Page 1

Table of Contents

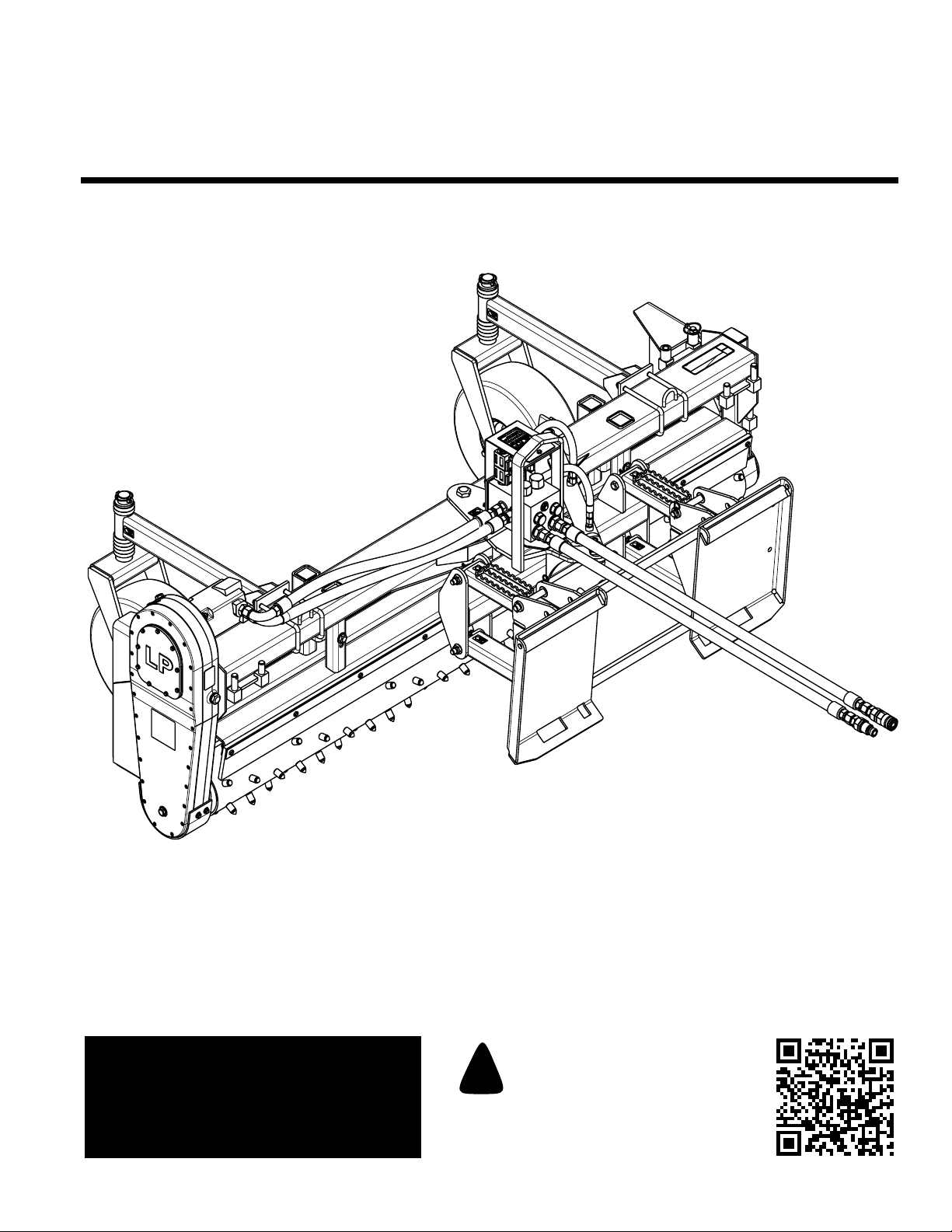

Powered Rakes

SR2672 & SR2690 Skid Steer

Operator’s Manual

Read the Operator’sManual entirely.When you

see this symbol, the subsequent instructions and

warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

Coverphoto may show optional equipment

not supplied with standard unit.

© Copyright 2012 Printed

24533

321-004M

4/05/12

Page 2

Table of Contents

Table of Contents

Important Safety Information . . . . . . . . . . . . . 1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

Look For The Safety Alert Symbol . . . . . . . . . . . . .1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Further Assistance . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 1: Assembly & Set-up . . . . . . . . . . . . 8

Skid Steer Requirements . . . . . . . . . . . . . . . . . . . . . 8

Hydraulic Motor Hose Assembly . . . . . . . . . . . . . . . 8

Gauge Wheel Assembly . . . . . . . . . . . . . . . . . . . . . 8

End Plate Assembly (SR2672) . . . . . . . . . . . . . . . . 9

End Plate Assembly (SR2690) . . . . . . . . . . . . . . . . 9

Skid Steer Hook-Up . . . . . . . . . . . . . . . . . . . . . . . . 10

Hydraulic Hose Hook-up . . . . . . . . . . . . . . . . . . . . 10

Wiring Harness Electrical Hook-Up . . . . . . . . . . . . 11

Push Button Wiring Harness (Standard) . . . . . . . 11

Deutsch 14 Pin Plug & Cable (Accessory) . . . . . 11

Zip Tie Hoses & Electrical Cable . . . . . . . . . . . . . . 11

Section 2: Operating Instructions . . . . . . . . 12

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . . . 12

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . 12

General Operating Instructions . . . . . . . . . . . . . . . 13

Section 3: Adjustments . . . . . . . . . . . . . . . . . 14

Powered Rake Roller . . . . . . . . . . . . . . . . . . . . . . . 14

Gauge Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Setting Working Depth . . . . . . . . . . . . . . . . . . . . . . 14

Parallel Linkage Mounting . . . . . . . . . . . . . . . . . . . 14

Material Control Blade Adjustment . . . . . . . . . . . .14

Drive Chain Adjustment . . . . . . . . . . . . . . . . . . . . . 15

SR2672 End Plate Positioning . . . . . . . . . . . . . . . . 16

SR2690 End Plate Positioning . . . . . . . . . . . . . . . . 17

Section 4: Maintenance & Lubrication . . . . . 18

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Drive Chain Maintenance . . . . . . . . . . . . . . . . . . . 18

Sprocket and Chain Replacement . . . . . . . . . . . . . 18

Chain Case Skid Shoe Replacement . . . . . . . . . . . 18

Gauge Wheel U-Bolts . . . . . . . . . . . . . . . . . . . . . . 19

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Gauge Wheel Spindle . . . . . . . . . . . . . . . . . . . . . 20

Gauge Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Drive Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Pivot Arm Bushings (8 Places) . . . . . . . . . . . . . . 21

Non-Drive Bearing . . . . . . . . . . . . . . . . . . . . . . . 21

Section 5: Specifications & Capacities . . . . . 22

Section 6: Features & Benefits . . . . . . . . . . . 24

Section 7: Troubleshooting . . . . . . . . . . . . . . 25

Section 8: Torque Values Chart . . . . . . . . . . 26

Section 9: Warranty . . . . . . . . . . . . . . . . . . . . 27

© Copyright 2012 All rights Reserved

Land Pride provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the

preparationof this manual,Land Pride assumesno responsibility forerrors oromissions. Neither isany liabilityassumedfor damagesresulting from theuse

oftheinformation contained herein. LandPridereservesthe right to reviseandimprove its productsasit sees fit. This publicationdescribes the state of this

product at the time of its publication, and may not reflect the product in the future.

Land Pride is a registered trademark.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

4/05/12

Page 3

▲

Table of Contents

Important Safety Information

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

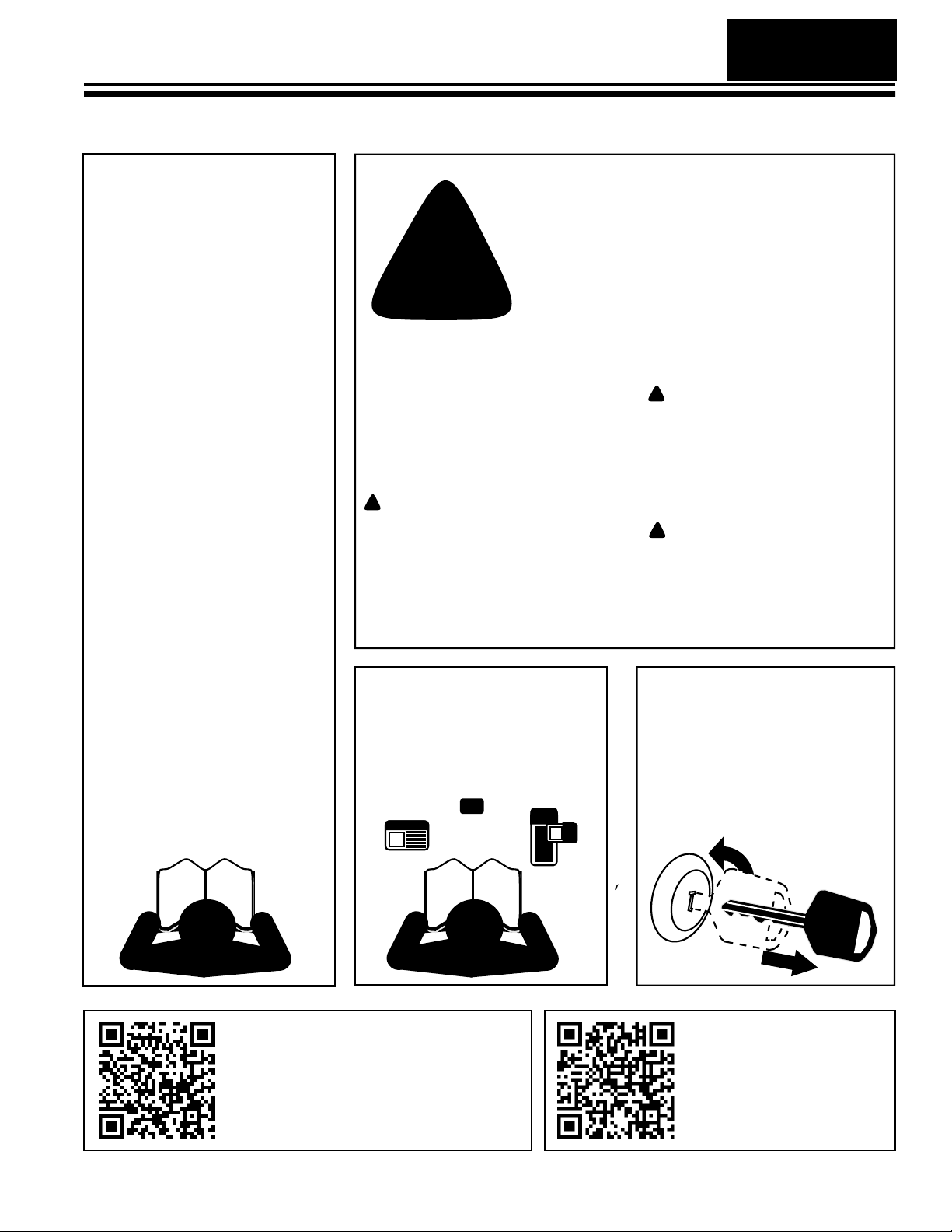

Safety at All Times

Thoroughly read and understand

the instructions given in this

manual before operation. Refer to

the “Safety Label” section, read

all instructions noted on them.

Do not allow anyone to operate

this equipment who has not fully

read and comprehended this

manual and who has not been

properly trained in the safe

operation of the equipment.

▲ Operator should be familiar with

all functions of the unit.

▲ Operate implement from the

driver’s seat only.

▲ Make sure all guards and shields

are in place and secured before

operating implement.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Dismounting from a moving

tractor could cause serious injury

or death.

▲ Do not allow anyone to stand

between tractor and implement

while backing up to implement.

▲ Keep hands, feet, and clothing

away from power-driven parts.

▲ Wear snug fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of

working area.

▲ Turning tractor too tight may

cause implement to ride up on

wheels. This could result in injury

or equipment damage.

▲ Do not carry passengers on

implement at any time.

Look For The Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

!

Be Aware of

Signal Words

A Signal word designates a degree or

level of hazard seriousness. The

signal words are:

!

DANGER

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for

functional purposes, cannot be

guarded.

For Your Protection

▲ Thoroughly read and understand

the “Safety Label” section, read all

instructions noted on them.

equipment, hazard control, and accident prevention

are dependent upon the awareness, concern,

prudence, and proper training of personnel involved

in the operation, transport, maintenance, and storage

of equipment.

!

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may also

be used to alert against unsafe

practices.

!

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine, and

remove the key.

▲ Detach and store implements in a

area where children normally do

not play. Secure implement by

using blocks and supports.

OFF

4/05/12

Parts Manual QR Locator

The QR (Quick Reference) code on the front

cover and to the left will take you to the

Parts Manual for this equipment. Download

the appropriate App on your camera phone,

open the App, point your phone on the QR

code and take a picture.

REMO

VE

Dealer QR Locator

The QR code on the left will

link you to available dealers

for Land Pride products.

Refer to Parts Manual

QR Locator on this page for

detailed instructions.

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

1

Page 4

Table of Contents

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Operating Loader and

Attachment

▲ The operator must not use drugs

or alcohol that can change the

alertness or coordination of that

person while operating the

equipment. The operator should,

if he is taking over-the-counter

drugs, seek medical advise on

whether he can safelyoperate the

equipment.

▲ Start loader with steering levers

and hydraulic controls in neutral.

Keep bystanders away.

▲ Always contact your local utility

companies (electrical, telephone,

gas, water, sewer and others)

before digging so that they may

mark the location of any under

ground services in the area. Be

sure to ask how close you can

work to the marks they

positioned.

▲ Avoid contact with any over head

utility lines or electrically charged

conductors.

Getting On and Off Safely

Before leaving the

operator’s seat:

▲ Lower lift arms and put

attachment flat on the ground.

▲ Stop engine.

▲ Engage parking brake.

▲ Raise seat bar and move controls

until both lock.

Practice Safe

Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment, refer to Operator’s

Manual for additional information.

▲ Work in a clean dry area.

▲ Lower implement to the ground,

put skid steer in park, turn off

engine, and remove key before

performing maintenance.

▲ Allow implement to cool

completely.

▲ Remove key to prevent

unauthorized starting.

▲ Use steps, grab-handles, and

skid-resistant surfaces when

getting on or off the loader.

▲ Disconnect battery groundcable (-)

before servicing or adjusting

electrical systems or before

welding on implement.

▲ Do not grease or oil implement

while it is in operation.

▲ Inspect all parts. Make sure parts

are in good condition & installed

properly.

▲ Remove buildup of grease, oil, or

debris.

▲ Remove all tools and unused parts

from implement before operation.

Use Safety

Lights and Devices

▲ Slow moving tractors, self-

propelled equipment, and towed

implements can create a hazard

whendriven on publicroads.They

are difficult to see, especially at

night.

▲ Flashing warning lights and turn

signals are recommended

whenever driving on public roads.

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

2

Transporting the Loader

and Attachment

▲ Comply with state and local laws.

▲ Never travel at a speed which

does not allow adequate control

of steering and stopping. Some

rough terrain require a slower

speed.

▲ Always drive up/down the ramp

with heavy end uphill. Engage

parking brake when stopped on

an incline.

▲ Secure loader and attachments

using tie downs and chains. Use

towing vehicle and trailer of

adequate capacity.

▲ Sudden braking can cause a

towed load to swerve and upset.

Reduce speed if towed load is not

equipped with brakes.

▲ Avoid contact with any over head

utility lines or electrically charged

conductors.

▲ IMPORTANT: Do not tow a load

that is more than double the

weight of vehicle pulling the tow

load.

4/05/12

Page 5

Table of Contents

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

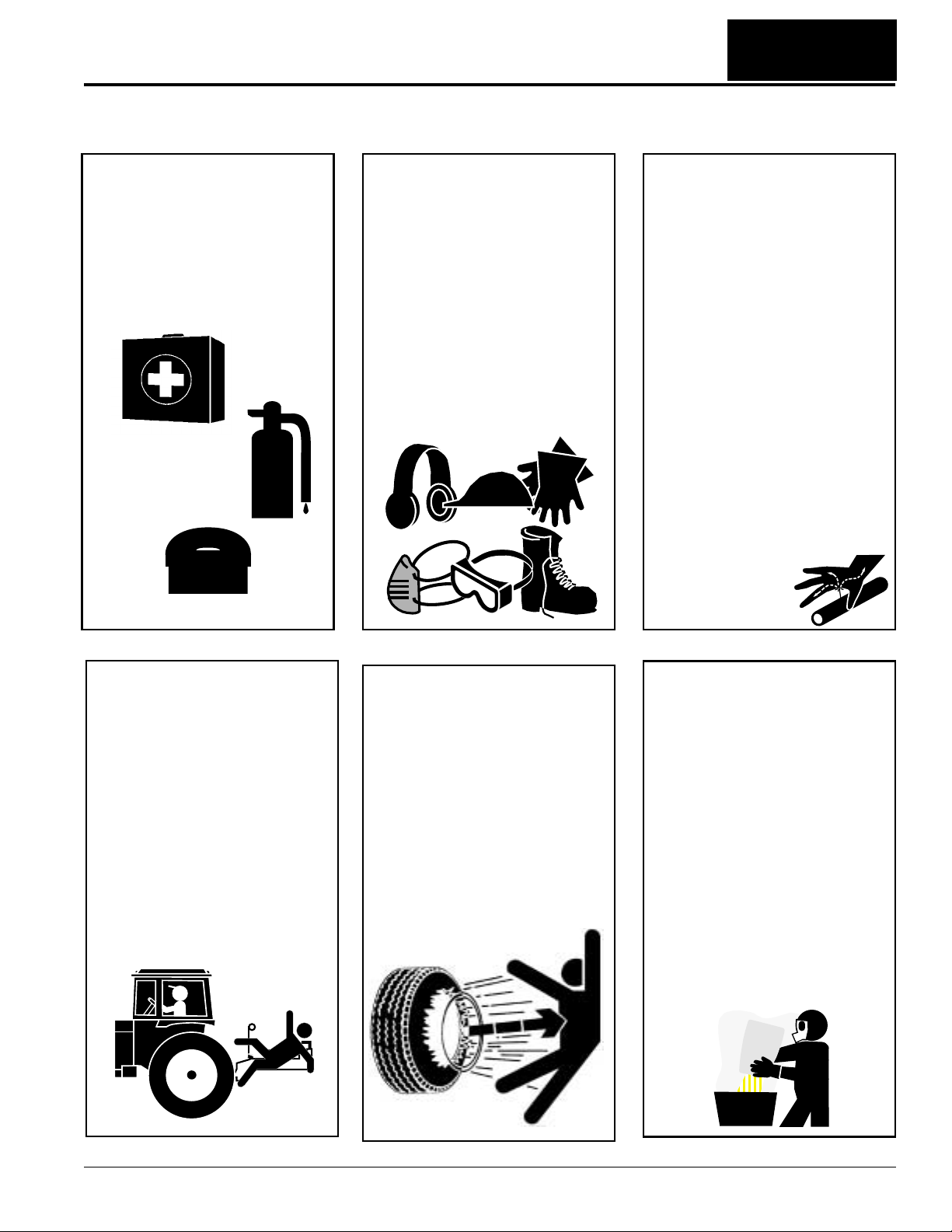

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire

extinguisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital, and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment appropriate for the job.

Avoid loose fitting clothing.

▲ Prolonged exposure to loud noise

can cause hearing impairment or

hearing loss. Wear suitable

hearing protection such as

earmuffs or earplugs.

▲ Operating equipment safely

requires the full attention of the

operator. Avoid wearing radio

headphones while operating

machinery.

Avoid High

Pressure Fluids Hazard

▲ Escaping fluidunder pressure can

penetrate the skin causing

serious injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydrauliclines or performing work

on the system.

▲ Make sure all hydraulic fluid

connections are tight and all

hydraulic hoses and lines are in

good condition before applying

pressure to the system.

▲ Use a piece of paper or

cardboard, NOT BODY PARTS,to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a

doctor immediately. Any fluid

injected into the skin must be

treated within a few hours or

gangrene may result.

Keep Riders

Off Machinery

▲ Riders obstruct the operator’s

view, they could be struck by

foreign objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

Tire Safety

▲ Tire changing can be dangerous

and should be performed by

trained personnel using the

correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side and NOT in front of or

over the tire assembly. Use a

safety cage if available.

▲ When removing and installing

wheels, use wheel handling

equipment adequate for the

weight involved.

Handle

Chemicals Properly

▲ Do not use chemicals in the dust

suppression system.

▲ Protective clothing should be

worn when handling chemicals.

▲ Handle all chemicals with care.

▲ Follow instructions on container

label.

▲ Agricultural chemicals can be

dangerous. Improper use can

seriously injure persons, animals,

plants, soil, and property.

▲ Inhaling smoke from any type of

chemical fire is a serious health

hazard.

▲ Store or dispose of unused

chemicals as specified by the

chemical manufacturer.

4/05/12

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

3

Page 6

Important Safety Information

Table of Contents

Safety Labels

Your Powered Rake comes equipped with all safety labels in

place. They were designed to help you safely operate your

implement. Read and follow their directions.

1. Keep all safety labels clean and legible.

2. Replace all damaged or missing labels. To order new

labels go to your nearest Land Pride dealer.

3. Some new equipment installed during repair requires

safety labels to be affixed to the replaced component as

specified by Land Pride. When ordering new components

make sure the correct safety labels are included in the

request.

4. Refer to this section for proper label placement.

To install new labels:

a. Clean the area the label is to be placed.

b. Spraysoapy water on the surfacewhere the label isto

be placed.

c. Peel backing from label. Press firmly onto the sur-

face.

d. Squeeze out air bubbles with the edge of a credit card.

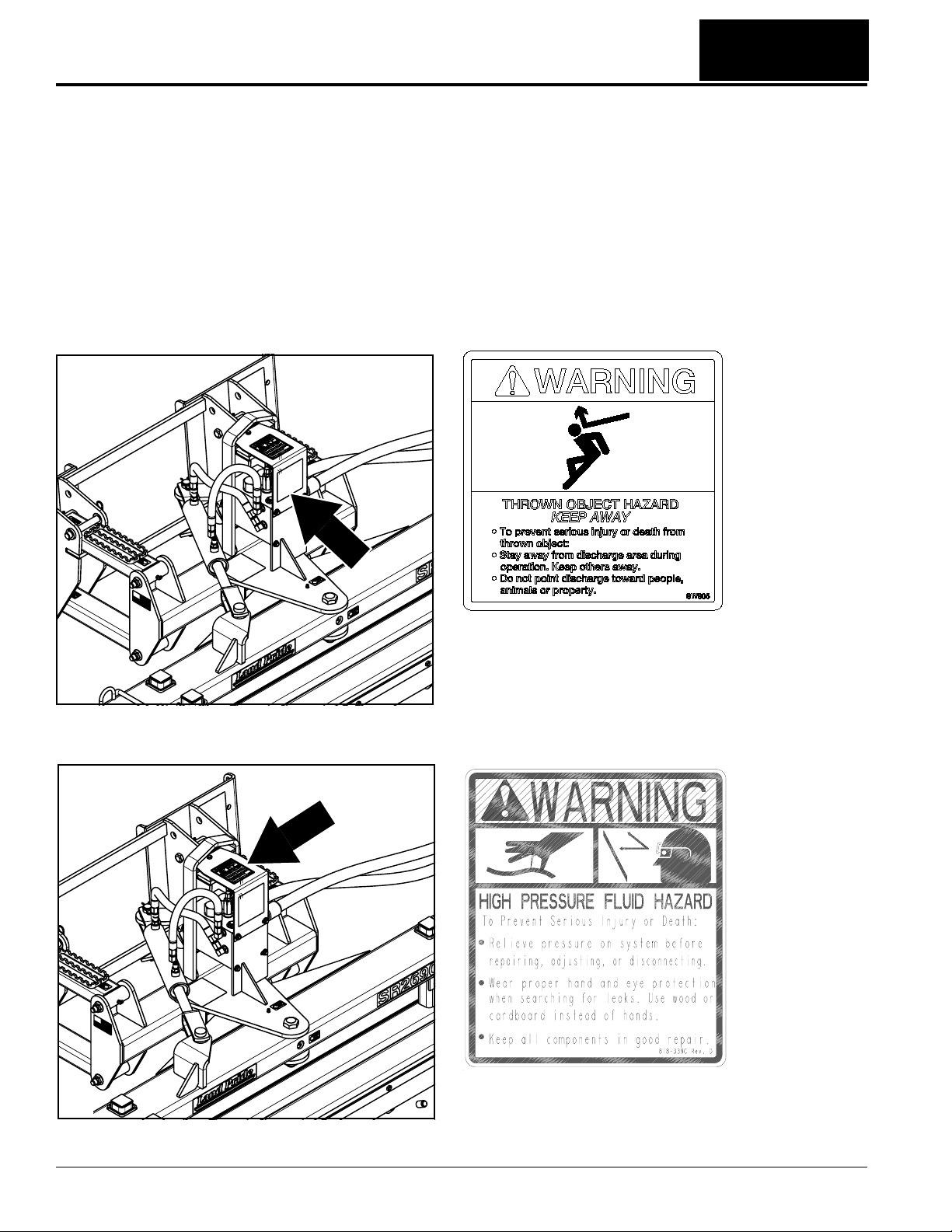

24534

24534

838-107C

Warning:

Thrown Object Hazard

818-339C

Warning:

High Pressure Fluid Hazard

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

4

4/05/12

Page 7

Important Safety Information

Table of Contents

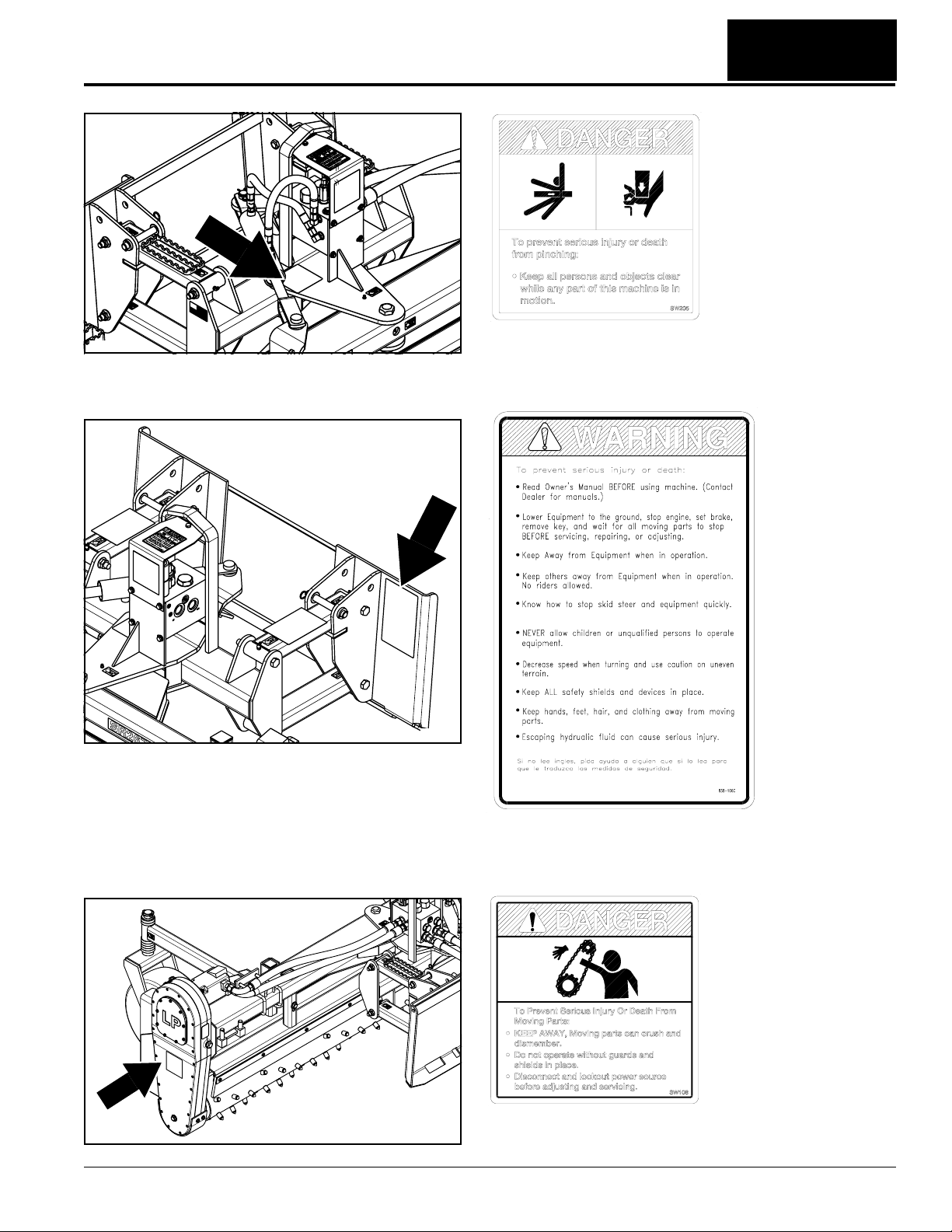

24534

838-112C

Danger: Pinching Hazard

21101

4/05/12

24533

838-106C

Warning: General Safety

838-111C

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

5

Page 8

Important Safety Information

Table of Contents

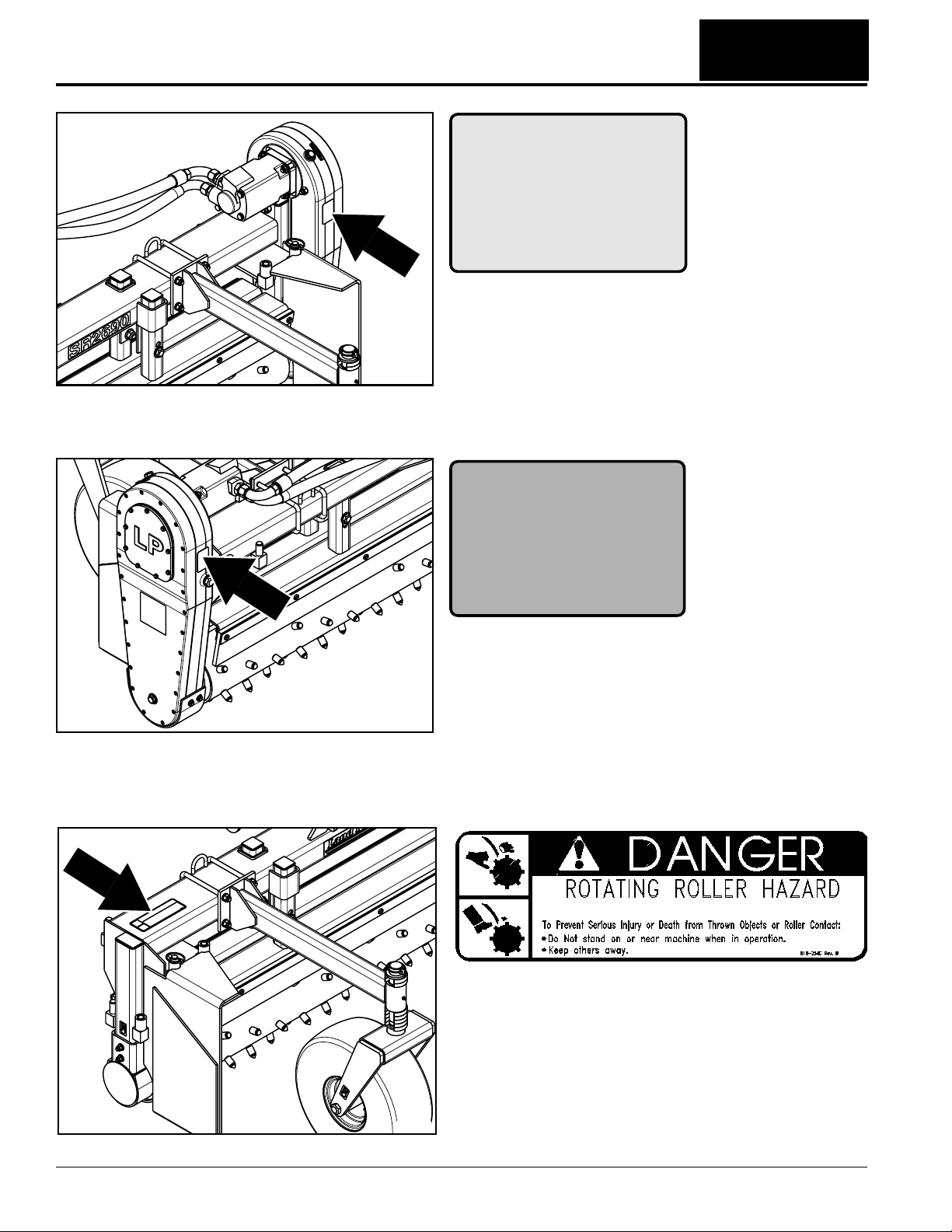

818-229C

Amber Reflector

24534

24533

818-230C

Red Reflector

KEEP AWAY

818-254C

Danger:

Rotating Roller Hazard

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

6

24534

4/05/12

Page 9

Table of Contents

Introduction

Introduction

Land Pride welcomes you to the growing family of new

product owners.

This Powered Rake has been designed with care and

built by skilled workers using quality materials. Proper

assembly, maintenance and safeoperating practiceswill

help you get years of satisfactory use from the Powered

Rake.

Application

Land Pride’s SR2672 and SR2690 Skid Steer Powered

Rakes,with their carbide tipped studded roller,adjustable

andhighlydurableurethanematerialcontrol deflector,and

20-degree left and right angling will turn your skid steer

loader into the perfect landscaping tool. These skid steer

powered rakes are designed to grade, level,rake, and

remove unwanted objects such as rocks, stones, clods,

small roots, limbs, twigs, and other material of similar

nature or size. They can also alleviate unwanted weed

growth and prepare a seedbed for planting. These

powered rakes are excellent tools to renovate and

rejuvenate gravel and cinder driveways, storage lots, and

warning tracks. They are also very effective at

reconditioning earthen race tracks and arenas. The

hydraulic driven roller rotates in both directions for

travelingboth forward and backward. Both models allow

you to move dirt like a box scraper, windrow rocks like a

rake and work soil like a pulverizer - all in one tool.

See “Specifications & Capacities” on page 22 and

“Features & Benefits” on page 24 for additional

information and performance enhancing options.

Owner Assistance

The Warranty Registration card should be filled out by

the dealer at the time of purchase. This information is

necessary to provide you with quality customer service.

If customer service or repair parts are required contact a

LandPride dealer.Adealer has trained personnel,repair

parts, and equipment needed to service the Powered

Rake.

The parts on your Powered Rake have been specially

designedand shouldonly be replacedwith genuineLand

Pride parts. Therefore, should your PoweredRake

require replacement parts go to your Land Pride Dealer.

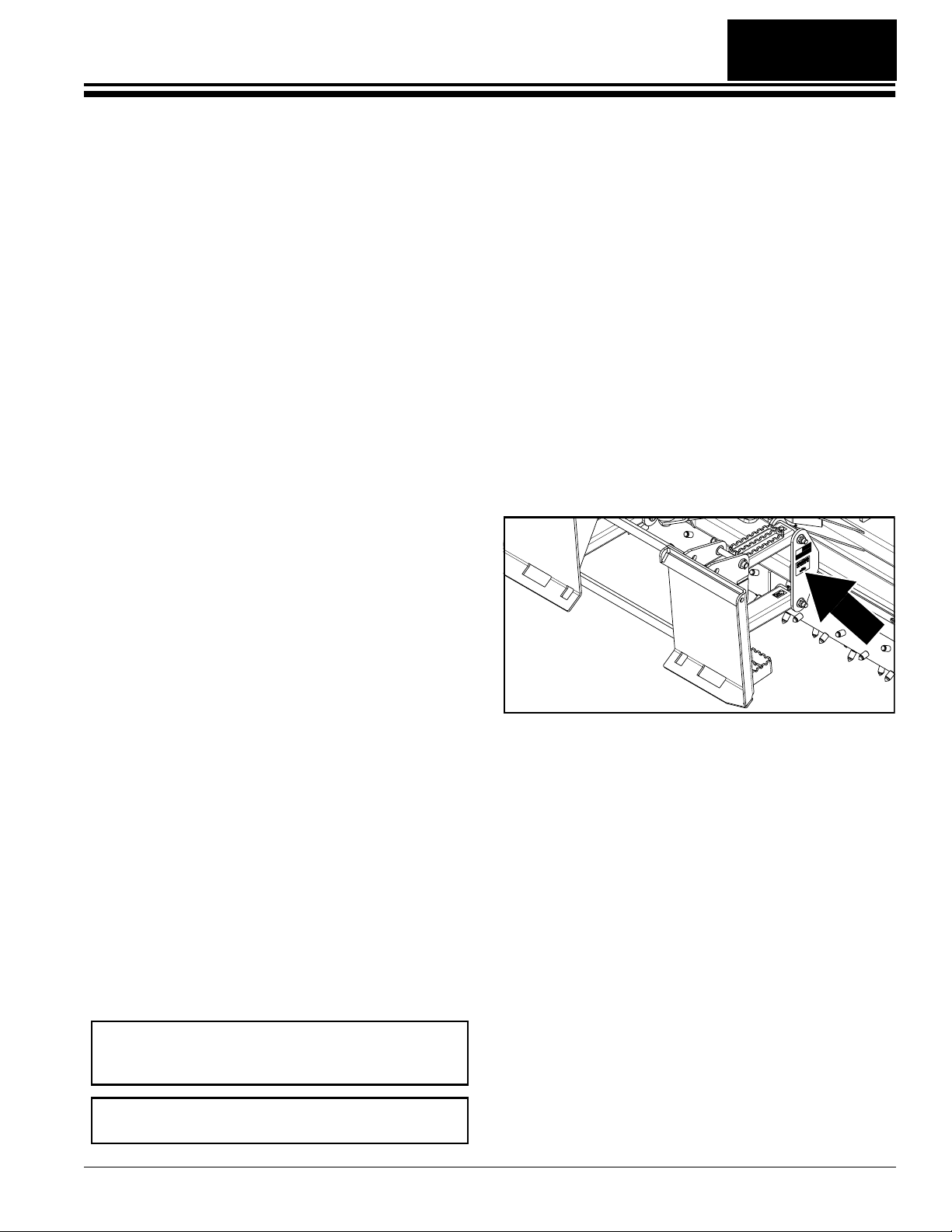

Serial Number

Model No. _____________Serial No. _______________

For quick reference and prompt service, record model

number and ser ial number in the spaces provided above

and again on warranty page 27. Always provide model

numberand serial number when ordering parts and in all

correspondences with your Land Pr ide dealer. Refer to

Figure 1 for location of your serial number plate.

Using This Manual

•

This Operator’s Manual is designed to help familiarize

you with safety, assembly, operation, adjustments,

troubleshooting, and maintenance. Read this manual

and follow the recommendations to help ensure safe

and efficient operation.

• The information contained within this manual was

current at the time of printing. Some parts may change

slightly to assure you of the best performance.

• To order a new Operator’s or Parts Manual contact

your authorized dealer. Manuals can also be

downloaded, free-of-charge from our website at

www.landpride.com.

Terminology

“Right” or “Left” as used in this manual is determined by

facingthe direction the machine will operate while in use

unless otherwise stated.

Definitions

IMPORTANT: A special point of information related

to the following topic. Land Pride’s intention is this

information must be read & noted beforecontinuing.

NOTE: A special point of information that the

operator should be aware of before continuing.

30939

Serial Number Plate Location

Figure 1

Further Assistance

Your dealer wants you to be satisfied with your new

Powered Rake. If for any reason you do not understand

any part of this manual or are not satisfied with the

service received, the following actions are suggested:

1. Discuss the matter with your dealership ser vice

manager making sure he is aware of any problems

youmay haveand that he has had the oppor tunity to

assist you.

2. If you are still not satisfied, seek out the owner or

general manager of the dealership, explain the

problem and request assistance.

3. For further assistance write to:

Land Pride Service Department

1525 East North Street

P.O.Box 5060

Salina, Ks. 67402-5060

E-mail address

lpservicedept@landpride.com

4/05/12

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

7

Page 10

Table of Contents

Section 1: Assembly & Set-up

Section 1: Assembly & Set-up

Skid Steer Requirements

The Powered Rake is designed to fit on Skid Steer

Loaders with the following minimum requirements:

• SR2672

SAE Lift Capacity. . . . . . . . . . . . . . . . . . . . . 1200 lbs.

Hydraulic Requirements. . . . . . . 11 GPM at 2200 psi

Maximum Hydraulic Pressure . . . . . . . . . . . 3500 psi

• SR2690

SAE Lift Capacity. . . . . . . . . . . . . . . . . . . . . 1600 lbs.

Hydraulic Requirements. . . . . . . 15 GPM at 2500 psi

Maximum Hydraulic Pressure . . . . . . . . . . . 3500 psi

IMPORTANT: Ballast may need to be added to your

skidsteer to maintain steering controland to prevent

tipping of the skid steer. Refer to your skid steer’s

operator manual to determine if additional ballast is

needed.

Hydraulic Motor Hose Assembly

Refer to Figure 1-1:

Check hoses between by-pass valve and hydraulic

motor. Hoses must arch up to prevent becoming

entangled in the hitch pivot points. If hoses do not arch

up, the following should be done:

1. Loosen hose fittings at the valve by-pass.

2. Rotate hoses until they arch up.

3. Retighten hose fittings.

Gauge Wheel Assembly

Refer to Figure 1-1:

1. Attach gauge wheels (#1) to the rear frame with

u-bolts (#4), lock washers (#3), and nuts (#2) as

shown.

2. Tighten nuts to correct torque.

By-Pass Valve

Hydraulic Hoses

Must Arch Up

Hydraulic

Motor

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

8

30940

Gauge Wheel Assembly

Figure 1-1

4/05/12

Page 11

Section 1: Assembly & Set-up

Table of Contents

End Plate Assembly (SR2672)

Refer to Figure 1-2:

Included with the SR2672 Powered Rake are two end

plates, one right hand and one left hand.

1. Install right hand end plate (#1) over the two side

support pins as shown.

2. Rotate spacer A1 under hitch pin spacer A2 and

insert hitch pin (#2) through spacers A1 & A2.

3. Secure hitch pin with hair pin cotter (#3).

4. Repeat steps 1 through 3 for left hand end plate.

End Plate Assembly (SR2690)

Refer to Figure 1-3:

Included with the SR2690 Powered Rake are two end

plates, one right hand and one left hand.

1. Install right hand end plate (#1) over the three

support pins as shown.

2. Secure end plate with linchpin (#2).

3. Repeat steps 1 & 2 for left hand end plate.

SR2672 End Plate Assembly (Right Hand Side Shown)

Figure 1-2

4/05/12

24535

24536

SR2690 End Plate Assembly (Right Hand Side Shown)

Figure 1-3

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

9

Page 12

Section 1: Assembly & Set-up

Table of Contents

Skid Steer Hook-Up

!

DANGER

Hydraulic fluid under pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin, it must be treated by a

doctor within a few hours or gangrene may result.

Refer to Figure 1-4:

!

CAUTION

Do not stand between the skid steer loader and implement

during hookup.

1. Drive the skid steer slowly to the Powered Rake

making sure the front hitch plate of the skid steer is

parallel with the Powered Rake hitch.

2. Tilt the top of the skid steer hitch plate slightly

forward.

3. Place the skid steer’s hitch plate top under the top

angled bar of the Powered Rake.

4. Slowly lift the skid steer’s hitch until the Powered

Rake’s hitch and the skid steer’s top angle bar have

come together.

5. Push lock handles of the skid steer down so that the

pins go through the bottom slots of the Powered

Rake’s hitch and the handles lock down.

6. Connect hydraulic hoses on Powered Rake to the

skid steer loader.

Hydraulic Hose Hook-up

Refer to Figure 1-5:

!

DANGER

Hydraulic fluid under pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin, it must be treated by a

doctor within a few hours or gangrene may result.

!

DANGER

Make sure hydraulic hoses are properly routed without twists

to prevent becoming pinched or kinked while operating.

A pinched or kinked hose can burst and leak hydraulic fluid.

NOTE: The preferred hose connections will allow

continues hydraulic flow for raking. Line (#2B) is the

pressure line for raking. Therefore, attach line (2B)

to the Skid Steer or Tractor hydraulic line that is

pressurizedwhen controlsare locked for continuous

operation (continuous hydraulic flow).

7. See your skid steer or Tractor Operator’sManual to

determine which coupler on your unit is under

pressurewhenunit is lockedincontinuousoperation.

If coupling (#4) does not mate with your unit’s

coupling that is under pressure, then switch

couplings (#3) and (#4) on lines (#2A & 2B).

8. Make certain both couplings (#3 & #4) are screwed

on tight. Connect couplings to the Skid Steer/Tractor

high pressure outlets.

9. Hydraulic hoses will be zip tied together after

installation of wiring harness. Continue with “Wiring

Harness Electrical Hook-Up” on page 11.

Bottom Slots

Top Angle Bars

Skid Steer Hitch Plate

Figure 1-4

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

10

30938

30939

Skid Steer Hitch Plate

Figure 1-5

4/05/12

Page 13

Table of Contents

Section 1: Assembly & Set-up

Wiring Harness Electrical Hook-Up

The wiring harness activates the hydraulic cylinder on

the rake for angling the roller 15oleft or right.

Push Button Wiring Harness (Standard)

Refer to Figure 1-6:

The push button wiring harness is supplied from the

factory with your Powered Rake. Push and hold one of

thebuttons to angle the roller in one direction andrelease

thebuttonto stoprotation.Push and holdthe other button

toangle theroller inthe opposite directionandrelease the

button to stop rotation.

1. Install power cord (#1) by connecting red wire

terminal (A) to a 12 volt power source and black wire

terminal (B) to ground.

2. Mount push button control switch (#3) in a

convenient, easy to reach location.

3. Connect power cord (#1) to control switch wire (#2).

4. Install black and green cord (#4) from control switch

to bottom solenoid wire (#5) and red and white wire

(#6) to top solenoid wire (#7).

5. With hydraulics hooked-up, start Skid Steer/Tractor

and press right button to angle Powered Rake to the

right and left button to angle rake to the left.

6. If Powered Rake angles in opposite directions, then

switch plugs (#4 & #6) with solenoid wires (#5 & #7).

Deutsch 14 Pin Plug & Cable (Accessory)

Refer to Figure 1-7:

If the Skid Steer Loader is equipped with a Deutsch 14

Pinmale connector,then the push button control box can

be eliminated and a 73 inch or 10 foot long Deutsch 14

pin plug & cable (#8) can be purchased to connect the

solenoid directly to the Skid Steer Loader controls.

Purchase the one that is the r ight length for your skid

steer from your nearest Land pride Dealer.

823-384C DEUTSCH HD30 14 PIN PLUG 73"

823-303C DEUTSCH HD30 14 PIN PLUG 10’

1. Reference solenoid on by-pass valve. Attach

connector (#4) with green wire to the bottom

solenoid connector and connector (#6) with red wire

to the top solenoid connector.

2. Install powercord (#8) by connecting the 14 pin plug

to your equipment’s mating 14 pin connector.

3. With hydraulics hooked-up, start Skid Steer/Tractor

and press right button to angle Powered Rake to the

right and left button to angle rake to the left.

4. If Powered Rake angles in opposite directions, then

switch plugs (#4 & #6) with solenoid wires (#5 & #7)

shown in Figure 1-6.

7

Push Button

Control Switch

Solenoid

Valve

+ Red 12V

- Black

33719

Standard Push Button Wiring Harness

Figure 1-6

30941

Deutsch 14 Pin Plug & Cable

Figure 1-7

Zip Tie Hoses & Electrical Cable

Refer to Figure 1-6 or Figure 1-7:

1. Securepowercord(#10) near thesolenoid valvewith

zip tie (#11).

Refer to Figure 1-5 on page 10:

2. Make certain hydraulic hoses (#2A B) are kept

awayfrom all pinch points.

3. Tie hydraulic hoses (#2A & #2B) and electr ical

cable(#10) together at 12" and 29"from end of quick

couplers (#3 & #4) with zip ties (#1).

NOTE: Additional zip ties may be needed to

properly secure the wiring harness. Customer to

supply and locate all additional zip ties.

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

11

4/05/12

Page 14

Table of Contents

Section 2: Operating Instructions

Section 2: Operating Instructions

Operating Checklist

Hazard control and accident prevention are dependent

upon the awareness, concern, prudence, and proper

traininginvolvedin the operation, transport, storage, and

maintenance of the Powered Rake. Therefore, it is

absolutely essential that no one operates the Powered

Rake without first having read, fully understood, and

becometotally familiarwith the Operator’sManual.Make

sure the operator has paid particular attention to:

• Important Safety Information, page 1

• Section 1: Assembly & Set-up, page 8

• Section 2: Operating Instructions, page 12

• Section 3: Adjustments, page 14

• Section 4: Maintenance & Lubrication, page 18

Before beginning to operate your Powered Rake the

following inspection should be performed.

Operating Checklist

✔ Check Reference

Checkrollerchain tension.Referto“Drive Chain

Adjustment”

Check oil lev el in chaincase. Ref er to

“Lubrication” on page 20

Check that all plugs have been replaced

properly in the chaincase.

Check the Powered Rake initially and

periodically forloose bolts &pins,T orqueValues

Chart.

Grease all fittings. Refer to “Lubrication”

Make Sure all guards and shields are in place

and secure.

Inspect Hydraulic hoses for wear, damage

and hydraulic leaks. Replace damaged and

worn hoses with genuine Land Pride parts.

Check air pressure in gauge wheel tires. Tire

pressure should be 45 psi.

Make the following inspections after attaching the

Powered Rake to the skid steer. Make cer tain the rake is

completely stopped before continuing.

1. Inspectskid steersafety equipment to make sureit is

in good working condition.

2. Carefully raise and lower implement with the

Powered Rake set at the maximum angle to ensure

that the tires and other equipment on the skid steer

do not contact the rake

3. Inspect hydraulic hoses for pinch points. Reposition

hoses if needed. For correct hose set-up, see

“HydraulicMotorHoseAssembly”set-up instructions

on Page 8.

4. Inspect hydraulic hoses for wear, damage and

hydraulic leaks. See “Avoid High Pressure Fluids

Hazard” on page 3. Replace damaged and worn

hoses with genuine Land Pr ide parts.

Page 15

Page 20

Page 21

Page 26

page 20

page 1

page 3

Page 26

Transporting

!

CAUTION

When traveling on public roadswhether at night or during the

day, use accessory light and devices for adequate warning to

operatorsof other vehicles. Comply with all federal,state,and

local laws.

1. Be sure to reduce ground speed when turning; and,

leave enough clearance so the Powered Rake does

not contact obstacles such as buildings, trees, or

fences.

2. Select a safe ground travelspeed when transporting

from one area to another. When traveling on

roadways,transport in sucha waythat faster moving

vehicles may pass you safely.

3. Decreasetranspor t speed whentravelingoverrough

or hilly terrain.

4. When transporting skid steer and Powered Rake on

a trailer:

• Use towing vehicle and trailer of adequate

capacity.

• Always drive up a ramp with heavy end uphill.

• Engage skid steer park brake and remove ignition

switch key once it is loaded.

• Secure Skid Steer Loader and attachment using

tiedowns and chains.

Safety Information

!

DANGER

Do not operate lift controls with someone directly between the

skid steer and Powered Rake or close to the rake.

!

CAUTION

Keep bystanders at least 20 feet away when operating!

!

WARNING

Do not become entangled in the hydraulic hoses. Tripping

over the hoses while entering or exiting the Skid Steer

operator station can cause serious injury to the body.

!

DANGER

Hydraulic fluid under pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin, it must be treated by a

doctor within a few hours or gangrene may result.

!

DANGER

Never carry a person on the rake. A rider can fall and be ran

over causing serious injury or death.

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

12

4/05/12

Page 15

Table of Contents

Section 2: Operating Instructions

!

WARNING

Always shut off all power, disengage auxiliary hydraulics, set

park brake, remove ignition key, and wait for the spiked roller

to come to a complete stop before dismounting from tractor.

!

WARNING

Do not use raketo lift or carry objects. Lifting and/or carrying

objects can brake the rake and/or cause serious bodily injury.

IMPORTANT: Do not allow hydraulicmotor hoses to

become pinched between the rake frame and hitch

plate pivot points. For correct hose set-up, see

“Hydraulic Motor Hose Assembly” set-up

instructions on Page 8.

IMPORTANT: Avoidcatching the hydraulichoseson

brush, post, stumps, and other protrusions that

could damage and/or break them.

IMPORTANT: Shut off all power, disengage

auxiliary hydraulics, set park brake and remove

ignition key any time the Powered Rake is not

operating properly or needs adjustment.

General Operating Instructions

First completely familiarize yourself with the Operator’s

Manual! Then complete the Operator’s checklist,

properly attachthe PoweredRaketo your skid steer,and

make the initial depth setting, level settings, and roller

angle adjustments. After completing the above, you will

need to perform operational safety checks. Choose a

work site and make any final adjustments before using

your Land Pr ide Powered Rake.

It’snow timeforarunning operationalsafetycheck.Make

certain that the loader’s park brakeis engaged, auxiliary

hydraulics are disengaged, and the Powered Rake is

resting on the ground. Start the loader and back off

engine rpm to approximately one-quarter throttle. Using

the hydrauliclift control, lift the PoweredRake about half

wayoff the groundand then engage auxiliary hydraulics.

Increase throttle speed if everything is running smoothly

until you have reached full operating speed. Never

engage the auxiliary hydraulics at full engine rpm.

Damage to the rake driveline and/or rake could occur.

To make final adjustments, choose a work site that is dry

and allows you to make at least a 50 ft. straight run.

Raise the Powered Rake half way off the ground,

disengage the loader auxiliary hydraulics, release the

park brake, andtravelto yourstarting point. Travelspeed

should be between 3 and 5 mph and the rake height

should be positioned for best road view.

Once at the site, idle the loader engine, engage the

auxiliary hydraulics,and then increase engine speed

until the loader is at full operating speed. Begin traveling

forwardwhile gently lowering the running PoweredRake

to the ground. Make slight changes to the loader’s

ground speed as you travel forward to determine the

desired ground finish. Generally, a slower speed results

in a finer finish, while a higher speed results in a coarser

finish. Excessive ground speed may result in dirt or

material passing over the top of the material control

deflectoror too much material being windrowed offto the

side. Powered Rakes do not perform well in wet sticky

soil and making sharp turns when in contact with the

ground.

Normal operating rake angle is 15 degrees left or right.

However, you may want to make subtle auxiliary

hydraulic adjustments to the roller angle to determine

varying effects on the surface finish. The end plates can

be taken out of storage position and installed to create a

box blade effect which will greatly assist in filling in low

spots and depressions.

You can also vary the effect on the surface finish by

setting the material control deflector height above the

roller.The material control deflectorsifts out clods,rocks,

andother debris as the soil passes over the top of the bar

roller. Adjusting the blade down decreases the gap

between the deflector and roller and will sift out more

objects for a finer soil finish. Adjusting the blade up

allows more clods, rocks, and debris to pass over the

roller and produces a coarser soil finish.

Set the working depth and level the rake at the caster

gauge wheels and not with the loader. Nor mally a 1"

cultivation depth is considered ideal for a surface finish.

Makeadjustments tothe working depth if toomany rocks

orexcessivedebris passunder theroller bychanging the

C-spacers on the gauge wheel spindles. Increase

working depth by moving the spacers from below the

support arms to above the support arms. Decrease

working depth by moving the spacers from above the

gauge wheel support arms to below the support arms.

The Powered Rake should also be set to operate level.It

has a tendency to go in deeper on the driveline side (left

side) because that is the heavy side of the rake.

Compensate for this by changing the C-spacers on the

right gauge wheel so that it is set approximately 1"

deeper than the left gauge wheel.

After you have traveled 50 feet, properly shut down the

skid loader and Powered Rake to inspect the finish and

determine what, ifany,additional adjustmentsneed tobe

made. Check for any foreign objects that may be

wrapped around the roller or lodged between the studs.

Remember that the right finish is achieved through a

combinationof proper soilmoisture conditions,operating

depth, ground speed, material control deflector opening

and roller angle. Your Powered Raking capabilities will

improve rapidly with experience.

4/05/12

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

13

Page 16

Table of Contents

Section 3: Adjustments

Section 3: Adjustments

Powered Rake Roller

The roller is powered by a roller chain attached to a

sprocketmountedon thehydraulicmotor that runs off the

auxiliary circuit of the skid steer loader.

A hydraulic directional valve is utilized to power a

hydrauliccylinderthat anglesthe roller frame 20degrees

in either direction for windrowing material to the side.

This valve allows 3 gpm of oil to be routed from the

auxiliary circuit of the skidsteer loaderand is actuated by

a solenoid valve connected to a toggle switch in the cab.

Gauge Wheels

Caster gauge wheels are mounted on the front of the

frame to control the height of the roller during field

operation and when the parallel linkage mounting plates

are in the float position.

Setting Working Depth

Refer to Figure 3-1:

The operating depth is controlled by adjusting the caster

gauge wheels up or down and not with the skid steer

hydraulics. There are easy to remove and install

C-spacers (#7) on all gauge wheel spindles (#1). Move

gauge wheels up for greater raking depth and down for

less raking depth.

NOTE: The gauge wheel on the chain case side

should be down approximately 1 inch more than the

non-drive side to compensate for extra weight.

1. Move wheels up by repositioning the desired

number of C-spacers (#2) from below to above

gauge wheel support arms (#3). Make certain flat

washer (#4) is located above all the C-spacers.

2. Move wheels down by repositioning the desired

number of C-spacers (#2) from above to below the

gauge wheel support arms (#3). Make certain flat

washer (#4) is located above all the C-spacers.

Parallel Linkage Mounting

Refer to Figure 3-2:

The skid steer loader parallel linkage mounting plates

allows the operator to lock the parallel linkage arms in

order to apply down pressure to the rake roller. The pin

can be placed in the back hole to permit parallel linkage

to move in float position. This allows the rake roller with

theaid of thecaster gauge wheelsto followthe contourof

the ground.

.

Move Pin To This Location Allows Rake

Roller To Follow Contour Of Ground

Pin Shown in Locked Position

(Locked Parallel Linkage Arms)

30936

Parallel Linkage

Figure 3-2

Material Control Blade Adjustment

Refer to Figure 3-3:

Material control blades are mounted above the roller so

control can be established over both the size and shape

of materials being cleaned or raked. The gap between

the front material control blade and the rakeroller can be

adjusted to widen or narrow the opening. A wider

opening will allow more dirt and rock to pass through.

A narrow opening will allow for finer raking.

The height of the front material control blade can be

adjusted by loosening bolt (A) and sliding material

control blade (B) up or down to desired height.

Depth Adjustment

Figure 3-1

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

14

30935

A

B

24534

Front Material Control Blade Adjustment

Figure 3-3

4/05/12

Page 17

Section 3: Adjustments

Table of Contents

Drive Chain Adjustment

Refer to Figure 3-4:

!

CAUTION

BEFORE any maintenance is performed, lower the Powered

Rake to the ground, stop skid steer loader engine and remove

the key. DO NOT attempt to make maintenance adjustments

while skid steer is running.

1. Check chain tension by removing 1/4" x 5/8" hex

bolts (#4), lockwashers (#9), and access cover (#2)

from the chain case.

2. Inspect chain for tightness and excess wear.

Replace worn out chains. See “Sprocket and Drive

Chain Replacement” page 18.

3. If the chain should become loose, either the spring

(#11)on theidler armsor thechain (#12)needs tobe

replaced. See “Drive Sprocket and Drive Chain

Replacement” page 18.

4. Apply 1/8" bead of Land Pride No.821-049C sealant

to the surface of the main cover (#1) where access

cover(#2)contactsmain cover(#1). Reinstall access

cover (#2) and secure with lockwashers (#9) and

1/4"-20x 5/8"GR5 hex bolts(#4). Torquehexboltsto

the correct torque.

4/05/12

Drive Chain Adjustment

Figure 3-4

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

21104

15

Page 18

Section 3: Adjustments

Table of Contents

SR2672 End Plate Positioning

End plates are utilized to gather and keep rocks and

debris in front of the roller for the purpose of distributing

material over low areas.

Working Position

Refer to Figure 3-5:

The end plates are attached to the mounting pins on the

front side for gathering and distributing material while

traveling forward.

1. Install right hand end plate (#1) over the two side

support pins as shown.

2. Rotate spacer A1 under hitch pin spacer A2 and

insert hitch pin (#2) through spacers A1 & A2.

3. Secure hitch pin with hair pin cotter (#3).

4. Repeat steps 1 through 3 for left hand end plate.

Storage Position

The end plates can be removed, turned over, and

repositioned on their mounting pins for storage during

final grading.

Refer to Figure 3-5:

1. Remove hair pin cotter (#3) and hitch pin (#2).

2. Remove right hand end plate (#1).

Refer to Figure 3-6:

3. Tur n end plate over and insert Spacer B1 over

mounting pin B2.

4. Rotatespacer A1 overspacerA2 and insert hitchpin

(#2) up through spacers A2 & A1.

5. Secure hitch pin with hair pin cotter (#3).

6. Repeat steps 1 through 5 for left hand end plate.

SR2672 End Plate Assembly (Right Hand Side Shown)

Figure 3-5

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

16

24535

21106

SR2672 Final Grading Position of End Plates

Figure 3-6

4/05/12

Page 19

Section 3: Adjustments

Table of Contents

SR2690 End Plate Positioning

End plates are utilized to gather and keep rocks and

debris in front of the roller for the purpose of distributing

material over low areas.

Working Position, Forward Travel

Refer to Figure 3-7:

1. Install right hand end plate (#1) over the three front

support pins on the Powered Rake as shown.

2. Secure end plate with linchpin (#2).

3. Install left hand end plate (not shown) on the

opposite end of the Powered Rake.

4. Secure end plate with linchpin (#3).

Working Position, Reverse Travel

Refer to Figure 3-8:

1. Install left hand end plate (#3) over the back three

support pins on the Powered Rake as shown.

2. Secure end plate with linchpin (#4).

3. Install right hand end plate (not shown) on the

opposite end of the Powered Rake.

4. Secure end plate with linchpin (#4).

Storage Position, Forward Travel

Refer to Figure 3-8:

1. Install left hand end plate (#3) over the back three

support pins on the Powered Rake as shown.

2. Secure end plate with linchpin (#4).

3. Install right hand end plate (not shown) on the

opposite end of the Powered Rake.

4. Secure end plate with linchpin (#4).

Storage Position, Reverse Travel

Refer to Figure 3-7:

1. Install right hand end plate (#1) over the three front

support pins on the Powered Rake as shown.

2. Secure end plate with linchpin (#2).

3. Install left hand end plate (not shown) on the

opposite end of the Powered Rake.

4. Secure end plate with linchpin (#3).

SR2690 End Plate Assembly (Front Mounted)

Figure 3-7

4/05/12

24536

SR2690 End Plate Assembly (Back Mounted)

Figure 3-8

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

24537

17

Page 20

Table of Contents

Section 4: Maintenance & Lubrication

Section 4: Maintenance & Lubrication

Maintenance

Properser vicing and adjustment is the keyto the long life

of any implement. With careful and systematic

inspection, you can avoid costly maintenance, time, and

repair.

After using your PoweredRake for several hours, check

all bolts to be sure they are tight. Replace any worn,

damaged, or illegible safety labels by obtaining new

labels from your Land Pride Dealer.

!

CAUTION

BEFORE any maintenance is performed, lower the Powered

Rake to the ground, stop skid steer engine, and remove key.

DONOTattempt to make maintenance adjustments while skid

steer is running.

IMPORTANT: If chaincase and/or sprocket shafts

are disassembled, it may be necessary to shim

between the chaincase and frame tube during

reassembly to properly realign the sprocket shafts.

Shim Pack 314-254A may be purchased from your

nearest Land Pride Dealer for this purpose.

socket cap screws (#6 & #7). Tighten cap screws to

the correct torque.

11. Remove top and bottom plugs (#15). Fill chain case

with 80-90 weight gear lube through top plug hole

until oil escapes out bottom plug hole. (Equivalent to

2 1/2 pints.)

12. Reinstall and tighten top and bottom plugs (#15).

Drive Chain Maintenance

The operator should check chain tightness after initial

run in and periodically thereafter to make sure that the

drive chain is tensioned correctly. If adjustment is

needed referto “Drive Chain Adjustment” on page 15.

Sprocket and Chain Replacement

Refer to Figure 4-1:

1. Remove1/4"x 1 1/4"and 1/4"x 11/2" hex socket cap

screws (#6 & #7).

2. Remove main cover plate (#1).

NOTE: Oil in chain case! Be prepared to capture oil

when taking off bottom cover.

3. Loosen chain tension byremoving spring (#11) from

idler arms.

4. Remove bolt (#5) and lockwasher (#10).

5. Remove top sprocket and chain.

NOTE: If bottom sprocket needs to be replaced,

remove nut (#8) and bottom sprocket.

6. Install new chain and sprockets.

7. Reinstall bolt (#5), lockwasher (#10), and nut (#8).

8. Reinstall spring (#11).

9. Tur n the roller several turns and observe chain to

make sure everything is working properly.

10. Apply 1/8" bead of Land Pride No. 821-049C sealant

on the chain case edge where cover plate (#1)

contacts the chain case. Reinstall cover plate with

1/4" -20 x 1 1/4" GR2 and 1/4" -20 x 1 1/2" GR2 hex

21104

Drive Sprocket and Drive Chain Replacement

Figure 4-1

Chain Case Skid Shoe Replacement

Refer to Figure 4-2:

1. Replace chain case skid shoe (#1) by removing four

3/8" x 3/4" hex head bolts (#2) and lockwashers(#3).

2. Replace worn skid shoe with new shoe.

3. Secureskidshoe (#1)with3/8" lockwashers(#3) and

3/8" x 3/4" hex head bolts (#2).

4. Torque hex bolts to correct torque.

21105

Chain Case Skid Shoe Replacement

Figure 4-2

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

18

4/05/12

Page 21

Table of Contents

Section 4: Maintenance & Lubrication

Gauge Wheel U-Bolts

Refer to Figure 4-3:

Torque gauge wheel u-bolts to 49 ft-lbs. after first day of

use and every 100 hours thereafter.

24534

Gauge Wheel U-Bolts

Figure 4-3

Storage

Clean, inspect, service, and make necessary repairs to

the Powered Rake when par king it for long periods and

when parking it at the end of a wor king season. This will

help ensure that the rake is ready for field use the next

time you hook-up to it.

!

DANGER

Alwaysdisconnect hydraulic lines fromSkid Steer/Tractorand

secure rake in the up position with solid supports before

servicing underside of the rake.

1. Clean off any dirt and grease that may have

accumulated on the rake and moving parts. Scrape

off compacted dirt from the roller and then wash

surface thoroughly with a garden hose.

2. Checktheroller spikes for wear andreplacethe roller

and/or spikes if necessary.

3. Inspect the Powered Rake for parts out of

adjustment, loose, and damaged or worn.

• Make required adjustments.

• Tighten all loose hardware.

• Replace damaged and worn parts as needed.

4. Repaint parts where paint is worn or scratched to

preventrust. Ask your dealer for Land Pride aerosol

touch-up paint. They are also available in touch-up

bottleswith brush,quar ts, andgallon sizes byadding

TU, QT,or GL to the end of the aerosol part number.

Land Pride Aerosol Touch-up Paint

Part No.Part Descr iption

821-011CPAINT LP BEIGE AEROSOL SPRAY CAN

821-002CPAINT LP BLACK AEROSOL SPRAY CAN

821-066CPAINT ORANGE AEROSOL SPRAY CAN

5. Replace all damaged or missing decals.

6. Lubricate as noted in “Lubrication” on page 20.

7. A light coat of oil or grease may be applied to the

roller and to any exposed hydraulic cylinder rods to

minimize oxidation.

8. Drain chain case oil by removing large cover (#1)

Figure 4-1. Be sure to refill chain case with chain

case oil. See “Drive Chain” on page 21 for detailed

instructions

9. StorePoweredRakeonalevelsurfaceina clean,dry

place. Inside storage will reduce maintenance and

make for a longer rake life.

4/05/12

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

19

Page 22

Section 4: Maintenance & Lubrication

Lubrication

Table of Contents

Lubrication

Legend

21101

Multi-purpose

spray lube

Multi-purpose

grease lube

Multi-purpose

oil lube

50

Intervals in hours

at which lubrication

is required

Gauge Wheel Spindle

Grease gauge wheel spindle every 25 hours

One grease zerk for each gauge wheel

Type of Lubrication: Multi-Purpose Grease

Quantity: Add grease until grease begin to emerge from

either top or bottom bushings.

25

Hours

25

Hours

21101

Gauge Wheel

Grease gauge wheel axle every 25 hours

One grease zerk for each gauge wheel

Type of Lubrication: Multi-Purpose Grease

Quantity: Add grease until grease begin to emerge from

either side of the axle hub.

25

Hours

Pivot

Grease pivot point every 25 hours

Two grease zerks

Type of Lubrication: Multi-Purpose Grease

Quantity: Add grease until grease begin to emerge from

either top or bottom bushings.

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

20

30936

4/05/12

Page 23

Table of Contents

Section 4: Maintenance & Lubrication

Fill Plug

Lower Plug

As

Required

Drive Chain

Fill through top fill plug and check quantity at lower plug.

Type of Lubrication: 80-90 Gear Lube

Quantity: 2 1/2 pints (Gear Lube will run out of lower plug

when full.)

30937

25

Hours

30665

Pivot Arm Bushings (8 Places)

Grease pivot arm bushings every 25 hours

Two grease zerks for each pivot arm

Type of Lubrication: Multi-Purpose Grease

Quantity: Add grease until grease begin to emerge from

either side of the bushings.

25

Hours

Non-Drive Bearing

Grease gauge non-drive bearing every 10 hours

One grease zer k inside skid shoe

Type of Lubrication: Multi-Purpose Grease (Remove Skid

Shoe to grease)

Quantity: Add grease until grease begin to emerge from

either side of the axle.

24533

4/05/12

Remove Skid Shoe

To Grease

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

21

Page 24

Table of Contents

Section 5: Specifications & Capacities

Section 5: Specifications & Capacities

Skid Steer Powered Rakes

SR2672 SR2690

Hydraulic Drive Requirements 11 GPM at 2200 psi minimum 15 GPM at 2500 psi minimum

Maximum Hydraulic Pressure 3500 psi 3500 psi

Non-Angled Working Width 82 1/2" 100"

Angled Working Width 72 1/2" 90"

Non-Angled Length 72 1/2"

Overall Height 41 1/8" 41 1/8"

Machine Weight 930 lbs. 1200 lbs.

Direction of Travel Bi-directional

Material Control Blade 2 each - 1/2" x 5" Urethane

Spike Roller 9 3/8" Dia. with 3/4" x 1 1/2" Carbide Tipped Studs

Roller Speed Variable from 180 - 260 RPM

Roller End Bearings Roller Bearings

Drive Chain #50 Double Continuous Roller Chain, High Tensile,

Enclosed in oil bath

Angle Adjustment Hydraulically controlled

18 degrees right and 22 degrees left

Angle Cylinder 2" X 8"

End Plates Standard, Removable with Storage Rack

Gauge Wheels / Depth Control 2 Each 16.5" x 6.5" Air Tires W/ sealant and 3/4" Roller bearings and Spacer height

adjustment

Skid Shoes Replaceable

Chain Case Lubrication 2 1/2 pints of 80-90 weight Gear Lube -

Add gear lube until it escapes from lower plug hole.

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

22

4/05/12

Page 25

Table of Contents

Section 5: Specifications & Capacities

4/05/12

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

30641

23

Page 26

Table of Contents

Section 6: Features & Benefits

Section 6: Features & Benefits

SR26 Series (Skid Steer)

Features Benefits

Working width 72" & 90"

Hydraulics 72": 11 GPM at 2200 psi

90": 15 GPM at 2500 psi

15 cu. in. Displacement motor Able to handle high torque loads in heavy conditions.

72" = 3" x 3" x 1/4" Tube Frame

90" = 6" x 3" x 1/4" Tube Frame

Angling adjustment:

22 degrees left & 18 degrees right

3/4" x 1 1/2"

Carbide tipped stud roller

16.5" x 6.5" Gauge wheels with

sealant

End plates with storage End plates can be used to hold dirt to aid in filling low spots. Easily store the end

Two material control deflectors Material control deflectors determine what size of material to let pass through the

Bi-directional roller Enables more complete finish and control

Variable roller speed 180 to 260 r pm variable roller speed is controlled by the skid steer hydraulics and can

#50 Double continuous roller

chain

Cast Iron chain guard housing Strong enough to protect chain in harsh conditions.

Drive chain enclosed in oil bath A small amount of oil keeps the chain and sprockets lubricated to keep abrasion to a

Replaceable skid shoes Skid shoes protect larger and vital parts of the unit. As they wear due to soil contact,

Hydraulic Motor Warranty 2 Years parts and labor. Shows our confidence in the gearbox integrity.

Universal fit Universal fit with new and late model skid steer units.

Superior in strength.

Angling allows proper flow of material wanting to be windrowed to allow for easy

collection of large rocks and debris.

Carbide tipped studs are very tough, used in the mining industry, this offers a long life

to the studs. Studs can be replaced one at a time.

Easy to adjust vertically to set working depth. Has tall and wide tires that keep turning

in fluffy soil. Sealant helps seal against punctures.

plates on the Powered Rake so that they are always with the Rake when needed.

roller and what size to move out. Two deflectors allow for forward and reverse rotation

of the roller.

be used in tight areas to lessen the possibility of flying debris.

Double chain can take the fluctuation loads from the roller due to varying ground

conditions.

minimum.

they can easily be replaced.

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

24

4/05/12

Page 27

Table of Contents

Section 7: Troubleshooting

Section 7: Troubleshooting

Problem Solution

Machine makes intermittent clicking

noise

Rake angles wrong direction when

pushing control box b uttons

Roller will not turn

Operating depth insufficient

Check for damaged gear and replace if necessary.

Check for worn drive chain and replace if necessary.

Refer to Figure 1-6 on page 11:

Switch plugs (#4 & #6) with solenoid wires (#5 & #7).

Hydraulic valve on skid steer loader not engaged.

Relief valve setting on skid steer loader not properly adjusted. See skid steer

loader manual.

Worn, damaged, insufficient, or inadequate hydraulic pump.

Insufficient oil in system.

Worn or damaged housing.

Air in hydraulic hoses.

Broken hose.

Loose or damaged hoses.

Obstruction between roller and material control blade.

Drive Chain is off.

Loose or damaged connections.

Oil leaks. Worn or damaged seal.

Raise gauge wheels.

Increase skid steer RPM.

Roller gouging on the end

T oo muc h dirt going into the windrow or

dirt going over the top of the material

control blade

T oo many r ocks passing between

material control blade and the roller

Roller balling up with soil

Powered Rake b umping on ground

Roller angling opposite of switch

Clean roller.

The gauge wheel on chaincase side should be approximately 1" lower than the

non-drive side gauge wheel for consistent leveling.

Set gauge wheel depth.

Correct air pressure in gauge wheels.

Reduce ground speed.

Raise material control blade.

Lower gauge wheels.

Lower material control blade.

Wait until soil dries.

Clean roller.

Increase roller speed if roller is turning slow.

Decrease roller speed if roller is turning fast.

Move wire on top solenoid to bottom solenoid and wire on bottom solenoid to top

solenoid.

4/05/12

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

25

Page 28

Section 8: Torque Values Chart

Section 8: Torque Values Chart

Bolt Head Identification

Table of Contents

Torque Values Chart

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 436597

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16" - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 l215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 20101 in-tpi = nominal thread diameter in inches-threads per inch

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 27103 ft-lb= foot pounds

1 1/2" - 6 1180 870 2640 1950 4290 31604mm x pitch = nominal thread diameter in millimeters x thread

1 1/2" - 12 1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 2 Grade 5

N·m2ft-lb3N·m ft-lb N·m ft-lb mm x pitch4N·m ft-lb N·m ft-lb N·m ft-lb

Grade 8

Bolt Size

(Metric)

2

N· m = newton-meters

pitch

5.8

Class 5.8 Class 8.8 Class 10.9

8.8 10.9

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

26

Tire Inflation Chart

TireSize Inflation

16.5 x 6.5 2- Ply

PSI

45

4/05/12

Page 29

Section 9: Warranty

Section 9: Warranty

be free from defects in material and workmanship beginning on the date of

purchase by the end user according to the following schedule when used as

intended and under normal service and conditions for personal use.

and the installation by the dealer of anysuch replacement part, and does not cover

common wear items such as blades, belts, tines, etc.Land Pride reserves the right

to inspect any equipment or parts which are claimed to have been defective in

material or workmanship.

judgment shall have been misused or damaged by accident or lack of normal

maintenance or care, or which has been repaired or altered in a way which

adversely affects its performance or reliability, or which has been used for a

purpose for which the product is not designed. Misuse also specifically includes

failure to properly maintain oil levels, grease points and driveline shafts.

the product and all warranty adjustments must be made throughsuch dealer. Land

Pride reserves the right to make changes in materials or design of the product at

any time without notice.

of any kind, direct, consequential, or contingent to property. Furthermore, Land

Pride shall not be liable for damages resulting from any cause beyond its

reasonable control. This Warranty does not extend to loss of crops, any expense

or loss for labor, supplies, rental machinery or for any other reason.

with respect to this sale; and all implied warranties of merchantability and

fitness for a particular purpose which exceed the obligations set forth in this

written warranty are hereby disclaimed and excluded from this sale.

the date of purchase by the end user.

Table of Contents

Warranty

Land Pride warrants to the original purchaser that this Land Pride product will

Overall Unit: One year Parts and Labor

Hydraulic Motor: Two years Parts and Labor

Roller: Considered a wear item

This Warranty is limited to the replacement of any defective part by Land Pride

This Warranty does not apply to any part or product which in Land Pride’s

Claims under this Warranty must be made to the dealer which originally sold

This Warranty shall not be interpreted to render Land Pride liable for damages

No other warranty of any kind whatsoever, express or implied, is made

This Warranty is not valid unless registered with Land Pride within 30 days from

Model Number ____________________ Serial Number ____________________

4/05/12

SR2672 & SR2690 Skid Steer Powered Rakes 321-004M

27

Page 30

Corporate Office: P.O. Box 5060

Salina, Kansas 67402-5060 USA

www.landpride.com

Loading...

Loading...