Page 1

In-Vehicle Computing

Hardware Platforms for mobile applications

LVC-5770

V1.2

>>

User's Manual

Publication date:2014-07-01

Page 2

About

About

Overview

Icon Descriptions

The icons are used in the manual to serve as an indication

of interest topics or important messages. Below is a

description of these icons:

NOTE: This check mark indicates that

there is a note of interest and is something

that you should pay special attention to

while using the product.

Online Resources

The listed websites are links to the on-line product

information and technical support.

Resource Website

Lanner http://www.lannerinc.com

Product Resources

RMA http://eRMA.lannerinc.com

WARNING: This exclamation point

indicates that there is a caution or

warning and it is something that could

damage your property or product.

http://www.lannerinc.com/

support/download-center

Acknowledgement

Intel, Pentium and Celeron are registered trademarks of

Intel Corp.

Microsoft Windows and MS-DOS are registered trademarks

of Microsoft Corp.

All other product names or trademarks are properties of

their respective owners.

Compliances and Certification

CE Certication

This product has passed the CE test for environmental

specifications. Test conditions for passing included the

equipment being operated within an industrial enclosure.

In order to protect the product from being damaged by

ESD (Electrostatic Discharge) and EMI leakage, we strongly

recommend the use of CE-compliant industrial enclosure

products.

FCC Class A Certication

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required

to correct the interference at his own expense.

e Mark Certication

E13 - Luxembourg

Copyright and Trademarks

This document is copyrighted, © 2014. All rights are

reserved. The original manufacturer reserves the right to

make improvements to the products described in this

manual at any time without notice.

No part of this manual may be reproduced, copied,

translated or transmitted in any form or by any means

without the prior written permission of the original

manufacturer. Information provided in this manual is

intended to be accurate and reliable. However, the original

manufacturer assumes no responsibility for its use, nor for

any infringements upon the rights of third parties that

may result from such use.

Embedded and Industrial Computing

2

Page 3

About

Mechanical compliance

Vibration:

General Vibration (operating): Refer to MIL-STD-810G, •

Method 514.6, Procedure I (Transportation), Category

4 – Common carrier (US highway truck vibration

exposure)

General Vibration (non-operating): Refer to MIL-STD- •

810G, Method 514.6, Procedure I (Transportation),

Category 24 – General minimal integrity

Shock:

Operating (Functional Test for Ground Equipment): •

Refer to MIL-STD-810G, Method 516.6, Procedure I,

40g, 11ms

Non-Operating (Crash Hazard Shock Test for Ground •

Equipment): Refer to MIL-STD-810G, Method 516.6,

Procedure V, 75g, 11ms

Electrical transient conduction along supply lines only

(12V/24V)

About

Revision History

Version Changes

1.2 Change the default BIOS values for DIO

Embedded and Industrial Computing

3

Page 4

TTaTTable of Contentsbeable of Contents

Chapter 1: Introduction 5

System Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2: System Components 7

System Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Block Diagram: The MainBoard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Block Diagram: The Ignition Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Front Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Rear Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power Adaptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Chapter 3: Board Layout 14

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Ignition Board Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

External Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Internal Connectors and Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Internal Connectors and Jumpers (backside) . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Connectors and Jumpers List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Chapter 4: The Flow Chart 29

Chapter 5: Hardware Setup 30

Preparing the Hardware Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Installing the System Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Wireless Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3G SIM Card Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Installing the Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Appendix A: Using the Ignition System Manager (ISM) 33

Appendix B: Digital Input/Output 34

Appendix C: Accessing the Digital Accelerometer Data from the LVC-5770 40

Appendix D: Accessing the GPS Data from the LVC-5770 42

Appendix E: Programming System Watchdog Timer of the LVC-5770 44

Appendix F: Terms and Conditions 48

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

RMA Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

4

Page 5

Chapter 1

Chapter 1:

Introduction

Introduction

Thank you for choosing the LVC-5770. The LVC-5770

is a fanless mobile NVR system which equips with a

suspension kit. It is designed to be installed on a moving

transportation system. In addition, the LVC-5770 is also

a Power sourcing equipment (PSE); the multiple PoE LAN

ports on the system can be used to connect to powered

device (PD) to supply power to the device through the

Ethernet cables.

The system encompasses a wide variety of communication

ports to facilitate every possible in-vehicle applications

including surveillance, event data recorder and the

GPS receiver. It also features an external HDD drive bay

for easy insertion of the HDD/SSD. The following list

highlights the capabilities of the LVC-5770 system.

One PoE power adapter which can accept vehicle •

power for 9~36 input voltage and supply 48VDC

output voltage for PoE power and 9~36 VDC output

for PC power and 9~36VDC for Aux power.

One Digital I/O port for 4 digital input and 3 output •

connections (via a DE-15 connector).

Two additional pins from the above Digital I/O can •

be used for system wake-up to power on the system

automatically.

PC audio ports with • line in, line out and microphone

ports.

Rich I/O ports: 2 RS-232/422/485 via D-Sub 9, 2 LAN •

ports, 6 USB ports (6 type A)

Dual Mini-PCIe connectors for 3G Internet services •

(with 1 SIM card readers for 3G wireless Internet

connections) and an additional PCIe expansion

suitable for Wi-Fi connection.

Dual video display: DVI-D+VGA or HDMI+VGA output •

with Intel HD Graphics 3000

Power ignition control mechanism with programmable •

on/off/delay switch

Wide range of DC power input from 9V to 36V, suitable •

for vehicular 12V or 24V battery with Ignition control.

–Power input current protection by the 10A fuse and

15KP30A TVS

--12V DC output current protection by the 1A Polyfuse

Battery voltage protection: Over Voltage Protection •

and Under Voltage Protection

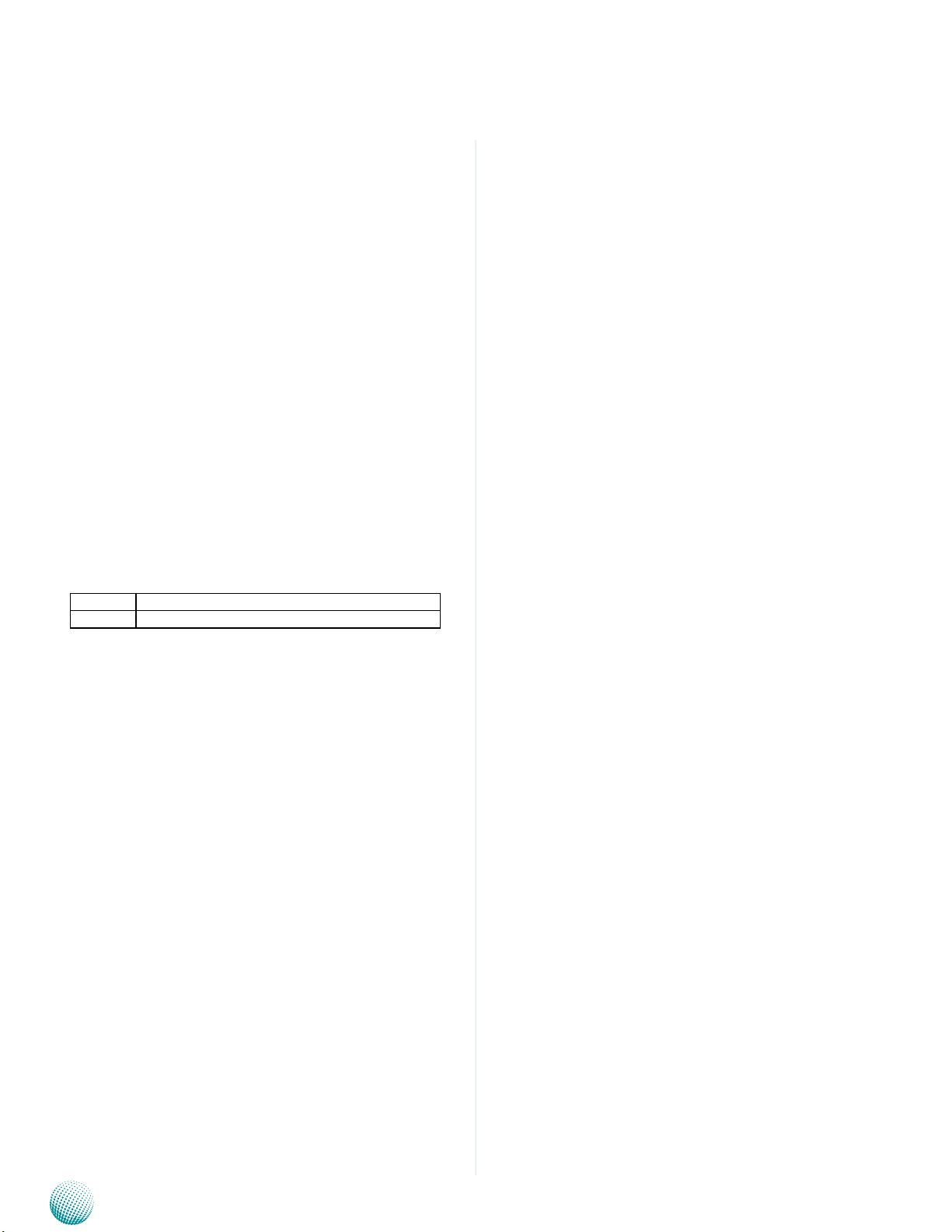

System Specification

Dimensions (WxHxD)

Processor Intel Sandy Bridge Processors

Chipset Intel HM65

System

Memory

Ethernet Controller Intel 82574Lx2

Graphic Controller Intel integrated HD graphics engine

Audio Controller ALC886

IO

Power Input

PoE Power Adapter LVP-POE936A included

OS Support

Certications CE, FCC Class A, E13, RoHS

Technology DDR3 SO-DIMMx2

Max. Capacity Up to 16GB

SATA

LAN GbE RJ45 x2

Display

Audio

Serial I/O 2xRS-232/422/485 with RI/5V/12V

GPIO

GPS Ublox NEO-6Q GPS receiver module

G-sensor ADXL 345

USB 2.0 Type A x6

Power Input 3-pin terminal block (+, -, ignition)

Expansion

Others

276.4x190x85.3mm

(10.88”x7.48”x3.36”)

Removable 2.5” SSD/HDD drive

bayx2, on-board 8GB SSD

DVI-D, maximum resolution up to

1920x1200@60Hz

VGA, maximum resolution up to

2048x1536@75Hz

HDMI, maximum resolution up to

1920x1200@60Hz

Dual display function supports independent, clone and extended mode

(VGA+DVI or VGA+HDMI).

Mic-in and Line-out with 2 watt by

DB9 female connector

4x DI 12V Level

3x DO 12V Level

2x DI (from MCU) 5V Level

Mini-PCIe x2 (one with SIM card

reader)

External: 3x SMA antenna hole,

reset, Remote Power switch

Internal: 9~36Vdc (max. 10A) On/

Off software controllable

+9~36VDC input range, ATX mode

support ignition delay on/off

control

Linux Kernel 2.6.18 or later

Windows XPE/WES2009, XP Pro

FES, WS7E, Win 7 Pro FES

Standby power consumption are well under 12V/81mA

and 24V/83mA

Extended operating temperature between -20 ~ 55 ºC •

(-4 ~ 131ºF)

Embedded and Industrial Computing

5

Page 6

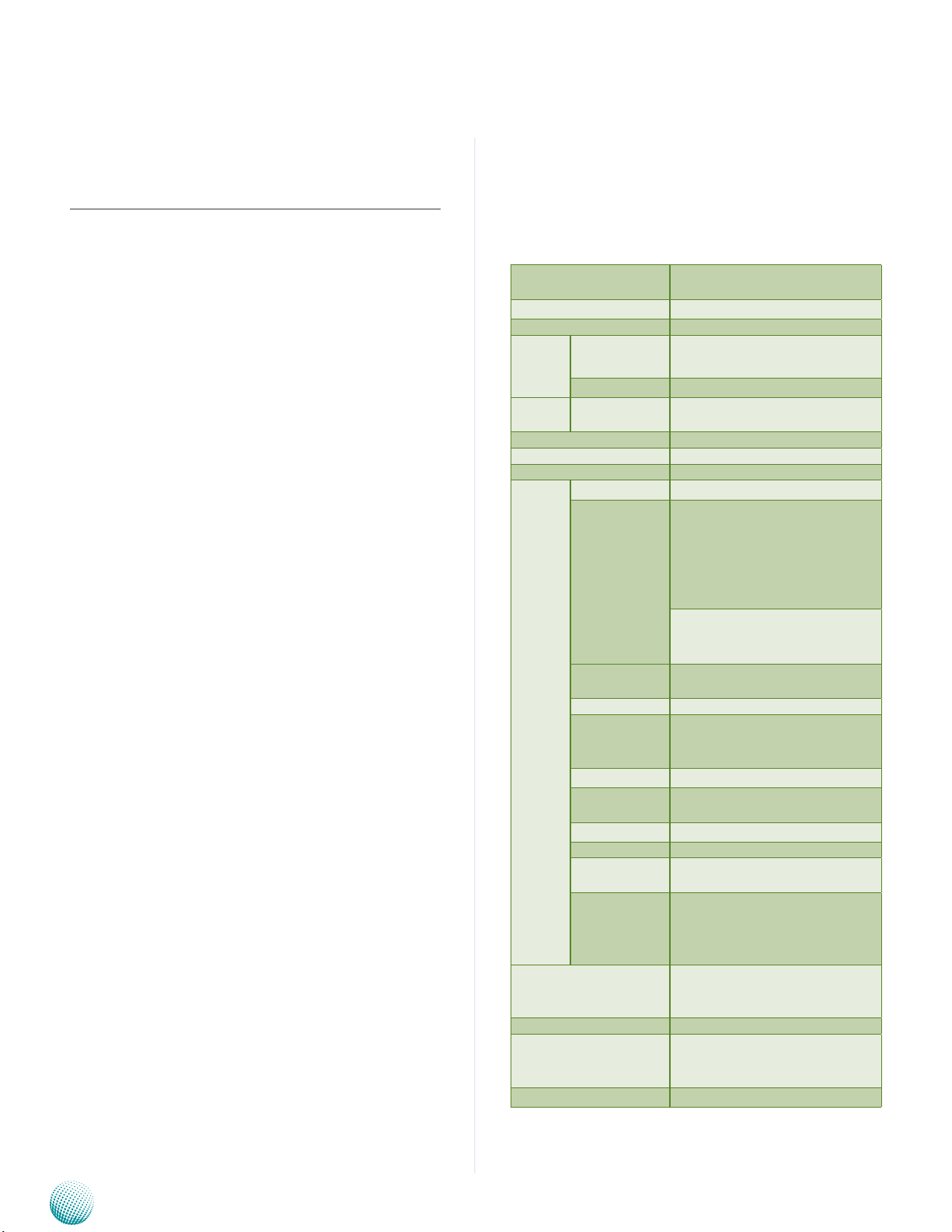

Chapter 1

Introduction

Compliance

Operating

Temperature

Range

Extended

Standard

Vibration: MIL-STD-810G, Method

514.6 with SSD and suspension kit

Shock: MIL-STD-810G, Method

516.6 with SSD and suspension kit

With Selected Industrial Compo-

nents

-20~55°C/-4~131°F

With Commercial Components

-5~45°C / 23~113°F

Package Contents

Your package contains the following items:

LVC-5770 Fanless Embedded System with a suspension •

kit

Terminal Block Connectors •

(P/N: 2 pin 04AW20021E101, 3 pin 04AW20031E001 ,

4pin 04AW20043E101)

LVP-POE936A POE power adapter •

(P/N:SE9ESSC69R01A)

HDD Screws x 4 (P/N: 070W102400602) •

Mini-PCIe screw x8 (P/N: 070W101000401) •

Embedded and Industrial Computing

6

Page 7

Chapter 2

Chapter 2:

System Components

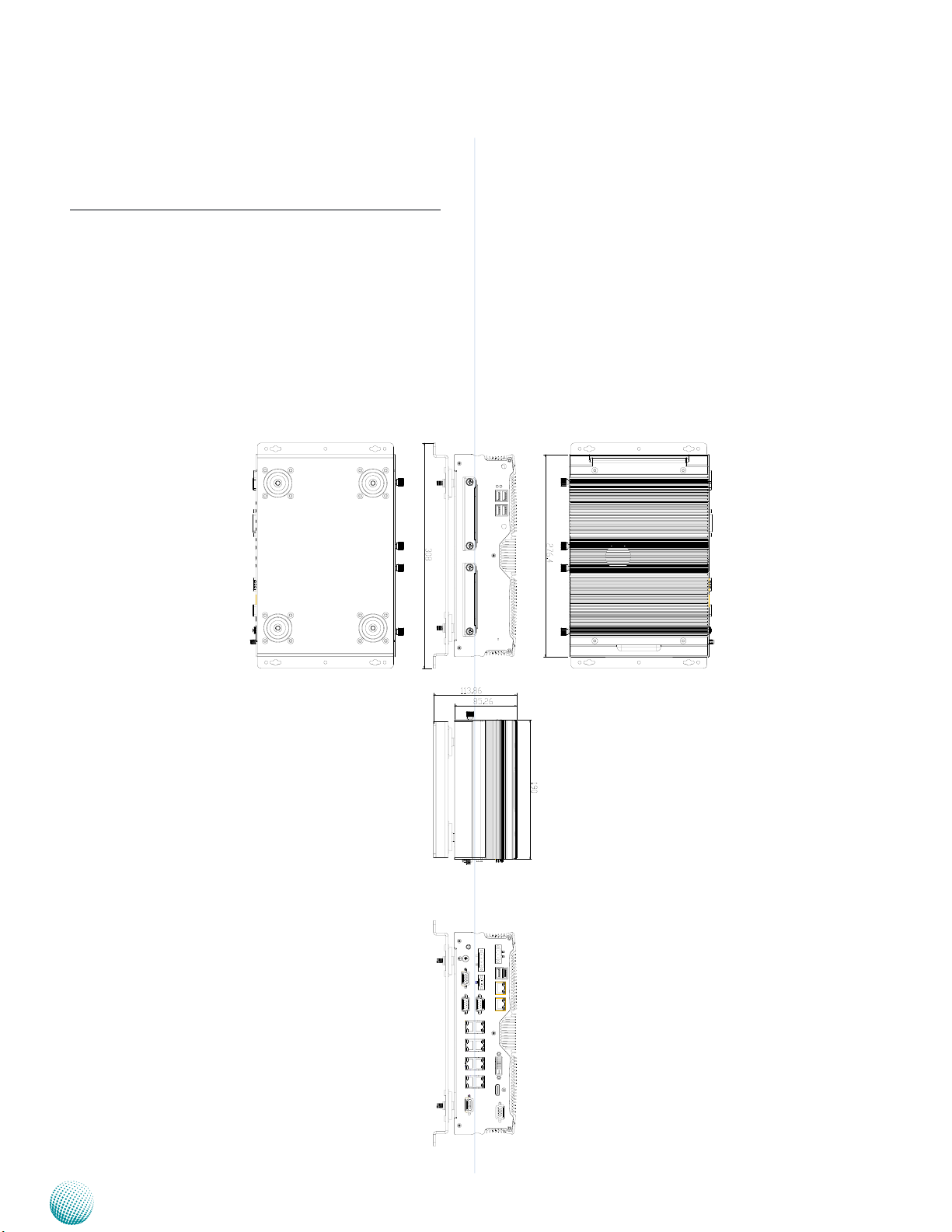

System Drawing

Mechanical dimensions of the LVC-5770 with the

suspension kit

Unit: mm

System Components

Embedded and Industrial Computing

7

Page 8

Chapter 2

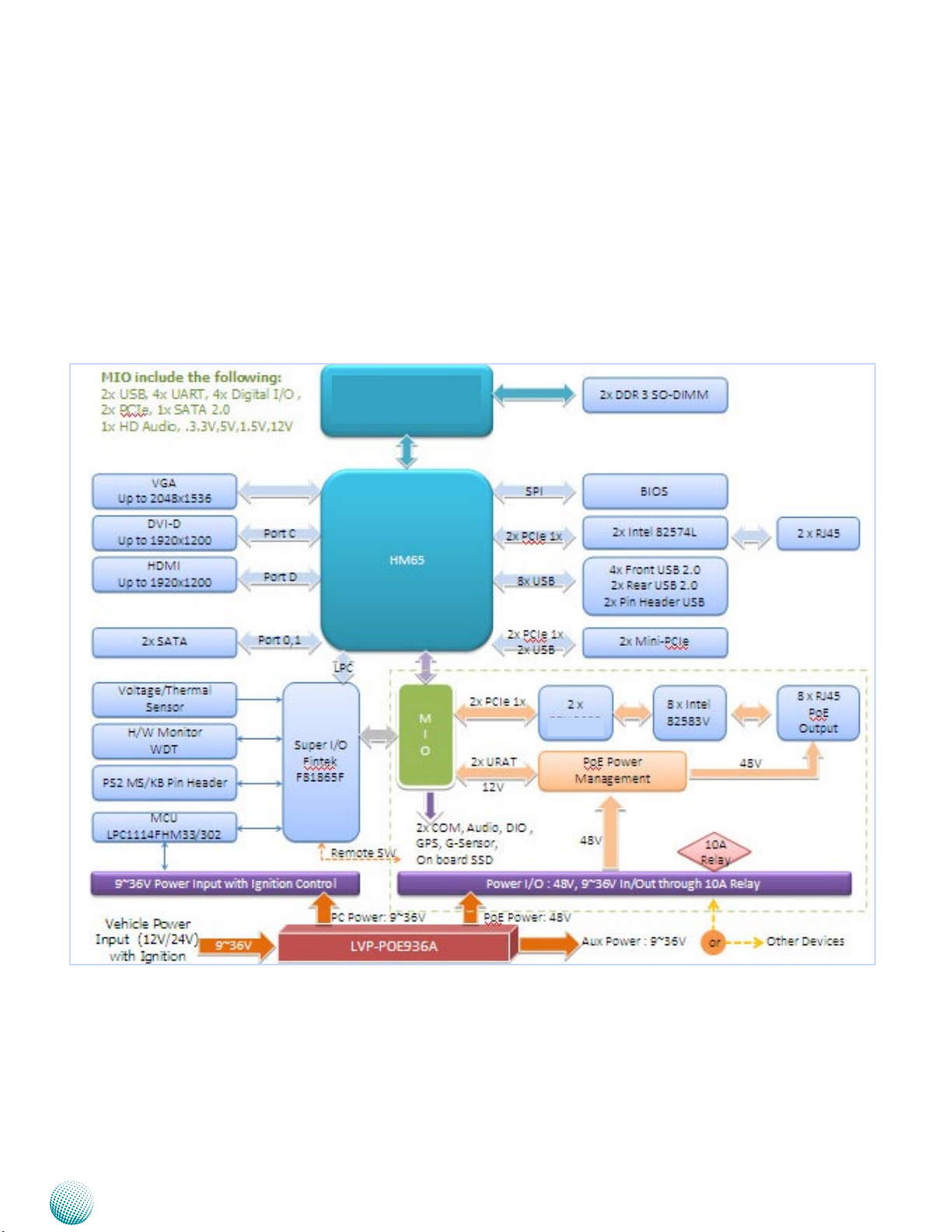

Block Diagram: The MainBoard

The block diagram depicts the relationships among the

interfaces and modules on the motherboard.

Intel® Sandy Bridge

Processors

System Components

PEx8606

Embedded and Industrial Computing

8

Page 9

Chapter 2

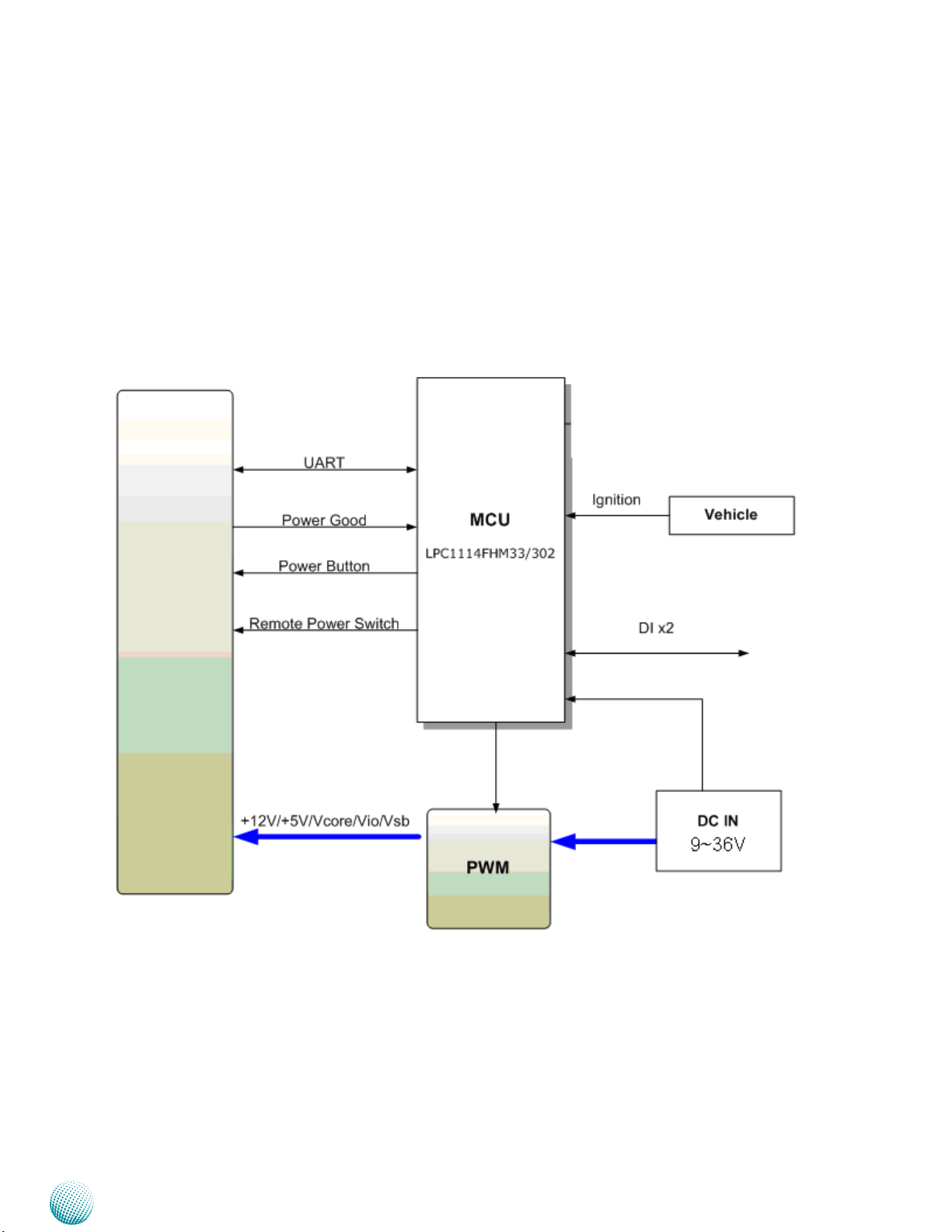

Block Diagram: The Ignition Board

The block diagram depicts the relationship between the

power ignition board and the mainboard.

System Components

LVB-5770

Embedded and Industrial Computing

9

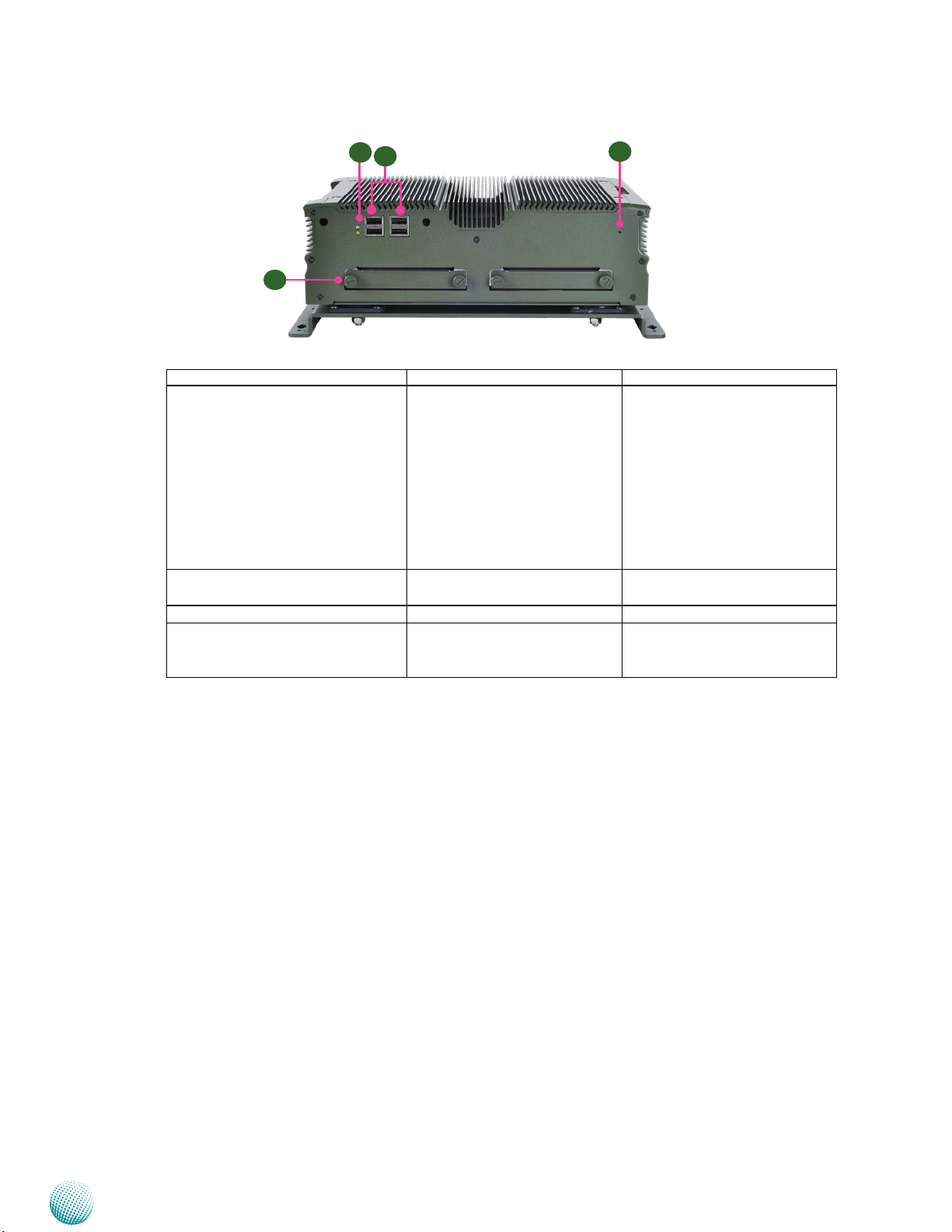

Page 10

Chapter 2

System Components

Front Components

F1 HDD (Yellow) and

Power LED (Green)

F2 Four USB 2.0 Ports USB type A connectors Dual USB Port #0, #1 and #2, #3

F3 Reset Switch A hardware reset button RST1 on page 24

F4 Hard Disk Slot External SATA 2.5” hard disk

F1

F2

F3

LVC-5770

USB USB

F4

Component Description Pin Definition Reference

RST

HDD

Blinking: data access •

activities

Off: no data access •

activities or no hard disk

present

Power

On: The computer is on.•

Off: The computer is off .•

(USB1,USB2) on page 26

SATA1/SATA2 on page 23

drive for easy access and replacement of the data storage.

Embedded and Industrial Computing

10

Page 11

Chapter 2

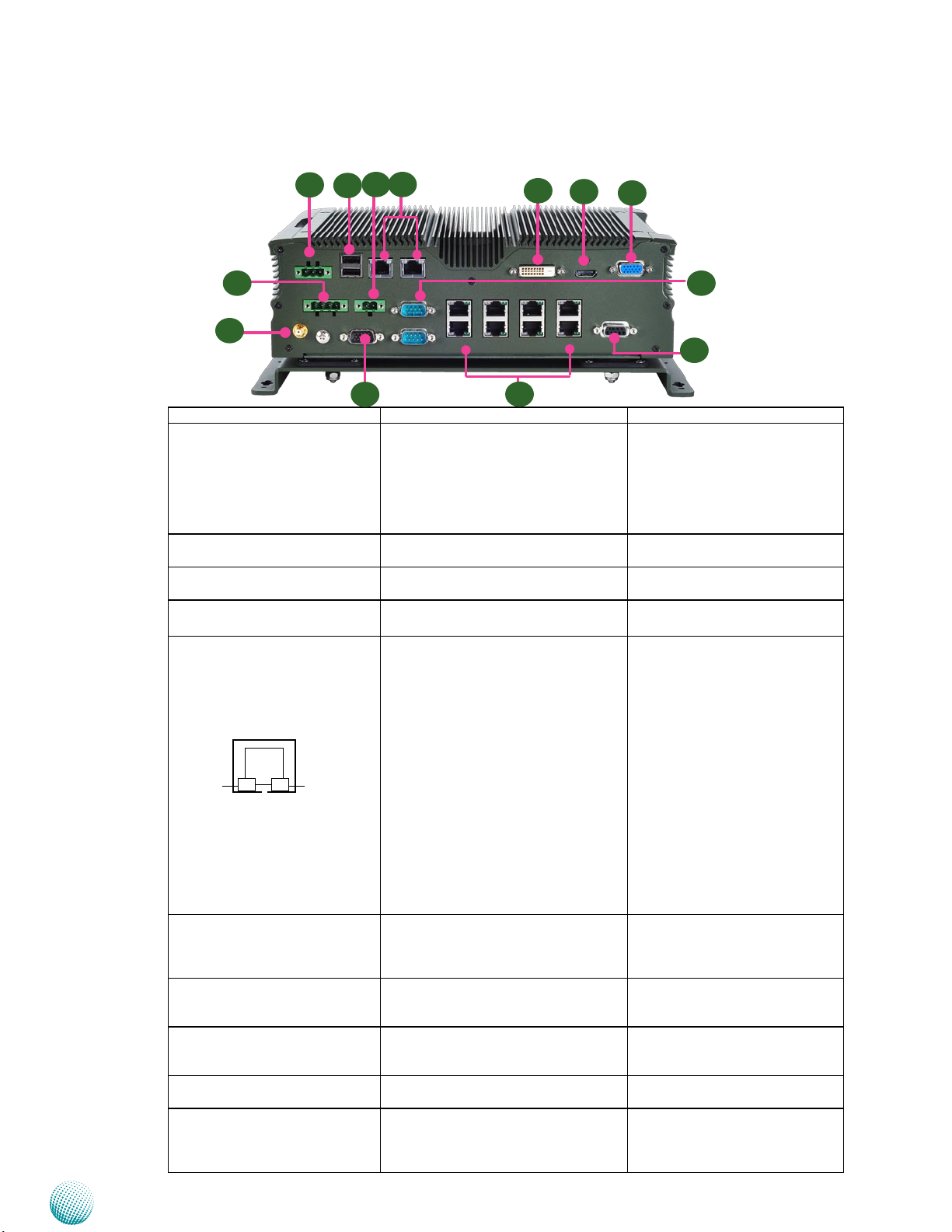

Rear Components

R9

R2

R1

R4

DC Input 9~36V

USB LAN2 LAN1

OUT + - - + IN

DC Relay Bypass PoE Power 48V

+ -

R3

R5

COM2

COM1

R6

DVI-D HDMI VGA

POE POE POE POE

R7

Audio

System Components

R8

R10

R11

R12

Component Description Pin Definition Reference

R1 Power-In (DC) Power-in with ignition support. The

LVC-5770 support a wide range of

R13

DC_IN Connector (CN4) on page

25

power input (+9V ~ +36) including

the prevalent 12V and 24V vehicular

power system. It has a 2KV ESD

protection on the DC input and

ignition line.

R2 DC Relay Bypass (DC) 9~36V, 10A (GND, Power-Out)

CN4 on page 21

Integrated in 1x 4-pin terminal block

R3 PoE Power 48V 48V power input for supplying power

CN3 on page 21

to the PoE devices

R4 Two USB 2.0 Ports USB type A connectors Dual USB Port Connector #4 and

#5 (USB3) on page 26

R5 Two 10/100/1000Mbps LAN

ports

Two RJ-45 (network) jacks (provided

by Intel 82574L) with LED indicators

LANB1/LANB2 on page 25

as described below

LINK/ACT (Yellow)

On/Flashing: The port is linking •

and active in data transmission.

Off: The port is not linking.•

SPEED

LINK/ACT

SPEED (Green/Amber)

Amber: The connection speed is •

1000Mbps.

Green: The connection speed is •

100Mbps

Off: .The connection speed is •

10Mbps.

R6 DVI-D (*) A DVI-D port (single link) which

DVID1 on page 24

is provided by Intel HD Graphic

Engine. This port can support up to

1920x1200@60Hz resolution.

R7 HDMI Port (*) A DVI-D port (single link) which

HDMI1 on page 24

is provided by Intel GMA 3650

(resolution: 1920x1200@60Hz).

R8 VGA Port (*) It connects an external VGA

VGA1 on page 24

monitor or projector (resolution:

2048x1536@75Hz)

R9 GPS Antenna It connects an antenna for the build-

in GPS module.

R10 Serial Ports COM1 and COM2 provide RS232/

RS422/RS485 communications with

RS-232 COM Port (COM1, COM2)

on page20

a dip switch selecting among these

standards.

Embedded and Industrial Computing

11

Page 12

Chapter 2

R11 PC Audio Ports D-sub 9 connector for MIC input and

R12 MIO Connector A DE-15 male connector for 4 Digital-

R13 Power over Ethernet Ports Eight RJ-45 jacks with LED indicators

SPEED

* Only DVI-D +VGA or HDMI + VGA can work at the same time.

System Components

Component Description Pin Definition Reference

Audio1 on page 20

HD Audio output (w/2 Watt) from

LEK-IOA7.

J15 on page 21

In & 3Digital-output, at 12V level.

The digital input helps triggering

between open and closed circuit such

as PIRs, door/window contact, glass

break detector. And the output can

connect to devices such as sirens.

In addition to the above Digital I/O

function, two IGN_in pins can be used

to wake up the system even when the

system is shut down.

LAN1~LAN8 on page 22

LINK/ACT (Yellow)

On/Flashing: The port is linking •

and active in data transmission.

Off: The port is not linking.•

SPEED (Green/Amber)

LINK/ACT

Amber: The connection speed is •

1000Mbps.

Green: The connection speed is •

100Mbps

Off: .The connection speed is •

10Mbps.

They are provided by Intel 82583V

GbE chips with Power over Ethernet

power source capability (48V, 15W).

Embedded and Industrial Computing

12

Page 13

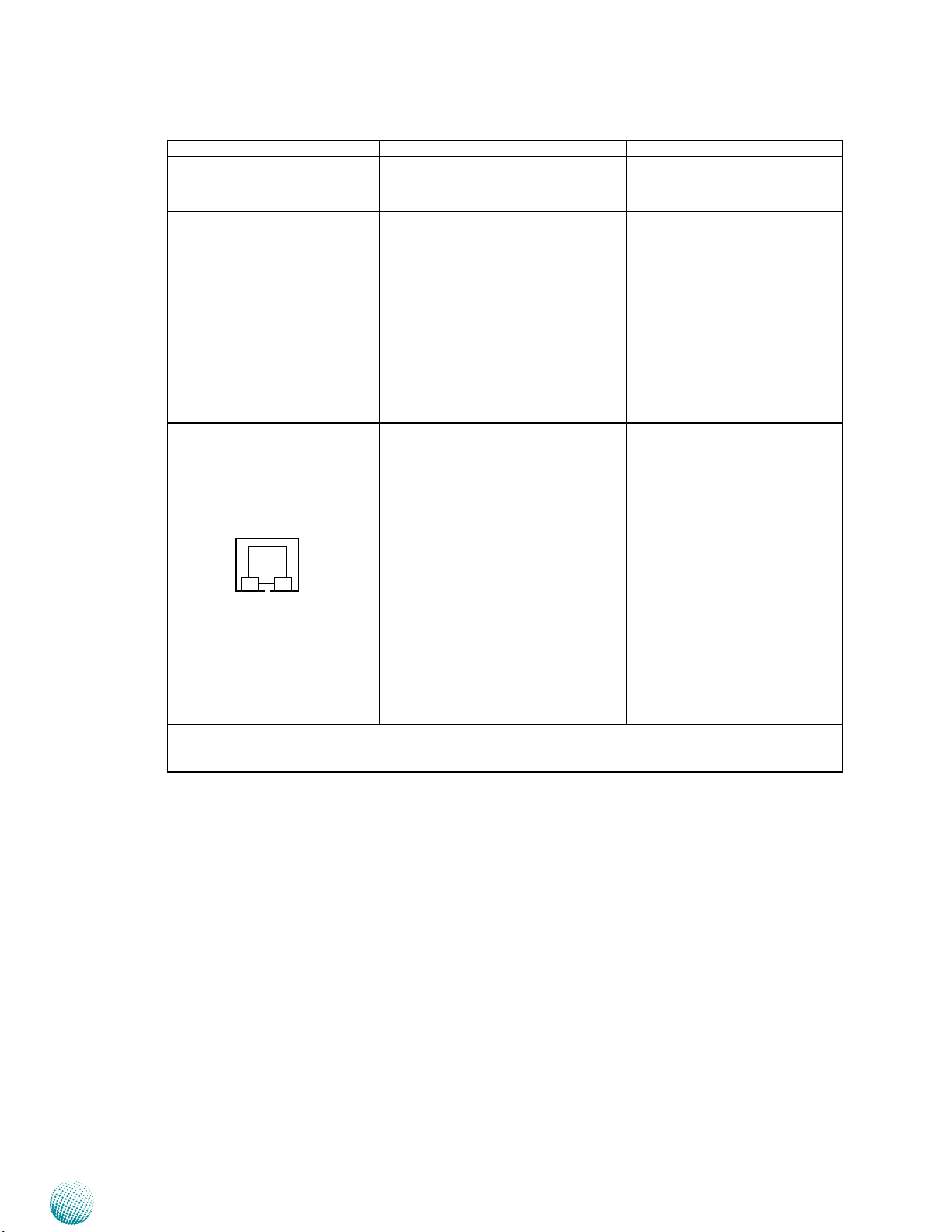

Chapter 2

Power Adaptor

System Components

R1

PoE Power PC Power

48V 9~36 Bypass

Output1 - + IG - + Output2 - + Output3

R2

Aux Power

9~36V Bypass

R3

Vehicle Power (12V/24V) w/ Ignition

IG - + - +

R4

Input Range: 9~36VDC

48V

IG

The system comes with a power adaptor that is capable to transfer power input from 9~36VDC to 48VDC

output.

Component Description Pin Definition Reference

R1 Power output (DC) to the

LVC-5770 System

9~36V, 10A (GND, Power-Out)

Integrated in 1x 5-pin terminal block.

POWER_CON1 on page 28

The output port on the connector

will supply power to the LVC-5770

system.

R2 Power Output (DC) The output port of this connector can

POWER_CON3 on page 28

bypass power from the input port

(see R3) to supply additional 9~36V

power for other uses.

R3 Power Input (DC) with

Ignition control

Power-in with ignition support. The

LVC-5770 support a wide range of

POWER_CON2 on page 28

power input (+9V ~ +36) including

the prevalent 12V and 24V vehicular

power system. It has a 2KV ESD

protection on the DC input and

ignition line.

R4 LED Green: On means that PoE Power 48V

port is connected (refer to R3 on the

rear panel)

Yellow: On means that car ignition is

turned on.

The power board also equips with jumpers that can be switched to enable or disable automatic power

management control.

Embedded and Industrial Computing

13

Page 14

Chapter 3

Chapter 3:

Board Layout

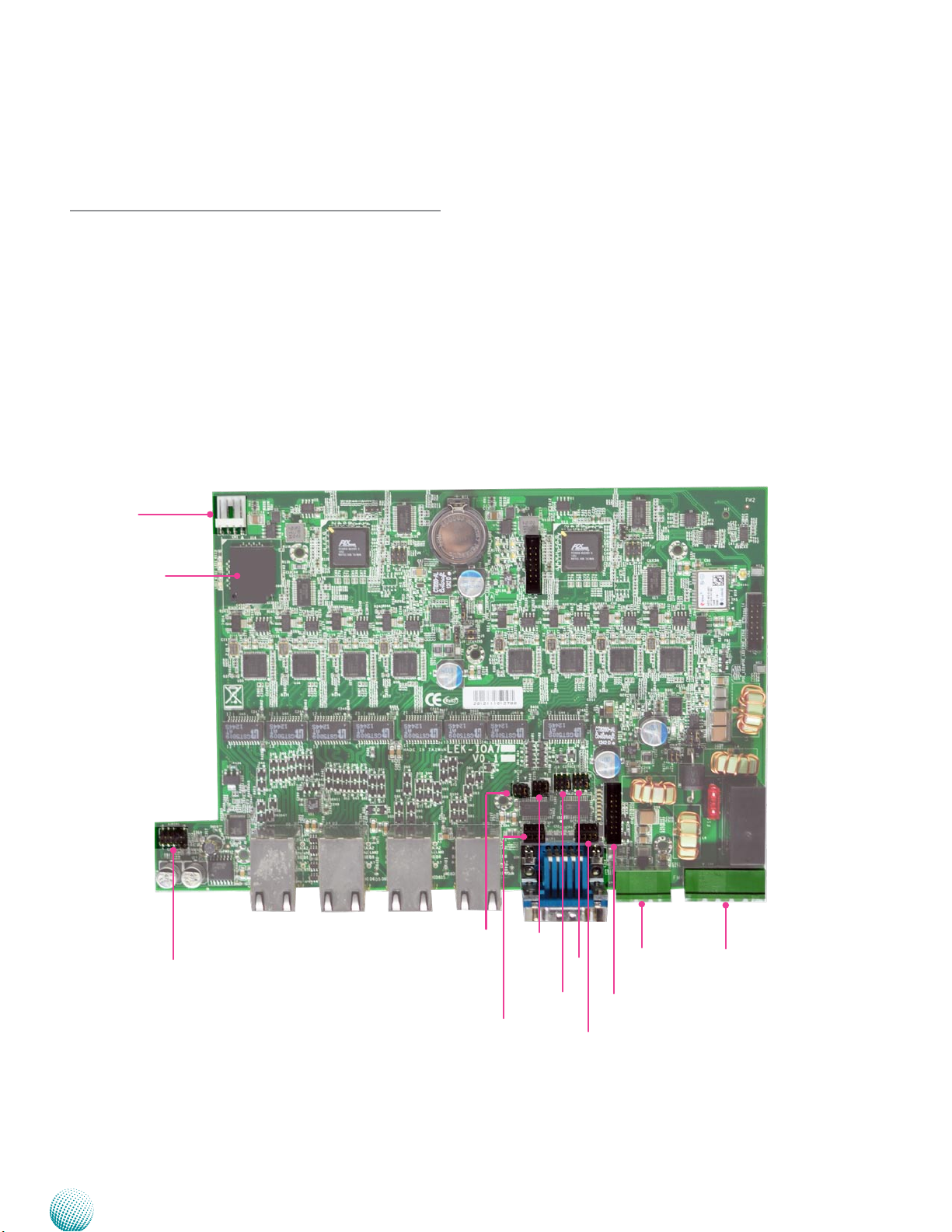

Connectors

The following picture highlights the location of the COM

ports and other connectors on the expansion card. Refer

to the table 3.1 Connector List for more details.

CN1

Board Layout

Onboard 8G SSD

Audio1

SCT2

SCT4

SCT1

J13

J14

SCT3

J15

CN3

CN4

Embedded and Industrial Computing

LEK-IOA7

14

Page 15

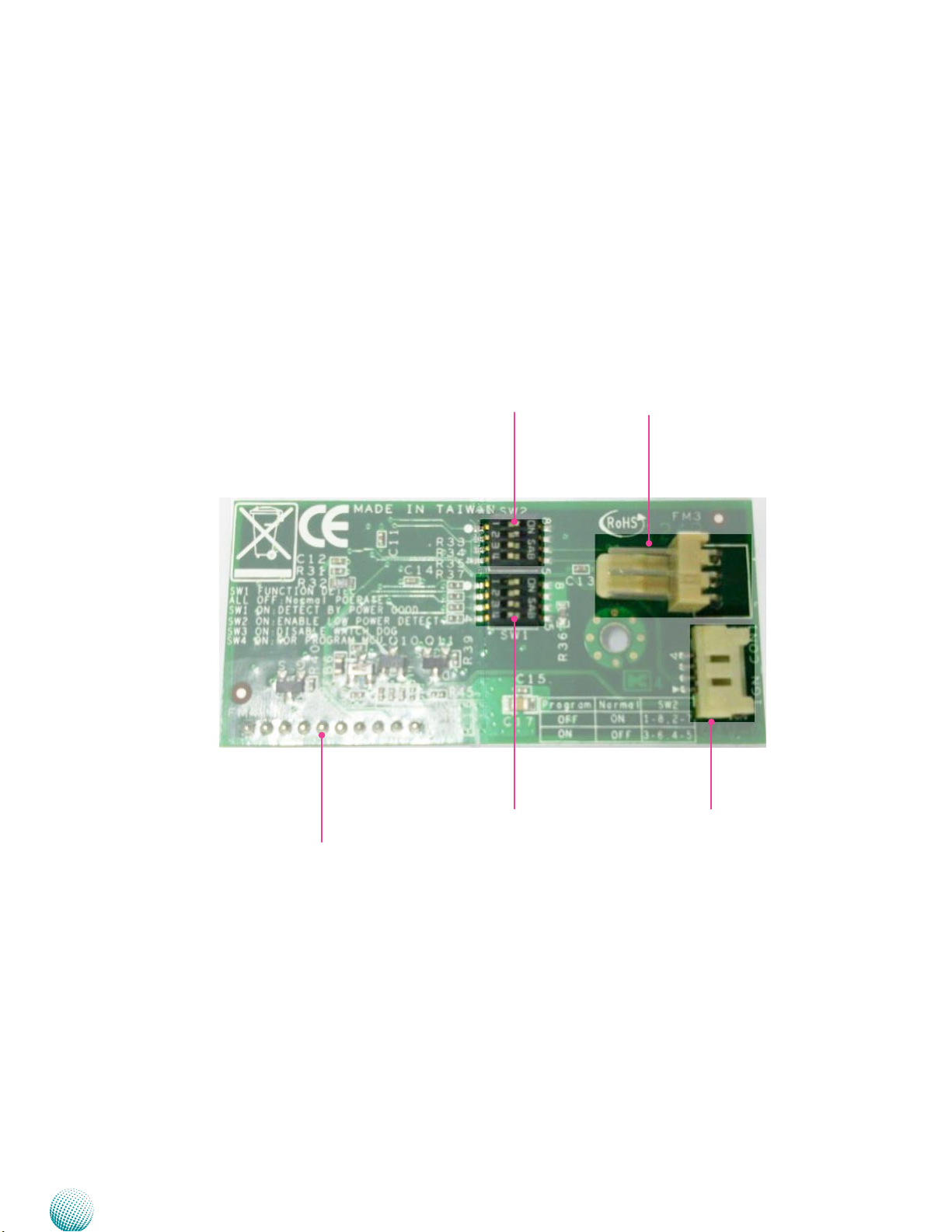

Chapter 3

Ignition Board Connectors

The following picture highlights the location of ignition

board connectors. The ignition board also equips with

jumpers that can be switched to enable or disable

automatic power management control. Refer to the table

3.2 Connector List for more details.

Board Layout

IGNITION1

SW2

SW1

CN1

IGN_CON1

Embedded and Industrial Computing

LEK-IG1

15

Page 16

Chapter 3

External Connectors

The following picture highlights the location of external

input/output connectors. Refer to the table 3.3 Connector

List for more details.

Board Layout

VGA1

HDMI1

DVID1

LAN1/LAN2

USB3

CN4

CN3/

DCJK1

(optional)

USB1

LED1

Embedded and Industrial Computing

USB2

RST1

LEB-5570

16

Page 17

Chapter 3

Internal Connectors and Jumpers

The following picture highlights the location of internal

connectors and jumpers. Refer to the table 3.3 Connector

List for more details.

Board Layout

CMOS2

COMSLT2

COMSLT1

SIM1

SATA_PW2

CMOS1

FAN2

MPCIE2

MPCIE1

LPC1

SPI1

Ignition1

FRONT1

Embedded and Industrial Computing

SO-DIMM

J1

LEB-5570 (The LEB-5570 is used on both

LVC-5570 and LVC-5770)

FAN1

17

Page 18

Chapter 3

Internal Connectors and Jumpers

(backside)

The following picture highlights the location of internal

connectors and jumpers on the backside of the board.

Refer to the table 3.3 Connector List for more details.

Board Layout

MIO1

SATA1

SATA2

SATA_PWR1

PCIEIO1

Embedded and Industrial Computing

KBM1

LEB-5570

18

Page 19

Chapter 3

Board Layout

Connectors and Jumpers List

The tables below list the function of each of the board

jumpers and connectors by labels shown in the above

section. The next section in this chapter gives pin

definitions and instructions on setting jumpers.

Table 3.1 Connector List for LEK-IOA7 Board

Labels Function Pin Denition Reference

Page

AUDIO1 HD Audio Connector (D-Sub) P20

CN3 48V for PoE Power Supply P21

CN4 DC_in and out Connector P21

COM1 RS232/422/485 Serial Port P20

COM2 RS232/422/485 Serial Port P20

J13/J14 Select COM1 and COM2 Pin9 Function P21

JAUD1 Audio Select P22

LAN1~LAN8 POE Ports P22

MIO1(J15) Digital Input and Output P21

MIO Connector to the LEB-5570 board P22

SCT1/SCT3 Select COM2 Protocol Setting P20

SCT2/SCT4 Select COM1 Protocol Setting P20

SSDSLT1 SSD enable/disable P22

Table 3.2Connector List for LEK-IG1 Board

Labels Function Pin Denition Reference

Page

CN1 MCU Programming Connector P27

IGNITION1 Ignition Control Connector P27

IGN_CON1 Power Connector P27

SW1 Power Ignition Behavior Switch P27

The ignition board also equips with jumpers that can be switched to enable or disable automatic power management control.

Table 3.3 Connector List for LEB-5570 Board

Labels Function Pin Denition Reference

Page

CMOS1 Cleaning CMOS Data Including RTC P26

CMOS2 Cleaning CMOS Data Only P29

COMSLT1 Daughter board LEK-IOA7 enable/disable P25

COMSLT2 Daughter board LEK-IG1 enable/disable P26

CN43 Power Connector with Power -ignition Control P25

DCJK1 (optional) Optional DC Jack Type of Power Connector P25

DVID1 DVI-D Connector P24

FAN1/FAN2 System Fan Connector P24

Front1 Front Panel Function Pin Header P23

HDMI1 HDMI Port P24

Ignition1 Connector for power Ignition Control P26

J1 PEG16X Lane Function Selection P24

KBM1 PS/2 Keybaord and Mouse Connector P26

LAN1/LAN2 Ethernet Connector 1/Ethernet Connector 2 P25

LPC1 Low Pin Count Interface Reserved for factory use

MIO1 COM and Audio Expansion Card Connector (to the LEK-IOA7) P23

MPCIE1 Mini-PCIe Connector P25

MPCIE2 Mini-PCIe Connector P25

RST1 Reset Button P24

SATA1/SATA2 Serial-ATA Connector (SATA2 supports SATA-DOM) P23

SATA_PWR1 SATA Power Connector P23

SATA_PW2 Switch for SATA port 2 power state P23

SIM1 SIM Card Reader P25

SPI1 Serial Peripheral Interface Bus Reserved for factory use

USB1/USB2/USB3 USB Type A Connector #0,1; #2,3; #4,5 P26

VGA1 VGA Port P24

Embedded and Industrial Computing

19

Page 20

Chapter 3

Board Layout

Jumper Settings

LEK-IOA7 Board

Line-out Audio Jack (Audio, AUDIO1): a D-sub 9 male

connector for HD Audio

12345

6789

Note: The driver for the VGA and Audio ports

should be installed with the following order:

Chipset INF->Graphic->Audio

COM1 RS-232 Serial Port (COM1): a RS-232/422/485 port

through the D-SUB9 connector.

Pin No. Pin Name

1 DCD TXD- DATA2 RXD TXD+ DATA+

3 TXD RXD+

4 DTR RXD5 GND

6 DSR

7 RTS

8 CTS

9 RI

Pin No. Function Pin No. Function

1 AUDIO_IN_L 6 AUDIO_IN_R

2 N/A 7 N/A

3 FRONT_OUT_L 8 GND

4 FRONT_OUT_R 9 GND

5 N/A 10

12345

6789

RS-232 RS-422 RS-485

SCT2, SCT4: Select COM1 Protocol Setting

SCT2

5

6

1

2

9

5

1

SCT4

12

8

4

RS-232

5

6

1

2

9

5

1

12

8

4

RS-422

5

6

1

2

9

5

1

12

8

4

RS-485

5

6

Switch

1

2

9

5

1

SCT2 SCT4

12

8

4

Protocol

RS-232 (default) 1-2 1-5, 2-6, 3-7, 4-8

(default)

RS-422 3-4 5-9, 6-10, 7-11, 8-12

RS-485 5-6 5-9, 6-10, 7-11, 8-12

SCT1, SCT3: Select COM2 Protocol Setting

RS-232/422/485 Serial Port(COM2): a RS-232/422/485

port through the D-SUB9 connector.

Pin No. Pin Name

RS-232 RS-422 RS-485

1 DCD TXD- DATA2 RXD TXD+ DATA+

3 TXD RXD+

4 DTR RXD5 GND

6 DSR

7 RTS

8 CTS

9 RI

Embedded and Industrial Computing

SCT1

5

6

SCT3

1

2

9

5

1

12

8

4

20

Page 21

Chapter 3

Board Layout

5

6

5

6

5

6

Switch

1

2

1

2

1

2

9

5

1

9

5

1

9

5

1

SCT1 SCT3

12

8

4

12

8

4

12

8

4

Protocol

RS-232 (default) 1-2 1-5, 2-6, 3-7, 4-8

(default)

RS-422 3-4 5-9, 6-10, 7-11, 8-12

RS-485 5-6 5-9, 6-10, 7-11, 8-12

J13, J14: Select COM1 and COM2 Pin9 Function (in

RS-232) respectively. The Ring indicator pinout of the RS232 COM port can be altered according to the following

jumper settings.

Maximum input/output current for each port is

100mA

For all Input/

output pins:

Voltage Logic Register

Di: <0.8V

Low 0

Do: <0.4V

DI: 0.9 ~ 5V

High 1

Do:5V

The default BIOS value is 1 for DI and 1 for DO

Pin 11 is used for remote power switch.1.

Pin 6 is used for relay power switch.2.

Pin12 and pin13 can be used for DI wake-up 3.

function (Refer to the flow chart in Chapter 4 and

the ISM in Appendix A).

DC_in and out (CN4) : 9~36V DC power input and output

Integrated in a 4-pin terminal.

4 3 2 1

Pin No. Function

1 P930V_IN

2 P930V_GND

3 GND_930V

4 P930V_OUT

J13 J14

2

1

6

5

2

1

Pin No. Function

1-2 Supply +5V to

6

3-4 Supply +12V to

5

5-6 Ring-in (default)

the Device

the Device

Digital Input and Output (MIO, J15): A DE-15 Male

Connector for 4 DI & 3 DO, 12V

15 11

5 1

Pin Signal Pin Signal Pin Signal

1 RIO_IN0 6 RIO_OUT0 11 EXT_POWER_ON

2 RIO_IN1 7 RIO_OUT1 12 IGN_IN0

3 RIO_IN2 8 RIO_OUT2 13 IGN_IN1

4 RIO_IN3 9 RIO_OUT3 14 GND

5 GND 10 GND 15 12V_OUT (1A)

48V DC_IN for PoE Power Supply (CN3):

2 1

Pin No. Function

1 GND

2 48V_IN

Optional Connector (CN1):

CN1

4 3 2 1

Pin No. Function

1 VCC12

2 GND

3 GND

4 VCC5

Embedded and Industrial Computing

21

Page 22

Chapter 3

Board Layout

LAN1~LAN8 Ports: The LAN ports are provided by Intel

82583V Ethernet controller whose interface complies

with PCI-e 1.1 (2.5 Ghz). Theses ports are PoE capable (48V,

.

15W)

Pin

Description Pin

No.

No.

Description Pin

No.

Description

A1 LAN2_MX0P B1 LAN1_MX0P LED1 LAN2_ACTLED_N

A2 LAN2_MX0N B2 LAN1_MX0N LED2 LAN2_ACTLED_P

A3 LAN2_MX1P B3 LAN1_MX1P LED3 LAN2_L100_N

A4 LAN2_MX1N B4 LAN1_MX1N LED4 LAN2_L1000_N

A5 LAN2_MX2P B5 LAN1_MX2P LED5 LAN1_ACTLED_N

A6 LAN2_MX2N B6 LAN1_MX2N LED6 LAN1_ACTLED_P

A7 LAN2_MX3P B7 LAN1_MX3P LED7 LAN1_L100_N

A8 LAN2_MX3N B8 LAN1_MX3N LED8 LAN1_L1000_N

Enable or disable the onboard SSD memory

(SSDSLT1)

5

6

1

2

Pin No. Function

1-3, 2-4 short

3-5, 4-6 open

3-5, 4-6 Short

1-3, 2-4 open

Enable

Disable

Note: When trying to install an OS on the external

SATA 2.5 hard disk or SSD, disable it first by setting

the jumpers accordingly. Enable it after finishing

the OS installation.

Audio Select (JAUD1): Jumper for mic-in or line-in

switch for connector AUDIO1 (page 20)

Pin No. Function

1-3, 2-4 short Mic-in

3-5, 4-6 Short Line-in

Mini PCI Express Connector (MIO1) on the LEK-IOA7:

Connector for connecting to the mainboard

PIN Pin Name PIN Pin Name

1 GND 51 HDA_BCLK

2 N/A 52 HDA_SYNC

3 N/A 53 HDA_RST

4 GND 54 HDA_SDIN0

5 N/A 55 HDA_SDO

6 N/A 56 SPK

7 GND 57 VCC3_SB

8 VCC3P3_PS 58 VCC3_SB

9 VCC3P3_PS 59 VCC3_SB

10 VCC3P3_PS 60 VCC3_SB

11 GND 61 VCC3_SB

12 N/A 62 N/A

13 N/A 63 N/A

14 N/A 64 N/A

15 N/A 65 N/A

16 N/A 66 N/A

17 N/A 67 N/A

18 IGN_DI2 68 IGN_DI1

19 N/A 69 N/A

20 N/A 70 N/A

21 DCIN_VCC 71 REMOTE_POWER_

ON

22 +12V 72 3G_POWER_ON

23 N/A 73 N/A

24 VCC5_SB 74 N/A

25 VCC5 75 GND

26 VCC5 76 N/A

27 VCC5 77 N/A

28 GND 78 GND

29 N/A 79 N/A

30 N/A 80 N/A

31 N/A 81 N/A

32 N/A 82 N/A

33 GND 83 GND

34 N/A 84 COM1_DCD#

35 N/A 85 COM1_RI#

36 N/A 86 COM1_CTS#

37 N/A 87 COM1_DTR#

38 N/A 88 COM1_RTS#

39 N/A 89 COM1_DSR#

40 N/A 90 COM1_SOUT

41 N/A 91 COM1_SIN

42 GND 92 GND

43 N/A 93 COM2_DCD#

44 N/A 94 COM2_RI#

45 N/A 95 COM2_CTS#

46 N/A 96 COM2_DTR#

47 N/A 97 COM2_RTS#

48 N/A 98 COM2_DSR#

49 N/A 99 COM2_SOUT

50 N/A 100 COM2_SIN

Embedded and Industrial Computing

22

Page 23

Chapter 3

Board Layout

LEB-5570 Board

Serial-ATA Connector (SATA1/SATA2): It is for connecting

a 2.5’’ hard disk to be served as your system’s storage. It

can support SATA II which features Data transfer rates up

to 6.0 Gb/s (600 MB/s). SATA II connector also supports

SATA-DOM (the power line of SATA-DOM can be disabled

with a jumper on, see SATA_PW2).

1 2 3 4 5 6 7

SATA1

7 6 5 4 3 2 1

SATA2

Pin No. Function

1 GND

2 TX0_P

3 TX0_N

4 GND

5 RX0_N

6 RX0_P

7 GND

Pin No. Function

1 GND

2 TX1_P

3 TX1_N

4 GND

5 RX1_N

6 RX1_P

7 VCC5

The controller contains two modes of operation—a

legacy mode using I/O space, and an AHCI mode using

memory space. Software that uses legacy mode will not

have AHCI capabilities.

The AHCI ( Advanced Host Controller Interface) is a

programming interface which defines transactions

between the SATA controller and software and enables

advanced performance and usability with SATA. Platforms

supporting AHCI may take advantage of performance

features such as no master/slave designation for SATA

devices—each device is treated as a master—and

hardware assisted native command queuing. AHCI also

provides usability enhancements such as Hot-Plug.

Use the BIOS menu to configure your hard disk

to be AHCI compatible.

4-pin Serial-ATA Power Connector (SATA_PWR1): It is

for connecting the SATA power cord.

Pin No. Function

1 +12V

4 3 2 1

2 GND

3 GND

4 +5V

SATA_PW2: A switch for supply of SATA Connector II’s

power.

1

2

3

Embedded and Industrial Computing

Pin No. Pin Name

1-2 SATAII Connector without power

2-3 SATA II Connector with 5V power

Front Panel Function Pin Header (FRONT1): It provides

LED signal and button function on the front panel.

10

Pin No. Pin Name Function Pin No. Pin Name Function

1 HD_LED+ HDD LED 2 PWR_LED+ Power LED

3 HD_LED- 4 PWR_LED5 Reset System Reset

7 GND 8 GND

Button

9

8

7

6

5

4

3

2

1

6 POWER_BTN Power On/Off

Push Button

Mini PCI Express Connector (MIO1) on the mainboard:

COM and Audio Expansion Card Connector

PIN Pin Name PIN Pin Name

1 GND 51 HDA_BCLK

2 SATATXN2 52 HDA_SYNC

3 SATATXP2 53 HDA_RST

4 GND 54 HDA_SDIN0

5 SATARXN2 55 HDA_SDO

6 SATARXP2 56 SPK

7 GND 57 VCC3_SB

8 VCC3P3_PS 58 VCC3_SB

9 VCC3P3_PS 59 VCC3_SB

10 VCC3P3_PS 60 VCC3_SB

11 GND 61 VCC3_SB

12 PCIE_RXN5 62 PCIE_RXN6

13 PCIE_RXP5 63 PCIE_RXP6

14 PCIE_TXN5 64 PCIE_TXN6

15 PCIE_TXP5 65 PCIE_TXP6

16 PCIE_CKN5 66 PCIE_CKN6

17 PCIE_CKP5 67 PCIE_CKP6

18 IGN_DI2 68 IGN_DI1

19 PLTRST 69 SMBCLK_

20 WAKE_N 70 SMBDATA

21 DCIN_VCC 71 REMOTE_POWER_

22 VCC12_PS 72 3G_POWER_ON

23 VCC5_SB 73 USB_N12

24 VCC5_SB 74 USB_P12

25 VCC5 75 GND

26 VCC5 76 USB_N13

27 VCC5 77 USB_P13

28 GND 78 GND

29 DGOUT_0 79 DGIN_0

30 DGOUT_1 80 DGIN_1

31 DGOUT_2 81 DGIN_2

32 DGOUT_3 82 DGIN_3

33 GND 83 GND

34 COM3_DCD# 84 COM1_DCD#

35 COM3_RI# 85 COM1_RI#

36 COM3_CTS# 86 COM1_CTS#

37 COM3_DTR# 87 COM1_DTR#

38 COM3_RTS# 88 COM1_RTS#

39 COM3_DSR# 89 COM1_DSR#

40 COM3_SOUT 90 COM1_SOUT

41 COM3_SIN 91 COM1_SIN

42 GND 92 GND

43 COM4_DCD# 93 COM2_DCD#

44 COM4_RI# 94 COM2_RI#

45 COM4_CTS# 95 COM2_CTS#

46 COM4_DTR# 96 COM2_DTR#

47 COM4_RTS# 97 COM2_RTS#

48 COM4_DSR# 98 COM2_DSR#

49 COM4_SOUT 99 COM2_SOUT

50 COM4_SIN 100 COM2_SIN

ON

23

Page 24

Chapter 3

Board Layout

DVI-D Connector (DVID1): A single link DVI-D Connector

Pin No. Description Pin No. Description

1 TXD_2- 2 TXD_2+

3 GND 4 N/A

5 N/A 6 DDC_CLK

7 DDC_DATA 8 N/A

9 TXD_1- 10 TXD_1+

11 GND 12 N/A

13 N/A 14 VCC5

15 GND 16 HPD

17 TXD_0- 18 TXD_0+

19 GND 20 N/A

21 N/A 22 GND

23 TXD_CLK_P 24 TXD_CLK_N

HDMI Connector (HDMI1): An HDMI Connector

System FAN Connector (FAN1/FAN2)

FAN1

3 2 1

FAN2

Pin No. Description

3

2

1

1 GND

2 VCC5

3 FAN TAC

Reset Button (RST1)

Pin NO. Description

2

4

1

3

1 RST_BTN

2 GND

3 GND

4 N/A

Pin No. Description Pin No. Description

1 HDMI_DATP2_P 2 GND

3 HDMI_DATP2_N 4 HDMI_DATP1_P

5 GND 6 HDMI_DATP1_N

7 HDMI_DATP0_P 8 GND

9 HDMI_DATP0_N 10 HDMI_CLK_P

11 GND 12 HDMI_CLK_N

13 N/A 14 N/A

15 HDMI_DDC_CLK 16 HDMI_DDC_DAT

17 GND 18 PHDMI

19 HDMI_HPD

VGA (VGA1)

5 4 3 2 1

15 14 13 12 11

Pin Signal Pin Signal Pin Signal

1 RED 6 CRT DET 11 N/A

2 GREEN 7 GND 12 DDC DAT

3 BLUE 8 GND 13 HSYNC

4 N/A 9 VCC5 14 VSYNC

5 GND 10 GND 15 DDC CLK

Note: The driver for the VGA and Audio ports

should be installed with the following order:

Chipset INF->Graphic->Audio

Embedded and Industrial Computing

24

Page 25

Chapter 3

Board Layout

MPCIE1: Mini-PCIe Connector with one SIM Card

Reader(SIM1). It supports both Wi-Fi and 3G module.

Both USB and PCIe signal card type can be used on the

connector.

Pin Signal Pin Signal

1 WAKE# 2 VCC3.3

3 N/A 4 GND

5 N/A 6 VCC1.5

7 CLKREQ# 8 USIM_PWR

9 GND 10 UIM_DATA

11 PCIE_CLK_N3 12 UIM_CLK

13 PCIE_CLK _P3 14 UIM_RESET

15 GND 16 UIM_VPP

17 RSV 18 GND

19 RSV 20 N/A

21 GND 22 PLTRST

23 PCIE_RX_N3 24 VCC3.3

25 PCIE_RX_P3 26 GND

27 GND 28 VCC1.5

29 GND 30 SMBCLK

31 PCIE_TX_N3 32 SMBDATA

33 PCIE_TX_P3 34 GND

35 GND 36 USB_N8

37 GND 38 USB_P8

39 VCC3.3 40 GND

41 VCC3.3 42 N/A

43 GND 44 N/A

45 RSV 46 N/A

47 RSV 48 VCC1.5

49 RSV 50 GND

51 RSV 52 VCC3.3

MPCIE2: Mini-PCIe Connector. It does not come with a

SIM card reader so only Wi-Fi modules are supported.

Both USB and PCIe signal card type can be used on the

connector.

Pin Signal Pin Signal

1 WAKE# 2 VCC3.3

3 N/A 4 GND

5 N/A 6 VCC1.5

7 CLKREQ# 8 N/A

9 GND 10 N/A

11 PCIE_CLK _N4 12 N/A

13 PCIE_CLK _P4 14 N/A

15 GND 16 N/A

17 RSV 18 GND

19 RSV 20 N/A

21 GND 22 PLTRST

23 PCIE_RX_N4 24 VCC3.3

25 PCIE_RX_P4 26 GND

27 GND 28 VCC1.5

29 GND 30 SMBCLK

31 PCIE_TX_N4 32 SMBDATA

33 PCIE_TX_P4 34 GND

35 GND 36 USB_N9

37 GND 38 USB_P9

39 VCC3.3 40 GND

41 VCC3.3 42 N/A

43 GND 44 N/A

45 RSV 46 N/A

47 RSV 48 VCC1.5

49 RSV 50 GND

51 RSV 52 VCC3.3

SIM Card Socket (SIM1):

C1 C3

C5 C7

Pin No. Description

C1 UIM_PWR

C2 UIM_RST

C3 UIM_CLK

C5 GND

C6 UIM_VPP

C7 UIM_DAT

CN3: A power connector with power -ignition Control

1 2 3

Pin No. Pin Name

1 Ignition

2 GND

3 DC_VIN

DCJK1 (Optional): An optional DC Jack type of Power

Connector

Pin No. Pin Name

1 DC_VIN

2 GND

3 GND

LAN1/LAN2 Ports (LAN1/LAN2): The LAN ports are

provided by Intel 82574L Ethernet controller whose

interface complies with PCI-e 1.1 (2.5 Ghz). It has advanced

management features including IPMI pass-through via

SMBus or NC-SI, WOL, PXE remote boot, ISCSI boot and

VLAN filtering.

Pin No. Description

Fast Ethernet Gigabit Ethernet

1 TX+ BI_DA+

2 TX- BI_DA3 RX+ BI_DB+

4 -- BI_DC+

5 -- BI_DC6 RX- BI_DB7 -- BI_DD+

8 -- BI_DD-

Enable or Disable Daughter Board LEK-IOA7 (COMSLT1):

This jumper is for enabling or disabling COM3/COM4

daughter board LEK-IOA7.

1

2

3

Pin No. Pin Name

1-2 Disable

2-3 Enable

Embedded and Industrial Computing

25

Page 26

Chapter 3

Board Layout

Enable or Disable Daughter Board LEK-IG1 (COMSLT2):

This jumper is for enabling or disabling COM5/COM6 of

daughter board LEK-IG1. If this jumper is set to disable,

the ISM will not work (refer to Appendix A Using the Ignition

System Manager (ISM)).

1

2

3

Pin No. Pin Name

1-2 Disable

2-3 Enable

Dual USB 2.0 Port Connector #0 and #1 (USB1)

Dual USB 2.0 Port Connector #2 and #3 (USB2)

Dual USB 2.0 Port Connector #4 and #5 (USB3)

Pin No. Pin Name

1 VCCUSB

5 6 7 8

1 2 3 4

2 USB0N

3 USB0P

4 GND

5 VCCUSB1

6 USB1N

7 USB1P

8 GND

Clear CMOS jumper (CMOS1/CMOS2): It is for clearing

the CMOS data. CMOS1clears CMOS data with real-time

clock (RTC) whereas CMOS2 clears CMOS data only.

PS/2 Keyboard and Mouse Connector (KBM1)

1

2

3

4

5

6

7

8

Pin No. Pin Name

1 VCC

3 MDATA

5 KDATA

7 GND

Pin No. Pin Name

2 MCLK

4 NC

6 NC

8 KCLK

Ignition Connector on Board (ignition1): Power

ignition connector.

1 2 3 4 10

Pin No. Pin Name Pin No. Pin Name

1 DCIN_VCC 6 DC2DC_PWROK

2 DC_VIN 7 COM5_SIN

3 GND 8 SOUT

4 SYS_PWROK 9 PWR_BTN_IGN

5 DC2DC_EN 10 IGNITION

1

2

3

Pin No. Pin Name

1-2 Normal (Default)

2-3 Clear CMOS and RTC (CMOS1)

Clear CMOS only (CMOS2)

To erase the CMOS data:

Turn off the computer and unplug the power cord.

Move the jumper cap from pins 1-2 (default) to pins 1.

2-3. Keep the cap on pins 2-3 for about 5-10 seconds,

then move the cap back to pins 1-2.

Plug the power cord and turn on the computer.2.

Enter BIOS setup to re-enter data.3.

Embedded and Industrial Computing

26

Page 27

Chapter 3

Board Layout

LEK-IG1 Board

Select MCU detect function for power ignition behavior

(SW1):

SW1

1

2

3

4

Selector No. SW1 Ignition Function

1 Power Good Detection ON: Enable

2 Low Voltage Detection

3 Watchdog

4 Programming MCU Reserved

The default value is ON for selector 1, ON for selector 2, OFF for selector 3, and OFF for selector 4

8

7

6

5

ON

OFF: Disable

The functions of the above jumpers are further explained

here.

1. : A power-good signal

Power Good Detection

from the main board will be sent to the ignition

controller so that the ignition controller can

decide or alter the power state upon the following

instances. (Refer to the flow chart in Chapter 4):

MCU (Microcontroller) Function Selection (SW1, SW2):

It is for selecting the microcontroller’s function.

SW1

1

2

3

4

ON

Download Data

1

2

3

4

ON

Jumper Pin No. Pin NO.

SW1 1-ON, 2-ON, 3-OFF, 4-ON 1-ON, 2-ON, 3-OFF, 4-OFF

SW2 1-OFF, 2-OFF, 3-ON, 4-ON 1-ON, 2-ON, 3-OFF, 4-OFF

Function Download Data Normal (Default)

1

2

3

4

ON

SW2

1

2

3

4

ON

Normal (Default)

1

2

3

4

ON

1

2

3

4

ON

An external RS-232 connector for MCU programming

(CN1)

1

2

3

Pin No. Pin Name

1 EXT_TXD_R

2 GND

3 EXT_RXD_R

Power-on instance

•

Power-good signal turned-low instance •

Low Voltage Detection2. : Turn on this switch to

enable the automatic detection of low voltage

state of the battery. It will automatically turn

off the system when low voltage state has been

detected (Note: the low-voltage condition needs

to remain 30 seconds continually). The voltage

level can be set in the Ignition System Manager

(ISM) which is provided by Lanner as sample code

for functions on the power ignition module. The

default setting of this function: Shutdown

Voltage in the ISM is disabled. (Refer to the flow

chart in Chapter 4 and the Using the Ignition

System Manager (ISM) in Appendix A.)

Watchdog: 3. Enable this switch to enable shutdown

after watchdog timer count-down to zero. This is a

programmable function. If there is no program to

control and monitor the watchdog timer, set this

jumper to disabled to avoid abnormal shutdown.

The default time-out value is 300 sec( you will need

an AT command to reset watchdog timer; contact

Lanner rep for this program).

IGN_CON1

4

3

2

1

Pin No. Pin Name

1 REMOTE_POWER_ON

2 3G_POWER_ON

3 IGN_DI0

4 IGN_DI1

Ignition Control Connector (IGNITION1)

10 9 8 7 1

Pin No. Pin Name Pin No. Pin Name

1 IGNITION 6 D2D_EN

2 SYS_POWER_

SWITCH

3 COM_SOUT 8 GND

4 COM_SIN 9 DC_VIN

5 D2D_PWROK 10 DCIN_VCC

7 SYS_POWER_OK

Embedded and Industrial Computing

27

Page 28

Chapter 3

LEB-POE936A Board

The following pin definitions refer to the connectors on

the LVP-POE936A board which is the board of the power

adaptor. It corresponds to the connectors of the power

adaptor in Chapter 2 System Components.

Vehicle Power (12V/24V) w/Ignition (Power_CON2):

This connector accepts 9~36V DC power input for

powering the LVC-5770. Additionally, it accepts another

9~36V DC input integrated together in this 5-pin terminal

connector.

Board Layout

1 2 3 4 5

Pin No. Function

1 Ignition

2 GND

3 DC9~36V IN

4 GND

5 DC9~36V IN

POE 48V Output & PC Power 9~36V Out (Power_CON1):

This connector connects to the LVC-5770 and provides

48V DC for POE and 9~36V DC for the entire system.

Pin No. Function

1 2 3 4 5

1 GND

2 48V Out

3 Ignition

4 GND

5 DC 9~36V Out

AUX 9~36V Bypass (Power_CON3): As the Power_CON2

can accept additional power input (9~36V) to be bypassed,

this connector can supply/bypass 9~36V power for other

uses.

1 2

Pin No. Function

1 GND

2 9~36V Out

MCU Programming (CN1)

1 2 3

Embedded and Industrial Computing

Pin No. Function

1 TX

2 GND

3 RX

28

Page 29

Chapter 4

Chapter 4:

The Flow Chart

The flow chart section contains all flow chart used in the

system. The flow chart describes the system’s behavior on

powering on and off the system via power ignition control

or on/off switch when the appropriate timer control

parameters are set.

Flow Chart

Note:

1.

For power-good and low-voltage

mechanism to function in the workflow,

you will need to enable the power-good

and low-voltage detection function

with selector 1 and selector 2 jumper

respectively of SW1 on LEK-IG1 board.

(Refer to Chapter 3 Board Layout).

Embedded and Industrial Computing

For power on and power off delay timer 2.

parameter, refer to Appendix A Using the

Ignition System Manager (ISM).

For DI wake-up function, refer to jumper 3.

MIO (DIO, J15) in Chapter 3 Board Layout.

And refer to Appendix A Using the Ignition

System Manager (ISM) for parameter

setting.

When the system’s shutdown timer starts 4.

counting down 180sec, using ignition

or External PWR_BTN to start the system

again during shutdown process will not

work until the countdown finishes.

29

Page 30

Chapter 5

Hardware Setup

Chapter 5:

Hardware Setup

Preparing the Hardware Installation

To access some components and perform certain service

procedures, you must perform the following procedures

first.

WARNING: To reduce the risk of personal injury,

electric shock, or damage to the equipment,

remove the power cord to remove power from

the server. The power switch button does not

completely shut off system power. Portions of the

power supply and some internal circuitry remain

active until power is removed.

Unpower the LVC-5770 and remove the power cord.1.

Unscrew the 4 threaded screws from the top cover.2.

Open the cover.3.

Installing the System Memory

The motherboard supports DDR3 memory to meet the

higher bandwidth requirements of the latest operating

system and Internet applications. It comes with two

Double Data Rate Three (DDR3) Small Outline Dual Inline

Memory Module (SO-DIMM) socket.

Align the memory module’s key with the SO-DIMM 1.

socket’s key.

Install the SO-DIMM.2.

2

1

Note:

If the CPU thermal pad mounting breaks apart,

use your hands to reattach the falling parts and

stick them together.

Note:

The system can support memory of DDR3 SODIMM up to 16 GB in maximum with 2 SO-DIMM

sockets.

Embedded and Industrial Computing

30

Page 31

Chapter 5

Wireless Module Installation

Align the wireless module’s key with the Mini-PCIe slot 1.

notch.

Insert the wireless module into the connector 2.

diagonally.

Push down the wireless module and then tighten it 3.

with the screws.

2

3

Hardware Setup

Lock

Note: To remove the SIM card, slide the card

reader outward to unlock it.

Unlock

3G SIM Card Installation

Unlock the SIM card reader first by sliding it outward.1.

Flip the SIM card reader diagonally. 2.

Place the SIM card in the reader. The angled corner of 3.

the SIM ensures that the card fits only the correct way

in the reader. Make sure the ICs will be in contact with

the SIM card reader.

Insert the 4. SIM card into the reader and close the tray.

You should feel a click when the SIM card is locked

securely in the SIM card reader.

4

2

3

Embedded and Industrial Computing

31

Page 32

Chapter 5

DC_IN

IGNITION

DC_GND

IG - +

LVC-5770

PoE Power 48V

DC Input 9~36V

Ignition Gnd DC9~36V_in Gnd DC9~36V_in

48V_out Gnd Ignition Gnd DC9~36V_out

Gnd DC9~36V_out

+ -

OUT + - - + IN

DC Relay Bypass

Hardware Setup

Installing the Hard Disk

The system can accommodate two Serial-ATA disk. Follow

these steps to install the hard disk into the system:

Place the HDD/SSD on the hard disk tray of the front 1.

panel and align the holes of the hard disk with the

mounting holes on the tray.

Fix the HDD/SSD on the hard disk tray by using 2 2.

mounting screws

Push the HDD/SSD into the hard disk slot and secure it 3.

in place with the thumb screws.

1

Drive Connector

Connecting Power

Connect the LVC-5770 to a +12V or +24V vehicle battery.

The DC power-in connector comes with a 3-pin terminal

block for its Phoenix contact. This power socket can only

accept the power supply with the right pin contact so be

cautious when inserting power to the system.

Note:

Power Connector

The system only supports 2.5” HDD/SSD.1.

Make sure that you insert the HDD in 2.

Silver plate

the right orientation (shown as the

above picture) to prevent damage to the

connectors. Do not force the HDD into the

slot; it indicates wrong orientation if the

insertion is not smooth.

Warning:

Connect the power to the DC-IN connector in the

right orientation or the LVC-5770 will be damaged.

Embedded and Industrial Computing

32

Page 33

Appendix A

Appendix A:

Using the Ignition System

Manager (ISM)

The Ignition System Manager (ISM) is a software that

can monitor the system’s voltage level and configure the

functions that the Power Ignition Module provides.

Using the Ignition System Manager (ISM)

For sample ISM code, see ISM folder under LVC-5770 Utility

on the Driver and Manual CD.

Running the Program

Just double click the ISM.exe to launch the ISM.

The program can configure the following values:

Voltage: It shows the current power system.

Power Input System: Select either 12V or 24V for vehicular

power input.

Startup Voltage (V): If the DC-in voltage is not higher

than this value, the system will not be able to start up.

Shutdown Voltage (V): If the DC-in voltage is lower than

the shutdown voltage, the system will start shutdown

process automatically. (Refer to selector 2 of SW1 dip

switch on the LEK-IG1 board)

Power-on Delay (min/sec): Select power-on delay value

to indicate the time to delay powering on the system.

(Refer to the flow chart in Chapter 4)

Power-off Delay (hr/min/sec): Select power-off delay

value to indicate the time to delay powering off the system

(Refer to the flow chart in Chapter 4)

Serial Port: Select the serial communication port for the

ISM. Choose COM5.

D1/D2 Wakeup: Digital input triggering to enable

automatic wake-up function. Select this option and it will

start the system automatically once an input has been

triggered.

COM5

Note:

You will have to enable (the default is enabled) 1.

the selector 2 (Low Voltage Detection) of SW1

dip switch on the LEK-IG1 to enable automatic

shutdown function. (Refer to Select MCU detect

function for power ignition behavior (SW1) in

Chapter 3 Board Layout).

DI1/DI2 Wakeup function is detected via pin 2.

12/13 of J15 ( the MIO port on the rear panel)

Refer to the 3. flow charts in Chapter 4 for

more information about how the system behave

according to these parameter set here.

.

After you have made changes, click Apply to apply the

changes to the Ignition controller or Cancel to cancel the

changes.

Click Cancel to exit the ISM program.

Embedded and Industrial Computing

33

Page 34

Appendix B

Digital Input/Output Control

Appendix B:

Digital Input/Output

The Digitanl I/O on the rear panel is designed to provide

the input and output operations for the system. For sample

DIO code, see SuperIO folder under LVC-5770 Utility on the

Driver and Manual CD. Make sure that you have installed

the Lanner GPIO driver as instructed below.

Driver Installation

Before you could access or control the operation of the

G-sensor and Digital I/O functions, install the the L_IO

driver which is the library and driver needed for Lanner

General Purpose Input/Output interface or functions.

To install the L_IO driver:

Restart the computer, and then log on with 1.

Administrator privileges.

Insert the Drivers and User’s Manual CD to the USB-2.

optical drive.

Select Next to proceed5.

Answer “Yes” to the question and select Next to 6.

proceed.

Browse the contents of the support CD to locate the 3.

file in the LIO folder.

From the control panel, click the ADD Hardware 4.

program

Select Add a new hardware device.7.

Embedded and Industrial Computing

34

Page 35

Appendix B

Digital Input/Output Control

Choose to select the hardware Manually8.

Choose Show all device and click Next.9.

Click HaveDisk to locate the L_IO.inf file11.

Select the L_IO.inf12.

Click HaveDisk to locate the L_IO.inf file10.

Embedded and Industrial Computing

Select OK to confirm with the installation13.

35

Page 36

Appendix B

Digital Input/Output Control

Select the Lanner IO driver and click Next.14.

Click Next15.

To verify the GPIO driver installation, do the following

steps:

Right-click on the My Computer icon, and then select 1.

Properties form the menu.

Click the Hardware tab, then click the Device Manager 2.

button.

Click the + sign next to the Lanner_Device, then the 3.

Lanner IO Driver should be listed.

Click 16. Complete to close the installation program.

Embedded and Industrial Computing

36

Page 37

Appendix B

A sample DIO program in C:

ioaccess.c: IO access code for Lanner Platfomr Digital IO

program

*********************************************************

**********************/

Digital Input/Output Control

#include <time.h>

#include <stdint.h>

#include <fcntl.h>

#include <errno.h>

#include <string.h>

#include “../include/config.h”

#ifdef DJGPP

/* standard include file */

#include <stdio.h>

#include <stdlib.h>

#include <unistd.h>

/* For DOS DJGPP */

#include <dos.h>

#include <inlines/pc.h>

#else //DJGPP

/* For Linux */

#define delay(x) usleep(x)

#endif

#ifdef MODULE

#include <linux/kernel.h>

#include <linux/module.h>

#include <linux/kernel.h>

#include <linux/fs.h>

#include <asm/io.h>

#include <linux/delay.h>

#undef delay

#define delay(x) mdelay(x)

#undef fprintf

#define fprintf(S, A) printk(A)

#ifdef DIRECT_IO_ACCESS

/* For Linux direct io access code */

/* standard include file */

#include <stdio.h>

#include <stdlib.h>

#include <unistd.h>

#if defined(LINUX_ENV)

#include <sys/io.h>

#endif

#if defined(FreeBSD_ENV)

#include <machine/cpufunc.h>

#endif

Embedded and Industrial Computing

#endif //MODULE

#ifdef KLD_MODULE

#include <sys/types.h>

#include <sys/param.h>

#include <sys/systm.h>

#include <sys/malloc.h>

#include <sys/kernel.h>

#include <sys/bus.h>

#include <sys/errno.h>

37

Page 38

Appendix B

Digital Input/Output Control

#include <machine/bus.h>

#include <machine/resource.h>

#endif

#endif

/* local include file */

#include “../include/ioaccess.h”

#if (defined(MODULE) || defined(DIRECT_IO_ACCESS) ||

defined(KLD_MODULE))

/*

*---------------------------------------------------------------------------

---

* LEB-5770 Version V1.0

*output3-0 = GPIO 03-00, input3-0= GPIO 53-50

*---------------------------------------------------------------------------

--------

outportb(INDEX_PORT, 0xAA);

return;

}

unsigned char read_SIO_reg(int LDN, int reg)

{

outportb(INDEX_PORT, 0x07); //LDN register

delay(5);

outportb(DATA_PORT, LDN);

delay(5);

outportb(INDEX_PORT, reg);

delay(5);

return(inportb(DATA_PORT));

}

void write_SIO_reg(int LDN, int reg, int value)

{

*/

/*

* Device Depend Definition :

*/

#define INDEX_PORT 0x2E

#define DATA_PORT 0x2F

void enter_SIO_config(void)

{

outportb(INDEX_PORT, 0x87); // Must Do It Twice

outportb(INDEX_PORT, 0x87);

return;

}

void exit_SIO_config(void)

{

outportb(INDEX_PORT, 0x07); //LDN register

delay(5);

outportb(DATA_PORT, LDN);

delay(5);

outportb(INDEX_PORT, reg);

delay(5);

outportb(DATA_PORT, value);

return;

}

void dio_gpio_init(void)

{

enter_SIO_config();

write_SIO_reg(0x6, 0x30,0x01); //enable GPIO

Port

write_SIO_reg(0x6, 0xf0,((read_SIO_reg(0x6,

0xf0)& 0xF0)|0x0f)); //RxF0[3-0]=1111b, output

write_SIO_reg(0x6, 0xA0, (read_SIO_reg(0x6,

0xA0)& 0xF0)); //RxA0[3-0]=0000b, input

Embedded and Industrial Computing

38

Page 39

Appendix B

exit_SIO_config();

return;

}

void dio_set_output(unsigned char out_value)

{

enter_SIO_config();

write_SIO_reg(0x6, 0xf1, ((read_SIO_reg(0x6,

0xf1)& 0xF0)|out_value));

exit_SIO_config();

return;

}

unsigned int dio_get_input(void)

{

Digital Input/Output Control

unsigned int tmp=0x00;

enter_SIO_config();

tmp=read_SIO_reg(0x6, 0xA2)& 0x0f;

exit_SIO_config();

return tmp;

}

//======================================

========================================

=================

#endif

Embedded and Industrial Computing

39

Page 40

Appendix C

Accessing the Digital Accelerometer

Appendix C:

Accessing the Digital

Accelerometer Data from

the LVC-5770

The system employs Analog Devices’s ADXL345 Digital

Accelerometer which is a small, thin, ultralow power, 3-axis

accelerometer with high resolution (13-bit) measurement

at up to ±16 g. It interfaces with the LVC-5770 through a

SPI interface.

Driver Installation

To access the G-Sensor data, use the following

instructions:

Make sure you already installed the Lanner GPIO driver on

your LVC-5770 as instructed in Appendix B.

To access the Gsensor data, locate the adxl345_v001 folder

and execute the executable file adxl345 and it will show G

value of 3 axes.

A sample program in C:++

// main.cpp

// The adxl345.exe utility shows the 3 axis G value.

//

// History:

// 07/15/2011: Initial version

#include <winsock2.h>

#include <windows.h>

#include <stdio.h>

#include “ich7.h”

#include “adxl345.h”

void adxl345_init()

{

ich7_SM_WriteByte (0x1D, POWER_CTL, ACT_INACT_

SERIAL | MEASURE) ; // Power CTL:

Measure mode, Activity and Inactivity Serial

ich7_SM_WriteByte (0x1d, BW_RATE, RATE_100);

/ /

Output Data Rate: 100Hz

ich7_SM_WriteByte (0x1d, DATA_FORMAT, FULL_

RESOLUTION | DATA_JUST_LEFT | RANGE_16G);

/ /

Data Format: 16g range, right justified, 256->1g

}

Embedded and Industrial Computing

int main(int argc, char* argv[])

{

adxl345_init () ;

40

Page 41

Appendix C

while (1)

{

short x = (short) ich7_SM_ReadByte

(0x1d, DATAX1) << 8 | ich7_SM_ReadByte (0x1d,

DATAX0)<<0 ;

short y = (short) ich7_SM_ReadByte

(0x1d, DATAY1) << 8 | ich7_SM_ReadByte (0x1d,

DATAY0)<<0 ;

short z = (short) ich7_SM_ReadByte

(0x1d, DATAZ1) << 8 | ich7_SM_ReadByte (0x1d,

DATAZ0)<<0 ;

printf (“\rX=%.2f Y=%.2f Z=%.2f”, ((float)

x)/2048,((float)y)/2048,((float)z)/2048) ;

}

Accessing the Digital Accelerometer

}

Embedded and Industrial Computing

41

Page 42

Appendix D

Accessing the GPS Data

Appendix D:

Accessing the GPS Data

from the LVC-5770

The LVC-5770 employs an onbard u-blox NEO-6Q GPS

module for vehicle tracking and navigation system. You

could read the GPS data through the RS-232 serial port.

It has the following listed key features and performance

ratings:

Receiver type 50 Channels

GPS L1 frequency, C/A Code

SBAS: WAAS, EGNOS, MSAS

Time-To-First-Fix (All satellites at -130 dBm)

Sensitivity Tracking &Navigation: •

Maximum Navigation

update rate

Horizontal position accurach (CEP, 50%, 24 hours

static, -130dBm, SEP:

<3.5m)

Congurable Timepulse

frequency range

Accuracy for Timepulse

signal

Velocity accuracy 0.1m/s

Heading accuracy 0.5 degrees

Operational Limits Dynamics: less than and

Cold Start: 26 s

Warm Start: 26 s

Hot Start: 1 s

Aided Starts: 1 s

-162dBm

Reacquisition: -160dBm•

Cold Start (without aid-•

ing): -148 dBm

Hot Start: -157 dBm•

5Hz

GPS: 2.5m

SBAS: 2.0m

0.25 Hz to 1 kHz

RMS: 30 ns

99%: <60 ns

Granularity: 21 ns

Compensated: 15 ns

equal to 4g

Altitude: 50,000m

Velocity: 500m/s (Assuming

Airborne <4g platform)

To access the GPS data, follow the following steps:

Select Programs from the Start menu on your windows

and open the Hyper Terminal program.

Choose COM4 from the Connection using drop-down

menu:

Embedded and Industrial Computing

42

Page 43

Appendix D

Specify the following communication parameters:

Bits per Second: 9600

Data Bits: 8

Parity: None

Stop Bit: 1

Flow Control: None

9600

Accessing the GPS Data

The hyper terminal should display GPS data:

Embedded and Industrial Computing

43

Page 44

Appendix E

Programming Watchdog Timer

Appendix E:

Programming System

Watchdog Timer of the

LVC-5770

A watchdog timer is a piece of hardware that can be

used to automatically detect system anomalies and reset

the processor in case there are any problems. Generally

speaking, a watchdog timer is based on a counter that

counts down from an initial value to zero. The software

selects the counter’s initial value and periodically restarts

it. Should the counter reach zero before the software

restarts it, the software is presumed to be malfunctioning

and the processor’s reset signal is asserted. Thus, the

processor will be restarted as if a human operator had

cycled the power.

For sample watchdog code, see watchdog folder under

LVC-5770 Utility on the Driver and Manual CD

#include “F81865.h”

#define PARAMETER_HELP “\n”\

“The F81865 GPIO utility of Lanner\n”\

“-------------------------------------\n”\

“Usage:\n”\

“ F81865_test DIO_IN port_

number\n”\

“ F81865_test DIO_OUT port_number

value\n”\

“ F81865_test PIO port_number

value\n”\

“ F81865_test RunLED port_number

value\n”\

“ F81865_test AlarmLED port_number

value\n”\

“ F81865_test GPS_LED port_number

value\n”\

Executing through the Command Line:

Execute the WD.EXE file under DOS (WD.EXE and CWSDPMI.

EXE should be placed on same directory), then enter the

values from 0~255. The system will reboot automatically

according to the time-out you set.

/////////////////////////////////////////////////////////

You can write your own program by modifying the source

code F81865_Test.cpp.. The index address is 2EH.

/////////////////////////////////////////////////////////////////////

////

// F81865_Test.cpp : F81865_test.exe utility for F81865.lib

APIs demonstration.

//

// History:

// 7/15/2011 Brand new F81865_test

program.

“ F81865_test WirelessLED port_number

value\n”\

“ F81865_test WatchDog seconds\n”\

“ F81865_test CaseOpen\n”\

“ F81865_test CaseOpen_Clear\n”\

“ F81865_test Sleep

milliseconds\n”\

“\n”\

“Argement:\n”\

“ DIO_IN Read state from DIO

In.\n”\

“ DIO_OUT Set DIO Out state.\n”\

“ PIO Set PIO LED state.\n”\

“ RunLED Set RUN LED state.\n”\

“ AlarmLED Set Alarm LED state.\n”\

#include <winsock2.h>

#include “Windows.h”

#include “stdio.h”

Embedded and Industrial Computing

“ GPS_LED Set GPS LED state.\n”\

“ WirelessLED Set Wireless LED state.\n”\

44

Page 45

Appendix E

Programming Watchdog Timer

“ Watchdog Set

Watchdog timer.\n”\

“ CaseOpen Check case opened state.\n”\

“ CaseOpen_Clear Clear case open state.\n”\

“ port_number The port number.\n”\

“ value 1 for on and 0 for off.\n”\

“ seconds The

watchdog count down seconds. 0 for disable.\n”\

“ milliseconds Milliseconds to

delay\n”

#define RETMSG(a,b) {printf (b) ; return a;}

#define CHECK_ARGC(a) {if (argc

!= a) throw PARAMETER_HELP ;}

// Translate Hex string to a long value

LONG Hex2Long (char *str)

{

LONG nLong ;

if (scanf (str, “%x”, &nLong) != 1)

throw “Error parsing parameter\n” ;

return nLong ;

}

// Make sure the argument is numeric

void CheckNumeric (char *szBuf )

{

int nLen = strlen (szBuf ) ;

for (int i = 0 ; i < nLen ; i++)

if (!strchr (“01234567890ABCDEFabcdef”, szBuf[i]) )

throw “Wrong argument\n” ;

}

// Common GPIO output function definition

#define GPIO_OUT(a,b,c) \

int a (int argc, char *argv[]) \

{

\

CHECK_ARGC (4) ;

\

\

int nPort = atoi (argv[2]) ; \

int nValue = atoi (argv[3]) ; \

\

c (nPort, nValue) ;

\

\

printf (b “ #%d = %d\n”, nPort, nValue) ; \

\

return 0

; \

}

// Function generate by common function definition

GPIO_OUT (mDIO_

OUT , “DIO_OUT” , Write_DIO)

G P I O _ O U T

(mPIO , “DIO_OUT” , PIO)

G P I O _ O U T

(mRunLED , “RunLED” , RunLED)

G P I O _ O U T

(mAlarmLED , “AlarmLED” , AlarmLED)

GPIO_OUT (mGPS_

LED , “GPS_LED” , GPS_LED)

G P I O _ O U T

(mWirelessLED , “WirelessLED” , WirelessLED)

// Check case open

int mCaseOpen (int argc, char* argv[])

{

CHECK_ARGC (2) ;

BOOL bOpen = CaseOpen () ;

printf (“Case is %s\n”, bOpen ? “Open” : “Close”) ;

return bOpen ;

}

CheckNumeric (argv[2]) ; \

CheckNumeric (argv[3]) ; \

Embedded and Industrial Computing

45

Page 46

Appendix E

Programming Watchdog Timer

// Clear case open state

int mCaseOpen_Clear (int argc, char* argv[])

{

CHECK_ARGC (2) ;

CaseOpen_Clear () ;

BOOL bOpen = CaseOpen () ;

printf (“CaseOpen state %s”, bOpen ? “not cleared”

: “cleared”) ;

return bOpen ;

}

// Get DIO_IN state

int mDIO_IN (int argc, char* argv[])

{

CHECK_ARGC (3) ;

CheckNumeric (argv[2]) ;

return 0 ;

}

// Watchdog

int mWatchDog (int argc, char *argv[])

{

if (argc != 3 && argc != 2)

RETMSG (-1, PARAMETER_HELP) ;

if (argc == 3)

{

CheckNumeric (argv[2]) ;

int nValue = atoi (argv[2]) ;

WatchDog_Enable (nValue) ;

}

int nLeft = WatchDog_GetLeft () ;

int nPort = atoi (argv[2]) ;

BOOL ret = Read_DIO (nPort) ;

printf (“DIO_IN #%d = %d\n”, nPort, ret) ;

return ret ;

}

// Milli-second delay

int mSleep (int argc, char *argv[])

{

CHECK_ARGC (3) ;

CheckNumeric (argv[2]) ;

Sleep (atoi (argv[2]) ) ;

printf (“Watchdog timer left %d seconds\n”, nLeft)

;

return nLeft ;

}

// Argument - function mapping

typedef struct

{

char *szCmd ;

int (*function) (int argc, char *argv[]) ;

} CMD2FUN ;

CMD2FUN c2f[] =

{

Embedded and Industrial Computing

46

Page 47

Appendix E

{“DIO_IN” , mDIO_IN

},

{“DIO_OUT” , mDIO_OUT

},

{“PIO” , mPIO

},

{“RunLED” , mRunLED

},

{“AlarmLED” , mAlarmLED

},

{“GPS_LED” , mGPS_LED

},

{“WirelessLED” , mWirelessLED },

{“CaseOpen” , mCaseOpen },

{“CaseOpen_Clear”,mCaseOpen_Clear},

{“Watchdog” , mWatchDog

},

Programming Watchdog Timer

// No match argument

RETMSG (-1, “Wrong Argument\n”) ;

}

catch (char *str)

{

// Output the error message

printf (“\n%s\n”, str) ;

}

catch (...)

{

// Unknown exception

printf (“\nUnknown Exception\n”) ;

}

{“Sleep” , mSleep }

} ;

// Program start here

int main(int argc, char *argv[])

{

try

{

// The total argument allowed

int num = sizeof (c2f) / sizeof (c2f[0]) ;

// Too few argument

if (argc < 2)

RETMSG (-1, PARAMETER_HELP)

;

return -1 ;

}

// Find the match argument and execute

the mapping function

for (int i = 0 ; i < num ; i++)

if (stricmp (argv[1], c2f[i].szCmd)

== 0)

return c2f[i].function

(argc, argv) ;

Embedded and Industrial Computing

47

Page 48

Appendix F

Terms and Conditions

Appendix F:

Terms and Conditions

Warranty Policy

All products are under warranty against defects in 1.

materials and workmanship for a period of one year

from the date of purchase.

The buyer will bear the return freight charges for 2.

goods returned for repair within the warranty period;

whereas the manufacturer will bear the after service

freight charges for goods returned to the user.

The buyer will pay for repair (for replaced components 3.

plus service time) and transportation charges (both

ways) for items after the expiration of the warranty

period.

If the RMA Service Request Form does not meet the 4.

stated requirement as listed on “RMA Service,” RMA

goods will be returned at customer’s expense.

The following conditions are excluded from this 5.

warranty:

RMA Service

Requesting a RMA#

To obtain a RMA number, simply fill out and fax the 6.

“RMA Request Form” to your supplier.

The customer is required to fill out the problem code 7.

as listed. If your problem is not among the codes listed,

please write the symptom description in the remarks

box.

Ship the defective unit(s) on freight prepaid terms. 8.

Use the original packing materials when possible.

Mark the RMA# clearly on the box. 9.

Note: Customer is responsible for shipping

damage(s) resulting from inadequate/loose

packing of the defective unit(s). All RMA# are valid

for 30 days only; RMA goods received after the

effective RMA# period will be rejected.

Improper or inadequate maintenance by the customer

Unauthorized modification, misuse, or reversed

engineering of the product Operation outside of the

environmental specifications for the product.

Embedded and Industrial Computing

48

Page 49

Appendix F

RMA Service Request Form

When requesting RMA service, please fill out the following form. Without

this form enclosed, your RMA cannot be processed.

RMA No:

Reasons to Return: Ŀ Repair(Please include failure details)

Ŀ Testing Purpose

Company: Contact Person:

Phone No. Purchased Date:

Fax No.: Applied Date:

Return Shipping Address:

Shipping by: Ŀ Air Freight Ŀ Sea Ŀ Express ___

Ŀ Others:________________

Item Model Name Serial Number Configuration

Item Problem Code Failure Status

*Problem Code:

01:D.O.A.

02: Second Time

R.M.A.

03: CMOS Data Lost

04: FDC Fail

05: HDC Fail

06: Bad Slot

07: BIOS Problem

08: Keyboard Controller Fail

09: Cache RMA Problem

10: Memory Socket Bad

11: Hang Up Software

12: Out Look Damage

13: SCSI

14: LPT Port

15: PS2

16: LAN

17: COM Port

18: Watchdog Timer

19: DIO

20: Buzzer

21: Shut Down

22: Panel Fail

23: CRT Fail

24: Others (Pls specify)

Request Party

Confirmed By Supplier

Authorized Signature / Date Authorized Signature / Date

Terms and Conditions

Embedded and Industrial Computing

49

Loading...

Loading...