Page 1

Installation

Operation

Maintenance

Model: ECCO-C

Electric Full Size Convection Oven

Lang Manufacturing Company 6500 Merrill Creek Parkway Everett, WA 98203

Part Number 60800-02 Revision B Phone: 425-349-2400 Fax: 425-349-2483 July 1995

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS..............................................................................................................................1

INSTALLATION................................................................................................................... ....................... 1

RECEIVING THE OVEN....................................................................................................................... 1

DATA PLATE INFORMATION............................................................................................................ 1

CLEARANCES....................................................................................................................................... 1

LEGS....................................................................................................................................................... 1

STACKING THE OVENS...................................................................................................................... 2

ELECTRICAL CONNECTION.............................................................................................................. 2

OPERATION................................................................................................................................................ 4

GENERAL............................................................................................................................................... 4

CONTROL PANEL................................................................................................................................. 4

STATUS READOUT DISPLAY ............................................................................................................5

PRODUCT AND SHELF BUTTONS..................................................................................................... 5

PRODUCT CHANGING............................................................................................................... ....... 6

TIME RECALL..................................................................................................................................... 6

CANCEL SHELF.................................................................................................................................. 6

MANUAL PROGRAMMING................................................................................................................. 6

TEMPERATURE RECALL BUTTON................................................................................................... 7

READ/CLEAR BUTTON....................................................................................................................... 7

MANUAL CONTROL OVERRIDE....................................................................................................... 7

MAINTENANCE .......................................................................................................................................... 8

CLEANING............................................................................................................................................. 8

DOOR CHAIN ADJUSTMENT ............................................................................................................. 8

SERVICE....................................................................................................................................................... 9

CALIBRATION......................................................................................................................................9

CONTROL PANEL REMOVAL............................................................................................................ 9

ELEMENT REMOVAL.......................................................................................................................... 9

MOTOR REMOVAL.............................................................................................................................. 9

SAFETY THERMOSTAT REMOVAL................................................................................................ 10

PARTS......................................................................................................................................................... 11

CONTROL PANEL LAYOUT ............................................................................................................. 11

PARTS LIST ......................................................................................................................................... 12

WIRING DIAGRAMS ............................................................................................................................... 13

208 /240 VOLT ..................................................................................................................................... 13

480 VOLT OVEN .................................................................................................................................14

Lang Manufactur ing Company 800-224-5264

6500 Merrill Creek Parkway Fax: 425-349-2733

Everett, WA 98203

USA Copyright 1995

Page 3

INSTALLATION

RECEIVING THE OVEN

Upon receipt, check for freight damage, both

visible and concealed. Visible damage should be

noted on the freight bill at the time of delivery

and signed by the carrier's agent. Concealed loss

or damage means loss or damage which does not

become apparent until the merchandise has been

unpacked. If concealed loss or damage is

discovered upon unpacking, make a written

request for inspection by the carrier's agent

within 15 days of delivery. All packing material

should be kept for inspection. Do not return

damaged merchandise to Lang Manufacturing

Company. File your claim with the carrier.

Uncrate the appliance as near its intended

location as practical. The crating will help

protect the unit from the physical damage

normally associated with moving it through

hallways and doorways.

The installation of any components such as vent

hood, grease extractors, fire extinguisher

systems, must conform to their applicable

nationally recognized installation standards.

CLEARANCES

Standard minimum clearance from

construction is as follows:

2 inches from sides

4 inches from back

6 inches from floor

If the oven is set without legs on a

noncombustable

a 4 inch back clearance.

If the oven is set directly against a

noncombustible

clearance to the floor.

Do not

from an uncontrolled heat source, such as open

flame burners or char broilers, on the right side

(control side) unless a

installed. With the spacer installed the distance

to an uncontrolled heat source can be reduced to

3 inches.

Do not

another oven on the right hand side (control

side).

install the oven closer than 12 inches

install the oven closer than 3 inches from

floor or a curbed base maintain

back wall maintain a 6 inch

Hi Temperature Spacer

combustible

is

DATA PLATE INFORMATION

A data plate is located inside the control

compartment above the control. Look through

the perforated opening above the control panel

and to the left to view the data plate. A flashlight

my be helpful.

The oven voltage, wattage, serial number, wire

size, and clearance specifications are on the data

plate.

This information should be carefully read and

understood before proceeding with the

installation.

The oven is field settable for voltages 208 and

240. 480 volt ovens require being manufactured

for 480 volt. The phase of the oven is field

settable for single and three phase.

Refer to the ELECTRICAL section for the

instructions on setting voltage and phase.

LEGS

Legs are available for both the single and double

deck installations. Single deck installations

require a 27 inch leg. Double deck installations

require a 6 inch leg or caster.

To install the 27 inch legs, place some cardboard

on the floor and gently tip the oven onto its back.

Fasten two legs to the oven's front corners using

the four 5/16 inch bolts provided in the leg kit.

Lift the oven onto its front legs and block the

back up using one o f the 27 inch legs set upside

down in the center rear of the oven body. Install

the last 27 inch leg onto the oven body on the

control side rear. Gently lift the oven rear,

remove the leg set to support the oven center and

install it on the last rear corner.

To install the 6 inch legs or casters, attach the leg

or caster to the leg supports supplied in the oven

by following the instructions in the box, then

attach the leg support to the oven.

1

Page 4

The adjustable feet on the bottom of each leg

may be screwed in or out as necessary to level

the oven.

A spirit level placed on an oven rack will assist

in leveling the oven.

ELECTRICAL CONNECTION

The electrical connection must be made in

accordance with local codes or in the absence of

local codes with NFPA No. 70 latest edition (in

Canada use: CSA STD. C22.1)

STACKING THE OVENS

Remove all the plug buttons from the top of the

lower oven.

Remove the stacking kit from the oven

compartment of one oven and install the 1 1/4

inch plastic bushing into the top of the lower

oven.

Tip the top oven backwards and install two 3/8

inch socket head bolts, found in the stacking kit,

into the two front leg holes that match the holes

in the top of the lower oven. Install the socket

head bolts with the heads of the bolt pointing

away from the oven.

Lift the top oven and gently set on top of the

lower oven so that the heads of the socket head

bolts nest into the holes in the top of the lower

oven.

IMPORTANT

IF THE SERVICE CONNECTION IS TO BE

MADE AT THE FRONT OF THE OVEN, BE

SURE TO FEED THE TOP OVENS

SUPPLY WIRES DOWN THROUGH THE

BUSHING INSTALLED IN THE TOP OF

THE LOWER OVEN. ALL THE WIRES

SHOULD THEN TERMINATE NEAR THE

CIRCUIT BREAKERS OF THE LOWER

OVEN.

The ovens may now be set into position. Be

careful if sliding the ovens, they were not

designed to slide over cracks or obstructions in

the floor.

The electrical service entrance is provided by a 1

1/4 inch knockout in the bottom right front

corner of each oven, or at the oven back directly

behind the co ntr o l co mpa rt ment. G ro und ing lugs

are provided at both the front and rear service

entrances.

The 208/240 volt oven is a dual voltage oven and

is shipped from the factory as 208 volt. The

oven must be field converted to operate on a 240

volt power supply.

To convert the oven to 240 volt, remove the

jumper wire located on a terminal strip located

inside the lower portion to the control

compartment.

With 480 volt installations check to be sure that

the motor rotates in a clockwise direction as

viewed from the front of the oven.

To reverse the motor rotation, switch any two

incoming power supply leads and recheck the

rotation.

Supply wire size must be large enough to carry

the amperage load for the number of ovens being

installed. Wire size information can be found on

the oven DATA PLATE.

This oven can be installed on both single and

three phase supplies and is shipped from the

factory unphased .

To phase the oven to match the power supply,

follow the charts below for proper wire size and

grouping.

2

Page 5

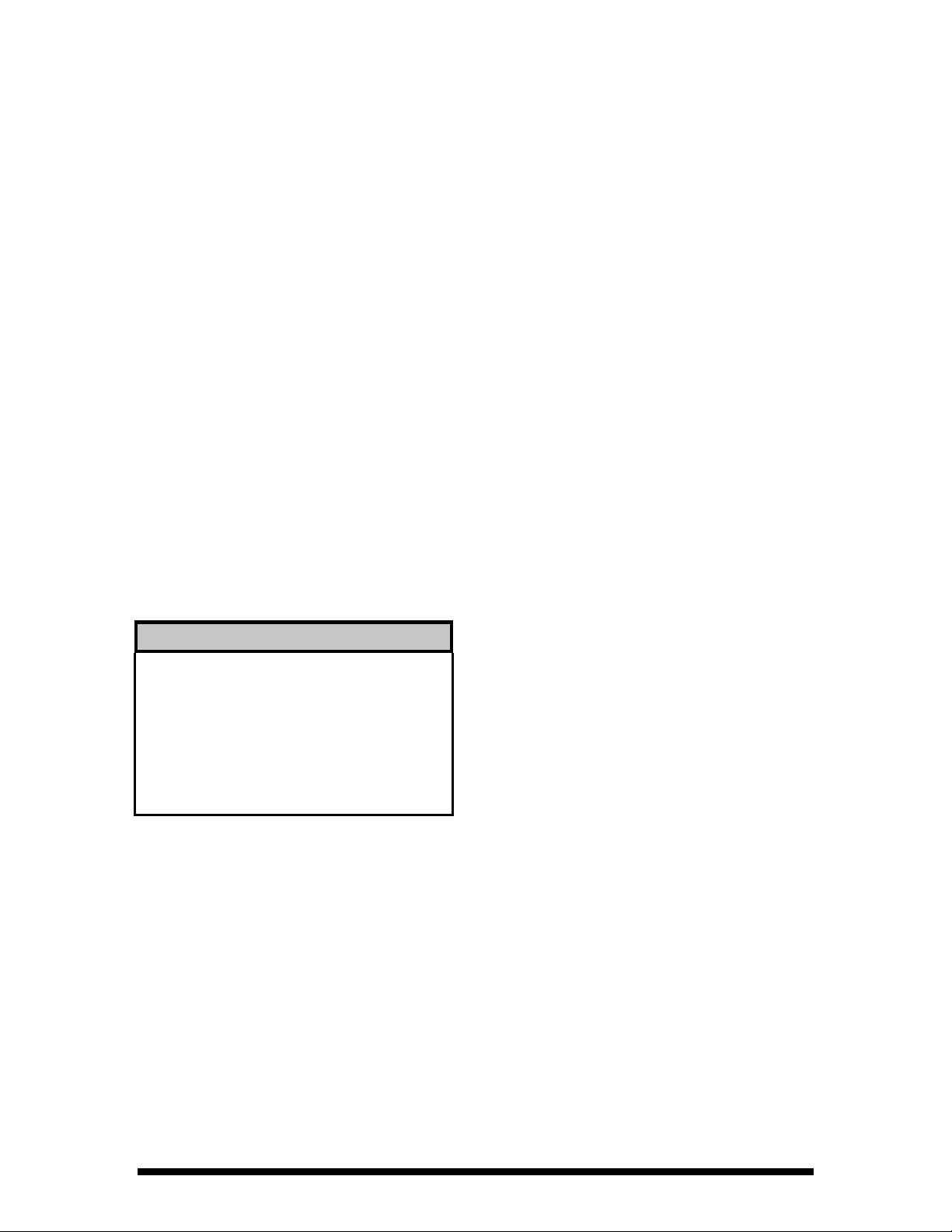

AMPERAGE AND KW CHART

MODEL VOLT KW AMPERAGE

3 PHASE 1 PHASE

L1 TO L2 L2 TO L3 L3 TO L1 TOTAL LINE 1 LINE 2 LINE 3

1 OVEN 208 6.0 2.7 2.7 11.5 36.5 36.5 22.9 55.3

1 OVEN 240 4.2 3.7 3.7 11.5 28.3 28.3 26.5 47.9

1 OVEN 480 6.0 2.7 2.7 11.5 15.6 15.6 10.5 N/A

2 OVENS 208 8.8 8.8 5.5 23.0 59.4 72.9 59.4 110.6

2 OVENS 240 7.8 7.8 7.3 23.0 54.8 56.6 54.8 95.8

2 OVENS 480 8.8 8.8 5.5 23.0 25.5 31.2 25.5 N/A

SERVICE CONNECTION

MODEL FRONT CONNECTION WIRE NUMBERS

3 PHASE 1 PHASE

LINE 1 LINE 2 LINE 3 LINE 1 LINE 2

1 OVEN 1,4 2 3 1,3 2,4

2 OVENS 1,4,7 2,5,8 3,6 1,3,5,7 2,4,6,8

REAR CONNECTION WIRE NUMBERS

1ST OVEN 5,8 6 7 5,7 6,8

2ND OVEN 7 5,8 6 5,7,5,7 6,8,6,8

3

Page 6

GENERAL

OPERATION

Convection ovens constantly circulate air over

and around the product. This strips away the thin

layer of moisture and cool air from around the

product allowing heat to penetrate more quickly.

Cooking times can be shortened and cooking

temperatures can be reduced.

To convert standard deck oven recipes, reduce

the temperature 50 degrees and the time by 25%.

Make minor adjust ments a s necessary.

The lower the oven temperature the more even

the bake.

Check the product near the end of the initial

cooking cycle by turning on the oven light and

looking through t he oven door windows.

CONTROL PANEL

The control panel consist of the following items:

LIGHT SWITCH

POWER SWITCH

STATUS READOUT

Turns the oven interior lights on and off.

Turns the oven on and off.

Displays the oven status (

timer.

Do not open the oven doors during baking as this

will change the baking characteristics of the oven

and make it difficult to determine a final

program.

If the product is overdone on the outside and

underdone on the inside, reduce the baking

temperature.

If the product is pulling away from the edge of

the pan, the temperature is too high or the

cooking time too long.

Load each shelf evenly. Spaces should be

maintained equally between the pan and oven

walls, front and back.

For best baking results, load the oven from the

top to the bottom during random loading.

etc.) and is the count down

TIER LIGHTS

PRODUCT BUTTONS

SHELF BUTTONS

"MAN PROG"

"TEMP"

"READ/CLEA R"

Displays the tier that the program is running, mainly used during

programming.

Numbered 0 to 9 these buttons contain the programs that, when selected,

will run the oven.

Labeled A to E these buttons indicate which shelf the product is placed

on, A being the top shelf.

Short for Manual Program, this button allows the operator to enter a time

and temperature without being required to enter the programming code.

The program is lost once the oven is turned off.

When pushed this button will display the current operating temperature of

the oven in the STATUS READOUT.

Pressing this button twice then pressing a Product button instructs the

oven to "read back" the times and temperatures for that product button in

the STATUS READOUT. It will also switch the oven from a running

program to "

STATUS READOUT

" when pressed and held until " " appears in the

4

Page 7

MANUAL OVERRIDE

Located below the control panel, behind the louvered access door. In the

event of a computer failure, this switch takes control of the oven away

from the computer and directs the temperature control to a manual

thermostat located next to the switch.

BACK-UP THERMOSTAT

Activated when the MANUAL OVERRIDE switch it set to ON. This

thermostat controls the oven temperature in the event of a computer

failure.

STATUS READOUT DISPLAY

The STATUS READOUT informs the operator

of the oven's status.

It can be used as a countdown timer, shelf in use

or internal oven temperature display during the

cooking cycle (see seperate PROGRAMMING

instructions).

"

" The oven is energized and ready for an operator command.

" Stands for PREHEAT. A product has been selected and the oven is

"

heating to the set temperature.

"

" The oven's internal temperature is below what is programmed.

" A product change has been made and the oven's internal temperature is

"

above what is programmed.

"

" A product selection has been made after the oven has preheated and the

computer is asking which shelf the product is placed on.

" " There is a fault in the control system, the computer will not operate until

service is performed.

The STATUS READOUT display informs the

operator when the oven is ready to bake, or if the

oven is above or below the progroammed

temperature.

Below is a list of displays and their definitions:

" " Stands for CONTINOUS. The oven has been programmed without a time

being entered. The oven will operate continuously at the programmed

temperature.

" An entry has been made during the programming which is outside the

"

parametes of the computer.

PRODUCT AND SHELF BUTTONS

Once the PRODUCT BUTTONS are

programmed, all of the oven's operation is

controlled by the computer.

To select a product simply push any of the

programmed PRODUCT BUTTONS which is

labeled for the product you wish to cook.

Once a product button is selected, the oven will

preheat to the preprogrammed temperature.

The control will not allow the operator to select a

shelf until it has reached its programmed

temperature.

Once the programmed temperature is reached the

STATUS READOUT will display "

the beeper will sound briefly.

Only the PRODUCT BUTTONS programmed at

the oven's temperature will now be activated (the

button lamp will be on).

To cook, place the product into the oven cavity

and shut the oven doors. Select the PRODUCT

BUTTON labeled for that product.

" and

5

Page 8

The STATUS READOUT will then display

"

", at that time press the SHELF

BUTTON(S) that match the shelf position(s) the

product was placed on (A equals the top shelf, E

equals the bottom shelf).

If the product program is a MULTIPLE TIERED

program, the operator has only one opportunity

to enter a PRODUCT and SHELF selection. The

computer will not allow a second selection

during the cooking cycle (see seperate

PROGRAMMING instructions).

When the product is done the STATUS

READOUT will display "

sound, and a SHELF BUTTON will flash

indicating which product has finished baking.

Pressing the SHELF BUTTON will turn off the

beeper and allow the oven to continue baking or

go to stand-by with the STATUS READOUT

displaying "

PRODUCT CHANGING

If you wish to change to a product which is

programmed at a different temperature you must

first press the

"

" is displayed in the STATUS

READOUT. Release the

and the STATUS READOUT will display

"

" and allow the selection of the new

product.

When a product which is programmed at a

different temperature is selected, the STATUS

READOUT will display "

oven has reached the programmed temperature.

The computer will not allow a shelf selection

until the STATUS READOUT displays "

Once the computer reaches the programmed

temperature the beeper will sound briefly and the

STATUS READOUT will display "

When the STATUS READOUT displays "

any PRODUCT BUTTON which is programmed

at the same temperature will also light up.

When a PRODUCT button is selected, that

button will flash slowly, indicating which product

is being baked.

".

READ/CLEAR

", the beeper will

button until

READ/CLEAR

" or " " until the

"

button

".

CANCEL SHELF

Press the

the shelf to be canceled. The STATUS

READOUT will display

the next to time to done.

READ/CLEAR

button twice then press

or the time for

MANUAL PROGRAMMING

The button on the control panel labeled

PROG

is the MANUAL PROGRAM button.

The MANUAL PROGRAM (MAN PROG)

button allows the operator in create a short-term

program for one time products.

The program will be erased when the oven is

turned off or the

pushed.

The MANUAL PROGRAM button is active only

when the STATUS READOUT displays "

To operate the MANUAL PROGRAM feature

press the

The STATUS READOUT will display "

Select the desired temperature using the

PRODUCT buttons 0 through 9 to a maximum

of 450 degrees.

Once a temperature is entered the STATUS

READOUT will display "

asking for a co oking time input.

Enter the desired cooking time using the

PRODUCT buttons 0 through 9 to a maximum

of 9:59:59.

If the program does not require a time, press the

flashing E button when the STATUS READOUT

displays "

continuously at the programmed temperature

with the STATUS READOUT displaying "

"

No other buttons will be activated until the oven

has reached the programmed temperature.

Once the oven has reached the programmed

temperature the STATUS READOUT will

display "

all PRODUCT buttons which are programmed at

the same temperature will also flash.

MAN PROG

READ/CLEAR

button.

". The control is

". The oven will run

", the buzzer will sound briefly and

MAN

button is

".

".

".

TIME RECALL

To check the remaining cook time on a product

that is baking, press the corresponding SHELF

button, the STATUS READOUT will display the

remaining time on the cook cycle.

To run the MANUAL PROGRAM, load the

product to be baked.

Press the

READOUT will display "

lights will flash.

MAN PROG

button, the STATUS

" and the shelf

6

Page 9

Press the SHELF button(s) which correspond to

where the product is loaded in the oven (A equals

the top shelf).

When the product is finished baking the beeper

will sound continuously, the STATUS

READOUT will display "

button will flash indicating which shelf is to be

removed from the oven.

", and a SHELF

The STATUS READOUT will scroll through the

product program one entry at a time.

Always start the "read" sequence with the

STATUS READOUT displaying "

It is used during the initial programming to back

up a step if an error is made during the

programming sequence.

".

Press the flashing SHELF button to turn the

beeper off.

To erase a MANUAL PROGRAM press and

hold the

STATUS READOUT displays "

release.

READ/CLEAR

button until the

" then

TEMPERATURE RECALL BUTTON

When pressed, the

actual oven temperature in the STATUS

READOUT.

During the preheat cycle the

cannot be used .

TEMP

button will display the

TEMP

button

READ/CLEAR BUTTON

READ/CLEAR

The

from a run mode to "

operator to select another product which is

programmed at a different temperature.

To change from "

running program, push and hold the

READ/CLEAR

the STATUS READOUT then release the button.

The STATUS READOUT will display "

and the control is ready to accept a new operator

command.

The READ/CLEAR button can also be used to

"read" and existing program.

button will change the oven

", allowing the

" to " " or cancel a

button until "

" appears in

MANUAL CONTROL OVERRIDE

Should the computer control system develop a

fault causing it not to function, the MANUAL

OVERRIDE switch, when energized, will bypass

the computer and change the oven control to a

mechanical thermostat allowing the oven to

continue to operate in a manual mode until

service can be performed on the computer.

The MANUAL OVERRIDE control can also be

used to run the oven until the computer is

programmed.

The switch for the MANUAL OVERRIDE is

located behind the louvered door, below the

control panel.

With the switch in the Off (down) position the

oven is operated by the computer.

With the switch in the On (up) position the oven

is operated by the mechanical thermostat located

just to the left of the switch.

Rotate the thermostat knob clockwise until the

desired temperature appears at the top of the

knob.

When the MANUAL OVERRIDE switch is

"

energized, the computer control panel will turn

off all displays and will not time the product.

If service is required on the Lang computer, refer

to the Lang Authorized Service Agency

Directory for the nearest repair agency.

To "read" and existing program, press the

READ/CLEAR

PRODUCT button to be read.

button twice and then press the

7

Page 10

CLEANING

MAINTENANCE

Always start with a cold oven.

The porcelain or stainless interiors can easily be

cleaned using most domestic or commercial oven

cleaners.

Follow the manufacturer's instructions when

using any cleaner.

Care should be taken to prevent caustic cleaning

compounds from coming in contact with the

blower wheel or the aluminized steel panel

located directly behind the fan baffle.

The oven racks and rack slides may be cleaned

by removing them from the oven and soaking

them in a solution of ammonia and water.

The stainless steel door liners and oven front

should normally be cleaned with a soap and

water solution.

The painted surfaces should also be cleaned with

a mild soap and water solution.

Discoloration or heat tint may be removed with

any of the following cleaners: Penny Brite

Copper Brite

Steel

, Du-Bois Temp, or Past Nu-

.

Always apply these cleaners when the oven is

cold and rub in the direction of the metal's grain.

DOOR CHAIN ADJUSTMENT

WARNING

DISCONNECT THE OVEN FROM POWER

The door chain assembly is located directly

beneath the oven doors, inside the lower trim

piece.

To reach the door chain assembly remove the

three screws holding the bottom trim piece in

place.

Pull the trim piece forward off of the oven.

Adjustment to the door chain assembly is made

by loosening the lock nut on the turnbuckle then

turning the turnbuckle until the door chain is

,

tight and the door without the handle closes just

ahead of the door with the handle.

8

Page 11

SERVICE

WARNING

SERVICE ON THIS, OR ANY OTHER, LANG APPLIANCE MUST BE PERFORMED BY

QUALIFIED PERSONNEL ONLY. CONSULT YOUR AUTHORIZED SERVICE STATION

DIRECTORY OR CALL THE FACTORY AT 206-881-7569 FOR THE SERVICE STATION

NEAREST YOU.

CALIBRATION

The Lang Computerized Convection Oven is

electronically controlled. Calibration of the

control is not necessary nor is it available.

CONTROL PANEL REMOVAL

WARNING

DISCONNECT THE OVEN FROM POWER

Remove the two sheet metal screws going

vertically into the top of the control panel.

Open the oven doors and remove the two screws

holding the lower trim piece in place.

Remove the one sheet metal screw holding the

bottom of the control panel to the lower trim

piece.

Remove the lower trim piece from the oven.

Remove the one sheet metal screw from the

lower right cor ner o f the c o ntr ol p a nel b e hind the

trim piece.

ELEMENT REMOVAL

WARNING

DISCONNECT THE OVEN FROM POWER

Remove the oven racks and rack slides from the

oven cavity.

Remove the four thumb screws located at the

corners of the fan baffle. Remove the fan baffle

from the oven.

Remove the six sheet metal screws holding the

element plate to the back oven wall.

Grasp the oven element and pull the element

forward into the oven cavity.

Remove the wires from the element terminals.

Be sure to note the wire color for proper

replacement on the element.

Reverse the above procedures for installation.

MOTOR REMOVAL

Grasp the control panel assembly and gently pull

it forward on its slide until access is gained to the

control components.

Take care when sliding the control assembly in

or out so as not to snag any wires or kink the

manual thermostat capillary tube.

Reverse the above procedure for installation.

WARNING

DISCONNECT THE OVEN FROM POWER

Remove the oven racks and rack slides from the

oven cavity.

Remove the four thumb screws located at the

corners of the fan baffle. Remove the fan baffle

from the oven.

Remove the eight 1/4 X 20 bolts from the motor

plate located behind the blower wheel.

Grasp the motor plate and slide the entire motor

assembly into the oven compartment.

9

Page 12

Remove the wires from the motor and safety

thermostat. Be sure to mark the wires for proper

replacement.

Loosen the set screws holding the blower fan to

the motor shaft.

Remove the oven racks and rack slides from the

oven cavity.

Remove the four thumb screws located at the

corners of the fan baffle. Remove the fan baffle

from the oven.

Using a three finger wheel puller, grasp the

puller ring on the blower wheel hub and tighten

the puller until the blower comes off of the motor

shaft.

Remove the four 5/16 bolts holding the motor to

the motor mount.

Reverse the above procedure for replacement.

IMPORTANT NOTE

When replacing the blower wheel onto the motor

shaft, locate the blower so the blower hub is flush

with the end of the motor shaft. Adjust the motor

so the blower spins straight with the motor plate

before tightening the motor to the motor mount.

SAFETY THERMOSTAT REMOVAL

WARNING

DISCONNECT THE OVEN FROM POWER

Remove the eight 1/4 X 20 bolts from the motor

plate located behind the blower wheel.

Grasp the motor plate and slide the entire motor

assembly into the oven compartment.

Remove the wires from the safety thermostat. Be

sure to mark the wires for proper replacement.

Remove the screws holding the safety thermostat

bracket to the motor plate.

Remove the safety thermostat bracket from the

motor plate.

Remove the screws holding the safety thermostat

to the bracket.

Remove the safety thermostat from the bracket.

Reverse the above procedure for replacement.

10

Page 13

PARTS

CONTROL PANEL LAYOUT

ITEM NO. DESCRIPTION ITEM NO. DESCRIPTION

1 Touch control panel 6 Manual override switch

G - Temperature sensor connection

H - Output to contactors 8 Heat contactor

2 Microprocessor 9 Motor contactor

A - 12 volt supply 10 Manual override relay

B - Ribbon connectors 11 Terminal block

3 Beeper board 12 12 volt transformer

4 Power switch 13 24 volt transformer

5 Manual override thermostat 14 Light switch

11

Page 14

PARTS LIST

DESCRIPTION PART #

Bulb Socket: Oven Lamp 31602-04

Bulb: Oven Lamp 31603-04

Circuit Board Assembly: Buzzer 40102-10

Circuit Board Assembly: Front Panel 40102-08

Circuit Board Assembly: Microprocessor 40102-11

Circuit Breaker: 1 Pole 31800-01

Circuit Breaker: 3 Pole (480 Volt Units Only) 31800-04

Contactor: 2 Pole, 24 Volt Coil, 2 Speed Motor 30701-05

Contactor: 3 Pole, 24 Volt Coil, Motor/Element 30700-06

Element: Oven Heating, 208/240 Volt 11090-16

Element: Oven Heating, 480 Volt 11090-18

Fan: Convection Blower 71500-05

Fuse Holder: 15 Amp Fuse 30901-08

Fuse: Control, 15 Amp 30900-10

Handle: Oven Door 70603-15

Knob: Damper 70701-25

Knob: Manual Override Thermostat 70701-19

Motor: Convection Fan, 208/240 Volt 30200-17

Motor: Convection Fan, 480 Volt 30200-16

Rack Slide: Oven Interior 50200-32

Rack: Oven Interior 50200-59

Relay: Manual Override 30600-02

Sensor: Oven Temperature 41100-08

Switch: Micro, Oven Door 30301-02

Switch: Toggle, On-Off 30303-06

Switch: Toggle, Oven Lights 30303-07

Switch: Toggle, Manual Override 30303-06

Thermostat: Hi Limit 30401-09

Thermostat: Manual Override 30402-27

Transformer: 240/12 31400-12

Transformer: 240/24 31400-10

Transformer: 480/240 (480 Volt Units Only) 31400-04

Window: Oven Door 71301-04

12

Page 15

208 /240 VOLT

WIRING DIAGRAMS

13

Page 16

480 VOLT OVEN

14

Loading...

Loading...