Page 1

NCA-1513 User Manual

NCA-1513

User Manual

Date of Release:2019-12-26

Network Appliance

Platform

Hardware Platforms for Network Computing

1

Version: 1.0

Page 2

About this Document

Example

Convention

Usage

A command to be entered at a shell

Setup page

Bold

A title of a dialog box or a page

<Enter>

Between a pair of inequality signs

A physical keyboard button

A menu option or a software button to be

clicked

Readme.txt

In Italic

A filename or a file path

The name of another document or a chapter

in this document

Icon

This mark indicates that there is a caution or warning and it is

Note or Information

This manual describes the overview of the various functionalities of this product and the information you

need to get it ready for operation. It is intended for those who are:

- responsible for installing, administering and troubleshooting this system or information technology

professionals.

- assumed to be qualified in the servicing of computer equipment, such as professional system

integrators, or service personnel and technicians.

The latest version of this document can be found on Lanner’s official website, available either

through the product page or through the

password.

Lanner Download Center page with a login account and

Conventions & Icons

This document utilizes different font types and icons in order to make the selected text more transparent

and explicable to users. This document contains the following conventions:

Font Conventions

iptables –F

“Menu” Between a pair of quotation marks

IPMI User Guide Underlined

Monospace, shaded

Icon Descriptions

Warning or Important

This mark indicates that there is something you should pay special

attention to while using the product.

something that could damage your property or product.

command-line

Usage

Online Resources

To obtain additional documentation resources and software updates for your system, please visit the

Lanner Download Center. As certain categories of documents are only available to users who are logged in,

please b

documents and downloadable resources.

For troubleshooting the issues with your system, please visit the

procedures and troubleshooting steps.

e registered for a Lanner Account at http://www.lannerinc.com/ to access published

2

Lanner Q&A page for diagnostic

Page 3

NCA-1513 User Manual

Technical Support

In addition to contacting your distributor or sales representative, you could submit a request to our Lanner

Technical Support at http://www.lannerinc.com/technical-support where you can fill in a support ticket to

our technical support department.

Copyright and Trademarks

This document is copyrighted © 2019 by Lanner Electronics Inc. All rights are reserved. The original

manufacturer reserves the right to make improvements to the products described in this manual at any

time without notice.

No part of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without the prior written permission of the original manufacturer.

Information provided in this manual is intended to be accurate and reliable. However, the original

manufacturer assumes no responsibility for its use, nor for any infringements upon the rights of third

parties that may result from such use.

Documentation Feedback

Your feedback is valuable to us, as it will help us continue to provide you with more accurate and relevant

documentation. To provide any feedback, comments or to report an error, please email

contact@lannerinc.com. Thank you for your time.

3

Page 4

Contact Information

Taiwan Corporate Headquarters

China

No. 9 Huinan Road,

USA

Canada

Lanner Electronics Inc.

7F, No.173, Sec.2, Datong Rd. Xizhi District,

New Taipei City 22184, Taiwan

立端科技股份有限公司

221 新北市汐止區

大同路二段 173 號 7 樓

T: +886-2-8692-6060

F: +886-2-8692-6101

E:

contact@lannerinc.com

Lanner Electronics Inc.

47790 Westinghouse Drive Fremont, CA 94539

T: +1-855-852-6637

F: +1-510-979-0689

E:

sales_us@lannerinc.com

Beijing L&S Lancom Platform Tech. Co., Ltd.

Guodong LOFT 9 Layer

Huilongguan Town, Changping District, Beijing

102208 China

T: +86 010-82795600

F: +86 010-62963250

E:

service@ls-china.com.cn

LEI Technology Canada Ltd

3160A Orlando Drive Mississauga, ON L4V 1R5

Canada

T: +1 877-813-2132

F: +1 905-362-2369

E:

sales_ca@lannerinc.com

Acknowledgment

Intel® and Intel® Atom® are trademarks of Intel Corporation or its subsidiaries in the U.S. and/or other

countries.

Microsoft Windows and MS-DOS are registered trademarks of Microsoft Corp.

All other product names or trademarks are properties of their respective owners.

4

Page 5

NCA-1513 User Manual

Note

Federal Communication Commission Interference Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

FCC Caution

Any changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate this equipment.

This transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

1. An unshielded-type power cord is required in order to meet FCC emission limits and also to prevent interference

2. Use only shielded cables to connect I/O devices to this equipment.

3. Changes or modifications not expressly approved by the party responsible for compliance could void the user’s

1. Operations in the 5.15-5.25GHz band are restricted to indoor usage only.

2. This device meets all the other requirements specified in Part 15E, Section 15.407 of the FCC Rules.

to the nearby radio and television reception. It is essential that only the supplied power cord be used.

authority to operate the equipment.

Important

5

Page 6

Safety Guidelines

Follow these guidelines to ensure general safety:

Keep the chassis area clear and dust-free during and after installation.

Do not wear loose clothing or jewelry that could get caught in the chassis. Fasten your tie or scarf and

roll up your sleeves.

Wear safety glasses if you are working under any conditions that might be hazardous to your eyes.

Do not perform any action that creates a potential hazard to people or makes the equipment unsafe.

Disconnect all power by turning off the power and unplugging the power cord before installing or

removing a chassis or working near power supplies

Do not work alone if potentially hazardous conditions exist.

Never assume that power is disconnected from a circuit; always check the circuit.

Consignes de sécurité

Suivez ces consignes pour assurer la sécurité générale :

Laissez la zone du châssis propre et sans poussière pendant et après l’installation.

Ne portez pas de vêtements amples ou de bijoux qui pourraient être pris dans le châssis. Attachez votre

cravate ou écharpe et remontez vos manches.

Portez des lunettes de sécurité pour protéger vos yeux.

N’effectuez aucune action qui pourrait créer un danger pour d’autres ou rendre l’équipement

dangereux.

Coupez complètement l’alimentation en éteignant l’alimentation et en débranchant le cordon

d’alimentation avant d’installer ou de retirer un châssis ou de travailler à proximité de sources

d’alimentation.

Ne travaillez pas seul si des conditions dangereuses sont présentes.

Ne considérez jamais que l’alimentation est coupée d’un circuit, vérifiez toujours le circuit. Cet appareil

génère, utilise et émet une énergie radiofréquence et, s’il n’est pas installé et utilisé conformément aux

instructions des fournisseurs de composants sans fil, il risque de provoquer des interférences dans les

communications radio.

Lithium Battery Caution

There is risk of explosion if the battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

Installation should be conducted only by a trained electrician or only by an electrically trained person

who knows all installation procedures and device specifications that are to be applied.

Do not carry the handle of power supplies when moving to another place.

Please conform to your local laws and regulations regarding safe disposal of lithium battery.

Disposal of a battery into fire or a hot oven, or mechanically crushing or cutting of a battery can result in

an explosion.

Leaving a battery in an extremely high temperature environment can result in an explosion or the

leakage of flammable liquid or gas.

A battery subjected to extremely low air pressure may result in an explosion or the leakage of flammable

liquid or gas.

Avertissement concernant la pile au lithium

Risque d’explosion si la pile est remplacée par une autre d’un mauvais type.

Jetez les piles usagées conformément aux instructions.

L’installation doit être effectuée par un électricien formé ou une personne formée à l’électricité

connaissant toutes les spécifications d’installation et d’appareil du produit.

Ne transportez pas l’unité en la tenant par le câble d’alimentation lorsque vous déplacez l’appareil.

6

Page 7

NCA-1513 User Manual

Operating Safety

Electrical equipment generates heat. Ambient air temperature may not be adequate to cool equipment

to acceptable operating temperatures without adequate circulation. Be sure that the room in which you

choose to operate your system has adequate air circulation.

Ensure that the chassis cover is secure. The chassis design allows cooling air to circulate effectively. An

open chassis permits air leaks, which may interrupt and redirect the flow of cooling air from internal

components.

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD damage occurs

when electronic components are improperly handled and can result in complete or intermittent failures.

Be sure to follow ESD-prevention procedures when removing and replacing components to avoid these

problems.

Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact. If no wrist strap is

available, ground yourself by touching the metal part of the chassis.

Periodically check the resistance value of the antistatic strap, which should be between 1 and 10

megohms (Mohms).

Sécurité de fonctionnement

L’équipement électrique génère de la chaleur. La température ambiante peut ne pas être adéquate pour

refroidir l’équipement à une température de fonctionnement acceptable sans circulation adaptée.

Vérifiez que votre site propose une circulation d’air adéquate.

Vérifiez que le couvercle du châssis est bien fixé. La conception du châssis permet à l’air de

refroidissement de bien circuler. Un châssis ouvert laisse l’air s’échapper, ce qui peut interrompre et

rediriger le flux d’air frais destiné aux composants internes.

Les décharges électrostatiques (ESD) peuvent endommager l’équipement et gêner les circuits

électriques. Des dégâts d’ESD surviennent lorsque des composants électroniques sont mal manipulés et

peuvent causer des pannes totales ou intermittentes. Suivez les procédures de prévention d’ESD lors du

retrait et du remplacement de composants.

Portez un bracelet anti-ESD et veillez à ce qu’il soit bien au contact de la peau. Si aucun bracelet n’est

disponible, reliez votre corps à la terre en touchant la partie métallique du châssis.

Vérifiez régulièrement la valeur de résistance du bracelet antistatique, qui doit être comprise entre 1 et

10 mégohms (Mohms).

Mounting Installation Precautions

The following should be put into consideration for rack-mount or similar mounting installations:

Do not install and/or operate this unit in any place that flammable objects are stored or used in.

The installation of this product must be performed by trained specialists; otherwise, a non-specialist

might create the risk of the system’s falling to the ground or other damages.

Lanner Electronics Inc. shall not be held liable for any losses resulting from insufficient strength for

supporting the system or use of inappropriate installation components.

Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than room ambient. Therefore, consideration

should be given to installing the equipment in an environment compatible with the maximum ambient

temperature (Tma) specified by the manufacturer.

Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of airflow

required for safe operation of the equipment is not compromised.

Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition

is not achieved due to uneven mechanical loading.

Circuit Overloading - Consideration should be given to the connection of the equipment to the supply

circuit and the effect that overloading of the circuits might have on overcurrent protection and supply

wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing this

concern.

Reliable Grounding - Reliable grounding of rack-mounted equipment should be maintained. Particular

7

Page 8

attention should be given to supply connections other than direct connections to the branch circuit (e.g.,

use of power strips).

Electrical Safety Instructions

Before turning on the device, ground the grounding cable of the equipment. Proper grounding

(grounding) is very important to protect the equipment against the harmful effects of external noise and to

reduce the risk of electrocution in the event of a lightning strike. To uninstall the equipment, disconnect

the ground wire after turning off the power. A ground wire is required and the part connecting the

conductor must be greater than 4 mm2 or 10 AWG.

Consignes de sécurité électrique

Avant d’allumer l’appareil, reliez le câble de mise à la terre de l’équipement à la terre.

Une bonne mise à la terre (connexion à la terre) est très importante pour protéger l’équipement contre

les effets néfastes du bruit externe et réduire les risques d’électrocution en cas de foudre.

Pour désinstaller l’équipement, débranchez le câble de mise à la terre après avoir éteint l’appareil.

Un câble de mise à la terre est requis et la zone reliant les sections du conducteur doit faire plus de 4

mm2 ou 10 AWG.

Grounding Procedure for DC Power Source

Loosen the screw of the earthing point.

Connect the grounding cable to the ground.

The protection device for the DC power source must provide 30

A current.

This protection device must be connected to the power source

before DC power.

Procédure de mise à la terre pour source

d’alimentation CC

Desserrez la vis du terminal de mise à la terre.

Branchez le câble de mise à la terre à la terre.

L’appareil de protection pour la source d’alimentation CC

doit fournir 30 A de courant.

Cet appareil de protection doit être branché à la source

d’alimentation avant l’alimentation CC.

8

Page 9

NCA-1513 User Manual

Instruction for the installation of the conductor to building earth by a skilled person.

This equipment must be grounded. The power cord for product should be connected to a socket-outlet

with earthing connection.

Cet équipement doit être mis à la terre. La fiche d'alimentation doit être connectée à une prise de terre

correctement câblée

Suitable for installation in Information Technology Rooms in accordance with Article 645 of the National

Electrical Code and NFPA 75.

Peut être installé dans des salles de matériel de traitement de l'information conformément à l'article 645

du National Electrical Code et à la NFPA 75.

The machine can only be used in a restricted access location and has installation instructions by a skilled

person (for Fan side).

Les matériels sont destinés à être installés dans des EMPLACEMENTS À ACCÈS RESTREINT.

9

Page 10

Table of Contents

Chapter 1: Product Overview .......................................................... 11

Package Content ......................................................................................................................... 11

Optional Kits ............................................................................................................................... 11

Ordering Information ................................................................................................................. 11

System Specifications ................................................................................................................. 12

Front Panel ................................................................................................................................. 13

Rear Panel ................................................................................................................................... 14

Motherboard Information .......................................................................................................... 15

Chapter 2 Hardware Installation..................................................... 24

Installing Nano SIM Card ............................................................................................................ 25

Mounting an SMA-Mount Antenna Cable Assembly ................................................................. 26

Rack-mounting the System ........................................................................................................ 27

Chapter 3 Software Setup ............................................................... 29

BIOS Setup .................................................................................................................................. 29

Appendix A: LED Indicator Explanations ....................................... 72

Appendix B: Network Interface Renaming ..................................... 73

Prerequisite ................................................................................................................................ 73

Description ................................................................................................................................. 73

Config(rnif.conf) ......................................................................................................................... 73

Appendix C: Terms and Conditions ................................................ 78

Warranty Policy .......................................................................................................................... 78

RMA Service ................................................................................................................................ 78

RMA Service Request Form ........................................................................................................ 79

10

Page 11

NCA-1513 User Manual

SKU No.

Main Features

NCA-1513A

Atom 4C C3558 w/QAT + 6x GbE RJ45 with 2 pair bypass function

NCA-1513B

Atom 2C C3308 w/QAT+ 6x GbE RJ45 with 2 pair bypass function

NCA-1513C

Atom 2C C3338 w/o QAT + 4x GbE RJ45 without bypass function

NCA-1513D

Atom 4C C3558 w/QAT +2x SFP + 4x GbE RJ45 with 2 pair bypass function

NCA-1513

Power Cord

CHAPTER 1: PRODUCT OVERVIEW

NCA-1513 series is an Intel ATOM based system desktop platform, based on 4-Core CPU with max 6x GbE

copper ports or 4xGbE + 2x SFP ports (by SKU). The system is targeted at low-cost desktop with ECC or

Non-ECC DDR4 memory support.

Package Content

Your package contains the following items:

1 x NCA-1513 series Network Security Platform

1 x Power cord(Default US Type)

1 x 40W power adaptor

1 Accessory Pack including 4 x Rubber foot + 1 x Plastic Spacer + 3 x Screw

Optional Kits

Ear Bracket with adaptor Holder kit

HDD Kit

WIFI Kit

LTE Kit

Ordering Information

Power Adapter

Accessory Pack

11

Page 12

System Specifications

Form Factor

Desktop

SKU A/D: Intel Atom C3558, 2.2GHz

SKU C: Intel Atom C3338, 1.5GHz

CPU Socket

1x BGA

Chipset

N/A

Security Acceleration

Intel® QuickAssist Technology (SKU A/B/D)

BIOS

AMI SPI Flash BIOS

DDR4 2133MHz ECC / Non-ECC (1866MHz

for C3308/C3338; 2133MHz for C3558)

Max. Capacity

16GB

DIMM )

SKU A: 6x GbE RJ45 (4x Marvell 88E1543 +

(4x Marvell 88E1543 +2x Intel i210-IS)

Bypass

SKU A/B/D: 2 pair bypass

NIC Module Slot

N/A

IO Interface

N/A

OPMA slot

N/A

Reset Button

1

LED

Power/Status/HDD/LAN

Power Button

1x Power Switch

Console

1x RJ45

LCD Module

N/A

Display

N/A

Power input

12V DC power inlet

HDD/SSD Support

1x 2.5” HDD/SSD Internal Bays

Onboard Slots

1x M.2 (w/ SATA support)

1x M.2 2280/2242 B Key for storage

1x M.2 3042 (USB3.0) for LTE

mini-PCIe

1x Mini-PCIe (PCIe/USB2.0)

SIM card Slot

1x Nano SIM Slot

Watchdog

Yes

Internal RTC with Li Battery

Yes

TPM

Yes (Optional)

Cooling

System

1x system FAN with Smart FAN function

0~40ºC Operating

-20~70ºC Non-Operating

5~90% Operating

5~ 95% Non-Operating

(WxDxH)

231mm x 200mm x 44mm

Weight

TBD

(WxDxH)

TBD

Weight

TBD

Type/Watts

12V power connector x1

Input

AC 100-240V~50-60Hz 1.7A

Approvals and Compliance

CE/FCC Class B, EU RoHS 2.0, China RoHS

Chapter 1: Product Overview

Platform

System Memory

Networking

LOM

Processor Options

Technology

Socket

Ethernet Ports (By SKU)

SKU B: Intel Atom C3308, 1.6GHz

1x 260-pin SO-DIMM (one channel one

2x Intel i210-AT)

SKU B: 6x GbE RJ45 (4x Marvell 88E1543 +

2x Intel i211-AT)

SKU C: 4x GbE RJ45 (4x Marvell 88E1543)

SKU D: 4x GbE RJ45 + 2x 10G SFP

I/O Interface

Storage

Expansion

Miscellaneous

Environmental Parameters

System Dimensions

Package Dimensions

USB 2x USB 3.0 or 2x USB 2.0 (by SKU)

M.2

Temperature

Humidity (RH)

Power

12

Page 13

NCA-1513 User Manual

F1

F2

System Power

LAN Ports

Front Panel

No. Description

F1 SIM Card Slot

1x Nano SIM Slot

F2 LED Indicators

System Status

HDD Activity

13

Page 14

Rear Panel

For hardware reset

6x RJ45 Port or 2x SFP Port + 4x RJ45 Port (by SKU)

Appendix B: Renaming Network Interface

R2

R4

R5 R3R6

R1

R7

No. Description

R1 Power Switch 1x Power Button

R2 Reset Button

R3 DC Jack 1x DC Power Jack

R4 Console Port 1x RJ45 console port

Chapter 1: Product Overview

R5 USB Port 2x USB 3.0 Port or 2x USB 2.0 Port (by SKU)

R6 LAN Port

R7 Antenna Port 4x Reserved antenna port for Wi-Fi / LTE module

Port Sequence (from left to right): 213456

For instructions on modifying the port sequence, please refer to

14

Page 15

NCA-1513 User Manual

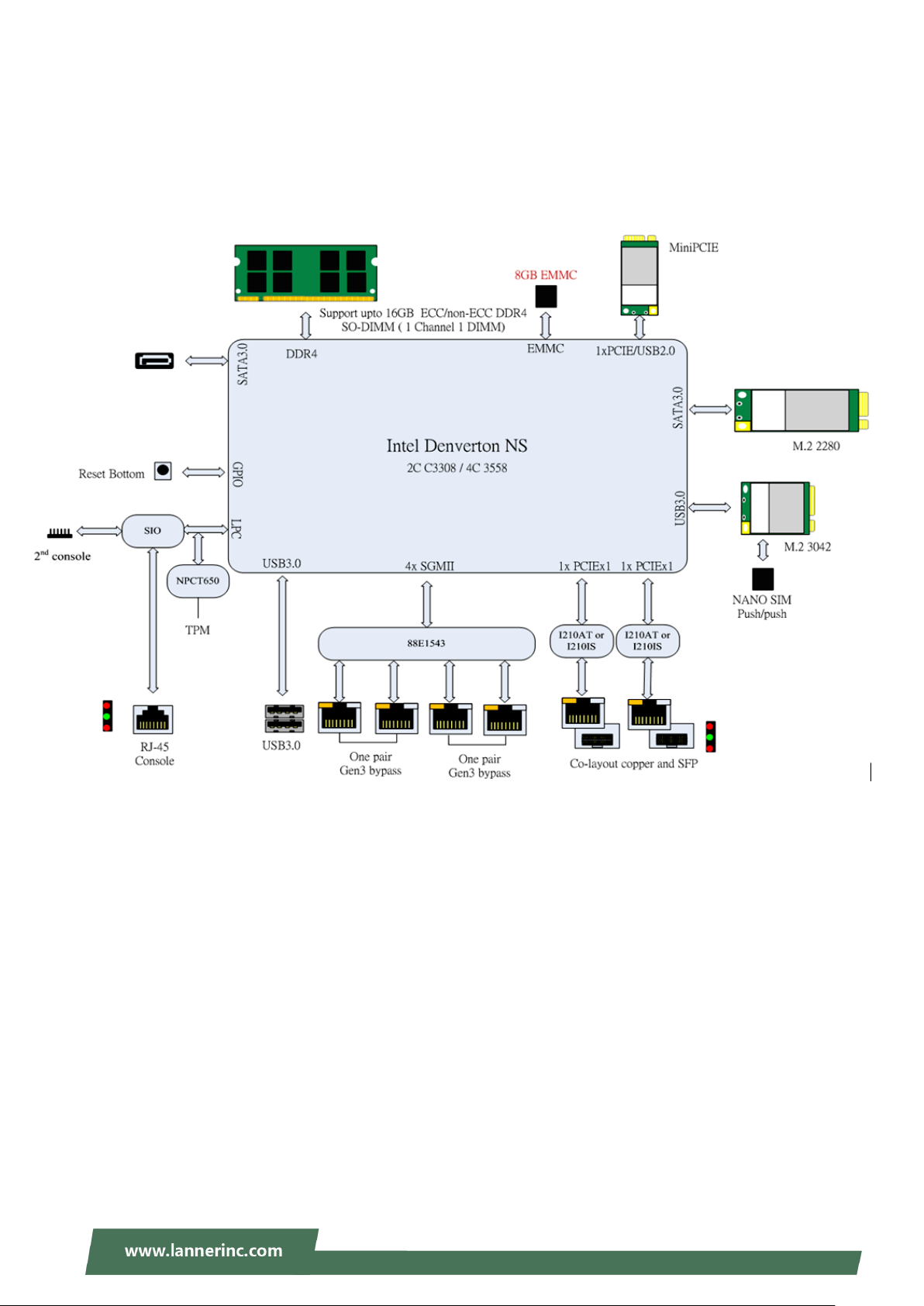

Motherboard Information

Block Diagram

The block diagram indicates how data flows among components on the motherboard. Please refer to the

following figure for your motherboard’s layout design.

15

Page 16

Chapter 1: Product Overview

FFAANN22

SSIIMM22

MMPPCCIIEE11

SSAATTAA11

CCOONN11

GGPPIIOO11

JJ8800PPOORRTT11

JJOOPPEENN11

CCOOMMBB22

JJ88 CCOONN22

MM22__LLTTEE

MM22_SSTTOORRAAGGEE

JJRRTTCC11

JJRRTTCC22

BBAATT11

JJSSPPIIRROOMM11

SSWW33

SSWW22

JJRREESSEETT11

CCOONNNN22

DDDDRR44

Jumper Setting and Pin Assignment

The motherboard board layout shows the connectors on the board. Refer to the below picture as a

reference of the pin assignments.

16

Page 17

NCA-1513 User Manual

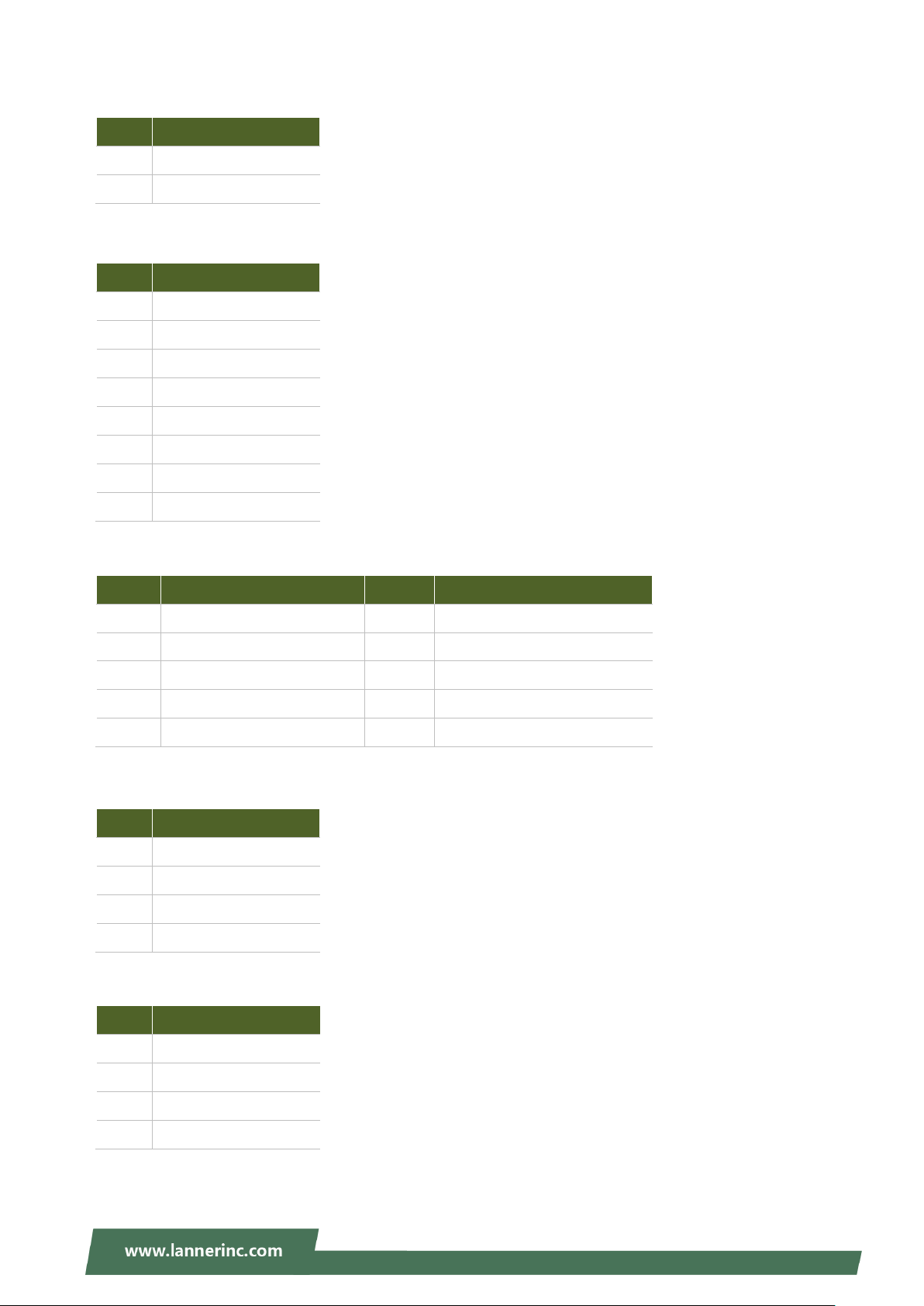

BAT1: RTC Battery connector

PIN Description

1

2

COM1: Console port

PIN Description

1

2

3

4

5

6

7

8

COMB2: Internal COM port for debug

PIN Description PIN Description

V_BATTERY

GND

COM1_RTS_N

COM1_DTR_N

COM1_TXD

LGND

LGND

COM1_RXD

COM1_DSR_N

COM1_CTS_N

1

3

5

7

9

CON1: SATA power connector

PIN Description

1

2

3

4

CON2: Gen3 bypass flash connector

PIN Description

1

NDCD2-

NRXD2

NTXD2

NDTR2-

IOGND2

P12V_SB

GND

GND

P5V_AUX

P3V3_AUX

2

4

6

8

10

NDSR2-

NRTS2NCTS2-

NRI2-

NC

2

3

4

IO_RXD

GND

IO_TXD

17

Page 18

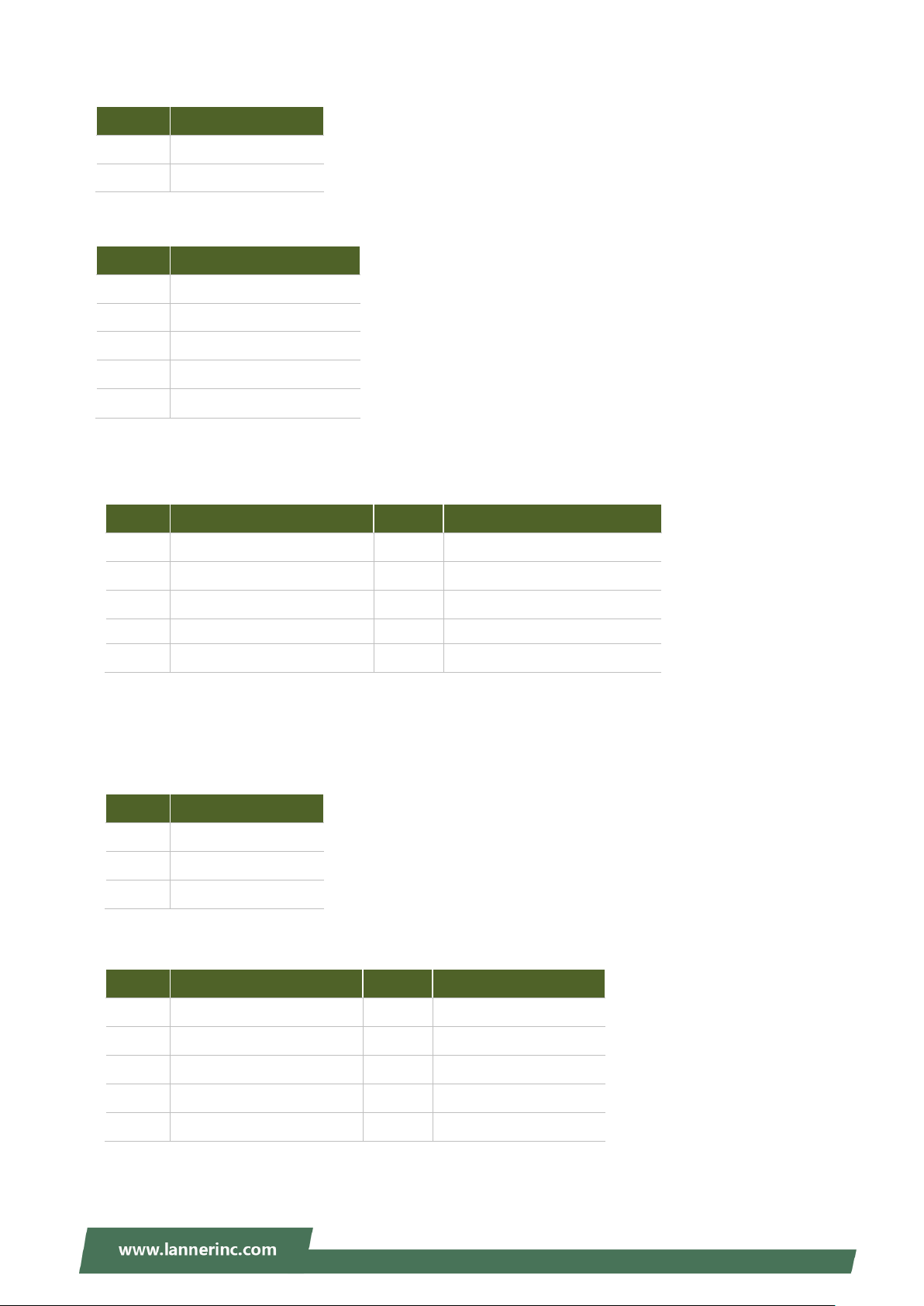

CONN2: Power pin header

7

GPO_B_4-

8

GPI_B_4

PIN Description

Chapter 1: Product Overview

1

2

FAN2: CPU FAN

PIN Description

5

4

3

2

1

GPIO1: GPIO connector

PIN Description PIN Description

1

3

GND

PWRON#

CPUFANOUT

NC

CPUFANIN

P12V_S

GND

GPO_B_1-

GPO_B_2

2

4

GPI_B_1

GPI_B_2

5

9

J8: Gen3 bypass flash jumper for ARM Programming Selection

0(2- 3) : Enable

1(1-2) : Disable (default)

PIN Description

1

2

3

J80PORT1: PORT80 connector

PIN Description PIN Description

1

3

GPO_B_3

GND

P3V3_AUX

PIO0_1

GND

CLK_LPC_OUT

80PORT_RST#

2

4

6

10

SOC_LPC_LAD1

SOC_LPC_LAD0

GPI_B_3

GND

5

7

9

SOC_LPC_FRAME_N

SOC_LPC_LAD3

SOC_LPC_LAD2

6

8

10

P3V3_S

NC

GND

18

Page 19

NCA-1513 User Manual

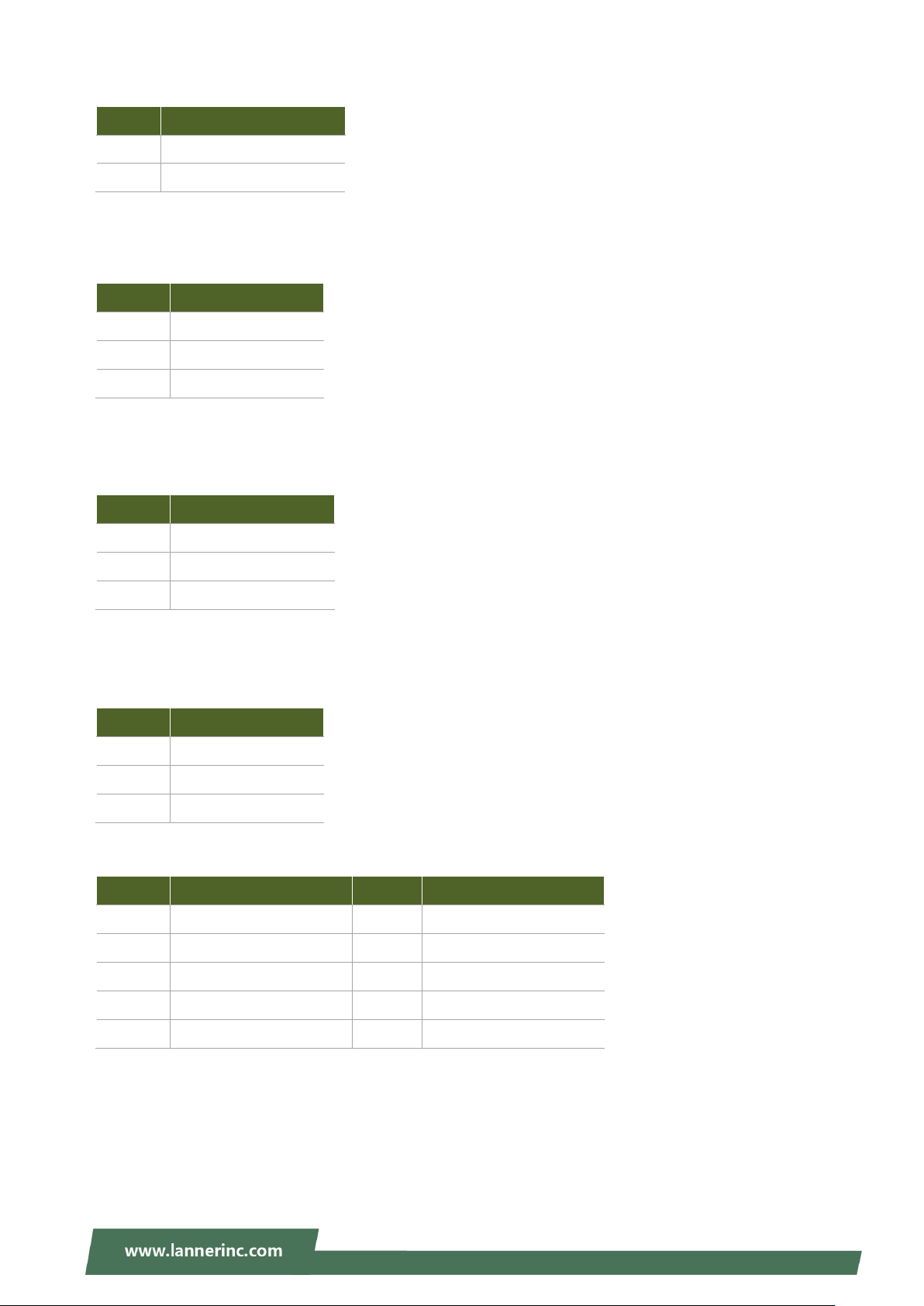

JOPEN1: Case open connector

PIN Description

1

2

JRESET1: H/W & S/W Reset

1-2 :Hardware Reset

2-3 :Software Reset (Default)

PIN Description

1

2

3

JRTC1: Clear CMOS

1-2 : NORMAL

2-3 : CLEAR RTC

PIN Description

1

2

3

SIO_CASEOPEN0_N

GND

FP_RST_BTN_N

GND

SW_RST_GP_N

P3V3_RTC

SOC_SRTCRST_N

GND

JRTC2: Clear CMOS

1-2 : NORMAL

2-3 : CLEAR RTC

PIN Description

1

2

3

JSPIROM1: Flash BIOS connector

PIN Description PIN Description

1

3

5

7

9

P3V3_RTC

SOC_RTEST_N

GND

SPI_HD1#

SOC_SPI_CS0_R

SPI_MISO_DUAL_R

NC

GND

2

4

6

8

10

P3V3_SB_SPI

SPI_HOLD0_L

SPI_CLK_DUAL_R

SPI_MOSI_DUAL_R

NC

19

Page 20

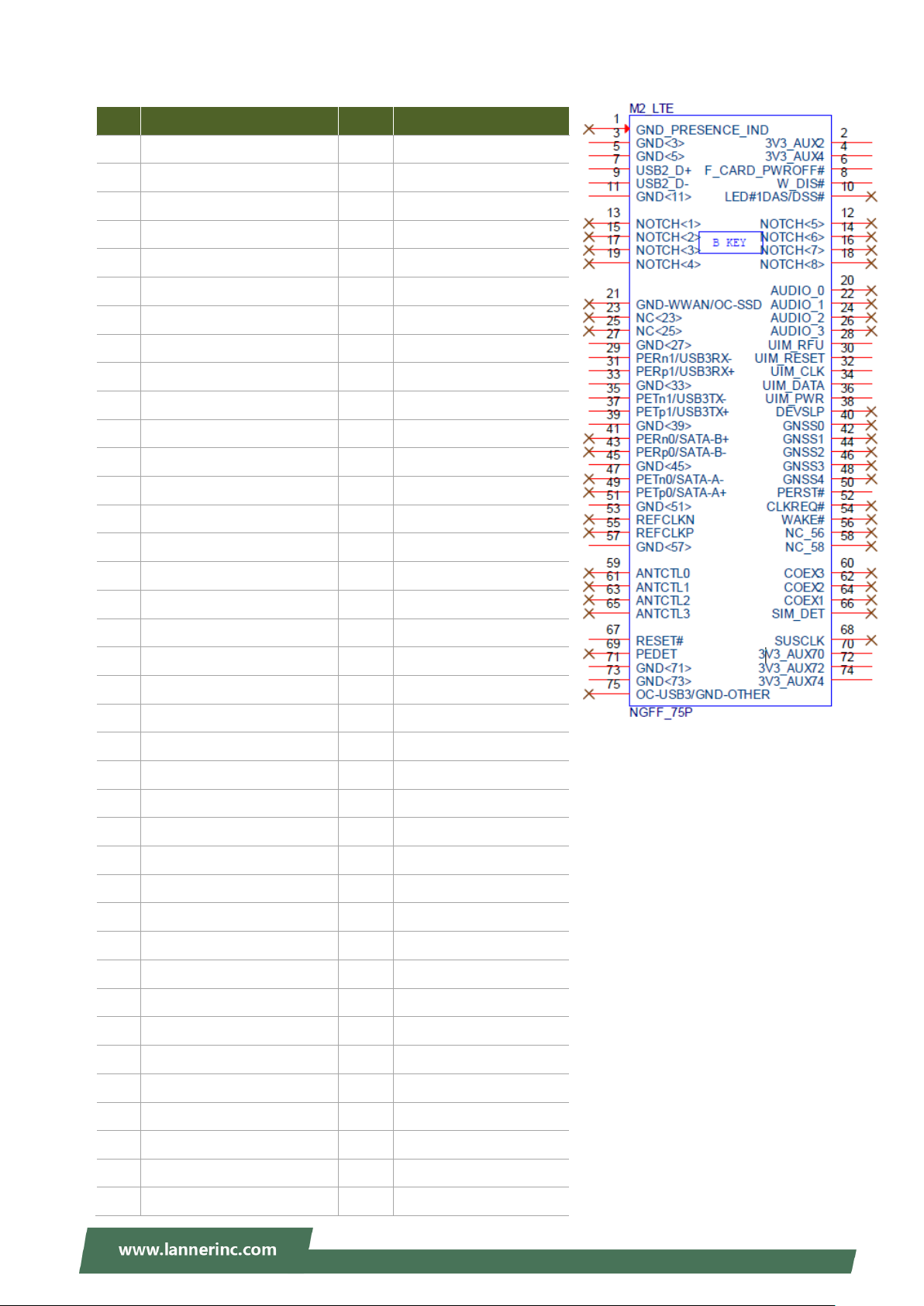

M2_LTE: M.2 con (Only LTE)

7

USB1_SB_L_DP

8

W_DIS#

17

NC

18

NC

23

NC

24

NC

29

USB3_HRX_L_DTX_N16

30

UIM1_RST1

35

USB3_HTX_L_DRX_N16

36

UIM1_PWR

41

NC

42

NC

45

GND

46

NC

57

GND

58

NC

63

NC

64

NC

69

NC

70

P3V3_AUX

75

NC

PIN Description PIN Description

1 NC 2 P3V3_AUX

3 GND 4 P3V3_AUX

5 GND 6 PWROFF#

9 USB1_SB_L_DN 10 NC

11 GND 12 NC

13 NC 14 NC

15 NC 16 NC

19 NC 20 NC

21 NC 22 NC

25 NC 26 NC

Chapter 1: Product Overview

27 GND 28 UIM1_VPP1

31 USB3_HRX_L_DTX_P16 32 UIM1_CLK1

33 GND 34 UIM1_DAT1

37 USB3_HTX_L_DRX_P16 38 NC

39 GND 40 NC

43 NC 44 NC

47 NC 48 NC

49 NC 50 NGFF_LTE_RST#

51 GND 52 NC

53 NC 54 NC

55 NC 56 NC

59 NC 60 NC

61 NC 62 NC

65 NC 66 NC

67 P1V8_A 68 NC

71 GND 72 P3V3_AUX

73 GND 74 P3V3_AUX

20

Page 21

NCA-1513 User Manual

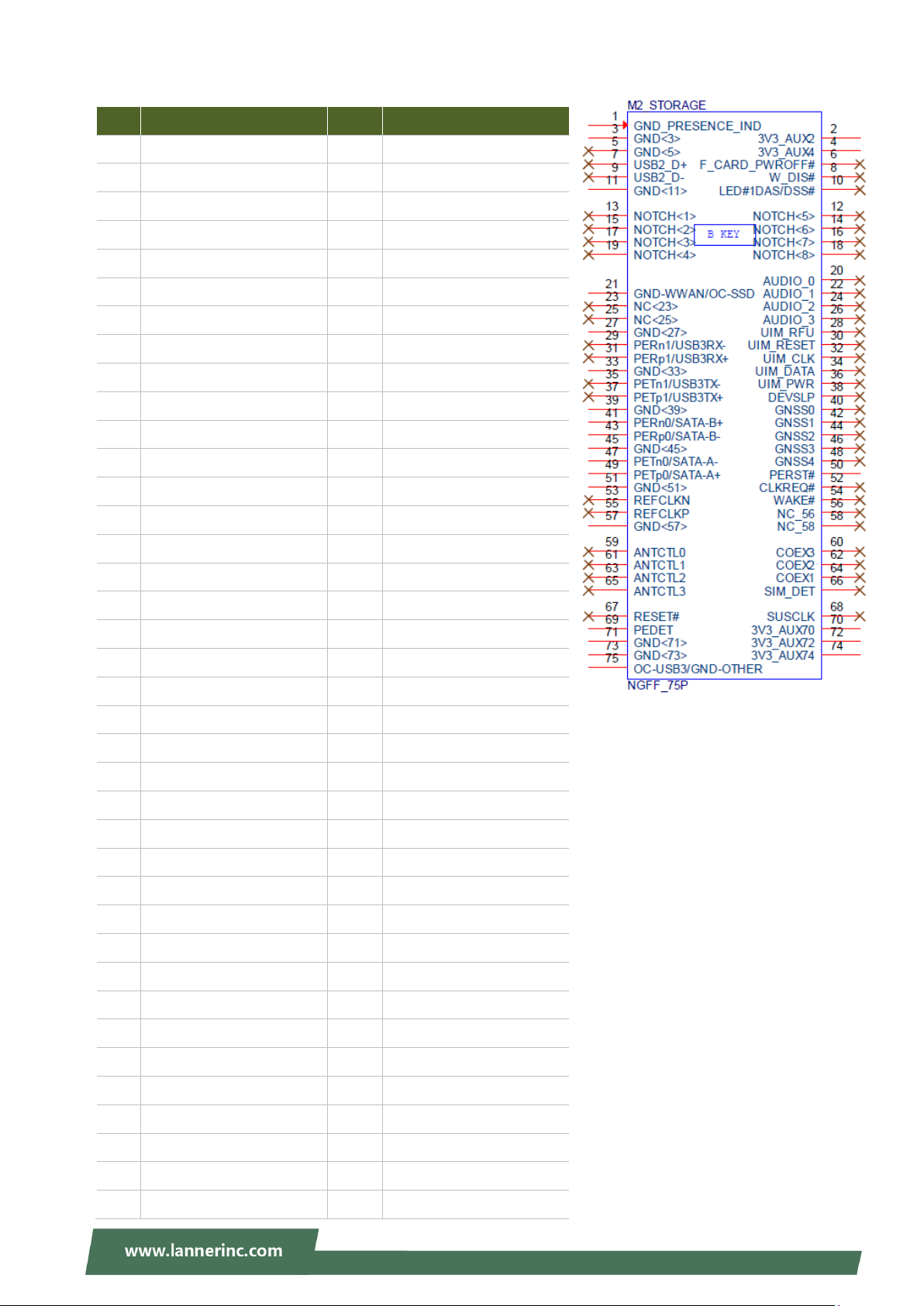

M2_STORAGE: M.2 storage connector (Only Storage)

PIN Description PIN Description

1

3

5

7

9

11

13

15

17

19

21

23

25

27

GND

GND

NC

NC

NC

GND

NC

NC

NC

NC

GND

NC

NC

GND

2

4

6

8

10

12

14

16

18

20

22

24

26

28

P3V3_AUX

P3V3_AUX

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

29

31

33

35

37

39

41

43

45

47

49

51

53

55

57

59

NC

NC

GND

NC

NC

GND

SATA_HRX_C_DTX_P4

SATA_HRX_C_DTX_N4

GND

SATA_HTX_C_DRX_N4

SATA_HTX_C_DRX_P4

GND

NC

NC

GND

NC

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NGFF_STORAGE_RST#

NC

NC

NC

NC

NC

61

63

65

67

69

71

73

75

NC

NC

NC

NC

GND

GND

GND

GND

62

64

66

68

70

72

74

NC

NC

NC

NC

P3V3_AUX

P3V3_AUX

P3V3_AUX

21

Page 22

Chapter 1: Product Overview

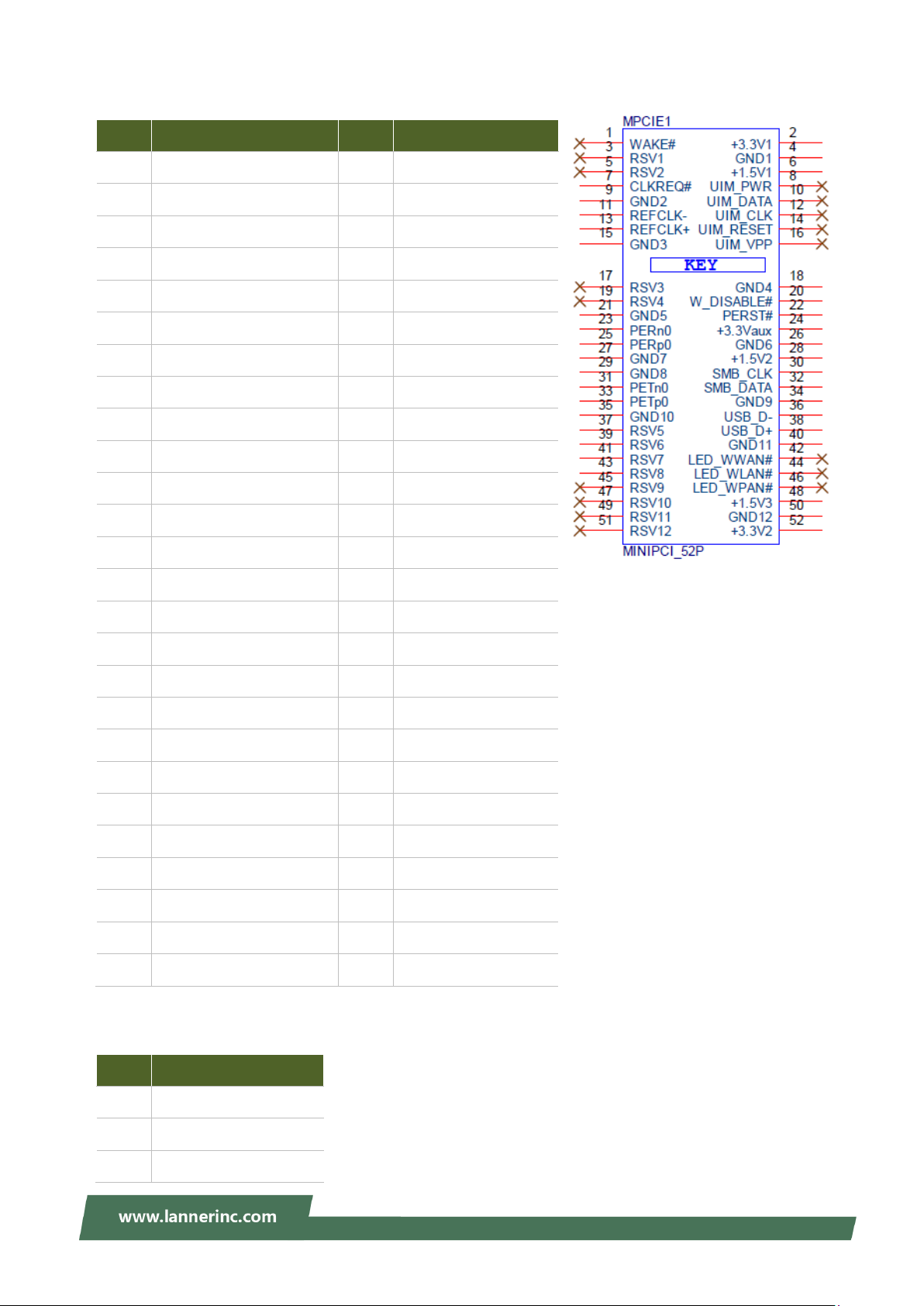

MPCIE1: Mini PCIE 52PIN

PIN Description PIN Description

1

3

5

7

9

11

13

15

17

19

21

23

25

CLKREQ_MPCIE_SLOT2

GND

CLK100_PCIE_SLOT1_4N

CLK100_PCIE_SLOT1_4P

GND

GND

PEX_RX5N

PEX_RX5P

NC

NC

NC

NC

NC

2

4

6

8

10

12

14

16

18

20

22

24

26

P3V3_AUX

GND

P1V5_A

NC

NC

NC

NC

NC

GND

P3V3_AUX

MINI_PCI_RST#

P3V3_AUX

GND

27

29

31

33

35

37

39

41

43

45

47

49

51

GND

GND

PEX_TX5N_C

PEX_TX5P_C

GND

GND

P3V3_AUX

P3V3_AUX

GND

NC

NC

NC

NC

28

30

32

34

36

38

40

42

44

46

48

50

52

P1V5_A

SMB_MPCIE_CLK

SMB_MPCIE_DATA

GND

USB2_P0_DN_L

USB2_P0_DP_L

GND

NC

NC

NC

P1V5_A

GND

P3V3_AUX

PW1: DC power connector

PIN Description

2

3

1

GND

GMD

P12V_SB

22

Page 23

NCA-1513 User Manual

SATA1: SATA connector

PIN

1

2

3

4

5

6

7

SIM2: M2_LTE SIM card slot

PIN Description PIN Description

C1

C2

C3

Description

GND

SATA_TX_DP0_C

SATA_TX_DN0_C

GND

SATA_RX_DN0_C

SATA_RX_DP0_C

GND

UIM1_PWR

UIM1_RST1

UIM1_CLK1

C4

C5

C6

UIM1_DAT1

UIM1_VPP1

GND

SW2: Reset Button

PIN Description PIN Description

4

2

SW3: Power Button

PIN Description PIN Description

4

3

L2

GND

GND

PWRON#

PWRON#

PRLED-

3

1

2

1

L1

SUSLED-

GND

SW_RST_GP_N

GND

GND

23

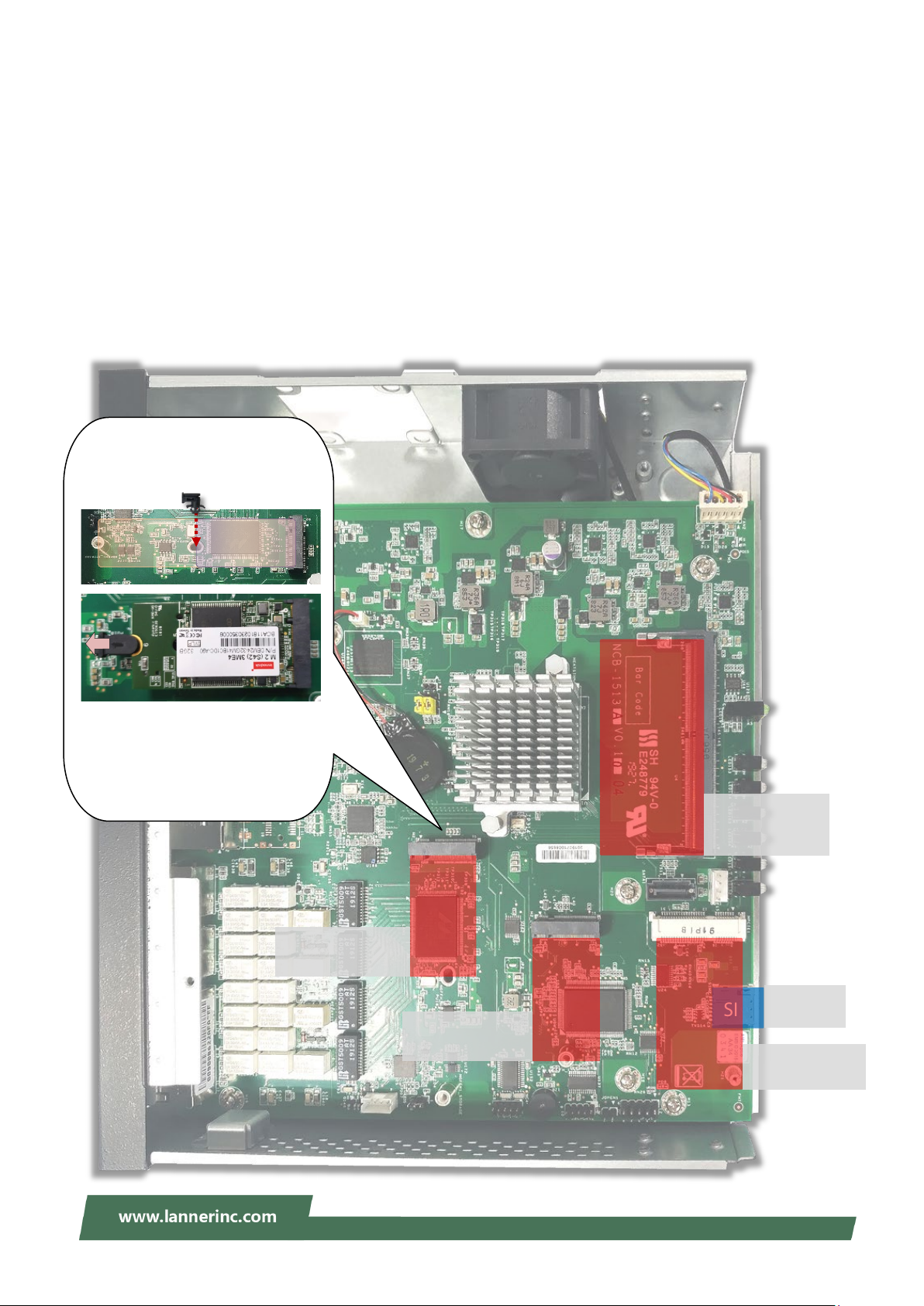

Page 24

Chapter 2 Hardware Installation

SIM

DDR4-2400

or Non-ECC

M.2 2280/2242

M.2 3042

USB3.0

mPCIE

PCIe/USB2.0 signal

Nano SIM

For M.2 LTE

For 2242 M.2 SSD module, insert

To secure the module, pull the clip of

After you

to fasten the card.

CHAPTER 2 HARDWARE INSTALLATION

To reduce the risk of personal injury, electric shock, or damage to the equipment, please remove all power

connections to completely shut down the device. Also, please wear ESD protection gloves when conducting

the steps described hereafter.

This system supports multiple wireless connectivity methods with two M.2 slots and an MPCIE slot. Based

on your application and modules used, install modules in the corresponding slots.

the plastic spacer into the

mounting hole on MB to secure the

module.

2280 2242

the spacer open while pressing

down on the card.

release the clip, it will bounce back

SATA signal (B key)

M.2

(SSD)

signal (B key)

M.2

(LTE)

System

Memory

Up to 16GB ECC

Mini-PCIe

(Wi-fi)

24

Page 25

NCA-1513 User Manual

Installing Nano SIM Card

The SIM slot on front panel supports an LTE module. The SIM socket supports the push-push mechanism,

allowing inserting and ejecting the SIM card to be as easy as one push.

1. Loosen the two screws that secure the SIM slot cover and remove the slot cover. With the angled

corner facing inward, push the SIM card all the way in until it clicks into place.

2. To remove the SIM card, use your fingertip to push it a little to have the card automatically ejected.

25

Page 26

Chapter 2 Hardware Installation

SMA Female

Bulkhead

Washer

Nut

Mounting an SMA-Mount Antenna Cable Assembly

To mount the Wi-Fi/LTE antennas:

1. Take out the antenna pigtail cable from the Antenna Kit. From inside the chassis, insert the SMA Female

Bulkhead through the antenna hole on the panel.

2. From outside the panel, attach the Washer and Nut, and tighten the Nut using an SMA Torque Wrench.

Warning: Do not use any tool other than an SMA Torque Wrench to fasten the Nut. For

example, general pliers or tweezers without limited twisting force are very likely to cause the

distortion of SMA connector.

26

Page 27

NCA-1513 User Manual

bracket to the screw holes on the side

Ear Bracket

Adapter Bracket

1

Screws

Screws

(for Rack-mounting)

Rack-mounting the System

With the rack mount kit, this system can be fixed onto rack posts. Please contact Lanner‘s sales

representative for purchasing this kit.

What’s in the Rack-mount Kit

Check the kit for the following items:

2x Ear Bracket

1x Adapter Bracket

1x Adapter Holder

Screws for the fixture of the Brackets and

the Holder

Rack-mounting Screws

Attaching the Assembly to the Chassis

1. On one side of the system, align the ear

panel and fix it using three screws.

2. Secure the other ear bracket to the other

side of the system.

3. Fix the adapter holder to the left side panel using two screws.

4. The adapter holder assembly is designed to secure a 5V adapter or a 3V adapter. Secure the adapter

onto the holder with the adapter bracket and two

bracket is as shown in the picture.

5. Attach the power adapter’s connector to the power supply jack on the system’s rear panel.

6. Secure the adapter’s cable onto the adapter holder.

provided screws. Make sure the way you place the

27

Page 28

Chapter 2 Hardware Installation

Installing the System to the Rack

In the rack, install a shelf to support the system (recommended). Hold the system with its front facing you,

lift and carefully insert the system into the rack. Attach the brackets to the rail rack using rack-mounting

screws and/or retainer nuts.

28

Page 29

NCA-1513 User Manual

CHAPTER 3 SOFTWARE SETUP

BIOS Setup

BIOS is a firmware embedded on an exclusive chip on the system’s motherboard. Lanner's BIOS firmware

offering including market-proven technologies such as Secure Boot and Intel Boot Guard technology

deliver solid commitments for the shield protection against malware, uncertified sequences and other

named cyber threats. BIOS update for Lanner PCs are available for download at

http://www.lannerinc.com/products/firmware-and-software/securityenhanced-bios

Main Setup

To enter the BIOS setup utility, simply follow the steps below:

1. Boot up the system.

2. Pressing the <Tab> or <Del> key immediately allows you to enter the Setup utility, and then you will

be directed to the BIOS main screen. The instructions for BIOS navigations are as below:

Control Keys Description

<Enter> select an item/option or enter a sub-menu

+/- adjust values for the selected setup item/option

F1 display General Help screen

F2

F3 load optimized default values

F4 save configurations and exit BIOS

<Esc> exit the current screen

select a setup screen

select an item/option on a setup screen

retrieve previous values, such as the last configured parameters during the last

time you entered BIOS

29

Page 30

Setup main page contains BIOS information and project version information.

Feature

Description

Access Level: Administrator / User

To set the Date, use <Tab> to switch between Date elements.

Days: dependent on Month.

System Tine

To set the Date, use <Tab> to switch between Date elements.

Chapter 3 Software Setup

BIOS

Information

System Date

BIOS Vendor: American Megatrends

Core Version: AMI Kernel version, CRB code base, X64

Compliancy: UEFI version, PI version

Project Version: BIOS release version

Build Date and Time: MM/DD/YYYY

Default Range of Year: 2005-2099

Default Range of Month: 1-12

30

Page 31

NCA-1513 User Manual

Advanced Page

Select the Advanced menu item from the BIOS setup screen to enter the “Advanced” setup screen. Users

can select any of the items in the left frame of the screen.

31

Page 32

Trusted Computing

Chapter 3 Software Setup

32

Page 33

NCA-1513 User Manual

Feature Options Description

Enables or disables BIOS support for security device.

Security Device

Support

SHA-1 PCR Bank

SHA256 PCR Bank

Pending

operation

Platform

Hierarchy

Storage Hierarchy

Endorsement

Hierarchy

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

None

TPM Clear

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

By disabling this function, OS will not show Security

Device. TCG EFI protocol and INT1A interface will not

be available.

Enables or disables SHA-1 PCR Bank.

Enables or disables SHA256 PCR Bank.

Schedules an Operation for the Security Device. NOTE:

Your computer will reboot during restart in order to

change State of Security Device.

Enables or disables Platform Hierarchy.

Enables or disables Storage Hierarchy.

Enables or disables Endorsement Hierarchy.

TPM2.0 UEFI Spec

Version

Physical Presence

Spec Version

TPM 20

InterfaceType

Device Select

TCG_1_2

TCG_2

1.2

1.3

TIS

TPM 1.2

TPM 2.0

Auto

Select the TCG2 Spec Version,

TCG_1_2: Supports the Compatible mode for

Win8/Win10

TCG_2: Supports new TCG2 protocol and event format

for Win10 or later.

Select to tell OS to support PPI Spec Version 1.2 or 1.3.

NOTE: Some HCK tests might not support 1.3.

Select TPM 20 Device for the Communication

Interface.

TPM 1.2 will restrict support to TPM 1.2 devices; while

TPM 2.0 will restrict support to TPM 2.0 devices; Auto

will support both with the default set to TPM 2.0

devices. If not found, TPM 1.2 devices will be

enumerated.

33

Page 34

Super IO Configuration

Chapter 3 Software Setup

34

Page 35

NCA-1513 User Manual

Serial port 1 Configuration

Feature Options Description

Serial Port

Enabled

Disabled

Device Settings NA IO=3F8h; IRQ = 7

Enables or disables Serial Port 1.

35

Page 36

Serial port 2 Configuration

Chapter 3 Software Setup

Feature Options Description

Serial Port Enabled

Disabled

Device Settings NA IO=2F8h; IRQ = 10

Enable or Disable Serial Port 2.

36

Page 37

NCA-1513 User Manual

H/W Monitor

37

Page 38

Watch Dog Timer Configuration

Chapter 3 Software Setup

Feature Options Description

Watch Dog Timer Enabled

Disabled

Enables or disables Watch Dog Timer function

38

Page 39

NCA-1513 User Manual

Digital I/O Configuration

Feature Options Description

Digital I/O Output 1

Digital I/O Output 3

Digital I/O Output 5

Digital I/O Output 7

Output Low

Output High

Output Low

Output High

Output Low

Output High

Output Low

Output High

Configure Digital I/O Pin1

Configure Digital I/O Pin3

Configure Digital I/O Pin5

Configure Digital I/O Pin7

39

Page 40

Status LED Configuration

Chapter 3 Software Setup

Feature Options Description

OFF

Status LED

GREEN

RED

Configures Status LED color

40

Page 41

NCA-1513 User Manual

Feature

Options

Description

Redirection

Serial Port Console Redirection

COM0

Console

Enabled

Disabled

Enables or disables Console Redirection

41

Page 42

Console Redirection Settings

Feature

Options

Description

ANSI: Extended ASCII char set

9600

115200

8

None

Space

2

Flow Control

None

Flow Control can prevent data loss from

Chapter 3 Software Setup

Terminal Type

Bits per second

Data Bits

Parity

VT100

VT100+

VT-UTF8

ANSI

19200

38400

57600

7

Even

Odd

Mark

VT100: ASCII char set

VT100+:Extends VT100 to support color,

function keys, etc.

VT-UTF8:Uses UTF8 encoding to map

Unicode chars onto 1 or more bytes

Selects serial port transmission speed. The

speed must be matched on the other side.

Long or noisy lines may require lower speeds.

Data Bits

A parity bit can be sent with the data bits to

detect some transmission errors.

Stop Bits

1

Indicates the end of a serial data packet.

42

Page 43

NCA-1513 User Manual

RTS/CTS

Key Support

Enabled

for ANSI/VT100 terminals

Disabled

Enabled

With this mode enabled, only text will be

sent. This is to capture Terminal data.

VT400

Hardware

buffer overflow.

VT-UTF8 Combo

Disabled

Recorder Mode

VT100

LINUX

Putty KeyPad

XTERM86

SCO

ESCN

Enables VT-UTF8 Combination Key Support

Selects FunctionKey and KeyPad on Putty.

43

Page 44

Console Redirection Settings

Feature

Options

Description

80x24

80x25

On Legacy OS, the Number of Rows and

Columns supported redirection.

is set to Always Enable.

Chapter 3 Software Setup

Redirection COM

Port

COM0 Select a COM port to display redirection of Legacy

Resolution

Always

Redirection After

Enable

BIOS POST

BootLoader

OS and Legacy OPROM Messages.

When Bootloader is selected, Legacy Console

Redirection is disabled before booting to

legacy OS. When Always Enable is selected,

then Legacy Console Redirection is enabled

for legacy OS. Default setting for this option

44

Page 45

NCA-1513 User Manual

Enable or Disables 64bit capable Devices to be

Decoded in Above 4G Address Space (Only if

option enables or disables Single Root IO

PCI Subsystem Settings

Feature Options Description

Above 4G

Decoding

Feature Options Description

SR-IOV Support

Disabled

Enabled

System Supports 64 bit PCI Decoding).

If the system has SR-IOV capable PCIe Devices, this

Disabled

Enabled

Virtualization Support.

45

Page 46

Network Stack Configuration

Enables Ipv4 PXE Boot Support. If IPV4 is

Enables Ipv4 HTTP Boot Support. If IPV4 is

Enables Ipv6 PXE Boot Support. If IPV6 is

Enables Ipv6 HTTP Boot Support. If IPV6 is

Chapter 3 Software Setup

Feature Options Description

Network Stack

Ipv4 PXE Support

Ipv4 HTTP Support

Ipv6 PXE Support

Ipv6 HTTP Support

PXE boot wait time 0

Disabled

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

Enabled

Enables or disables UEFI Network Stack

disabled, PXE boot option will not be created.

disabled, HTTP boot option will not be created.

disabled, PXE boot option will not be created.

disabled, HTTP boot option will not be created.

Wait time to press <ESC> key to abort the PXE

boot

Media detect count 1

Number of times the presence of media will be

checked

46

Page 47

NCA-1513 User Manual

Determines OpROM execution policy for

devices other than Network, Storage, or

CSM Configuration

Feature Options Description

CSM Support

Network

Storage

Video

Other PCI device

Disabled

Enabled

Do Not Launch

UEFI

Legacy

Do Not Launch

UEFI

Legacy

Do Not Launch

UEFI

Legacy

Do Not Launch

UEFI

Legacy

Enables or disables CSM Support

Controls the execution of UEFI and Legacy

PXE OpROM

Controls the execution of UEFI and Legacy

Storage OpROM

Controls the execution of UEFI and Legacy

Video OpROM

Video

47

Page 48

SDIO Configuration

Auto Option: Access SD device in DMA mode if

controller supports it,otherwise in PIO mode.DMA

Chapter 3 Software Setup

Feature Options Description

Auto

SDIO Access

Mode

ADMA

SDMA

PIO

Option: Access SD device in DMA mode.PIO Option:

Access SD device in PIO mode..

48

Page 49

NCA-1513 User Manual

will keep USB devices

off support. The XHCI

ownership change should be claimed by

Enables or disables USB Mass Storage

USB mass storage device Start Unit

USB Configuration

Feature Options Description

Legacy USB Support

XHCI Hand-off

USB Mass Storage

Driver Support

USB transfer time-out

Enabled

Disabled

Auto

Enabled

Disabled

Enabled

Disabled

1 sec

5 sec

10 sec

Enables Legacy USB support.

Auto option disables legacy support if no

USB devices are connected;

Disabled option

available only for EFI applications.

This is a workaround for OSes without

XHCI hand-

XHCI driver.

Driver Support.

The time-out value for Control, Bulk, and

Interrupt transfers

Device reset time-out

20 sec

1 sec

5 sec

10 sec

20 sec

command time-out

49

Page 50

Chapter 3 Software Setup

it properly reports itself to the Host

Maximum time the device will take before

Device power-up delay

Auto

Controller. Auto uses default value: for a

Manual

Root port, it is 100 ms, for a Hub port the

delay is taken from Hub descriptor.

50

Page 51

NCA-1513 User Manual

Control Legacy PXE Boot

Feature Options Description

Control Legacy PXE

Boot From

Disabled

Lan3

Control Legacy PXE Boot from which

Lan4

Lan.

Lan5

Lan6

51

Page 52

NVME Configuration

Chapter 3 Software Setup

52

Page 53

NCA-1513 User Manual

IntelRCSetup

Select the IntelRCSetup menu item from the BIOS setup screen to enter the Platform Setup screen. Users

can select any of the items in the left frame of the screen.

Feature Options Description

Relax Security

Configuration

Restore On Power Loss Power On

Disable

Enabled

Power Off

Last State

Relaxes the security configuration to be

able to use BIOS update tool.

Specify what state to go to when power is

re-applied after a power failure (G3 state).

53

Page 54

Processor Configuration

Enables/Disable EIST. GV3 must be

This option only applies to ES2 and

Chapter 3 Software Setup

Feature Options Description

EIST (GV3)

Turbo

CPU C State

Package C state limit

Max core C-state

Disable

Enable

Enable

Disable

Disable

Enable

No Pkg C-state

No S0Ix

No limit

C1

C6

enable for Turbo.

.

Enable or Disable CPU Turbo capability.

above.

Enable the Enhanced Cx state of the CPU,

takes effect after reboot.

Package C state limit.

Options are:C1 and C6.

Enhanced Halt

State(C1E)

Monitor/Mwait Enable

L1 Prefetcher Enable

Disable

Enable

Disable

Disable

Enables the enhanced C1E state of the

CPU, takes effects after reboot.

Enable or Disable the Monitor/Mwait

Instruction.

Enable/Disable L1 Prefetch.

54

Page 55

NCA-1513 User Manual

enables, enable fast strings for

When disabled, forces the XD feature

L2 Prefetcher Enable

Enable/Disable L2 Prefetch

Disable

Fast String Disable

Machine Check Disable

Execute Disable Bit Disable

VMS Disable

AES-NI Disable

Enable

Enable

Enable

Enable

Enable

When

REP MOVS/STOS.

Enable or Disable the Machine Check.

flag to always return 0.

Enables the Vanderpool Technology,

takes effect after reboot.

Enable/disable AES-NI support.

55

Page 56

Server ME Configuration

Chapter 3 Software Setup

56

Page 57

NCA-1513 User Manual

which skips memory

training and attempts to boot using fast known

North Bridge Chipset Configuration

Feature Options Description

Enables/Disables fast boot,

good configuration.

DDR memory frequency:

DDR4 up to DDR-2666

DDR3 up to DDR-1867.

Option to enable /Disable VT-d.

Fast Boot

Memory

Frequency

VT-d Disable

Disabled

Enabled

DDR-1600

DDR-1867

DDR-2133

DDR-2400

Enable

57

Page 58

South Bridge Chipset Configuration

Chapter 3 Software Setup

58

Page 59

NCA-1513 User Manual

Enables/Disables SATA Controller if supported by

Indicates the highest allowable speed of the

SATA Configuration

Feature Options Description

Enable controller Enabled

Disabled

LPM Enabled

Disabled

ALPM Enabled

Disabled

Speed Limit Gen 1

Gen 2

Gen 3

current CPU sku

Enables/Disables Link Power Management

Enable/Disables Agresive Link Power Management

interface

59

Page 60

SATA1 Configuration

Chapter 3 Software Setup

Feature Options Description

Enable/disable port Enabled

Disabled

Hot plug Enabled

Disabled

Spin up Enabled

Disabled

Enables/Disables SATA Controller port if

supported by current cpu SKU.

Hot plug

Spin up

60

Page 61

NCA-1513 User Manual

M2SATA1 Configuration

Feature Options Description

Enable/disable port Enabled

Disabled

Hot plug Enabled

Disabled

Spin up Enabled

Disabled

Enables/Disables SATA Controller port if

supported by current cpu SKU.

Hot plug

Spin up

61

Page 62

PCIE IP Configuration

Chapter 3 Software Setup

Feature Options Description

Bifurcation PCIE0

Bifurcation PCIE1

Auto

X8

X4x4

X4x2x2

X2x2x4

X2x2x2x2

Auto

X8

X4x4

X4x2x2

X2x2x4

X2x2x2x2

Select and force Root Complex Bifurcation

Configuration regardless board or trident

detection.

Select and force Root Complex Bifurcation

Configuration regardless board or trident

detection.

62

Page 63

NCA-1513 User Manual

IQAT Configuration

Feature Options Description

IQAT Enabled

Disabled

Hides IQAT device from and OS.

63

Page 64

System Event Log

Enable/Disable Memory Error logging

Enable/Disable Correctable Memory

correctable Memory

Enable/Disable Error

Enable/Disable PCIe Error logging

Chapter 3 Software Setup

Feature Options Description

System Errors

Memory Elog Support

Parity Check

Log Correctable

Log Un-Correctable

Cloaking

PCIE Elog Support

Disable

Enable

Auto

Disable

Enable

Enable

Disable

Enable

Disable

Enable

Disable

Disable

Enable

Disable

Enable

System Error enabling and logging setup

option.

support

Enable/Disable Parity Check

Error logging support

Enable/Disable UnError logging support

Error Cloaking Feature to hide CE Error to

OS

support

Log Fatal Error

Log Non-Fatal Error

Log Correctable Error Disable Send system event Signal on Correctable

Disable

Enable

Disable

Enable

Send system event Signal on Fatal error

Send system event Signal on Non Fatal

error.

64

Page 65

NCA-1513 User Manual

reporting on all

enumerated Root ports, bridges and

Enable Parity Error reporting on all

enumerated Root ports, bridges and

type with address and vendor

Enable error.

PCIe System Error

PCIe Parity Error

WHEA Support

WHEA Error Injection

5.0 Extension

Whea Logging

WHEA PCIe Error

Injection

Disable

Enable

Disable

Enable

Disable

Enable

Disable

Enable

Disable

Enable

Disable

Enable

Enable System Error

devices.

devices .

Enable/Disable WHEA ACPI support.

When EINJ ACPI 5.0 support for set error

extensions.

Enable/Disable Whea logging of errors.

Enable/Disable WHEA PCIe Error

Injection .

65

Page 66

Chapter 3 Software Setup

If ONLY the Administrator's password is set, it only

limits access to Setup and is only asked for when

If ONLY the User's password is set, it serves as a

Security

Select the Security menu item from the BIOS setup screen to enter the Security Setup screen. Users can

select any of the items in the left frame of the screen.

Feature Description

Administrator Password

User Password

entering Setup.

power-on password and must be entered to boot or

enter Setup. In Setup, the User will have Administrator

rights.

66

Page 67

NCA-1513 User Manual

a physically present user without full

Secure Boot

Feature Options Description

Secure Boot

Enable

Secure Boot Mode

Disabled

Enabled

Standard

Custom

Secure Boot is activated when Platform Key(PK) is

enrolled, System mode is User/Deployed, and CSM

function is disabled.

Customizable Secure Boot mode: In Custom mode,

Secure Boot Policy variables can be configured by

authentication.

67

Page 68

Key Management

Allows the image to run in Secure Boot mode.

Chapter 3 Software Setup

Feature Options Description

Factory Key

Provision

Restore Factory

keys

Enroll Efi Image None

Disabled

Enabled

None

Provision factory default keys on next re-boot only

when System in Setup Mode.

Force System to User Mode. Configure NVRAM to

contain OEM-defined factory default Secure Boot

keys.

Enroll SHA256 hash of the binary into Authorized

Signature Database (db)

68

Page 69

NCA-1513 User Manual

Boot Menu

Select the Boot menu item from the BIOS setup screen to enter the Boot Setup screen. Users can select any

of the items in the left frame of the screen.

Feature Options Description

The number of seconds to wait for setup

Setup Prompt Timeout 5

Bootup NumLock State

Quiet Boot

Boot mode select

Choose boot priority from the boot option group.

Choose specifies boot device priority sequence from available Group device.

On

Off

Disabled

Enabled

LEGACY

UEFI

DUAL

activation key.

65535 means indefinite waiting.

Select the keyboard NumLock state

Enables or disables Quiet Boot option.

Select boot mode for LEGACY or UEFI.

69

Page 70

NCA-1513 User Manual

Save and Exit Menu

Select the Save and Exit menu item from the BIOS setup screen to enter the Save and Exit Setup screen.

Users can select any of the items in the left frame of the screen.

■ Save Changes and Reset

When Users have completed the system configuration changes, select this option to save the changes and

exit from BIOS Setup in order for the new system configuration parameters to take effect. The following

window will appear after selecting the “Save Changes and Exit” option. Select “Yes” to Save Changes and

Exit Setup.

■ Discard Changes and Exit

Select this option to quit Setup without saving any modifications to the system configuration. The following

window will appear after the “Discard Changes and Exit” option is selected. Select “Yes” to Discard

changes and Exit Setup.

70

Page 71

■ Restore Defaults

Note

Restore default values for all setup options. Select “Yes” to load Optimized defaults.

Chapter 3 Software Setup

: The items listed under Boot Override depend on devices connected to system.

71

Page 72

NCA-1513 User Manual

Green

The system is powered and running

Off

The system is powered off

Solid Green

Defined by GPIO

Solid Red

Defined by GPIO

Off

Defined by GPIO

Green

A hard disk is detected

Off

No hard disk is detected

BBlliinnkkiinngg AAmmbbeerr

Link has been established, and there is activity on this port

SSoolliidd AAmmbbeerr

Link has been established and there is no activity on this port

Off

No link is established

SSoolliidd AAmmbbeerr

Operating as a Gigabit connection (1000 Mbps)

Solid Green

Operating as a 100-Mbps connection

Off

Operating as a 10-Mbps connection

Power Status

System Status

HDD Activity

RJ45 Port

Link Activity

APPENDIX A: LED INDICATOR EXPLANATIONS

The status explanations of LED indicators on the Front Panel are as follows:

System Power

System Status

This LED indicator is programmable. You could program it to display the operating status of the behaviors

described below:

HDD Activity

Speed

Link Activity

Speed

Link Activity

Speed

72

Page 73

Appendix B: Renaming Network Interface

APPENDIX B: RENAMING NETWORK INTERFACE

Prerequisite

1. Login as “root.”

2. Have all network interfaces disconnected.

Description

It requires five steps to rename system’s network interface in Linux.

1. Scan all network-related interfaces in the system.

2. Filter the network interfaces. Please only preserve the interface that you want to rename.

3. Check interfaces’ status.

4. Rename.

5. Save the new name to the configuration file.

Config(rnif.conf)

There are some parameters that can be modified in the config file. (E.g. Character ‘#’ in the config file

means comment).

Filter: The network interface that user wants to rename.

UdevAddress: The path of udev rule files.

UdevFilename: Udev rule file name.

IfcfgAddress: The path of ifcfg files.

SaveStep: If set to 0, the program will skip the step of saving.

AutoNaming: The program will auto rename the network interface if user sets AutoNaming in the

config file. The format is “AutoNaming oldName:newName.” For example, if set “AutoNaming

eth0:lanner0”, the program will rename eth0 to lanner0 automatically.

Config Example

Filter eth

UdevAddress /etc/udev/rules.d

UdevFilename 10-lanner_net.rule

IfcfgAddress /etc/sysconfig/network-scrips

AutoSave 0

AutoNaming eth0:lanner0

AutoNaming eth1:lanner1

AutoNaming eth2:eth10

73

Page 74

NCA-1513 User Manual

Screenshots of Renaming Procedures

1. Scan and filter.

74

Page 75

2. If any network interface is still running, the utility will exit.

Appendix B: Renaming Network Interface

3. Renaming will start after the message shows “PASS: All interfaces are DOWN”.

75

Page 76

NCA-1513 User Manual

4. If renaming fails (using the same name), the utility will skip saving step and exit.

5. If renaming is successful, choose a save method or just leave.

76

Page 77

6. Save successfully.

7. You can skip saving and set AutoNaming.

Appendix B: Renaming Network Interface

77

Page 78

NCA-1513 User Manual

APPENDIX C: TERMS AND CONDITIONS

Warranty Policy

1. All products are under warranty against defects in materials and workmanship for a period of one year

from the date of purchase.

2. The buyer will bear the return freight charges for goods returned for repair within the warranty period;

whereas the manufacturer will bear the after service freight charges for goods returned to the user.

3. The buyer will pay for the repair (for replaced components plus service time) and transportation charges

(both ways) for items after the expiration of the warranty period.

4. If the RMA Service Request Form does not meet the stated requirement as listed on “RMA Service,“ RMA

goods will be returned at customer’s expense.

5. The following conditions are excluded from this warranty:

Improper or inadequate maintenance by the customer

Unauthorized modification, misuse, or reversed engineering of the product

Operation outside of the environmental specifications for the product.

RMA Service

Requesting an RMA#

1. To obtain an RMA number, simply fill out and fax the “RMA Request Form“ to your supplier.

2. The customer is required to fill out the problem code as listed. If your problem is not among the codes

listed, please write the symptom description in the remarks box.

3. Ship the defective unit(s) on freight prepaid terms. Use the original packing materials when possible.

4. Mark the RMA# clearly on the box.

Note: Customer is responsible for shipping damage(s) resulting from inadequate/loose packing

of the defective unit(s). All RMA# are valid for 30 days only; RMA goods received after the

effective RMA# period will be rejected.

78

Page 79

Appendix C: Terms and Conditions

RMA Service Request Form

When requesting RMA service, please fill out the following form. Without this form enclosed, your RMA

cannot be processed.

79

Loading...

Loading...