Page 1

NCA-5710

User Manual

Version: 1.2

Date of Release:2019-06-11

Network Appliance

Platform

1

Page 2

This manual describes the overview of the various functionalities of this product and the information you

Example

Convention

Usage

iptables –F

Monospace, shaded

A command to be entered at a shell

command-line

Setup page

Bold

A title of a dialog box or a page

<Enter>

Between a pair of inequality signs

A physical keyboard button

“Menu”

Between a pair of quotation marks

A menu option or a software button to be

clicked

Readme.txt

In Italic

A filename or a file path

IPMI User Guide

Underlined

The name of another document or a chapter

in this document

Icon

Usage

This mark indicates that there is something you should pay special

attention to while using the product.

This mark indicates that there is a caution or warning and it is

something that could damage your property or product.

Note or Information

Warning or Important

need to get it ready for operation. It is intended for those who are:

- responsible for installing, administering and troubleshooting this system or information technology

professionals.

- assumed to be qualified in the servicing of computer equipment, such as professional system

integrators, or service personnel and technicians.

The latest version of this document can be found on Lanner’s official website, available either through the

product page or through the Lanner Download Center page with a login account and password.

This document utilizes different font types and icons in order to make selected text more transparent and

explicable to users. This document contains the following conventions:

2

Page 3

NCA-5710 User Manual

To obtain additional documentation resources and software updates for your system, please visit the

Lanner Download Center. As certain categories of documents are only available to users who are logged in,

please be registered for a Lanner Account at http://www.lannerinc.com/ to access published documents

and downloadable resources.

For troubleshooting the issues with your system, please visit the Lanner Q&A page for diagnostic

procedures and troubleshooting steps.

In addition to contacting your distributor or sales representative, you could submit a request to our Lanner

Technical Support at http://www.lannerinc.com/technical-support where you can fill in a support ticket to

our technical support department.

This document is copyrighted © 2019 by Lanner Electronics Inc. All rights are reserved. The original

manufacturer reserves the right to make improvements to the products described in this manual at any

time without notice.

No part of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without the prior written permission of the original manufacturer.

Information provided in this manual is intended to be accurate and reliable. However, the original

manufacturer assumes no responsibility for its use, nor for any infringements upon the rights of third

parties that may result from such use.

Your feedback is valuable to us, as it will help us continue to provide you with more accurate and relevant

documentation. To provide any feedback, comments or to report an error, please email to

contact@lannerinc.com. Thank you for your time.

3

Page 4

Taiwan Corporate Headquarters

Lanner Electronics Inc.

7F, No.173, Sec.2, Datong Rd. Xizhi District,

New Taipei City 22184, Taiwan

T: +886-2-8692-6060

F: +886-2-8692-6101

E: contact@lannerinc.com

China

Beijing L&S Lancom Platform Tech. Co., Ltd.

Guodong LOFT 9 Layer No. 9 Huinan Road,

Huilongguan Town, Changping District, Beijing

102208 China

T: +86 010-82795600

F: +86 010-62963250

E: service@ls-china.com.cn

USA

Lanner Electronics Inc.

47790 Westinghouse Drive Fremont, CA 94539

T: +1-855-852-6637

F: +1-510-979-0689

E: sales_us@lannerinc.com

Canada

LEI Technology Canada Ltd

3160A Orlando Drive Mississauga, ON L4V 1R5

Canada

T: +1 877-813-2132

F: +1 905-362-2369

E: sales_ca@lannerinc.com

Intel® and Intel® Xeon® are trademarks of Intel Corporation or its subsidiaries in the U.S. and/or other

countries.

Microsoft Windows and MS-DOS are registered trademarks of Microsoft Corp.

All other product names or trademarks are properties of their respective owners.

4

Page 5

NCA-5710 User Manual

Note

1. An unshielded-type power cord is required in order to meet FCC emission limits and also to prevent interference

to the nearby radio and television reception. It is essential that only the supplied power cord be used.

2. Use only shielded cables to connect I/O devices to this equipment.

3. Changes or modifications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

Important

1. Operations in the 5.15-5.25GHz band are restricted to indoor usage only.

2. This device meets all the other requirements specified in Part 15E, Section 15.407 of the FCC Rules.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Any changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate this equipment.

This transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

5

Page 6

Follow these guidelines to ensure general safety:

Keep the chassis area clear and dust-free during and after installation.

Do not wear loose clothing or jewelry that could get caught in the chassis. Fasten your tie or scarf and

roll up your sleeves.

Wear safety glasses if you are working under any conditions that might be hazardous to your eyes.

Do not perform any action that creates a potential hazard to people or makes the equipment unsafe.

Disconnect all power by turning off the power and unplugging the power cord before installing or

removing a chassis or working near power supplies

Do not work alone if potentially hazardous conditions exist.

Never assume that power is disconnected from a circuit; always check the circuit.

Suivez ces consignes pour assurer la sécurité générale :

Laissez la zone du châssis propre et sans poussière pendant et après l’installation.

Ne portez pas de vêtements amples ou de bijoux qui pourraient être pris dans le châssis. Attachez votre

cravate ou écharpe et remontez vos manches.

Portez des lunettes de sécurité pour protéger vos yeux.

N’effectuez aucune action qui pourrait créer un danger pour d’autres ou rendre l’équipement

dangereux.

Coupez complètement l’alimentation en éteignant l’alimentation et en débranchant le cordon

d’alimentation avant d’installer ou de retirer un châssis ou de travailler à proximité de sources

d’alimentation.

Ne travaillez pas seul si des conditions dangereuses sont présentes.

Ne considérez jamais que l’alimentation est coupée d’un circuit, vérifiez toujours le circuit. Cet appareil

génère, utilise et émet une énergie radiofréquence et, s’il n’est pas installé et utilisé conformément aux

instructions des fournisseurs de composants sans fil, il risque de provoquer des interférences dans les

communications radio.

There is risk of explosion if the battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

Installation should be conducted only by a trained electrician or only by an electrically trained person

who knows all installation procedures and device specifications which are to be applied.

Do not carry the handle of power supplies when moving to another place.

Please conform to your local laws and regulations regarding safe disposal of lithium battery.

Disposal of a battery into fire or a hot oven, or mechanically crushing or cutting of a battery can result in

an explosion.

6

Page 7

NCA-5710 User Manual

Leaving a battery in an extremely high temperature environment can result in an explosion or the

leakage of flammable liquid or gas.

A battery subjected to extremely low air pressure may result in an explosion or the leakage of flammable

liquid or gas.

Risque d’explosion si la pile est remplacée par une autre d’un mauvais type.

Jetez les piles usagées conformément aux instructions.

L’installation doit être effectuée par un électricien formé ou une personne formée à l’électricité

connaissant toutes les spécifications d’installation et d’appareil du produit.

Ne transportez pas l’unité en la tenant par le câble d’alimentation lorsque vous déplacez l’appareil.

Electrical equipment generates heat. Ambient air temperature may not be adequate to cool equipment

to acceptable operating temperatures without adequate circulation. Be sure that the room in which you

choose to operate your system has adequate air circulation.

Ensure that the chassis cover is secure. The chassis design allows cooling air to circulate effectively. An

open chassis permits air leaks, which may interrupt and redirect the flow of cooling air from internal

components.

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD damage occurs

when electronic components are improperly handled and can result in complete or intermittent failures.

Be sure to follow ESD-prevention procedures when removing and replacing components to avoid these

problems.

Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact. If no wrist strap is

available, ground yourself by touching the metal part of the chassis.

Periodically check the resistance value of the antistatic strap, which should be between 1 and 10

megohms (Mohms).

L’équipement électrique génère de la chaleur. La température ambiante peut ne pas être adéquate pour

refroidir l’équipement à une température de fonctionnement acceptable sans circulation adaptée.

Vérifiez que votre site propose une circulation d’air adéquate.

Vérifiez que le couvercle du châssis est bien fixé. La conception du châssis permet à l’air de

refroidissement de bien circuler. Un châssis ouvert laisse l’air s’échapper, ce qui peut interrompre et

rediriger le flux d’air frais destiné aux composants internes.

Les décharges électrostatiques (ESD) peuvent endommager l’équipement et gêner les circuits

électriques. Des dégâts d’ESD surviennent lorsque des composants électroniques sont mal manipulés et

7

Page 8

peuvent causer des pannes totales ou intermittentes. Suivez les procédures de prévention d’ESD lors du

retrait et du remplacement de composants.

Portez un bracelet anti-ESD et veillez à ce qu’il soit bien au contact de la peau. Si aucun bracelet n’est

disponible, reliez votre corps à la terre en touchant la partie métallique du châssis.

Vérifiez régulièrement la valeur de résistance du bracelet antistatique, qui doit être comprise entre 1 et

10 mégohms (Mohms).

Mounting Installation Precautions

The following should be put into consideration for rack-mount or similar mounting installations:

Do not install and/or operate this unit in any place that flammable objects are stored or used in.

The installation of this product must be performed by trained specialists; otherwise, a non-specialist

might create the risk of the system’s falling to the ground or other damages.

Lanner Electronics Inc. shall not be held liable for any losses resulting from insufficient strength for

supporting the system or use of inappropriate installation components.

Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than room ambient. Therefore, consideration

should be given to installing the equipment in an environment compatible with the maximum ambient

temperature (Tma) specified by the manufacturer.

Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of airflow

required for safe operation of the equipment is not compromised.

Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition

is not achieved due to uneven mechanical loading.

Circuit Overloading - Consideration should be given to the connection of the equipment to the supply

circuit and the effect that overloading of the circuits might have on overcurrent protection and supply

wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing this

concern.

Reliable Grounding - Reliable grounding of rack mounted equipment should be maintained. Particular

attention should be given to supply connections other than direct connections to the branch circuit (e.g.

use of power strips).

8

Page 9

NCA-5710 User Manual

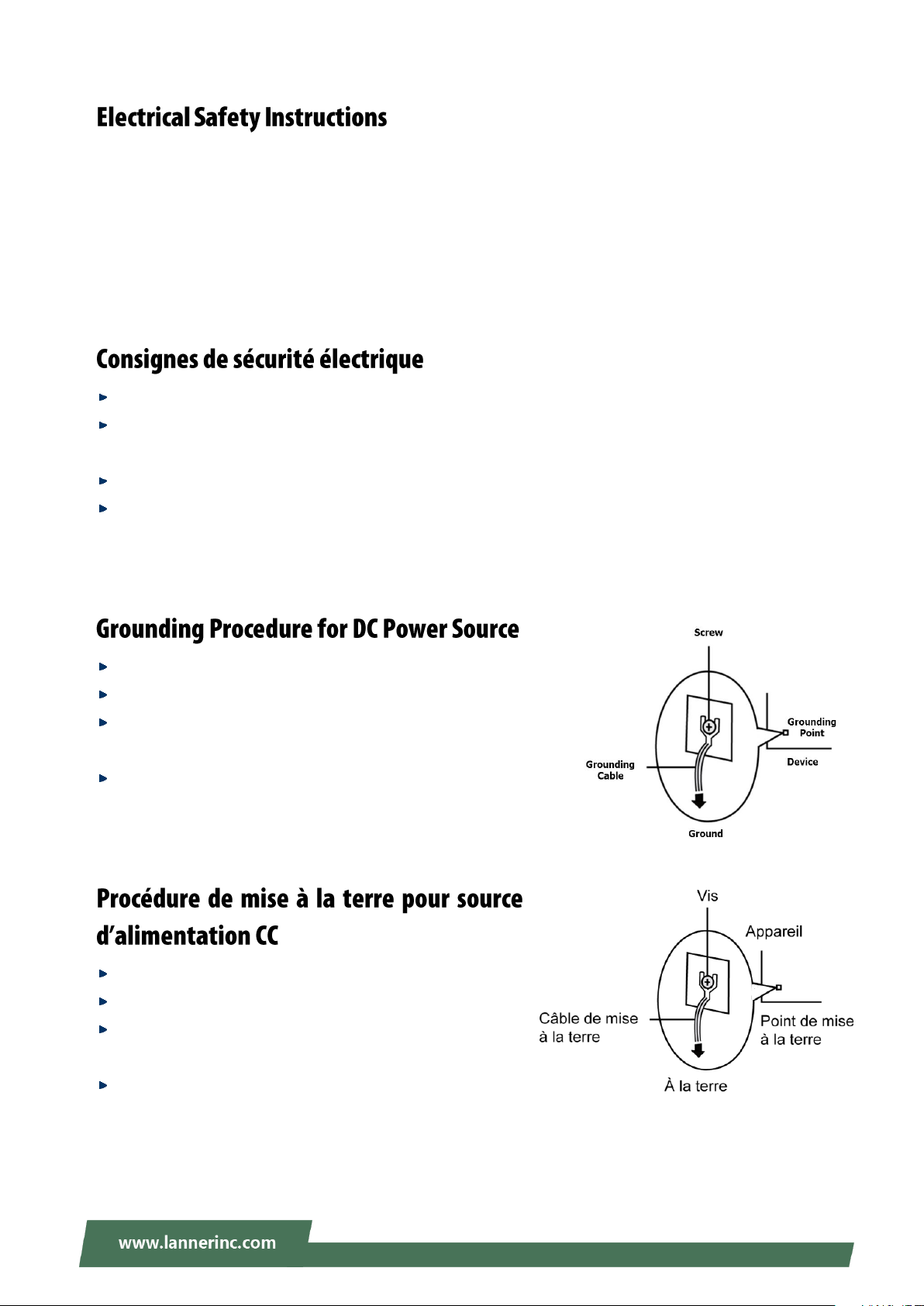

Before turning on the device, ground the grounding cable of the equipment. Proper grounding

(grounding) is very important to protect the equipment against the harmful effects of external noise and to

reduce the risk of electrocution in the event of a lightning strike. To uninstall the equipment, disconnect

the ground wire after turning off the power. A ground wire is required and the part connecting the

conductor must be greater than 4 mm2 or 10 AWG.

Avant d’allumer l’appareil, reliez le câble de mise à la terre de l’équipement à la terre.

Une bonne mise à la terre (connexion à la terre) est très importante pour protéger l’équipement contre

les effets néfastes du bruit externe et réduire les risques d’électrocution en cas de foudre.

Pour désinstaller l’équipement, débranchez le câble de mise à la terre après avoir éteint l’appareil.

Un câble de mise à la terre est requis et la zone reliant les sections du conducteur doit faire plus de 4

mm2 ou 10 AWG.

Loosen the screw of the earthing point.

Connect the grounding cable to the ground.

The protection device for the DC power source must provide 30

A current.

This protection device must be connected to the power source

before DC power.

Desserrez la vis du terminal de mise à la terre.

Branchez le câble de mise à la terre à la terre.

L’appareil de protection pour la source d’alimentation CC

doit fournir 30 A de courant.

Cet appareil de protection doit être branché à la source

d’alimentation avant l’alimentation CC.

9

Page 10

This equipment must be grounded. The power cord for product should be connected to a socket-outlet

with earthing connection.

Cet équipement doit être mis à la terre. La fiche d'alimentation doit être connectée à une prise de terre

correctement câblée

Suitable for installation in Information Technology Rooms in accordance with Article 645 of the National

Electrical Code and NFPA 75.

Peut être installé dans des salles de matériel de traitement de l'information conformément à l'article 645

du National Electrical Code et à la NFPA 75.

The machine can only be used in a restricted access location and has installation instructions by a skilled

person (for Fan side).

Les matériels sont destinés à être installés dans des EMPLACEMENTS À ACCÈS RESTREINT.

10

Page 11

NCA-5710 User Manual

Package Content ......................................................................................................................... 13

Ordering Information ................................................................................................................. 13

System Specifications ................................................................................................................. 14

Front Panel ................................................................................................................................. 15

Rear Panel ................................................................................................................................... 16

Motherboard Information .......................................................................................................... 17

Installing the CPU ....................................................................................................................... 24

Installing the Disk Drive(s) .......................................................................................................... 30

Installing the NIC Modules ......................................................................................................... 32

Replacing the Cooling Fans ......................................................................................................... 34

Installing the System Memory .................................................................................................... 35

Mounting the System ................................................................................................................. 38

Connecting the Grounding Cable ............................................................................................... 43

Replacing the Power Supply Units ............................................................................................. 44

DC Power Supply Installation ..................................................................................................... 45

Remote Server Management ..................................................................................................... 46

Lanner SDK .................................................................................................................................. 52

Installing Operating System........................................................................................................ 53

BIOS Setup .................................................................................................................................. 56

11

Page 12

Why Dual BIOS? ........................................................................................................................ 121

Addressing BIOS Start-up Failure with Dual BIOS .................................................................... 122

Introduction .............................................................................................................................. 125

Pre-requisites ........................................................................................................................... 125

Warranty Policy ........................................................................................................................ 131

RMA Service .............................................................................................................................. 131

RMA Service Request Form ...................................................................................................... 132

12

Page 13

NCA-5710 User Manual

SKU No.

Main Features

NCA-5710A

2x Skylake SP (165W) + C621 + 4x RJ45 MGMT

NCA-5710B

2x Skylake SP (165W) + C621 + 4x RJ45 MGMT + BMC

NCA-5710C

2x Skylake SP (165W) + C627 + 4x 10G SFP+ with LED + BMC

Thank you for choosing NCA-5710. The NCA-5710, powered by Intel® Xeon® Processor Scalable Family

and Intel® C627/C621 chipset, features optimized computing power and virtualization capacity in a

compact 1U form factor with dual CPU sockets, 4x NIC module slots and up to 384GB DDR4 system

memory. It delivers a multitude of advanced networking features for maximizing packet processing

efficiency and cryptography acceleration.

Your package contains the following items:

1x NCA-5710 Network Security Platform

2x Power Cable

1x Short Ear Rack Mount Kit with screws

1x Console Cable

1x LAN Cable (Grey)

13

Page 14

Chapter 1: Product Overview

Form Factor

1U 19“ Rackmount

Platform

Processor Options

Intel® Xeon® Processor Scalable Family

(Skylake-SP)

CPU Socket

2x LGA3647

Chipset

Intel® C621/627

Security Acceleration

Intel® QuickAssist Technology (By SKU)

BIOS

AMI SPI Flash BIOS

System Memory

Technology

DDR4 2666 MHz REG DIMM

Max. Capacity

384GB

Socket

12x 288pin DIMM

Networking

Ethernet Ports

4x GbE RJ45 or 4x 10G SFP+ Lewisburg

Internal MAC

Bypass

Depends on NIC module specifications

NIC Module Slot

4

LOM

IO Interface

1x RJ45 (Optional) *Share with ETH0

OPMA slot

IPMI Chip Onboard (SKU B & C)

I/O Interface

Reset Button

1

LED

Power/Status/Storage

Power Button

1x ATX Power Switch

Console

1x RJ45, 1x mini USB

USB

2x USB 3.0

LCD Module

N/A (Optional)

Display

1x Internal Pin Header

Power input

AC power inlet on PSU

Storage

HDD/SSD Support

2x 2.5”Internal Bays

Onboard Slots

1x M.2

Expansion

PCIe

1x PCI-E*16 FH/HL (Optional)

mini-PCIe

N/A

SIM card Slot

N/A

Miscellaneous

Watchdog

Yes

Internal RTC with Li Battery

Yes

TPM

Yes (Optional)

Cooling

Processor

Passive CPU heat sink

System

6x individual hot-swappable cooling fans

with smart fan

Environmental Parameters

Temperature

0~40ºC Operating

-40~70ºC Non-Operating

Humidity (RH)

5~90% Operating

5~ 95% Non-Operating

System Dimensions

(WxDxH)

610mm x 438mm x 44mm

Weight

24kg

Package Dimensions

(WxDxH)

841mmx588mmx215mm

Weight

18kg

Power

Type/Watts

850W 1+1 ATX Redundant PSUs

Input

AC 100~240V @47~63 Hz

Approvals and Compliance

RoHS, CE/FCC Class A

14

Page 15

NCA-5710 User Manual

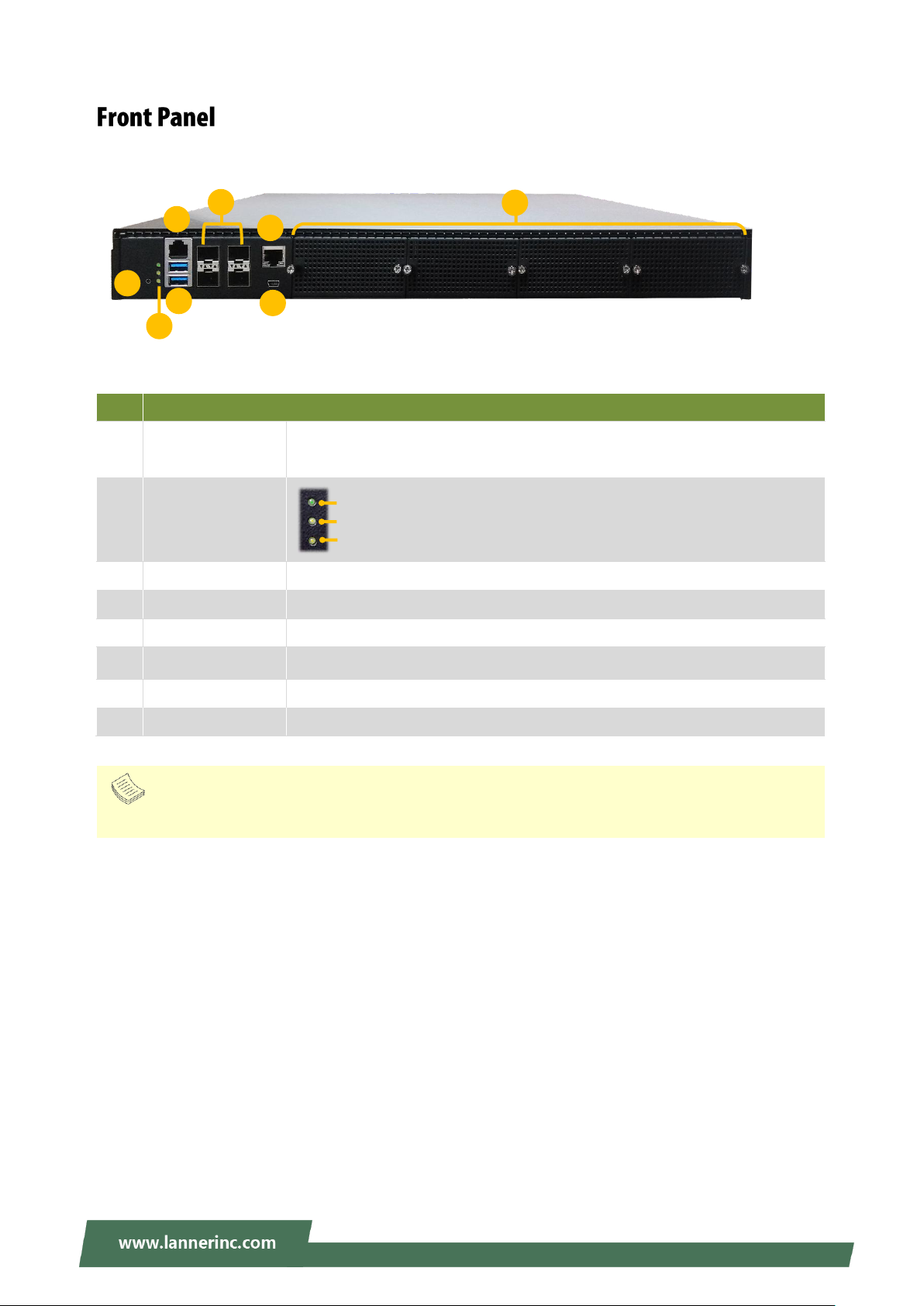

No.

Description

F1

Reset Button

For hardware /software reset, default is software reset. The setting is

configurable by changing the JRST1 jumper on motherboard.

F2

LED Indicators

F3

Console Port

1x RJ45 console port

F4

USB Ports

2x USB 3.0 port

F5

RJ45/SFP+ Ports

4x RJ45 port with LED or 4x 10G SFP+ port (by model)

F6

MGMT/LOM Port

1x RJ45 for MGMT or LOM share port (by model)

F7

Micro USB

1x console port

F8

NCS2 Module

4x STD NIC Module

System Power

System Status

HDD Activity

F5

F4

F6

F3

F1

F2

F8

F7

Note

Please refer to Appendix A: LED Indicator Explanations for descriptions of the LED Indicators.

15

Page 16

Chapter 1: Product Overview

No.

Description

R1

Grounding Stud

1x grounding stud for connecting the grounding wire

R2

ESD Jack

1x ESD Jack

R3

Fans

6 x hot-swappable cooling fans with smart fan

R4

Power Switch

1x Power Button

R5

Alarm Off Button

1x Alarm Off Button to disable the system alarm

R6

Power Supply

2x 850W 1+1 ATX Redundant PSUs

R1

R4

R5 R3R2

R6

16

Page 17

NCA-5710 User Manual

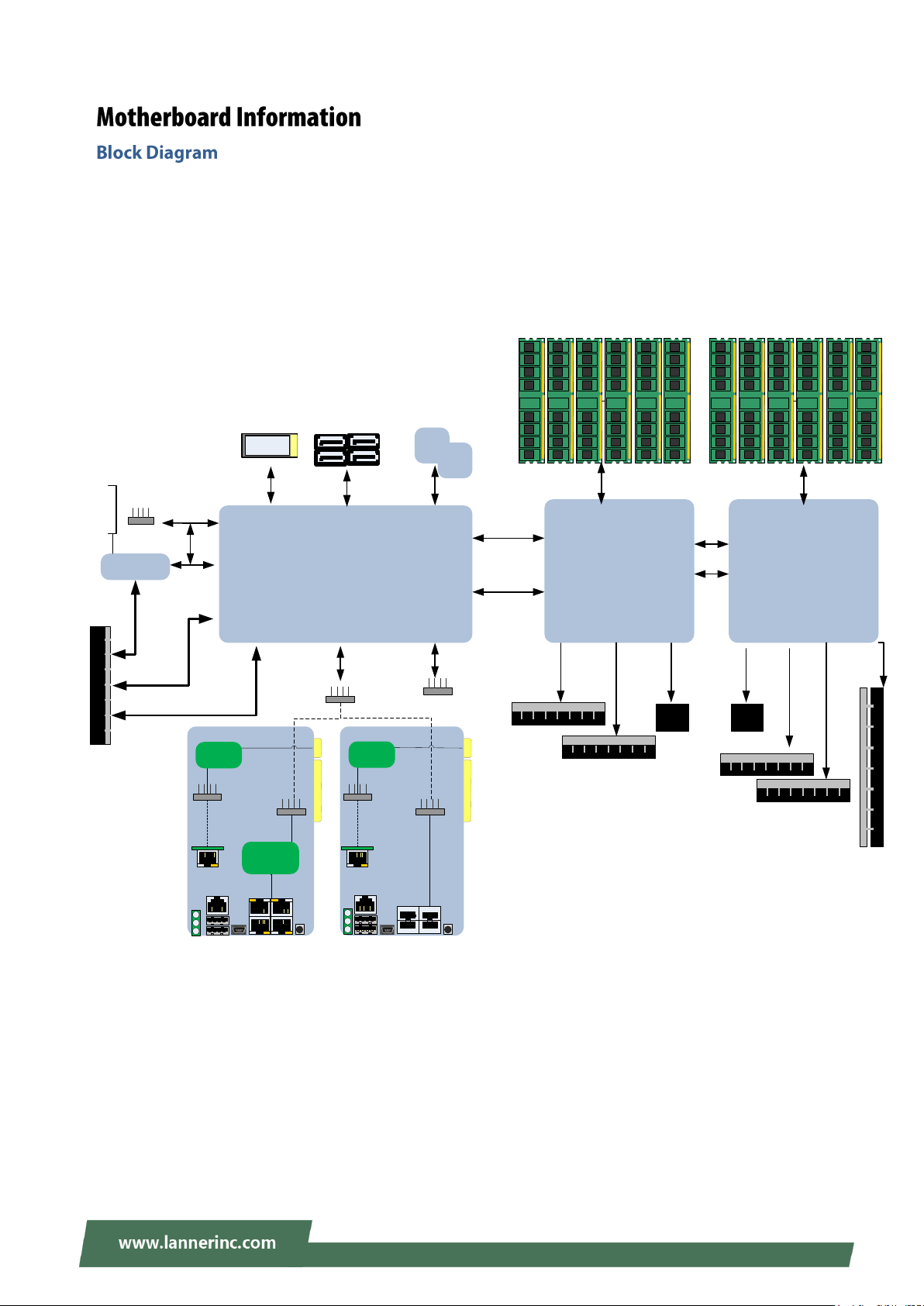

SkyLake-SP

6 Channel DDR4 RDIMM 2400 Mhz up to 384GB

PCIe x8

Intel Lewsburg PCH

BIOS

LPC

TPM

SATAIII*4

NMI

PCIe x8 or PCIEx4*2 auto selection

SPI

PCIe x8 PCIe x16

PCIe x16

DMI*4

BIOS

Dual BIOS

PCIe x1

PCIe x1

AST-2400

USB 3.0x2 SFI*4

Marvell

88E1543

connectorconnector

GPIO

Fan Monitor

Watchdog

Thermal Monitor

LOM/ MGNT share

port (optional)

LOM/ MGNT share

port (optional)

connector

NCSI with AST2400NCSI with AST2400

Two type of IO card for different purpose

I210-AT

I210-AT

NCA-5710 Block Diagram

SkyLake-SP

ZD

PCIe x16ZDPCIe x8 PCIe x8

UPI

reserved reserved

PCIe x16

PCIe 2.0

USB3.0

SATA3.0

Mini

PCIE

M.2B Key

The block diagram indicates how data flows among components on the motherboard. Please refer to the

following figure for your motherboard’s layout design.

17

Page 18

Chapter 1: Product Overview

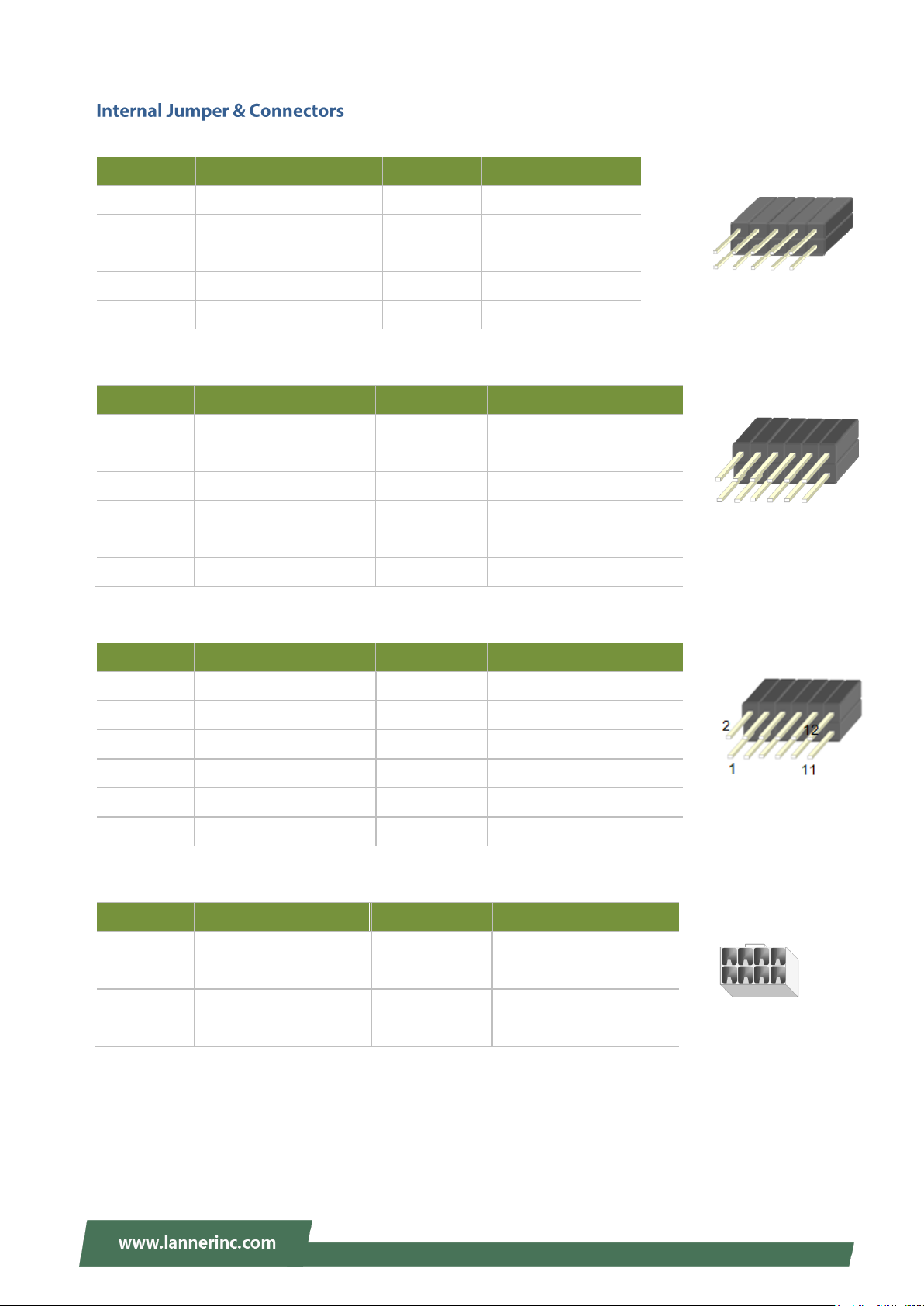

JJFFAANN66 JJFFAANN55 JJAATTXX22 JJFFAANN44 JJFFAANN33 JJAATTXX44 JJFFAANN22 JJFFAANN11

This layout shows the connectors and jumpers on the board, as a reference of the pin assignments and the

internal connectors.

18

Page 19

NCA-5710 User Manual

Pin No.

Description

Pin No.

Description

1

+P5V_USB1

2

+P5V_USB1

3

USB20_L_N3

4

USB20_L_N4

5

USB20_L_P3

6

USB20_L_P4

7

USBGND1

8

USBGND1

9

USBGND1

10

USBGND1

Pin No.

Description

Pin No.

Description

1

IRQ_SERIAL

2

LPC_LFRAME#

3

LPC_LAD0

4

CLK_24M_LPC

5

LPC_LAD1

6

+P3V3_AUX

7

LPC_LAD2

8 9

LPC_LAD3

10

+P3V3

11

TPM_RST#

12

GND

Pin No.

Description

Pin No.

Description

1

DAC_RO

2

GND

3

DAC_GO

4

GND

5

DAC_BO

6

GND

7

HSYNC_O 8

9

VSYNC_O

10

GND

11

DDC_DATA

12

DDC_CLK

Pin No.

Description

Pin No.

Description

1

GND

2

+P5V

3

GND

4

+P5V_SB

5

GND

6

+P12V_STBY_PSU

7

GND

8

+P12V_STBY_PSU

2

10

9

1

11

12

2

1

JUSB1: USB2.0

JTPM1

JVGA1

JATX6: 8 Pin Power Connector

19

Page 20

JNMI1

Pin No.

Description

Pin No.

Description

1

GND

2

NMIBTN#

Pin No.

Description

1

GND

2

TX_P

3

TX_N

4

GND

5

RX_N

6

RX_P

7

GND

Pin No.

Description

1

PWM Status

2

RPM Sense

3

RPM Sense

4

12V

5

Ground

Pin No.

Description

1

GND

2

GND

3

GND

4

GND

5

+12V

6

+12V

7

+12V

8

+12V

JATX2 & JATX4: 8 pin Power Connector

Chapter 1: Product Overview

JSATA1~JSATA4: SATA

JFAN1~6: FAN Connector

20

Page 21

NCA-5710 User Manual

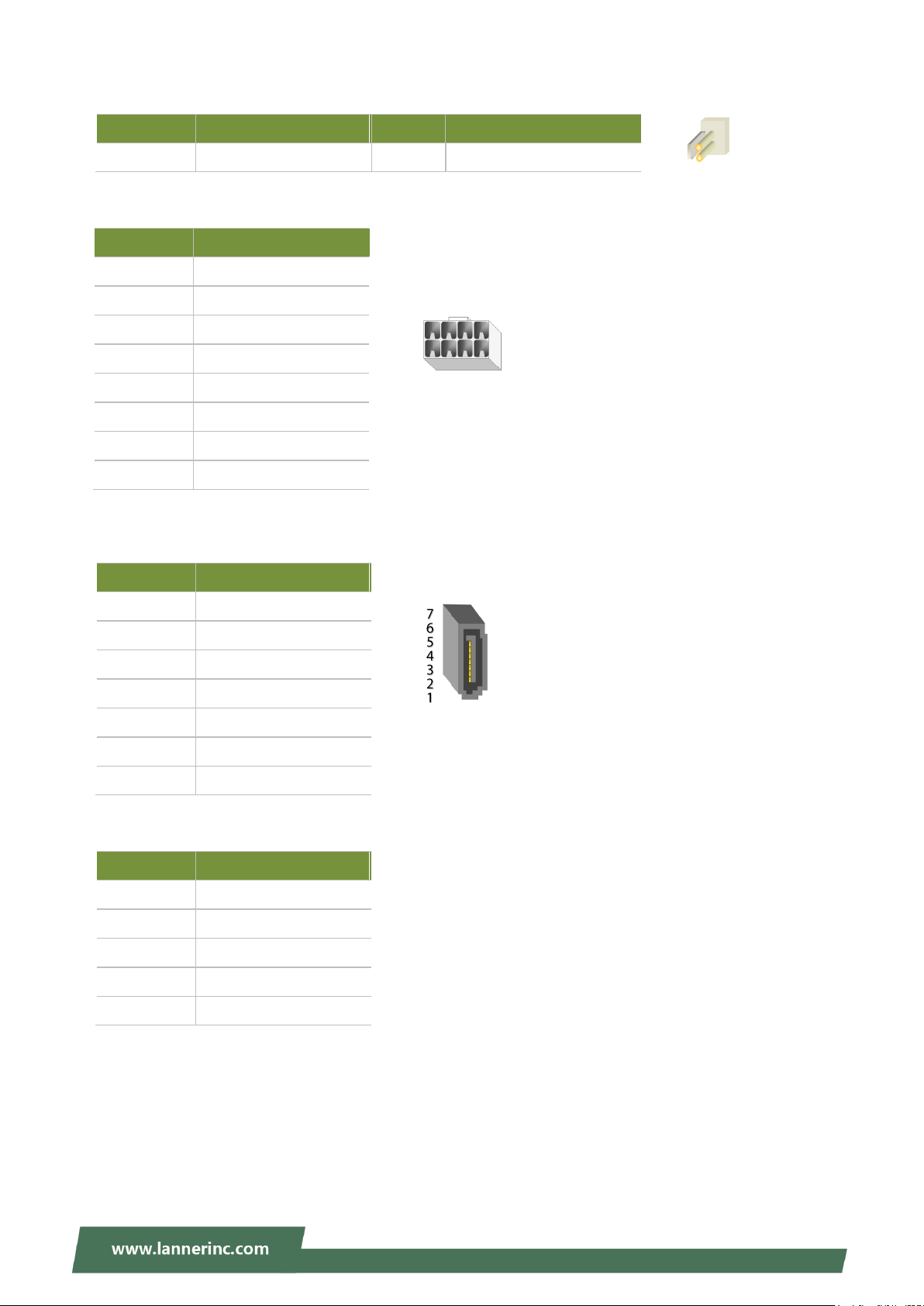

Pin

Description

Pin

Description

1.2

HW reset

2.3

SW reset

(Default)

JRST1: Controls the software reset method of the Reset button on front panel.

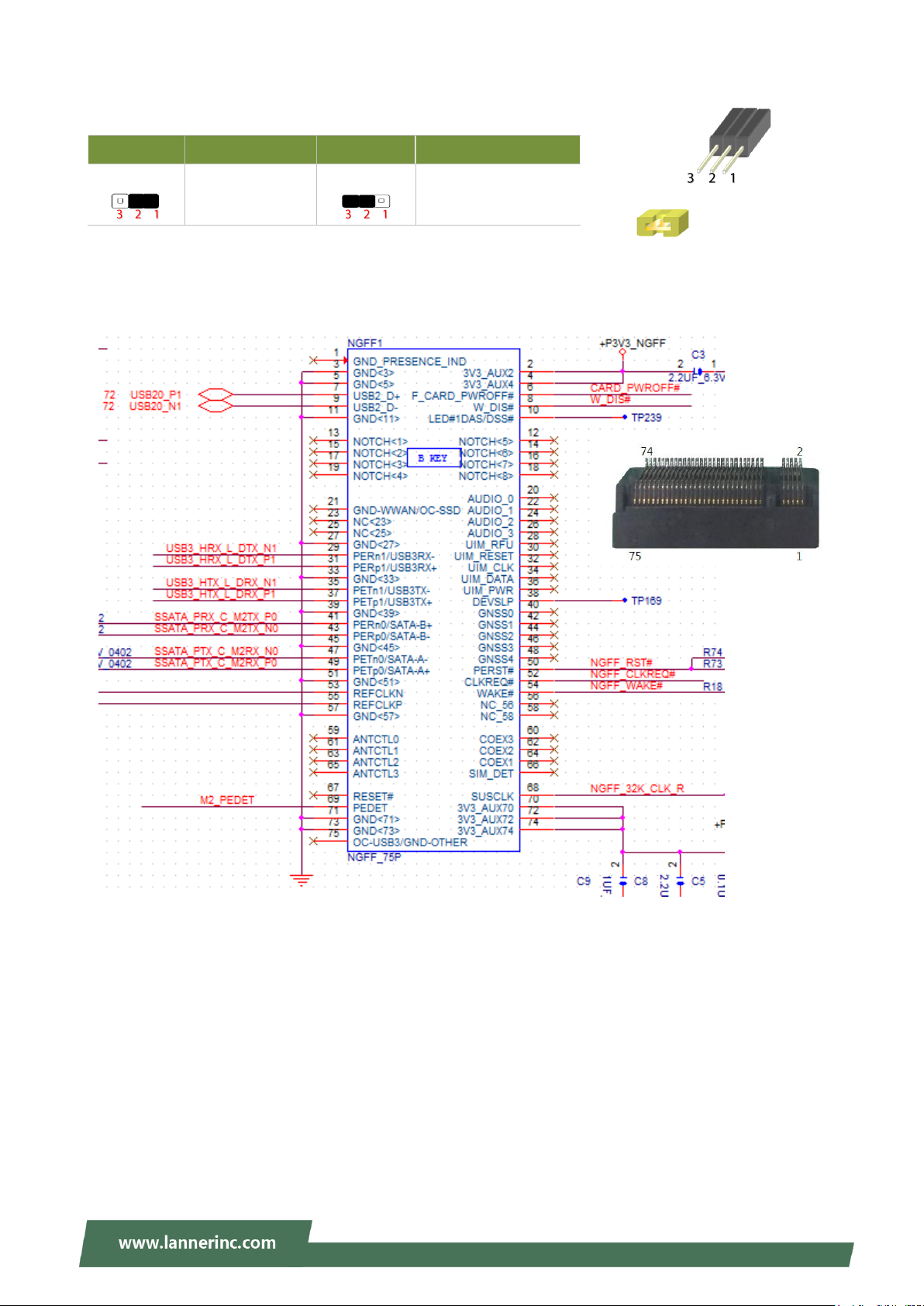

NGFF1: M.2 Connector B Key

21

Page 22

JCOMA2: COM PORT

Pin No.

Description

Pin No.

Description

1

BMC_COM2_DCD#

2

BMC_COM2_DSR#

3

BMC_COM2_RX

4

BMC_COM2_RTS

5

BMC_COM2_TX

6

BMC_COM2_CTS#

7

BMC_COM2_DTR

8 9

COM2_GND2

10

Pin No.

Description

Pin No.

Description

1

PSU_TTL1

2

PSU_TTL2

3

ATX_PSON#

4

GND

5

ATXPWGD

6

PMBUS_CLK

7

PMBUS_DAT

8

PMBUS_ALERT#

Pin No.

Description

Pin No.

Description

1

GND

2

FM_INTRUDER#

Pin No.

Description

Pin No.

Description

1

VRTC

2

PCH_RTCRST#

3

GND

Pin No.

Description

Pin No.

Description

1

SPI_HD1#

2

SPI_CS1#_DUAL

3

SPI_CS0#_DUAL

4

+P3V3_SPI_ME

5

SPI_MISO

6

SPI_PCH_IO3

7 8

SPI_CLK

9

GND

10

SPI_MOSI

Pin

Description

Pin

Description

1.2

Normal (Default)

2.3

Clear CMOS

2

10

9

1

2

8

7

1

2

10

9

1

JPMB1: PMBUS

Chapter 1: Product Overview

JOPEN1: Case open

JCMOS1: Clear CMOS

JSPIROM1: Flash BIOS

22

Page 23

NCA-5710 User Manual

Pin No.

Description

Pin No.

Description

1

GPO_B_1

2

GPI_B_1

3

GPO_B_2

4

GPI_B_2

5

GPO_B_3

6

GPI_B_3

7

GPO_B_4

8

GPI_B_4

9

GND

10

GND

Pin No.

Description

Pin No.

Description

1

GND

2

ATX_PSON#

JGP1: EXT GPIO header

JPWR1: Power on

23

Page 24

Chapter 2: Hardware Installation

Tool

Description

Torque screwdriver

(Star T30)

Set to 1.36 N.m. or 12 in-lbf for tightening

the nuts which fasten the PHM on the

bolster plate.

ESD Protection

(ESD gloves, ESD-safe

work surface, etc.)

During the entire assembly process, at

least wear a pair of ESD gloves to avoid

damaging or contaminating the electronic

parts while enhancing your own safety.

Note

The images of tools shown in this document are merely for reference; the actual tools you use

might differ.

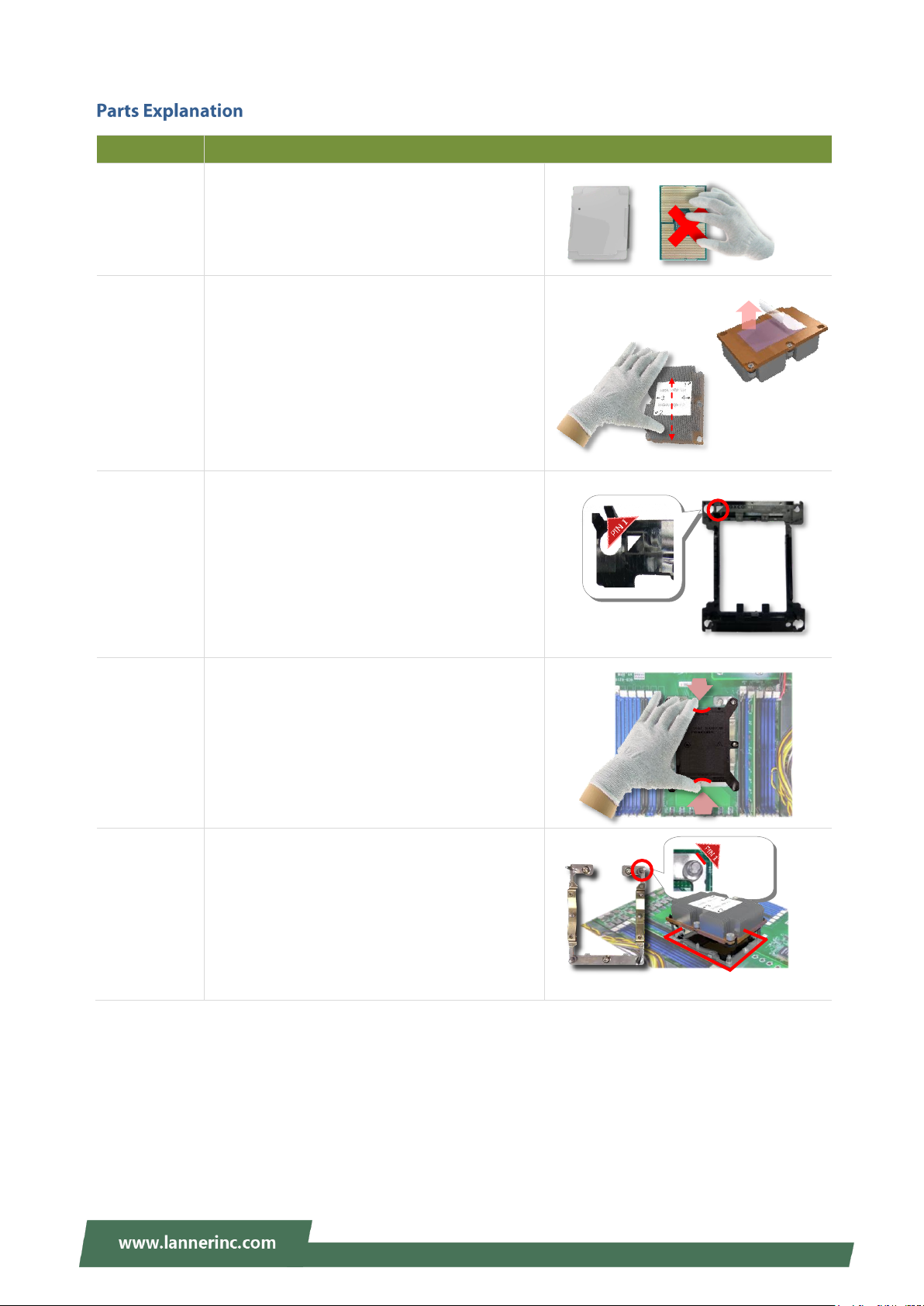

To reduce the risk of personal injury, electric shock, or damage to the system, please remove all power

connections to completely shut down the device. Also, please wear ESD protection gloves when conducting

the steps narrated in this chapter.

Please note that the system delivered to you is already installed with the processor and that this processor,

LGA3647, comes with rather sophisticated design; therefore, the assembly of which must be handled with

exclusive tools and extreme care by professionals. It is strongly recommended that you not make any

adjustments to, remove or even re-install the processor on your own. If handling the processor on your

own is inevitable, please read through the instructions in this section and refer to the official tutorial

released by Intel® to make sure you have acquired the necessary knowledge and comply with the

requirements.

Installing the processor onto the motherboard involves two stages:

1. Mount the processor onto the heat sink to make a PHM (Processor + Heat Sink Module)

2. Install the PHM onto the motherboard.

24

Page 25

NCA-5710 User Manual

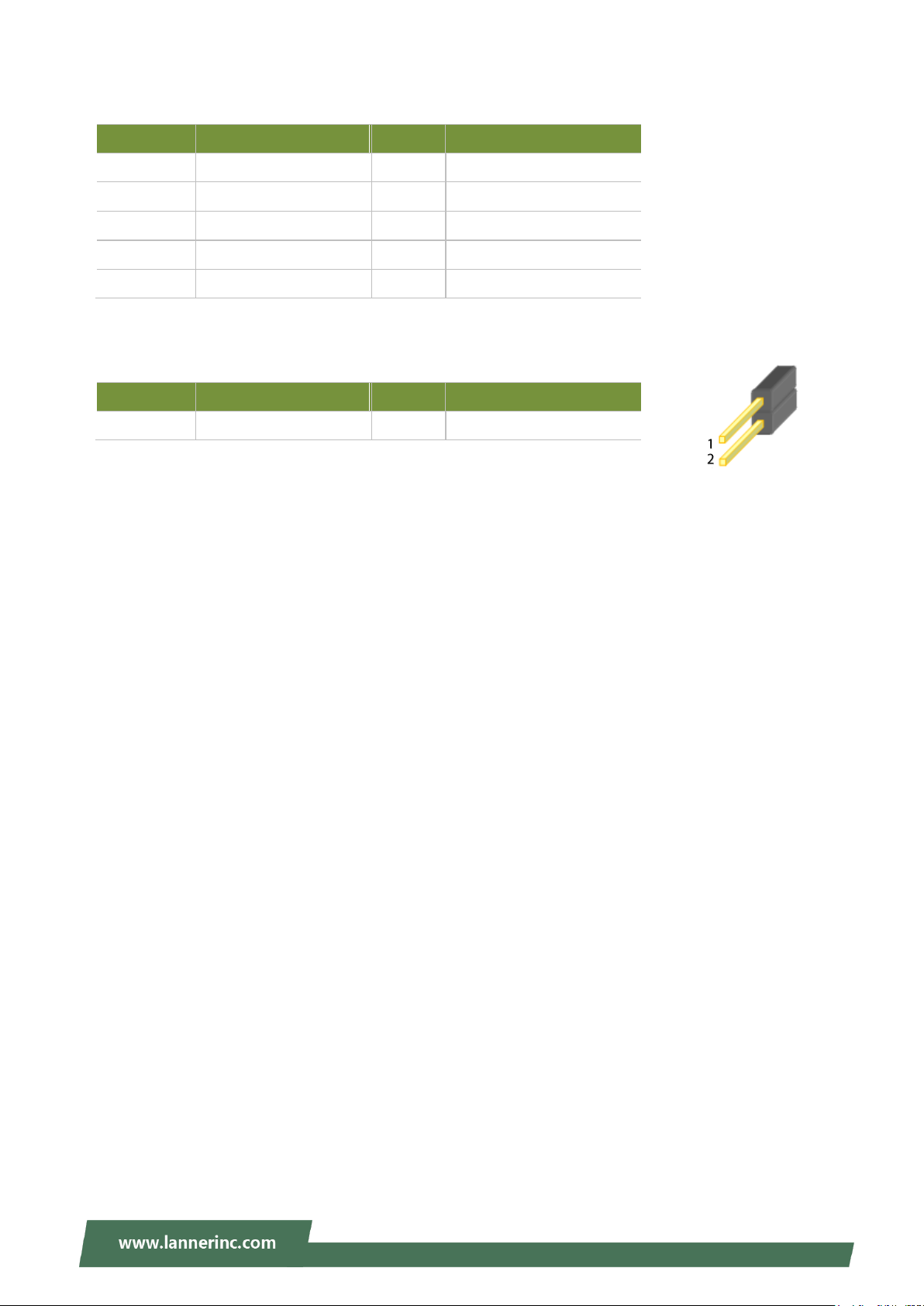

Item

Description

Processor

Please avoid touching the gold fingers or

package lands of the processor even if you are

wearing ESD gloves.

Heat Sink

If a TIM (Thermal Interface Material) protective

film is already attached to the base of the heat

sink, remove it before you mount the processor

on it.

When holding it, please grip it along the axis of

its fins with your thumb and your index finger.

Processor

Carrier

This is packed along with the processor. Before

performing any assembly involving this part,

please locate PIN1 on one of the corners, an

important indicator used to align this carrier

with the processor and the bolster plate

correctly.

Dust

Cover

This cover is used to protect the package land

surface of the processor from contamination.

To remove it from the processor, grasp the

holding features with your thumb and your

index finger while pulling the cover off

vertically.

Bolster

Plate

A robust bolster plate is used to assist in PHM

alignment for installation, while effectively

helping eliminate PCB bowing during

compression. Please locate the Cutout on one

of the four corners before starting PHM

installation.

Axis

Cutout

25

Page 26

Chapter 2: Hardware Installation

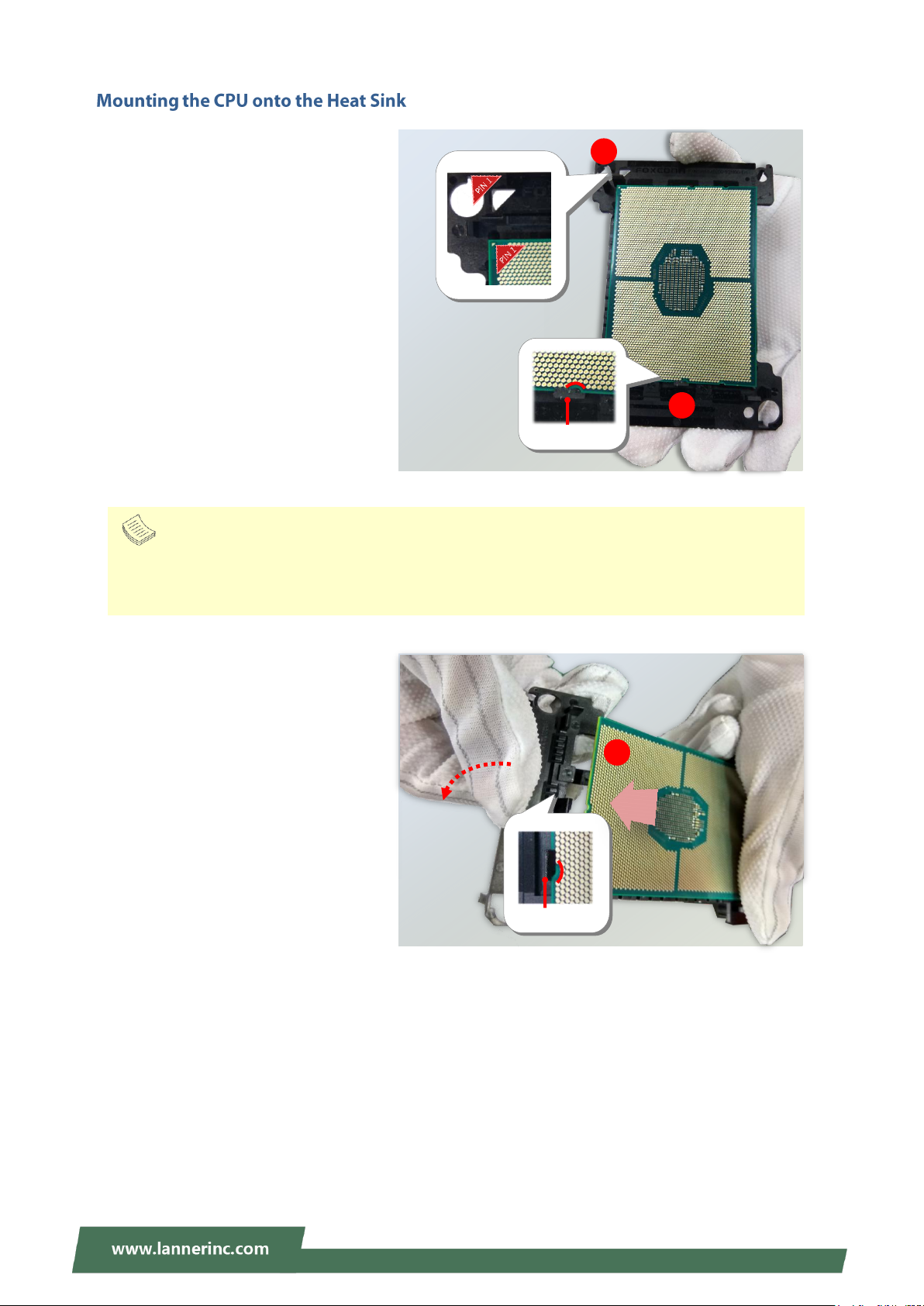

1. Align the PIN1 indicator on the

processor with that on the carrier.

2. Gently insert one side of the

processor into the carrier and make

sure the alignment feature is aligned

with the latch of the carrier.

3. For the other end of the carrier, align

the alignment feature of the

processor with the carrier latch, and

then gently bend over the carrier end

to have the latch secured on the

processor.

Latch

1 2 3

Latch

Note

During assembly, it is essential to have (1) PIN1 on the processor aligned with that on the carrier,

and (2) the alignment features on the top and the bottom of the CPU aligned with the

corresponding carrier latches.

26

Page 27

NCA-5710 User Manual

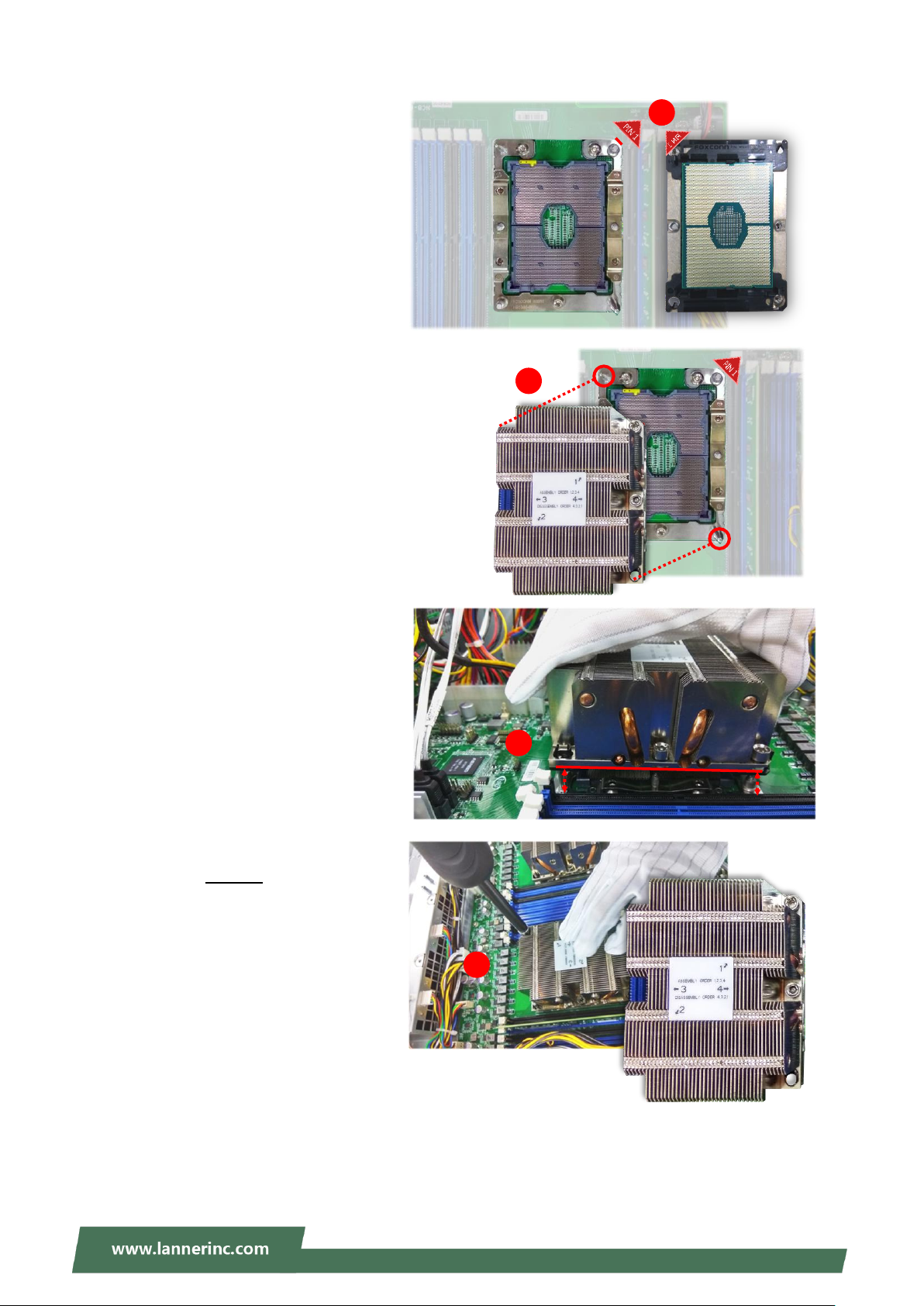

4. Align PIN1 of the processor with the

corner cutout of the heat sink (if

there are two corner cutouts on one

heat sink, either will do).

5. With a little pressure, push the four

corners of the carrier down to

engage their latching features with

the corresponding corners of the

heat sink. You might hear a clicking

sound when the latch clicks into

place.

6. Inspect the four corners to make sure

the latches are all engaged. If

correctly latched, the corners of the

carrier should be tightly attached to

the heat sink, with no gap

in-between observed.

1. Remove the dust cover from the

socket contacts of the motherboard.

Cutout

5

6

Unlatched

1

4

Note

Inspect the surface of the socket under

sufficient light to ensure there is no

contamination or damage prior to the PHM

installation.

27

Page 28

Chapter 2: Hardware Installation

2. Flip the PHM over to align PIN1 of

the carrier with the Cutout of the

bolster plate.

3. Flip the PHM over, so the package

land of the processor will face the

socket. Lower the PHM vertically to

engage it to the alignment pins of

the bolster plate.

4. Make sure the PHM is sitting

horizontally on the bolster plate.

5. Use a torque driver to tighten the

four nuts to 12 in-lbf into the bolster

plate following the sequence

indicated on the heat sink (#1

#2#3#4).

2

Cutout

Alignment Pin

Alignment Pin

3 4 5

28

Page 29

NCA-5710 User Manual

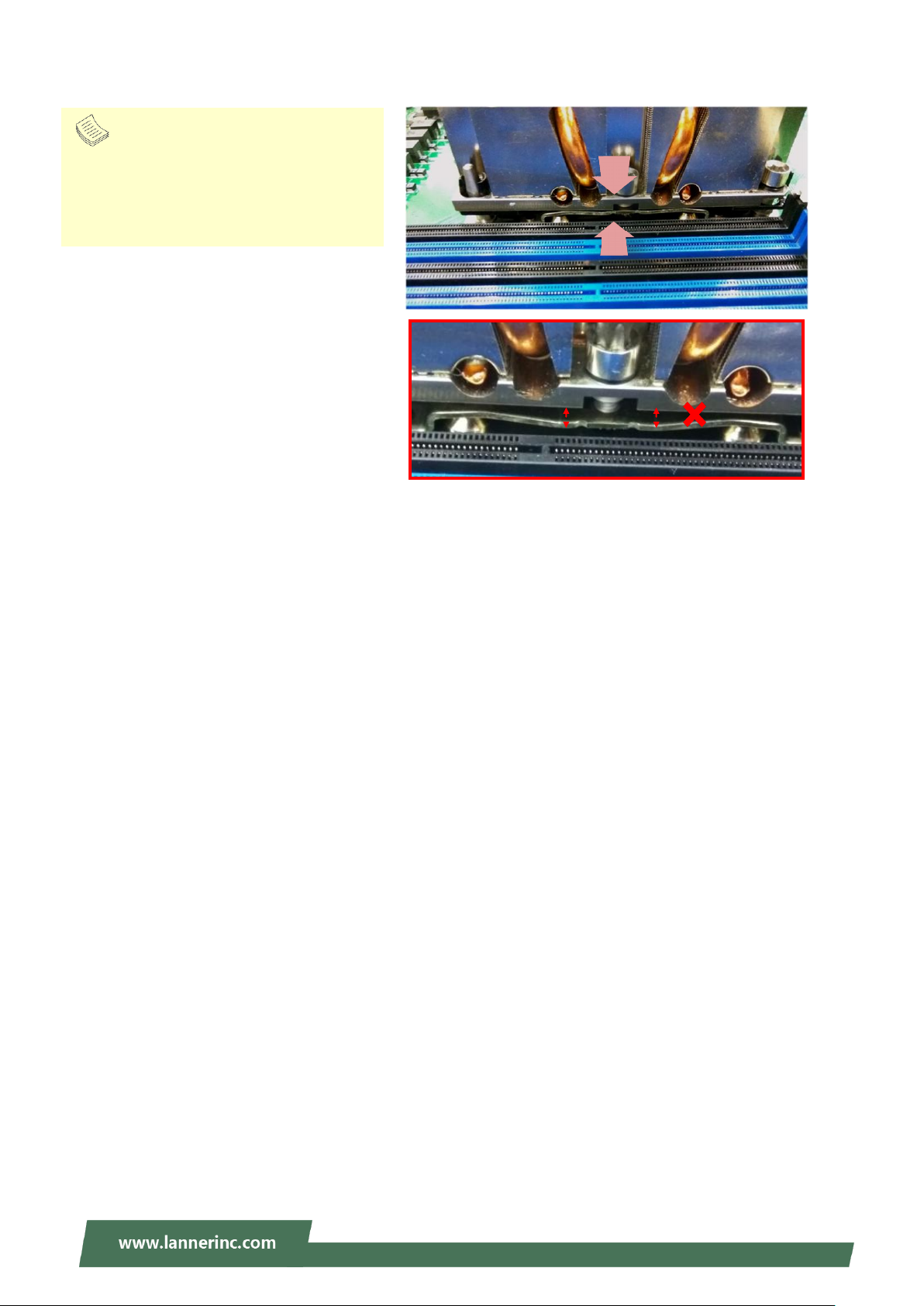

Note

When fastening #3 and #4 nuts, the gap

between the metal spring leaf of the bolster

plate and the PHM will gradually diminish

as you drive the nuts.

29

Page 30

Chapter 2: Hardware Installation

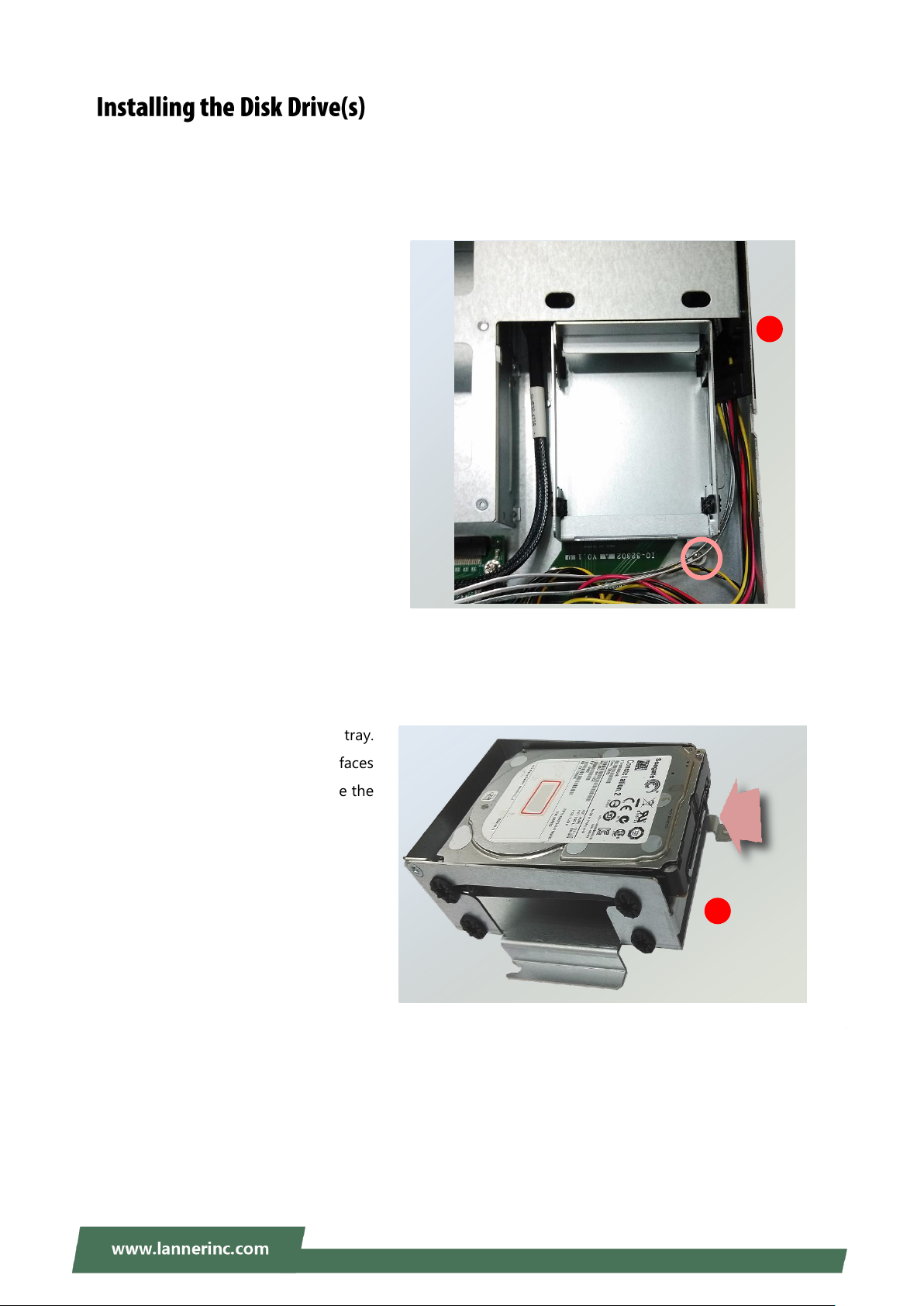

1. Power off the system.

2. Loosen the screw that fixes the tray

onto the motherboard.

3. Mount the disk onto the empty tray.

Make sure the disk connector faces

towards the SATA contacts inside the

system.

SATA Contacts

2

3

NCA-5710 is built with two 2.5” HDD/SSD slot (HDD preferred) drive bay. The following will discuss disk

drive installation procedures based on their HDD/SSD designs.

30

Page 31

NCA-5710 User Manual

4. Install the tray back to the original

position with the screw. Make sure

the notch of the tray’s side engages

properly into the pin as shown in the

picture.

5. Connect the SATA cable and SATA

power cable to the hard disk.

4

Pin

5

31

Page 32

Chapter 2: Hardware Installation

2. Loosen the two lock-screws.

3. Remove the door and locate the

socket for module insertion.

1

2 2 3

Socket

NCA-5710 comes with 4 NIC Ethernet module slots for network bandwidth expansion. Please follow the

steps for installation.

1. On the front panel, select a NIC Ethernet module slot.

32

Page 33

NCA-5710 User Manual

4. Insert your NIC module. (The module

shown in the image below is for

reference only).

5. Once the module is firmly seated,

tighten the two lock-screws.

Align the golden fingers to the socket on

the motherboard carefully while inserting

this module.

4 5 5

33

Page 34

Chapter 2: Hardware Installation

1. Locate the cooling fans at the rear panel.

2. From the rear side of the fan, loosen the

screw that secures the fan connector.

3. Disconnect the fan connector.

4. Loosen the lock-screw that fixes the fan on

the rear panel and take out the worn fan.

1 4 2

3

Cooling fans may wear down eventually. Please refer to the steps below for replacing cooling fans. When

using a new cooling fan, simply reverse the steps to install the fan back onto the enclosure and the system.

34

Page 35

NCA-5710 User Manual

Total Slots

12 (6 slots per processor)

Number of Channels

6 (Channel 0~5, 1 DIMM per channel) per processor

Supported DIMM Capacity

4GB, 8GB, 16GB, 32GB

Memory Size

Maximum 384 GB RDIMM (32GB*12)

Memory Type

DDR4 1.2 V ECC RDIMM 2666/2400/2133 MHZ

Minimum DIMM Installed

JCPU0 requires at least 1 memory module to boot and run from.

JCPU0

JCPU1

JDDR0~JDDR9 are assigned to

JCPU0.

JDDR10~JDDR19 are assigned to

JCPU1.

The motherboard supports 12 memory slots for DDR4 registered DIMM. JCPU0 requires at least 1 memory

module to boot and run from.

35

Page 36

Chapter 2: Hardware Installation

Type

DIMM

Rank

Data

Width

DIMM Capacity (GB)

Speed (MT/s)

DRAM Density

Voltage (V): 1.2V

1 DIMM per Channel

4Gb 8Gb

RDIMM

SR

x4

8GB

16GB

2666 MT/s

x8

4GB

8GB

DR

x8

8GB

16GB

x4

16GB

32GB

Processor

JCPU0

JCPU1

JDDR #

4 2 0 5 7 9 14

12

10

15

17

19

Number of DIMMs

Installed

for 1 CPU

1 DIMM

2 DIMMs

3 DIMMs

4 DIMMs

6 DIMMs

Number of DIMMs

Installed

for 2 CPUs

2 DIMMs

4 DIMMs

6 DIMMs

8 DIMMs

10 DIMMs

12 DIMMs

Please do follow the memory module installation instructions to install the DIMMs, and make sure

At least one CPU is installed

If two CPUs are installed, install at least 1 DIMM for JCPU0.

Try to split the DIMMs evenly across the CPUs.

Please use memory modules of the same capacity, speed and from the same manufacturer to avoid

compatibility issues.

Recommended DIMM Population Scheme

The table below shows the recommended schemes for DIMM population. To guarantee balanced system

performance, please install identical DIMMs of the same capacity, speed, number of ranks, and from the

same manufacturer.

DDR4 Memory Support vs. System Memory Speed

The table below lists the supported DDR4 types and the theoretical overall system memory speed. For

optimal system speed, please install identical DIMMs of the same capacity, speed, number of ranks, and

from the same manufacturer.

36

Page 37

NCA-5710 User Manual

Click

Click

Notch

Socket Key

Please follow the steps below to install the DIMM memory modules.

1. Power off the system.

2. Pull open the DIMM slot latches.

3. Align the notch of the module with the socket key in the slot and carefully insert the card into the slot.

4. Push the module down into the slot until it is firmly seated. Press vertically on both corners of the card

until it clicks into place.

37

Page 38

With Slide Rail Kit + Short Ear Brackets

The Slide Rails can secure the system

while making the equipment more

easily accessible.

The Ear Brackets fix the

system onto the front rack

posts.

Chapter 2: Hardware Installation

38

Page 39

NCA-5710 User Manual

1. Check the package contents of the Slide Rail Kit. The kit shall include the following items:

1x pack of M4X4L screws (for securing the sliding rail on the system)

2 x Slide Rails

The rail consists of the following parts:

Attaching the Rail Brackets

2. Unpack a slide rail and slide the

Inner Channel all the way to the

end.

3. Stretch the Rail Bracket to the

fullest.

4. Remove the Rail Bracket from the

Inner Channel by pushing the

Release Tab on the Rail Bracket

outwards while sliding it out.

Outer Channel

Inner Channel

Rail Bracket

Release Tab

Rail Lock

Release Tab

39

Page 40

Chapter 2: Hardware Installation

5. Align the Rail Bracket to the side of the chassis and make sure the screw-holes on it match and properly

engage the four buttons on the side panel as shown in the picture.

6. Carefully pull the Rail Bracket backward to have the buttons locked into the four screw holes as shown

in the picture.

7. Repeat Steps 5-6 to attach the Rail Bracket to the other side of the chassis.

Front

Rear

Aligning

Left Bracket

Buttons

Right Bracket

Locked

40

Page 41

NCA-5710 User Manual

Assembling the Ear Brackets

1. Check the package contents, which

shall include the items below:

1x pack of screws

2x Ear Brackets

2. Install the Ear Brackets on both

sides of the system using the

provided screws.

Installing the Slide Rails

Now, you shall install the slide rail

assemblies onto the rack.

1. This slide-rail kit does NOT require

screw-fixing. Simply aim at 3

available screw holes on the rack

front and snap the rail front into

the rack post as shown in the

image. You should hear a “click”

sound once it is firmly attached.

2. For the rear rack installation, slide

the rail to aim and engage the

bolts on the rail’s rear end with the

2 available holes on the post, and

the rail assembly will click into

place.

For securing the Ear

Brackets on the unit

Right Ear

Use this clamp

to fix the front

end of the rail

onto the post.

Click

Click

41

Page 42

Chapter 2: Hardware Installation

Installing the System into the Rack

1. Stretch both of the Inner Channels

out to their fullest extent. You will

hear a click sound when they are

fully stretched and stop.

2. Hold the system with its front

facing you, lift the chassis and

gently engage the Rail Brackets on

the model while aligning them with

the slide-rail assemblies as shown

in the image, and then push the

system into the cabinet.

While pushing in the system, please

also push and hold the Rail Lock

tab on both Rail Brackets.

3. Secure the Ear Brackets onto both

front posts with provided screws.

Click

The inner rail will click

when it is fully stretched.

Rail Lock

42

Page 43

NCA-5710 User Manual

Ground

Before connecting any other cable to this system, you should first attach the grounding cable to the

system’s grounding stud.

1. Obtain a proper grounding cable.

2. Position the grounding cable against the grounding stud on the system’s rear panel, and then tighten

the nut to secure the cable.

3. Secure the other end of the grounding cable to the earth ground in your site (through a grounding

point on the rack if necessary).

43

Page 44

Chapter 2: Hardware Installation

1. On the rear panel, locate the power

supply units and disconnect the

power cords.

2. Pull the original unit out and replace

it with the new one.

Power supply units may wear down eventually. Please be noted that NCA-5710 series supports 850W PSU.

Please prepare the power supply units matching this capacity.

44

Page 45

NCA-5710 User Manual

Power Source

+一

Follow the instructions below to connect the DC power cord to the connector on the PSU. This instruction is

for the installation of the conductor to build earthing by a skilled person.

1. Loosen the + and - screws.

2. Respectively attach the two cables to the connectors: the red cable to the right (Positive Pole) and the

black cable to the left (Negative Pole).

3. Fasten the screws.

4. Connect the power cables to the power source.

This product is intended to be supplied by a UL Listed DC power source, rated -48- -60Vdc, 21A

minimum, Tma = 40 degrees C, and the altitude of operation = 5000m.

The cable should be 12AWG (21A minimum, 60V minimum).

If you need further assistance with purchasing the power source, please contact to Lanner Electronics Inc.

for further information.

45

Page 46

Chapter 3: Software Setup

Feature

Description

IPMI 2.0 Standard Features

System Interface support

KCS (System Interface Support)

LAN (RMCP+)

IPMI 2.0 based Management

BMC stack with an IPMI 2.0

implementation

System Management

Sensor monitoring

System power management

Watchdog timer

Fan speed monitor and control

FRU information

Event Log

System Event Log (SEL)

Text Console Redirection: SOL

Support in IPMI stack for SOL to remotely

access BIOS and text console before OS

booting

User Management

IPMI based user management

Multiple user permission level

Non-IPMI functions

Web User Interfaces

BMC management via web user interface

Integrated KVM and Virtual Media

User authorization

RADIUS support

LDAP support

Security

SSL and HTTPS support

Maintenance

Auto sync time with NTP server

Remote firmware update by Web UI or

Linux tool

This chapter will introduce the features of Lanner’s BMC firmware and how to perform server remote

management through it. For detailed instructions on using each function, please refer to the full version of

NCA-5710 BMC manuals available on http://www.lannerinc.com/support/download-center/user-manuals.

Lanner has implements IPMI 2.0 based on ASPEED service processor, performing all the BMC defined by

IPMI 2.0. In addition, Lanner’s BMC firmware runs an embedded web-server for full configuration using

Web UI, which has a low learning curve.

46

Page 47

NCA-5710 User Manual

User Name

Password

User Access

Characteristics

admin

admin

Enabled

Password can be changed

System Power Management

The BMC implements chassis power and resets functions for system administrators to control and manage

the system power behavior. These functions can be activated by sending the IPMI 2.0 compatible chassis

commands to the BMC over messaging interfaces. The following list summaries the supported functions.

Chassis power on

Chassis power off

Chassis power cycle

Chassis power reset

Chassis power soft

Server’s power status report

Watchdog Timer

The BMC provides an IPMI 2.0 compatible watchdog timer which can prevent the system from system

hanging.

User Management

The BMC supports 9 IDs for IPMI user accounts. The maximum length of the username and password are 16

and 20 respectively, and the possible privilege levels are Callback, User, Operator, and Administrator.

Moreover, the account creator is allowed to enable/disable the user account at any time. If not specified,

the default user accounts are listed follows:

Keyboard, Video, Mouse (KVM) Redirection

The BMC provides keyboard, video, and mouse (KVM) redirection over LAN. This application is

available remotely from the embedded web server.

Support video recording, recorded videos to be downloaded & playable.

Virtual Media Redirection

The BMC provides remote virtual CD, HD and FD redirection. CD image could be mounted directly

in KVM window.

Efficient USB 2.0 based CD/DVD redirection with a typical speed of 20XCD.

Completely secured transmission.

47

Page 48

IPMI Commands Support List

COMMANDS

NETFN

CMD

IPM Device “Global” Commands

Get Device ID

APP (06h)

00h

Cold Reset

APP (06h)

02h

Warm Reset

APP (06h)

03h

Get Device GUID

APP (06h)

08h

BMC Watchdog Timer Commands

Reset Watchdog Timer

APP (06h)

22h

Set Watchdog Timer

APP (06h)

24h

Get Watchdog Timer

APP (06h)

25h

BMC Device and Messaging Commands

Get System GUID

APP (06h)

37h

Get Channel Info

APP (06h)

42h

Set User Access

APP (06h)

43h

Get User Access

APP (06h)

44h

Set User Name

APP (06h)

45h

Get User Name

APP (06h)

46h

Set User Password

APP (06h)

47h

Chassis Device Commands

Get Chassis Capabilities

Chassis (00h)

00h

Get Chassis Status

Chassis (00h)

01h

Chassis Control

Chassis (00h)

02h

Chassis Reset

Chassis (00h)

03h

SDR Device Commands

Get SDR Repository Info

Storage (0Ah)

20h

Get SDR Repository Allocation Info

Storage (0Ah)

21h

Get SDR

Storage (0Ah)

23h

Get SDR Repository Time

Storage (0Ah)

28h

LAN Device Commands

Set LAN Configuration Parameters

Transport (0Ch)

01h

Get LAN Configuration Parameters

Transport (0Ch)

02h

Chapter 3: Software Setup

48

Page 49

NCA-5710 User Manual

Note

(1) If not specified, the default IP to access BMC is https://192.168.0.100(Console Management Port).

(2) Please use https to access Web UI.

In the address bar of your Internet browser, input the IP address of the remote server to access the BMC

interface of that server.

Initial access of BMC prompts you to enter username and password. A screenshot of the login screen is

given below:

Login Page

Username: Enter your username in this field.

Password: Enter your password in this field.

Login: After entering the required credentials, click the Login to log in to Web UI.

49

Page 50

Chapter 3: Software Setup

Note

Duplicate usernames shouldn’t exist across various authentication methods like LDAP, RADIUS or IPMI

since the privilege of one Authentication method is overwritten by another authentication method

during logging in, and hence the correct privilege cannot be returned properly.

Default User Name and Password

Username: admin

Password: admin

The default username and password are in lower-case characters. When you log in using the default

username and password, you will get full administrative rights, and it will ask you to change the default

password once you log in. The dialog is shown below:

Change the default password - Dialog

Clicking OK will take you to the User Management Configuration page to set a password.

Change the default password – Set password

The BMC Web UI consists of various menu items:

50

Page 51

NCA-5710 User Manual

Menu Bar

The menu bar displays the following:

Dashboard

Configuration

Remote Control

Maintenance

A screenshot of the menu bar is shown below:

Menu Bar

Quick Button and Logged-in User

The user information and quick buttons are located at the top right of the Web UI.

User Information

The logged-in user information shows the logged-in user’s username, privilege, with the quick buttons

allowing you to perform the following functions:

User information: The icon shows the logged-in user name and privilege.

Refresh: Click the icon to reload the current page.

Print: Click the icon to print the current page.

Logout: Click the icon to log out of the Web UI.

This option shows the logged-in username and privilege. There are four kinds of privileges:

User: Only valid commands are allowed.

Operator: All BMC commands are allowed except for the configuration commands that can change the

behavior of the out-of-hand interfaces.

Administrator: All BMC commands are allowed.

No Access: Login access denied.

Help: The Help icon is located at the top right of each page in Web UI. Click this help icon to view

more detailed field descriptions.

51

Page 52

Chapter 3: Software Setup

To meet today's security requirements, Lanner SDK derives unique platform identity design and integrates

TPM software stack 2.0 on optional base. By leveraging Lanner SDK, the application development can be

shortened and time-to-market can be easily met, download the SDK package and instruction guide from

http://www.lannerinc.com/products/firmware-and-software/platform-sdk

52

Page 53

NCA-5710 User Manual

If your system is shipped without an operating system, install the supported operating system using the

following resources.

1. Download the ISO image and make a bootable DVD from it.

2. Connect a DVD player or other type of readers (floppy disk, or a drive) to a computer.

3. Connect to your target system from this computer. (Refer to Using BMC Web UI for instructions on how

to access the target system through Web UI.

4. After entering the main screen, select “Remote Control”>“Console Redirection,” and then click on “Java

Console.”

53

Page 54

Chapter 3: Software Setup

5. After a JViewer screen pops up, select “Media” and then “Virtual Media Wizard” from the toolbar.

6. On Virtual Media screen, select your media type to load the image. For example, click on “Browse” of

CD/DVD Media 1 and then “Connect CD/DVD.”

54

Page 55

NCA-5710 User Manual

7. The Status window will display the connection status.

8. The installation process will automatically start. Please follow the onscreen instruction to complete the

rest of the steps and restart the target system manually.

55

Page 56

Chapter 3: Software Setup

Control Keys

Description

select a setup screen

select an item/option on a setup screen

<Enter>

select an item/option or enter a sub-menu

+/-

adjust values for the selected setup item/option

F1

display General Help screen

F2

retrieve previous values, such as the last configured parameters during the last

time you entered BIOS

F3

load optimized default values

F4

save configurations and exit BIOS

<Esc>

exit the current screen

BIOS is a firmware embedded on an exclusive chip on the system’s motherboard. Lanner's BIOS firmware

offering including market-proven technologies such as Secure Boot and Intel Boot Guard technology

deliver solid commitments for the shield protection against malware, uncertified sequences and other

named cyber threats. BIOS update for Lanner PCs are available for download at

http://www.lannerinc.com/products/firmware-and-software/securityenhanced-bios

To enter the BIOS setup utility, simply follow the steps below:

1. Boot up the system.

2. Pressing the <Tab> or <Del> key immediately allows you to enter the Setup utility, and then you will

be directed to the BIOS main screen. The instructions for BIOS navigations are as below:

56

Page 57

NCA-5710 User Manual

Feature

Description

BIOS Information

BIOS Vendor: American Megatrends

Core Version: AMI Kernel version, CRB code base, X64

Compliancy: UEFI version, PI version

Project Version: BIOS release version

Build Date and Time: MM/DD/YYYY

Access Level: Administrator / User

System Date

To set the Date, use <Tab> to switch between Date elements. Default

Range of Year: 2005-2099

Default Range of Month: 1-12

Days: dependent on Month.

System Time

To set the Date, use <Tab> to switch between Date elements.

Setup page contains BIOS information and project version information.

57

Page 58

Chapter 3: Software Setup

58

Page 59

NCA-5710 User Manual

Feature

Options

Description

Security Device

Support

Enabled

Disabled

Enables or disables BIOS support for security device.

By disabling this function, OS will not show Security

Device. TCG EFI protocol and INT1A interface will not

be available.

Trusted Computing

59

Page 60

Trusted Computing (TPM1.2)

Feature

Options

Description

Security Device

Support

Enabled

Disabled

Enables or disables BIOS support for security device.

By disabling this function, OS will not show Security

Device. TCG EFI protocol and INT1A interface will not

be available.

TPM State

Enabled

Disabled

Enables or disables Security Device.

Pending

operation

None

TPM Clear

Schedules an Operation for the Security Device.

Device Select

TPM 1.2

TPM 2.0

Auto

TPM 1.2 will restrict support to TPM 1.2 devices; while

TPM 2.0 will restrict support to TPM 2.0 devices; Auto

will support both with the default set to TPM 2.0

devices. If not found, TPM 1.2 devices will be

enumerated.

Note

Your computer will reboot during restart in order

to change state of the device.

Note

Your computer will reboot during restart in order

to change state of the device.

Chapter 3: Software Setup

60

Page 61

NCA-5710 User Manual

Trusted Computing (TPM2.0)

61

Page 62

Chapter 3: Software Setup

Feature

Options

Description

Security Device

Support

Enabled

Disabled

Enables or disables BIOS support for security device.

By disabling this function, OS will not show Security

Device. TCG EFI protocol and INT1A interface will not

be available.

SHA-1 PCR Bank

Enabled

Disabled

Enables or disables SHA-1 PCR Bank.

SHA256 PCR Bank

Enabled

Disabled

Enables or disables SHA256 PCR Bank.

Pending

operation

None

TPM Clear

Schedules an Operation for the Security Device.

Platform

Hierarchy

Enabled

Disabled

Enables or disables Platform Hierarchy.

Storage Hierarchy

Enabled

Disabled

Enables or disables Storage Hierarchy.

Endorsement

Hierarchy

Enabled

Disabled

Enables or disables Endorsement Hierarchy.

TPM2.0 UEFI Spec

Version

TCG_1_2

TCG_2

Select the TCG2 Spec Version.

TCG_1_2: Supports the Compatible mode for

Win8/Win10

TCG_2: Supports new TCG2 protocol and event format

for Win10 or later.

Physical Presence

Spec Version

1.2

1.3

Select to tell OS to support PPI Spec Version 1.2 or 1.3.

TPM 20

InterfaceType

TIS

Select TPM 20 Device for the Communication

Interface.

Device Select

TPM 1.2

TPM 2.0

Auto

TPM 1.2 will restrict support to TPM 1.2 devices; while

TPM 2.0 will restrict support to TPM 2.0 devices; Auto

will support both with the default set to TPM 2.0

devices. If not found, TPM 1.2 devices will be

enumerated.

Note

Your computer will reboot during restart in order to

change state of the device.

Note

Some HCK tests might not support 1.3.

62

Page 63

NCA-5710 User Manual

Trusted Computing (PTT Enable)

63

Page 64

Chapter 3: Software Setup

Feature

Options

Description

Security Device

Support

Enabled

Disabled

Enables or disables BIOS support for security device.

By disabling this function, OS will not show Security

Device. TCG EFI protocol and INT1A interface will not

be available.

SHA-1 PCR Bank

Enabled

Disabled

Enables or disables SHA-1 PCR Bank.

SHA256 PCR Bank

Enabled

Disabled

Enables or disables SHA256 PCR Bank.

Pending

operation

None

TPM Clear

Schedules an Operation for the Security Device.

Platform

Hierarchy

Enabled

Disabled

Enables or disables Platform Hierarchy.

Storage Hierarchy

Enabled

Disabled

Enables or disables Storage Hierarchy.

Endorsement

Hierarchy

Enabled

Disabled

Enables or disables Endorsement Hierarchy.

TPM2.0 UEFI Spec

Version

TCG_1_2

TCG_2

Select the TCG2 Spec Version.

TCG_1_2: Supports the Compatible mode for

Win8/Win10

TCG_2: Supports new TCG2 protocol and event

format for Win10 or later.

Physical Presence

Spec Version

1.2

1.3

Select to tell OS to support PPI Spec Version 1.2 or

1.3.

TPM 20

InterfaceType

CRB

Select the CRB (Communication Interface) for TPM 20

device.

Device Select

TPM 1.2

TPM 2.0

Auto

TPM 1.2 will restrict support to TPM 1.2 devices; while

TPM 2.0 will restrict support to TPM 2.0 devices; Auto

will support both with the default set to TPM 2.0

devices. If not found, TPM 1.2 devices will be

enumerated.

Note

Your computer will reboot during restart in order to

change state of the device.

Note

Some HCK tests might not support 1.3.

64

Page 65

NCA-5710 User Manual

Super IO Configuration

65

Page 66

Serial port 1 Configuration

Feature

Options

Description

Serial Port

Enabled

Disabled

Enables or disables Serial Port 1

Device Settings

NA

IO=3F8h; IRQ = 4

Serial Port 1

Chapter 3: Software Setup

66

Page 67

NCA-5710 User Manual

Feature

Options

Description

Serial Port

Enabled

Disabled

Enables or disables Serial Port 2

Device Settings

NA

IO=2F8h; IRQ = 3

Serial Port 2

Serial port 2 Configuration

67

Page 68

Case Open Configuration

Feature

Options

Description

Case Open

Enabled

Disabled

Enables or disables Case Open function

Chapter 3: Software Setup

68

Page 69

NCA-5710 User Manual

Feature

Options

Description

Control Legacy

PXE Boot

Disabled

MGT LAN1

Select On Board LAN# Boot

MGT LAN Port

Control Legacy PXE Boot

69

Page 70

NCA-5710 User Manual

Feature

Options

Description

Status LED

OFF

GREEN

RED

Configures Status LED color

Status LED Configuration

70

Page 71

Digital I/O Configuration

Feature

Options

Description

Digital I/O Output 1

Output High

Output Low

Configure Digital I/O Pin5

Digital I/O Output 2

Output High

Output Low

Configure Digital I/O Pin6

Digital I/O Output 3

Output High

Output Low

Configure Digital I/O Pin7

Digital I/O Output 4

Output High

Output Low

Configure Digital I/O Pin8

Chapter 3: Software Setup

71

Page 72

NCA-5710 User Manual

Feature

Options

Description

Watch Dog

Timer

Enabled

Disabled

Enables or disables Watch Dog Timer function

Watch Dog Timer Configuration

72

Page 73

Serial Port Console Redirection

Feature

Options

Description

COM0

Console

Redirection

Enabled

Disabled

Enables or disables Console Redirection

Chapter 3: Software Setup

73

Page 74

NCA-5710 User Manual

Feature

Options

Description

Terminal Type

VT100

VT100+

VT-UTF8

ANSI

VT100: ASCII char set

VT100+:Extends VT100 to support color, function

keys, etc.

VT-UTF8:Uses UTF8 encoding to map Unicode

chars onto 1 or more bytes

ANSI: Extended ASCII char set

Bits per second

9600

19200

38400

57600

115200

Selects serial port transmission speed. The speed

must be matched on the other side. Long or noisy

lines may require lower speeds.

Data Bits

7

8

Data Bits

Parity

None

Even

Odd

Mark

Space

A parity bit can be sent with the data bits to detect

some transmission errors.

Stop Bits

1

2

Indicates the end of a serial data packet.

Flow Control

None

Flow Control can prevent data loss from buffer

Console Redirection Settings

74

Page 75

Chapter 3: Software Setup

Hardware

RTS/CTS

overflow.

VT-UTF8 Combo Key

Support

Disabled

Enabled

Enables VT-UTF8 Combination Key Support for

ANSI/VT100 terminals

Recorder Mode

Disabled

Enabled

With this mode enabled, only text will be sent. This

is to capture Terminal data.

Resolution 100x31

Disabled

Enabled

Enables or disables extended terminal resolution

Legacy OS

Redirection

Resolution

80x24

80x25

On Legacy OS, the Number of Rows and Columns

supported redirection.

Putty KeyPad

VT100

LINUX

XTERM86

SCO

ESCN

VT400

Selects FunctionKey and KeyPad on Putty.

Redirection After

BIOS POST

Always Enable

BootLoader

When Bootloader is selected, Legacy Console

Redirection is disabled before booting to legacy

OS. When Always Enable is selected, then Legacy

Console Redirection is enabled for legacy OS.

Default setting for this option is set to Always

Enable.

75

Page 76

NCA-5710 User Manual

Feature

Options

Description

Legacy Serial

Redirection Port

COM0

Select a COM port to display redirection of Legacy OS

and Legacy OPROM Messages

Legacy Serial Redirection Port

Legacy Console Redirection Settings

76

Page 77

PCI Subsystem Settings

Feature

Options

Description

Above 4G

Decoding

Disabled

Enabled

Enables or disables 64bit capable Devices to be

Decoded in Above 4G Address Space (Only if

System Supports 64 bit PCI Decoding)

SR-IOV Support

Disabled

Enabled

If the system has SR-IOV capable PCIe Devices, this

option enables or disables Single Root IO

Virtualization Support.

Chapter 3: Software Setup

77

Page 78

NCA-5710 User Manual

Feature

Options

Description

Network Stack

Disabled

Enabled

Enables or disables UEFI Network Stack

Ipv4 PXE Support

Disabled

Enabled

Enables Ipv4 PXE Boot Support. If IPV4 is

disabled, PXE boot option will not be created.

Ipv4 HTTP Support

Disabled

Enabled

Enables Ipv4 HTTP Boot Support. If IPV4 is

disabled, HTTP boot option will not be created.

Ipv6 PXE Support

Disabled

Enabled

Enables Ipv6 PXE Boot Support. If IPV6 is

disabled, PXE boot option will not be created.

Ipv6 HTTP Support

Disabled

Enabled

Enables Ipv6 HTTP Boot Support. If IPV6 is

disabled, HTTP boot option will not be created.

PXE boot wait time

0

Wait time to press <ESC> key to abort the PXE

boot

Media detect count

1

Number of times the presence of media will be

checked

Network Stack Configuration

78

Page 79

CSM Configuration

Feature

Options

Description

CSM Support

Disabled

Enabled

Enables or disables CSM Support

Network

Do Not Launch

UEFI

Legacy

Controls the execution of UEFI and

Legacy PXE OpROM

Storage

Do Not Launch

UEFI

Legacy

Controls the execution of UEFI and

Legacy Storage OpROM

Video

Do Not Launch

UEFI

Legacy

Controls the execution of UEFI and

Legacy Video OpROM

Other PCI device

Do Not Launch

UEFI

Legacy

Determines OpROM execution policy for

devices other than Network, Storage, or

Video

Chapter 3: Software Setup

79

Page 80

NCA-5710 User Manual

NVMe Configuration

USB Configuration

80

Page 81

Chapter 3: Software Setup

Feature

Options

Description

Legacy USB Support

Enabled

Disabled

Auto

Enables Legacy USB support.

Auto option disables legacy support if

no USB devices are connected;

Disabled option will keep USB devices

available only for EFI applications.

XHCI Hand-off

Enabled

Disabled

This is a workaround for OSes without

XHCI hand-off support. The XHCI

ownership change should be claimed by

XHCI driver.

USB Mass Storage

Driver Support

Enabled

Disabled

Enables or disables USB Mass Storage

Driver Support.

USB transfer time-out

1 sec

5 sec

10 sec

20 sec

The time-out value for Control, Bulk, and

Interrupt transfers

Device reset time-out

1 sec

5 sec

10 sec

20 sec

USB mass storage device Start Unit

command time-out

Device power-up delay

Auto

Manual

Maximum time the device will take

before it properly reports itself to the

Host Controller. Auto uses default value:

for a Root port, it is 100 ms, for a Hub

port the delay is taken from Hub

descriptor.

81

Page 82

NCA-5710 User Manual

Feature

Options

Description

PCH Configuration

None

Displays and provides option to change

the PCH Settings

Server ME

Configuration

None

Configure Server ME Technology

Parameters

Runtime Error Logging

None

Press <Enter> to view or change the

runtime error log configuration.

Select the Platform menu item from the BIOS setup screen to enter the Platform Setup screen. Users can

select any of the items in the left frame of the screen.

82

Page 83

PCH Configuration

Feature

Options

Description

PCI Express

Configuration

None

PCI Express Configuration settings

PCH SATA

Configuration

None

SATA devices and settings

PCH sSATA

Configuration

None

sSATA devices and settings

Security Configuration

None

Security Configuration settings

Restore AC Power Loss

Power ON

Power Off

Last State

Select S0/S5 for ACPI state after a G3

Serial IRQ Mode

Quiet

Continuous

Configure Serial IRQ Mode.

RTC Lock

Disabled

Enabled

Enabling this feature will lock bytes

38h-3Fh in the lower/upper 128-byte

bank of RTC RAM

BIOS Lock

Disabled

Enabled

Enables or disables the PCH BIOS Lock

Enable feature.

Chapter 3: Software Setup

83

Page 84

NCA-5710 User Manual

Feature

Options

Description

PCIe Root Port

Function Swapping

Disabled

Enabled

Enable PCIe root port function swapping

feature to dynamically assign function 0

to enabled root port.

Max Read Request Size

MRRS 128B

MRRS 256B

MRRS 512B

MRRS 1024B

MRRS 2048B

MRRS 4096B

PCIE Max Read Request Size Selection.

PCI Express Configuration

84

Page 85

PCH SATA Configuration

Feature

Options

Description

SATA Controller

Disabled

Enabled

Enables or disables SATA Controller

Configure SATA as

AHCI

RAID

This will configure SATA as RAID or AHCI.

Support Aggressive

Link Power

Management

Disabled

Enabled

Enables or disables SALP

Port 0/1/2/3/4

Disabled

Enabled

Enable or Disable SATA Port

Hot Plug

Disabled

Enabled

Designates this port as Hot Pluggable.

Configure as eSATA

Disabled

Enabled

Configures port as External SATA (eSATA)

Mechanical Presence

Switch

Disabled

Enabled

Controls reporting if this port has a

Mechanical Presence Switch; requires

hardware support.

Spin Up Device

Disabled

Enabled

If enabled for any of ports Staggered Spin Up

will be performed and only the drives which

Chapter 3: Software Setup

85

Page 86

NCA-5710 User Manual

have this option enabled will spin up at boot.

Otherwise all drives spin up at boot.

SATA Device Type

Hard Disk Drive

Solid State Drive

Identify the SATA port is connected to Solid

State Drive or Hard Disk Drive

SATA Topology

Unknown

ISATA

Direct Connect

Flex

M2

Identify the SATA Topology if it is Default or

ISATA or Flex or DirectConnect or M2

86

Page 87

PCH SATA Configuration

Feature

Options

Description

sSATA Controller

Disabled

Enabled

Enables or disables SATA Controller

Configure SATA as

AHCI

RAID

This will configure SATA as RAID or

AHCI.

Support Aggressive

Link Power

Management

Disabled

Enabled

Enables or disables SALP

Port 0

Disabled

Enabled

Enable or Disable SATA Port

Hot Plug

Disabled

Enabled

Designates this port as Hot Pluggable.

Configure as eSATA

Disabled

Enabled

Configures port as External SATA

(eSATA)

Mechanical Presence

Switch

Disabled

Enabled

Controls reporting if this port has a

Mechanical Presence Switch; requires

hardware support.

Spin Up Device

Disabled

Enabled

If enabled for any of ports Staggered

Spin Up will be performed and only the

Chapter 3: Software Setup

87

Page 88

NCA-5710 User Manual

drives which have this option enabled