Page 1

RS12-38800

Manual

1

Page 2

RS12-38800

Manual

Copyright 2009, Lanner Electronics, Inc. All rights reserved. This document

contains proprietary information that is protected by copyright. No part of

this document may be reproduced, transmitted, transcribed, stored in a

retrieval system, or translated into any language in any form by any means

without the written express of Lanner Electronics, Inc.

The author and Lanner Electronics, Inc. have used their best efforts in

preparing this manual. However, the author and Lanner Electronics, Inc.

make no warranties of any kind, expressed or implied, with regard to the

informational content, documentation, or files contained in this manual, and

shall not be liable for technical or editorial errors or omissions contained

herein. In no event shall the author or publisher be responsible or liable for

any incidental or consequential damages resulting from the furnishing,

performance, or use of this material.

TRADEMARKS Internet Explorer, Windows Explorer, and Windows are

trademarks or registered trademarks of Microsoft Corporation. Other

products mentioned herein may be trademarks/or registered trademarks of

their respective owners.

2

Page 3

Safety Guidelines

Follow these guidelines to ensure general safety:

Keep the chassis area clear and dust-free during and after installation.

Do not wear loose clothing or jewelry that could get caught in the chassis.

Fasten your tie or scarf and roll up your sleeves.

Wear safety glasses if you are working under any conditions that might

be hazardous to your eyes.

Do not perform any action that creates a potential hazard to people or

makes the equipment unsafe.

Disconnect all power by turning off the power and unplugging the power

cord before installing or removing a chassis or working near power

supplies

Do not work alone if potentially hazardous conditions exist.

Never assume that power is disconnected from a circuit; always check

the circuit.

LITHIUN BATTERY CAUTION :

Risk of Explosion if Battery is replaced by an incorrect type. Dispose of

used batteries according to the instruction

Operating Safety

Electrical equipment generates heat. Ambient air temperature may not

be adequate to cool equipment to acceptable operating temperatures

without adequate circulation. Be sure that the room in which you choose

to operate your system has adequate air circulation.

Ensure that the chassis cover is secure. The chassis design allows

cooling air to circulate effectively. An open chassis permits air leaks,

which may interrupt and redirect the flow of cooling air from internal

components.

Electrostatic discharge (ESD) can damage equipment and impair electrical

circuitry. ESD damage occurs when electronic components are improperly

handled and can result in complete or intermittent failures. Be sure to follow

ESD-prevention procedures when removing and replacing components to

avoid these problems.

Wear an ESD-preventive wrist strap, ensuring that it makes good skin

contact. If no wrist strap is available, ground yourself by touching the

metal part of the chassis.

Periodically check the resistance value of the antistatic strap, which

should be between 1 and 10 mega ohms (Mohms).

3

Page 4

EMC Notice

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case users will

be required to correct the interference at their own expense.

Class A Notice for FCC

Modifying the equipment without the authorization of Lanner Electronics, Inc.

may result in the equipment no longer complying with FCC requirements for

Class A digital devices. In that event, your right to use the equipment may be

limited by FCC regulations, and you may be required to correct any

interference to radio or television communications at your own expense.

This equipment is in compliance with the essential requirements and other

relevant provisions of Directive 1999/5/EC.

4

Page 5

Contents

Safety Guidelines ....................................................................... 3

EMC Notice ................................................................................. 4

Contents..................................................................................... 5

1. Product overview--................................................................. 6

1.1 Product Introduction ...................................................... 6

1.2 Features and Benefits ..................................................... 6

1.3 Specifications: RS12-38800-........................................... 7

1.4 Specifications: MB-8675B ............................................... 8

1.5 Package Content ............................................................. 9

1.6 Technical Assistance....................................................... 9

2. System components ............................................................. 10

2.1 MB-8675 System Board................................................. 11

2.2 Mechnical Overview ...................................................... 33

3. Hardware Installation Guide ................................................ 35

3.1 CPU Installation............................................................ 35

3.2 System Memory ............................................................ 35

3.3 Installation Compact Flash Card ................................... 35

3.4 Rack Mounting Installation ........................................... 36

4. Bios Setup ............................................................................ 39

A. Appendix A: Power Supply ................................................... 53

B. Appendix B: Watchdog Timer ............................................... 54

C. Appendix C: Console Redirection .......................................... 55

D. Appendix D: LCM Module and Keypad for FW-8650 .............. 56

E. Appendix E: LAN Bypass Function ........................................ 57

F. Appendix F: Hot-Swap Hard Disk .......................................... 58

Terms and Conditions............................................................... 59

Warranty Policy ................................................................. 59

RMA Service

..................................................................................

60

5

Page 6

1. Product Overview

1.1 Product Introduction

Figure 1 – RS12-38800 Outlook

The RS12-38800, 3U Rack mount storage platform designed for networking

storage demands of high-end markets, the RS12-38800 is equipped with

Intel Xeon 5100 series CPU support, eight PCI Express interfaces, redundant

power supply and an optional Ethernet module. It is designed with an Intel

Blackford 5000P as its Northbridge and Intel ESB2 (6321) as its Southbridge.

1.2 Features and Benefits

Listed below are the key features of RS12-38800:

Supports 12 hot-swappable 3.5” hard drives

Supports Intel Dual-Core Xeon 5100 Processor

Supports 8 x Fully Buffer DIMM, up to 32GB

Supports up twelve Gigabit Ethernet ports Marvell 88E8062 chipset

Equipped with Compact Flash port, Console port (RJ-45), USB Ports x 2,

LCM module x 1

N+1 Redundant Switch Power Supply ensure a higher level of system

reliability and stability

Optional Cavium CN1010 delivers high-speed encryption and packet

throughput

Customization of the front panel and chassis colors tailored solutions for

OEM and ODM customers

格格格格式化

式化:::: 項目符號及編號

式化式化

6

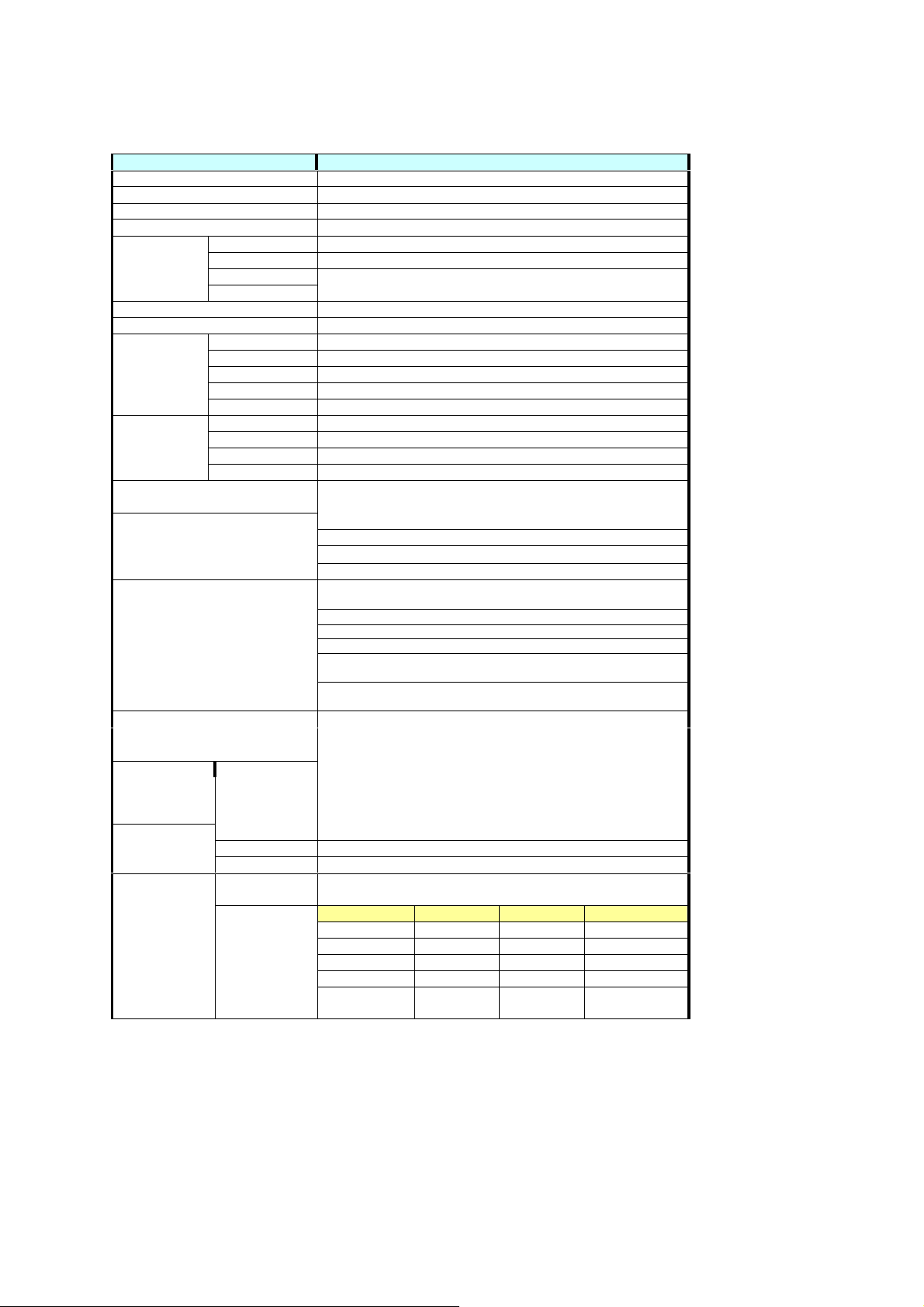

Page 7

Feature

Description

1.3 Specifications: RS12-38800 (19

Platform + EM

Platform + EM----8675B)

Platform + EMPlatform + EM

Form Factor 3U 19” Rack mount

Color Black U

Temperature 0 – 40 Degree Celsius

Humidity 5% -95%RH, Non-Condensing

Dimensions

Material SGCC

Compartment Orientation NIC module on bottom of HDD bay

HDD Bay

System Fan

Cooling

Exposure I/O

Expansion Slot 1 x PCI-E Slot or 2 x PCI-X Slot

Network Interface

Temperature

Humidity 5 ~ 95%, non condensing

Miscellaneous

Certification

Power supply

8675B)

8675B)8675B)

Height 130mm, 5.12 in

Width 442mm, 17.4 in

Depth 610mm, 24 in

Weight 30kg

Number 12

HDD Form-factor 3.5”

HDD Orientation Based on Lanner standard design

LED Indicators 2 x LED per Tray, Reference: NSB-38800 “Disk LED Activity”

Dimensions 198.2mm x 107.2 mm x27mm

Number

Fan Speed Sensing

Fan Speed Control

Others Easy to replace

LCD Module

Watchdog

Internal RTC

with Li Battery

Safety CE, FCC Class A,

EMC FCC Part 15 Class A,

ROHS EU, China

Model 1 x Zippy M3W-6950P 950W N+1 Redundant Switch Power Supply

Output

Characteristics

3 x 4700rpm (80x80x25mm)

Yes

Yes

2U CPU active heat-sink

Smart Fan x 2(Swappable)

1 x RJ45 Console Port (Front)

2 x USB Port (Front)

1 x RJ-45 for IPMI Netwrok Control(Front)

NCM-IG407A:4 Port sRJ-45 Gbe

(2 Pair By-Pass supported)

NCM-IG407B:4 Ports RJ-45 Gbe

NCM-IG411A:4 Ports SFP Gbe

NCM-IG411B : 2 Ports SFP Gbe

NCM-IG208A : 2 Ports SFP

1000Base-SX

NCM-IG208B : 2 Ports SFP

1000Base-LX (with By-Pass supported)

Operating 0℃ ~ 40℃

Ambient Storage 0℃ ~ 70℃

2 x 20 Character

Yes

Yes

Detail spec. see M3W-6950P.pdf

Connector Length Unit Mapping

24 Pin 150mm 1 MB

8 Pin 250mm 1 MB

20 Pin 150mm 1 BP

4 Pin 150mm 1 BP

2 Pin (TTL

Signal)

(with By-Pass supported)

19”””” 3U Rack

1919

150mm 1 MB

3U Rack----Mount Network Storage

3U Rack 3U Rack

Mount Network Storage

Mount Network Storage Mount Network Storage

7

Page 8

Features

Description

1.4 Specifications: EM-8675B (LGA 771 for Intel Dual

and Quad

and Quad----Core

and Quadand Quad

Processor

(2 x LGA771)

BIOS

Chipset

Memory

VGA

SSD

Security processor

On Board I/O Connector

Expansion Slot

IPMI 1 x OPMA Connector

Network interface Depends on LAN Modules

Manageability

System fan

Watch Dog Timer Super IO, 1~255

RTC Internal RTC w/ Li Battery

Temperature

Humidity

Certification

Dimension

Core (

(Clovertown

Clovertown)

CoreCore

( (

ClovertownClovertown

) XEON)

XEON)

) )

XEON)XEON)

Northbridge

Southbridge

I/O Controller

Safety

EMC

ROHS

Dual Intel LGA 771 for Dual-Core a nd Quad-Core XEON,Up to 3.0G

8M EEPROM,AMI Plug & Play BIOS (with Console Re-Direction)

Intel Blackford 5000P

Intel ESB2 (6321)

ITE8712F-S/KX-L

8 x Fully Buffer DIMM , up to 32GB

ATI ES1000

1 x Compact Flash Type II (DMA support)

Cavium CN1010 (Optional)

2 x USB Port(Front)

1 x RJ-45 Console Port(Front)

1 x RJ-45 for IPMI Netwrok Control(Front;Optional)

1 x Serial Console Port Pin Header on Board

1 x KeyBoard/Mouse Pin Header(2x4 Pin)

1 x LCM & KeyPad Pin Header(2x7 Pin)

1 x Reset Button Pin Header(2 Pin)

PCI-E Slot(Rear)

PCI-X Slot(Rear)

Temperature and Fan Speed Sensing

3 x Fan connector by IAC-FAN02A

Operating 0℃ ~ 40℃

Ambient Storage 0℃ ~ 70℃

5 ~ 95%, non condensing

CE, FCC Class A

FCC Part 15 Class A

EU, China

12” x 14”(304.8mm x 355.6mm)

LGA 771 for Intel Dual----Core

LGA 771 for Intel DualLGA 771 for Intel Dual

Core((((Woodcrest

Woodcrest))))

CoreCore

WoodcrestWoodcrest

8

Page 9

1.5 Package Contents

Carefully unpack your package and make sure that you have the following

items.

RS12-38800 Network Storage Platform x 1

Console cable (RJ-45) x 1

1.8 meters cross-over Ethernet cable x 1

1.8 meters straight-through Ethernet cable x 2

Power cable x 3

Screw Set

Slide & Bracket Set

Note: If you should find any components missing or damaged, please contact your dealer immediately

for assistance.

格格格格式化

式化:::: 項目符號及編號

式化式化

1.6 Technical Assistance

Should you have any questions or problems with your product, please

contact the Lanner sales team.

Phone: 886-2-8692-6060

Fax: 886-2-8692-6101

E-mail: sales@lannerinc.com

Prior to contacting us, we ask that you first check the electronic product

documentation for assistance. Should you still have questions, we

recommend you have the following information on hand in order to expedite

the process:

1. RS12-38800 model name

2. Part number

3. Abnormal behavior and/or error messages reported by your network

storage system

4. Your questions or a description of the problem you are experiencing

格格格格式化

式化:::: 項目符號及編號

式化式化

9

Page 10

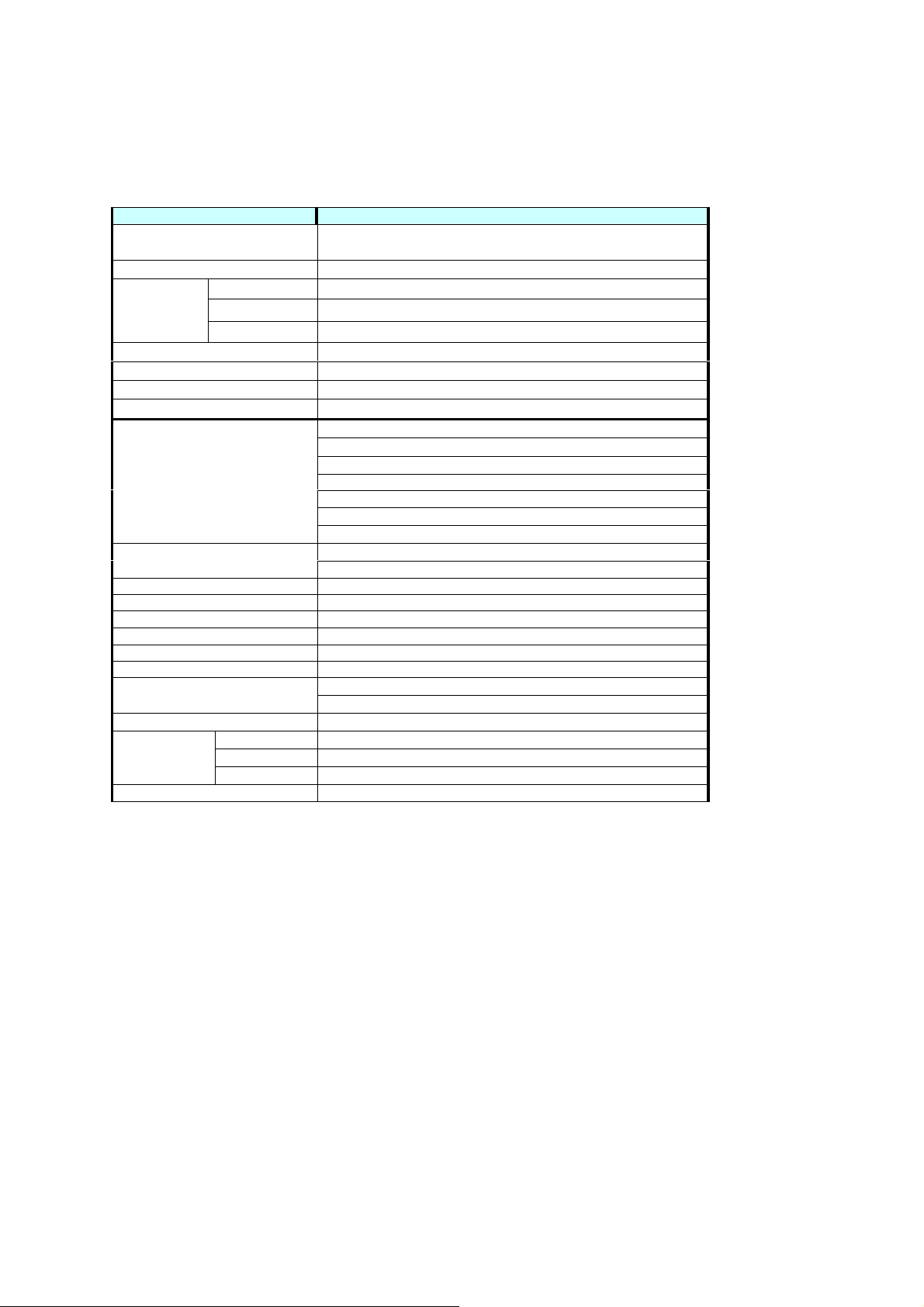

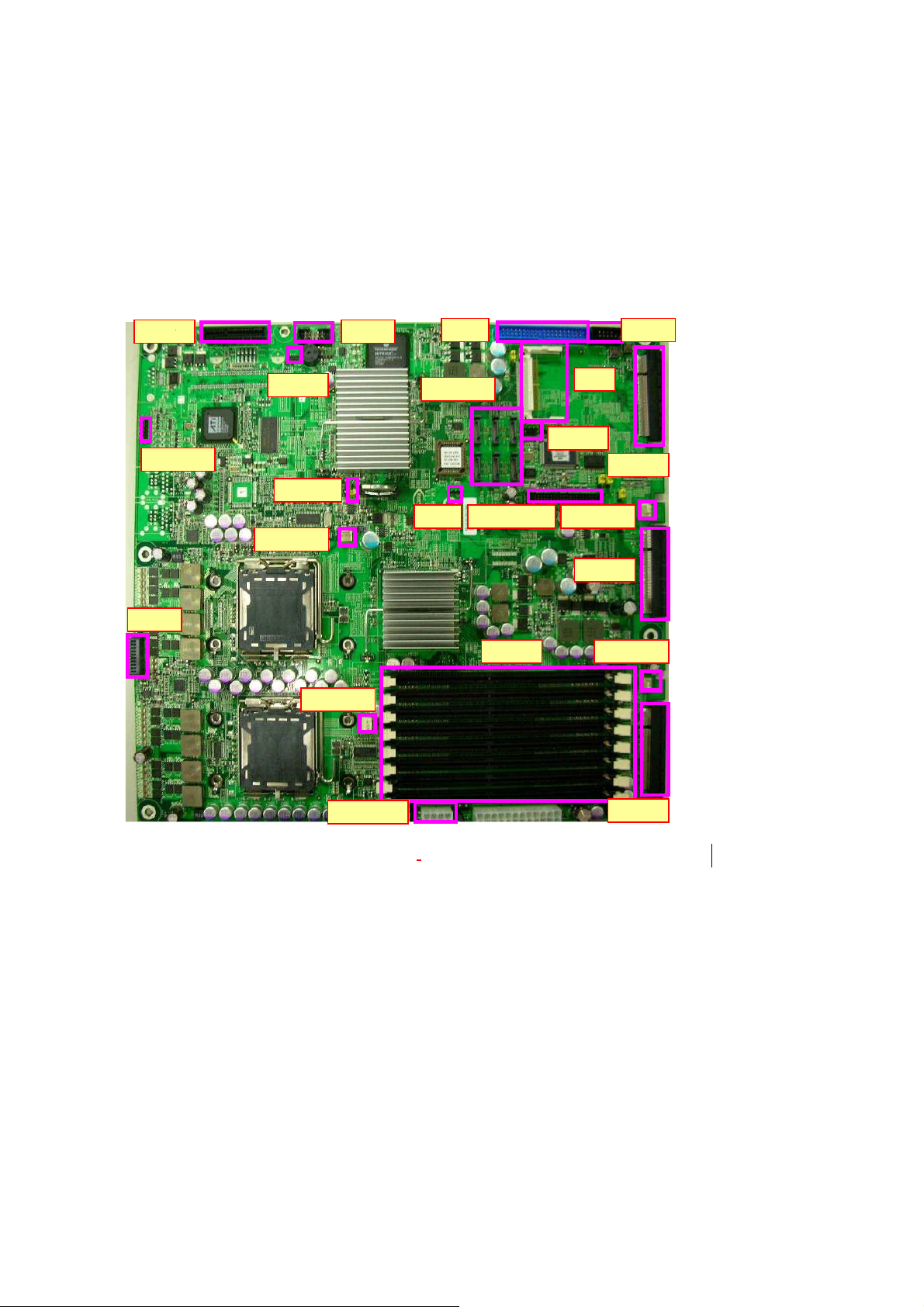

2. System Components

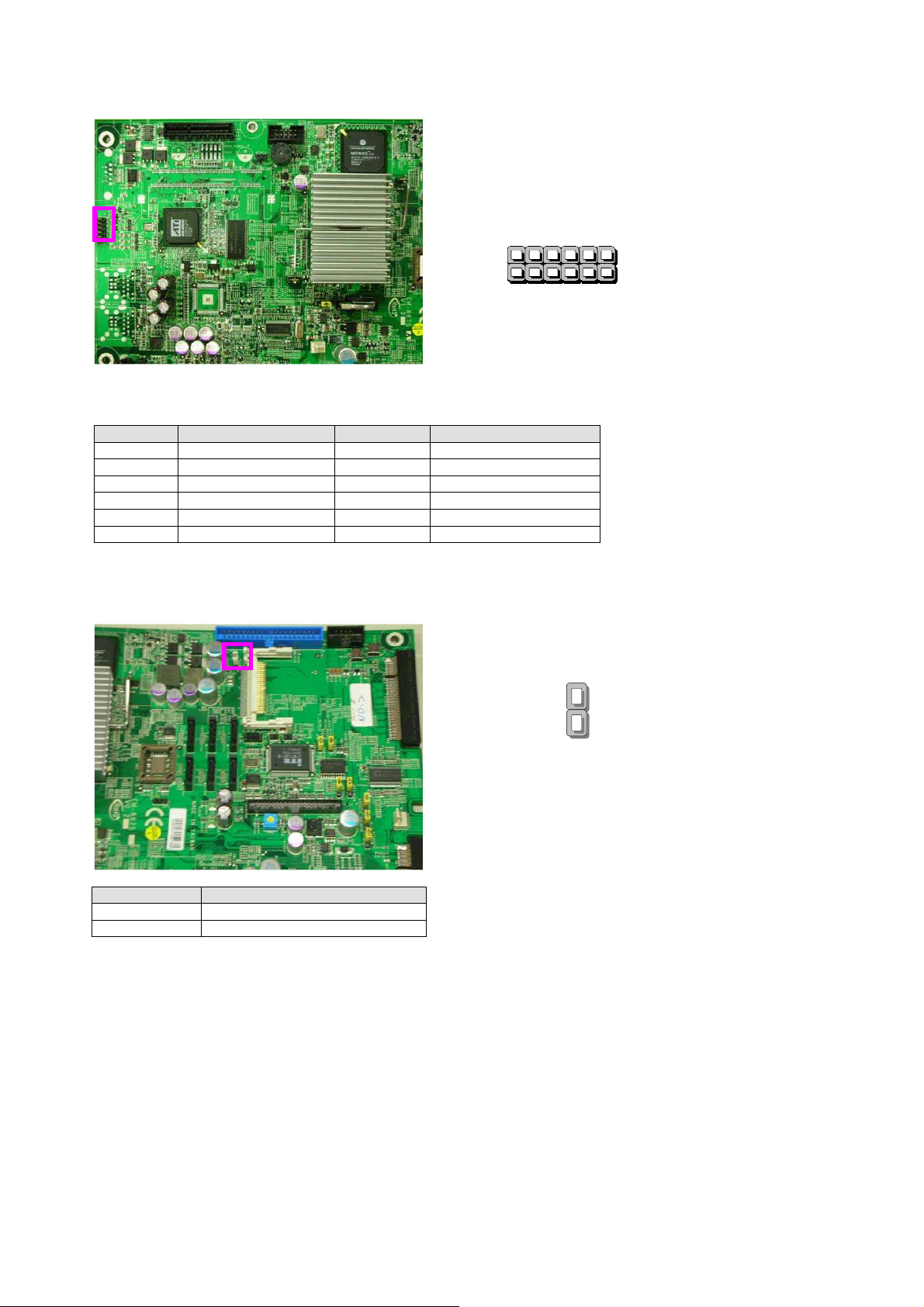

2.1

EM-8675 system Board

EM-8675 is the system board bundled with the RS12-38800 Network security

platform. The succeeding sections list all EM-8572 related jumper settings

and connector pin assignments.

2.1.1

Board

PCIE6

VGACON1

Layo

CPUFAN1

ut

IPMI1

CCMOS2

CON3

IDE1

SATA1~6

WP1 LUSBCOM1 AUXFAN3

CN1

PKMB1

CON1

J1~J8

AUXFAN1

ATXPWR1

Figure 2 – EM-8675 Key Features

PCIE4

FPIO1

PCIE5

AUXFAN2

PCIE3

10

Page 11

2.1.2

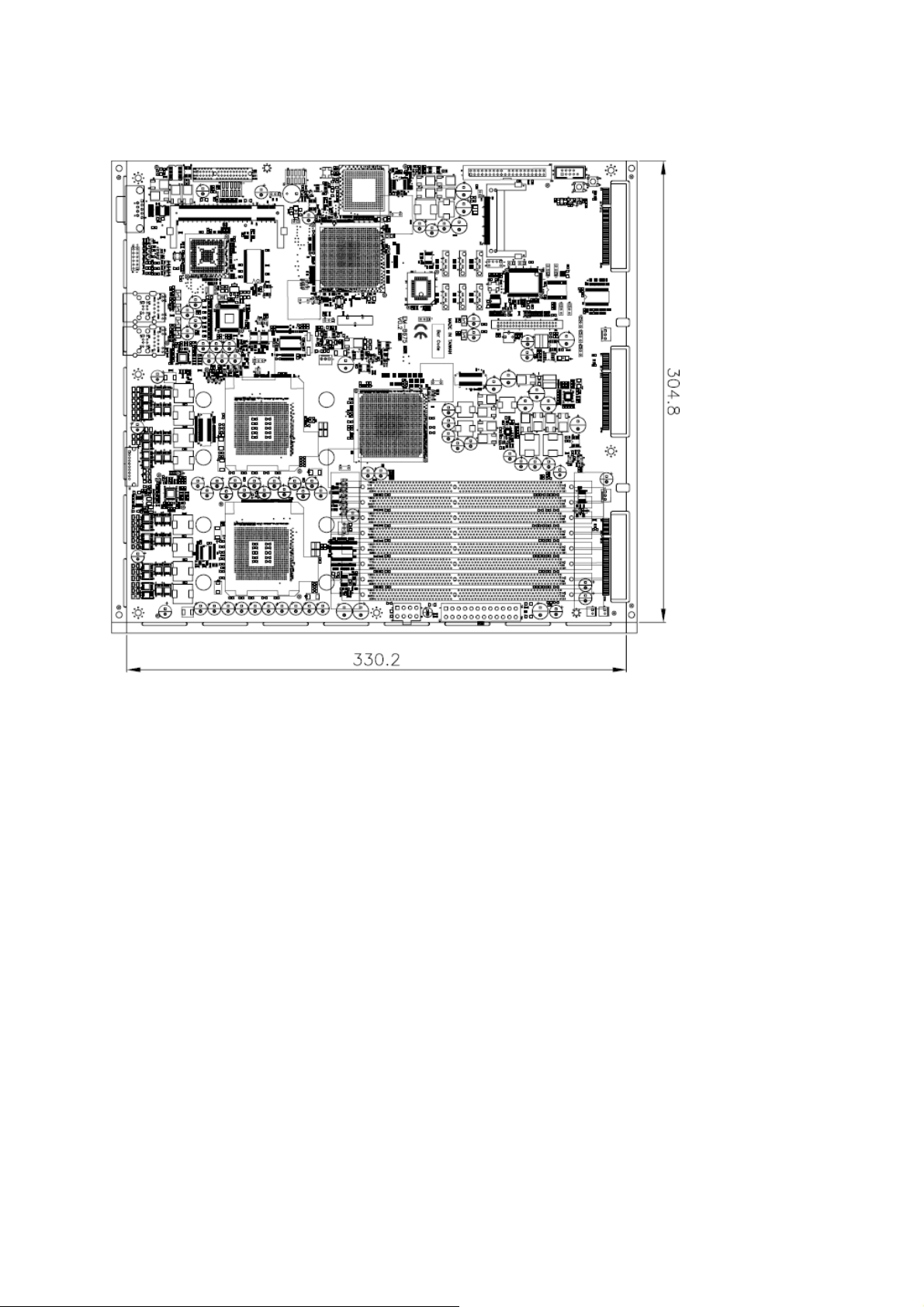

Dimensions (mm)

11

Figure 3 – Dimensions

Page 12

2.1.3

Jumper Settings and I/O Conne

ctors

The jumper settings and I/O connectors of the EM-8675 board

to the FW-8890. Changing these setting

damage to yo

ur

system

.

s

may

re

sult in malfunction

Jumper Settings and I/O Connector Summary for EM-8675

JUMPER

PKMB1 2x4 Header PS/2 Keyboard & Mouse Connector (2.54mm)

CCMOS2 Clear CMOS Data

IDE1 40 Pin IDE Interface Connector (2.54mm)

CN1 Compact Flash Connector

FPIO1 9 Pin Front Panel Connector (2.54mm)

CPUFAN1/AUXFAN1

AUXFAN2 ~ AUXFAN3 3 Pin FAN Header

3 Pin Smart FAN Header

FUNCTION

are

specifi

s or

:

c

ATXPWR1 8 Pin Power Connector

LUSBCOM1 2X20 Pin BOX Connector (2.00mm)

VGACON1 12 Pin External VGA Header (2.54mm)

JP1 1x2 Pin Compact Flash Mode (2.54mm)

JP2 4 Pin TACT Power Button

JP3 4 Pin TACT Reset Button

JP8 ~ JP11 1x3 Pin Select KEYPAD or USB_RJ1 Lan LED (2.54mm)

JP12 2 Pin For TTL1 detect

JP13 2 Pin For TTL2 detect

JP14 1x2 Pin For SIO GPIO Pin (2.54mm)

JP15 1x2 Pin For SIO GPIO Pin (2.54mm)

JP16~JP18 1x3 Pin Select Bypass Function (2.54mm)

JP19 1x2 Pin For I2C BUS Pin (2.54mm)

CON1 10 Pin Smart FAN Connector

CON3 10 Pin SMD OPMA_LAN Connector (2.54mm)

WP1 1x3 Pin U41 Flash Rom Write Protect (2.54mm)

IPMI1 1x3 Pin Header (2.54mm)

SATA1~SATA6 180º SATA Connector

PCIEC6 PCI Express x4 Standard Connector

PCIEC3 ~ PCIEC5 Splint PCI Express x8 Standard Connector

12

Page 13

J1~J8 240Pin FB-DIMM Connector

13

Page 14

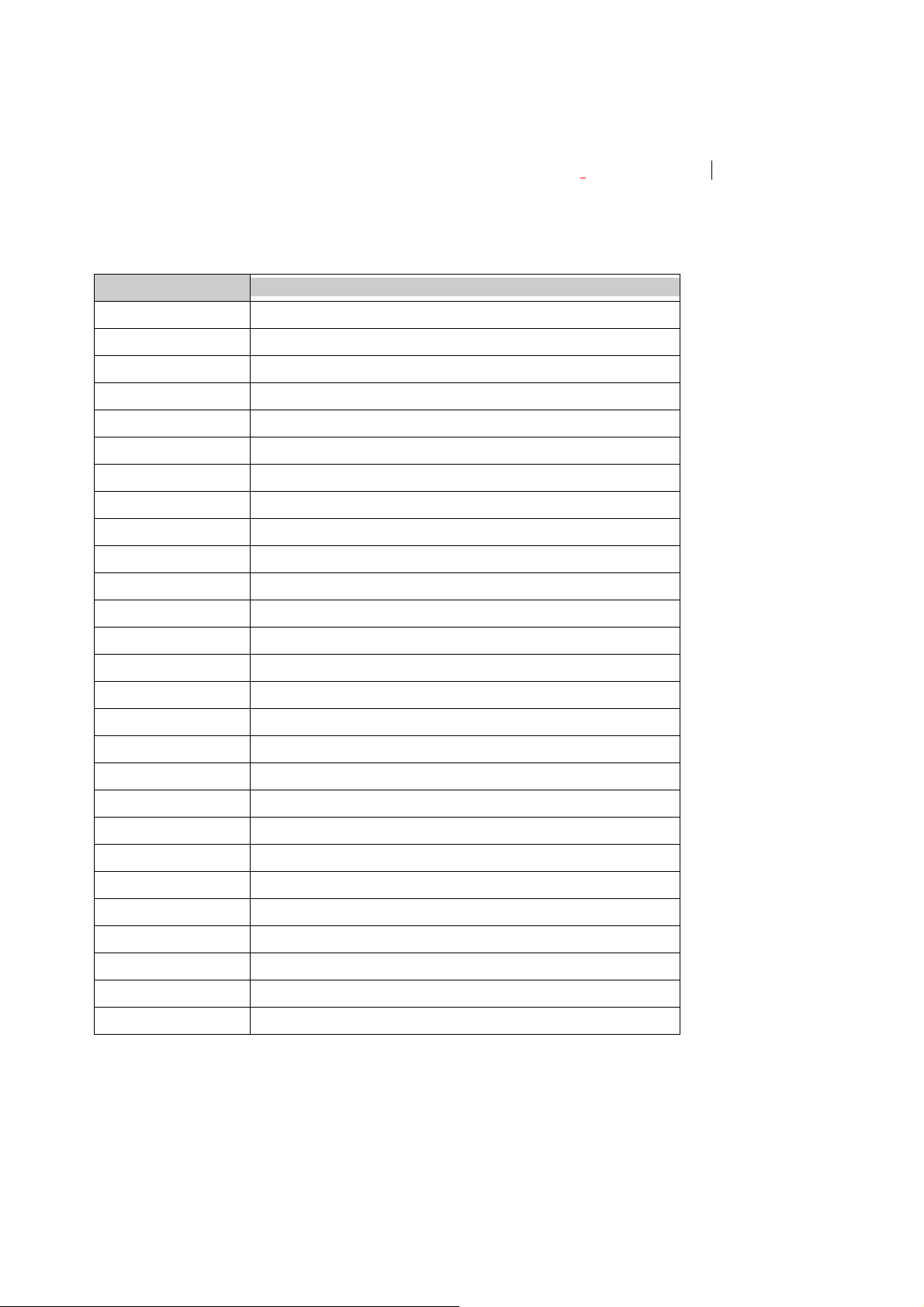

2.1.4

PKMB1:2x4

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1

3

5

7

CCMOS2: Clear CMOS Data

DESCRIPTION CMOS

Normal (Default)

Clear CMOS

Conne

Header PS/2

VCC

MSDATA

KBDATA

GND

ctors Pin

2

4

6

8

1-2

2-3

Assignment

Keyboard & Mouse Connector

MSCLK

KEY

KEY

KBCLK

Clear CMOS1

CCMOS2

1

2

3

1

2

3

CCMOS2

1

2

3

14

Page 15

15

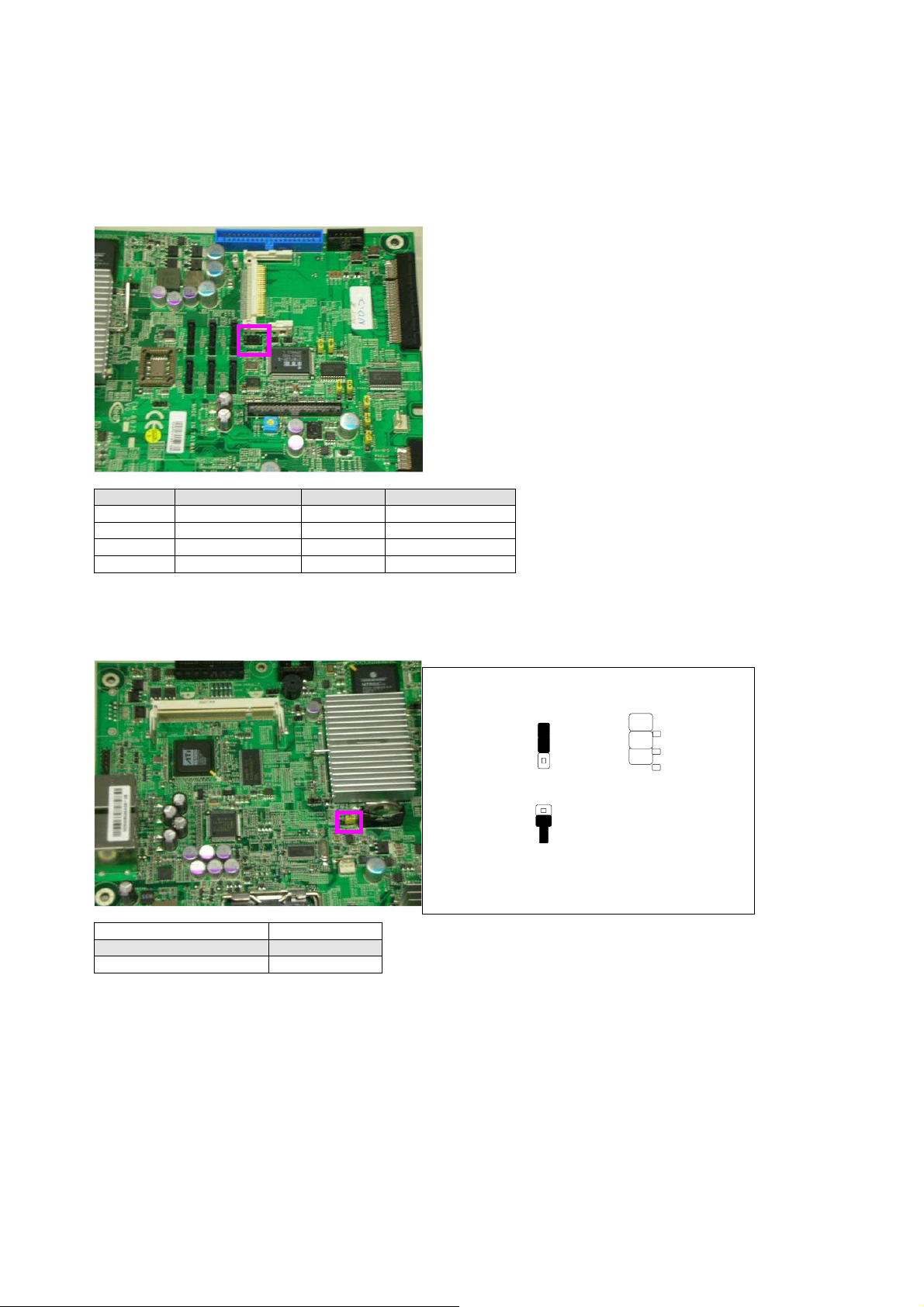

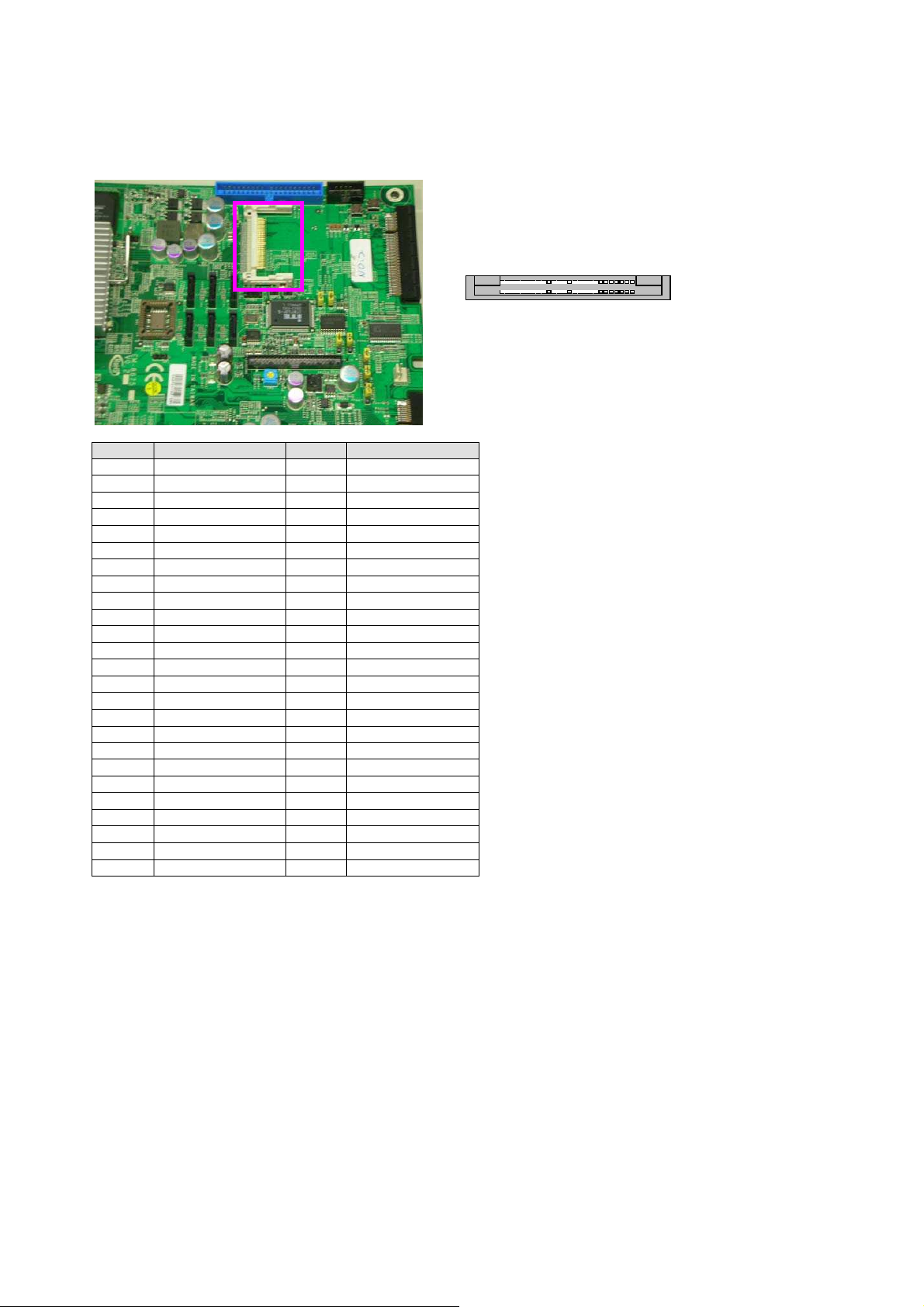

IDE1:40Pin

PIN NO. DESCRIPTION PIN NO.

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

IDE Interface

Reset #

Data 7

Data 6

Data 5

Data 4

Data 3

Data 2

Data 1

Data 0

Ground

DMA REQ#

IOW #

IOR #

IOCHRDY

DMA ACK #

Interrupt

SA1

SA0

HDC CS0 #

HDD Active LED #

Connect

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

or (2

2

1

.54mm)

IDE1

DESCRIPTION

Ground

Data 8

Data 9

Data 10

Data 11

Data 12

Data 13

Data 14

Data 15

KEY

Ground

Ground

Ground

Ground

Ground

NC

PD80P / SD80P

SA2

HDC CS1 #

Ground

40

Page 16

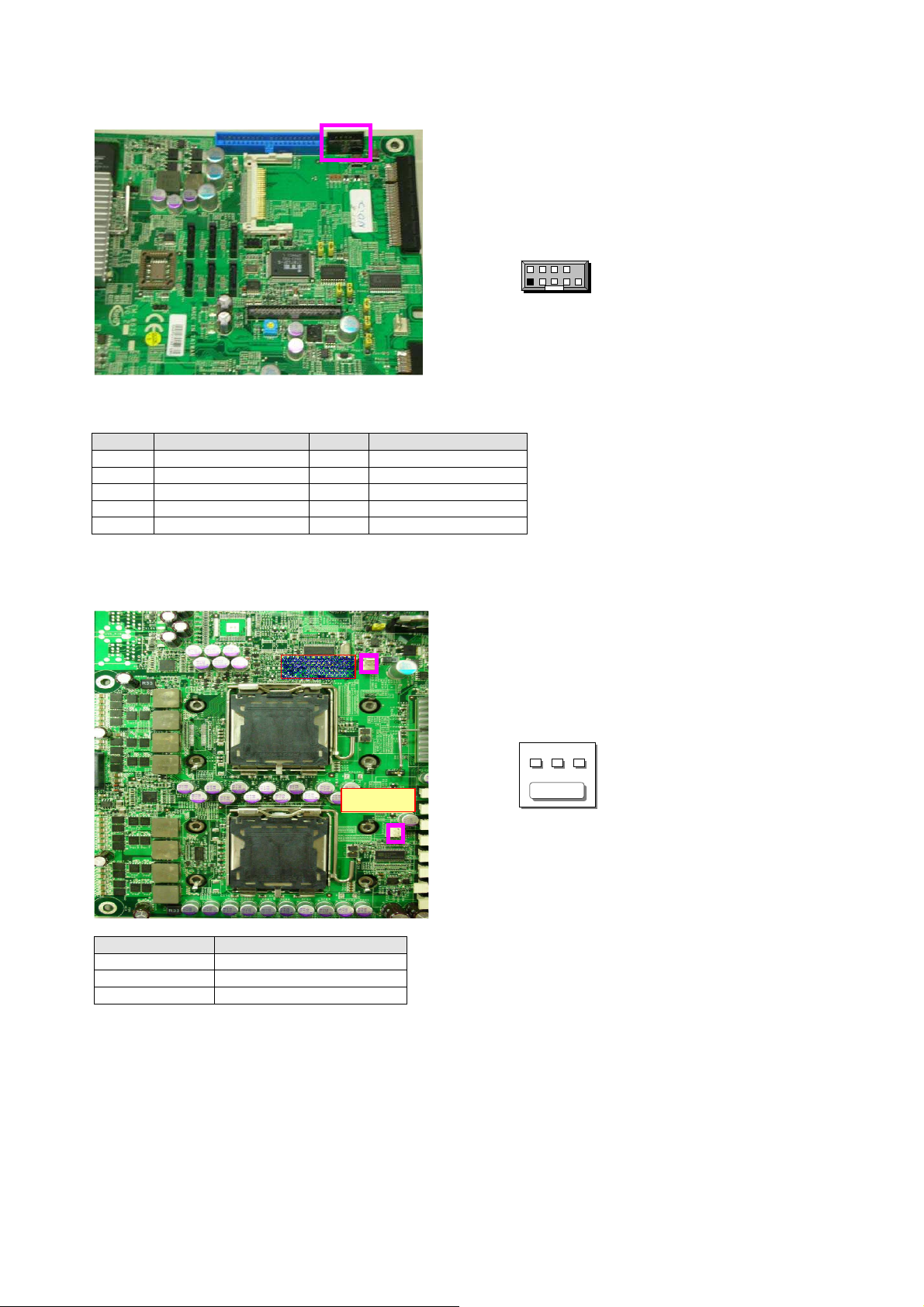

CN1:Compact

Flash Connector

PIN NO DESCRIPTION PIN NO DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

GND

DATA3

DATA4

DATA5

DATA6

DATA7

CE1#

NC

GND

NC

NC

NC

CFVCC3

NC

NC

NC

NC

A2

A1

A0

DATA0

DATA1

DATA2

WP

CD2-

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

CD1-

DATA11

DATA12

DATA13

DATA14

DATA15

CE2#

NC

IOR#

IOW#

WE#

READY#

CFVCC3

CSEL

NC

RESET

WAIT#

INPACK#

REG#

DASP#

DIAG#

DATA8

DATA9

DATA10

GND

CN1

16

Page 17

FPIO1:9Pin

PIN NO DESCRIPTION PIN NO DESCRIPTION

1

3

5

7

9

HDD_LEDH

HDD_LEDL

Ground

FP_RST#_N

NMI_N

CPUFAN1/AUXFAN1:3Pin Smart

PIN NO DESCRIPTION

1

2

3

Front Pa

Ground

VFAN1~2

FAN Speed

nel Connector (2.54mm)

2

4

6

8

10

SP_LEDH

SP_LEDL

Ground

PS_ON#

KEY

FAN

CPUFAN1

AUXFAN1

Header

2 10

1 9

FPIO1

1 2 3

17

Page 18

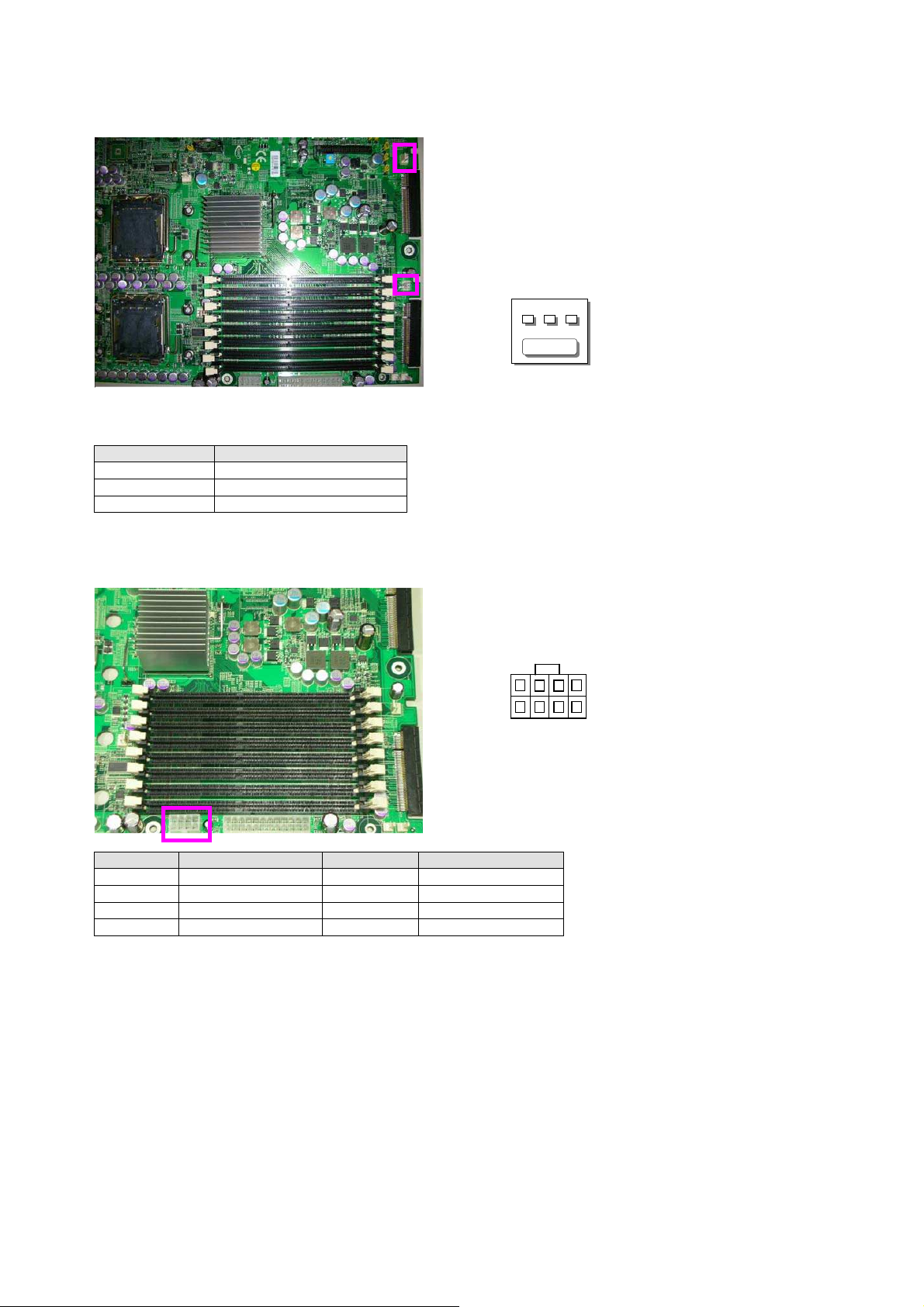

AUXFAN2 ~ AUXFAN3:3

PIN NO DESCRIPTION

1

2

3

ATXPWR1:

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1

2

3

4

Ground

VFAN1~2

FAN Speed

8Pin Power C

Ground

Ground

Ground

Ground

Pin

FAN

AUXFAN3

AUXFAN2

onnector

5

6

7

8

Header

P12V_A

P12V_A

P12V_B

P12V_B

8 5

4 1

1 2 3

18

Page 19

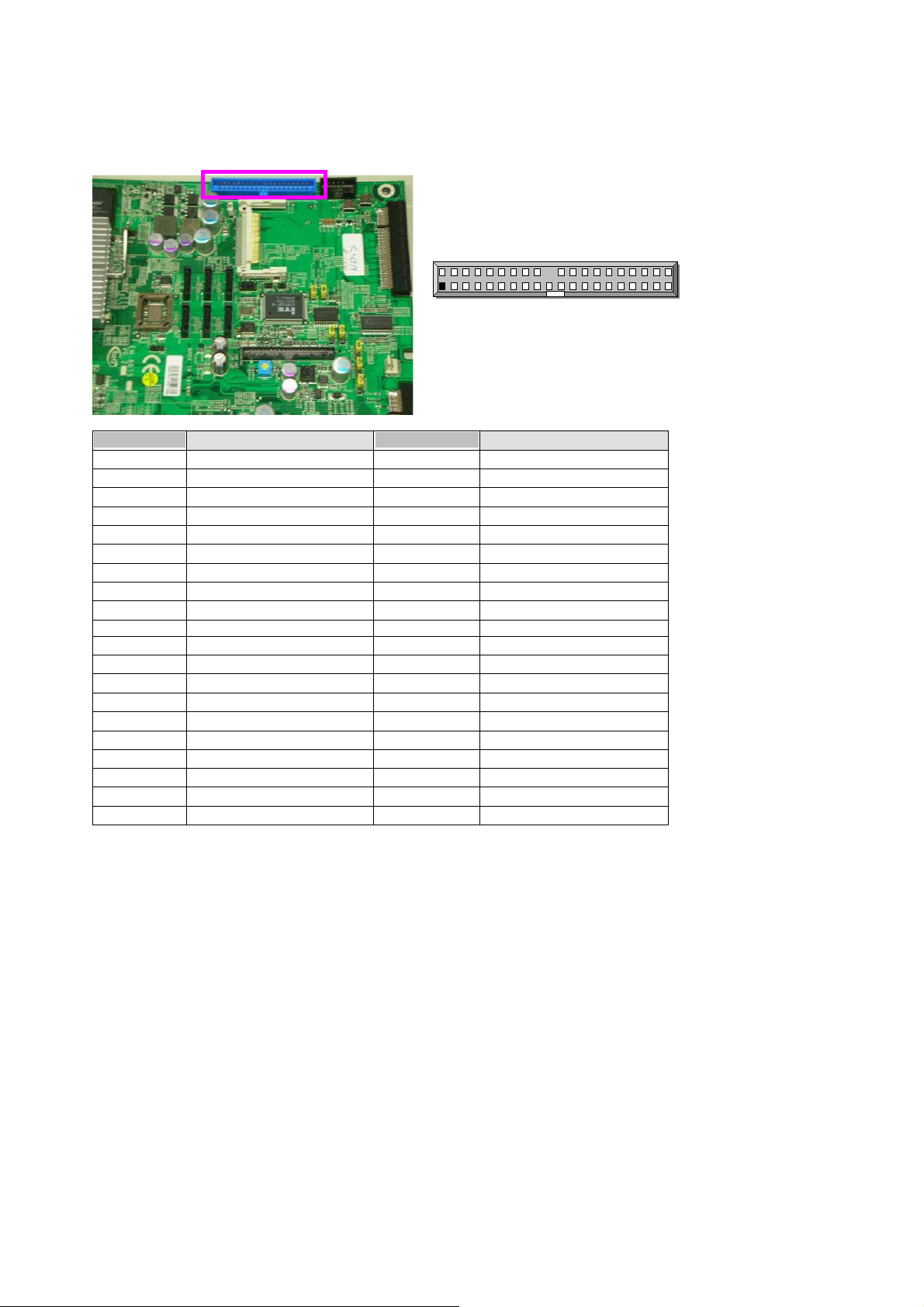

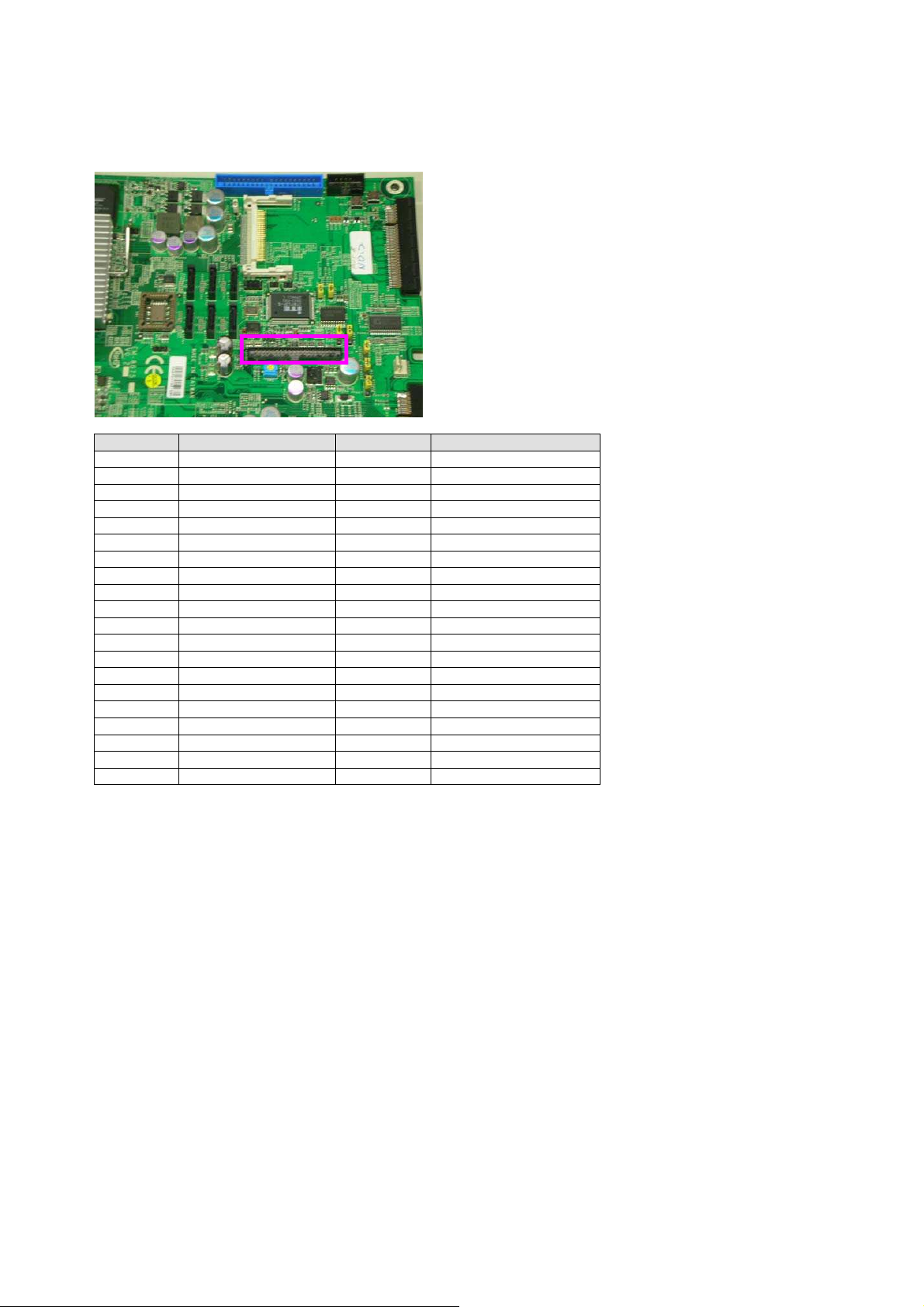

LUSBCOM1:2 x 20

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

NDCDB#

NSINB

NSOUTB

NDTRB#

Ground

+5V

CTR_GRN

P5V_USB4

USB_4N_C

USB_4P_C

LPT17

LPT14

LPT3

LPT5

LPT7

LPT9

LCD-

KPA1_JP

KPA3_JP

FP_RST#_N

Pin BOX Conne

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

ctor

(2.00mm)

NDSRB#

NRTSB#

NCTSB#

NRIB#

Ground

+5V

HDD_LED#

CTR_RED

P5V_USB5

USB_5P_C

USB_5N_C

Ground

VEE(LCD)

LPT16

LPT2

LPT4

LPT6

LPT8

KPA2_JP

KPA4_JP

19

Page 20

VGA1: External VGA Conne

ctor

(12 Pin Header)

2 12

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1

3

5

7

9

11

R

G

B

H-SYNC

V-SYNC

Detect-display Data

2

4

6

8

10

12

Ground

Ground

Ground

Ground

Ground

Deteck-display CLOCK

JP1:1x2

Pin Compact

Flash

Mode (2.54mm)

PIN NO. DESCRIPTION

OPEN

SHORT

Slave

Master

Default JP1 (1-2)

1 11

1

JP1

2

20

Page 21

JP2:4

Pin TACT Power

PIN NO. DESCRIPTION

1

2

3

4

Ground

Ground

PS_ON#

PS_ON#

JP3:4

Pin TACT Reset Button

PIN NO. DESCRIPTION

1

2

3

4

Ground

Ground

PS_ON#

PS_ON#

Bu

tton

2 1

○

_○ ○

4 3

2 1

○

_○ ○

4 3

21

Page 22

JP8~JP11:1x3

Pin Select KEYPAD

PIN NO. DESCRIPTION

1

2

3

Default (1-2),(2-3) for ODM

JP12:2Pin

PIN NO. DESCRIPTION

1

2

KPAx

KPAx_JP

Lan_LEDx

For TTL1

Ground

TTL1(IT8712F GP30)

detect

or

USB_RJ1

JP8/JP10

JP9/JP11

Lan

LED

3

1

JP12

1

2

22

Page 23

JP13:2Pin

For TTL2

PIN NO. DESCRIPTION

1

2

JP14:1x2

PIN NO. DESCRIPTION

1

2

Ground

TTL1(IT8712F GP31)

Pin

For SIO

Ground

IT8712F GP16

detect

GPIO Pin

1

2

1

2

(2.54

mm)

JP13

23

Page 24

JP15:1x2

Pin

For SIO

PIN NO. DESCRIPTION

1

2

JP16~JP18:1x3

Ground

IT8712F GP17

Pin Select Bypass Function (2.54mm)

PIN NO. DESCRIPTION

1

2

3

IT8712F(GP32~34)

PCIEC3~5 Pin B12

Ground

Default (1-2,Bypa

ss

Enable)

GPIO Pin

(2.54

JP16

JP17

JP18

mm)

1

2

3

1

24

Page 25

JP19:1x2

Pin

For I2C BUS

PIN NO. DESCRIPTION

1

2

CON1:

PIN NO. DESCRIPTION

1

2

3

4

5

6

7

8

9

25

I2C_CHIPSET_SCL

I2C_CHIPSET_SCA

10

Pin Smart

Ground

FAN3 speed

VFAN3

Ground

FAN4 speed

VFAN4

Ground

FAN5 speed

VFAN5

FAN

Pin (2.54mm)

Conne

ctor

1

2

Page 26

10

Ground

26

Page 27

CON3:

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1

3

5

7

9

WP1:1x3

PIN NO. DESCRIPTION

1

2

3

10

Pin SMD OPMA_LAN C

MCARD_TX_H

MCARD_TX_L

POE_GND

POE_PWR

LAN_BUSY_LED_L

Pin U

FWP#

Ground

NC

41

Fla

sh Rom Wr

2

4

6

8

10

onnector

MCARD_RX_H

MCARD_RX_L

POE_GND

POE_PWR

LAN_LINK_LED_L

(2.54mm)

ite Protect (2.54mm)

3

1

27

Page 28

IPMI1:1x3

Pin Header (2.54mm)

PIN NO. DESCRIPTION

1

2

3

IPMB_SDA

GND

IPMB_SCL

SATA1~SATA6:180º

SATA

CONNECTOR

SATA1/SATA2/SATA3

SATA4/SATA5/SATA6

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1

3

5

7

9

GND

SATA_TXN

SATA_RXN

GND

GND

2

4

6

8

SATA_TXP

GND

SATA_RXP

GND

3

1

28

Page 29

PCIEC6:PCI Ex

press x4

Standard Conne

PCIEC3~PCIEC5:Splint PCI Express

ctor

x8

Standard Connector

PCIE 5

PCIE 4

PCIE 3

29

Page 30

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

B36

B37

B38

B39

+12V

+12V

+12V

GND

SMCLK

SMDAT

GND

+3.3V

JTAG1

3.3VAUX

WAKE#

BYPASS Mode

GND

PETP0

PETN0

GND

PRSNT#2

GND

PETP1

PETN1

GND

GND

PETP2

PETN2

GND

GND

PETP3

PETN3

GND

REFCLKB+

REFCLKB-

GND

PETP4

PETH4

GND

GND

PETP5

PETN5

GND

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

B36

B37

B38

B39

PRSNT1#

+12V

+12V

GND

JTAG2

JTAG3

JTAG4

JTAG5

+3.3V

+3.3V

PERST#

GND

REFCLKA+

REFCLKA-

GND

PERP0

PERN0

GND

RSVD

GND

PERP1

PERN1

GND

GND

PERP2

PERN2

GND

GND

PERP3

PERN3

GND

RSVD

RSVD

GND

PERP4

PERN4

GND

GND

PERP5

30

Page 31

B40

B41

GND

PETP6

B40

B41

PERN5

GND

31

Page 32

B42

B43

B44

B45

B46

B47

B48

B49

PETN6

GND

GND

PETP7

PETN7

GND

PRSNT2#

GND

J1~J8:240Pin

or

GND

PERP6

PERN6

GND

GND

PERP7

PERN7

GND

J1

J2

J3

J4

J5

J6

J7

J8

B42

B43

B44

B45

B46

B47

B48

B49

FB

-DIMM Connect

32

Page 33

RS12-38800

33

Ethernet Ports

2.2 Mechanical Overview

This section of the manual describes the mechanical and device

nomenclature of the RS12-38800.

2.2.1 Face Panel LED Status and Behavior

Figure 5 – RS12-38800 Front Panel

The following table provides a description of each LED on the RS12-38800

front panel:

Console Port: The console port cable connects RS12-38800 to

the host PC via. The Default baud rate is 115200

• LAN Connector: Require an Ethernet RJ-45 cable

• LCM & Keypad: Please reference the Appendix B

LED Color Status

PWR

HDD

Link/ACT

Status Lanner Provide the Sample Codes(Please

Green

N/A Off No power connected

Yellow

N/A Off No Data is being accessed

Green On LAN is connected

Orange Flash Data is being accessed

On Indicates when RS12-38800 power is

switched ON

On Hard disk is being accessed

reference the Driver/ Manual CD, under

“LED Status” for more information)

Description

Page 34

34

2.2.2 Rear View

:

<sp>

RS12-38800

Figure 6 – RS12-38800 Rear View

Warning: Faulty or improper use of the power adaptor may cause permanent damage to

the power supply and the RS12-38800. Plug the adaptor to an electrical wall outlet that

matches its specifications.

刪除

刪除

刪除刪除

Page 35

RS12-38800

35

Step1

Step2

Step3

Step4

3. Hardware Installation Guide

3.1 CPU Installation

Step 1: Open Socket by pushing lever down and away from socket.

Step 2: Open load plate.(Don’t Touch Socket Contacts)

Step 3: Align notches with socket

Step 4: Close load plate.

刪除

刪除: Removing the Top

刪除刪除

Cover

Step 1 : Unscrew

screws from the system.

Step 2 : Pull up the top

cover

<sp><sp>

3.2 System Memory

Position the Fully Buffer DIMM memory module to the DIMM socket properly,

so the notch on the memory module fits the socket. Push the memory card

into the socket.

Note: The Fully Buffer DIMM memory module requires the proper orientation in order to fit

into the socket properly.

Warning: Please note that the DIMM socket must be used in sequence.

格格格格式化

式化:::: 項目符號及編號

式化式化

Page 36

RS12-38800

36

Installing Hard Disk

3.3 Installing Compact Flash Card

刪除

刪除:

刪除刪除

Drive

Step 1: screws the bracket.

Step 2: Moving the hard

disk bracket.

Step 3:

Step 4:

<sp><sp><sp><sp>

<sp>

Carefully insert the Compact Flash card into the slot as shown in the

illustration above.

3.4 Install the Rail slider

Page 37

RS12-38800

37

Page 38

RS12-38800

38

Page 39

RS12-38800

39

Page 40

RS12-38800

40

"Rack Mount Instructions - The following or similar rack-mount instructions are

included with the installation instructions:

i.

rack assembly, the operating ambient temperature of the rack environment may be

greater than room ambient. Therefore, consideration should be given to installing

the

equipment in an environment compatible with the maximum ambient temperature

(Tma) specified by the manufacturer.

ii.

should be such that the amount of air flow required for safe operation of the

equipment is not compromised.

iii.

be such that a hazardous condition is not achieved due to uneven mechanical

loading.

iv.

of the equipment to the supply circuit and the effect that overloading of the circuits

might have on overcurrent protection and supply wiring. Appropriate consideration

of equipment nameplate ratings should be used when addressing this concern.

Elevated Operating Ambient - If installed in a closed or multi-unit

Reduced Air Flow - Installation of the equipment in a rack

Mechanical Loading - Mounting of the equipment in the rack should

Circuit Overloading - Consideration should be given to the connection

v. Reliable Earthing - Reliable earthing of rack-mounted

equipment should be maintained. Particular attention should be given to

supply connections other than direct connections to the branch circuit (e.g. use

of power strips)."

CAUTION :

Slide/rail mounted equipment is not to be used as a shelf or a work space.

Page 41

RS12-38800

41

4. BIOS Setup

BIOS Setup

AMI’s ROM BIOS provides a built-in Setup program that allows users to modify the

basic system configuration and settings. The modified data will be stored in a

battery-backed CMOS RAM so that this data will be retained even when the power

is turned off. In general, the information saved in the CMOS RAM remains

unchanged unless there is a configuration change in the system, such as hard drive

replacement or new equipment installment.

Running AMI BIOS

The Setup Utility is stored in the BIOS ROM. When the power of the computer

system is turned on, a screen message will appear to give you an opportunity to call

up the Setup Utility while the BIOS will enter the Power On Self Test (POST)

routines. The POST routines perform various diagnostic checks while initializing the

board hardware. If the routines encounter an error during the tests, the error will

be reported in one of two ways, a series of short beeps or an error message on the

screen. There are two kinds of errors, fatal and non-fatal. The system can usually

continue the boot up sequence with non-fatal errors. Non-fatal error messages

usually appear on the screen along with the following

Instructions:

“ Press <F1> to RESUME ”

Write down the message and press the F1 key to continue the boot up sequence.

After the POST routines are completed, the following message appears:

“ Press DEL to enter SETUP ”

Entering Setup

Turn on the power of the computer system and press <Del> immediately. If you

don’t have the chance to respond, reset the system by simultaneously pressing the

<Ctrl>, <Alt> and <Delete> keys, or by pushing the ‘ Reset ’ button on the system

cabinet. You can also restart by turning the system OFF then ON.

CMOS Setup Utility

To access the AMI BIOS SETUP program, press the <DEL> key. The screen display

will appear as shown below:

Page 42

RS12-38800

42

4.1 Main Program Screen

This screen provides access to the utility‘s various functions.

Listed below is explanation of the keys displayed at the bottom of the screen:

<ESC>: Exit the utility.

<↑↓→ ←>: Use arrow keys↑↓→ ← to move cursor to your desired selection.

<F1>: General Help

<F10>: Saves all changes made to Setup and exits program.

Main

For changing the basic system configuration

Advanced

Boot

Security For changing the Security setting

Exit

For selecting the exit options and loading default

For changing the advanced system settings

For changing the system boot configuration

Settings

Page 43

RS12-38800

43

4.2 Main CMOS Setup

When you select the “Main CMOS SETUP” on the main program, the screen display

will appears as:

The Main CMOS Setup utility is used to configure the following components such as

date, time, display and memory.

Processor

Displays the auto-detected CPU specification

System Memory

System Time [xx:xx: xxxx]

System Date [Day xx/xx/xxxx]

Displays the auto-detected system memory

Allows

you to set the system time.

Allows you to set the system date.

Page 44

RS12-38800

44

4.3 Advanced Menu

When you select the “Advanced Menu” on the main program, the screen display will

appear as:

The following explains the options for each of the features as listed in the above

menu:

IDE Configuration:

The items in this menu allow you to set or change the

configurations. Four IDE devices were installed in the system. Select an

item then press <Enter>if you wish to configure the item.

ATA/IDE Configuration: These 2 items allow you to select the ATA/IDE and SATA

Page 45

RS12-38800

45

configuration. Select [Disabled] in ATA/IDE Configuration if you want to disable

both ATA/IDE configuration. Select [Compatible] or [Enhanced] to use the IDE,

S-ATA and PATA devices. Refer to the following tables for details.

Primary, Third and Fourth IDE Master/Slave

While entering Setup, the BIOS automatically detects the presence of IDE devices.

There is a separate sub-menu for each IDE device. Select a device item then press

<Enter> to display the IDE device information.

The BIOS automatically detects the values opposite the dimmed items

(Device, Vendor, Size, LBA Mode, Block Mode, PIO Mode, Async DMA, Ultra

DMA, and SMART monitoring). These values are not user-configurable.

These items show N/A if no IDE device is installed in the system.

Hard disk boot priority: Select boot sequence for onboard (or add-on cards) SCSI,

RAID, etc.

Type: Selects the type of IDE drive. Setting to Auto allows automatic selection of

the appropriate IDE device type. Select CDROM if you are specifically configuring a

CD-ROM drive. Select ARMD (ATAPI Removable Media Device)

If your device is either a ZIP, LS-120, or MO drives.

Configuration options: [Not Installed] [Auto] [CDROM] [ARMD]

LBA/Large Mode: Enables or disables the LBA mode. Setting to Auto enables the

LBA mode if the device supports this mode, and if the device was not previously

formatted with LBA mode disabled.

Page 46

RS12-38800

46

Configuration options: [Disabled] [Auto].

Block (Multi-sector Transfer): Enables or disables data multi-sector transfers.

When set to Auto, the data transfer from and to the device occurs multiple sectors

at a time if the device supports multi-sector transfer. When set to [Disabled], the

data transfer from and to the device occurs one sector at a time.

Configuration options: [Disabled] [Auto].

PIO Mode: Selects the PIO mode,

Configuration options: [Auto] [0] [1] [2] [3] [4].

DMA Mode: Selects the DMA mode.

Configuration options: [Auto] [DMA0][SWDMA1] [SWDMA2] [MWDMA0]

[MWDMA1] [MWDMA2] [UDMA0] [UDMA1] [UDMA2] [UDMA3] [UDMA4] [UDMA5].

SMART Monitoring: Sets the Smart Monitoring, Analysis, and Reporting

Technology. Configuration options: [Auto] [Disabled] [Enabled].

32Bit Data Transfer: Enables or disables 32-bit data transfer.

Configuration options: [Disabled] [Enabled].

Hard Disk Write Protect: Write protection effective only if device is accessed

through BIOS.

Configuration options: [Disabled] [Enabled].

IDE Detect Time Out (Sec): Select the time out value for detecting ATA/ATAPI

device(s).

Configuration options: [0] [5] [10] [15] [20] [25] [30] [35]

ATA (PI) 80Pin Cable Detection: Select the mechanism for detecting 80Pin ATA

(PI) cable.

Configuration options: [Host & Device] [Host] [Device]

Super IO Configuration: Press <Enter> to enter the sub-menu and the following

screen appears:

Serial Port1/2 Address:

These items specify the base I/O port addresses of the onboard Serial Port 1

Page 47

RS12-38800

47

Selecting [Auto] allows BIOS to automatically determine the correct base I/O

port address. Settings: [3F8/IRQ4], [2F8/IRQ3], [3E8/IRQ4], [2E8/IRQ3] and

[Disabled].

Serial Port2 Mode:

This item allows you to select mode for Serial Port2. Setting options: [Normal],

[IrDA], [ASK IR].

Parallel Port Address: Allows you to select the Parallel Port base addresses.

Configuration options: [Disabled] [378] [278] [3BC].

Parallel Port Mode: Allows you to select the Parallel Port mode.

Configuration options: [Normal] [Bi-directional] [EPP] [ECP].

Parallel Port IRQ:

Configuration options: [IRQ5] [IRQ7].

Restore on AC Power Loss by IO

This setting specifies whether your system will reboot after a power failure or

interrupt occurs. Available settings are:

[Power Off] Leaves the computer in the power off state.

[Power On] Leaves the computer in the power on state.

[Last State] Restores the system to the previous status before power

failure or interrupt occurred.

Hardware Health Configuration: Press <Enter> to enter the sub-menu and the

following screen appears:

H/W Health Function: Enable/Disable Hardware Health Monitoring Device.

Page 48

RS12-38800

48

SYS/CPU/Power FAN Speed, CPU Vcore, FBD_VCC, +3V, +5V, +12V,

FBD_VTT, -12V, 5VSB,VBAT: These items display the current status of all of the

monitored hardware devices components such as CPU voltages, and all fans’

speeds.

USB Configuration: Press <Enter> to enter the sub-menu and the following

screen appears:

Legacy USB Support: Enables support for legacy USB. AUTO disable legacy

support if no USB devices are connected.

Configuration options: [Disable] [Enable] [Auto].

USB 2.0 Controller Mode: Configures the USB 2.0 controller in HiSpeed or

FullSpeed).

Configuration options: [FullSpeed] [HiSpeed].

BIOS EHCI Hand-Off: this is a workaround for Oses without EHCI hand-off

support. The EHCI ownership change should claim by EHCI driver.

Configuration options:[Disable] [Enable].

Hotplug USB FDD Support: A dummy FDD device is created that will be

associated with the hot plugged FDD later. AUTO creates this dummy device only if

there is no USB FDD present.

Configuration options: [Disable] [Enable] [Auto].

USB Mass Storage Device Configuration: Press <Enter> to enter the

sub-menu and the following screen appears:

Page 49

RS12-38800

49

USB MASS Storage Reset Delay: Number of seconds POST waits for the USB

mass Storage device after start unit command.

Emulation Type: If AUTO, USB devices less than 530MB will be emulated as floppy

and remaining as hard drive. Forced FDD option can be used to force a HDD

formatted drive to boot as FDD (Ex. ZIP drive).

AHCI Configuration: Press <Enter> to enter the sub-menu and the following

screen appears:

AHCI Port0/1/2/3/4/5[Not Detected]: While entering setup, BIOS auto detects the presence of

IDE devices. This displays the status of auto detection of IDE device.

Remote Access Configuration: Press <Enter> to enter the sub-menu and enable

Remote Access, the following screen appears:

Page 50

RS12-38800

50

Serial port number: Select Serial Port for console redirection.

Serial Port Mode: Select Serial Port setting.

Flow Control: Select Flow Control for console redirection.

Redirection After BIOS POST: DISABLE, Turns off the redirection after POST.

Boot Loader, Redirection is active during POST and during Boot Loader. Always,

Redirection is always active.

Terminal Type: Select the target terminal type.

VT-UTF8 Combo Key Support: Enable VT-UTF8 Combination Key Support for

ANSI/VT100 terminals.

Sredir Memory Display Delay: Gives the delay in seconds to display memory

information.

Page 51

RS12-38800

51

4.4 Boot Menu

The Boot menu items allow you to change the system boot options. Select

an item then press <Enter> to display the sub-menu.

Boot Setting Configuration: Press <Enter> to enter the sub-menu and the

following screen appears:

Quick Boot :

while booting to decrease the time needed to boot the system. When set to [Disabled], BIOS

performs all the POST items. Configuration options: [Disabled] [Enabled]

Full Screen Logo: This allows you to enable or disable the full screen logo display

feature. Configuration options: [Disabled] [Enabled]

Add On ROM Display Mode: Sets the display mode for option ROM.

Enabling this item allows the BIOS to skip some power on self tests (POST)

Page 52

RS12-38800

52

Configuration options: [Force BIOS] [Keep Current].

Bootup Num-Lock: Allows you to select the power-on state for the NumLock.

Configuration options: [Off] [On]

PS/2 Mouse Support: Allows you to enable or disable support for PS/2 mouse.

Configuration options: [Disabled] [Enabled] [Auto].

Wait for ‘F1’ If Error: When set to Enabled, the system waits for the F1 key to be

pressed when error occurs. Configuration options: [Disabled] [Enabled].

Hit ‘DEL’ Message Display: When set to Enabled, the system displays the

message. “Press DEL to run Setup” during POST. Configuration options: [Disabled]

[Enabled].

Interrupt 19 Capture: When set to [Enabled], this function allows the option

ROMs to trap Interrupt 19. Configuration options: [Disabled] [Enabled].

Boot Device Priority: Press <Enter> to enter the sub-menu and the following

screen appears:

1st ~ xxth Boot Device: These items specify the boot device priority sequence

from the available devices. The number of device items that appears on the screen

depends on the number of devices installed in the system. Configuration options:

[xxxxx Drive] [Disabled].

Page 53

RS12-38800

53

4.5 Security Menu

Press <Enter> to enter the sub-menu and the following screen appears:

Type the password, up to 6 characters in length, and press <Enter>. The typed

password now will replace any previously set password from CMOS memory. You

will be prompted to confirm the password. Retype the password and press <Enter>.

You may also press <Esc> to abort the selection and not enter a password.

To clear a set password, just press <Enter> when you are prompted to enter the

password. A message will show up confirming the password will be disabled. Once

the password is disabled, the system will boot and you can enter Setup without

entering any password.

When a password has been set, you will be prompted to enter it every time you try

to enter Setup. This prevents an unauthorized person from changing any part of

your system configuration.

Change Supervisor Password: Install or Change the password.

Change User Password: Install or Change the password.

Boot Sector Virus Protection: Enable/Disable Boot Sector Virus protecting.

Page 54

RS12-38800

54

4.6 Exit Menu

Press <Enter> to enter the sub-menu and the following screen appears:

Save Changes and Exit: Once you are finished making your selections, choose

this option from the Exit menu to ensure the values you selected are saved to the

CMOS RAM. An onboard backup battery sustains the CMOS RAM so it stays on even

when the PC is turned off. When you select this option, a confirmation window

appears. Select Yes to save changes and exit.

Discard Changes and Exit: Select this option only if you do not want to save the

changes that you made to the Setup program. If you made changes to fields other

than System Date, System Time, and Password, the BIOS asks for a confirmation

before exiting.

Discard Changes: This option allows you to discard the selections you made and

restore the previously saved values. After selecting this option, a confirmation

appears. Select Yes to discard any changes and load the previously saved values.

Load Optimal/Failsafe Defaults: This option allows you to load the default

values for each of the parameters on the Setup menus. When you select this option

or if you press <F9/F8>, a confirmation window appears. Select Yes to load default

values. Select Exit & Save Changes or make other changes before saving the values

to the non-volatile RAM.

Page 55

RS12-38800

55

A. Appendix A: Power Supply

A.1 Power Supply Specifications

AC Input Specifications: Voltage 90 ~ 264 VAC FULL RANGE

Output Specifications

Output

Voltage

+5V

-5V 0.2 1.2 ±5%/-10% ±1% 120mV

+12V 6 60.00 +6% ±1% 120mV

-12V 0.2 1.20 +5%/-10% ±1% 120mV

+3.3V 3.5

+5VSB 0.4

A.2 Features:

Output

Current

Min.

Output

Current Max.

6 56.00 ±5% ±1% 70mV

44

3.5

Output

Current Peak

Regulation

±5% ±1% 70mV

+5%/-6% ±1% 70mV

Load

Regulation

Line

Output Ripple &

Noise Max.[P-P]

Active PFC (full range), meets IEC-1000-3-2 Class D requirements

12V, Maximum Current: 60A

Temperature Range: Operating ranges from 0℃~40℃, Storage ranges

from -20℃~70℃

EMI: FCC CLASS B, CISPR 22 CLASS B

Safety: UL 1950, CSA 22.2 No./ 950, TUV IEC 950

Hot-Swappable / Hot-Pluggable Redundancy Function

Uses 48-pin industrial connectors

Cooling: 38 x 38 x 28mm DC Fans (Module)

AC Inlet in each module

Page 56

RS12-38800

56

Watch Dog Timer Control

= 01 Power LED pin is drived

= 10 Power LED pin is a 1Hz

Bit 2 : Enable the rising edge

zerovalue to Watch Dog

B. Appendix B: Watchdog Timer

B.1 Introduction

Most systems need to be self-reliant. If an error should occur it is typically

not possible to wait for the system to be rebooted manually. In some cases,

the system is simply not accessible to human operators. If such systems

should ever hang, they would be permanently disabled. In other cases, the

speed at which a human operator would reset the system would be too slow

to meet the uptime requirements of the product.

A watchdog timer is a piece of hardware that can be used to automatically

detect system anomalies and reset the processor in the case any problems

are found. Generally speaking, a watchdog timer is based on a counter that

counts down from an initial value to zero. The software selects the counter's

initial value and periodically restarts it. Should the counter reach zero

before the software restarts it, the software is presumed to be

malfunctioning, and the processor's reset signal is asserted. Thus, the

processor will be restarted as if a human operator had cycled the power.

Note: The watchdog function is the Intel 82571EB. Lanner provides sample

codes in the Manual/ Driver CD under the path:// WATCHDOG

刪除

刪除: Detail Register

刪除刪除

Descriptions

A watchdog action consists

of a series of watchdog

instructions. A watchdog

instruction is the operation

on a register region. This

section describes the detail

register in LPC

I/O(W83627HF).

Register

Watch Dog Timer is

controlled by CRF5, CRF6,

CRF7 of Logical Device.

CRF5 (PLED mode

register. Default 0x00)

Bit 7-6 : select PLED mode

= 00 Power LED pin is

tri-stated.

low.

toggle pulse with 50 duty

cycle

= 11 Power LED pin is a

1/4Hz toggle pulse with 50

duty cycle.

Bit 5-4 : Reserved

Bit 3 : select WDTO count

mode.

= 0 second

= 1 minute

of keyboard Reset(P20) to

force Time-out event.

= 0 Disable

= 1 Enable

Bit 1-0 : Reserved

CRF6 (Default 0x00)

Watch Dog Timer Time-out

value. Writing a non-zero

value to this register causes

the counter toload the value

to Watch Dog Counter and

start counting down. If the

Bit 7 and Bit 6 are set,

anyMouse Interrupt or

Keyboard Interrupt event

will also cause the reload of

previously-loaded

nonCounter and start counting

down. Reading this register

returns current value

inWatch Dog Counter

instead of Watch Dog Timer

Time-out value.

Bit 7 - 0 = 0x00 Time-out

Disable

= 0x01 Time-out occurs

... [1]

Page 57

RS12-38800

57

C. Appendix C: Console Redirection

Console redirection lets you maintain a system from a remote location by

re-directing keyboard input and text output through the serial port. This

section will tell you how to use this feature.

1. Attach the console cable to the RS12-38800 and Remote Client

System.

2. Choose the following settings in the BIOS Setup menu for

RS12-38800.

BIOS > Advanced > Remote Access Configuration > Serial Port Mode > [115200, 8 ,

n , 1 ](Defult)

3. Configure Console Redirection on the client system. The following

example is applicable for a Windows platform:

A. Click the start button, point to Programs > Accessories >

Communications and select Hyper Terminal.

B. Enter any name for the new connection and select any icon.

C. Click OK.

D. From the “Connect to”. Pull-down menu, select a Com2 port

available on the client system and click OK.

E. Select Baud Rate > 115200 > Flow Control > None.

F. Select Data bit > 8.

G. Select Parity Check > None.

H. Select Stop bit > 1.

I. Power on the RS12-38800, and it should display the BIOS

information on the client system..

Page 58

RS12-38800

58

D. Appendix D: LCM Module and Keypad

for RS12-38800

D.1 Purpose of this chapter

The purpose of this document is to provide installation information for the

LCM module and key pad installed in the RS12-38800

D.2 LCM module specification overview

The LCM module is designed to provide real-time operating status and

configuration information for the system. The detail specifications can be

referenced in the Manual/ Driver CD under the path:// LCM/

LCD_Datasheet.pdf

The driver and library can be found on the Manual/ Driver CD under the

path://LCM

Page 59

RS12-38800

59

E. Appendix E: LAN Bypass Function

E.1

Introduction

The bypass

ports when the system

equipped with a LAN Bypa

interrupt yo

for

the bypas

Lanner provides three methods

1.

2. Use

3. A

Please

the path// LAN_Bypa

func

tion is used to link (or short) two independent Ethernet

cr

ash

or

powe

rs off.

ss fu

nction, a condition in yo

ur

network tra

s f

uncti

When the system powe

function directly

r can

enable or disable the LAN Bypa

which Control by GPIO

watchdog timer(WDT)can be used to control the LAN Bypa

function via programming.

refer to

the Intel 82571EB datasheet on the Manual/ Driver CD under

ffic. There are

on,

one is “Normal” state and another is “Bypass” state.

for

enabling the LAN Bypass

..

ss.

Lann

rs off, it

.

er

will be

also provides sample code

This means if yo

typically two communication state

forced to

enable the LAN Bypass

ss

function by programming

ur s

ur

system will not

fu

for reference.

nction.

ystem i

ss

s

s

LAN Bypass

Page 60

RS12-38800

60

F. Appendix F: Hot-swap Hard disk

F.1

Introduction

Hot swap is a

Interface(AHCI). Hot swap allows devices to be

the system is running

In

orde

r for

1.

bios select Advanced

2.

Operating system must to be support the AHCI driver. But be notes that

fully supported out

operating system

fe

ature supported by the Advanced Host Controlle

re

moved and inserted while

.

hot swap to be enabled, the following must to be true :

IDE configuration -

of

the box

from

kernel

for

2.6.19 or

Configure SATA as -

Microsoft Window

late

r.

s

and the Linux

AHCI

r

AHCI is

Page 61

RS12-38800

61

Terms and Conditions

Date: 2008.03.19

Warranty Policy

1. All products are under warranty against defects in materials and workmanship for

a period of one year from the date of purchase.

2. The buyer will bear the return freight charges for goods returned for repair within

the warranty period; whereas the manufacturer will bear the after service freight

charges for goods returned to the user.

3. The buyer will pay for repair (for replaced components plus service time) and

transportation charges (both ways) for items after the expiration of the warranty

period.

4. If the RMA Service Request Form does not meet the stated requirement as listed

on “RMA Service,” RMA goods will be returned at customer’s expense.

5. The following conditions are excluded from this warranty:

Improper or inadequate maintenance by the customer

Unauthorized modification, misuse, or reversed engineering of the product

Operation outside of the environmental specifications for the product.

格格格格式化

式化:::: 項目符號及編號

式化式化

RMA Service

Requesting a RMA

1. To obtain a RMA number, simply fill out and fax the “RMA Request Form” to your

supplier.

2. The customer is required to fill out the problem code as listed. If your problem is

not among the codes listed, please write the symptom description in the remarks box.

3. Ship the defective unit(s) on freight prepaid terms. Use the original packing

materials when possible.

4. Mark the RMA# clearly on the box.

Note: Customer is responsible for shipping damage(s) resulting from inadequate/loose packing of the

defective unit(s). All RMA are valid for 30 days only; RMA goods received after the effective RMA#

period will be rejected.

Page 62

RS12-38800

62

RMA Service Request Form

When requesting RMA service, please fill out the following form. Without

this form enclosed, your RMA cannot be processed.

RMA No:

Company: Contact Person:

Phone No. Purchased Date:

Fax No.: Date:

Return Shipping Address:

Shipping by: □ Air Freight □ Sea □ Express ___

□ Others:________________

Item Model Name Serial Number Configuration

Item Problem Code Failure Status

*Problem Code:

01:D.O.A.

02: Second Time

R.M.A.

03: CMOS Data Lost

04: FDC Fail

05: HDC Fail

06: Bad Slot

07: BIOS Problem

08: Keyboard Controller Fail

09: Cache RMA Problem

10: Memory Socket Bad

11: Hang Up Software

12: Out Look Damage

Reasons Return: □ Repair(Please include failure details)

□ Testing Purpose

13: SCSI

14: LPT Port

15: PS2

16: LAN

17: COM Port

18: Watchdog Timer

19: DIO

20: Buzzer

21: Shut Down

22: Panel Fail

23: CRT Fail

24: Others (Pls specify)

Request Party

Authorized Signature / Date Authorized Signature / Date

Confirmed By Supplier

Page 63

第第第第 56

56 頁頁頁頁: [1]

: [1] 刪除

56 56

刪除 KevinYu

: [1] : [1]

刪除刪除

KevinYu 2005/6/22 3:21:00 PM

KevinYuKevinYu

2005/6/22 3:21:00 PM

2005/6/22 3:21:00 PM2005/6/22 3:21:00 PM

Detail Register Descriptions

A watchdog action consists of a series of watchdog instructions. A watchdog instruction is the

operation on a register region. This section describes the detail register in LPC I/O(W83627HF).

Watch Dog Timer Control Register

Watch Dog Timer is controlled by CRF5, CRF6, CRF7 of Logical Device.

CRF5 (PLED mode register. Default 0x00)

Bit 7-6 : select PLED mode

= 00 Power LED pin is tri-stated.

= 01 Power LED pin is drived low.

= 10 Power LED pin is a 1Hz toggle pulse with 50 duty cycle

= 11 Power LED pin is a 1/4Hz toggle pulse with 50 duty cycle.

Bit 5-4 : Reserved

Bit 3 : select WDTO count mode.

= 0 second

= 1 minute

Bit 2 : Enable the rising edge of keyboard Reset(P20) to force Time-out event.

= 0 Disable

= 1 Enable

Bit 1-0 : Reserved

CRF6 (Default 0x00)

Watch Dog Timer Time-out value. Writing a non-zero value to this register

causes the counter toload the value to Watch Dog Counter and start counting

down. If the Bit 7 and Bit 6 are set, anyMouse Interrupt or Keyboard Interrupt

event will also cause the reload of previously-loaded non-zerovalue to Watch

Dog Counter and start counting down. Reading this register returns current

value inWatch Dog Counter instead of Watch Dog Timer Time-out value.

Bit 7 - 0 = 0x00 Time-out Disable

= 0x01 Time-out occurs after 1 second/minute

= 0x02 Time-out occurs after 2 second/minutes

= 0x03 Time-out occurs after 3 second/minutes

= 0xFF Time-out occurs after 255 second/minutes

Page 64

CRF7 (Default 0x00)

Bit 7 : Mouse interrupt reset Enable or Disable

= 1 Watch Dog Timer is reset upon a Mouse interrupt

= 0 Watch Dog Timer is not affected by Mouse interrupt

Bit 6 : Keyboard interrupt reset Enable or Disable

= 1 Watch Dog Timer is reset upon a Keyboard interrupt

= 0 Watch Dog Timer is not affected by Keyboard interrupt

Bit 5 : Force Watch Dog Timer Time-out, Write only

= 1 Force Watch Dog Timer time-out event; this bit is self-clearing.

Bit 4 : Watch Dog Timer Status, R/W

= 1 Watch Dog Timer time-out occurred

= 0 Watch Dog Timer counting

Bit 3 -0 : These bits select IRQ resource for Watch Dog. Setting of 2 selects SMI.

Loading...

Loading...