Page 1

Installation

Operation

Maintenance

Troubleshooting

Model: CSG24

Add-on Clamshell® Hood

Star Manufacturing International

Part Number: 2M-W361

Rev. D

265 HOBSON ST

Phone: 800-438-5264 Fax: 314-781-2714

WWW.LANGWORLD.COM

SMITHVILLE, TN, 37166

JULY 10, 2018

Page 2

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ,

UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS CONTAINED

IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

POST IN A PROMINENT LOCATION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS. THIS

INFORMATION SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS

SUPPLIER. AS A MINIMUM, TURN OFF THE GAS AND CALL YOUR GAS

COMPANY AND YOUR AUTHORIZED SERVICE AGENT. EVACUATE ALL

PERSONNEL FROM THE AREA.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE

OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPME NT.

Model #:

Purchased From:

Serial #: Location:

Date Purchased: Date Installed:

Purchase Order #: For Service, Call:

2

Page 3

TABLE OF CONTENTS

CHAPTER PAGE

1. READ FIRST .................................................................................................................4

2. EQUIPMENT DESCRIPTION........................................................................................6

3.

UNPACKING .................................................................................................................7

4.

INSTALLATION.............................................................................................................8

5.

INITIAL START-UP .......................................................................................................10

OPERATION..................................................................................................................

6.

SEQUENCE OF OPERATION ..................................................................................... 12

7.

11

CLEANING & MAINTENANCE PROCEDURES.......................................................... 13

8.

9. TROUBLESHOOTING ..................................................................................................14

10. PARTS LISTS................................................................................................................16

11. WIRING DIAGRAMS..................................................................................................... 18

3

Page 4

IMPORTANT READ FIRST IMPORTANT

NOTICE: If the Clamshell® is to be attached to a griddle/ charbroiler in the

field – it is recommended to complete the installation of mounting adapter

before un-crating the Clamshell®.

CAUTION: UNIT IS EXTREMELY HEAVY. FOR SAFE HANDLING, INSTALLER SHOULD

OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE MATERIALS

HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR PALLET

JACK) TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO THE

PLACE OF INSTALLATION.

WARNING: INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL QUALIFIED

TO WORK WITH ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE

TO EQUIPMENT. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

NOTICE: The installation of this unit must conf orm to applicable National, State and

locally recognized installation standards.

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN

CUT.

DANGER: DO NOT REMOVE THE MOUNTING NUTS OFF OF THE MOUNTING PLATE

STUDS WHILE THE UNIT IS IN THE LOWERED POSITION. THE

STANCHION BACK IS UNDER TENSION AND CAN CAUSE BODILY INJURY.

NOTICE: The data plate is located on the inside surface of the hood wrap. The

Clamshell® voltage, wattage, serial number, clearance and gas

specifications are on the data plate. This information should be carefully

read and understood before proceeding with the installation.

NOTICE: This unit is approved to be installed only on equipment which meets NSF

standards, and for which the adapter kit is provided.

WARNING: BEFORE LIGHTING, USE A SOAP AND WATER SOLUTION TO TEST ALL

JOINTS FOR GAS LEAKS.

NOTICE: The installation of any components such as a vent hood, grease extractors,

fire extinguisher systems, must conform to their applicable National, State

and locally recognized installation standards.

WARNING: DURING INITIAL USE, OR USE AFTER SERVICE, IF THE PILOT DOES NOT

IGNITE ON FIRST TRY THE MAIN GAS VALVE MUST BE TURNED OFF FOR

AT LEAST FIVE MINUTES.

CAUTION: ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

CAUTION: KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR

FALLS.

NOTICE: While cooking, the Clamshell® must be monitored at all times. Do not leave

the Clamshell® unattended while cooking.

NOTICE: Fan in Clamshell® runs continuously. For the safety of the unit, the fan

must run continuously to provide cooling to the electrical components.

Component cooling is required if the base unit is running. If power to the

Clamshell® is turned off, gas to base will be turned off. If it is necessary to

remove power from the Clamshell®, the base unit must be cooled below

200°F first.

4

Page 5

IMPORTANT READ FIRST IMPORTANT

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR

HOSE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO

WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE

CLOTHING. CAREFULLY READ THE WARNING AND FOLLOW THE

DIRECTIONS ON THE LABEL OF THE CLEANER TO BE USED.

CAUTION: A COMMERCIAL LIQUID GRIDDLE CLEANER IS NOT RECOMMENDED FOR

CLEANING THE GRIDDLE OR CHARBROILER UNDER THE CLAMSHELL®

AS MOST CONTAIN POTASSIUM HYDROXIDE

WHICH IS HARMFUL TO THE CLAMSHELL® BURNER TILES.

NOTICE: Do not spray any liquids on to the tiles, or wipe the tiles with any materials.

Liquids and direct contact on the tiles can damage them.

CAUTION: DO NOT USE YOUR HAND TO CHECK GRIDDLE/CHARBROILER

TEMPERATURE.

NOTICE: Service on this, or any other, LANG appliance must be performed by

qualified personnel only. Consult your LANG authorized service agent

directory or call the factory at 1-800-438-5264, or WWW.LANGWORLD.COM

for the service agent nearest you.

DANGER: BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THIS

APPLIANCE WHEN THE UNIT IS PLUGGED/WIRED INTO A LIVE

RECEPTACLE. BEFORE PERFORMING ANY WORK ON INTERNAL

COMPONENTS, DISCONNECT THE APPLIANCE FROM THE ELECTRIC

POWER SUPPLY.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

LANG OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE BODILY

INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

CAUTION: BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE

OPERATING INSTRUCTIONS, CAUTIONS AND SAFETY INSTRUCTIONS

CONTAINED IN THIS MANUAL.

WARNING: WHEN MULTIPLE CLAMSHELLS® ARE USED ON A GRIDDLE, ALL THE

CLAMSHELLS MUST BE CONNECTED TO THE SAME 120V SOURCE.

OR SODIUM HYDROXIDE

5

Page 6

2. EQUIPMENT DESCRIPTION

Lang Model: CSG24

ADD-ON CLAMSHELL® HOOD

2.1 Exterior Construction

• The Clamshell® dimensions are 19 1/2” (49.53cm) High in the lowered position, 38 1/3” (97.36cm)

High in the raised position, 36 3/4” (93.35cm) Deep, and width is 24” (60.96cm).

• The stainless steel hood makes for easy cleaning.

• Pivoting heat deflector redirects excess grill heat to either side of the equipment and away from

employees.

2.2 Operation

• By heating only when in the down position, you can conserve energy and save money with a cooler

backroom environment.

• Cook different products at the same time with no height adjustments needed.

2.3 Technical

• Griddle operates on either Natural Gas or Propane. This must be specified when ordering. It is

shipped with a Power Cord and Plug attached.

• Clearances required from non-combustible surfaces: Back: 0 inches, Sides: maintain side clearance

of base appliance or 3 inches which ever is greater, Bottom: 6 inches below the bottom of the

stanchions.

2.4 Griddle Gas and Voltage Specifications

The Lang Clamshell® can be connected to any 120 Volt source. In applications where multiple

clamshells are installed on the same griddle, they all need to be plugged into the same receptacle

circuit.

The gas specifications are listed on the data label located on the inside surface of the hood wrap.

WARNING: WHEN MULTIPLE CLAMSHELLS® ARE USED ON A GRIDDLE, ALL THE

CLAMSHELLS MUST BE CONNECTED TO THE SAME 120V SOURCE.

6

Page 7

3. UNPACKING

3.1 Receiving the Clamshell®

Upon receipt, check for freight damage, both visible and concealed. Visible damage should be noted

on the freight bill at the time of delivery and signed by the carrier's agent. Concealed loss or damage

means loss or damage which does not become apparent until the merchandise has been unpacked. If

concealed loss or damage is discovered upon unpacking, make a written request for inspection by the

carrier's agent within 15 days of delivery. All packi ng material should be kept for inspection. Do not

return damaged merchandise to Star Manufacturing International. File your claim with the

carrier.

3.2 Location

Prior to un-crating, move the Clamshell® as near to its intended location as practical. The crating will

help protect the unit from physical damage normally associated with moving it through hallways and

doorways.

NOTICE: If the Clamshell® is to be attached to a griddle/ charbroiler in the field –

it is recommended to complete the installation of mounting adapter

before un-crating the Clamshell®.

3.3 Un-crating the Add-on Clamshell® Hood

If Clamshell® is received already attached to a Griddle/Charbroiler skip to section 3.4.

The Clamshell® will arrive completely assembled inside a wood frame covered by a cardboard box

and bolted to a skid. Remove the cardboard cover, unbolt Clamshell® from the support

brackets. Discard the skid and brackets.

Remove Clamshell® from skid and place in intended location.

There are several parts that are not installed in the unit. Be careful not to misplace the following parts

when un-crating the unit.

Inner Component Co

Ou

In

Oute

In

Manual Shut-off Valv

Tw

Note: See Mounting Adapter kit for instructions on installing these parts.

ter Component Cov

ner Fl

ue

r Fl

ue

sulation

o 3/8 X 16 Nuts

ver

er

e

CAUTION: UNIT IS EXTREMELY HEAVY. FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE

MATERIALS HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY,

OR PALLET JACK) TO REMOVE THE UNIT FROM THE SKID AND MOVE

IT TO THE PLACE OF INSTALLATION.

3.4 Un-crating Griddle/Charbroiler with Clamshell® Attached

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK

WHEN CUT.

The griddle will arrive completely assembled inside a wood frame covered by a cardboard box and

strapped to a skid. Remove the cardboard cover, cut the straps and remove the wood

frame.

Remove griddle from skid and place in intended location. The legs and gas regulator are located in the

grease drawer.

7

Page 8

4. INSTALLATION

WARNING: INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING.

IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL

AND/OR DAMAGE TO EQUIPMENT. UNIT MUST BE INSTALLED IN

ACCORDANCE WITH ALL APPLICABLE CODES.

NOTICE: The data plate is located on the inside of the hood wrap. The

Clamshell® voltage, wattage, serial number, clearance and gas

specifications are on the data plate. This information should be

carefully read and understood before proceeding with the installation.

NOTICE: This unit is approved to be installed only on equipment which meets

NSF standards, and for which the adapter kit is provided.

WARNING: WHEN MULTIPLE CLAMSHELLS® ARE USED ON A GRIDDLE, ALL THE

CLAMSHELLS MUST BE CONNECTED TO THE SAME 120V SOURCE.

4.1 Electrical Connection

The Clamshell® is supplied with a cord and plug. The receptacle is not provided with the Clamshell®.

Follow the receptacle manufacturer’s instructions when connecting the receptacle to the power supply.

When multiple Clamshells are installed on the same griddle, you must plug them into the same

electrical circuit (receptacle) to prevent from doing damage to the units transformers.

4.2 Gas Connection

WARNING: BEFORE LIGHTING, USE A SOAP AND WATER SOLUTION TO TEST

ALL JOINTS FOR GAS LEAKS.

This Clamshell® is manufactured for use with the type of gas indicated on the nameplate.

Contact the factory if your type of gas does not match the nameplate data.

All gas connectors must be in accordance with local codes and comply with the National Fuel

Federal Gas Codes ANSI Z223.1 latest edition.

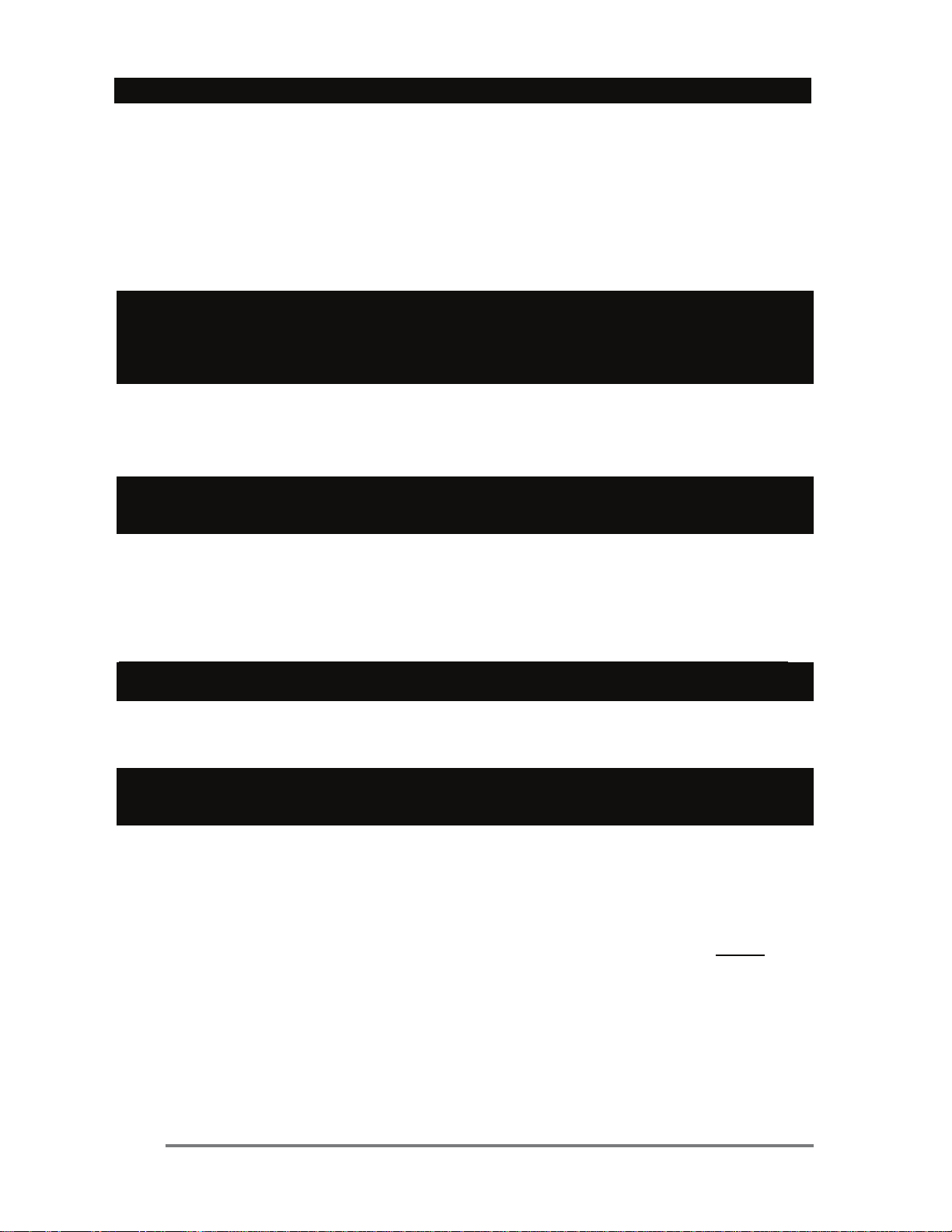

There are two gas connections involved in the installation of the Clamshell®:

The first is the gas supply to the Clamshell® itself. This connection should be made positioning

the manual shut-off valve supplied with the Clamshell® to isolate the appliance from the kitchens

main gas supply during any future service activity (See figure 1). (A service agent should be able

to shutoff and disconnect the gas supply to the Clamshell® without affecting the main gas supply

to the kitchen.) Use gas lines that have a minimum diameter of at least 1/2 an inch.

The second is the gas supply to the base appliance (the appliance to which the Clamshell® is

mounted). The Clamshell® has an external solenoid valve (the Automatic Cutoff Valve (ACV))

at the end of a flexible conduit. The ACV must be installed in line with the gas supply to the base

appliance in a location, which will ensure the ACV is not exposed to temperatures above 175°F

(See figure 1). Remove the cover to the ACV to ensure the correct flow direction through the

valve when making the connections. Replace the cover after the connections are complete. Use

gas lines that have a minimum diameter of at least 1/2 an inch.

NOTE: If this Clamshell® is received already mounted on a Lang griddle no further installation is

required. If this Clamshell® is a separate unit proceed to section 4.3 below.

NOTICE: The installation of any components such as a vent hood, grease

extractors, fire extinguisher systems, must conform to their applicable

National, State and locally recognized installation standards.

8

Page 9

4. INSTALLATION CONT’

4.3 Installation Instructions

Refer to the Installation instructions provided with the adapter kit, on how to connect this Clamshell®

to the griddle/charbroiler.

Figure 1

D

ACV

ACV

Regulator

CSG24

Manual Shut-off

Valve

CSG24

Griddle / Charbroiler

Legend:

ACV = Automatic Cut-off Valve

A = 1” Pipe

B = Reduction to 3/4” Pipe

C = Reduction to 1/2” Pipe

D = Increase to 3/4” Pipe

O = Optional second AGC Parts

9

Page 10

5. INITIAL START UP

5.1 Initial Lighting Procedure for an Clamshell®

WARNING: DURING INITIAL USE, OR USE AFTER SERVICE, IF THE PILOT DOES

NOT IGNITE ON FIRST TRY THE MAIN GAS VALVE MUST BE TURNED

OFF FOR AT LEAST FIVE MINUTES.

NOTICE: While cooking, the Clamshell® must be monitored at all times.

DO NOT

NOTICE: Fan in Clamshell® runs continuously. For the safety of the unit, the fan

must run continuously to provide cooling to the electrical components.

Component cooling is required if the base unit is running. If power to

the Clamshell® is turned off, gas to base will be turned off. If it is

necessary to remove power from the Clamshell®, the base unit must be

cooled below 200°F first.

• The Clamshell® has two positions, the lowered position for cooking and the raised position for gridd le

loading, cleaning, or griddle only use.

• No thermostats are provided for temperature control. The Clamshell® is a radiant cooking device,

which operates only in the lowered position.

leave the Clamshell® unattended while cooking.

• Ignition is automatic and occurs as the Clamshell® is lowered.

• Raising the Clamshell® turns the gas burner off.

5.2 Initial Lighting Procedure for the Griddle/Charbroiler

See Operator manual for the griddle/charbroiler.

10

Page 11

6. OPERATION

6.1 Clamshell® Operation

CAUTION: ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

CAUTION: KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR

FALLS.

NOTICE: While cooking, the Clamshell® must be monitored at all times. Do not

leave the Clamshell® unattended while cooking.

• The Clamshell® has two positions, the lowered position for cooking and the raised position fo

gri

ddle loading, cleaning, or griddle only use.

• No thermostats are provided for temperature control. The Clamshell® is a radiant cooking device,

which operates only in the lowered position.

• Ignition is automatic and occurs as the Clamshell® is lowered.

r

• Raising the Clamshell® turns the gas burn

• Place

• Lo

6.2 Opera

See Operator’s Manual for the base unit.

food on griddle/charbroiler and immediately lower the Clamshell®. The tiles will

ish-orange in approximately 30-45 seconds. The radiant heat from the Clamshell® will cook

redd

from the top while the griddle/charbroiler cooks the product from the bottom

ad product under the Clamshell® following the normal loading procedures for th

g

riddle/charbroiler to which it is attached

tion When Attached to a Griddle/Charbroiler

er off.

glow

.

e

.

11

Page 12

7. SEQUENCE OF OPERATION

7.1 Power On

• When the Clamshell® is plugged in, 115 Volts is applied to the blower motor. The Clamshell® is

designed to have a constantly running blower motor.

• The air switch then senses the blower motor, closes, and applies the 115 Volts to a 24 VAC transformer.

• The transformer then supplies 24 VAC to the tilt switch, and to the automatic cutoff valve.

• The 24 VAC to the automatic cutoff valve opens the gas valve to the griddle/charbroiler, thus allowing the

base unit to operate.

• When the Clamshell® is lowered, the tilt switch allows 24 VAC to go to the spark module.

• The spark module then supplies 24 VAC to open the Clamshell® gas valve, and high voltage to the spark

igniter.

• When the burner ignites, the sense probe senses the flame is ignited and the spark module turns off the high

voltage to the spark igniter.

• When the Clamshell® is raised the tilt switch opens the 24 VAC to the spark module, which removes the

24 VAC to the gas valve, turning off the Clamshell®.

12

Page 13

8. MAINTENANCE & CLEANING

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR

HOSE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO

WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE

CLOTHING. CAREFULLY READ THE WARNING AND FOLLOW THE

DIRECTIONS ON THE LABEL OF THE CLEANER TO BE USED.

CAUTION: A COMMERCIAL LIQUID GRIDDLE CLEANER IS NOT RECOMMENDED FOR

CLEANING THE GRIDDLE OR CHARBROILER UNDER THE CLAMSHELL®

AS MOST CONTAIN POTASSIUM HYDROXIDE

WHICH IS HARMFUL TO THE CLAMSHELL® BURNER TILES.

NOTICE: Do not spray any liquids on to the tiles, or wipe the tiles with any materials.

Liquids and direct contact on the tiles can damage them.

OR SODIUM HYDROXIDE

8.1 Weekly Cleaning

• The Clamshell® tiles are self cleaning, which is accomplished by leaving the Clamshell® on with no

product being cooked, thus allowing the heat of the broiler to burn debris from th

• To clea

• Tu

n the Clamshell®, start with a

rn off the griddle/charbroiler thermostats and wait until the griddle/charbroiler is cool

e tiles.

clean griddle plate.

.

CAUTION: DO NOT USE YOUR HAND TO CHECK GRIDDLE/CHARBROILER

TEMPERATURE.

• Lower the Clamshell® and let it run for 45 minutes, then raise the Clamshell® and ensure the blower moto

ntinues to blow cooling air through the burner tiles (Do not unplug or turn off Clamshell® po

co

• On

tiles with

ce the Clamshell® has cooled, wipe ash from around the burner tiles. Take care not to touch th

the cleaning

rag.

wer).

e burner

NOTICE: Do not spray any liquids on to the tiles, or wipe the tiles with any materials.

Liquids and direct contact on the tiles can damage them.

8.2 Burner Air Shutter Adjustment

• The air shutters are pre-set at the factory, and should not need adjustment. However, if adjustment

required, contact your local authorized service station for in

being

8.3

Disconnecting Power from Blower Motor

If power is to be removed from the blower motor, the following must be completed:

s are

structions.

r

The gas to the base unit and the gas to the Clamshell® must be turn

The base unit must be cooled below 200°F.

13

ed off.

Page 14

8. MAINTENANCE & CLEANING CONTINUED

CAUTION: DO NOT REMOVE THE REAR DRIP SHIELD. THE DRIP SHIELD SHOULD

ONLY BE REMOVED DURING SPECIFIC REPAIRS BY A TRAINED SERVICE

PROFESSIONAL.

Do not remove the drip shields. The drip shields should only be removed during

specific repairs by a trained service professional. Check the screws on your unit

during your periodic inspection.

• If you cannot turn a screw to the left or counter-clockwise, then do not do anything further

with that screw.

• If you can turn a screw to the left or counter-clockwise, then use the Lang kit,

part number PS-60101-W8, provided to you at no charge to rework the screw.

14

Page 15

9. TROUBLESHOOTING

9.1 Symptoms

What follows is a chart of Symptoms and Possible Causes to aid in diagnosing faults with the Clamshell®.

Refer to the Symptoms column to locate the type of failure then to the Possible Cause for the items to be

checked.

To test for a possible cause, refer to the TEST section and lo cate the Possible Cause then refer to test to

identify test procedures.

SYMPTON POSSIBLE CAUSE

Igniter not sparking

Spark but no ignition

Clamshell® turns off after extended use

Taking too long to light

Hazy blue flame on tile face

Not hot enough

Clamshell® not turning off

Blower runs continuously

• Failed spark modu

• Failed

• Failed air switch

• Failed motor blow

• Failed

• Failed spark electrode

• Failed spark controlle

• Fai

• Clamshell® gas valve turned off

• Pl

• Incorrectly adjusted sense ele

• Incorrectly adjusted spark elec

• Pl

• Plugged burner tiles

• Incorrectly adjusted air sh

• Leak i

• Incorrectly adjusted gas regulator

• Incorrectly adjusted gas regulato

• Pl

• Plugged burner tiles

• Failed tilt switch

• Failed gas solenoid valv

• Normal operation

tilt switch

transfor

led gas solenoid valv

ugged orifice

ugged enrichment orifi

n air path to burner face

ugged main burner orifi

le

er

mer

r

e

ctrode

trode

ce

utter

ce

e

r

15

Page 16

9. TROUBLESHOOTING CONT’D

9.2 TESTS

NOTICE: Service on this, or any other, LANG appliance must be performed by

qualified personnel only. Consult your LANG authorized service agent

directory or call the factory at 1-800-807-9054, or WWW.STAR-MFG.COM

For the service agent nearest you.

WARNING: BOTH HIGH AND LOW VOLTAG ES ARE PRESENT INSIDE THIS

APPLIANCE WHEN THE UNIT IS PLUGGED/WIRED INTO A LIVE

RECEPTACLE. BEFORE REPLACING ANY PARTS, DISCONNECT THE

UNIT FROM THE ELECTRIC POWER SUPPLY AND CLOSE THE MAIN GAS

VALVE. ALLOW FIVE MINUTES FOR UNBURNED GAS TO VENT.

If an item on the list is followed by an asterisk (*), the work should be done by a factory

authorized service representative.

Possible Cause TEST

Failed tilt switch

Failed gas valve

Failed spark module

Failed air switch

Failed combustion blower

Improper gas pressure

Failed transformer

• Unplug switch and test for continuity while raising/lowering

the hood

• Remove the wires and check for continuity across the valve

coil

• Check for 24 VAC on TH*

• Observe spark

• Unplug switch and test for continuity while blower motor is

running*

• Check for proper voltage to unit/blower*

• Check for continuity across the motor’s windings

• Ensure gas pressure is adjusted properly*

• Check for proper voltage*

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

LANG OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE BODILY

INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

16

Page 17

1

2

3

4

5

6

7

8

9

10

11

15 14 13

16

19

20

24

25

26

27

28

21

17

22

23

12

29

30

31

32

33

34

Model: CSG24 GAS 24” CLAMSHELL

SK2476, Rev. B 07/09/2018

Page 18

PARTS LIST

JULY 09, 2018, Rev. A

Gas Clamshell Hood Parts List

R

Fig No Part No Qty Description Application

1 K9-60101-851 1 HOOD WRAP ASSY, w/DIE CAST LOGOS

2 2M-60301-W2 1 LANG CLAMSHELL LOGO

3 K9-70603-24 1 AGC HOOD HANDLE ASSY COMPLETE

4 K9-60301-43-1 1 SATIN CHRM-LANG DIE CAST

5 2K-70801-19 1 BUSHING HEYCO 5/8#2077

6

7 2P-51002-11 2 HOOD SPRING

8 2P-51002-05 2 SPRING GAS HOOD

9

2P-70201-06

2

BRNZ BR FLN BUSHING

10 K9-50312-40 2 SPRING PISTON / WASHER

11 2C-20104-37 2 SCRW 3/8-16X12 H/H CAP 2 THD

12 2V-80502-03

1

SOLENOID VALVE 24VAC 1/2PIPE

2 CSG24B

CSG24

13 K9-30307-01 1 SWT MERC TLT W/250°C 18GA

14 2J-80300-10 1 SPRK IGN CNTRL

2V-80501-03 1 GAS REG 1/2X1/2CLSIISET10 LP

15

2V-80501-10 1 GAS REG 1/8X1/2 CLS I NAT

Y9-80403-04

2A-80400-26 ORIFICE HOOD .1360 #29

16

Y9-80403-05

2A-80400-27 ORIFICE HOOD .0860 #44

90 DEG FITING W/#29 DRL

1

90 DEG FITING W/#44DRL

1

NAT

LP

17 2E-103-232 1 HARNESS, AGC HOOD #1

19 2J-80302-06 1 IGNITOR/SENSOR CHANNEL

20 K9-103-3 1 SPARK COVER

21 K9-51100-59 1 BURNER TILE ASSY, GLUED

- - 2H-60106-67 1 INSULATION BURNER TILE KIT (INCLUDED w/K9-51100-59)

22 2U-103-193 1 LEFT SKIRT

23 2V-103-194 1 RIGHT SKIRT

24 2V-103-197 1 FRONT SKIRT w/HINGE

25 K9-60102-1964 1 FRONT SKIRT INNER WALL w/SCREWS

26 2C-20103-02 3 SCRW SM PLT 10 X .5 PHLSL

27 K9-103-A88 1 FLAPPER ASSY

28 2B-50201-08 1 WIRE GUARD ADD-ON-BROILER

29 2K-70101-51 1 BRAS TBE ELBOW 1/4CC X 1/4CC

30 K9-103-4 1 TOP SEAL PLATE

31 K9-103-89 1 TOP PLATE SEAL

32 2C-20201-03 1 WSHR FLT AN960-716

33 K9-103-71 1 TUBE #5

2A-80401-04

34

2A-80401-05 PILOT BURNER ORIFICE, .010DRL LP

PILOT BURNER ORIFICE, .021DRL NAT

1

NI 2H-103-124 1 COMPONENT COVER INSULATION

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

1

Page 19

1

2

11

10

6

5

7

12

13

14

15

17

16

8

3

4

9

18

19

21

22

23

20

27

Model: CSG24 GAS 24” CLAMSHELL, FRAME ASSY

24

25

26

SK2477, Rev. A, 3/23/2015

Page 20

PARTS LIST August 04, 2015, Rev. -

Gas Clamshell Frame Parts List

Fig No Part No Qty Description Application

K9-103-702-W2

1

K9-103-702-1 LEFT OUTER STANCHION CSG24B

LEFT OUTER STANCHION - ASSY CSG24

1

R

2 K9-103-701 1 BLOWER DUCT - SPOT

3 2U-30200-44 1 MOTOR & BLOWER ASSY FOR AGC

4 OB-60102-194 1 OBS AGC BLOWER HOUSE ASSY

K9-103-301

5

K9-103-301-2 CSG24B

K9-103-303

6

K9-103-303-2 CSG24B

1 STANCHION COVER LH

1 INNER DRIP EDGE

CSG24

CSG24

7 K9-103-304 1 BAFFLE CLIP RH

8 K9-103-305-1 1 BAFFLE CLIP LH

K9-103-300

9

K9-103-300-2 STANCHION COVER RH CSG24B

STANCHION COVER RH CSG24

1

10 K9-103-323 1 HOODWRAP DRIP CATCHER

11 K9-103-164 1 REAR ACCESS COVER

12 2C-20104-08 2 SCRW HXHD CAP PLT 1/4-20

13 2C-20202-05 2 WSHR PLT 1/4 LOCK SPLIT

14 2C-20201-05 2 WSHR LFT 1/4 USS PLTD

15 2P-70201-07 4 BRNZ BR FLN 5/8IDX3/4ODX1

16 K9-60102-1911 2 HOOD PIVOT SHAFT ASSY

K9-103-115-W3

17

K9-103-115-3 RH OUTER STANCHION CSG24B

RIGHT OUTER STANCHION CSG24

1

18 2C-20109-04 16 SCREW THD MS SS 10-32X

19 K9-103-102 1 FIXED BOTTOM

20 2E-30501-02 1 TRM STRP 3 POLE W/PUSH ON TRM

21 2E-31200-01 1 BOX CONNECTOR 3/8

2E-30600-11

22

2E-30600-04 RLAY 24VAC 2FRMC DPDT FLNG MNT

RELAY 120V SPDT FLANGE MNT used w/Envirozone Griddles

1

23 2E-31400-07 1 XFRMR, 120-208-240/24V,40V

24 K9-103-101 1 COMPONENT TRAY

25 2E-70505-07 1 CONDUIT CNNCTR 3/8 90° FLEX

26 2E-31107-06 1 CORD SET 14/3 X 6’ 15A

27 2V-80502-03 1

SOLENOID VALVE 24VAC

NI 2E-30308-01 1 SWITCH AIR 10WC 1/4

NI K9-103-95 1 AIR SWITCH HOSE

NI 2E-40704-04 1 CAP - BLOWER START FOR

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Page 21

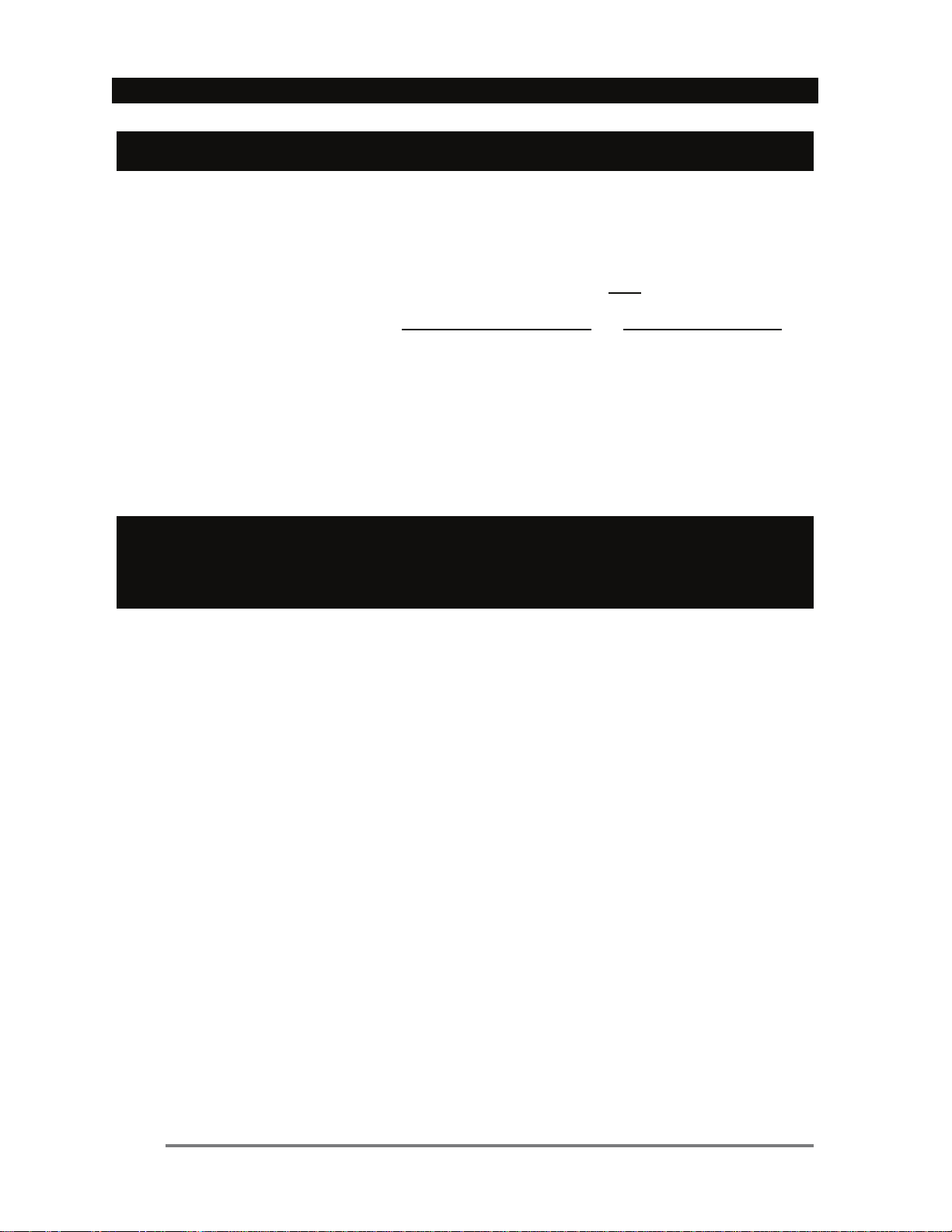

MODELS:

ADD ON GAS CLAMSHELL

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

2M-61113-24 Rev F

6-8-2011

TO 2ND OR 3RD

CLAMSHELL TB1

WHEN PRESENT

GRN

BLK

WHT

AIR

SWITCH

1 TAN

2 TAN

4 TAN

3 TAN

GRIDDLE SWITCH

(GRIDDLES ONLY - WIRES NOT SHOWN)

TO 2ND OR 3RD

CLAMSHELL

WHEN PRESENT

TO 2ND OR 3RD

CLAMSHELL

WHEN PRESENT

35 GRN

INSULATED SPADE

CONNECTORS

FOR USE WITH

OPTIONAL EXTERNAL

TIMER RELAY.

STOWED WHEN

NOT IN USE

33 GRN

32 RED

31 WHT

34 GRN

29 YEL

30 GRN

AUTOMATIC

CUTOFF VALVE

(ACV)

16 BLU

15 BRN

17 BRN

CAPACITOR

6 WHT

25 GRN

1 C GRN

1 B WHT

1 A BLK

POWER

CORD

6 WHT

5 BLK

8 BLK

7 GRN

TB1

3

2

1

10 BLK

9 WHT

CNO

11 YEL

EBM

BLOWER

12 YEL

20 YEL

24

115

XFMR

CARRIAGE HOOD

19 BLU

18 BLK

20 YEL

21 TAN

22 TAN

23 RED

24 GRN

26 GRN

27 ORG

28 TAN

IGNITOR

SENSOR

TILT SWITCH

SOLENOID

VALVE

HVT

SPARK MODULE

GROUND

GROUND

SENSOR

VALVE

TH

F

WHEN 2 OR 3 HOODS ARE PRESENT, ONLY ONE POWER

CORD IS USED FOR ALL HOODS.

1

1

REV. DATE/ECO DESCRIPTION OF CHANGE

F

6/8/2011

ECO 10748

REDRAWN IN SOLDWORKS.

ADDED POWER JUMPER FOR 2ND & 3RD HOOD

Page 22

SJD

SLLEHSMALC 42GSC HTIW ELDDIRG SAG "84 PMETUCCA D/W

OT SERIW 2 NAT ,1 NAT DEGNAHC

22W-22116-M2

ETON DEDDA & DEHSAD

.2 ETON DEDDASJD

.ON TRAP

DROC REWOP

NRG

THW

KLB

7002/11/21

6269 OCE

5046 OCE

0102/32/6

THW 2

KLB 1

RENRUB

LEY 02

ULB 71

RENRUB

ULB 42

RENRUB

KLB

ULB

HCTIWS REWOP

LEY 4

THW 8

KLB 7

LEY 21

ULB 11

EVLAV

LEY 91LEY 62LEY 33

ULB 81ULB 52ULB 23

EVLAV

EVLAV

.ON LEDOM

.VEROCE/ETADEGNAHC FO NOITPIRCSEDRD

ELTIT

SNOISIVER

0102/2/7

ETAD:

510. ± xxx. :DETON SSELNU :ECNARELOT

SELGNA 1

LAIRETAM

HSINIF

:ravoS naD

RD.KC

R

L'TNI .GFM RATS OT LAITNEDIFNOC NOITAMROFNI SNIATNOC GNIWARD SIHT

DETTIMREP SI STNETNOC STI FO ERUSOLCSID RO NOITCUDORPER ON .CNI

.CNI LANOITANRETNI GNIRUTCAFUNAM RATS

ASU ,34136 .OM ,SIUOL .TS

EVIRD NENNUS 01 #

KLB

THW

A

B

V021

REMROFSNART

V42

LEY

LEY

EVLAV

TOLIP

RENRUB

TOLIP

RENRUB

TOLIP

EMAS EHT OTNI DEGGULP EB TSUM SDROC DOOH.2

RENRUB

TOLIP

KRAPS

KRAPS

KRAPS

ELUDOM

NLG

ELUDOM

NLG

ELUDOM

NLG

ULB 5

THW 51THW 22THW 92

KLB 41KLB 12

1LN

ULB 6

HCTIWS

EMALF

LEY 31

ULB 01

NRG 9NRG 61NRG 32NRG 03

HCTIWS

EMALF

HCTIWS

EMALF

LEY 72

2

DROC REWOP

NRG

B

ROTACIDNI

PMAL

KLB

TATSOMREHT

TATSOMREHT

TATSOMREHT

THW

KLB

LEY 02

4 NAT

1 NAT

3 NAT

LEY 21

A

1 NAT

2 NAT

A

1 NAT

2

DROC REWOP

NRG

THW

B

KLB

2 NAT

NEHW D'QER YLNO ERA SERIW DEHSAD .1

HCTIWS

EMALF

LEY 43

KLB 82

ELUDOM

RENRUB

TOLIP

KRAPS

NLG

ULB 13

RENRUB

EVLAV

TATSOMREHT

LEY 21

.DESU ERA SDOOH )2(

.

ELCATPECER

ELDDIRG

XOB EGAIRRAC

:SETON

B

A

LEY 92

LEY 92

KLB 5

ULB 61

KLB 5

ULB 61

REMROFSNART

KLB 81

NRB 71

REMROFSNART

KLB 81

NRB 71

FFOTUC OTUA

EVLAV

NRG 03

321

HCTIWS RIA

CON

KLB 01

V021

V42

ULB 91

NRB 51

ROTICAPAC

FFOTUC OTUA

EVLAV

LEY 02

HCTIWS RIA

CON

KLB 01

V021

V42

ULB 91

NRB 51

ROTICAPAC

KLB 8

THW 13

THW 9

LEY 21

NEHW WOTS

DESU TON

REWOLB

NRG 53

EDAPS DETALUSNI

NRG 03

321

KLB 8

THW 13

THW 9

LEY 21

NEHW WOTS

DESU TON

REWOLB

NRG 53

EDAPS DETALUSNI

SROTCENNOC

ELUDOM KRAPS

NAT 12

HCTIWS TLIT

NRG 43

THW 6

NRG 7

DER 23

NRG 33

REMIT LANOITPO

HTIW ESU ROF

SROTCENNOC

YALER

ELUDOM KRAPS

NAT 12

HCTIWS TLIT

NRG 43

THW 6

NRG 7

DER 23

NRG 33

REMIT LANOITPO

HTIW ESU ROF

YALER

TVH

DNUORG

DNUORG

ROSNES

EVLAV

HT

NAT 22

NRG 52

ROSNES

ROTINGI

HT

NAT 22

NRG 52

ROSNES

ROTINGI

NRG 62

NAT 82

GRO 72

1 XOB EGAIRRAC & DOOH LLEHSMALC)LANOITPO( 2 XOB EGAIRRAC & DOOH LLEHSMALC

DER 32

NRG 42

RENRUB

EVLAV

TVH

DNUORG

DNUORG

ROSNES

EVLAV

NRG 62

NAT 82

GRO 72

DER 32

NRG 42

RENRUB

EVLAV

DOOH LLEHSMALC

Page 23

Page 24

STAR INTERNATIONAL HOLDINGS INC. COMPANY

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

265 HOBSON ST,

(800) 807-9054 (314) 781-2777

Parts & Service (800) 807-9054

SMITHVILLE, TN 37166 U.S.A.

www.star-mfg.com

Loading...

Loading...