Lang Manufacturing 124s Service Manual

SELECTRONIC

ELECTRIC GRIDDLE

Commercial & Marine

124S, 124SHE

136S, 136SHE

148S, 148SHE, 148SR

160S, 160SHE, 160SR, 160S-SC

172S, 172SR, 172SC

Installation and

Operation

Instructions

2M-W353 Rev. G 10/13/08

148S

IL1381

1

SAFETY SYMBOL

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS. THIS

INFORMATION SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS SUPPLIER.

AS A MINIMUM, TURN OFF THE GAS AND CALL YOUR GAS COMPANY AND YOUR

AUTHORIZED SERVICE AGENT. EVACUATE ALL PERSONNEL FROM THE AREA.

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION,

OPERATION & MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

FOR YOUR SAFTEY

THE VICINTIY OF THIS OR ANY OTHER APPLIANCE.

POST IN PROMINENT LOCATION

WARNING

SERVICING THIS EQUIPMENT.

WARNING

RISK OF FIRE OR ELECTRIC SHOCK

DO NOT OPEN

WARNING, TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE

CONTROL PANEL. NO USER-SERVICABLE PARTS INSIDE.

REPAIRS SHOULD BE DONE BY AUTHORIZED SERVICE PERSONNEL ONLY.

NOTICE

Using any part other than genuine Lang factory supplied parts relieves the manufacturer of all

liability.

Star reserves the right to change speci¿ cations and product design without notice. Such

revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies and regulations, the

speci¿ cations contained in this sheet are subject to change without notice. While Star

Manufacturing exercises good faith efforts to provide information that is accurate, we are

not responsible for errors or omissions in information provided or conclusions reached as a

result of using the speci¿ cations. By using the information provided, the user assumes all risks

in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local dealer for service or required maintenance. Please record the model number, serial

number, voltage and purchase & Installation Information in the area below and have it ready when you

call to ensure a faster service.

Model No.:

Purchased From:

Serial No.:

Voltage:

1-Phase or 3 Phase:

Location:

Purchase Date:

Installed Date:

2

PROBLEMS, QUESTIONS or CONCERNS

Before you proceed consult you authorized Lang service agent directory

or

Call the Lang Technical Service & Parts Department at 1-800-807-9054.

TABLE OF CONTENTS

Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . 6

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation

Leg Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ventilation & Clearence . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . 9

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Phasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Initial Start-Up

Pre-Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Seasoning Cooking Surface . . . . . . . . . . . . . . . . . . . . 10

Operation

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Suggested Times and Temperatures . . . . . . . . . . . . . . . 11

Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Troubleshooting

Symptoms / Possible Causes . . . . . . . . . . . . . . . . . . . 13

Possible Causes / Test . . . . . . . . . . . . . . . . . . . . . . 14

Wiring Diagram

208/240VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

480VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

380VM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . 18-26

NOTICE Service on this or any other Lang appliance must be performed by qualifi ed

personnel only. Consult your Lang Authorized Service Agent Directory.

You can call our toll free number 1-800-807-9054 or visit our website

WWW.STAR-MFG.COM for the service agent nearest you.

3

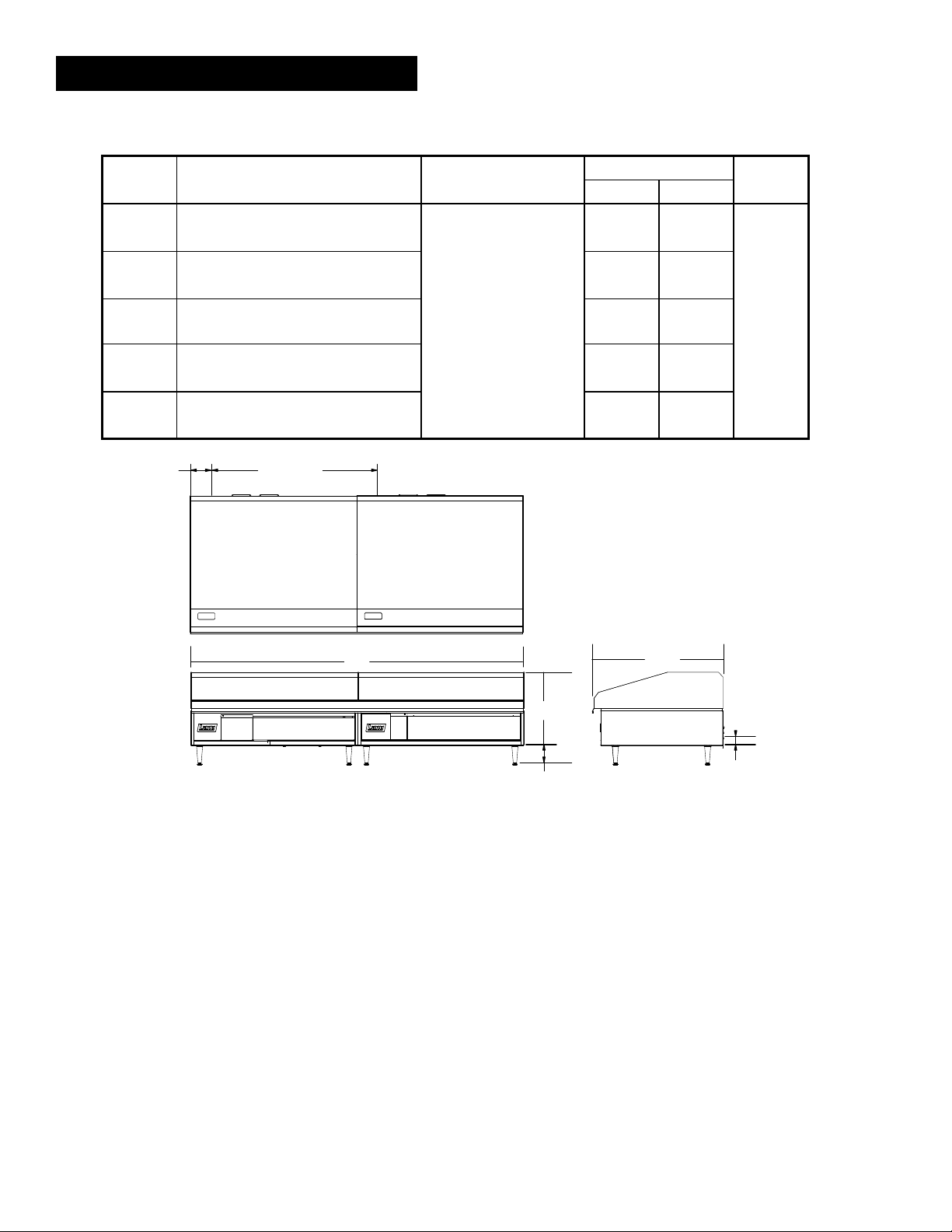

EQUIPMENT SPECIFICATIONS

Height x Width x Depth Clearance from Weight

Model

124

136

148

160

172

15.0" x 24.0" x 28.2" 243 lbs. 280 lbs.

381mm x 610mm x 717mm 110 kg 127 kg

15.0" x 36.0" x 28.2" 368 lbs. 410 lbs.

381mm x 914mm x 717mm 167 kg 186 kg

15.0" x 48.0" x 28.2" Sides: 2" 483 lbs. 515 lbs.

381mm x 1219mm x 717mm Back: 2" 220 kg 234 kg

15.0" x 60.0" x 28.2" 621 lbs. 665 lbs.

381mm x 1524mm x 717mm 282 kg 302 kg

15.0" x 72.0" x 28.2" 724 lbs. 800 lbs.

381mm x 1830mm x 717mm 329 kg 364 kg

Freight Class(Not including legs) combustible surface Actual Shipping

85

6.8”

Elec. Connect.

36”

Elec. Connect.

(160 & 172 only)

W

H

4” (101.6mm)

D

IL1547

2.5”

Elec. Connect.

4

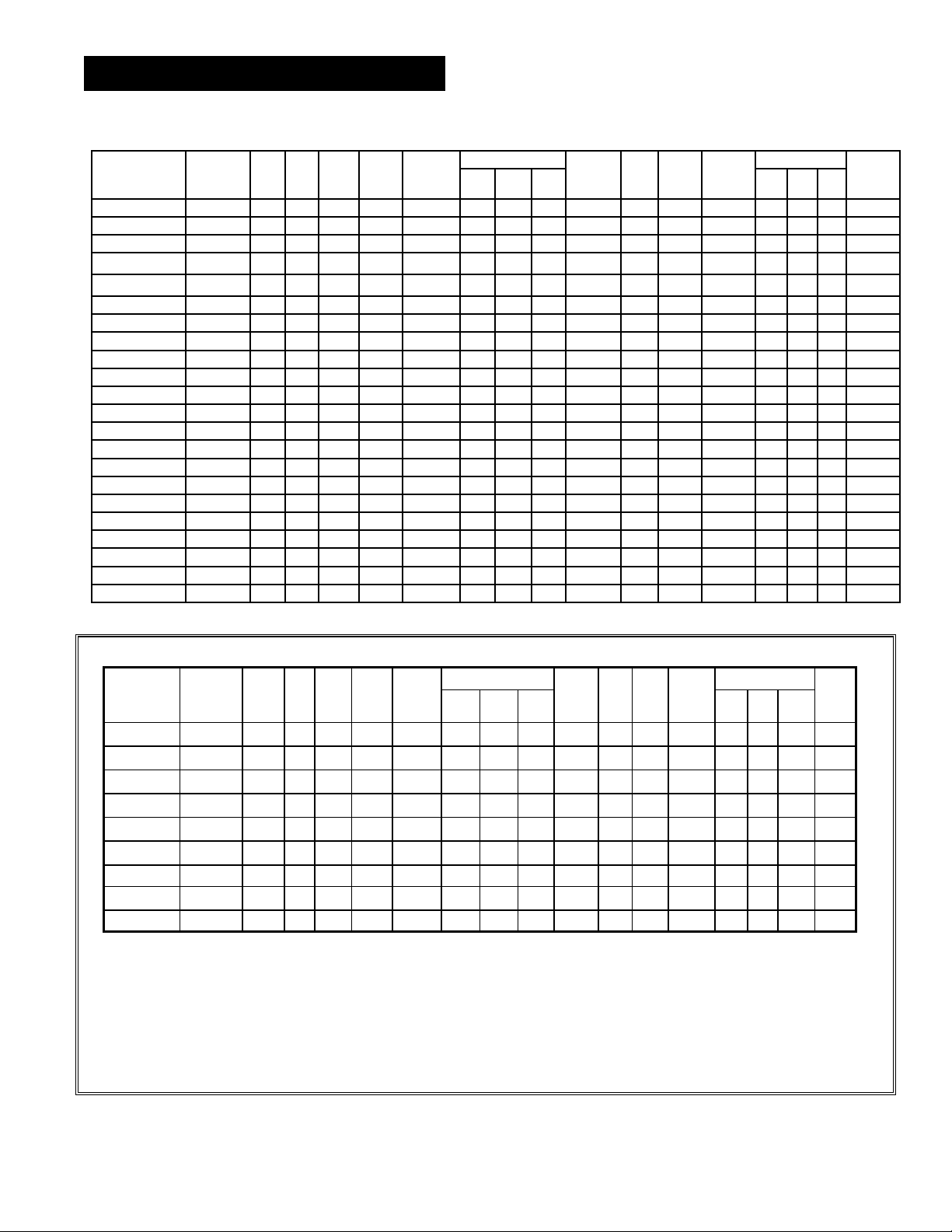

EQUIPMENT SPECIFICATIONS

SPECIFICATIONS

Current Model Volts AC Hz. PH. Kw

124S 208/240 60 1/3 12 58 4 50 29 29 6

124S-480V 480 60 3 12 22 13 13 12

124SHE 208/240 60 1/3 12 58 4 50 29 29 6

136S 440 60 1/3 18 87 2 50 50 50 6

136S-480V 480 60 3 18 22 22 22 12

136SB-WB 208/240 60 1/3 18 87 2 50 50 50 6

136SHE 208/240 60 1/3 18 87 2 50 50 50 6

148S 208/240 60 1/3 24 116 1 75 75 50 3

148S-480V 480 60 3 24 33 33 22 8

148SHE-480V 480 60 3 24 33 33 22 8

148S-SC 208/240 60 1/3 24 116 1 75 75 50 3

160S 208/240 60 1/3 1 58 2 50 29 29 6 18 87 2 50 50 50 6

160S-480V 480 60 3 12 22 13 13 12 18 22 22 22 12

160SC 208/240 60 1/3 12 58 4 50 29 29 6 18 87 2 50 50 50 6

160SHE 208/240 60 1/3 12 58 2 50 29 29 6 18 87 2 50 50 50 6

160SR 208/240 60 1/3 12 58 2 50 29 29 6 18 87 2 50 50 50 6

160S-SC 208/240 60 1/3 12 58 2 50 29 29 6 18 87 2 50 50 50 6

160S-WB 208/240 60 1/3 12 58 2 50 29 29 6 18 87 2 50 50 50 6

172S 208/240 60 1/3 18 87 2 50 50 50 6 18 87 2 50 50 50 6

172S-480V 480 60 3 18 22 22 22 12 18 22 22 22 12

172SR 208/240 60 1/3 18 87 2 50 50 50 6 18 87 2 50 50 50 6

172S-SC 208/240 60 1/3 18 87 2 50 50 50 6 18 87 2 50 50 50 6

TOT

Amp

1PH.

Supply

Wire

1 PH

Amp 3 Ph Supply

L1 L2 L3 L1 L2 L3

Wire

3 PH

Kw

TOT

Amp

1PH.

Supply

Wire

1 PH

Amp 3 Ph Supply

Wire

3 PH

SPECIFICATIONS MARINE

Current Model Volts AC Hz. Ph. Kw

124S-440VM 440V 50/60 3 10.1 20 12 12 12

124S-480VM 480V 60 3 12 22 13 13 12

136S-380VM 380V 60 3 18 27.3 27.3 27.3 10

136S-440VM 440V 60 3 18 23.6 23.6 23.6 12

136S-480VM 480V 60 3 18 22 22 22 12

148S-480VM 480V 60 3 24 33 33 22 8

160S-M 208/240V 60 1/3 12 58 2 50 29 29 6 18 87 2 50 50 50 6

172S-440VM 440V 60 3 18 23.6 23.6 23.6 12 18 23.6 23.6 23.6 12

172SM 208/240V 60 1/3 18 87 2 50 50 50 6 18 87 2 50 50 50 6

TOT.

Amp

1PH.

Supply

Wire 1

PH

Amp 3 Ph

L1 L2 L3 L1 L2 L3

Supply

Wire 3

PH

Kw

TOT.

Amp

1PH.

Supply

Wire 1

PH

Amp 3 Ph

Supply

Wire 3

PH

MARINE EQUIPMENT IS APPROVED FOR INSTALLATION ONLY ON VESSELS GREATER

THAN 65 FEET IN LENGTH, IN ACCORDANCE WITH USCG REGULATIONS IN TITLE 46

CFR 110-113.

ANY WIRING USED IN THE INSTALLATION OF THIS APPLIANCE MUST BE STRANDED

COPPER.

5

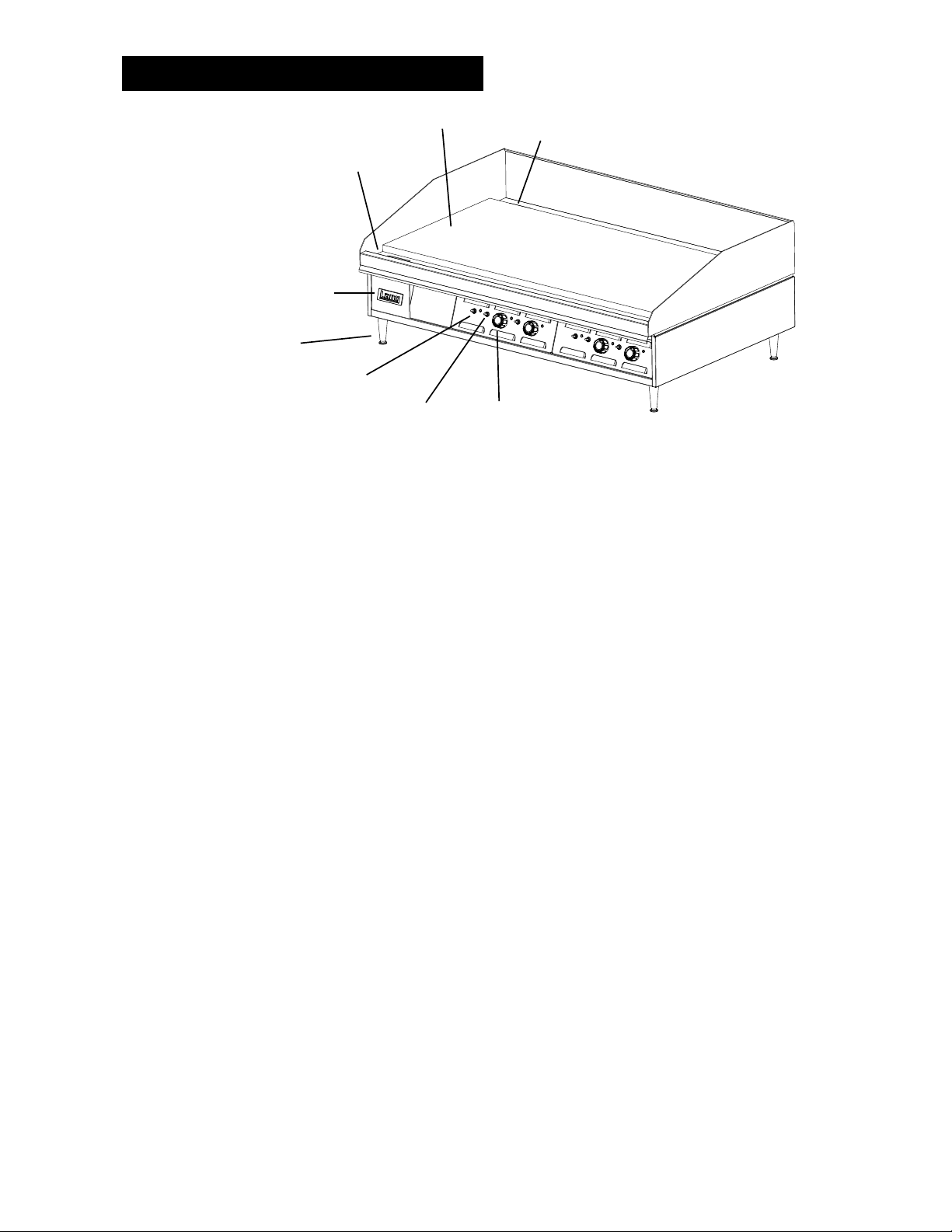

EQUIPMENT DESCRIPTION

Rear Gutter

(certian models)

IL1548

Grease Pan

Legs

Main Section

Power Switch

Gutter

Power Switch

1” Griddle Surface

Section

Temp. Dial

Section

Exterior Construction

The griddle dimensions are 17” (43.18cm) High, 30” (76.20cm) Deep, and width is dependent on the

actual model number.

The Sides, Bottom, and Rear wall are constructed of double wall stainless steel, which allows closer

installation to combustible surfaces.

The griddle surface is made of 1” thick, highly polished steel to reduce hot and cold spots, recovery

problems, warping, and ensure even heat to the edges of the griddle.

Controls

Each twelve-inch section has its own temperature selector switch that snaps into place to lock in any

temperature from 175°F to 450°F (79°C to 232°C) in 25° increments.

Each twelve-inch section of the griddle is controlled by an area sensitive RTD probe, which can sense

and react to a temperature change of +/- 4°F.

Each twelve-inch section has a set of 6 K.W. elements for high effi ciency, quick recovery and outstanding

performance

Technical

The 100 Series Selectronic griddle operates on either 208/240V or 480V, at either single or three phase.

This must be specifi ed when ordering.

Minimum clearances: 2” from side and back

NOTICE The data plate is on the right side of the griddle. The oven voltage,

wattage, serial number, wire size, and clearance specifi cations are

on the data plate. This information should be carefully read and

understood before proceeding with the installation.

6

CAUTION

UNPACKING

Receiving the Griddle

Upon receipt, check for freight damage, both visible and concealed.

Visible damage should be noted on the freight bill at the time of delivery and

signed by the carrier’s agent. Concealed loss or damage means it does not

become apparent until the merchandise has been unpacked. If concealed

loss or damage is discovered upon unpacking, make a written request for

inspection by the carrier’s agent within 15 days of delivery. All packing

material should be kept for inspection. Do not return damaged

merchandise to Star Manufacturing Company. File your claim with the

carrier.

Location

Prior to un-crating, move the oven as near to its intended location as practical. The crating will help

protect the unit from the physical damage normally associated with moving it through hallways and

doorways.

Un-crating

The griddle will arrive completely assembled inside a wood frame and strapped to a skid. Cut the

straps and remove the wood frame.

The oven can now be removed from the skid.

THE UNIT IS EXTREMELY HEAVY. FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR PALLET JACK)

TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH OVEN WILL BE

LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE GRIDDLE.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

7

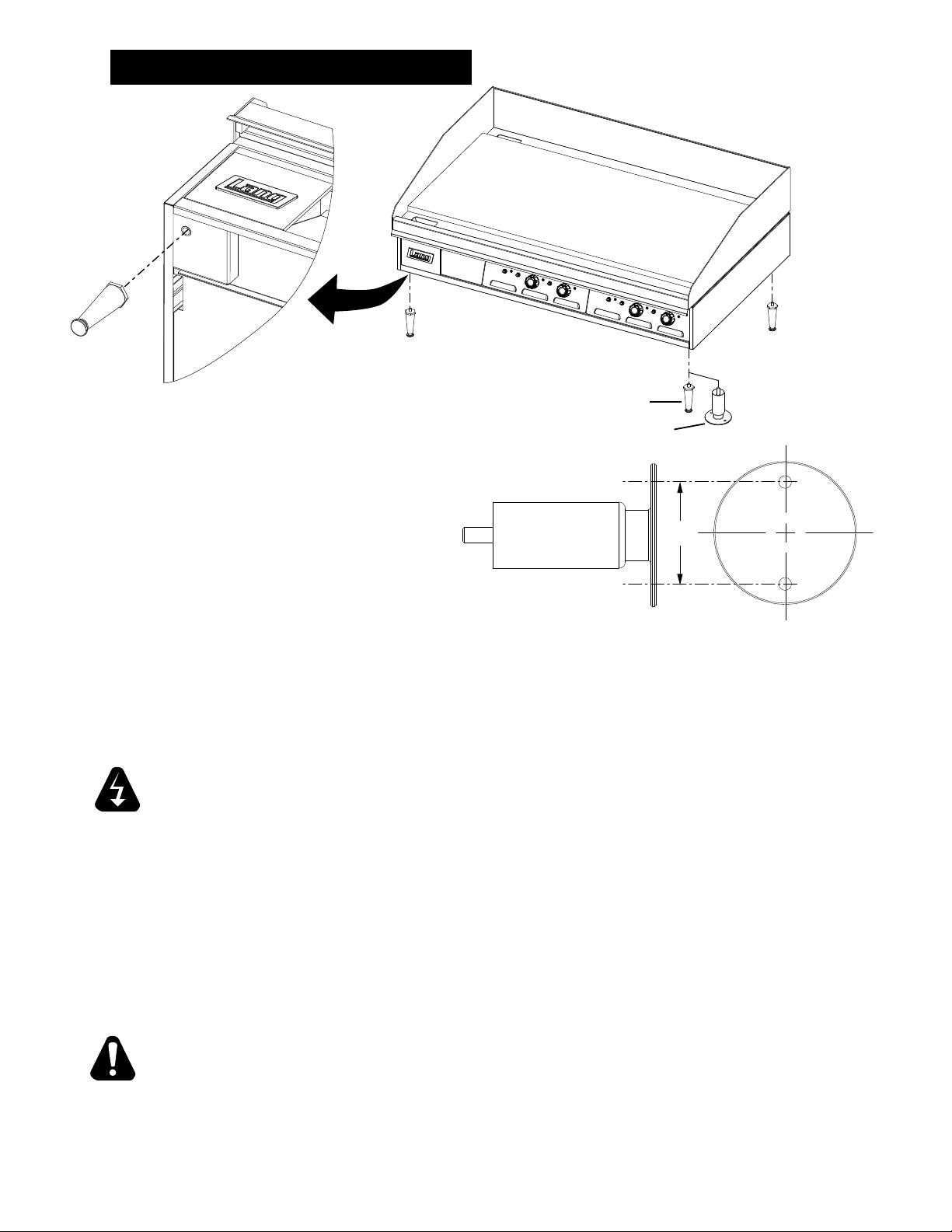

INSTALLATION

Std Leg

Marine Bolt Down Leg

Above: typical leg installation.

Leg Installation

There are four, 4” legs provided for 2, 3 and

4 foot griddles.

There are eight 4” legs provided for 5 and 6

foot griddles.

The legs are shipped in the grease drawers

of the griddle. Install them into the threaded

holes on the underside of the griddle body.

Leveling adjustment may be done by screwing the bottom portion of the leg in and out.

For bolt down legs see above illustration for dimensions.

2.5”

IL1549

IL1550

DANGER: THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL PROVIDED.

FAILURE TO GROUND THE APPLIANCE COULD RESULT IN ELECTROCUTION

AND DEATH.

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL QUALIFIED TO

WORK WITH ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN

WARNING

CAUSE INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. UNIT

MUST BE INSTALLED IN ACCORDANCE WITH ALL APPLICABLE CODES.

NOTICE: The data plate is located behind access panel between controls and grease

drawer. The grill voltage, wattage, serial number, wire size, and clearance

specifi cations are on the data plate. This information should be carefully

read and understood before proceeding with the installation.

NOTICE: The installation of any components such as a vent hood, grease extractors,

fi re extinguisher systems, must conform to their applicable National, State

and locally recognized installation standards.

ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

CAUTION

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR FALLS.

8

Loading...

Loading...