Page 1

SHIPBOARD ELECTRIC

CONVECTION OVEN

ECOD-AT, ECODL-AT

ECOF-AT, ECOFL-AT

Installation and

Operation

Instructions

2M-W483 Rev. B 6/14/07

ECOF-AT

1

Page 2

SAFETY SYMBOL

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change speci¿ cations and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the speci¿ cations contained in this sheet are subject to change

without notice. While Star Manufacturing exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

speci¿ cations. By using the information provided, the user assumes all risks in

connection with such use.

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please record

the model number, serial number, voltage and purchase date in the area below and have it

ready when you call to ensure a faster service.

Model No.

Serial No.

Voltage

Purchase Date

Authorized Service Agent

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Telephone: (800) 807-9054 Local (314) 781-2777

The Star Service Help Desk

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 807-9054 Local (314) 781-2777

Fax: (800) 396-2677 Local (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Mailing Address: Star Manufacturing International Inc.

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

Page 3

Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page

1. Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. List of Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3. Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7. Maintenance & Troubleshooting Procedures . . . . . . . . . . . . .8

8. Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

9. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15, 17, 19, 21, 23

Fig# Title of Illustraion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page #

1. Picture of Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cover

2. Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Leg Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4. Stacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5. Wiring Diagram 208/240 VAC . . . . . . . . . . . . . . . . . . . . . . . . . 11

6. Wiring Diagram 440 VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

7. Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14, 16, 18, 20, 22

NOTICE: Service on this, or any other, LANG appliance must be

Table of Contents

List of Illustrations

performed by qualifi ed personnel only. Consult your LANG

authorized service agent directory or call the factory at

1-800-807-9054, or WWW.STAR-MFG.COM for the service agent

nearest you.

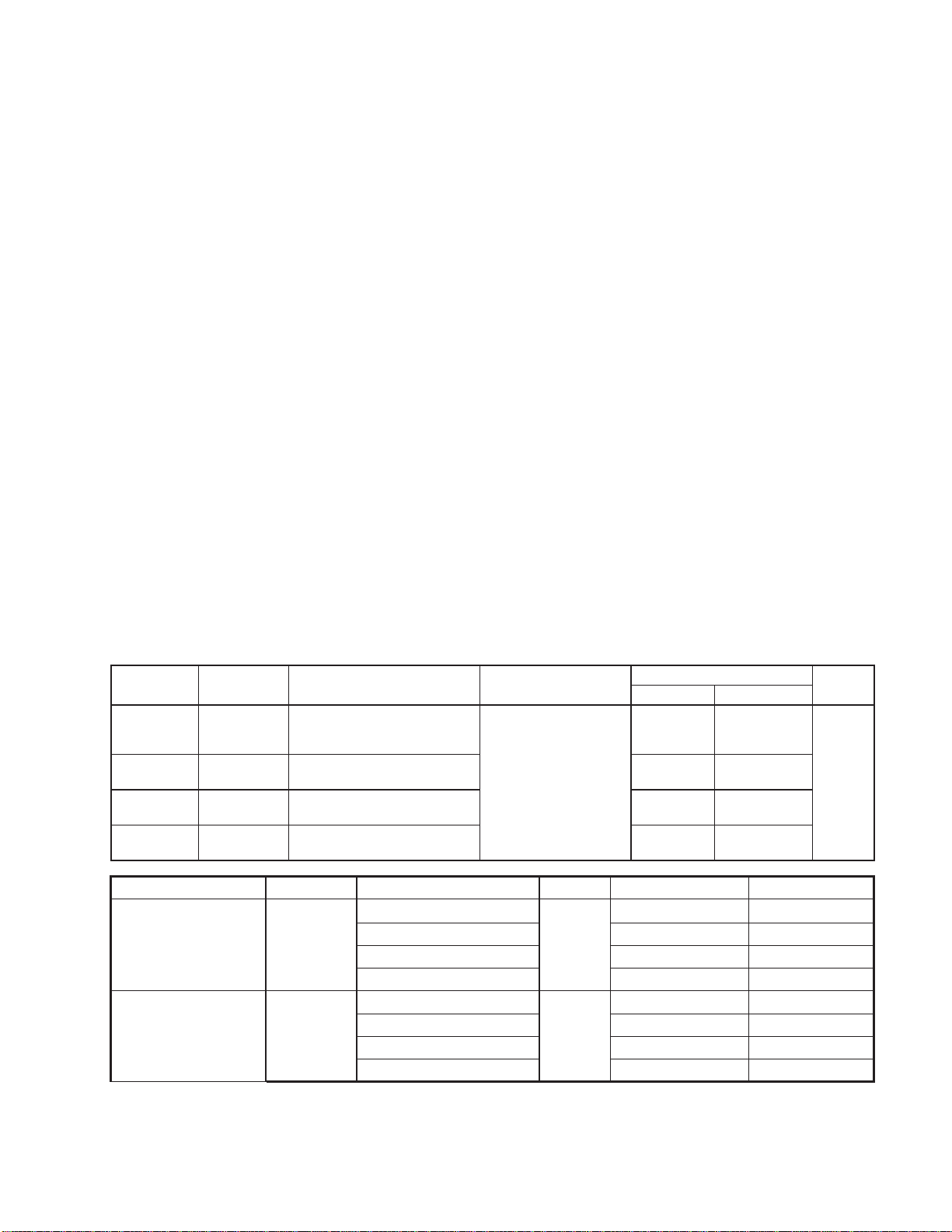

SPECIFICATIONS:

Star Model Lang Model Height x Width x Depth

ECOD-AT ECO-6M

ECOF-AT ECO-7M

ECOD-AT

ECODL-AT

ECOF-AT

ECOFL-AT

Star Model Lang Model Volts AC - Hz Total kW Amps - 3Ph Amps - 1Ph

ECO-8M

ECO-9M

25.0” x 38.0” x 45.2”

635mm x 966mm x 1148mm

25.0” x 38.0” x 38.2”

635mm x 966mm x 970mm

50.0” x 38.0” x 45.2”

1270mm x 966mm x 1148mm

50.0” x 38.0” x 38.2”

1270mm x 966mm x 970mm

Clearance from

conbustible surface

Side: 6” (153mm)

Back: 6” (153mm)

Floor: 6” (153mm)

Actual Shipping

380 lbs.

173 kg

360 lbs.

164 kg.

820 lbs.

373 kg

780 lbs.

355 kg

208 - 50/60

Single Stack

ECOD-AT

ECOF-AT

ECO-6M

ECO-7M

240 - 50/60 28.8 48.6

440 - 50/60 17.1 N/A

11.7

480 - 50/60 16.1 N/A

208 - 50/60

Double Stack

ECOD-AT, ECODL-AT

ECOF-AT, ECOFL-AT

ECO-8M

ECO-9M

240 - 50/60 57.7 97.2

440 - 50/60 34.2 N/A

23.3

480 - 50/60 32.2 N/A

Weight

430 lbs.

195 kg

410 lbs.

186 kg

870 lbs

395 kg

830 lbs.

377 kg

37.1 56.1

74.2 112.1

Freight

Class

70

Figure 2

3

Page 4

EQUIPMENT DESCRIPTION

INTRODUCTION

This manual contains the necessary information to install, operate, maintain, and service the Lang model

ECO convection ovens.

Replacement parts should be genuine Lang parts. Failure to use genuine Lang replacement parts may

result in malfunction of the appliance or possible injury to the contractor or service technician.

PURPOSE AND FUNCTION

Convection ovens constantly circulate air over the product. This removes a layer of moisture and cool

air from around the product. This allows heat to penetrate the product more quickly. Cooking times are

shortened and cooking temperatures are reduced.

CAPABILITIES

This convection oven is suitable for cooking all types of products requiring baking or roasting.

ENVIRONMENTAL REQUIREMENTS

The following minimum spacing from combustible surfaces must be maintained: Sides – 2 inches, Back

– 2 inches

ITEMS FURNISHED (Listed by Model Number)

SINGLE STACKED UNITS

ECOD-AT

ECO-6 or ECO-6M (Previouse Model)

1 ea. Oven, Type I, Size 2

4 ea. Legs

16 ea. 3/8 – 16 x 5/8 Bolts (For mounting legs)

16 ea. 3/8 – 16 Hex Nuts (For mounting legs)

32 ea. Washers (For mounting legs)

2 ea. Rack Slides, Extra Deep

5 ea. Racks, Extra Deep

2 ea. Manuals, Technical

ECOD-AT or ECOF-AT

ECO-7 or ECO-7M (Previouse Model)

1 ea. Oven, Type I, Size 1

4 ea. Legs

16 ea. 3/8 – 16 x 5/8 Bolts (For mounting legs)

16 ea. 3/8 – 16 Hex Nuts (For mounting legs)

32 ea. Washers (For mounting legs)

2 ea. Rack Slides, Standard Depth

5 ea. Racks, Standard Depth

2 ea. Manuals, Technical

DOUBLE STACKED UNITS

ECOD-AT, ECODL-AT or ECOF-AT, ECOFL-AT

ECO-8 or ECO-8M (Previouse Model)

2 ea. Oven, Type II, Size 2

4 ea. Legs

16 ea. 3/8 – 16 x 5/8 Bolts (For mounting legs)

16 ea. 3/8 – 16 Hex Nuts (For mounting legs)

32 ea. Washers (For mounting legs)

4 ea. Rack Slides, Extra Deep

10 ea. Racks, Extra Deep

2 ea. Manuals, Technical

1 ea. Stacking Kit

ECOD-AT, ECODL-AT or ECOF-AT, ECOFL-AT

ECO-9 or ECO-9M (Previouse Model)

2 ea. Oven, Type II, Size 1

4 ea. Legs

16 ea. 3/8 – 16 x 5/8 Bolts (For mounting legs)

16 ea. 3/8 – 16 Hex Nuts (For mounting legs)

32 ea. Washers (For mounting legs)

4 ea. Rack Slides, Standard Depth

10 ea. Racks, Standard Depth

2 ea. Manuals, Technical

1 ea. Stacking Kit

4

Page 5

ITEMS REQUIRED

An adequate supply of wire suitable for the loads and application specifi ed on the data sheet must be

provided. The data sheet is on Page 4 of this manual.

TOOLS AND TEST EQUIPMENT REQUIRED

For Installation:

1 set – Open End Wrenches

1 – Flat Blade Screwdriver

1 – Phillips Screwdriver

1 – Wire Cutter/Stripper

1 – AMP Probe

1 – Voltmeter

1 – Drill

4 – #27 Drill Bits

For Service: All of the above plus –

1 – Needle Nose Pliers

1 – Crimping Pliers

1 – Allen Wrench Set

1 – Temperature Meter

1 – Very Small Flat Blade Screwdriver

1 – #10 Square Drive Screwdriver

INSTALLATION

CAUTION: THE OVEN IS EXTREMELY HEAVY. FOR SAFE HANDLING,

INSTALLER SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY

APPROPRIATE MATERIALS HANDLING EQUIPMENT (SUCH AS

A FORKLIFT, DOLLY, OR PALLET JACK) TO REMOVE THE UNIT

FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

CAUTION: ANY STAND, COUNTER OR OTHER DEVICE ON WHICH OVEN

WILL BE LOCATED MUST BE DESIGNED TO SUPPORT THE

WEIGHT OF THE OVEN(S).

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK

WHEN CUT.

DANGER: THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL

PROVIDED. FAILURE TO GROUND THE APPLIANCE COULD

RESULT IN ELECTROCUTION AND DEATH.

WARNING: INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL

AND/OR DAMAGE TO EQUIPMENT. UNIT MUST BE INSTALLED IN

ACCORDANCE WITH ALL APPLICABLE CODES.

NOTICE: The data plate is located on the door of the oven. The oven

voltage, wattage, serial number, wire size, and clearance

specifi cations are on the data plate. This information should be

carefully read and understood before proceeding with the

installation.

5

Page 6

NOTICE: The installation of any components such as a vent hood, grease

extractors, fi re extinguisher systems, must conform to their

applicable National, State and locally recognized installation

standards.

INSTALLATION

INSPECTION AND INSTALLATION

Upon receipt of the oven(s) any damage should be noted on the Bill of Lading and countersigned by the

carrier. If concealed damage is discovered the carrier should be notifi ed. All claims must be fi led with

the carrier.

Move the crate(s) containing the oven(s) as close to the place of installation as possible before removing

the protective crating. Uncrate the oven(s) and move them as close as practical to the fi nal installation

site.

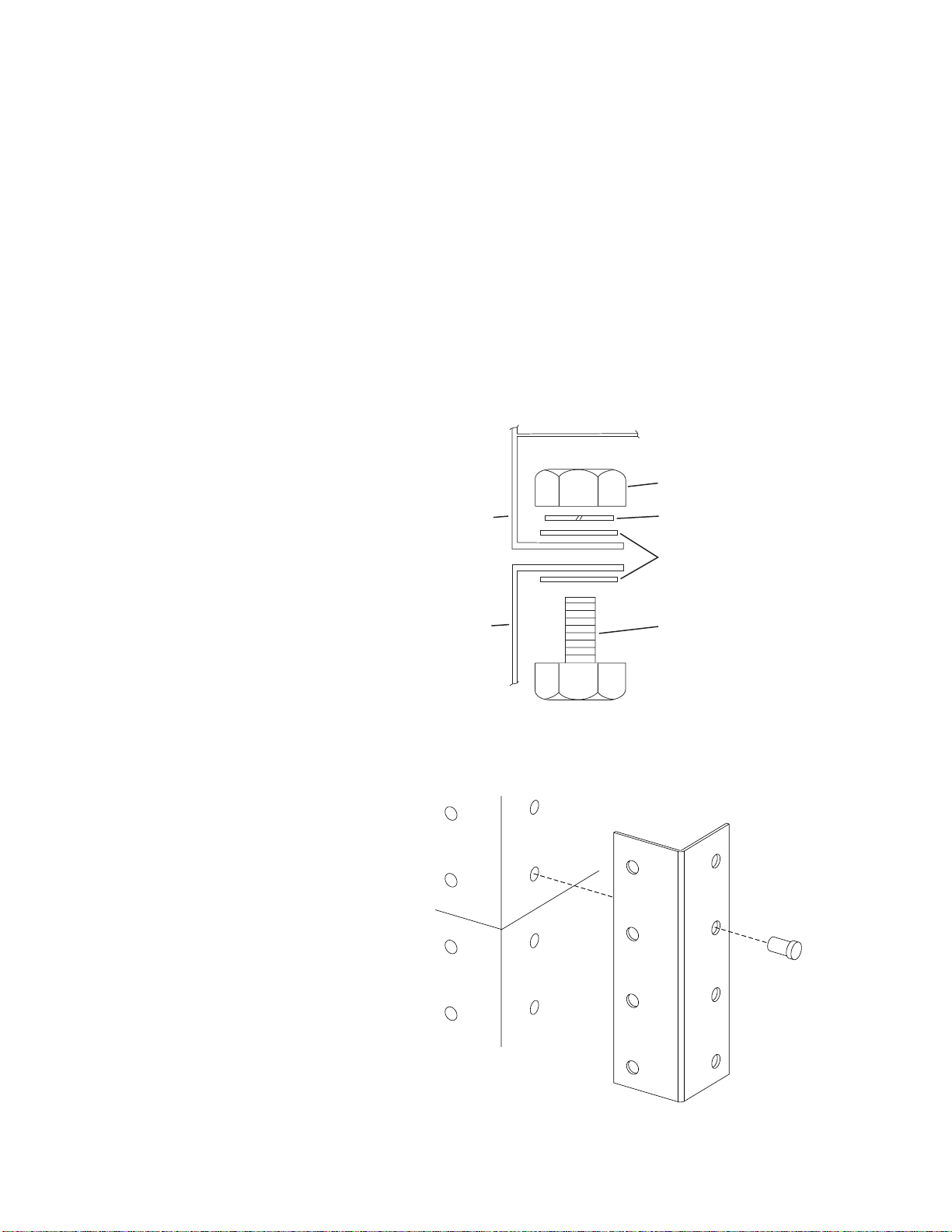

Bolt the legs to the bottom oven, (See fi gure #2). Use the 3/8 – 16 x 5/8 Bolts, Hex Nuts and Washers

provided. There are pre-punched holes provided in the legs and oven bottom to aid in leg installation.

Now the oven can be set upright in or near its fi nal position.

SINGLE OVENS:

Connect power throught the knockout on the

bottom of the unit.

The oven can be placed in its fi nal position

and leveled. The oven is ready for initial startup procedures now. (See page 7)

STACKED OVENS:

Be careful to route the power supply wire

between the two ovens using the holes

provided. Do not pinch or cut the supply wires

when stacking the ovens. Use the stacking kit

provided to secure the top oven to the bottom

oven.

The stacking kit contains four (4) identical

corner braces, one brace goes on each corner.

Drill pilot holes for the mounting screws using

the pre-punched holes as a guide. Secure the

top oven to the bottom oven with the sheet

metal screws provided. (See fi gure #3)

Connect the power supply leads from the top

oven to the power supply leads of the bottom oven and incoming power per the wiring

diagram on Page 11 or 12.

Oven Bottom

Nut 3/8 - 16 Hex

Flange

Leg

Figure 2, Bolting Legs to bottom oven

Top Oven

Lock Washer

Washer

Bolt 3/8 - 16 x 5/8

Corner Brace

IL1321

Now the bottom oven can be connected to the

incoming power supply through the knockout provided in the bottom of the oven. Be

sure the power supply voltage matches the

voltage specifi ed on the nameplate located on

the front of the oven! Then the oven can be

placed in its fi nal position and leveled. The

oven is ready for initial start-up procedures

now. See page 7.

Bottom Oven

IL1322

Figure 3, Securing the top & bottom ovens together.

6

Page 7

OPERATING INSTRUCTIONS

NOTICE: During the fi rst few hours of operation you may notice a small

amount of smoke coming off the oven, and a faint odor from the

smoke. This is normal for a new oven and will disappear after the

fi rst few hours of use.

CAUTION: ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

CAUTION: KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF

SPILLS OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER

OF SLIPS OR FALLS.

Each oven has the following controls:

Vent – Pull to Open, Push to close.

Timer – Adjust to desired setting.

Temperature – Turn to desired cooking temperature.

Power Switch – Pull up to turn oven ON, push down to turn oven OFF.

Light Switch – Pull up to turn oven light ON, release and oven light goes out automatically.

Motor Speed Switch – Pull up for High Speed, push down for low speed.

INITIAL START-UP

Set oven(s) at 350°F and allow oven to operate empty for 3 hours, prior to initial use.

NORMAL OPERATION

Turn the Power Switch On, turn to the desired temperature and select motor speed. (Hi or Low)

7

Page 8

MAINTENANCE

Wash the stainless interior & exterior often with a solution of hot water and mild detergent to prevent grease

build-up and preserve the oven’s appearance. The oven racks, slides and stainless steel oven liners are

removable for easier cleaning of the oven interior.

NOTE: Wipe up spillage as soon as possible. Never use scouring powder. It is diffi cult to remove completely

and a residue build-up can damage the oven.

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER

SPRAY OR HOSE CONTROL CONSOLE, ELECTRICAL

CONNECTIONS, ETC.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES,

MUCOUS MEMBRANES AND CLOTHING. PRECAUTIONS

SHOULD BE TAKEN TO WEAR RUBBER GLOVES, GOGGLES OR

FACE SHIELD AND PROTECTIVE CLOTHING. CAREFULLY READ

THE WARNING AND FOLLOW THE DIRECTIONS ON THE LABEL

OF THE CLEANER TO BE USED.

NOTICE: Service on this, or any other, LANG appliance must be performed

by qualifi ed personnel only. Consult your authorized service

station directory or call the factory at 1-800-224-LANG (5264), or

WWW.LANGWORLD.COM For the service station nearest you.

WARNING: BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THIS

APPLIANCE WHEN THE UNIT IS PLUGGED/WIRED INTO A LIVE

RECEPTACLE. BEFORE REPLACING ANY PARTS, DISCONNECT

THE UNIT FROM THE ELECTRIC POWER SUPPLY.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUP-

PLIED BY LANG OR THEIR AUTHORIZED DISTRIBUTORS CAN

CAUSE BODILY INJURY TO THE OPERATOR AND DAMAGE TO

THE EQUIPMENT AND WILL VOID ALL WARRANTIES.

TROUBLESHOOTING GUIDE

SYMPTOM PROBLEM REMEDY

Internal Circuit Breakers Off Turn on

Oven will not turn on

Power Supply Circuit Breakers Trip

Internal circuit breakers trip Supply voltage & oven voltage do not match change voltage to match oven

Oven takes to long to bake and will not

maintain temperature

Power supply circuit breakers off Turn on

Improperly Phased Phase per wiring diagram

Fuse Open Change fuses

Supply circuit breakers of insuffi cient size Install proper size breakers

Supply voltage & oven voltage do not match change voltage to match oven

Improperly Phased

Phase oven to match power

supply per wiring diagram

8

Page 9

MAINTENANCE and TROUBLESHOOTING CONT’D

PERFORMANCE AND INSPECTION

A periodic check of thermostat calibration should be performed. To check oven calibration attach a

thermocouple to the mid-point of the thermostat bulb in the oven cavity . Turn the temperature dial to 350°F

and turn the oven ON. Wait approximately 20 minutes until the oven temperature has stabilized. If the

average of the ON and OFF thermostat readings is within 10°F of 350°F the oven is in calibration. If not,

remove the temperature knob and turn the small screw in the middle until oven is in calibration. Replace

the knob and the oven is ready for normal operation.

MAJOR COMPONENT DISASSEMBLY, REPAIR, REPLACEMENT & REASSEMBLY

(Refer to fi gure #4, page 22)

THERMOSTAT, CONTACTORS (RELAYS), SWITCHES

These parts are located behind the control panel assembly on the right hand side of each oven. Remove

the screws attaching the control panel to the front of the oven. Slowly pull out the control panel until the

component requiring replacement is accessible.

THERMOSTAT REPLACEMENT:

Inside the oven cavity remove the retaining clips holding the thermostat-sensing bulb in place. Feed the

bulb through the oven wall into the control panel area. Remove the wires attached to the thermostat

terminals. Remember the terminal each wire was on and attach the wires to the same terminal on the

new thermostat. Remove the screws holding the old thermostat to the front of the control panel. Discard

old thermostat. Mount the new thermostat to the control panel, carefully feed the sensing bulb through

the oven wall, and reattach the sensing bulb to the oven side using the retaining clips removed earlier.

Close control compartment. Restore power to oven. Refer to the “Performance and Inspection” section

to verify proper operation of the new thermostat.

ELEMENT REPLACEMENT:

The element is located inside the oven cavity. To replace the element, remove the baffl e at the back

of the oven. This will expose the elements to plain view and allow easy access. Remove the element

mounting screws located near the top of the oven. Gently , pull the element into the oven cavity. There is

enough wire connected to the element to allow easy access to the terminals located behind the element

mounting plate. Move each wore from the existing terminal to the corresponding terminal on the new

element. DO NOT mix up these wires! After all wires are transferred to the new element, feed the wire

back through the access hole in the back of the oven and attach the element to the oven wall with the

screws removed earlier. Replace the baffl e. Refer to the “Initial Start-up” section to restore the oven to

proper operation.

CONTACTOR (RELAY), SWITCH REPLACEMENT:

Pull out control panel as previously outlined. Remove the wires from the contactor or switch being changed.

Place those wires on the corresponding terminal of the new part. Remove old part and mount new part

with wires attached in the spot where the old part used to be. Reinstall the control panel, restore power

to the oven. Turn oven on, set thermostat to 200°F and allow oven to cycle 3 times or until the technician

is satisfi ed with the proper operation of the oven.

BLOWER WHEEL REPLACEMENT:

The blower wheel is located inside the oven cavity. To replace the blower wheel, remove the baffl e at

the back of the oven. This will expose the blower wheel to plain view and allow easy access. Loosen

the two (2) set screws holding the blower wheel onto the motor shaft. Using a three-fi nger blower wheel

puller, grasp the puller ring with all three fi ngers and tighten the puller until the blower wheel hub clears

the motor shaft. Place new blower wheel on the motor shaft and position exactly 5/8” from the oven back

motor plate. Tighten the set screw positioned over the fl at on the motor shaft. Spin the fan to make sure

it spins straight. Tighten the second set screw and re-tighten the fi rst set screw. Replace the baffl e. The

oven is now ready to re-start.

9

Page 10

MAINTENANCE and TROUBLESHOOTING CONT’D

MOTOR REPLACEMENT:

The motor is located inside the oven cavity. To replace the motor, remove the baffl e at the back of the

oven. This will expose the blower wheel and motor shaft to plain view and allow easy access. Remove

the blower wheel as described in “BLOWER WHEEL REPLACEMENT”. Next, remove the bolts holding

the motor plate to the back wall of the oven cavity . Gently pull the motor forward and lay on the bottom of

the oven cavity . Mark the wires so they can be placed on the same terminals of the new motor. Remove

the motor wires. Remove the motor from the oven. Remove the motor mounting bolts, remove the old

motor and replace with the new one. Reveres the above steps to remount the motor and see “BLOWER

WHEEL REPLACEMENT” for proper re-installation of the blower wheel.

TRANSFORMER REPLACMENT:

Pull out control panel as previously outlined. Mark the wires attached to the transformer. Remove the wires.

Remove the screws holding the transformer to the control panel. Install the new transformer. Reconnect

the wires making sure they are attached to the same terminals as on the original transformer. Reinstall

the control panel, restore power to the oven. The oven is now ready for normal operation.

MICROSWITCH REPLACEMENT:

Open the oven doors and remove the screws from the micro switch cover located below the doors. Remove

the micro switch cover. Remove the two (2) small screws (6/32) holding the micro switch to its’ mount.

Mark the wires attached to the micro switch, then remove the wires. Attach the wires to the new micro

switch. Mount the micro switch with the two 6/32 screws. Adjust the micro switch arm for proper switch

actuation. Replace cover and restart oven.

10

Page 11

Figure 5

11

Page 12

Figure 6

12

Page 13

2

1

8

3

4

5

8

11

SEE DETAIL B

6

7

9

10

SEE DETAIL A

Model:

ECOF-AT1M Electric Marine Convection Oven

ECO-7M Electric Marine Convection Oven

14

SK2257 Rev. - 6/12/07

Page 14

PARTS LIST June 15, 2007, Rev B

Model No: ECOD-AT, ECODL-AT, ECOF-AT, ECOFL-AT

SHIPBOARD ELECTRIC CONVECTION OVEN

Key

Number

1 Q9-ECO-471 1 TOP-TOP DECK ECOF

Q9-ECO-472 1 TOP-BOTTOM DECK ECOFL

Q9-ECO-477 1 TOP-TOP-DECK DEEP OVEN ECOD

Q9-ECO-478 1 TOP-BOTTOM DECK DEEP ECODL

Q9-ECO-471-1 1 TOP FRONT - TOP DECK - HATCHABLE

2 Q9-ECO-471-2 1 TOP REAR - TOP DECK - SUB HATCHABLE

3 2P-70901-01 1 PLG BTN BLKPLSTC 1DP-1000 ECOD-AT-440G, ECODL-AT440M, ECOFL-AT208M,

ECOFL-AT440M

2P-70901-01 2 PLG BTN BLKPLSTC 1DP-1000 ECOF-AT-480M, ECOD-AT-480M

4 Q9-ECO-437 1 DAMPER PIVOT ALL

5 Q9-ECO-446 1 DAMPER ROD A ECOF

Q9-ECO-461 1 DAMPER ROD A - DEEP ECOD

6 2C-20103-02 2 SCRW SM PLT 10 X .5 PHLSL HATCHABLE

7 Q9-ECO-479-1 1 BTM COVER BTM DECK ONLY - HATCHABLE

8 Q9-ECO-177 1 BODY WRAP ASSY ECOF

Q9-ECO-177-1 1 BODY WRAP DEEP ASSY ECOD

9 Q9-ECO-196-1 1 FRONT ASSY - SUB ALL

10 Q9-ECO-203 1 SWITCH DOOR ASSY ALL

11 2R-70701-25 1 KNOB DAMPER BLACK PLAIN ALL

RACKS

NI 2B-50200-20 5 RACK ECCO/GCCO OVEN ECOF

NI 2B-50200-31 5 RACK ECO DEEP OVEN ONLY ECOD

NI 2B-50200-32 2 RACK SLIDE 5 POS ECO OVEN ECOF

NI 2B-50200-33 2 RACK SLIDE 5 POS ECO DEEP ECOD

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

2

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

15

Page 15

Front

12

13

14

15

16

17

SEE DETAIL

C

Model:

ECOF-AT1M Electric Marine Convection Oven

ECO-7M Electric Marine Convection Oven

SK2258 Rev. - 6/12/07

16

Page 16

PARTS LIST June 15, 2007, Rev B

Model No: ECOD-AT, ECODL-AT, ECOF-AT, ECOFL-AT

SHIPBOARD ELECTRIC CONVECTION OVEN

Key

Number

12 Q9-ECO-423 VENTS ASSY ALL

13 Q9-ECO-435 VENT CAP - MILITARY ALL

14 Q9-ECO-449 1 DAMPER ROD B ASSY ALL

15 Q9-ECO-391 1 MOTOR MOUNT ASSY 440/480V 440V/480V

Q9-ECO-391-1 1 MOTOT MOUNT ASSY 208V 208V

16 Q9-ECO-172 1 REAR FIREWALL ASSY ALL

17 Q9-ECO-184 1 BODY BACK ALL

ELEMENTS

ni 2N-11090-18 1 ELMNT ECCO 480V 11KW 480V

ni 2N-11090-30 1 ELE 415 440V11KW 440V

ni 2N-11090-16 1 ELE ECCO OVN 208/240V 11KW 208V

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

2

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

17

Page 17

44

33

32

55

53

45

SEE DETAIL D

37

35

34

33

39

38

36

48

49

41

39

43

47

46

42

41

40

54

53

55

52

61

60

59

58

51

56

57

62

10

49

18

51

50

DETAIL A

Typical Door Assy

SK2260

Page 18

PARTS LIST June 15, 2007, Rev B

Model No: ECOD-AT, ECODL-AT, ECOF-AT, ECOFL-AT

SHIPBOARD ELECTRIC CONVECTION OVEN

Key

Number

32 2C-20109-25 4 SCRW S/S 10-32 X 3/4 T/H ALL

33 2C-20201-07 4 WSHR FLT 1/4 SAE PLTD ALL

34 2C-20301-29 4 NUT HEX ACORN 1/4-20 S/S ALL

35 2C-20102-04 4 SCRW PHD ST 8-32X.5 PLTD ALL

36 Q9-ECO-595 2 ECO DOOR HANDLE ALL

37 2R-50800-91 2 DOOR HANDLE ALL

38 Q9-ECO-200-3 1 DOOR CATCH ASSY - SUB ALL

39 2C-20109-04 2 SCRW THD MS SS 10-32X3/8 ALL

40 2C-20115-01 10 SCRW S/S 8-32X1/2 P/H S/T ALL

41 Q9-ECO-507 4 HINGE PIN WELD - ECO ALL

42 2C-20109-15 8 SCRW PHD MS SS 10-32X1/2 ALL

43 Q9-ECO-557 4 HANDLE SPACER ALL

44 2R-70602-03 2 CATCH DOOR MAGNET 3 PC ALL

45 Q9-ECO-533 2 MAGNET BACKER ALL

46 2C-20101-10 4 SCRW THD MS 1/4-20X2 1/4 ALL

47 2C-20201-07 4 WSHR FLT 1/4 SAE PLTD ALL

48 Q9-ECO-563 4 RETAINER ALL

49 2C-20306-03 10 AVK CAD 10-32 1ST GRP ALL

50 Q9-ECO-572 1 RH DOOR VANE ASSY S/S ALL

50 Q9-ECO-584 1 LH DOOR VANE ASSY S/S ALL

51 2C-20103-02 AR SCRW SM PLT 10 X .5 PHLSL ALL

52 Q9-ECO-777-1 2 SWITCH CAM ASSY - 1/2 ALL

53 2C-20109-30 8 SCRW MS SS 10-32 X .75 PH ALL

54 2P-70201-19 4 BRNZBRFLN1/2IDX5/8ODX3/8 ALL

55 Q9-ECO-508-1 1 HINGE BOTTOM RH - ECO ALL

Q9-ECO-508-2 1 HINGE BOTTOM LH - ECO ALL

Q9-ECO-508-3 1 HINGE TOP LH - ECO ALL

Q9-ECO-508-4 1 HINGE TOP RH - ECO ALL

56 Q9-ECO-782 1 SWITCH BOX COVER ALL

57 Q9-ECO-786 2 SWITCH BRACKET MILITARY ALL

58 2C-20101-17 4 SCRW RND MS 6-32X1 PLTD ALL

59 2E-30301-02 2 SWT MICRO #2HLT-5 UNIMAX ALL

60 2C-20301-10 4 NUT HEX 6-32 PLTD ALL

61 2K-70801-03 1 SNAP BUSH 3/8 SB375-4 BLK ALL

62 2C-31901-01 1 CABLE TIE MOUNT ALL

NI 2H-60106-13 2 INSULATION KIT ECO DOOR ALL

NI 2Q-71301-04 2 WINDOW ASSY 9-5/8X16-5/8 ALL

NI Q9-ECO-480 1 RH DOOR ASSY COMPLETE ALL

NI Q9-ECO-480-1 1 LH DOOR ASSY COMPLETE ALL

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

2

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

19

Page 19

20

25

24

23

21

22

21

18

19

26

27

28

29

20

31

30

DETAIL C

Motor Mount Assy

20

SK2259

Page 20

PARTS LIST June 15, 2007, Rev B

Model No: ECOD-AT, ECODL-AT, ECOF-AT, ECOFL-AT

SHIPBOARD ELECTRIC CONVECTION OVEN

Key

Number

18 2U-30200-16 1 MTR 1/3HP 460V/1/60HZ 2SP 480V

2U-30200-17 1 MTR 1/3HP208/240V 1PH 2SPD 208V

19 2C-20118-01 4 SCRW CARRAGE PLT 5/16X.75 ALL

20 2C-20202-09 4 WSHR LOCK 3/8 STD SPLIT ALL

21 2C-20301-09 12 NUT HEX 10-24 PLTD ALL

22 Q9-GCCO-167 1 MOTOR SHIELD ALL

24 2C-20101-42 4 SCRW THD MS 10-24X2 PLTD ALL

25 2U-71500-05 1 BLOWER WHEEL ECCO/GCCO ALL

26 2C-20101-13 2 SCRW RHD MS 6-32X1/2 PLTD ALL

27 Q9-GCCO-166-2 1 SPACER - SAFETY STAT ALL

28 2T-30401-09 1 STAT FXD 500 DEG OPEN ALL

29 2C-20301-10 2 NUT HEX 6-32 PLTD ALL

30 2C-20301-06 4 NUT HEX 5/16-18 PLTD ALL

31 2C-20202-08 4 WSHR PLT 5/16 LOCK SPLIT ALL

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

2

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

21

Page 21

66

64

65

81

79

78

82

80

77

76

83

84

DETAIL B

DETAIL D

75

74

72

73

72

67

68

70

71

85

102

101

Typical Door Stop Assy

Left Hand

Q9-50301-52 DOOR STOP LH ARM & BRACKET ASSY

Q9-50301-50-1 DOOR STOP ASSY L/H

Right Hand

Q9-50301-88-1 DOOR STOP ASSY R/H

Q9-50301-90 DOOR STOP RH ARM & BRACKET ASSY

103

97

22

96

104

100

98

94

99

95

93

86

87

88

89

90

91

92

SK2261

Page 22

PARTS LIST June 15, 2007, Rev B

Model No: ECOD-AT, ECODL-AT, ECOF-AT, ECOFL-AT

SHIPBOARD ELECTRIC CONVECTION OVEN

Key

Number

64 2E-30705-01 1 CONTC 2-SPD MTR-COIL 240 ALL

65 2E-30700-03 1 CONTC 3POLE 40A208-240VAC ALL

66 2E-31400-04 1 XFRMR 480/240VAC 100VA ALL

67 2E-30500-09 1 TRM BLOCK 3 POLE SMALL 95 440V, ECOF-AT-480G, ECOFL-AT208M,

68 2E-31800-07 1 CB 2/10 AMP 2 POLE

2E-31800-01 4 CB 250V 50A 1 POLE CRLNGSW ECOFL-AT208M

70 2E-30901-08 1 FUSE HLDR FOR SC FUSE ALL

71 2E-30900-10 1 FUSE 15AMP 300V (SC-15) ALL

72 2E-30303-06 2 SWT TOG ON-ON DPDT BLK ALL

73 2E-30303-16 1 SWT TOG ON-ON BLK MOM ALL

74 2T-30402-27 1 STAT ADJ 450 DEG 48 PILOT ALL

75 2J-30801-03 1 TIMER MECHANICAL 5 HOUR ALL

76 2E-30303-09 1 SWT PLATE HI/LOW ALL

77 2E-30303-10 1 SWT PLATE ON/OFF IND ALL

78 2E-30303-05 1 SWT PLATE ON/OFF ALL

79 2R-70702-08 1 DIAL PLATE 450o STAT ALL

80 2R-70700-01 1 KNOB BLNK UNIVERSAL BLACK ALL

81 2R-70701-55 1 KNOB 5 HOUR TIMER ALL

82 2R-70702-37 1 DIAL PLATE, 5 HOUR TIMER ALL

83 2S-31600-01 1 LAMP FLOUR 9 NOM. LENGTH ALL

84 2S-31603-04 1 LAMPS INC 250V 50W ALL

85 2C-20109-04 10 SCRW THD MS SS 10-32X3/8 ALL

86 Q9-50301-54 1 DOOR STOP ARM L/H ALL

86 Q9-50301-92 1 DOOR STOP ARM R/H ALL

87 2C-20111-02 2 SCRW HXHD CAP 1/4-20X3/4 ALL

88 Q9-50301-52 1 DOOR STOP LH ARM&BRACKET ALL

Q9-50301-90 1 DOOR STOP RH ARM&BRACKET ALL

89 2C-20303-01 2 NUT HX SS 1/4-20 ALL

90 2C-20109-52 4 SCRW PAN HD MS SS M3X8MM ALL

91 Q9-50301-51 1 DOOR STOP SLIDE L.H. ALL

Q9-50301-89 1 DOOR STOP SLIDE R/H ALL

92 Q9-50301-51-3 4 BACKUP WASHER ALL

93 2A-20401-04 4 SPCER 1/8IDX3/160DX1/16LG ALL

94 2C-20301-42 4 NUT HEX ACORN M3-A2 ALL

95 2C-20406-02 2 RVT 5/32X1 1/4 FH 100o ALL

96 2P-51001-23 2 SPRING DOOR STOP-ECO ALL

97 Q9-50301-51-4 2 DOOR STOP SPRING TUBE ALL

98 Q9-50301-51-2 1 SPRING STOP & RAMP L/H ALL

Q9-50301-89-2 1 DOOR STOP & RAMP R/H ALL

99 Q9-50301-51-1 1 DOOR STOP LATCH L.H. ALL

Q9-50301-89-1 1 DOOR STOP LATCH R/H ALL

100 Q9-50301-51 1 DOOR STOP SLIDE L.H. ALL

Q9-50301-89 1 DOOR STOP SLIDE R/H ALL

101 2C-20405-02 2 RVT SOLID 3/16X 5/8R/H ALL

102 Q9-50301-54-1 2 DOOR STOP WASHER ALL

103 2P-70203-01 2 BEARING STL #41 ROLLER ALL

104 Q9-50301-55 2 DOOR STOP PAD ALL

Part

Number

Qty

Per

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

2

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

23

Loading...

Loading...