Page 1

TM S6161-DR-FSE-010/34931

OPERATION AND SERVICE MANUAL

FOR

ELECTRIC CONVECTION OVEN RANGE

MODEL NUMBER 9P-RT36D-440VG (ALSO KNOWN AS RF21SM-A)

LANG MANUFACTURING COMPANY

A DIVISION OF STAR MANUFACTURING INTERNATIONAL

10 SUNNEN DR

ST. LOUIS, MO 63143

DISTRIBUTION STATEMENT

THIS PUBLICATION IS REQUIRED FOR OFFICIAL USE OR FOR ADMINISTRATIVE OR OPERATIONAL

PURPOSES. DISTRIBUTION IS LIMITED TO U.S. GOVERNMENT AGENCIES ONLY. OTHER REQUESTS FOR

THIS DOCUMENT MUST BE REFERRED TO COMMANDER NAVAL SEA SYSTEMS COMMAND, SEA 09,

WASHINGTON, DC 20362.

2M-W1095, Rev. - May 16, 2007

Page 2

S6161-DR-FSE-010/34931

MARCH 2001

IDENTIFYING TECHNICAL PUBLICATION SHEET

1. IDENTIFICATION DATA: LANG MFG. CO. MODEL 9D-RT36D-440VG (ALSO KNOWN AS RF21SM-A)

2. PURPOSE: THIS TECHNICAL PUBLICATION IS ISSUED FOR THE PURPOSE OF IDENTIFYING AN

AUTHORIZED TECHNICAL MANUAL FOR NAVY USE AND FOR PROVIDING SUPPLEMENTAL

TECHNICAL INFORMATION.

A. MANUFACTURER: LANG MFG. DIVISION OF STAR MANUFACTURING INTERNATIONAL

B. CONTRACT NUMBER: _________________________________

C. EQUIPMENT: ELECTRIC CONVECTION OVEN RANGE, MODEL NUMBER RF21SM-A

D. REQUISITION NUMBER: NOT REFERENCED

E. NATIONAL STOCK NUMBER (NSN): 7310-01-104-3349

F. TITLE: MAINTENANCE MANUAL FOR ELECTRIC CONVECTION OVEN RANGE MODEL NUMBER

RF21SM-A

G. DATE OF PUBLICATION: MARCH 2001

H. PREPARING ACTIVITY: DEFENSE GENERAL SUPPLY CENTER

I. APPLICABLE TMCR NUMBER: XXXX XXXXXX-XXX

J. EXTENT OF PROPOSED SUPPLEMENTAL DATA (10% MAXIMUM): 1%

K. LIST OF TECHNICAL MANUAL FOR THIS EQUIPMENT PROCURED UNDER ANOTHER CONTACT:

3. ADDITIONAL COPIES ARE AVAILABLE FROM:

NAVAL PUBLICATION AND FORMS CENTER

5801 TABOR AVE

PHILADELPHIA, PA 19120-5099

4. COVER: THE TECHNICAL MANUAL OUTSIDE COVER SHALL CONTAIN THE FOLLOWING STATEMENTS:

PUBLISHED BY DIRECTION OF COMMANDER, NAVAL SEA SYSTEMS COMMAND

THIS PUBLICATION IS REQUIRED FOR OFFICIAL USE OR FOR ADMINISTRATIVE OR OPERATIONAL

PURPOSES. DISTRIBUTION IS LIMITED TO U.S. GOVERNMENT AGENCIES ONLY. OTHER REQUESTS MUST

BE REFERRED TO COMMANDER, NAVAL SEA SYSTEMS COMMAND, SEA09, WASHINGTON, DC 20362

2

Page 3

XXXXX-XX-XXX-XXX/XXXX

MARCH 2001

APPROVAL AND PROCUREMENT RECORD

APPROVAL DATA FOR: LANG ELECTRIC CONVECTION OVEN RANGE MODEL NUMBER RF21SM-A.

TITLE OF MANUAL: MAINTENANCE MANUAL FOR ELECTRIC CONVECTION OVEN RANGE MODEL

NUMBER RF21SM-A

APPROVAL AUTHORITY: NAVAL SHIP SYSTEMS ENGINEERING STATION

CONTRACT NUMBER NSN # OF UNITS APL/CID

7310-01-104-3349

REMARKS:

DATE: MARCH 2001

CERTIFICATION:

IT IS HEREBY CERTIFIED THAT THE TECHNICAL MANUAL PROVIDED UNDER CONTRACT NUMBER

_______________________

FOR LANG RF21SM-A HAS BEEN APPROVED BY THE APPROVAL DATA SHOWN

ABOVE:

________________________________

DIRECTOR, GOV’T CONTRACTS

LANG MANUFACTURING COMPANY

FSCM / CAGE #: 34931

3

Page 4

CHANGE RECORD

Change no. Date Title and/or Brief Description Signature of Validating Officer

4

Page 5

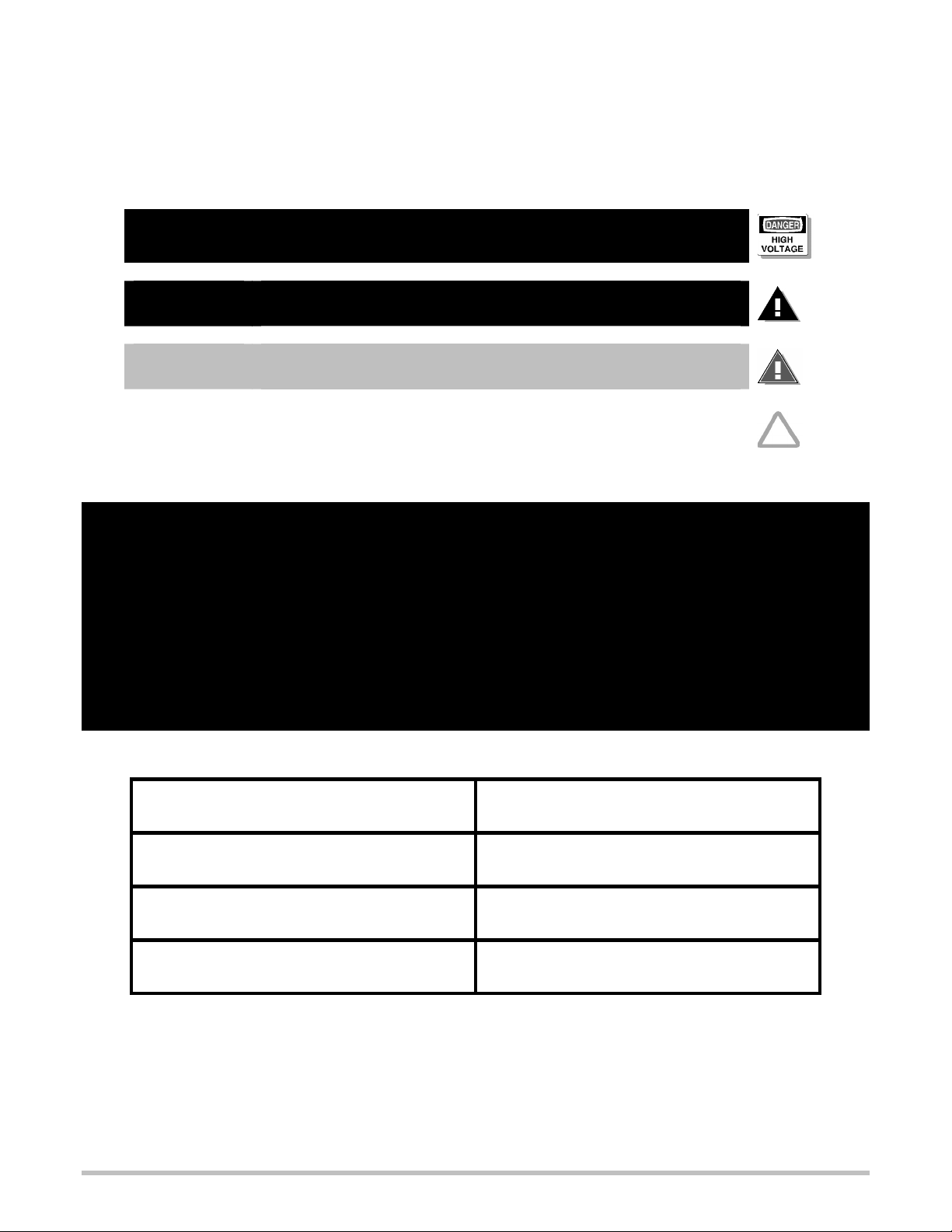

THE INFORMATION IN THIS MANUAL IS CRUCIAL AND MUST BE

RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND AND

FOLLOW THE INSTRUCTIONS AND WARNINGS CONTAINED IN THIS

MANUAL.

DANGER

WARNING

CAUTION

NOTICE

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH.

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH OR SERIOUS INJURY.

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY.

Helpful operation and installation instructions and tips are

present.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY

OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

Model #: Purchased From:

Serial #:

Location:

Date Purchased:

Purchase Order #:

Date Installed:

For Service, Call:

5

Page 6

TABLE OF CONTENTS

CHAPTER PAGE

1. TABLE OF CONTENTS..........................................................................6

2. LIST OF ILLUSTRATIONS .....................................................................7

3. READ FIRST ..........................................................................................8

4. SPECIFICATION SHEET .......................................................................11

5. EQUIPMENT DESCRIPTION .................................................................13

6. UNPACKING ..........................................................................................14

7. INSTALLATION ......................................................................................15

8. INITIAL START-UP.................................................................................16

9. OPERATION........................................................................................... 17

10. MAINTENANCE & CLEANING ...............................................................18

11. ILLUSTRATED PARTS BREAK DOWN .................................................23

12. PARTS LIST ...........................................................................................29

13. WIRING DIAGRAM.................................................................................30

14. WARRANTY ...........................................................................................31

6

Page 7

LIST OF ILLUSTRATIONS

ILLUSTRATION

1. SPECIFICATION SHEET .......................................................................11

2. RANGE TOP CONFIGURATION............................................................13

3. LEG LAYOUT .........................................................................................14

4. ASSEMBLY ............................................................................................15

5. ILLUSTRATED PARTS BREAKDOWN ..................................................23

6. WIRING DIAGRAM.................................................................................30

PAGE

7

Page 8

IMPORTANT READ FIRST IMPORTANT

CAUTION

CAUTION

CAUTION

DANGER

EACH UNIT IS EXTREMELY HEAVY. FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE

MATERIALS HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR

PALLET JACK) TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO

THE PLACE OF INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH RANGE WILL BE

LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE

RANGE.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN

CUT.

THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL PROVIDED.

FAILURE TO GROUND THE APPLIANCE COULD RESULT IN

ELECTROCUTION AND DEATH.

WARNING

NOTICE

NOTICE

CAUTION

WARNING

CAUTION

NOTICE

CAUTION

CAUTION

WARNING

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE

TO EQUIPMENT. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

The data plate is located on the serial tag, which is riveted to the front of

the unit in the lower right hand corner. The range voltage, wattage, serial

number, wire size, and clearance specifications are on the data plate.

This information should be carefully read and understood before

proceeding with the installation.

The installation of any components such as a vent hood, grease

extractors, fire extinguisher systems, must conform to their applicable

National, State and locally recognized installation standards.

MAKE SURE THE SIX WIRE LEADS TO SUPPLY ELECTRICITY TO THE

COOK TOP ARE NOT CRIMPED BETWEEN THE OVEN AND RANGE TOP.

MAKE SURE THE MAIN POWER SUPPLY TO THE RANGE IS TURNED OFF

AT THE SOURCE PRIOR TO CONNECTING POWER TO THE RANGE.

BE SURE THE POWER SUPPLY VOLTAGE MATCHES THE VOLTAGE

SPECIFIED ON THE NAME-PLATE LOCATED ON THE FRONT OF THE

RANGE.

During the first few hours of operation you may notice a small amount of

smoke coming off the range, or out of the oven, and a faint odor from the

smoke. This is normal for a new range and will disappear after the first

few hours of use.

ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR

FALLS.

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR

HOSE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

8

Page 9

IMPORTANT READ FIRST IMPORTANT

CAUTION

NOTICE

WARNING

CAUTION

WARNING

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO

WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ THE WARNING AND

FOLLOW THE DIRECTIONS ON THE LABEL OF THE CLEANER TO BE

USED.

Service on this, or any other, LANG appliance must be performed by

qualified personnel only. Consult your LANG authorized service station

directory or call the factory at 1-800-807-9054, or WWW.STAR-MFG.COM

For the service agent nearest you.

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THIS

APPLIANCE WHEN THE UNIT IS PLUGGED/WIRED INTO A LIVE

RECEPTACLE. BEFORE REPLACING ANY PARTS, DISCONNECT THE

UNIT FROM THE ELECTRIC POWER SUPPLY.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

LANG OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE BODILY

INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

MAKE SURE THE RANGE HAS BEEN PROPERLY SECURED FROM

POWER BEFORE REMOVING ANY COMPONENTS.

9

Page 10

LANG MANUFACTURING COMPANY

MANUAL FOR MODEL 9D-RT36A-440VG (ALSO KNOWN AS RF21SM-A)

ELECTRIC CONVECTION OVEN RANGE

ISSUED DATE: JULY 2001

LANG MANUFACTURING COMPANY

6500 MERRILL CREEK PARKWAY

EVERETT, WA 98203

ELECTRIC CONVECTION OVEN RANGE PER: MIL-X-XXXXXXXX

MIL SPEC LANG MODEL NUMBER SPECIFIC NSN

MIL-R-43954 RF21SM-A 7310-01-104-3349

* N.S.A. FOR “NAVAL SHIPBOARD APPLICATION”. ALL COMPONENTS WILL FIT THROUGH A 26”

WATERTIGHT HATCH.

10

Page 11

SPECIFICATION SHEET

11

Page 12

SPECIFICATION SHEET

12

Page 13

EQUIPMENT DESCRIPTION

ELECTRIC RANGE EXTERIOR

¾ The Range dimensions are 30” (76.2cm) High (without legs), 38” (96.5cm) Deep, and 36”

(91.5cm) Wide.

¾ The Sides, Bottom, and Rear wall are constructed stainless steel.

¾ The Range surface comes with a 24” griddle and two 9” in diameter French Plates.

ITEMS

¾ 1 ea. 9P-RT36A-440VG (Range Top) RF21-AM-U

¾ 1 ea. 9Q-FCOFL-AT440G (Convection Oven) F-6S-M-U

¾ 4 ea. Bolt down legs

¾ 2 ea. Operation Manuals

¾ 1 ea. Marine Handle

¾ 4 ea. ¼-20x½” HXD bolt S/S.

¾ 4 ea. Lock Washer, S/S

RANGE TOP CONTROLS

The RT36A (also known as RF21SM-A) Series Range comes with one 24”x24” Griddle that

has a temperature range of 100°F -450°F and two French Plates that have a temperature range

of 200°F-750°F. Each section of the grill is controlled by a 450°F thermostat and each French

Plate is controlled by a 6-heat switch. In addition the range comes with a convection oven that

is controlled by one thermostat that has a temperature range of 150°F-450°F. Below is a layout

of the top configuration.

RT36A (RF21SM-A)

One 24”x24” Griddle controlled by two 450°F

thermostats and two French Plates controlled by two 6-

heat switches.

FRENCH

PLATE

24" x 24"

GRIDDLE

FRENCH

PLATE

RANGE TOP CONFIGURATION

13

Page 14

CAUTION

CAUTION

CAUTION

EACH UNIT WEIGHS 600 LBS (THE TOP WEIGHS 410 LBS). FOR SAFE

HANDLING, INSTALLER SHOULD OBTAIN HELP AS NEEDED, OR

EMPLOY APPROPRIATE MATERIALS HANDLING EQUIPMENT (SUCH AS

A FORKLIFT, DOLLY, OR PALLET JACK) TO REMOVE THE UNIT FROM

THE SKID AND MOVE IT TO THE PLACE OF INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH RANGE WILL BE

LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE

RANGE.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN

CUT.

RECEIVING THE OVEN

Upon receipt, check for freight damage, both visible and concealed. Visible damage

should be noted on the freight bill at the time of delivery and signed by the carrier's

agent. Concealed loss or damage means loss or damage, which does not become

apparent until the merchandise has been unpacked. If concealed loss or damage is

discovered upon unpacking, make a written request for inspection by the carrier's

agent within 15 days of delivery. All packing material should be kept for inspection.

Do not return damaged merchandise to Lang Manufacturing Company. File your

claim with the carrier.

LOCATION

Prior to un-crating, move the range as near its intended location as practical. The

crating will help protect the unit from the physical damage normally associated

with moving it through hallways and doorways.

UN-CRATING

The range will arrive in two packages, each inside a wood frame covered by

cardboard box and strapped to a skid. Remove the cardboard cover, cut the

straps and remove the wood frame. The oven may now be removed from the

skid.

INSTALLING THE LEGS

To install the legs, place some cardboard on the floor and gently tip the oven

portion of the range onto its back. A ½-13 threaded weld nut is provided in each of

the four corners of the oven. Thread each leg into the threaded weld nuts and lift

oven back onto the legs. (See leg layout below).

UNPACK-ING

14

Page 15

DANGER

INSTALLATION

THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL PROVIDED.

FAILURE TO GROUND THE APPLIANCE COULD RESULT IN

ELECTROCUTION AND DEATH.

WARNING

NOTICE

NOTICE

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE

TO EQUIPMENT. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

The data plate is located on the serial tag, which is riveted to the front of

the unit in the lower right hand corner. The range voltage, wattage, serial

number, wire size, and clearance specifications are on the data plate.

This information should be carefully read and understood before

proceeding with the installation.

The installation of any components such as a vent hood, grease

extractors, fire extinguisher systems, must conform to their applicable

National, State and locally recognized installation standards.

ELECTRICAL CONNECTION

A 1¼” knockout is provided on the bottom left hand side of the oven below the

control panel for power connection.

The electrical connection must be made in accordance with local codes or in the

absence of local codes with National Electrical Code latest edition (in Canada

use: CSA STD. C22.1).

Place spacers, (ie. 2 x 4 wood block not supplied) at the front and rear of the oven

top.

Place the range top on the spacers (ie. 2 x 4 wood block not supplied) that are

located on top of the oven.

The six wire leads to supply electricity to the cook top are bundled under the front

bottom of the top. Route these wires through the bushing provided in the oven

top.

Align the four locating pins at the bottom corners of the Range bottom with the

four holes in each corner of the oven top.

Remove the spacers and lower the Range onto the oven.

CAUTION

WARNING

The range can now be connected to power.

MAKE SURE THE SIX WIRE LEADS TO SUPPLY ELECTRICITY TO THE

COOK TOP ARE NOT CRIMPED BETWEEN THE OVEN AND RANGE TOP.

MAKE SURE THE MAIN POWER SUPPLY TO THE RANGE IS TURNED OFF

AT THE SOURCE PRIOR TO CONNECTING POWER TO THE RANGE.

CAUTION

Use the wiring diagram provided in this manual for determining the connections of

the cook top wires to the oven terminal block.

BE SURE THE POWER SUPPLY VOLTAGE MATCHES THE VOLTAGE

SPECIFIED ON THE NAMEPLATE LOCATED ON THE FRONT OF THE

RANGE.

15

Page 16

INITIAL PREHEAT

Prior to putting any range or oven into full time operation at normal cooking

temperatures, it must be thoroughly dried out. Moisture absorption in the closed

spaces, in the insulation, and even inside the heating elements can cause future

trouble if not properly treated.

Griddles

To “dry out” the griddle, set the thermostat to 250°F. Allow the unit to operate at

least 15 minutes at this heat level. Set the thermostat to 350°F and allow another 15

minutes to elapse. Set the thermostat to 450°F and allow the unit to maintain the

temperature for a minimum of 4 hours. More time may be required if the unit has to

operate in a moist environment.

If the unit is out of use for three or more days, a one-hour preheat schedule should be

used, especially when exposed to high humidity and/or cool temperatures.

Before any griddle plate can be put into full operation it will need to be properly

seasoned. To do this, turn the griddle to 200°F and wait for the red heat indicator

lamp to shut off. Once the indicator lamp has shut off, apply a thin coat of highgrade, non-salted vegetable oil t the griddle surface with a metal spatula or towel.

Wait approximately five minutes and re-coat any dry spots. Repeat this procedure at

300°F and at 400°F.

French Plates

To “dry out” the French plates, set the 6-heat switch to position three. Allow the unit

to operate at least 15 minutes at this heat level. Set the 6-heat switch to position four

and allow another 15 minutes to elapse. Set the 6-heat to position six and allow the

unit to maintain the temperature for a minimum of 4 hours. More time may be

required if the unit has to operate in a moist environment.

INITIAL START-UP

If the unit is out of use for three or more days, a one-hour preheat schedule should be

used, especially when exposed to high humidity and/or cool temperatures.

Ovens

To “dry out” the oven, set the thermostat to 250°F and turn on the power switch.

Allow the unit to operate at least 15 minutes at this heat level. Set the thermostat to

350°F and allow another 15 minutes to elapse. Set the thermostat to 450°F and allow

the unit to maintain the temperature for a minimum of 4 hours. More time may be

required if the unit has to operate in a moist environment.

If the unit is out of use for three or more days, a one-hour preheat schedule should be

used, especially when exposed to high humidity and/or cool temperatures.

16

Page 17

NOTICE

During the first few hours of operation you may notice a small amount of

smoke coming off the range, or out of the oven, and a faint odor from the

smoke. This is normal for a new range and will disappear after the first

few hours of use.

OVEN

The convection oven roasts and bakes in shorter time and at lower temperatures with less

shrinkage than conventional commercial ovens.

A blower in the Lang convection oven circulates air within the chamber to heat the entire space

evenly and transfer heat efficiently to the product, even with stacked loading.

The airflow continuously removes the thick layer of moist, cool air that otherwise would

surround the product. When properly loaded and operated, it maintains this airflow throughout

the chamber to eliminate hot spots and roasts or bakes with minimum power consumption at

twice the output capacity of a conventional oven.

The power switch on the lower portion of the control panel energizes the fan motor and

activates the thermostatically controlled circuit for the oven heating elements. When this

switch is in the on position, the red indicator light will illuminate.

Rotating the thermostat control knob from "off" position to selected temperature causes the

indicator light to illuminate and closes the contactor that feeds power to the heating elements.

This light will cycle "on and off" as the thermostat calls for heat in the oven. The blower,

however, operates continuously while the power switch is in the "on" position.

The black control knob operates a damper in the oven vent stack. The damper is open when

knob is pulled outward.

Circuit breakers behind the control panel protect the electrical components from overload.

OPERATION

Griddle

Thermostats control 24” x 24” grill plate.

Temperature ranges from 100°-450°F.

Recommended: All heavy and light frying.

Set the thermostat dial at the desired temperature and allow for a thirty-minute preheat time.

The red indicator light will be on until the desired temperature is reached and then shut off.

The pilot light will cycle on and off as the elements cycle on and off.

French Plate

6-heat switch controls one, French Plate.

Temperature settings range from 1(low) to 6(high).

Recommended: Light duty sauce pans and small stockpots.

Not Recommended: Heavy stock pots, or heavy urns, or kettles.

Set the 6-heat dial to the desired setting and allow for a thirty-minute preheat time.

17

Page 18

MAINTENANCE & CLEANING

CAUTION

CAUTION

WARNING

CAUTION

ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF SLIPS OR

FALLS.

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR

HOSE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO

WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND

PROTECTIVE CLOTHING. CAREFULLY READ THE WARNING AND

FOLLOW THE DIRECTIONS ON THE LABEL OF THE CLEANER TO BE

USED.

CLEANING

• Always start with a cold range.

• The stainless exterior can easily be cleaned using Lang Mfg. Prime Shine

(72804-41) oven cleaner.

• Always follow the cleaner manufacturer's instructions when using any cleaner.

• Care should be taken to prevent caustic cleaning compounds from coming in

contact with the aluminized blower wheel and aluminized inside of the oven.

• Discoloration or heat tint may be removed using Lang Mfg. Carbon Release

(72804-32) oven cleaner.

Always apply these cleaners when the oven is cold and rub in the direction of the

metal's grain

The range should be thoroughly cleaned at least once a week in addition to the

normal daily cleaning to insure against the accumulation of foreign material.

Keep drip pans under range top plates clean.

Keep hot plate and french plate surfaces clean.

Outside of range and top should be kept clean.

Electric equipment is inherently clean and sanitary, but may become unsanitary if

grease is allowed to accumulate on it. Take advantage of the clean, sanitary features

of electric equipment, give it the regular attention that it deserves the same as any

other highly perfected machinery, to insure best results and continued high operating

efficiency.

EMERGENCY LOCKOUT

Locate power disconnect at source and remove power from range.

LONG TERM STORAGE

Secure range from power.

Apply a generous amount of Lang Mfg. Prima Shine (72804-41) to the stainless

steel.

Apply a generous amount of Lang Mfg. Shipping Preservative Grease (72804-08) to

the hop plate surface and the French plate surface.

18

Page 19

NOTICE

WARNING

CAUTION

Service on this, or any other, LANG appliance must be performed by

qualified personnel only. Consult your authorized service station

directory or call the factory at 1-800-224-LANG (5264), or

WWW.LANGWORLD.COM For the service station nearest you.

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THIS

APPLIANCE WHEN THE UNIT IS PLUGGED/WIRED INTO A LIVE

RECEPTACLE. BEFORE REPLACING ANY PARTS, DISCONNECT THE

UNIT FROM THE ELECTRIC POWER SUPPLY.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY

LANG OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE BODILY

INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT AND

WILL VOID ALL WARRANTIES.

TROUBLE SHOOTING

OVEN

OVEN WILL NOT HEAT

PROBABLE CAUSE CORRECTIVE ACTION

Oven circuit breaker not on

MAINTENANCE & CLEANING

Cycle breaker to the “ON” position.

Incorrect wiring

Defective transformer

Defective Fuses

Defective Contactor

Defective Thermostat

Defective Element

OVEN MOTOR WILL NOT COME ON

PROBABLE CAUSE CORRECTIVE ACTION

Incorrect wiring

Defective transformer

Defective Fuses

Defective Contactor

Confirm that oven is getting proper voltage.

Confirm that range is phased correctly.

Confirm that transformer is getting correct voltage.

Confirm that transformer is putting out correct voltage.

Replace fuses.

Confirm that contactor is getting correct voltage on the coil.

Confirm that thermostat is getting correct voltage.

Confirm that thermostat is operating properly.

Confirm that element is getting correct voltage

Check element for normal operation. (11.5 Amps )

Confirm that oven is getting proper voltage.

Confirm that range is phased correctly.

Confirm that transformer is getting correct voltage.

Confirm that transformer is putting out correct voltage.

Replace fuses.

Confirm that contactor is getting correct voltage on the coil.

Defective Motor

Confirm that motor is getting power and working properly.

Replace Motor.

19

Page 20

RANGE

Griddle

GRIDDLE WILL NOT HEAT

PROBABLE CAUSE CORRECTIVE ACTION

Incorrect wiring

MAINTENANCE & CLEANING

Confirm that oven is getting proper voltage.

Confirm that range is phased correctly.

Oven circuit breaker not on

Defective Thermostat

Defective Element

FRENCH PLATE

FRENCH PLATE WILL NOT HEAT

PROBABLE CAUSE CORRECTIVE ACTION

Incorrect wiring

Defective 6-Heat switch

Defective French Plate

Cycle breaker to the “ON” position.

Confirm that thermostat is getting correct voltage.

Confirm that thermostat is operating properly.

Confirm that element is getting correct voltage

Check element for normal operation (Inside 5.7 Amps, Outside 3.5

Amps).

Confirm the French Plate is wired correctly.

Confirm that range is phased correctly.

Confirm that switch is wired correctly.

Confirm that switch is operating correctly.

Confirm that French Plate is getting correct voltage.

Confirm that French Plate is operating correctly. (See Technical Data)

CALIBRATION

Calibration Check

Place thermometer or thermocouple in the center of oven cavity or grill section.

Set thermostat to 350°F.

Allow the oven or grill to preheat for at least half an hour.

Note cycle on temperatures and cycle off temperatures for 3 cycles. (Red indicator light indicates

when oven is calling for heat)

After 3 cycles average the temperature, (Add all six temperatures and divide by 6) The

temperature should be +/- 15°F.

Calibration Adjustment

A 1/16” flat blade screwdriver with a 2” shaft is required to make adjustments on the thermostat.

Maintain the oven temperature at 350°F.

Without turning the thermostat, remove the knob.

Locate the adjustment screw at the base of the shaft and insert the screwdriver.

Grasp the shaft and turn the screw. Counter clockwise to increase and clockwise to decrease (1/8

of a turn will move the temperature 5-7 °F in either direction).

Reinstall the oven knob and recheck the oven temperature.

20

Page 21

MAINTENANCE & CLEANING

WARNING

REMOVAL INSTRUCTIONS

OVEN

Thermostat, Contactor, Transformer, and Switch

These parts are located behind the control panel assembly on the right hand side of the oven.

To access control panel, remove the vent knob and the seven screws around the outside of

the control panel assembly. Slowly pull the control panel toward you until the component is

accessible.

Thermostat

Inside the oven, remove the fan baffle and the retaining clips holding the thermostat

capillary tube to the inside of the oven. Feed the bulb through the oven wall into the control

panel area. Pull out control panel as previously outlined. Remove knob and two screws that

hold the thermostat to the oven control panel. Remove the wires from the old thermostat and

attach to the corresponding terminal of the new thermostat. Discard old thermostat.

Reinstall the thermostat and capillary tube into oven and the control panel and restore power

to the oven. Test for proper operation.

Contactor and Switch

Pull out control panel as previously outlined. Remove the wires from the contactor or

switch being changed. Place those wires on the corresponding terminal of the new contactor

or switch. Remove old contactor or switch and mount new contactor or switch with wires

attached. Discard old contactor or switch. Reinstall the control panel and restore power to

the oven. Test for proper operation.

MAKE SURE THE RANGE HAS BEEN PROPERLY SECURED FROM

POWER BEFORE REMOVING ANY COMPONENTS.

Transformer

Pull out control panel as previously outlined. Remove the wires from the old transformer.

Place the wires on the corresponding terminal of the new transformer. Remove old

transformer and mount new transformer with wires attached. Discard old transformer.

Reinstall the control panel and restore power to the oven. Test for proper operation.

Blower Wheel

Inside the oven, remove the racks and right hand rack slide. Remove wing nut holding oven

baffle. Remove oven baffle exposing the blower wheel. Loosen the two 1/4-20-set screws

holding the blower wheel to the motor shaft. Using a three-fingered wheel puller, grasp the

puller ring with all three fingers and tighten the puller until the blower wheel hub clears the

motor shaft. Place new blower-wheel on the motor shaft and position the new blower wheel

so that it is flush with front inlet ring. Tighten the set-screw over the flat spot on the motor

shaft and spin the blower wheel to confirm that blower wheel is strait. Adjust if necessary

and tighten second set screw. Test for proper operation.

Motor

Remove the blower wheel as outlined above. Once blower wheel is removed, remove the

six bolts holding the motor plate to the side wall of the oven. Gently pull the motor out and

lay on the bottom of the oven cavity. Note each wire location on the motor and remove the

wires. Remove motor from cavity and remove old motor from motor mounting plate.

Attach new motor to motor mounting plate. Reverse removal instructions to assemble.

Discard old motor and test for proper operation.

21

Page 22

MAINTENANCE & CLEANING

REMOVAL INSTRUCTIONS

OVEN CONTINUED

Elements

Remove oven racks and right hand rack slide from oven. Remove the wing nuts holding oven

baffle to right hand of oven. Remove oven baffle from oven. Remove 4 screws holding oven

elements to right hand of oven. Gently pull elements away from right hand of oven. Noting

wire locations, disconnect wires from element. Discard old element. Reverse removal

instructions to assemble.

RANGE TOP

Thermostat

Secure range top from power. Open front control panel and feed capillary tube up towards grill

plate. Using two 9” braces, lift the griddle plate up and secure with the two 9” braces. Remove

capillary tube holders from the center of the element pan assembly and gently remove from

griddle area. Remove two sheet metal screws holding control panel to range top and remove

control panel. Remove the thermostat knob and two screws holding the thermostat to the

control panel. Discard old thermostat. Reverse removal instructions to install new thermostat.

Elements

Secure range top from power. Using two 9” braces, lift the griddle plate up and secure with the

two 9” braces. Remove capillary tube holders from the center of the element pan assembly and

gently remove from griddle area. Remove wires from element terminals, noting the wire

locations. Remove the five nuts holding the element pan assembly to the bottom of the griddle.

Remove defective element from the element pan and discard defective element. To install

reverse removal instructions.

6-Heat Switch

Secure range top from power. Remove two sheet metal screws holding control panel to range

top and remove control panel. Remove the 6-heat switch knob and two screws holding the 6heat switch to the control panel. Remove wires from the 6-heat switch terminals noting the wire

locations. Discard old 6-heat switch. Reverse removal instructions.

French Plate

Secure range top from power. Using two 9” braces, lift the French plate frame assembly up and

secure with the two 9” braces. Remove wires from the element terminals, noting the wire

locations. Remove defective French plate assembly from the range. To install reverse removal

instructions.

22

Page 23

ILLUSTRATED PART BREAKDOWN

23

Page 24

ILLUSTRATED PARTS BREAKDOWN

24

Page 25

ILLUSTRATED PARTS BREAKDOWN

25

Page 26

ILLUSTRATED PARTS BREAKDOWN

34

26

Page 27

ILLUSTRATED PARTS BREAKDOWN

27

Page 28

ILLUSTRATED PARTS BREAKDOWN

28

Page 29

PARTS LIST

Item # Description Lang Part # Vendor Vendor #

Range Plate Assembly 1/2” x 3ft 50401-03 Lang Mfg. 50401-03

Element (Griddle) 440V I/S 3000 Watts 11010-24 Caloritech 1x1-11216-02

Element (Griddle) 440V O/S 2000 Watts 11010-23 Caloritech 1x1-11217-02

Element Pan Assembly w/ Snout 50300-20 Lang Mfg. 50300-20

Wire Bracket 50306-25 Lang Mfg. 50306-25

Thermostat Capillary Tube Holder 60102-17 Lang Mfg. 60102-17

Element Terminal Guard 50306-33 Lang Mfg. 50306-33

Indicator Light 440V 31601-02 Wes-Grade 1854-1-20-20310

Knob Thermostat 450°F Griddle

Terminal Block 3 Pole 30500-07 All-West Fasteners 162-04-3L

Thermostat 450°F Griddle

French Plate Assembly, 480V, 2600 Watt 11120-14 E.G.O. Products 12.22454.484

6-Heat Switch 30304-09 E.G.O. Products 49.27214.500

Thermostat 850°F

French Plate Frame Assembly 50300-82 Lang Mfg. 50300-82

Ship Rail 90° 13”

Ship Rail Hooked 11⅜” 50901-01 Lang Mfg. 50901-01

Ship Rail Hooked 32¼” 50901-04 Lang Mfg. 50901-04

Ship Rail Socket 50902-03 Lang Mfg. 50902-03

Ship Rail Socket 50902-05 Lang Mfg. 50902-05

Knob 6-heat switch 70701-41 Lang Mfg. 70701-41

Range Top Control Panel Front RF21-306-1 Lang Mfg. RF21-305-1

Range Top Front RF21-711 Lang Mfg. RF21-711

Pan / Grease Drawer RF21-705 Lang Mfg. RF21-705

Grab Bar Assembly 36” Long 50300-44 Lang Mfg. 50300-20

Marine Pan Latch Assembly 60102-93 Lang Mfg. 60102-93

Range Top Left Hand Assembly RF21-710 Lang Mfg. RF21-710

Range Top Center Channel RF21-704 Lang Mfg. RF21-704

Range Top Right Hand Assembly RF21-709 Lang Mfg. RF21-709

Range Top Rear Assembly RF21-703 Lang Mfg. RF21-703

21 Fuse Holder 15 Amp 30901-02 H.D. Campbell HKP-H-H Bussman

22 Switch Toggle On-Off 30303-06 Carling Tech 2GL231-78-XLN2

23 Knob Manual Timer 70701-09 Lang Mfg 70701-09

24 Knob Damper Black 70701-25 Reid Tool DK-49-Reid

25

Knob Thermostat 450°F Oven

26 Pilot Light 208/240V 31601-01 Wes-Grade 2152-1-23-20110

27

Thermostat 450°F Oven

28 Timer Mechanical Long Ring 30801-01 M.H. Rhodes 220012

29 Contactor 2 Pole 208/240 VAC 30701-02 Products Unltd 3100-20U3198

30 Contactor 3 Pole 208/240 VAC 30700-05 Products Unltd 3100-30U8198LM

31 Circuit Breaker 440 Volt 3 Pole 31800-04 Carling Tech EA3X00191832CHB

32 Transformer 440/240 VAC 31400-04 Argo Inter’l HD/2221109T00

33 Circuit Breaker 440 Volt 2/10 Amp 2 Pole 31800-07 Carling Tech CB3B02422022CC

34 Fuse 15 Amp 30900-01 H.D. Campbell ABC-15

35 Motor 1/3 HP 440 Volt 30200-03 Merkle-Korff 101356.00

36 Motor Mount Assembly F6-188 Lang Mfg. F6-188

37 Baffle Deflector F6-123-1 Lang Mfg. F6-123-1

38 Insulation R/H F6-158 Lang Mfg. F6-158

39 Insulation Rear F6-251 Lang Mfg. F6-251

40 Can R/H side F6-104-5 Lang Mfg. F6-104-5

41 Blower Wheel 71500-03 Revcor Inc 1-7981

42 Element (Oven) 440 Volt 6000 Watts 11090-11 Caloritech 1x1-11090-11

43 Baffle F6-122-1 Lang Mfg. F6-122-1

44 Hinge Bracket, Lower Left (Oven) 70601-28 Kason Ind 91510004080035C

45 Door Handle 11 1/2” Long Black 50800-12 Prodeco 50800-12

46 Door Outer Skin F6-145 Lang Mfg. F6-145

47 Door Insulation F6-144-1 Lang Mfg. F6-144-1

48 Door Inner Skin F6-144-6 Lang Mfg. F6-144-6

49 Door Micro switch assembly 60102-1661 Lang Mfg. 60102-1661

50 Door Stop & Slide 50301-50 Lang Mfg. 50301-50

51 Hinge Bracket, Upper Left (Oven) 70601-27 Kason Ind 91511005100035C

52 Hinge Pin 70601-06 Kason Ind 915230005410033F

53 Hinge Plate & Bushing (Door) 70601-05 Kason Ind 9152300050

Complete Door Assembly 60102-2031 Lang Mfg. 60102-2031

70701-16 Lang Mfg. 70701-16

30402-08 Invensys SP-173-72

30402-23 Invensys KNP-5-48

50900-01 Lang Mfg. 50900-01

70701-19 Lang Mfg 70701-19

30402-27 Invensys KXP-356-48

29

Page 30

WIRING DIAGRAM

30

Page 31

Lang Manufacturing Limited Warranty to Commercial Purchasers*

(Contiguous U.S. Including Hawaii, Alaska & **Canada.)

Lang Manufacturing Equipment (“Lang Equipment”)

has been skillfully manufactured, carefully inspected

and packaged to meet rigid standards of excellence.

Lang warrants its Equipment to be free from defects in

material and workmanship for (12) twelve consecutive

months. Exception: School Food Services for (3 6)

Thirty-six consecutive months effective June 1, 2001,

for all full size convection ovens with AP or AT

controllers, with the following conditions and subject to

the following limitations.

I. This parts and labor warranty is limited to Lang

Equipment sold to the original commercial

purchaser/users (but not original equipment

manufacturers), at its original place of installation, in

the continental United States, Hawaii and Canada.

Quartz elements are warranted for ninety (9 0) days from

the date of installation.

II. Damage during shipment is to be reported to the

carrier, is not covered under this warranty, and is the

sole responsibility of purchaser/user.

III. Lang, or an authorized service representative, will

repair or replace, at Lang’s sole election, and Lang

Equipment, including but not limited to, safety valves,

gas and electric components, found to be defective

during the warranty period. As to warranty service in

the territory described above, Lang will absorb labor

and portal to portal transportation costs (time &

mileage) for the first (12) twelve months from the date

of installation or eighteen (18) months from date of

shipment from Lang Manufacturing, which ever comes

first.

IV. This warranty does not cover routine general

maintenance, periodic adjustments, as specified in

operating instructions or manuals, and consumable parts

such as quartz elements, or labor costs incurred for

removal of adjacent equipment or objects to gain access

to Lang Equipment. This warranty does not cover

defects caused by improper installation, abuse, careless

operation, or improper maintenance of equipment.

V.

THIS WARRANTY IS EXCLUSIVE AND IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, EACH

OF WHICH IS HEREBY EXPRESSLY

DISCLAIMED. THE REMEDIES DESCRIBED

ABOVE ARE EXCLUSIVE AND IN NO EVENT

SHALL LANG BE LIABLE FOR SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAM AGES

FOR THE BREACH OR DELAY IN PERFORMANCE

OF THIS WARRANTY.

VI. Lang Equipment is for commercial use only. If sold

as a component of another (OEM) manufacturer’s

equipment, or if used as a consumer product, such

Equipment is sold AS IS and without any warranty.

*Canada warranty paid in US dollars based on

current exchange rates

Page 32

STAR MANUFACTURING

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(800) 807-9054 (314) 781-2777

Parts & Service (800) 807-9054

www.star-mfg.com

Loading...

Loading...