LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 1

LAPLACE INSTRUMENTS LTD

RF300 LARGE LOOP ANTENNA

USER GUIDE

Serial Number 9072

Issue 5 May 2010

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 2

INDEX

Introduction 3

Packing list 3

Assembly 5

Calibration loop 12

Calibration 13

Operation 14

In use with the

EMCEngineer software 14

Appendix A...Calibration data 16

Appendix B… CISPR16 20

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 3

Introduction

The RF300 large loop antenna has been developed to meet the requirements of

EN55015, section 9.9.1, which refers to CISPR16-1-4, section 4.6.1. This specifies the

limits for magnetic field induced current for luminaires with lamp operating

frequencies in excess of 100Hz.

Construction of the RF300 is as detailed in annex C of EN55016. This antenna is fully

compliant with the standard and details of the calibration factors are included in this

manual. These antenna factors should be added to the results to obtain correct

measurements that can be compared directly with the limits.

Test setup and limits should be conducted as required by EN55015, section 4.4.

Packing List

On receipt of the RF300, check the contents of the packages against the diagram shown

in fig 1.

Identify each component and check for shortages.

See also list overleaf.

Qty 4 Corner posts Qty 3 loops

Qty 4 Base extensions

Qty 3 Loop

transducers

Switch unit

with cable

Central pillar

Qty 4 Post stabilisers

Qty 8 long +

8 short wood

screws

Qty 5

tiewraps

10dB

attenuator

Qty 1 5m

cable

Qty 3

loop

leads

Qty 4 Corner posts Qty 3 loops

Qty 4 Base extensions

Qty 3 Loop

transducers

Switch unit

with cable

Central pillar Central pillar

Qty 4 Post stabilisers

Qty 8 long +

8 short wood

screws

Qty 5

tiewraps

10dB

attenuator

Qty 1 5m

cable

Qty 3

loop

leads

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 4

Qty Item

3 Large loops fitted with connectors at each end

4 Corner posts

4 Base extensions

4 Post stabilisers

1 Central pillar

1 Switch unit

1 Short co-ax patch cable fitted with BNC connectors

3 Loop transducers

5 Tiewraps

8 1¾ x 8 wood screws

8 1” x 8 wood screws

1 5m BNC - BNC lead

3 2m BNC-BNC lead fitted with ferrite absorbers

1 10dB in-line BNC attenuator

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 5

Assembly

1. Establish an appropriate area to erect the RF300. This needs to be a clear area at

least 4m square with a flat floor and a ceiling height of at least 3m.

2. In the centre of this area, stand the central pillar and fit the base extensions as shown

in fig 2.

Figure 2.

Base assembly.

Set centre and base

extensions

Figure 2.

Base assembly.

Set centre and base

extensions

3.Attach corner post stabilisers with 2 short brass screws as shown in fig 3a and then

slot the corner posts into the square hole at the end of each base. Secure each with the

long brass wood screws as shown in fig 3b.

Figure 3a

Screw post

stabilisers to

post bases

Figure 3a

Screw post

stabilisers to

post bases

Figure 3b

Secure posts to

base extensions

Figure 3b

Secure posts to

base extensions

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 6

Figure 4

Loop assembly

Figure 4

Loop assembly

4. Prepare the 3 loops. The configuration of these loops is as shown in fig 4 and fig 5.

The connectors on each end of the loop are mated with the sockets either side of each

loop transducer. The retaining ring on each connector needs to be screwed firmly to the

socket but take care. These rings will bind and be difficult to turn unless the loop is

aligned properly. Force is not necessary, simple jiggle the loop into alignment and the

ring will turn easily.

Screw loops connectors into

transducer sockets. Do not

force, adjust alignment to ease

tightening

BNC outlet for cable to selector

unit

Figure 5

Loop transducer connection

Screw loops connectors into

transducer sockets. Do not

force, adjust alignment to ease

tightening

BNC outlet for cable to selector

unit

Figure 5

Loop transducer connection

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 7

5. The first loop to mount is the horizontal loop. To mount the loops, at least two

people are required. Do not try to do this single handed....it will only end in tears.

Mount the loop in the recesses at the top of each corner post with the loop transducer

close to (within 5 cm) of a corner post. See fig 6.

Slight ‘drooping’ of the loop between the posts has no effect on the performance of the

antenna.

Rest horizontal loop

on top of posts

Position transducer

close to one post

Figure 6

Mounting of horizontal loop

Rest horizontal loop

on top of posts

Position transducer

close to one post

Figure 6

Mounting of horizontal loop

6. The second loop is now fitted. Figs 7, 8, 9 show the details.

This loop is fitted inside the first (horizontal) loop, orientated so that it fits in the lower

‘slot’ in the central pillar (fig 9) and is held between the ‘ears’ on the corner posts (fig

8). Arrange the loop so that the transducer is within 20 cm of the central pillar.

For the moment, the loop will sag and generally not hold its shape. This will be

resolved later.

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 8

Install first vertical loop.

Note orientation of

central post. Position

transducer near bottom

Figure 7

Mounting of second

loop

Install first vertical loop.

Note orientation of

central post. Position

transducer near bottom

Figure 7

Mounting of second

loop

Figure 9

Central post configuration

Second loop

Third loop

Figure 9

Central post configuration

Second loop

Third loop

Add tywrap as

shown

Figure 8

Attachment of loops to

posts

Add tywrap as

shown

Figure 8

Attachment of loops to

posts

Add tywrap as

shown

Figure 8

Attachment of loops to

posts

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 9

7. The final loop is now fitted INSIDE the other two. See fig 10.

This fits in the upper slot in the central pillar, between the corner post ‘ears’ and under

the other vertical loop at the top. Again arrange the loop so the transducer is close to

the central pillar.

Adjust loops to

optimum

configuration and

add tywrap at peak

Figure 10

Mounting of third loop

Adjust loops to

optimum

configuration and

add tywrap at peak

Figure 10

Mounting of third loop

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 10

8. The loops can now be adjusted for best shape and position. Generally the vertical

loops will tend to sag into the lower half of the antenna. These are held up in position

by using the tiewraps as shown in fig 8 on each corner post to take some on the weight

of the loop. The top of the vertical loops can be adjusted for best shape and the two

loops fastened together with the fifth tiewrap. With care, the tiewraps can be adjusted

to produce reasonable circles for each loop.

Note that the exact shape is not critical. Deviation from perfect circles is inevitable but

this has no significant effect on antenna performance. EN55015 states in section 7.2

that even the position of the UUT in the antenna is not critical.

9. Within the loop, construct a wooden stand or table to suit the products to be tested.

This is not included with the RF300 because it needs to be matched to individual

customers requirements. The stand should hold the product roughly central within the

loop.

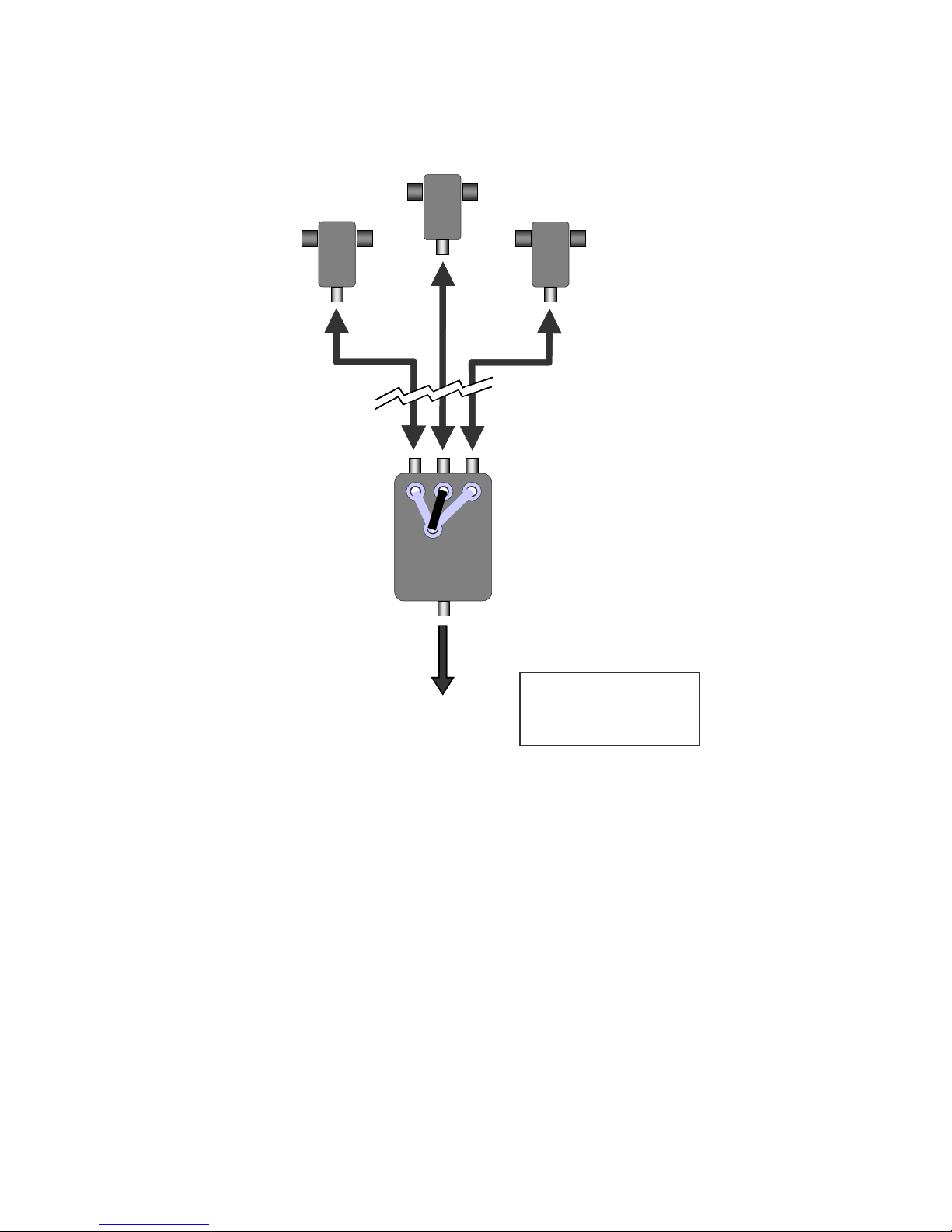

10. Connect the loop transducers to the switch unit as shown in fig 11. The 3

transducer cables are identified by having thick RF absorber filters along their length.

Fit the cables so that these filters are nearest to the switch unit.

The switch unit is intended for floor mounting, or may be mounted on a suitable table

if preferred. The short co-ax cable acts as a patch cable to switch each input, one at a

time, to the output.

The output from the switch unit is connected direct to the analyser or receiver.

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 11

Figure 11

Connections to

selector unit

To analyser

Horiz

(X)

Vert

(Y)

Vert

(Z)

Loop transducers

Ferrite absorbers are

at this end of cables

Select loop

using link cable

Figure 11

Connections to

selector unit

To analyser

Horiz

(X)

Vert

(Y)

Vert

(Z)

Loop transducers

Ferrite absorbers are

at this end of cables

Select loop

using link cable

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 12

Calibration loop

The RF300C calibration loop is manufactured to comply with CISPR16.

Full details of the use of this loop are provided in this standard.

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 13

Calibration data

See appendix A

The calibration data for each loop is virtually identical. The following details therefore

apply to all three axes, although full data for each axis is given in the appendix.

For reference, the ‘ideal’ curve is shown in graph 1. This is taken directly from

EN55016, annex C, Figure C8.

The antenna factor data for the RF300 are also given.

This ‘antenna factor’ correction data effectively converts the output from the RF300

(measured in dBuV) directly to dBuA.

The data can be used with any analyser or receiver capable of EMC measurements.

The estimated measurement uncertainty is 3dB.

For a detailed explanation of the calibration of the RF300 and discussion of changes to

CISPR15 (EN55015) and CISPR16, see appendix B

If using the SA1002 or SA3000 analyser:

The RF300 is listed under the normal Inputs menu. Just select this device and the

software automatically applies the appropriate correction factors so that the trace reads

correctly in dBuA and can be compared directly with the EN55015 limits.

Further details are given overleaf.

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 14

Operation

Details of the measurements and limits are given in EN55015, section 4.4. A copy of

this should be consulted if performing compliance tests.

The UUT should be mounted on a wooden frame or table in the centre of the antenna.

The position is not critical.

Connecting cables to the EUT should leave the volume enclosed by the loops in such a

way as to be kept away from the loops to avoid capacitive coupling. See Fig C6 in

CISPR16.

Each axis (loop) should be measured in turn. Each should meet the requirements of the

standard. The loops are individually selected by connecting the short patch lead to the

appropriate input socket as shown in fig 11.

Measurement with the SA1002 or SA3000 and EMCEngineer Windows software.

1. Select the RF300 item under the input menu. The vertical scale will indicate units

of dBuA. (If this item is not available, you need a later version of the software.

Contact your supplier)

2 Under the limits menu, select the EN55015 ......... 2m loop antenna limit line.

3. Connect the switch unit to the analyser input.

4. With the UUT switched off, check the background signal level. At frequencies

below 1MHz, the background can be very strong. If strong signals do exist, check that

the analyser is not in compression by changing the input attenuator setting on the

analyser and comparing scans. Apart from the base line, the traces should overlay. If

this happens then it is OK to use the analyser with that attenuator setting. If not,

increase the attenuation and try again.

5. If the background is strong, it is advisable to either find a ‘quieter’ location or screen

the room.

6. Switch the UUT on. Check the levels of signal over the background levels using the

techniques used for conventional radiated testing as described in the user guide.

The levels displayed are fully compensated for the RF300 characteristics and can be

compared directly with the limit lines.

7. ALWAYS check for compression (overload) when taking measurements. The

amplitude of the reading on the screen cannot be used directly as a guide for

compression because the readings have been adjusted for the RF300 characteristics.

If it is suspected that the signals are too strong even with the attenuator switched in,

install the 10dB attenuator in the input lead to the switch unit. This additional

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 15

attenuator can be automatically compensated for in the software by adjusting the preamp settings on the screen.

8. If the background and the product is ‘quiet’, and especially at frequencies above

20MHz, use 0dB attenuation.

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 16

APPENDIX A

CALIBRATION DATA

1. CISPR16 ‘ideal’ plot

2. Calibration data.

3. RF300 actual sensitivity plots and RF300 correction

plot (Antenna Factor)

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 17

EN55015 Standard antenna response

CISPR16 LLA (2m diameter)

60

65

70

75

80

85

90

95

100

105

110

0.01 0.1 1 10 100

Freq (MHz)

Validation factor (dBohms)

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 18

Calibration data

Calibration sources

Laplace Instruments Ltd, RF300C calibration loop to CISPR16, annex C5.

Laplace Instruments Ltd, SA1002 Spectrum analyser s/n 1010

Calibration: Laplace: 16.03.2009

Marconi TF2016A signal generator, s/n 118032/004

Calibration: Checked against Marconi TF2019A, s/n 118449-169

Advantest R4131D calibrated by Schaffner, 20.11.02 and checked against

Marconi TF2019A, s/n 118449-169

Marconi TF2019A, serial number 118449-169, calibrated by Industrial

Calibration Ltd, 22.06.07

Freq.

Calibration

Freq. EN

MHz 9072A 9072B 9072C MHz Average Max Min Range Freq 55015 Freq A.F

0.01 37.68 37.68 36.68 0.01 37.35 37.68 36.68 1.00 0.01 46 0.01 8.65

0.04 48.68 47.68 48.68 0.04 48.35 48.68 47.68 1.00 0.04 46.5 0.04 -1.85

0.10 55.68 55.68 55.68 0.10 55.68 55.68 55.68 0.00 0.10 46.5 0.10 -9.18

0.20 62.68 62.68 62.68 0.20 62.68 62.68 62.68 0.00 0.20 46.5 0.20 -16.18

0.50 69.68 69.68 69.68 0.50 69.68 69.68 69.68 0.00 0.50 46 0.50 -23.68

1.00 71.68 71.68 71.68 1.00 71.68 71.68 71.68 0.00 1.00 45.5 1.00 -26.18

2.50 71.68 71.68 71.68 2.50 71.68 71.68 71.68 0.00 2.50 44 2.50 -27.68

5.00 67.68 67.68 67.68 5.00 67.68 67.68 67.68 0.00 5.00 41 5.00 -26.68

10.00 62.68 62.68 62.68 10.00 62.68 62.68 62.68 0.00 10.00 37.5 10.00 -25.18

15.00 60.68 59.68 59.68 15.00 60.01 60.68 59.68 1.00 15.00 35 15.00 -25.01

20.00 55.68 55.68 55.68 20.00 55.68 55.68 55.68 0.00 20.00 32.5 20.00 -23.18

25.00 55.68 55.68 55.68 25.00 55.68 55.68 55.68 0.00 25.00 30.5 25.00 -25.18

30.00 52.68 52.68 53.68 30.00 53.01 53.68 52.68 1.00 30.00 28 30.00 -25.01

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 19

Actual output plots for the loops

Output

Output RF300 s/n 9072

0

10

20

30

40

50

60

70

80

0 0 1 10 100

Frequency (MHz)

Output (dBuV)

Antenna factor

Antenna factor s/n 9072

-30

-25

-20

-15

-10

-5

0

5

10

15

0.01 0.10 1.00 10.00 100.00

Frequency (MHz)

Antenna factor (dB)

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 20

Appendix B

Technical Report Laplace Instruments Ltd January 2010

RF300 Large loop antenna, an analysis of changes to the standards

These changes are due to the amendments to CISPR15 and CISPR16

The latest versions are now …..

CISPR15:2006 + A2:2009 and

CISPR16-1-4:2007 + A1:2008

The key changes related to LLAs are:

1. Sections related to the construction and specification of LLAs are moved from CISPR15 to

CISPR16. Note that in the new CISPR15, the requirements for the LLA are referred to Section

4.7.1 in the new CISPR16, which does not exist! It seems that the reference should be to Section

4.6.1. The same error is repeated in CISPR16 which again refers in Annex C to the non-existent

section 4.7.

2. The definition of the calibration data has been re-defined.

Note 1.

The details of the LLA were given in Annex B of CISPR15. These are now transferred to Annex C of

CISPR16. Most of the content has remained the same, but Table 1 summarises the changes.

Previous

CISPR15

New

CISPR16

Notes

Significant changes

Annex B Annex C Description, construction and

validation of LAS

Both annexes combined into one.

Annex C

Clause B1 Clause C1 Introduction Loop antenna named LAS (Loop

Antenna System

Clause B2 Clause C2 Construction of LAS Additional requirements for cables

and connectors.

Clause C3 Construction of loop Information previously included with

diagrams now included in text. Note

low R for inner conductor is required.

Clause B3 ----- Positioning of the LAS Requirement for minimum distance to

nearby objects,…… not included in

new CISPR16

Clause B4 Clause C4 Validation New definition for validation factor.

(see below).

Figure B1 Figure C1 General view None

Figure B2 Figure C2 Position of slits None

Figure C3 Construction of slits None

Figure C5 Metal box for current probe None

Figure B3 Figure C4 Example slit construction None

Figure B4 Figure C8 Validation factor Converted from dBuA to dB(Ω). See

below.

Figure C7 Positions of calibration loop None

Figure C9 Construction of calibration

loop

None

Figure C1 Figure C11 Sensitivity vs diameter None

Figure C2 Figure C10 Conversion factors between

loop current and magnetic

field strength at a distance.

Factors for magnetic field with

electric field added. Factors for

distance 30m removed.

LAPLACE INSTRUMENTS LTD RF300 USER GUIDE

Page 21

Note 2

CISPR15 gave the verification data as a plot of loop current in dBuA vs frequency for the standard test

signal (1V, open circuit voltage with a source impedance of 50ohm). This seems to be a straightforward

method, especially as the limits are quoted in dBuA, so it’s a direct correlation between the calibration

loop and the limits.

CISPR16 is essentially the same information, but presented differently. It specifies the relationship

between the source voltage (1V, as specified above) and the output current in the loop as measured by

the current probe. Note that the current probe has a transfer characteristic of 1V/A. The relationship

between volts and current is ohms, hence the use of dB(ohms) as the ‘validation factor’.

The result is therefore a conversion factor scaled in dB(Ω) to convert current to voltage,

CISPR16 defines the validation factor dB(Ω) = 20*log(Vs/Ii) where Vs is the source voltage and Ii is

the loop current.

Vs = 1V = 1,000,000uV

Under ‘old’ CISPR15, for Ii @ 100KHz = 46dBuA = 200uA

So the new CISPR16 value is 20*log(1000000/200) = 74 dB(Ω)

and

Old CISPR15 for Ii @ 30MHz = 29dBuA = 29uA

So the new CISPR16 value is 20*log(1000000/29) = 91 dB(Ω)

These calculations confirm the relationship between the CISPR15 plot and the CISPR16 validation

factor.

The plots in the standards assume a current probe with a 1V/A transfer function. Such probes are ‘active’

but provide a flat frequency response. The RF300 uses passive probes which have a non-flat frequency

response. This is not important if the probe is ‘inside’ the calibration loop and has a linear transfer

function with amplitude. These factors hold true for the probe that is used. So the RF300 antenna uses an

antenna factor correction to produce a calibration that agrees with the validation factor. This antenna

factor is supplied with each antenna, and is equivalent to the correction factors as supplied with all EMC

antennas, test cells, LISNs and other types of transducer.

Using the antenna factor data with the RF300 enables the output to be compared directly with the limits

as specified in EN55015.

Loading...

Loading...