Copyright © Februar 2019

User manual

FLS 106 IC set / FLS 106 PCB set

IC scanner 4-axis positioning system /

PCB scanner 3-axis positioning system

- Translation of the original German user manual into English -

2019.07.04 User Manual FLS 106 eng

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Table of contents: Page

Declaration of Conformity............................................................................................ 6

1

General Remarks .......................................................................................................... 7 2

User Manual ........................................................................................................................ 7 2.1

Reading and Understanding the User Manual ..................................................................... 7 2.2

Local Safety and Accident Prevention Regulations .............................................................. 7 2.3

Images ................................................................................................................................ 7

2.4

Limitation of Liability ............................................................................................................ 7 2.5

Errors and Omissions .......................................................................................................... 7 2.6

Copyright ............................................................................................................................. 7 2.7

Description of Symbols ................................ ................................ ................................ ........ 8 2.8

Scope of Delivery ......................................................................................................... 9

3

FLS 106 IC Scope of Delivery * ........................................................................................... 9 3.1

FLS 106 PCB Scope of Delivery * ....................................................................................... 9 3.2

Technical Parameters ................................................................................................ 10 4

General Parameters of the FLS 106 Scanner .................................................................... 10 4.1

Technical Parameters of the Subassemblies ..................................................................... 11

4.2

UH DUT ................................................................ ................................ ....................... 11 4.2.1

Claw 01 and Claw 02 ................................................................................................... 11 4.2.2

GND 25 Holder............................................................................................................. 12 4.2.3

GND 25 Ground Plane ................................................................................................. 13 4.2.4

SH 01 Probe Holder ..................................................................................................... 13

4.2.5

SUH 106 Safety Enclosure ........................................................................................... 14 4.2.6

External NA5 EMERGENCY STOP Switch .................................................................. 14 4.2.7

Requirements for the ChipScan-Scanner Software ............................................................ 15 4.3

Intended Use ............................................................................................................... 16 5

Staff requirements ............................................................................................................. 16

5.1

Risks if Not Used for Its Intended Purpose ........................................................................ 17 5.2

Safety Instructions ............................................................................................................. 17 5.3

Hazard Due to Electrical Voltage .................................................................................. 17 5.3.1

Hazard Due to Movements along the Axes .................................................................. 18 5.3.2

Airborne noise emission if used for its intended purpose ................................................... 18

5.4

Safety Devices ................................................................................................ ............ 19 6

Prerequisites for Safe Operation ........................................................................................ 19 6.1

Operation with the Protective Enclosure ....................................................................... 19 6.1.1

Operation with a Spatial Separation ............................................................................. 19 6.1.2

Switching the Scanner on in Normal Operation and after a Power Failure ......................... 19

6.2

EMERGENCY STOP Switch ................................ ............................................................. 19 6.3

- 2 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Overcurrent Protective Device ................................ ................................ ........................... 19 6.4

Environmental Protection .......................................................................................... 20 7

Nameplate ................................................................................................................... 20

8

Overview of the FLS 106 Scanner ............................................................................. 21 9

Description of the Subassemblies ...................................................................................... 21 9.1

Guide Rails along the X-Axis ........................................................................................ 21 9.1.1

Guide Rails along the Y-Axis (Long Side)..................................................................... 22 9.1.2

Z-Axis Tower ................................................................................................................ 22

9.1.3

Gantry .......................................................................................................................... 23 9.1.4

Rotary Unit ................................................................................................................... 23 9.1.5

Aluminium Mounting Bracket ........................................................................................ 24 9.1.6

T-Slot Table ................................................................................................................. 25 9.1.7

Control Panel with EMERGENCY STOP Device and Control LEDs ............................. 26

9.1.8

Height-Adjustable Machine Feet .................................................................................. 26 9.1.9

ON / OFF Switch ................................ ................................ .......................................... 27 9.1.10

Connectors ........................................................................................................................ 27 9.2

Connectors on the Z-Axis Tower .................................................................................. 27 9.2.1

Connectors on the Control Panel ................................................................................. 28

9.2.2

Power Supply Socket ................................................................................................... 28 9.2.3

Connector for External Emergency Stop Switch or Safety Enclosure ........................... 29 9.2.4

Overview of Attachments........................................................................................... 30 10

KA 220 Camera Arm ......................................................................................................... 30 10.1

DM-CAM Holder.3 ............................................................................................................. 30

10.2

DM-CAM with Camera Screw ............................................................................................ 31 10.3

Clamping Pieces................................................................................................................ 32 10.4

UH DUT with Claw 01 and Claw 02 ................................................................................... 32 10.5

GND 25 Holder ................................ ................................................................ .................. 33 10.6

GND 25 Ground Plane....................................................................................................... 33

10.7

SH 01 Probe Holder .......................................................................................................... 34 10.8

Delivery ....................................................................................................................... 35 11

Acceptance Inspection....................................................................................................... 35 11.1

Storage .............................................................................................................................. 35 11.2

Opening the Transport Box ................................................................................................ 35

11.3

Packaging.......................................................................................................................... 35 11.4

Preparations for Putting the FLS 106 Scanner into Service ................................... 36 12

Preparations for the Safe Operation of the FLS 106 Scanner ............................................ 36 12.1

Setting Up the FLS 106 Scanner ....................................................................................... 36 12.2

Removing the Transport Protection from the Guide Rails ................................ .................. 38

12.3

Information on the Pre-Installed Components' Torque ....................................................... 38 12.4

- 3 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Checking / Releasing the EMERGENCY STOP Switch ..................................................... 39 12.5

Putting the FLS 106 Scanner into Service for the First Time.................................. 40 13

Installation................................................................................................................... 41

14

Ensuring the System's Safe Operation .............................................................................. 41 14.1

Operation with the SUH 106 Safety Enclosure ............................................................. 41 14.1.1

Operation with Spatial Separation and External NA 5 EMERGENCY STOP Switch ..... 41 14.1.2

Checking the Cables of the Rotary Unit ............................................................................. 43 14.2

Installing the Digital DM-CAM Microscope Camera on the FLS 106 IC .............................. 43

14.3

Installing the DM-CAM Holder.3 for the Microscope Camera........................................ 43 14.3.1

Installing the Digital DM-CAM Microscope Camera ...................................................... 44 14.3.2

Installation of the Digital DM-CAM Microscope Camera on the FLS 106 PCB ................... 45 14.4

Connecting the C13/C14 Device Lead ............................................................................... 45 14.5

Connecting a Computer ..................................................................................................... 46

14.6

Connecting a Measuring Device for Near-Field Scans by Taking a Spectrum Analyzer as 14.7

an Example ................................................................................................................................ 46

Switching the FLS 106 Scanner on .................................................................................... 47 14.8

Software Installation .................................................................................................. 48 15

Installing the scanner driver ............................................................................................... 48 15.1

Installing the ChipScan-Scanner Software ......................................................................... 50 15.2

Putting the FLS 106 Scanner into Service with the ChipScan-Scanner Software ............... 51 15.3

Fastening the Device Under Test .............................................................................. 53 16

Fastening a Device Under Test With the Clamping Pieces ................................................ 53 16.1

Fastening a Circuit Board with the UH DUT Universal Holder ............................................ 54 16.2

Installing the UH DUT................................................................................................... 55 16.2.1

Fastening the GND 25 Ground Plane for IC Measurements .............................................. 56 16.3

Installing the GND 25 Ground Plane ............................................................................ 56 16.3.1

Information on Using the GND 25 Ground Plane .......................................................... 57 16.3.2

Installing the GND 25 Holder ........................................................................................ 57 16.3.3

Installing an ICR Near-Field Microprobe................................................................... 59 17

Laying the Connecting Cables ................................................................ ........................... 59 17.1

Connecting the ICR Near-Field Microprobe ....................................................................... 61 17.2

Installing the BT 706 Bias-Tee ........................................................................................... 63 17.3

Collision control of the ICR probe ...................................................................................... 63 17.4

Installing a Near-Field Probe with the SH 01 Probe Holder .................................... 65 18

Installing a Near-Field Probe on the FLS 106 IC ................................................................ 65 18.1

Connecting a Near-Field Probe Directly to the FLS 106 IC Scanner ............................. 66 18.1.1

Connecting a Near-Field Probe With a Pre-Amplifier .................................................... 67 18.1.2

Installing a Near-Field Probe on the FLS 106 PCB ............................................................ 68 18.2

Connecting a Near-Field Probe Directly to the FLS 106 PCB Scanner ......................... 70 18.2.1

- 4 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Connecting a near-field probe with a pre-amplifier ....................................................... 70 18.2.2

Collision Control for the Near-Field Probe.......................................................................... 71 18.3

Information on How to Operate the FLS 106 Scanner ............................................. 72

19

Checking the Measuring Set-Up before Each Use ............................................................. 72 19.1

Adjusting the Exact Height of the Probe Tip above the DUT .............................................. 72 19.2

Estimating the Duration of a Measurement with the FLS 106 Scanner .............................. 73 19.3

Number of Measuring Points ........................................................................................ 73 19.3.1

19.3.2

Travel Distance ............................................................................................................ 73

Sweep Time ................................................................................................................. 73 19.3.3

Transmission Time ....................................................................................................... 73 19.3.4

Storage Requirements for the Measurement ..................................................................... 73 19.4

After Completing the Measurement ................................................................ .......... 74 20

Dismantling after Completing the Measurement(s) ................................................. 74

21

Removing the ICR Probe ................................................................................................... 74 21.1

Removing the Near-Field Probe ........................................................................................ 74 21.2

Removing the SH 01 Probe Holder from the FLS 106 IC ................................................... 74 21.3

Removing the Pre-Amplifier / BT 706 Bias-Tee.................................................................. 74 21.4

Removing a Device Under Test from the T-slot Table........................................................ 75

21.5

Removing a Circuit Board from the UH DUT ...................................................................... 75 21.6

Removing the UH DUT ...................................................................................................... 75 21.7

Removing the GND 25....................................................................................................... 75 21.8

Removing the GND 25 Holder ........................................................................................... 75 21.9

Removing the DM-CAM Microscope Camera ................................................................ 75

21.10

Removing the DM-CAM Holder.3 Camera Holder ......................................................... 75 21.11

Maintenance ................................................................................................................ 76 22

Maintenance Intervals........................................................................................................ 76 22.1

Replacing Labels and Signs .............................................................................................. 76 22.2

Dismantling/Disposal ................................................................................................. 77

23

Hazards during Dismantling/Disposal ................................................................................ 77 23.1

Dismantling ........................................................................................................................ 77 23.2

Disposal ............................................................................................................................ 77 23.3

Customer Service ....................................................................................................... 78 24

Warranty ...................................................................................................................... 79 25

- 5 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Declaration of Conformity 1

Manufacturer:

Langer EMV-Technik GmbH

Nöthnitzer Hang 31

01728 Bannewitz

Germany

Langer EMV-Technik GmbH herewith declares that the

FLS 106 IC / FLS 106 PCB positioning system

conforms with the following relevant regulations:

- Machinery Directive 2006/42 EC

- EMC Directive 2014/30/EU

- RoHS 2011/65/EU

The system complies with the protection objectives of the Low Voltage Directive 2014/35/EU.

The following applicable standards were used to implement the requirements specified by the

aforementioned directives:

- DIN EN ISO 12100:2011 (Safety of Machinery – General Principles for Design – Risk assessment

and risk reduction)

- DIN EN 60204-1:2014-10 (Safety of Machinery – Electrical equipment of machines – Part 1:

General requirements)

- EN 61000-6-4:2007 (Generic Standards – Emission standard for industrial environments)

- EN 61000-6-2:2006 (Generic Standards – Immunity for industrial environments)

Name of the person authorised to compile the technical file:

Gunter Langer

Bannewitz, 02.04.2019

Signature:

_________________

(Signature)

G. Langer, Managing Director

- 6 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

General Remarks 2

User Manual 2.1

This user manual enables the safe and efficient use of the FLS 106 scanner. It must be kept with

the scanner so that it is accessible for the user.

Reading and Understanding the User Manual 2.2

Read the user manual carefully, observe the safety information (section 5.3) and follow the

instructions given in this manual before putting the device into service.

Local Safety and Accident Prevention Regulations 2.3

The local accident prevention and general safety regulations also apply to ensure that the FLS 106

scanner is used for its intended purpose.

Images 2.4

Figures have been included in this user manual to assist the reader's understanding but may differ

from the device's actual version.

Limitation of Liability 2.5

In the following cases, Langer EMV-Technik GmbH can assume no liability for damage to property

and personal injury if:

- The information given in this user manual has not been observed.

- The FLS 106 scanner was operated by staff not qualified in the field of EMC.

- The FLS 106 scanner was subjected to unauthorised modifications or technical changes.

- The FLS 106 scanner was not used according to its intended purpose.

- Spare parts or accessories were used that had not been approved by EMV-Technik GmbH.

The actual scope of delivery may deviate from the illustrations and texts in this user manual due to

the customisation of orders or due to technical changes and innovations.

Errors and Omissions 2.6

The information in this manual has been carefully checked and is believed to be accurate;

however, the Langer EMV-Technik GmbH assumes no responsibility for any clerical, typographical,

or proofreading errors, or omissions.

Copyright 2.7

The content of this user manual is protected by copyright law and may only be used in connection

with the FLS 106 scanner. This user manual may not be used for any other purpose without the

prior written approval of Langer EMV-Technik GmbH.

- 7 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

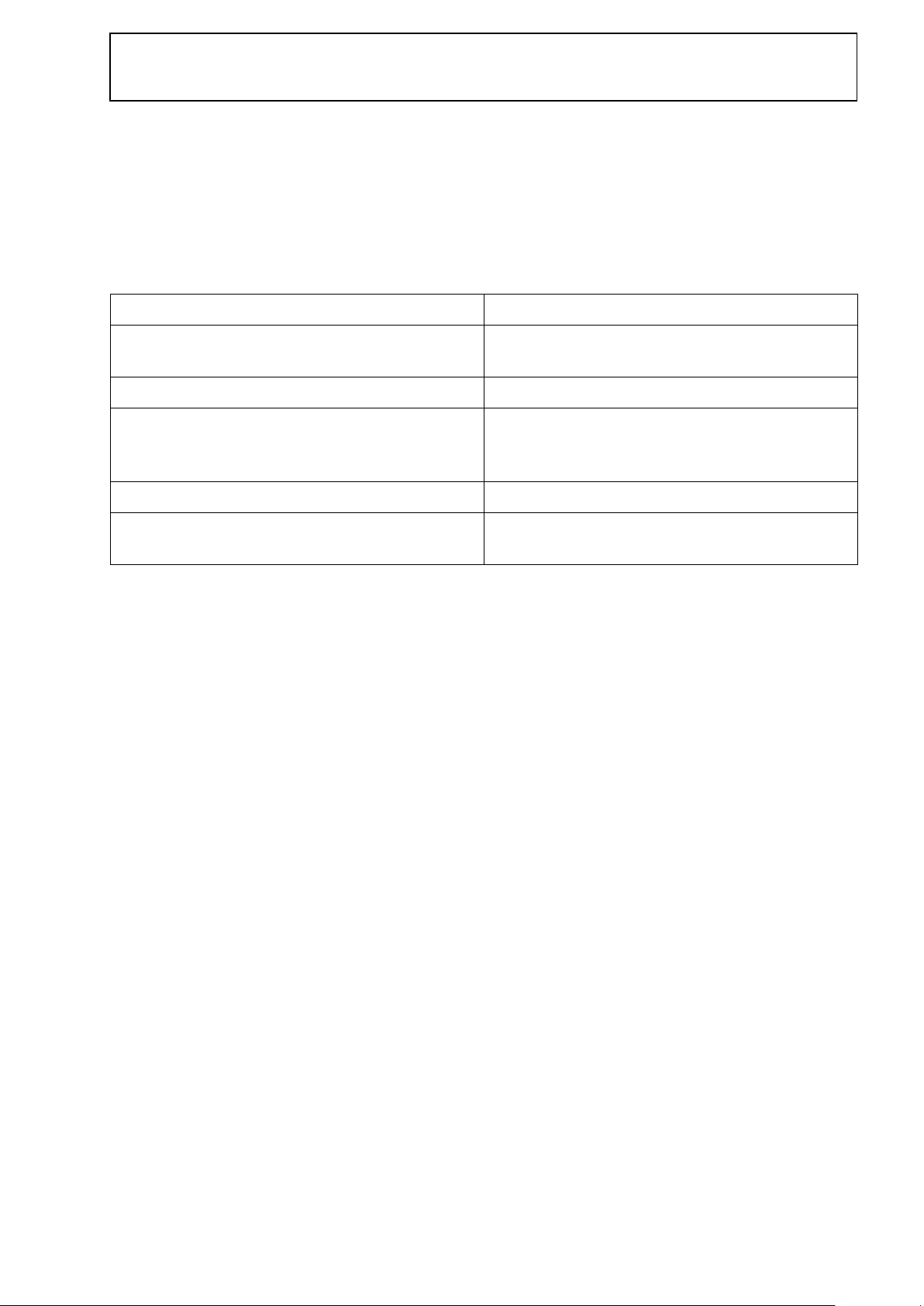

Mandatory signs

Warning signs

Disconnect the mains plug

General warning sign

Wash your hands

Warning against dangerous

electrical voltage hazard

Warning against hand injury

hazard

Table 1: Symbols

Description of Symbols 2.8

- 8 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Scope of Delivery 3

FLS 106 IC Scope of Delivery * 3.1

Item Name of article Short name Qty.

1 4-axis positioning system FLS 106 IC 1

2 ChipScan-Scanner software / CD-ROM CS-Scanner 1

3 Holder for GND 25 GND 25 holder 1

4 Ground plane GND 25 1

5 Holder for microscope camera DM-CAM holder.3 1

6 Digital microscope camera DM-CAM 1

7 Rotary unit Rotary unit 1

8 EMERGENCY STOP switch, external NA 5 1

9 User manual FLS 106 m 1

----------------------------------------------------------------------------------------------------------------------------------

* The scope of delivery may deviate depending on the respective order.

FLS 106 PCB Scope of Delivery * 3.2

Item Name of article Short name Qty.

1 3-axis positioning system FLS 106 PCB 1

2 ChipScan-Scanner software / CD-ROM CS-Scanner 1

3 Universal holder for Langer scanner UH DUT 1

4 Claw claw 01 4

5 Claw claw 02 4

6 Digital microscope camera DM-CAM 1

7 Probe holder for Langer scanner SH 01 1

8 Camera arm KA 220 1

9 EMERGENCY STOP switch, external NA 5 1

10 User manual FLS 106 m 1

----------------------------------------------------------------------------------------------------------------------------------

* The scope of delivery may deviate depending on the respective order.

- 9 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

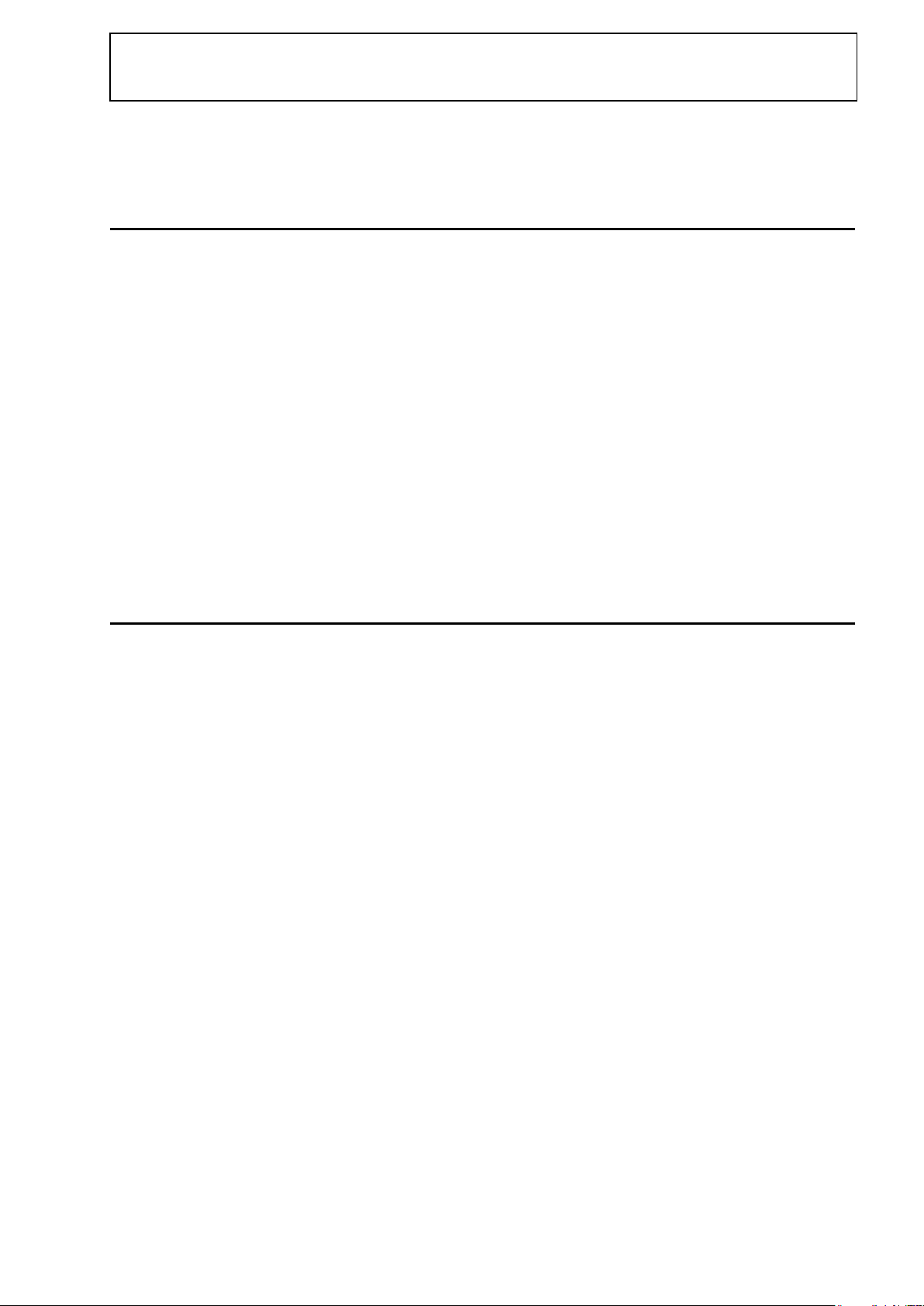

Figure 1: Axes of the FLS 106 scanner

Supply voltage

100 - 250 V (50/60 Hz)

Current consumption

4.5 A

Interface

USB 2.0 type B (Hi-speed)

Weight

75 kg

Dimensions (L x W x H)

(1030 x 775 x 900) mm

Table 2: General technical parameters of the FLS 106 scanner

Axes

X Y Z

α rotation

Max. positioning

distance

400 mm

600 mm

120 mm

±180°

Min. positioning

distance

20 µm

20 µm

20 µm

1°

Positioning speed

20 mm/s

25 mm/s

10 mm/s

90°/s

Table 3: Technical parameters of the four axes

Technical Parameters 4

General Parameters of the FLS 106 Scanner 4.1

- 10 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 2: Dimensions of the DUT UH universal holder

Figure 3: Dimensions of the claws for the DUT UH (claw 01 and claw 02)

Technical Parameters of the Subassemblies 4.2

UH DUT 4.2.1

Claw 01 and Claw 02 4.2.2

- 11 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 4: Claws from above with the long hole and M3 screw

Figure 5: GND 25 holder

with anti-rotation element

GND 25 Holder 4.2.3

- 12 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 6: GND 25 ground plane

Diameter

218 mm

Depth of the recess

1.7 mm

Recess dimensions (L x W)

(103 x 103) mm

Weight

2 kg

Height

24 mm

Table 4: Technical parameters of the GND 25 ground plane

Figure 7: SH 01 probe holder

Probe sleeve

Length: 40 mm

Inner diameter 9.9 mm

Outer diameter 12 mm

Table 5: Technical parameters of the SH 01 probe holder

GND 25 Ground Plane 4.2.4

SH 01 Probe Holder

4.2.5

- 13 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Length

1260 mm

Width

890 mm

Height

1000 mm

Connection

25-pin D-Sub

Weight

50 kg

Table 6: Technical parameters of the SUH 106 safety enclosure

Figure 8: External EMERGENCY STOP switch with cable and plug

Cable length

5 m

Table 7: Technical parameters of the external NA 5 EMERGENCY STOP switch

SUH 106 Safety Enclosure 4.2.6

External NA5 EMERGENCY STOP Switch 4.2.7

- 14 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Operating system

Windows 7 64 bit (latest service packs)

Monitor resolution

(1280 x 1024) px

Hard-disk storage

1 GB minimum / 10 GB recommended

Table 8: System requirements for the ChipScan-Scanner software

Processor

Intel Core i7 2.7 GHz

RAM memory

8 GB

Graphics card

AMD Radeon 7950

Graphics card memory

3 GB

Table 9: PC specifications recommended for use with the ChipScan-Scanner software

Requirements for the ChipScan-Scanner Software 4.3

- 15 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Intended Use 5

The FLS 106 scanner is a positioning system for probes from Langer EMV-Technik GmbH and is

used exclusively to test and/or carry out measurements on printed circuit boards (PCBs) and

integrated circuits (ICs).

The system supports the following probe types from Langer EMV-Technik GmbH:

- ICR near-field micro-probes

- Passive near-field probes

The system allows the measurement of fields coupled out by the device under test (DUT).

The probes can be moved across the DUT surface on the X-, Y- and Z-axis.

In addition, the FLS 106 IC allows the probe's rotation around the Z-axis. The probe tip position

can be checked visually with the digital DM-CAM microscope camera at any time.

The FLS 106 is controlled with the ChipScan-Scanner software via a PC.

The system is used for applications such as:

- Surface scans in compliance with standard DIN IEC/TS 61967-3

- Volume scans

- Pin scans

The FLS 106 scanner may only be used in accordance with the prerequisites described in

section 6.1.

The user must comply with all information and instructions given in this user manual.

The FLS 106 scanner should only be used in an environment with a temperature of

10 to 35 degree Celsius and a humidity of 20 to 85 percent without condensation.

Keep the scanner free of foreign objects, dirt and liquids to prevent adverse effects on

measurements and damage to the scanner.

Staff requirements 5.1

Only persons who are trained and qualified in the field of electromagnetic compatibility (EMC) may

operate the FLS 106 scanner.

Persons whose responses are impaired by alcohol, medicines, drugs or similar substances must

not be allowed to operate the FLS 106 scanner.

- 16 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Risks if Not Used for Its Intended Purpose 5.2

Incorrect use of the FLS 106 scanner may put the user at risk, damage the scanner and/or the

technical equipment connected to the scanner.

Examples of improper use that may put persons/equipment at risk:

- Safety devices are bypassed or rendered ineffective.

- The FLS 106 scanner is used in a defective state.

- The FLS 106 scanner is used outside the specified range of technical parameters.

- The field of application is changed by modifications to the design.

Claims due to the scanner's abnormal use are excluded!

Safety Instructions 5.3

Risks cannot be totally excluded even if the FLS 106 scanner is used for its intended purpose.

Observe the safety information and hazard warnings listed below to prevent damage to property

and personal injury. Also observe the operating and safety instructions for all other devices used in

the measurement set-up.

Carry out a visual check before performing a measurement with a product from

Langer EMV-Technik GmbH. Replace any damaged connecting cables, attachments and probes.

Please contact Langer EMV-Technik GmbH if damaged parts need to be replaced or repaired.

Wear tight-fitting clothes when using the scanner.

Hazard Due to Electrical Voltage 5.3.1

Your life is at risk if you touch damaged electrical cables.

Important: Always check any attachments, measuring devices, cables and probes before using the

scanner. Never use any damaged or defective devices.

Do not connect or disconnect any cables whilst the FLS 106 scanner is in operation.

Only staff from Langer EMV-Technik GmbH may open the scanner and work on the electrical

components and electrical lines.

Switch the device off immediately, disconnect the mains plug and contact Langer EMV-Technik

GmbH if you detect any damaged insulation on lines, cables or electric components!

- 17 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Hazard Due to Movements along the Axes 5.3.2

There is a risk of injuries when the scanner is in motion.

Important: The scanner may only be operated within a protective enclosure (section 6.1.1 and

14.1.1) or with a spatial separation (section 6.1.2 and 14.1.2). As a result, attachments, probes and

DUTs can only be installed and removed when the FLS 106 scanner is at a standstill.

Airborne noise emission if used for its intended purpose 5.4

The noise level is below 70 dB(A) if the FLS 106 scanner is used for its intended purpose

No ear protection is required.

- 18 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Safety Devices 6

Prerequisites for Safe Operation 6.1

The FLS 106 scanner may only be operated if either

- a protective enclosure or

- a spatial separation in connection with the external NA 5 EMERGENCY STOP switch is

used.

The FLS 106 scanner is stopped immediately if

- the EMERGENCY STOP switch on the device is actuated,

- the external EMERGENCY STOP switch is actuated,

- the protective enclosure is opened.

After the EMERGENCY STOP switch on the scanner has been pressed, it has to be released by

turning it clockwise before the scanner can be switched back on.

After the external NA 5 EMERGENCY STOP switch has been pressed, it has to be released by

pulling before the scanner can be switched back on.

The scanner then has to be recalibrated with the software.

Operation with the Protective Enclosure 6.1.1

The FLS 106 scanner is operated inside the SUH 106 protective enclosure.

Operation with a Spatial Separation 6.1.2

The user provides a spatial separation at an appropriate distance to prevent persons from

interfering with the scanner's operation. Measures such as cordoning off or fencing off the site are

suitable precautions. The external EMERGENCY STOP switch has to be connected to the scanner

and placed outside the isolated space so that it is accessible at any time.

Switching the Scanner on in Normal Operation and after a Power 6.2

Failure

The FLS 106 scanner can only be activated or operated via the software after passing a selftesting routine.

EMERGENCY STOP Switch 6.3

The emergency stop function is triggered by pressing the EMERGENCY STOP switch.

The FLS 106 scanner is stopped immediately.

After the EMERGENCY STOP switch has been pressed, it has to be released by turning it

clockwise before the scanner can be switched back on.

Overcurrent Protective Device 6.4

Line-side fuses protect the scanner in the event of a fault. The power supply unit is resistant to

short circuits.

- 19 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Environmental Protection 7

Dispose of any packaging material paying due regard to the local environmental protection

regulations.

Do not allow lubricants such as grease and oil based on mineral oils to escape into the

environment. These lubricants must be disposed of in compliance with the local, official regulations

through corresponding collection points.

Nameplate 8

The nameplate is on the rear of the FLS 106 scanner and identifies the scanner clearly.

The nameplate provides the following details:

- Name of the device

- Company name and full address of the manufacturer

- CE mark

- Serial number and article number

- Year of construction (year in which the manufacturing process has been completed)

- 20 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 9: Overview

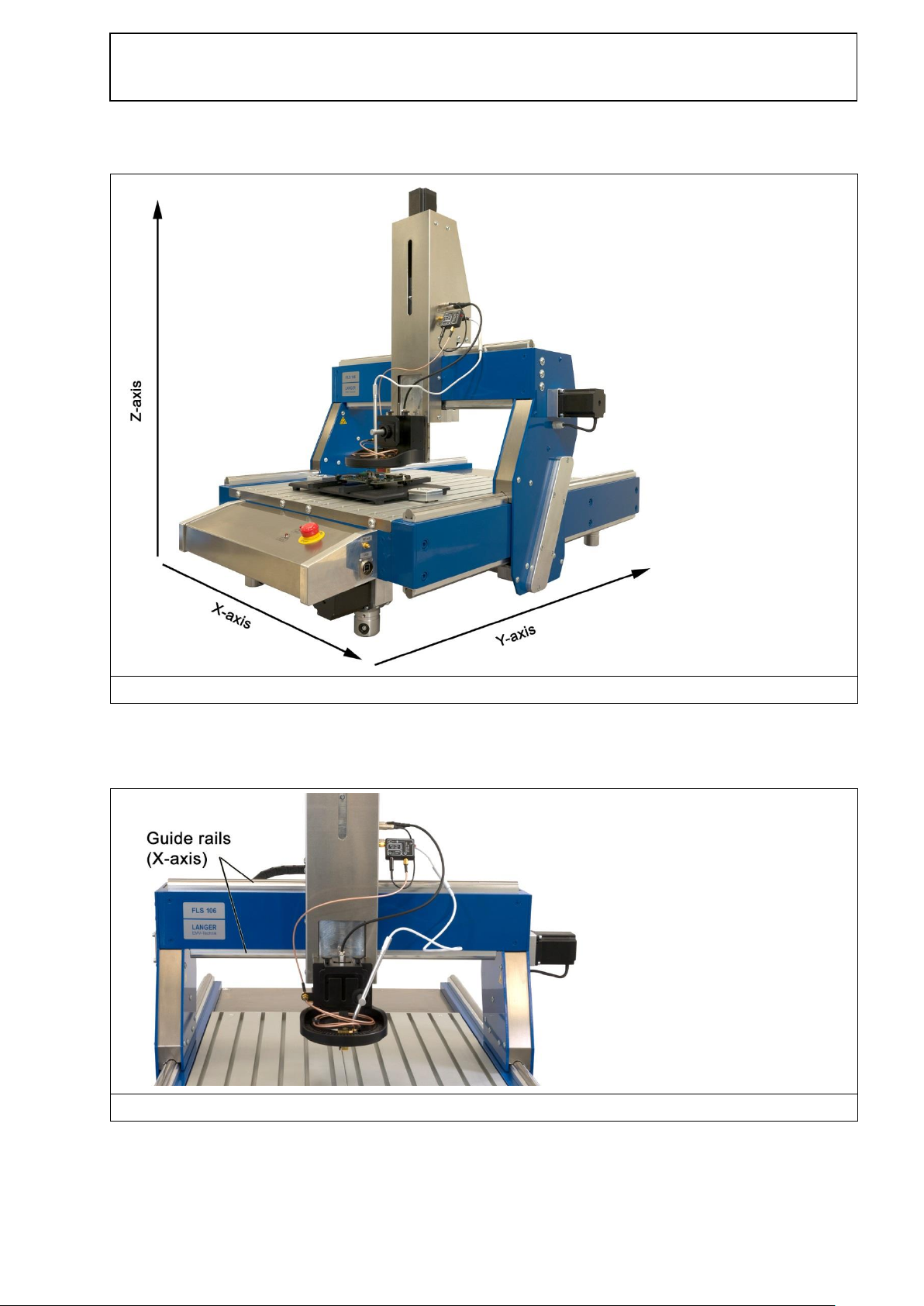

Figure 10: Guide rails of the X-axis

Overview of the FLS 106 Scanner 9

Description of the Subassemblies 9.1

Guide Rails along the X-Axis 9.1.1

The electrically driven stepping motor moves the Z-axis tower on the guide rails along the X-axis

over a working range of 400 mm.

- 21 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 11: Guide rail along the Y-axis

Figure 12: Z-axis tower with rotary unit

Guide Rails along the Y-Axis (Long Side) 9.1.2

The electrically driven stepping motor moves the gantry on the guide rails along the Y-axis over a

working range of 600 mm.

Z-Axis Tower 9.1.3

A rotary unit is located at the bottom of the Z-axis tower on the FLS 106 IC. The SH 01 probe

holder and the KA 220 camera arm are located at the bottom of the Z-axis tower on the

FLS 106 PCB.

The Z-axis's positioning distance is 125 mm.

- 22 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 13: Gantry on the FLS 106

Figure 14: Rotary unit with SMA-SMA coupling and fastening screws

Gantry 9.1.4

The gantry transports the probe that is attached to the rotary unit and the digital DM-CAM

microscope camera along the Y-axis.

Rotary Unit 9.1.5

The FLS 106 IC scanner comes with a rotary unit as a standard feature.

- 23 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 15: SMA coupling

The rotary unit is used as a fourth axis that allows the installed probe to rotate around the Z-axis by

±180°.

The DM-CAM holder.3 for the digital microscope camera is attached to the rotary unit. Either an

ICR probe or the SH 01 probe holder can be mounted on the rotary unit's rotary ring.

The SMA measuring cables can be connected to the SMA coupling (Figure 15).

The SSMB-SSMB cable is connected to the SSMB port for collision control (Figure 15).

Aluminium Mounting Bracket 9.1.6

The FLS 106 PCB scanner comes with an aluminium mounting bracket as a standard feature.

The aluminium mounting bracket is used to mount the KA 220 camera arm and the SH 01 probe

holder.

- 24 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 16: T-slot table

T-slots with openings for the T-nuts

Figure 17: Two versions of T-nuts

T-Slot Table 9.1.7

The T-slot table (600 mm x 540 mm x 19 mm) has several hollow sections. T-nuts (Figure 17) can

be inserted into the individual hollow sections (T-slots) to fasten the clamping pieces (section 10.4)

or the GND 25 holder (section 10.6) with the corresponding screws (M8).

The T-slots' inside height and width is 13.6 mm (DIN 508).

- 25 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 18: Control panel of the FLS 106 scanner

Figure 19: Height-adjustable machine foot

Control Panel with EMERGENCY STOP Device and Control LEDs 9.1.8

The EMERGENCY STOP device ("Emergency Stop") that is integrated in the control panel is used

to stop the FLS 106 scanner immediately.

The control LEDs show whether the scanner is switched on ("Power") or in motion ("Moving").

Height-Adjustable Machine Feet 9.1.9

The height of the four machine feet can be adjusted separately to align and level the scanner.

- 26 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 20: ON / OFF switch

Figure 21: Connectors on the Z-axis tower

ON / OFF Switch 9.1.10

An ON / OFF toggle switch is located on the rear of the FLS 106 scanner.

Connectors 9.2

Connectors on the Z-Axis Tower 9.2.1

- HR10 connectors:

12-pin connector marked "Camera" to connect the digital DM-CAM microscope camera

10-pin connector marked "rot. Axis" to connect the rotary unit or the SSMB-HR10 cable

(depth test cable)

6-pin connector marked "12 V DC" to connect the bias-tee or pre-amplifier power supply

- SMA SMA connector marked "RF in" to connect a near-field probe, a bias-tee or pre-amplifier

via an RF cable.

- 27 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 22: Connectors on the control panel: "RF out" and "USB"

Figure 23: Mains plug socket (power supply)

Connectors on the Control Panel 9.2.2

- USB connector, type B, marked "USB" to connect to a PC via a corresponding USB cable,

- SMA connector marked "RF out" to connect a measuring device such as a spectrum analyzer or

oscilloscope via an RF cable.

Power Supply Socket 9.2.3

A C13 power supply socket is located on the rear of the FLS 106 scanner beside the ON / OFF

switch.

- 28 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 24: "ext. Stop" connector

Connector for External Emergency Stop Switch or Safety Enclosure 9.2.4

The connector marked "ext. Stop" is located on the rear of the FLS 106 scanner and is used to

connect the SUH 106 safety enclosure or the external NA 5 EMERGENCY STOP switch.

- 29 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 25: KA 220 camera arm

Figure 26: DM-CAM holder.3

Overview of Attachments 10

KA 220 Camera Arm 10.1

The KA 220 camera arm of the FLS 106 PCB scanner holds the digital DM-CAM microscope

camera. It is attached to the aluminium mounting bracket.

DM-CAM Holder.3 10.2

The DM-CAM holder.3 of the FLS 106 IC scanner is used to position and mount the digital

DM-CAM microscope camera on the rotary unit.

There are three slots that allow an individual installation of the DM-CAM such as to the right or left

of or above the installed ICR probe.

- 30 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 27: Camera screw shown separately and as connected to the DM-CAM holder.3

Figure 28: DM-CAM microscope camera

DM-CAM in the connected state

DM-CAM with Camera Screw 10.3

The digital DM-CAM microscope camera is used to monitor the probe tip position and the distance

between the probe tip and DUT.

The camera screw is needed to mount the DM-CAM on the DM-CAM holder.3.

The camera can be fixed by sliding it into the opening of the camera screw and tightening the

small, silver-coloured knurled screw. The large, silver-coloured knurled screw and the large, black,

knurled plastic nut are used to mount the camera screw on the DM-CAM holder.3.

The DM-CAM is connected to the HR10 connector marked "Camera" on the scanner's Z-axis

tower.

The DM-CAM's focus can be set by turning its rear knurled nut.

- 31 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 29: Clamping piece with grub screws

Hexagon socket screw for clamping piece

Figure 30: UH DUT with claw 01 and claw 02 on the T-slot plate

Clamping Pieces 10.4

The clamping pieces are used as fasteners to individually position and mount the UH DUT

universal holder or a DUT on the FLS 106 scanner's T-slot table.

The clamping pieces can be mounted in a T-slot with the hexagon socket screw M6 (hexagon

socket 5 mm) and a T-nut. The clamping pieces' angle and height can be adjusted with the two

grub screws (hexagon socket 6 mm).

UH DUT with Claw 01 and Claw 02 10.5

The UH DUT universal holder is used to fix the DUT. The universal holder is 297 mm long, 210 mm

wide and 8 mm high.

The 20 mm x 20 mm grid of M3 threaded holes allows the DUT's individual positioning.

The DUT can be fixed with the respective claw 01 or claw 02. There are two types of claws that

can be chosen depending on the DUT's height.

- 32 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 31: GND 25 holder on the T-slot plate

Figure 32: GND 25 ground plane on the T-slot plate

GND 25 Holder 10.6

The GND 25 holder holds the GND 25 ground plane.

The GND 25 holder can be mounted directly on the T-slot table or on the UH DUT universal holder.

The GND 25 holder has an anti-rotation element to prevent the GND 25 from turning or slipping.

GND 25 Ground Plane 10.7

The GND 25 ground plane is installed on the GND 25 holder. The GND 25's recess is 103 mm

long and wide.

The recess size allows the GND 25 to hold standardised test circuit boards (100 x 100 TEM cell) or

your own test circuit boards. Please refer to section 16.3.2 for further information.

- 33 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 33: SH 01 comprising the mounting bracket with a magnetic holder and probe sleeve

Figure 34: SH 01's magnetic holder and probe sleeve with SSMB connector and clamping screw to hold the near-field

probe

SH 01 Probe Holder 10.8

The SH 01 probe holder is designed to hold a near-field probe. The SH 01 comprises a mounting

bracket, the magnetic holder and the probe sleeve.

The probe sleeve is held magnetically and can be loosened quickly and easily to install a probe

without any problem, for example.

The probe sleeve has a bore on the rear so that it can be returned into its correct position on the

magnetic holder by simply positioning the bore directly above the magnetic holder's pin.

In addition, the SH 01 has a collision protection function:

- The probe moves up with the magnetic holder if the probe touches an obstacle when moving

down. The scanner can recognise this displacement and stop the movement.

- The probe sleeve with the probe is released from the magnetic holder and falls off if the probe

hits an obstacle when moving sideways. This normally prevents any damage to the DUT.

Please read section 18.3 on how to set up the collision protection when the probe is moving down

(collision control).

- 34 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Delivery 11

The FLS 106 scanner is delivered in a customised transport box. The scanner itself weighs 75 kg.

The transport box's dimensions and weight may vary depending on the equipment and place of

destination. Therefore, the total weight cannot be provided here.

Due to its high weight, the transport box should always be transported with a pallet truck or fork-lift

truck.

Acceptance Inspection

11.1

The packaging must be inspected for any damage incurred during transport on receipt of the

goods. Any visible transport damage should be noted in the forwarder's shipping documents.

Please contact the supplier immediately if there are problems in this respect.

Defects can only be claimed within the complaints period.

Storage 11.2

Observe the following points when storing the transport box including the scanner, devices and

accessories:

- Store the box in a dry place.

- Only store the box in closed rooms.

- Store the box on a safe, level surface.

- Store the box on the correct side (do not tilt).

- Do not stack the box on another box and do not stack anything on top of the transport box.

Incorrect storage may damage the FLS 106 scanner, devices and/or accessories.

Opening the Transport Box 11.3

Ensure that the transport box is placed on level ground. Use appropriate tools to open the transport

box and prevent damage to the equipment. Do not break open the box by brute force.

When unpacking the box, carry out a thorough check that the consignment is complete on the

basis of the scope of delivery and that it has not been damaged during transport.

Defects can only be claimed within the complaints period.

Packaging 11.4

The packaging should prevent any damage during transport, corrosion and other damage.

Therefore, it should only be removed shortly before the set-up. Dispose of the packaging material

in compliance with the disposal regulations applicable at the place of installation.

Note: We recommend that the packaging material for the attachments be put aside to ensure that

the FLS 106 attachments and accessories can be stored safely.

- 35 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Preparations for Putting the FLS 106 Scanner into 12

Service

Preparations for the Safe Operation of the FLS 106 Scanner 12.1

There are two options to ensure the system's safe operation: use the SUH 106 safety enclosure or

provide for a spatial separation (see Section 6.1).

When choosing the place of installation, consider which of the aforementioned safety solutions is to

be implemented.

Setting Up the FLS 106 Scanner 12.2

Only remove the protective film after setting up the FLS 106 scanner at its place of installation.

The scanner dimensions are 1,030 x 775 x 990 mm and its weight is 75 kg.

There is thus an increased risk of injuries when carrying or moving the scanner.

Do not carry or move the scanner alone.

The FLS 106 scanner may only be used in closed rooms under appropriate light conditions.

Take the space requirements for cordoning off the area into account if you intend to operate the

system with a spatial separation.

The scanner should be installed on a raised surface such as a table, workbench, etc. Check the

worktop's size and load-bearing capacity before installing the system.

Ensure that the worktop is large enough and its load-bearing capacity is not exceeded (total weight

including the SUH 106 approx. 125 kg) if you intend to operate the system with the SUH 106 safety

enclosure.

Make sure that the free working area around the scanner is large enough for the scanner to be

handled properly.

The scanner should be set up on a level, firm and clean surface. Secure the

scanner against slipping and falling down if there is a risk of it slipping. There is

an increased risk of injuries due to the scanner's high weight.

After setting up the scanner at its place of installation, remove the protective film by hand. Do not

use any tools such as knives, cutters or scissors to remove the protective film. There is a risk that

sharp-edged, metallic tools cause damage to the system, such as scratches on the scanner or

damage to the insulation of cables or to persons by cuts.

- 36 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 35: Machine feet on the scanner

The height-adjustable machine feet allow the user to adjust the scanner to uneven work surfaces.

The feet can be set to the desired height with the height adjustment screw (hexagon socket 4 mm).

The clamping screw (hexagon socket 2.5 mm) fixes the feet at the respective height.

The adjustable height is 3.8 mm.

Instructions on how to change the height of the feet:

- Loosen the height-adjustment lock by turning the clamping screw counter-clockwise. Turn the

height-adjustment screw (hexagon socket 4.0 mm) clockwise to raise the scanner. Turn the

height-adjustment screw counter-clockwise to lower the scanner. Tighten the clamping screw

after adjusting the correct height.

Give the scanner enough time to acclimatize before putting it into service if it is brought from a cold

into a warm environment. Condensation may settle down on the scanner's surface. The

condensation should be promptly removed with dry, clean cloths. Acclimatization may take up to

several hours depending on the temperature difference. We recommend that further steps only be

taken after the scanner has adjusted to the working area's ambient temperature.

Langer EMV-Technik GmbH assumes no liability for damage to property and/or personal injury

or for consequential damage that arises from the incorrect unpacking or installation of

the FLS 106 scanner.

- 37 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 36: Cleaning the greased sliding rails with a paper towel

Removing the Transport Protection from the Guide Rails 12.3

Langer EMV-Technik GmbH applies a thin layer of grease to all sliding rails so as to ensure

appropriate corrosion protection during transport and storage. Remove this grease before putting

the system into service.

Use dry towels made of cloth or fabric to remove the grease. Dispose of the towels under due

consideration of the local, official regulations.

Prevent the grease from coming into contact with your clothes, skin, hair and eyes.

Wash the grease off with water and soap if it comes into contact with your skin.

Information on the Pre-Installed Components' Torque 12.4

All components for which a special tightening torque is defined have already been installed and

tightened.

The screws of all attachments that have to be installed later should only be fastened hand-tight. No

torque wrench is needed for this purpose.

- 38 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 37: EMERGENCY STOP switch in the locked

state

and in the released state

Checking / Releasing the EMERGENCY STOP Switch 12.5

Only transport the FLS 106 scanner with the EMERGENCY STOP switch locked in place. If the

EMERGENCY STOP switch is locked, the scanner cannot be put into service. Therefore, the user

should check whether the EMERGENCY STOP switch is locked before switching the scanner on. If

it is locked, turn the EMERGENCY STOP switch in the direction of the printed arrows until it is

released (see Figure 37).

- 39 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Putting the FLS 106 Scanner into Service for the First 13

Time

Read chapter 12 before putting the system into service for the first time.

Standard procedure:

a) Install and connect the digital microscope camera:

- refer to section 14.3.2 for FLS 106 IC or

- refer to section 14.4 for FLS 106 PCB

b) Check that the cable of the rotary unit is connected correctly (connect if necessary)

(Figure 40).

c) Connect the mains cable (Figure 49).

d) Ensure the system's safe operation:

- set up the spatial separation and connect the external NA 5 EMERGENCY STOP switch

(section 14.1.2) or

- set up and connect the SUH 106 safety enclosure (section 14.1.1)

e) Check the EMERGENCY STOP switch and release if necessary (section 12.5).

f) Connect the measuring device to the SMA connector on the control panel (please refer to

the list of measuring devices supported by the CS-Scanner software) (section 14.7).

g) Connect the scanner to the PC via a USB type A/B cable (section 14.6).

h) Close the SUH 106 safety enclosure if this option has been chosen.

i) Switch on and boot the PC.

j) Switch on the scanner and install the driver on the PC (section 15.1).

k) Install the ChipScan-Scanner software on the PC (section 15.2).

l) Start the ChipScan-Scanner software and detect the devices that are connected

(section 15.3).

m) Calibrate and test the scanner via the ChipScan-Scanner software (section 15.3 item 3).

- 40 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Installation 14

Ensuring the System's Safe Operation 14.1

Operation with the SUH 106 Safety Enclosure 14.1.1

The user may be at risk when working on the scanner whilst this is in operation.

The safety enclosure protects the user and prevents any work on the scanner whilst this is in

operation.

Install the SUH 106 safety enclosure according to the corresponding user manual and connect the

SUH 106 connecting cable to the "ext. Stop" port of the FLS 106 scanner.

The EMERGENCY STOP switch on the scanner has to be released and the SUH 106 door closed

before the scanner can be started.

Operation with Spatial Separation and External NA 5 EMERGENCY STOP Switch 14.1.2

The user may be at risk when working on the scanner whilst this is in operation.

A spatial separation protects the user and can prevent any work on the scanner whilst this is in

operation.

The spatial separation must meet the following requirements:

- stable overall structure made of a durable material

- clearly recognizable as a separation (use bright colours if necessary)

- the separation must be provided around the scanner without any interruptions

- the distance to the scanner must be sufficient to safely prevent any interference with the scanner.

The spatial separation can be provided by different means such as separators, barriers with

barricade tape, protective fences, light barriers, light grids, etc.

The external NA 5 EMERGENCY STOP switch has to be installed outside the spatial separation so

that it can be seen and reached at any time.

The D-Sub connector of the external EMERGENCY STOP switch has to be installed before putting

the scanner into service as otherwise a fault message appears and the operation is prevented.

- 41 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 38: D-Sub port (ext. Stop)

Figure 39: NA 5 EMERGENCY STOP switch with D-Sub

connector

- 42 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 40: Cable of the rotary unit on the "rot. Axis“ connector

Figure 41: Rotary unit without DM-CAM holder.3

Figure 42: DM-CAM holder.3 camera holder mounted on

the unit

Checking the Cables of the Rotary Unit 14.2

Check that the rotary unit is connected to “rot. Axis" on the Z-axis tower.

Installing the Digital DM-CAM Microscope Camera on the 14.3

FLS 106 IC

Installing the DM-CAM Holder.3 for the Microscope Camera 14.3.1

Mount the DM-CAM holder.3 (Figure 41) for the camera on the rotary unit with two black knurled

screws M4.

- 43 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 43: Mounted camera screw

Camera screw shown in detail

Figure 44: Digital DM-CAM microscope camera installed and connected to the Z-axis tower via a cable

Installing the Digital DM-CAM Microscope Camera 14.3.2

Use the large, silver-coloured knurled screw and the black, knurled plastic nut to mount the camera

screw on the DM-CAM holder.3. Insert the digital microscope camera into the opening of the

camera screw and fix it in the desired place with the small, silver-coloured knurled screw. The

microscope camera can be installed before or after mounting the DM-CAM holder.3.

Then connect the DM-CAM cable to the HR10 connector marked "Camera" on the Z-axis tower

(Figure 44).

- 44 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 45: Digital DM-CAM microscope camera

Figure 46: KA 220 camera arm

Figure 47: Digital DM-CAM microscope camera installed

on the KA 220 camera arm

Figure 48: Connecting the HR10 plug of the DM-CAM to

the "Camera“ connector on the Z-axis tower

Figure 49: C13 socket on the scanner

Installation of the Digital DM-CAM Microscope Camera on the 14.4

FLS 106 PCB

Mount the DM-CAM on the KA 220 camera arm (Figure 47) with the FLS 106 PCB. Insert the

DM-CAM into the opening of the camera screw located on the camera arm and fix with the small,

silver-coloured knurled screw.

Then connect the HR10 plug of the DM-CAM connecting cable to the "Camera" connector on the

Z-axis tower of the FLS 106 PCB (Figure 48).

Connecting the C13/C14 Device Lead 14.5

Connect the power supply via the C13/C14 device lead (Figure 49).

- 45 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 50: Connecting the USB type B plug to the scanner's USB type B port

Figure 51: Connecting the measuring cable with SMA plug to the scanner's "RF out" port

1

1

Connecting a Computer 14.6

Use a USB 2.0 type A/B cable (fully rated, Hi speed, maximum length of 2 meters) to connect the

scanner to a computer. Connect the USB type A plug to the PC and the USB type B plug to the

USB type B port (Figure 50) on the FLS 106 scanner's control panel.

Connecting a Measuring Device for Near-Field Scans by Taking a 14.7

Spectrum Analyzer as an Example

To connect a spectrum analyzer to the FLS 106 scanner, one end of the corresponding measuring

cable is connected to the spectrum analyzer's RF input and the other end (SMA plug) to the

"RF out" SMA connector on the FLS 106 control panel (Figure 51).

Please refer to the annex of the ChipScan-Scanner software user manual or the www.langeremv.de website for a list of measuring devices supported by the ChipScan-Scanner software

www.langer-emv.com/fileadmin/ChipScan-ESA%20Supported%20Spectrum%20Analyzers.pdf

- 46 / 79 -

.

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 52: Switching the scanner on

Switching the FLS 106 Scanner on 14.8

Bring the toggle switch on the rear of the scanner into the "I" position to switch the FLS 106

scanner on properly.

After switching the FLS 106 on, the control panel LED marked "Power" comes on.

- 47 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

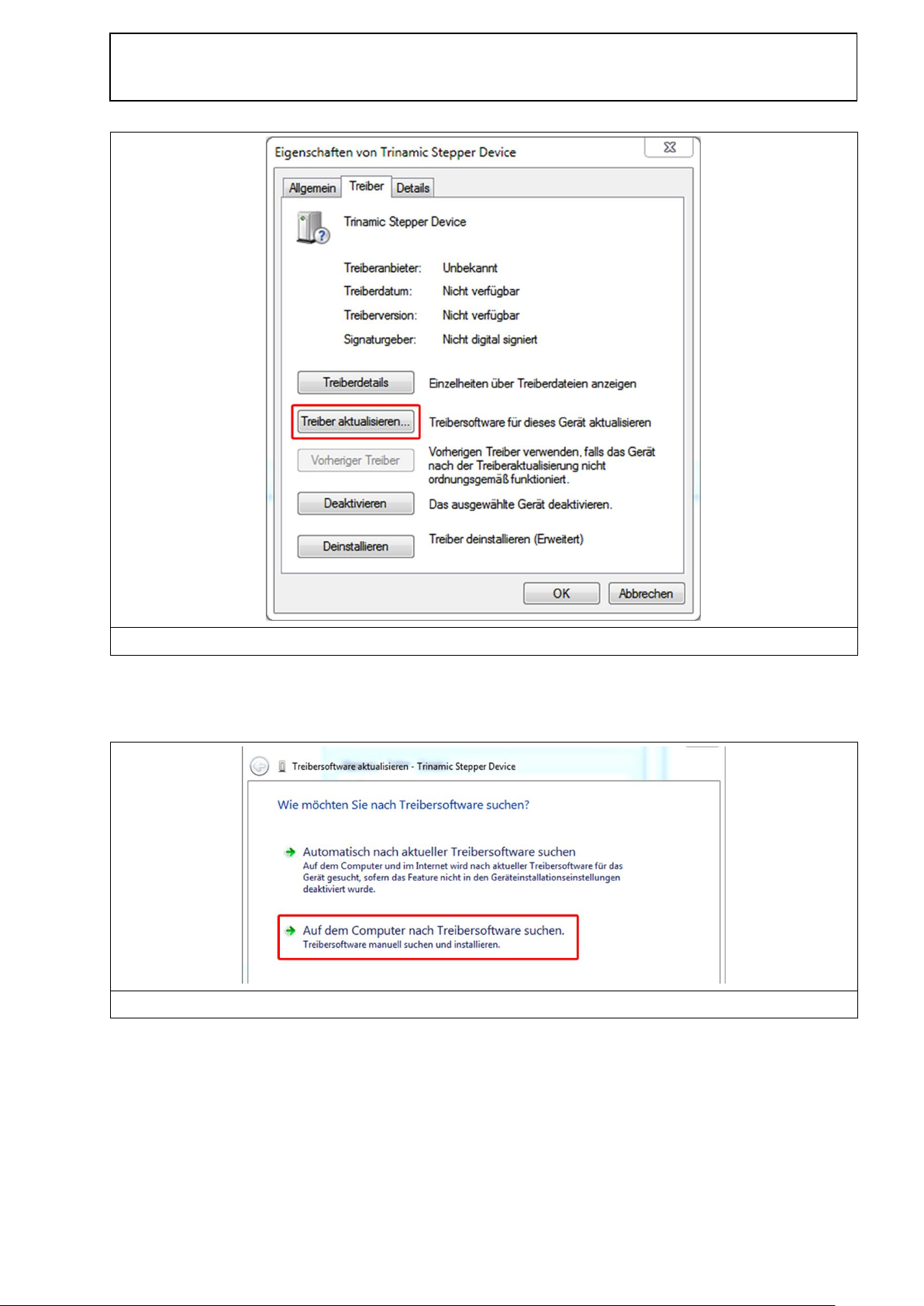

Figure 53: Device manager with the "Trinamic Stepper Device" entry and a warning sign

Software Installation 15

Put the device into service as described in chapter 13 before installing the software. Start the

installation process by inserting the installation CD with the ChipScan-Scanner software into the

CD drive or connecting the USB memory stick to the computer.

Installing the scanner driver 15.1

Windows installs the scanner driver automatically when the FLS 106 scanner is connected to the

respective PC. The driver does not have to be installed by hand.

Process:

a) Connect the scanner to the PC via a USB type A/B cable (section 14.6).

b) Switch on and boot the PC.

c) Switch the scanner on (section 14.8)

d) Insert the installation CD or plug in the USB memory stick.

Then on the PC:

1) Open the Windows system control, search for and open the device manager.

2) Double click the "Trinamic Stepper Device" entry under "Other devices" in the device

manager.

3) Select the "Driver" tab and click "Update driver…" in the open characteristics window.

- 48 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 54: Updating the driver

Figure 55: Selection for driver search

4) Select the "Browse my computer for driver software" option in the dialogue window that

opens.

5) Click the "Browse" button that appears, select the CD drive or USB memory stick, select

the "Driver" sub-folder and click the "OK" button.

- 49 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 56: Browsing the enclosed CD for the driver

Figure 57: The scanner driver has been installed (the warning sign has disappeared)

6) The driver will now be installed. The "TRINAMIC Stepper Device" entry should then appear

under "Ports" in the device manager.

Installing the ChipScan-Scanner Software 15.2

Please refer to the chapter 1 of the software's user manual with the file name "chipscan.pdf" for

additional information on installing the ChipScan-Scanner software. The user manual is in the

"Documentation" folder on the installation CD or USB memory stick.

The installation file is on the installation CD in the "ChipScan-Scanner" folder.

1. To start the installation process, insert the installation CD into the CD drive, access the

"ChipScan-Scanner" folder on the CD and double click the desired installation file. You can

choose between a 32-bit and a 64-bit version.

2. Confirm the question in the user account control window by clicking "Yes".

3. Click "Next" in the new window.

4. Then read the license agreement and confirm this by clicking "Accept".

5. Select the target inventory where you want to install the ChipScan-Scanner software and click

"Next".

6. Think about whether to create a start menu folder with program shortcuts and, if you do not

want any shortcuts, tick the "Do not create shortcuts" checkbox.

7. Then click "Install".

- 50 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

8. When installation is complete, you can decide whether to start the software immediately or

not by ticking the appropriate checkbox.

9. Click "Finish".

Putting the FLS 106 Scanner into Service with the 15.3

ChipScan-Scanner Software

Ensure that the system has been set up as described in chapter 13 (item a – m) and the driver

described in section 15.1 has been installed.

The ChipScan-Scanner software user manual with additional information on the individual steps

can be accessed if the software is open via the "Manual" entry in the "Help" menu.

The scanner and the PC must be switched on and connected via a USB 2.0 cable.

The following steps have to be carried out to check whether the FLS 106 scanner functions

properly:

1. Start the ChipScan-Scanner software.

2. Connect the ChipScan-Scanner software to the FLS 106 scanner:

- Click the "Device Manager…" entry in the "Devices" menu in the ChipScan-Scanner

software.

- Click the "Detect Devices" button.

- Searching for the connected devices takes some time. The following entries should then

appear in the "Identified devices used for measurement" section:

o In the "Video Device" selection box -> Name of the connected camera

o In "Scanner" selection box -> Name of the connected scanner

o In the "Spectrum Analyzer" selection box -> Name of the connected spectrum

analyzer

- Optional steps to speed up the device identification:

In the open "Device Manager" window:

o Select the COM interface to which the scanner is connected in the "RS232"

selection box in the "Scanner" section.

o Select the "Langer FLS 106" entry in the selection box below "RS232".

o Then click the "Detect Devices" button.

- After a successful search, close the "Device Manager" by clicking the cross in the upper

right corner.

- Please refer to chapter 4 in the ChipScan-Scanner software user manual for further

information.

- 51 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 58: DM-CAM microscope camera

3. Calibrate the FLS 106 scanner.

- Click "Calibrate" (lower right corner) to move the scanner to its home position. This has to

be done each time the ChipScan-Scanner software is started, each time the scanner is

switched on and each time the scanner is stopped.

- The scanner can then be moved into the desired position with the arrow keys of the

directional pad.

4. Open "Video View".

- Click the "Video…" entry in the "Devices" menu to follow the video transmission of the

digital microscope camera.

- The desired brightness can be adjusted with the "Camera Brightness" controller in the

lower right section above "Calibrate".

- The focus can be adjusted with the adjusting nut at the rear end of the DM-CAM.

- 52 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 59: Inserting the T-nut into the T-slot

Figure 60: Fastening the clamping piece with the

hexagon socket screw on the T-slot plate

Figure 61: Adjusting the height and angle of the clamping

piece with the grub screws

Fastening the Device Under Test 16

Fastening a Device Under Test With the Clamping Pieces 16.1

Fasten the clamping pieces with the hexagon socket screws M6 (hexagon socket 5 mm) and the

T-nuts in the selected T-slots.

The clamping pieces' angle and height can be changed with the grub screws M8 (hexagon socket

4 mm).

Note: Scratches and/or other traces may be left on the T-slot table if the clamping pieces are

fastened too tight, fasten the screw only hand-tight.

Process:

Insert the first T-nut into the desired T-slot and move to the desired position.

Then place the clamping piece above the T-nut and secure loosely with the hexagon socket

screw M6.

- 53 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 62: Device under test installed between two clamping pieces

Adjust the height and angle with the grub screws so that the device under test can be pushed

under the projecting part of the clamping piece. Align the device under test and fix the clamping

piece with the hexagon socket screw M6.

Repeat the aforementioned steps for the second clamping piece on the opposite side of the device

under test.

Check that the device under test is held firmly enough so that it cannot slip away.

Fastening a Circuit Board with the UH DUT Universal Holder 16.2

As a prerequisite, the UH DUT has already been installed on the T-slot table (section 16.2.1).

Place the circuit board in the middle of the UH DUT.

Use either claw 01 or claw 02 depending on the height of the board. Claw 01 is designed to hold a

circuit board with a height of less than 8 mm. Claw 02 is designed to hold a circuit board with a

height of less than 14 mm.

The claws can be adjusted continuously and have to be fixed with the screws M3 (length of 12 mm,

hexagon socket of 2.5 mm) in the holes of the UH DUT.

The circuit board should be fastened with two claws each on two opposite sides (Figure 63).

- 54 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 63: Fastening example with claw 02

Figure 64: Positioning the UH DUT

The claws have to be fastened so that the circuit board cannot be moved in any direction.

The remaining claws can also be used for this purpose.

Installing the UH DUT 16.2.1

Note: Scratches and/or other traces may be left on the T-slot table if the clamping pieces are

fastened too tight. Take due care.

Place the UH DUT universal holder on the T-slot table precisely in the middle between two T-nuts

(Figure 64).

Insert a T-nut into each of the T-slots directly alongside the UH DUT and push them up to the

middle of the UH DUT.

Place the clamping pieces above the T-nuts and secure loosely with the hexagon socket

screw M6.

- 55 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 65: Fastening the UH DUT with the clamping pieces on the T-slot table

Figure 66: GND 25 ground plane

Adjust the height and angle with the grub screws as required. Fix the clamping pieces with the

hexagon socket screw M6.

After installing the UH DUT universal holder, check that this cannot slip. If necessary, further

tighten the screws M8 with care.

Fastening the GND 25 Ground Plane for IC Measurements 16.3

Installing the GND 25 Ground Plane 16.3.1

As a prerequisite, the GND 25 holder has already been installed on the T-slot table

(section 16.3.3).

Place the GND 25 ground plane (Figure 66) on the GND 25 holder so that the anti-rotation element

is located in the desired notch on the lower side of the GND 25. The GND 25 can be quickly

rotated by 45° or 90° if necessary by using a different notch.

Important: Remember that the GND 25 rests loosely on the GND 25 holder. This means that the

installed GND 25 may fall off or down when the scanner is transported, for example. This may

result in damage to property and/or personal injury. Therefore, always remove the GND 25 before

transporting the scanner.

- 56 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 67: Placing the T-nut in the provided T-slot

2

Information on Using the GND 25 Ground Plane 16.3.2

The GND 25 ground plane is designed to hold TEM cell prints with a length and width of 100 mm.

Furthermore, individual test circuit boards may be developed and manufactured for measurements

on ICs or other components.

Test circuit boards can either be developed by customers themselves using the

"IC test instructions"2 from Langer EMV-Technik GmbH or by Langer EMV-Technik GmbH on the

basis of the customer's specifications.

Installing the GND 25 Holder 16.3.3

First insert and position two T-nuts into the desired T-slot (Figure 67).

Then place the GND 25 holder on the T-slot table above the T-nuts (Figure 68). Insert the

countersunk screws M6 (hexagon socket 4 mm, DIN 7991) into the openings of the GND 25 holder

one after the other and fasten them with the T-nuts.

Available via mail@langer-emv.de

- 57 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 68: Fastening the GND 25 holder

Figure 69: Part of the GND 25 holder with the anti-rotation element

The anti-rotation element can be fastened in one of the four outer holes as required. It ensures that

the installed GND 25 ground plane does not turn by accident.

- 58 / 79 -

LANGER

EMV-Technik

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.de

FLS 106 IC set / FLS 106 PCB set

Figure 70: Unscrewing the cable holder

Figure 71: Connecting the SMA-SMA measuring cable

Figure 72: SSMB connector on the rotary unit