4 10/100/1000T + 4 10/100/1000T/Dual

Speed SFP L2 Managed Industrial Switch

w/ Pro-Ring

IGS-2404

User Manual

Content

Overview

Introduc

.............................................................1

tion ..............................................................1

Features................................................................... 4

Packing List

Safety Precaution

Hardware Description

Front Panel

Top View

..............................................................6

.....................................................6

.........................................7

...............................................................7

..................................................................8

Wiring the Power Inputs

LED Indicators

Ports

Cabling

.......................................................................10

...................................................................11

..........................................................9

Mounting Installation

DIN-Rail Mounting

Wall Mount Plate Mounting

..................................................15

Hardware Installation

...........................................8

........................................15

....................................16

........................................18

Installation Steps....................................................18

X-Ring Application.................................................. 19

Coupling Ring Application...................................... 20

Dual Homing Application........................................21

Console Management......................................23

Connecting to the Console Port.............................23

Pin Assignment......................................................23

Login in the Console Interface ............................... 24

CLI Management.................................................... 25

Commands Level.............................................................26

Commands Set List..........................................................27

System Commands Set ...................................................27

Port Commands Set.........................................................30

Trunk Commands Set......................................................32

VLAN Commands Set......................................................33

Spanning Tree Commands Set........................................35

QOS Commands Set .......................................................38

IGMP Commands Set......................................................39

Mac / Filter Table Commands Set....................................39

SNMP Commands Set.....................................................40

Port Mirroring Commands Set

802.1x Commands Set

TFTP Commands Set

SystemLog, SMTP and Event Commands Set

SNTP Commands Set

Pro-ring Commands Set

.....................................................43

......................................................45

......................................................48

...................................................49

Web-Based Management

About Web-based Management

Preparing for Web Management

..........................................42

.................................50

............................50

............................50

................46

System Login

Main interface

System Information

.........................................................51

.........................................................52

................................................53

IP Configuration .....................................................53

DHCP Server – System configuration

DHCP Client – System Configuration

DHCP Server - Port and IP Bindings

TFTP - Update Firmware

.......................................56

....................54

....................55

.....................56

TFTP – Restore Configuration

TFTP - Backup Configuration

...............................57

.................................57

System Event Log – Syslog Configuration

.............58

System Event Log - SMTP Configuration .............. 59

System Event Log - Event Configuration...............61

Fault Relay Alarm................................................... 63

SNTP Configuration...............................................63

IP Security.............................................................. 66

User Authentication................................................ 67

Port Statistics.........................................................68

Port Control............................................................ 69

Port Trunk ..............................................................70

Aggregator setting............................................................70

Aggregator Information ....................................................71

State Activity ....................................................................72

Port Mirroring .........................................................73

Rate Limiting..........................................................73

VLAN configuration................................................74

VLAN configuration - Port-based VLAN...........................75

802.1Q VLAN...................................................................78

Rapid Spanning Tree.............................................81

RSTP - System Configuration..........................................81

RSTP - Port Configuration ...............................................82

SNMP Configuration

System Configuration

Trap Configuration

SNMPV3 Configuration

QoS Configuration

QoS Policy and Priority Type

Port Base Priority

COS Configuration

TOS Configuration

.............................................................90

..............................................83

.......................................................84

...........................................................85

....................................................86

..................................................89

...........................................................91

...........................................................91

...........................................89

IGMP Configuration

Pro-Ring System

Security

802.1X/Radius Configuration

MAC Address Table

..................................................................95

Factory Default

....................................................93

.....................................................101

Save Configuration

System Reboot

Troubles shooting

.....................................................101

...........................................102

................................................91

...........................................95

.........................................................98

...............................................101

Technical Specification

...................................103

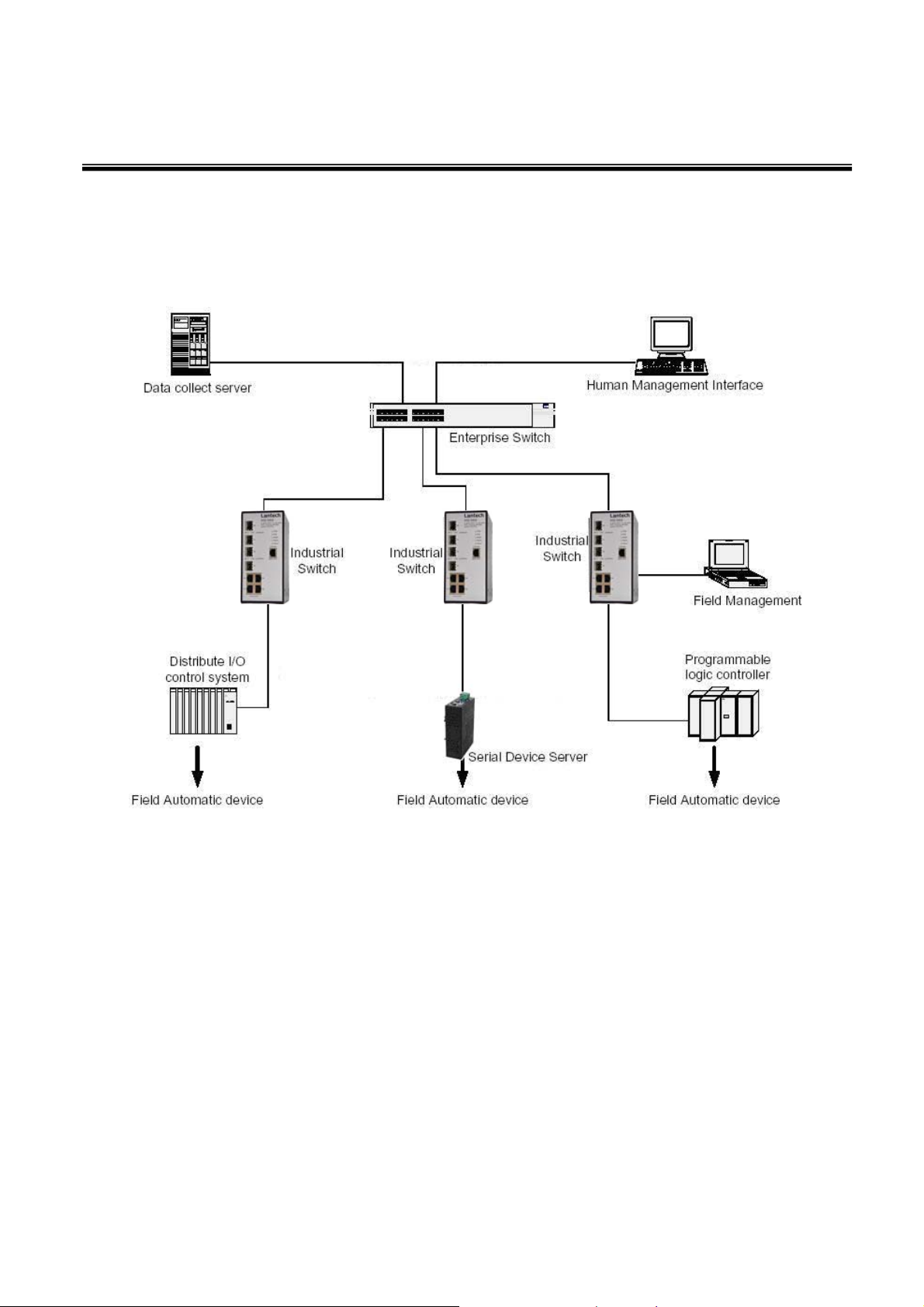

Overview

Introduction

To create reliab

Managed Industrial Switch comes equipped with a proprietary

redundant network protocol:Pro-Ring provides users with an easy way

to establish a redundant Ethernet network with ultra high-speed

recovery time less than 10 ms. Also, the long MTBF (Mean Time

Between Failures) ensures that the industrial switch will continue to

operate until a Gigabit network infrastructure has been established,

without requiring any extra upgrade costs.

Aside from 4 x 10/100/1000Base-TX fast Ethernet ports, the 4

10/100/1000T + 4 SFP Managed Industrial Switch comes equipped with

4 SFP (mini-GBIC) ports. Traditional RJ-45 ports can be used for

uplinking wide-band paths in short distance (< 100 m), while the SFP

slots can be used for the applic

distance transmissions to fit the field request flexibility. Also, the long

MTBF (Mean Time Between Failures) ensures that the 4 10/100/1000T

+ 4 SFP Managed Industrial Switch will continue to operate until a

ility in your network, the 4 10/100/1000T + 4 SFP

ation of wideband uploading and long

Gigabit network infrastructure has been established, without requiring

any extra upgrade costs.

The SFP Advantage

The SFP fiber slots provide a lot of flexibility when planning and

implementing a network. The slot can accept any SFP-type fiber module

and these modules are designed for transmitting over distances of

either 500m (multi-mode), 10km, 30km, 50km, 70km or 110km

(single-mode) – and the slot support SFP modules for WDM single-fiber

transmissions. This means that you can easily change the transmission

mode and distance of the switch by simply pulling out the SFP module

and plugging in a different module. The SFP modules are

hot-swappable and plug-and-play.

1

High-Speed Transmissions

The 4 10/100/1000T + 4 SFP Managed Industrial Switch includes a

switch controller that can automatically sense transmission speeds

(10/100/1000 Mbps). The RJ-45 interface can also be auto-detected, so

MDI or MDI-X is automatically selected and a crossover cable is not

required. All Ethernet ports have memory buffers that support the

store-and-forward mechanism. This assures that data is properly

transmitted.

Dual Power Input

The redundant power input design of 4 10/100/1000T + 4 SFP Managed

Industrial Switch is with power reserve protection to prevent the switch

device broken by wrong power wiring. When one of power input is fail,

P-Fail LED will turn on and send an alarm through a relay output for

notifying user.

Flexible Mounting

4 10/100/1000T + 4 SFP Managed Industrial Switch is compact and can

be mounted on a DIN-rail or panel, so it is suitable for any

space-constrained environment.

Advanced Protection

The power line of 4 10/100/1000T + 4 SFP Managed Industrial Switch

supports up to 3,000 VDC EFT protection, which secure equipment

against unregulated voltage and make systems safer and more reliable.

Meanwhile, 4,000 VDC ESD protections for Ethernet ports make 4

10/100/1000T + 4 SFP Managed Industrial Switch more suitable for

harsh environments.

Wide Operating Temperature

2

The operat

ing temperature of the 4 10/100/1000T + 4 SFP Managed

Industrial Switch is between -20 ~ 60 ℃. With such a wide range, you

can use the 4 10/100/1000T + 4 SFP Managed Industrial Switch in

some of the harshest industrial environments that exist.

Troubleshooting

Easy

LED indic

ators make troubleshooting quick and easy. Each

10/100/1000 Base-TX port has 2 LEDs that display the link status,

transmission speed and collision status. Also the three power indicators

P1, P2 and Fault help you diagnose immediately.

3

Features

Provides 4 x 10/100/1000Base-T Mbps Ethernet ports

Provides 4 x SFP (mini-GBIC) port (support 100/1000 Dual Mode)

Supports full/half duplex flow control

Supports auto-negotiation

Supports MDI/MDI-X auto-crossover

Supports Packet Buffer up to 1Mbits

Supports MAC Address up to 8Kbytes

Supports surge (EFT) protection 3,000 V

Supports 4,000 V

hernet ESD protection

Et

DC

Power Supply

¾ Wide-range Redundant Power Design

¾ Power Polarity Reverse Protect

¾ Overload Current Protection

Case/Installation

¾ IP-30 Protection

¾ DIN Rail and Wall Mount Design

Spanning Tree

¾ Support IEEE802.1d Spanning Tree

¾ Support IEEE802.1w Rapid Spanning Tree

VLAN

¾ Port Based VLAN

¾ Support 802.1 Q Tag VLAN

¾ GVRP

¾ Double Tag VLAN (Q in Q)*

for power line

DC

¾ Private VLAN**

Pro-Ring

¾ X-Ring, Dual Homing, Couple Ring Topology

¾ Provide redundant backup feature and the recovery time below

10ms

Port Trunk with LACP

Support 802.1ab LLDP

QoS (Quality of Service)

¾ Support IEEE 802.1p Class of Service

¾ Per port provides 4 priority queues

¾ Port Base, Tag Base and Type of Service Priority

Bandwidth Control

¾ Ingress Packet Filter and Egress Rate Limit

4

Broadcast/Multicast Packet Filter Control

¾

Port Mirror: Monitor traffic in switched networks.

¾ TX Packet only

¾ RX Packet only

¾ Both of TX and RX Packet

System Event Log

¾ System Log Server/Client

¾ SMTP e-mail Alert

¾ Relay Alarm Output System Events

Security

¾ Port Security: MAC address entries/filter

¾ IP Security: IP address security management to prevent

unauthorized intruder

¾ Login Security: IEEE802.1X/RADIUS

SNMP Trap

¾ Device cold start

¾ Power status

¾ Authentication failure

¾ X-Ring topology changed

¾ Port Link up/Link down

IGMP with Query mode for Multi Media Application

TFTP Firmware Update and System Configure Restore and Backup

Supports operating temperatures from -40 ~ 85 ℃ (wide operating

temperature model) or -20 ~ 60 ℃ (standard model)

5

Packing List

1 x 4 10/100/1000T + 4 SFP Managed Industrial Switch

1 x User Manual

2 x Wall Mounting Bracket and Screws

Safety Precaution

Attention IF DC voltage is supplied by an external circuit, please use a

protection device on the power supply input.

6

Hardware Description

In this paragraph, we will introduce the Industrial switch’s hardware spec, port, cablin

information, and wiring installation.

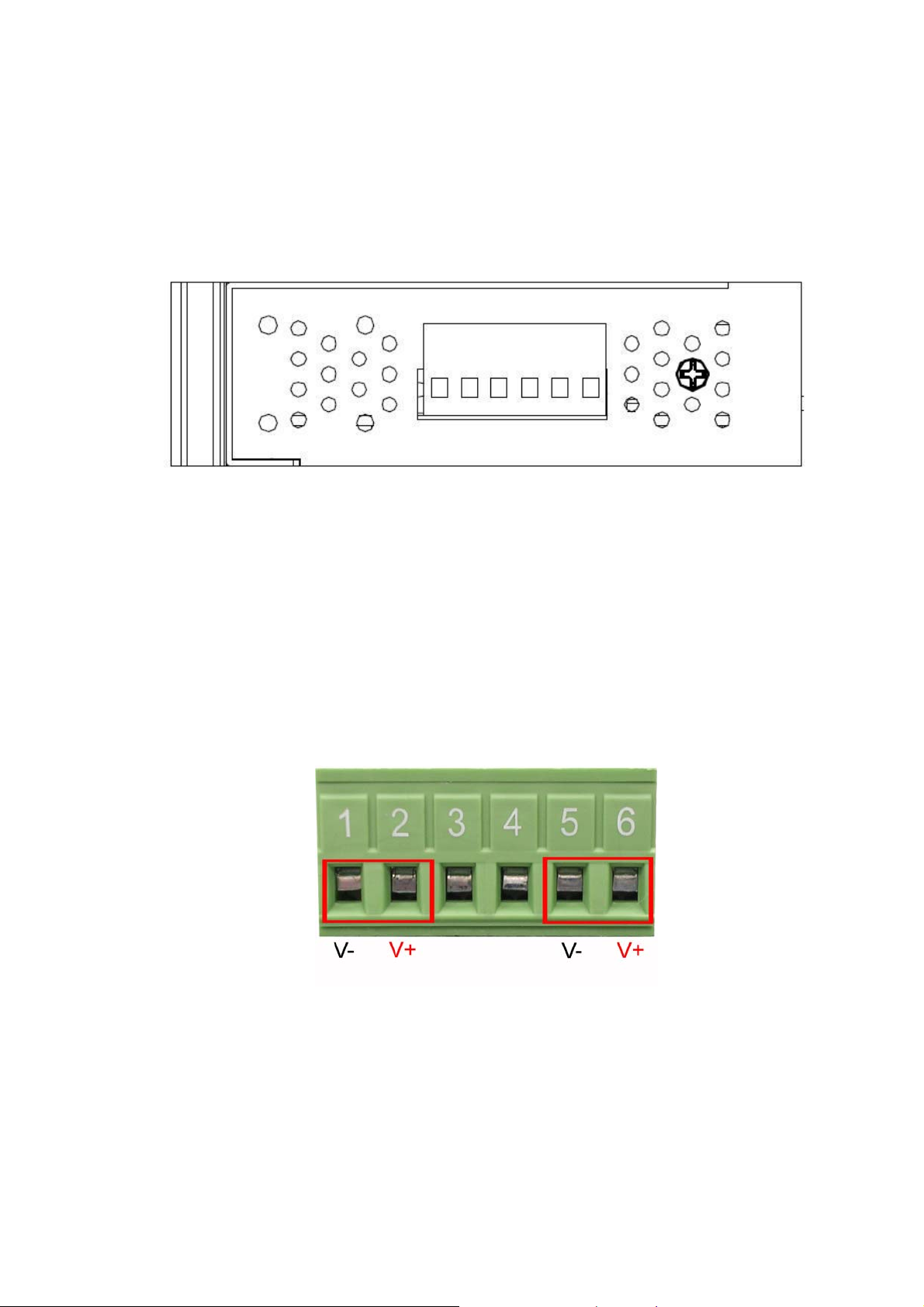

Front Panel

The Front Panel of 4 10/100/1000T + 4 SFP Managed Industrial Switch is shown as

below.

g

Standard Model

7

-E Model

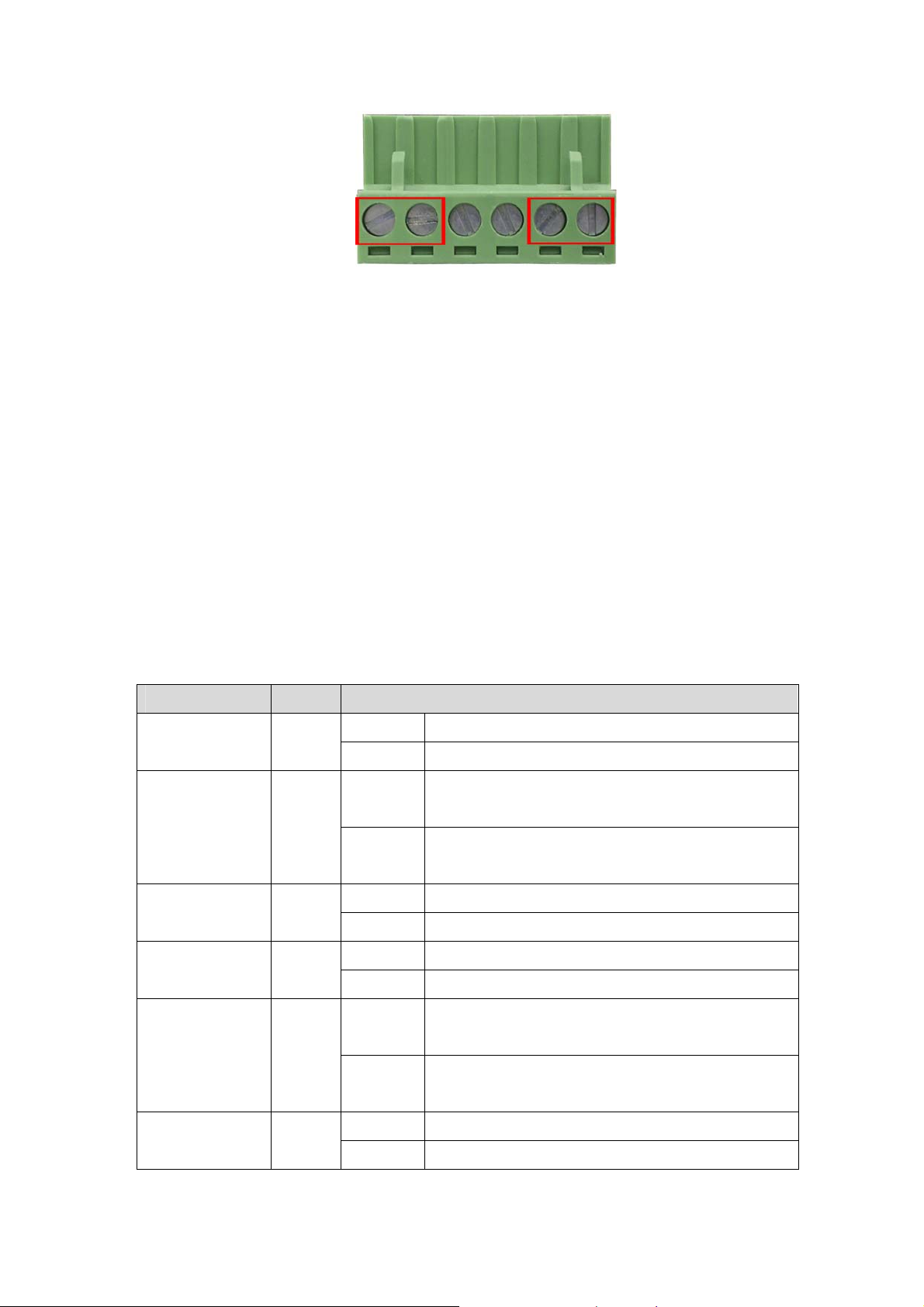

Top View

The top panel of 4 10/100/1000T + 4 SFP Managed Industrial Switch is equipped one

terminal block connector of two DC power inputs.

Top panel of the 4 10/100/1000T + 4 SFP Industrial Switch

Wiring the Power Inputs

Please follow the steps below to insert the power wire.

Insert the positive and negative wires into the V+ and V- contacts on the terminal block

connector.

8

Tighten the wire-clamp screws for preventing the wires from loosing.

Note

The wire gauge for the terminal block should be in the range

between 12~ 24 AWG.

LED Indicators

There are few LEDs display the power status and network status located on the front

panel of 4 10/100/1000T + 4 SFP Industrial Switch, each of them has its own specific

meaning as tabled below.

LED Color Description

PWR Green

R.M. Green

On System power on

Off No power inputs

The industrial switch is the master of the X-ring

On

group

The industrial switch is not the master of the X-ring

Off

group

PWR1 Green

PWR2 Green

Fault Red

Green

(P5 ~ P8)

On Power input 1 is active

Off Power input 1 is inactive

On Power input 2 is active

Off Power input 2 is inactive

On

Off

On SFP port is linking Link/Active

Flashing Data is transmitting or receiving

Power input 1 or 2 is inactive or port link down

(depends on Fault Relay Alarm configuration)

Power input 1 and 2 are both functional, or no power

inputs

9

Off Not connected to network

P1 ~ P4

(Upper LED)

(Lower LED)

Ports

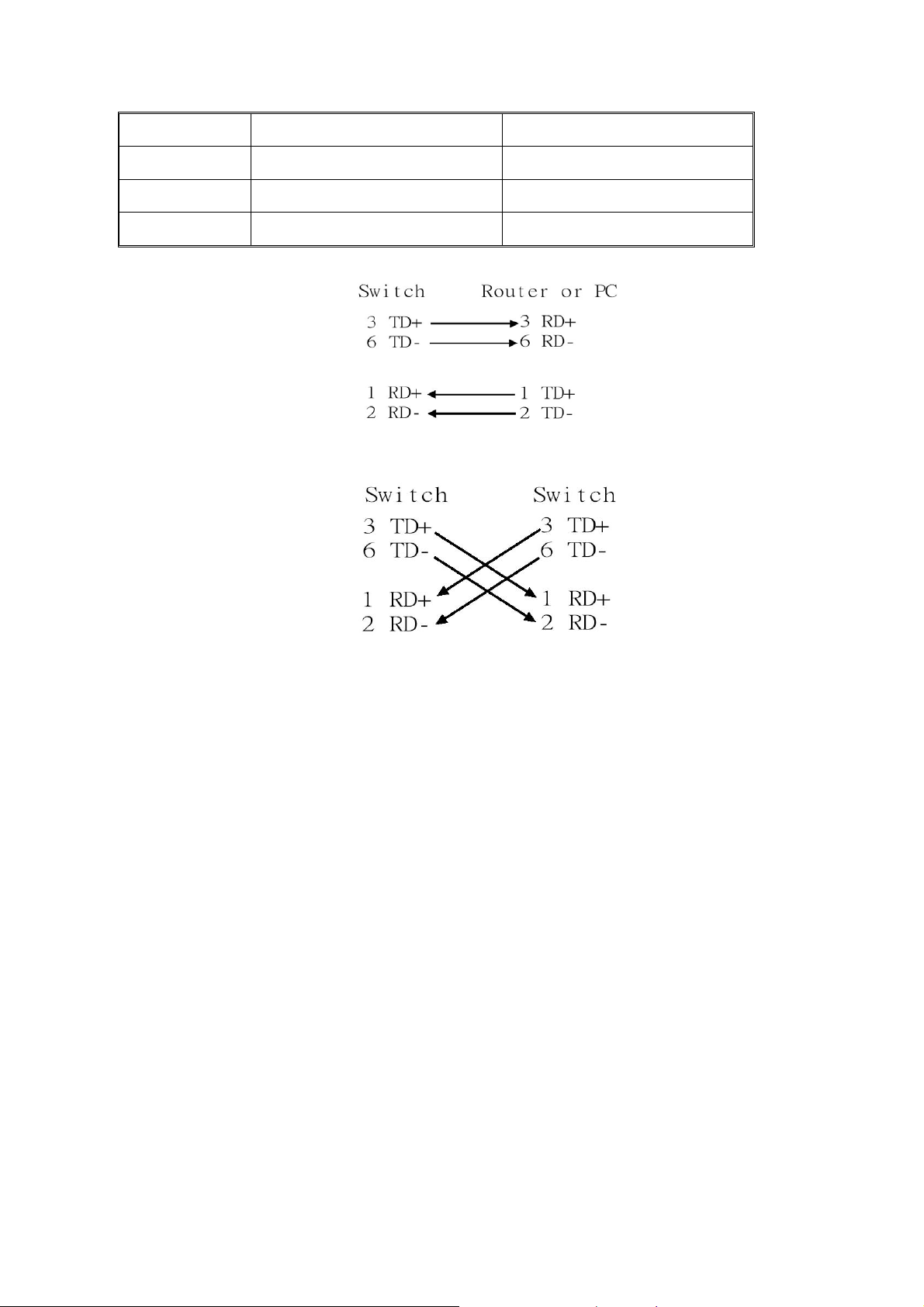

RJ-45 ports (Auto MDI/MDIX): The RJ-45 ports are auto-sensing for 10Base-T,

100Base-TX or 1000Base-T devices connections. Auto MDI/MDIX means that you can

connect to another switch or workstation without changing straight through or

crossover cabling. See figures as below for straight through and crossover cable

schematic.

On Connected to network

Green

Green

LED indicators of 4 10/100/1000T + 4 SFP Managed Industrial Switch

Flashing Networking is active at speed of 100Mbps

Off Not connected to network

On Connected to network at speed of 1000Mbps P1 ~ P4

Off Not connected to network

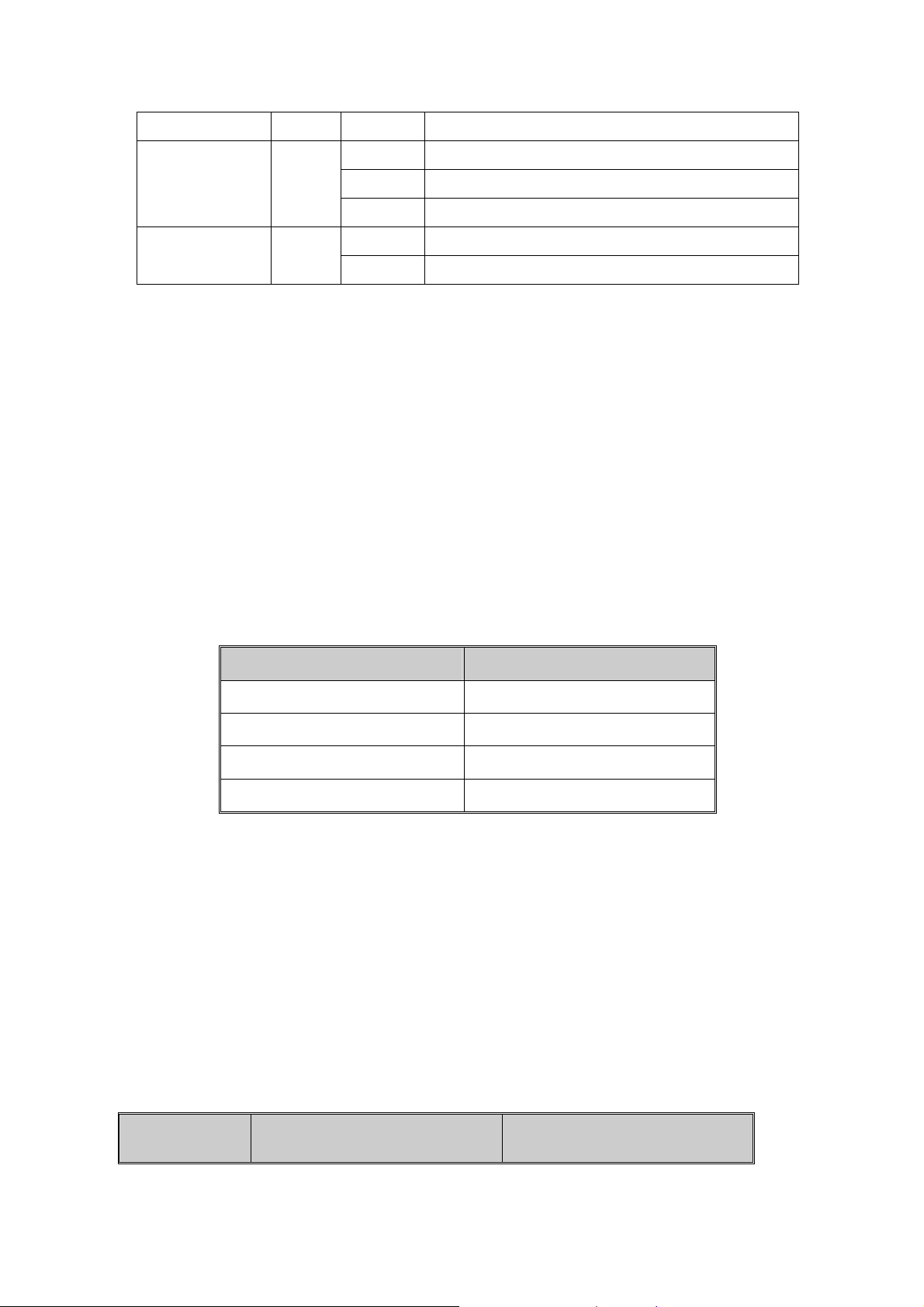

RJ-45 Pin Assignments

Pin Number Assignment

1 Tx+

2 Tx3 Rx+

6 Rx-

Note “+” and “-” signs represent the polarity of the wires that make up each wire

pair.

All ports on this industrial switch support automatic MDI/MDI-X operation, you can use

straight-through cables (See Figure below) for all network connections to PCs or

servers, or to other switches or hubs. In straight-through cable, pins 1, 2, 3, and 6, at

one end of the cable, are connected straight through to pins 1, 2, 3 and 6 at the other

end of the cable. The 10BASE-T/100BASE-TX/1000BASE-T MDI and MDI-X port pin

outs are as tabled below.

Pin MDI-X Signal Name MDI Signal Name

10

1 Receive Data plus (RD+) Transmit Data plus (TD+)

2 Receive Data minus (RD-) Transmit Data minus (TD-)

3 Transmit Data plus (TD+) Receive Data plus (RD+)

6 Transmit Data minus (TD-) Receive Data minus (RD-)

Straight Through Cable Schematic

Cabling

Use the four twisted-pair, Category 5e or above cabling for RJ-45 port connection. The

cable between the switch and the link partner (switch, hub, workstation, etc.) must be

less than 100 meters (328 ft.) long.

As for the small form-factor pluggable (SFP), which is a compact optical transceiver

used in optical communications for both telecommunication and data communication

applications.

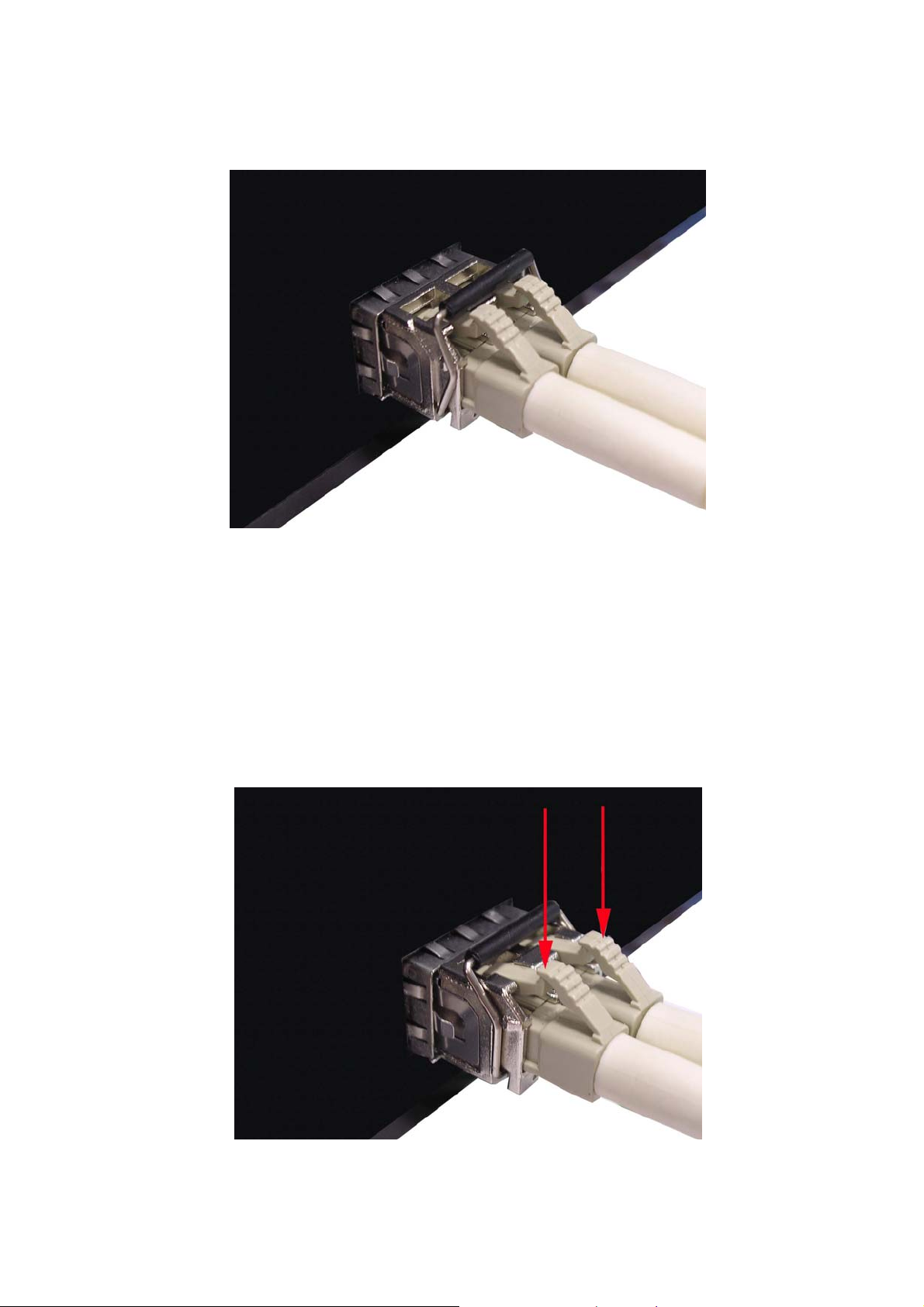

To connect the transceiver and LC cable, please take the steps shown as follows:

First, insert the transceiver into the SFP module. Notice that the triangle mark is the

bottom of the module.

Cross Over Cable Schematic

11

Transceiver to the SFP module

Transceiver Inserted

12

Second, insert the fiber cable of LC connector into the transceiver.

LC connector to the transceiver

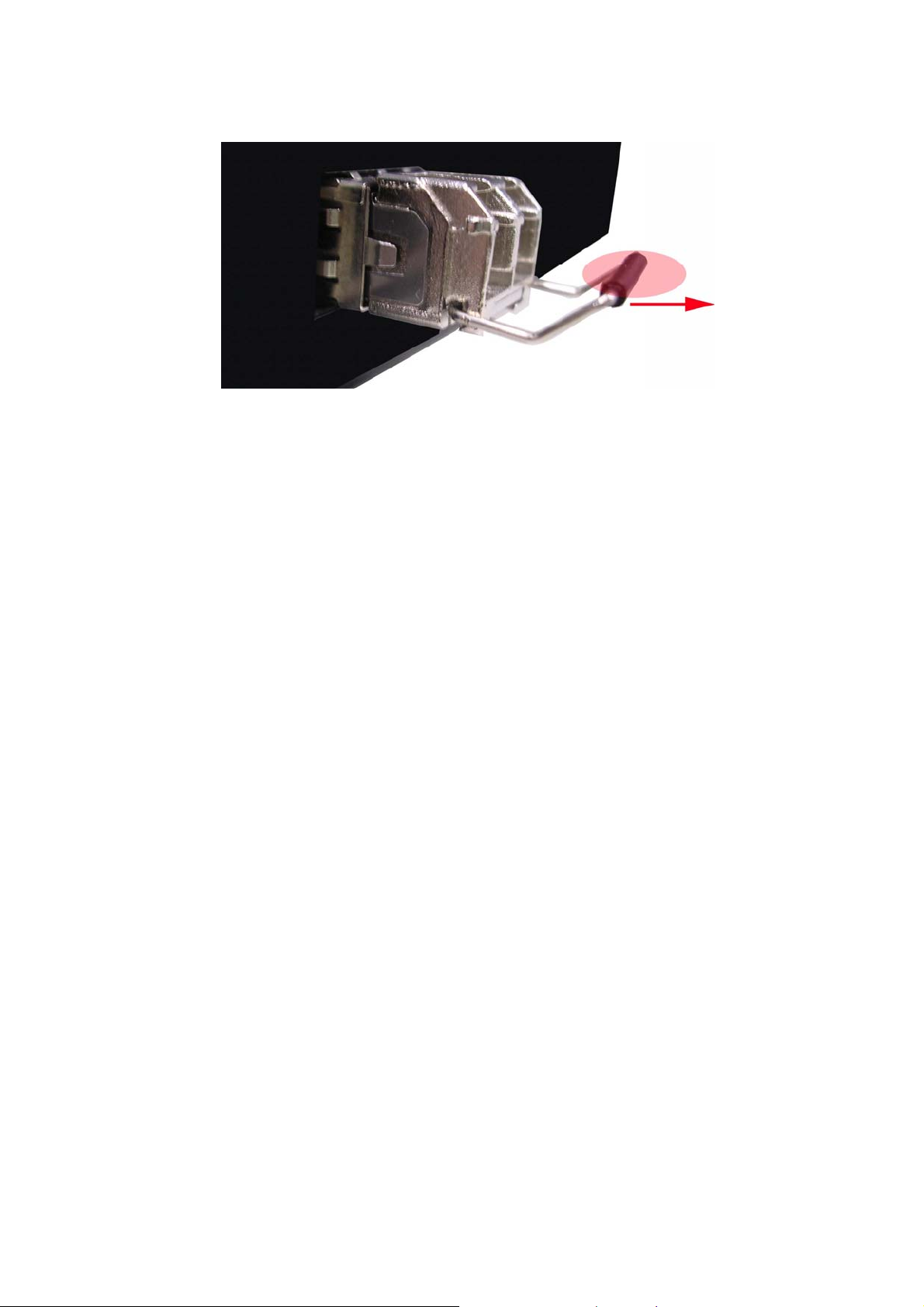

To remove the LC connector from the transceiver, please follow the steps shown

below:

First, press the upper side of the LC connector from the transceiver and pull it out to

release.

Remove LC connector

13

Second, push down the metal loop and pull the transceiver out by the plastic part.

Pull out from the SFP module

14

Mounting Installation

DIN-Rail Mounting

The DIN-Rail is screwed on the industrial switch when out of factory. If the DIN-Rail is

not screwed on the industrial switch, please see the following figure to screw the

DIN-Rail on the switch. Follow the below steps to hang the industrial switch.

Step 1: Use the screws to screw on the DIN-Rail on the industrial switch.

Step 2: To remove the DIN-Rail, reverse step 1.

15

1. First, insert the top of DIN-Rail into the track.

2. Then, lightly push the button of DIN-Rail into the track.

3. Check the DIN-Rail is tightly on the track.

4. To remove the industrial switch from the track, reverse the steps above.

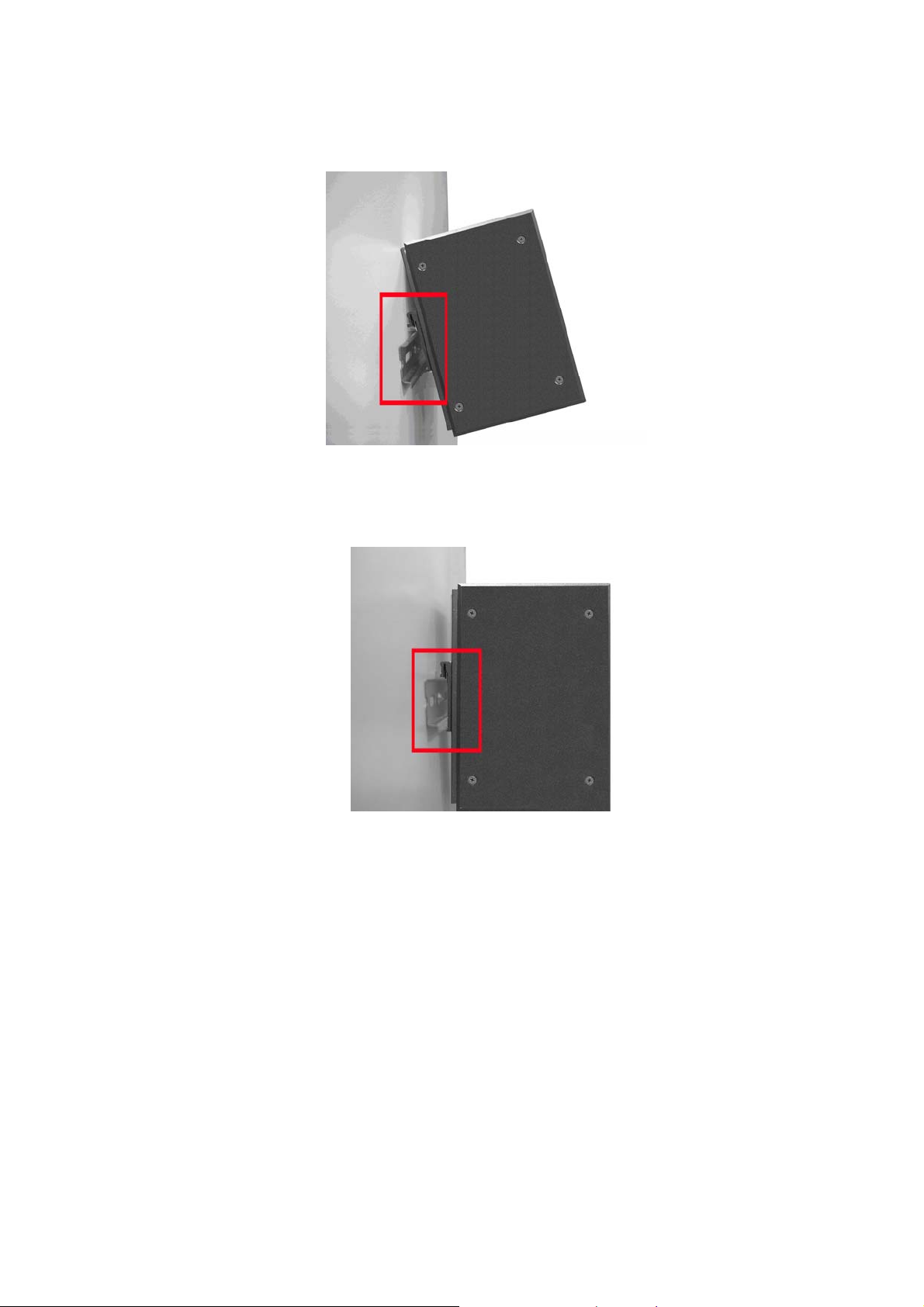

Wall Mount Plate Mounting

Follow the steps as below to mount the industrial switch with wall mount plate.

1. Remove the DIN-Rail from the industrial switch; loose the screws to remove the DIN-Rail.

2. Place the wall mount plate on the rear panel of the industrial switch.

3. Use the screws to screw the wall mount plate on the industrial switch.

16

4. Use the hook holes at the corners of the wall mount plate to hang the industrial switch on

the wall.

5. To remove the wall mount plate, reverse steps above.

Use screws to screw the wall mount plate on the rear side

17

Hardware Installation

In this paragraph, we will describe how to install the 4 10/100/1000T + 4 SFP Industrial Switc

and the installation points for the attention.

h

Installat

Unpacked the Industrial switch packing.

1.

2. Check the DIN-Rail is screwed on the Industrial switch. If the DIN-Rail is not screwed on

the Industrial switch. Please refer to DIN-Rail Mounting section for DIN-Rail installation.

If you want to wall mount the Industrial switch, then please refer to Wall Mount Plate

Mounting section for wall mount plate installation.

3. To hang the Industrial switch on the DIN-Rail track or wall, please refer to the Mounting

Installation section.

ion Steps

18

Power on the Industrial switch. How to wire the power; please refer to the Wiring the

4.

Power Inputs section. The power LED on the Industrial switch will light up. Please refer

to the LED Indicators section for meaning of LED lights.

5. Prepare the twisted-pair, straight through Category 5e/above cable for Ethernet

connection and SFP transceiver with LC cable for fiber connection.

6. Insert one side of Category 5e or above cables into the Industrial switch Ethernet port

(RJ-45 port) and another side of category 5e or above cables to the network devices’

Ethernet port (RJ-45 port), ex: switch, PC or Server. The UTP port (RJ-45) LED on the

Industrial switch will light up when the cable connected with the network device. Please

refer to the LED Indicators section for LED light meaning.

Note Be sure the connected network devices support MDI/MDI-X. If it does not

support, then use the crossover category 5e/above cable.

7. As for the SFP (mini-GBIC) port, please refer to the Cabling segment.

8. When all connections are all set and LED lights all show in normal, the installation is

complete.

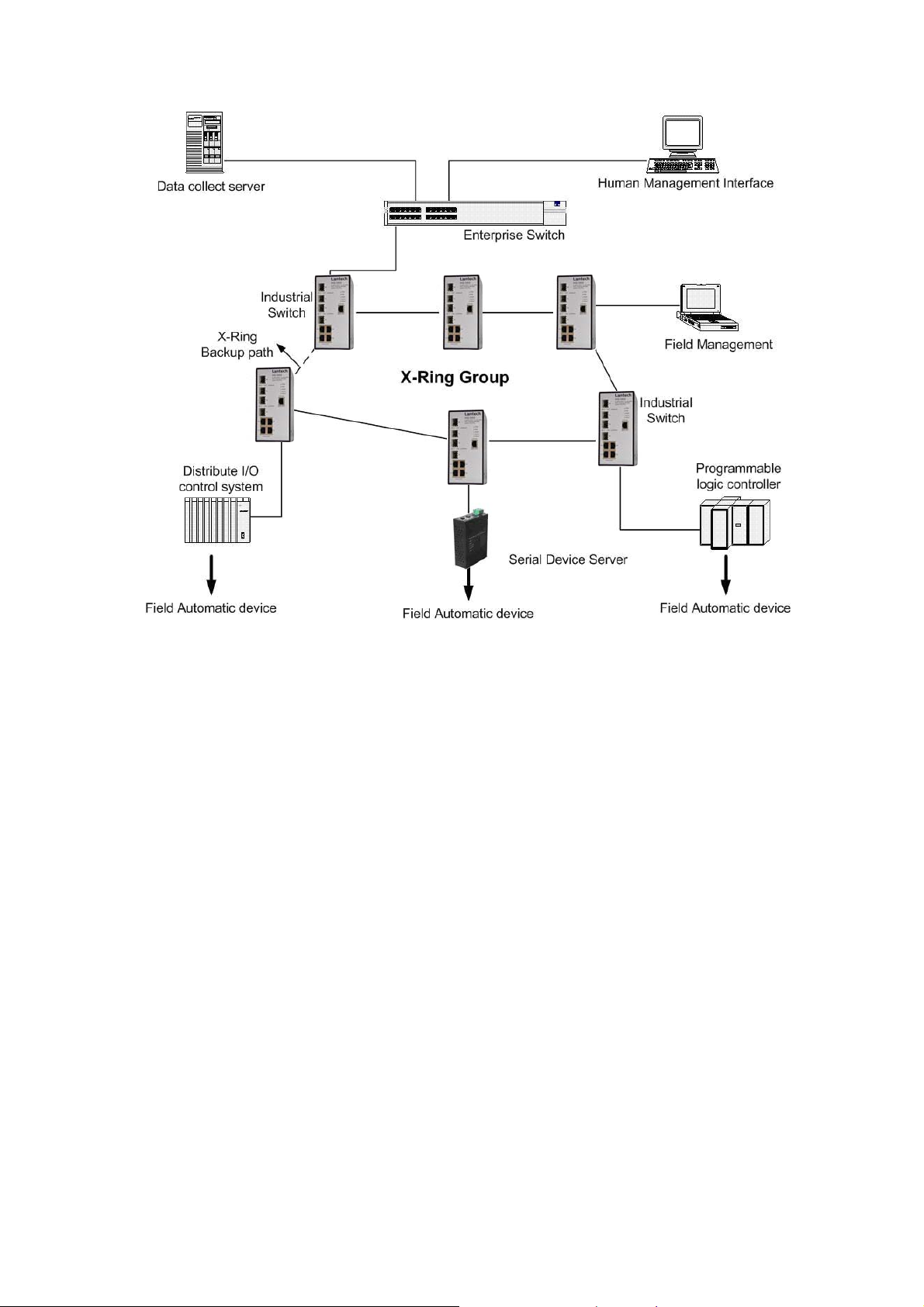

X-Ring Application

The industrial switch supports the X-Ring protocol that can help the net

recover from network connection failure within 10ms or less, and make the network

system more reliable. The X-Ring algorithm is similar to Spanning Tree Protocol (STP)

and Rapid STP (RSTP) algorithm but its recovery time is less than STP/RSTP. The figure

below is a sample of X-Ring application.

work system

19

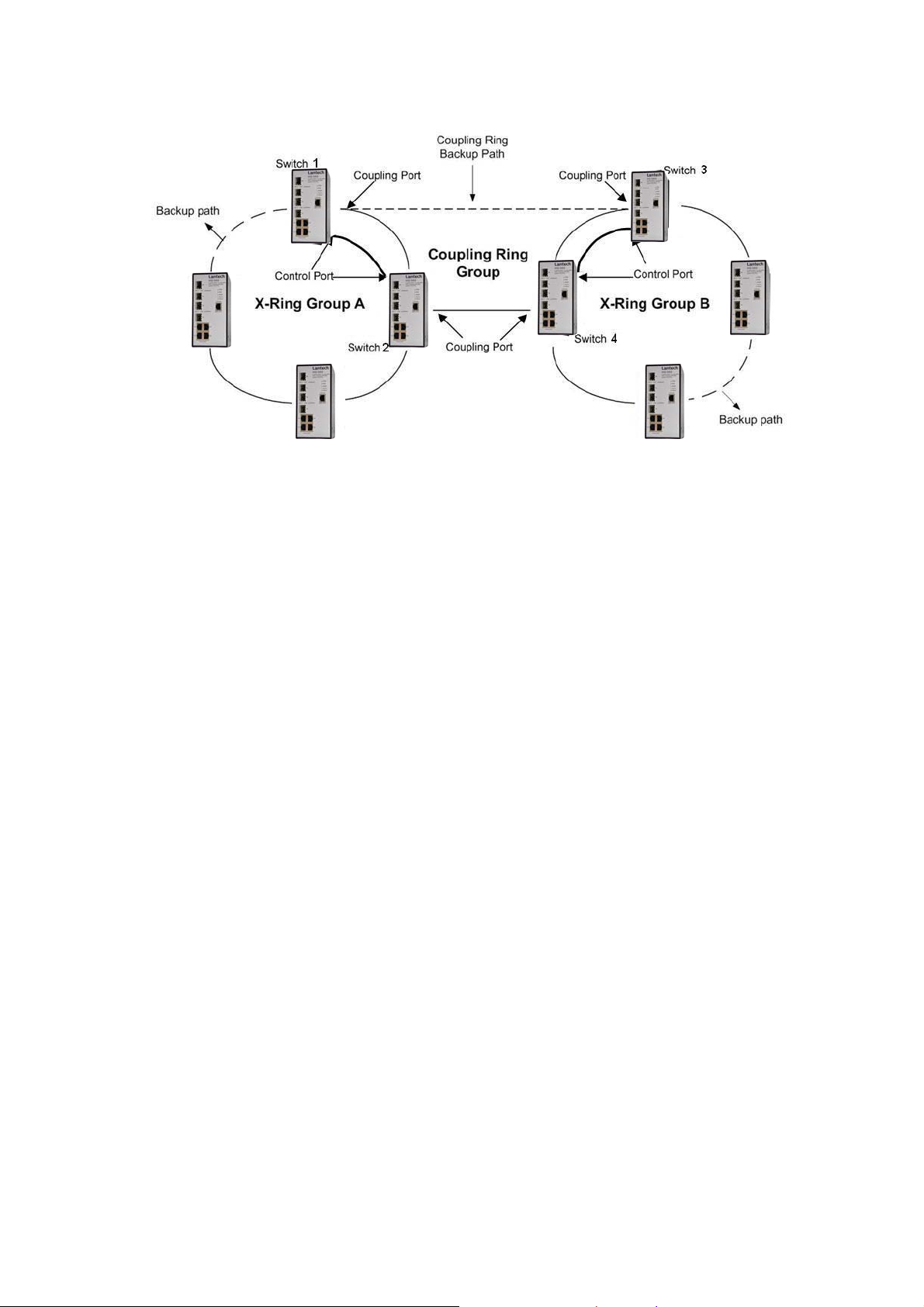

Coupling Ring Application

In the netw

can connect each X-Ring for the redundant backup. It can ensure the transmissions

between two ring groups not to fail. The following figure is a sample of coupling ring

application.

ork, it may have more than one X-Ring group. Using the coupling ring function

20

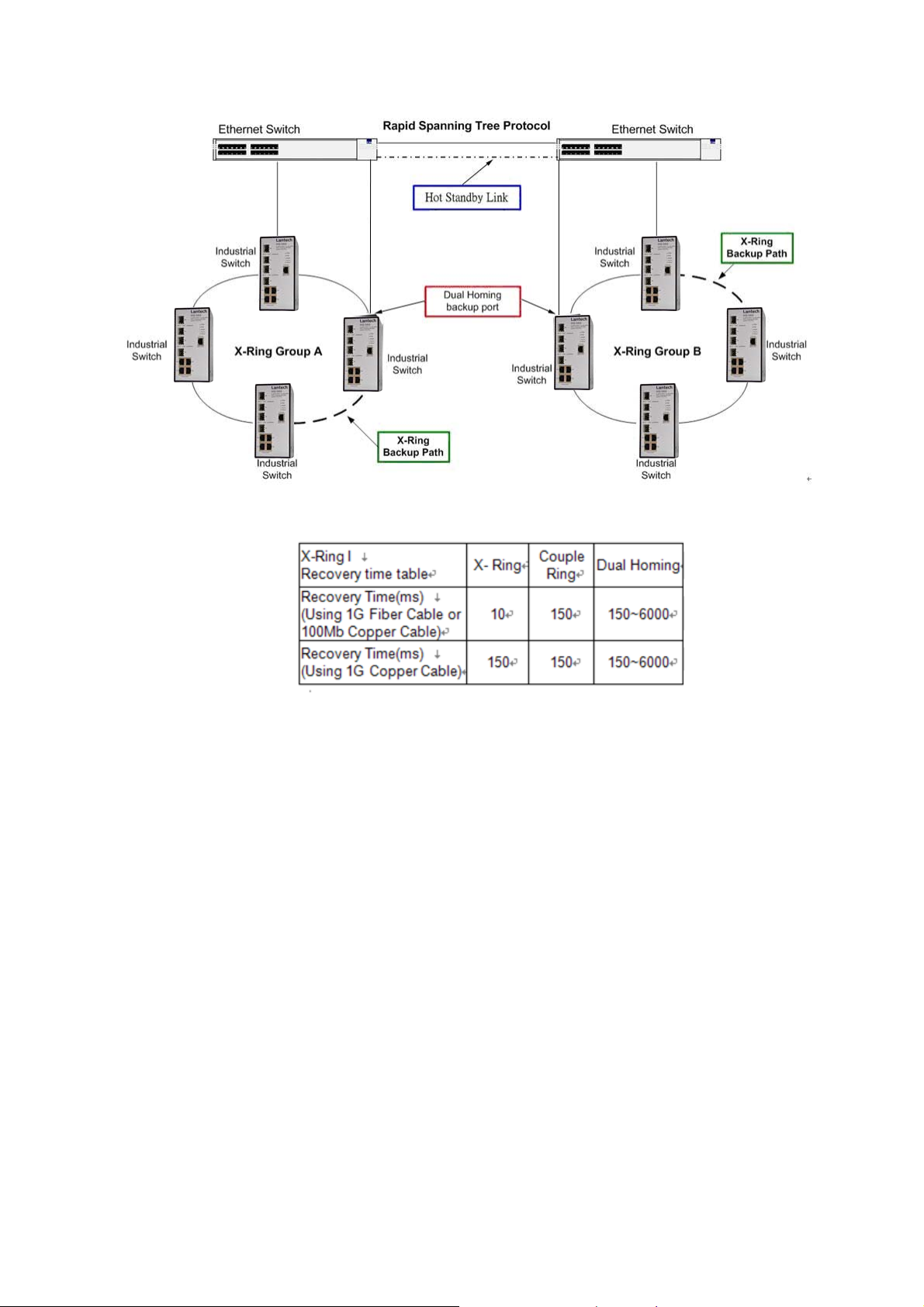

Dual Homing Application

Dual Homing function is to prevent the connection loss from between X-Ring group and

upper level/core switch. Assign two ports to be the Dual Homing port that is backup port

in the X-Ring group. The Dual Homing function only works when the X-Ring function is

active. Each X-Ring group only has one Dual Homing port.

Note In dual Homing application architecture, the upper level switches need to

enable the Rapid Spanning Tree protocol.

21

22

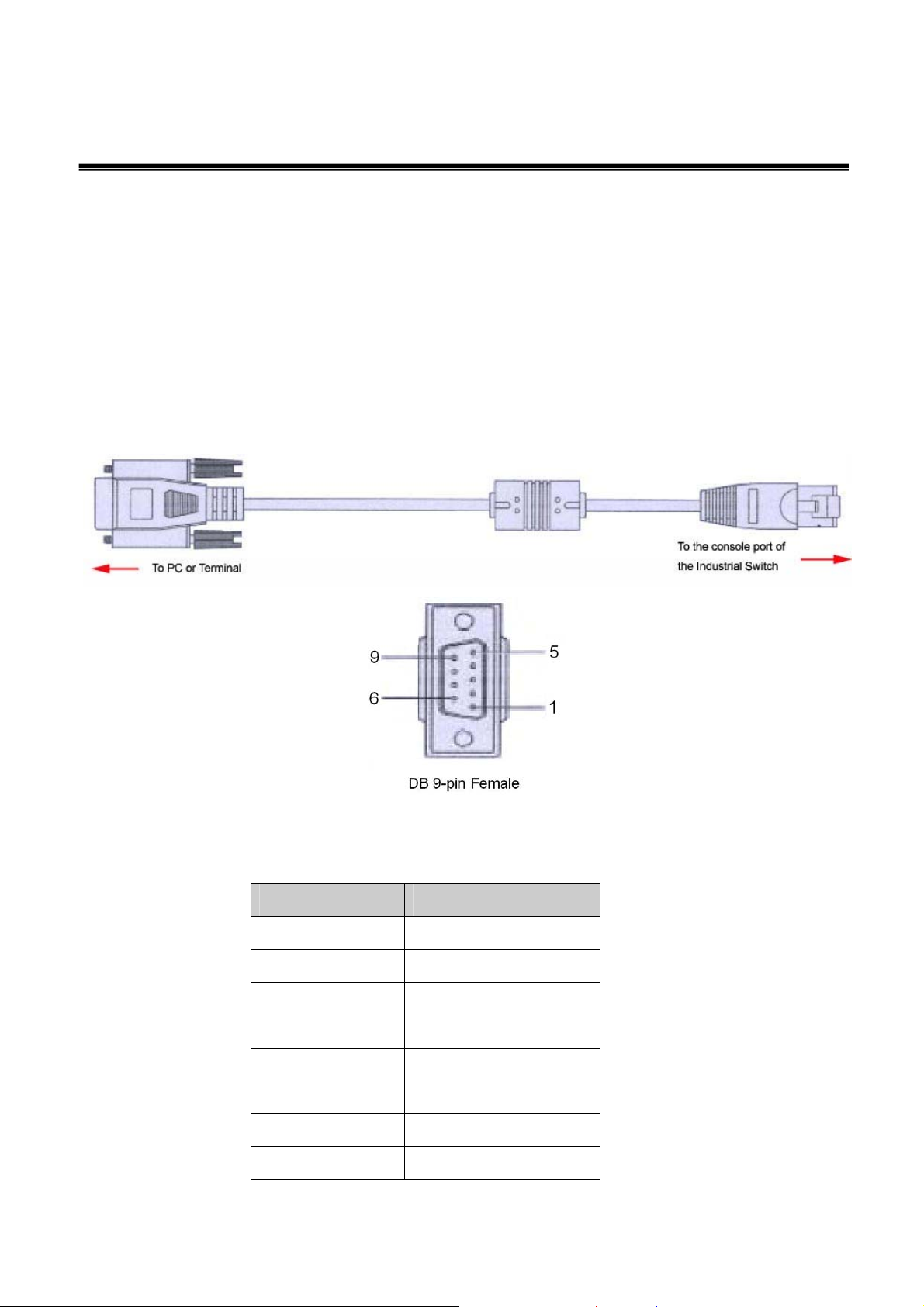

Console Management

Connecting to the Console Port

The supplied cable which one end is RS-232 connector and the other end is RJ-45

connector. Attach the end of RS-232 connector to PC or terminal and the other end of

RJ-45 connector to the console port of switch. The connected terminal or PC must

support the terminal emulation program.

Pin Assignment

DB9 Connector RJ-45 Connector

NC 1 Orange/White

2 2 Orange

3 3 Green/White

NC 4 Blue

5 5 Blue/White

NC 6 Green

NC 7 Brown/White

NC 8 Brown

23

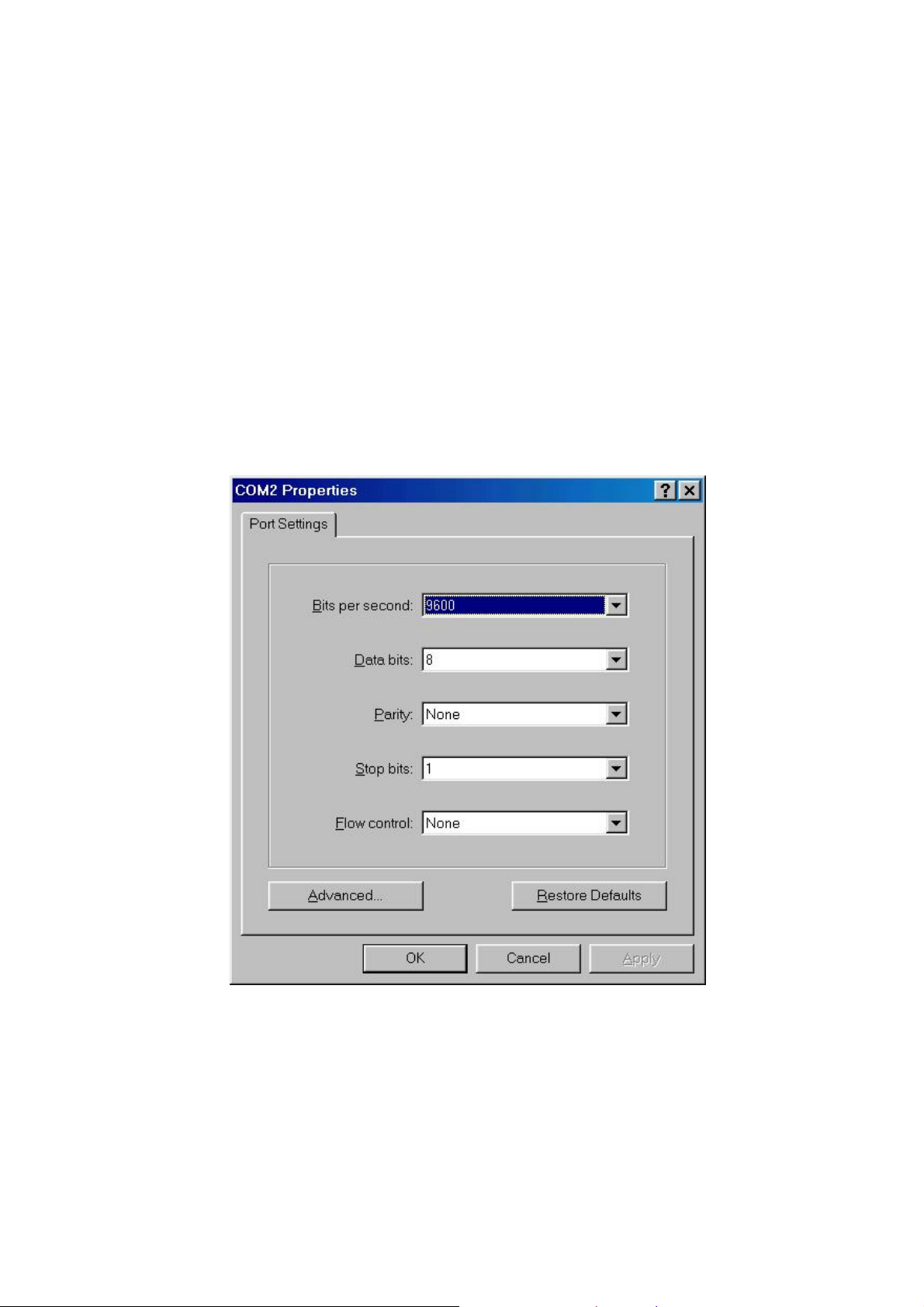

Login in the Console Interface

When the connection between Switch and PC is ready, turn on the PC and run a terminal

emulation program or Hyper Terminal and configure its communication parameters to

match the following default characteristics of the console port:

Baud Rate: 9600 bps

Data Bits: 8

Parity: none

Stop Bit: 1

Flow control: None

The settings of communication parameters

After finishing the parameter settings, click ‘OK’. When the blank screen shows up, press

Enter key to bring out the login prompt. Key in the ‘root’ (default value) for the both User

name and Password (use Enter key to switch), then press Enter key and the Main Menu

of console management appears. Please see below figure for login screen.

24

Loading...

Loading...