Page 1

Network Computing Platforms

NCA-5510

User Manual

Rev 1.4 Aug 21th, 2018

Page 2

Network Computing Platforms

Revision History

This document contains proprietary information of Lanner Electronics Inc. –and is not to be

disclosed or used except in accordance with applicable agreements.

Copyright © 2018. All Rights Reserved.

Copyright© 2015 Lanner Electronics Inc. All rights reserved. The information in this document

is proprietary and confidential to Lanner Electronics Inc. No part of this document may be

reproduced in any form or by any means or used to make any derivative work (such as

translation, transformation, or adaptation) without the express written consent of Lanner

Electronics Inc. Lanner Electronics Inc. reserves the right to revise this document and to make

changes in content from time to time without obligation on the part of Lanner Electronics Inc. to

provide notification of such revision or change.

The information in this document is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Lanner Electronics Inc. Lanner

Electronics Inc. assumes no responsibility or liability for any errors or inaccuracies that may

appear in this document or any software that may be provided in association with this document.

Rev

Date

Descriptions

0.1

2015/08/06

Preliminary

1.0

2015/11/03

Official release

1.1

2015/12/01

Added BIOS chapter

1.2

2016/04/22

Added maximum heights for SATA storage tray

1.3

2017/08/24

Updated motherboard layout, Jumpers and Connectors

List, and Jumper Setting and Connector Pin-out

1.4

2018/08/21

Modified Pin Assignment for LCM

Page 3

Network Computing Platforms

Online Resources

The listed websites are links to the on-line product information and technical support.

Resource

Website

Lanner

www.lannerinc.com

Product Resources

www.lannerinc.com/support/download-center

RMA

http://eRMA.lannerinc.com

Acknowledgement

Intel, Pentium and Celeron are registered trademarks of Intel Corp.

Microsoft Windows and MS-DOS are registered trademarks of Microsoft Corp.

All other product names or trademarks are properties of their respective owners.

Compliances and Certification

CE Certification

This product has passed the CE test for environmental specifications. Test conditions for

passing included the equipment being operated within an industrial enclosure. In order to

protect the product from being damaged by ESD (Electrostatic Discharge) and EMI leakage,

we strongly recommend the use of CE-compliant industrial enclosure products.

FCC Class A Certification

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference

at his own expense.

Page 4

Network Computing Platforms

EMC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case users will be required to correct the interference at

their own expense.

Safety Guidelines

Follow these guidelines to ensure general safety:

Keep the chassis area clear and dust-free before, during and after installation.

Do not wear loose clothing or jewelry that could get caught in the chassis. Fasten your tie

or scarf and roll up your sleeves.

Wear safety glasses/goggles if you are working under any conditions that might be

hazardous to your eyes.

Do not perform any action that creates a potential hazard to people or makes the

equipment unsafe.

Disconnect all power by turning off the power and unplugging the power cord before

installing or removing a chassis or working near power supplies

Do not work alone if potentially hazardous conditions exist.

Never assume that power is disconnected from a circuit; always check the circuit.

LITHIUM BATTERY CAUTION:

Risk of explosion could occur if battery is replaced by an incorrect type. Please dispose of

used batteries according to the recycling instructions of your country.

Installation only by a trained electrician or only by an electrically trained person who knows

all the applied or related installation and device specifications..

Do not carry the handle of power supplies when moving to other place.

The machine can only be used in a fixed location such as labs or computer facilities.

Page 5

Network Computing Platforms

Operating Safety

Electrical equipment generates heat. Ambient air temperature may not be adequate to

cool equipment to acceptable operating temperatures without adequate circulation. Be

sure that the room in which you choose to operate your system has adequate air

circulation.

Ensure that the chassis cover is secure. The chassis design allows cooling air to circulate

effectively. An open chassis permits air leaks, which may interrupt and redirect the flow of

cooling air from internal components.

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD

damage occurs when electronic components are improperly handled and can result in

complete or intermittent failures. Be sure to follow ESD-prevention procedures when removing

and replacing components to avoid these problems.

Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact. If no wrist

strap is available, ground yourself by touching the metal part of the chassis.

Periodically check the resistance value of the antistatic strap, which should be between 1

and 10 megohms (Mohms).

Mounting Installation Environment Precaution

1. Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the

operating ambient temperature of the rack environment may be greater than room ambient.

Therefore, consideration should be given to installing the equipment in an environment

compatible with the maximum ambient temperature (Tma) specified by the manufacturer.

2. Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of

air flow required for safe operation of the equipment is not compromised.

3. Mechanical Loading - Mounting of the equipment in the rack should be such that a

hazardous condition is not achieved due to uneven mechanical loading.

4. Circuit Overloading - Consideration should be given to the connection of the equipment to

the supply circuit and the effect that overloading of the circuits might have on over-current

protection and supply wiring. Appropriate consideration of equipment nameplate ratings

should be used when addressing this concern.

5. Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained.

Particular attention should be given to supply connections other than direct connections to the

branch circuit (e.g. use of power strips).”

Page 6

Network Computing Platforms

Consignes de sécurité

Suivez ces consignes pour assurer la securite generale :

Laissez la zone du chassis propre et sans poussiere pendant et apres l’installation.

Ne portez pas de vetements amples ou de bijoux qui pourraient etre pris dans le chassis.

Attachez votre cravate ou echarpe et remontez vos manches.

Portez des lunettes de securite pour proteger vosmyeux.

N’effectuez aucune action qui pourrait creer un dangermpour d’autres ou rendre

l’equipement dangereux.

Coupez completement l’alimentation en eteignant l’alimentation et en debranchant le

cordon d’alimentation avant d’installer ou de retirer un chassis ou de travailler a proximite

de sources d’alimentation.

Ne travaillez pas seul si des conditions dangereuses sont presentes.

Ne considerez jamais que l’alimentation est coupee d’un circuit, verifiez toujours le circuit.

Cet appareil genere, utilise et emet une energie radiofrequence et, s’il n’est pas installe et

utilise conformement aux instructions des fournisseurs de composants sans fil, il risque de

provoquer des interferences dans les communications radio.

Avertissement concernant la pile au lithium

Risque d’explosion si la pile est remplacee par une autre d’un mauvais type.

Jetez les piles usagees conformement aux instructions.

L’installation doit etre effectuee par un electricien forme ou une personne formee a

l’electricite connaissant toutes les specifications d’installation et d’appareil du produit.

Ne transportez pas l’unite en la tenant par le cable d’alimentation lorsque vous deplacez

l’appareil.

La machine ne peut etre utilisee qu’a un lieu fixe comme en laboratoire, salle d’ordinateurs

ou salle de classe.

Sécurité de fonctionnement

L’equipement electrique genere de la chaleur. La temperature ambiante peut ne pas etre

adequate pour refroidir l’equipement a une temperature de fonctionnement acceptable

sans circulation adaptee. Verifiez que votre site propose une circulation d’air adequate.

Verifiez que le couvercle du chassis est bien fixe. La conception du chassis permet a l’air

de refroidissement de bien circuler. Un chassis ouvert laisse l’air s’echapper, ce qui peut

interrompre et rediriger le flux d’air frais destine aux composants internes.

Les decharges electrostatiques (ESD) peuvent endommager l’equipement et gener les

Page 7

Network Computing Platforms

circuits electriques. Des degats d’ESD surviennent lorsque des composants electroniques

sont mal manipules et peuvent causer des pannes totales ou intermittentes. Suivez les

procedures de prevention d’ESD lors du retrait et du remplacement de composants.

- Portez un bracelet anti-ESD et veillez a ce qu’il soit bien au contact de la peau. Si aucun

bracelet n’est disponible, reliez votre corps a la terre en touchant la partie metallique du

chassis. Verifiez regulierement la valeur de resistance du bracelet antistatique, qui doit etre

comprise entre 1 et 10 megohms (Mohms).

Consignes de sécurité électrique

Avant d’allumer l’appareil, reliez le cable de mise a la terre de l’equipement a la terre.

Une bonne mise a la terre (connexion a la terre) est tres importante pour proteger l

equipement contre les effets nefastes du bruit externe et reduire les risques d’electrocution

en cas de foudre.

Pour desinstaller l’equipement, debranchez le cable de mise a la terre apres avoir eteint

l’appareil.

Un cable de mise a la terre est requis et la zone reliant les sections du conducteur doit

faire plus de 4 mm2 ou 10 AWG.

Procédure de mise à la terre pour source

d’alimentation CC Procédure de mise à la terre pour

source d’alimentation CC

• Desserrez la vis du terminal de mise a la terre.

• Branchez le cable de mise a la terre a la terre.

• L’appareil de protection pour la source d’alimentation

CC doit fournir 30 A de courant. Cet appareil de protection doit etre branche a la source

d’alimentation avant l’alimentation CC.

Page 8

Network Computing Platforms

Table of Contents

NCA-5510 ................................................................................................................... 1

User Manual ................................................................................................................ 1

Revision History ............................................................................................................ 2

Online Resources ......................................................................................................... 3

Acknowledgement ....................................................................................................... 3

Compliances and Certification .................................................................................... 3

CE Certification ........................................................................................................... 3

FCC Class A Certification ........................................................................................... 3

EMC Notice ................................................................................................................. 4

Safety Guidelines ......................................................................................................... 4

LITHIUM BATTERY CAUTION:.............................................................................. 4

Operating Safety .......................................................................................................... 5

Mounting Installation Environment Precaution .......................................................... 5

Consignes de sécurité .................................................................................................. 6

Avertissement concernant la pile au lithium ................................................................ 6

Sécurité de fonctionnement ......................................................................................... 6

Consignes de sécurité électrique ................................................................................. 7

Procédure de mise à la terre pour source d’alimentation CC Procédure de mise à la

terre pour source d’alimentation CC ........................................................................... 7

Chapter 1: Introduction ................................................................................................ 10

System Specification ................................................................................................. 11

Ordering Information ................................................................................................. 12

Package Contents ....................................................................................................... 12

Optional Accessories ................................................................................................. 12

Chapter 2: System Overview ....................................................................................... 13

Mechanical Drawing.................................................................................................. 13

Block Diagram ........................................................................................................... 14

Front I/Os ................................................................................................................... 15

Rear I/Os .................................................................................................................... 16

Chapter 3: Board Layout .............................................................................................. 17

Jumpers and Connectors on the Motherboard ........................................................... 17

Jumpers and Connectors List ..................................................................................... 18

Jumper Setting and Connector Pin-out ...................................................................... 19

Chapter 4: Hardware Setup .......................................................................................... 28

Installing the CPU ..................................................................................................... 30

Installing the System Memory ................................................................................... 33

Installing Disk Drives ................................................................................................ 34

Installing a CFast Card .............................................................................................. 36

Installing an IPMI Card ............................................................................................. 36

Page 9

Network Computing Platforms

Replacing Redundant Power Supply Unit ................................................................. 37

Replacing Cooling Fans ............................................................................................ 38

Installing Ethernet NIC Modules ............................................................................... 39

Installing Riser Card (Optional) ................................................................................ 41

Rackmount Installation .............................................................................................. 43

Chapter 5: BIOS Setup................................................................................................. 48

Main ........................................................................................................................... 49

Advanced ................................................................................................................... 50

Above 4G Decoding .................................................................................... 50

SR-IOV Support........................................................................................... 50

NCT6776 Super IO Configuration............................................................... 51

NCT7904D HW Monitor ............................................................................. 54

Serial Port Console Redirection ................................................................... 56

COM Console Redirection Settings ............................................................. 57

Trusted Computing ...................................................................................... 63

USB Configuration ...................................................................................... 64

LAN Boot Select .......................................................................................... 68

IntelRCSetup ............................................................................................................. 70

IOAT Configuration..................................................................................... 70

Intel (R) VT for Directed I/O (VT-d) Configuration ................................... 73

IIO0 Configuration....................................................................................... 76

Processor Configuration............................................................................... 77

PCH Configuration ...................................................................................... 79

PCH SATA Configuration ........................................................................... 80

Security ...................................................................................................................... 83

Boot ........................................................................................................................... 84

Save & Exit ................................................................................................................ 86

Appendix A: Programming Watchdog Timer .............................................................. 87

Appendix B: Setting up Console Redirection .............................................................. 88

Appendix C: Programming Generation 3 LAN Bypass .............................................. 89

Appendix D: Programming the LCM .......................................................................... 91

Appendix E: Terms and Conditions ............................................................................. 96

Page 10

Network Computing Platforms

Chapter 1: Introduction

Thank you for choosing NCA-5510. NCA-5510 is a high-performance 1U rackmount network

appliance utilizing Intel® Haswell-EP CPU with Wellsburg PCH, codenamed Grantley. The

adoption of this platform aims to deliver supreme network performance. With Intel® Grantley,

NCA-5510 supports registered DDR4 memory at 2133 MHz frequency and capacity up to

256GB. This will help maximize data efficiency in virtualization and next-generation

firewall/UTM/IPS applications.

As designed for optimal network computing, NCA-5510 offers high-port density by delivering

up to 32 GbE RJ-45 ports in just 1U form factor. The LAN expansion is scalable through 4 NIC

slim type module slots, supporting 40G/10G/1G/Fiber/Copper/Bypass specifications. The

variety and scalability makes NCA-5510 the ideal deployment for enhancing network traffic

management and virtualized network security.

Other significant features include CFast NAND Flash storage, 1+1 ATX redundant power at

300W and optional TPM support.

Here is the summary of the key features:

Intel® Xeon® processor E5-2600 v3 series on LGA2011-R3 socket (Haswell-EP)

Intel® Chipset

4 NIC module slots support 40G/10G/1G/Fiber/Copper/Bypass

DDR4 memory at 2133 MHz, maximum capacity up to 256GB

1 x 3.5” or 2 x 2.5” SATA HDD/SSD drive bays, max 9.5mm height (disk drive is not

included)

1 x CFast socket

Please refer to the following chart for a detailed description of the system's specifications.

Page 11

Network Computing Platforms

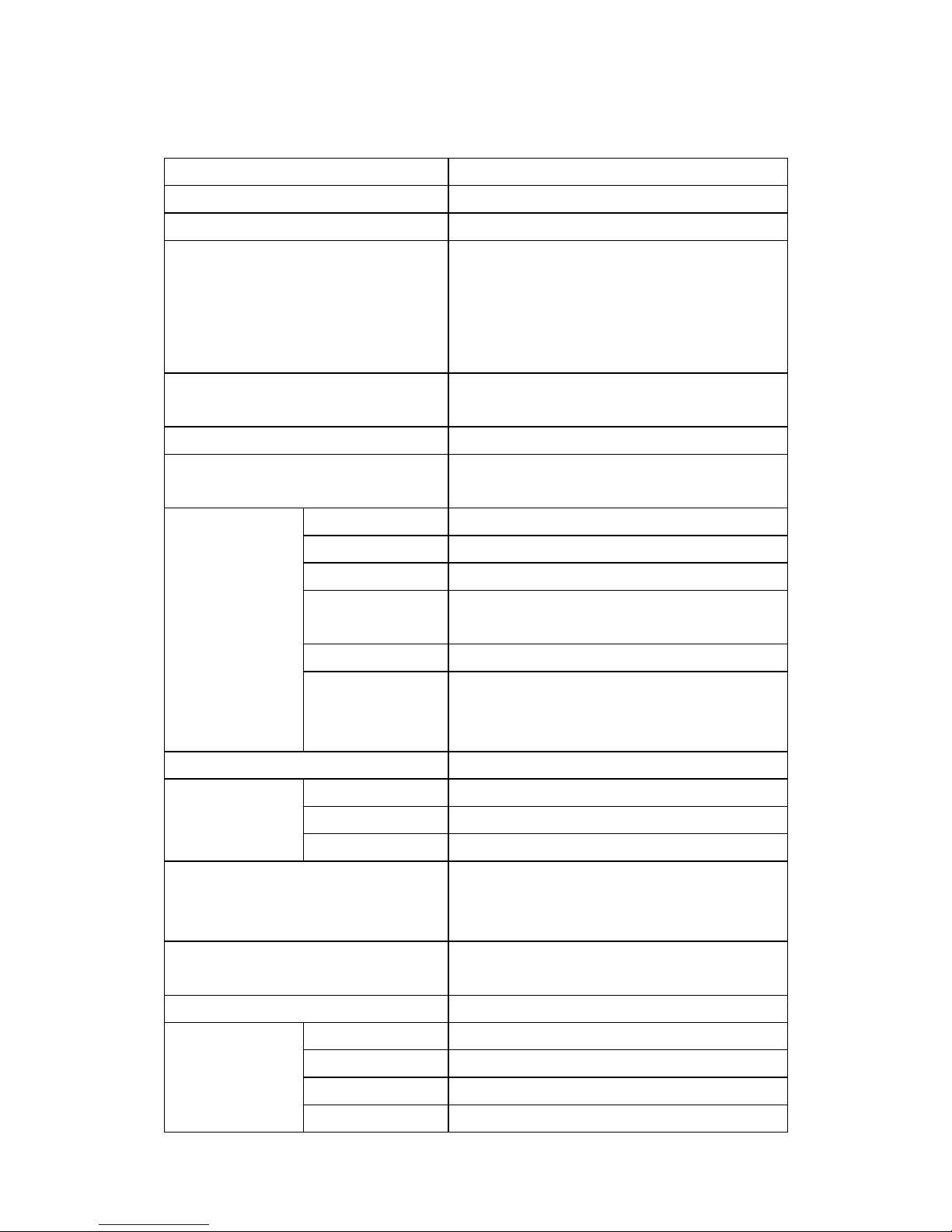

System Specification

Processor Options

Intel® Haswell-EP CPU at 95W

CPU Socket

LGA2011-R3

Chipset

Intel® C612 Chipset

BIOS

AMI SPI BIOS

Support PXE function

Support Console redirection

Watchdog/ Watchdog control LAN Bypass

function/ Power off LAN Bypass function

System Memory

8 x 288-pin DIMM DDR4 up to 2133MHz ECC

RDIMM at 256GB

USB

2 x USB 2.0 Type-A ports

Storage

1 x 3.5” or 2 x 2.5” HDD/SSD, max 9.5mm height

1 x CFast socket

Networking

LAN

2x RJ-45 of 10/100/1000Mbps Ethernet ports

Controller

2 x Intel i210AT

Management

1 x Management Port, shared with IPMI

NIC Module space

4 x Slim Type NIC module sockets (1xPCIE8 or

2xPCIE4)

Console

1 x RJ-45 console port

IPMI

OPMA socket to support IPMI IAC-AST2300

1x 10/100/GBE

VGA via IPMI (OPMA socket)

Fan

4 x Cooling fans

Display

LCM

1x character type LCM

LED

POWER/STATUS/HDD

Keypad

4x Keypads

Expansion

4 x PCIex8 sockets for slim type NIC modules on

the front

1 x PCIex8 half-sized module at the rear

TPM

1x 12-pin 2.54pitch pin header support TPM

module

Thermal

1 x passive heat sink

Physical

Characteristics

Form Factor

1U rackmount

Housing

SPGC

Dimensions

438mm x 580mm x 44mm (W x D x H)

Mounting Options

Rackmount by sliderail

Page 12

Network Computing Platforms

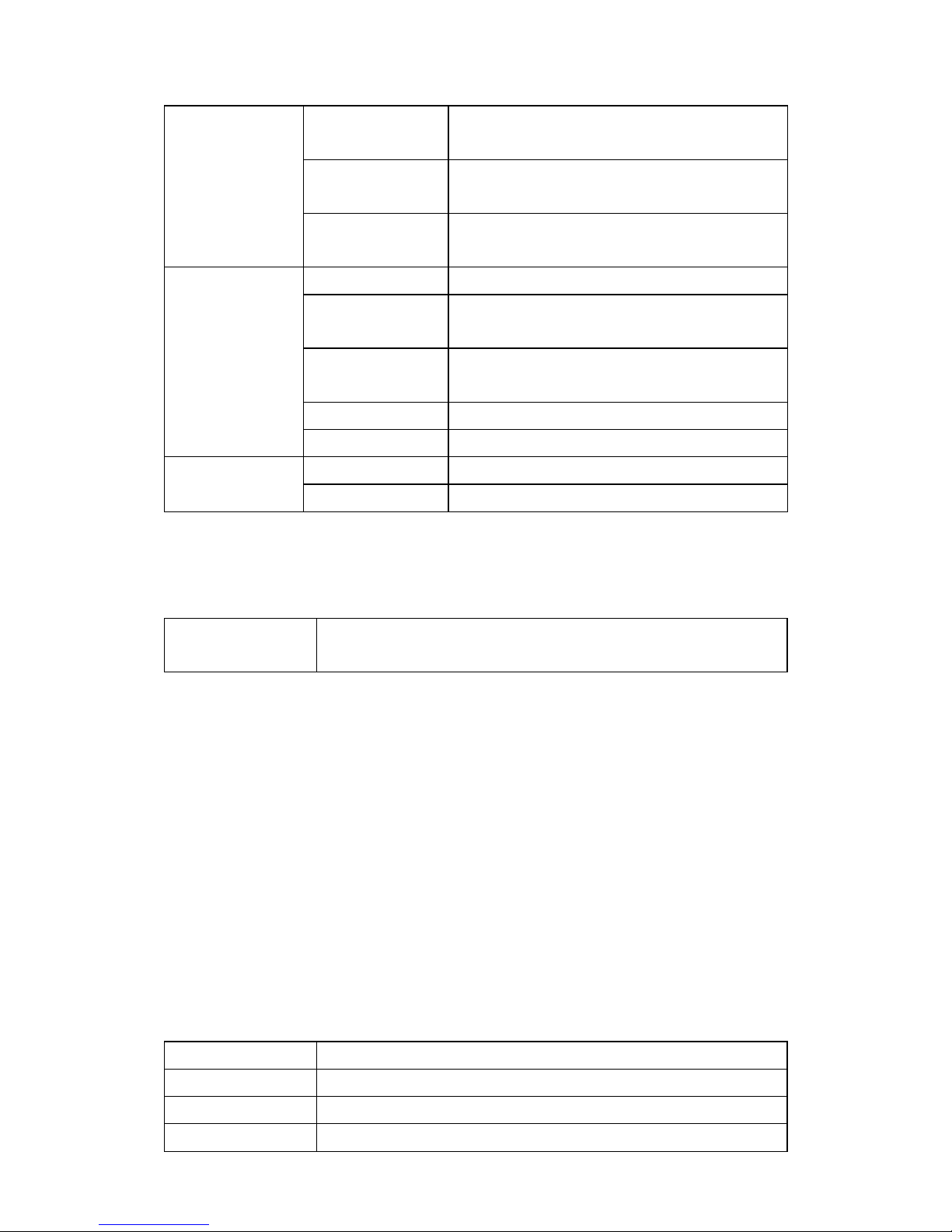

Environment

Operating

Temperature

0℃~40°C

Non-operating

Temperature

-40℃~70℃

Ambient

Humidity

5 to 90% (non-condensing)

Power

Power switch

1x power switch, slim type ATX

Reset

1x reset, Software / Hardware reset (Control by

GPIO) default SW reset

Internal

1 x ATX 24-pin connector

1 x ATX 8-pin connector

Input

110 to 240 VAC

Power supply

300W 1U redundant PSU w/ PM bus

Certifications

EMC

CE/FCC Class A

Green product

RoHS

Ordering Information

NCA-5510A

NCB-5510A + 4 Slimtype NIC module space + NCC-5510A +

IO-88951A + BP-55101A + RC-88771A(Optional)

Package Contents

1 – NCA-5510 Network Security Platform

1 – power cable

1 – Ear Rack mount kit with screws

1 – Console cable

1 – LAN Cable (Grey)

1 – LAN Cable (Red)

Note:If you should find any components missing or damaged, please contact your dealer

immediately for assistance

Optional Accessories

NCS2-ISM405A

1x Intel i350 4port SFP w/ bypass

NCS2-ISM802A

2x Intel i350 8port RJ45 w/o bypass

NCS2-IXM405A

2x Intel 82599 4port SFP+ w/o bypass

NCS2-ITM202A

Page 13

Network Computing Platforms

Chapter 2: System Overview

Mechanical Drawing

Unit: mm

Page 14

Network Computing Platforms

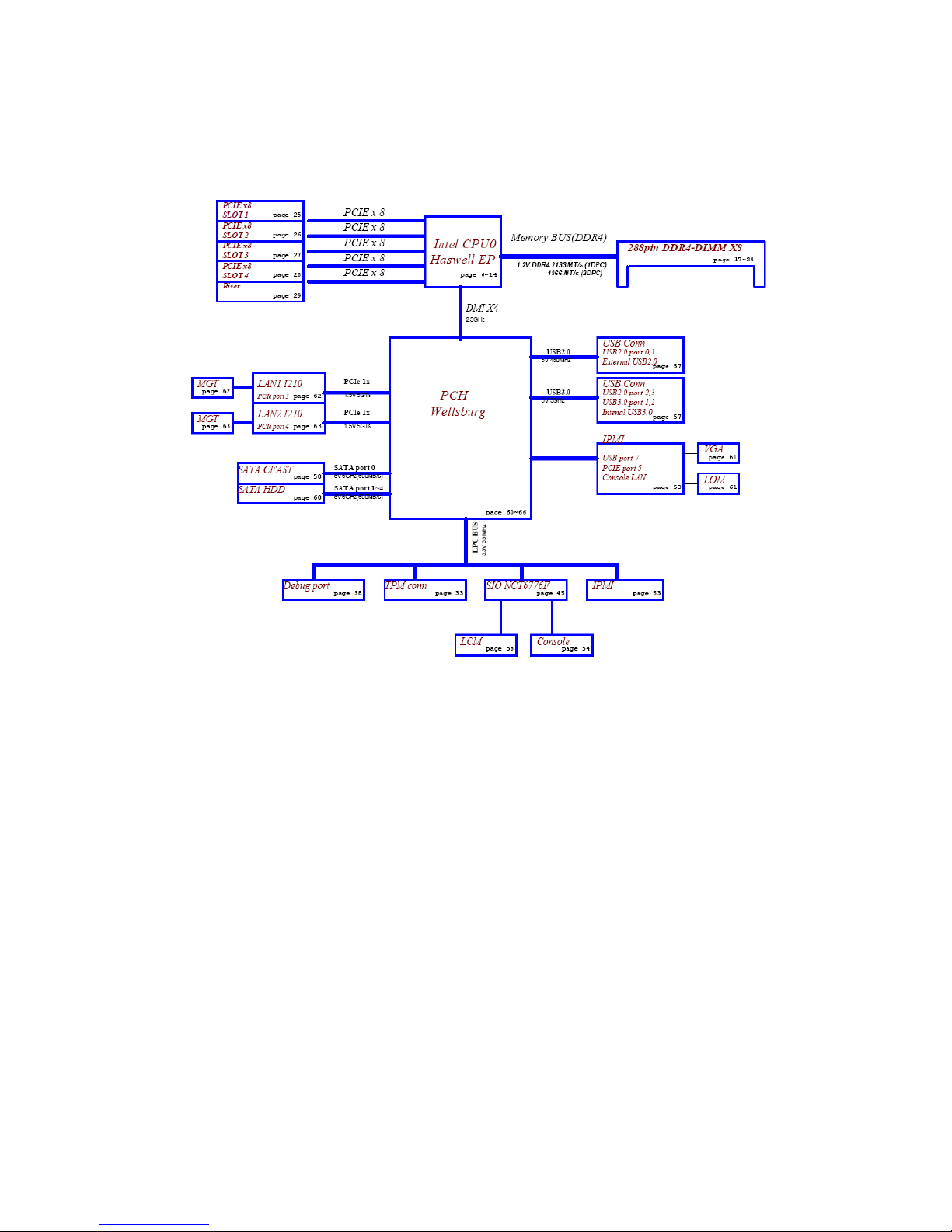

Block Diagram

Page 15

Network Computing Platforms

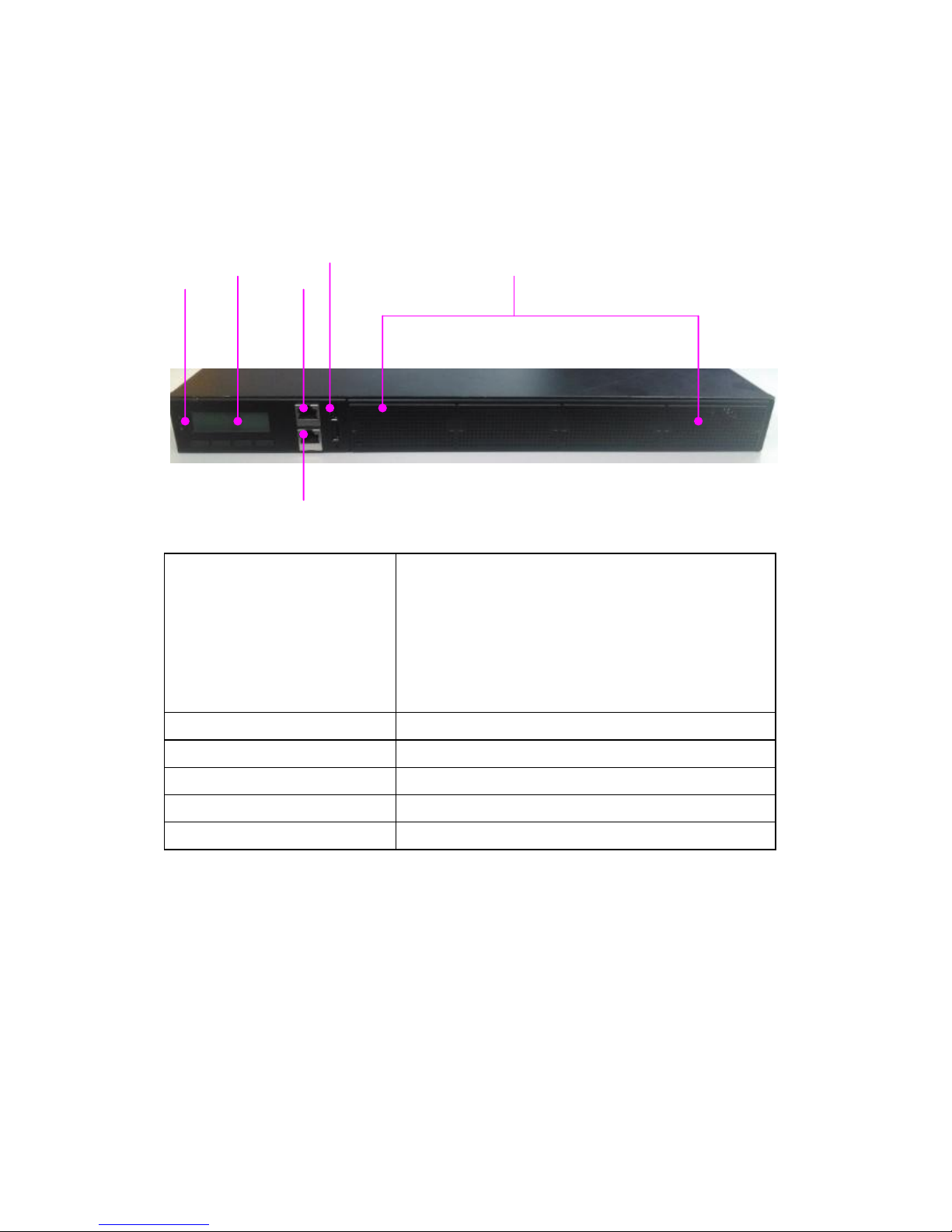

Front I/Os

F1 LED Indicators

POWER/STATUS/HDD

Power: status about power supply

Status: programmable status LED signals for system

activities

HDD: status about storage devices, such as HDD or

SSD

F2 LCM

LCM with 4 x keypads

F3 LAN

1 x RJ-45 Management Port

F4 COM

1 x RJ-45 console port

F5 USB

2 x USB 2.0 Type-A ports in double stacked form

F6 NIC

4 x Slim type NIC module spaces

F1

F2

F3

F4

F5

F6

Page 16

Network Computing Platforms

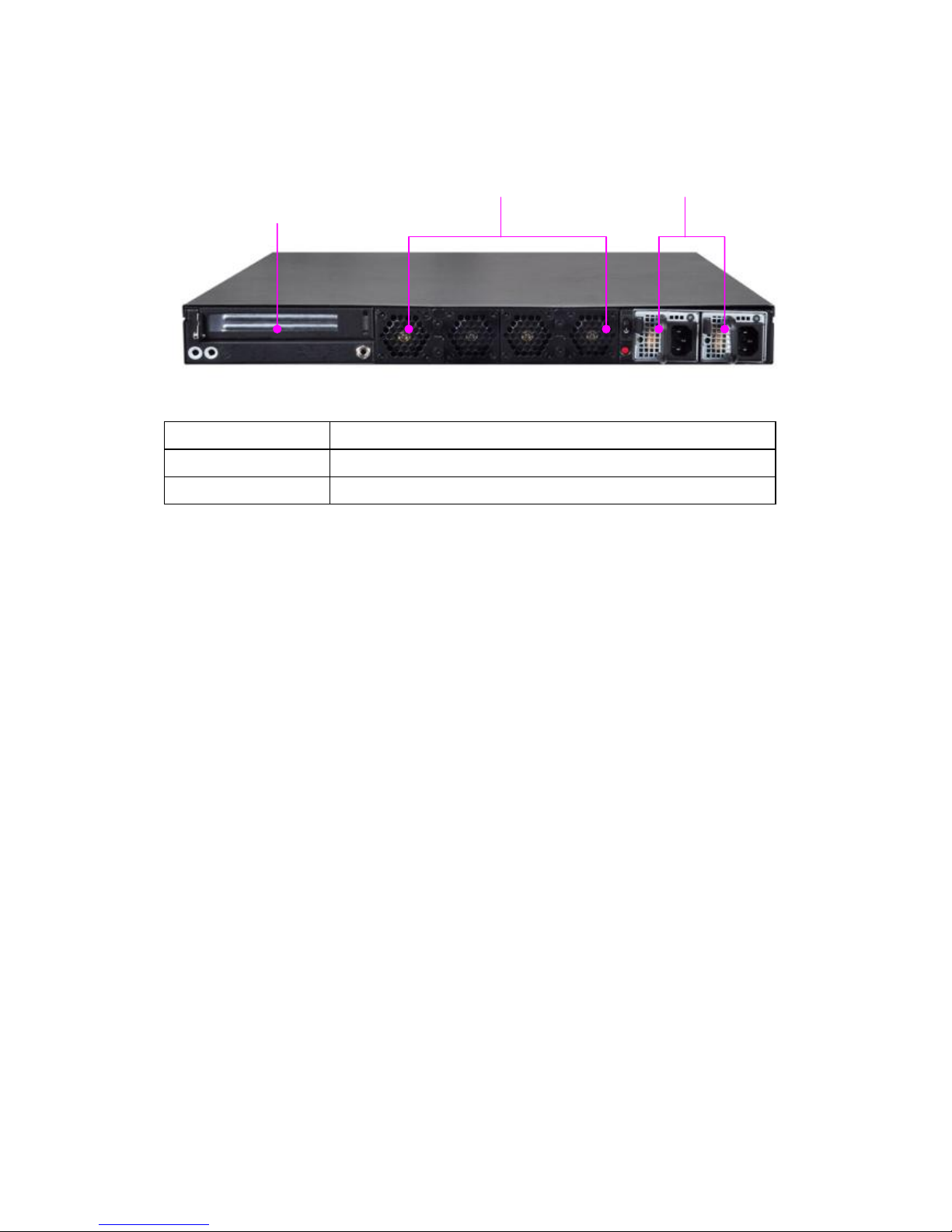

Rear I/Os

R1 PCIe Expansion

1 x PCIe expansion slot

R2 Fans

4 x replaceable cooling fans

R3 Power

2 x redundant power supply units (300W)

R1

R2

R3

Page 17

Network Computing Platforms

Chapter 3: Board Layout

Jumpers and Connectors on the Motherboard

FFAANN11 FFAANN22

AATTXX11

FFAANN33 FFAANN44

LLCCMM__SS11 MMGGTT22 MMGGTT11 VVGGAA11

JJTTPPMM11

JJCCFFAASSTT11

CCOOMMBB11

JJGGPP11

JJ8800PPOORRTT11

LLOOMM11

OOPPMMAA11

AATTXX22

SSAATTAA22 SSAATTAA11

SSAATTAA44 SSAATTAA33

JJCCMMOOSS11

JJUUSSBB11

JJPPCCIIEESSLL11 JJPPCCIIEESSLL22 JJPPCCIIEESSLL33 JJPPCCIIEESSLL44

OOPPEENN11

CCOONNNN22

CCOONN33

AATTXX55

JJCCOOMMAA11

LLCCMM__PP11

CCOONNNN55

SSWW11

SSWW33

JJ2277

JJUUSSBB22

CCOONN11

Page 18

Network Computing Platforms

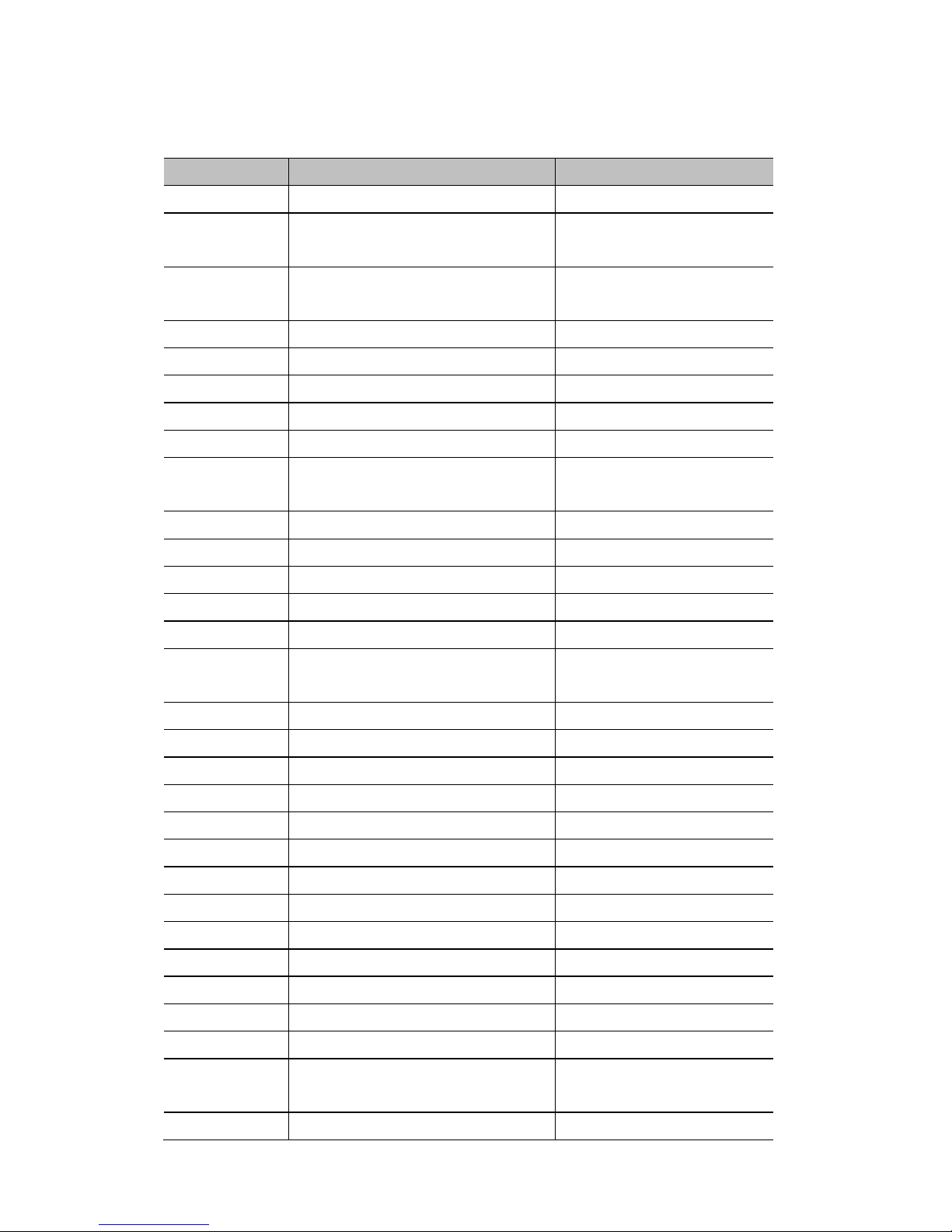

Jumpers and Connectors List

Labels

Descriptions

Remarks

LCM_S1

USB type LCM module pin header

MGT2

An internal LAN pin header to serve as

Management Port 2

MGT1

An internal LAN pin header to serve as

Management Port 1

VGA1

VGA internal pin header

Enabled via IPMI/OPMA only

COMB1

COM port pin header

JCFast

CFast card socket

JGP1

GPIO

J80PORT

Debug use

LOM1

An internal LAN pin header to serve as

LOM port

LOM is optional and must be

enabled through IPMI/OPMA

SATA1, 2, 3, 4

4 x SATA signal connectors

OPMA1

OPMA socket for IPMI card

JCMOS1

Clear CMOS jumper setting

JUSB1

USB 2.0 internal pin header

JUSB2

USB 2.0/3.0 internal pin header

OPEN1

Chassis Open Detect mainboard

protection jumper

ATX2

4-pin power connector

FAN1~4

4 x 5-pin fan connectors

ATX1

8-pin power connector

CONN2

ATX Mode power switch

CON3

PMBus connector

ATX5

24-pin ATX power connector

JCOMA1

COM port pin header

LCM_P1

LCM module connector

SW1

PSON power switch for debug

SW3

Reset Switch

CONN5

AT Mode power switch

J27

Software reset jumper selection

CON1

4-pin power connector

JTPM1

Supports a Trusted Platform Module

(TPM) system

JCMOS1

Jumper selection to clear CMOS

Page 19

Network Computing Platforms

Jumper Setting and Connector Pin-out

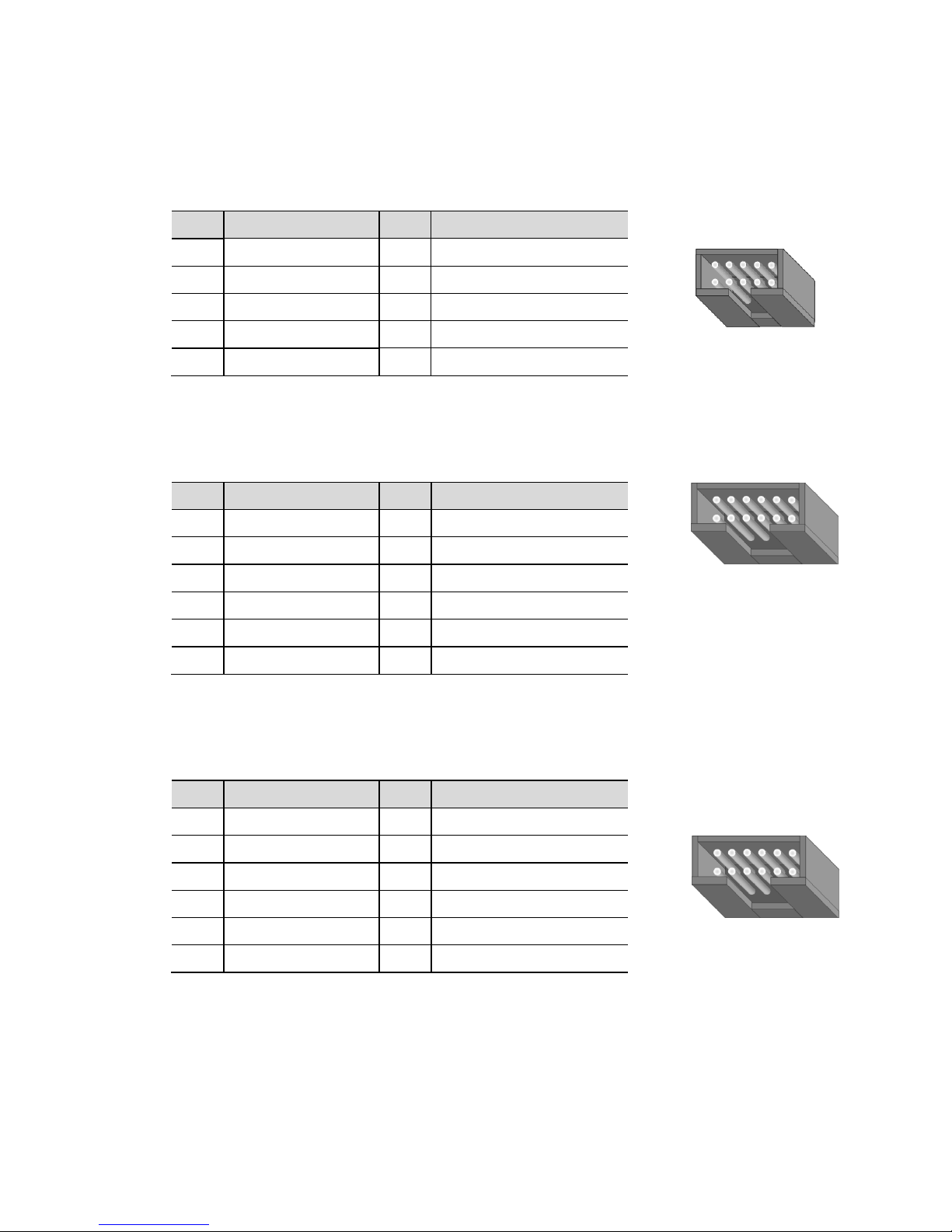

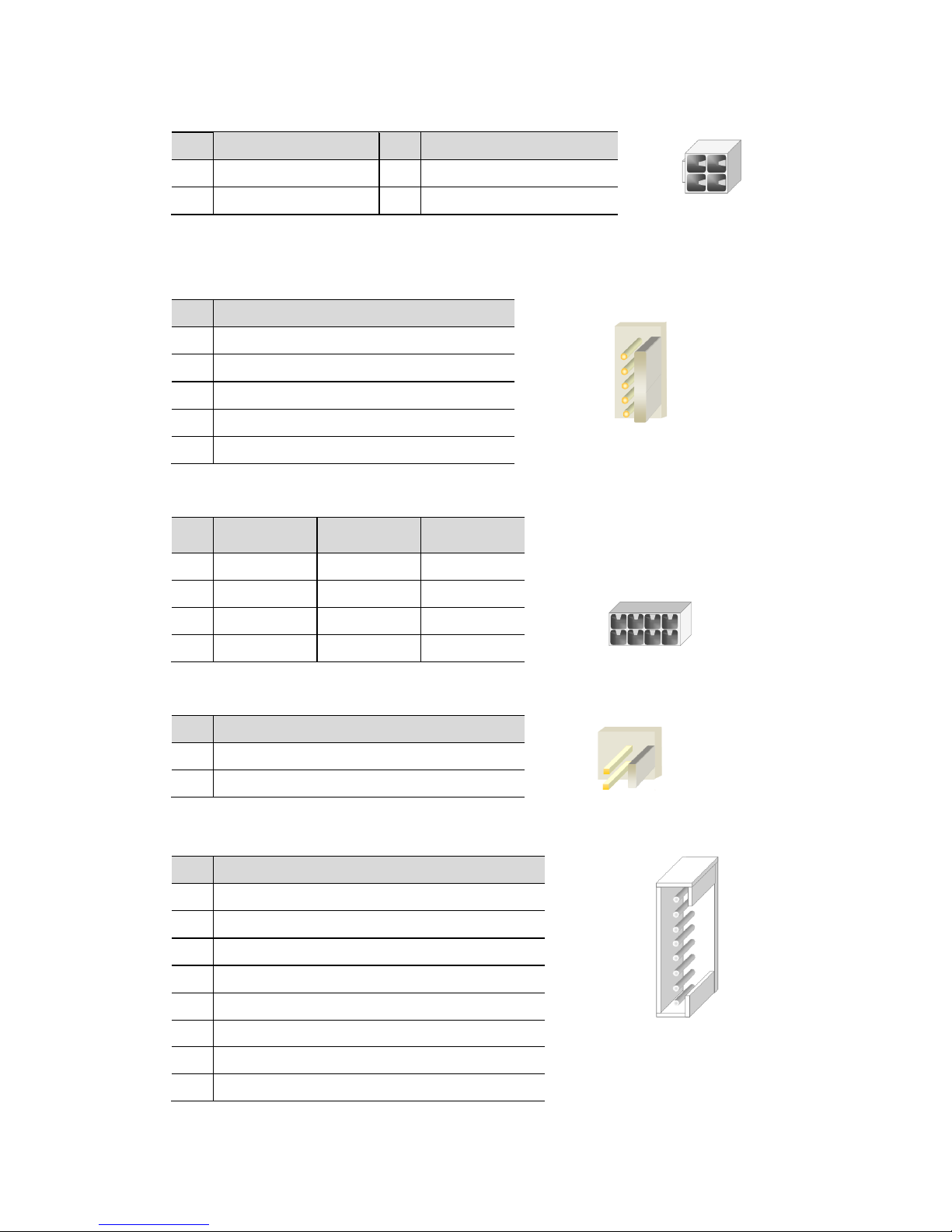

LCM_S1: USB_LCM

USB-type front LCD Message Display Module (LCM).

Pin

Description

Pin

Description

1

P5V_SB 2 P5V

3

USB_PCH_P5N

4 5

USB_PCH_P5P

6

HDD_LED_N

7

GND 8 GND

9

NTXD2

10

NRXD2

MGT2: LAN

An internal LAN pin header to serve as Management Port 2

Pin

Description

Pin

Description

1

MGT2_MDIP_0

2

MGT2_MDIN_0

3

MGT2_MDIP_1

4

MGT2_MDIN_1

5

MGT2_MDIP_2

6

MGT2_MDIN_2

7

MGT2_MDIP_3

8

MGT2_MDIN_3

9

MGT_LAN2_100#

10

MGT_LAN2_ACT#

11

MGT_LAN2_1G#

12

P3V3_AUX

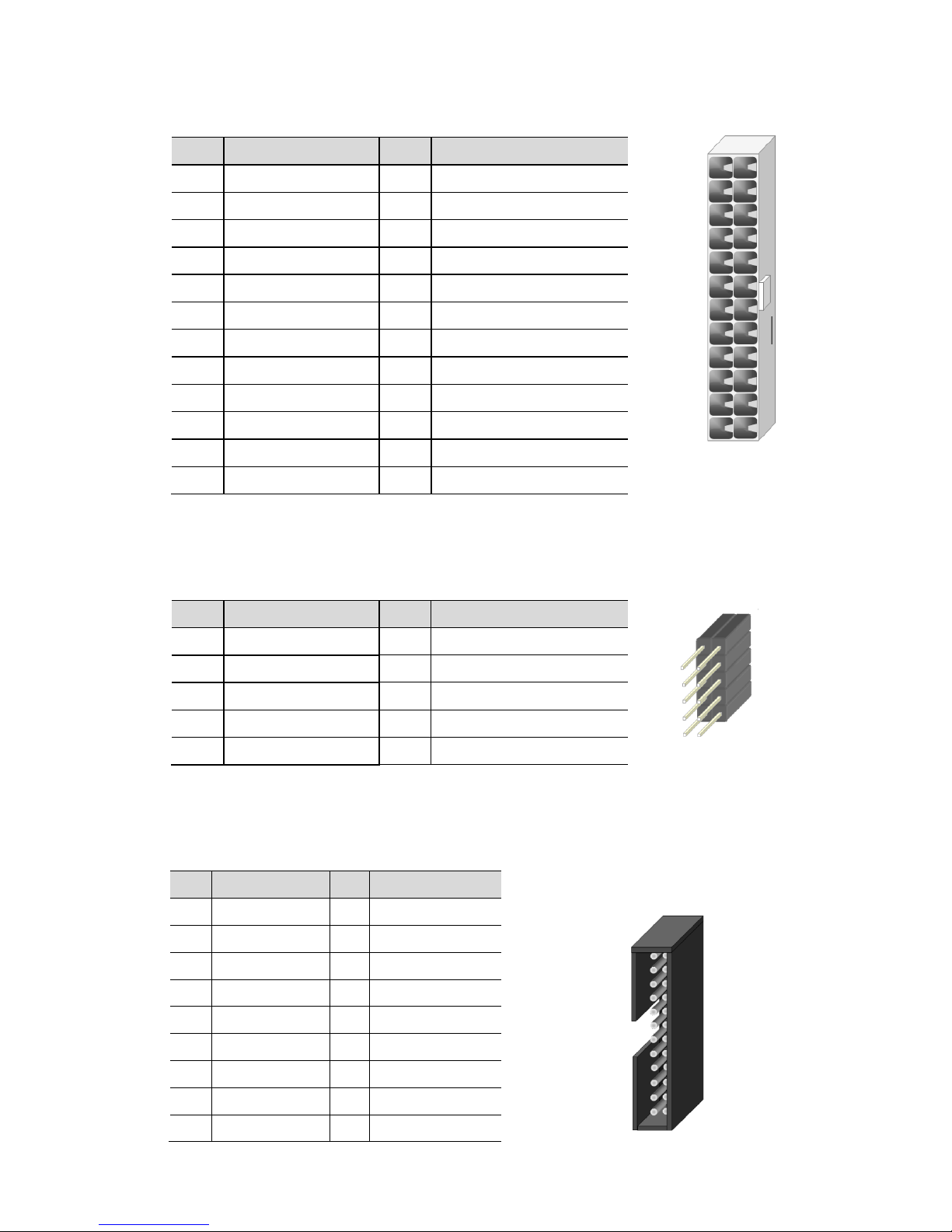

MGT1: LAN

An internal LAN pin header to serve as Management Port 1

Pin

Description

Pin

Description

1

MGT1_MDIP_0

2

MGT1_MDIN_0

3

MGT1_MDIP_1

4

MGT1_MDIN_1

5

MGT1_MDIP_2

6

MGT1_MDIN_2

7

MGT1_MDIP_3

8

MGT1_MDIN_3

9

MGT_LAN1_100#

10

MGT_LAN1_ACT#

11

MGT_LAN1_1G#

12

P3V3_AUX

22 1100

11 99

22 1122

11 1111

22 1122

11 1111

Page 20

Network Computing Platforms

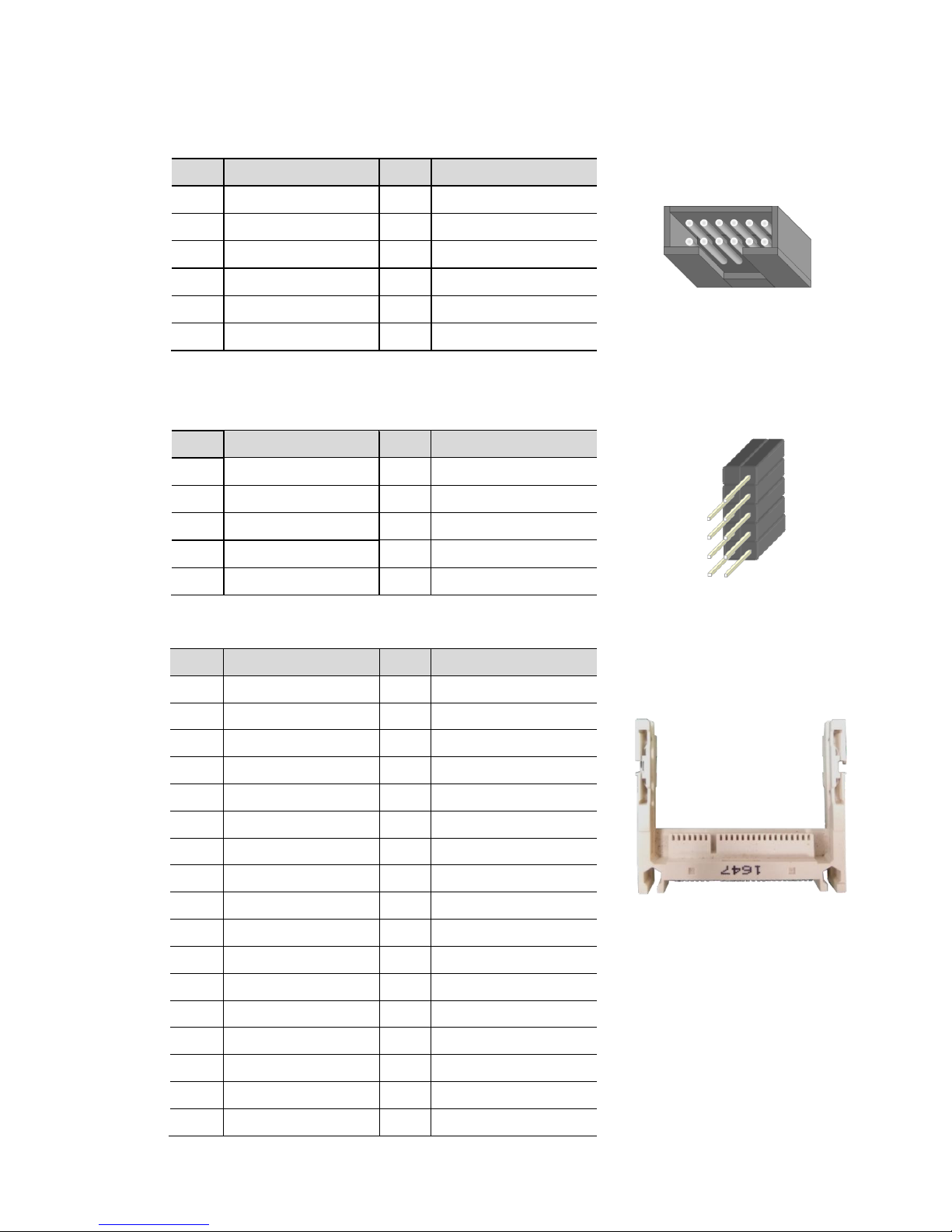

VGA1: VGA

The VGA function is enabled via IPMI (OPMA socket)

Pin

Description

Pin

Description

1 R 2

GND 3 G 4 GND 5 B 6 GND

7

H-SYNC

8

GND

9

V-SYNC

10

GND

11

Detect-display Data

12

Deteck-display CLOCK

COMB1: COM PORT

Serial COM port pin header

Pin

Description

Pin

Description

1

NDCD2-

2

NDSR2-

3

NRXD2

4

NRTS2-

5

NTXD2

6

NCTS2-

7

NDTR2-

8

NRI2-

GND

10

JCFAST1: CFast card socket

Pin

Description

Pin

Description

PC1

Tie to Pin 17

S1

GND

PC2

GND

S2

SATA_TX_P0

PC3 S3

SATA_TX_N0

PC4 S4

GND

PC5 S5

SATA_RX_N0

PC6 S6

SATA_RX_P0

PC7

GND

S7

GND

PC8

LED_CFAST#

PC9 PC10

PC11

PC12 PC13

P3V3

PC14

P3V3

PC15

GND

PC16

GND

PC17

Tie to Pin 1

99

88

22 11

SS11 SS77 PPCC11 PPCC1177

2 12

1 11

Page 21

Network Computing Platforms

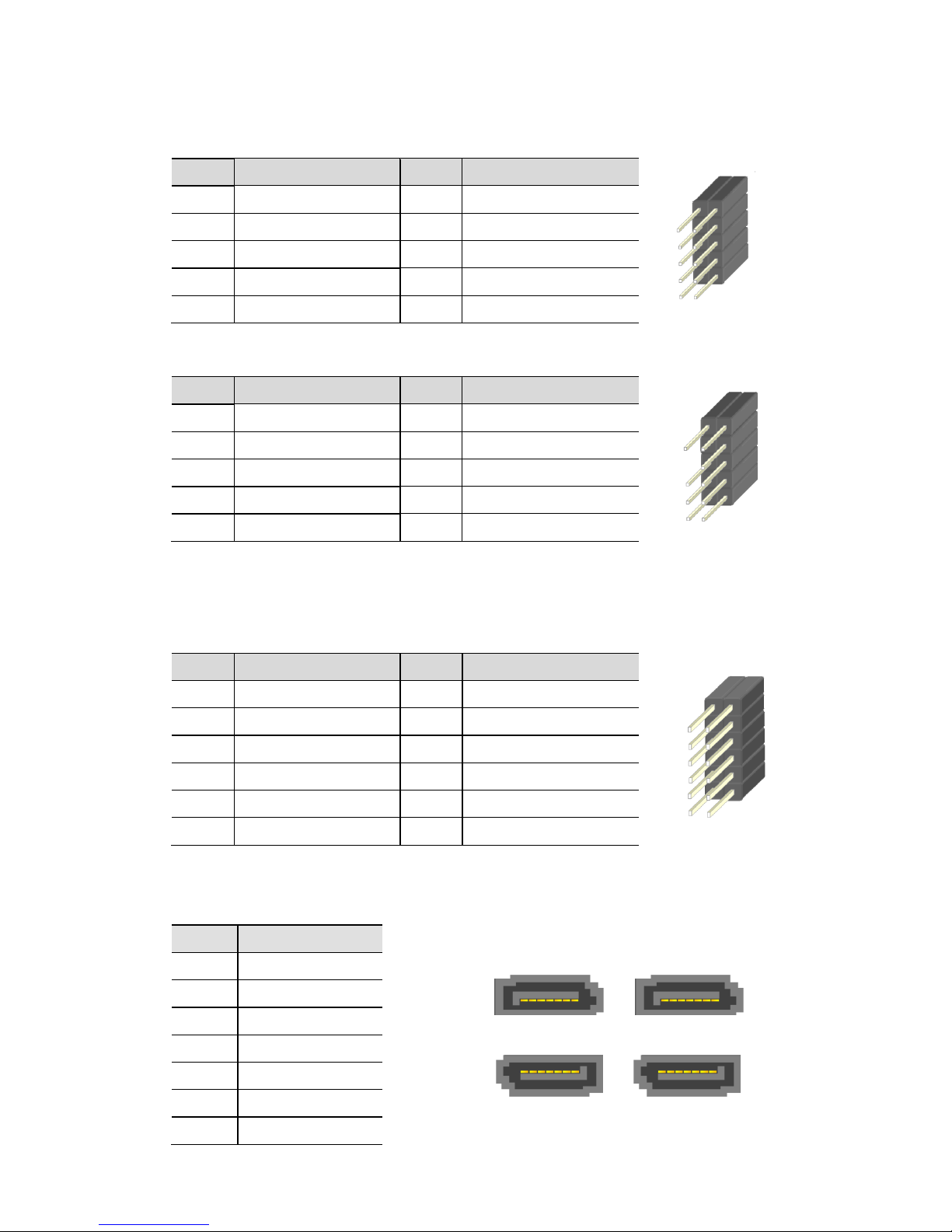

JGP1: GPIO

GPIO pin header

Pin

Description

Pin

Description

1

GPO_GPIO50

2

GPI_GPIO22

3

GPO_GPIO52

4

GPI_GPIO38

5

GPO_GPIO54

6

GPI_GPIO48

7

GPO_GPIO18

8

GPI_GPIO39

9

GND

10

GND

J80PORT1 : 80Port Debug

Pin

Description

Pin

Description

1

CLK

2

LAD1

3

RST-

4

LAD0

5

LRAME-

6

P3V3

7

LAD3 8 9 LAD2

10

GND

LOM1: LAN

An internal LAN pin header to serve as LOM port. Please be noted that the LOM function is

optional and has to be enabled via IPMI/OPMA.

Pin

Description

Pin

Description

1

MGT0_MDIP_0

2

MGT0_MDIN_0

3

MGT0_MDIP_1

4

MGT0_MDIN_1

5

MGT0_MDIP_2

6

MGT0_MDIN_2

7

MGT0_MDIP_3

8

MGT0_MDIN_3

9

IPMI_SPEED_100_L_N

10

IPMI_ACT_L_N

11

IPMI_SPEED_1G_L_N

12

IPMI_P3V3_AUX_L

SATA1~SATA4: SATA

SATA 7-pin signal connector for SATA storage devices

Pin

Description

1

GND

2

TX_P

3

TX_M

4

GND

5

RX_M

6

RX_P

7

GND

11 22

99 1100

SATA2 SATA1

SATA4 SATA3

77665544332211 77665544332211

11223344556677 11223344556677

1100 99

22 11

11 22

1111 1122

Page 22

Network Computing Platforms

OPMA1: OPMA socket for IPMI card to activate IPMI functions

LPC

I2C

Debug

UART

Debug

ID

Debug

Control

Analog

Sensor

Power

DVI-I

FAN

FAN

FAN

SOL

LED

USB

Button

ICMB

LAN

Status

OPMA

CON7

OPMA

GND

1

RSVD

3

GND

5

RSVD

7

GND

9

LDRQ_L

11

LFRAME_L

13

LAD0

15

LCLKRUN_L

17

LAD1

19

LAD2

21

LAD3

23

SERIRQ

25

LRST_L

27

LCLK

29

GND

31

RSVD

33

RSVD

35

GND

37

I2C_PRIV0_SCL

39

I2C_PRIV0_SDA

41

GND

43

I2C_IPMB_SCL

45

I2C_IPMB_SDA

47

GND

49

I2C_SB_NIC_SCL

51

I2C_SB_NIC_SDA

53

I2C_SB_NIC_ALERT

55

GND

57

I2C_PRIV1_SCL

59

I2C_PRIV1_SDA

61

GND

63

I2C_SHARED_SCL

65

I2C_SHARED_SDA

67

GND

69

DEBUG_IF0

71

DEBUG_IF1

73

DEBUG_IF2

75

DEBUG_IF3

77

GND

79

DTR0_L

81

DCD0_L

83

DSR0_L

85

RI0_L

87

RXD0

89

TXD0

91

CTS0_L

93

RTS0_L

95

GND

97

DEBUG_PWR0

99

DEBUG_PWR1

101

GND

103

ID0

105

ID1

107

ID2

109

GND

111

DEBUG_IF4

113

DEBUG_IF5

115

DEBUG_IF6

117

DEBUG_IF7

119

GND

121

LOCAL_LOCK_L

123

SYS_SPKR_DATA

125

CLR_CMOS_L

127

GND

129

CLK_32768

131

GND

133

DETECT_L

135

GND

137

ACOMP_ADC0

139

ACOMP_ADC1

141

ACOMP_ADC2

143

ACOMP_ADC3

145

ACOMP_ADC4

147

ACOMP_ADC5

149

GND

151

SCI_INT_L

153

RSVD

155

GND

157

RSVD

159

RSVD

161

RSVD

163

RSVD

165

GND

167

GND

169

VDD_3.3_DUAL

171

VDD_3.3_DUAL

173

VDD_3.3_DUAL

175

VDD_3.3_DUAL

177

GND

179

GND

181

VDD_5_DUAL

183

VDD_5_DUAL

185

RSVD

187

RSVD

189

RSVD

191

RSVD

193

RSVD

195

GND

197

RSVD

199

RSVD

2

GND

4

RSVD

6

GND

8

DVI_TX0_H

10

DVI_TX0_L

12

GND

14

DVI_TX1_H

16

DVI_TX1_L

18

GND

20

DVI_TX2_H

22

DVI_TX2_L

24

GND

26

DVI_TXCLK_H

28

DVI_TXCLK_L

30

GND

32

DVI_DDC_DATA

34

DVI_DDC_CLK

36

RSVD

38

ANALOG_DDC_DATA

40

ANALOG_DDC_CLK

42

GND

44

ANALOG_RED

46

ANALOG_GREEN

48

ANALOG_BLUE

50

ANALOG_HSYNC

52

ANALOG_VSYNC

54

GND

56

RSVD

58

RSVD

60

GND

62

FAN_PWM_CPU

64

FAN_PWM_SYS

66

FAN_PWM_PS

68

GND

70

FAN_TACH0

72

FAN_TACH1

74

FAN_TACH2

76

FAN_TACH3

78

GND

80

FAN_SEL0_L

82

FAN_SEL1_L

84

FAN_SEL2_L

86

FAN_SEL3_L

88

GND

90

RXD_SOL

92

TXD_SOL

94

GND

96

FAULT_LED_L

98

CHASSIS_ID_L

100

GND

102

USB_P

104

USB_N

106

GND

108

PWRBTN_L

110

RSTBTN_L

112

NMIBTN_L

114

GND

116

AUX_SOL_CTRL_L

118

RSVD

120

GND

122

RXD1

124

TXD1

126

TXD1_ENABLE

128

GND

130

ALL_PWROK

132

SYS_THERMTRIP_L

134

SYS_INTRUDER_L

136

SYS_LINE_AC_L

138

SYS_PWRBTN_L

140

SYS_RSTBTN_L

142

SYS_NMIBTN_L

144

SYS_SMI_L

146

SYS_PCI_RST

148

SYS_ACPI_STATE0

150

SYS_ACPI_STATE1

152

SYS_ACPI_STATE2

154

SYS_IO_EXT_INT_L

156

GND

158

RSVD

160

RSVD

162

RSVD

164

RSVD

166

GND

168

TX_H

170

TX_L

172

GND

174

RX_H

176

RX_L

178

POE_GND

180

POE_PWR

182

POE_PWR

184

POE_GND

186

LAN_BUSY_LED_L

188

LAN_LINK_LED_L

190

GND

192

RSVD

194

GND

196

RSVD

198

GND

200

0000 119999

4422 4411

4400 3399

22 11

Page 23

Network Computing Platforms

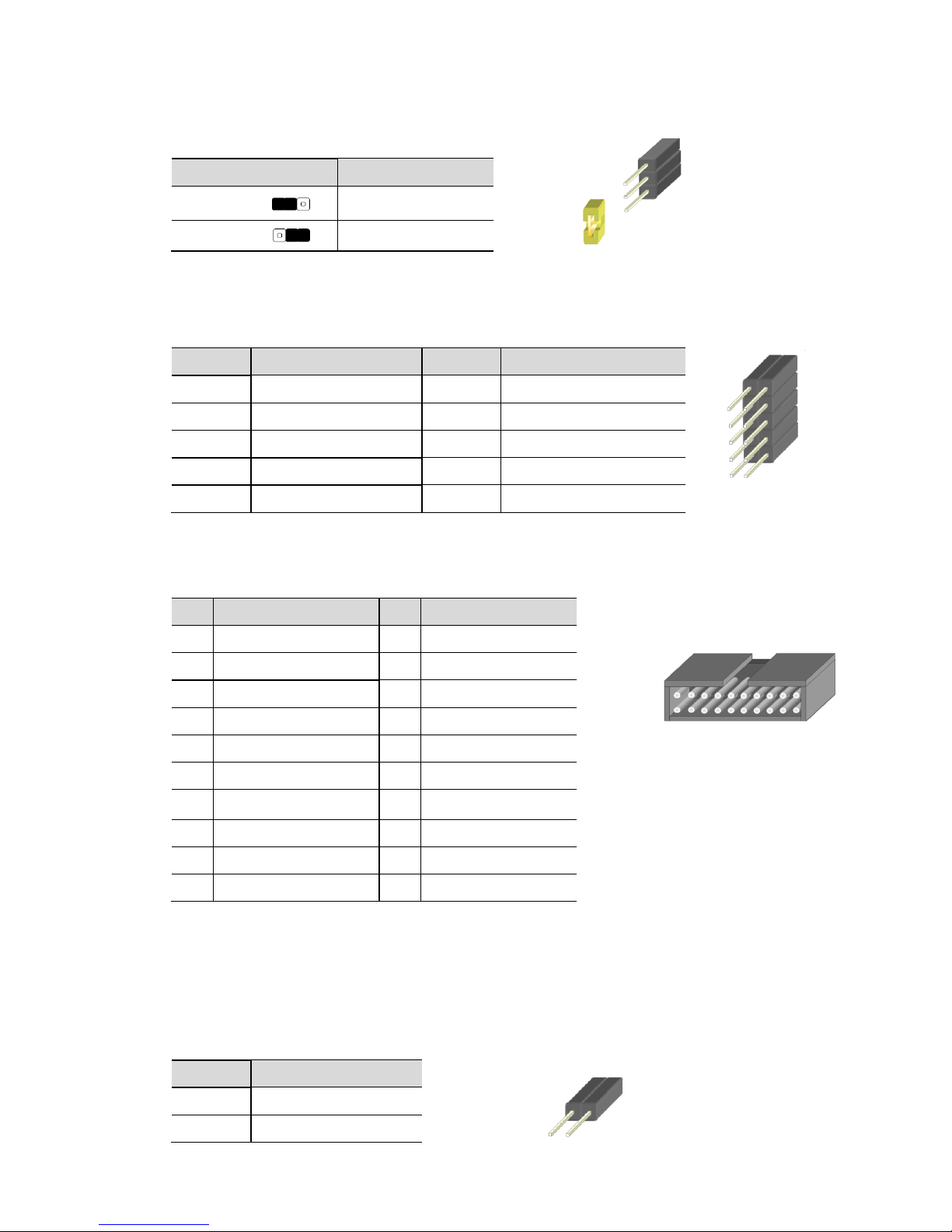

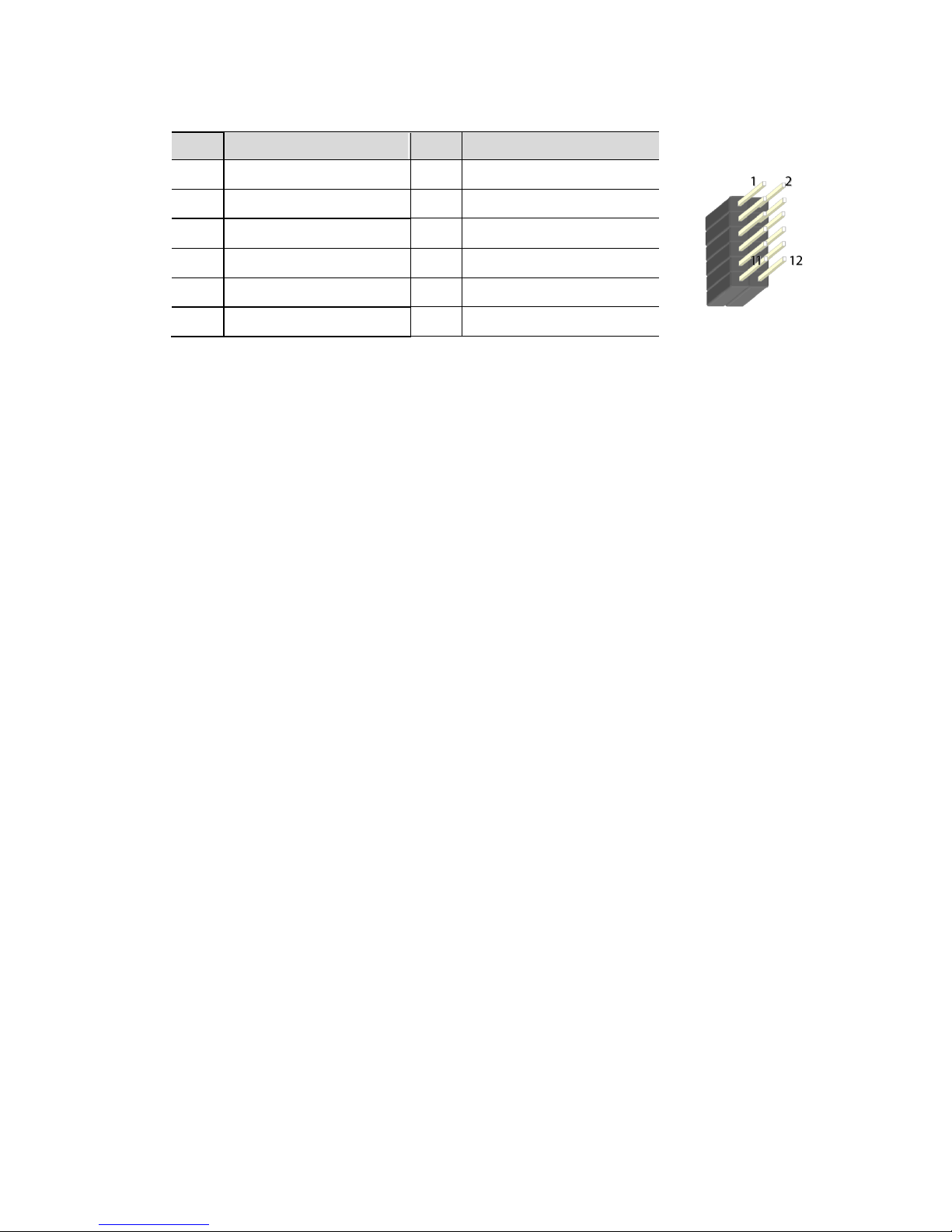

JCMOS1:CMOS

Jumper selection to clear CMOS

JUSB1: USB

USB internal pin header

Pin

Description

Pin

Description

1

USB_VCC

2

USB_VCC

3

USBD0-

4

USBD1-

5

USBD0+

6

USBD1+

7

GND 8 GND

9

USB Port#1Ground

10

USB Port#2 Ground

JUSB2: USB 3.0

USB internal connector with USB2.0 and USB3.0 signals

Pin

Description

Pin

Description

1

P5V_USB2

11

USB20_L_P2

2

USB30_RX1N_L

12

USB20_L_N2

3

USB30_RX1P_L

13

GND

4

GND

14

USB30_TX2P_C_L

5

USB30_TX1N_C_L

15

USB30_TX2N_C_L

6

USB30_TX1N_C_L

16

GND

7

GND

17

USB30_RX2P_L

8

USB20_L_N3

18

USB30_RX2N_L

9

USB20_L_P3

19

P5V_USB2

10

NC

20

NC

OPEN1: CASE OPEN pin header

Chassis Open Detect mainboard protection jumper. (a short-pin cap will be connected to the

top compartment of the system chassis. When the top compartment is lifted/removed, the

board functions will be disabled once the jumper cap is lifted along with the top compartment.

This is to protect the board from being tampered by anyone who remove the top compartment.

Pin

Description

1

GND

2

CSOPEN_N

Pin

Description

Short 1-2

Normal (Default)

Short 2-3

Clear CMOS

11 1100

1111 1122

11 22

99 1100

33

22

11

11 22

Page 24

Network Computing Platforms

ATX2: 4 pin Power Connector

Pin

Description

Pin

Description

1

GND

2

12V

3

CSOPEN_N

4

+12V

FAN1~4: FAN Connectors

4 x 5-pin cooling fan connectors

Pin

Description

1

GND

2

12V

3

RPM Sense

4

RPM Sense

5

PWM Status

ATX1: 8-pin Power Connector

CONN2: ATX Mode Power Switch

Pin

Description

1

GND

2

FP_SWIN_R

CON3

Pin

Description

1

RDPW_TTL1

2

RDPW_TTL2

3

RDPW_TTL3

4

GND 5

6

SMB_PS_CLK

7

SMB_PS_DATA

8

IRQ_SML1_PMBUS_ALERT_N

Pin

Description

Pin

Description

1

GND

2

+12V

3

GND

4

+12V

5

GND

6

+12V

7

GND

8

+12V

55

44

33

22

11

11 77

22 88

22

11

11

22

33

44

55

66

77

88

2 1

4 3

Page 25

Network Computing Platforms

ATX5: 24-Pin ATX Power Connector

Pin

Description

Pin

Description

1

+3.3V 2 +3.3V

3

+3.3V 4 -12V

5

GND 6 GND

7

+5V 8 PSON-

9

GND

10

GND

11

+5V

12

GND

13

GND

14

GND

15

Power Good

16

NC

17

Stand-By 5V

18

+5V

19

+12V

20

+5V

21

+12V

22

+5V

23

3.3V

24

GND

JCOMA1:COM PORT

Serial COM port pin header

Pin

Description

Pin

Description

1

NDCD1

2

NDSR1

3

NRXD1 4 NRTS1

5

NTXD1 6 NCTS1

7

NDTR1 8 NRI1

GND

10

FP_RESET_N

LCM_P1:LCM

LCM module connector

Pin

Description

Pin

Description

1

P5V

2

LCM_P1

3

P_SLIN_N

4

VEE

5

P_AFD_N

6

P_INIT_N

7

LPD1

8

LPD0

9

LPD3

10

LPD2

11

LPD5

12

LPD4

13

LPD7

14

LPD6

15

LCD-

16

VCC

17

KPA1

18

KPA2

23 24

1 2

10 9

2 1

11 22

2233 2244

Page 26

Network Computing Platforms

19

KPA3

20

KPA4

21

LCM_RST

22

CTR_GRN

23

CTR_YEW

24

HDD_LED#

SW1: PSON Power Switch for Debug

Pin

Description

1.2

GND

3.4

FP_SWIN_R

SW3: Reset Switch

Pin

Description

1.2

GND

3.4

FP_RST_SEL

CONN5:

AT Mode Power Switch

J27: Front Panel Reset Jumper

Select Front Panel reset (software reset by default)

Pin

Description

Short 1-2

Hardware Reset

Short 2-3

Software Reset

CON1

Pin

Description

1

12V

2

GND

3

GND 4 5V

Pin

Description

1

GND

2

FP_SWIN_R

44 33

22 11

44 33

22 11

Page 27

Network Computing Platforms

JTPM1: This connector supports a Trusted Platform Module (TPM) system

Pin

Description

Pin

Description

1

LPC_SERIRQ

2

LPC_FRAME_N

3

LPC_LAD0

4

CLK_LPC_OUT

5

LPC_LAD1

6

P3V3_STBY

7

LPC_LAD2

8

NC

9

LPC_LAD3

10

P3V3_A

11

RESET_N

12

GND

Notes: the TPM pin header is configured as optional by default. To enable it, please contact

Lanner for customization order.

Page 28

Network Computing Platforms

Chapter 4: Hardware Setup

Preparing the Hardware Installation

To access some components and perform certain service procedures, you must perform the

following procedures first.

WARNING:

To reduce the risk of personal injury, electric shock, or damage to the equipment, please

remove all power sources.

Please wear ESD protected gloves before conducting the following steps.

1. Power off NCA-5510 completely.

2. Remove the screws at the rear and both sides, as circled in the figures below.

Page 29

Network Computing Platforms

3. Slide and lift the top compartment of the chassis by following the arrows of directions as

defined as step 1 and 2 below.

1

2

Page 30

Network Computing Platforms

Installing the CPU

The motherboard supports one Intel Haswell-EP CPU with LGA2011-R3 socket. Please follow

the steps below for installing the processor.

1. Push the both left and right load levers as shown in the figure below.

2. When both load levers are released, gently pull the left load lever towards the arrow of

direction as shown in the figure below.

3. Now open the load plate and prepare to insert CPU. Align the CPU and the notch on the

socket. The CPU should fit perfectly into the socket. Note that the CPU fits in the socket in only

Page 31

Network Computing Platforms

one direction.

4. Reverse steps 3, 2, and 1 to close the load plate and protective cap, and return the load

levers to its original positions.

5. Prepare the radiation mounting-bracket set as the figure below.

6. Clip the bracket to the edge of the motherboard, which is near the CPU. Make sure the two

screw holes are aligned. Then, apply screws to secure the bracket.

7. Place the bracket along the CPU and apply screws to the holes circled in the figure below.

Page 32

Network Computing Platforms

Page 33

Network Computing Platforms

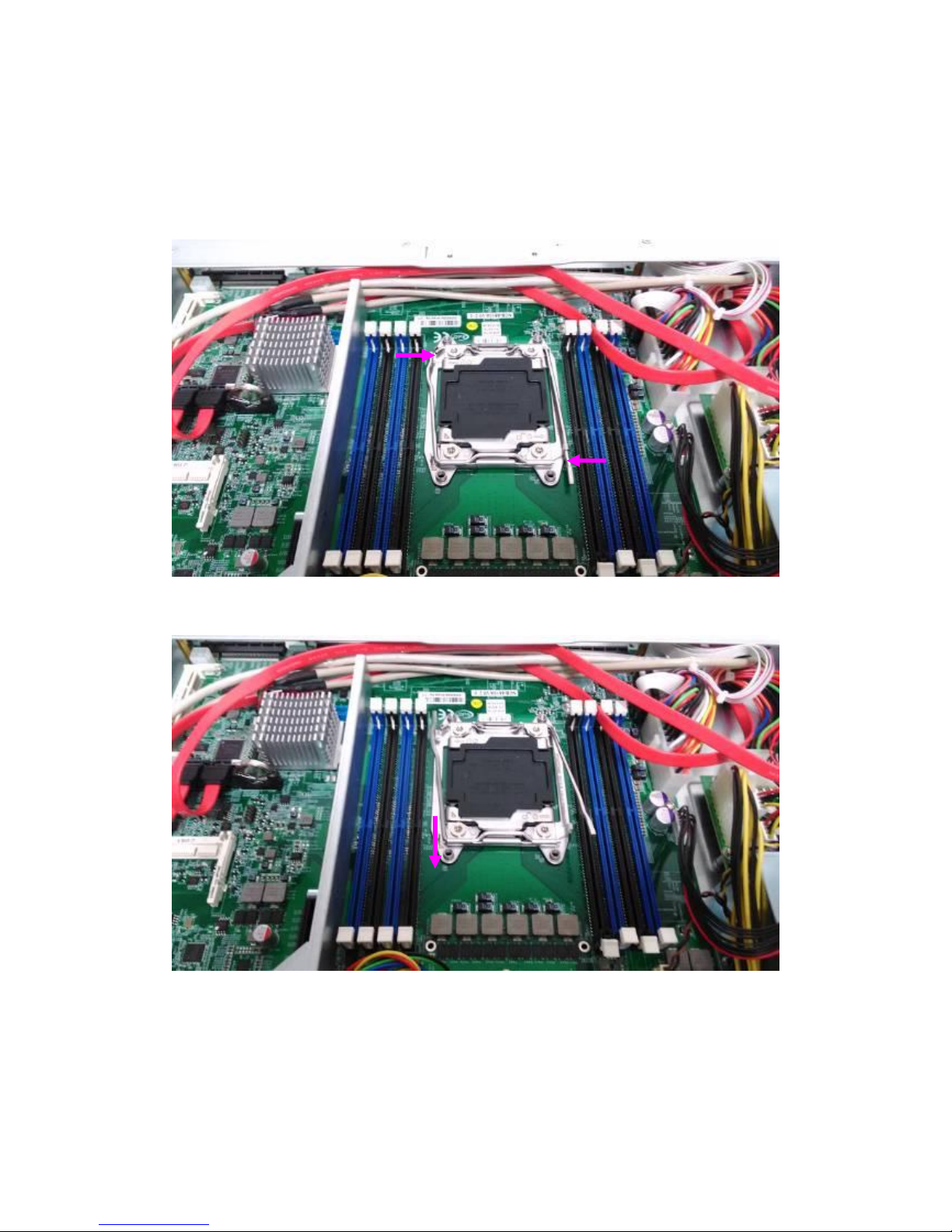

Installing the System Memory

The motherboard supports DDR4 registered DIMM memory for heavy-duty operations. Please

follow the steps below to install the DIMM memory modules.

1. Power off the system.

2. Pull open the DIMM slot latches

3. Align the DIMM module and make sure the notches of the module aligned with the socket

keys in the slot.

4. Insert the module into the slot until it’s firmly seated.

Page 34

Network Computing Platforms

Installing Disk Drives

The system supports 1 x 3.5” or 2 x 2.5” SATA HDDs or SSDs (max 9.5mm height) as data

storage. Please follow the steps below for installation.

1. Remove the 4 screws that secure the disk drive tray.

2. Take the tray out from the system and refer to the figures below for either 1x 3.5” SATA

HDD/SSD or 2 x 2.5” SATA HDD/SSD mounting option.

3. Place the HDD/SSD mounted disk drive tray back to the system. Remember to connect

Page 35

Network Computing Platforms

SATA 7-pin signal cable and SATA 15-pin power cable to the installed disk drives.

4. Please remember to establish SATA connections to the motherboard.

Page 36

Network Computing Platforms

Installing a CFast Card

The motherboard provides one CFast slot. Follow the procedures below for installing a CFast

card.

1. Locate the CFast socket.

2. Insert a CFast card until completed seated.

Installing an IPMI Card

The motherboard provides one OPMA socket which is used to install an IPMI card. Please

follow the steps below for instructions.

1. Locate the OPMA socket.

2. Insert an IPMI card into the socket until it is firmly seated. Please be noted that the insertion

is similar to installing a SO-DIMM module.

Page 37

Network Computing Platforms

Replacing Redundant Power Supply Unit

NCA-5510 comes with two redundant power supply units. To replace a power supply unit

when it reaches the end of its lifetime, please follow the steps below.

1. Hold the handle and the locking clip at the same time.

2. Apply some force and pull it out.

Notes: the power supply unit must meet the specifications of DC output 12V/24A, 300W

Locking Clip

Handle

Page 38

Network Computing Platforms

Replacing Cooling Fans

NCA-5510 supports 4 cooling fans. To replace a worn-down fan, please follow the steps

below.

1. Rotate and loosen the locks for the fan to be replaced.

2. Hold the lock and pull fan out.

3. Insert a new cooling fan. Push it to the end and rotate the lock until it is locked and secured.

Page 39

Network Computing Platforms

Installing Ethernet NIC Modules

NCA-5510 can fit up to 4 Ethernet NIC modules to expand its network throughput. Please

follow the instructions below.

Notes: For information about compatible modules, please refer to the “Ordering Information”

and “Optional Accessories” sections, or contact Lanner for more details.

1. Remove the two screws on the bezel of the module slot and open the bezel. It is strongly

recommended to use mini-sized screwdriver to perform this task.

2. Position the gold finger of module as shown in the image below. When sliding the module

into the slot, make sure the module stays in the guides of the expansion slot.

3. Slide your Ethernet NIC module into the space, until it is firmly attached.

Page 40

Network Computing Platforms

4. Secure the module with two screws on the bezel.

Page 41

Network Computing Platforms

Installing Riser Card (Optional)

NCA-5510 supports 1 x Riser Card installation. Please follow the steps below for installation.

Please be noted that riser card is an optional and not included by default.

1. Remove the screws circled in the figure below and then take out the divider compartment

which comes with a PCIe expansion slot.

2. Remove the screw that locks the PCIe expansion slot.

3. Attach a riser card to the bracket by applying 3 screws as circled in the figure below.

Page 42

Network Computing Platforms

4. Mount the riser card into the riser card socket. Meanwhile, mount the protection bracket

back into its original place.

Page 43

Network Computing Platforms

Rackmount Installation

Attach the Inner Rails

1. Check the package contents.

2 x 438mm Slide-Rails

1 x pack of screws

2. Turn a slide rail upside down and release the inner bracket.

4. Slide the inner bracket all the way up to end of the slide-rail assembly. You may

hear a “click” sound.

5. Push the white slide-rail lock outwards as the arrow of direction below. Then pull

the inner bracket out of the slide-rail assembly.

6.

Releas

e the inner bracket as shown below.

Page 44

Network Computing Platforms

7. Align the inner bracket to the side of the chassis and make sure the screw-holes are

matched. Then secure the bracket onto the chassis with provided screws.

8. Repeat Steps 2 to 7 for another slide-rail and attach its inner bracket onto another

side of the chassis.

Installing Slide Rails

1. In the previous section, you have already detached the inner brackets and attached

them onto the chassis of your purchased model. By now, you shall install the slide-rail

assemblies onto the rack.

As the image below, this slide-rail kit does NOT require screw-fixing. Simply aim at 3

available screw holes on the rack-front and lock it by clipping the slide-rail assembly

to the rack-front as shown in the image below. You should hear a “click” sound once it

is firmly attached.

2. For the rear rack installation, also aim at 3 available holes and click the slide-rail

assembly onto the rear rack.

Click

Page 45

Network Computing Platforms

3. Repeat Step 1 and 2 for another slide-rail assembly in order to install in onto the

rack.

Installing NCA-5510 onto the Rack

Reminder: it is strongly recommended to carry out this procedure with two or three

persons.

Click

Page 46

Network Computing Platforms

1. Hold the applicable model with its front facing you, lift the chassis and gently

insert the model by aligning with the slide-rail assemblies, as shown in the image

below. Then push the model as far as possible.

2. Simultaneously push the release tabs on both sides in the arrow of direction below,

while pushing the appliance into the end of the rack.

Caution: the appliance will be locked during the half way of sliding-in if the release

tabs are not pushed.

Page 47

Network Computing Platforms

3. To slide the appliance out, gently pull it outwards. Then, press the slide-rail locks

on both side and slide the appliance out.

Page 48

Network Computing Platforms

Chapter 5: BIOS Setup

To enter the BIOS setup utility, simply follow the steps below:

1. Boot up the system.

2. Press <Delete> during the boot-up. Your system should be running POST

(Power-On-Self-Test) upon booting up.

3. Then you will be directed to the BIOS main screen.

4. Instructions of BIOS navigations:

[<--] [-->]: select a setup screen, for instance, [Main], [Advanced], [Chipset], [Boot], [Security],

and [Save & Exit]

[↑] [↓]: select an item/option on a setup screen

Enter: select an item/option or enter a sub-menu

ESC: exit the current screen

+/- = to adjust values for the selected setup item/option

F1 = to display General Help screen

F2 = to retrieve previous values, such as the parameters configured the last time you had

entered BIOS.

F3 = to load optimized default values

F4 = to save configurations and exit BIOS

Notes: the images in the following section are for reference only

Page 49

Network Computing Platforms

Main

The [Main] is the first setup screen when you enter BIOS. The [Main] displays general system

and BIOS information

and you may configure the “System Language”, “System Date”, and “System Time”.

BIOS Information

BIOS Vendor: displays BIOS vendor information

Core Version: displays the BIOS core version

Compliancy: displays the BIOS compliancy

Project Version: displays BIOS project version

Build Date and Time: displays the date and time the BIOS was built.

Press “Enter” if you want to configure “System Language”, “System Date”, and “System

Time”.

System Language: English

System Date: Day/Month/Year

System time: Hour/Minutes/Seconds

Access Level: Administrator by default

Page 50

Network Computing Platforms

Advanced

Use [<--] / [-->] to select [Advanced] setup screen. Under this screen, you may use [↑] [↓] to

select an item you wish to configure.

Above 4G Decoding

This option enables or disables 64bit capable devices to be decoded in above 4G address

space (only if the system supports 64bit PCI decoding). You may select “Enabled” or

“Disabled”.

SR-IOV Support

This option enables or disables SRIOV (Single Root I/O Virtualization) support. You may

Page 51

Network Computing Platforms

select “Enable” or “Disable”.

NCT6776 Super IO Configuration

Press “Enter” to access configuration sub-menu for super IO chip (NCT6776) parameters.

You may access settings for Serial Port 1 or 2 or the Parallel port.

NCT6776 Super IO Configuration - Serial Port 1 Configuration

The super IO chip for this model is NCT6776. You may enable or disable Serial Port 1(COMA).

Page 52

Network Computing Platforms

Press “Enter” to enable or disable the Serial Port 1 (COMA). Device setting is fixed as default.

NCT6776 Super IO Configuration - Serial Port 2 Configuration

Once Serial Port 2 is accessed, you may press “Enter” to enable or disable the Serial Port 2

(COMB). Device setting is fixed as default.

Page 53

Network Computing Platforms

Parallel Port Configuration

This option allows you to set parameters for parallel port (LPT/LPTE).

Page 54

Network Computing Platforms

Once Parallel Port is accessed, you may press “Enter” to enable or disable the Parallel Port.

Device setting is fixed as default.

NCT7904D HW Monitor

This option allows you to view hardware health status.

Page 55

Network Computing Platforms

Page 56

Network Computing Platforms

Serial Port Console Redirection

This option allows you to configure parameters about serial port console redirection. Press

“Enter” to access the submenu.

Console Redirection: select “Enabled” or “Disable” for COM port console redirection.

The default is “Enabled”.

Page 57

Network Computing Platforms

Console Redirection Settings: select this item to enter the setting sub-menu.

COM Console Redirection Settings

Terminal Type: the emulation configuration. Select “VT100”, “VT100+”, “VT-UTF8” or

“ANSI”.

VT100: ASCII character set

Page 58

Network Computing Platforms

VT100+: extends VT100 to support color function keys

VT-UTF8: uses UTF8 encoding to map Unicode characters onto 1 or more

ANSI: Extended ASCII character set

Bits per second: select “9600”, “19200”, “38400”, “57600”, or “115200” for bits per

second. The Bps will determine serial port transmission speed. The speed must be matched

on the other side. Long or noisy lines may require lower speeds

Data Bits: select the value for data bits. In this case, “7” or “8”.

Page 59

Network Computing Platforms

Parity Bits: a parity bit can be sent with the data bits to detect some transmission errors.

Select “None”, “Even”, “Odd”, “Mark” or “Space”.

Stop Bits: stop bits indicate the end of a serial data packet. The standard is 1 stop bit.

Communication with slow devices may require more than 1.

Page 60

Network Computing Platforms

Flow Control: flow control can prevent data loss from buffer overflow. When sending data, if

the receiving buffers are full, a “stop” signal can be sent to stop the data flow. You may select

“None” or “Hardware RTS/CTS”, depending on the circumstances.

VT-UTF8 Combo Key Support: this option enables/disables VT-UTF8 combination key

support for ANSI/VT100 terminals.

Page 61

Network Computing Platforms

Recorder Mode: on this mode, when “Enabled”, only text will be sent. This is to capture

terminal data.

Resolution 100 x 31: select “Enable” or “Disable” for extended terminal resolution.

Page 62

Network Computing Platforms

Legacy OS Redirection Resolution: select “80x24” or “80x25”. The default for this case

is “80x24”.

Putty KeyPad: select Function Key and Key Pad on Putty. You may select “VT100”,

“LINUX”, “XTERMR6”, “SCO”, “ESCN”, or “VT400”.

Page 63

Network Computing Platforms

Redirection After BIOS POST: The settings specify if BootLoader is selected than Legacy

console redirection is disabled before booting to Legacy OS. Default value is “Always Enable”

which means Legacy OS console redirection is always enabled after BIOS.

Trusted Computing

This option allows you to configure Trusted Computing Settings.

Page 64

Network Computing Platforms

Configuration - Security Device Support

This option enables or disables BIOS support for security devices, such as TPM module. OS

will not show Security Device. TCG EFI protocol and INT1A interface will not be available.

Note: to enable this function, TPM module must have been installed or else it will only show

“No Security Device” under “Current Status Information”.

USB Configuration

This option allows you to configure USB device Settings.

Page 65

Network Computing Platforms

USB Module Version: displays USB module version

USB Devices: displays USB devices

Legacy USB Support: this function enables or disables legacy USB support. Auto option

disables legacy support if no USB devices are connected. Disable option will keep USB

devices available only for EFI applications.

EHCI Hand-off: enables or disables EHCI Hand-off function. This is a workaround for

operating systems without EHCI hand-off support. The EHCI ownership change should be

claimed by EHCI driver.

Page 66

Network Computing Platforms

USB Mass Storage Driv: this option allows you to enable or disable USB mass storage

driver. The default is “Enabled”.

Port 60/64 Emulation: this option enables I/O port 60h/64h emulation support. This should

be enabled for the complete USB keyboard legacy support for non-USB aware operating

systems.

Page 67

Network Computing Platforms

USB transfer time-out: set USB time-out value (1, 5, 10 or 20 seconds) for Control, Bulk

and Interrupt transfers.

Device reset time-out: set USB mass storage device Start Unit command time-out (10, 20,

30 or 40 seconds).

Page 68

Network Computing Platforms

Device power-up delay: set the maximum time the device will take before it properly

reports itself to the Host Controller. “Auto” uses default value. For example, it is 100ms as a

root port.

LAN Boot Select

This option allows you to select one of the onboard LAN boot. Press “Enter” to access the

sub-menu.

Page 69

Network Computing Platforms

On Board LAN Boot: select “Disabled” or “MGT1” management port booting priority.

Page 70

Network Computing Platforms

IntelRCSetup

Use [<--] / [-->] to select [IntelRCSetup] setup screen. Under this screen, you may use [↑] [↓]

to select an item you want to configure.

RC Revision: displays RC revision information

Numa: enables or disables Non-Uniform Memory Access (NUMA)

IOAT Configuration

Press Enter to access the sub-menu of all IOAT (Intel I/O Acceleration Technology)

configuration items.

Enable IOAT: enables or disables IOAT devices. This function allows you to enable Intel I/O

Acceleration Technology which benefits system data flows by reducing CPU overheads. The

Page 71

Network Computing Platforms

freed CPU resources will improve system responsiveness and avoid performance bottleneck.

No Snoop: no snoop enable/disable for each CB device

Page 72

Network Computing Platforms

Disable TPH: TLP Processing Hint disable

Relaxed Ordering: relaxed ordering enable/disable.

Page 73

Network Computing Platforms

Intel (R) VT for Directed I/O (VT-d) Configuration

This option allows users to configure items of Intel Virtualization Technology for Directed I/O

(VT-d). Press “Enter” to access its sub-menu.

VTd Azalea VCp Optimization: this option allows you to enable or disable Azalea VCp

Optimization.

Page 74

Network Computing Platforms

Intel VT For Directed I/O (VT-d): enable or disable Intel Virtualization Technology for

Directed I/O (VT-d) by reporting the I/O device to VMM through DMAR ACPI tables.

Interrupt Remapping: enable or disable VT-d Interrupt Remapping support.

Page 75

Network Computing Platforms

Coherency Support (Non-Isoch): enable or disable VT-d Engine Coherency support.

Coherency Support (Isoch): enable or disable Isoch VT-d Engine Coherency support

Page 76

Network Computing Platforms

IIO0 Configuration

This function allows users to check PCIe port lane width switch status. Press Enter to access

the sub-menu.

Set PCIE Port Bifurcation By Present Card Lane: displays PCIe port information and

status

Page 77

Network Computing Platforms

Processor Configuration

This function allows users to view and configure options that can change processor settings.

Press Enter to access the sub-menu.

Processor Configuration: displays processor status and information.

Page 78

Network Computing Platforms

Execute Disable Bit: an Intel hardware-based protection against malicious code. It will

detect the memory in which a code can be executed or not. When enabled, it will prevent

certain classes of malicious buffer overflow attacks when combined with a supporting OS.

When disabled, it forces the XD feature flag to always return 0.

AES-NI: enables or disables AES-NI (Advanced Encryption Standard - New Instruction)

support.

Page 79

Network Computing Platforms

PCH Configuration

This function allows users to view and configure PCH settings. Press Enter to access the

sub-menu.

PCH State after G3: select S0/S5 for ACPI state after a G3. The default is “Last State”.

Page 80

Network Computing Platforms

PCH SATA Configuration

Press Enter to access items for SATA devices and settings.

SATA Controller: enables or disables SATA controller

Page 81

Network Computing Platforms

Configure SATA as: this item identifies whether the SATA port is connected to a SSD and

HDD. Select IDE, AHCI or RAID. The default is “AHCI”.

SATA Port 0/1/2/3/4: displays status of SATA port 0/1/2/3/4

Software Preserve: displays information of Software Preserve

Port 0/1/2/3/4: enable or disable this SATA port

* The captured images are based on SATA port0 only. All SATA ports configurations on this

BIOS version are identical.

Page 82

Network Computing Platforms

Hot Plug: designates this port as hot pluggable

Spin Up Device: if enabled for any of ports, Staggered Spin Up will be performed and only

the drives which have this option enabled will spin up at boot. Otherwise all drives spin up at

boot.

Page 83

Network Computing Platforms

SATA Device Type: identifies the SATA port is connected to SSD (Solid State Drive) or

HDD (Hard Disk Drive).

Security

Use [<--] / [-->] to select [Security] setup screen. Under this screen, you may use [↑] [↓] to

select an item you want to configure.

Administrator Password: set administrator password. Once set, then this only limits

access to Setup and is only asked for when entering Setup.

User Password: set user password. Once set, then this is a power-on password and must

be entered to boot or enter Setup. In Setup, the user will have Administrator rights.

Page 84

Network Computing Platforms

Boot

Use [<--] / [-->] to select [Boot] setup screen. Under this screen, you may use [↑] [↓] to select

an item you want to configure.

Boot Configuration

Setup Prompt Timeout: number of seconds to wait for setup activation key. “65535

(0xFFFF)” means indefinite waiting.

Bootup Numlock State: select the keyboard “Numlock” state

Page 85

Network Computing Platforms

Quiet Boot: this option allows you to enable or disable “Quiet Boot”. The default is

“Disabled” based on Intel’s server environment setting.

Boot Option #1: set devices as boot option #1

USB Device BBS Priorities: set USB device BBS priorities

Page 86

Network Computing Platforms

Save & Exit

Use [<--] / [-->] to select [Save & Exit] setup screen. Under this screen, you may use [↑] [↓] to

select an item you want to configure.

Save Changes and Exit: exit system setup after saving the configuration changes

Discard Changes and Exit: exit system setup without saving the configuration changes

Save Changes and Reset: reset the system after saving the configuration changes

Discard Changes and Reset: reset the system without saving the configuration changes

Save Options

Save Changes: save the configuration changes

Discard Changes: discard all the configuration changes

Restore Defaults: restore to factory default setting

Save as User Defaults: save changes as the new user default

Restore User Defaults: restore the user default

Boot Override

AMI Virtual CDROM0 1.00

Page 87

Network Computing Platforms

Appendix A: Programming Watchdog Timer

A watchdog timer is a piece of hardware that can be used to automatically detect system

anomalies and reset the processor in case there are any problems. Generally speaking, a

watchdog timer is based on a counter that counts down from an initial value to zero. The

software selects the counter’s initial value and periodically restarts it. Should the counter reach

zero before the software restarts it, the software is presumed to be malfunctioning

and the processor’s reset signal is asserted. Thus, the processor will be restarted as if a

human operator had cycled the power.

For sample watchdog code, see folder under Driver and Utility on the

Page 88

Network Computing Platforms

Appendix B: Setting up Console

Redirection

Console redirection lets you monitor and configure a system from a remote terminal computer

by re-directing keyboard input and text output through the serial port. These following steps

illustrate how to use this feature. The BIOS of the system allows the redirection of console I/O

to a serial port. With this configured, you can remotely access the entire boot sequence

through a console port.

1. Connect one end of the console cable to console port of the system and the other end to

serial port of the Remote Client System.

2. Configure the following settings in the BIOS Setup menu:

BIOS > Advanced > Remote Access Configuration > Serial Port Mode > [115200, 8 , n ,1 ]

3. Configure Console Redirection on the client system. The following is an example on

Windows platform:

a. A. Click the start button, point to Programs > Accessories > Communications and select

Hyper Terminal.

b. B. Enter any name for the new connection and select any icon.

c. Click OK.

d. From the “Connect to”. Pull-down menu, select the appropriate Com port on the client

system and click OK.

e. Select 115200 for the Baud Rate, None. for Flow control, 8 for the Data Bit, None for Parity

Check, and 1 for the Stop Bit.

Page 89

Network Computing Platforms

Appendix C: Programming Generation 3

LAN Bypass

The bypass function is used to link two independent Ethernet ports when the system crashes

or powers off. This means if your system is equipped with a LAN Bypass function, a condition

in your system will not interrupt your network traffic. Different from the previous two

generations (Gen1 and Gen2), the Lanner Bypass Gen 3 employs a programming method to

control the bypass function by software. There are typically two communication status for the

bypass function, one is “Normal” and another is “Bypass” status. Furthermore, the Lanner

Bypass software is capable to control the bypass status in the following 3 instances.

1. When the system powers off, it can be forced to enable the LAN Bypass function.

2. When the system is in the just-on state which is a brief moment when it powers up.

3. When the system is running

Please refer to the LAN_Bypass_Watchdog folder on the Driver and Manual CD.

Lanner bypass possess the following features:

1. Communication through SMBUS (I2C)

2. Independent bypass status control for each pair up to a total of 4 pairs

3. Lanner Bypass Modules can bypass systems Ethernet ports on a host system during three

instances: Just-on (Just-on is the brief moment when the internal power supply turns on and

booting process starts), System off, or upon software request (during run-time).

4. Software programmable bypass or normal mode

5. Software programmable timer interval:

- JUST-ON watchdog timer, used during JUST-ON, has timer setting of 5~1275 seconds of

timer interval.

- Run-Time watchdog timer, used during run-time, has setting of 1~255 seconds of timer

interval.

6. Multiple Watchdog Timers:

-Two for run-time: It is designed to give you a more variety of controls of the bypass on port

basis. By using dedicated watchdogs for different pairs of bypass, you have the flexibility to

manage the bypass status for them differently.

-One for just-on: It is designed to give you the precise control of the bypass during this phase.

You can use this timer to delay enabling the bypass in just-on state.

For sample LAN bypass code and the Bypass Manual, see the LAN_Bypass folder on the

Driver and Manual CD or the Lanner Support Website at

http://www.lannerinc.com/download-center/ and browse the download center and look for

Page 90

Network Computing Platforms

Lanner LAN Bypass Watchdog User Manual under the Accessories folder.

Fro a description of the physical LAN ports equipped with this function, refer to Front Panel

Features in Chapter1 Introduction.

Page 91

Network Computing Platforms

Appendix D: Programming the LCM

The LCD panel module (LCM) is designed to provide real-time operating status and

configuration information for the system. For sample LCM code, see LCM folder in the Driver

and Manual CD. The driver and the program library can also be found in the folder.

The system supports the following 2 kinds of LCM:

• Parallel Text-based LCM: The LCM connects to the motherboard’s parallel port. The LCD

screen can display 2 lines, 16 (or 20) characters per line.

• USB and Serial Text or Graphic-based LCM: Our next generation LCM. Lanner engineers

design a common source code to be deployed on these two differently interfaced LCM

modules. Jumpers are used to select between text and graphic types. See next section.

For Parallel Text-based LCM

Build

To build program source code on Linux platform, please use the following steps as a guideline:

1. Extract the source file:

# tar -xzvf plcm_drv_v0XX.tgz

(0XX is the version of the program.)

2. Change directory to the extracted folder:

# cd plcm_drv_v0XX

(0XX is the version of the program.)

Note: Apply our Parallel Text-based LCM to the environment of virtualization, please use the

version 013 or above of the program.

3. Type “make” to build source code:

# make

After compiling, the executable programs (plcm_test, plcm_cursor_char, ppdev_test, Test)

and the driver (plcm_drv.ko) will appear in the program’s folder.

Note: The OS supported by Parallel Text-based LCM function includes platforms based on

Linux Kernel series 2.4.x, Linux Kernel series 2.6.x and Linux Kernel series 3.0.x or above.

Install

Install the driver and create a node in the /dev directory by:

#insmod plcm_drv.ko

#mknod /dev/plcm_drv c 248 0

Page 92

Network Computing Platforms

Note:

If you cannot install the driver, check whether you have enabled the parallel port in the

BIOS setting . Once the message of “insmod”: error inserting ‘plcm_drv.ko’: -1

Input/output

error” appears, please check that whether the major number is repeated or not. The

major number needed with the “mknod” command varies with different software

versions; please look up the Readme file for this value.

Execute

This section contains sample executable programs that you could test on your platform. It

demonstrates some useful functionality that the LCM provides. Note that the installation needs

to be completed before proceeding with these executions.

To execute, run the command:

#./plcm_test

Backlight Off/On turning off/on the backlight of the LCM display

Display Off turning off the LCM display

Cursor Off/On NOT showing/showing the cursor on the LCM display

Blinking off/On turning off/on the cursor blinking

Writing “Lanner@Taiwan” displaying the specific sentences

Reading “Lanner@Taiwan” reading the specific sentence

CGram Test displaying the user-stored characters

Keypad Testing Get the keypad input: the 1st button is read in as Left, the 2nd button is read

in as Up, the 3rd button is read in as Right, and the 4th button is read in as Down)

Corresponding Commands for “plcm_test”

You can directly input the specific command to have its corresponding function worked on your

LCM. This will be much more convenient once you would like to merely execute the keypad

testing.

-On

— Turn on the backlight of the LCM display.

— To execute, please type:

#./plcm_test -On

-Off

— Turn off the backlight of the LCM display.

— To execute, please type:

#./plcm_test –Off

-LCM1

— Writing “Lanner@Taiwan” in line1.

— To execute, please type:

Page 93

Network Computing Platforms

#./plcm_test -LCM1

-LCM2

— Writing “2013-11-05” in line 2.

— To execute, please type:

#./plcm_test -LCM2

Keypad