Page 1

User’s Guide

© 2005 Ricoh Printing Systems, Ltd.

N905363

Page 2

© 2005 Ricoh Printing Systems, Ltd. All rights reserved.

No part of this document may be reproduced without the express permission of Ricoh

Printing Systems, Ltd.

The material in this document is for informational purposes and is subject to change

without notice. Ricoh Printing Systems, Ltd. assumes no responsibility for errors or

omissions in this doc ument. No l iabi lit y is ass umed for a ny damage s resul ting f rom the

use of the information it contains.

NOTICE TO USER

In an effort to meet t he demands of a ra pidly changing t echn ology, the manufac turer is

continually developing new features and functions to meet your changing printing or

printer needs. As a result, this manual may not exact ly reflect future changes made to

the product. Please be sure to consult all manual updates or addenda when using this

product’s documentation.

Page 3

Rev. Table

Rev. for

Manual

Machine

Rev.

Page No. (Contents) Date

00 - First Edition Jul. 21, 2005

Page 4

Blank

Page 5

Table of Contents

SAFETY SUMMARY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Safety Summary-1

SICHERHEIT ZUSAMMENFASSUNG . . . . . . . Siche rheit Zu sammenf assung-1

Introduction

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-1

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-1

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-2

For More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-2

Chapter 1. Printer Overview

What This Chapter Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

I/O Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Operator Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

External View of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Internal View of the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Powering On the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Powering Off the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Clearing Error Condition s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Space Required for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Chapter 2. Control Panels

What This Chapter Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Description of Control Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

OCP Menu Icons and Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Using the OCP Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Using the Option Button Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Using the Ten Key Pad Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Using the + / - C hange Button Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Using the Enable/Disab le Change Button Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

OCP Menu Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Information Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Printer Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Setup Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Reports Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Jobs Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Sub Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Table of Contents v

OG L

0 0

Page 6

Chapter 3. Paper Handling

What This Chapter Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Unacceptable Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Storing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Paper Sizes, Paper Weights, Paper Types and Paper Color . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Paper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Paper Size Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Paper Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Paper Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Proper Paper Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Loading Paper in Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Loading Special Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Setting the Non-Standard Paper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setting the Paper Weight Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Setting the HV Adjust Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Setting the Table Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Setting the Paper Moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Preparing the Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Set the Basket into the Stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Removing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Removing Paper from the Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Chapter 4. Care and Maintenance

What This Chapter Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Replacing Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Adding Toner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Replacing the Toner Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Replacing the Developer Mix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Replacing the Fuser Cleaning Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Replacing the Fine Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Winding the OPC Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Regist Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Input Station Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Regist Station Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Paper Feed Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Container Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

High Capacity Feeder (HCF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Cleaning the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

Cleaning the Printer Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Cleaning Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Cleaning the Container Baskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Cleaning the Toner Bottle Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Cleaning the Discharger and the Detach Corotoron. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

vi Table of Contents

OG L

0 0

Page 7

Clearing the Inverter Valve Peace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

Handling and Storing Supplies and Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

Toner and Developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Chapter 5. Troubleshooting

What This Chapter Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Guidelines Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Basic Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

General Printing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Duplex Printing Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Printer Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

OCP Display Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Printer Status Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Printer Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Printer Error Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Chapter 6. Web Utilities

What This Chapter Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Access and Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Accessing the Web Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Web Page Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Manage Status Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Status-General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Status-Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Status-Paper Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Status-Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Status-Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Status-Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Status-Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Status-Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Status-Revision. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Manage System Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

System-General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

System-Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

System-Paper Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

System-Virtual Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

System-Accounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

System-Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

System-Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Manage Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

Configuration-General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Configuration-Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Configuration-Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

OG L

Table of Contents vii

0 0

Page 8

Configuration-Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

Using the Accounting File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

Appendix A . Specifications

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Base Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Append ix B. Pa per S pecifications

Media Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

General Media Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Paper Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Paper Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Paper Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Paper Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Paper Smoothness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Paper Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Paper Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

Recycled Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Grain Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Paper Smoothness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Special Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Preprinted Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Prepunched Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-10

Adhesive Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Perforated Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

Printing Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-17

Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-17

Preprinted Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-18

Preprint Inhibited Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-18

Glossary

viii Table of Contents

OG L

0 0

Page 9

SAFETY SUMMARY

General Safety Guidelines

Before operating the machi ne, read the following instructions carefully:

■ Allow all the operating procedures provided in this manual.

■ Pay special attention to and follow all the hazard warning on the machine and in

the manual. Failure to do so can cause injury to yourself or damage to the

machine.

■ The hazard warnings which appear on the warning labels on the machine or in the

manual have one of the following alert headings consisting of an alert symbol and

a signal ward, DANGER, WARNING, or CAUTION.

DANGER! : indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING!: indicates a potentially hazardous situation which, if not avoided,

can result in death or serious injury.

CAUTION!: indicates a hazardous situation which, if not avoided, will or can

result in minor or moderate injury, or serious damage of product.

The alert symbol shown left precedes every signal word for hazard

warnings, and appears in safety related descriptions in the man ual.

The signal word ’NOTE’ is used to present warn ings which are not directly related to

personal injury hazards.

■ Do not perform any operation or action in any way other than as provided in this

manual. When in doubt, call the d esignated field engineer.

■ Keep in mind that the hazard warn ings in this manual or on the machine cannot

cover every possible case, as it is impossible to predict and evaluate all

circumstances beforehand. Be alert and use your common sense.

OG L

Safety Summary -1

0 0

Page 10

SAFETY SUMMARY

Hazard Warming Statements

WARNING Statement

■ “Use of controls, adj ustments or performance of procedures othe r than those

specified in this manual may result in hazardous laser radiation exposure.” on

page Safet y Summa r y-5

■ “Connect the power plug only to a properly rated power outlet. Otherwise, a fire

or shock hazard may result.” on pa ge Safety Summary-7

■ “Never use multi-plug adaptors to plug multiple power plugs into the same power

source. Be sure to operate the printer on a sole-use receptacle. Multiple

connectors can cause overheating and a fire could result.” on page Safety

Summary-7

■ “The pri nter must be connected to the grounding power outlet for safe and proper

operation.” on page Safety Summary-7

■ “Apparatet må kun tilkoples jordet stikkontakt.” on page Safety Summary-7

■ “Apparaten skall ansulatas till jordat uttag när den ansluts till ett nätverk.” on

page Safet y Summa r y-7

■ “Für einen sicheren und ordnungsgemäßen Betrieb muß der Drucker an eine

geerdete Steckdose angeschlossen werden.” on pa ge Safety Summary-7

■ “These statements indicate a need for special care and safety to prevent you from

harming yourself when carrying, unpacking, assembling, installing, or operating

the product.” on page 1-2

■ “To avoid serious injury or death, disconnect the power cord from the power

outlet. Do not attempt to perform any servicing operation when the power cord is

connected to the power outlet. The AC line voltage is present inside the controller

enclosure regardless of the main power switch position.” on page 1-3

■ “Do not throw the toner bottle into a fire because it may suddenly burn, causing a

risk of fire or personal injury.” on page 4-6

■ “Dispose the toner bottle as incombustible waste.” on page 4 -6

■ “Waste materials should be disposed of or incinerated under conditions which

meet all federal, state and local environmental regulations. Since regulations may

vary from one region to another, check with the agency that governs waste

disposal i n your area for proper proce dures.” on page 4-8

■ “Do not throw the developer bottle in to a fire because it may suddenly burn,

causing a risk of fire or personal injury.” on page 4-16

■ “The Fuser Unit is very hot. Do not touch any parts of the Fuser Unit ex cept those

parts which are used to replace the Fuser Cleaning Web.” on page 4-17

■ “The Fuser Unit is very hot. Do not touch any parts of the Fuser Unit ex cept those

parts which are used to remove the paper . It is better to use the Bamboo Tweezers

to remove the paper. (The Bamboo Tweezers is an attatced accessory.)” on page

4-34

Safety Summary -2

OG L

0 0

Page 11

CAUTION Statement

■ “Never unplug or replug the printer while it is on.” on page Sa fety Summa ry-8

■ “Do not place the printer near heaters or volatile, flammable, or combustible

materials.” on page Safety Summ ary-9

■ “Once the printer is powered off, wait at least 5 seconds to next po wer on.” on

page 1-6

■ “If the printer does not power on, power off the printer, wait at least 30 seconds,

then power on the printer again.” on page 1-6

■ “You must set the correct paper weight value. The incorrect paper weight value

may cause pa per jam.” on page 3-19

■ “Depending on amount of paper, the Basket is very heavy. Take care not to hurt

your back when lifting a heavy Basket.” on page 3-29

■ “Toner is not harmful to the human body, but if some toner has come in contact

with your skin or clothes, you should wash it immediately with cold water.” on

page 4-3

SAFETY SUMMARY

■ “The toner is not harmful to the human b ody. However, take care not to inhale or

swallow it because you may feel sick.” on page 4-6

■ “If the toner goes into your eyes, immediately rinse with running water. If

affected eyes are not rinsed, it may become injured. If the skin or clothing is

contacted, wash with soap and water” on page 4-6

■ “Hold the developer bottle when you turn the cap so that the bottle is not turned

together with the cap.” on page 4-10

■ “Hold the developer bottle when you turn the cap so that the bottle is not turned

together with the cap.” on page 4-13

■ “Incorrect setting of the Developer Bottle cause damage to the Developer Unit.

Make sure the setting of the Developer Bottle before go to next step.” on page 413

■ “If the developer is spilled out on the floor, the floor becomes very slippy. This

may result in a fall and/or injury. Clean up the spilled developer with a toner-safe

vacuum cleaner.” on page 4-15

■ “If the developer goes into your eyes, immediately rinse with running water. If

affected eyes are not rinsed, it may become injured. If the skin or clothing is

contacted, wash with soap and water” on page 4-15

■ “Surface of the Photoconductor Drum (OPC Sheet) is very sensitive. Carefully

remove a paper to avoid scratch the surface of the Photoconductor Drum.” on

page 4-32

■ “Power off the printer prior to cleaning.” on page 4-51

■ “Do not use solvent on the printer. Using solvent may dissolve the plastic and

paint of t he printer.” on page 4-51

■ “Do not us e cleaning sol utions to clean inside and around th e printer. Use only a

water-moistened cloth.” on page 4-51

Safety Summary -3

OG L

0 0

Page 12

SAFETY SUMMARY

■ “For cleaning up toner or developer spillage, use a s pecially-designed toner-safe

vacuum cleaner. If you use a regular vacuum cleaner, the drawn toner/developer

powder may scatter in the air. If you inhale or your eyes come into contact with

such powder, you may feel sick or injure your eyes. Further, the drawn toner/

developer powder may render the vacuum cleaner defective when it enters the

vacuum cleaner’s motor section.” on page 4-51

■ “The Paper Height Sensor in the Tray is sensitive. Carefully cleaning a Tray to

avoid a damage to the Paper Height Sensor.” on page 4-52

■ “Do not use paper that contains CaCO3 as it can drastically reduce fuser life.” on

page B-4

■ “Adhesive that comes in contact with the prin ter may contaminate the

photoconductor and the internal printer mechanism. To test label stock for

adhesive exposure, press a sheet of plain paper against a sheet of label stock . The

plain pap er should not adhere to the label stock at a l l.” on page B-12

Safety Summary -4

OG L

0 0

Page 13

Laser Safety

This printer is certified as a Class 1 laser pr oduct under the U.S. Department of Health

and Human Services (DHHS) Radiation Performance Standard according to the

Radiation Control for Health and Safety Act of 1 968. Th is means th at the printer does

not emit hazardous laser radiation.

Since radiation emitted inside the printer is completely confined within the protective

housings and external covers, the laser beam cannot escape from the machine during

any phase of user operation.

The Center for Devices an d Radiological Health (CDRH) of the U.S. Food and Drug

Administration implemented regulations for laser products on August 1976. These

regulations apply to laser products marketed in th e United States. The label on the

printer indicates compliance with the CDRH regulations and must be attached to laser

products marketed in the United States.

This printer is classified as a Class 1 laser product both under EN60825 and the Code

of Federal Regulations, 1040.10 of Title 21.

SAFETY SUMMARY

LOUKAN 1 LASERLAITE

CLASS 1 LASER APPARAT

Internal Laser Radiation

Maximum Radiation Power: 10mW x 4 diodes

Wave Lengt h: 780nm

WARNING!

Use of controls, adjustments or performance of procedures other than

those specified in this manual may result in hazardou s laser radiation

exposure.

OG L

Safety Summary -5

0 0

Page 14

Certifications

FCC Notice

This equipment has been tested and found to comply with th e limits for a Class A

digital device pursuant to Part 15 of FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with this user’s guide,

may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interf erence. If this occurs, users are

required to correct the interference at their own expense.

Use of shielded cables is required to comply with Class A limits in Subpart B of

Part 15 of FCC Rules.

Do not make any changes or modifications to the equipment other than those specified

in this user’s guide.

You may find the following booklet prepared by the Federal Communications

Commission helpful: How to Identify and Resolve Radio - TV Interference Problems.

This booklet is available from the U.S. Government Printing Office, Washington, D.C.

20402, Stock N o. 00 4- 000-00345-4.

SAFETY SUMMARY

Canadian Certification

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

VCCI Notice (Japan)

This is a class 1 product based on the standard of t he Voluntary Control Council for

Interference by Information Technology Equipment (VCCI). If this equipment is used

in a domestic environment, radio disturbance may arise. When such trouble occurs, you

may be required to take corrective action s.

Safety Summary -6

OG L

0 0

Page 15

SAFETY SUMMARY

When Installing and Relocating the Printer

Power Specifications

Power Cords

WARNING!

Connect the power plug only to a properly rated power outlet. Otherwise,

a fire or shock hazard may result.

Never use multi-plug adaptors to plug multiple power plugs into the same

power source. Be sure to operate the printer on a sole-use receptacle.

Multiple connectors can cause overheating and a fire could result.

Ensure that the plug connection is free of dust. In a damp environment, a contaminated

connector can draw a non-negligible amount of current that can generate heat and

eventually cause a fire over an extended period of time.

To prevent the risk of electric shocks and personal injury, fire, and printer damage:

■ Always use the power cord provided with your printer. When an extension power

cord is required, always use a properly rated cord.

Rated Voltage

200/208/220/230/240V 50/60Hz 21A

380/400/415V 50/60Hz 21A

Rated

Frequency

Rated Current

If the power cord is not provided, use the following types of power cords:

❒ For North America:

4 wires, Type SJT 4x12 AWG (4x4.0 mm

2

) or thicker

Rated min. 30 0V/ 2 5A (w it h gr ounding plug).

❒ For Europe

5 wires, min. 5x4.0 mm

2

Harmoni zed (<HA R >), Rated min. 300V/25A (with grounding plug).

WARNING!

The printer must be connected to the grounding power outlet for safe and

proper operation.

Apparatet må kun tilkoples jordet stikkontakt.

Apparaten skall ansulatas till jordat uttag när den ansluts till ett nätverk.

Für einen s i cheren und ordnungsgemäßen Betrieb muß der Dr uck er an

eine geerdete Steckdose angeschlossen werden.

Safety Summary -7

OG L

0 0

Page 16

SAFETY SUMMARY

■ Do not attempt to rework, pull, bend, chafe, or otherwise damage the power cord.

Do not place a heavy object on the cord.

■ Never touch a power cord with wet hands.

■ If your printer produces smoke, excessive heat, unusual noises or odors, or if any

liquid is spilled into the printer, immediately switch off and unplug the printer.

■ If the power cord is broken or insulated wires are exposed, be sure to get them

replaced. (Do not use the damaged cord.)

CAUTION!

Never unplug or replug the printer while it is on.

■ When unplugging the printer, grasp the plug instead of the cord.

■ Be sure to switch off and un plug the printer before accessing its interior for

cleaning or maintenance.

■ When the printer is not used over an ex tended period of time, switch it off and

unplug it.

■ Once a month, unplug the printer and check that:

❒ t he power cord is plugged firmly into a receptacle.

❒ t he power cord is not cracked or frayed.

❒ t he plug is not excessively heated, rusted, or bent.

❒ t he plug and receptacle are free of dust.

NOTE:

If you notice any unusual conditions, contact your service represen tative.

Safety Summary -8

OG L

0 0

Page 17

SAFETY SUMMARY

Position in g the Printer Safely

To prevent the risk of electric shocks and personal injury, fire, and printer damage:

■ Switch off the printer before connecting the interface cable or optional accessory.

CAUTION!

Do not place the printer near heaters or vola tile, flammable, or

combustible materials.

■ Place the printer on a level and sturd y surface that can withstand the printer’s

weight. If tilted, the printer may fall over and cause injuries.

■ Do not place the printer in a hot, humid, dusty, or poorly ventilated environment.

■ When moving the printer, be sure to unplug the power cord from the outlet. If the

printer is moved with the power cord connected, it can cause damage to the cord.

■ When moving the printer, do not tilt it mor e than 10 degrees. If tilted excessively ,

the printer may fall over and cause injuries.

■ If you need to move the p r inter over a long distance, consult your Technical

Representative.

Environmental Limit

■ The printer is capable of operating normally within the fo llowing recommended

environmental limits:

❒ Temperature range: 60 °-89°F (16°-32°C).

❒ Humidity ra nge: 20-80% RH (no conden sation).

NOTE:

Sudden temperature fluctuations can affect print quality. Rapid heating of

a cold room can cause condensation inside the printer, directly in terfering

with image transfer.

■ Do not expose the printer to direct sunlight, or the printer's performance may

decline.

OG L

Safety Summary -9

0 0

Page 18

SAFETY SUMMARY

Operating Precautions

■ Take care not to allow ties, sleeves, shirts, or long hair to be caught in the printer

while operating.

■ Be careful not to touch the hazard ous parts near the caution labels.

■ Be sure to avoid accidentally powering on the printer or pressing switches on the

operator’s panel while operating the printer.

■ Never touch the high voltage portions of the prin ter, where cautio n labels are

attached, when the printer is on. It may cause personal injuries if accidentally

touched.

■ Make sure that the printer paper complies with the supplies specifications.

Printing on paper which does not comply with the specifications may result in

paper jams and print quality degradation.

■ Properly load the paper into the hopper to preven t paper skew and paper jams.

■ It is absolutely necessary to follow the procedures and instructions described in

this manual in order to optimize the printer’s performance and to assure its safe

operation.

Safety Summary -10

OG L

0 0

Page 19

SAFETY SUMMARY

SAFETY PRECAUTIONS

■ Always keep the area around the printer tidy. Use the printer under the proper

lighting (500-1,000 lux.). Keep sufficient space around the printer so the hoppers

can be pulled forward. Space required in the vicinity of the printer is as follows:

Front side: 1 meters

Left, right and rear side: 1 m eter

■ Do not place anything on the printer.

■ Do not open any covers during printing operation. It may cause personal injuries

if moving elements or electrical parts are accidentally touched.

■ Be particularly careful when working in the fuser unit area. Do not touch the

inside of the fuser unit. The fuser unit becomes very hot (approx. 374°F [190°C])

and it may cause personal injuries if accidentally touched.

■ Toner and developer are comp rised of po wdery particles. Avoid inhaling toner or

developer when it accidentally spills and circulates. If it spills o n the floor,

immediately clean it with water-damped cloth. Do not leave it on the floor. I t may

cause accidents if stepped on as they are slippery beads of metal.

■ Limit your operations to those described in this manual. Contact the field engineer

or service technician for further operations which are not explained in this

manual.

■ This equipment generates ozone. Long-term exposure should be limited to 0.1

ppm calculated as an 8 hr. time weighted average concentration. Provide proper

ventilation. Avoid installing the unit in a small room (smaller than 27cub ic

meter). If installing in a space smaller than 27cubic meter, frequent ventilation is

necessary

OG L

Safety Summary -11

0 0

Page 20

SAFETY SUMMARY

Care of Printer Supplies

■ Store the paper, toner , and other supplies in a place free from d irect sunlight and

away from any heating apparatus. Keep them in a dry, cool, clean environment.

■ Store paper that has been removed from its wrapper, but not loaded into the

drawer, in a sealed, plastic bag in a cool, dark place.

■ If your hands become soiled with toner, wash them with soap and water

immediately.

Caution Labels

Follwing figure shows the caution labels affixed on the printer.

Safety Summary -12

OG L

0 0

Page 21

SICHERHEIT ZUSAMMENFASSUNG

Allgemeine Sicherheit Richtlinien

Bevor Sie die Maschine laufen lassen, lesen Sie die f olgenden Anweisungen sorgfaltig:

■ Erlauben Sie alle Betriebsverfahren, die in diesem Handbuch b ereitgestellt

werden.

■ Lenken Sie besondere Aufmerksamkeit auf und folgen Sie der ganzer

Gefahrwarnung auf der Maschine und im Handbuch. Nichtbeachten kann

Verletzung oder Beschädigung der Maschine verursachen selbst.

■ Die Gefahrwarnungen, die auf den warnenden Aufklebern auf der Maschine

erscheinen, oder im H andbuch eine der folg enden Alarmüberschri ften haben S ie,

die aus einem Alarmsymbol und einem Sig nalbezirk bestehen, DANGER,

WARNING, or CAUTION.

DANGER! : zeigt eine in bedrohlicher Weise gefährliche Situation an, die, wenn

sie nicht vermieden wird, Tod oder ernste Verlet zung ergibt.

WARNING!: zeigt eine möglicherweise gefährliche Situation an, die, wenn sie

nicht vermieden wird, Tod oder ernste Verletzung ergeben kann.

CAUTION!: zeigt eine gefährliche Situ ation an, die, wenn sie nicht, kleine oder

gemäßigte Verletzung ergeben wird vermi eden wird oder kann,

oder ernste Beschädigung des Produktes.

Das Alarmsymbol, das nach links gezeigt wird, geht jedes

Kennzeichenwort fü r Gefahrwarnungen voran und erscheint in

Sicherheit bezogenen Beschreibungen im Handbuch.

Das Kennzeichenwort 'NOTE' wird verwendet, Warnungen darzust ellen, die nicht

direkt mit Personenschä dengefahren zusammenhängen.

■ Führen Sie keinen Betrieb oder Tätigkeit in keiner Weise anders als durch, wie in

diesem Handbuch zur Verfügung gestellt. Wenn im Zweifel, rufen Sie den

gekennzeichneten Kundendiensttechniker an.

■ Halten Sie im Verstand, dem die Gefahrw arnungen in diesem Handbuch oder auf

der Maschine ni cht jeden möglichen Fall abd ec k en k önnen, da es unmöglich ist,

alle Umstände vorher vorauszusa gen und auszuwerten. Seien Sie Ala rm und

verwende n Sie Ihren ge sunden Menschenversta nd.

OG L

Sicherheit Zusammenfassung -1

0 0

Page 22

SICHERHEIT ZUSAMMENFASSUNG

Gefahr-W ärmende Aussagen

WARNING Aussage

■ “Use of controls, adj ustments or performance of procedures othe r than those

specified in this manual may result in hazardous laser radiation exposure.” on

page Safet y Summa r y-5

■ “Connect the power plug only to a properly rated power outlet. Otherwise, a fire

or shock hazard may result.” on pa ge Safety Summary-7

■ “Never use multi-plug adaptors to plug multiple power plugs into the same power

source. Be sure to operate the printer on a sole-use receptacle. Multiple

connectors can cause overheating and a fire could result.” on page Safety

Summary-7

■ “The pri nter must be connected to the grounding power outlet for safe and proper

operation.” on page Safety Summary-7

■ “Apparatet må kun tilkoples jordet stikkontakt.” on page Safety Summary-7

■ “Apparaten skall ansulatas till jordat uttag när den ansluts till ett nätverk.” on

page Safet y Summa r y-7

■ “Für einen sicheren und ordnungsgemäßen Betrieb muß der Drucker an eine

geerdete Steckdose angeschlossen werden.” on pa ge Safety Summary-7

■ “These statements indicate a need for special care and safety to prevent you from

harming yourself when carrying, unpacking, assembling, installing, or operating

the product.” on page 1-2

■ “To avoid serious injury or death, disconnect the power cord from the power

outlet. Do not attempt to perform any servicing operation when the power cord is

connected to the power outlet. The AC line voltage is present inside the controller

enclosure regardless of the main power switch position.” on page 1-3

■ “Do not throw the toner bottle into a fire because it may suddenly burn, causing a

risk of fire or personal injury.” on page 4-6

■ “Dispose the toner bottle as incombustible waste.” on page 4-6

■ “Waste materials should be disposed of or incinerated under conditions which

meet all federal, state and local environmental regulations. Since regulations may

vary from one region to another, check with the agency that governs waste

disposal i n your area for proper proce dures.” on page 4-8

■ “Do not throw the developer bottle in to a fire because it may suddenly burn,

causing a risk of fire or personal injury.” on page 4-16

■ “The Fuser Unit is very hot. Do not touch any parts of the Fuser Unit ex cept those

parts which are used to replace the Fuser Cleaning Web.” on pag e 4-17

■ “The Fuser Unit is very hot. Do not touch any parts of the Fuser Unit ex cept those

parts which are used to remove the paper . It is better to use the Bamboo Tweezers

to remove the paper. (The Bamboo Tweezers is an attatced accessory.)” on

page 4-34

Sicherheit Zusammenfassung -2

OG L

0 0

Page 23

SICHERHEIT ZUSAMMENFASSUNG

CAUTION Aussage

■ “Never unplug or replug the printer while it is on.” on page Sa fety Summa ry-8

■ “Do not place the printer near heaters or volatile, flammable, or combustible

materials.” on page Safety Summ ary-9

■ “Once the printer is powered off, wait at least 5 seconds to next po wer on.” on

page 1-6

■ “If the printer does not power on, power off the printer, wait at least 30 seconds,

then power on the printer again.” on page 1 -6

■ “You must set the correct paper weight value. The incorrect paper weight value

may cause pa per jam.” on page 3-19

■ “Depending on amount of paper, the Basket is very heavy. Take care not to hurt

your back when lifting a heavy Basket.” on page 3-29

■ “Toner is not harmful to the human body, but if some toner has come in contact

with your skin or clothes, you should wash it immediately with cold water.” on

page 4-3

■ “The toner is not harmful to the human b ody. However, take care not to inhale or

swallow it because you may feel sick.” on page 4-6

■ “If the toner goes into your eyes, immediately rinse with running water. If

affected eyes are not rinsed, it may become injured. If the skin or clothing is

contacted, wash with soap and water” on page 4-6

■ “Hold the developer bottle when you turn the cap so that the bottle is not turned

together with the cap.” on page 4-10

■ “Hold the developer bottle when you turn the cap so that the bottle is not turned

together with the cap.” on page 4-13

■ “Incorrect setting of the Developer Bottle cause damage to the Developer Unit.

Make sure the setting of the Developer Bottle before go to next step.” on page 413

■ “If the developer is spilled out on the floor, the floor becomes very slippy. This

may result in a fall and/or injury. Clean up the spilled developer with a toner-safe

vacuum cleaner.” on page 4-15

■ “If the developer goes into your eyes, immediately rinse with running water. If

affected eyes are not rinsed, it may become injured. If the skin or clothing is

contacted, wash with soap and water” on page 4-15

■ “Surface of the Photoconductor Drum (OPC Sheet) is very sensitive. Carefully

remove a paper to avoid scratch the surface of the Photoconductor Drum.” on

page 4-32

■ “Power off the printer prior to cleanin g.” on page 4-51

■ “Do not use solvent on the printer. Using solvent may dissolve the plastic and

paint of t he printer.” on page 4-51

Sicherheit Zusammenfassung -3

OG L

0 0

Page 24

SICHERHEIT ZUSAMMENFASSUNG

■ “Do not us e cleaning sol utions to clean inside and around th e printer. Use only a

water-moistened cloth.” on page 4-51

■ “For cleaning up toner or developer spillage, use a s pecially-designed toner-safe

vacuum cleaner. If you use a regular vacuum cleaner, the drawn toner/developer

powder may scatter in the air. If you inhale or your eyes come into contact with

such powder, you may feel sick or injure your eyes. Further, the drawn toner/

developer powder may render the vacuum cleaner defective when it enters the

vacuum cle aner’s motor section.” on page 4-51

■ “The Paper Height Sensor in the Tray is sensitive. Carefully cleaning a Tray to

avoid a damage to the Paper Height Sensor.” on page 4-52

■ “Do not use paper that contains CaCO3 as it can drastically reduce fuser life.” on

page B-4

■ “Adhesive that comes in contact with the prin ter may contaminate the

photoconductor and the internal printer mechanism. To test label stock for

adhesive exposure, press a sheet of plain paper against a sheet of label stock . The

plain pap er should not adhere to the la bel stock at a ll.” on page B-12

Sicherheit Zusammenfassung -4

OG L

0 0

Page 25

SICHERHEIT ZUSAMMENFASSUNG

Laser-Sicherheit

Dieser Druc ker ist ein Laser-Produkt der Klasse 1 unter dem Radiation Per formance

Standard des U.S. Department of Health and Human Services (DHHS) gemäß dem

Radiation Control for Health and Safety Act 1968. Dies bedeutet, dass der Druc ker

keine gefährliche Laserstrahlung ausstrahlt.

Da die im Inneren dieses Druckers auftre tende S trahlung vollständ ig von den

Schutzgehäusen und externen Abdeckungen abgeschirmt wird, kann der Laserstrahl

während der richtig en Bedienun g durch den Anwender aus dem Drucker ni cht

austreten.

Das Center for Devices and Radiol ogical Health (CDRH) der U.S. Food and Drug

Administration implementierte V orschriften für Laser-Produkte im August 1976. Diese

Vorschriften treffen auf Laser-Produkte zu, die in den Vereinigten Staaten vertrieben

werden. Das Etikett an dem Drucker weist auf Über einstimmung mit den CDRHVorschriften hin und muss an in den V ereinigten Staaten vertriebenen Laser-Produkten

angebracht sein.

Der Drucker ist sowohl unter EN60825 als auch dem Code of Federal Regulations,

1040.10 des Title 21 als Laser-Produkt der Klasse 1 klassifiziert.

LOUKAN 1 LASERLAITE

CLASS 1 LASER APPARAT

Interne Laserstrahlu ng

Maximale Strahlungsleistung: 10mW x 4 Dioden

Wellenlänge: 780nm

WARNING!

Die Verwendung von Bedienelementen, Einstellungen oder die Ausführung

von Vorgängen, die nicht in dieser Anleitu ng beschrieben sind, kann dazu

führen, dass der Anwender gefährlicher Laserstrahlung ausgesetzt wird.

OG L

Sicherheit Zusammenfassung -5

0 0

Page 26

SICHERHEIT ZUSAMMENFASSUNG

Zertifizierungen

FCC-Hinweis

Dieses Gerät wurde getestet u nd in Übereinstimmung mit den Grenzwerten für

Digitalgeräte der Klasse A befunden, wie sie in T eil 15 der FCC-Vorschriften festgelegt

sind. Diese Grenzwerte sind so au sgelegt, dass ausreichender Schutz gegen schädliche

Interferenzen gewährleistet wird, wenn das Gerät in einem kommerziellen Umfeld

betrieben wird. Dieses Gerät generiert, verwendet und kann Radiofrequenzenergie

abstrahlen, wenn es nicht gemäß dieser Bedienungsanleitung installiert und verwendet

wird. Der Betrieb dieses Gerätes in einem Wohnbereich führt wahrscheinlich zu

schädlichen Interferenzen. In diesem Fall werden die Anwender aufgefordert, diese

Interferenzen auf eigene Kosten zu berichtigen.

Die Verwendung von abgeschirmte n Kabeln gemäß den Grenzw erten der Klasse A in

Unterabschnitt B von Teil 15 der FCC-Vorschriften ist erforderlich.

Nehmen Sie niemals andere als in dieser Bedienungsanleitung vorgeschriebene

Änderungen oder Modifikationen vor.

Sie werden wa hrs ch e i nli ch da s folge n de vo n de r F ede r al Com mu ni ca ti o ns

Commission veröffentliche Büchlein „How to Identify and Resolve Radio – TV

Interference Problems“ nützlich finden. Dieses Büchlein ist von dem U.S. Government

Printing Office, Washin gton, D.C. 20402, Stock No. 004-000-0035-4 erhältlich.

Kanadische Zertifikation

Dieses Digi talgerät de r Klasse A ent s pricht den ka nadischen Vorschriften ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

VCCI-Hinweise (Japan)

Dies ist ein Produkt der Klasse 1 gemäß dem Standard des Volun t ary Control Council

for Interference by Information Technology Equipment (VCCI). Falls dieses Gerät in

einem domestischen Umfeld verwendet wird, kann es zu Radiostörungen kommen.

Falls solche Störungen auftr eten, müssen Sie ggf. di e berichtigenden Akti onen

ausführen.

Sicherheit Zusammenfassung -6

OG L

0 0

Page 27

SICHERHEIT ZUSAMMENFASSUNG

Installation und Neuaufstellung des Druckers

Anforderungen an di e Stromversorgung

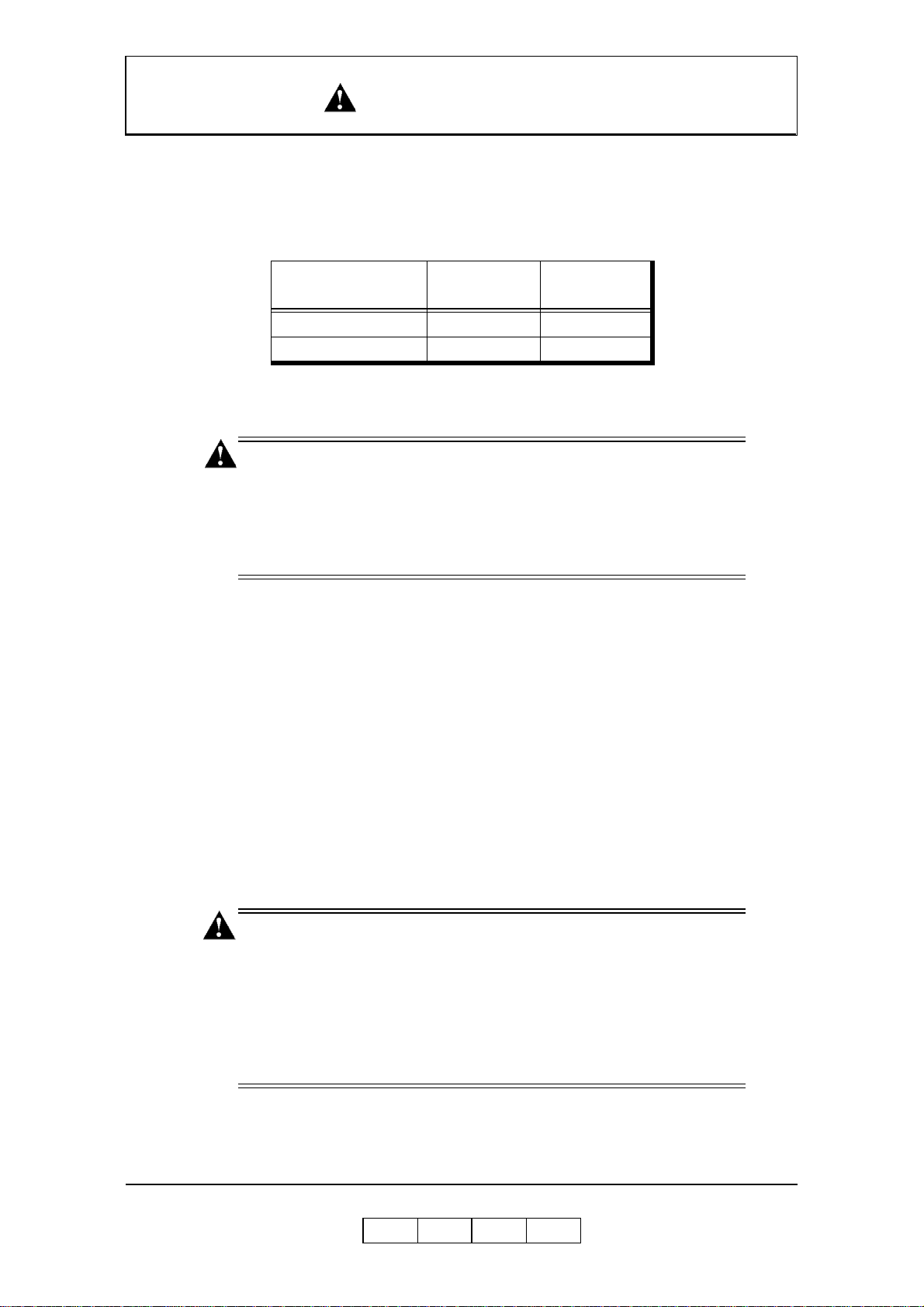

Nennspannung Nennfrequenz Nennstromstärke

200/208/220/230/240V 50/60Hz 21A

380/400/415V 50/60Hz 21A

Netzkabel

WARNING!

Stecken Sie den Netzstecker nur an eine Netzdose mit den

vorgeschriebenen Nennwerten an. Anderenfalls kann es zu Feuer- oder

Stromschlaggefahr kommen.

Verwenden Sie niemals Verzweigungsstecker, um mehrere Netzstecker an

die gleiche Netzdose anzuschließen . Betreiben Sie den Drucker nur von

einer separaten Netzdose. Mehrfachanschlüsse können zu Überhitzung

und Feuer füh ren.

Achten Sie darauf, dass d er Steckeranschluss frei von Staub ist. Bei feuchten

Bedingungen kann ein verschmutzter Stecker zu einem nicht vernachlässigbaren

Stromverbrauch führen, der Hitze erzeugen und über eine längere Zeitdauer zu einem

Brand führe n kann .

Um das Risiko von elektrischen Schlägen, persönlichen Verletzungen, Feuer u nd

Beschädigu ng des Druckers zu vermeiden:

■ Verwenden Sie nur das mit Ihrem Drucker mitg elieferte Netzkabel. Falls ein

Verlängerungskabel erforderlich ist, verwenden Sie nur ein Verlängerungskabel

mit den geeigneten Nennwerten.

Falls mit Ihrem Drucker kein Netzkabel mitgeliefert wurde, verwenden Sie die

folgend en Typen von Netzkabel:

❒ Für Nordamerika:

4 Dräht e, Typ SIT 4x12 AWG (4 x 4.0 mm²) oder dic k er

Nennwerte mindestens 300 V/25 A (mit Erdungsstecker)

❒ Für Europa :

5 Drähte, min. 5x4.0 mm

2

Harmonisiert (<HAR>), Nennwerte m indestens 300 V/25 A (mit

Erdungsstecker)

WARNING!

Für einen s i cheren und ordnungsgemäßen Betrieb muß der Dr uck er an

eine geerdete Steckdose angeschlossen werden.

OG L

Sicherheit Zusammenfassung -7

0 0

Page 28

SICHERHEIT ZUSAMMENFASSUNG

■ Ändern, zie hen, biegen, schaben oder beschädig en Sie nicht das Netzkabel.

Stellen Sie keine schweren Gegenstände auf dem Netzkabel ab.

■ Berühren Sie ni emals das Netzkabel mi t nas s en H änden.

■ Falls Rauch, übermäßige Hitze, ungewöhnliche Betriebsgeräusche oder ein

ungewöhnlicher Geruch an Ihrem Drucker auftreten sollten oder Flüssigkeit auf

den Drucker verschüttet wurde, schalten Sie den Drucker unverzüglich ab, und

ziehen Sie den Netzstecker.

■ Falls das Netzkabel beschädigt ist oder blanke Drähte freiliegen, lassen Sie das

Netzkabel erneuern. (Verwenden Sie niemals ein besch ädigtes Netzkabel.)

CAUTION!

Ziehen Sie niemals den Netzstecker ab, wenn die Stromversorgung des

Druckers eingeschaltet ist.

■ Wenn Sie den Drucker vom Netz abtrennen, ziehen Sie immer am Netzsteck er

und niemal s am Net z ka be l .

■ Schalten Sie unbedingt den Drucker aus, und ziehen Sie den Netzstecker von der

Netzdose ab, bevor Sie Reinigung s- oder Wartungsarbeiten im Inneren des

Druckers ausführen.

■ Falls Sie den Drucker für läng ere Zeit nicht verwenden, schalten Sie diesen aus,

und ziehen Sie den Netzstecker vo n der Netzdose ab.

■ Ziehen Sie den Netzstecker des Druckers einmal monatlich ab, und prüfen Sie,

dass:

❒ der Netzstecker richtig an die Netzdose angesteckt ist.

❒ das Netzkabel nicht beschädigt oder ausgefranst ist.

❒ d er Netzstecker nicht übermäßig erhitz t, verrostet oder verb ogen ist.

❒ d er Netzsteck er und die Netzdose frei von Staub sind.

NOTE:

Falls Sie ungewöhnliche Bedingungen feststellen sollten, wenden Sie sich

bitte an Ihren Kundendienst.

Sicherheit Zusammenfassung -8

OG L

0 0

Page 29

SICHERHEIT ZUSAMMENFASSUNG

Sichere Positionierun g des Druckers

Um das Risiko von elektrischen Schlägen, persönlichen Verletzungen, Feuer u nd

Beschädigu ng des Druckers zu vermeiden:

■ Schalten Sie den Drucker aus, bevor Sie das Schnittstellenkabel oder das

optionale Zubehör anschließen.

CAUTION!

Stellen Sie den Drucker niemals in der Nähe von Heizungen oder

flüchtigen, entzündbaren oder brennbaren Materialien auf.

■ Stellen Sie den Drucker auf einer waagerechten und stabilen Fläche auf, die das

Gewicht de s Druckers abstützen kann. Bei ge neigter Aufstellung kann der

Drucker herunterfallen und Verletzungen verursachen.

■ Stellen Sie den Drucker niemals an einem heiß en, feuchten, staubigen oder

schlecht belüfteten Ort auf.

■ Falls Sie den Drucker an einen anderen Ort bringen müssen, ziehen Sie vorher

unbedingt den Netzstecker von der Netzdose ab. Falls der Drucker mit

angeschl ossenem Netzkabel transportiert wird, kann das Netzkabel beschädigt

werden.

■ Falls Sie den Drucker an einen anderen Ort bringen müssen, neigen Sie diesen

niemals um mehr als 10 Grad. Bei übermäßiger Neigung kann der Drucker

umfallen und Verletzungen verursachen.

■ Falls Sie den Drucker über eine große Strecke transportieren müssen, wenden Sie

sich bitte an einen Kundendienst.

Umfeldgrenzwerte

■ Dieser Drucker gewährleistet Normalbetrieb innerhalb der nachfolgend

empfohlenen Umfel dgrenzwerte:

❒ Temperaturbereich: 16 °C bis 32 °C

❒ Luftfeuchtigkeitsbereich: 20 bis 80 % relative Luftfeuchtigkeit (ohne

Kondensation)

NOTE:

Plötzliche Temperaturschwankungen können die Druckqualität

beeinträchtigen. Schnelles Aufheizen eines kalten Raumes kann zu

Kondensation im Inneren des Druckers führen, wodurch die

Bildübertragung beeinträchtigt werden kann.

■ Setzen Sie dem Drucker keinem direkten Sonnenlicht aus, da anderenfalls das

Leistungsvermögen des Druckers nachlassen könnte.

OG L

Sicherheit Zusammenfassung -9

0 0

Page 30

SICHERHEIT ZUSAMMENFASSUNG

VORSICHTSMASSNAHMEN BEIM BETRIEB

■ Passen Sie auf, daß sich Krawatten, Ärmel, Hemden und langes Haar beim

Betrieb nicht im Drucker verfangen.

■ Berühren Sie nicht die gefährlichen Teile im Bereich der Aufkleber mit den

W arnhinweisen.

■ Schalten Sie den Druc ker nicht versehentlich ein, un d drücken Sie während des

Druckerbetriebs keine Schalter im Bedienerfeld.

■ Beriihren Sie bei eingeschaltetem Drucker unter keinen Umständen die Hochsp

annungsteile des Druckers, an denen Aufkleber mit W arnhinweisen angebracht

sind.

■ Vergewissern Sie sich, daß das Druckerpapier die Angaben für Materialen erfüllt.

Drucken auf Papier, das diesen Angaben nicht entspricht, kann zu Papierstaus und

Einbußen bei der Druckqualität führen. Versehentliches Berühren kann zu

Verletzungen führen.

■ Legen Sie das Papier sachgemäß in den Behälter ein, um Papierstaus und schiefen

Einzug des P a pie r s z u ve r me i d en.

■ Es ist underläßlich , daß Sie die in di esem Handbuch beschri ebenen

Verfahrensweisen un d Anweisungen befol gen, um die Leistung d es Drucker s zu

oprimieren und einen sicheren Betrieb zu gewährleisten.

Sicherheit Zusammenfassung -10

OG L

0 0

Page 31

SICHERHEIT ZUSAMMENFASSUNG

SICHERHEITSVORKEHRUNGEN

■ Halten Sie im Bereich des Druckers stets Ordnung. Verwenden Sie den Drucker

bei den richtigen Lichtverhältnissen (500-1,000 lux).

Sorgen Sie für ausreichenden Platz um den Drucker herum, damit die Behälter

herausgezogen werden kön nen. Im Druckerbereich wird folgender Platz benötigt:

Vorderseite: 1 Meter

Links, rechts und auf der Rückseite: 1 Meter

■ Legen Sie keine Gegenstände auf den Drucker.

■ Ôffnen Sie die Abdeckungen nicht während des Druck vorgangs. Versehentliches

Berühren beweglicher oder elektrischer Teile kann zu Verletzungen führen.

■ Seien Sie bei Arbeiten in Bereich der Fixiereinheit besonders vorsichtig.

Berühren Sie auf keinen Fall das Innere der Fixiereinheit. Die Fixiereinheit wird

sehr heiß (etwa 190

führen.

■ Toner und Entwickler bestehen aus pulverförmigen Partikeln. Vermeiden Sie das

Einatmen von Toner oder Entwickler, wenn Substanzen aus Versehen v erschüttet

werden und in der Luft zirkulieren. Werden diese Substanzen auf den Boden

verschüttet, entfernen Sie sie sofort rait einem mit Wasser angefeuchteten Tuch.

Belassen Sie diese Substanzen nicht auf d em Boden. Dies könnte zu Unfällen

führen, da Sie auf den schlüpfrigen Metallkügelchen ausrutschen könnten.

°C) und versehentliches Berühren kann zu Verletzungen

■ Führen Sie nur die in diesem Handbuch b eschriebenen Operationen aus.

Setzen Sie sich mit dem zuständigen technischen AuBendienst oder mit dem

Kundendienst in V erbindung, wenn Sie Operationen ausführen möchten. die nicht

in diesem Handbuch beschrieben sind.

■ Dieses Gerät erzeugt Ozon. Die langzeitige Belastung solite auf 0.1 ppm.

berechnet als 8-stündige mittlere Konzentration beschränkt sein. Gute Belüftung

gewhären und das Gerät nicht in einem kleinen Raum (kleiner als 27 Kubikmeter)

aufstellen. W ird es jedoch in einem kleinen Raum von weniger als 27 Kubikmeter

aufgestellt, so ist es erforderlich, die Luft öfters aufzufrischen.

OG L

Sicherheit Zusammenfassung -11

0 0

Page 32

SICHERHEIT ZUSAMMENFASSUNG

Behandlung der Druckerverbrauchsartikel

■ Bewahren S ie das Papier, den Toner und die anderen Ve r bra u chsartikel an einem

Ort auf, de r fre i von dir ekte m Sonn enlic ht und e ntfe rnt vo n Heiz ungen ist. L agern

Sie diese Artikel nur an einem trockenen, kühlen und sauberen Ort.

■ Bewahren Sie das aus der Verpackung entfernte und noch nicht in den Drucker

eingesetzte Papier in einen versiegelten Plastik beutel eingesetzt an einem kühlen,

trockenen Ort auf.

■ Falls Sie Ihre Hände mit Toner verschmutzen sollten, waschen Sie Ihre Hände

unverzüglich mit Seife und W a sser.

Vorsicht Aufkleber

Folgende A bbildung zeigt die Vorsicht Aufkleber, die auf dem Drucker hinzugefügt

werden.

Sicherheit Zusammenfassung -12

OG L

0 0

Page 33

About This Manual

This manual provides easy access to the information you need to operate the 156PPM

(Pages Per Minute) laser printer.

NOTE:

This User’s Guide is intended to be viewed online. W hen viewing it online,

use the bookmarks and page reference links for easy navigation

throughout the do c ume n t .

To find out about a specific topic, refer to:

■ SAFETY INFORMATION – For safety information and printer characteristics,

including environmental and electrical requirements.

■ Chapter 1: Printer Overview – For printer components and features.

■ Chapter 2: Operator Control Panel – To access and use the liquid crystal display

(LCD) window and the menus screens.

■ Chapter 3: Paper Handling – For media recommendations and paper handling

procedures.

Introduction

Audience

This manual is written for those persons responsible for operating the printer. A basic

understanding of computer equipment and its operations is required.

■ Chapter 4: Care and Maintenance – For detailed instructions on replacing

consumables, clearing paper jams, and cleaning and maintaining the printer.

■ Chapter 5: Troubleshooting – For information on printing problems and printer

error and warning messages.

■ Chapter 6: Web Utilities – For information on accessing th e printer via the

Internet or your company’s Intranet.

■ Appendix A: Specifications – For printer specifications.

■ Appendix B: Paper Specifications – For me dia specifications and printing

guidelines.

■ Glossary – For definitions of terms and acronyms.

OG L

Introduction 0-1

0 0

Page 34

Manual Conventions

The following conventions are u sed in this manual:

■ Bold and Italics are used sparingly for emphasis.

■ Information yo u enter: Looks Like This.

■ Key Names (or Labels): Look Like This.

■ System message s: Look Like This.

■ Variable user information: Looks Like This.

Pay particular attention to Notes, Cautions, and Warnings. These alert you to critical

information, as follows:

NOTE:

Provides important additional information.

CAUTION!

Alerts you to an operat ing procedure, practice, or condition that, if not

strictly observed, might result in damage to the equipment.

WARNING!

Alerts you to an operat ing procedure, practice, or condition that, if not

strictly observed, can result in safety hazards to personnel, severe injury,

or loss of life.

For More Information

Refer to the following related documents for more details about your printer.

■ Installation Guide

■ Engine Maint enance Manual

■ Controller Maintenance Manual

■ Parts Catalog

0-2 Introduction

OG L

0 0

Page 35

What This Chapter Provides

This chapter describes the parts and functions of the printer.

■ Printer Features

■ External View of the Printer

■ Internal View of the Printer

■ Powering On the Printer

■ Powering Off the Printer

■ Space Required for Installation

Chapter 1

Printer Overview

OG L

Printer Overview 1-1

0 0

Page 36

Printer Features

The printer is a high-speed, heavy duty laser printer for a 1.5M page/month printing

environment. It incorporates a wide variety of features:

■ High-Speed and High-Quality Printing.

❒ Print speed is up to 156 pages per minute (ppm), A4/Letter/Legal (Simplex).

❒ The printing output is at a reso lut i o n of 60 0 dots per inch (dpi), assuri ng

razor-sharp graphic and text output, even at very small point sizes.

■ Flexible Paper Source and Delivery.

Paper Source:

❒ Standard – One 2,500-sheet and one 1,000-sheet universal paper trays.

❒ Option – High Capacity Feeder with 3,000 to 12,000-sheet capacity.

Paper Delivery:

❒ Standard – Contai ner St acker with 2,000 to 4,000-sheet capac ity and sta cking

capability.

❒ Option – Additional Container S tacker with 2,000 to 4 ,000-sheet capacity and

stacking capability.

■ Multiple Original Printing (MOP) – for printing of multiple collated document

sets without multiple file transfers. Processes PCL and PostScript jobs once,

stores the images on disk, and prints each set from disk (after the first set).

■ Virtual Printer Technology (VPT) – allows a single printer to offer print services,

or virtual printers, each of which is conf ig ured by the Network Administrator.

■ Web Utili ties – for remote access to the printer through the Internet or your

company’s Intranet.

■ Ergonomic operation.

❒ The easy-to-read display clearly shows the operational status of the pr inter.

1-2 Pri nter Overview

OG L

0 0

Page 37

■ High-volu me pr i nti ng .

❒ Two standard paper trays with appr oximately 3,500-sheet capacity total.

❒ Optional High Capacity Feeder (HCF) adds up to 12,000 additional sheets.

❒ Together they allow continuous printing of up to 15,500 sheets.

■ Supports a wide-range of media types (plain, bond, letterhead, special application,

recycled, labels) and sizes. See “Paper” on page 3-2 for more information.

■ Printer Language Support.

❒ PCL5e and PCL XL printer langua g e.

❒ PostScript Level III (Adobe) printer language.

❒ P DF and TIFF files printing.

NOTE:

PDF Files printing is only supported for PDF Version 1.3.

■ Network.

❒ Ethernet 10/100/1000 Base-T with onboard network

❒ Additional Ethernet 10/100 Base-T with Multi-protocol NIC option.

■ Network Protocol.

❒ TCP/IP, LPR/LPD and IPP with onboard network.

❒ TCP/IP, LPR/LPD, NetWare IPX/SPX, Ethertalk with Multi-protocol NIC

option.

■ Easy installation of additional fonts and macros using the PCL Startup File.

I/O Configurations

■ Ethernet 10/100/1000 Base-T with onboard network.

■ Additional Ethernet 10/100Base-T with Multi-protocol NIC option.

Operator Control Panel

The Operator Control Panel (OCP) is your physical interface to the printer's features

and functions. From the control panel, you can monitor the printer's operating status

and configure the specific printer functions.

See Chapter 2 for detailed information about the OCP.

OG L

Printer Overview 1-3

0 0

Page 38

External View of th e Printer

The following illustration shows the printer with an optional Container Stacker,

optional High Capacity Feeders and optional Attention Light are installed.

7. High Capacity Feede r 1

10. High Capacity Feeder 2

12. HCF2 Upper Tray

11. HCF2 Lower Tray

3. Toner Supply Cover

9. HCF1 Upper Tray

8. HCF1 Lower Tray

Figure 1-1. External View of the Printer

1. Power Switch

6. Tray 2

4. Operator Control Panel

13. Sample Tr ay

2. Front Cover

5. Tray 1

20. Attention Light

14. Container Stac ker 1

17. Container Stacker 2

19. Container 2

Upper T ray

15. Container1 Lower Tray

16. Container1 Upper Tray

18. Container 2

Lower Tray

Table 1-1. External Vie w of the Print er

Key Component Description

1 Power Switch Press to turn the printer on and off.

2 Front Cover Open to replace units, clear paper jams, or clean the printer.

3 Toner Supply Cover Open to replenish the toner supply.

4 Operator Control Panel (OCP) Displays printer status and menu information.

5 Tray 1 Holds up to 2,500 sheets of paper.

6 Tray 2 Holds up to 1,000 sheets of paper.

7 High Capacity Feeder 1 Two 3,000-sheet input trays.

8 HCF1 Lower Tray Holds up to 3,000 sheets of paper.

9 HCF1 Upper Tray Holds up to 3,000 sheets of paper.

10 High Capacity Feeder 2 Two 3,000-sheet input trays.

11 HCF2 Lower Tray Holds up to 3,000 sheets of paper.

12 HCF2 Upper Tray Holds up to 3,000 sheets of paper.

13 Sample Tray 100-sheet output tray

14 Container Stacker 1 Two 2,000-sheet output trays

15 Container1 Lower Tray Stacks up to 2,000 sheets of paper.

16 Container1 Upper Tray Stacks up to 2,000 sheets of paper.

17 Container Stacker 2 Two 2,000-sheet output trays

18 Container2 Lower Tray Stacks up to 2,000 sheets of paper.

19 Container2 Upper Tray Stacks up to 2,000 sheets of paper.

20 Attention Light Indicates error, warning and printer ready status.

1-4 Pri nter Overview

OG L

0 0

Page 39

Internal View of the Printer

1. Toner Supply Cover

2. Developer Duct

3. Drum Unit

4. Fuser Unit

6. SF Cover

5. Toner Bottle / Toner Bag

7. Main AC Power Switch

Figure 1-2. Internal V iew of the Printer

Table 1-2. Internal View of the Printer

Key Component Description

1 Toner Supply Cover Open this cover when supplying the new toner.

2 Developer Duct

3 Drum Unit OPC drum.

4 Fuser Unit Fuses the toner on the paper.

5 Toner Bottle/Toner Bag Collect the waste toner.

6 SF Cover Open this cover when replacing the Fine Filter.

7 Main AC Power Switch Turn the printer main AC power on and off

Mount the developer bot tle onto th e devel op er du ct to repla ce

consumed developer

OG L

Printer Overview 1-5

0 0

Page 40

Powering On the Printer

The printer has two power switches, the Main AC Power Switch and the Power

Switch. The location of switches are shown below. Both switches are marked “I” for

power on.

Main AC Power Switch

When the printer is powered on, the prin ter go through a power-up sequence that takes

approximately 5 minutes. During the power-up sequence, the printer runs a series of

internal tests.

CAUTION!

Once the printer is powered off, wait at least 5 seconds to next power on.

If the printer does not power on, power off the printer, wait at least 30

seconds, then power on the printer again.

Power Switch

Figure 1-3. Powering On the Printer

1-6 Pri nter Overview

OG L

0 0

Page 41

Power ing Off the Printer

The printer should only be powered off when it is in a “Ready” state; that is, there are

no jobs printing or pr ocessing. The following OCP displays indicate norm al

conditions. In these conditions, wait until printing is complete and the printer is

Ready, then switch off the Power Switch.

Figure 1-4. Normal Conditions

If the printer status is Pause/Offline, touch the “” button to return printer to a Ready

status bef ore pow eri n g off.

Figure 1-5. Pause/Offline

OG L

Printer Overview 1-7

0 0

Page 42

Clearing Error Con di tio ns

OCP Alternates between Ready and Processing

1. Cancel the print job(s). For detail of canceling print job,

Figure 1-6. OCP Alternates between Ready and Processing

E0XX, E1XX Error

1. Correct the error and touch the “” button on the OCP display.

2. Wait until printing is complete and the printer returns to Ready, then switch off

the main power.

1-8 Pri nter Overview

Figure 1-7. E0XX, E1XX Error

OG L

0 0

Page 43

E2XX, EC#XX Call for Service Error

1. Touch the “” button on the OCP display .

2. Wait until printing is complete and the printer returns to Ready.

Figure 1-8. Call for Service Error

3. If the Call for Service error persists, cancel the print job(s) , power off the printer,

and contact your authorized service technician.

OG L

Printer Overview 1-9

0 0

Page 44

Space Required for Installation

)

Install the printer in a well-ventilated place and keep around the printer as shown

below for safe and effective operation.

Required Sp ace (for Maximum Configuration

1264 905 905

968 1318

Figure 1-9. Space Required for Installation

(Top View)

1-10 Printer Overview

OG L

0 0

Page 45

What This Chapter Provides

This chapter contains information on the following topics.

■ Description of Control Panels

■ OCP Menu Icons and Buttons

■ Using the OCP Menus

■ OCP Menu Struc ture

■ Sub Panel

Chapter 2

Control Panels

OG L

Control Panels 2-1

0 0

Page 46

Description of Control Panels

The Operator Control Panel (OCP) is a touch panel display that you use to set up print

options and monitor job and printer status. It is also used by the Network Administrator

to configure the printer and by the Service Technician to perform maintenance on the

printer.

This prin ter also have sub panel equipped to eac h Input and Output Trays. Sub panel

has some functions to each Input and Ou tput Tr ays.

Sub Panel (Input Tray)

Operator Control Panel

Sub Panel

(Output Tra y)

Figure 2-1. Operator Control Panel

2-2 Control Panels

OG L

0 0

Page 47

OCP Menu Icons and Buttons

The menus are accessed via the touch panel. Each OCP menu consists of icons and

buttons that you use to make selections. The icons and buttons are defined below . See

“Main Menu” on page 2-8 for more icons.

Table 2-1. OCP Menu Icons and Buttons

Icon or

Button

?

i

Name Function

Help Touch to display Help on the current screen.

Information From the Main Menu, displays infor ma ti on about the printer and

Pause/Offline Touch to pause the printer.

Resume/Online When the printer is offline, touch to return to Ready status.

Return to Main

Menu