JINAN LANGRUI DETECTION TECHNOLOGY CO.,LTD.

R

LR-G200 Integrated Rebar Scanner

Operating Instructions

PREFACE

Your choice of the products made by Jinan Langrui Detection Technology

Co., Ltd.(LANGRY)is greatly appreciated. We are committed to deliver you

excellent products and satisfied sales services. Please carefully read the instruc-

tions prior to use.

1. The instructions are prepared to provide the correct and complete

descriptions of related products and data. However, we do not guarantee that

there are no errors or omissions. Therefore, we will not bear responsibilities for

any resulting consequences.

2. LANGRY keeps the right of updating the instructions without prior notice.

3. LANGRY bears no responsibilities for possible losses from data deviation

or incorrect testing conclusion arising from instrument failure and other errors.

4. When the instrument is put into operation, it means that you have

carefully read and had full picture of all terms in the instructions, and you have

fully agreed to all the terms in the instructions.

5. LANGRY will not bear responsibilities for all the signed agreements violat-

ing the statement during the sales and services process not involving LANGRY.

Contents

1 Overview ......................................................................................................................1

1.1 Introduction ...............................................................................................................1

1.2 Functions and characteristics..................................................................................1

1.3 Technical indicators..................................................................................................2

1.4 Performance Indicators............................................................................................4

1.5 Precaution..................................................................................................................4

1.6 Responsibility.............................................................................................................6

2 Instrument Description.............................................................................................7

2.1 Instrument Composition..........................................................................................7

2.2 Testing Principle .......................................................................................................9

3 Operation Descriptio .................................................................................................9

3.1 System Overview .......................................................................................................9

3.2 Function description ..............................................................................................10

3.3 Firmware upgrading ...............................................................................................44

4 Maintenance and repair ..........................................................................................45

4.1 Pre-operation inspection .......................................................................................45

4.2 Cleaning ....................................................................................................................45

4.3 Battery.......................................................................................................................45

5 Precautions on field detection...............................................................................46

6 Metering and calibration.........................................................................................47

7 Data analysis software description.......................................................................49

7.1 Introduction..............................................................................................................49

7.2 Software installation...............................................................................................50

7.3 System setting ..........................................................................................................51

7.4 Receiving component data ....................................................................................52

7.5 Data processing .......................................................................................................54

7.6 Upgrading.................................................................................................................58

1 Overview

1.1 Introduction

LR-G200 integrated rebar scanner is a portable intelligent NDT device, which is

mainly used for structural testing of reinforced concrete, and able to carry out

accurate testing on depth of rebar cover and diameter of rebar on the surface of

reinforced concrete, and analyze distribution of rebar.

1.2 Functions and characteristics

1. The instrument sensor is of integrated structure in small size, thus permitting

easy operation.

2. Carry out testing with combination of high-power transmitting coil and

multiple small coil to ensure higher accuracy and resolution.

3. Perform displacement scanning and rebar distance measurement at a higher

accuracy level with use of high-accuracy grating sensor.

4. Provide different types of scanning to suit the different measurement cases.

5. Permit large and small-range testing, with the scanning distance up to 65m

max. Perform data testing in a flexible way. The instrument itself allows storage

of max. 4000 components.

6. Permit correction of multiple stirrup so as to obtain more accurate testing

results.

7. Furthermore, the USB wire data transmission and Bluetooth wireless data

1

transmission are allowed so that the quick data uploading is possible.

8. Use 3.2" 65K color LCD screen to yield the higher resolution and better display,

plus the capacitive touch screen, thus facilitating the man-machine interaction.

9. Perform power supply with use of 8.4v 3200mah high capacity lithium-ion

battery to ensure that the instrument can continuously operate around-the-clock.

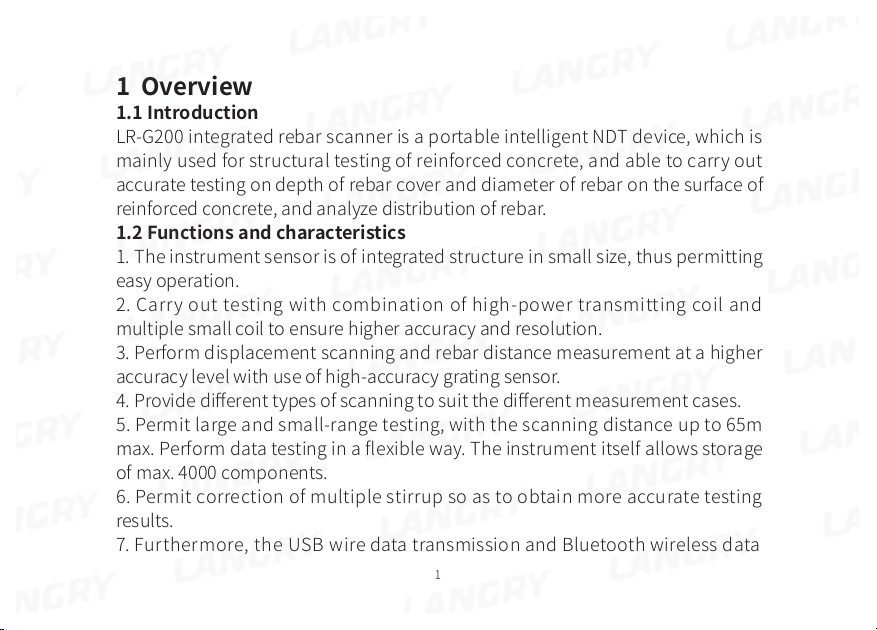

1.3 Technical indicators

Description

Applicable range of rebar diameter(mm)

st

Max. range (mm)

Max. allowable deviation

on concrete cover depth

1 range

nd

2 range

±1(mm)

±2(mm)

±3(mm)

±4(mm)

Applicable range on diameter estimate (mm)

Max. deviation on diameter estimate

Display accuracy on diameter estimate (mm)

2

Technical indicators

Φ6-Φ50

2~100

2~200

2~80

81~120

121~160

161-200

Φ6-Φ50

±1 spec

0.1

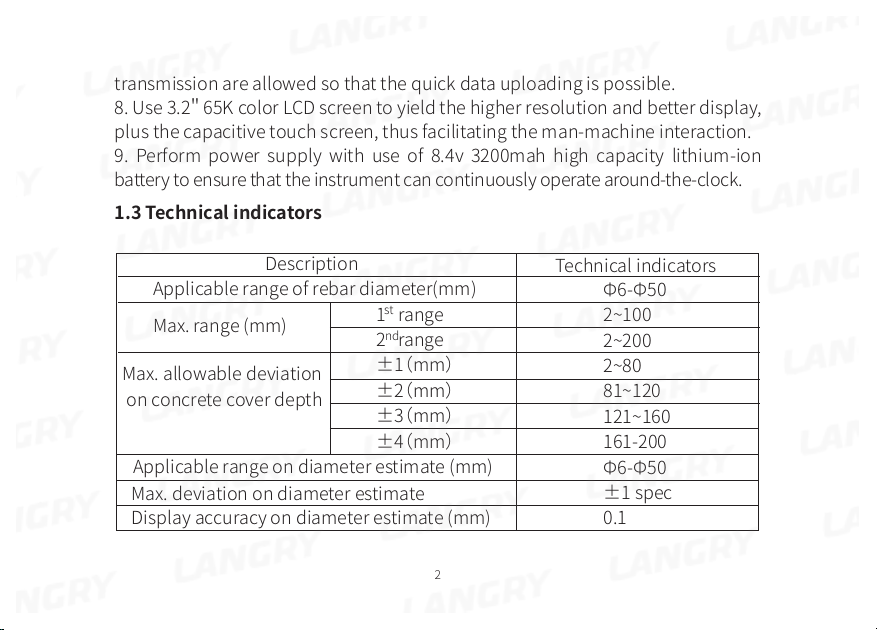

Detailed specification on testing of concrete cover depth

Dia.

Range

6

8

10

12

14

16

18

20

22

25

28

32

36

40

50

Small

2~70 2~97

2~70

2~75

2~75

2~75

3~85

3~85

3~85

3~85

3~90

3~90

4~95

4~95

4~95

6~100

3

Large

2~97

3~100

3~107

3~117

3~120

3~125

3~137

3~140

3~145

3~145

4~155

4~155

5~185

6~200

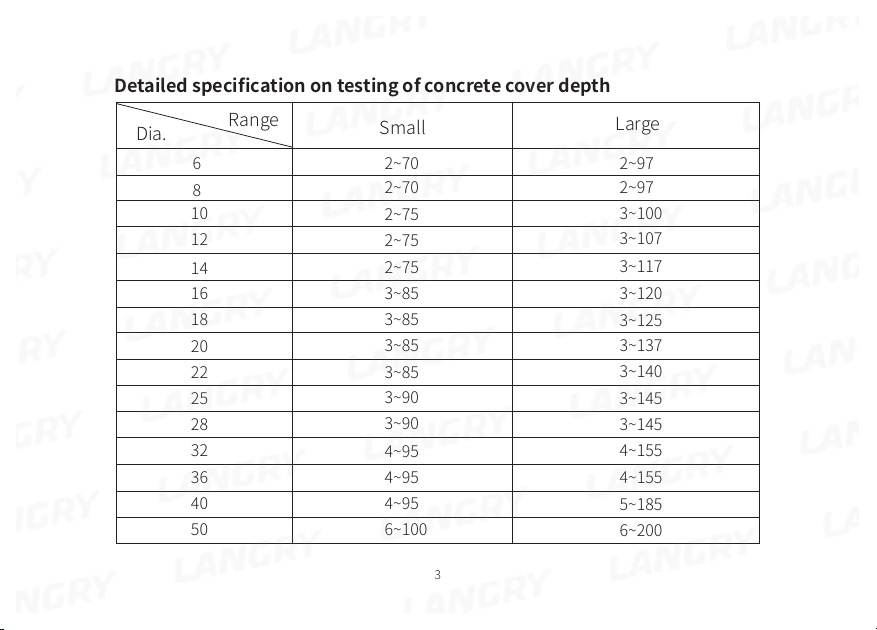

1.4 Performance Indicators

Performance indicators on LR-G200 integrated rebar scanner

Grid scanning

Yes

Screen size

3.2"

Mode of data

transmission

Instrument size

235x120x130

Quick scanning

Yes

Data correction

Yes

Image

scanning

Yes Yes

Laser positioning

3-wire

Fine scanning

Profile scanning

Yes Yes

Way of power

supply

Lithium battery

3-D imaging

Instrument

weight

1KG

Range of

scanning

Unbounded Bluetooth or US

Touch screen

operation

Yes

Screen lattice

320x240

1.5 Precaution

1. Please carefully read the instructions prior to use.

2. Expected operating environment:

Ambient temp.: -10℃~40℃

Relative humidity: <90%RH

Electromagnetic interference: no strong alternating electromagnetic field

4

Exposure to direct sunshine for an extended period prohibited

Corrosion control: take necessary measures to ensure proper operation at the

humid, dust and corrosive gas environment.

3. Expected storage environment:

Ambient temp.: -20℃~50℃

Relative humidity: <90%RH

In case of out of use for an extended period, please regularly switch on the instru-

ment and recharge it. The instrument shall be placed at a well ventilated, cool

and dry location without repeated exposure to direct sunshine.

4. Prevent moisture impact, and operation at the intense magnetic fields, such as

in the vicinity of large electrical magnet, transformer, VFD, etc.

5. Vibration control: take measures to prevent violent vibration and impact during

operation and handling.

6. Charge management: the instrument is recharged with the rechargeable

lithium battery. In case of low battery, recharge the instrument without delay to

avoid battery damage. Perform recharge with the recharger specific to the instru-

ment rather than other types of adapter or recharger, which may otherwise lead

to battery damage.

7. Maintenance: conduct proper cleaning at the end of operation every time to

prevent declined performance or property damage due to dust presence in the

5

instrument or plug connector.

1.6 Responsibility

The instrument is a precision detector. We will bear no responsibility in case of

the following user operations being identified.

1. Incompliance with the above working environment requirements or storage

environment requirements.

2. Non-standard operation.

3. Unauthorized removal of the casing and parts.

4. Serious instrument damage by operator or accident.

6

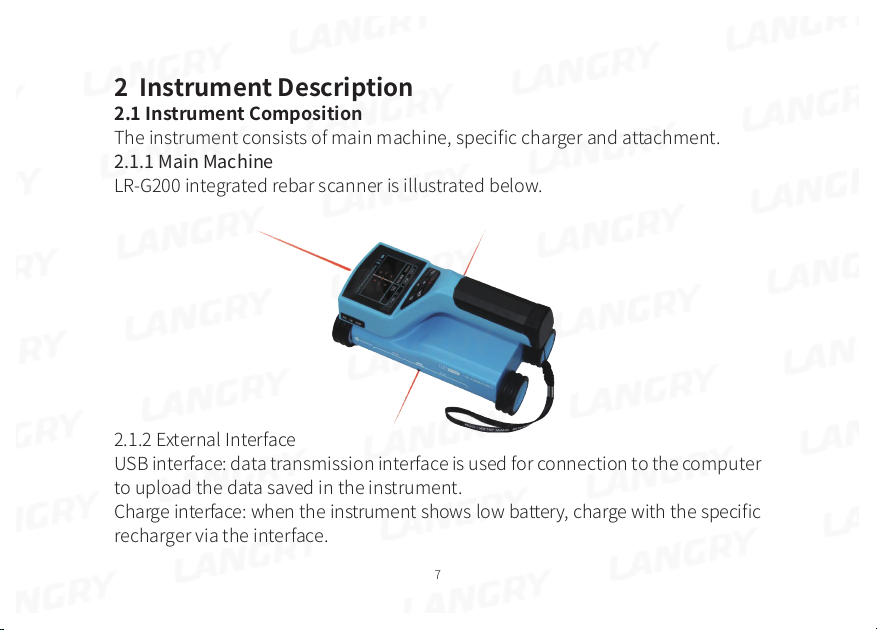

2 Instrument Description

2.1 Instrument Composition

The instrument consists of main machine, specific charger and attachment.

2.1.1 Main Machine

LR-G200 integrated rebar scanner is illustrated below.

2.1.2 External Interface

USB interface: data transmission interface is used for connection to the computer

to upload the data saved in the instrument.

Charge interface: when the instrument shows low battery, charge with the specific

recharger via the interface.

7

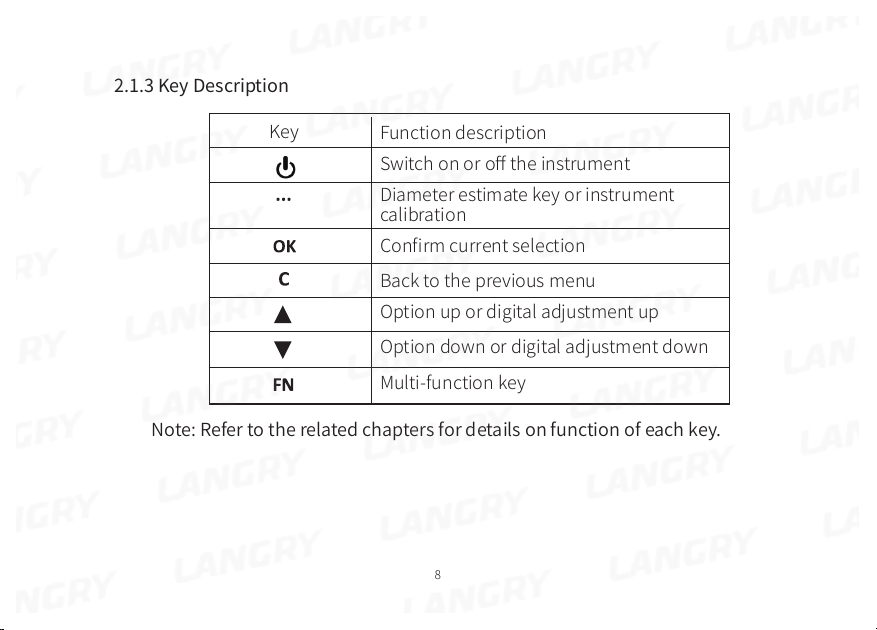

2.1.3 Key Description

Key

Function description

Switch on or off the instrument

Diameter estimate key or instrument

calibration

Confirm current selection

Back to the previous menu

Option up or digital adjustment up

Option down or digital adjustment down

Multi-function key

Note: Refer to the related chapters for details on function of each key.

8

2.2 Testing Principle

The instrument will generate the pulsed magnet field via high-current excitation

transmitting coil. In case of rebar being detected underneath the magnetic field,

the rebar will produce the turbulence at the excitation of pulsed magnet field, and

then make an induced magnetic field. The receiving coil will convert the induced

magnetic field to an electrical signal. The main machine performs real-time analysis

of the electrical signal, and then identify the location of rebar, concrete cover

depth and diameter. The receiving coil is configured in a multiple set of coil

combination, thus yielding the higher testing accuracy against the traditional coil

testing in a single way.

3 Operation Description

3.1 System Overview

LR-G200 Integrated rebar scanner system is designed to assure indication of each

function menu, instrument status, measurement data and result. The man-machine

interaction for the entire system is achieved through the key and touch units,

which is easier to operate than the traditional simple key operation.

3.1.1 Interface Description

The system interface mainly contains the menu selection and data result display,

in which there are title display zone and content display zone. In the title display

zone, the current interface title, Bluetooth device and USB interface readiness

9

and instrument battery status appear. In the content display zone, the main

content in the current interface appears.

3.1.2 Operation Method Description

The user can work via key or touch screen. Use of touch screen is more convenient

so we recommend to run the instrument with touch screen.

Key operation: the user can select the desired menu via Up or Down key in each

interface, and confirm with 【OK】 key. Exit or cancel with【C】 key.

Touch screen operation: the user can work with the icon in the touch screen.

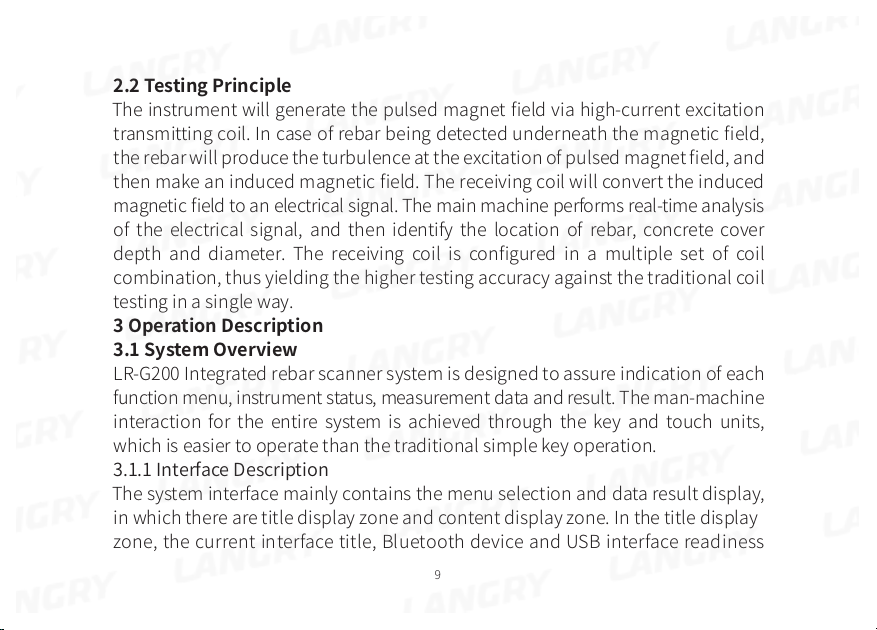

3.2 Function description

The instrument is designed for rebar detection, data view, data uploading, data

deleting, system setting, instrument information, etc. The main interface of the

system is illustrated in Fig.3.1

Fig.3.1 Main interface

10

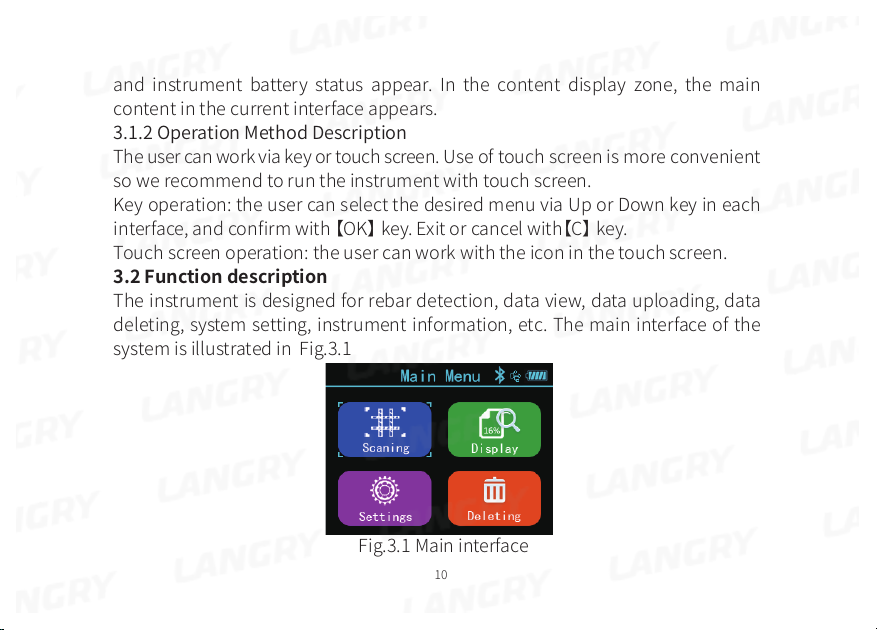

3.2.1 Rebar Detection

The rebar detection function is designed for detection on depth of rebar cover,

rebar location, rebar diameter and distribution. Moreover, the obtained testing

data can be saved to facilitate data view or uploading after detection. The rebar

detection interface is illustrated in Fig.3.2.

Fig.3.2 Main interface on rebar detection

The following operations are allowed in the rebar detection interface:

Key:

【 】and【 】key: select the mode of rebar scanning

【OK】key: go to the parameter setting interface under the appropriate mode of

scanning

【C】key: return to the main menu

11

Touch: touch the appropriate icon to go to the appropriate mode of scanning

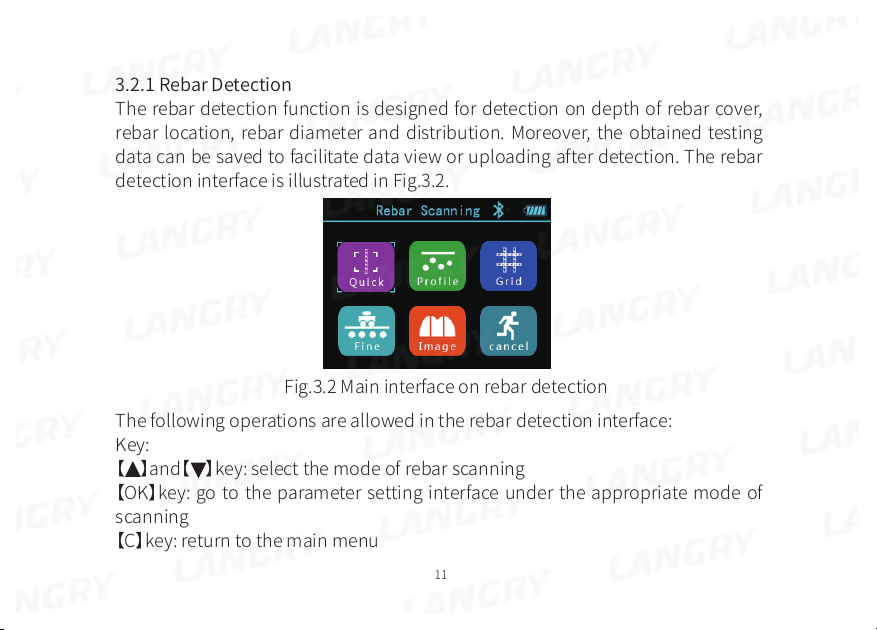

3.2.1.1 Scanning parameter setting

The scanning parameter setting is mainly used to set the parameters which may

be selected under the current mode of scanning. The parameter scanning

interface is illustrated in Fig.3.3 (take the quick scanning parameter setting

interface as an example).

Fig.3.3 Scanning parameter setting interface

The following operations are allowed in the parameter setting interface:

Key:

【 】and【 】key: select the option requiring adjustment

12

【OK】key: go to the status of change for the option

【C】key: exit the parameter change status or return to the rebar detection

interface.

【FN】key: go to detection

Touch: touch the area requiring change to complete parameter change. Touch

the appropriate icon button to function as expected.

The parameters permitting change are as follows:

Component No.

The component no. consists of digit, letter and symbol. The user can set a

component no. in max. 12 digits and min. 1 digit. The user may carry out setting

whenever required, as detailed below:

Move the cursor to the desired component no. Press 【OK】 key or directly touch

the field to go to the component no. edit status. Now, a soft keyboard will appear

in the bottom of screen. Select the character to be entered with use of direction

key, and press 【OK】key to confirm or directly touch Enter. Later, press 【C】 key or

touch the return button to exit the edit status.

Design Diameter

It is used to set the diameter of rebar being detected. Total 15 types of rebar diameter

can be selected, ie. 6, 8, 10, 12, 14, 16, 18, 20, 22, 25, 28, 32, 36, 40, 50.

You have to set the design diameter at both X and Y directions simultaneously

13

under the grid scanning and image scanning modes.

Design Depth

It is used to set the depth of design cover for the rebar being detected within a

range of 2-200.

You have to set the design depth at both X and Y directions simultaneously under

the grid scanning and image scanning modes.

Type Of Component

It is used to set the type of rebar component being detected. You may select two

types of component, i.e. “Beam” and “Slab”.

Notes:

1)The component no. can be set in max. 12 digits without space. If you start

detection without entering the component no., a prompt message will appear,

reminding you of entering the component no.

2)For rebar cover depth measurement, it is required to set the rebar diameter

beforehand. Only with correct setting of design diameter, can the correct Detailed

specification on testing of concrete cover depth being measured be assured.

Otherwise, deviation to a varying extent may occur.

3)Setting of design depth and component type parameters is a basis of assessing

if the Detailed specification on testing of concrete cover depth at the measuring

point during measurement is acceptable. All unacceptable measurements in the

14

measurement interface are highlighted in red for quick identification.

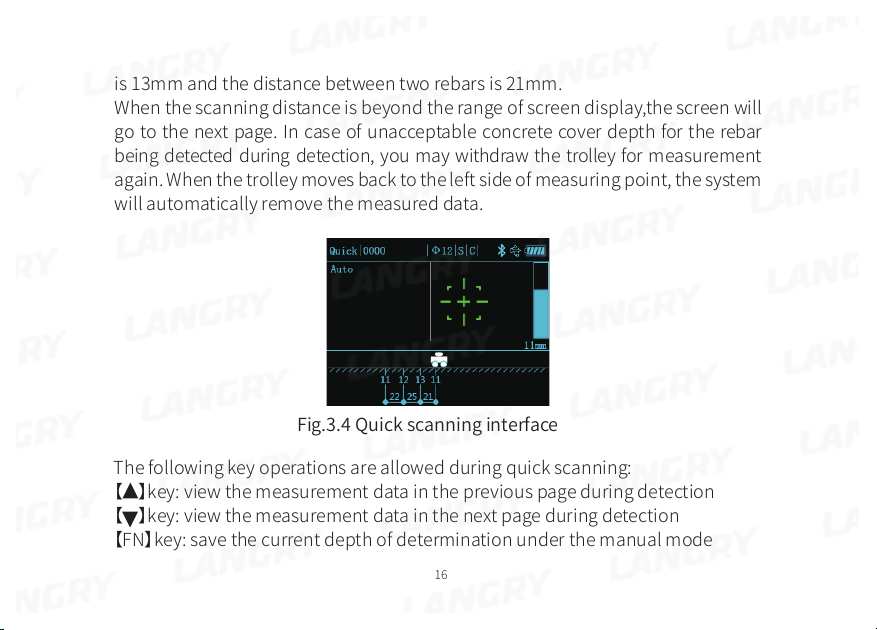

3.2.1.2 Quick scanning

In the quick scanning interface, slowly move the trolley at constant speed to the

right to start measurement. When the trolley approaches the rebar, a green

aiming box appears. Now, slowly move the trolley while the aiming box slowly

approaches the centerline. When the aiming box completely fits the centerline,

the aiming box turns out to be red and the red light gets lit, plus beep sound being

heard. The laser light in front of the instrument will emit a red line,indicating that

the instrument has detected the rebar, right below the red line. In case of

automatic storage mode being set, automatic storage is performed to assess the

concrete cover depth. In case of manual storage mode being set, press 【FN】key

to save the depth value, which appears in the bottom of screen. When the trolley

moves far from the rebar, the aiming box gets away from the centerline. When the

aiming box moves beyond the effective range of detection, the aiming box

returns back to the centerline, highlighted in grey. When the trolley stays between

two rebars, the aiming box is in blue.

Continue to move the trolley to the right for detection of next rebar. The same

hint will appear in the instrument. Now, the concrete cover depth and distance to

the previous rebar will appear simultaneously. As illustrated in Fig.3.4, the

concrete cover depth is now 11mm, concrete cover depth for the previous rebar

15

is 13mm and the distance between two rebars is 21mm.

When the scanning distance is beyond the range of screen display,the screen will

go to the next page. In case of unacceptable concrete cover depth for the rebar

being detected during detection, you may withdraw the trolley for measurement

again. When the trolley moves back to the left side of measuring point, the system

will automatically remove the measured data.

Fig.3.4 Quick scanning interface

The following key operations are allowed during quick scanning:

【 】key: view the measurement data in the previous page during detection

【 】key: view the measurement data in the next page during detection

【FN】key: save the current depth of determination under the manual mode

16

【OK】key: switch between the manual or automatic save mode

【C】key: exit the scanning interface

【�】key: keep pressing the key to estimate the diameter of rebar being scanned,

and instantaneously press for instrument self-calibration.

Touch operation: complete appropriate operation in the field corresponding to

the touch status bar.

3.2.1.3 Profile scanning

Profile scanning is a type of scanning designed to display the location of rebar

being detected, concrete cover depth, distance of neighboring rebars, measurement

diameter, etc. in the longitudinal profile distribution diagram. This type of

scanning is similar to the quick scanning. The profile scanning is illustrated in

Fig.3.5.

With use of profile scanning, slowly move the trolley to the right. When the trolley

moves above the rebar, the aiming box in the bottom right will turn out to be red,

with the same display as that for quick scanning. Refer to the related chapter for

more details. In the bottom left of the screen, the current displacement value may

appear in a real-time manner. When the rebar is being scanned, you may see the

display in the profile point in the screen, in which the concrete cover depth is

marked. The following key operations are allowed for calculation of distance of

neighboring rebars during profile scanning:

17

Fig.3.5 profile scanning interface

Key:

【 】key: view the measurement data in the previous page during detection

【 】key: view the measurement data in the next page during detection

【�】key: keep pressing the key to estimate the diameter of rebar being

scanned, and instantaneously press for instrument self-calibration.

【C】key: exit the profile scanning

Touch operation: complete appropriate operation in the field corresponding to

the touch status bar.

18

3.2.1.4 Fine scanning

The mode of fine scanning provides the real-time indication of waveform of the

rebar being detected, rebar location, concrete cover depth, center-to-center

distance of neighboring rebars, estimated diameter, etc. in the waveform

diagram. The user may also manually add or delete the measuring point of rebar

according to the waveform distribution pattern.

It is required to determine the location of rebar in a real-time manner under the

quick scanning. Thus, the quick scanning is not suitable for scanning of heavi-

ly-distributed rebar. The fine scanning is specifically designed for heavily-distrib-

uted rebar. The fine scanning interface is illustrated in Fig.3.6.

Fig.3.6 Fine scanning interface

19

In the fine scanning interface, locate the instrument on the surface of object to

be measured, and slowly move to the right to start measurement. The signal

waveform will appear in the screen, and the real-time displacement value will

appear in the bottom left of screen. The signal value starts to increase with the

instrument approaching the rebar, and the waveform curve slowly rises. When

the instrument moves far from the rebar, the waveform curve slowly lowers

down. Now, a peak may appear. The location of peak is just the location of rebar.

A white line appears at the peak, indicating that there is a rebar here. The

concrete cover depth for the rebar will appear above the peak. When a number

of rebar is detected, the instrument will automatically calculate the rebar

distance, to be displayed below the waveform.

In case of intensive distribution of rebar distance occurring during detection, the

waveform signal will get gentle, wider than the waveform signal in the single

rebar waveform diagram. Now, the instrument has to make judgment on rebar

location in combination with variation in the neighboring waveforms. Thus, the

delayed determination of rebar location may occur.

It is required to switch to the pretty heavily-distributed rebar mode in case of

need to measure the heavily-distributed rebar. In the detection interface, press

the Down key to switch to the pretty intensive rebar mode. Under the pretty

intensive rebar mode, slowly move the trolley at constant speed to assure detection

20

accuracy. Press the Down key again to return to the intensive rebar mode.

When the scanning distance is beyond the range of screen display, the instrument

will automatically conduct screen scrolling for display, and permit max. 10m

range of scanning.

The following operations are allowed in the fine scanning:

Key:

【 】key: view the measurement data in the previous page during detection

【 】key: view the measurement data in the next page during change on mode of

detection or during detection

【�】key: keep pressing the key to estimate the diameter of rebar being scanned,

and instantaneously press for instrument self-calibration.

【FN】key: keep pressing the key to go to the manual addition and deletion of

measuring point interface

【C】key: exit the fine scanning

Touch operation: keep pressing the waveform display field in the touch screen to

go to the manual addition and deletion of measuring point interface to complete

appropriate operation in the field corresponding to the touch status bar.

In case of unacceptable waveform signal or deviation in rebar determination

occurring during detection, you may withdraw to the left to erase the waveform

with determination deviation, and restart scanning. Alternatively, you may keep

21

pressing 【FN】key at the end of scanning or keep pressing the waveform display

field in the touch screen to go to the manual addition and deletion of measuring

point interface, as illustrated in Fig.3.7. Now, the user is allowed to manually add

or delete the rebar measuring point in the interface.

The following operations are allowed in the manual addition and deletion of

measuring point interface.

Key:

【 】key: instantaneously press the key to move the cursor to the location of last

signal. Keep pressing for quick move

【 】key: instantaneously press the key to move the cursor to the location of next

signal. Keep pressing for quick move

【FN】key: add or delete a rebar at current position

【C】key: exit the fine scanning

Touch:

Touch the waveform data display field to move the cursor to the location where

the rebar needs to be added or deleted. In case that rebar addition at the current

position is allowed, the rebar button in the top of screen is highlighted. Now, you

can touch the button for rebar addition. Similarly, when the button for rebar

deletion is On, touch the button for rebar deletion.

22

Fig.3.7 Manual rebar addition/deletion

measuring point interface for fine scanning

Note:

Max. 10m scanning is permitted under fine scanning.

With access to the manual addition/deletion measuring point function under fine

scanning, the instrument is not able to return to continue measurement of this

component.

Set to the intensive rebar mode in default under the fine scanning. Measurement

of most intensive rebars can be accomplished under the fine scanning. For the

pretty intensive rebar measurement, press the Down key to switch to the pretty

intensive rebar mode, in which the rebar diameter has to be correctly set.

Conduct scanning slowly at constant speed to assure accuracy of sampling data.

23

3.2.1.5 Grid scanning

Fig.3.8 Grid scanning interface

Grid scanning is a type of measurement designed to display the location of rebar

being measured, concrete cover depth and rebar distance in the grid schematic.

In the grid schematic obtained from grid scanning, the user can clearly view the

rebar distribution. The grid scanning is illustrated in Fig.3.8.

For grid detection, firstly carry out “Grid horizontal” scanning, and slowly move

the trolley to the bottom left of screen to start recording the displacement. When

the rebar is detected, plot the rebar measuring point and concrete cover depth

with use of the grid line at the appropriate location, and calculate and display the

distance of neighboring rebars. At the end of scanning the rebar in the horizontal

direction, press 【OK】 key to switch to the “Grid vertical” scanning to continue

24

detection. At the end of entire detection, press 【C】key to save data and exit the

grid detection.

The following key operations are allowed in the grid scanning:

【 】key: view the measurement data in the previous page during detection

【 】key: view the measurement data in the next page during detection

【�】key: keep pressing the key to estimate the diameter of rebar being scanned,

and instantaneously press for instrument self-calibration.

【OK】key: switch the direction of scanning

【C】key: exit the grid detection

Touch operation: complete appropriate operation in the field corresponding to

the touch status bar.

3.2.1.6 Image scanning

Image scanning is a type of measurement for comprehensive analysis following

repeated scanning horizontally and vertically in a field of given area based on

combination of fine scanning and grid scanning, which is suitable for measure-

ment of rebar in an irregular distribution.

For image scanning, the user can conduct scanning in max. 5x5 grid (or 2x2, 3x3,

4x4 grid), i.e. horizontal scanning 5 times and longitudinal scanning 5 times. The

sequential location of scanning is up to your desire. Fig.3.9 shows the location

selection interface for image scanning.

25

Fig.3.9 Image scanning location selection interface

The following operations are allowed in the image scanning location selection

interface:

Key:

【 】【 】 key: select the location to be scanned

【FN】key: go to the location scanning or cancel the scanned data for measure-

ment again

【C】key: exit the image scanning.

Touch:

Touch the location field requiring scanning for selection. Use the touch button to

complete operation.

During the single scanning measurement for image scanning, the measurement

26

results are displayed via the waveform diagram. For detailed function and operation

parameter, refer to the fine scanning chapter for more details.

At the end of all data acquisition, the user can perform data import to the

computer for data analysis, and meanwhile generate the 3D graphics to view the

rebar distribution more accurately.

Note:

An individual scanning can cover max. 1m for image scanning mode.

An individual scanning for image scanning mode is not suitable for the manual

addition/deletion rebar measuring point function.

3.2.1.7 Diameter estimation

It is able to display the estimated diameter under all scanning modes. In case of

need to estimate the rebar diameter, move the trolley to a point just above the

rebar, and keep pressing 【...】key to go to the diameter estimate function. Wait for

3sec. after measurement, and the instrument interface will display the estimated

diameter and concrete cover depth. Automatically exit 3 sec. later.

Note:

Keep the instrument location constant during diameter measurement, which

may otherwise lead to deviation of measurement result.

The diameter measurement results are displayed only, and not saved.

3.2.1.8 Signal resetting calibration

27

In case of change to the detection environment or considerable difference

between the measured depth of rebar cover and the design, it is necessary to

carry out signal resetting calibration for the instrument. Under any mode of

measurement, press【...】key to start the signal calibration function.

Note:

Instrument calibration shall be carried out to atmosphere, far from the ferromag-

netic substances. As instructed in the interface, press【OK】key to start calibration.

Exit at the end of instruct self-calibration.

The unacceptable calibration signal indicates calibration failure. Now, carry out

calibration again.

3.2.2 Data view

There are two ways of viewing the component data available in the instrument,

i.e. in graphic and list. The user can select an appropriate way of view on a

case-by-case basis. Set to the graphic data view in default.

3.2.2.1 Component list display

In the data view interface, the component list appears, as illustrated in Fig.3.10,

including:

Component list information and data statistics of designated component

The following operations are allowed in the component list display interface:

Key:

28

【 】key: move upward to select a component

【 】key: move downward to select a component

【OK】key: go to the graphic display interface containing the selected component

data

【C】key: exit the data view interface

Touch: complete operation by touching the appropriate field or button.

Fig.3.10 Data view interface

Note:

The content of component data statistics information may vary depending on the

different modes of component scanning:

Display content of quick, profile and fine scanning: scanning type, design diameter,

design depth, scanning distance, no.s of measuring point, pass rate and detection

29

time, etc.

Display content of grid scanning: scanning type, design diameter X and Y, design

depth X and Y, scanning distance X and Y, no.s of measuring point X and Y, pass

rate X and Y, and detection time, etc.

Display content of image scanning: scanning type, design diameter X and Y,

design depth X and Y, detection time, etc.

3.2.2.2 Component data graphic display

The component data graphic interface display is designed to display the current

component’s measurement data in graphics, which is easily read and under-

stood. The graphic display interface for each mode of scanning is illustrated

below. The following operations are allowed in the component data graphic

display interface:

Key:

【 】key: scroll up to view the data in the previous screen

【 】key: scroll down to view the data in the next screen

【OK】key: go to the component data list display interface

【FN】key: switch horizontally or vertically to view the data (only grid scanning

data allowed)

【C】key: exit the component data graphic view interface

Touch: complete operation by touching the appropriate button.

30

Fig.3.11 Quick scanning

Fig.3.12 Profile scanning

31

Fig.3.13 Fine scanning

Fig.3.14 Grid scanning

32

Fig.3.15 Image scanning

Note:

1. The title bar of component data graphic display interface mainly provides

information on the scanning type of the component, no. of component and

design diameter; the graphic display field provides information on location,

depth and distance of measuring point in the measurement data in graphics.

2. In the graphic display interface of image scanning component data, you will

see the summary of all measurements first, as illustrated in Fig.3.16. The user

shall press the down direction key to select the scanning location to be viewed,

and then press【OK】key to go to the graphic data view interface for selection of

scanning location.

33

Fig.3.16 Scanning location view interface with image scanning

3.2.2.3 Component data list display

The component data list display interface is designed to display the measure-

ment data for the component in the data list. The list display interface for each

mode of scanning is illustrated below.

34

Fig.3.17 Quick scanning

Fig.3.18 Profile scanning

35

Fig.3.19 Fine scanning

Fig.3.20 Grid scanning at the horizontal direction

36

Fig.3.21 Grid scanning at the vertical direction

Fig.3.22 Image scanning

The following operations are allowed in the component data list display

interface:

37

Key:

【 】key: scroll up to view the data in the previous screen

【 】key: scroll down to view the data in the next screen

【FN】key: switch horizontally or vertically to view the data (only grid scanning-

mode allowed)

【C】key: return to the component data graphic display interface

Note:

The symbols in the component data list display interface are interpreted below:

No.⸺No. of current measuring point

Hx⸺Measured depth at the current measuring point at Direction X under the

quick, profile, fine, grid and image scanning modes

Hy⸺Measured depth at the current measuring point at Direction Y under the

grid scanning mode

Sx⸺Measured displacement at the current measuring point at Direction X

under the quick, profile, fine, grid and image scanning modes

Sy⸺Measured displacement at the current measuring point at Direction Y

under the grid scanning mode

△H ⸺Difference between the depth value at current measuring point and the

design

△S ⸺Displacement variation at the current measuring point and previous one.

38

3.2.3 Data deletion

The data deletion function is designed to allow data deletion manually. With

access to the data deletion interface, the instrument will ask you if you want to

delete data or not? (Y/N). Now, press 【OK】key or the corresponding button in the

touch screen to delete data. Press 【C】key or the corresponding button in the

touch screen to cancel data deletion. The data deletion interface is illustrated in

Fig.3.23.

Fig.3.23 Data deletion confirmation interface

39

Fig.3.24 Data deletion process interface

Note:

1. Figure out if the data are uploaded to the computer prior to data deletion since

the data are not retrieved after deletion.

2. The instrument is not configured to cancel with key or touch during data

deletion.

3.2.4 Data uploading

It is advisable to upload the data to the computer on completion of data detec-

tion or with the memory nearly fully loaded. The user can upload the data via

USB or Bluetooth interface. For Bluetooth transmission, which is an extended

function, the specific mobile phone software is required to complete uploading.

The user may make choice as required. Only USB transmission is outlined below.

40

USB transmission is carried out in steps below:

1. Conduct wiring to the instrument and computer via specific USB data cable;

2. Switch on the instrument;

3. Activate the Langrui rebar scanner management software already in the

computer;

4. Click the import component data menu in the menu bar;

5. Select the component data requiring uploading, and click the upload to start

uploading the data;

6. Wait until data transmission ends.

3.2.5 System setting

The system setting menu interface is designed to provide the user with the

system setting parameter information for his/her own adjustment, including the

power saving setting, sound setting, date setting, scan setting and system

management, as illustrated in Fig.3.25.

3.2.5.1 Power saving setting

In the power saving setting, the user can set the backlight brightness, standby

time, automatic shutdown time and horizontal laser light switch. At factory

delivery, the backlight brightness is set at 50% brightness, standby time at

10min., automatic shutdown time at 25min., and horizontal laser light On. The

user may make setting himself/herself whenever required, which can be accom-

41

plished via key and touch screen.

Fig.3.25 System setting interface

3.2.5.2 Sound setting

The sound setting includes the key tone and warning tone. The key tone is the

tone from the user's key operation and the warning tone is the tone when the

rebar is detected. The user may make setting himself/herself whenever required,

which can be accomplished via key and touch screen.

3.2.5.3 Date setting

Set the system time, including the year, month, day, hour and minute, which can

be accomplished via key and touch screen.

3.2.5.4 Scan setting

42

The scan setting menu covers the stirrup distance, range selection and rebar type.

Stirrup distance: during field detection, it is necessary to pre-scan the stirrup

distance. In case of less than 120mm, set the parameter at [100], [80], [60] and [40]

on a case-by-case basis. Now, the instrument will undergo the appropriate

compensation correction. In case of stirrup distance above 120mm, set the

parameter at [>120].

Range selection: select the small range for the small depth of rebar cover being

measured. Otherwise, switch to the large range mode. Make selection on a

case-by-case basis.

Rebar type: it includes the deformed bar and round steel.Make the appropriate

setting based on the type of rebar being detected. Ensure correct setting on rebar

type prior to detection, which may otherwise affect the measurement accuracy.

3.2.5.5 System management

Bluetooth-based uploading: instrument's extended function, to be used with the

specific mobile phone software.

Language selection: select the different operation language depending on the

user's need.

3.2.6 About device

The About device menu provides the information on the device, as illustrated in

Fig.3.26, including the following:

43

Instrument type and name

Firmware version no.

Device no.

Company contact tel.

Company website

Fig.3.26 About device interface

3.3 Firmware upgrading

There is a built-in firmware online upgrading program so that the user can carry

out firmware upgrading through connection to the computer via data cable.

Through connection to the computer via data cable, the computer software can

automatically detect the firmware version no. In case of latest version of

firmware, the computer software may ask the user if upgrading is required. Refer

44

to the software description profile for details.

Note:

You shall not shut down the instrument during firmware upgrading. If upgrading

fails, shut down the instrument and manually go to the upgrading interface for

upgrading again.

4 Maintenance and repair

4.1 Pre-operation inspection

Switch on the instrument and go to any mode of scanning for instrument self-cal-

ibration. Later, carry out scanning in the calibrated unit to check for correct

signal.

4.2 Cleaning

The instrument has no water resistance function. Cleaning with wet rag is prohibited.

Cleaning the instrument and accessories with the organic solvent is prohibited.

Clean the instrument and accessories with the clean and soft dust-free rag.

4.3 Battery

The instrument is charged with the chargeable lithium battery. The instrument

can operate for continuously 24h when it is fully charged. In case of low battery, it

will provide a warning on low battery and automatically goes to shutdown. Now,

the instrument has to be charged. In order to ensure that the instrument is fully

charged, please keep charging for 6-8h.

45

Note:

Charging at high temperature is prohibited. In case of out of use for an extended

period, the battery may have slight power loss, leading to reduced power.

Recharge prior to use. It is acceptable that the charger may be hot during

charging. Keep the charging environment well ventilated to facilitate heat

dissipation. Carry out charging with the specific charger. Use of other types of

charger or adaptor may damage the instrument.

5 Precautions on field detection

1. The rough or uneven detection surface may affect the detection accuracy.

Thus, keep the scanning surface flat without large protrusion. If the surface is too

rough to be cleaned, place a sheet on the scanning surface. The depth of the

sheet shall be deducted from the measurement result;

2. Keep the instrument to slowly move at constant speed during scanning;

3. Set the instrument to scan in a direction perpendicular to the rebar routing

direction. Otherwise, it may lead to misjudgment or deviation in depth measure-

ment;

4. For mesh rebar, typically locate the rebar at the top, and then carry out

measurement between two rebars at the top to locate the rebar in the base;

5. In case of change to the detection environment or considerable deviation in

measurement result, carry out resetting calibration on instrument signal. It is

46

recommended to carry out resetting calibration on instrument signal before

every measurement. During resetting calibration, keep away from the ferromag-

netic materials for calibration to atmosphere to ensure calibration accuracy;

6. The instrument is configured to allow large and small range switchover. There

is a higher measurement accuracy for small range case, so it is recommended to

use the small range for detection provided the conditions on range of measure-

ment are met;

7. The design diameter in the measurement parameter setting must be correctly

entered. Otherwise, deviation may occur on depth judgment.

6 Metering and calibration

The instrument will be calibrated according to the national calibration criteria

before factory delivery. The calibration content and procedure are outlined

below:

1)Calibration environment: room temperature, free of strong magnetic interfer-

ence, air relative humidity of less than 80%.

2)Calibration device: 3 rebar calibration coupons, separately standing for the

deformed bar of Φ12, Φ16 and Φ25.

3)Calibration content and detection method:

Depth: For the deformed bar in 3 sizes, the calibrated depth varies. For the Φ12

rebar, depth up to 40mm shall be detected.For the Φ25 rebar, depth above 60mm

47

shall be detected.

Carry out detection with the large and small ranges, and take 3-5 key sampling

points for continuous measurement and take note of results.

The detection results shall be acceptable to the requirements in 1.3 Performance

indicator.

Diameter: make measurement on diameter of deformed bar in 3 sizes in the

coupon. Make measurement on the deformed bar of each size 3 times and figure

out the average value. The detection results shall be acceptable to the require-

ments in 1.3 Performance indicator.

Diameter: make measurement on diameter of deformed bar in 3 sizes in the

coupon. Make measurement on the deformed bar of each size 3 times and figure

out the average value. The detection results shall be acceptable to the require-

ments in 1.3 Performance indicator.

48

7 Data analysis software description

7.1 Introduction

The rebar detection data analysis software is a multi-function analysis software

developed by Jinan Langrui Detection Technology Co., Ltd. for processing the

rebar detection data. The software can run in XP/win7/win10 OS, presenting

friendly interface and easy operation, which is specifically designed for project

detection staff.

1)Conduct management on all component information as well as the detection

data at each measuring point;

2)Conduct analysis and evaluation on detection data according to the construc-

tion quality acceptance criteria;

3)Display the component data in a graphic way;

4)Generate a detection data file through integration of several ones; it is easy to

add or remove the detection data;

5)Print the preview and export treatment results;

6)It is easy to import the rebar scanner data into the computer with use of the

software to facilitate further analysis and archive;

7)Automatically generate the detection report in word format.

The data files saved in the software has the file extension name in . xgjy format.

The detection report automatically generated has the file extension name in

49

.docx format.

7.2 Software installation

7.2.1 Installation of port driver

LR-G200 rebar scanner is furnished with the program U-disc. Please attach the

U-disc to the available USB port in the computer prior to operation. Activate the

U-disc and find out the port driver folder and open it. Double click the installation

program “setup” dialog box and then click “INSTALL”.

Start installation. Later, the “Driver pre-installation success” may appear in the

screen and click Ok. Next, attach the computer USB communication port to the

rebar scanner USB port via communication cable. Switch on the rebar scanner,

and the computer will show that the new hardware has been located. Several

minutes later, you may start operation on completion of hardware identification.

If you are asked to confirm the authorized selection, please select “Ok” and

confirm.

7.2.2 Software installation

The rebar scanner is furnished with the program U-disc. Please attach the U-disc

to the available USB port in the computer prior to operation. Activate the U-disc

and find out the “Rebar scanner online system” folder and open it. Double click

the installation program “setup-x.x” and open the installation wizard. Please

complete installation as instructed and operate it.

50

★ Please tick the option to generate a desktop shortcut. Then, you can run the

software by double clicking the desktop shortcut.

7.3 System setting

7.3.1 Enterprise information

Click “Tool (T) → Enterprise information” menu item so that the enterprise,

information option card may appear below. The enterprise information as shown

below may appropriately appear at the corresponding page location in the

testing report.

51

7.3.2 Report setting

Click “Tool (T) → Report setting” so that the following dialog box appears, showing

the print report title and print report options. A set of proposed report template

has been provided in the software for user's use. The template may be customized

to meet the user's special requirements.

7.4 Receiving component data

7.4.1 Connection to the rebar scanner host computer

1)Wiring of communication cable: confirm that the USB communication cable

leading the computer to the rebar scanner host computer has been attached.

2)Instrument power-on: press the power-on key to switch on the rebar scanner

host computer, and keep it online.

3)Click the title bar “Rebar scanner”option. Select the“Import detection data”

option in the pull-down menu, and click it. The rebar scanner data dialog box

52

appears. The software provides the automatic port identification function. If the

rebar scanner host computer is correctly attached to the computer, and main-

tained online, the software can automatically identify the communication port

and Baud rate, and display it. If the software fails to identify the communication

port or the communication port is incorrect, please click the“Refresh”in the

dialog box.

7.4.2 Data uploading

Select to import all components or partial components as illustrated above.

Then, click “Import” so that the instrument can automatically upload the select-

ed component data. No operation is required during uploading.

★When the data are transmitted the computer, the data saved in the instrument

will not get lost.

53

★You may click Cancel to stop uploading at any time during uploading.

7.5 Data processing

7.5.1 Original data processing

In the software's home page, fill out the detection information and enterprise

information, and then automatically generate a “Detection report” and “Original

data record”, which can be separately printed. In the “Detection data” master

window, you can alter all the parameters which were not correctly entered, and

make calculations again to meet the need of different clients.

54

When the data are uploaded, select the component no. in the left navigation bar,

and fill out and set the component information in the right item box. Further-

more, you can view the detection results on the component.

Grid scanning and image scanning can display 3D stereogram and plan in the

right graphic display box.

55

Display the waveform schematic via fine scanning

56

7.5.2 Report generation

Click the title bar “Data processing (D)” → Generate report to generate a report. A

report no. (for example, Report 001) may appear in the “Detection report” bar in

the left navigation bar. Click the “Report 001” to display the report fillout

interface. In the right report composition option, select the report type and tick in

the square box before the data in the bottom the data requiring report generation.

After completing the report, you may select print preview to print the report.

★In the print pre-view, click “Export word” to save the pre-viewed report in word

format.

57

7.5.3 Data deletion

If you want to delete a component, click selection and press “Data processing (D)

”→“ Delete component” to delete the selected component.

★The deleted component goes to the list of deleted components, in which you

may select the component deleted by mistake and retrieve it.

7.5.4 Data save

The original data or completed report can be saved in the computer. Click the

title bar “File (F)” →“ Save” to save the file in a format of .xgjy.

7.6 Upgrading

The user can manually carry out software upgrading and firmware upgrading.

The computer shall be attached to the internet.

Software upgrading: click the title bar “Help” →“ Check new version” so that the

software will automatically check for latest version of software. If so, the comput-

er may ask the user if upgrading is required. Click “Upgrade” to start automatic

upgrading.

Firmware upgrading: attach the rebar scanner to the computer’s USB port via

data cable. Switch on the rebar scanner, and click the software title bar “Rebar

scanner” →“ Upgrade the rebar scanner” so that the software may automatically

check for latest version of firmware software. If so, the computer may ask the user

if upgrading is required. Click “Upgrade” to start automatic upgrading

58

Components

1.LR-G200 Integrated rebar scanner

2. U-disk memory

3.Charger

4.Communication data line

5.Instrument box

6.Instrument package

7.Operating instructions

8.Product certificate

59

1 2 3

4

7 8

5 6

60

Manufacturer warranty

LANGRY guarantees that the tool is free from defects in materials and manufac-

turing processes when it leaves the factory, and the warranty is valid only if the

user correctly installs, operates, maintains and cleans the tool in accordance with

Langry's operating instructions.

The warranty covers the free replacement or repair of damaged parts during the

whole service life of this tool. If the parts need to be repaired or protected due to

normal wear and tear, they are not covered by the warranty.

Other claims are not covered by the warranty unless there is a different provision

under the specific law of the customer's country. In particular, langry shall not be

liable for any direct, indirect, incidental or inevitable damage, financial loss or

additional expenses caused by or related to the improper use or abuse of this

tool. Expressly exclude implied warranties of merchantability and fitness for a

particular purpose.

In case of repair or replacement, the tool or relevant parts shall be sent to

Langry's market organization immediately after the failure is determined.

61

JINAN LANGRUI DETECTION TECHNOLOGY CO.,LTD.

Email:langry@jnlrkj.com

Website:www.langry.cn

Loading...

Loading...