Page 1

Installation, Operation, and

Maintenance

Instructions

Deck Oven

Model: DO36 and DO36L

Star Manufacturing International 10 Sunnen Drive St. Louis, MO.63143-3800

Part Number: 2M-W475 Ph: 314-781-2777 Fax: 314-781-2714

Rev.A

WWW.STAR-MFG.COM May 16, 2007

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS ..............................................................................................................1

INTRODUCTION

DESCRIPTION................................................................................................................1

FEATURES.....................................................................................................................1

SAFETY PRECAUTIONS AND WARNINGS..............................................................................2

INSTALLATION

RECEIVING AND UNCRATING.....................................................................................3

INSTALLING THE LEGS................................................................................................3

CLEARANCES...................................................................................................3

DECK OVEN ASSEMBLY ..............................................................................................3

STACKING THE OVENS...................................................................................3

ELECTRICAL CONNECTION............................................................................4

INTERCONNECTING THE OVENS..................................................................4

OVEN PHASING................................................................................................5

LOAD REQUIREMENTS...................................................................................5

RANGE ASSEMBLY.......................................................................................................6

INSTALLATION ON OVEN BASE.....................................................................6

ELECTRICAL CONNECTION............................................................................6

PHASING RANGE ASSEMBLY.........................................................................7

LOAD REQUIREMENTS...................................................................................7

OPERATION

INITIAL START-UP.........................................................................................................8

NORMAL OPERATION ..................................................................................................8

PREHEATING....................................................................................................8

OVEN RACK......................................................................................................8

CONTROL PANEL..........................................................................................................9

3-HEAT SWITCHES ..........................................................................................9

PAN PLACEMENT.............................................................................................10

VENT CONTROL...............................................................................................10

TIMER................................................................................................................10

PRODUCTIVE MAINTENANCE

CLEANING......................................................................................................................11

THERMOSTAT CALIBRATION......................................................................................11

CALIBRATION CHECK PROCEDURE..........................................................................11

CALIBRATION ADJUSTMENT..........................................................................12

INSTALLATION TROUBLESHOOTING GUIDE ........................................................................13

OVEN PARTS LIST.....................................................................................................................14

DECK OVEN WIRING SERIES...................................................................................................15

WIRING DIAGRAM

208/240V.........................................................................................................................16

240V................................................................................................................................17

Page 3

INTRODUCTION

This manual contains the necessary information to install, operate, and maintain the Lang

DO36L Series Electric Deck Oven.

DESCRIPTION

The DO36 Series Deck Oven is designed

as a single pan all purpose baking and

roasting oven. The oven can be stacked

with other 36 bake ovens, stacked with a

F6 Convection Oven, or assembled with a

three section Cook Top to create a range

with any top configuration.

FEATURES

The oven cavity is large enough to accept

a single full size sheet pan. The pan can

be placed on the pebble oven deck or

raised off of the deck and placed in the

middle of the cavity on a rack, supplied

with the oven.

The heating elements are located above

the product and below the oven deck.

They are controlled by a thermostat with

an operational range of 150°F to 550°F

and two Hi-Medium-Low (3-Heat)

switches.

The oven features a 1 hour timer and

oven cavity vent as standard equipment.

The oven door is a self closing pull down

type that when fully open is strong enough

to act as a loading platform for the oven.

The oven front is a high quality stainless

steel; the oven sides, top, and back are

baked enamel or optional stainless steel.

The oven cavity is a durable aluminized

finish.

Page 4

SAFETY PRECAUTIONS AND WARNINGS

DANGER

MAKE SURE THE MAIN POWER SUPPLY IS TURNED OFF AT THE SOURCE PRIOR TO

CONNECTING POWER TO THE APPLIANCE.

Disconnect the appliance from power before attempting any repair

The following clearances to combustible surfaces must be maintained.

4 inches to sides

3 inches to back

Make sure the wire leads that supply electricity to the cook top or upper oven decks are not

pinched between the oven and range top or between the decks.

Be sure the power supply voltage matches the voltage specified on the data plate.

This appliance must be phased per the wiring diagram.

Any cleaner used in the oven cavity must be labeled "Safe on Aluminum".

2

Page 5

RECEIVING AND UNCRATING

Upon receipt of the equipment, check for

freight damage, both concealed and

visible. Visible damage must be noted on

the freight bill at the time of delivery and

signed for by the freight company's agent.

Concealed loss or damage means loss or

damage which does not become apparent

until the merchandise has been unpacked.

When concealed damage is discovered,

make a written request for inspection by

the carrier’s agent within 15 days of the

delivery date. In either case, do not

return the damaged merchandise to

Star Manufacturing, file your claim with

the carrier.

Before uncrating the equipment confirm

that the voltage marked on the box

matches that of the building. The oven

voltage must match the voltage supplied.

Place the crate as near the intended

installation as possible before uncrating

the equipment. The crate will help protect

the equipment while it is being moved

through doorways and down halls.

Uncrate the oven and set as near the

intended installation as practical. Save

the crating materials as they may be used

during the installation.

INSTALLING THE LEGS

If the oven is to be assembled as a range

the legs are packaged in with the range

top. If the oven is to be stacked on

another oven the legs are packaged in a

separate box marked "Fabricated Legs".

Place some cardboard on the floor and

gently tip the oven backwards onto it.

INSTALLATION

sure the legs are screwed firmly into the

nuts.

The stacked oven fabricated legs attach to

the bottom corners of the oven with the

nuts and bolts supplied with the legs.

Set the oven on the legs, push it into

position, and level it using the adjusters

on the bottom of the legs.

CLEARANCES

THE FOLLOWING CLEARANCES TO

COMBUSTIBLE SURFACES MUST BE

MAINTAINED:

4 INCHES TO SIDES

3 INCHES TO BACK

DECK OVEN ASSEMBLY

STACKING THE OVENS

If the oven is to be assembled as a range,

skip this section refer to the Range Top

Installation Manual.

Remove the envelope labeled "Stacking

Kit" from the oven cavity.

Place some cardboard on the floor and

gently tip the oven that is to be stacked

backwards onto it. Install four pins from

the stacking kit into the threaded holes on

the side flanges of the oven bottom.

Remove the plastic plugs from the top of

the oven on legs so the pins just installed

in the top oven can nest into the holes.

Lift the oven that is lying on its back onto

the oven on legs. Align the pins so they

drop into the holes in the bottom oven.

The range legs are screwed into 4 nuts

welded to the bottom of the oven. Make

3

Page 6

ELECTRICAL CONNECTION

DANGER

MAKE SURE THE POWER SUPPLY TO THE APPLIANCE IS TURNED OFF BEFORE MAKING

THE CONNECTION.

If the oven is to be assembled as a range, skip this section and refer to the

Range Top Installation Manual.

The electrical connection is made through

a 1 1/4 inch knockout in the bottom of the

oven to a terminal block located behind an

access door that is below the control

panel.

Before connecting the oven to power

check the data plate located behind the

access door to confirm that the power

supply wires are large enough to carry the

load.

A one deck oven requires a single phase

connection only; however, this does not

mean the oven cannot be connected to a

three phase service, simply use two lines

of the three phase.

INTERCONNECTING THE OVENS

If the oven is assembled as a 2 deck

model, remove the wire from one of the

Stacking Kit envelopes and cut it in half.

Strip the cut ends of the wires 3/4 inch

and install them into the terminal block of

the top oven. Snap a 3/4 inch plastic

bushing from one of the Stacking Kit

envelopes into the hole in the bottom of

the top oven and run the wires from the

top oven through it to the terminal block in

the bottom oven. Connect the top oven

wires into the terminal block with the wires

from the bottom oven. Refer to the wiring

diagram in this manual for the correct

phasing of the wires.

If the oven is assembled as a 3 deck

model, remove the wires from all three

Stacking Kit envelopes and cut one

half. Use the 2 full length wires to connect

to the top deck and the cut wire to connect

to the middle deck. Refer to the figure

below or the wiring diagram in back of this

manual for the correct wire grouping at the

bottom oven terminal block.

in

4

Page 7

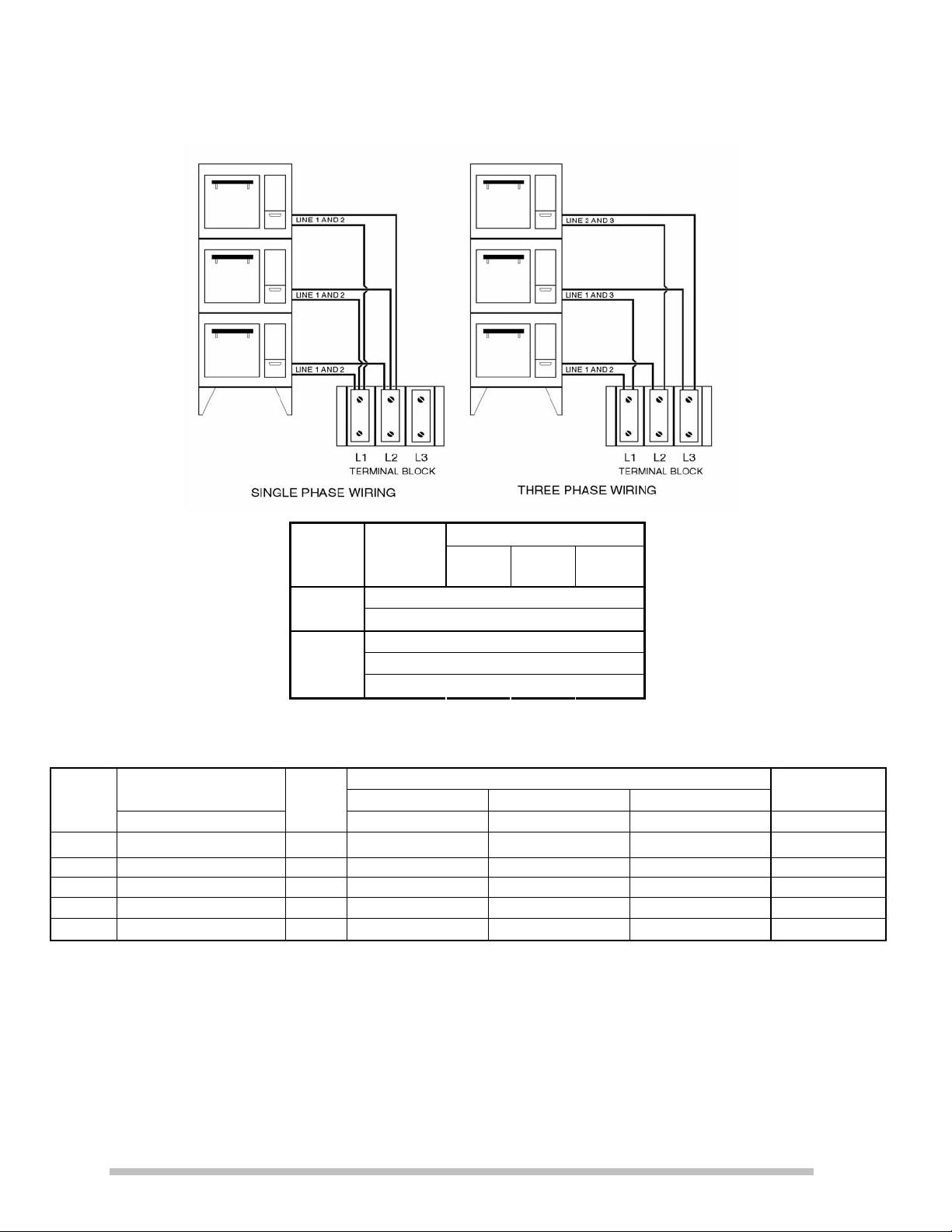

OVEN PHASING

MODEL

NO.

DO36I

DO36L

D036

DO362

D0363

Power

Supply

Terminal

Block

1ST

Deck

OVEN

2ND

Deck

3RD

Deck

L1 X X X Single

Phase

L2 X X X

L1 X X

Three

Phase

L2 X X

L3 X X

LOAD REQUIREMENTS

LOADING THREE PHASE AMPS

KW PER PHASE

LI L2 L2 L3 L3 L1

TOTA

L Kw

208 VOLT 240 VOLT 480 VOLT

L1 L2 L3 L1 L2 L3 L1 L2 L3 208V 240V

6 0 0 6 28.8 28.8 0 25 25 0 12.5 12.5 0 28.8 25

6 0 0 6 28.8 28.8 0 25 25 0 12.5 12.5 0 28.8 25

6 0 0 6 28.8 28.8 0 25 25 0 12.5 12.5 0 28.8 25

6 0 6 12 50 28.8 28.8 43.3 25 25 21.7 12.5 12.5 57.7 50

6 6 6 18 50 50 50 43.3 43.3 43.3 21.7 21.7 21.7 86.5 75

SINGLE

PHASE AMPS

5

Page 8

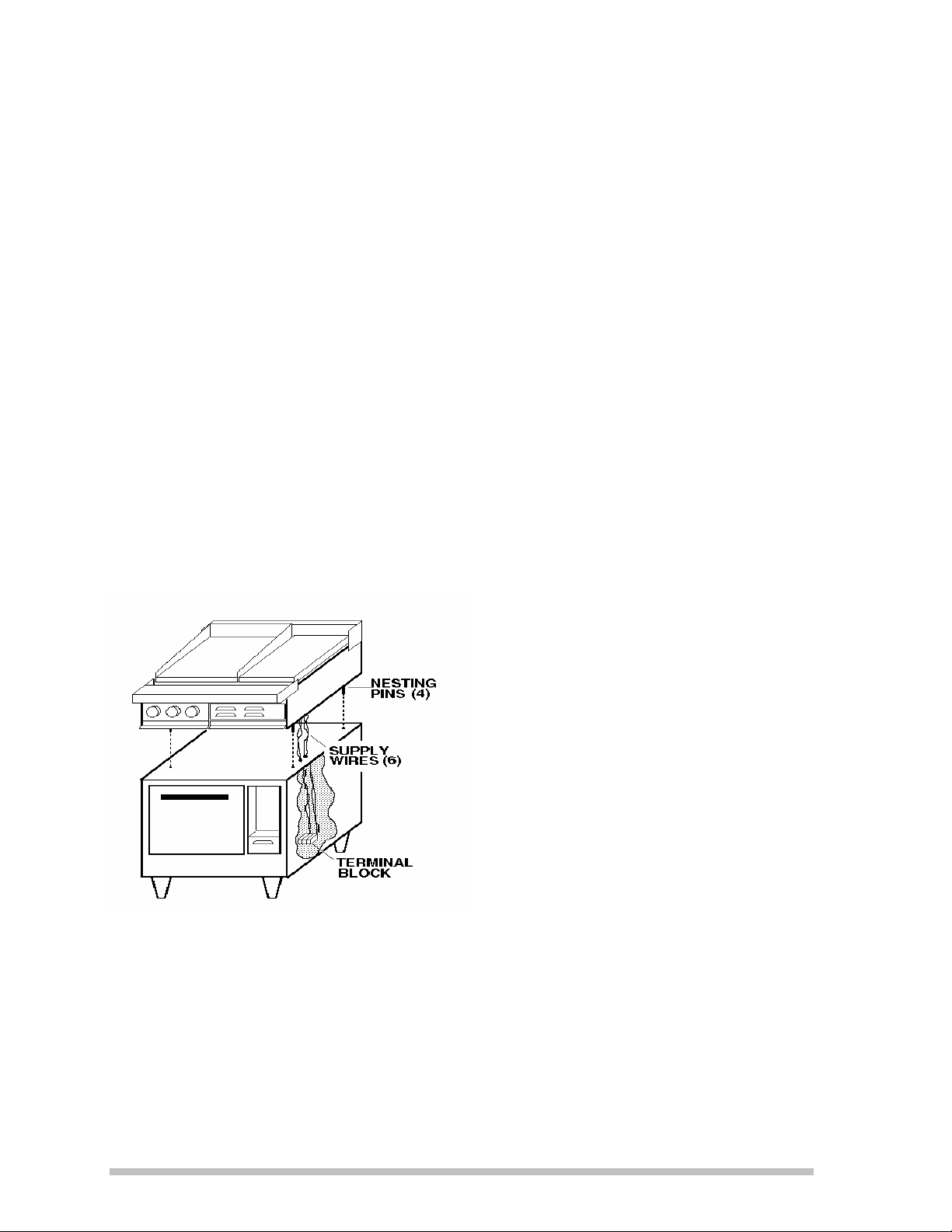

RANGE ASSEMBLY

INSTALLATION ON OVEN BASE

Remove all the plastic plug buttons from

the top of oven(s).

Lay a 2 X 4 or cardboard corner pad

across the top of the oven.

Lift the range top off of the shipping skid

and place it on top of the oven so that the

front edge of the range top is sitting on the

2 X 4 and is elevated off of the oven top.

Feed the two groups of power supply

wires through the two holes in the oven

top until all the wire slack is inside the

oven control compartment.

Lift the front of the range top and remove

the 2 X 4.

Allow the range top to set into place so

that the pins in the bottom if the range top

nest into the holes in the top of the oven

base.

ELECTRICAL CONNECTION

The electrical connection must be made in

accordance with local codes or in the

absence of local codes with NFPA No. 70

latest edition (in Canada use: CSA STD.

C22.1)

Supply wire size must be large enough to

carry the amperage load for the range

being installed. Wire size information can

be found on the range data plate.

This range can be installed on both single

and three phase supplies and is shipped

from the factory un-phased.

The range top wires connect into a

terminal block located in the oven base

control compartment.

6

Page 9

PHASING RANGE ASSEMBLY

Follow the drawings, below, to group the supply wires to match the power phase.

THREE PHASE SINGLE PHASE

LOAD REQUIREMENTS

For proper supply wire and circuit breaker size, refer to the chart below.

THREE PHASE LOADING NOMINAL AMPS PER LINE

Star

Model

Number

136SB 36S 6.0 10.0 5.0 21.0 45.8 66.7 62.5 39.7 57.8 54.2 19.9 28.9 27.1 101.0 87.5

N/A 72S #1 6.0 10.0 5.0 21.0 45.8 66.7 62.5 39.7 57.8 54.2 19.9 28.9 27.1 101.0 87.5

N/A 72S #2 6.0 10.0 5.0 21.0 45.8 66.7 62.5 39.7 57.8 54.2 19.9 28.9 27.1 101.0 87.5

R36C RF21S 6.6 10.0 5.0 21.6 48.3 69.2 62.5 41.9 59.9 54.2 20.9 30.0 27.1 103.8 90.0

N/A RF42S#1 6.6 10.0 5.0 21.6 48.3 69.2 62.5 41.9 59.9 54.2 20.9 30.0 27.1 103.8 90.0

N/A RF42S#2 6.6 10.0 5.0 21.6 48.3 69.2 62.5 41.9 59.9 54.2 20.9 30.0 27.1 103.8 90.0

TOP ONLY

Number

Lang

Model

Total

K.W. PER PHASE

L1 - L2 L2 -L3 L3 -L1

5.0 5.0 5.0 15.0 41.7 41.7 41.7 36.1 36.1 36.1 18.1 18.1 18.1 72.1 62.5

KW

Conn

208 VOLT 240 VOLT 480 VOLT

L1 L2 L3 L1 L2 L3 L1 L2 L3

THREE PHASE

SINGLE

PHASE

208V 240V

7

Page 10

INITIAL START-UP

OPERATION

The preservatives must be cleaned off the

oven front before it is heated. Wipe the

oven front with a damp rag and a mild

soap solution, rinse with warm water and

a damp rag, and then completely dry the

oven front.

Before the initial use of the oven it must

be allowed to thoroughly dry the elements

out. This is accomplished by setting the

top and bottom oven 3-heat switches to

the "Low" position and the thermostat to

350 degrees. Allow the oven to heat until

all vapor and smoke has been eliminated.

Somewhere along the rising temperature

curve between 250 and 350 degrees a

moderate amount of smoke will issue from

within the oven. Preservative oils and oil

accumulated during manufacture will

come off as smoke at these temperatures.

Do not be alarmed.

NORMAL OPERATION

PREHEATING

The oven will not bake uniformly if not

allowed to thoroughly preheat before

loading the product. To compensate for

the temperature loss during loading, set

the oven thermostat 50

desired cooking temperature,

then reset the thermostat to the proper

temperature after closing the oven door.

The oven can be preheated with the 3Heat switches set on any position,

however, the fastest preheat will be

accomplished with both the switches set

to the "High" position. Once the oven is at

the set temperature and the product is

loaded reset the 3-Heat switches to their

proper setting. An indicator light, located

below the oven thermostat knob, will go

out once the oven has recieved the set

temperature. Allow the oven indicator

lamp to cycle on and off at least two times

during the preheat.

degrees over the

load the oven,

OVEN RACK

The oven is equipment with a removable

rack as standard. Baking pies, bread, or

for roasting operations the rack can be

placed directly on the metal deck and the

pans placed on the rack. For cakes or

pastries the rack can be slid into the rack

supports, located about halfway up the

oven sides, and the pans placed on the

rack in this raised position.

8

Page 11

CONTROL PANEL

3-HEAT SWITCHES

While the oven thermostat controls the

temperature, the 3-Heat switches control the

amount of power from the upper and lower

elements. Setting the top element 3-Heat

switch to "High" will burn (or broil) the tops

and setting the bottom 3-Heat switch to "Low"

will not cook the bottom of most products. Set

the 3-Heat switches to achieve the best

uniformity between the top and bottom of the

Class of

product

Average

Temperature

Switch Settings Rack Position

Top Bottom

product. Best results for baking will be

accomplished with the top 3-Heat switch set to

the "Low" position and the bottom 3-Heat

switch set to either "Medium" or "High".

The following Temperature Switch Setting and

Rack Position chart is suggested as a guide in

baking the various classes of product. Be

aware this chart is only a suggestion

temperature, switch settings and rack

positions will be arrived at through experience.

Pie 375-425 Low Medium On Deck

Rolls 375-400 Low High Rack Support

Cake 350-400 Low High Rack Support

Pastries 325-375 Low High Rack Support

Bread 425-450 Low Medium On Deck

. Correct

Roast 300-325 Low Medium On Deck

9

Page 12

PAN PLACEMENT

Place the pan in the center of the oven

rack for the best baking results. Keep the

oven door closed as much as possible.

Excessively opening the oven door will

cool the front section of the oven and the

products placed near the opening will

bake slower.

VENT CONTROL

The oven is supplied with an oven vent

control located above the thermostat dial.

If cooking products with high moisture

content open the vent by pulling the knob

out. The moisture will be vented out the

back of the oven as steam. If the

products require a moist baking

environment push the vent damper

closed.

TIMER

A 60 minute mechanical timer is supplied

as standard equipment. To set, turn the

dial until the desired time is at the top of

the dial. If setting the timer for less than

10 minutes the dial must first be turned

past the 10 minute mark then reset to the

required time. Once the timer has timedout it will sound a bell for about 5 seconds

then automatically turn off.

10

Page 13

PRODUCTIVE MAINTENANCE

"Productive Maintenance" is defined as a means of keeping the appliance as efficient and productive

after years of service as it was when new.

CLEANING

Cleaning the appliance on a regular basis will assure years of efficient performance and

maintain the gleaming appearance it has when new.

Clean the exterior of the oven using a mild soap and water solution. Rinse with clear water

and a damp rag.

Do not

CAUTION

The oven interior must be cleaned with a cleaner that states it is "Safe on

Aluminum". Use of any other cleaner will severely damage the coating on the

inside of the oven and it can not be repaired.

Pay particular attention around the door opening, door edges and at the bottom of the door

so the door continues to close tightly. Should the paint around the door opening begin to

wear off, it can be recoated using a high temperature silver paint found in any hardware

store.

use a pressure washer of any kind to clean the appliance exterior or interior.

THERMOSTAT CALIBRATION

All thermostats are factory calibrated and are extremely reliable mechanical devices.

Thermostat calibration should be attempted only when continued experience indicates

inaccurate cooking temperatures and then only after the calibration of the thermostat has

been thoroughly checked.

However, as the appliance becomes older the thermostat should be checked once a year in

order to make minor adjustments to the calibration.

CALIBRATION CHECK PROCEDURE

Locate an oven thermometer or thermocouple in the center of the oven cavity.

Set the thermostat to 350°F degrees, the upper element 3-Heat switch to "Low", and the

lower element 3-Heat switch to "High".

Allow the oven to heat for at least one hour before attempting any calibration check.

Watch the red indicator lamp below the thermostat dial. When the lamp comes on the oven

elements are "cycling on", when the indicator lamp goes out the elements are "cycling off".

After the oven has heated of an hour record the temperature of the oven when the indicator

lamp "cycles on".

Allow the oven to continue heating and record the temperature when the indicator lamp

"cycles off".

Continue taking the "cycle on" and "cycle off" readings three times.

After 3 complete "cycles" average the six temperature readings (add them up and divide by

6). The average temperature should be within 25 degrees, plus or minus, of 350°F degrees.

11

Page 14

CALIBRATION ADJUSTMENT

A 1/16 inch flat blade screwdriver with a 2 inch shaft is required to adjust the thermostat.

Maintain the oven temperature at 350°F degrees.

Without turning the thermostat dial, pull it off the shaft of the thermostat.

Locate the screw at the base of the thermostat shaft; this is the thermostat calibration screw.

Insert a small flat blade screwdriver down the thermostat shaft until it contacts the screw.

Grasp the thermostat shaft so it does not move while turning the calibration screw.

Use caution when making adjustments to the thermostat, a 1/8 turn of the calibration screw

will adjust the oven temperature about 5 to 7 degrees.

To raise the oven temperature, turn the calibration screw Counter-Clock-Wise.

To lower the oven temperature, turn the calibration screw Clock-Wise.

Reinstall the oven knob and recheck the oven temperature

.

12

Page 15

INSTALLATION TROUBLE SHOOTING GUIDE

SYMPTOM PROBLEM CAUSE

Not Heating Breakers off

Reset Breakers

Not Connected to Power

Improper Phasing at Terminal

Block

Defective Thermostat

Connect to Power

Correct Phasing

Replace Thermostat

One Deck Works Others Do

Not

Internal Circuit Breakers off

Ovens Not Interconnected

Improper Phasing at Terminal

Block

Reset Breakers

Connect all Decks to Lower

Terminal Block

Correct Phasing

Circuit Breakers Trip Supply and Oven Voltage Do

Not Match

Thermostat Capillary Tube

Shorted to Element

Correct Voltage Mismatch

Replace Thermostat to Clear

Short

Too Long To Preheat Supply and Oven Voltage Do

Not Match

"3-Heat" Switches Set on Low

Correct Voltage Mismatch

Set Switches to High

13

Page 16

SK2423 Rev. - 6/08/09

Model:

DO36 Deck Oven

LA36 Deck Oven

2

1

3

5

6

7

1

9

1

10

11

12

13

14

15

16

8

4

See Detail A

See Detail B

Page 17

PARTS LIST June 8, 2009, Rev -

Model No: DO36

36” Bake Deck Oven

Key

Number

1 2C-20103-02 37 SCRW SM PLT 10 X .5 PHLSL

2 N9-LA36-159 1 TOP LA OVEN S/S DO36L (LOWER STACKED UNITS)

N9-LA36-159-1 1 TOP LA OVEN S/S DO36

3 2N-11050-25 2 ELE 36OVN 240V O/S 1.8KW DO36-240VM

2N-11050-29 2 ELMNT 36” OVEN 480V O/S DO36-440VM, DO36-480V, CLDO36L-440V

2N-11050-31 2 ELE 36”OVN 208V O/S 1.8KW DO36-208VM

4 2N-11050-26 2 ELE 36OVN 240V I/S 1.2KW DO36-240VM

2N-11050-30 2 ELMNT 36” OVEN 480V I/S DO36-440VM, DO36-480V, CLDO36L-440V

2N-11050-32 2 ELE 36”OVN 208V I/S 1.2KW DO36-208VM

5 P9-50301-09 12 LONG ELEMENT CLIP S/S

6 P9-50301-10 12 SHORT ELEMENT CLIP

7 2C-20301-15 8 NUT HEX 10-32 PLTD

8 N9-LA36-109-1 1 CAPILLARY SHIELD

9 2P-70901-05 1 PLGBTNBLKPLSTC 3/4DP-750

10 2E-31200-02 1 LUG GROUNDING UL APPROVED

11 2C-20103-01 2 SCRW SM PLT 10X7/8 PHIL

12 2E-30500-07 1 TRM BLOCK 3PLELRGE 125AMP

13 N9-LA36-128 1 SWITCH DOOR ASSY

14 N9-LA36-193 1 DOOR ASSY A/L

15 2M-60301-43 1 DIE CAST PLT LANG SATIN

16 N9-LA36-184 1 DECK CHANNEL ASSY A/L

NI 2A-72500-06 4 LEG 5 1/2 W/BOLT DOWN ADJ CLDO36L-440V

NI 2B-50200-09 1 RACK 36 OVEN

NI 2B-50200-52 1 RACK 36 OVEN CRUISE LINE CLDO36L-440V

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

2

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 18

SK2424 Rev. - 6/08/09

Model:

DO36 Deck Oven, Details A & B

LA36 Deck Oven, Details A & B

33

1

3

5

11

10

12

13

14

15

17

18

20

21

22

23

24

25

28

29

30

15

31

32

27

26

19

16

6

7

8

9

4

2

Detail A

Detail B

Page 19

PARTS LIST June 8, 2009, Rev -

Model No: DO36

36” Bake Deck Oven, Details A & B

Key

Number

1 N9-LA36-116 1 VENT PIPE ASSY

2 2T-30402-07 1 STAT ADJ 550o 48 C/T

3 2E-30304-35 2 SWTROT3HT 240/480VAC20AMP

4 2J-30801-01 1 TIMER MECHANICAL LONG

5 N9-LA36-130 1 CONTROL SLIDE ASSY

6 2C-20103-02 37 SCRW SM PLT 10 X .5 PHLSL

7 2C-20303-01 1 NUT HX SS 1/4-20

8 2R-70701-25 1 KNOB DAMPER BLACK PLAIN

9 Y9-70701-10-1 2 KNOB 3-HEAT 208-240V

10 Y9-70701-12-1 1 KNOB 550o A PHANTOM

11 Q9-70701-09-1 1 KNOB MANUAL TIMER PHANTOM

12 2J-31601-01 1 PILOT LT 250V 6LEAD BLK 208V, 240V, 440V

12 2J-31601-02 1 PILOT LT 480V 6LEAD BLK DO36-480V, DO36-480VM

13 2C-20101-77 2 SCRW MS PLT 6-32 X .25

14 2E-31800-01 2 CB 250V50A 1 POLE CRLNGSW DO36-208VM

14 2E-31800-04 1 CB 480V 50A 3-POLE DO36-480V, DO36-480VM, CLDO36L-440V

15 2C-20102-04 4 SCRW PHD ST 8-32X.5 PLTD

16 2C-20102-06 2 SCRW PHD ST 6-32X3/8 PLTD

17 Q9-50312-81 1 BREAKER HOLDER

18 2C-20301-29 2 NUT HEX ACORN 1/4-20 S/S

19 2C-20204-02 2 WASHER SS 1/4 SPLIT LOCK

20 N9-LA36-142 1 DOOR INSIDE PANEL

21 2H-LA36-312 1 INSULATION DOOR #2

22 2H-LA36-311 1 INSULATION DOOR #1

23 2A-50800-07 2 TENSION DISC STD OVEN

24 2A-LA36-145 2 DOOR RODS LA36

25 2A-LA36-146 2 DOOR PIPE LA36

26 2P-51001-01 1 SPRING OVN LH DOOR

26 2P-51001-02 1 SPRING OVN RH DOOR

27 2C-20105-04 2 SCREW SET 1/4-20X1/2

28 2C-20101-24 3 SCRW MS PLT 10-32 X .375

29 K9-60301-43-1 1 DIE CAST LOG + TINNERMAN

30 P9-50312-79 RANGE HANDLE

31 2R-50800-91 1 DOOR HANDLE

32 2C-20101-10 2 SCRW THD MS 1/4-20X2 1/4

33 Y9-50300-38 1 HANDLE MARINE MARINE APPLICATIONS

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

2

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 20

WIRING DIAGRAM

15

Page 21

1

2ND DECK

3RD DECK

TERMINAL BLOCK

1ST DECK

L1 L2 L3

LA-336S "

USE ON ALL E SERIAL NUMBERS

6.0

6.0

2

36S RANGE

LA-236S "

LA-136S OVEN

6.0

6.0

6.0

10.0

0.0

0.0

1

2L1CL2

3

1

5

NUMBER

MODEL

L1 L2 L2 L3 L3 L1

KW PER PHASE

LOADING

C21L1

3

L2

4

2ND AND 3RD DECK

WIRING IDENTICAL

TO 1ST DECK

OVEN WIRING

2

2

3

4

5

6

CONNECT WIRES FROM RANGE

TOP OR ADDITIONAL DECKS TO

LOWER OVEN TERMINAL BLOCK

AS SHOWN AT RIGHT

7

CIRCUIT BREAKER

SPEED UNIT

6 HEAT SWITCH

3 HEAT SWITCH

PILOT LAMP

1

HEAT ELEMENT

THERMOSTAT

36S-10

36S-20

36S-2

36S-3A

36S-0

MODEL DESIGNATION

SCALE:

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

ANGLES

± .5°

.XXX ± .015

.XX ± .03

TO FIT

NEXT HIGHER ASSY.

SHEET

OF

2M-61106-01

DRAWING NUMBER REV

DR:

CK:

FRACTIONS DECIMALS

± 1/64

TOLERANCES

DATE:

DATE:

PART NUMBERQTY ITEM DESCRIPTION / MATERIAL

2-1-94

.X ± .05

208/240VAC

LANG MANUFACTURING

TITLE:

LA36 OVEN / 36S RANGE

CREATED BY STUART R. CARTIER

6.0

18.0

50.0

50.0

50.0

43.3

43.3

43.3

86.5

75.0

6.0

12.0

50.0

28.8

28.8

43.3

25.0

25.0

57.7

50.0

0.0

6.0

28.8

28.8

0.0

25.0

25.0

0.0

28.8

25.0

5.0

21.0

45.8

66.7

62.5

39.7

57.8

54.2

101.0

87.5

TOTAL

L1

L2

L3

L1

L2

L3

208V

240V

KW

ELECTRICAL DATA

PHASE

208 VOLT 240 VOLT

THREE PHASE AMPS

L3 2-4-6

-2

SINGLE

PHASE AMPS

21-21

PHASE

THREE

L2

L1

L2

1-532-4-6

2

1

2

-12

SUPPLY

SINGLE

BLOCK

L1

TOP

1-3-5 1

1st DECK 2nd DECK 3rd DECK

1

SEC-1

A

B

B

A

C

SEC-2

A

B

B

A

55

POWER

5

ABC

TERMINAL

GRILL HOT TOP SPEED UNITS

RANGE

ELECTRICAL CONNECTIONS

4

5

2

55

2

OVEN

C

SEC-3

C

B

C

A

C

2000

3000

1

4

4

2134 2134

7

2

1

1667

1

3

2

4

3

1667

1

1667

4

2

3

1

6

TOP ARRANGEMENT

ECN NO.REV DESCRIPTION DR: DATEMFG ENG

TOP SECTION WIRE DIAGRAMS

REVISION BLOCK

D

Page 22

TERMINAL BLOCK

1

4A

8A

8B

8C

8A

1ST DECK

2

5

L1 L2 L3

36S RANGE

LA-236S "

LA-336S "

LA-136 OVEN

3

3

L2

L1

1B

1A2

NUMBER

MODEL

1

2L1C

L2

7

3

5B 5A

L3

1C

4A

8B

8C

C21L1

L2

4

66

7

TO LOWER OVEN TERMINAL

BLOCK

CONNECT WIRES FROM RANGE

TOP TO OVEN CIRCUIT

BREAKER. CONNECT WIRES

FROM ADDITIONAL DECKS

6 HEAT SWITCH

2ND DECK

1

3

4

5

6

3 HEAT SWITCH

PILOT LAMP

CIRCUIT BREAKER

SPEED UNITS

3RD DECK

2ND AND 3RD DECK

WIRING IDENTICAL

TO 1ST DECK

3

2

2

1

36S-10

36S-20

HEAT ELEMENT

THERMOSTAT

1

36S-3A

2

36S-2

3

36S-0

OVEN WIRING

MODEL DESIGNATION

SCALE:

NONE

OF

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

± 1/64

ANGLES

± .5°

.XXX ± .015

.XX ± .03

.X ± .05

NEXT HIGHER ASSY.

480 VAC

SHEET

6.0

USE ON ALL E SERIAL NUMBERS

6.0

6.0

18.0

21.7

21.7

21.7

PART NUMBERQTY ITEM DESCRIPTION / MATERIAL

FRACTIONS DECIMALS

TOLERANCES

DR: SRC

CK:

DATE:

DATE:

2-1-94

LANG MANUFACTURING

TITLE:

LA36 OVEN / 36S RANGE

CREATED BY STUART R. CARTIER

6.0

0.0

6.0

12.0

21.7

12.5

12.5

6.0

0.0

0.0

6.0

12.5

12.5

0.0

6.0

10.0

5.0

21.0

19.9

28.9

27.1

L1 L2 L2 L3 L3 L1

TOTAL

L1

L2

L3

KW PER PHASE

LOADING

ELECTRICAL DATA

KW

PHASE

480 VOLT

AMPS

L3 2-4-6

-2

BREAKER

POWER

THREE

SUPPLY

ABC

L1

L2

CONNECT TO

BREAKER

OVEN CIRCUIT

1-5

31

1st DECK 2nd DECK 3rd DECK

BOTTOM DECK TERMINAL BLOCK

2

GRILL HOT TOP SPEED UNITS

RANGE TOP

ELECTRICAL CONNECTIONS

UPPER OVENS CONNECT TO

OVEN 3 POLE

CIRCUIT

L1

L2

L3

TO BREAKER TO BREAKER TO BREAKER

123456

B

A

C

SEC-1

TOP ARRANGEMENT

A

B

SEC-2

A

B

B

A

C

SEC-3

C

B

C

A

C

2000

4

2

4

4

3

2

3000

1

ECN NO.REV DESCRIPTION DR: DATEMFG ENG

TOP SECTION WIRE DIAGRAMS

1667

1

1667

1

1667

2

REVISION BLOCK

2M-61106-10

DRAWING NUMBER REV

D

-

21-

1

2134 2134

4

2

7

2

1

3

1

4

3

6

Page 23

Page 24

STAR MANUFACTURING GROUP

Star - Holman - Lang - Wells - Bloomeld

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(800) 807-9054 (314) 781-2777

Parts & Service (800) 807-9054

www.star-mfg.com

Loading...

Loading...