Page 1

Installation, Operation,

Maintenance, & Troubleshooting

Model: R60S

Standard Bake Oven Range

Star Manufacturing International 10 Sunnen Drive St. Louis, MO.63143-3800

Part Number: 2M-W822 Ph: 314-781-2777 Fax: 314-781-2714

Rev. B

WWW.STAR-MFG.COM October 8, 2008

Page 2

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

POST IN A PROMINENT LOCATION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER

SMELLS GAS. THIS INFORMATION SHALL BE OBTAINED BY

CONSULTING YOUR LOCAL GAS SUPPLIER. AS A MINIMUM,

TURN OFF THE GAS AND CALL YOUR GAS COMPANY AND

YOUR AUTHORIZED SERVICE AGENT. EVACUATE ALL

PERSONNEL FROM THE AREA.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

Model #: Purchased From:

Serial #: Location:

Date Purchased: Date Installed:

Purchase Order #: For Service, Call:

2

Page 3

Table of Contents

CHAPTER PAGE

1. Table Of Contents.................................................................................................3

2. Read First..............................................................................................................4

3. Equipment Description..........................................................................................6

4. Unpacking .............................................................................................................7

5. Installation.............................................................................................................8

6. Initial Start-Up .......................................................................................................9

7. Operation ..............................................................................................................10

8. Cleaning & Maintenance Procedures ..................................................................12

9. Troubleshooting ....................................................................................................13

10. Exploded View & Parts Lists.................................................................................15 - 19

11. Wiring Diagrams....................................................................................................20

3

Page 4

Warnings

CAUTION: THE RANGE WEIGHS 900 LBS. (408 KILOGRAMS).

FOR SAFE HANDLING, INSTALLER SHOULD OBTAIN

HELP AS NEEDED, OR EMPLOY APPROPRIATE

MATERIALS HANDLING EQUIPMENT (SUCH AS A

FORKLIFT, DOLLY, OR PALLET JACK) TO REMOVE

THE UNIT FROM THE SKID AND MOVE IT TO THE

PLACE OF INSTALLATION.

CAUTION: ANY STAND, COUNTER OR OTHER DEVICE ON

WHICH RANGE WILL BE LOCATED MUST BE

DESIGNED TO SUPPORT THE WEIGHT OF THE

RANGE (900 LBS.).

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN

SNAP BACK WHEN CUT.

DANGER: THIS APPLIANCE MUST BE GROUNDED AT THE

TERMINAL PROVIDED. FAILURE TO GROUND THE

APPLIANCE COULD RESULT IN ELECTROCUTION

AND DEATH.

WARNING: INSTALLATION OF THE UNIT MUST BE DONE BY

PERSONNEL QUALIFIED TO WORK WITH

ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

UNIT MUST BE INSTALLED IN ACCORDANCE WITH

ALL APPLICABLE CODES.

NOTICE: The data plate is located right of the range top

controls and circuit breaker door on oven. The oven

voltage, wattage, serial number, wire size, and

clearance specifications are on the data plate. This

information should be carefully read and understood

before proceeding with the installation.

NOTICE: The installation of any components such as a vent

hood, grease extractors, fire extinguisher systems,

must conform to the applicable National, State and

locally recognized installation standards.

NOTICE: During the first few hours of operation you may

notice a small amount of smoke coming off the unit,

and a faint odor from the smoke. This is normal for a

new range and will disappear after the first few hours

of use.

CAUTION: ALWAYS KEEP THE AREA NEAR THE APPLIANCE

FREE FROM COMBUSTIBLE MATERIALS.

CAUTION: KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN

AND DRY. IF SPILLS OCCUR, CLEAN IMMEDIATELY,

TO AVOID THE DANGER OF SLIPS OR FALLS.

4

Page 5

Warnings

WARNING KEEP WATER AND SOLUTIONS OUT OF CONTROLS.

NEVER SPRAY OR HOSE CONTROL CONSOLE,

ELECTRICAL CONNECTIONS, ETC.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES,

MUCOUS MEMBRANES AND CLOTHING. WEAR

RUBBER GLOVES, GOGGLES/FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ THE

WARNING AND FOLLOW THE DIRECTIONS ON THE

LABEL OF THE CLEANER TO BE USED.

NOTICE: Service on this or any other Lang appliance must be

performed by qualified personnel only. Consult your

Lang Authorized Service Agent Directory. You can call

our toll free number 1-800-807-9054 or visit our website

WWW.STAR-MFG.COM for the service agent nearest you.

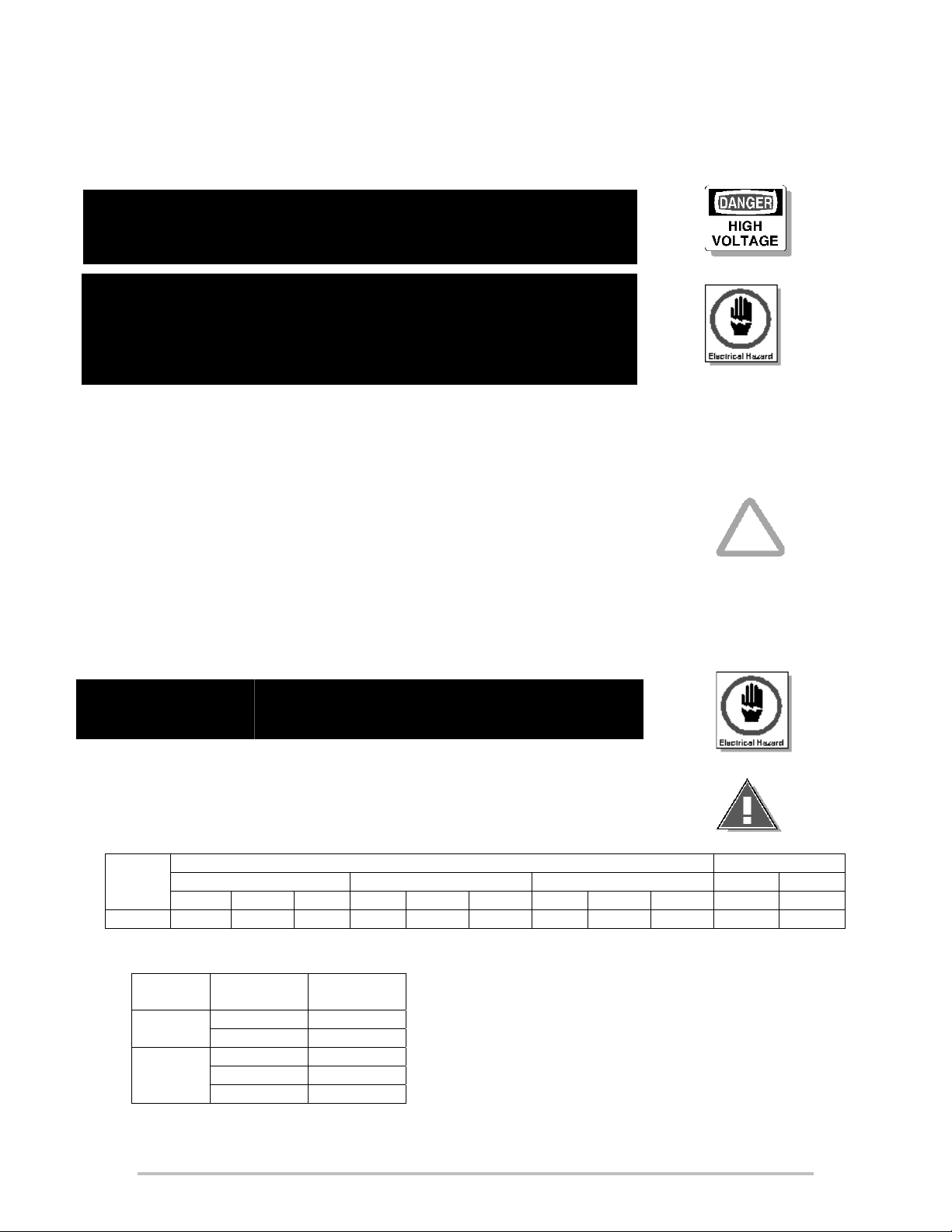

WARNING: BOTH HIGH AND LOW VOLTAGES ARE PRESENT

INSIDE THIS APPLIANCE WHEN THE UNIT IS

PLUGGED/WIRED INTO A LIVE RECEPTACLE. BEFORE

REPLACING ANY PARTS, DISCONNECT THE UNIT

FROM THE ELECTRIC POWER SUPPLY.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN

THOSE SUPPLIED BY LANG OR THEIR AUTHORIZED

DISTRIBUTORS CAN CAUSE BODILY INJURY TO THE

OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

5

Page 6

Equipment Description

Double Bake Oven Range

Exterior

The range dimensions are 30” (76.2cm) High, 35” (89.0cm) d eep, and 60”

(152.5cm) wide.

The sides, bottom, and rear wall are constructed stainless steel.

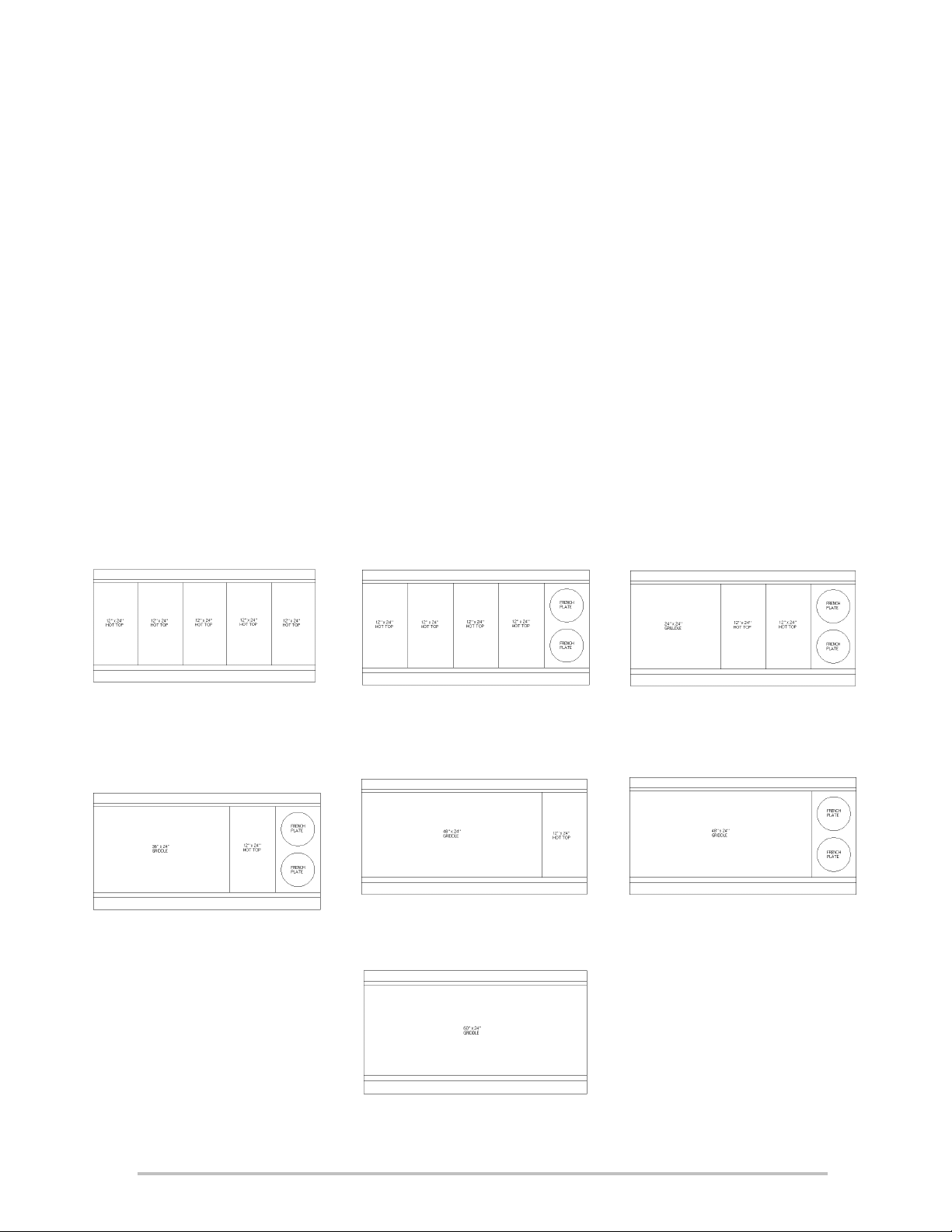

The range surface can come in 7 different configurations.

Controls

The R60S Series Range is available with various controls depending upon

model number. A layout of each top configuration with its proper model

number and a brief description of the controls is shown below. All R60S

Ranges have two or the same type of standard bake oven, which has two 3heat switches, one to control the top element and one to control the bottom

element. In addition, the oven has a thermostat that controls the overall

temperature of the oven

Five 12”x24” Hot tops controlled by five

R60S -A

850°F Thermostats.

Four 12”x24” Hot tops controlled by four

850°F thermostats and two French

plates controlled by two 6-heat switches.

R60S -B

R60S -C

24”x24” Griddle controlled by two 450°F

thermostats, two Hot tops controlled by

two 850° thermostats, and two French

plates controlled by two 6-heat switches.

36”x24” Griddle controlled by three

R60S -D

450°F thermostats, 12”x24” Hot top

controlled by one 850° thermostat and

two French plates controlled by two 6heat switches.

R60S -G

R60S -E

48”x24” Griddle controlled by four 450°F

thermostats, and one 12”x24” Hot top

controlled by one 850° thermostat.

R60S -F

48”x24” Griddle controlled by four 450°F

thermostats, and two French plates

controlled by two 6-heat switches.

60”x24” Griddle controlled by five 450°F

thermostats.

6

Page 7

Unpacking

Receiving the Oven

Upon receipt, check for freight damage, both visible and concealed. Visible

damage should be noted on the freight bill at the time of delivery and

signed by the carrier's agent. Concealed loss or damage means loss o r

damage, which does not become apparent until the merchandise has been

unpacked. If concealed loss or damage is discovered upon unpacking,

make a written request for inspection by the carrier's agent within 15 days

of delivery. All packing material should be kept for inspection. Do not

return damaged merchandise to Lang Manufacturing Company. File your

claim with the carrier.

Location

Prior to un-crating, move the range as near its intended location as

practical. The crating will help protect the unit from the physical damage

normally associated with moving it through hallways and doorways.

Un-crating

The range will arrive completely assembled inside a wood frame covered by

cardboard box and strapped to a skid. Remove the cardboard cover, cut

the straps and remove the wood frame.

RANGE WEIGHS 900 LBS (408 kilograms). FOR SAFE

HANDLING, INSTALLER SHOULD OBTAIN HELP AS

NEEDED, OR EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A FORKLIFT,

DOLLY, OR PALLET JACK) TO REMOVE THE UNIT

FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

CAUTION ANY STAND, COUNTER OR OTHER DEVICE ON WHICH

RANGE WILL BE LOCATED MUST BE DESIGNED TO

SUPPORT THE WEIGHT OF THE OVEN (900 LBS.).

SHIPPING STRAPS ARE UNDER TENSION AND CAN

SNAP BACK WHEN CUT.

Remove range from skid and place in intended location.

Installing the Legs

Legs or casters are available and must be specified upon ordering.

To install the 6-inch legs, remove the legs from the oven cavity, place some

cardboard on the floor and gently tip the range onto its back. Fasten the

legs into the threaded holes provided and then gently flip the oven onto its

legs.

To install the 6-inch casters, remove the casters from the oven cavity, place

some cardboard on the floor and gently tip the range onto its back. Attach

the casters to the adapter plates. Gently tip the oven onto its casters.

7

Page 8

Installation

INSTALLATION

DANGER: THIS APPLIANCE MUST BE GROUNDED AT THE

TERMINAL PROVIDED. FAILURE TO GROUND THE

APPLIANCE COULD RESULT IN ELECTROCUTION AND

DEATH.

WARNING: INSTALLATION OF THE UNIT MUST BE DONE BY

PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY.

IMPROPER INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO EQUIPMENT. UNIT

MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

NOTICE: The data plate is located right of range top controls and

behind the circuit breaker door on oven. The oven voltage,

wattage, serial number, wire size, and clearance

specifications are on the data plate. This information

should be carefully read and understood before

proceeding with the installation.

NOTICE: The installation of any components such as a vent hood,

grease extractors, fire extinguisher systems, must

conform to their applicable National, State and locally

recognized installation standards.

Electrical Connection

All connections can be made through 1 3/4” hole in the bottom of the oven.

Connections should be made to the wires coming form the circuit breaker.

WARNING:

The range can now be connected to power.

CAUTION:

Total

K.W.

Conn

37.0

PHASING

POWER

SUPPLY

PHASE

THREE

PHASE

MAKE SURE THE MAIN POWER SUPPLY TO THE

RANGE IS TURNED OFF AT THE SOURCE PRIOR

TO CONNECTING POWER TO THE RANGE.

BE SURE THE POWER SUPPLY VOLTAGE

MATCHES THE VOLTAGE SPECIFIED ON THE

NAMEPLATE LOCATED ON THE FRONT OF THE

RANGE.

Three Phase Single Phase

208 Volt 240 Volt 480 Volt 208 V 240 V

L1 L2 L3 L1 L2 L3 L1 L2 L3 L1 L2

108.0 100.0 100.0 93.9 86.7 86.7 46.9 43.3 43.3 177.9 154.2

TERMINAL

BLOCK

L1 1,3,5,7,9 SINGLE

L2 2,4,6,8,10

L1 1,4,7,10

L2 2,5,8

L3 3,6,9

RANGE

TOP

8

Page 9

Operation

Prior to putting any range or oven into full time operation at normal cooking

temperatures, it must be thoroughly "seasoned" or dried out. Moisture absorption in

the closed spaces, in the insulation and even inside the heating elements can cause

future trouble if not properly treated.

Before the initial use of the range, the ovens must be thoroughly allowed to dry out.

This is done by setting the top and bottom oven switches to the “low” position, and

setting the thermostat to 350

vapor and condensation has been eliminated. For best operating results allo w the

range ovens to thoroughly dry out. Allow 8 to 12 hours for this process. Clean top

plates thoroughly. Apply salad oil. Turn each plate switch or thermostat to a low

position and allow plate to heat for three hours.

If the unit is out of use for three or more days, a one hour preheat schedule should

be used, especially when exposed to high humidity and/or cool temperatures.

NOTICE: During the first few hours of operation you may notice a small

amount of smoke coming off the unit, and a faint odor from the

smoke. This is normal for a new unit and will disappear after the

first few hours of use.

O

F degrees. Allow the range ovens to saturate until all

9

Page 10

Operation

Ovens

WARNING

ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.KEEP FLOOR IN FRONT OF

EQUIPMENT CLEAN AND DRY. IF SPILLS OCCUR, CLEAN

IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR FALLS.

The range ovens must be thoroughly, preheated before satisfactory baking can be

done. The range ovens will not bake uniformly if not sufficiently preheated.

To compensate for temperature drop when loading the range ovens, set the

thermostat up 50

the ovens is loaded.

The range ovens may, of course, be preheated with the 3 heat switches set at a

lower position than "High", but the time required will be proportionally longer. After

preheating, set the two 3 heat switches for proper ratio of "top" and "bottom" heat to

suit the product to be baked or roasted.

The 12" high "Roasting and Baking" range ovens is equipped with a removable rack.

For baking pies, bread, or for roasting operations, the rack may be placed directly on

the metal deck and the pans placed on the rack. For baking cakes or pastries the

rack should be located in the lower position provided by the rack supports at the

sides of the range and the pans placed on the rack in this lower position.

The following temperature, time, switch setting and rack positions are suggested as a

guide in baking various classes of products:

O

F degrees over the desired temperature. Reset thermostat after

Product Average Range

Temperature

Pies 375-425OF

Rolls 375-400 OF 15-30 Low High Rack Support

Cake 350-400 OF 20-45 Low High Rack Support

Pastries 325-375 OF 8-20 Low High Rack Support

Bread 425-450 OF 25-45 Low Medium Rack on Deck

Roast Beef 300-325 OF Low High or Medium Rack on Deck

Time

(Min.)

35-60 Low Medium Rack on Deck

With Metal Switch

Settings

Top Bottom

Rack Position

10

Page 11

Operation cont'd.

RANGE TOP

Consists of the various top arrangements, depending on specific model purchased:

12" x 24" hot plate controlled by high temperature thermostats. Temperature ranges from 0°F-

850°F. Recommended: Stock pots and heavy kettle work.

Round French Plates, controlled by indicating type 6-heat switch. Temperature ranges from

0°F -750°F. Recommended: Light duty sauce pans and small stockpots. Not Recommended:

Heavy stock pots, or heavy urns, or kettles.

60” x 24” or 48” x 24” or 36" x 24" or 24" x 24" grill plates, controlled by thermostats.

Temperature ranges from 0°F -450°F. Recommended: All heavy and light frying. Set the

thermostat dial at the desired temperature. The red pilot light will be on until the desired

temperature is reached. The pilot light indicates when the plate is heating.

11

Page 12

Maintenance and Cleaning

Cleaning

WARNING

KEEP WATER AND SOLUTIONS OUT OF CONTROLS.

NEVER SPRAY OR HOSE CONTROL CONSOLE,

ELECTRICAL CONNECTIONS, ETC.

CAUTION

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES,

MUCOUS MEMBRANES AND CLOTHING. PRECAUTIONS

SHOULD BE TAKEN TO WEAR RUBBER GLOVES, GOGGLES

OR FACE SHIELD AND PROTECTIVE CLOTHING. CAREFULLY

READ THE WARNING AND FOLLOW THE DIRECTIONS ON

THE LABEL OF THE CLEANER TO BE USED.

The range should be thoroughly cleaned at least once a week in addition to the

normal daily cleaning to insure against the accumulation of foreign material. Keep

inside of oven and metal deck clean, particularly around door opening, door edges

and at bottom of door opening so that the door may close tightly.

NOTICE Oven cleaner used should be marked: "safe on aluminum".

Keep drip pans under range top plates clean.

Keep hotplate and griddle surfaces clean.

Outside of range and top should be kept clean.

Electric equipment is inherently clean and sanitary,

but may become unsanitary if dirt is allowed to

accumulate on it. Take advantage of the clean,

sanitary features of electric equipment. Give it the

regular attention that it deserves, the same as any

other highly perfected machinery, to insure best

results and continued high operating efficiency.

CALIBRATION

Calibration Check

Place thermometer in the center of oven cavity.

Set thermostat to 350°F and place both 3-heat switches in the “HIGH” position.

Allow the oven to preheat for at least half an hour.

Note cycle on temperatures and cycle off temperatures for 3 cycles. (Red indicator

light indicates when oven is calling for heat)

After 3 cycles average the temperature. ( Add all six temperatures and divide by 6)

Calibration Adjustment

A 1/16” flat blade screwdriver with a 2” shaft is required to make adjustments on the

thermostat.

Maintain the oven temperature at 350°F.

Without turning the thermostat, remove the knob.

Locate the adjustment screw at the base of the shaft and insert the screwdriver.

Grasp the shaft and turn the screwdriver. Counter clockwise to increase and

clockwise to decrease (1/8 of a turn will move the temperature 5-7°F in either

direction).

Reinstall the oven knob and recheck the oven temperature.

12

Page 13

Troubleshooting

Symptom Cause Corrective Action

No power to oven Turn on power

Internal breaker tripped Reset breaker

Oven will not heat

Range will not heat

Product is burning

Product is not

cooked

Defective Thermostat Verify calibration

Defective 3-heat switch Failed 3-heat or 6-heat switch*

Defective oven element

No power to oven Turn on power

Internal breaker tripped Reset breaker

Defective thermostat or 6-heat switch Verify calibration

Defective 3-heat switch

Failed thermostat Verify calibration

Product is cooked too long Operational condition

Failed thermostat Verify calibration

Failed 3-heat switch

Remove the wires and check for continuity

across the element

Call factory or consult service manual for

correct checks on each switch*

Call factory or consult service manual for

correct checks on each switch*

TESTS

NOTICE Service on this or any other Lang appliance must be performed

by qualified personnel only. Consult your Lang Authorized

Service Agent Directory. You can call our toll free number

1-800-807-9054 or visit our website WWW.STAR-MFG.COM

the service agent nearest you.

WARNING

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE

THIS APPLIANCE WHEN THE UNIT IS PLUGGED/WIRED

INTO A LIVE RECEPTACLE. BEFORE REPLACING ANY

PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC

POWER SUPPLY.

CAUTION

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE

SUPPLIED BY LANG OR THEIR AUTHORIZED DISTRIBUTORS CAN

CAUSE BODILY INJURY TO THE OPERATOR AND DAMAGE TO THE

EQUIPMENT AND WILL VOID ALL WARRANTIES.

for

13

Page 14

45

1

36

34

34

33

46

43

42

41

RANGE

CONTROLS

OVEN

CONTROLS

30

40

10

39

7

8

9

46

11

38

44

35

12

37

2

3

4

5

6

23

26

31

32

29

25

28

24

27

MODEL: R60S Electric 60” Range

21

20

22

19

18

15

14

16

17

SK2316 Rev. - 9/26/07

13

Page 15

PARTS LIST October 8, 2008, Rev B

Model No: R60S-ATA, R60S-ATB, R60S-ATC, R60S-ATD, R60S-ATE, R60S-ATF, R60S-ATG, R60S-ATH

COMMERCIAL & MARINE ELECTRIC 60” RANGE

Key

Number

1 P9-50302-297 1 SEARAIL ASSY 1’(RF&500) R60S-ATE208M/480M

P9-50302-298 1 SEARAIL ASSY 2’ (RF&500) R60S-ATD440M/480M

P9-50302-300 1 SEARAIL ASSY 5’ {500} R60S-ATA-440M/480M,

P9-50302-301 1 SEARAIL ASSY 3’ (RF&500) R60S-ATC240M/440M/480M

2 P9-50401-02 1 RANGE PLATE ASSY 1/2 X 2’ R60S-ATC

P9-50401-03 1 RANGE PLATE ASSY 1/2 X 3’ R60S-ATD

P9-50401-11-1 1 RANGE PLATE ASSY 1” X 4’ R60S-ATE-208/208M, R60S-ATF-240/480

P9-50401-12-1 1 RANGE PLATE MODULE 1 X 5’ R60S-ATG

3 GROOVING GRIDDLE GROOVING

4 P9-50300-82-1 1 EGO PLAT FRM ASY PHANT R60S-ATB, R60S-ATC, R60S-ATD, R60S-ATF

P9-50300-82-1 5 EGO PLAT FRM ASY PHANT R60S-ATH

5 2N-11120-12 2 ELMNT TK 208V 2600W R60S-ATB-208/208M, R60S-ATC-208,

2N-11120-12 10 ELMNT TK 208V 2600W R60S-ATH-208

2N-11120-13 2 ELMNT TK 240V 2600W R60S-ATB-240/240M, R60S-ATC-240/240M,

2N-11120-13 10 ELMNT TK 240V 2600W R60S-ATH-240

2N-11120-14 2 ELMNT TK 480V 2600W R60S-ATB-480M, R60S-ATC-480/440M/480M,

2N-11120-14 10 ELMNT TK 480V 2600W R60S-ATH-480

6 P9-11010-37-1 1 HOTPLATE 400V 500W CAST R60S-ATD380M

P9-11010-37-1 4 HOTPLATE 400V 500W CAST R60S-ATB380M

PS-11010-34-W1 1 ASY, HOTPLATE 208V 5000W R60S-ATD-208

PS-11010-34-W1 2 ASY, HOTPLATE 208V 5000W R60S-ATC-208

PS-11010-34-W1 4 ASY, HOTPLATE 208V 5000W R60S-ATB-208

PS-11010-34-W1 5 ASY, HOTPLATE 208V 5000W R60S-ATA-208

PS-11010-35-W1 2 ASY, HOTPLATE 240V 5000W R60S-ATC-240V

PS-11010-35-W1 4 ASY, HOTPLATE 240V 5000W R60S-ATB-240, R60S-ATB240M

PS-11010-35-W1 5 ASY, HOTPLATE 240V 5000W R60S-ATA-240

PS-11010-36-W1 2 ASY, HOTPLATE 480V 5000W R60S-ATC-480/440M/480M

PS-11010-36-W1 4 ASY, HOTPLATE 480V 5000W R60S-ATB480M

PS-11010-36-W1 5 ASY, HOTPLATE 480V 5000W R60S-ATA440M, R60S-ATA-480M R60S-ATA-480V

7 2N-11010-10 2 ELMNT T/P 208V 3KW I/S R60S-ATC-208V

2N-11010-10 3 ELMNT T/P 208V 3KW I/S R60S-ATD-208

2N-11010-10 4 ELMNT T/P 208V 3KW I/S R60S-ATE-208/208M, R60S-ATF-208

2N-11010-10 5 ELMNT T/P 208V 3KW I/S R60S-ATG-208

2N-11010-22 2 ELMNT T/P 240V I/S 3KW R60S-ATC-240/240M

2N-11010-22 3 ELMNT T/P 240V I/S 3KW R60S-ATD-240

2N-11010-22 4 ELMNT T/P 240V I/S 3KW R60S-ATE-240, R60S-ATF-240

2N-11010-22 5 ELMNT T/P 240V I/S 3KW R60S-ATG-240

2N-11010-24 2 ELMNT T/P 480V I/S 3KW R60S-ATC-480/440M/480M

2N-11010-24 3 ELMNT T/P 480V I/S 3KW R60S-ATD-480/440M/480M

2N-11010-24 4 ELMNT T/P 480V I/S 3KW R60S-ATE480M, R60S-ATF-480

2N-11010-24 5 ELMNT T/P 480V I/S 3KW R60S-ATG-480/480M

2N-11010-26 3 ELMNT T/P 380V 1/S 3KW R60S-ATD380M

2N-11050-34 4 ELE 360VN 380V 1/S 1.2KW R60S-ATB380M

8 2N-11010-09 2 ELMNT T/P 208V 3KW O/S R60S-ATC-208V

2N-11010-09 3 ELMNT T/P 208V 3KW O/S R60S-ATD-208V

2N-11010-09 4 ELMNT T/P 208V 3KW O/S R60S-ATE-208/208M, R60S-ATF-208

2N-11010-09 5 ELMNT T/P 208V 3KW O/S R60S-ATG-208

2N-11010-21 2 ELMNT T/P 240V O/S 2KW R60S-ATC-240/240M

2N-11010-21 3 ELMNT T/P 240V O/S 2KW R60S-ATD-240

Part

Number

Qty

Per

Description

R60S-ATB-208M/240M/480M

R60S-ATD-208, R60S-ATF-208

R60S-ATD-240, R60S-ATF-240

R60S-ATD-480/440M/480M, R60S-ATF-480

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 1

INCLUDE MODEL AND SERIAL NUMBER OF 4

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 16

PARTS LIST October 8, 2008, Rev B

Model No: R60S-ATA, R60S-ATB, R60S-ATC, R60S-ATD, R60S-ATE, R60S-ATF, R60S-ATG, R60S-ATH

COMMERCIAL & MARINE ELECTRIC 60” RANGE

Key

Number

8 2N-11010-21 4 ELMNT T/P 240V O/S 2KW R60S-ATE-240, R60S-ATF-240

2N-11010-21 5 ELMNT T/P 240V O/S 2KW R60S-ATG-240

2N-11010-23 2 ELMNT T/P 480V O/S 2KW R60S-ATC-480/440M/480M

2N-11010-23 3 ELMNT T/P 480V O/S 2KW R60S-ATD-480/440M/480M

2N-11010-23 4 ELMNT T/P 480V O/S 2KW R60S-ATE480M, R60S-ATF-480

2N-11010-23 5 ELMNT T/P 480V O/S 2KW R60S-ATG-480/480M

2N-11010-26 3 ELMNT T/P 380V 1/S 3KW R60S-ATD380M

2N-11050-33 4 ELE 360VN 380V O/S 1.8KW R60S-ATB380M

9 P9-50300-42 2 ZIG ZAG ASSY W/SNOUT 5KW R60S-ATC-480/240M/440M/480M

P9-50300-42 3 ZIG ZAG ASSY W/SNOUT 5KW R60S-ATD-208/240/480/440M/480M

P9-50300-42 4 ZIG ZAG ASSY W/SNOUT 5KW R60S-ATE-208/240/208M/480M,

P9-50300-42 5 ZIG ZAG ASSY W/SNOUT 5KW R60S-ATG-208/240/480/480M

10 P9-50300-41 2 ELEM PAN ASSY W/SNOUT 5KW R60S-ATC-480/240M/440M/480M

P9-50300-41 3 ELEM PAN ASSY W/SNOUT 5KW R60S-ATD-208/240/480/440M/480M

P9-50300-41 4 ELEM PAN ASSY W/SNOUT 5KW R60S-ATE-208/240/208M/480M,

P9-50300-41 5 ELEM PAN ASSY W/SNOUT 5KW R60S-ATG-208/240/480/480M

11 P9-50300-22 2 208-240V 3/16 BULB R60S-ATC-240M

P9-50300-22 3 208-240V 3/16 BULB R60S-ATD-208/240

P9-50300-22 4 208-240V 3/16 BULB R60S-ATE-240/208M, R60S-ATF-208

P9-50300-22 5 208-240V 3/16 BULB R60S-ATG-208/240

P9-50300-43 2 480V 3/16 BULB HOLDER R60S-ATC-480/440M/480M

P9-50300-43 3 480V 3/16 BULB HOLDER R60S-ATD440M/480/480M

P9-50300-43 4 480V 3/16 BULB HOLDER R60S-ATE480M

P9-50300-43 5 480V 3/16 BULB HOLDER R60S-ATG-480/480M

12 P9-500-101-1 1 BODY WRAP L/H SIDE ALL

13 P9-500-101 1 BODY WRAP R/H SIDE ALL

14 2A-72500-03 4 LEG 6” SS ADJ WITH 3/4-10 COMMERCIAL

2A-72500-06 4 LEG 5 1/2” W/BOLT DOWN ADJ MARINE

15 P9-500-125 1 SWITCH DOOR FRONT ALL

16 2N-11050-26 4 ELE 36OVN 240V I/S 1.2KW 240V

2N-11050-30 4 ELMNT 36OVEN 480V (C&C R60S-ATA440M/480M/480V, R60S-ATB480M,

2N-11050-32 4 ELE 36OVN 208V I/S 1.2KW 208V

2N-11050-36 4 ELE 36OVN 240V I/S 1.2KW R60S-ATA-240V

17 2N-11050-25 4 ELE 36OVN 240V O/S 1.8KW 240V

2N-11050-29 4 ELMNT 36OVEN 480V 9 (C&C R60S-ATA440M/480M/480V, R60S-ATB480M,

2N-11050-31 4 ELE 36OVN 208V O/S 1.8KW 208V

18 P9-60102-292 2 PAN ASSY 500 ASSY , COMMERCIAL COMMERCIAL

19 2C-20111-01 AR SCRW HXHD CAP 1/4-20X1/2 R60S-ATA440M

20 2C-20203-02 24 WSHR FLT SS 1/4 USS MS R60S-ATA440M

21 Y9-50300-14 2 MARINE HANDLE CHANNEL R60S-ATA440M, R60S-ATA-480M, R60S-ATB-208M,

22 N9-LA36-193 2 DOOR ASSY A/L ALL

23 2P-51001-01 2 SPRING OVN LH DOOR R60S-ATA440M

2P-51001-02 2 SPRING OVN RH DOOR R60S-ATA440M

24 2A-50800-07 4 TENSION DISC STD OVEN R60S-ATA440M

25 N9-LA36-145 4 DOOR RODS LA36 ALL

26 N9-LA36-146 4 DOOR PIPE LA36 ALL

27 K9-60301-43-1 2 DIE CAST LOG + TINNERMAN R60S-ATA440M

Part

Number

Qty

Per

Description

R60S-ATF-208/240/480

R60S-ATF-208/240/480

R60S-ATC-480/440M/480M,

R60S-ATC-480/440M/480M,

R60S-ATB480M

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 17

PARTS LIST October 8, 2008, Rev B

Model No: R60S-ATA, R60S-ATB, R60S-ATC, R60S-ATD, R60S-ATE, R60S-ATF, R60S-ATG, R60S-ATH

COMMERCIAL & MARINE ELECTRIC 60” RANGE

Key

Number

28 Y9-50300-38-1 2 HANDLE MARINE - ASSY ALL MARINE APPLICATIONS

Y9-50312-80 2 HANDLE ASSY, DOOR R60S-ATA-208, R60S-ATC-208

29 P9-50312-33 2 DOOR OUTSIDE PANEL R60S-ATA440M

30 2T-30402-09 2 STAT ADJ 550o 72 C/T ALL

31 2E-30304-35 4 SWTROT3HT 240/480VAC20AMP R60S-ATA-208/240/480/440M/480M,

32 P9-500-306 1 CTRL PNEL 208/240/480V ALL

33 P9-70701-41 2 KNOB 6 HEAT EGOTK PHANTOM R60S-ATB-208/240/480M,

P9-70701-41 4 KNOB 6 HEAT EGOTK PHANTOM R60S-ATC440M, R60S-ATC480M

Y9-70701-10-1 4 KNOB 3-HEAT 208-240V R60S-ATA-208/240/480/440M/480M,

Y9-70701-10-1 6 KNOB 3-HEAT 208-240V R60S-ATB-208M

Y9-70701-12-1 2 KNOB 550° A PHANTOM R60S-ATA440M/480M, R60S-ATB-

Y9-70701-16 2 KNOB 450° A PHANTOM R60S-ATC440M/480M,

Y9-70701-16 4 KNOB 450° A PHANTOM R60S-ATE208M, R60S-ATF-208/240/480

Y9-70701-16 5 KNOB 450° A PHANTOM R60S-ATG-208/240/480/480M

Y9-70701-17 2 KNOB ASSY 450° B R60S-ATC-208V

Y9-70701-35 2 KNOB ASSY 850° B R60S-ATD380M

34 Y9-31601-01-1 2 PILOT LT 250V W/TIN CLIP R60S-ATH-208/240

Y9-31601-01-1 4 PILOT LT 250V W/TIN CLIP R60S-ATD-208/240

Y9-31601-01-1 6 PILOT LT 250V W/TIN CLIP R60S-ATB-208/240, R60S-ATC-208/240,

Y9-31601-01-1 7 PILOT LT 250V W/TIN CLIP R60S-ATA-208, 240, R60S-ATE-208/240,

Y9-31601-02-1 6 PILOT LT 480V W/TIN CLIP R60S-ATB480M, R60S-ATC-480,

Y9-31601-02-1 7 PILOT LT 480V W/TIN CLIP R60S-ATA-480

Y9-31601-02-1 9 PILOT LT 480V W/TIN CLIP R60S-ATA440M

35 P9-50300-46 1 GRAB BAR ASSY 60 RANGE ALL MARINE APPLICATIONS

2E-31800-02 10 CB 250V 50A 1 POLE SMALL R60S-ATA-208/240,

Part

Number

Qty

Per

Description

R60S-ATB-208/240/208M/240M/480M,

R60S-ATC-208/240/480/240M/440M/480M,

R60S-ATD-208/240/480/440M/480M,

R60S-ATE-208/240/208M/480M,

R60S-ATF-208/240/480, R60-ATF-480,

R60S-ATG-480/480M,

R60S-ATH-208/240/480

R60S-ATD-208/240/480/440M/480M,

R60S-ATF-208/240/480, R60S-ATH-480

R60S-ATB-208/240/240M/480M, R60S-ATC440M/

480M, R60S-ATD-208/240/480/440M/480M,

R60S-ATE208M, R60S-ATF-208/240/480,

R60S-ATG-208/240/480/480M, R60S-ATH-480

208/240/208M/240M/480M, R60S-ATC440M/480M,

R60S-ATD-208/240/480/440M/480M,

R60S-ATE208M, R60S-ATF-208/240/480,

R60S-ATG-208/240/480/480M, R60S-ATH-480

R60S-ATD-208/240/380M/480/440M/480M,

R60S-ATE208M, R60S-ATF-208/240/480,

R60S-ATG-208/240/480/480M

R60S-ATF-208/240

R60S-ATG-208/240

R60S-ATC440M/480M

R60S-ATB-208/240/208M/240M,

R60S-ATC-208/240/240M, R60S-ATD-208/240,

R60S-ATE-208/240/208M, R60S-ATF-208/240,

R60S-ATG-208/240, R60S-ATH-208/240

3

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

4

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 18

PARTS LIST October 8, 2008, Rev B

Model No: R60S-ATA, R60S-ATB, R60S-ATC, R60S-ATD, R60S-ATE, R60S-ATF, R60S-ATG, R60S-ATH

COMMERCIAL & MARINE ELECTRIC 60” RANGE

Key

Number

36 2E-31800-04 2 CB 480V 50A 3 POLE R60S-ATA480/440M/480M, R60S-ATB480M,

37 2E-30304-09 2 SWTROT 6 HEAT+OFF208/240V R60S-ATB-208/240/208M/240M,

2E-30304-09 10 SWTROT 6 HEAT+OFF208/240V R60S-ATH-208/240/480

38 P9-500-308 1 TOP CONTROL PNL HOLE PATTEN R60S-ATB-208/240/208M/240M,

P9-500-308-10 1 TOP CONTROL PANEL CUSTOM R60S-ATH-208/240

P9-500-308-12 1 TP CTRL PNEL CUSTOM 480V R60S-ATA440M/480M, R60S-ATG480M

P9-500-308-13 1 TP CTRL PNEL CUSTOM 480V R60S-ATC-240V

P9-500-308-17 1 TOP CNTRL PNL 480V ALL R60S-ATH-480

P9-500-308-5 1 TOP CONTROL PANEL CUSTOM R60S-ATB480M, R60S-ATC-480/440M/480M,

P9-500-309-1 1 HOLE PATTERN A, E, G 480V R60S-ATA-480, R60S-ATE480M, R60S-ATG-480

39 P9-500-312 1 C.B. DOOR FRAME ASSY R60S-ATA-208, R60S-ATC-208

40 P9-500-310-2 1 BREAKER COVER HINGE 208/240V

41 2C-20201-13 2 WSHR BRASS #8 FLAT SAE R60S-ATA440M

42 2P-51001-19 1 SPRING SWT DR HINGE EHS 440M/480/480M

2P-51001-19 2 SPRING SWT DR HINGE EHS 208/208M/240/240M

43 P9-500-433 1 SPOT BREAKER COVER R60S-ATA-208, R60S-ATC-208

44 2C-20103-02 4 SHT METAL SCRW #10 X 1/2 R60S-ATA-208

45 2T-30402-08 2 STAT ADJ 450° 72 C/T R60S-ATC

2T-30402-08 3 STAT ADJ 450° 72 C/T R60S-ATD

2T-30402-08 4 STAT ADJ 450° 72 C/T R60S-ATE, R60S-ATF

2T-30402-08 5 STAT ADJ 450° 72 C/T R60S-ATG

2T-30402-23 1 STAT ADJ 850o 48C/T NAK R60S-ATD, R60S-ATE

2T-30402-23 2 STAT ADJ 850o 48C/T NAK R60S-ATC

2T-30402-23 4 STAT ADJ 850o 48C/T NAK R60S-ATB

2T-30402-23 5 STAT ADJ 850o 48C/T NAK R60S-ATA

46 P9-70701-35 1 KNOB 850o B PHANTOM R60S-ATD-208/240/480

P9-70701-35 2 KNOB 850o B PHANTOM R60S-ATC-208V, R60S-ATD440M/480M

P9-70701-35 4 KNOB 850o B PHANTOM R60S-ATB-208/240/208M/240M/480M

P9-70701-35 5 KNOB 850o B PHANTOM R60S-ATA440M/480M

NI 2B-50200-09 2 RACK OVEN ALL

NI 2E-30500-08 1 TRM BLOCK 2 POLE SMALL 95 R60S-ATA440M/480M, R60S-ATB480M,

NI 2E-30500-08 2 TRM BLOCK 2 POLE SMALL 95 R60S-ATC-480, R60S-ATD440M/480M,

NI 2E-30500-09 1 TRM BLOCK 3 POLE SMALL 95 R60S-ATA440M/480M, R60S-ATB480M,

NI 2E-30500-15 1 TRM BLOCK 4 POLE 115AMP R60S-ATC440M/480M

NI 2E-31200-02 1 LUG GROUNDING UL APPROVED R60S-ATA440M

NI 2M-61104-02 1 WD 500 RNG 480VAC R60S-ATC-480/440M/480M, ATD440M/480M,

Part

Number

Qty

Per

Description

R60S-ATC-480/440M/480M,

R60S-ATD-480/440M/480M, R60S-ATE480M,

R60S-ATF-480, R60S-ATG-480/480M,

R60S-ATH-480

R60S-ATC-208/240/240M/440M/480/480M,

R60S-ATD-208/240/480/440M/480M,

R60S-ATF-208/240/480

R60S-ATC-208/240M, R60S-ATD-208/240,

R60S-ATF-208/240

R60S-ATD-480/440M/480M, R60S-ATF-480

R60S-ATG-208/240/480/480M

R60S-ATE480M,

R60S-ATG-208/240/480/480M

R60S-ATE480M

4

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

4

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 19

Wiring Diagram 208/240 Volt

16

Page 20

Range Top Wiring

17

1. Griddle and Top Plate Element

2. Pilot Light

3. 450° Griddle thermostat

4. Circuit breakers

5. French plate

6. 6-Heat switch

7. Hot Top

8. 800° Hot Top thermostat.

GRIDDLE HOT TOP FRENCH PLATE

Page 21

Wiring Diagram 480 Volt

18

Page 22

Page 23

Page 24

STAR MANUFACTURING

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(800) 807-9054 (314) 781-2777

Parts & Service (800) 807-9054

www.star-mfg.com

Loading...

Loading...