Lang Manufacturing 224ZT Installation Manual

ENVIROZONE-TSTAT

GAS GRIDDLE

Commercial

224ZT, 236ZT, 248ZT, 260ZT, 272ZT

Installation and

Operation

Instructions

2M-W1785 Rev. C 4/23/15

272ZT

IL2412

SAFETY SYMBOL

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

The installation of the Appliance must conform to the NATIONAL FUEL GAS CODE "ANSI Z223.1 - LATEST

EDITION" AND ALL LOCAL GAS COMPANY RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE CURRENT CAN/CGA-B149.1 NATURAL

GAS INSTALLATION CODE OR CAN/CGA-B149.2 PROPANE INSTALLATION CODE AND LOCAL CODES WHERE

APPLICABLE.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS. THIS INFORMATION

SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS SUPPLIER. AS A MINIMUM, TURN

OFF THE GAS AND CALL YOUR GAS COMPANY AND YOUR AUTHORIZED SERVICE AGENT.

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATION

& MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

These symbols are intended to alert the user to the presence of important operating

and maintenance instructions in the manual accompanying the appliance.

FOR YOUR SAFTEY

THE VICINTIY OF THIS OR ANY OTHER APPLIANCE.

POST IN PROMINENT LOCATION

EVACUATE ALL PERSONNEL FROM THE AREA.

WARNING

EQUIPMENT.

WARNING

RISK OF FIRE OR ELECTRIC SHOCK

DO NOT OPEN

WARNING, TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE

CONTROL PANEL. NO USER-SERVICABLE PARTS INSIDE.

REPAIRS SHOULD BE DONE BY AUTHORIZED SERVICE PERSONNEL ONLY.

NOTICE

Using any part other than genuine Lang factory supplied parts relieves the manufacturer of all liability.

Lang reserves the right to change speci cations and product design without notice. Such

revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies and regulations, the

specifications contained in this sheet are subject to change without notice. While Lang

Manufacturing exercises good faith efforts to provide information that is accurate, we are

not responsible for errors or omissions in information provided or conclusions reached as a

result of using the speci cations. By using the information provided, the user assumes all risks in con-

nection with such use.

MAINTENANCE AND REPAIRS

Contact your local dealer for service or required maintenance. Please record the model number, serial

number, voltage and purchase & Installation Information in the area below and have it ready when you

call to ensure a faster service.

Model No.:

Serial No.:

Voltage:

1-Phase or 3 Phase:

Purchased From:

Location:

Purchase Date:

Installed Date:

2

PROBLEMS, QUESTIONS or CONCERNS

Before you proceed consult you authorized Lang service agent directory

or

Call the Lang Technical Service & Parts Department at (314) 678-6315

TABLE OF CONTENTS

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation

Leg Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilation & Clearence . . . . . . . . . . . . . . . . . . . . . . 7

Electrical & Gas Connection. . . . . . . . . . . . . . . . . . . . 8

Initial Start-Up

Initial Lighting Procedure . . . . . . . . . . . . . . . . . . . . . 9

Seasoning Cooking Surface . . . . . . . . . . . . . . . . . . . . 9

Operation

Setting the Griddle Temperature . . . . . . . . . . . . . . . . .10

Suggested Times and Temperatures . . . . . . . . . . . . . . .10

Loading the Griddle . . . . . . . . . . . . . . . . . . . . . . . . 11

Sequence of Operation

Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance

Daily Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Weekly Cleaning . . . . . . . . . . . . . . . . . . . . . . . . .12

Burner Air Shutter Adjustment . . . . . . . . . . . . . . . . . . . 12

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting

Symptoms / Possible Causes / Test . . . . . . . . . . . . . . . . 14

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .15 - 17

Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . 18-23

NOTICE ServiceonthisoranyotherLangappliancemustbeperformedbyqualied

personnel only. Consult your Lang Authorized Service Agent Directory.

You can call technical service at (314) 678-6315 or visit our website

WWW.LANGWORLD.COM for the service agent nearest you.

3

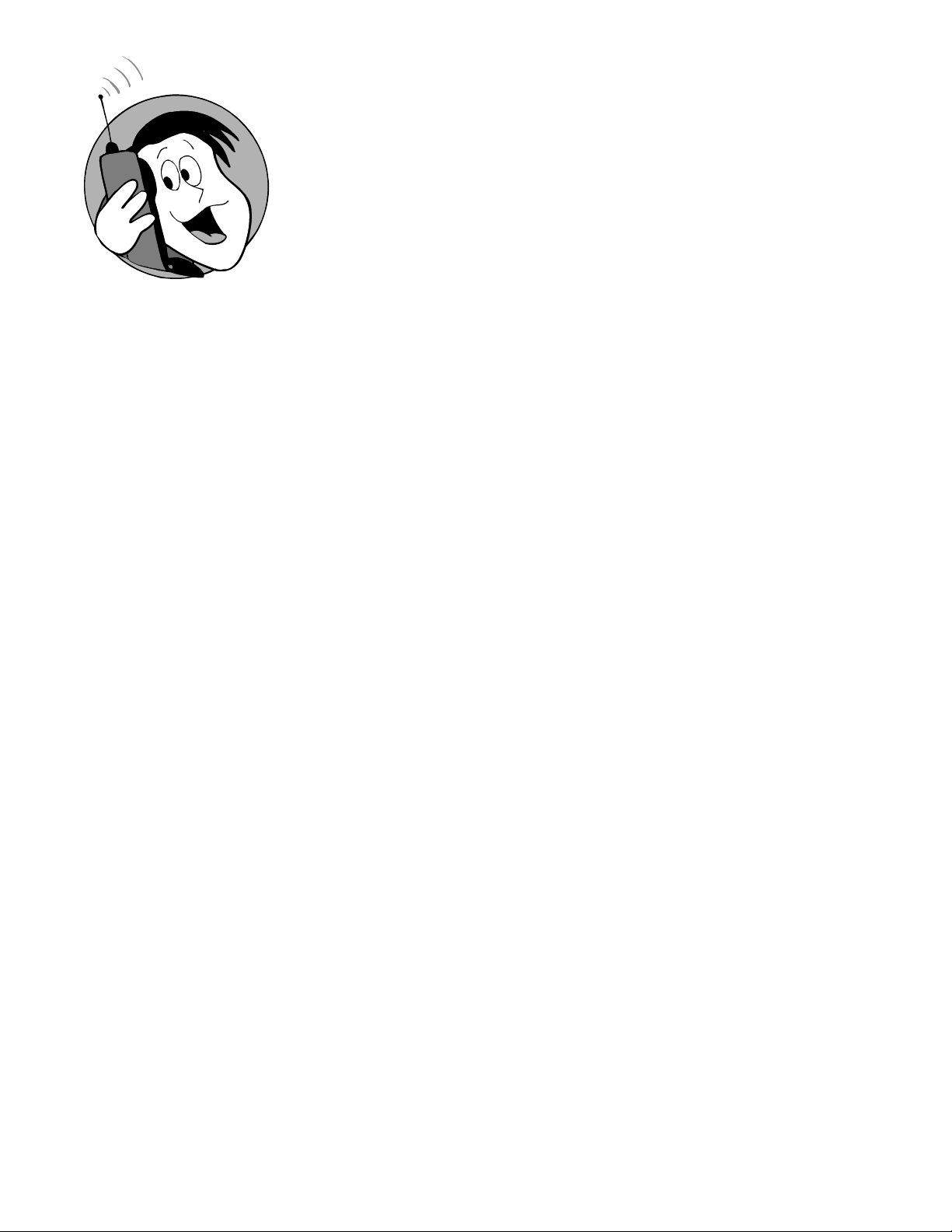

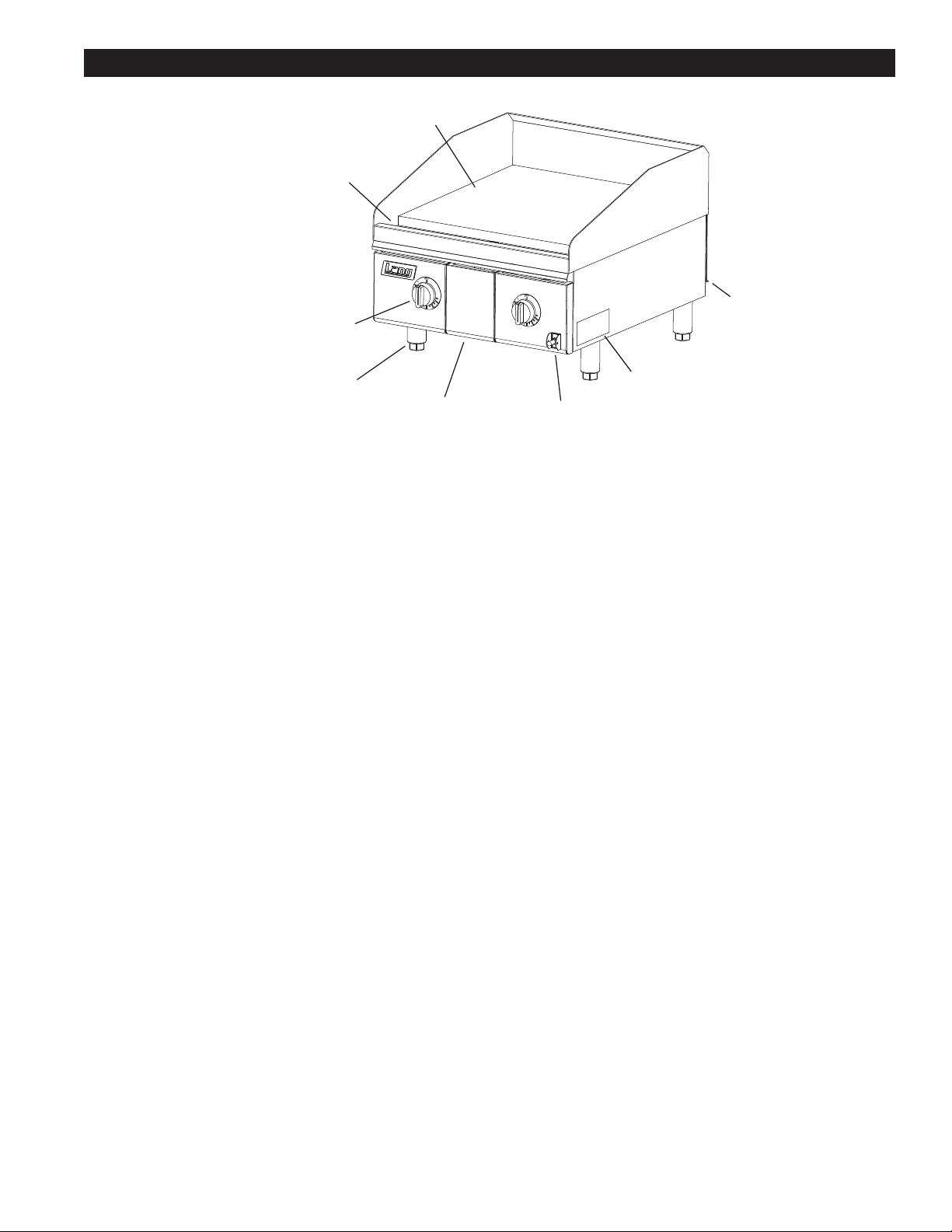

Front Side

Top

31.375”

16.5”

20”

4”

IL2411

EQUIPMENT SPECIFICATIONS

GAS AND ELECTRIC INPUT REQUIRMENTS

MODEL

NUMBER

224ZT

224ZTD 30” 70,000 70,000

236ZT

236ZTD 30” 105,000 105,000

248ZT

248ZTD 30” 140,000 140,000

260ZT

260ZTD 30” 175,000 175,000

272ZT

272ZTD 30” 210,000 210,000

DESCRIPTION TOTAL BTU INPUT

Unit

Width

24”

36”

48”

60”

72”

Griddle Surface

Depths

24” 54,000 54,000

24” 81,000 81,000

24” 108,000 108,000

24” 135,000 135,000

24” 162,000 162,000

NATURAL PROPANE

5” WC 10” WC VOLTAGE AMPS

GAS

CONNECTION

ELECTRICAL

CONNECTION

CORD/PLUG

& PRESSURE

REGULATOR

ONE 3/4” NPT 115 VOLT 2 SUPPLIED

MODEL

NUMBER

224ZT

224ZTD 30 “ 720

236ZT

236ZTD 30 “ 1,080

248ZT

248TDC

260ZT

260ZTD 30 “ 1,800

272ZT

272ZTD 30 “ 2,160

GRILL SURFACE

OVERALL

WIDTH DEPTH SIDES BACK BOTTOM ACTUAL SHIPPING

24 “

36 “

48 “

60 “

72 “

23 “ 552

23 “ 828

23 “ 1,104

30 “ 1,440

23 “ 1,380

23 “ 1,656

SPECIFICATIONS AND INFORMATION

SQUARE

INCHES OF

GRIDDLE

NUMBER

BURNERS

NUMBER OF

OF

CONTROLS

2 2 1 0 “ 5 “ 4 INCH LEG 255 300

3 3 1 0 “ 5 “ 4 INCH LEG 336 400

4 4 2 0 “ 5 “ 4 INCH LEG 435 500248ZTD

5 5 2 0 “ 5 “ 4 INCH LEG 530 625

6 6 2 0 “ 5 “ 4 INCH LEG 610 725

NUMBER

OF GREASE

DRAWERS

CLEARANCE FROM NON-

COMBUSTIBLE SURFACES

4

WEIGHT

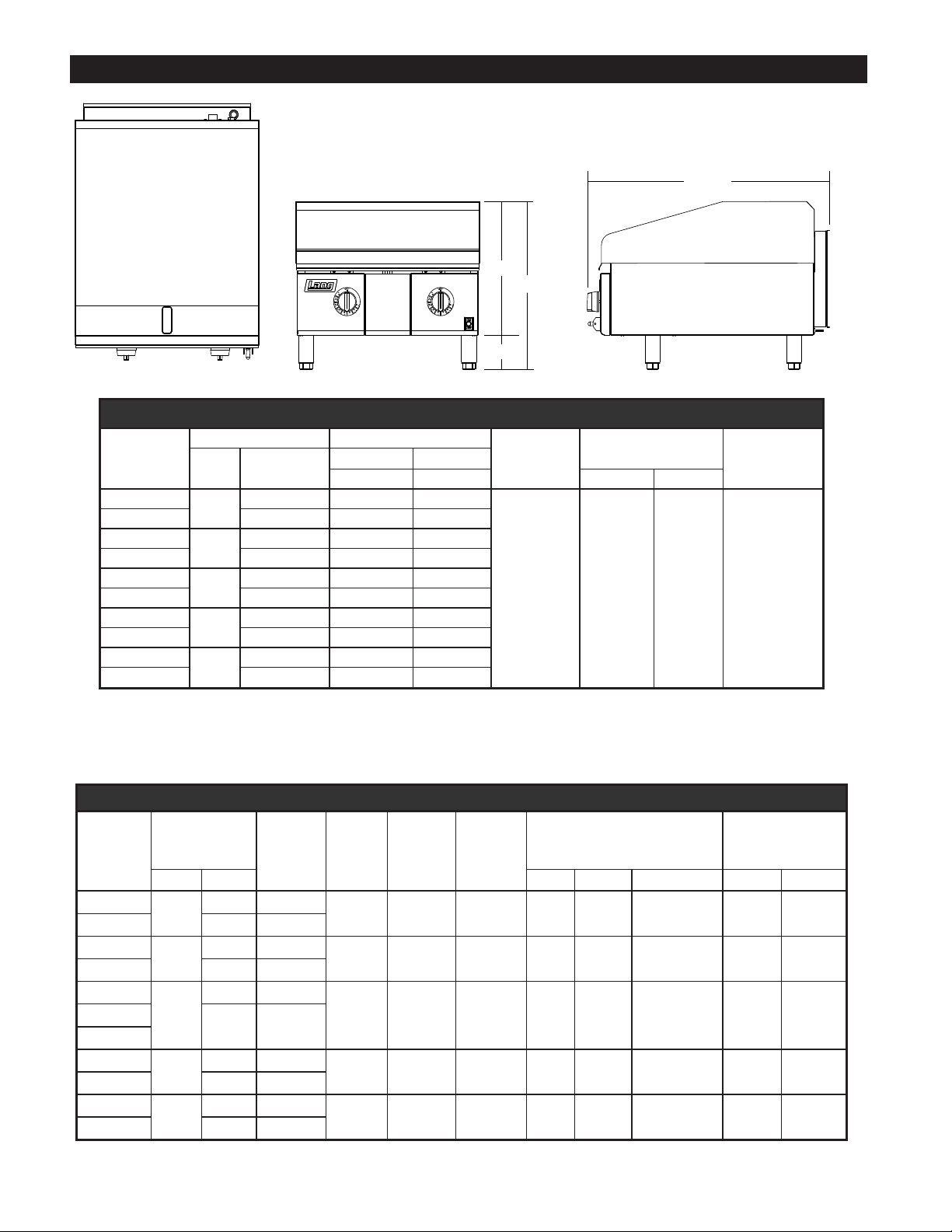

EQUIPMENT DESCRIPTION

1” Griddle Surface

Gutter

Section Temp Dial

Wall Anchor

& Gas Inlet

Adj. Legs

Grease Pan Main Power Switch

Nameplate

IL2410

Exterior Construction

The griddle dimensions are 17” (43.18cm) High, 30” (76.20cm) Deep, and width is dependent on the actual model

number.

The Sides, Bottom, and Rear wall are constructed of double wall stainless steel, which allows closer installation to

combustible surfaces.

The griddle surface is made of 1” thick, highly polished steel to reduce hot and cold spots, recovery problems,

warping, and ensure even heat to the edges of the griddle.

Operation

• Each 12” section has its own snap-action thermostat and gas valve that are fully “ON” or fully “OFF”.

• The control has factory congurable maximum and minimum temperature settings. The maximum temperature

value can be set at 550°F (288°C). The minimum temperature value can be set at 200°F (93°C).

Technical

• Griddle operates on either Natural gas or Propane, which must be specied when ordering.

• It is shipped with a power cord and plug attached.

• Floor space required is 30” (76.20cm) Deep, and width is 2 ft, 3ft, 4ft, 5ft, or 6ft depending on actual model

number.

• The griddle weighs 255, 336, 435, 530, 610 lbs. depending on actual model number.

GriddleGasandVoltageSpecications

The Lang Model can be connected to any 120 Volt source. The gas and electrical specications are listed in the

table on the previous page.

NOTICE The data plate is on the right side of the griddle. The voltage, wattage, serial

number,wiresize,andclearancespecicationsareonthedataplate.This

information should be carefully read and understood before proceeding with

the installation.

5

CAUTION

UNPACKING

Receiving the Griddle

Upon receipt, check for freight damage, both visible and concealed.

Visible damage should be noted on the freight bill at the time of delivery and

signed by the carrier’s agent. Concealed loss or damage means it does not

become apparent until the merchandise has been unpacked. If concealed

loss or damage is discovered upon unpacking, make a written request for

inspection by the carrier’s agent within 15 days of delivery. All packing

material should be kept for inspection. DO NOT return damaged

merchandise to Lang Manufacturing. File your claim with the carrier.

Location

Prior to un-crating, move the griddle as near to its intended location as practical. The crating will help

protect the unit from the physical damage normally associated with moving it through hallways and

doorways.

Un-crating

The griddle will arrive completely assembled inside a wood frame and strapped to a skid.

Cut the straps and remove the wood frame.

The griddle can now be removed from the skid.

THE UNIT IS EXTREMELY HEAVY. FOR SAFE HANDLING, INSTALLER SHOULD

OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE MATERIALS HANDLING

EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR PALLET JACK)

TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH GRIDDLE WILL BE

LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE GRIDDLE.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

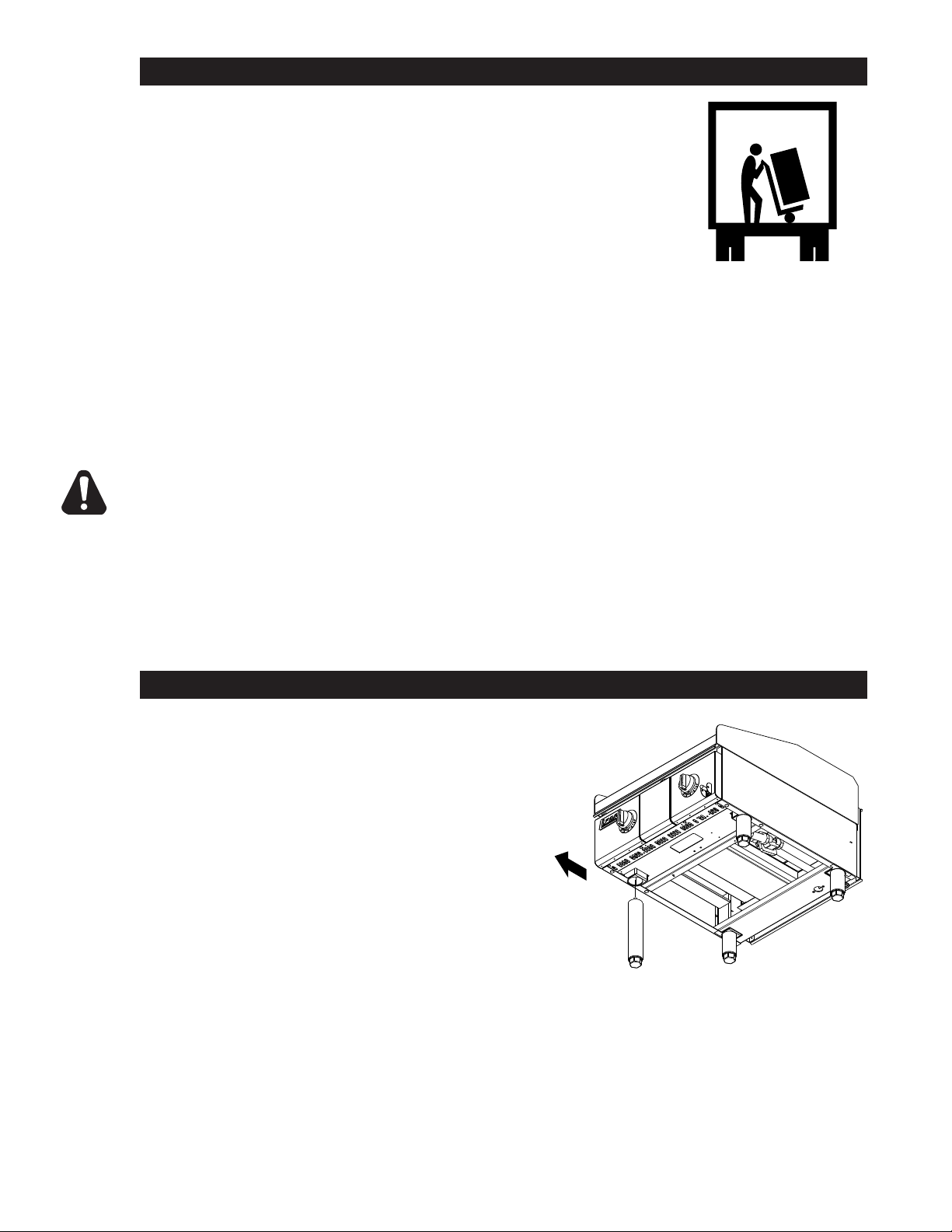

LEG INSTALLATION

The legs are installed by sliding the threaded ends of the

legs into the leg receiver tubes located in each corner of

the griddle.

Slide the leg up until contact is made with the threaded

nut at the top of the reciever tube. Screw the leg counterclockwise until it is hand tight.

After the griddle is in its nal position, adjust the legs to

create 1/8 inch slant from back to front. This will allow the

grease to run into the front grease gutter and provide the

proper combustion air for the burners. It will also allow

exposed gasses to escape out the rear of the unit.

Level unit by adjusting the (4) legs for accurate and perfect

lineup with other units.

Front

IL2379

6

VENTILATION & CLEARENCE

CLEARANCE

For use on non-combustible countertops only.

Combustible and non-combustible material must be at least 48” (120cm) from the top of the

appliance. Combustible material must be 5” (150mm) from the sides and back, while clearance to

non-combustible material on the sides and back is 0”. Adequate clearance should also be provided

for proper operation and servicing.

AIR SUPPLY

Make certain not to obstruct the ow of combustion and ventilation air. Provisions for adequate air

supply must be furnished. The legs supplied with the unit must be installed. Make certain that air

intake openings in the bottom of the appliance are not obstructed. They are essential for proper

combustion and operation of the appliance.

EXHAUST CANOPY

It is essential that facilities be provided over the griddle to carry off fumes and gases. However,

the unit should not be directly connected to a ue or stack.

7

INSTALLATION

Electrical Connection

The griddle is supplied with a cord and plug. The receptacle is not provided with the griddle.

Follow the receptacle manufacturer’s instructions when connecting the receptacle to the power supply.

Gas Connection

This griddle is manufactured for use with the type of gas indicted on the nameplate.

Contact the factory if your type of gas does not match the nameplate data.

All gas connectors must be in accordance with local codes and comply with the National Fuel Federal

Gas Codes ANSI Z223.1 latest edition.

This appliance should be installed with a separate gas valve in the gas line ahead of the unit. Use a

3/4 inch or larger gas supply line.

Remove the 5/16 inch nuts securing the rear of burners. These nuts are for securing the main burners

during transportation only. The rear burner shield must be removed to gain access to the nuts.

A pressure regulator for the type of gas specied is installed on each appliance.

This regulator must be installed in the gas supply line. (Note the direction of the gas ow arrow.)

The pressure in the manifold of the appliance should be tested with a manometer and the regulator

adjusted for proper pressure with the appliance operating at full re. A 1/8 inch NPT tap is provided in

the manifold for connecting a manometer.

Correct manifold pressures are:

5 inches water column for natural gas

10 inches water column for propane

When replacing the plug in the manifold, a pipe joint compound or sealant should be used that is

resistant to the action of liquid petroleum gas.

Initial adjustments are the responsibility of the installer and are not chargeable to Lang Manufacturing

International.

After the griddle is in its nal position, adjust the legs to create 1/8 inch slant from back to front.

This will allow the grease to run into the grease gutter and provide the proper combustion air for the

burners.

DANGER: THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL

PROVIDED. FAILURE TO GROUND THE APPLIANCE COULD

RESULT IN ELECTROCUTION AND DEATH.

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL

WARNING

AND/OR DAMAGE TO EQUIPMENT. UNIT MUST BE INSTALLED IN

ACCORDANCE WITH ALL APPLICABLE CODES.

NOTICE: The data plate is located on the right side of the griddle. The

griddlevoltage,serialnumber,gasspecications,andclearance

specicationsareonthedataplate.Thisinformationshould

be carefully read and understood before proceeding with the

installation.

NOTICE: The installation of any components such as a vent hood, grease

extractors,reextinguishersystems,mustconformtotheir

applicable National, State and locally recognized installation

standards.

8

Loading...

Loading...