User Manual (Hardware)

T(P)ES-R6616XFT

16 10/100TX + 4 10G Copper + 2 10G SR Fiber Q-ODC (w/ PoE at/af)

EN50155 OS4 Managed Ethernet Switch

T(P)ES-R6616XT

16 10/100TX + 6 10G Copper (w/ PoE at/af) EN50155 OS4 Managed

Ethernet Switch

Nov. 2019

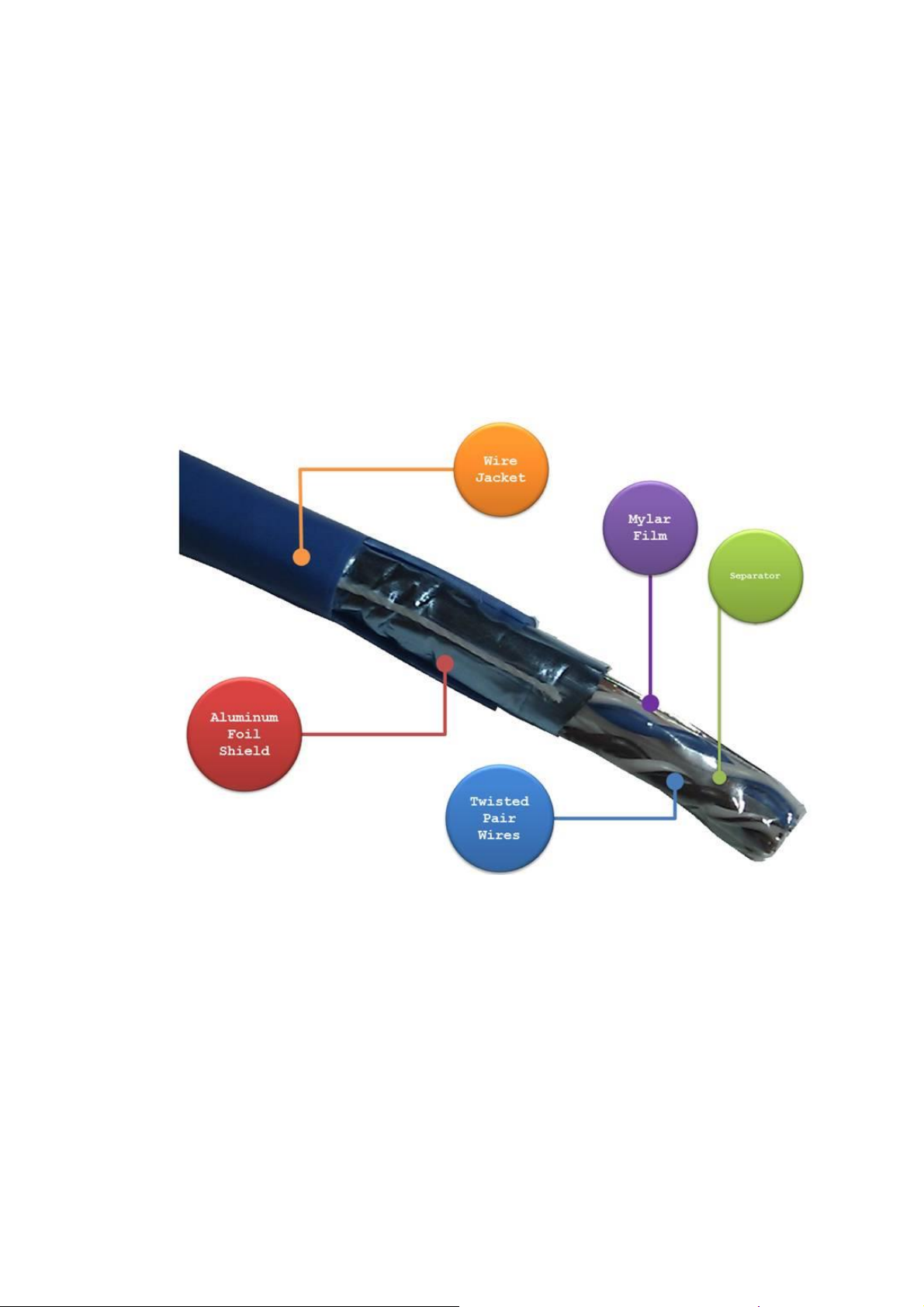

Recommendation for Shielded network cables

STP cables have additional shielding material that is used to reduce external interference.

The shield also reduces emissions at any point in the path of the cable. Our

recommendation is to deploy an STP network cable in demanding electrical environments.

Examples of demanding indoor environments are where the network cable is located in

parallel with electrical mains supply cables or where large inductive loads such as motors

or contactors are in close vicinity to the camera or its cable. It is also mandatory to use an

STP cable where a power device (like an IP camera) is used outdoors or where the

network cable is routed outdoors.

Important Notice

Lantech Communications Global, Inc. reserves the right to modify the

equipment, its specification or this manual without prior notice, in the interest

of improving performance, reliability, or servicing. At the time of publication

all data is correct for the operation of the equipment at the voltage and/or

temperature referred to. Performance data indicates typical values related to

the particular product.

No part of this documentation or information supplied may be divulged to any

third party without the express written consent of Lantech Communications

Global Inc. Products offered may contain software which is proprietary to

Lantech Communications Global Inc. The offer or supply of these products

and services does not include or infer any transfer of ownership.

Interference Issues

This Equipment has been tested and has been found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful

interference in a commercial or industrial installation. This equipment

generates, uses, and can radiate radio frequency energy. It may cause

harmful interference to radio communications if the equipment is not installed

and used in accordance with the instructions.

FCC Warning

This Equipment has been tested and found to comply with the limits for a

Class-A digital device, pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy. It may cause harmful interference to radio

communications if the equipment is not installed and used in accordance

with the instructions. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

CE Mark Warning

This is a Class-A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

Content

Chapter 1 Hardware Description............................ 5

1.1 Physical Dimension .................................... 5

1.2 Package Content: ........................................ 6

1.3 IP Protection ................................................ 7

1.4 LED Indicators............................................10

1.5 Bypass design............................................11

Charter 2. Hardware Installation ............................ 13

2.1 Wall mount installation ..............................13

Chapter 3 Connect Cable ..................................... 16

3.1 Power input M12 connector. .....................16

3.2 Console & USB dongle M12 connector ....18

3.3 10/100Tx interface M12 connector ............19

3.4 10G interface M12 connector ....................21

3.5 Fiber interface Q-ODC connector .............22

3.6 Ground interface M6 connector ................23

Chapter 4 Maintenance......................................... 24

Chapter 5 Console Management.......................... 25

5.1 Connecting to the Console Port ................25

5.2 Login in to the Console Interface ..............25

Chapter 1 Hardware Description

Lantech T(P)ES-R6616XFT / T(P)ES-R6616XT are high performance OS4 EN50155

10G uplink Ethernet switches with 16 10/100TX (with up to 16 PoE at/af injectors) by

M12 connectors which provides L2 wire speed and advanced security function for

connecting PD network.

In this paragraph, it will describe the Industrial switch’s hardware spec, port, cabling

information, and wiring installation.

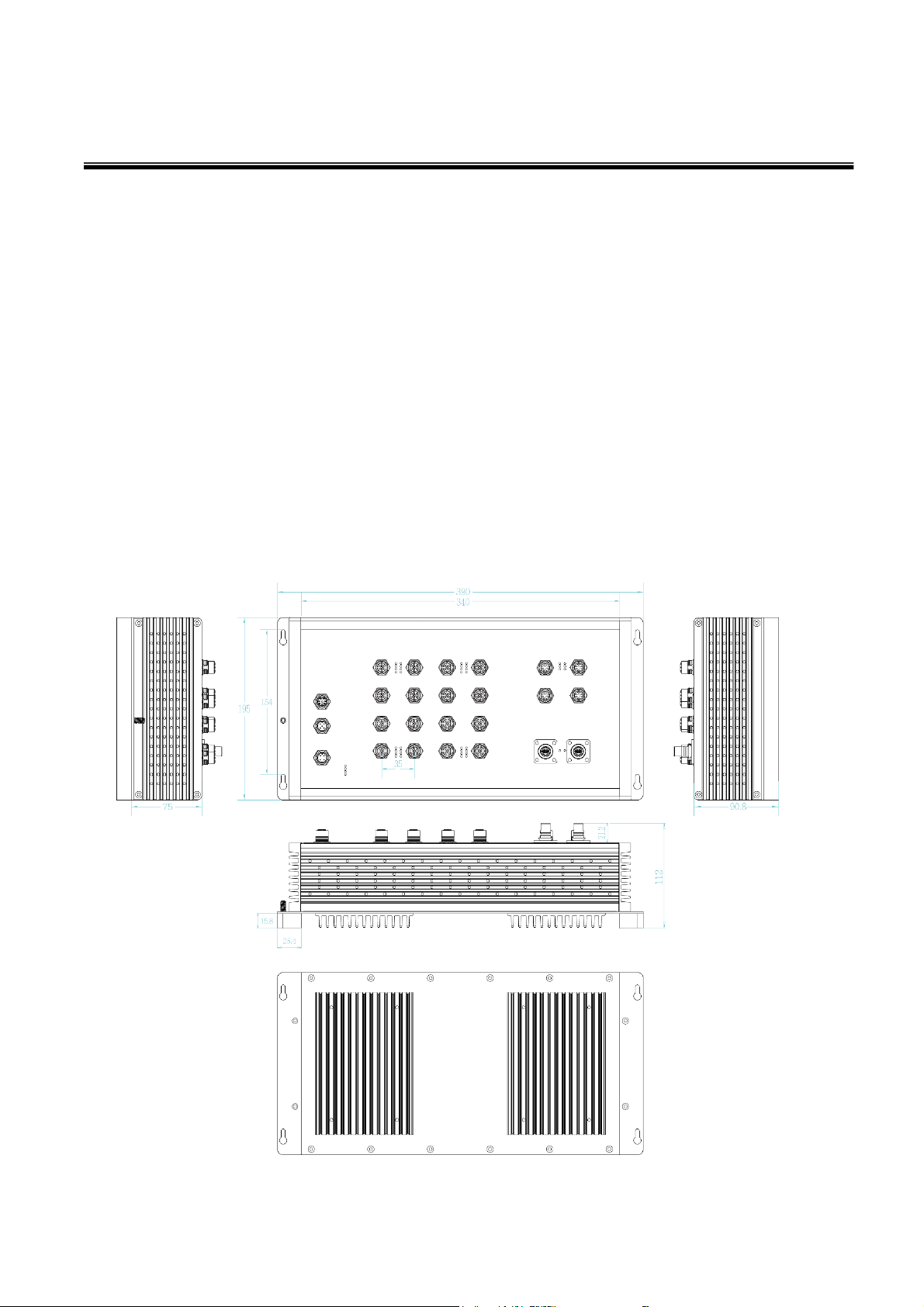

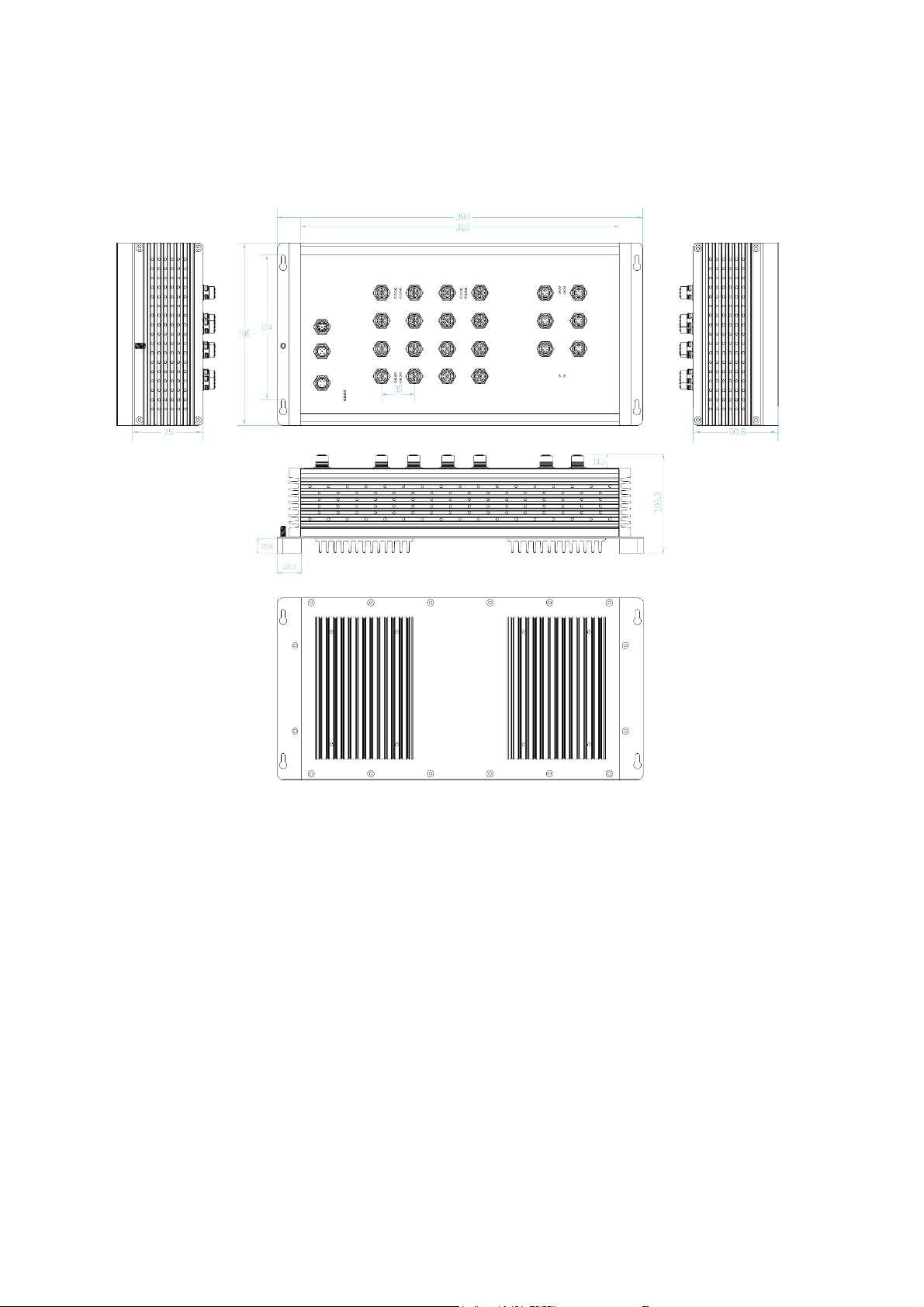

1.1 Physical Dimension

T(P)ES-R6616XFT

Aluminum case. IP-21,

390 (W) x 195 (D) x 112 (H) mm

5

T(P)ES-R6616XT

Aluminum case. IP-21,

390 (W) x 195 (D) x 105.3 (H) mm

1.2 Package Content:

Product

Console cable

6

Level

Object size

protected against

Effective against

0

—

No protection against contact and ingress of objects

1

>50 mm

Any large surface of the body, such as the back of a

hand, but no protection against deliberate contact

with a body part

2

>12.5 mm

Fingers or similar objects

3

>2.5 mm

Tools, thick wires, etc.

4

>1 mm

Most wires, screws, etc.

5

Dust protected

Ingress of dust is not entirely prevented, but it must

not enter in sufficient quantity to interfere with the

satisfactory operation of the equipment; complete

protection against contact

6

Dust tight

No ingress of dust; complete protection against

contact

1.3 IP Protection

The IP Code, Ingress Protection Rating, sometimes also interpreted as International

Protection Rating, classifies and rates the degree of protection provided against the

intrusion (including body parts such as hands and fingers), dust, accidental contact, and

water in mechanical casings and with electrical enclosures. It is published by the

International Electrotechnical Commission (IEC)

Solid particle protection

The first digit indicates the level of protection that the enclosure provides against access

to hazardous parts (e.g., electrical conductors, moving parts) and the ingress of solid

foreign objects.

7

Level

Protected

against

Testing for

Details

0

Not

protected

—

—

1

Dripping

water

Dripping water (vertically

falling drops) shall have no

harmful effect.

Test duration: 10 minutes

Water equivalent to 1 mm

rainfall per minute

2

Dripping

water when

tilted up to

15°

Vertically dripping water

shall have no harmful effect

when the enclosure is tilted

at an angle up to 15° from

its normal position.

Test duration: 10 minutes

Water equivalent to 3 mm

rainfall per minute

3

Spraying

water

Water falling as a spray at

any angle up to 60° from

the vertical shall have no

harmful effect.

Test duration: 5 minutes

Water volume: 0.7 litres per

minute

Pressure: 80–100 kPa

4

Splashing

of water

Water splashing against

the enclosure from any

direction shall have no

harmful effect.

Test duration: 5 minutes

Water volume: 10 litres per

minute

Pressure: 80–100 kPa

5

Water jets

Water projected by a

nozzle (6.3 mm) against

enclosure from any

direction shall have no

harmful effects.

Test duration: at least

15 minutes

Water volume: 12.5 litres per

minute

Pressure: 30 kPa at distance

of 3 m

Liquid ingress protection

The second digit indicates the level of protection that the enclosure provides against

harmful ingress of water.

8

6

Powerful

water jets

Water projected in powerful

jets (12.5 mm nozzle)

against the enclosure from

any direction shall have no

harmful effects.

Test duration: at least

3 minutes

Water volume: 100 litres per

minute

Pressure: 100 kPa at

distance of 3 m

7

Immersion

up to 1 m

Ingress of water in harmful

quantity shall not be

possible when the

enclosure is immersed in

water under defined

conditions of pressure and

time (up to 1 m of

submersion).

Test duration: 30 minutes

Immersion at depth of at

least 1 m measured at

bottom of device, and at least

15 cm measured at top of

device

8

Immersion

beyond 1 m

The equipment is suitable

for continuous immersion in

water under conditions

which shall be specified by

the manufacturer.

Normally, this will mean

that the equipment is

hermetically sealed.

However, with certain types

of equipment, it can mean

that water can enter but

only in such a manner that

it produces no harmful

effects.

Test duration: continuous

immersion in water

Depth specified by

manufacturer

9

Powerful

high

temperature

water jets

Protected against closerange high pressure, high

temperature spray downs.

—

9

LED

Color

Status

Meaning

R.M

Green

On

The switch unit is owner switch of ITURing

Off

The switch is not owner switch

PWR1

Green

On

Power 1 is active

Off

Power 1 is inactive

PWR2

Green

On

Power 2 is active

Off

Power 2 is inactive

FAULT

Red

On

Power or port failure

Off

No failure

P1 ~ P16

Link/Act

Green

On

A network device is detected.

Blinking

The port is transmitting or receiving

packets from the TX device.

Off

No device attached

P17 ~ P22

(R6616XT)

Link/Act

P17 ~ P20

(R6616XFT)

Link/Act

Yellow /

Orange

On(Yellow)

A network device with 1G/2.5G/5G

interface is detected.

On(Orange)

A network device with 10G copper

interface is detected.

Blinking

The port is transmitting or receiving

packets from the TX device

Off

No device attached

1.4 LED Indicators

The diagnostic LEDs that provide real-time information of system and optional status are

located on the front panel of the industrial switch. The following table provides the

description of the LED status and their meanings for the switch.

10

P21&P22

(R6616XFT)

Link/Act

Orange

On

A network device is detected.

Off

No device attached

Notification: P21&P22 ports are designed with 10G fiber interface and extend from

CPU, not PHY chipset. So both these ports don’t support blinking status when data is

forwarding via port21 or port22 or both.

PoE

(TPES-R6616XFT & TPESR6616XT)

On

The port is operating in PoE mode.

Off

The port is not operating in PoE mode.

1.5 Bypass design

(Available on -BT/-BBT/-BF/-BBT-BF models)

The bypass module is like an alarm relay but it has default position – close. When

system finish booting procedures, CPU will ask bypass module change position from

close to open and keep in open status. That’s why when switch loss the power, bypass

module will be active, because CPU has no ability to ask bypass module keep in open

status then bypass will be restored to default position – close.

There is another condition will trigger bypass module -- CPU hang. When CPU is hang,

it also loss ability to ask bypass module keep in open status. But at this time, watch dog

chipset will force to reset CPU then system will reboot. The CPU will back to normal

status after rebooting then ask bypass module to keep in open status.

Bypass mechanism in open status

11

Bypass mechanism in close status

12

Charter 2. Hardware Installation

There are no mechanically active moving parts in the switch, to fix the switch into an

installation position, please use M4 size screw and corresponding nut and standard M4

screwdriver to install switch in the field.

2.1 Wall mount installation

1. Please make sure the screw diameter is M4.

2. Check all 4 fix holes on the switch and find corresponding position in the wall .Use

the appropriate tool to drill 4 holes onto the corresponding position, make sure the

diameter of holes is compatible with the M4 screws, fix the 4 screws into these 4

holes but don’t screw tightly, in order to have enough space to mount the switch.

3. Mount switch in wall with 4 fixed screws.

13

4. Attach switch in wall with 4 screws

5. Move down

6. Tighten 4 screws

14

15

Chapter 3 Connect Cable

After the hardware installation is complete, please connect the cable to the switch. All the

external interfaces use M12 connector design and follow IEC 61076 standard except the for

the fiber interface with QODC connector. The M12 connector on the 10G copper interface

supports IEC 61076-2-109 standard, make sure the connector for the 10G cable also

supports this standard or it will reduce the Max throughput of the 10G copper interface.

3.1 Power input M12 connector.

Spec. of power input

Voltage of Power Input:

Dual DC input, 16.8VDC~137.5VDC

Total PoE budget: 80W

Please make sure that the external power supply unit can satisfy the total power

consumption in field.

Ping assignment of power input

Make sure the direction of connector is correct before you connect it.

16

Plug power connector and screw in clockwise direction to fix it.

17

3.2 Console & USB dongle M12 connector

Ping assignment of console & USB dongle

Note: The USB port is USB 2.0 speed, not USB 3.0

Make sure the connector is the right direction before you connect it.

Plug console connector and screw in clockwise direction to fix it.

18

3.3 10/100Tx interface M12 connector

(Port 1 – Port 16 on TPES-R6616XFT and TPES-R6616XT)

Ping assignment of the 10/100Tx port

19

Make sure the direction of connector is correct before you connect it.

Plug the 10/100Tx connector and screw in clockwise direction to fix it.

20

3.4 10G interface M12 connector

(Port 17 – Port 20 on TPES-R6616XFT and Port 17 – Port 22 on TPES-R6616XT)

Ping assignment of the 10G port

Make sure the direction of connector is correct before you connect it.

Plug 10G connector and screw in clockwise direction to fix it.

21

3.5 Fiber interface Q-ODC connector

(Port 21 – Port 22 on TPES-R6616XFT & TES-R6616XFT)

Make sure the direction of the connector is correct before you connect it.

Plug 10G connector and move in different directions to make sure the Q-ODC connector

is correctly connected with the interface.

22

3.6 Ground interface M6 connector

Ground

The chassis is grounded via a separate grounding nut (M6).

Use toothed locking washers for a good electrical connection.

23

Ground screw of the switch

Chapter 4 Maintenance

1 Check each switch connection and make sure they are all screwed correctly.

2 Keep the anti-dust cap on all un-used switch interface

3 Access switch via web browser and check the below points:

3.1 Compare the physical connection of the switch port with the switch icon on the web

user interface to make sure the connecting status match each other.

3.2 Check the information on the hardware monitor to make sure all conditions are in

normal status.

3.3 Check event log to see if there are any abnormal events.

24

Chapter 5 Console Management

5.1 Connecting to the Console Port

The supplied cable has one M12 4-pole connector end and another RS-232 connector

end. Attach the RS-232 connector end to a PC or terminal and the other M12 connector

end to the console port of the switch. The connected terminal or PC must support the

terminal emulation program.

5.2 Login in to the Console Interface

When the connection between Switch and PC is ready, turn on the PC and run a

terminal emulation program or Hyper Terminal and configure the communication

parameters to match the following default characteristics of the console port:

Baud Rate:115200 bps

Data Bits: 8

Parity: none

Stop Bit: 1

Flow control: None

25

The settings of communication parameters

Having finished setting up the parameters, click ‘OK’. When the blank screen shows up,

press the Enter key to have the login prompt appear. Key in ‘admin’ (default value) for

both User name and Password (use Enter key to switch), then press Enter and the Main

Menu of console management should appear. Please see below figure for login screen.

Console login interface

===============Notice===============

For web-based management, please refer to our “Software Management Manual”.

Please contact support@lantechcom.tw for more information.

26

Loading...

Loading...