Lapis Roll Laminator PL-LR, Roll Laminator PL-RL User Manual

Passport-Laminator

User Manual

Lapis Drucktechnologie GmbH

Weinheimerstr. 62

68309 Mannheim

Tel.: +49(0)621/7363866

Fax.: +49(0)621/7363868

Email: info@lapis-online.de

Version: S20/V3.42

Drucktechnologie GmbH

1

Table of contents

1. General information...........................................................5

Product description................................................................5

Symbols and conventions....................................................... 6

Intended use........................................................................6

Safety information.................................................................6

Environmental information......................................................7

2. Connection and commissioning..........................................9

Device overview....................................................................9

Unpacking and setting up the device........................................10

Mounting the feed table.........................................................10

Connecting the device............................................................11

Connecting to the power supply.........................................11

Connecting to a computer.................................................11

Switching on the device.........................................................11

Inserting film.......................................................................12

Inserting a document............................................................13

3. The control panel...............................................................15

Control panel configuration....................................................15

Key functions in the start menu..............................................15

Key functions in the configuration menu..................................16

Device statuses....................................................................17

4. Configuration.....................................................................19

Configuration via control panel................................................19

Configuration via interface......................................................21

Configuration settings............................................................23

Test....................................................................................32

System................................................................................33

5. Control...............................................................................35

Control commands................................................................35

Status query........................................................................36

3

1

6. Troubleshooting................................................................37

Types of errors and elimination................................................37

Error messages......................................................................38

7. Service...............................................................................41

Firmware upgrade.................................................................41

AVR programming protocol.....................................................42

8. Certifications......................................................................45

EG-Konformitätserklärung....................................................... 45

Safety Standard FCC..............................................................46

EMC Zertifikat.......................................................................47

4

General information

Product description

The passport laminator laminates all pages of the passport including the inside of

the cover. A wafer-thin holographic film is applied to the paper surface via a

temperature-controlled heated roller. The laminator can be integrated into an

automatic personalisation system or can function as an independent station. The

passport is fed in from the left, right or front depending on the device

configuration.

Symbols and conventions

The following symbols and conventions are applied in this user manual.

The symbol indicates parts of the device that are hot and should not

be touched.

The symbol indicates important information, which must be

observed. A failure to do so may lead to injuries.

Good advice or information regarding important working steps.

Ready

Text in monospace type indicates contents on the display.

Taste

Framed text corresponds with a key on the control panel.

5

1

1

1

Intended use

The device is constructed in accordance with the latest engineering practice and

per the recognised safety regulations. Nevertheless, danger to the life and limb of

the user or third parties or damage to the device and other property may occur

when using it.

The device must be operated exclusively when in a technically faultless condition,

as intended, with an awareness of safety and potential hazards, and in accordance

with the operating manual.

The device is intended exclusively for laminating suitable materials. Any other use

or any use exceeding this is considered unintended use. The manufacturer shall

not be liable for any damage that results from misuse. The operator is solely

responsible for the resultant risk.

Safety instructions

The device is designed for an AC mains supply from 100 V to 240 V. It must be

connected exclusively to sockets with a grounded conductor contact.

The device must be operated exclusively in a dry environment and must not be

exposed to any moisture (spray, mist, etc.).

Do not operate the device in potentially explosive atmospheres.

Do not operate the device in close proximity to high voltage lines.

If the device is operated with an open cover then it is essential to ensure that

clothing, hair, jewellery and similar personal effects cannot come into contact

with the exposed, rotating parts.

The device or parts of it may become hot during lamination. Do not touch during

operation and allow to cool prior to changing the film if necessary.

Risk of crushing when locking the heated rollers or closing the cover.

Only execute the actions described in this user manual. Further work must be

carried out exclusively by trained personnel or service technicians.

Unprofessional intervention or modifications to the device may endanger

operational safety.

6

1

Environmental information

When opening the housing cover a risk of death exists due to live

parts.

The device comprises materials that can be reused when processed by specialist

recycling companies. The optimum design of the laminator facilitates a

straightforward separation of the recyclable materials. Label the device as scrap

and dispose of it in accordance with the legal regulations

7

1

Connection and

commissioning

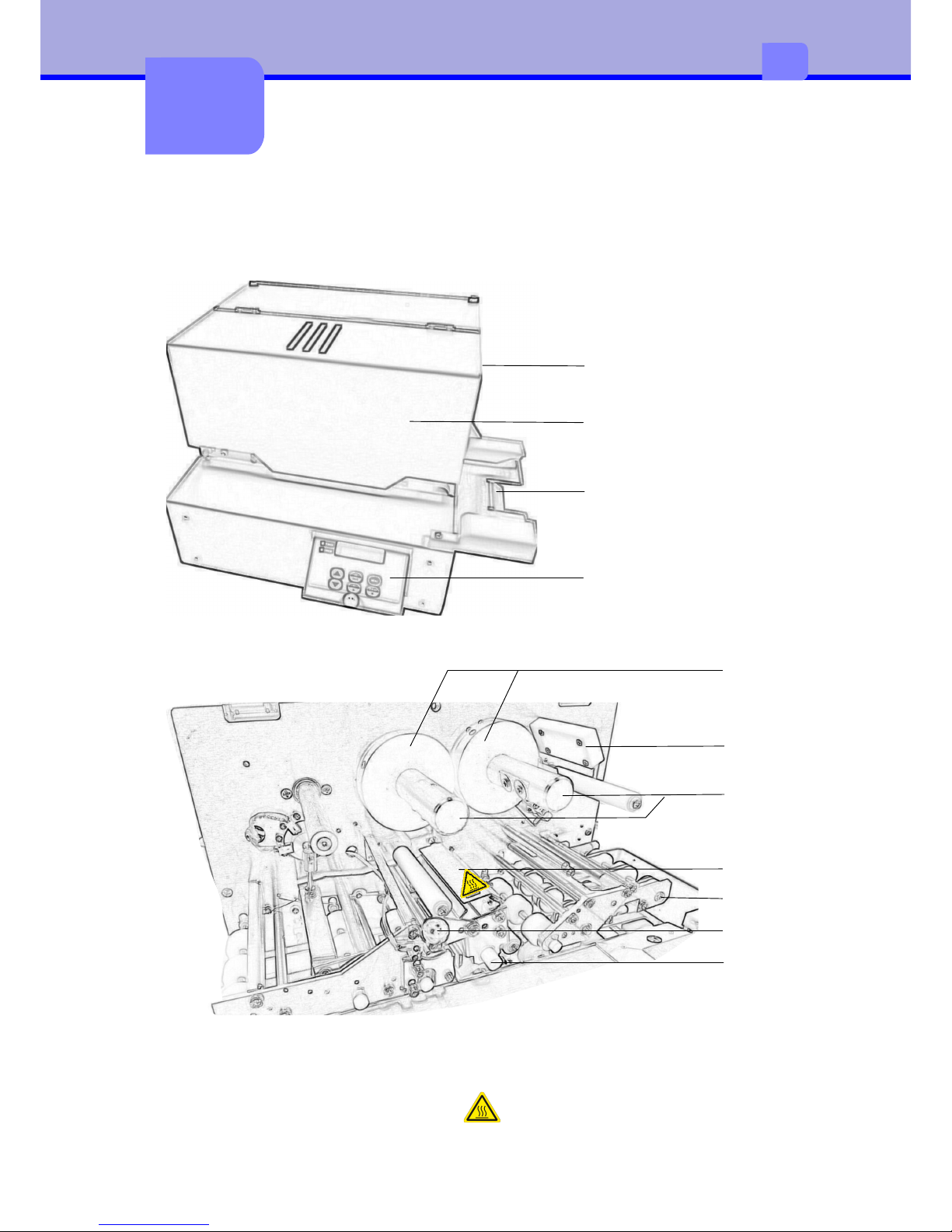

Device overview

1

2

4

3

6

7

5

1Spacer ring5Rocker for passport infeed

2RFID module6Heated roller interlocking

3Carrier roller7Heated roller

4Safety guard for heated roller

Cover hood

Feed table

Control panel

Lock

9

2

2

Unpacking and setting up the device

•Remove the device from its packaging and place on a level surface.

•Check the laminator for transport damage.

•Check delivery for completeness.

Scope of supply:

•Passport laminator

•Mains cable

•Feed table

•Key for cover hood

Store original packaging for subsequent transportation.

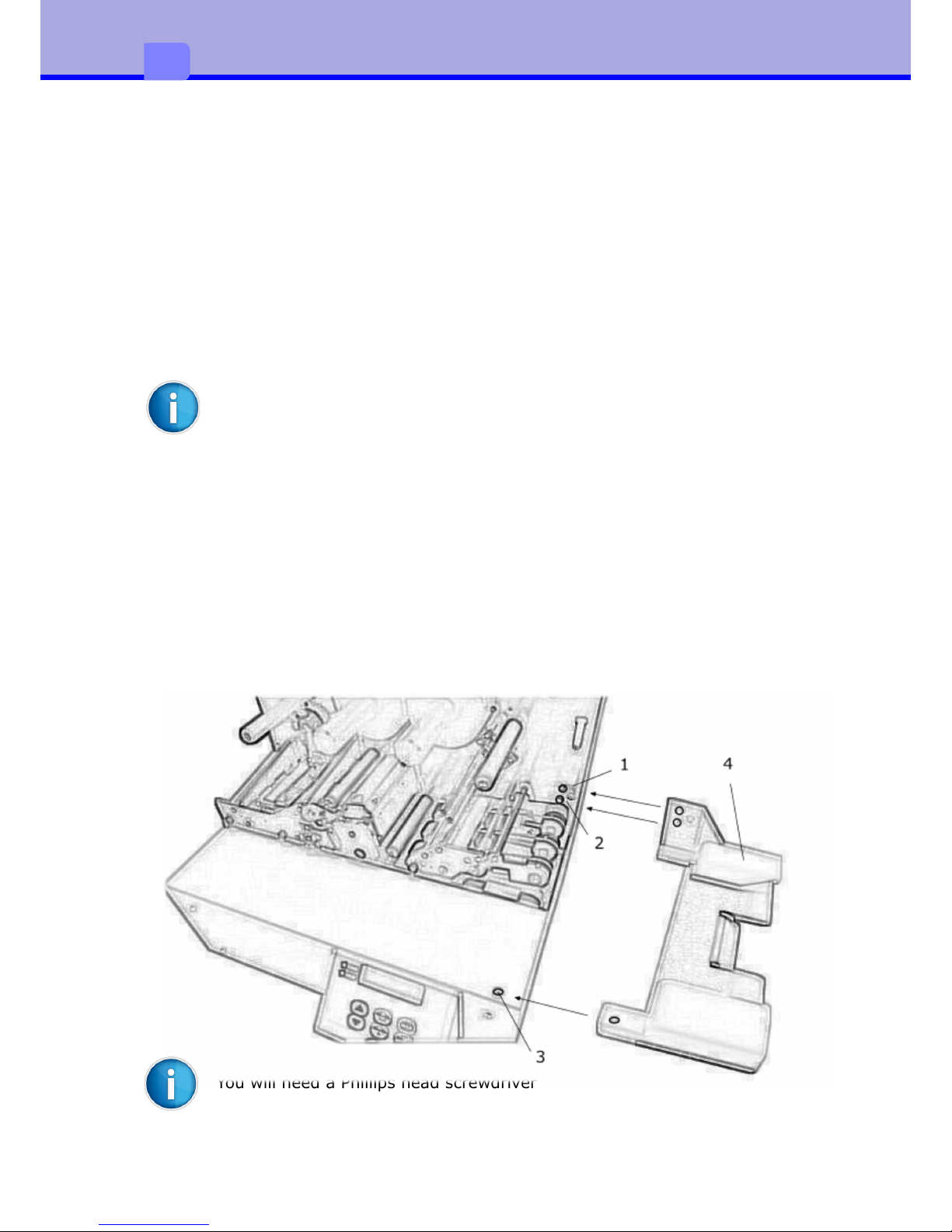

Mounting the feed table

•Open housing cover, if necessary unlock the lock first

•Remove the crosshead screws (1-3) from the device.

•Attach the feed table (4) such that the holes line up and screw in place.

You will need a Phillips head screwdriver

10

2

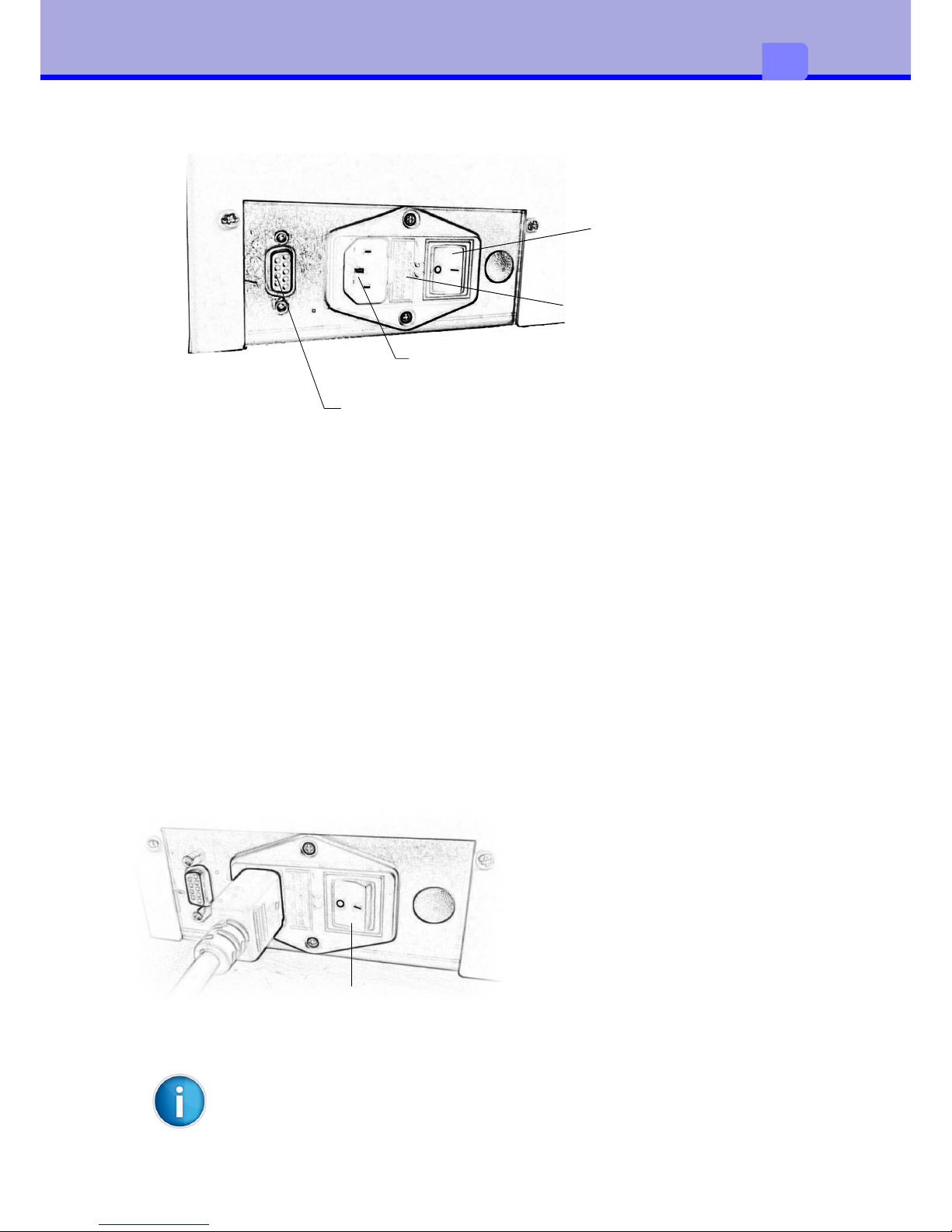

Connecting the device

Mains switch

Mains fuse 2A slow blow

Mains connection jack

RS232 interface

Connecting to the power supply

The laminator is equipped with a broad-range power pack for a mains voltage of

100 V to 240 V.

•Ensure that the device is switched off.

•Plug the mains cable into the mains connection jack.

•Plug the mains cable plug into an earthed socket

Connecting to a computer

For configuration and service purposes the laminator must be connected to the

computer with a suitable interface cable (optional).

Switching on the device

Once all connections have been

established it is possible to switch

the laminator on via the mains

switch.

The device carries out initialisation

with a simultaneous self-test. If no

error is present, heated roller

heating commences and the display

indicates HEATING. After roughly 10 minutes the laminator is ready for operation

and the display switches to the Ready status.

Mains switcher

It is assumed that film is already present inside the device.

11

2

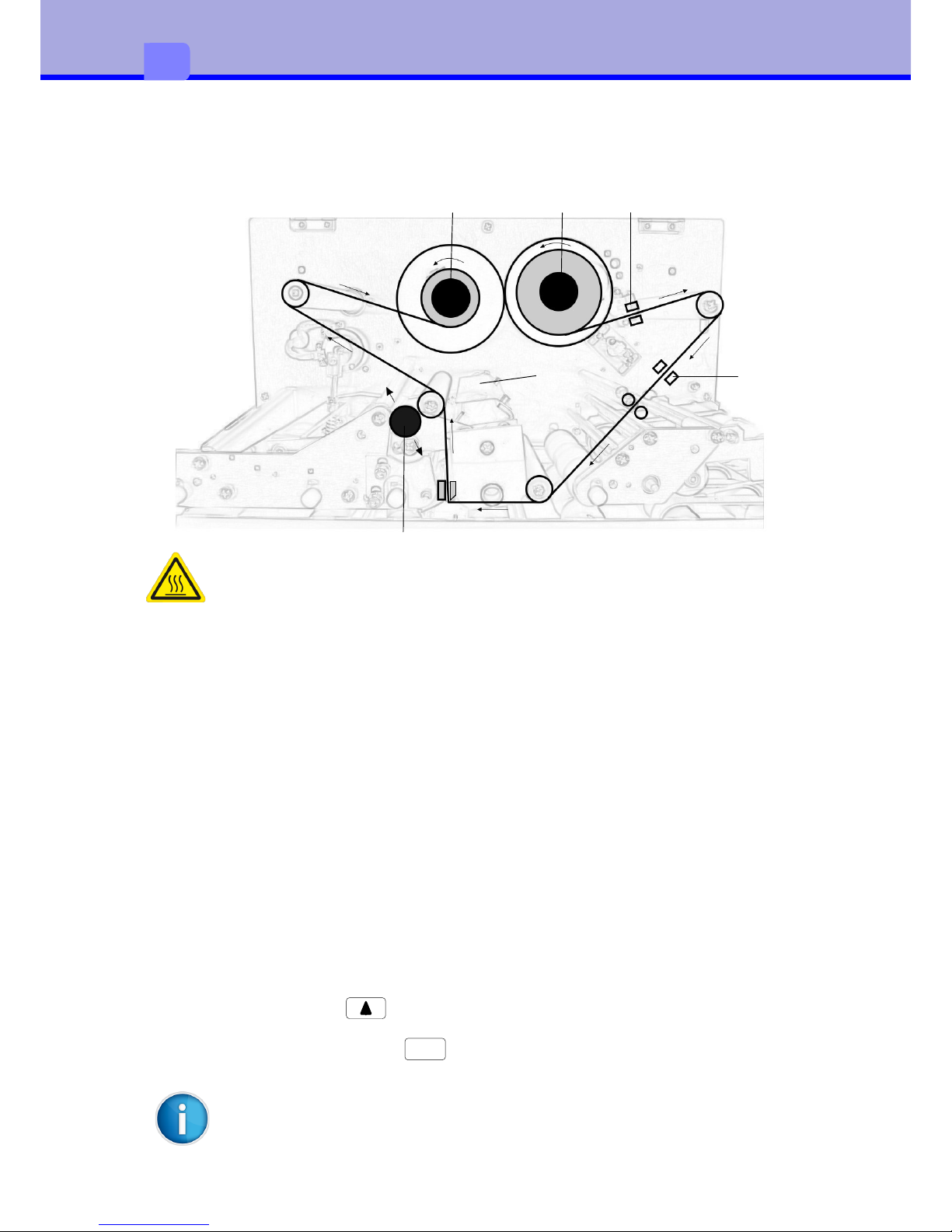

Inserting film

21

3

4

4

5

There is a risk of burning on the safety guard for the heated roller (5)

Newly inserted patch film must be subsequently synchronised. This is not

necessary in the case of holographic film without an index mark. The process

therefore differs very slightly. Refer also in this regard to the menu under Device.

When inserting or exchanging patch film proceed as follows:

•Open housing cover, if necessary unlock the lock first

•Switch off the device and let it cool down

•Release the heated roller interlocking. To do so push the lever (3) up.

•When exchanging the film additionally empty carrier rollers (1,2)

•Switch on the device. An error message is displayed.

•Slide the film roll onto the unwinding carrier roller (1) until it reaches the

limit stop.

•Slide an empty film core onto the winding carrier roller (2) until it reaches the

limit stop.

•Insert the film in accordance with the drawing shown above. Attach the start

of the film to the empty core with adhesive tape.

•Close the heated roller interlocking. To do so push the lever (3) down.

•Transport film with to the first patch and when doing so check that the

film runs correctly and crease-free.

•Delete error message with . The film is re-synchronised.

CLEAR

The first index mark on the film should lie between the two sensors (4),

in order that no patch is lost.

12

2

When inserting or exchanging holographic film without an index mark proceed as

follows:

•Open housing cover, if necessary unlock the lock first

•Switch off the device and let it cool down

•Release the heated roller interlocking. To do so push the lever (3) up.

•When exchanging the film additionally empty carrier rollers (1,2)

•Switch on the device.

•Slide the film roll onto the unwinding carrier roller (1) until it reaches the

limit stop.

•Slide an empty film core onto the winding carrier roller (2) until it reaches the

limit stop.

•Insert the film in accordance with the drawing shown above. Attach the start

of the film to the empty core with adhesive tape.

•Close the heated roller interlocking. To do so push the lever (3) down.

•Transport film with to the start and when doing so check that the film

runs correctly and crease-free.

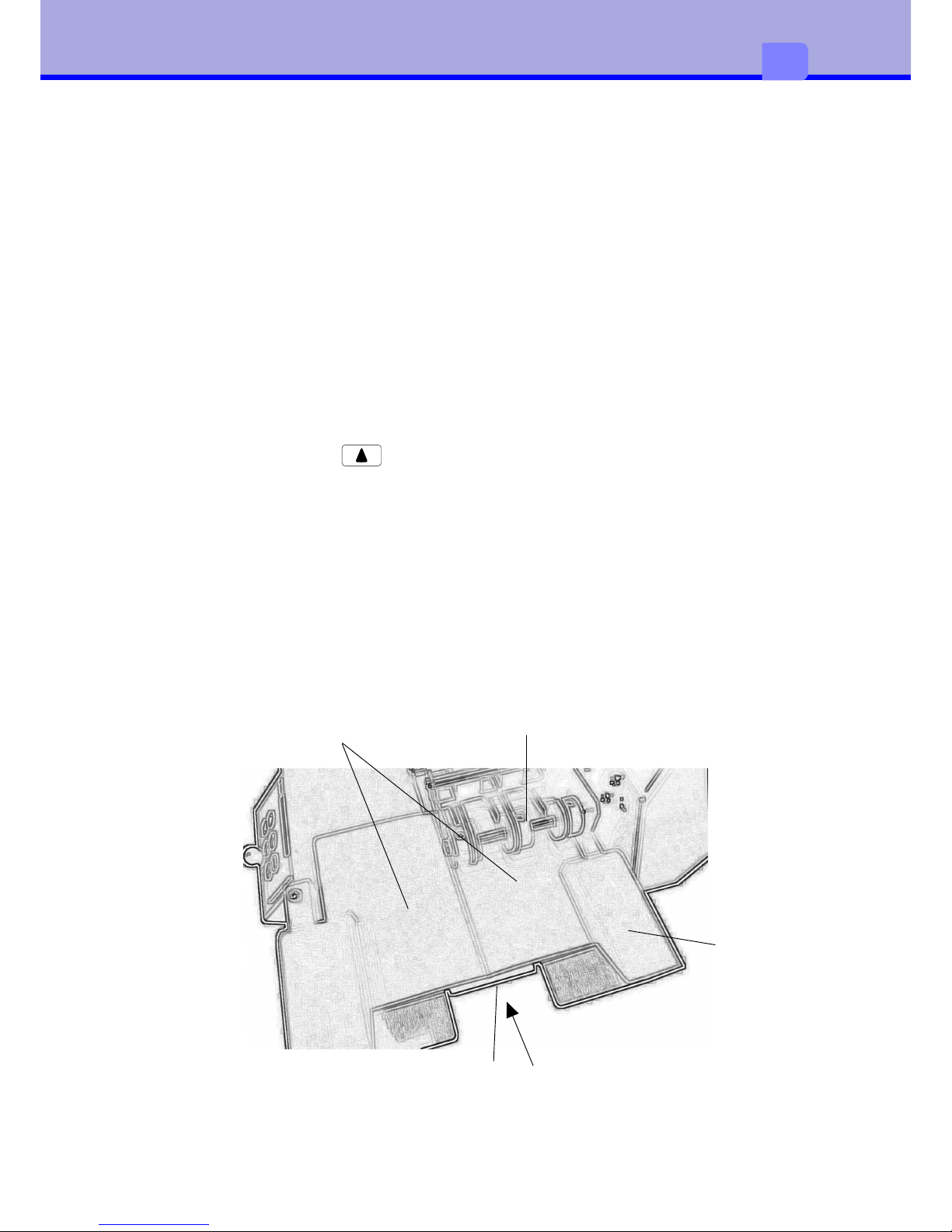

Inserting a document

Insert the passport (1) in the feed table (2) and slide it forwards until it reaches

the middle edge (3). The rocker (4) closes, takes hold of the document and

draws it in.

1

2

3

4

13

2

The control panel

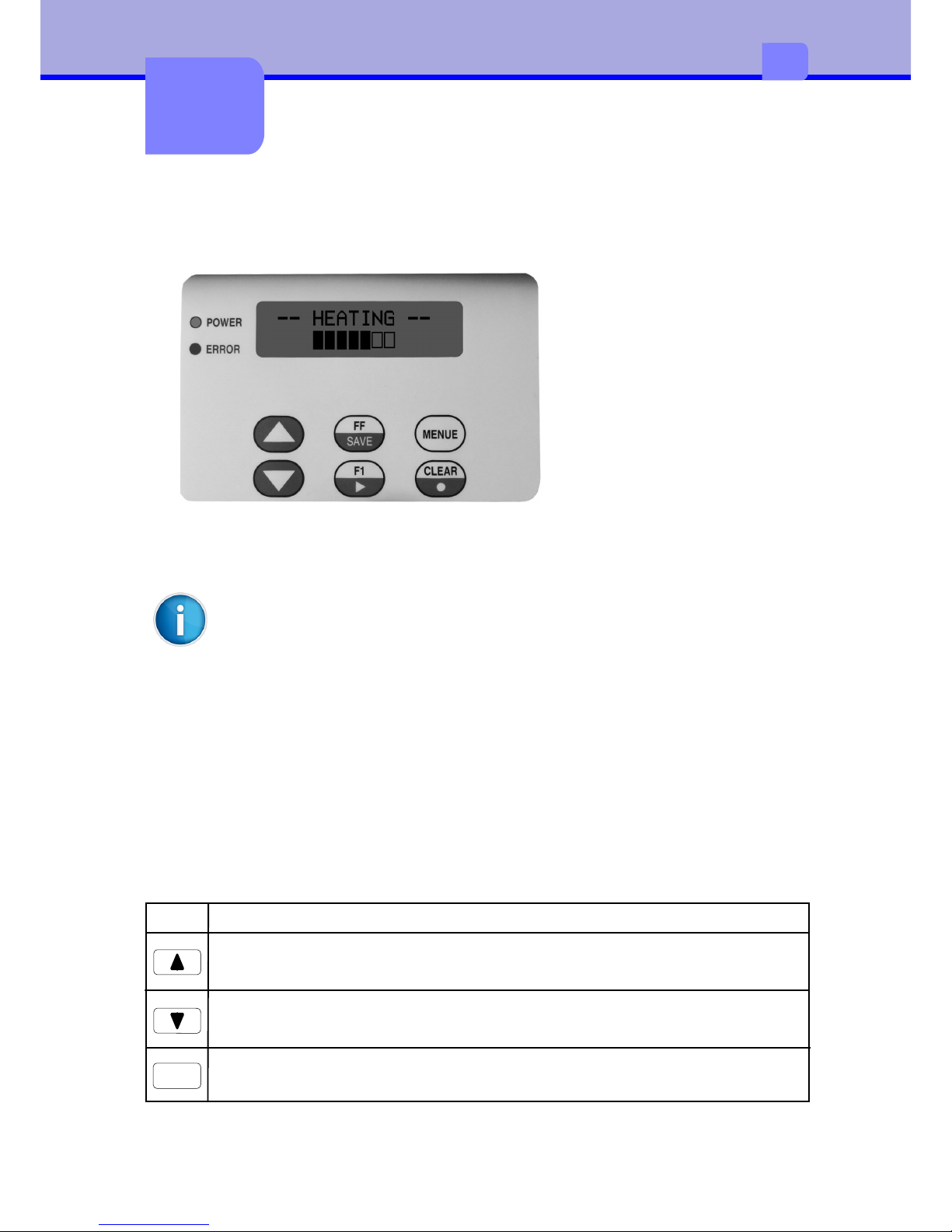

Control panel configuration

The display informs the

user of the current device

status, reports errors and

indicates configuration

settings in the menu.

The keys enable control

functions, the accessing of

information and navigation

within the menu.

If the device is switched on then the green LED illuminates. An error is

additionally signalled via the red LED.

The control panel can be folded out for improved ease of operation and

legibility. To do this draw the black button on the bottom edge of the

control panel forwards

The functionality of the control panel differs in the start menu and the

configuration menu.

Key functions in the start menu

The start menu contains all functions on one level, making these directly

accessible. Key navigation is not required. During lamination the buttons are

locked.

KeyFunction

Transports the film forwards. Useful when inserting new film

Transports the film backwards. Useful when inserting new film

FF

Transports a document manually from the tray

15

3

3

Loading...

Loading...