop)

2 metre diameter

Mk II-A

USER MANUAL

Ver 2.00 October 2011

Serial number: XXXX

Page 1

Laplace Instruments Ltd

This Page intentionally blank

Page 2

Index

1.0 Introduction

2.0 Packing List

3.0 Assembly

4.0 Calibration loop

5.0 Calibration

6.0 Operation

Appendix

A. Calibration data

B. Latest changes to standards

Laplace Instruments Ltd

CISPR15 & CISPR16.

Page 3

Laplace Instruments Ltd

This Page intentionally blank

Page 4

Laplace Instruments Ltd

1.0 Introduction

The RF300 large loop antenna has been developed to meet the

requirements of EN55015: 2006 + A2: 2009, section 9.9.1, which

refers to CISPR16-1-4: 2007 + A1: 2008 section 4.6.1. This specifies

the limits for magnetic field induced current for luminaires with lamp

operating frequencies in excess of 100Hz.

Construction of the RF300 is as detailed in annex C of EN55016. This

antenna is fully compliant with the standard and details of the

calibration factors are included in this manual. These antenna factors

should be added to the results to obtain correct measurements that

can be compared directly with the limits.

Test setup and limits should be conducted as required by EN55015,

section 4.4.

The design of the RF300 is such that it can be readily erected and

provide a rigid and stable configuration for accurate and repeatable

measurements.

A calibration loop (RF300C) is available as an option if on-site

calibration is deemed necessary. The RF300C allows the calibration

loop to be used on all three axes and rotated within each as required

by the standards.

Page 5

Laplace Instruments Ltd

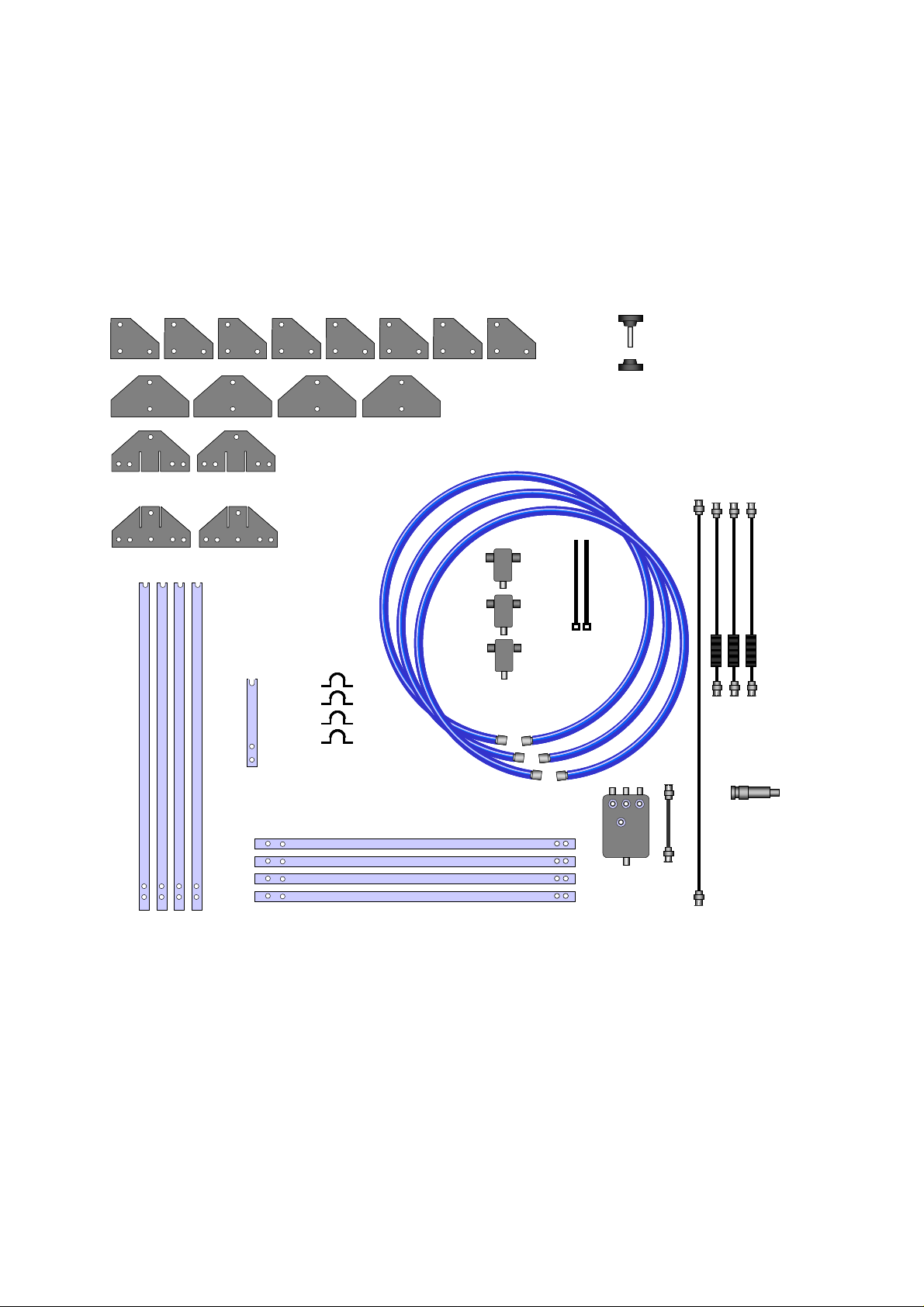

2.0 Packing List

On receipt of the RF300, check the contents of the packages against the

diagram shown in fig 1.

Qty 31 Grip

Qty 31 Grip

Screws and

Screws and

qty 31 grip nuts

qty 31 grip nuts

Qty 8 M6 x 12 screws

Qty 8 M6 x 12 screws

Qty 8 M6 nuts

Qty 8 M6 nuts

Qty 2 Plate B

Qty 2 Plate B

Qty 4

Qty 4

Plate C

Plate C

Qty 3 loops

Qty 3 loops

Qty 8

Qty 8

Plate D

Plate D

Qty 2 Plate A

Qty 2 Plate A

Qty 4

Qty 4

Corner

Corner

posts

posts

Central

Central

pillar

pillar

Qty 4

Qty 4

Saddle clips

Saddle clips

Qty 4 Base extensions

Qty 4 Base extensions

Qty 3 Loop

Qty 3 Loop

transducers

transducers

Qty 2

Qty 2

tiewraps

tiewraps

Identify each component and check for shortages.

Switch unit

Switch unit

with cable

with cable

Qty 3

Qty 3

loop

loop

leads

leads

10dB

10dB

attenuator

attenuator

Qty 1

Qty 1

5m cable

5m cable

Page 6

Quantity Item

2 Plates A

2 Plates B

4 Plates C

8 Plates D

3 Loop antennas (Blue)

4 Corner posts

4 Base extensions

Laplace Instruments Ltd

1 Central pillar

4 Saddle Clips

31 Grip screws (M10)

31 Grip nuts (M10)

8 M6 x 12 screws and nuts

3 Loop transducers (current sensors)

1 Switch Unit

1 Short BNC—BNC cable, patch cable

1 BNC—BNC cable (5m), output cable

3 BNC—BNC cable (1.5m), loop leads

1 10dB attenuator

2 Tiewraps

Page 7

Laplace Instruments Ltd

3.0 Assembly

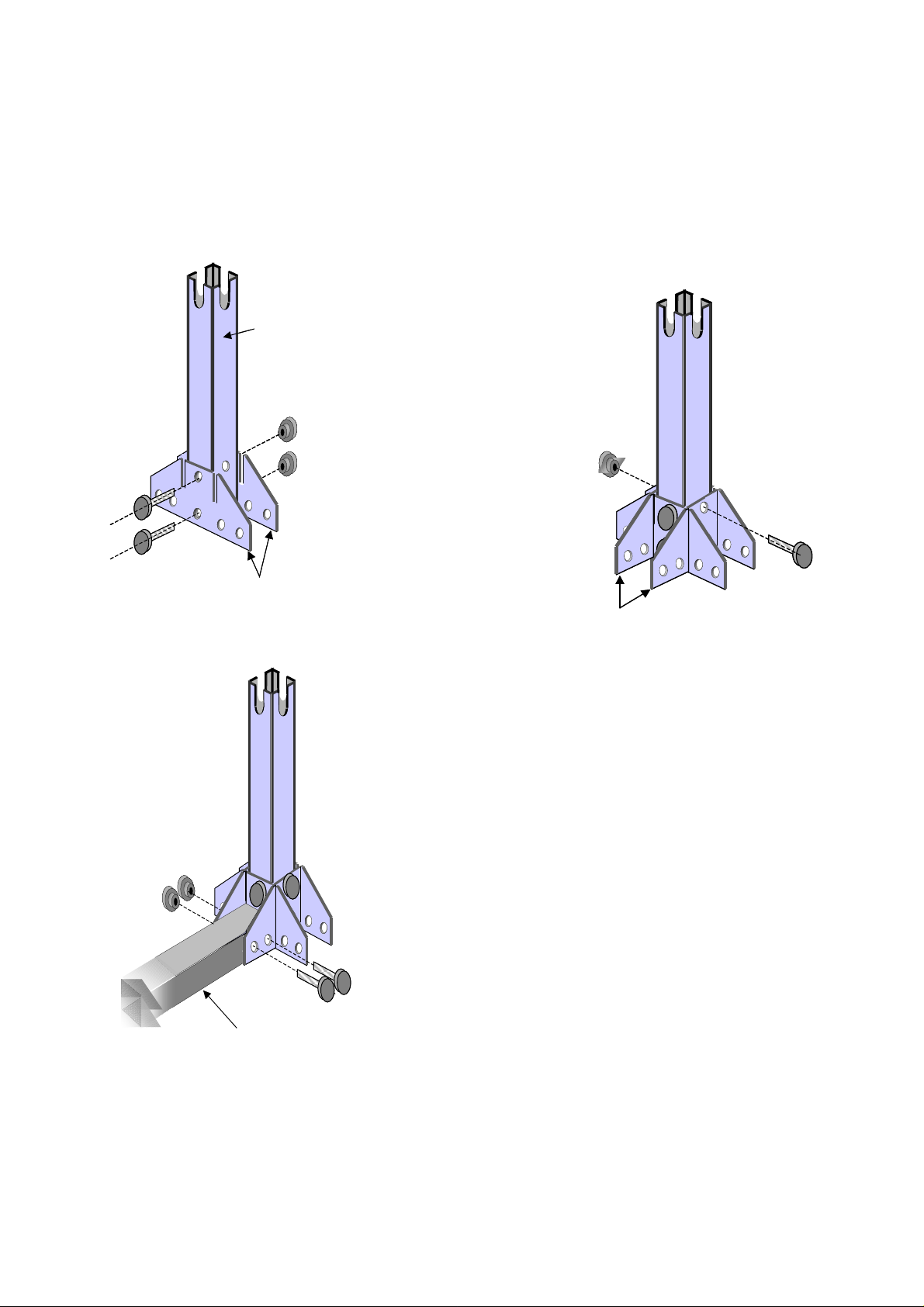

3.1 Stage 1 Central sub-assembly

Establish a clear area with a level floor clear of metallic structures and

having a 3m clearance height.

1(a)….Secure Plates A to

the central pillar using the

supplied grip screws..

Note that the plates have

tapered holes to mach the

taper on the grip screws,

so ensure that these

plates are assembled

correct way round.

1(b)….Secure Plates B as

shown in fig 3.

Plates BPlates B

Figure 3

1(c)…..Place the central post assembly in the

centre of the prepared area and add the 4 base

extensions, each using 2 grip screws.

Plates A

Plates A

Figure 2

Horizontal strut

Repeat in 4 places

Figure 4

Central pillar

Central pillar

Page 8

Corner

Corner

post

post

Figure 5

Plate C

Plate C

Join posts to

Join posts to

horizontal struts

horizontal struts

Laplace Instruments Ltd

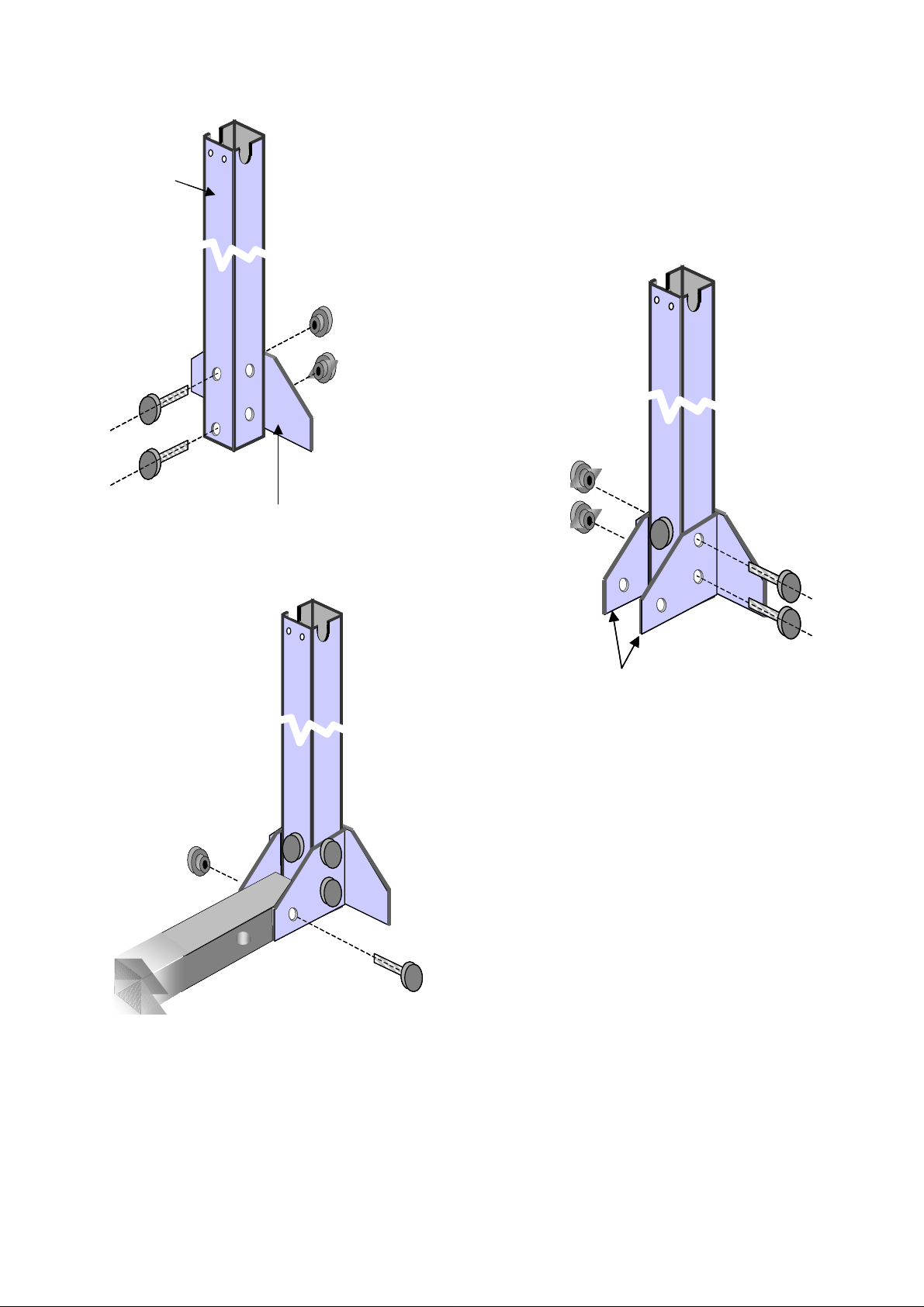

3.2 Stage 2 Corner post assembly

2(a) ….Add plate C to the base of each corner

post using 2 grip screws. Repeat for the other

corner posts. Note that the plate is fitted on the

opposite side to the 2 mounting holes at the top

of the post.

2(b)…. Add the 2 Plates

D to each corner post

as shown. In Fig 6.

Plates DPlates D

Figure 6

2(c.)…..Secure the corner posts to the

outer end of each base extension.

Figure 7

Page 9

Laplace Instruments Ltd

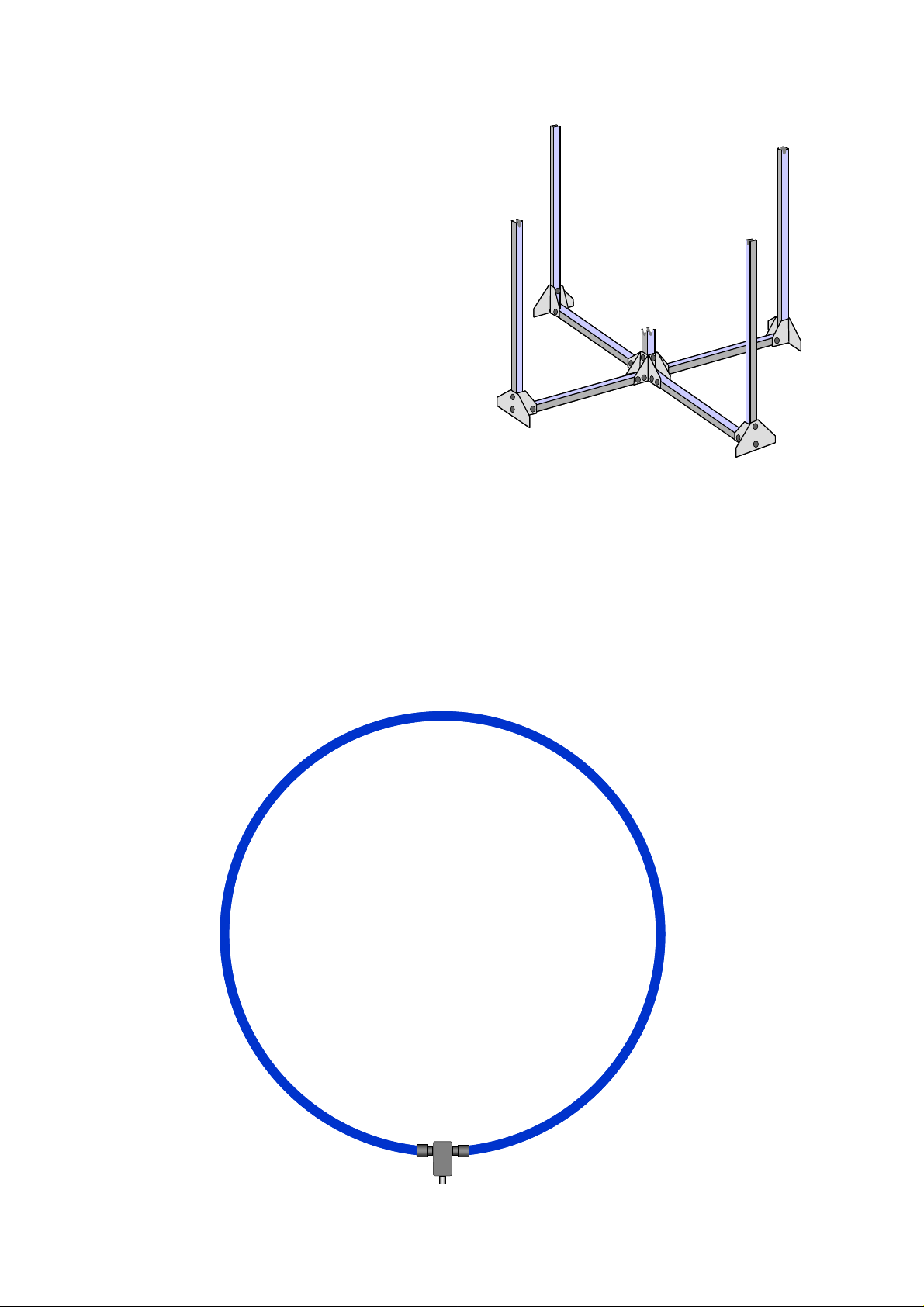

3.3 Assembly of Loops

The frame should now look like that

shown in Figure 8.

The next steps are to add the loops.

Figure 8

3.3(a) The configuration of these loops is as shown in fig 9 and fig 10.

The connectors on each end of the loop are mated with the sockets either

side of each loop transducer. The retaining ring on each connector needs

to be screwed firmly to the socket but take care. These rings will bind

and be difficult to turn unless the loop is aligned properly. Force is not

necessary, simple jiggle the loop into alignment and the ring will turn

easily.

Figure 9

Page 10

Loading...

Loading...