Passport-Laminator

User Manual

Lapis Drucktechnologie GmbH

Weinheimerstr. 62

68309 Mannheim

Tel.: +49(0)621/7363866

Fax.: +49(0)621/7363868

Email: info@lapis-online.de

Version: S20/V3.42

Drucktechnologie GmbH

1

Table of contents

1. General information...........................................................5

Product description................................................................5

Symbols and conventions....................................................... 6

Intended use........................................................................6

Safety information.................................................................6

Environmental information......................................................7

2. Connection and commissioning..........................................9

Device overview....................................................................9

Unpacking and setting up the device........................................10

Mounting the feed table.........................................................10

Connecting the device............................................................11

Connecting to the power supply.........................................11

Connecting to a computer.................................................11

Switching on the device.........................................................11

Inserting film.......................................................................12

Inserting a document............................................................13

3. The control panel...............................................................15

Control panel configuration....................................................15

Key functions in the start menu..............................................15

Key functions in the configuration menu..................................16

Device statuses....................................................................17

4. Configuration.....................................................................19

Configuration via control panel................................................19

Configuration via interface......................................................21

Configuration settings............................................................23

Test....................................................................................32

System................................................................................33

5. Control...............................................................................35

Control commands................................................................35

Status query........................................................................36

3

1

6. Troubleshooting................................................................37

Types of errors and elimination................................................37

Error messages......................................................................38

7. Service...............................................................................41

Firmware upgrade.................................................................41

AVR programming protocol.....................................................42

8. Certifications......................................................................45

EG-Konformitätserklärung....................................................... 45

Safety Standard FCC..............................................................46

EMC Zertifikat.......................................................................47

4

General information

Product description

The passport laminator laminates all pages of the passport including the inside of

the cover. A wafer-thin holographic film is applied to the paper surface via a

temperature-controlled heated roller. The laminator can be integrated into an

automatic personalisation system or can function as an independent station. The

passport is fed in from the left, right or front depending on the device

configuration.

Symbols and conventions

The following symbols and conventions are applied in this user manual.

The symbol indicates parts of the device that are hot and should not

be touched.

The symbol indicates important information, which must be

observed. A failure to do so may lead to injuries.

Good advice or information regarding important working steps.

Ready

Text in monospace type indicates contents on the display.

Taste

Framed text corresponds with a key on the control panel.

5

1

1

1

Intended use

The device is constructed in accordance with the latest engineering practice and

per the recognised safety regulations. Nevertheless, danger to the life and limb of

the user or third parties or damage to the device and other property may occur

when using it.

The device must be operated exclusively when in a technically faultless condition,

as intended, with an awareness of safety and potential hazards, and in accordance

with the operating manual.

The device is intended exclusively for laminating suitable materials. Any other use

or any use exceeding this is considered unintended use. The manufacturer shall

not be liable for any damage that results from misuse. The operator is solely

responsible for the resultant risk.

Safety instructions

The device is designed for an AC mains supply from 100 V to 240 V. It must be

connected exclusively to sockets with a grounded conductor contact.

The device must be operated exclusively in a dry environment and must not be

exposed to any moisture (spray, mist, etc.).

Do not operate the device in potentially explosive atmospheres.

Do not operate the device in close proximity to high voltage lines.

If the device is operated with an open cover then it is essential to ensure that

clothing, hair, jewellery and similar personal effects cannot come into contact

with the exposed, rotating parts.

The device or parts of it may become hot during lamination. Do not touch during

operation and allow to cool prior to changing the film if necessary.

Risk of crushing when locking the heated rollers or closing the cover.

Only execute the actions described in this user manual. Further work must be

carried out exclusively by trained personnel or service technicians.

Unprofessional intervention or modifications to the device may endanger

operational safety.

6

1

Environmental information

When opening the housing cover a risk of death exists due to live

parts.

The device comprises materials that can be reused when processed by specialist

recycling companies. The optimum design of the laminator facilitates a

straightforward separation of the recyclable materials. Label the device as scrap

and dispose of it in accordance with the legal regulations

7

1

Connection and

commissioning

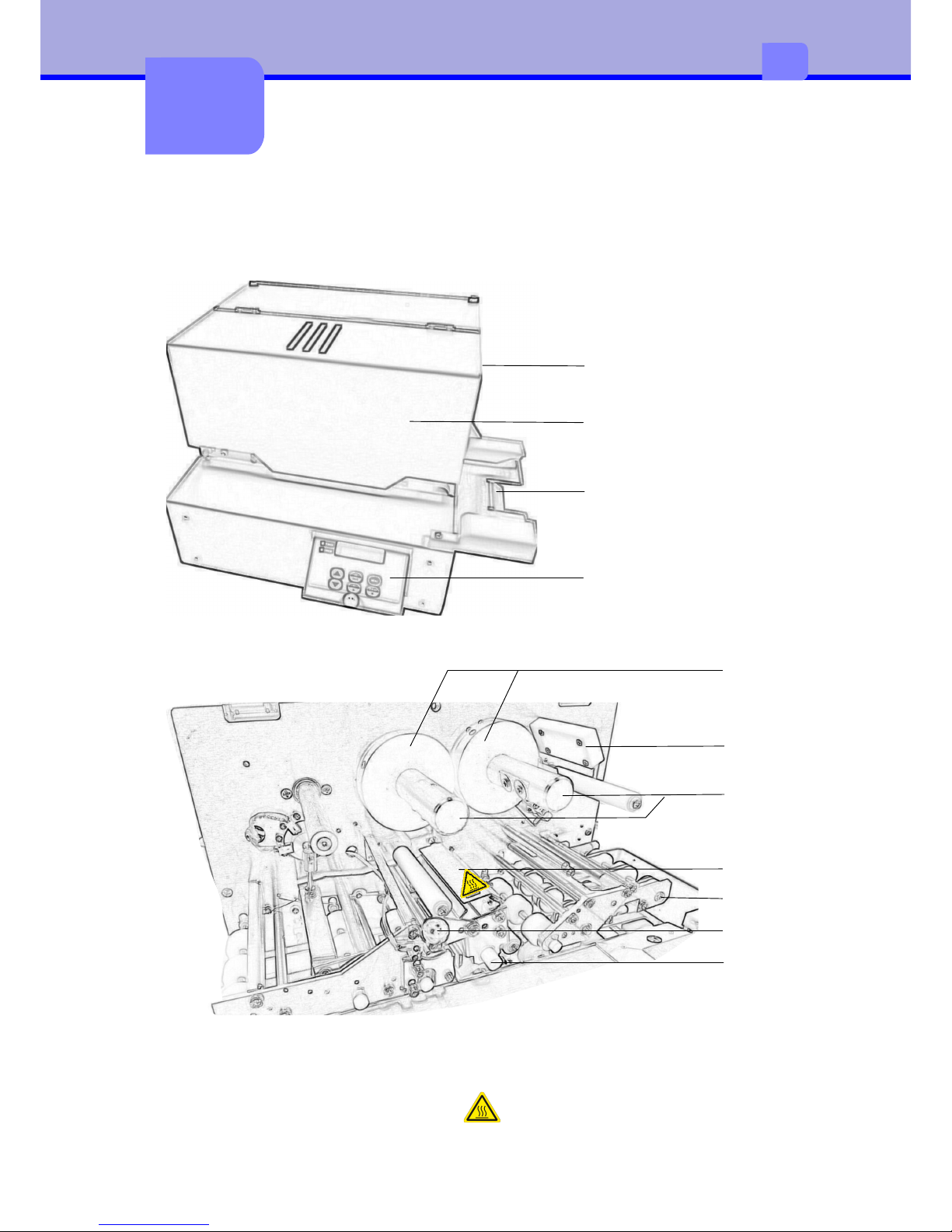

Device overview

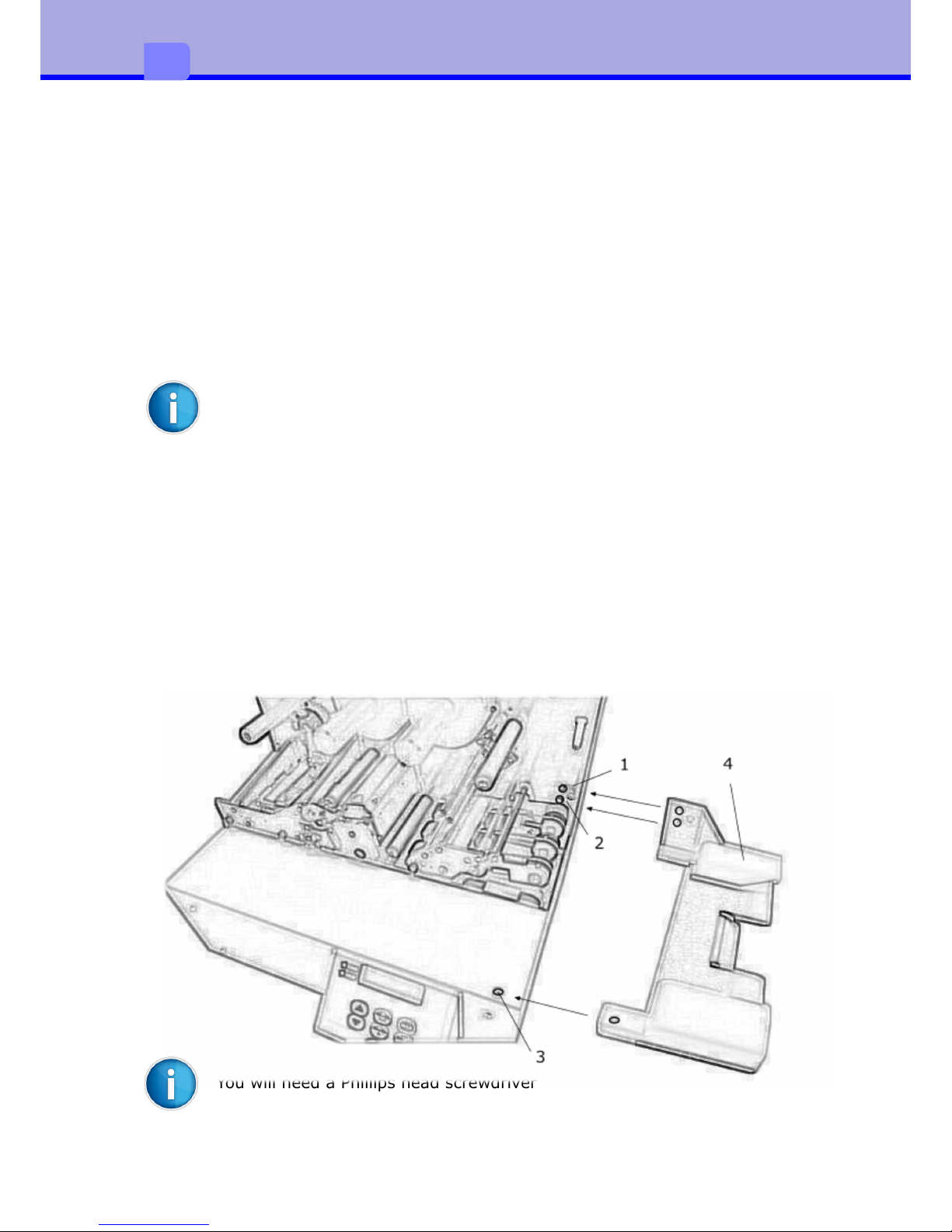

1

2

4

3

6

7

5

1Spacer ring5Rocker for passport infeed

2RFID module6Heated roller interlocking

3Carrier roller7Heated roller

4Safety guard for heated roller

Cover hood

Feed table

Control panel

Lock

9

2

2

Unpacking and setting up the device

•Remove the device from its packaging and place on a level surface.

•Check the laminator for transport damage.

•Check delivery for completeness.

Scope of supply:

•Passport laminator

•Mains cable

•Feed table

•Key for cover hood

Store original packaging for subsequent transportation.

Mounting the feed table

•Open housing cover, if necessary unlock the lock first

•Remove the crosshead screws (1-3) from the device.

•Attach the feed table (4) such that the holes line up and screw in place.

You will need a Phillips head screwdriver

10

2

Connecting the device

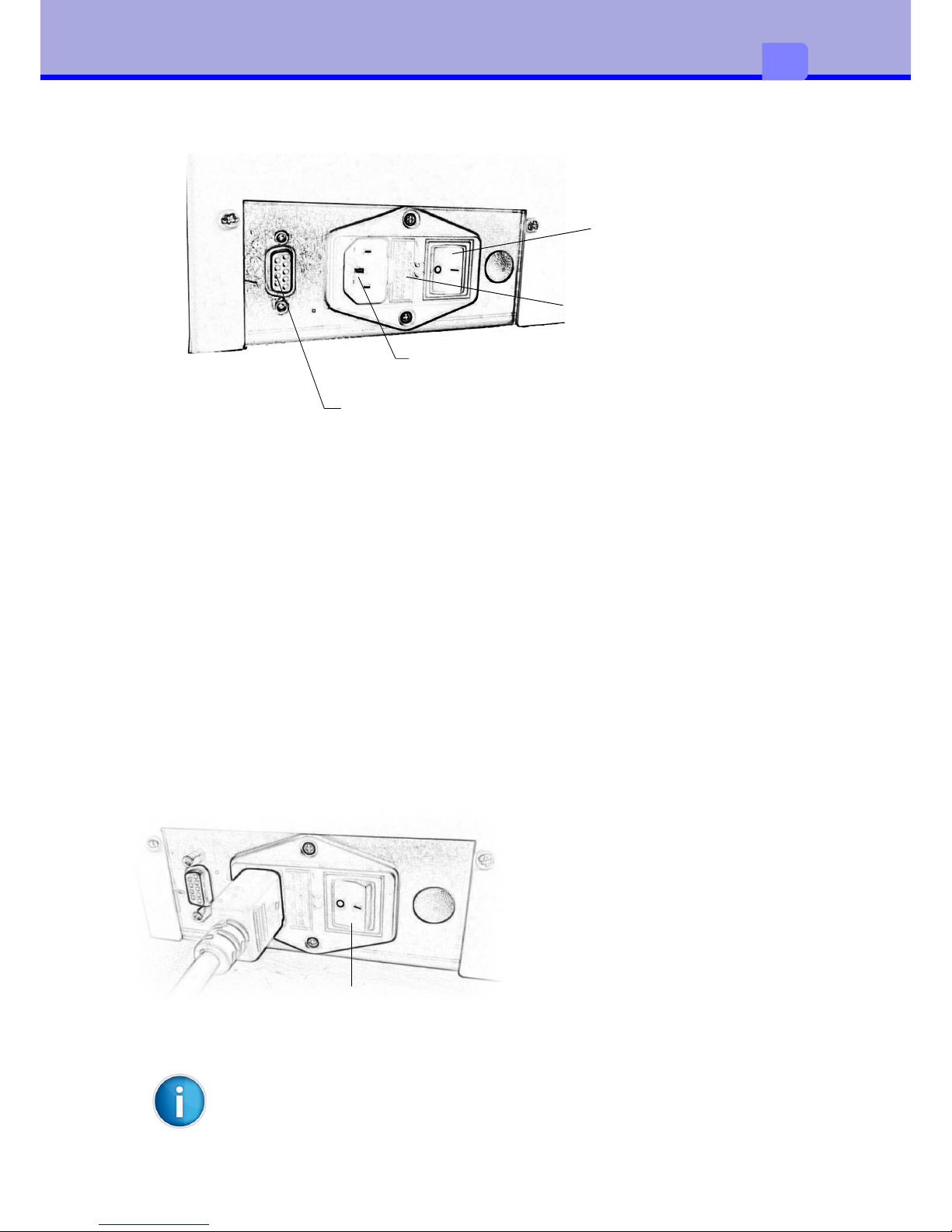

Mains switch

Mains fuse 2A slow blow

Mains connection jack

RS232 interface

Connecting to the power supply

The laminator is equipped with a broad-range power pack for a mains voltage of

100 V to 240 V.

•Ensure that the device is switched off.

•Plug the mains cable into the mains connection jack.

•Plug the mains cable plug into an earthed socket

Connecting to a computer

For configuration and service purposes the laminator must be connected to the

computer with a suitable interface cable (optional).

Switching on the device

Once all connections have been

established it is possible to switch

the laminator on via the mains

switch.

The device carries out initialisation

with a simultaneous self-test. If no

error is present, heated roller

heating commences and the display

indicates HEATING. After roughly 10 minutes the laminator is ready for operation

and the display switches to the Ready status.

Mains switcher

It is assumed that film is already present inside the device.

11

2

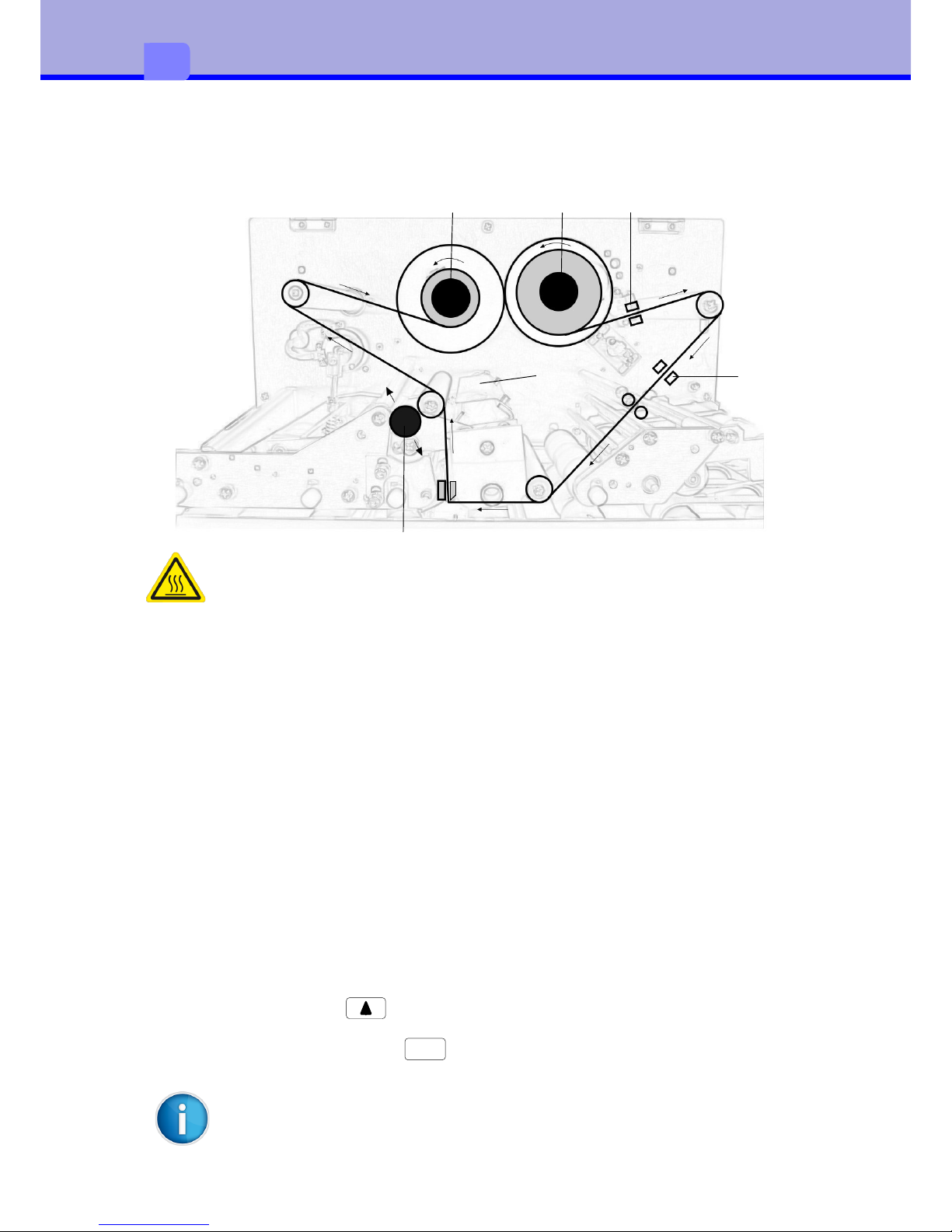

Inserting film

21

3

4

4

5

There is a risk of burning on the safety guard for the heated roller (5)

Newly inserted patch film must be subsequently synchronised. This is not

necessary in the case of holographic film without an index mark. The process

therefore differs very slightly. Refer also in this regard to the menu under Device.

When inserting or exchanging patch film proceed as follows:

•Open housing cover, if necessary unlock the lock first

•Switch off the device and let it cool down

•Release the heated roller interlocking. To do so push the lever (3) up.

•When exchanging the film additionally empty carrier rollers (1,2)

•Switch on the device. An error message is displayed.

•Slide the film roll onto the unwinding carrier roller (1) until it reaches the

limit stop.

•Slide an empty film core onto the winding carrier roller (2) until it reaches the

limit stop.

•Insert the film in accordance with the drawing shown above. Attach the start

of the film to the empty core with adhesive tape.

•Close the heated roller interlocking. To do so push the lever (3) down.

•Transport film with to the first patch and when doing so check that the

film runs correctly and crease-free.

•Delete error message with . The film is re-synchronised.

CLEAR

The first index mark on the film should lie between the two sensors (4),

in order that no patch is lost.

12

2

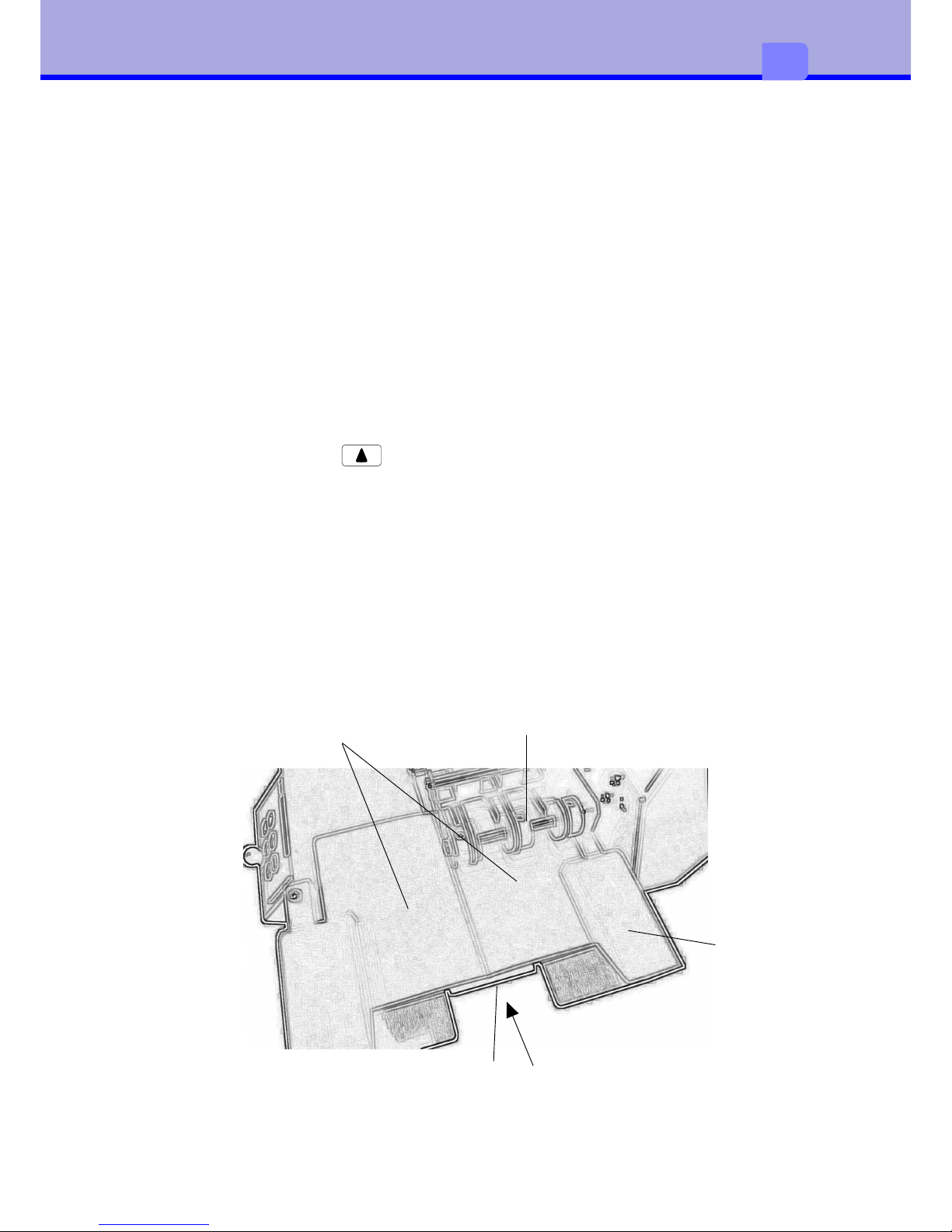

When inserting or exchanging holographic film without an index mark proceed as

follows:

•Open housing cover, if necessary unlock the lock first

•Switch off the device and let it cool down

•Release the heated roller interlocking. To do so push the lever (3) up.

•When exchanging the film additionally empty carrier rollers (1,2)

•Switch on the device.

•Slide the film roll onto the unwinding carrier roller (1) until it reaches the

limit stop.

•Slide an empty film core onto the winding carrier roller (2) until it reaches the

limit stop.

•Insert the film in accordance with the drawing shown above. Attach the start

of the film to the empty core with adhesive tape.

•Close the heated roller interlocking. To do so push the lever (3) down.

•Transport film with to the start and when doing so check that the film

runs correctly and crease-free.

Inserting a document

Insert the passport (1) in the feed table (2) and slide it forwards until it reaches

the middle edge (3). The rocker (4) closes, takes hold of the document and

draws it in.

1

2

3

4

13

2

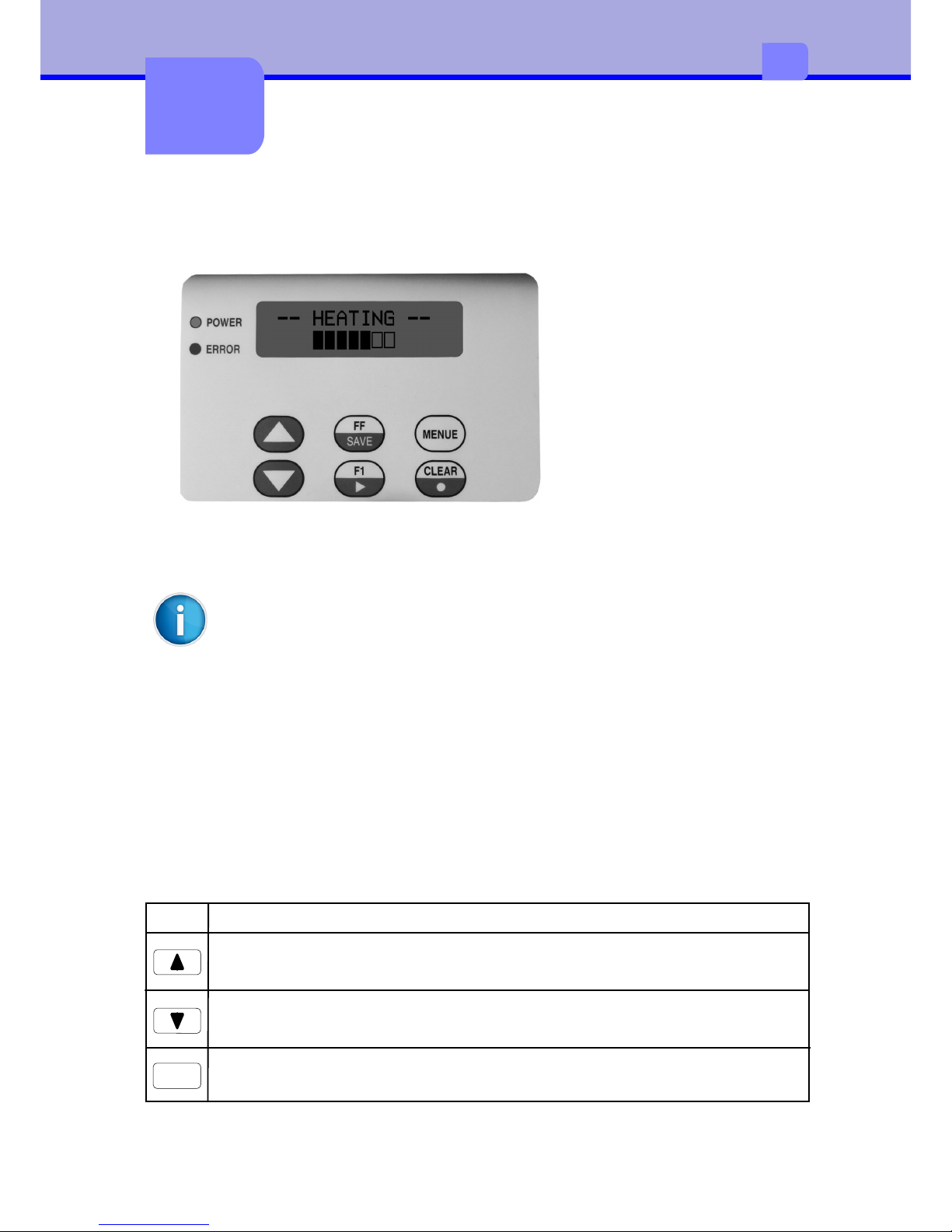

The control panel

Control panel configuration

The display informs the

user of the current device

status, reports errors and

indicates configuration

settings in the menu.

The keys enable control

functions, the accessing of

information and navigation

within the menu.

If the device is switched on then the green LED illuminates. An error is

additionally signalled via the red LED.

The control panel can be folded out for improved ease of operation and

legibility. To do this draw the black button on the bottom edge of the

control panel forwards

The functionality of the control panel differs in the start menu and the

configuration menu.

Key functions in the start menu

The start menu contains all functions on one level, making these directly

accessible. Key navigation is not required. During lamination the buttons are

locked.

KeyFunction

Transports the film forwards. Useful when inserting new film

Transports the film backwards. Useful when inserting new film

FF

Transports a document manually from the tray

15

3

3

TasteFunktion

Displays the device no. and program version

Switches to the configuration menu

F1

CLEAR

Deletes error messages

MENUE

Key functions in the configuration menu

The configuration menu offers setting options across multiple levels, in order to

configure the laminator for the specific requirements. It is also equipped with test

and service functions in order to support the configuration and function of the

device. During lamination the buttons are locked.

TasteFunktion

Start the configuration menu

Scrolls forwards within the respective menu level. At access level

changes or reduces the value.

MENUE

Scrolls forwards within the respective menu level. At access level

changes or reduces the value.

One menu level up

SAVE

Scrolls forwards within the respective menu level. At access level

changes or reduces the value.

One menu level down

With some firmware versions please note the following deviation

from the table shown above:

MENUE

One menu level down

16

3

Device statuses

StatusDescription

The laminator is ready for operation

Ready

-- HEATING --

The laminator is in the heat-up phase

-- COOLING --

The laminator is in the cool-down phase

in process

The laminator is ready for operation

Initialization

After the switch-on process the laminator is in the

initialisation phase and carrying out the self-test

STANDBY

If the laminator is not used for 30 minutes it switches

to energy-saving mode. The temperature of the

heated roller drops in this mode.

Press to end.

The energy-saving mode must be activated in the

menu!

#64 retract

An error is displayed

CLEAR

17

3

Configuration

Configuration via control panel

Within the access level the user works in editing mode:

KeyFunction

Increases / reduces the value or changes an option

Exits the editing mode. Changes are lost after the device is switched

off.

Exits the editing mode. Changes are retained after the device is

switched off.

With some firmware versions the button is to be replaced with

MENUE

SAVE

1. Menu level 2. Menu level Access level

Startmenü

SETTING

DEVICE

SETUP

FoilType

Standby

Loop

Index=Yes

No

No

Special functions for some parameters

19

4

4

1. Menu level2. Menu levelAccess level

= Default value

SETTING

Temperature180 ºC

Lamination Speed 8 mm/sTest

Delay Heatroller200 ms

Transport Speed 60 mm/sTest

LaminationLength125 mm

FoilFurtherMove 35 mm

Foil Position 0 x1/10mm

Special function

on Access level

DEVICE

Foil TypeIndex = Yes

StandbyNo

LoopNo

Delay 1 retract300 ms

Delay 2 retract300 ms

Operation ModeNormal

Admin Password****

User Password****

Menu structure

SETUP

Pass Position240 x1/24mm

Lami Length Corr10 -10mm

SeparatePosition 23 mm

Heating Cycle750ms

Heating Offset0 ºC

Uref Step FP(mV)T=2500Test

Uref Step HP(mV)T=2000 Test

Uref DC re-c(mV)T=2500Test

Uref DC de-c(mV)T=2500Test

Standby Option130 ºC

SENSORS

Status Sensors

Sensor LS1 (mV)T=3000Automatic

Sensor LS4 (mV)T=3000Automatic

Sensor INDEX(mV)T=2000Automatic

Sensor INDEX2(mV)T=2000Automatic

TEST

DC re-coilerno active

DC de-coilerno active

DC heatrollerno activeTest

Solenoidno active

RFID Trigger...select

20

4

Configuration via interface

The parameters accessible via the control panel can also be adjusted via the serial

interface. Furthermore, there is an additional command for controlling the device.

The laminator is connected by means of a standard cable

RS-232 SERIAL SUB D9 connector jack

to the computer.

Die RS232-Parameter:

Baudrate19200

Databits8

Paritynone

Stopbits1

The sequences for the command transfer are constructed as follows:

<ESC> cmd [data] <CR>

A few communication rules:

•<LF> is ignored

•Every command transfer is acknowledged with <CR>

•Sequences without parameter data deliver the actual value (ReadBack)

•No data is sent back when not requested

Italic characters in the command description are placeholders and must be

replaced:

•d = Decimal number

•p = Boolean number: 0 oder 1 (1 Byte)

•h = Hexadecimal number: 1-9, A-F, a-f (1 Byte)

•c = Arbitrary character:0-9,A-Z,a-z(1 Byte)

•s = Arbitrary string:...

•<...> = Control caracter as <ESC> or <CR>

•Boldprinted Character are directly be taken on.

•Underline refers to default setting

Example:Send:Response:

<ESC>T175<CR><CR>

<ESC>T<CR>175<CR>

21

4

List of Commands

SETTING COMMANDS

DdDelay Heatroller

GdLamination Speed

HdTransport Speed

LdLamination Length

NdFoil Further Move

PdFoil Position

TdTemperature

DEVICE COMMANDS

K20;pFoil Type

K40;pStandby

K02;pLoop

CONTROL COMMANDS

!!Reset

!rAlife-Status

!fStatus

W0Open Retract

W1Close Retract

SYSTEM COMMANDS

!cClear Error

!vRead Programm-Version

y8aRead Serial Number (Board)

y8bRead Serial Number (Device)

y5Read Tag-Info

UFirmeware Upgrade

S Save Macro

22

4

Configuration settings

The different setting options configure the laminator for specific requirements. This

is carried out either via the control panel or via the interface by means of a

command set. There are exceptions, whereby access is only possible via one or the

other method.

Simultaneous switching on of the device and pressing of the key

resets all settings to the standard values. The set-up values are an

exception to this.

CLEAR

Menu: SETTING / Temperature

Command:<ESC>Td<CR>

Setting the thermal energy for the heated roller for lamination. The correct

temperature must be experimentally determined with consideration to the

lamination speed, the film and the document. The presetting must be considered

a guideline value.

Setting range:150...180...190 degree C

Menu: SETTING / Lamination Speed

Command:<ESC>Gd<CR>

Setting of the transport speed of the document during lamination. The correct

speed must be experimentally determined with consideration to the lamination

temperature, the laminate film and the document. The presetting must be

considered a guideline value.

In order to carry out a test it is possible to start the motor via

Setting range:4...8...20 mm/s

Menu: SETTING / Delay Heatroller

Command:<ESC>Dd<CR>

Setting the waiting time, once the heated roller has lowered and lies on the

document. Only after this time does the actual lamination start.

Setting range:0...200...2000 ms

SETTING

23

4

Menu: SETTING / Transport Speed

Command:<ESC>Hd<CR>

Setting the transport speed of the document outside of lamination. In order to

carry out a test it is possible to start the motor via .

Setting range:40...60...80 mm/s

Menu: SETTING / Lamination Length

Command:<ESC>Ld<CR>

Setting the lamination range.

Setting range:115...125...135 mm

Menu: SETTING / Foil Position

Command:<ESC>Pd<CR>

With a change in the document intake range, precise placement of the film is

carried out.

With an enlarging of the intake range, the lamination of the document starts later.

Conversely, with a reduction in the intake range lamination starts earlier.

The direction arrows on the display indicate the direction of travel once lamination

starts.

Setting range:-30...0...+30 x 1/10mm

24

4

Menu: DEVICE / Foil Type

Command:<ESC>K20;p<CR>

Setting the film type.

Setting range:0 = ohne Indexmarke

1 = mit Indexmarke

Menu: DEVICE / Standby

Command:<ESC>K40;p<CR>

If the laminator is not used for 30 minutes it switches to energy-saving mode.

The temperature of the heated roller drops in this mode. Press to finish.

The energy-saving mode must be active for this!

Setting range:0 = Standby off

1 = Standby on

CLEAR

DEVICE

Menu: DEVICE / Loop

Command:<ESC>K02;p<CR>

In its switched on status, with the start of lamination the film is drawn taut after

a delay. This can influence the quality at the edge of the document.

Setting range:0 = Loop off

1 = Loop on

Menu: DEVICE / Delay 1 retract

Stipulates the time between detecting the passport and lowering the rocker.

Setting range:100...300...10000 ms

Menu: DEVICE / Delay 2 retract

Stipulates the time for which the rocker remains lowered before the document is

drawn in.

Setting range:100...300...10000 ms

25

4

Menu: DEVICE / Operation Mode

The laminator operates in 3 different modes. 2 of these are exclusively suitable

for test purposes.

Setting range:Normal

Test: Hoff

Test: PassThrough

The standard setting is "normal" and reflects normal operation.

"Test: Hoff" also reflects the normal operating process, although the heating is off

in this case.

With the setting "Test: PassThrough" the document is merely driven through the

transport tray. The heated roller is not lowered and the heating is also switched

off here.

26

4

27

4

Menü: DEVICE / Admin Password

DEVICE / User Password

In factory state the password protection is inactive (password = 0000). If you

activate a password protection, the user must enter a password to start the

laminator after power on. The Administration-Access without restriction allows

input option of a user password with menu lock.

Keys for entering password:

Arrow key up: increment the digit

Arrow key down: decrement the digit

Arrow key right: next digit position

SAVE key:take password

Set new administrator password:

DEVICE/Admin Password/New Password= 1234

Repeat Password = 1234

Change administrator password:

DEVICE/Admin Password/ Old Password= 1234

DEVICE/Admin Password/ New Password= 4321

Repeat Password = 4321

Delete administrator password:

DEVICE/Admin Password/ Old Password= 4321

DEVICE/Admin Password/ New Password= 0000

Repeat Password = 0000

The user password is also cleared, so the password protection is inactive.

Set new user password:

DEVICE/User Password/ New Password= 1111

Repeat Password= 1111

Change user password:

DEVICE/User Password/ Old Password= 1111

DEVICE/User Password/ New Password= 2222

Repeat Password= 2222

Delete user password:

DEVICE/User Password/ Old Password = 2222

DEVICE/User Password/ New Password= 0000

Repeat Password= 0000

Menu: SETUP / Pass Position

Stipulation of the passport position at the heated roller. This is optimally set in the

factory and does not require adjustment.

Setting range:120...216...360 x 1/24mm

Menu: SETUP / Separate Position

Stipulation of the position at which the film is separated from the document after

lamination by way of a separator. This is optimally set in the factory and does not

require adjustment.

Setting range:5...23...60 mm

Menu: SETUP / Heating Cycle

This setting influences the switch-on cycle within the heating control. Too high a

value leads to an overshooting of the temperature range. This parameter is

optimally set in the factory and does not require adjustment.

Setting range:250...750...1500 mm

Menu: SETUP / Heating Offset

This setting influences the control algorithm of the heating control for the heated

roller. The value is optimally set in the factory and does not require adjustment.

Setting range:0..5 Grad Celsius

SETUP

28

4

Menü: SETUP / Lami Length Corr

Correction of lamination length in “Settings/LaminationLength”.

Einstellbereich:0...10...20 -10mm

Menu: SETUP / Uref Step HP(mV)

Indicates the motor current for the passport transport during lamination. It is

optimally set in the factory and does not require adjustment.

In order to carry out a test it is possible to start the motor via .

Setting range:0...2000...5000 mV

Menu: SETUP / Uref DC re-c(mV)

Indicates the motor current for the DC film re-winder. It is optimally set in the

factory and does not require adjustment.

In order to carry out a test it is possible to start the motor via .

Setting range:0...2500...5000 mV

Menu: SETUP / Uref DC de-c(mV)

Indicates the motor current for the DC film de-winder. It is optimally set in the

factory and does not require adjustment.

In order to carry out a test it is possible to start the motor via .

Setting range:0...2500...5000 mV

Menu: SETUP / Standby Option

Set the standby property, if it is activated.

Setting range:130 oC

Heating off

29

4

Menu: SETUP / Uref Step FP(mV)

Indicates the motor current for the passport transport. It is optimally set in the

factory and does not require adjustment.

In order to carry out a test it is possible to start the motor via

Setting range:0...2500...5000 mV

Menü: SENSORS / Status Sensors

Shows the actually Status of Sensors:

1 2 3 4 5 6 7 8 a b

□ . . □ □ □ □ ■ ■

1 Sensor LS1Transport channel 1. Sensor to the right of for retract and pass position

□ Document not identified

■ Document identified

4 Sensor LS4Transport channel 4. Sensor to the right of for controlling transport and eject

□ Document not identified

■ Document identified

5 Sensor INDEXSensor for Film synchronisation (Sensor below)

□ no Sync-Marke identified

■ Sync-Marke identified

6 SensorINDEX2Sensor for Film backward (Sensor above)

□ no Sync-Bar identified

■ Sync-Bar identified

7 SensorFOLIESensor for controlling the film transport

□ no gap identified

■ gap identified

a Sensor1Sensor Exzender (Sensor above)

□ no gap identified

■ gap identified

b Sensor2Sensor Exzender (Sensor below)

□ no gap identified

■ gap identified

a

b

5

6

1

2

7 (Backside)

SENSORS

30

4

Menu: SENSORS / Sensor LS4 (mV)

Indicates the transmission current for the LS4 sensor. This must be set such that

the reception current is shown as approx. 3500mV. The transmission current is

aut. determined via . This value is optimally set in the factory and does not

require adjustment.

Setting range:0...3000...5000 mV

Menu: SENSORS / Sensor LS1 (mV)

Indicates the transmission current for the LS1 sensor. This must be set such that

the reception current is shown as approx. 3500mV. The transmission current is

aut. determined via . This value is optimally set in the factory and does not

require adjustment.

Setting range:0...3000...5000 mV

Menu: SENSORS / Sensor INDEX (mV)

Indicates the transmission current for the INDEX sensor. This must be set such

that the reception current is shown as approx. 3500mV. The transmission current

is aut. determined via . This value is optimally set in the factory and does not

require adjustment.

Setting range:0...2000...5000 mV

Menu: SENSORS / Sensor INDEX2 (mV)

Indicates the transmission current for the INDEX2 sensor. This must be set such

that the reception current is shown as approx. 3500mV. The transmission current

is aut. determined via . This value is optimally set in the factory and does not

require adjustment.

Setting range:0...2000...5000 mV

31

4

Menu: TEST / DC re-coiler

Test of the DC film winder.

The The film winder rotates forwards, so that the film is wound on.

The film winder rotates backwards, so that the film is wound off.

Menu: TEST / DC re-coiler

Test of the DC film unwinder:

The film unwinder rotates forwards, so that the film is wound off.

The film unwinder rotates backwards, so that the film is wound on.

Menu: TEST / DC heatroller

Test of the DC motor for the heated roller eccentric:

The eccentric rotates forwards

The eccentric rotates backwards

The eccentric assumes the 2 end positions alternately. In doing so

the heated roller switches to the lower and upper position.

Menu: TEST / Solenoid

Test of the electromagnets:

The rocker is lowered

The separator is actuated

Menu: TEST / RFID-Trigger

Test of the RDK1 module:

RDK1 mode: read always

RDK1 mode: read by trigger

Test

32

4

System

Function:Clear Error

Startmenu:

Command:<ESC>!c<CR>

Deletes error messages, refer also to the "trouble-shooting" chapter.

CLEAR

Function:Read Programm-Version

Startmenu:

Command:<ESC>!v<CR>

Reads the firmware version. Is shown in line 1 on the display.

As a response following a command transfer the user receives a sequence in the

form e.g. "LAMI-S20/V3.30<CR>

F1

Function:Read Serial Number (Board)

Command:<ESC>y8a<CR>

Reads the serial number of board.

As a response following a command transfer the user receives a sequence in the

form e.g. "PL13091570B06RL<CR

Function:Read Serial Number (Device)

Startmenu:

Command:<ESC>y8b<CR>

Reads the serial number of device. Is shown in line 2 on the display.

As a response following a command transfer the user receives a sequence in the

form e.g. "PL13091570M02RL<CR>

F1

Function:Tag-Info

Command:<ESC>y5<CR>

Reads the 8-digit tag information.

As a response following a command transfer the user receives a sequence in the

form e.g. "12345678<CR>

33

4

Function:Firmware Upgrade

Command:<ESC>U<CR>

Calls up the bootloader to upgrade the firmware in flash. The protocol description

is located in the attachment.

Function:Storage of Macro

Menu:

Command:<ESC>S<CR>

All configuration parameters are stored in the EEPROM so that these values are

not lost after the switch-off process. When switching on the laminator the stored

settings are reloaded and reused.

The command sequence is acknowledged with “+”.

SAVE

34

4

Control

Control commands

Reset

Command:<ESC>!!<CR>

The laminator is reset. The process equates to a restart after a Power On.

Settings that are not saved in the macro are lost.

Open rocker

Befehl:<ESC>W0<CR>

Manual opening of the rocker.

Close rocker

Command:<ESC>W1<CR>

Manual closing of the rocker. This is aut. opened again in the process.

35

5

5

Status query

Function:Status

Command:<ESC>!f<CR>

Delivers detailed information on the current status of the laminator. The status

can be requested at any time.

The response consists of 7 Bytes.

Format: =hh/dd<CR>

hh: Statuscode Hint:

00: READYDevice is ready for work

01: WAITTemperature of heat roller too high / too low

02: BUSYLaminator is active

04: ERRORErrorcode is setting

10: GOT ITDocument identified to start lamination

20: LAMILamination od Document activ

40: EJECTEjection of Document activ

dd: ErrorcodeHint

00no Error

ddErrorcode, see chapter “Trouble shooting”

Status bits also occur in combination. E.g. status code “42” means that the

laminator is active and is presently outputting a document.

Function:Alife-Status

Command:<ESC>!r<CR>

Delivers information on the current status of the laminator. The status can be

requested at any time.

The response only consists of 2 Bytes.

Format: d<CR>

d: Statuscode Hint

0 = OKDevice is ready for work

1 = WAITTemperature of heat roller too high / too low

2 = BUSYLaminator is active

3 = ERRORErrorcode is setting

36

5

Troubleshooting

Types of errors and elimination

If an error occurs then this is signalled by the red ERROR LED whilst the error

message is shown on the display. Different error codes indicate the cause of the

problem. In a normal case it is possible to delete the error message after

eliminating the problem with after which the device is once again ready for

operation.

CLEAR

StatusLEDDisplay

Rectifiable errorsblinkserrorcode < #80

Non rectifiable errorsonerrorcode > #80

System errorsonerrorcode > #90

"Rectifiable errors" are usually film or transport errors, which are simple to

remedy.

"Non-rectifiable errors" are triggered by defective hardware. If a restart does not

solve the problem then service intervention is necessary.

In the event of a "system error" the device must be returned to the factory.

#61 card inside

As an alternative to the control panel it is also possible to query the error code via

the status message and delete this via the Clear command.

37

6

6

Error messages

Error messageCause

#52 Tag verify

Identification or ID does not

match with the initial version

of the film. Film was

probably exchanged after

restart.

Reinsert previous film or restart

laminator.

Remedy

#53 Tag invalid

Invalid tag information with

initial acquisition of the film.

Use permissible / approved film

material.

#54 RFID ERR=dd

Reader:Communication Error

dd=24 read err

dd=83 write err

Error message from tag reader.

Indicates signal between reader

and tag too weak. Visual

inspection!

#55 RFID CRC

Reader transfer error.

Contact problems between

board and tag reader

Check connection cable (service)

#56 RFID MSG

No response from tag

reader. Tag not seen or not

read.

Use permissible / approved film

material.

#61 card inside

Document located in the

transport tray after restart or

after and could not be

ejected

Remove document from the

transport tray manually.

CLEAR

#62 eject

Ejection of the document

failed.

Remove document from the

transport tray manually.

#63 transport

Transport of the document

failed.

Remove document from the

transport tray manually.

#64 retract

Intake of the document

failed.

Remove document from the

transport tray manually.

#65 ribbon end

Film end

Insert new film

#66 ribbon synch

Synchronisation of the film

failed.

- Insert film with index marks

- Insert film correctly

- Configure correct film type

38

6

#67 ribbon trans

No film transport.

Check film

#81 RFID no data

No response from tag reader. Check tag reader.

Contact service!

#82 ADC problem

Impermissible ADU values

Check temperature sensor.

Contact service!

#83 ADC problem

No temperature increase to

record

Check temperature sensor.

Contact service

#84 heat roller

Heated roller not in limit

position

Contact service!

#85 heating

Circuit breaker for high

temperature has triggered.

Contact service!

#86 Sensor ???

Both sensors in transport tray

see document

Check transport tray, otherwise

Contact service!

#98 EEPROM/SETUP

No access to the EEPROM

Contact service!

#99 Call Service

Electronic type plate missing Contact service!

Error messageCause Remedy

39

6

Service

Firmware upgrade

After starting the Windows application AVR-Bootloader it is possible to load new

firmware. Prior to this the interface agreements as well as the path for the

access to the application code (*.HEX) must be stipulated

The download process can be started as follows:

•Switch on laminator

•Press „Jump to Bootloader then Download“

or

•Press „Wait for Bootloader then Download“

•Switch on laminator and simultaneously hold the key down

For service purposes the laminator is connected with the computer via the serial

interface. A standard cable RS-232 SERIAL SUB D9 connector jack is used.

F1

41

7

7

The upgrade process can also be started without Windows software via the

sequence <ESC>U<CR>. The subsequent protocol must then be carried out

independently:

LaminatorHostHint

ˆBootLoader is ready

@&$Start Download Sequence

V1.31

?ready for Download

XONenable Interface

:naatddd…cSend 1 HexLine (Intel-Hex-Format)

-if Checksum Error

XOFFdisable interface

%if Verify-Error in Flash-Page

~HexLine closed

#EOF identified, exit with error

@EOF identified, exit without error

After the AVBRL is started (via a reset, a power-up, or a jump from the main

application), the following protocol must be observed:

1. Upon power-up, reset, or as a result of a jump from the main application, the

AVRBL sends a ‘^’ (BOOTLOADER_ACTIVE_CHAR) at your selected baud

rate.

2. The host is then required to send the three-character entry sequence. This is

used to prevent an inadvertent attempt of reprogramming from taking place. If

the AVRBL does not receive these characters within the timeout period, the

AVRBL tests to see if there is code located in the main application area of flash.

If there is, then the AVRBL jumps to it, otherwise, execution stays within the

AVRBL indefinitely, waiting for the entry sequence.

3. Once the three-character entry sequence has been sent, the bootloader sends

the version string (Vx.xx) followed by a ‘?’ (READY_CHAR).

4. Upon receipt of the READY_CHAR, the host application should send the hex file

for the new/updated application program observing an X-ON / X_OFF

handshaking protocol to control data flow. The handshaking is very important as

the flash memory area writes much more slowly than the serial port can send

data.

AVR Programming Protocol

42

7

The programming software continues sending the hex file until it is all sent. After

each line of “.hex” file is received by the bootloader, one of three characters is

transmitted by the bootloader:

- ‘~’ Line received with no errors.

- ‘%’Line received with no error, but an error occurred while flashing.

- ‘-‘ Checksum error detected while receiving the line.

5. After the programming is complete, the AVRBL sends either a ‘#’, meaning the

programming is all right, or an ‘@’ indicating that an error has occurred and the

program did not load successfully. In most cases an error during programming

means that the main application program is corrupted and will need to be resent.

6. The AVRBL then starts the newly programmed application software. As stated

in step 2, the AVRBL tests to see if there is code located in the main application

area of flash. If there is, the AVRBL jumps to it, otherwise, execution stays within

the AVRBL indefinitely, waiting for the entry sequence.

Character Definition

//define three character string to enter boot loader

#define char1 '@' /* reset codes.. start load codes.. */

#define char2 '&'

#define char3 '$'

// define bootloader active char

#define BOOTLOADER_ACTIVE_CHAR '^'

//define bootloader ready for file character

#define READY_CHAR '?'

// define line complete with no error character

#define LINE_COMPLETE_CHAR '~'

// define checksum error character

#define CS_ERROR_CHAR '-'

// define flash page error character

#define PAGE_ERROR_CHAR '%'

// define file complete, no errors character

#define FILE_COMPLETE_CHAR '@'

43

7

Certifications

45

8

8

46

8

47

8

Loading...

Loading...