Lantech

IGC-0101GB

10/100/1000T to Mini-GBIC Industrial

Switch Converter

User Manual

Content

Overview ............................................................ 1

Introduction .............................................................. 1

Features ................................................................... 3

Packing List .............................................................. 4

Safety Precaution ..................................................... 4

Hardware Description ......................................... 5

Front Panel ............................................................... 5

Top View .................................................................. 6

Wiring the Power Inputs ........................................... 6

Wiring the Fault Alarm Contact ................................ 7

LED Indicators .......................................................... 8

DIP-Switch ............................................................... 9

Ports ....................................................................... 10

Cabling ................................................................... 11

Mounting Installation ........................................ 15

DIN-Rail Mounting .................................................. 15

Wall Mount Plate Mounting .................................... 17

Hardware Installation ....................................... 18

Installation Steps .................................................... 18

Troubles shooting ............................................. 20

Technical Specification .................................... 21

FCC Warning

This Equipment has been tested and found to comply with the limits for a Class-A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy. It may cause

harmful interference to radio communications if the equipment is not installed and used in

accordance with the instructions. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

CE Mark Warning

This is a Class-A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Overview

Introduction

The 10/100/1000T to MINI-GBIC Industrial Switch Converter is

designed to convert Gigabit Ethernet networks to Gigabit fiber networks

by transparently converting Ethernet signals to optic signals. The

advantages of fiber optics are wide bandwidth, EMI immunity and

long-distance transmission capability. Therefore, the industrial switch

converter is an ideal solution for “fiber to building” applications at central

offices or local sites. The industrial switch converter supports MDI/MDIX

auto detection, so you don’t need to use crossover wires. Furthermore,

the industrial switch converter can work normally from -20 ~ 60o C and

accepts a wide voltage range from +9 ~ 56 VDC. Besides, it also

provides 3,000 VDC surge (EFT) protection against over-voltage, so it is

suitable for harsh operating environments.

Gigabit Fiber Converter

The 10/100/1000T to MINI-GBIC Industrial Switch Converter has one

SFP fiber slot which provides the flexibility when planning and

implementing a network. The slot can accept any 1000M SFP-type fiber

module and these modules are designed for transmitting over distances

of either 500m (multi-mode), 10km, 30km, 50km, 70km or 110km

(single-mode). This means you can easily change the transmission

mode and distance of the switch by simply pulling out the SFP module

and plugging in a different module. The SFP module is hot-swappable

and plug-and-play!

Dual Power Input

To reduce the risk of power failure, the 10/100/1000T to MINI-GBIC

Industrial Switch Converter provides +9 ~ 56 VDC dual power inputs. If

there is power failure, 10/100/1000T to MINI-GBIC Industrial Switch

Converter will switch automatically to the secondary power input.

1

Flexible Mounting

10/100/1000T to MINI-GBIC Industrial Switch Converter is compact

and can be mounted on a DIN-rail or a panel, so it is suitable for any

space-constrained environment.

Advanced Protection

The power line of 10/100/1000T to MINI-GBIC Industrial Switch

Converter supports up to 3,000 VDC EFT protection, which secure

equipment against unregulated voltage and make systems safer and

more reliable. Meanwhile, 6,000 VDC ESD protections for Ethernet ports

make the industrial switch converter more suitable for harsh

environments.

Wide Operating Temperature

The operating temperature of the 10/100/1000T to MINI-GBIC

Industrial Switch Converter is between -40 ~ 75 oC (wide operating

temperature model) or -20 ~ 60 oC (standard model). With such a wide

range, you can use the industrial switch converter in some of the

harshest industrial environments that exist.

Easy Troubleshooting

LED indicators make troubleshooting quick and easy. The 10/100/1000

Base-T port has 2 LEDs that display the link status, whether the port is

working at 1000M transmission speed or not. Also the three power

indicators P1, P2 and Fault help you diagnose immediately.

2

Features

Provides 1 x SFP (mini-GBIC) type socket (10/100/1000T to

MINI-GBIC model)

Provides 1 x 10/100/1000Mbps Ethernet ports with RJ-45 connector

Supports full/half duplex flow control

Supports MDI/MDI-X auto-crossover

Supports surge (EFT) protection 3,000 VDC for power line

Supports 6,000 VDC Ethernet ESD protection

Embedded with a switch controller, supports auto-negotiation

Supports store & forward transmission

Supports redundant +9 ~ 56 VDC power input

Provides flexible mounting: DIN-rail, Wall Mounting

Supports operating temperatures from -40 ~ 75oC (wide operating

temperature model) or -20 ~ 60oC (standard model)

3

Attention

IF DC voltage is supplied by an external circuit, please use a

protection device on the power supply input.

Packing List

1 x 10/100/1000 to Mini-GBIC Industrial Switch Converter

1 x User manual

2 x Wall Mounting Bracket and Screws

Safety Precaution

4

Hardware Description

In this paragraph, we will introduce the Industrial switch converter’s

hardware spec, port, cabling information, and wiring installation.

Front Panel

The Front Panel of the 10/100/1000T to MINI-GBIC/10/100/1000T is

shown as below.

Front Panel of the Industrial Switch Converter

5

Top View

The top panel of the Industrial Switch Converter is equipped one

terminal block connector of two DC power inputs.

Top panel of the Industrial Switch Converter

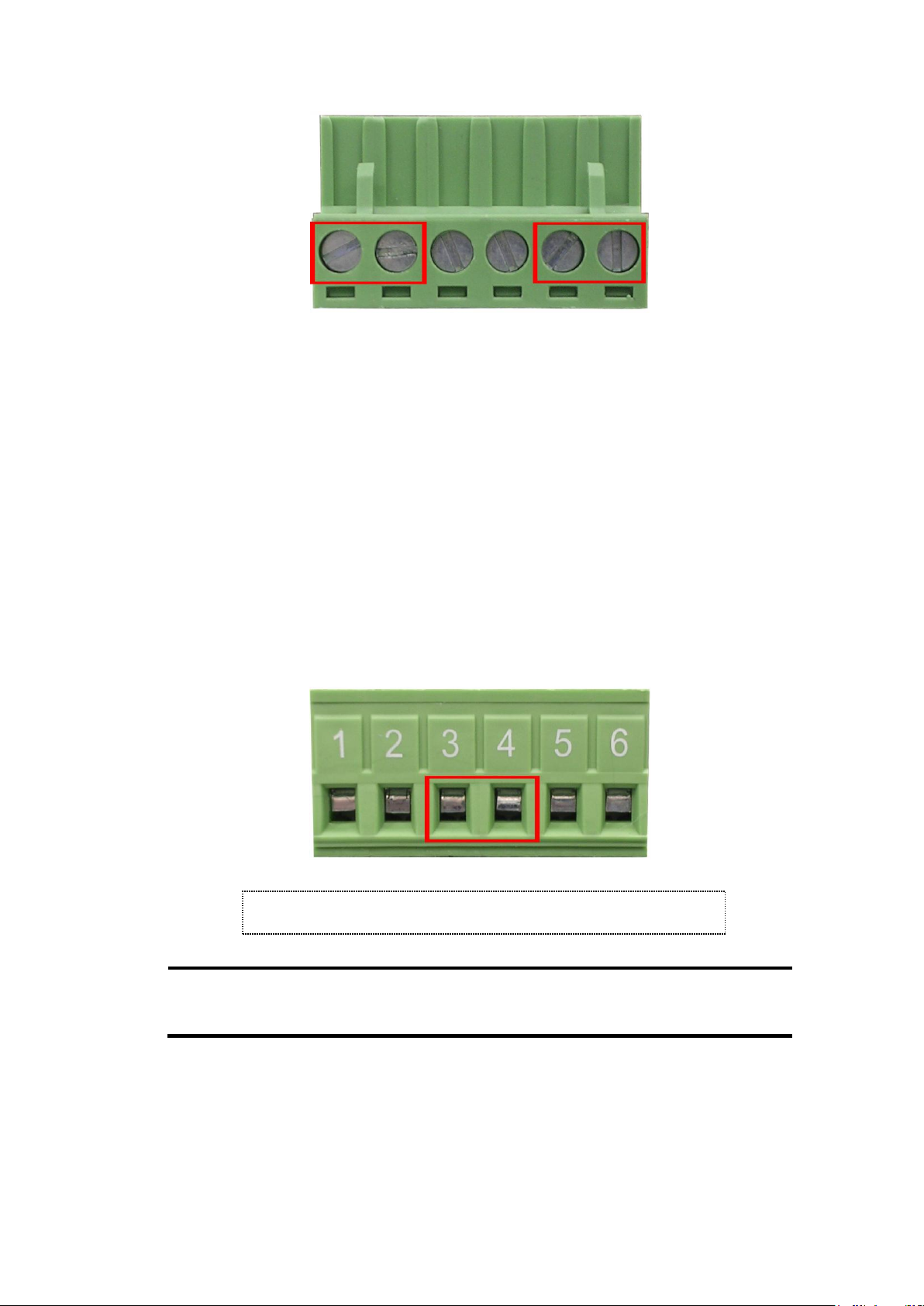

Wiring the Power Inputs

Please follow the steps below to insert the power wire.

1. Insert the positive and negative wires into the V+ and V- contacts on the

terminal block connector.

6

Note

The wire gauge for the terminal block should be in the range

between 12~ 24 AWG.

Insert the wires into the fault alarm contact (No. 3 & 4)

2. To tighten the wire-clamp screws for preventing the DC wires to loose.

Wiring the Fault Alarm Contact

The fault alarm contact is in the middle of terminal block connector as the

picture shows below. Inserting the wires, it will detect the fault status

which the power is failure or port link failure (for managed model) and form

an open circuit.

7

Table 2.1: Industrial Switch Converter LED Definition

LED

Color

Description

P1

Green

On

Power input 1 is active

Off

Power input 1 is inactive

P2

Green

On

Power input 2 is active

Off

Power input 2 is inactive

Fault

Red

On

Power input 1 or 2 has failed

Off

Power input 1 and 2 are both functional,

or no power input

LNK/ACT

(fiber port)

Green

On

Connected to network

Flashing

Networking is active

Off

Not connected to network

1000M

(RJ-45)

Yellow

On

Link to 1000M bps network

Off

Not connected to network or not working

at speed of 1000M

LNK/ACT

(RJ-45)

Green

On

Connected to network

Flashing

Networking is active

Off

Not connected to network

LED Indicators

There are few LEDs display the power status and network status

located on the front panel of the Industrial switch converter, each of

them has its own specific meaning as below table.

8

Table 2.2: Industrial Switch Converter DIP-Switch Definition

S/W No

Status

Description

1

ON

Enable Power Alarm

OFF

Disable Power Alarm

2

ON

Enables LLF

OFF

Disables LLF

Note

When SW 2 is on, once the fiber or UTP/STP cable is

disconnected, the LNK/ACT LED off. When the cable is

reconnected, the LNK/ACT LED blinks for 2 ~ 6 seconds which

means the connection is recovering from failure.

Note

Please don’t change the DIP-switch setting when UTP/STP or

fiber port is transmitting or receiving data. It may cause some data

error. Besides, if you change the DIP-switch setting, please power

off the converter and power on again to make the setting effective.

DIP-Switch

The DIP-Switch is used to configure operation mode for LLF (Link Lost

Forwarding) and power alarm. The default value of DIP-switch is OFF.

Link Lost Forwarding (DIP-Switch 2): When LLF is enabled, it allows

UTP link failures to be reported to the fiber side and also allows Fiber

link failures to be reported to the UTP side. Therefore, a link loss

forwarding feature is provided in both UTP and Fiber side.

9

Pin Number

Assignment

1

Tx+

2

Tx-

3

Rx+

6

Rx-

Note

“+” and “-” signs represent the polarity of the wires that make up

each wire pair.

Pin MDI-X

Signal Name

MDI Signal Name

1

Receive Data plus (RD+)

Transmit Data plus (TD+)

2

Receive Data minus (RD-)

Transmit Data minus (TD-)

3

Transmit Data plus (TD+)

Receive Data plus (RD+)

6

Transmit Data minus (TD-)

Receive Data minus (RD-)

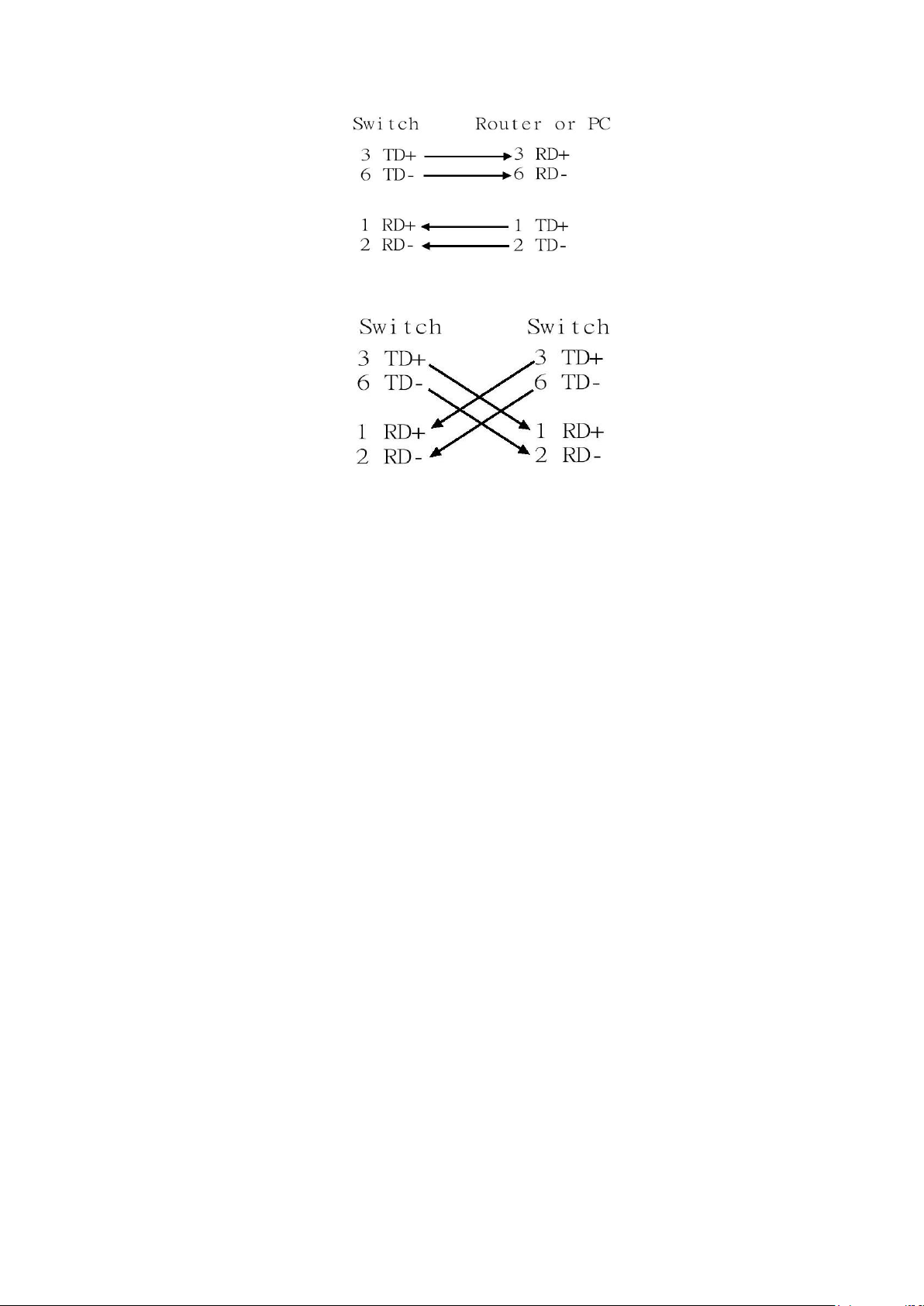

Ports

RJ-45 ports (Auto MDI/MDIX): The RJ-45 ports are auto-sensing for

10Base-T, 100Base-TX or 1000Base-T devices connections. Auto

MDI/MDIX means that you can connect to another switch or workstation

without changing straight through or crossover cabling. See figures as

below for straight through and crossover cable schematic.

RJ-45 Pin Assignments

All ports on this industrial switch converter support automatic

MDI/MDI-X operation, you can use straight-through cables (See Figure

below) for all network connections to PCs or servers, or to other

switches or hubs. In straight-through cable, pins 1, 2, 3, and 6, at one

end of the cable, are connected straight through to pins 1, 2, 3 and 6 at

the other end of the cable. The table below shows the 10BASE-T/

100BASE-TX /1000Base-T MDI and MDI-X port pin outs.

10

Straight Through Cable Schematic

Cross Over Cable Schematic

Cabling

Twisted-pair segment can use unshielded twisted pair (UTP) or

shielded twisted pair (STP) cabling. The cable between the link partner

(switch, hub, workstation, etc.) and the converter must be less than 100

meters (328 ft.) long and comply with the IEEE 802.3ab 1000Base-T

standard for Category 5e or above.

Fiber segment using single-mode connector type must use 9/125μm

single-mode fiber cable. You can connect two devices in the distance of

10 km. Fiber segment using multi-mode connector type must use

50/125 or 62.5/125μm multi-mode fiber cable. You can connect two

devices up to 550m distances.

The small form-factor pluggable (SFP) is a compact optical transceiver

used in optical communications for both telecommunication and data

communication applications.

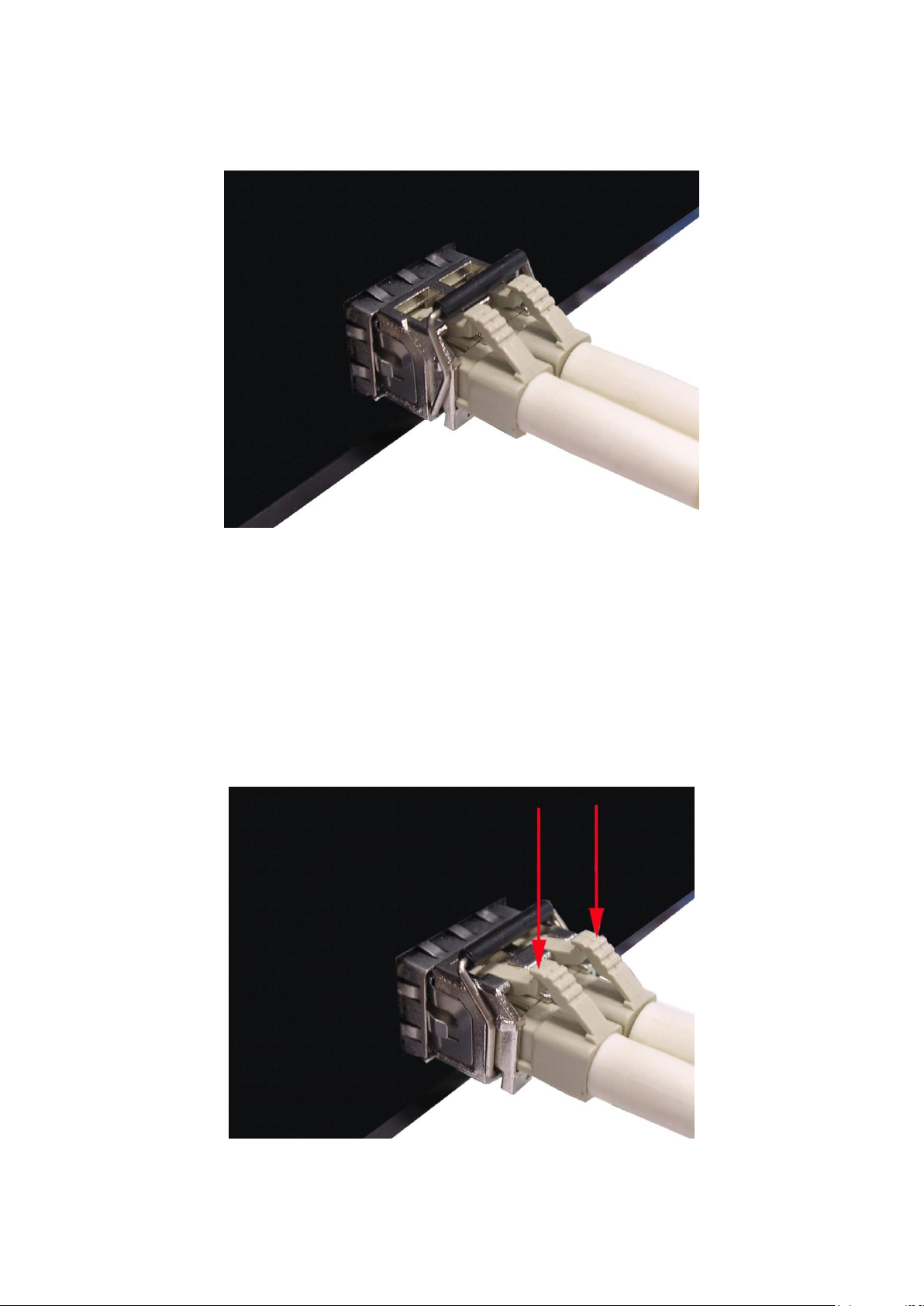

To connect the transceiver and LC cable, please follow the steps shown

below:

First, insert the transceiver into the SFP module. Notice that the triangle

mark is the bottom of the module.

11

Figure 2.8: Transceiver to the SFP module

Figure 2.9: Transceiver Inserted

12

Second, insert the fiber cable of LC connector into the transceiver.

Figure 2.10: LC connector to the transceiver

To remove the LC connector from the transceiver, please follow the steps

shown below:

First, press the upper side of the LC connector from the transceiver and pull it

out to release.

Figure 2.11: Remove LC connector

13

Second, push down the metal loop and pull the transceiver out by the plastic

part.

Figure 2.12: Pull out from the SFP module

14

Mounting Installation

DIN-Rail Mounting

The DIN-Rail is screwed on the industrial switch when out of factory. If

the DIN-Rail is not screwed on the industrial switch, please see the

following figure to screw the DIN-Rail on the switch. Follow the below

steps to hang the industrial switch.

1. Use the screws to screw on the DIN-Rail on the industrial switch

2. To remove the DIN-Rail, reverse the step 1.

15

3. First, insert the top of DIN-Rail into the track.

4. Then, lightly push the button of DIN-Rail into the track.

5. Check the DIN-Rail is tightly on the track.

6. To remove the industrial switch from the track, reverse steps above.

16

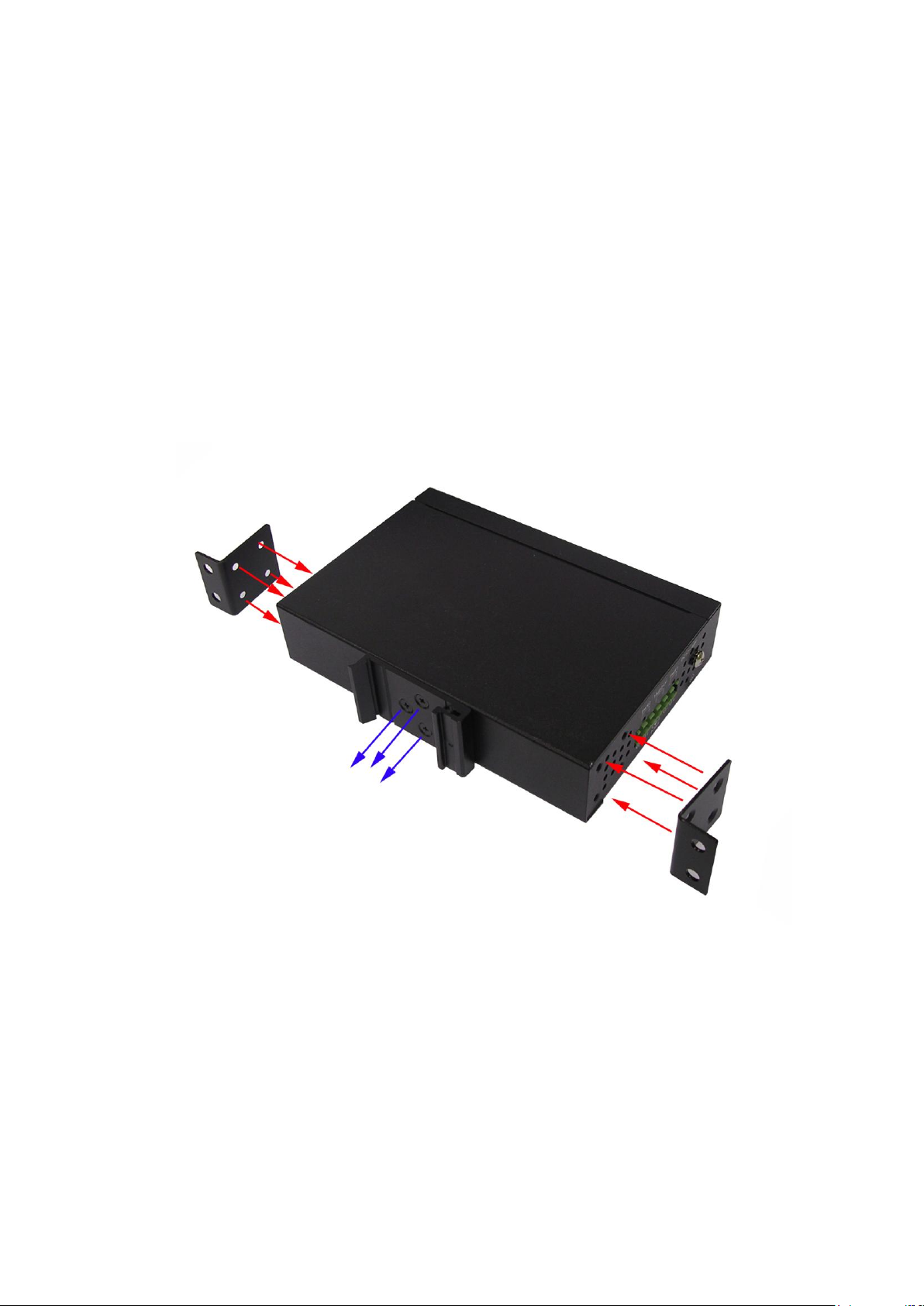

Wall Mount Plate Mounting

Follow the steps below to mount the industrial switch with wall mount plate.

1. Remove the DIN-Rail from the industrial switch; loose the screws to

remove the DIN-Rail.

2. Place the wall mount plate on the rear panel of the industrial switch.

3. Use the screws to screw the wall mount plate on the industrial switch.

4. Use the hook holes at the corners of the wall mount plate to hang the

industrial switch on the wall.

5. To remove the wall mount plate, reverse steps above.

17

Hardware Installation

In this paragraph, we will describe how to install the 5-port 10/100/1000Base-T

Industrial Switch converter and the installation points for the attention.

Installation Steps

1. Unpacked the Industrial switch converter packing.

2. Check the DIN-Rail is screwed on the Industrial switch converter. If the

DIN-Rail is not screwed on the Industrial switch converter. Please refer to

DIN-Rail Mounting section for DIN-Rail installation. If you want to wall

mount the Industrial switch converter, then please refer to Wall Mount

Plate Mounting section for wall mount plate installation.

3. To hang the Industrial switch converter on the DIN-Rail track or wall,

please refer to the Mounting Installation section.

18

Note

Be sure the connected network devices support MDI/MDI-X. If it does

not support, then use the crossover category 5e/above cable.

4. Power on the Industrial switch converter. How to wire the power; please

refer to the Wiring the Power Inputs section. The power LED on the

Industrial switch converter will light up. Please refer to the LED Indicators

section for meaning of LED lights.

5. Prepare the twisted-pair, straight through Category 5 cable for Ethernet

connection.

6. Insert one side of Category 5e or above cables into the Industrial switch

converter Ethernet port (RJ-45 port) and another side of category 5e or

above cables to the network devices’ Ethernet port (RJ-45 port), e.g.

switch, PC or Server. The UTP port (RJ-45) LED on the Industrial switch

converter will light up when the cable connected with the network device.

Please refer to the LED Indicators section for LED light meaning.

7. When all connections are all set and LED lights all show in normal, the

installation is complete.

19

Troubles shooting

Verify that you are using the right power cord/adapter (DC 9 ~ 56V),

please don’t use the power adapter with DC output higher than 56V, or it

will burn this switch converter down.

Select the proper UTP cable to construct your network. Please check that

you are using the right cable. Use unshielded twisted-pair (UTP) or shield

twisted-pair (STP) cable for RJ-45 connections: 100Ω Category 3, 4 or 5

cable for 10Mbps connections, 100Ω Category 5 cable for 100Mbps, or

100Ω Category 5e/above cable for 1000Mbps connections. Also be sure

that the length of any twisted-pair connection does not exceed 100 meters

(328 feet).

Diagnosing LED Indicators: To assist in identifying problems, the

industrial switch converter can be easily monitored through panel

indicators which describe common problems the user may encounter and

where the user can find possible solutions.

IF the power indicator does not light on when the power cord is plugged in,

you may have a problem with power cord. Then check for loose power

connections, power losses or surges at power outlet. IF you still cannot

resolve the problem, contact your local dealer for assistance.

If the Industrial switch converter LED indicators are normal and the

connected cables are correct and the packets still cannot transmit. Please

check your system’s Ethernet devices’ configuration or status.

20

Communications

Standard

IEEE 802.3, 802.3ab, 802.3u, 802.3x,

802.3z

LAN

10/100/1000Base-T

Transmission Distance

SFP (mini-GBIC) Fiber: Up to 110km

Ethernet: Up to 100 meters (STP or UTP)

Transmission Speed

Up to 1000 Mbps

Interface

Connectors

Fiber : 1 x SFP (mini-GBIC) fiber socket

(mini-GBIC model)

1 x RJ-45

6-pin removable screw terminal

(power & relay)

LED Indicators

TX port: 1000M, LNK/ACT

Fiber port: LNK/ACT

P1, P2, Fault

Power

Technical Specification

The technical specifications of the Industrial Switch Converter are listed as

follows.

21

Power Consumption

10/100/1000T to Mini-GBIC model:

5.28 W

Power Input

2 x Unregulated +9 ~ 56 VDC

Fault Output

1 Relay Output

Mechanism

Dimensions (WxDxH)

30 x 95 x 140 mm

Enclosure

IP30, Metal shell with solid mounting kits

Mounting

DIN-rail, wall

Protection

ESD (Ethernet)

6,000 VDC

Surge (EFT for power)

3,000 VDC

Reverse Polarity

Present

Overload

0.9A@12VDC (25oC)

Environment

Operating Temperature

Standard model: -20 ~ 60oC

Wide temp. model: -40 ~ 75oC

Storage Temperature

-40 ~ 85oC

Operating Humidity

5 ~ 95% (non-condensing)

Storage Humidity

0 ~ 95% (non-condensing)

22

Certifications

Safety

UL, cUL, CE/EN-60950-1

EMC

FCC Class A

CE EN61000-4-2 (ESD)

CE EN61000-4-3 (RS)

CE EN-61000-4-4 (EFT)

CE EN61000-4-5 (Surge)

CE EN61000-4-6 (CS)

CE EN61000-4-8

CE EN61000-4-11

CE EN61000-4-12

CE EN61000-6-2

CE EN61000-6-4

Free Fall

IEC60068-2-32

Shock

IEC60068-2-27

Vibration

IEC60068-2-6

23

Loading...

Loading...