Page 1

Contact Clamshell

Owner’s Manual

Models

CCSE12

This manual includes material related to installation,

use , cleaning, and care. Exploded view(s), as well

as any available parts list(s) and wiring diagram(s)

pertaining to the unit(s) covered by this manual are

also included.

This manual must be read and understood by all

persons using or installing this appliance. Contact

your Lang dealer if you have any questions concerning

installation, use, or maintenance of this equipment.

DO NOT DISCARD THIS MANUAL.

One [1] CCSE12

contact clamshells

mounted on

a 24-inch

griddle.

2M-W2121 • Rev. Q • 10.2018

Page 2

LIMITED EQUIPMENT WARRANTY

Lang Manufacturing [as well as its subsidiaries] warranties new products

to be free from defects in material and/or workmanship for a period

of one [1] year from the date of original installation, except as noted

below. Defects that occur as a result of normal use, within the time period

and limitations defined in this warranty, will at Lang’s discretion have the

parts replaced or repaired by Lang or a Lang-authorized service agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be performed by a Langauthorized service agency. Lang will not be responsible for charges

incurred or service performed by non-authorized repair agencies.

In all cases, the nearest Lang-authorized service agency must be used.

Lang will be responsible for normal labor charges incurred in the repair or

replacement of a warrantied product within 50 miles (80.5 km) of

an authorized service agency. Time and expense charges for anything

beyond that distance will be the responsibility of the owner. All labor

will need to be performed during regular service hours. Any overtime

premium will be charged to the owner. For all shipments outside the

U.S.A. and Canada, please see the International Warranty for specific

details.

It is the responsibility of the owner to inspect and report any shipping

damage claims, hidden or otherwise, promptly following delivery.

No mileage or travel charges will be honored on any equipment that is

deemed portable. In general, equipment with a cord and plug weighing

less than 50 lb. (22.7 kg) is considered portable and should be taken or

shipped to the closest authorized service agency, transportation

prepaid .

CONTACT

Should you require any assistance regarding the operation or

maintenance of any Lang equipment; write, phone, fax or email

our service department. In all correspondence mention the

model number and the serial number of your unit, as well as the

voltage or type of gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone 314.678.6315

Fax 314.781.2714

Email customerservice@star-mfg.com

www.langworld.com

WARRANTY EXCLUSIONS

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been used, cleaned, maintained,

or installed in accordance with the directions published in the

appropriate installation sheet and/or owner's manual as well

as national and local codes, including incorrect gas, electrical,

or water connection. Lang is not liable for any unit which has been

mishandled, abused, misapplied, subjected to chlorides, harsh

chemicals, or caustic cleaners, damaged from exposure

to hard water, modified by unauthorized personnel, damaged

by flood, fire, or other acts of nature [or God], or which have

an altered or missing serial number.

• Installation, labor, and job checkouts, calibration of heat controls,

air and gas burner/bypass/pilot adjustments, gas or electrical

system checks, voltage and phase conversions, cleaning

of equipment, or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety

controls, or reset buttons.

• Replacement of broken or damaged glass components, quartz

heating elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers and

hotplates, including but not limited to burners, grates, and radiants.

• Any labor charges incurred by delays, waiting time, or operating

restrictions that hinder a service technician’s ability to perform

service.

• Parts that fail or are damaged due to normal wear or labor for

replacement of Items that can easily be replaced during a daily

cleaning routine. such as but not limited to silicone belts, PTFE

non-stick sheets, knobs, control labels, bulbs, fuses, quartz

heating elements, baskets, racks, and grease drawers.

• Components that should be replaced when damaged or worn,

but have been field-repaired instead [eg. field-welded fry pots]

• Any loss of business or profits.

ADDITIONAL WARRANTIES

Specialty/chain specific versions may also have additional

and/or extended warranties.

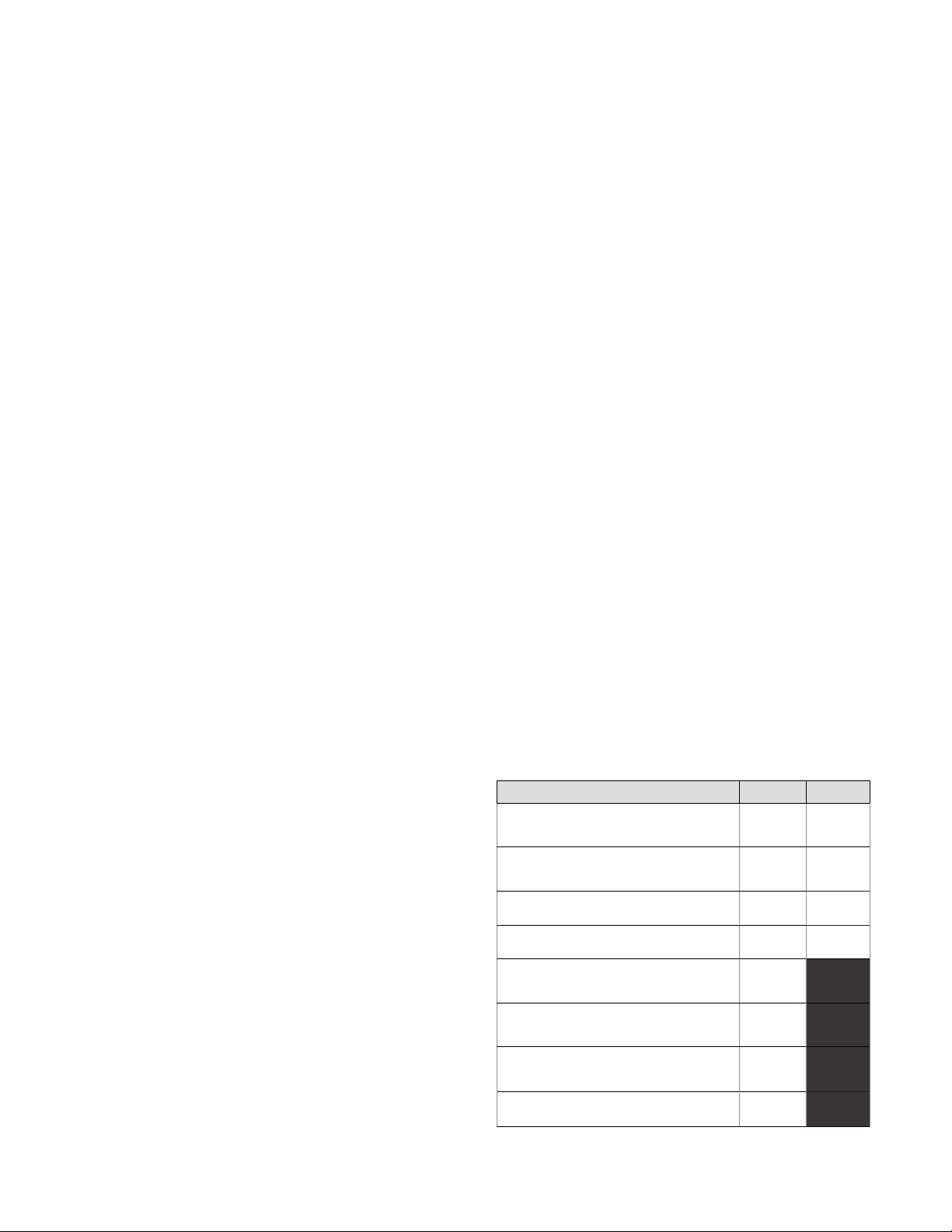

PRODUCTS PARTS LABOR

Lang Chef-Series™

convection ovens

Lang Strato-Series™

convection ovens

Lang convection oven doors

[excluding hardware]

2 years 2 years

2 years 2 years

lifetime

2 years

Lang griddles and charbroilers

chrome griddle surfaces [against

original Lang parts sold to repair

The fore going warrant y is in lieu of any and a ll other warranti es expresse d or implied and c onstitutes the e ntire warranty.

peeling]

cast iron grates, burners,

and burner shields

Lang equipment

Service First 1 year

2M-Z22519 • Rev - • 02.2018

2 years 2 years

5 years

180 days

90 days

Page 3

TABLE OF CONTENTS

Warranty

cifications

Spe

General Information and Installation

Control Box Wiring

Daily Operation / Cleaning

Troubleshooting

Wiring Diagram

Parts List

Exploded Views

PTFE Sheet Installation

i

iii

1–2

3

4

5

6

7

8–9

10

2M-W2121 Rev. Q Owner's Manual for CCSE12 Contact Clamshell

Page 4

SPECIFICATIONS

SAFETY SYMBOLS

These symbols are intended to alert the user to the

presence of important operating and maintenance

instructions in the manual accompanying the appliance.

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to ensure delivery of your unit

in perfect condition. However, there are instances in which the unit may be damaged in transit. In the

event you discover any type of damage to your product upon receipt, you must immediately contact

the transportation company who delivered the item to you and initiate your claim with that company.

If this procedure is not followed, it may affect the warranty status of the unit. If damage or loss is not

apparent until after equipment is unpacked, a request for inspection of concealed damage must be

made with carrier within 15 days. Please record the model number, serial number, voltage, and purchase

date in the area below at the time of receipt..

Model Number

Serial Number

Voltage

Purchase Date

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please have the

information in the above fields ready when you call to ensure a faster service.

Using any part other than genuine Star factory supplied parts relieves the manufacturer of all liability.

Due to periodic changes in designs, methods, procedures, policies, and regulations, the specifications

contained in this document are subject to change without notice. Star reserves the right to change

product specifications and design without notice. In regards to previously purchased equipment,

such revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements. While Star International Holdings Inc. exercises good faith efforts to provide information

that is accurate, we are not responsible for errors or omissions in information provided or conclusions

reached as a result of using the specifications. By using the information provided, the user assumes

all risks in connection with such use. When performing maintenance, power to the unit should be

unplugged or turned off.

PLEASE REFER TO THE WARRANTY PAGE FOR SPECIFIC WARRANTY INFORMATION.

AUTHORIZED SERVICE AGENT LISTING

Reference the listing provided with the unit or for an updated listing go to the website or call customer

service to find an agent.

Business hours: 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone: 314-678-6303

Fax: 314-781-2714

Email: customerservice@star-mfg.com

Website: www.langworld.com

Please visit www.starwebconnect.com/manuals.aspx for digital versions of any documents associated

with this unit.

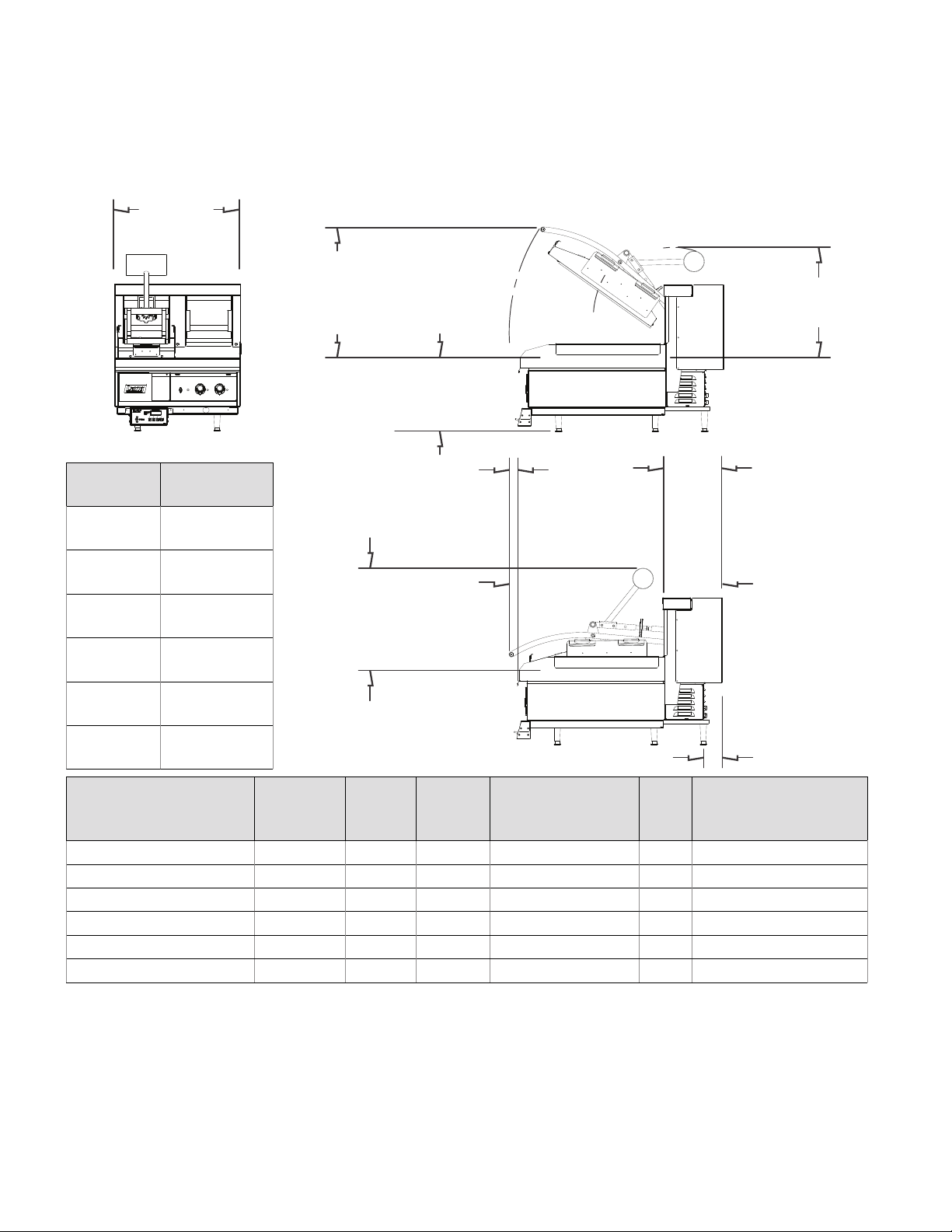

Two [2] CCSE12 mounted on

124THE griddle shown.

24.1 in.

(612 mm)

[no change]

NUMBER

OF HOODS

1

2

3

4

5

6

NUMBER OF

HOODS PER

CONNECTOR BOX

ADDITIONAL

WEIGHT

(36.3 kg)

(70.3 kg)

(106.6 kg)

(140.6 kg)

(176.9 kg)

(210.9 kg)

1 208, 1Φ 20.2 4.2 12 60 6-30P

2 208, 1Φ 40.4 8.4 8 60 6-50P

1 240, 1Φ 17.5 4.2 14 60 6-30P

2 240, 1Φ 35 8.4 8 60 6-50P

1 480, 1Φ 8.8 4.2 14 60 N/A

2 480, 1Φ 17.6 8.4 12 60 N /A

80 lb.

155 lb.

235 lb.

310 lb.

390 lb.

465 lb.

ADDITIONAL INSTALLATION INFORMATION

Dimensions are expected changes when mounted to griddle. For information on griddle

dimensions, refer to the spec sheet for that griddle. A griddle will support one [1] hood

per foot of griddle width. Up to two [2] hoods can use one [1] electrical connector box—

setups with more than two hoods will use additional electrical connector boxes.

24.8 in.

(630 mm)

[typical additional height

from griddle plate]

0.75 in.

(19 mm)

[added to platen height]

(41 mm)

[added to

griddle depth]

19.6 in.

(498 m m)

[typical additional height

from griddle plate]

VOLTAGE,

PHASE

AMPS TOTAL

1.6 in.

KW

MINIMUM SUPPLY

WIRE GAUGE

fully opened dimensions

21.1 in.

(536 mm)

fully closed dimensions

11.1 in.

(282 mm)

[added to

griddle depth]

40.9 in.

(1.04 m)

3.6 in.

(91 mm)

[additional foot

for stability]

HZ RECOMMENDED

NEMA PLUG

[NO PLUG INCLUDED]

iii

Page 5

SAFETY SYMBOLS

These symbols are intended to alert the user to the

presence of important operating and maintenance

instructions in the manual accompanying the appliance.

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to ensure delivery of your unit

in perfect condition. However, there are instances in which the unit may be damaged in transit. In the

event you discover any type of damage to your product upon receipt, you must immediately contact

the transportation company who delivered the item to you and initiate your claim with that company.

If this procedure is not followed, it may aff ect the warranty status of the unit. If damage or loss is not

apparent until after equipment is unpacked, a request for inspection of concealed damage must be

made with carrier within 15 days. Please record the model number, serial number, voltage, and purchase

date in the area below at the time of receipt..

Model Number

Serial Number

Voltage

Purchase Date

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please have the

information in the above fi elds ready when you call to ensure a faster service.

Using any part other than genuine Star factory supplied parts relieves the manufacturer of all liability.

Due to periodic changes in designs, methods, procedures, policies, and regulations, the specifi cations

contained in this document are subject to change without notice. Star reserves the right to change

product specifi cations and design without notice. In regards to previously purchased equipment,

such revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements. While Star International Holdings Inc. exercises good faith eff orts to provide information

that is accurate, we are not responsible for errors or omissions in information provided or conclusions

reached as a result of using the specifi cations. By using the information provided, the user assumes

all risks in connection with such use. When performing maintenance, power to the unit should be

unplugged or turned off .

PLEASE REFER TO THE WARRANTY PAGE FOR SPECIFIC WARRANTY INFORMATION.

AUTHORIZED SERVICE AGENT LISTING

Reference the listing provided with the unit or for an updated listing go to the website or call customer

service to fi nd an agent.

Business hours: 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone: 314-678-6303

Fax: 314-781-2714

Email: customerservice@star-mfg.com

Website: www.langworld.com

Please visit www.starwebconnect.com/manuals.aspx for digital versions of any documents associated

with this unit.

1

2M-W2121 Rev. Q Owner's Manual for CCSE12 Contact Clamshell

Page 6

THE NAMEPLATE IS LOCATED BEHIND THE CLAMSHELL BETWEEN THE TWO PIVOT ARMS.

THE CLAMSHELL VOLTAGES, WATTAGE, SERIAL NUMBER, WIRE SIZE, AND CLEARANCE

SPECIFICATIONS ARE ON THE DATA PLATE. CAREFULLY READ AND UNDERSTAND THIS

INFORMATION BEFORE PROCEEDING WITH THE INSTALLATION.

GENERAL SAFETY INFORMATION

This equipment is designed and sold for commercial use only, and is intended for use by personnel

trained and experienced in its operation. This is not sold for consumer use in and around the home

nor for use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions and labels associated

with the unit prior to putting it into operation. The presence of safety equipment and components

cannot, in and of themselves, assure absolute safety of operation. Diligent, capable, well-trained

operators and maintenance personnel, as well as proper programs of operation and maintenance,

are essential to the safe and reliable operation of this unit.

Lang manufacturing is not responsible for injury, damage, loss or other claim that may occur to person

or property from improper alteration, modification, addition, operation, maintenance or service, whether

it be mechanical, electrical, or otherwise, which may occur from such improper alteration, modification,

addition, operation, maintenance or service to this piece of equipment.

GENERAL INSTALLATION INFORMATION

The unit is shipped fully assembled. It will be shipped in a crate, and on a skid. The unit as a whole is very

heavy and should be moved carefully to avoid damage or injury. Make certain any counter or stand the

unit is being installed upon is rated to hold the total weight of the unit. Do not remove the crating until

the unit is as close as possible to the final install location. When removing crating, be careful of cutting

shipping straps as they are under tension and can snap back when cut.

Make certain to observe the minimal clearances recorded on the nameplate of the unit when installing.

If operated improperly, damage to persons or property may result. Installation of extractor or suppression

systems must conform to applicable national, state, and locally recognized installation standards.

Before using the unit for the first time, ensure to clean and season the griddle and clean the clamshell

properly.

ELECTRICAL CONNECTION

Electrical installation must only be performed by a certified electrical technician. The clamshell comes

in a 208 V, 240 V, or 480 V version, which must be specified at the time of ordering. The units

are shipped being set up for 3-phase, but can be converted to single phase in the field. Before making

any electrical connection to this unit, check that the power supply is adequate for the voltage, amperage,

and requirements stated on the rating plate. Start by ensuring the griddle has been correctly installed.

Do not connect equipment to power without proper ground connections. Improper grounding may

result in personal injury or fatality. Proceed to connecting electrical service to the box[es].

Make certain to disconnect the unit from the power source before installing or removing any parts.

BLK

RED

L3 L2 L1

WHT

GRN

BLK

WHT

2

Page 7

CONTROL BOX WIRING

1. Run the control box wiring through the tray.

The end of the control box wire with the circular

connector should extend from the rear side.

2. Loosen the two bolts under the griddle on the

stabilizer that line up with the slots in the tray.

Slide the tray into place and tighten bolts.

3A. Remove the bolt [1 of 2]

holding the connection box

to the stabilizer.

3B. Remove the bolt [2 of 2]

holding the connection box

to the stabilizer.

4. Slide the connection box back until the

wiring block can be accessed. Connect wiring

and reinstall box.

3

2M-W2121 Rev. Q Owner's Manual for CCSE12 Contact Clamshell

Page 8

LOCKOUT PROCEDURE

USE THIS PROCEDURE WHEN PERFORMING ANY

SERVICE OR REPAIR TO ENSURE THE SAFETY OF

ALL PERSONNEL ON SITE.

i. Announce the lockout to other personnel.

ii. Turn the power o at the main panel.

iii. Test lockout by turning power switch on and

observing if the elements come on.

iv. Check the heater circuit with a voltmeter.

v. Perform necessary repairs or tests.

vi. Clear the unit of personnel before starting

the griddle.

vii. Turn power on at main panel

viii. Announce unit is “on” to other personnel.

OPERATION

CERTAIN SURFACES ARE EXTREMELY HOT DURING

OPERATION AND CARE SHOULD BE TAKEN WHILE

USING THIS UNIT.

DO NOT LEAVE THE UNIT IN OPERATION WITHOUT

AN ATTENDANT.

DO NOT LEAVE THE UNIT AT HIGH TEMPERATURE

WHEN NOT IN USE OR DURING IDLE PERIODS.

ALWAYS KEEP THE AREA NEAR THE APPLIANCE

FREE FROM COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN

AND DRY. IF A SPILL OCCURS, CLEAN IMMEDIATELY

TO AVOID THE DANGER OF SLIPS OR FALLS.

INITIAL START UP

Each unit is tested and calibrated at the factory prior

to shipment. Due to temperature and climate changes

during shipment the unit can absorb moisture. Check

for moisture and allow the unit to dry before placing

the unit into full operation. Prior to putting any unit

into full-time operation at normal cooking temperatures,

it must be thoroughly dried out. Moisture absorption

in closed spaces— like the insulation and even inside

the heating elements—can cause future trouble if not

properly treated. Make certain to pre-heat the griddle

for one hour, if the unit has been out of service for three

days or more, especially when exposed to high humidity

and/or cool temperatures.

During the first few hours of operation, you may notice

a small amount of smoke and a faint odor from the

smoke. This is normal for a new unit and will disappear

after the first few hours of use.

DA ILY USE

The unit should be allowed to preheat for approximately

30 minutes in the up position prior to use. After this period,

the unit will be ready for use until powered down.

LEVELING ADJUSTMENT

The adjusting knob, centered above the clamshell body,

can be turned clockwise to raise the back and lower the

front of the unit and counterclockwise to raise the front

and lower the back of the unit.

CLEANING

Refer to your griddle’s manual for maintenance and

cleaning information regarding the griddle itself.

The clamshell hood should be wiped down daily with

cleaner to remove any excess grease or residue on the

exterior surfaces. DO NOT SUBMERGE THE UNIT OR

ALLOW FLUID TO PENETRATE THE REAR HOUSING.

If fluid is allowed to enter the rear housing, it will clean

away the permanent lubricant neccesary for quiet,

smooth operation of the clamshell. Do not allow excess

moisture to come in contact with the control for the

clamshell, mounted on the lower front of the griddle.

Once a week, with a cold griddle, lower the clamshell

hood and allow to heat for 30 minutes [or more if

necessary] to burn o excess carbon and baked-on

grease.

ADJUSTING TIME AND TEMPERATURE

EACH CLAMSHELL WILL HAVE ITS OWN INDEPENDENT

CONTROL BOX.

i. Press and hold “TEMP” [actual temperature displays].

ii. While holding “TEMP” press and hold any program

button on the for three seconds. The LED above the

program number will light and the display will read

“_ _ _ _”. Enter the four-digit security code sequence

4, 3, 2, 1. Once the sequence has been successfully

entered, the preset time will be displayed and the

LED for that program will begin to flash.

iii. Set the desired time with the “3/+” to increase time

or “4/-” to decrease time. Press the “TEMP” button

to save changes.

iv. The temperature setting will now be displayed and

can be programmed. Set the desired temperature

with the “3/+” to increase the temperature or “4/-”

to decrease temperature. Press the “TEMP” button

again to save changes.

v. Press any other program button within 15 seconds

to continue programming without re-entering the

security code.

4

Page 9

TROUBLESHOOTING

ERROR CODES

The con

diagnosis is still required as these codes are meant to show how or where a malfunction has been

detected, not necessarily what is causing the malfunction.

i. PRO1—If the control board detects that the temperature probe has an open or shorted circuit,

ii. RELY— If the unit is powered on and either remains below 150° F (66° C) for 30 minutes, or exceeds

trol can display codes based on perceived faults in the system. It should be noted, proper

this error code will display on the screen. Whenever this code is displayed, power will

be cut to the relay.

640° F (338° C), this error code will display on the screen. Whenever this code is displayed,

power will be cut to the relay.

CALIBRATION CHECK

BE EXTREMEL

Y CAREFUL WHEN WORKING ON THE UNIT WHEN IT IS WARM.

DIRECT CONTACT WITH THE COOKING SURFACE CAN RESULT IN SEVERE BURNS.

SUGGESTED EQUIPMENT

i. K-type thermocouple thermometer with a surface probe, rated to at least 500° F (260° C).

CLAMSHELL

The clamshell should be set at 350° F (177° C) to ensure accuracy. Refer to the owner’s manual

for instructions on how to set temperature.

i. Allow the unit to remain in the up position, with the power on, for 30 minutes.

ii. Place the thermocouple probe 15.75 in. (40 cm) from the front of the platen surface, centered

from left to right.

iii. If the temperature is set as directed above, the probe should read ±15° F (8° C) from the set

temperature.

iv. If the test does not fall within the given parameter, the temperature oset in the control

programming may be adjusted to compensate by authorized personnel or technician.

TEMPERATURE OFFSET ADJUSTMENT

A. To adjust the the temperature oset, press and hold the “TEMP” button and switches

“3” and “4” for 2–4 seconds. Release the buttons as soon as the oset value is displayed.

B. Increase the oset by pressing switch “3” or decrease the oset by pressing switch “4”

in order to adjust for the dierence in desired and observed temperatures. Increases and

decreases shall be in 1° F or 1° C increments depending on the unit’s current settings.

C. Once the desired oset is displayed, press the “TEMP” switch.

D. The current TCTD setting will be displayed. This value should not be adjusted during this

process. Press the “TEMP” switch to exit programming.

E. Perform step i–iii [above] again to confirm the change has had the desired result. If not,

repeat steps A–E.

5

2M-W2121 Rev. Q Owner's Manual for CCSE12 Contact Clamshell

Page 10

WIRING DIAGRAM

6

Page 11

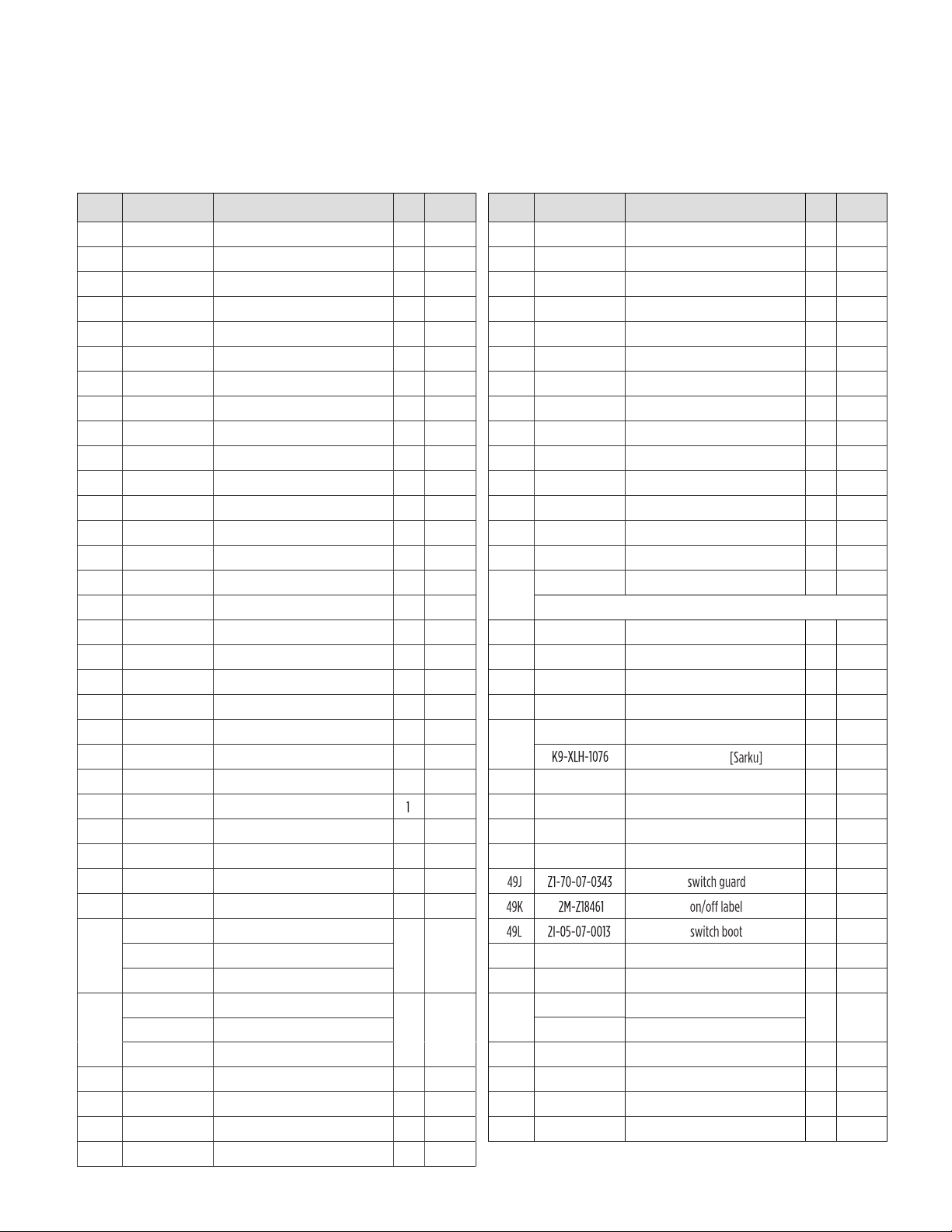

PARTS LIST

Side references are from the operator's point-of-view—from the front of the unit. Items labeled “NS”

are non-serviceable. Items labeled “NP” are not pictured. All quantities are per single clamshell hood

or per electrical connection in the case of parts 50, 51, 53, and 54. Other parts, such as a mounting frame,

will need to be purchased with the griddle and clamshell also.

REF NO PART NUMBER DESCRIPTION QTY PAGE NO

1 2V-XLH-901 counterweight 1

2 2V-XLH-890 rear leveling link bracket 1

3 2A-XLH-889 rear leveling link pivot shaft 1

4 2V-XLH-1010 rear section, leveling link 1

5 2F-XLH-1011 center section, leveling link 1

6 2V-XLH-1009 front section, leveling link 1

7 2V-XLH-917 upper leveling block base 2

8 2V-XLH-916 lower leveling block base 2

9 K9-XLH-1025 non-stick sheet clip 5

10 2V-XLH-866 leveling hinge block 2

11 2M-60301-W2 clamshell logo 1

12 2C-20111-09 #10-32 x 0.5-inch screw 8

13 2C-20602-04 tinnerman nut 2

14 K9-XLH-1023 conduit mounting bracket 1

15 K9-XLH-1022 conduit end seat 1

16 2C-20201-07 0.25-inch ID flat washer 14

17 2C-20202-05 0.25-inch ID split lock washer 10

18 2C-20111-03 1/4-20 x 0.625-inch screw 8

19 2C-20102-12 #10-32 x 0.375-inch screw 24

20 2C-302520 5/16-18 acorn nut 6

21 2C-20201-06 5/16 ID flat washer 18

22

2T-30401-35

fixed thermostat 1

23 2C-20102-08 8-32 x 0.375-inch screw

24 K9-XLH-929 bracket

25 K9-XLH-928 element hold-down bracket 1

26 K9-XLH-1035 element pan cover 1

27 K9-XLH-1037 element plate 1

28 K9-XLH-826 insulation 1

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8, 9

8

8

8

4 8

8

8

8

8

8

2N-11060-35 208 V inner element

29 2N-11060-39 240 V inner element 1

8

2N-11060-41 480 V inner element

2N-11060-34 208 V outer element

1

30 2N-11060-38

240 V outer element

8

2N-11060-40 480 V outer element

31 2C-20301-13 1/4-20 nut 14

32 2V-XLH-866 hinge block 1

33 2E-Z20781 RTD probe 1

34 K9-XLH-920 weld plate 1

8

8

8

8

REF NO PART NUMBER DESCRIPTION QTY PAGE NO

35 2C-20106-14 shoulder screw 2

36 2A-XLH-854 handle 1

37 2C-20105-22 3/8-16 x 3-inch set screw 4

38 2A-5401 0.09735-inch x 0.75-inch cotter pin 2

39 2V-XLH-893 spring shaft key 2

40 K9-XLH-875 right outside pivot bracket 1

41 K9-XLH-853 right arm 1

42 2K-XLH-915 aluminum bushing 2

43 2P-51001-42 spring, right 1

44 2A-XLH-876 shaft collar 1

45 2P-51001-43 spring, left 1

46 2V-XLH-888 spring shaft 1

47 K9-XLH-852 left arm 1

48 K9-XLH-874 left outside pivot bracket 1

49 K9-XLH-959 control box 1

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

THE BELOW PARTS [49A–49L] ARE PART OF THIS ASSEMBLY [49]

49A K9-XLH-962 control box front 1

49B 2E-Z12020 toggle switch 1

49C 2M-60301-187 control box overlay 1

49D 2A-20504-12 nylon spacer 4

49E

2J-Z17605

control board 1

control board

49F 2C-20301-11 #8-32 nut 4

49G K9-XLH-964 control box rear 1

49H K9-XLH-961 control box top 1

49I K9-XLH-960 control box bottom 1

9

9

9

9

9

1

9

9

9

9

9

NP

1

NP

1

NP

1

50 2E-30900-30 60 amp fuse 2 NP

51

52 1 NP

2E-30901-15 fuse block 1

2E-30600-15 208 V/240 V relay

2E-30600-16

480 V relay

53 2E-31200-02 lug ground 1

NP

NP

54 2E-Z15018 transformer 1 NP

54

55

K9-XLH-734 conduit assembly

K9-XLH-1132 bracket, high limit mount

1 NP

1 8

7

2M-W2121 Rev. Q Owner's Manual for CCSE12 Contact Clamshell

Page 12

MAIN BODY

1

2

3

4

5

6

7

9

8

15

14

16

17

18

19

55

22

23

Models After 10/2018

11

10

12

C

13

20

21

26

31

31

B

24

21

21

27

25

19

12

28

29

30

31

17

16

32

33

A

34

8

Page 13

HANDLE/ARMS

and CONTROLLER

35

36

35

38

39

40

41

42

43

44

37

45

42

46

47

48

39

49L

49K

49J

49B

49A

49C

49I

49D

49E

49F

49H

49G

19

9

2M-W2121 Rev. Q Owner's Manual for CCSE12 Contact Clamshell

Page 14

CCSE12 Contact Clamshell

PTFE Non-Stick Sheet Kit CCSE12C-10NS

PTFE Non-Stick Sheet Installation

BE CAREFUL DURING INSTALLATION. IF THE GRIDDLE AND/OR CLAMSHELL HAVE BEEN

IN OPERATION, THEY AS WELL AS THE MOUNTING CLIPS FOR THE PTFE WILL BE VERY

HOT AND SHOULD BE HANDLED/TOUCHED WITH CAUTION AND PROPER PROTECTION.

i. Insert the rod into the eyelet that runs through the rear of sheet.

ii. Line the rod up and set the ends into the two rear channels [one on each side].

iii. Tuck the back of the PTFE sheet up against the back splashguard and along griddle surface,

making a soft 90 degree fold where the two meet.

iv. Gently lower the clamshell onto the PTFE sheet making certain the flaps on both sides and

front are clear of the clamshell.

v. Fold the front flap up and around the top of the front tab and place a clamp over the top to

hold it in place. [labeled CF]

vi. Repeat the same process on the right and left, which will have two clips each. [labeled CS]

vii. Raise the clamshell and check to make sure PTFE is flush running the length of the clamshell.

There should still be a small amount of slack to allow for slight movement when raising and

lowering the clamshell.

Installation Instructions

CS

CF

PTFE NON-STICK SHEET

[all clips are identical, positions are simply labeled

dierently to relate to specific steps]

CS

CS

CS

CLIP

10

Page 15

NOTES

11

Page 16

LANG MANUFACTURING

•

www.langworld.com

265 Hobson St. • Smithville, Tennessee 37166

Telephone 314 678 6315 • Fax 314 781 3636

Printed in the U.S.A. • 2M-W2121 • Rev. Q • 10.2018

Specifications are subject to change without notice.

Loading...

Loading...