LANIER Aficio SP5200S, SP5200S, SP5200S, Aficio SP 5200SHW*, Aficio SP 5200SHT* Service Manual

...Page 1

M052/M053/M054

SERVICE MANUAL

Page 2

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Americas Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

F ASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH AMERICAS CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use of

any trade name, or web site is intended to convey endorsement or other

affiliation with Ricoh products.

© 2011 RICOH Americas Corporation. All rights reserved.

Page 3

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Americas Corporation.

Users of this manual should be either service

trained or certified by successfully completing a

Ricoh Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Americas Corporation

WARNING

Page 4

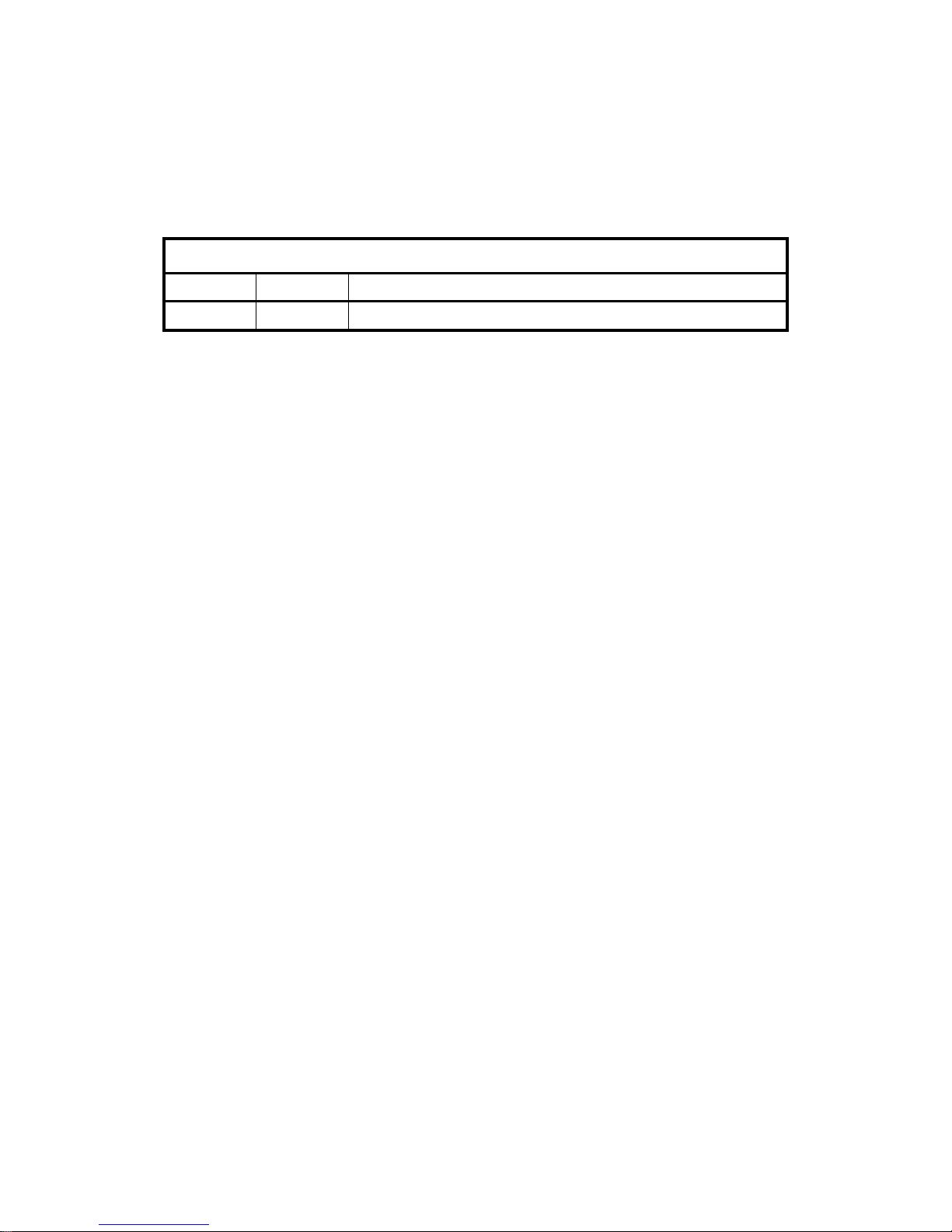

LEGEND

PRODUCT

CODE

COMPANY

LANIER RICOH SAVIN

M052

SP5200S

SP 5200SHW*

SP 5200SHT*

Aficio SP5200S

Aficio SP 5200SHW*

Aficio SP 5200SHT*

SP5200S

SP 5200SHW*

SP 5200SHT*

M053

SP5210SF

SP 5210SFHW*

SP 5210SFHT*

Aficio SP5210SF

Aficio SP 5210SFHW*

Aficio SP 5210SFHT*

SP5210SF

SP 5210SFHW*

SP 5210SFHT*

M054 SP5210SR Aficio SP5210SR SP5210SR

*HC (Healthcare models)

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

11/2011 Original Printing

Page 5

SM i M052/M053/M054

M052/M053/M054

TABLE OF CONTENTS

1. PRODUCT INFORMATION .......................................................... 1-1

1.1SPECIFICATIONS ..................................................................................... 1-1

1.2OVERVIEW ................................................................................................ 1-2

1.2.1 MECHANICAL COMPONENT LAYOUT ........................................... 1-2

1.2.2 DRIVE LAYOUT ............................................................................... 1-3

1.2.3 PAPER PATH ................................................................................... 1-4

Standard Model (M052)/ Fax and 1 Bin Tray Unit Model (M053) ......... 1-4

Finisher Model (M054) ......................................................................... 1-5

1.3MACHINE CONFIGURATION ................................................................... 1-6

1.3.1 MACHINE CONFIGURATION .......................................................... 1-6

Controller Devices ................................................................................ 1-8

2. INSTALLATION ............................................................................ 2-1

2.1INSTALLATION REQUIREMENTS ............................................................ 2-1

2.1.1 ENVIRONMENT ............................................................................... 2-1

2.1.2 MACHINE LEVEL ............................................................................. 2-1

2.1.3 MINIMUM OPERATIONAL SPACE REQUIREMENTS .................... 2-2

2.1.4 POWER REQUIREMENTS .............................................................. 2-2

2.2OPTIONAL UNIT COMBINATIONS ........................................................... 2-3

2.2.1 MACHINE OPTIONS ........................................................................ 2-3

Fax Options .......................................................................................... 2-3

2.2.2 CONTROLLER AND OTHER OPTIONS .......................................... 2-4

Controller Options ................................................................................ 2-4

Other Options ....................................................................................... 2-4

2.3COPIER ..................................................................................................... 2-5

2.3.1 ACCESSORY CHECK ...................................................................... 2-5

2.3.2 INSTALLATION PROCEDURE ........................................................ 2-6

Copier settings ..................................................................................... 2-6

Fax Settings only for M053 model ........................................................ 2-9

When Using an Smart Card Reader ..................................................... 2-9

2.3.3 METER CLICK CHARGE ............................................................... 2-11

2.4PAPER FEED UNIT TK1090 (M375) ....................................................... 2-13

2.4.1 INSTALLATION PROCEDURE ...................................................... 2-13

Page 6

M052/M053/M054 ii SM

2.5 PAPER FEED UNIT TK1100 (M376) ....................................................... 2-15

2.5.1 INSTALLATION PROCEDURE ...................................................... 2-15

When installing the three units (M375 and M376) .............................. 2-17

2.6 FAX OPTION TYPE SP5200 (M381) ....................................................... 2-18

2.6.1 COMPONENT CHECK ................................................................... 2-18

2.6.2 INSTALLATION PROCEDURE ...................................................... 2-19

2.7 COPY DATA SECURITY UNIT TYPE F (B829) ....................................... 2-23

2.7.1 COMPONENTS CHECK ................................................................. 2-23

2.7.2 INSTALLATION .............................................................................. 2-24

User Tool Setting ............................................................................... 2-25

2.8 CONTROLLER OPTIONS ....................................................................... 2-26

2.8.1 OVERVIEW .................................................................................... 2-26

SD Card Slots .................................................................................... 2-26

I/F Card Slot ....................................................................................... 2-26

USB Slots ........................................................................................... 2-26

2.8.2 SD CARD APPLI MOVE ................................................................. 2-27

Overview ............................................................................................ 2-27

Move Exec ......................................................................................... 2-28

Undo Exec .......................................................................................... 2-29

2.8.3 FILE FORMAT CONVERTER (D377) ............................................. 2-30

Installation Procedure ........................................................................ 2-30

2.8.4 IEEE 802.11 A/G, G (D377: WIRELESS LAN) ............................... 2-31

Installation Procedure ........................................................................ 2-31

UP Mode Settings for Wireless LAN .................................................. 2-33

SP Mode and UP Mode Settings for IEEE 802.11 a/g, g Wireless LAN2-35

2.8.5 BLUETOOTH INTERFACE UNIT TYPE D (D566) ......................... 2-36

Installation Procedure ........................................................................ 2-36

2.8.6 BROWSER UNIT TYPE E (D430) .................................................. 2-37

Installation Procedure ........................................................................ 2-37

Update Procedure .............................................................................. 2-38

2.8.7 GIGABIT ETHERNET BOARD TYPE A (G874)/ TYPE C (M397) .. 2-39

Installation Procedure ........................................................................ 2-39

2.8.8 IPDS UNIT TYPE 5210 (D571) ....................................................... 2-40

Installation Procedure ........................................................................ 2-40

2.8.9 MEMORY UNIT TYPE B 32MB (G578) .......................................... 2-41

2.8.10 CHECK ALL CONNECTIONS .................................................... 2-41

2.9 OPTIONAL COUNTER UNIT INTERFACE TYPE A ....................... 2-42

2.10 DATA OVERWRITE SECURITY UNIT TYPE I (D362) 2-45

Page 7

SM iii M052/M053/M054

3. PREVENTIVE MAINTENANCE .................................................... 3-1

3.1MAINTENANCE TABLES .......................................................................... 3-1

3.1.1 USER MAINTENANCE ..................................................................... 3-1

3.1.2 SERVICE MAINTENANCE ............................................................... 3-1

3.2PM PARTS SETTINGS .............................................................................. 3-2

3.2.1 BEFORE REMOVING THE OLD PM PARTS ................................... 3-2

3.2.2 AFTER INSTALLING THE NEW PM PARTS ................................... 3-2

3.2.3 OPERATION CHECK ....................................................................... 3-2

4. REPLACEMENT AND ADJUSTMENT ........................................ 4-1

4.1PRECAUTIONS ......................................................................................... 4-1

4.1.1 GENERAL ......................................................................................... 4-1

AIO ....................................................................................................... 4-1

Transfer Roller ..................................................................................... 4-1

Scanner Unit ........................................................................................ 4-1

Laser Unit ............................................................................................. 4-2

Fusing Unit ........................................................................................... 4-2

Paper Feed .......................................................................................... 4-2

4.1.2 LITHIUM BATTERIES ....................................................................... 4-2

4.1.3 HALOGEN-FREE CABLE ................................................................. 4-2

4.2SPECIAL TOOLS AND LUBRICANTS ...................................................... 4-3

4.3ADJUSTING COPY IM AGE AREA ............................................................ 4-4

4.3.1 PRINTING ......................................................................................... 4-4

Adjusting Registration .......................................................................... 4-4

Adjusting Blank Margin......................................................................... 4-6

Adjusting Main-Scan Magnification ...................................................... 4-7

4.3.2 SCANNING ....................................................................................... 4-7

Adjusting Registration .......................................................................... 4-7

Adjusting Magnification ........................................................................ 4-8

4.3.3 DF IMAGE ADJUSTMENT ............................................................... 4-9

4.4EXTERIOR COVERS .............................................................................. 4-11

4.4.1 LEFT COVER ................................................................................. 4-11

4.4.2 RIGHT COVER ............................................................................... 4-12

4.4.3 REAR LOWER COVER .................................................................. 4-13

4.4.4 FRONT DOOR ................................................................................ 4-14

4.4.5 DUPLEX UNIT ................................................................................ 4-15

4.4.6 OPERATION PANEL UNIT ............................................................. 4-16

Operation Panel Unit .......................................................................... 4-16

Key Tops ............................................................................................ 4-18

Page 8

M052/M053/M054 iv SM

4.4.7 TOUCH PANEL POSITION ADJUSTMENT ................................... 4-20

4.4.8 OUTPUT TRAY (M052/M053 MODELS ONLY) ............................. 4-21

4.5SCANNER UNIT ...................................................................................... 4-22

4.5.1 SCANNER FRONT COVER ........................................................... 4-22

4.5.2 SCANNER RIGHT AND LEFT COVERS ........................................ 4-23

Scanner Right Cover .......................................................................... 4-23

Scanner Left Cover ............................................................................ 4-23

4.5.3 SCANNER REAR COVER .............................................................. 4-24

4.5.4 EXPOSURE GLASS ....................................................................... 4-25

When reassembling the ARDF exposure glass .................................. 4-25

4.5.5 LED BOARD ................................................................................... 4-26

4.5.6 SCANNER MOTOR ........................................................................ 4-29

4.5.7 SENSOR BOARD UNIT (SBU) ....................................................... 4-30

When reassembling ........................................................................... 4-30

4.5.8 LED DRIVE BOARD ....................................................................... 4-31

4.5.9 SCANNER HP SENSOR ................................................................ 4-32

4.5.10 COVER SENSOR ....................................................................... 4-33

4.5.11 FRONT SCANNER WIRE........................................................... 4-34

Reinstalling the Front Scanner Wire ................................................... 4-35

4.5.12 REAR SCANNER WIRE ............................................................. 4-38

Reinstalling the Rear Scanner Wire ................................................... 4-39

4.6LASER OPTI CS ....................................................................................... 4-40

4.6.1 CAUTION DECAL LOCATIONS ..................................................... 4-40

4.6.2 SAFETY SWITCHES FOR LASER UNIT ....................................... 4-41

4.6.3 LASER UNIT ................................................................................... 4-41

Preparation before Removing the Laser Unit ..................................... 4-41

Removing the Laser Unit for All Models ............................................. 4-42

4.6.4 POLYGON MOTOR ........................................................................ 4-43

4.6.5 LASER SYNCHRONIZATION DETECTOR .................................... 4-44

4.7PAPER TRANSF ER ................................................................................ 4-45

4.7.1 TRANSFER ROLLER ..................................................................... 4-45

4.8DRIVE SECTION ..................................................................................... 4-46

4.8.1 GEARBOX ...................................................................................... 4-46

4.8.2 MAIN MOTOR ................................................................................ 4-47

4.8.3 DUPLEX MOTOR ........................................................................... 4-48

4.8.4 BY-PASS FEED CLUTCH .............................................................. 4-49

4.8.5 RELAY CLUTCH ............................................................................ 4-49

4.8.6 PAPER FEED CLUTCH .................................................................. 4-50

Page 9

SM v M052/M053/M054

4.8.7 REGISTRATION CLUTCH ............................................................. 4-50

4.9PAPER FEED .......................................................................................... 4-51

4.9.1 PAPER FEED ROLLER .................................................................. 4-51

4.9.2 FRICTION PAD .............................................................................. 4-52

When reassembling the friction pad ................................................... 4-52

4.9.3 PAPER END SENSOR ................................................................... 4-53

4.9.4 REMAINING PAPER SENSORS .................................................... 4-53

4.9.5 REGISTRATION SENSOR ............................................................. 4-54

4.9.6 BY-PASS PAPER SENSOR ........................................................... 4-54

4.9.7 DUPLEX RELAY SENSOR ............................................................. 4-55

When reassembling the duplex relay sensor ...................................... 4-55

4.9.8 JUNCTION GATE 1 SOLENOID .................................................... 4-56

4.9.9 JUNCTION GATE 2 SOLENOID .................................................... 4-57

4.9.10 FUSING EXIT SENSOR (M053 MODEL ONLY) ........................ 4-58

4.9.11 PAPER OVERFLOW SENSOR (M052/M053 MODELS ONLY) . 4-58

4.10 FUSING .............................................................................................. 4-59

4.10.1 FUSING UNIT ............................................................................. 4-59

4.10.2 HOT ROLLER AND PRESSURE ROLLER SECTIONS ............. 4-60

4.10.3 FUSING LAMP ........................................................................... 4-61

4.10.4 HOT ROLLER ............................................................................. 4-62

4.10.5 FUSING THERMISTOR ............................................................. 4-63

4.10.6 THERMOSTATS ......................................................................... 4-63

4.10.7 PRESSURE ROLLER ................................................................. 4-64

4.10.8 FUSING CLEANING ROLLER .................................................... 4-64

4.11 DUPLEX UNIT ................................................................................... 4-65

4.11.1 DUPLEX UNIT ............................................................................ 4-65

4.11.2 DUPLEX INVERTER MOTOR .................................................... 4-66

4.11.3 DUPLEX EXHAUST FAN ........................................................... 4-67

4.11.4 DUPLEX INVERTER SENSOR .................................................. 4-69

4.11.5 DUPLEX ENTRANCE SENSOR ................................................. 4-70

4.12 ELECTRICAL COMPONENTS .......................................................... 4-71

4.12.1 CONTROLLER UNIT .................................................................. 4-71

4.12.2 HDD UNIT ................................................................................... 4-72

4.12.3 HDD CONTROL BOARD ............................................................ 4-73

4.12.4 NVRAM ....................................................................................... 4-73

When reinstalling a new NVRAM ....................................................... 4-74

4.12.5 EEPROMS .................................................................................. 4-76

When reinstalling a new EEPROM ..................................................... 4-76

Page 10

M052/M053/M054 vi SM

4.12.6 DIMM RAM ................................................................................. 4-77

4.12.7 CONTROLLER BOARD ............................................................. 4-78

When installing a new controller board............................................... 4-79

4.12.8 BICU ........................................................................................... 4-80

BICU................................................................................................... 4-80

BICU Bracket ..................................................................................... 4-81

4.12.9 HVPS (HIGH VOLTAGE POWER SUPPLY) .............................. 4-83

4.12.10 RFID BOARD ............................................................................ 4-83

4.12.11 TONER END SENSOR ............................................................ 4-84

4.12.12 PAPER SIZE SENSOR BOARD ............................................... 4-84

4.12.13 PSU .......................................................................................... 4-85

4.13 ARDF ................................................................................................. 4-87

4.13.1 ARDF .......................................................................................... 4-87

When installing the Platen Sheet ....................................................... 4-88

4.13.2 ARDF REAR COVER ................................................................. 4-88

4.13.3 ARDF FRONT COVER AND ORIGINAL TRAY .......................... 4-89

4.13.4 ORIGINAL FEED UNIT ............................................................... 4-90

4.13.5 PICK-UP ROLLER ...................................................................... 4-91

4.13.6 FEED ROLLER ........................................................................... 4-92

4.13.7 ARDF FRICTION PAD ................................................................ 4-93

4.13.8 ARDF DRIVE BOARD ................................................................ 4-94

4.13.9 ORIGINAL SET SENSOR AND ARDF TOP COVER SENSOR . 4-95

4.13.10 ARDF FEED MOTOR ............................................................... 4-97

4.13.11 ARDF FEED CLUTCH .............................................................. 4-98

4.13.12 ARDF TRANSPORT MOTOR ................................................... 4-99

4.13.13 ARDF REGISTRATION SENSOR .......................................... 4-101

4.13.14 ARDF INVERTER SENSOR ................................................... 4-102

4.13.15 ARDF COOLING FAN ............................................................ 4-103

When installing the cooling fan ......................................................... 4-103

4.14 INTERNAL FINISHER ...................................................................... 4-104

4.14.1 INTERNAL FINISHER .............................................................. 4-104

When reinstalling the internal finisher .............................................. 4-105

4.14.2 FINISHER OUTPUT TRAY UNIT ............................................. 4-106

4.14.3 STAPLER UNIT ........................................................................ 4-107

4.14.4 GATHERING ROLLER MOTOR ............................................... 4-108

4.14.5 FINISHER PAPER EXIT MOTOR ............................................. 4-109

4.14.6 SHIFT ROLLER MOTOR .......................................................... 4-110

4.14.7 FINISHER TRANSPORT MOTOR ............................................ 4-111

Page 11

SM vii M052/M053/M054

4.14.8 TRAY LIFT MOTOR ................................................................. 4-112

4.14.9 JOGGER FENCE HP SENSOR ............................................... 4-113

4.14.10 JOGGER MOTOR .................................................................. 4-115

4.14.11 EXIT GUIDE PLATE MOTOR ................................................. 4-116

4.14.12 SHIFT ROLLER HP SENSOR ................................................ 4-117

4.14.13 GATHERING ROLLER HP SENSOR ..................................... 4-118

4.14.14 FINISHER ENTRANCE SENSOR .......................................... 4-119

4.14.15 FINISHER EXIT SENSOR ...................................................... 4-120

4.14.16 FINISHER PAPER SENSOR .................................................. 4-122

4.14.17 STAPLE TRAY PAPER SENSOR .......................................... 4-123

4.14.18 TRAY LOWER LIMIT SENSOR .............................................. 4-124

4.14.19 EXIT GUIDE PLATE HP SENSOR ......................................... 4-124

4.14.20 FINISHER MAIN BOARD ....................................................... 4-125

When reinstalling a new finisher main board .................................... 4-125

4.15 1 BIN TRAY UNIT ............................................................................ 4-126

4.15.1 1 BIN TRAY UNIT ..................................................................... 4-126

4.15.2 1 BIN TRAY PAPER EXIT SENSOR ........................................ 4-130

4.15.3 1 BIN TRAY PAPER SENSOR AND LED BOARD ................... 4-131

5. SYSTEM MAINTENANCE REFERENCE ..................................... 5-1

5.1SERVICE PROGRAM ................................................................................ 5-1

5.1.1 USING SP AND SSP MODES .......................................................... 5-1

5.1.2 TYPES OF SP MODES .................................................................... 5-1

SP Mode Button Summary ................................................................... 5-2

Switching Between SP Mode and Copy Mode for Test Printing ........... 5-3

Selecting the Program Number ............................................................ 5-3

Exiting Service Mode............................................................................ 5-4

Service Mode Lock/Unlock ................................................................... 5-4

5.1.3 REMARKS ........................................................................................ 5-5

Display on the Control Panel Screen ................................................... 5-5

Others .................................................................................................. 5-6

5.2SYSTEM SP1-XXX .................................................................................... 5-7

5.2.1 SP1-XXX (FEED) .............................................................................. 5-7

5.3SYSTEM SP2-XXX .................................................................................. 5-13

5.3.1 SP2-XXX (DRUM)........................................................................... 5-13

5.4SYSTEM SP3-XXX .................................................................................. 5-15

5.4.1 SP3-XXX (PROCESS) .................................................................... 5-15

5.5SYSTEM SP4-XXX .................................................................................. 5-16

5.5.1 SP4-XXX (SCANNER) .................................................................... 5-16

Page 12

M052/M053/M054 viii SM

5.6SYSTEM SP5-XXX .................................................................................. 5-34

5.6.1 SP5-XXX (MODE) .......................................................................... 5-34

5.7SYSTEM SP6-XXX ................................................................................ 5-102

5.7.1 SP6-XXX (PERIPHERALS) .......................................................... 5-102

5.8SYSTEM SP7-XXX ................................................................................ 5-105

5.8.1 SP7-XXX (DATA LOG) ................................................................. 5-105

5.9SYSTEM SP8-XXX ................................................................................ 5-116

5.9.1 SP8-XXX: DATA LOG2 ................................................................. 5-116

5.10 INPUT AND OUTPUT CHECK ......................................................... 5-164

5.10.1 INPUT CHECK TABLE ............................................................. 5-164

Mianframe ........................................................................................ 5-164

ARDF ............................................................................................... 5-168

Internal Finisher ............................................................................... 5-169

5.10.2 OUTPUT CHECK TABLE ......................................................... 5-170

Copier ............................................................................................... 5-170

ARDF ............................................................................................... 5-172

Internal Finisher ............................................................................... 5-173

5.11 PRINTER SERVICE MODE ............................................................. 5-174

5.11.1 SP1-XXX (SERVICE MODE) .................................................... 5-174

5.12 SCANNER SERVICE MODE ........................................................... 5-183

5.12.1 SP1-XXX (SYSTEM AND OTHERS) ........................................ 5-183

5.12.2 SP2-XXX (SCANNING-IMAGE QUALITY) ............................... 5-185

5.13 FAX SERVICE MODE ...................................................................... 5-186

5.14 FIRMWARE UPDATE ...................................................................... 5-187

5.14.1 TYPE OF FIRMWARE .............................................................. 5-187

5.14.2 BEFORE YOU BEGIN .............................................................. 5-189

5.14.3 UPDATING FIRMWARE ........................................................... 5-190

Preparation ....................................................................................... 5-190

Updating Procedure ......................................................................... 5-190

Error Messages ................................................................................ 5-191

Firmware Update Error ..................................................................... 5-191

Recovery after Power Loss .............................................................. 5-192

5.14.4 UPDATE PROCEDURE FOR APP2ME PROVIDER ................ 5-193

5.14.5 BROWSER UNIT UPDATE PROCEDURE ............................... 5-194

5.14.6 HANDLING FIRMWARE UPDATE ERRORS ........................... 5-195

Error Message Table ........................................................................ 5-195

5.15 SD CARD APPLI MOVE .................................................................. 5-197

5.15.1 OVERVIEW .............................................................................. 5-197

Page 13

SM ix M052/M053/M054

Outline of SD Card Appli Move: ....................................................... 5-197

5.15.2 MOVE EXEC ............................................................................ 5-198

5.15.3 UNDO EXEC ............................................................................ 5-199

5.16 NVRAM DATA UPLOAD/DOWNLOAD ............................................ 5-200

5.16.1 UPLOADING CONTENT OF NVRAM TO AN SD CARD ......... 5-200

5.16.2 DOWNLOADING AN SD CARD TO NVRAM ........................... 5-201

5.17 CARD SAVE FUNCTION ................................................................. 5-202

5.17.1 OVERVIEW .............................................................................. 5-202

Card Save: ....................................................................................... 5-202

5.17.2 PROCEDURE ........................................................................... 5-203

5.17.3 ERROR MESSAGES ................................................................ 5-205

5.18 USING SP MODES .......................................................................... 5-206

5.18.1 ADJUSTING REGISTRATION AND MAGNIFICATION ............ 5-206

5.18.2 TEST PATTERN PRINT (SP 5902) .......................................... 5-206

Executing Test Pattern Printing ........................................................ 5-206

Test Patterns .................................................................................... 5-206

5.18.3 SMC PRINT (SP 5990) ............................................................. 5-208

5.18.4 HOW TO READ THE AIO S/N (SP 5793-011) .......................... 5-208

6. TROUBLESHOOTING ................................................................. 6-1

6.1SERVICE CALL CONDITIONS .................................................................. 6-1

6.1.1 SUMMARY ....................................................................................... 6-1

6.1.2 SC CODE DESCRIPTIONS .............................................................. 6-2

SC1xx: Scanning .................................................................................. 6-3

SC2xx: Laser Exposure ........................................................................ 6-6

SC3xx: Image Processing – 1 .............................................................. 6-8

SC4xx: Image Processing - 2 ............................................................... 6-8

SC5xx: Paper Feed and Fusing ........................................................... 6-9

SC6xx: Device Communication .......................................................... 6-12

SC7xx: Peripherals ............................................................................ 6-17

SC8xx: Controller ............................................................................... 6-20

SC9xx: Others .................................................................................... 6-28

6.2ELECTRICAL COMPONENT DEFECTS ................................................. 6-32

6.2.1 BLOWN FUSE CONDITIONS ......................................................... 6-32

Power Supply Unit .............................................................................. 6-32

6.3JAM DETECTION .................................................................................... 6-33

6.3.1 PAPER JAM DISPLAY ................................................................... 6-33

6.3.2 JAM CODES AND DISPLAY CODES ............................................. 6-33

Page 14

M052/M053/M054 x SM

Paper Jam Detection Sensor Location ............................................... 6-39

7. ENERGY SAVING ........................................................................ 7-1

7.1ENERGY SAVE ......................................................................................... 7-1

7.1.1 ENERGY SAVER MODES ............................................................... 7-1

Timer Settings ...................................................................................... 7-1

Return to Stand-by Mode ..................................................................... 7-2

Recommendation ................................................................................. 7-2

7.1.2 ENERGY SAVE EFFECTIVENESS .................................................. 7-2

7.2PAPER SAVE ............................................................................................ 7-4

7.2.1 EFFECTIVENESS OF DUPLEX/COMBINE FUNCTION .................. 7-4

1. Duplex: ............................................................................................. 7-4

2. Combine mode: ................................................................................ 7-4

3. Duplex + Combine: ........................................................................... 7-4

How to calculate the paper reduction ratio ........................................... 7-5

M052/M053/M054 SERVICE MANUAL APPENDICES

SEE M052/M053/M054 SERVICE MANUAL APPENDICES SECTION FOR DETAILED TABLE

OF CONTENTS

FAX OPTION TYPE SP5200 (M381)

SEE M381 SECTION FOR DETAILED TABLE OF CONTENTS

PAPER FEED UNIT TK1090/TK1100/TK1120/TK1130

(M375/M376/M386/M389)

SEE M375/M376/M386/M389 SECTION FOR DETAILED TABLE OF CONTENTS

Page 15

Page 16

READ THIS FIRST

Safety Notices

Important Safety Notices

Prevention of Physical Injury

1. Before disassembling or assembling parts of the machine and peripherals, make sure that

the machine power cord is unplugged.

2. The wall outlet should be near the machine and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or open while

the main switch is turned on, keep hands away from electrified or mechanically driven

components.

4. The machine drives some of its components when it completes the warm-up period. Be

careful to keep hands away from the mechanical and electrical components as the machine

starts operation.

5. The inside and the metal parts of the fusing unit become extremely hot while the machine is

operating. Be careful to avoid touching those components with your bare hands.

Health Safety Conditions

Toner is non-toxic, but if you get either of them in your eyes by accident, it may cause temporary

eye discomfort. Try to remove with eye drops or flush with water as first aid. If unsuccessful, get

medical attention.

Observance of Electrical Safety Standards

The machine and its peripherals must be serviced by a customer service representative who

has completed the training course on those models.

The Controller board on this machine contains a lithium battery. The danger of explosion

exists if a battery of this type is incorrectly replaced. Replace only with the same or an

equivalent type recommended by the manufacturer. Discard batteries in accordance with

the manufacturer's instructions and local regulations.

The optional fax and memory expansion units contain lithium batteries, which can explode

if replaced incorrectly. Replace only with the same or an equivalent type recommended by

the manufacturer. Do not recharge or burn the batteries. Used batteries must be handled in

accordance with local regulations.

Page 17

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the organic

photoconductor in accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

To prevent a fire or explosion, keep the machine away from flammable liquids, gases,

and aerosols. A fire or an explosion might occur.

Lithium Batteries

Incorrect replacement of lithium battery(s) on the FCU, controller board and memory board unit

may pose risk of explosion. Replace only with the same type or with an equivalent type

recommended by the manufacturer. Discard used batteries in accordance with the

manufacturer's instructions.

Laser Safety

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based

optical units in the field. The optical housing unit can only be repaired in a factory or at a

location with the requisite equipment. The laser subsystem is replaceable in the field by a

qualified Customer Engineer. The laser chassis is not repairable in the field. Customer

engineers are therefore directed to return all chassis and laser subsystems to the factory or

service depot when replacement of the optical subsystem is required.

Use of controls, or adjustment, or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

Page 18

WARNING

WARNING:

Turn off the main switch before attempting any of the procedures in the Laser Optics

Housing Unit section. Laser beams can seriously damage your eyes.

CAUTION MARKING:

Symbols and Abbreviations

This manual uses several symbols and abbreviations. The meaning of those symbols and

abbreviations is as follows:

See or Refer to

Clip ring

E-ring

Screw

Connector

Clamp

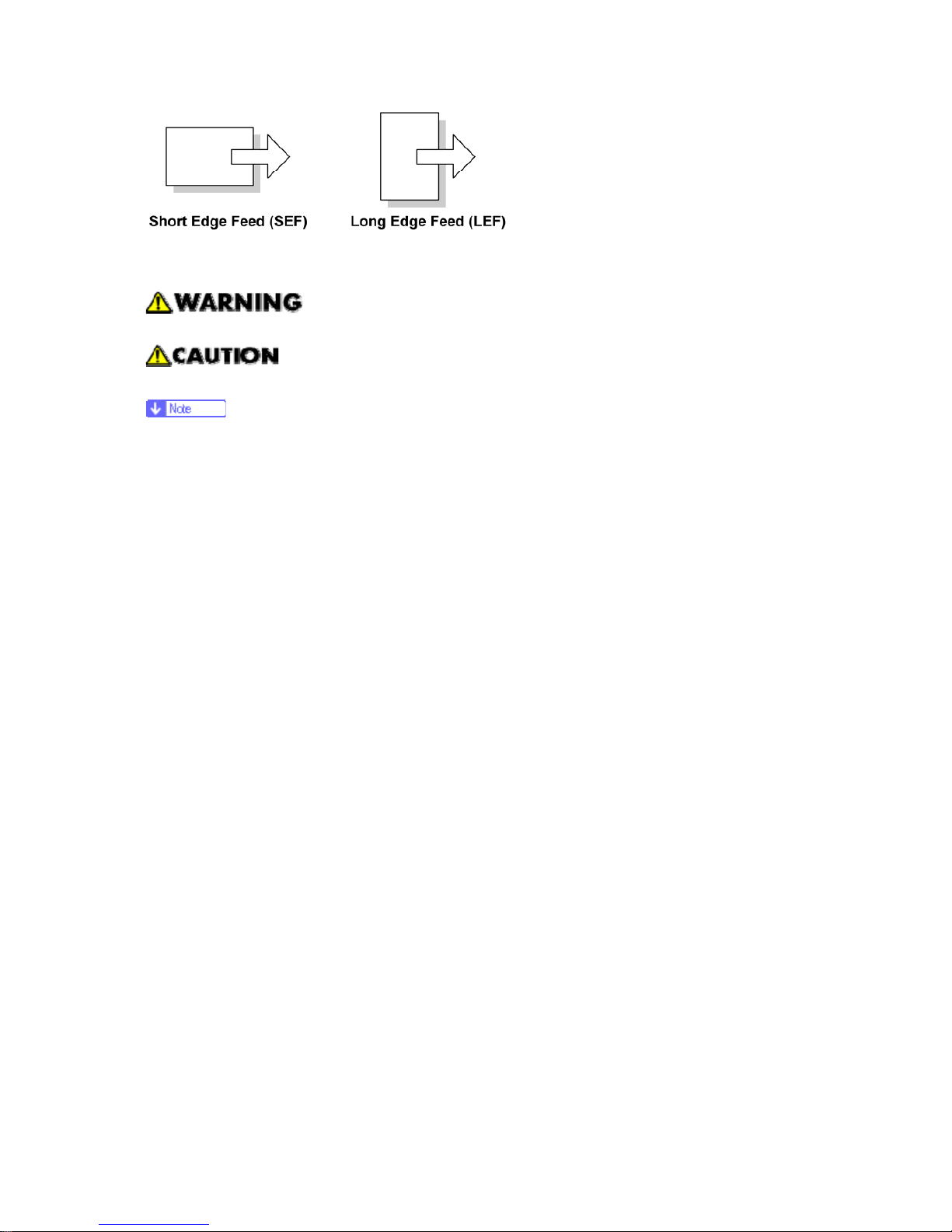

SEF Short Edge Feed

LEF Long Edge Feed

- Core Technology manual

Page 19

Cautions, Notes, etc.

The following headings provide special information:

Failure to obey warning information could result in serious injury or death.

Obey these guidelines to ensure safe operation and prevent minor injuries.

This information provides tips and advice about how to best service the machine.

Page 20

PRODUCT INFORMATION

REVISION HISTORY

Page Date Added/Updated/New

None

Page 21

Page 22

Specifications

SM 1-1 M052/M053/M054

Product

Information

1. PRODUCT INFORMATION

1.1 SPECIFICATIONS

See "Appendices" for the following information:

General Specifications

Supported Paper Sizes

Page 23

Overview

M052/M053/M054 1-2 SM

1.2 OVERVIEW

1.2.1 MECHANICAL COMPONENT LAYOUT

1. Scanner unit

2. Laser unit

3. Charge roller

4. Cartridge (AIO-type)

5. Drum

6. Development roller

7. By-pass feed tray

8. By-pass feed roller

9. Paper feed roller

10. Friction pad

11. Paper tray

12. Registration roller

13. Transfer roller

14. Pressure roller

15. Hot roller

16. Junction gate 1*

1

17. Paper exit roller*

2

18. Junction gate 2*

3

19. Inverter roller

*

1

: Junction gate 1 is not movable for the finisher model (M054).

*

2

: Paper exit roller is not used for the finisher model (M054).

*

3

: Junction gate 2 is not movable for the standard model (M052).

Page 24

Overview

SM 1-3 M052/M053/M054

Product

Information

1.2.2 DRIVE LAYOUT

1. Registration clutch

2. Relay clutch

3. By-pass clutch

4. Paper feed clutch

5. Main motor

6. Duplex motor

7. Inverter motor

Page 25

Overview

M052/M053/M054 1-4 SM

1.2.3 PAPER PATH

Standard Model (M052)/ Fax and 1 Bin Tray Unit Model (M053)

1. Paper feed from tray 1

2. Paper feed from by-pass tray

3. Paper feed from optional PFU (tray2)

4. Paper feed from optional PFU (tray3)

5. Paper feed from optional PFU (tray4)

6. Paper feed through duplex unit

7. Paper exit to 1 bin tray (M053 only)

Page 26

Overview

SM 1-5 M052/M053/M054

Product

Information

Finisher Model (M054)

1. Paper feed from tray 1

2. Paper feed from by-pass tray

3. Paper feed from optional PFU (tray2)

4. Paper feed from optional PFU (tray3)

5. Paper feed from optional PFU (tray4)

6. Paper feed through duplex unit

7. Paper exit to internal finisher (M054 only)

Page 27

Machine Configuration

M052/M053/M054 1-6 SM

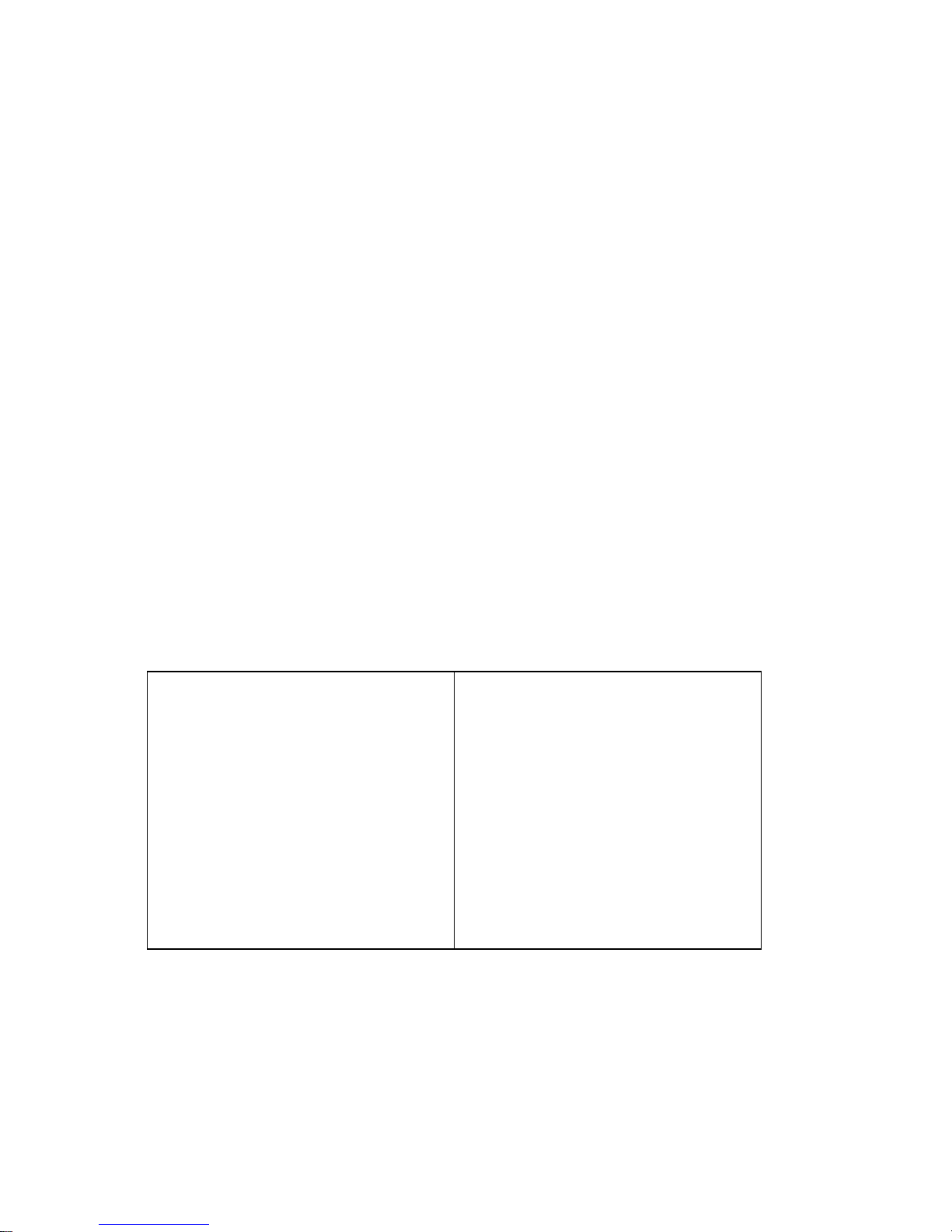

1.3 MACHINE CONFIGURATION

1.3.1 MACHINE CONFIGURATION

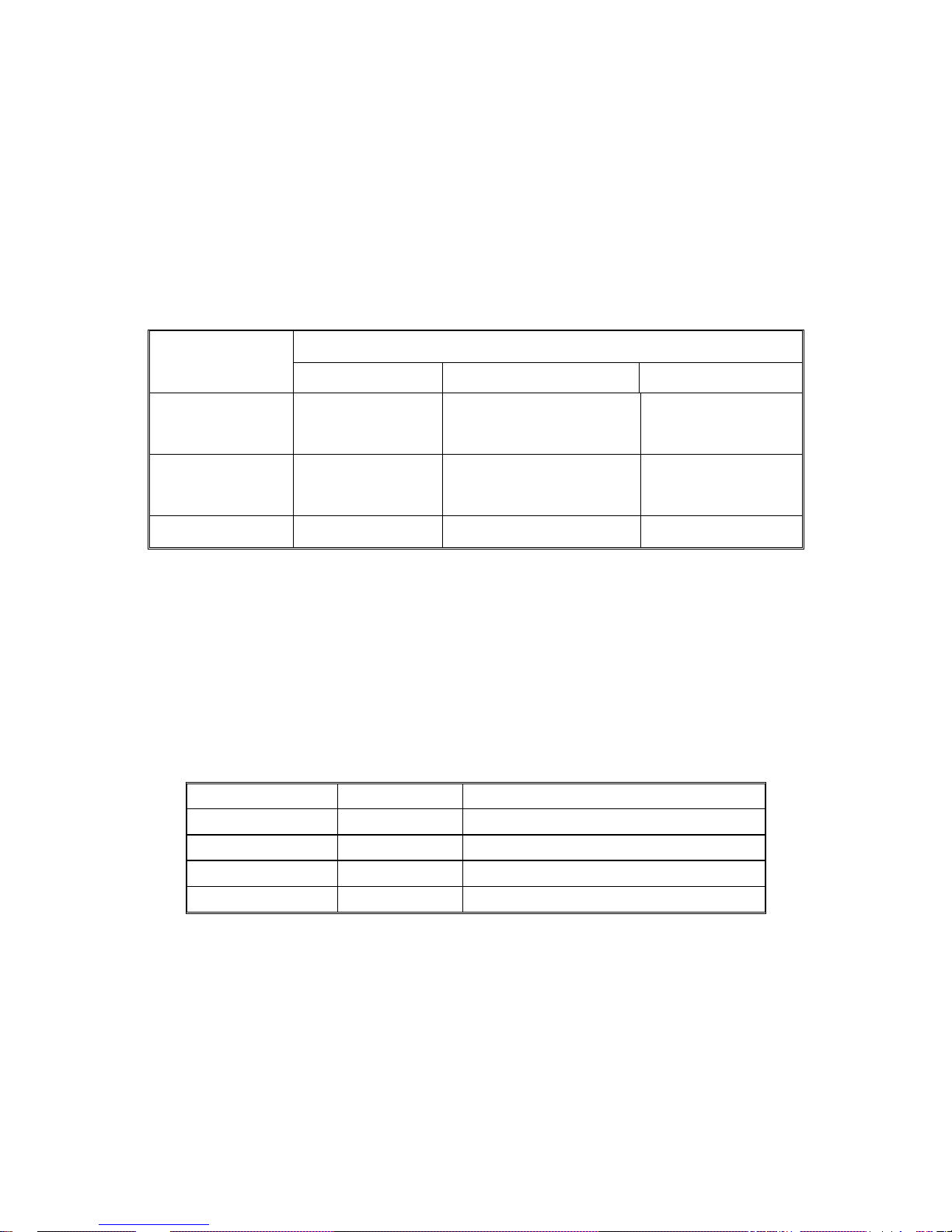

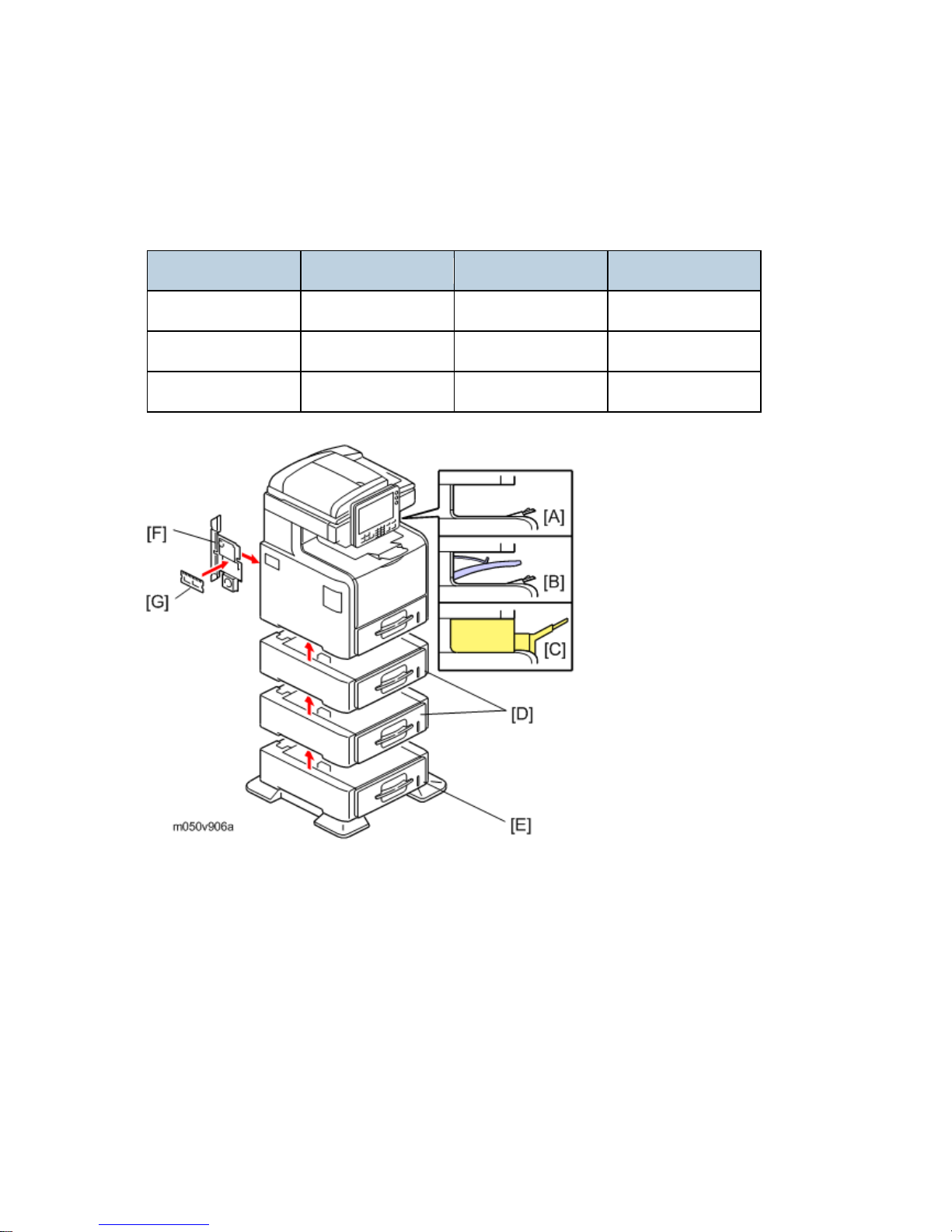

M052 M053 M054

Fax Unit Option Standard Option

1 Bin Tray Unit Not available Standard Not available

Internal Finisher Not available Not available Standard

Page 28

Machine Configuration

SM 1-7 M052/M053/M054

Product

Information

Item Machine Code Remarks

Main Unit [A] M052 Standard model

Main Unit [B] M053 Fax and 1 bin tray unit model

Main Unit [C] M054 Finisher model

Paper Feed Unit TK1090 [D] M375 Option

Paper Feed Unit TK1100 [E] M376 Option

Fax Option Type SP5200 [F] M381

Standard for M053

Option for M052 and M054

Memory Unit Type B [G] G578

SAF memory:

Requires the Fax Option.

Page 29

Machine Configuration

M052/M053/M054 1-8 SM

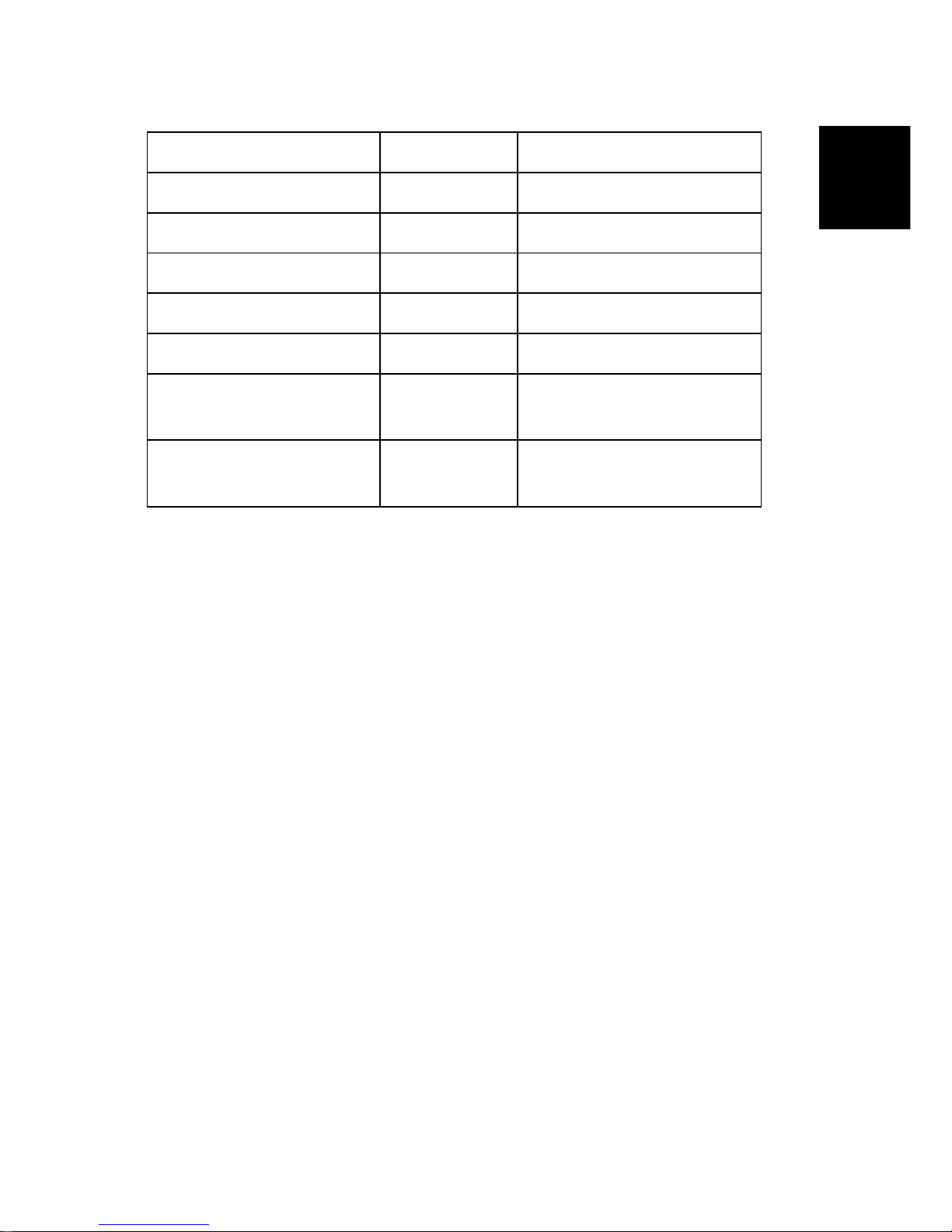

Controller Devices

Item Machine Code Remarks

VM Card [E] - Standard

Security Card [D] - Standard

Copy Data Security Unit Type

F [G]

B829 Option

Remote Communication Gate

A

D459 Option

IPDS Unit Type 5210 [D] D571 Controller Option

Gigabit Ethernet Board Type

A/ Type C [A]

Type A: G874

Type C: M397

Controller Option

IEEE802.11 a/g Interface Unit

Type J, K [B]

D377 Controller Option

Browser Unit Type E [E] D430 Controller Option

File Format Converter Type E

[C]

D377 Controller Option

Bluetooth Interface Unit Type

D [F]

D566 Controller Option

Page 30

INSTALLATION

REVISION HISTORY

Page Date Added/Updated/New

1 1 ~ 12 12/26/2012 Meter click charge

22 5/16/2012 Fax installation

42 ~ 44 12/27/2011 Optional Counter Unit Interface Type A

45 ~ 50 1 1/7/20 13 Data Overwrite Security Unit Type I (D362)

Page 31

Page 32

Installation Requirements

SM 2-1 M052/M053/M054

Installation

2. INSTALLATION

2.1 INSTALLATION REQUIREMENTS

2.1.1 ENVIRONMENT

–Temperature and Humidity Chart–

Temperature Range: 10°C to 32°C (50°F to 89.6°F)

Humidity Range: 15% to 80% RH

Ambient Illumination: Less than 1,500 lux (Do not expose to direct sunlight.)

Ventilation: Room air should turn over at least 3 times/hr/person

Ambient Dust: Less than 0.1 mg/m

3

Do not install the machine where it will be exposed to direct sunlight or to direct airflow

(from a fan, air conditioner, air cleaner, etc.).

Do not install the machine where it will be exposed to corrosive gas.

Install the machine at locations lower than 2,000 m (6,560 ft.) above sea level.

Place the machine on a firm and level base.

Do not install the machine where it may be subjected to strong vibration.

2.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

Page 33

Installation Requirements

M052/M053/M054 2-2 SM

2.1.3 MINIMUM OPERATIONAL SPACE REQUIREMENTS

Place the machine near the power source, providing clearance as shown.

A: Front – 350 mm (29.6")

B: Left – 100 mm (3.9")

C: Rear – 300 mm (3.9")

D: Right – 100 mm (3.9")

2.1.4 POWER REQUIREMENTS

Make sure that the wall outlet is near the machine and easily accessible. After

completing installation, make sure the plug fits firmly into the outlet.

Avoid multiple connections to the same power outlet.

Be sure to ground the machine.

Input voltage:

North America: 120 – 127 V, 60 Hz, 12 A

Europe/Asia: 220 – 240 V, 50/60 Hz, 8 A

Image quality guaranteed at rated voltage ± 10%.

Operation guaranteed at rated voltage ± 15%.

Page 34

Optional Unit Combinations

SM 2-3 M052/M053/M054

Installation

2.2 OPTIONAL UNIT COMBINATIONS

2.2.1 MACHINE OPTIONS

No. Options Remarks

1 Paper Feed Unit TK1090

Two units can be installed in the

mainframe.

2 Paper Feed Unit TK1100 This unit has casters.

Fax Options

No. Options Remarks

3 Fax Option Type SP5200

Standard for M053

Options for M052/M054

4 Memory Unit Type B

SAF memory:

Requires the fax option.

Page 35

Optional Unit Combinations

M052/M053/M054 2-4 SM

2.2.2 CONTROLLER AND OTHER OPTIONS

Controller Options

No. Options Remarks

1 IPDS Unit Type 5210 SD slot 1 (upper)

2 Browser Unit Type E

SD slot 2 (lower) during

installation only

3 Bluetooth Interface Unit Type D One of USB slots

4 Gigabit Ethernet Board Type A/ Type C

IF slot (one from three

options)

5 IEEE802.11 a/g Interface Unit Type J, K

6 File Format Converter Type E

Other Options

No. Options Remarks

7 Copy Data Security Unit Type F -

- Remote Communication Gate A -

Page 36

Copier

SM 2-5 M052/M053/M054

Installation

2.3 COPIER

2.3.1 ACCESSORY CHECK

Description Q’ty

AIO 1

Power Cord 1

VM Card 1

Extender (finisher support tray; M054 only) 1

Paper Size and Tray Decals 1

Warranty Sheet (NA only) 1

User Registration Card (NA only) 1

Help Desk Card (NA only) 1

EULA (16 languages) 1

Page 37

Copier

M052/M053/M054 2-6 SM

2.3.2 INSTALLATION PROCEDURE

Make sure that the copier remains unplugged during installation.

Copier settings

1. Remove the plastic bag.

2. Lift the machine by the inset grips on its sides.

At least four people are needed to lift the machine.

3. Lower the machine slowly and carefully to prevent trapping your hands.

4. Remove the adhesive tape attached on the machine's exterior.

5. Only for M054 model, do the following steps from 1) and 2).

1) Pull out tray 1 [A], and then remove the extender [B] for the internal finisher from tray

1.

Page 38

Copier

SM 2-7 M052/M053/M054

Installation

2) Attach the extender [A] to the finisher tray.

6. Lift the ARDF [A], and then remove the protective materials attached on the exposure

glass.

7. Close the ARDF.

8. Open the front door [A] pressing the button.

9. Remove the AIO [B], and then remove the protective material attached on the machine's

interior.

10. Install the AIO into the machine.

11. Close the front door.

Page 39

Copier

M052/M053/M054 2-8 SM

12. Remove the SD slot cover [A] ( x 1).

13. Install the VM card [B] provided in the accessories in the SD slot 2 (lower).

14. Attach the SD slot cover [A] (

x 1).

15. Plug in the machine, and then turn on the machine.

16. Start the SP mode.

17. Select SP5-302-002 and specify the time zone.

18. Select SP5-307-001, 003, and 004 and specify the daylight-saving-time settings.

19. Exit the SP mode and turn the main switch off and on.

20. Start the UP mode.

21. Specify the date and time with "Set Date" or "Set Time" (User Tool" > "System Settings" >

"Set Date" or "Set Time").

22. Turn the main switch off and on.

23. Check the operations.

24. Make a full size copy, and check if the side-to-side and leading edge registrations are

correct. If they are not, adjust the registrations.

Page 40

Copier

SM 2-9 M052/M053/M054

Installation

Fax Settings only for M053 model

Initializing the Fax unit

When you press the Fax key for the first time after installation, the error "SRAM problem

occurred / SRAM was formatted" will show on the LCD for initializing the program of the fax unit.

Turn the main power switch off/on to clear the error display.

If another error occurs after initialization, this can be a functional problem.

1. Select fax SP1-101-016 and specify the country code.

2. Select fax SP3-101-001 and specify the service station.

When Using an Smart Card Reader

If a customer wants to use a smart card reader, follow the installation procedure below. The

smart card reader must be placed on the specific place. If not, some antenna or transmitter in

the main machine may be interrupted.

1. ARDF rear cover (

p.4-88)

2. Attach the smart card reader [A].

1. Release the hook, and then put the cable outside.

Page 41

Copier

M052/M053/M054 2-10 SM

2. Route the cable [A] as shown above.

3. Remove the part [A] of the ARDF rear cover with nippers or a similar tool.

4. Reassemble the machine.

5. For details about connecting a smart card device to the machine, refer to the installation

procedure provided with the smart card device.

Page 42

Copier

SM 2-11 M052/M053/M054

Installation

2.3.3 METER CLICK CHARGE

Basically, there are two ways to set up this function.

Meter click charge enabled (SP 5-930-001 set to "enabled") and Parts replacement

operation type enabled (SP5-067-001 set to "0: Service"): The counter can be displayed and

printed by the customer. The technician can then call the customer and ask them to read the

counter.

Meter click charge disabled (SP 5-930-001 set to "disabled"; this is the default setting)

and Parts replacement operation type enabled (SP5-067-001 set to "1: User", this is the

default setting): The counter cannot be displayed or printed by the customer. To check the

counter, the technician must print the SMC report (SP 5-990).

You must select one of the counter methods (developments/prints) in accordance with

the contract by using SP5-045-001.

Item SP No. Function Default

Meter Click

Charge Setting

SP5-930-001

Enables or disables Meter Click

Charge.

When enabled:

The counter menu shows

immediately after you push the

"Menu" key. The "Counter

Method" (SP5-045) sets the

type of the counter.

You can print the counter from

the counter menu.

When disabled:

The counter menu does not

show.

"0": OFF

Meter Click

Charge: Life

Disp:

Maintenance Kit

SP5-930-002

Enables or disables the PM alert for

the maintenance kit.

If this SP is enabled, an alert

message is displayed when the

maintenance kit needs to be

replaced.

"0": Off

⇒

Rev. 12/26/2012

Page 43

INSTALLATION

REVISION HISTORY

Page Date Added/Updated/New

1 1 ~ 12 12/26/2012 Meter click charge

22 5/16/2012 Fax installation

42 ~ 44 12/27/2011 Optional Counter Unit Interface Type A

Page 44

Paper Feed Unit TK1090 (M375)

SM 2-13 M052/M053/M054

Installation

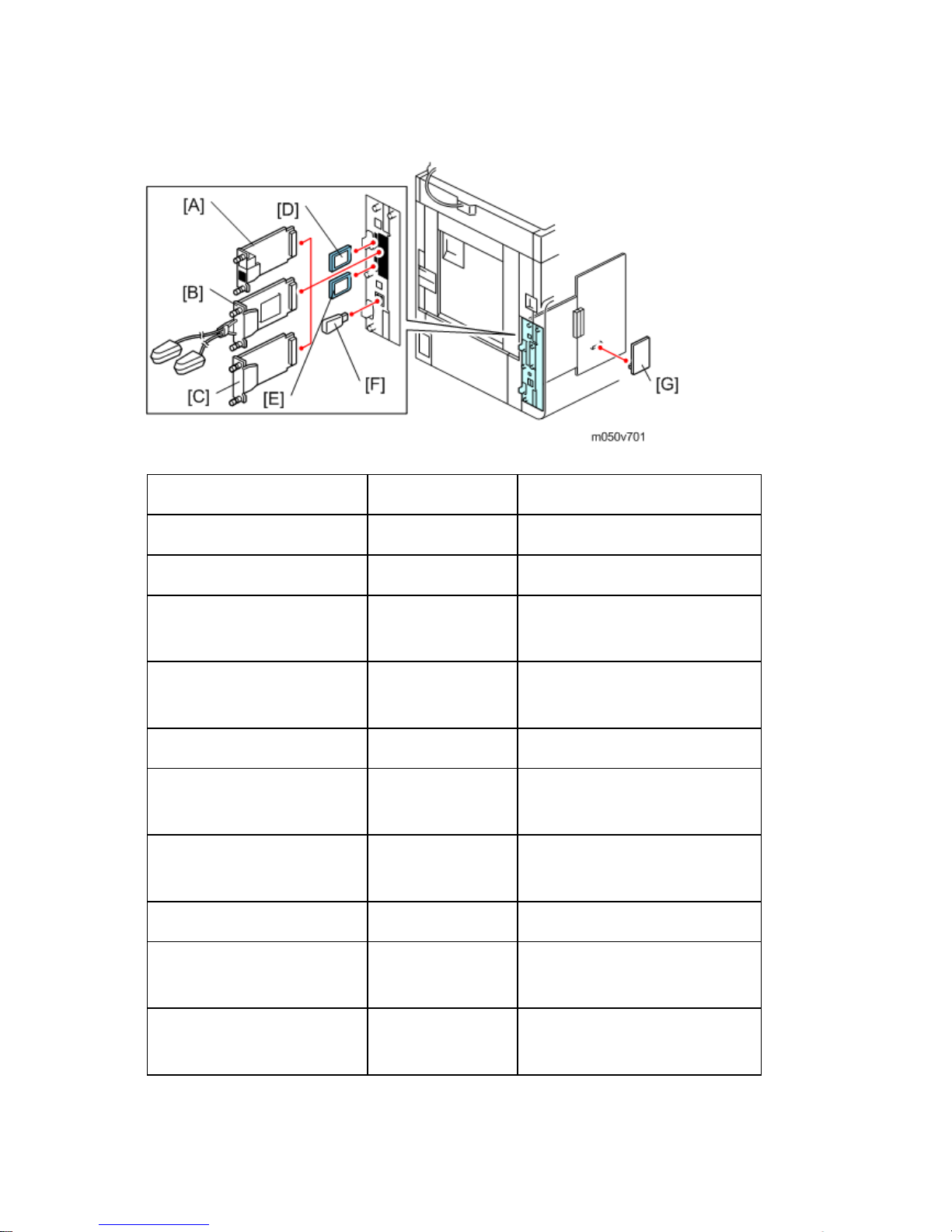

2.4 PAPER FEED UNIT TK1090 (M375)

2.4.1 INSTALLATION PROCEDURE

Unplug the main machine's power cord before starting the following procedure.

The number of optional paper feed units that can be attached depends on the location where

the machine is installed.

[A]: Only one paper feed unit (M375 [D]) can be installed on a desk.

[B]: Up to three units (M375 [D] and M376 [E]) can be installed on the floor. Attach the

optional paper feed unit with casters (M376 [E]) to the bottom of the machine to install the

machine directly on the floor.

[C]: Attach the optional paper feed unit with casters (M376 [E]) to the bottom of the machine

to install the machine directly on the floor.

Page 45

Paper Feed Unit TK1090 (M375)

M052/M053/M054 2-14 SM

1. Remove all tapes and cardboard on the paper feed unit [A].

2. Pull the paper tray part way out of the paper feed unit, remove the tape and cardboard in

the paper tray, and push the tray back in.

3. Set the machine [A] on the paper feed unit [B].

Two people are required to lift the machine.

When installing a second paper feed unit, place on the first paper feed unit before

placing the copier onto the pair of paper feed units

4. Remove the paper(s) tray from the paper tray unit(s).

5. Load paper into the paper tray(s). Adjust the side and end fences as necessary. If loading

8

1

/2"x 14" paper, remove the end fence and set it into the special compartment.

6. Set the paper tray(s) back into the paper tray unit(s).

Page 46

Paper Feed Unit TK1100 (M376)

SM 2-15 M052/M053/M054

Installation

2.5 PAPER FEED UNIT TK1100 (M376)

2.5.1 INSTALLATION PROCEDURE

Unplug the main machine's power cord before starting the following procedure.

The number of optional paper feed units that can be attached depends on the location where

the machine is installed.

[A]: Only one paper feed unit (M375 [D]) can be installed on a desk.

[B]: Up to three units (M375 [D] and M376 [E]) can be installed on the floor. Attach the

optional paper feed unit with casters (M376 [E]) to the bottom of the machine to install the

machine directly on the floor.

[C]: Attach the optional paper feed unit with casters (M376 [E]) to the bottom of the machine

to install the machine directly on the floor.

Page 47

Paper Feed Unit TK1100 (M376)

M052/M053/M054 2-16 SM

1. Remove all tapes and cardboard on the paper feed unit [A].

2. Pull the paper tray part way out of the paper feed unit, remove the tape and cardboard in

the paper tray, and push the tray back in.

3. Set the machine [A] on the paper feed unit [B].

Two people are required to lift the machine.

When installing a second paper feed unit, place on the first paper feed unit before

placing the copier onto the pair of paper feed units

4. Remove the paper(s) tray from the paper tray unit(s).

5. Load paper into the paper tray(s). Adjust the side and end fences as necessary. If loading

8

1

/2"x 14" paper, remove the end fence and set it into the special compartment.

6. Set the paper tray(s) back into the paper tray unit(s).

Page 48

Paper Feed Unit TK1100 (M376)

SM 2-17 M052/M053/M054

Installation

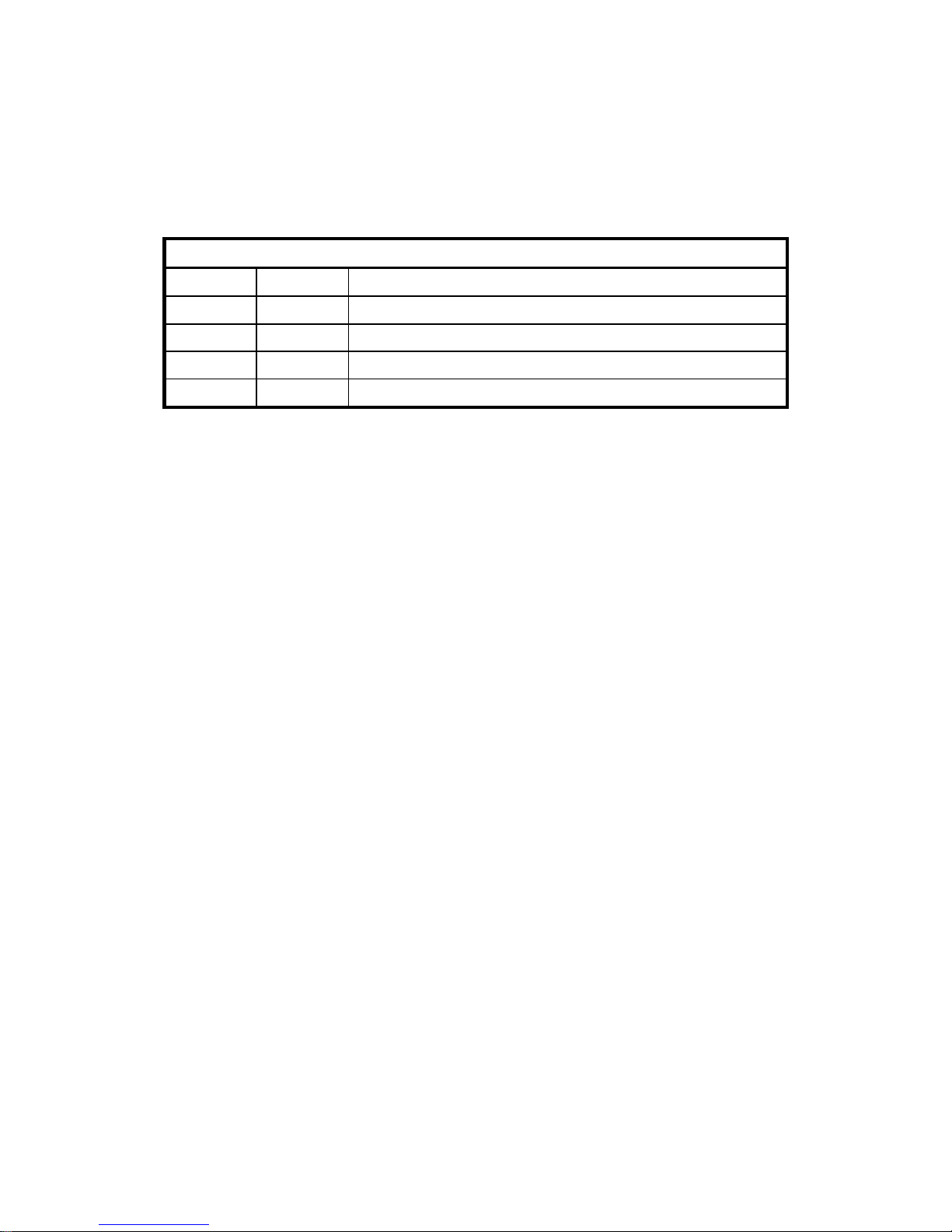

When installing the three units (M375 and M376)

1. Attach the six brackets and six screws as shown above.

2. Attach the screws into the paper feed units as shown above.

Page 49

Fax Option Type SP5200 (M381)

M052/M053/M054 2-18 SM

2.6 FAX OPTION TYPE SP5200 (M381)

2.6.1 COMPONENT CHECK

Check the quantity and condition of the components against the following list.

No. Description Q’ty

1 FCU 1

2 Fax Key top 2

3 G3 Decal 1

4 Serial Number Decal 1

5 FCC Decal (NA only) 1

6 Multi-Language Decals (EU only) 1

7 Ferrite Core 1 (Excluding NA)

8 Telephone Cord (NA only) 1

- EMC Address Card (EU only) 1

Page 50

Fax Option Type SP5200 (M381)

SM 2-19 M052/M053/M054

Installation

2.6.2 INSTALLATION PROCEDURE

Before installing this fax unit:

Print out all data in the printer buffer.

Turn off the main power switch and disconnect the power cord and the network cable.

1. Remove the FCU slot cover [A] (

x 3).

2. Switch the MBU battery jumper switch [A] to “ON” position.

Page 51

Fax Option Type SP5200 (M381)

M052/M053/M054 2-20 SM

3. Press down the place [A] on the MBU board.

4. Install the FCU [A] into the FCU slot [B] of the machine.

Align the top edge [C] of the FCU board with the rail [D] in the FCU slot when installing

the FCU.

5. Secure the FCU [A] (

x 3).

Use two screws which have already been removed in step 1.

6. Attach the serial number decal on the area [B] of the FCU bracket and FCC decal (NA only)

on the area [C] above the serial number decal of the machine.

7. Connect the telephone cord to the "LINE" jack.

Page 52

Fax Option Type SP5200 (M381)

SM 2-21 M052/M053/M054

Installation

For EU/AA, attach the ferrite core to the telephone cord before connecting the

telephone cord to the "LINE" jack.

For NA, use the core attached telephone cord (No.9) in the accessories of the fax unit

option.

8. Attach an appropriate multi-language decal [A] (EU only).

9. Replace the blank key [B] with the fax key [C].

10. Attach the decal [A] (SUPER G3) to the front door.

11. Put the power plug into the outlet and turn on the main power of the machine.

Page 53

Fax Option Type SP5200 (M381)

M052/M053/M054 2-22 SM

Make sure that the outlet is grounded.

"SRAM formatted" shows on the operation panel after you have turned the main

switch on. Turn the main switch off and on again for normal use.

12. Enter the "User Tools" mode and set date and time.

13. Enter SP3-102 in the fax SP mode and enter the serial number for the fax unit.

14. Enter the correct country code with UP mode (NCU Country/ Area Code Setting).

15. Exit the SP mode, and turn the machine off and on.

⇒

⇒

Rev. 05/16/2012

Page 54

Copy Data Security Unit Type F (B829)

SM 2-23 M052/M053/M054

Installation

2.7 COPY DATA SECURITY UNIT TYPE F (B829)

2.7.1 COMPONENTS CHECK

No. Description Q’ty

1 ICIB-3 1

2 Flexible cable: Long (Not used) 1

3 Flexible cable: Short (Not used) 1

4 Harness with bands (Not used) 1

5 Harness (Not used) 1

6 Saddle Clamp (Not used) 1

7 Screws: M3x6 6

8 Bracket (Not used) 1

Page 55

Copy Data Security Unit Type F (B829)

M052/M053/M054 2-24 SM

2.7.2 INSTALLATION

Unplug the main machine power cord before you do the following procedure.

1. Open the front door.

2. Pull out the tray 1 [A].

3. Remove the left cover [A] of the machine ( x 3).

4. Move the scanner I/F cable aside [A] (

x 1, x 2).

5. Move the harness guide [B] aside (

x 3).

Page 56

Copy Data Security Unit Type F (B829)

SM 2-25 M052/M053/M054

Installation

6. Attach ICIB-3 [A] to CN107 [B] on the BICU (

x 1).

7. Reassemble the machine.

User Tool Setting

1. Plug in the machine and turn on the main power switch.

2. Go into the User Tools mode, and select System Settings > Administrator Tools > Copy

Data Security Option > “On”.

3. Exit User Tools.

4. Check the operation.

The machine will issue an SC165 error if the machine is powered on with the

ICIB-3 removed and the “Data Security for Copying“ feature set to “ON”.

The machine will issue an uncertain SC165 error if ICIB-3 is defective when the

machine is powered on and the “Data Security for Copying“ feature is set to “OFF”.

When you remove this option from the machine, first set this feature to “OFF” with

the user tool before removing this board. If you forget to do this, “Data Security for

Copying “feature cannot appear in the user tool setting. Also, SC165 will appear

every time the machine is switched on, and the machine cannot be used.

5. Make sure that the machine can recognize the option.

Page 57

Controller Options

M052/M053/M054 2-26 SM

2.8 CONTROLLER OPTIONS

2.8.1 OVERVIEW

This machine has I/F card slots for optional I/F connections and SD card slot applications.

After you install an option, check that the machine can recognize it (see “Check All

Connections” at the end of this section).

SD Card Slots

Slot 1 (upper slot) [A] is used for Security Card (standard) or IPDS Unit.

If IPDS Unit is to be installed, first merge IPDS application into the Security Card with SP

mode.

Slot 2 (lower slot) [B] is used for VM card (standard) or service only (for example, updating

the firmware).

I/F Card Slot

The I/F card slot [C] is used for one of the optional I/F connections (only one can be

installed): Gigabit Ethernet, IEEE802.11a/g (Wireless LAN), or File Format Converter.

USB Slots

Both USB slots [D] are used for the Bluetooth option and a card authentication device.

Page 58

Controller Options

SM 2-27 M052/M053/M054

Installation

2.8.2 SD CARD APPLI MOVE

The PostScript3 application and fonts cannot be moved to another SD card. However,

other applications can be moved onto the PostScript3 SD card.

Overview

The service program “SD Card Appli Move” (SP5-873) lets you copy application programs from

one SD card to another SD card.

SD slot 1 (upper ) is used to store application programs. But there are two possible applications

(Security Card (Data Overwrite Security and HDD Encryption Unit), IPDS). You cannot run

application programs from Slot 2. However you can move application programs from SD slot 2

(lower slot) to SD slot 1 (upper slot) with the following procedure.

Make sure that the target SD card has enough space.

1. Enter SP5873 “SD Card Appli Move”.

2. Then move the application from the SD Card in SD slot 2 (lower slot) to the SD Card in SD

slot 1 (upper slot).

Do steps 1-2 again if you want to move another application program.

3. Exit the SP mode.

Be very careful when you do the SD Card Appli Move procedure:

The data necessary for authentication is transferred with the application program from an

SD card to another SD card. Authentication fails if you try to use the SD card af ter you copy

the application program from one card to another card.

Do not use the SD card if it has been used before for other purposes. Normal operation is

not guaranteed when such an SD card is used.

Keep the SD card in a safe place after you copy the application program from one card to

another card. This is done for the following reasons:

1) The SD card can be the only proof that the user is licensed to use the application

program.

2) You may need to check the SD card and its data to solve a problem in the future.

Page 59

Controller Options

M052/M053/M054 2-28 SM

Move Exec

The menu “Move Exec” (SP5-873-001) lets you copy application programs from the original SD

card to another SD card.

Do not turn ON the write protect switch of the system SD card or application SD card

on the machine. If the write protect switch is ON, a download error (e.g. Error Code 44)

occurs during a firmware upgrade or application merge.

1. Turn the main switch off.

2. Make sure that an SD card is in SD slot 1 (upper slot). The application program is copied to

this SD card.

3. Insert the SD card with the application program in SD slot 2 (lower slot). The application

program is copied from this SD card.

4. Turn the main switch on.

5. Start the SP mode.

6. Select SP5-873-001 "Move Exec".

7. Follow the messages shown on the operation panel.

8. Turn the main switch off.

9. Remove the SD card from SD slot 2 (lower slot).

10. Turn the main switch on.

11. Check that the application programs run normally.

Page 60

Controller Options

SM 2-29 M052/M053/M054

Installation

Undo Exec

“Undo Exec” (SP5-873-002) lets you copy back application programs from an SD card to the

original SD card. You can use this program when, for example, you have mistakenly copied

some programs by using Move Exec (SP5-873-001).

Do not turn ON the write protect switch of the system SD card or application SD card

on the machine. If the write protect switch is ON, a download error (e.g. Error Code 44)

occurs during a firmware upgrade or application merge.

1. Turn the main switch off.

2. Insert the original SD card in SD slot 2 (lower slot). The application program is copied back

into this card.

3. Insert the SD card with the application program in SD slot 1 (upper slot). The application

program is copied back from this SD card.

4. Turn the main switch on.

5. Start the SP mode.

6. Select SP5-873-002 “Undo Exec.”

7. Follow the messages shown on the operation panel.

8. Turn the main switch off.

9. Remove the SD card from SD slot 2 (lower slot).

This step assumes that the application programs in the SD card are used by the

machine.

10. Turn the main switch on.

11. Check that the application programs run normally.

12. Make sure that the machine can recognize the option (see ‘Check All Connections’ at the

end of this section).

Page 61

Controller Options

M052/M053/M054 2-30 SM

2.8.3 FILE FORMAT CONVERTER (D377)

Installation Procedure

Unplug the main machine power cord before you do the following procedure.

You can only install one of the following network interfaces or printer enhanced option at one

time: (IEEE 802.11 a/g, g (Wireless LAN), Gigabit Ethernet, or File Format Converter).

1. Remove the I/F-slot cover [A] (

x 2).

2. Install the file format converter [A] into the I/F-slot and then fasten it with screws.

3. Plug in and turn on the main power switch.

4. Check or set the following SP codes with the values shown below.

Page 62

Controller Options

SM 2-31 M052/M053/M054

Installation

SP No. Title Setting

SP5-836-001 Capture Function (0:Off 1:On) "1"

SP5-836-002 Panel Setting "0"

5. Check the operation.

6. Make sure that the machine can recognize the option (see ‘Check All Connections’ at the

end of this section).

2.8.4 IEEE 802.11 A/G, G (D377: WIRELESS LAN)

Installation Procedure

Unplug the main machine power cord before you do the following procedure.

You can only install one of the following network interfaces or printer enhanced option at one

time: (IEEE 802.11 a/g, g (Wireless LAN), Gigabit Ethernet, or File Format Converter).

1. Remove the I/F-slot cover [A] from the I/F-slot (

x 2).

2. Install the wireless LAN board [A] (Knob-screw x 2) into the I/F-slot.

3. Make sure that the machine can recognize the option (see ‘Check All Connections’ at the

Page 63

Controller Options

M052/M053/M054 2-32 SM

end of this section).

4. Peel off the cover from the double-sided tape on the Velcro fasteners [A], and then attach

the fasteners [A] at the scanner left cover of the machine.

5. Attach the antennas [B] to the fasteners on the scanner left cover.

6. Attach eight clamps as shown above.

7. Wire the cables and clamp them (

x 8).

Make sure that the cables are not slack. Keep them wired tightly along the covers.

You may have to move the machine if the reception is not clear.

Make sure that the machine is not located near an appliance or any type of equipment that

generates strong magnetic fields.

Put the machine as close as possible to the access point.

Page 64

Controller Options

SM 2-33 M052/M053/M054

Installation

UP Mode Settings for Wireless LAN

Enter the UP mode. Then do the procedure below to perform the initial interface settings for

IEEE 802.11 a/g, g. These settings take effect every time the machine is powered on.

You cannot use the wireless LAN if you use Ethernet.

1. Press the “User Tools/Counter” key.

2. On the touch panel, press “System Settings”.

The Network I/F (default: Ethernet) must be set for either Ethernet or wireless LAN.

3. Select “Interface Settings”.

4. Press “Wireless LAN”. Only the wireless LAN options show.

5. Communication Mode. Select either “802.11 Ad hoc” or “Infrastructure”.

6. SSID Setting. Enter the SSID setting. (The setting is case sensitive.)

7. Channel. You need this setting when Ad Hoc Mode is selected.

Region A (mainly Europe and Asia)

Range: 1-13, 36, 40, 44 and 48 channels (default: 11)

In some countries, only the following channels are available:

Range: 1-11 channels (default: 11)

Region B (mainly North America)

Range: 1-11, 36, 40, 44 and 48 channels (default: 11)

Page 65

Controller Options

M052/M053/M054 2-34 SM

The allowed range for the channel settings may vary for different countries.

8. WEP (Encryption) Setting. The WEP (Wired Equivalent Privacy) setting is designed to

protect wireless data transmission. The same WEP key is required on the receiving side in

order to unlock encoded data. There are 64 bit and 128 bit WEP keys.

WEP:

Selects “Active” or “Inactive” (“Inactive” is default.).

Range of Allowed Settings:

64 bit: 10 characters

128 bit: 26 characters

9. Press “Return to Default” to initialize the wireless LAN settings.

Press “Yes” to initialize the following settings:

Transmission mode

Channel

Transmission Speed

WEP

SSID

WEP Key

Page 66

Controller Options

SM 2-35 M052/M053/M054

Installation

SP Mode and UP Mode Settings for IEEE 802.11 a/g, g Wireless LAN

The following SP commands and UP modes can be set for IEEE 802.11 a/g, g.

SP No. Name Function

5840-006 Channel MAX

Sets the maximum range of the channel settings for the

country.

5840-007 Channel MIN

Sets the minimum range of the channels settings

allowed for your country.

5840-008

Transmission

Speed

Sets the transmission speed to one of the following:

Auto, 54 Mbps, 48 Mbps, 36 Mbps, 24 Mbps,

18 Mbps, 12 Mbps, 9 Mbps, 6 Mbps,

11 Mbps, 5.5 Mbps, 2 Mbps, 1 Mbps (default: Auto)

5840-011 WEP Key Select Used to select the WEP key (Default: 00).

UP mode Name Function

SSID Used to confirm the current SSID setting.

WEP Key Used to confirm the current WEP key setting.

WEP Mode

Used to show the maximum length of the string that

can be used for the WEP Key entry.

Page 67

Controller Options

M052/M053/M054 2-36 SM

2.8.5 BLUETOOTH INTERFACE UNIT TYPE D (D566)

Installation Procedure

Unplug the main machine power cord before you do the following procedure.

1. Install the Bluetooth [A] into the one of USB slots.

2. Make sure that the machine can recognize the option (see ‘Check All Connections’ at the

end of this section).

Page 68

Controller Options

SM 2-37 M052/M053/M054

Installation

2.8.6 BROWSER UNIT TYPE E (D430)

Installation Procedure

Unplug the main machine power cord before you do the following procedure.

Do not leave the SD card in the SD slot 2 after installing this application.

1. Remove the SD slot cover [A] for SD slots ( x 1).

2. Turn the SD-card label face [B] to the right (rear view), then push it slowly into SD slot 2

until you hear a click.

3. Plug in the machine and turn on the main power switch.

4. Push the "User Tools" key.

If an administrator setting is registered for the machine, step 5 and 6 are required.

Otherwise, skip to step 7

5. Push the "Login/ Logout" key.

6. Login with the administrator user name and password.

7. Touch "Extended Feature Settings" twice on the LCD.

8. Touch "Install" on the LCD.

9. Touch "SD Card".

10. Touch the "Browser" line.

11. Under "Install to" touch "Machine HDD" and touch "Next".

12. When you see "Ready to Install", check the information on the screen to confirm your

previous selection.

13. Touch "OK". You will see "Installing the extended feature... Please wait.", and then

"Completed".

14. Touch "Exit" to go back to the setting screen.

15. Touch "Change Allocation".

16. Touch the "Browser" line.

Page 69

Controller Options

M052/M053/M054 2-38 SM

17. Press the hard key that you want to use for the Browser Unit. As a default, this function is

assigned to the "Other Functions" key (the bottom key of the function keys).

18. Touch "OK".

19. Touch "Exit" twice to go back to the copy screen.

20. Turn off the main power switch.

21. Install the key top for "Browser Unit" to the key slot on the operation panel where you want.

22. Remove the SD card from the SD slot 2.

23. Attach the slot cover [A] (

x 1).

24. Keep the SD card in a safe place after you install the application program from the card to

HDD. This is because that the SD card can be the only proof that the user is licensed to use

the application program. You may need to check the SD card and its data to solve a

problem in the future.

25. Turn off and on the machine.

Update Procedure

1. Remove the SD slot cover for SD slots ( x 1).

2. Turn the SD-card label face to the right (rear view), then push it slowly into the SD slot 2

until you hear a click.

3. Plug in and turn on the main power switch.

4. Push the "User Tools" key.

If an administrator setting is registered for the machine, step 5 and 6 are required.

Otherwise, skip to step 7

5. Push the "Login/ Logout" key.

6. Login with the administrator user name and password.

7. Touch "Extended Feature Settings" twice on the LCD.

8. Touch "Uninstall" on the LCD.

9. Touch the "Browser" line

10. Confirmation message appears on the LCD.

11. Touch "Yes" to proceed.

12. Reconfirmation message appears on the LCD.