Landwin C-arm X-ray Service Manual

Mobile C-arm X-ray System Service Manual

Important! … X-Ray Protection

Please strictly observe the protective measures; otherwise the X-ray

equipment shall hurt the patients and the operators.

The X-ray equipment shall cause the injury in the event of improperly operation.

Therefore, please read the instructions carefully and fully understand them before

the equipment is brought into service. We are willing to help and coordinate with

you to put the equipment into service.

Although the equipment produced on the basis of the strict safety standards can

provide the effective protection of X-ray radiation and the useful beamline protection,

actually, no equipment can provide the complete protection, and further more, no

equipment can force the operators to take the adequate protective measures to prevent

oneself or other people from being exposed in the X-ray radiation due to the negligence,

rashness and involuntary of the operators.

Importantly, all operators who operate the X-ray equipment should be properly

trained, and the proper protective measures should be applied to avoid the hurt. The

manufacturers consider that all operators and maintainers who are authorized to use,

install, regulate and maintain the equipment have already known the hazard of the

immoderate exposure in the X-ray and received the sufficient training and grasped the

related knowledge. The manufacturers, agents and sales representatives are not

responsible for any injury and damage caused by exposure in the X-ray.

All kinds of protective materials and equipments can be obtained in market and the

clients are proposed to use these kinds of materials and equipments.

i

Mobile C-arm X-ray System Service Manual

Environment Explanation

Service Period of Equipment or System

The equipment or the system comprises the harmful components and materials

(such as PCB, electronic modules, wasted insulating oil, lead and battery etc.) which

can pollute the environment. Above-mentioned components and materials become

harmful when the life cycle of the equipment or system comes to the end.

Above-mentioned components and materials are considered to be harmful waste

material in accordance with the international law, domestic regulation and local

regulation.

The manufacturers propose to contact the authorized waste management

companies to deal with these equipments or systems when the life cycle of the

equipment or the system comes to the end.

Manufactured by

Shenzhen Landwind Industry Co., Ltd.

Address: 4F, Block E, Bijing Bldg. 81, Jingtian Road, Futian District, Shenzhen China.

Tel: +86-755-27353247

Fax: +86-755-27353240

Email: Int.service@landwind.com.cn

ii

Mobile C-arm X-ray System Service Manual

All rights reserved.

This Manual and the information contained herein are proprietary information of

Shenzhen Landwind Industry Co., Ltd. No information or any part hereof can be copied,

reproduced, compiled, modified, distributed or transmitted, in any form or by any means,

without the prior written consent of Shenzhen Landwind Industry Co., Ltd. This Manual is

intended for

users who are authorized to use such Manual as a part of the product purchased from

Landwind. Use of this Manual by unauthorized personnel is strictly forbidden.

Shenzhen Landwind Industry Co., Ltd. makes no representations or warranties of any

kind concerning the document, express or implied, including, without limitation,

warranties of merchantability and fitness for a particular purpose. Although every effort

has been exerted to ensure the accuracy of the information contained herein, Shenzhen

Landwind Industry Co., Ltd. assumes no liabilities for any errors or omissions and

reserves the right to modify the product to improve its reliability, function or design

without further notice. Shenzhen Landwind Industry Co., Ltd. may modify or improve the

product or program described herein at any time.

The product may contain recycled parts whose performance is equivalent to brand-new

parts or rarely used parts.

Is the trademark of Shenzhen Landwind Industry Co., Ltd. Other product

names may be trademarks of their respective owners.

iii

Mobile C-arm X-ray System Service Manual

Revision Record of Version

Revision numbers Date Revision Reasons

A0 Sep, 6 , 2010 Firstly edition

iv

Mobile C-arm X-ray System Service Manual

ADVISORY SYMBOLS

The following advisory symbols will be used throughout this manual .Their

application and meanings are described below. Users shall be familiar with these

symbols and meanings thereof before operation of the equipment.

Danger: it will cause the serious injuries or even death if people do not pay

attention to or not avoid this state or condition.

Warning: it will cause the serious injuries or heavy loss of equipment or data if

people do not pay attention to or not avoid this state or condition.

Caution: it will cause the injuries or loss of equipment or data if people do not

pay attention to or not avoid this state or condition.

Note: Remind the reader of the relative fact and condition. The notice items

show the important information which should be known but has not

necessary relationship with possible personal injury or damage of the

equipment.

Different configurations are available according to demands of user. In the event of

discrepancy between the actual and this edition, the actual configuration shall prevail.

Contact to the manufacture or the provider if there is any unsolvable problems of the

equipment.

v

Mobile C-arm X-ray System Service Manual

SAFETY SYMBOLS

The following safety symbols will be used in the equipment .Their meaning are

described below.

Attention! Consulting the document accompanying

with the machine

Ionizing radiation

Dock C-arm Inward before transport

Pinch Warning

X-ray radiation

B-type equipment

Dangerous voltage

Ground

vi

This symbol indicates that the waste of electrical and

electronic equipment must not be disposed as

unsorted municipal waste and must be collected

separately. Please contact an authorized

representative of the manufacturer or an authorized

waste management company for information

concerning the decommissioning of your equipment.

Mobile C-arm X-ray System Service Manual

Table of Contents

Chapter 1 Overview .......................................................................................................... 1

1.1 Main Components...............................................................................................................1

1.2 Console Panel......................................................................................................................2

1.3 C-Arm & Frame..................................................................................................................3

1.4 T echnique Specification......................................................................................................4

Chapter 2 Tools and test equipment.................................................................................. 9

2.1 T ools for installation ...........................................................................................................9

2.2 T ools for maintenance.........................................................................................................9

Chapter 3 Installation instruction......................................................................................11

3.1 Field requirement..............................................................................................................11

3.2 Running environment........................................................................................................12

3.3 Unpacking and Inspection.................................................................................................12

3.4 Installation.........................................................................................................................13

3.4.1 Mechanical Movement and Brake Function Test...........................................13

3.4.2 Install image intensifier ......................................................................................14

3.4.3 Installation of tube assembly ............................................................................17

3.4.4 Installation of circuit board ................................................................................19

3.4.5 Wiring of image intensifier and tube head ......................................................24

3.4.6 Installation of image intensifier cover ..............................................................26

3.4.7 Wiring of Unit.......................................................................................................27

Chapter 4 Debugging ...................................................................................................... 29

4.1 Debugging of main board voltage.....................................................................................29

4.2 Aligning the Combined Tube with Image Intensifier........................................................31

4.3 Center debugging of CCD camera....................................................................................31

4.4 The debugging of Resolution............................................................................................33

4.5 Tube seasoning..................................................................................................................34

Chapter 5 Acceptance test.............................................................................................. 35

5.1 Appearance inspection ......................................................................................................35

5.1.1 Appearance of Complete Machine and Its Parts ...........................................35

5.1.2 Components of Tube Head...............................................................................36

5.1.3 Image Intensifier .................................................................................................36

5.1.4 Operation Panel..................................................................................................36

5.2 Cable Connection Inspection............................................................................................36

5.3 Mechanical Inspection ......................................................................................................37

I

Mobile C-arm X-ray System Service Manual

5.4 Electrical Inspection..........................................................................................................37

5.5 Function inspection...........................................................................................................38

Chapter 6 Maintenance................................................................................................... 41

6.1 Precautions and Prohibitions.............................................................................................41

6.2 Cautions with X-Ray tube head ........................................................................................42

6.3 Periodic Routine Maintenance..........................................................................................44

6.4. Cleaning and Disinfection................................................................................................44

6.5 Troubleshooting ................................................................................................................45

6.5.1 Common faults analysis ....................................................................................45

6.5.2 Check of Main Circuit Board .............................................................................48

6.5.3 Other Troubleshooting .......................................................................................53

Chapter 7 Spare parts................................................................................................... 57

7.1 Whole machine..................................................................................................................57

7.2 Control cabinet..................................................................................................................58

7.3 High frequency inverter ....................................................................................................60

7.4 Rotating anode control module.........................................................................................61

7.5 Tube head..........................................................................................................................62

7.6 Image intensifier ...............................................................................................................63

7.7 TV System.........................................................................................................................65

7.8 Other .................................................................................................................................65

Appendix........................................................................................................................ 69

Schematics....................................................................................................................85

II

Mobile C-arm X-ray System Service Manual

Chapter 1 Overview

1.1 Main Components

The system comprises C-arm& Frame, control Cabinet, combined tube and image

intensifier, TV system (Image storage device, 14” monitor,14” Display and TV System

handcar).

3) C-Arm & Frame 4) Image Intensifier 5) TV System

1) Control Cabinet 2) Tube Head

Appearance of whole machine

1

Mobile C-arm X-ray System Service Manual

1.2 Console Panel

Console Panel

1 C-Arm Vertical Travel: ▲Up/▼Down 2 Power ON/OFF: ON⊙

3

Power ON/OFF: 〇 OFF

4 Emergency stop switch

5 Console LCD Panel 6 Settings

Target Parts (Target anatomical

7

parts from left to right: Head, Chest,

8 Type of patient: thin

Waist, Buttock, Knees, Hands)

9 Type of patient :Moderate 10 Type of patient :Large

11 Front/Lateral 12 Read/Write

13 Radiography 14 Manual Fluoroscopy

15 Automatic Fluoroscopy 16 Pulse Fluoroscopy

17 Enhance Fluoroscopy 18 Intensifier Diameters

19 Timer Reset 20 IRIS Collimator Shutter Open/Close

21 Two-Blade Collimator Shutter 22

2

Two-blade Collimator Left/Right

Mobile C-arm X-ray System Service Manual

Open/Close Rotation

X-Ray: Yellow indicator will light

23

when X-Ray is active. 24

READY: Green indicator will light

when the equipment is ready after

the Manual Switch 1 is pressed

FAULT: Red indicator will light only when over-loading or malfunction. X-Ray is in

25

inactive state. The Console LCD Panel displays “Fil fault” or “Rota fault” or “Fault”

1.3 C-Arm & Frame

C-Arm orbital motion, vertical travel, panning, horizontal travel, and pivot rotation can

all be manually controlled.

C-Arm & Frame

1) C-Arm Orbital Motion Lock/Unlock 2) C-Arm Panning Lock/Unlock

3

Mobile C-arm X-ray System Service Manual

3) C-Arm Pivot Rotation Lock/Unlock 4) C-Arm Horizontal Travel Lock./Unlock

5) Control Handle/Shutdown

6) Control Handle/Steering/brake lever

1.4 Technique Specification

X-Ray Generator

Max. Fluoroscopy Capacity

Max. Radiography Capacity 1s@40kV/ 80mA/1s

Fluoroscopy Current Range

Radiological Current Range Discrete: 80mA@40kV; 20mA@120kV

3h non-continuous operations@75kV/1mA

Continuous

0.2~4.0mA@ step 0.1mA

Fluoroscopy

Enhance Fluoroscopy

4.0~8.0mA@ step 0.1mA

Tube Voltage Range and

Tolerance

Radiography mAs Range

Maximum Output tube current

with Nominal tube Voltage

Maximum tube voltage with

maximum tube current

Fluoroscopy & Radiography: 40~120kV, Tolerance ≤

10%

1~180mAs; discrete; Tolerance ≤ 10%

Continuous Fluoroscopy

Pulse Fluoroscopy

Radiography

Continuous Fluoroscopy

Pulse Fluoroscopy

Radiography

120 kV,4 mA

120 kV,8mA

120 kV,30 mA

4.0mA,120 kV

8.0mA,120 kV

70 mA,49kV

Maximum Output Power

4

Continuous Fluoroscopy 120 kV×4.0mA=0.48

kW

X-ray tube

Mobile C-arm X-ray System Service Manual

Pulse Fluoroscopy 120 kV×8.0mA=0.96

kW

Radiography 59 kV×60 mA=3.54

kW

Nominal Power 100 kV×30mA=3.0 kW (0.1s)

Power 5kW

Anode Rotating anode

Focus 0.3mm/0.6mm

Heat capacity

800KHU(600KJ)

Collimator

Adjust electrical adjustable

Smallest X-ray field (@1m SID): L x W ≤ 5cm x 5cm.

Power 12V/70 mA;

Structure IRIS Lead Shutter: One pair lead blades,;

Image Intensifier

adjustable intensifier diameters 9", 6", 4.5" three view

C-Arm & Frame

Vertical Travel

400mm±2mm(electrical)

Horizontal Travel 200mm±5mm

Pivot Rotation ±180°

5

Mobile C-arm X-ray System Service Manual

Panning Motion ±12.5°

SID 900mm

Slide along arc

C-arm arc 650mm

CCD Camera

Sensitivity 0.0003LUX

SNR ≥45 dB

X-Ray TV System/Image storage device

Image Acquisition LIH: Last Image Hold

Image Resolution Horizontal Center: the level centre≥12

-25°~0~100°

LP/cm

Noise ≤70dB (Under no-load condition, maximum

noise level)

Image Grayscales ≥ 8 levels

Acquire rate 10bit

Monitor resolution 768×576

Storage frame

8+1

Monitor 14"

Display 14"

Other parameters

Power Source Single phase

Sinusoidal AC

6

Mobile C-arm X-ray System Service Manual

Power Supplies

Frequency 50Hz

Capacity ≥5kVA

Voltage Source 220V±10%

Internal Impedance ≤ 0.6Ω

Cassette holder 240mm×300mm

Tube Voltage (kV), Tube Current (mA), mAs, Output Power reference table.

kV mA mAs kW

110~100

99~80

79~70

69~60

59~50

49~40

20

30

40

40

50

60

1~80 2.40~2.00

1~125 2.97~2.40

1~125 3.16~2.80

1~125 2.76~2.40

1~125 2.95~2.50

1~125 2.94~2.40

7

Mobile C-arm X-ray System Service Manual

This page is intentionally left blank.

8

Chapter 2 Tools and test equipment

2.1 Tools for installation

NO. Name QTY

Multimeter

1

electric iron 、soldering tin

2

Inner-hexagon wrench

3

Mobile C-arm X-ray System Service Manual

1

1

1 set

Cross screwdriver (L,M,S)

4

Slotted screwdriver

5

Long nose plier

6

oblique clamp mouth

7

crimp wire pliers (crimp Pre-insulated

8

pipe-type head)

2.2 Tools for maintenance

1 set

1

1

1

1

NO. Name Type Units QTY

1 live wrench 8 inch Pcs 1

9

Mobile C-arm X-ray System Service Manual

2 inner Hexagon wrench metric set 1

3 philips screwdriver (L,M,S) set 1

4 slotted screwdriver (L,M,S) set 1

5 multimeter General Pcs 1

6 electrical iron STANLEY 69-033C Pcs 1

7 oblique clamp mouth STANLEY 84-009 Pcs 1

crimp wire pliers (crimp

8

Pre-insulated pipe-type

Pcs 1

head)

crimp wire pliers(crimp

9

Pre-Insulated fork-type

Pcs 1

head )

10 electrical tape 3M, wide 12mm roll 1

11 wire stripping pliers STANLEY 84-318 Pcs 1

12 solder Ф0.8mm roll 1

13 solid wrench M8 Pcs 1

14 needle nose pliers STANLEY 84-007 Pcs 1

15 Resolution test card Pcs 1

10

Mobile C-arm X-ray System Service Manual

Chapter 3 Installation instruction

This equipment can only be installed and tested by the manufacturer or other

personnel authorized by the manufacturer.

3.1 Field requirement

Field area should not be less than 50 ㎡ in principle. The room, with the narrowest

location not less than 4m, should be divided into operating room and control room, and

lead protective measures should be accordance with local requirement. For this

equipment is a mobile Unit, the ground should be leveled without doorsill at the joint

between rooms to facilitate free access of the equipment through the door with a width of

90cm..

The power supply required by the overall system is single phase AC with frequency

of 50Hz±1Hz, capacity no less than 3.5kW. Ask for 16A three-core inlet, rated voltage of

220V±10% and source resistance not higher than 0.6Ω. The power supply should be

grounded securely with earth resistance not higher than 4Ω. (Criteria for ground wire: a

metal rod buried to a depth of 1m underground with salt and carbon powder sprinkled

around and tamped.)

If the power level is at 220V with no X-Ray emission and drops more than 3V (for

example, if Tube V/A at 70KV/3mA) with X-Ray emission, this indicates that the power

source doesn’t supply sufficient power and a 5kW or above AC voltage stabilizer needs to

be installed (should be equipped with a reliable brand).

Supply the equipment with an independent power source is mandatory since shared

power source might cause severe electromagnetic interferences impacting normal

performance of the X-Ray equipment.

11

Mobile C-arm X-ray System Service Manual

3.2 Running environment

Normal working condition Transportation and storage

Temperature 10ºC ~ +40ºC

Relative humidity ≤70%

Atmospheric

70kPa ~ 1060kPa

-40℃~55℃

10%~80%

3

50×10

~106×103Pa.

pressure

Voltage 220V±22 V /

Power 50Hz±1Hz /

Power capacity ≥ 5kVA /

Internal Impedance ≤ 0.6Ω

Power plug ground wire must be connected to Earth ground.

Connect to temporary or low capacity power supply is strictly prohibited. Sharing

power source with other load bearing equipment (such as soldering machine etc.) is also

not recommended.

The equipment should be stored only at no-direct sunlight, dry, humidity-controlled and

well ventilated indoors. Direct contact with ground dirt should be strictly avoided.

Weather-resistant measures must be taken for temporary storage at all times.

3.3 Unpacking and Inspection

Unpack; check packed items according to the packing list. Make sure all parts are in

good condition. In case, there is any damage found, please contact the manufacturer

immediately for handling.

12

Mobile C-arm X-ray System Service Manual

Note: Use a box opener to unpack the upper case first and than the side covers at

last remove the fix objects.

z Check whether the accessories are complete and in perfect conditions after

unpacking.

z Please contact your supplier immediately if any accessory is incomplete or

damaged.

z The list of accessories depends on your purchase contract.

Note: Please reserve the packaging material for future reuse in transporting the

instrument.

The installation must be performed in accordance with technical data. Upon

completion of installation, make sure all protection ground wires provided by the

manufacturer are securely connected and protective covers are installed and fixed with

screws before turning on the power of the equipment.

3.4 Installation

3.4.1 Mechanical Movement and Brake Function Test

1. Push the equipment to check for its flexibility and smoothness of movement. Ensuring

it can be tightly locked. Run test on its movements to ensure there is no block in glide of

C-arm along arc, 200m range of forward/backward movement, 12.5° range of left/right

sway, rotation around horizontal axis, etc.

2. Braking mechanism: firstly open the rear cover of X-ray unit, wrap terminal L and N

with insulation tape to avoid occurrence of short circuit between terminals or between

terminal and floor, shown as follows:

13

Mobile C-arm X-ray System Service Manual

3. Connect power supply (220V AC) with the power line, press “Power ON” button and

then press “Brake” button as shown in the following figure. Now the equipment is braked

automatically. Confirm whether the equipment is braked completely by pushing it gently.

And switch off power and remove power line.

3.4.2 Install image intensifier

1. Release the handrails for C-arm circular arc movement, adjust C-arm to proper

position for convenient installation of image intensifier and then lock the locking handrails

again.

2. Take out image intensifier from package box and check whether there is any

appearance damage. Remove the six pieces of mounting screws supplied with image

intensifier connecting plate by using inner hexagon wrench, as shown in the following

figure.

Mounting screw

Connecting plate

3. Align the connecting holes to the ones on the connecting plate on image intensifier end

14

Mobile C-arm X-ray System Service Manual

of C-arm, and fix them with mounting screws supplied with the equipment.

Note: At least two persons are needed to avoid personal injury or device damage

caused by the drop of image intensifier

Keep the edge of connecting plate parallel to the one of mounting plate to assure

precision of image intensifier. mounting position.

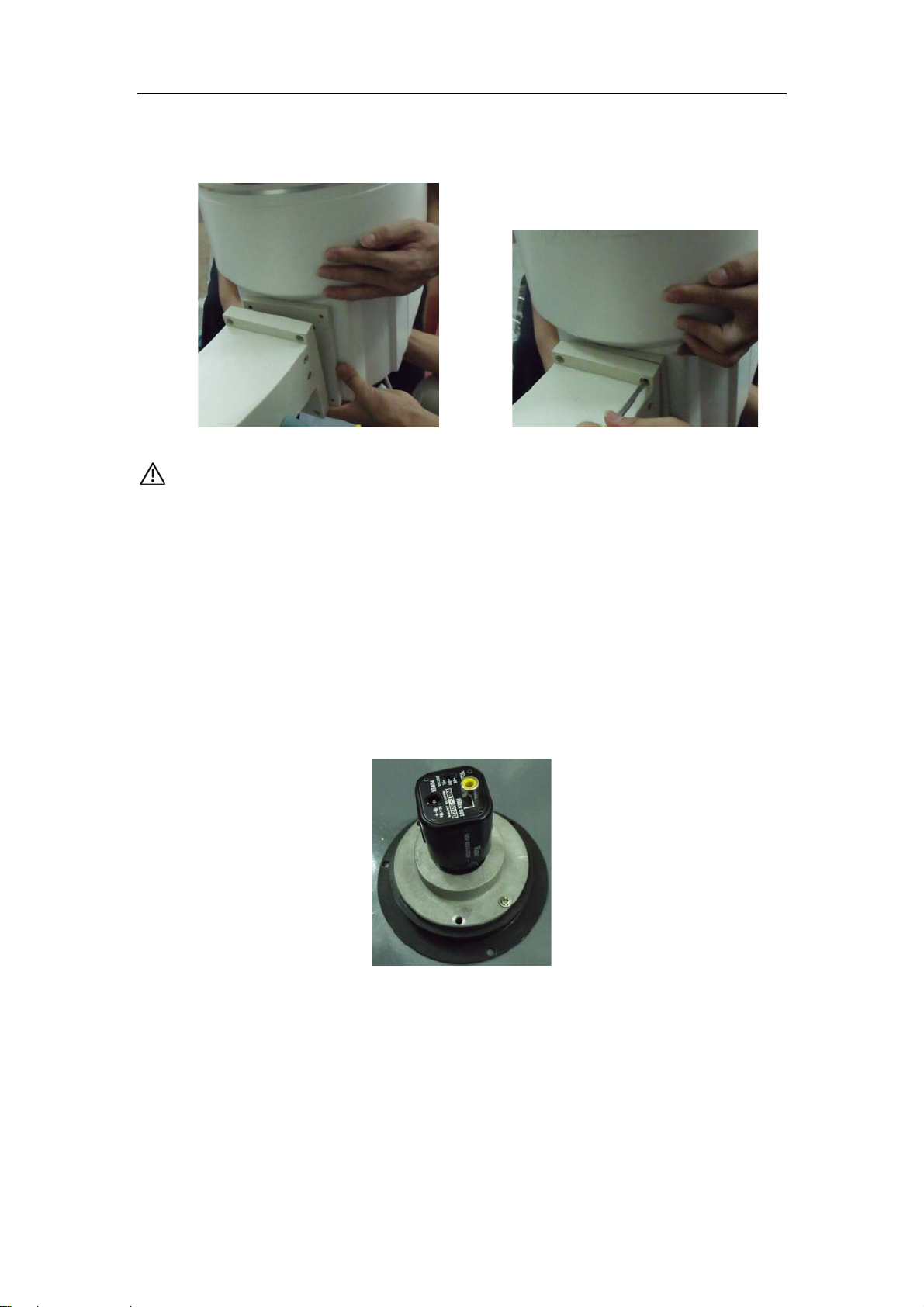

4. Take out CCD camera from the package box, and detach the cover base to take CCD

camera out.

5. Remove the blue plastic dust-proof cover for output screen from the bottom of image

intensifier, and check whether there is dust on the output screen. Blow away the dust with

blowing balloon if any. The cleanness within this region is extremely important as the

image intensifier output screen is the focal plane for imaging.

15

Mobile C-arm X-ray System Service Manual

p

Dust-proof cover for

out

ut screen

6. Remove lens cover of camera, align mounting holes of camera to the ones at the

bottom of image intensifier and fix with three pieces of screws.

Note: Rotate both CCD and image intensifier clockwise until an included angle is

presented up to 90°for installation and fixing.

Screws to fix camera

7. Align the cover base to the mounting holes at the bottom of image intensifier and fix it

with three pieces of screws.

Fixing screws

16

Mobile C-arm X-ray System Service Manual

3.4.3 Installation of tube assembly

1 Unpack the case of the tube assembly, take out the tube head.

2. Remove the flat washers, spring washers and mounting nuts from tube head. One

person is to hold the tube head and align the X-ray output window to the mounting hole of

L-shaped steel plate, install with the washers and fix the tube by tightening the nuts.

Note: Since the equipment before shipment has been marked with marking pen as to

the accurate mounting positions on L-shaped steel plate. And during the flat washers

were needed to facilitate the installation.

X-ray output window

Mounting washes and nuts

3. Connect the fan cable of tube head with the corresponding cable on C-arm as follows:

17

Mobile C-arm X-ray System Service Manual

4. Install collimator. Loosen the three pieces of screws on the collimator cover with

slotted screwdriver and detach the collimator cover;

5. Loosen the three pieces of jack screws at the bottom of collimator, align collimator to

the x-ray output window, put it in the mounting groove of tube output window, position the

collimator right through fine adjustment, and fix the collimator with jack screws tightened

by inner hexagon wrench.

18

Mobile C-arm X-ray System Service Manual

3.4.4 Installation of circuit board

The circuit boards were detached form the circuit board frame to facilitate the transport

and Unit safety. So on-site installation need to re-install the circuit board.

1. Remove screws on the wheel cover to detach the wheel cover: detach the two pieces

of screws on the rear cover of equipment to remove the rear cover of equipment.

2. Remove the fixed screws of frame and push the frame outward. At this juncture the

white nylon clips that are used for fixing the main control board on the four corners of

core component can be seen.

3. Take out main control board from the package box, align it to the mounting holes on

the four corners with connection side of green terminal upward and ribbon cable terminal

downward, and fix it on the frame.

19

Mobile C-arm X-ray System Service Manual

4. Plug in CP1—CP11 (except CP8) to the corresponding connection-peg one by one.

5. Power on the Unit to check if the voltage of CP8 is normal. The referring data shown

as follows:

CP8.1 CP8.2 CP8.3 CP8.4 CP8.5 CP8.6 CP8.7 CP8.8

0V 5V 12V 0V 24V 15V 0V 15V

Those voltages come from the three pieces of switching power supply beside the frame.

If the voltage from certain group is abnormal, check if the corresponding switch is

powered and if the wirings are connected properly.

6. Switch off the unit if the voltages above are measured normal. Connect CP8 terminal

line to CP8 terminal block and measure the voltage of measurement point on main

control board after power on again. At the same time, measure to confirm whether the

voltages of CP1 power terminal line and CP2 terminal line which is connected to filament

20

Mobile C-arm X-ray System Service Manual

board are correct. Refer to following table for measurement points and the related

reference data are shown below:

Set mA Set kV U15-3 CP1.1-CP1.3 CP2.

CP2.2 CP2.3

1

3.5-3.7V 2V 8.5V 135VAC±10% +15V 0V -15V

Relevant Voltage Measurement Points

Adjust the RP mA potentiometer if the Set mA voltage is abnormal; Adjust the RP kV

potentiometer if the Set kV voltage is abnormal; Adjust R50 potentiometer if U15-3

voltage is abnormal.

21

Mobile C-arm X-ray System Service Manual

7.Switch off the power of the equipment. Unpack the filament power board SCH S15 and

fix it to the white nylon clips on the right side of main body.

8. Connect the terminals on board S15.

9. Take the inverter out of the package box.

22

Loading...

Loading...