Page 1

LANG MANUFACTURING COMPANY • 6500 Merrill Creek Parkway, Everett, WA 98203

TOLL FREE: 800.882.6368 • FAX: 425.349.2733 • www.langworld.com

Item No.

Project

Quantity

Gas, Full-Size, Stacked/Std Depth Convection Ovens

Model: 2GCCO-[AP/SII/PP/PT]

CONSTRUCTION FEATURES

• Heavy duty 430 Series stainless steel exterior, with attractive No. 4 finish

• Fully enclosed oven back

• Cooking compartments are porcelainized steel

• 2” insulation on six sides of cooking compartments

• Heavy duty, simultaneously-opening compartment doors, with large double

pane tempered glass windows

•Two independent 55,000 BTU/hr gas burner systems

• Powerful blower centered in back of each compartment

• Compartment inspection lighting standard

• Chrome steel 10 or 11 position rack slides with five chrome plated wire racks

provided for each oven

• Choice of [Specify one]:

❏ 6” adjustable legs [standard] or

❏ 6” heavy duty casters

PERFORMANCE FEATURES

• 150 to 450˚F operating temperature range

• Solid state temperature control accurate to ± 4˚F

•Two speed fans with fan pulse capability

• Energy saving electronic ignition

• Door interlock switch cuts power to fan & burners

CONTROL PACKAGE [Specify One]

❏ Accu-Plus Controls [-AP]

• Simple knob-set time and temperature controls

• 1-hour timer with non-stop buzzer

• Pulse-fan and HIGH-LOW speed fan switches

• Power-ON and inspection light switches

❏ Selectronic II Controls [-SII]

• Solid state temperature control with digital time/temperature display

• Heat loss compensation

• 10-hour countdown timer, with non-stop buzzer

• Automatic Cook-n-Hold switch

• Pulse-fan and HIGH-LOW speed fan switches

• Power-ON and inspection light switches

❏ Purple Plus Controls [-PP]

• Solid state one-touch programmable controls

• 10 product buttons, programmable up to four tiers

•4 X 20 character LCD display panel

•Time, temperature, heat loss and adjustable shelf compensation

• Cook-n-Hold programming

• 2-speed fan & variable-rate pulse-fan control

• Power-ON and compartment inspection light switches

❏ Platinum Controls [-PT]

• Solid state, icon driven, one-touch programmable controls

• Up to 99 product programs, with multiple baking tiers

•Time, temperature, heat loss and adjustable shelf compensation

• Cook-n-Hold programming

• 2-speed fan & variable-rate pulse-fan control

• PC link programming

• Modem [Option]

• Power-ON and inspection light touch pads

SHORT/BID SPECIFICATION

Convection Oven shall be a LANG Manufacturing Model 2GCCO___

with [AP=Accu-Plus, SII=Selectronic II, PP=Purple Plus or

PT=Platinum] Control Packages, two factory stacked 55,000

BTU/hr. gas heated 5-pan full-size units, each with: simultaneousopening heavy duty doors; unitized stainless steel exterior and

porcelainized steel cooking compartment; powerful rear mounted

blowers with two speed motors and pulse control; compartment

inspection lights and five pan racks per oven standard; plus a

“lifetime” warranty on doors. Includes all the features listed and

options/accessories checked:

STANDARD PRODUCT WARRANTY

• One year, parts & labor, plus

• Lifetime warranty on oven doors

Pan Type Rack Positions Optimum

18” X 26” Full-Sheet 10 or 11/oven* 5/10

12” X 20” Hotel** - 10/20

PAN CAPACITY GUIDE [Per Oven/Total]

* AP & SII = 10; PP & PT = 11

** 2-1/2” deep pans

Sheet No. LSP-C2 (rev. 7/03)

Model 2GCCO-AP shown

®

Page 2

LANG MANUFACTURING COMPANY • 6500 Merrill Creek Parkway, Everett, WA 98203

TOLL FREE: 800.882.6368 • FAX: 425.349.2733 • www.langworld.com

© 2003 Lang Manufacturing Company Printed in U.S.A. 7/03-M-11895

Due to continuous improvements, specifications subject to change without notice.

Model

Height x Width x Depth Clearance from

Weight

Freight

(with standard legs) combustible surface

Actual Shipping

Class

76.1” x 40.1” x 38.8”

Sides: 6” (153mm)

945 lbs. 1025 lbs.

2GCCO

1937mm x 1019mm x 985mm

Back: 6” (153mm)

430 kg 466 kg

70

Floor: 6” (153mm)

OPTIONS & ACCESSORIES

❏ 6” heavy duty casters no-cost option

❏ Factory installed modems [Platinum/-PT models only]

❏ Factory recipe programming [Purple Plus/-PP & Platinum/-PT models only]

❏ Steam injection option [Purple Plus/-PP & Platinum/-PT models only]

❏ Direct vent connector

❏ 3” stainless steel spacer

❏ Gas Manifold Kit to branch single inlet line to both ovens

❏ Solid stainless steel doors, in lieu of doors with windows

❏ Extra wire pan racks [5 provided as std. in each oven]

Sheet No. LSP-C2 (rev. 7/03)

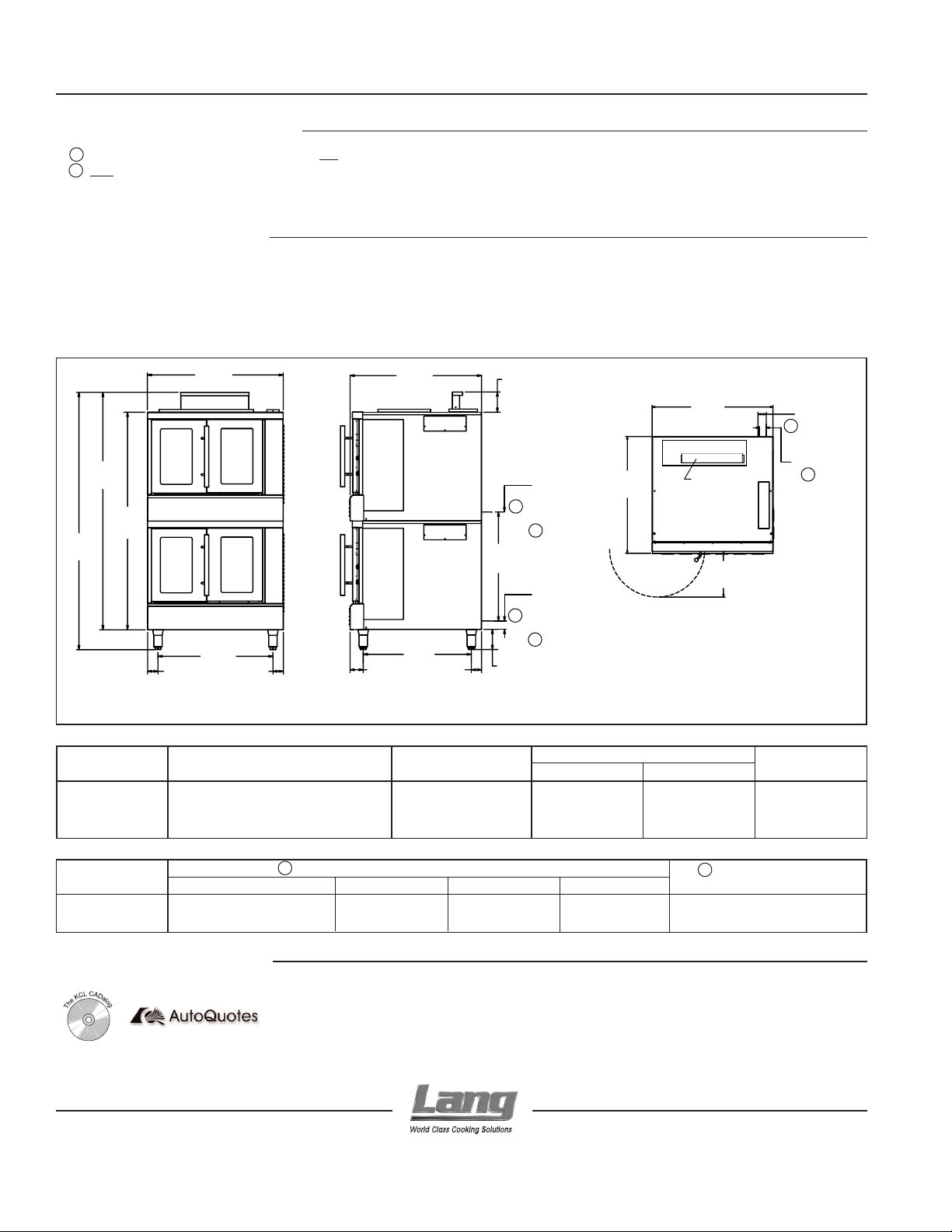

[Front View/Elevation] [Right Side View] [Top View/Plan]

Gas, Full-Size, Stacked/Std Depth Convection Oven Model: 2GCCO-[AP/SII/PP/PT]

CAD SYMBOLS & PRICING

INSTALLATION REQUIREMENTS

•G Specify: ❏ natural gas or ❏ propane gas: via two 1/2” NPT connections

•E

Two 120V 1-Phase, 50/60 Hz electrical connections

[Cords & Plugs supplied]

• Installation under approved vent hood required.

• Direct vent connector option required for venting through ducts

• Gas pressure regulator provided

[All connections from rear. See below]

Model

E Total Electrical Requirements [Via two connections]

G Total Gas Requirements

Voltage/Cycles Total kW Phase Amps/Line

[Via two connections]

2GCCO 120V/60Hz 1.0 1 7.1

1/2” NPT

(110,000 BTU/hr total)

1786mm

76.1"

1937mm

70.1"

1630mm

3.9"

99mm

38.8"

985mm

31.8"

808mm

3.1"

78mm

5.9"

150mm

E ELECTRICAL

CONNECTION

G GAS

CONNECTION

32.2"

816mm

E ELECTRICAL

CONNECTION

G GAS

CONNECTION

6.0"

151mm

2.5"

64mm

2.5"

64mm

38.8"

985mm

64.2"

3.1"

78mm

40.1"

1019mm

33.9"

862mm

3.1"

78mm

40.1"

1019mm

GAS VENT

EXHAUST

15.1"

384mm

3.5"/89mm

E ELECTRICAL

CONNECTIONS

2.6"/66mm

G GAS

CONNECTIONS

Loading...

Loading...