Page 1

Table of Contents

Rotary Cutter

SC2660 & SC2672 Skid Steer

24538

326-025M

Operator’s Manual

Read the Operator’s manual entirely. When

you see this symbol, the subsequent

!

instructions andwarningsare serious - follow

without exception. Your life and the lives of

others depend on it!

© Copyright 2009 Printed

Cover photo may show optional equipment

not supplied with standard unit.

1/07/09

Page 2

Table of Contents

T ab le of Contents

Land Pride

Important Safety Information . . . . . . . . . . .1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

Look For The Safety Alert Symbol . . . . . . . . . . . . .1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . .7

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . .7

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 8

Serial Number Plate . . . . . . . . . . . . . . . . . . . . . 8

Further Assistance . . . . . . . . . . . . . . . . . . . . . .8

Section 1: Assembly & Set-up . . . . . . . . . .9

Skid Steer Requirements . . . . . . . . . . . . . . . . . . . . 9

Dealer Preparations . . . . . . . . . . . . . . . . . . . . . . . . 9

Pre-Assembly Checklist . . . . . . . . . . . . . . . . . . . . . 9

Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Float Chain Assembly . . . . . . . . . . . . . . . . . . . . . . 9

SC2660 Motor And Hose Assembly . . . . . . . . . . .10

SC2672 Motor And Hose Assembly . . . . . . . . . . .10

SC2672 Vent Plug With Dipstick . . . . . . . . . . . . . 10

Hitch Hook-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hydraulic Hose Hook-up . . . . . . . . . . . . . . . . . . . 11

Gauge Wheel Assembly (Optional) . . . . . . . . . . . 12

Skid Shoe Assembly (Optional) . . . . . . . . . . . . . . 13

Operator Protective Door (Optional) . . . . . . . . . . 13

Section 2: Adjustments . . . . . . . . . . . . . .14

Hitch Positioning . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hitch Mounted Offset . . . . . . . . . . . . . . . . . . . 14

Hitch Mounted Centered . . . . . . . . . . . . . . . . . 14

Height Adjustment Safety Chain . . . . . . . . . . . . .15

Deck Leveling with Optional Gauge Wheel . . . . .16

Deck Leveling without Optional Gauge Wheel . . .17

Section 3: Operating Procedures . . . . . .18

Operating Information . . . . . . . . . . . . . . . . . . . . .18

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Cutting Instructions . . . . . . . . . . . . . . . . . . . . . . .19

General Operating Instructions . . . . . . . . . . . . . .19

Skid Steer Operating Instructions . . . . . . . . . .20

Rotary Cutter Operating Instructions . . . . . . . .20

Section 4: Optional Equipment . . . . . . . .21

Front Mounted Gauge Wheel . . . . . . . . . . . . . . . .21

Skid Shoe Bundles . . . . . . . . . . . . . . . . . . . . . . . .21

Motor and Hose Assembly . . . . . . . . . . . . . . . . . .21

Extended Hose Kit . . . . . . . . . . . . . . . . . . . . . . . .22

Operator Protective Door . . . . . . . . . . . . . . . . . . .22

Section 5: Maintenance & Lubrication . . 23

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cutter Blade Maintenance . . . . . . . . . . . . . . . . . .23

Skid Shoe Maintenance . . . . . . . . . . . . . . . . . . . .24

Hydraulic Maintenance . . . . . . . . . . . . . . . . . . . . .25

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . .26

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . .26

Hitch Plate Pivot . . . . . . . . . . . . . . . . . . . . . . .26

Gauge Wheel Parallel Arms . . . . . . . . . . . . . .26

Gauge Wheel Spindle & Axle Hub . . . . . . . . . .26

Axle Hub Bearing . . . . . . . . . . . . . . . . . . . . . .26

Motor Spindle Hub (SC2660 Only) . . . . . . . . .27

Gearbox (SC2672 Only) . . . . . . . . . . . . . . . . .27

Section 6: Specifications & Capacities . .28

Section 7: Features and Benefits . . . . . .29

Section 8: Troubleshooting . . . . . . . . . . .30

Section 9: Appendix . . . . . . . . . . . . . . . . .31

Torque Values Chart . . . . . . . . . . . . . . . . . . . . . .31

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

© Copyright 2009 All rights Reserved

Land Pride provides this publication “asis” without warranty ofany kind, either expressedor implied. While every precaution has beentaken in the preparationof this manual, Land

Pride assumesno responsibility forerrors oromissions. Neither isany liability assumedfor damagesresulting from theuse of theinformation contained herein.Land Pride reserves

the rightto revise andimprove itsproducts as it sees fit. This publicationdescribes the stateof this productat the time of its publication,and may notreflect the productin the future.

Land Pride isa registered trademark.

All other brands and product names are trademarksor registered trademarks of their respectiveholders.

Printed in the United States of America.

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

1/07/09

Page 3

Land Pride

▲

Table of Contents

Important Safety Information

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Safety at All Times

Thoroughly read and understand

the instructions given in this

manual before operation. Refer to

the “Safety Label” section, read

all instructions noted on them.

Do not allow anyone to operate

this equipment who has not fully

read and comprehended this

manual and who has not been

properly trained in the safe

operation of the equipment.

▲ Operator should be familiar with

all functions of the unit.

▲ Operate implement from the

driver’s seat only.

▲ Make sure all guards and shields

are in place and secured before

operating the implement.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Dismounting from a moving

tractor could cause serious injury

or death.

▲ Do not allow anyone to stand

between the tractor and

implement while backing up tothe

implement.

▲ Keep hands, feet, and clothing

away from power-driven parts.

▲ Wear snug fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of

working area.

▲ Turning tractor too tight may

cause implement to ride up on

wheels. This could result in injury

or equipment damage.

▲ Do not carry passengers on

implement at any time.

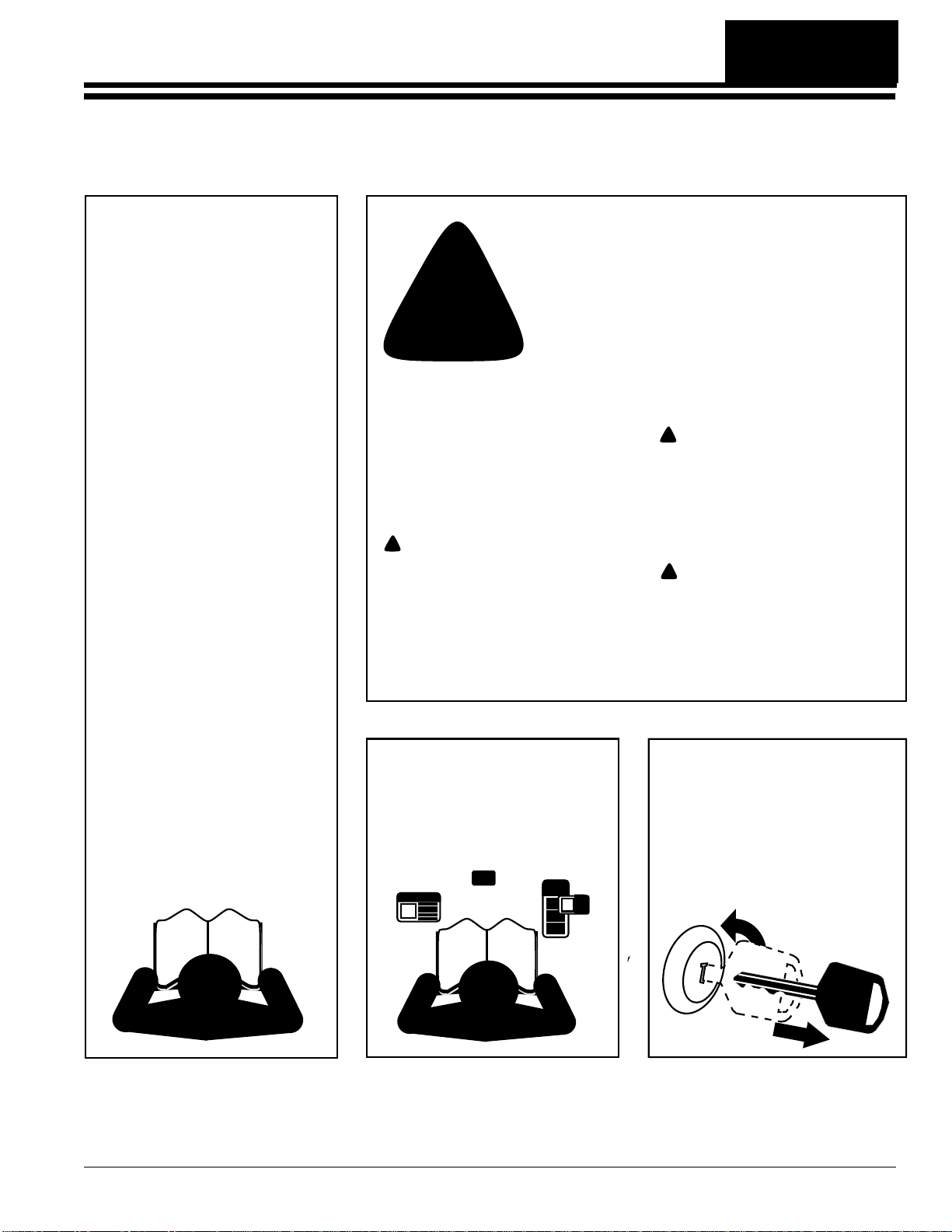

Look For The Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

!

Be Aware of

Signal Words

A Signal word designates a degree or

level of hazard seriousness. The

signal words are:

!

DANGER

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for

functional purposes, cannot be

guarded.

For Your Protection

▲ Thoroughly read and understand

the “Safety Label” section, read all

instructions noted on them.

equipment, hazard control and accident prevention

are dependent upon the awareness, concern,

prudence and proper training of personnelinvolved in

the operation, transport, maintenance and storage of

equipment.

!

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It mayalso

be used to alert against unsafe

practices.

!

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine, and

remove the key.

▲ Detach and store implements in a

area where children normally do

not play. Secure implement by

using blocks and supports.

1/07/09

OFF

REMO

VE

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

1

Page 4

Table of Contents

Land Pride

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

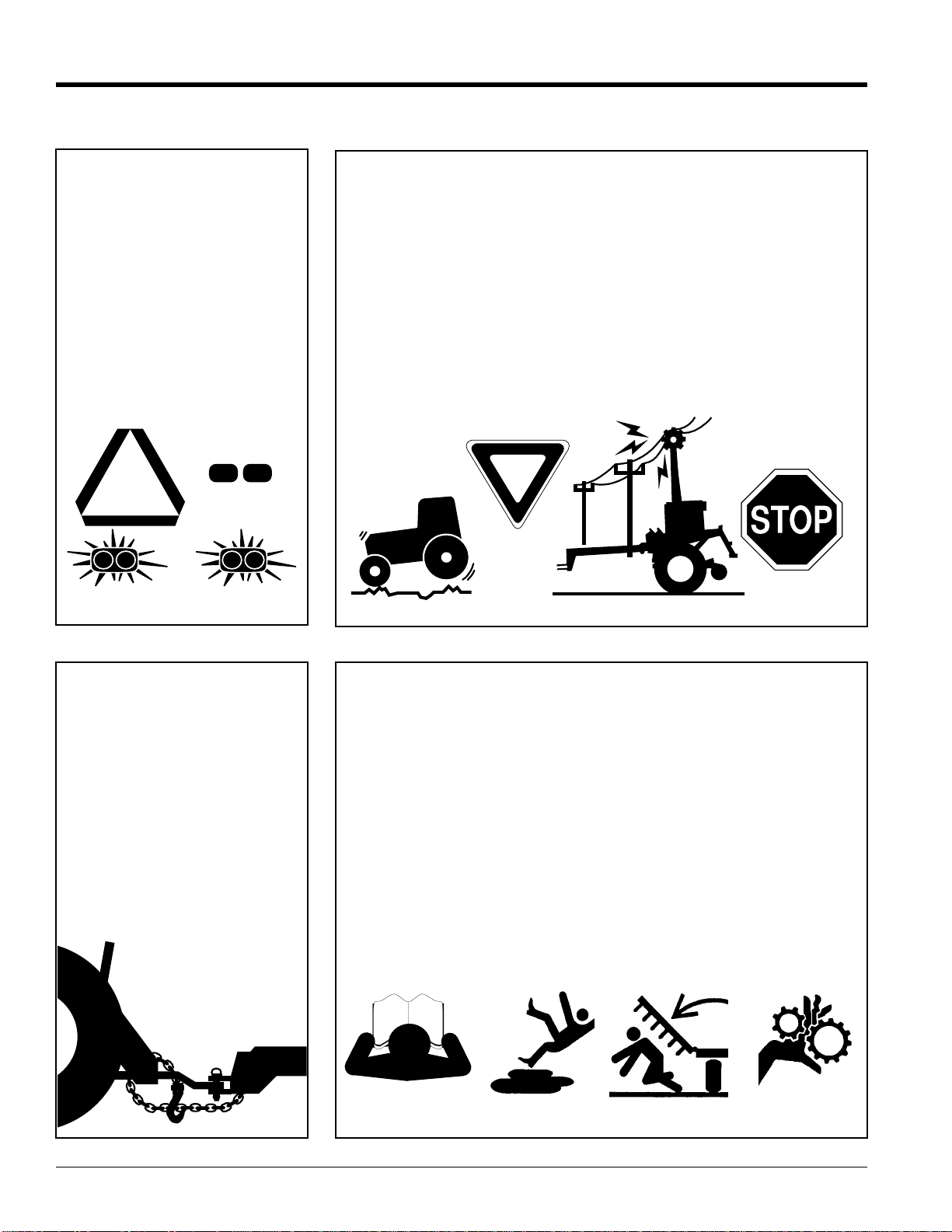

Use Safety

Lights and Devices

▲ Slow moving tractors, self-

propelled equipment, and towed

implements can create a hazard

when driven on public roads. They

are difficult to see, especially at

night.

▲ Flashing warning lights and turn

signals are recommended

whenever driving on public roads.

Transport

Machinery Safely

▲ Comply with state and local laws.

▲ Maximum transport speed for

implement is 20 mph. DO NOT

EXCEED.Never travel at a speed

which does not allow adequate

control of steering and stopping.

Some rough terrain require a

slower speed.

▲ Sudden braking can cause a

towed load to swerve and upset.

Reduce speed if towed load is not

equipped with brakes.

▲ Use the following maximum

speed - tow load weight ratios as

a guideline:

20 mph when weight is less

than or equal to the weight of

tractor.

10 mph when weight is double

the weight of tractor.

IMPORTANT: Do not tow a load that

is more than double the weight of

tractor.

Use A Safety Chain

▲ A safety chain will help control

drawn machinery should it

separate from the tractor

drawbar.

▲ Use a chain with the strength

rating equal to or greater than

the gross weight of the towed

machinery.

▲ Attach the chain to the tractor

drawbar support or other

specified anchor location. Allow

only enough slack in the chain to

permit turning.

▲ Do not use safety chain for

towing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment, refer to Operator’s

Manual for additional information.

▲ Work in a clean dry area.

▲ Lower the implement to the

ground, put tractor in park, turn off

engine, and remove key before

performing maintenance.

▲ Allow implement to cool

completely.

▲ Do not grease or oil implement

while it is in operation.

▲ Inspect all parts. Make sure parts

are in good condition & installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before

operation.

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

2

1/07/09

Page 5

Land Pride

Table of Contents

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

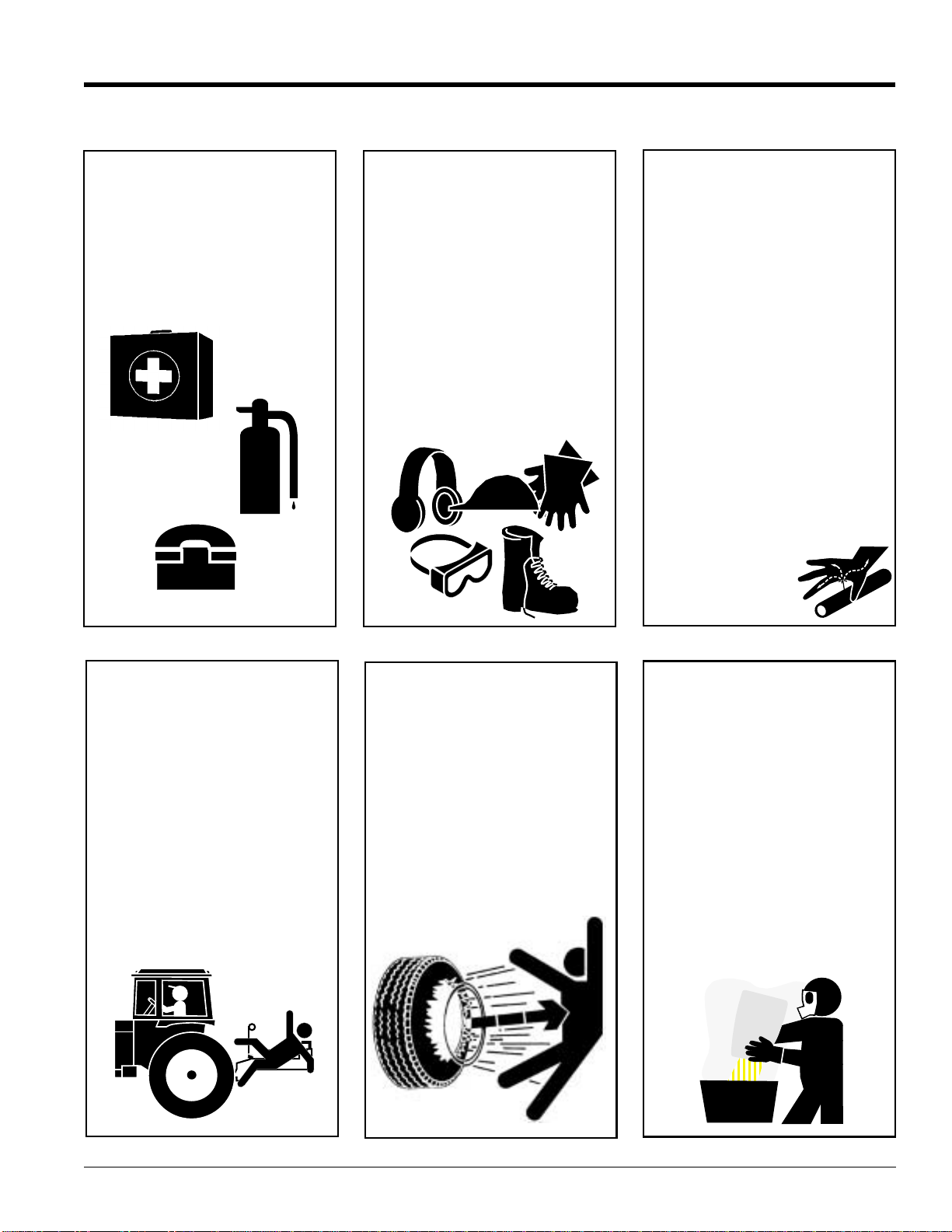

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire

extinguisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Protectiveclothingandequipment

should be worn.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose fitting clothing.

▲ Prolonged exposure to loud noise

can cause hearing impairment or

hearing loss. Wear suitable

hearing protection such as

earmuffs or earplugs.

▲ Operating equipment safely

requires the full attention of the

operator. Avoid wearing radio

headphones while operating

machinery.

Avoid High

Pressure Fluids Hazard

▲ Escaping fluid underpressurecan

penetratetheskincausingserious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines or performing work

on the system.

▲ Make sure all hydraulic fluid

connections are tight and all

hydraulic hoses and lines are in

good condition before applying

pressure to the system.

▲ Use a piece of paper or

cardboard, NOT BODYPARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a

doctor immediately. Any fluid

injected into the skin must be

treated within a few hours or

gangrene may result.

Keep Riders

Off Machinery

▲ Riders obstruct the operator’s

view, they could be struck by

foreign objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

Tire Safety

▲ Tire changing can be dangerous

and should be preformed by

trained personnel using the

correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side and NOT in front of or

over the tire assembly. Use a

safety cage if available.

▲ When removing and installing

wheels, use wheel handling

equipment adequate for the

weight involved.

Handle

Chemicals Properly

▲ Protective clothing should be

worn.

▲ Handle all chemicals with care.

▲ Follow instructions on container

label.

▲ Agricultural chemicals can be

dangerous. Improper use can

seriously injure persons, animals,

plants, soil, and property.

▲ Inhaling smoke from any type of

chemical fire is a serious health

hazard.

▲ Store or dispose of unused

chemicals as specified by the

chemical manufacturer.

1/07/09

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

3

Page 6

Important Safety Information

Table of Contents

Land Pride

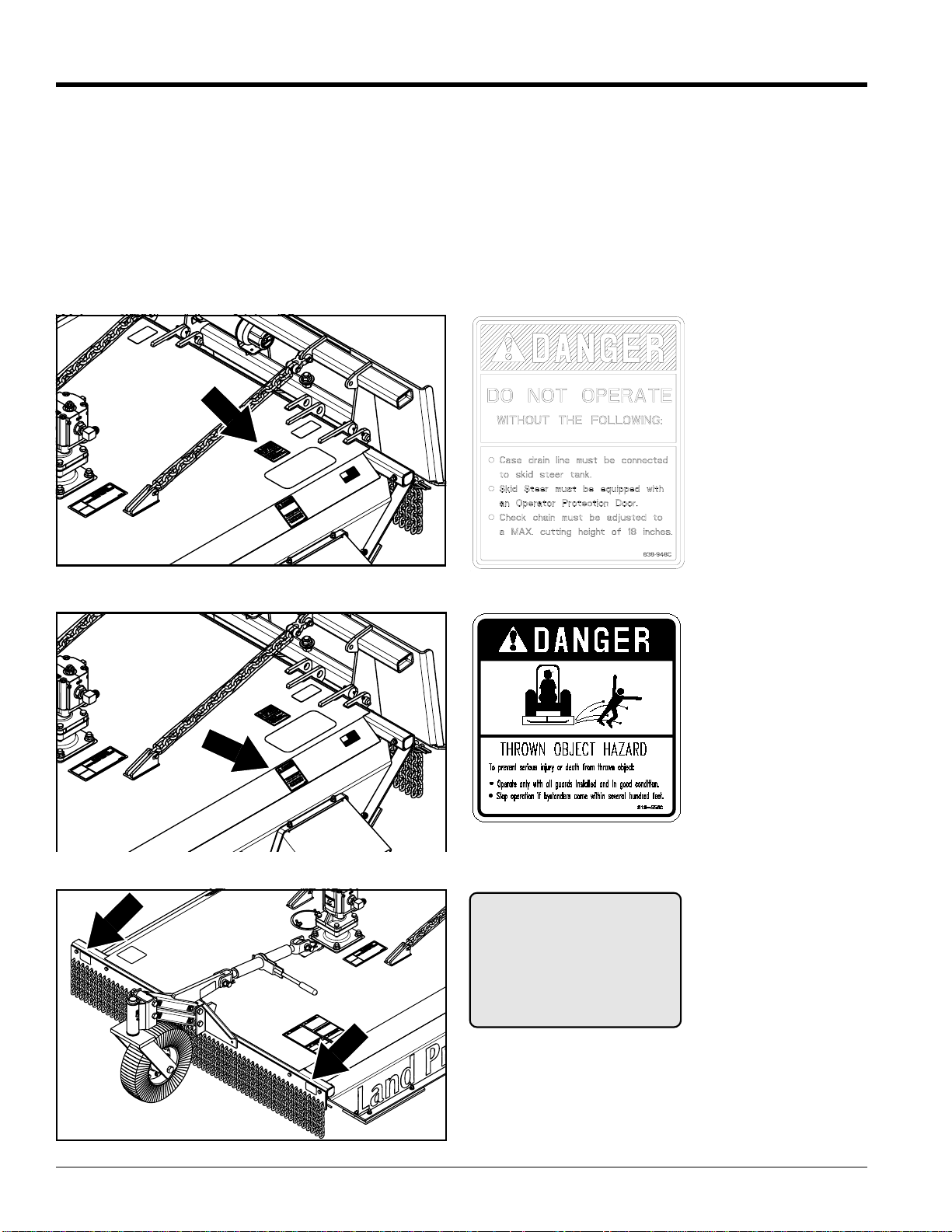

Safety Labels

YourRotary Cutter comes equippedwithallsafety labels

in place. They were designed to help you safely operate

your implement. Read and follow their directions.

1. Keep all safety labels clean and legible.

2. Replace all damaged or missing labels. To order new

labels go to your nearest Land Pride dealer or visit our

dealer locator at landpride.com.

3. Some new equipment installed during repair requires

safety labels to be affixed to the replaced component as

24539

specified by Land Pride. When ordering new components

make sure the correct safety labels are included in the

request.

4. Refer to this section for proper label placement.

To install new labels:

a. Clean the area the label is to be placed.

b. Spray soapy water on the surface where the label is to

be placed.

c. Peel backing from label.Pressfirmlyontothe surface.

d. Squeeze out air bubbles with the edge of a credit card.

838-948C

Danger: Do Not Operate

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

4

818-556C

Danger: Thrown Objects

24539

818-229C

Amber Reflector

24539

1/07/09

Page 7

Land Pride

Important Safety Information

Table of Contents

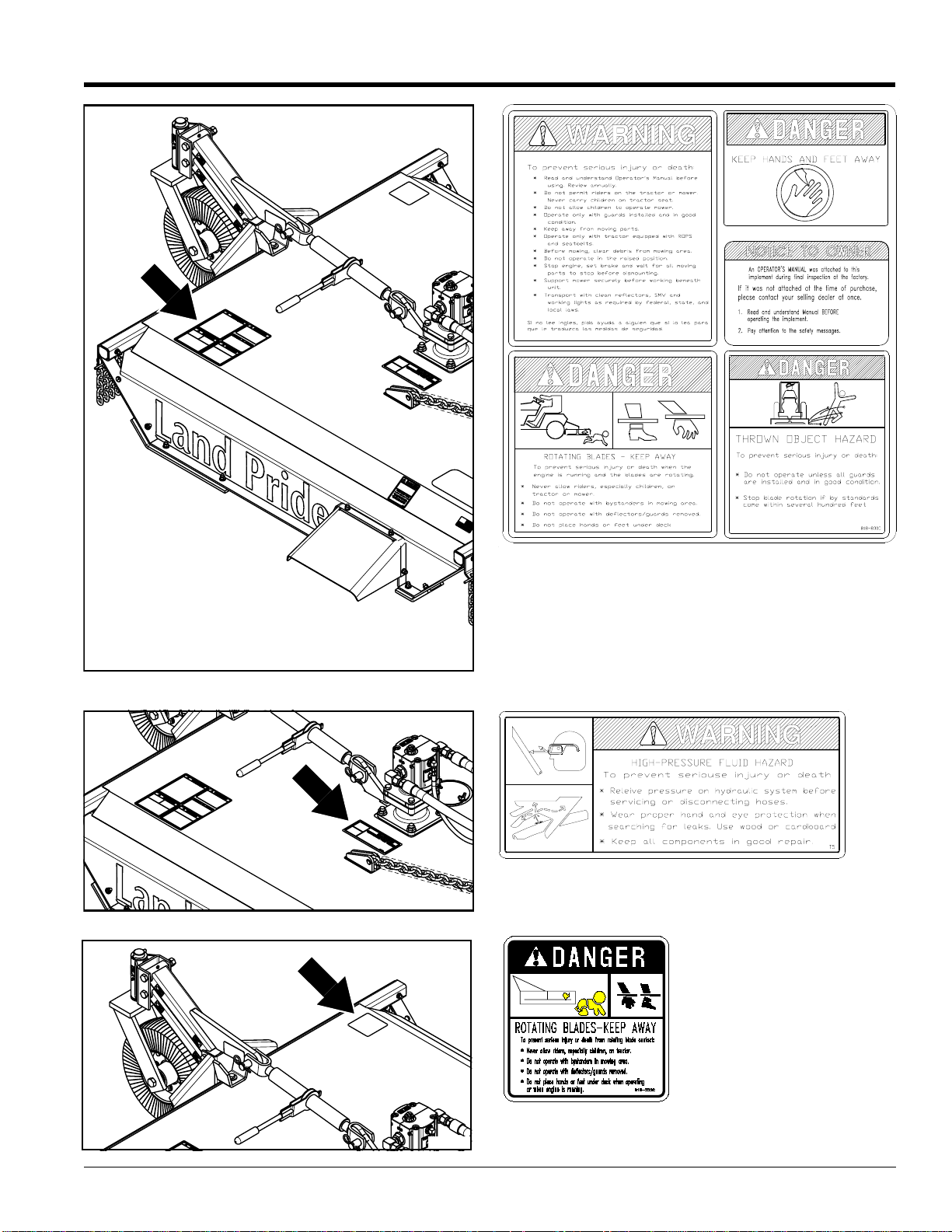

24538

24538

818-830C

Safety Combo

Danger: Keep Hands & Feet Away

Danger: Thrown Object Hazard

Danger: Rotating Blade Hazard

Warning: General Safety

Notice: Read Manual - Observe Safety Messages

818-831C

Warning: High Pressure

1/07/09

24538

818-555C

Danger: Rotating Blade Hazard

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

5

Page 8

Important Safety Information

Table of Contents

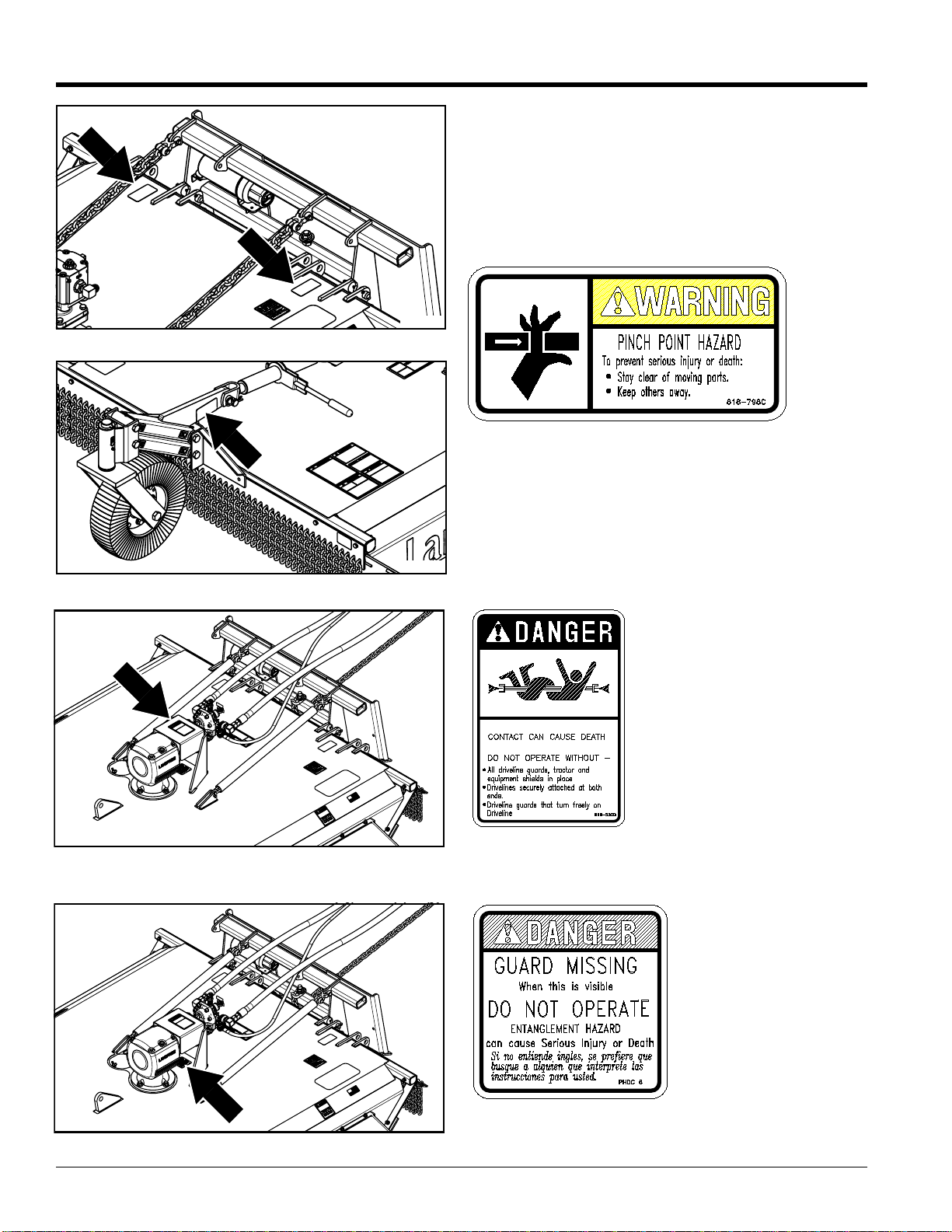

24539

818-798C

Warning: Pinch Point Hazard

3-Places

Land Pride

24539

25777

ROTATING DRIVELINE

KEEP AWAY!

818-552C

Danger: Rotating Driveline (SC2672 Only)

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

6

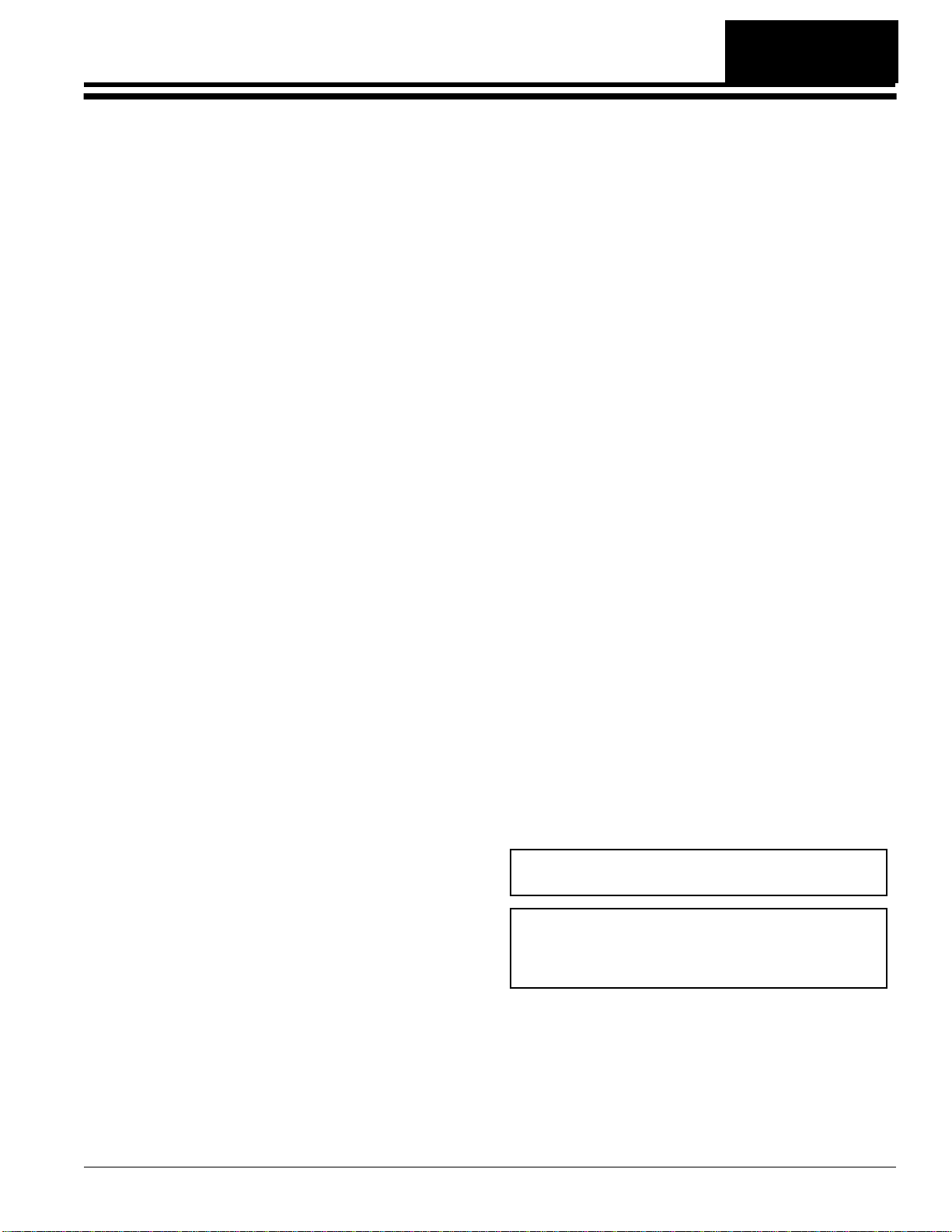

25777

818-543C

Danger: Guard Missing (SC2672 Only)

1/07/09

Page 9

Land Pride

Introduction

Introduction

Table of Contents

Land Pride welcomes you to the growing family of new

product owners.

ThisRotary Cutter has beendesignedwith care and built

by skilled workers using quality materials. Proper

assembly,maintenanceand safe operating practices will

help you get years of satisfactory use from the machine.

Application

The SC2660 and SC2672 Series Skid Steer Rotary

Cutters are built and designed by Land Pride for cutting

on gently sloping or slightly contoured right-of-ways,

pastures, set aside acres, and row crop fields. These

skid steer mounted cutters provide unparalleled access

to tightly restricted areas such as under fences, in and

around boxed in corner sections of corrals and out

buildings, vineyard and nursery rows, wooded lots, and

approaches to ditches and waterways. The 60" or 72"

cutting width, 8"offset capability to the right, 2" cutting

capacity, 1.5" to 18" cutting height range, and the

universal skid steer floating-hitch mounting plate make

the SC2660 and SC2672 highly versatile and easy to

use. The SC2660 is compatible with and designed for

attachment to skid steers having 1500 psi to 3000 psi

operating pressure and flow rates in the 11-15 gpm,

15-21 gpm, or 18-27 gpm ranges. The SC2672 is

compatible with and designed for attachment to skid

steers having 1500 psi to 3000 psi operating pressure

and flow rates in the 15-21 gpm, or 18-27 gpm ranges.

The SC2660 and SC2672 provide very high and clean

cutting blade tipspeeds but owner/operatorswill need to

select the motor that is appropriately matched to their

skid steers hydraulic flow and pressure capabilities. Our

low volume motor, which is available on the SC2660

only, produces a blade tip speed of 18,540 fpm at

15 gpm. Medium volume and high volume motors are

available for both models. On the SC2660, our medium

volume motor produces 18,850 fpm at 21 gpm, and our

high volume motor produces 19,000 fpm at 27 gpm. On

the SC2672, our medium volume motor produces

17,200 fpm at 21 gpm, and our high volume motor

produces 18,550 fpm at 27 gpm. Each unit is equipped

with two 1/2" x 4"updraft blades and a heavy duty round

pan stump jumper. A deflector chute is located tothe left

rearsideofthecuttertopreventcloggingin heavy cutting

conditions.

The SC2660 and SC2672 come standard with a front

mounted single row chain guard, a rear mounted double

row chain guard, and a safety chain to restrict deck lift

height. Four corner-mounted skid shoes are provided to

reducewear and to keepthecutterfrom bottoming out. A

Lexan protective cab door is available as optional

equipment or owner/operators may choose to use a

protective door provided or made available by their skid

steer supplier/manufacturer.

A pivoting and adjustable front mounted gauge wheel

with a single laminated tire is available to make mowing

even easier by pre-setting the mowing height and

allowing the cutter to float over uneven terrain. Hydraulic

hoses and a case-drain line are provided as standard

equipment but compatible couplersfor attachment tothe

individual skid steersauxiliary hydraulic outletswill need

to be provided by dealers or customers.

The addition of a Land Pride SC2660 or SC2672 Skid

Steer Rotary Cutter to your arsenal of skid steer

attachments will dramatically increasethe versatility and

value of your personal skid steer investment.

See “Section 6: Specifications & Capacities” on page

28 and “Section 7: Features and Benefits” on page 29

for additional information and performance enhancing

options.

Using This Manual

This Operator’s Manual is designed to help familiarize

•

you with safety, assembly, operation, adjustments,

troubleshooting, and maintenance. Read this manual

and follow the recommendations to help ensure safe

and efficient operation.

• The information contained within this manual was

current at thetime of printing. Some partsmay change

slightly to assure you of the best performance.

• To order a new Operator’s or Parts Manual contact

your authorized dealer. Manuals can also be

downloaded, free-of-charge from our website at

www.landpride.com.

• Store your Operator’smanualin the dry storage tubefor

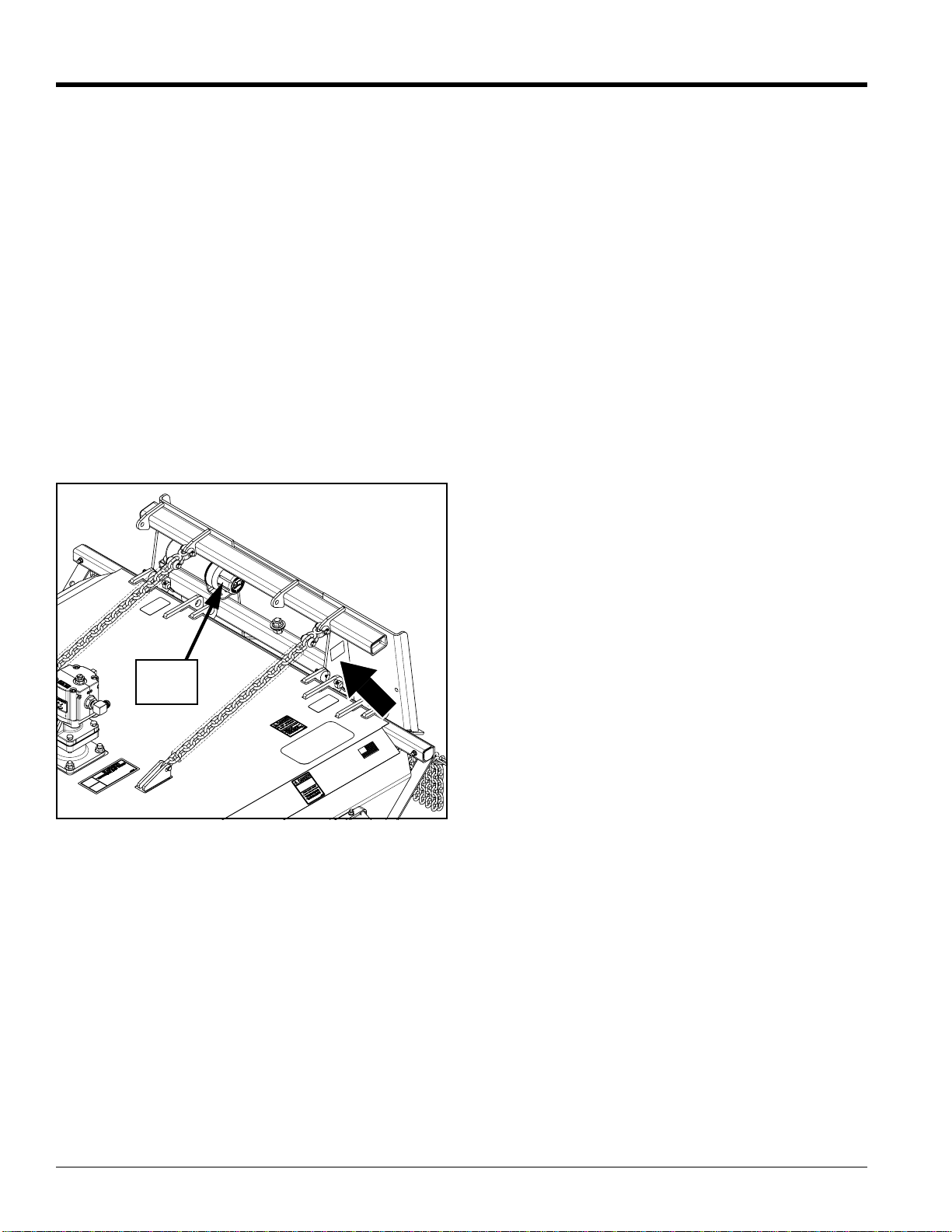

future reference. See Figure 1 on page 8 for location of

storage tube.

Terminology

“Right” or “Left” as used in this manual is determined by

facing the directionthe machine will operate while in use

unless otherwise stated.

Definitions

NOTE: A special point of information that the

operator must be aware of before continuing.

IMPORTANT: A special point of information related

to its preceding topic. Land Pride’s intention is that

this information should be read and noted before

continuing.

1/07/09

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

7

Page 10

Introduction

Table of Contents

Land Pride

Owner Assistance

The Warranty Registration card should be filled out by

the dealer at the time of purchase. This information is

necessary to provide you with quality customer service.

If customer service or repair parts are required contact a

LandPridedealer. A dealer has trained personnel, repair

parts and equipment needed to service the Rotary

Cutter.

The parts on your Rotary Cutter have been specially

designedandshouldonlybe replaced with genuine Land

Pride parts. Therefore, should your cutter require

replacement parts go to your Land Pride Dealer.

Serial Number Plate

For prompt service always use the serial number and

modelnumber when ordering partsfromyour Land Pride

dealer.Besuretoincludeyourserialandmodel numbers

incorrespondence also. Refer to Figure 1forthelocation

of your serial number plate.

24544

Further Assistance

Your dealer wants you to be satisfied with your new

Rotary Cutter. If for any reason you do not understand

any part of this manual or are not satisfied with the

service received, the following actions are suggested:

1. Discuss the matter with your dealership ser vice

manager making sure he is aware of any problems

youmay haveand that he has had the opportunity to

assist you.

2. If you are still not satisfied, seek out the owner or

generalmanagerof the dealership,explainthe problem

and request assistance.

3. For further assistance write to:

Land Pride Service Department

1525 East North Street

P.O. Box 5060

Salina, Ks. 67402-5060

E-mail address

lpservicedept@landpride.com

Manual

Storage

Tube

Serial Number Plate Location

Figure 1

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

8

1/07/09

Page 11

Land Pride

Table of Contents

Section 1: Assembly & Set-up

Section 1: Assembly & Set-up

Skid Steer Requirements

The Rotary Cutter is designed to attach to Skid Steer

Loaders with the following minimum requirements:

SAE Lift Capacity

SAE Lift Capacity . . . . . . . . . . . . . . . . . . . . .1200 lbs.

Operating Hydraulic Pressure

Hydraulic Pressure Rating . . . . . . . 1,500 - 3,000 PSI.

Hydraulic Flow Rate

Low Volume Motor & Hoses . . . . . . . . . 11 - 16 GPM.

Medium Volume Motor & Hoses . . . . . . 17 - 21 GPM.

High Volume Motor & Hoses. . . . . . . . . 22 - 27 GPM.

Hydraulic Connections

Hydraulic Hoses. . . . . . . . . . . . .2 - Hydraulic Outlets

Case Drain Hose . . . . . . . . . . . . .1 - Hydraulic Outlet

Read and understand the operator’s manual for your

cutter. An understanding of how it works will aid in the

assembly and setup of your cutter.

This Rotary Cutter has been partially assembled at the

factory. However, some assembly will be necessary.

It is best to go through the Pre-Assembly Checklist

before assembling the cutter. Speed up your assembly

task and make the job safer by having all the needed

parts and equipment readily at hand.

Ensure that the intended Skid Steer conforms to the

requirements stated under the heading “Skid Steer

Requirements” on page 9.

Uncrating

IMPORTANT: Skid Steer must be equipped with a

case drain system.

Protective Equipment

The Skid Steer MUST be equipped with a protective

doorshield. A universal operator protective door shield

is available from Land Pride. Refer to Page 13 and 22

for additional information and installation.

IMPORTANT: Ballastmay need tobe added to your

Skid Steer to maintain steering control and to

preventtipping of the Skid Steer. Refer to your Skid

Steer’s operator manual to determine if additional

ballast is needed.

Dealer Preparations

Pre-Assembly Checklist

All hardware from the factory has been installed. If a

part or fastener is temporarily removed for assembly

reasons, remember where it goes. Keep parts

separated.

Be sure the parts get used in the correct location. By

double checking while you assemble, you will lessen

the chance of using a bolt incorrectly that may be

needed later. Use Parts Manual to identify location of

parts you are unsure of where they are used.

All grease fittings are in place and lubricated.

!

Do notremovecutter fromcrateuntilafterithasbeensecurely

supported with an overhead crane, fork lift or other suitable

equipment. Cutter can fall and injury someone if crating

hardware is removed before properly supporting the deck.

1. Securedeck with an overheadcrane, fork liftorother

2. Cut bands securing parts bags to the shipping crate.

3. Remove bolts securing hitch to the shipping crate.

4. Cut center band securing hitch to shipping crate.

5. Carefully lower cutter onto its skids or onto support

6. Remove wood from under the front chain guard.

DANGER

suitable means before cutting shipping support

bands and unbolting cutter from shipping crate.

stands capableof supporting the cutter.

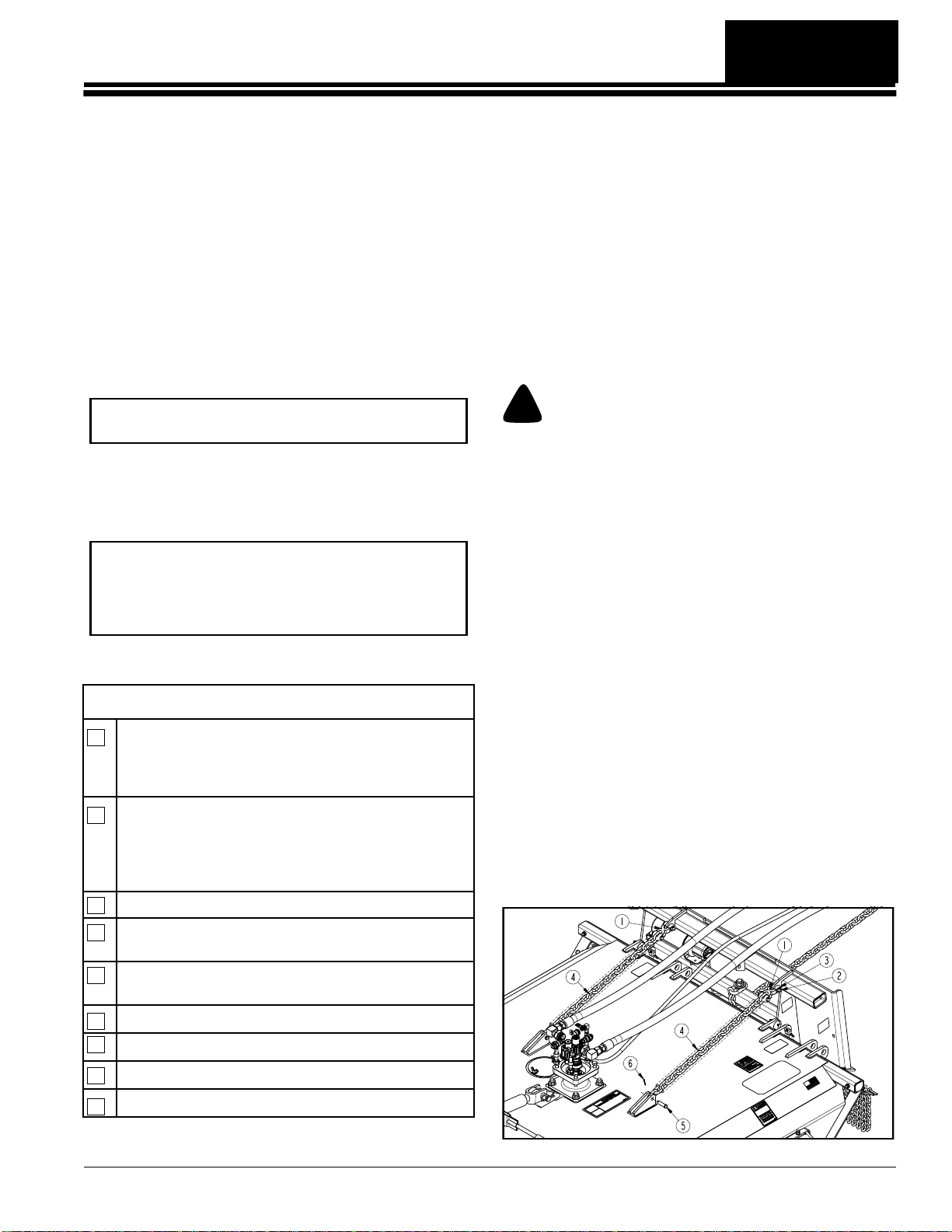

Float Chain Assembly

Refer to Figure 1-1:

1. (Not Shown) Unbolt andremoveshippingbrace bars

extending from hitch plate to center of deck.

2. Attach clevisend (#1) of float chains (#4) to hitch plate

with 9/16" clevis pins (#2) and cotter pins (#3). Bend

cotter pin legs to keep them from fallingout.

3. Install other end of float chains (#4) to deck with

1/2" clevispins (#5) and 1/8" cotter pins (#6). Bend

cotter pin legs to keep them from fallingout.

Miscellaneous assembly tools: hammer, tape measure,

assortment of wrenches and spirit level.

Have fork lift or loader along with chains and safety

stands sized for the job ready for the assembly task.

Auxiliary weights (depending on Skid Steer size).

Have a minimum of 2 people at hand while assembling.

Safety decals are legible and undamaged.

Loose parts bag/box shipped with the Rotary Cutter.

1/07/09

Figure 1-1

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

9

Page 12

Section 1: Assembly & Set-up

Table of Contents

Land Pride

SC2660 Motor And Hose Assembly

Your Skid Steer Rotary Cutter is factory supplied with

one of three motors mounted tothe deck. Makesure you

check GPM rating on the hydraulic motor decal to verify

if it matches your Skid Steer’s GPM rating. Skip

assembly instructions below if the motor GPM rating

matches your Skid Steer.

See “Motor and Hose Assembly” on page 21 to properly

select a motor that matches your Skid Steer.

Refer to Figure 1-2:

1. Remove fasteners (#1, 2, 3 & 4). Keep fasteners for

reassembly of new motor.

2. Removeexistingmotorandhoseassembly(#5).Clean

old gasketmaterial (#6) from gearbox flange (#7).

3. Place new gasket (#6) onto gearbox flange (#7).

4. Gently lower new motor and hose assembly (#5) onto

gasket (#6) with hoses extending towards the hitch

plate.

5. Secure hydraulicmotorassemblywith the fourexisting

1/2"-13 x 2 1/4" lg. GR 5 hex head bolts (#1), flat

washers (#4), lock washers (#3) and 1/2"-13 hex huts

(#2). Tighten nuts to the correct torque. See “T orque

V aluesChart” on page 31.

Refer to Figure 1-3:

1. Remove fasteners (#9 & #10) and coupling

guard (#8). Keep fasteners and coupling guard for

reassembly of new motor.

1. Remove fasteners (#1, 2, 3 & 4). Keep fasteners for

reassembly of new motor.

2. Removeexistingmotorandhoseassembly(#5).Clean

old gasketmaterial (#6) from mounting flange (#7).

3. Place new gasket (#6) onto mounting flange (#7).

4. Gently slide new motor and hose assembly (#5) onto

coupling (#12) with hoses extendingtowardsthe hitch

plate.

5. Secure hydraulicmotorassemblywith the fourexisting

1/2"-13 x 2 1/4" lg. GR 5 hex head bolts (#1), flat

washers (#4), lock washers (#3) and 1/2"-13 hex huts

(#2). Tighten nuts to the correct torque. See “T orque

V aluesChart” on page 31.

6. Reattach coupling guard (#8) with 5/16" spring lock

washers (#10) and 5/16"-18 x 3/4" GR5 hex head cap

screws (#9). Tighten nuts to correct torque.

Decal Location

Stating Motor

GPM Rating

24545

SC2660 Motor and hose Assembly

Figure 1-2

SC2672 Motor And Hose Assembly

Your Skid Steer Rotary Cutter is factory supplied with

one of three motors mounted tothe deck. Makesure you

check GPM rating on the hydraulic motor decal to verify

if it matches your Skid Steer’s GPM rating. Skip

assembly instructions below if the motor GPM rating

matches your Skid Steer.

See “Motor and Hose Assembly” on page 21 to properly

select a motor that matches your Skid Steer.

Decal Location Stating

Motor GPM Rating

SC2672 Motor and hose Assembly

Figure 1-3

SC2672 Vent Plug With Dipstick

IMPORTANT: Ref. Figure 1-4. A solid plug is

shippedwith the gearbox to preventloss of oil during

shipping and handling. Before operating the cutter,

this plug must be replaced with the vent plug and

dipstick included with this manual.

Vented Plug

WithDipstick

20822

Figure 1-4

Oil Level

Plug

DO NOT

OVERFILL

25732

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

10

1/07/09

Page 13

Land Pride

Section 1: Assembly & Set-up

Table of Contents

Hitch Hook-Up

Refer to Figure 1-5:

!

Do not stand between SkidSteer loader and implement during

hookup.

1. Make sure hydraulic hoses and height adjustment

2. Drive Skid Steer slowly to the Rotary Cutter making

3. Tilt top of Skid Steer hitch plate slightly forward.

4. Place top of Skid Steer hitch plate under the Rotary

5. Slowly lift Skid Steer’s hitch until Rotary Cutter’s hitch

6. Push lock handles of the Skid Steer down so that the

7. Loop height adjustmentsafetychainforwarddownand

CAUTION

safety chain do not interfere with hitch hook-up.

sure the front hitch plate of the Skid Steer is parallel

with the Rotary Cutter hitch.

Cutter top angle bar.

and Skid Steer’s top angle bar havecome together .

pins go through the bottom slots of the Rotary Cutter’s

hitch and the handles lock down.

under2" x 3" tubeand then attach toSkidSteer’slower

hitch loop.See “Height Adjustment Safety Chain” on

page 15.

Hydraulic Hose Hook-up

Refer to Figure 1-5:

Two high pressure hydraulic outlets are required for the

hydraulic motor hoses and one outlet for the case drain

hose.

!

Hydraulic fluid under pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin, it must be treated by a

doctor within a few hours or gangrene may result.

1. Remove plastic cap fromcase drain hoseandattach

2. Connect case drain hose to reservoir outlet.

3. Connect male and female couplers on the hydraulic

4. Operate skid steer to check blade rotation. Cutter

DANGER

hydrauliccoupler (supplied by customer)tothe hose.

motor hoses to the Skid Steer high pressure outlets.

blades should rotate clockwise when looking at the

blades from above. If cutter blades are rotating

counterclockwise, switch male and female couplers

and reconnect to skid steer outlets.

24538

1/07/09

Clockwise

Blade Rotation

Rear Skid Shoe

Skid Steer Hook--Up

Figure 1-5

Case Drain Line

Male Coupler

Top Angle Bar

Bottom Slots

Height Adjustment Safety Chain

(Attach to Skid Steer’s lower hitch loop.)

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

Female Coupler

11

Page 14

Table of Contents

Section 1: Assembly & Set-up

Gauge Wheel Assembly (Optional)

Required Tools:

• 1 ea. - Small hammer

• 2 ea. - 1/2" drift punches or alignment tools

• 2 ea. - 9/16" box end wrench

• 2 ea. - 3/4" box end wrench

• 1 ea. - Torque wrench with 9/16" and 3/4" sockets

Assembly Instructions:

Refer to Figure 1-6:

.

IMPORTANT: Do not enlarging any of the 5 bolt

holes used for mountingthe gauge wheel. Enlarging

bolt holes can severely decrease the longevity of

your gauge wheel operation.

1. Removefour3/8"-16 x3"lg.GR5 hexheadbolts (#2)

in the center of the front chain guard. Keep bolts,

washers and whiz nuts for reassembly of gauge

wheel arm (#1).

2. Install gauge wheel deck mount (#1) by inserting

1/2" x 3 3/4" lg. GR8 bolt (#3) through 1/2" flat

washer (#8), gauge wheel mounting bracket (#1) and

deck tube. Secure bolt with 1/2" flat washer (#8), lock

washer(#7) and hexnut (#4). Do not torque nutat this

time. Finger tighten nut only.

Land Pride

3. Checkalignmentofgaugewheel frontmountholeswith

chain guard holes. Skip to step 4 if mounting holes are

in alignment. If gauge wheel mounting holes are not in

alignment, loosen remaining chain guard bolts and

realign chain guard as follows .

a. Realign chain guard by inserting drift punches in

the outer two gauge wheel mounting holes. Tap

punches in with a hammer until secure. Do not

remove punches at this time.

b. Insert 3/8"-16 x3" lg. GR5 bolts (#2) with 3/8" flat

washers (#6) through the two inside holes.

Secure bolts with 3/8" whiz nuts (#5). Tighten

bolts to 31 ft-lbs.

c. Remove left hand drift punch and install

3/8" x 3" lg. GR5 hex bolt (#2), flat washer (#6)

and whiz nut (#5). Tighten 3/8" bolt to 31 ft-lbs.

d. Remove right hand drift punch and install

3/8" x 3" lg. GR5 hex bolt (#2), flat washer (#6)

and whiz nut (#5). Tighten 3/8" bolt to 31 ft-lbs.

e. Tighten remaining chain guard bolts to 31 ft-lbs.

f. Skip to step 5.

4. If gaugewheel mounting holesare in alignment,Install

four 3/8" x 3" lg. GR5 hex bolts (#2), flat washers (#6)

and whiz nuts (#5). Tighten 3/8" bolts to 31 ft-lbs.

5. Tighten 1/2" gauge wheel top bolt (#3) to 76 ft-lbs.

6. Attach heavy duty ratchet jack (#14) to cutter frame

andtogaugewheeldeckmount(#1)with1"x33/16"lg

clevis pins (#11). Secure with hair pin cotters (#10).

7. Insertfour1 1/2"I.D.machinewashers(#9)overgauge

wheel spindle (#13).

8. Insert gauge wheel spindle (#13) through yoke in

gauge wheel deck mount (#1) and 1 1/2" I.D. machine

washer (#9). Secure gauge wheel with 3/8" x 2 1/2" lg.

roll pin (#12).

Gauge Wheel Assembly

Figure 1-6

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

12

24547

1/07/09

Page 15

Land Pride

Table of Contents

Section 1: Assembly & Set-up

Skid Shoe Assembly (Optional)

Refer to Figure 1-7:

Cutters ordered with skid shoes are shipped loose.

Install skid shoes as follows:

1. Raise the Rotary Cutter 3" or more off the ground

andplacesupport blocksunderthecutter.Makesure

support blocks are positioned so they will not

interfere with skid shoe installation.

2. Lower cutter onto support blocks, place Skid Steer in

park, set park brakes,shut Skid Steer off and remove

switch key.

3. Install shortskidshoe (#2) to the backleftdeckcorner

as shown with 3/8”-16 x 1 1/4 GR5 plow bolts (#2), flat

washers (#6), lock washers (#5) and 3/8" lock nuts

(#4). Torque lock nuts (#4) to 31 ft-lbs.

4. Install longskid shoes (#1) to the remaining threedeck

corners with 3/8”-16X1 1/4 GR5 plow bolts (#2), flat

washers(#6),lock washers(#5)and3/8"locknuts(#4).

Torque lock nuts (#4) to 31 ft. lbs.

5. Raise cutter up and remove support blocks.

Operator Protective Door (Optional)

Refer to Figure 1-8:

!

Do not drill holes in the ROPS (Roll Over Protection System)

to attach this Operator Protective Door. Drilling unapproved

holes in the ROPS can weaken the structure and void its

warranty.

1. Cut notches in protective door as needed to provide

2. Install Operator ProtectiveDoor to the Skid Steer’s

WARNING

clearance around u-bolts and Skid Steer frame.

hand hold with two u-bolts (#3), flat bars (#2) and four

nuts (#1) as shown. Tighten nuts to correct torque.

24546

Skid Steer

Hand Hold

Skid Shoe Replacement

Figure 1-7

If needed,Locate & Cut

Notches in Door For

U-bolts Clearance.

Hook Elastic Tie-Down

To Skid Steer Cage To

Keep Door Closed.

If Needed, Locate

& Cut Notch in

Door To Clear Skid

Steer Frame.

1/07/09

Operator Protective Door

Figure 1-8

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

24608

13

Page 16

Table of Contents

Section 2: Adjustments

Section 2: Adjustments

Hitch P ositioning

Refer to Figure 2-1:

TheRotaryCutterhitchis designed to be centered on the

cutter or offset to position the cutter to the right.

Offsetting the cutter to the right will allow the unit to cut

close to obstacles.

Hitch Mounted Offset

1. Align hitch pivot pin bushings (#3) with cutter

mounting lug holes (A1).

2. Insert hitch pivot pins (#7) through mounting lug holes

(A1) and hitch bushings (#3).

3. Secure pivotpins bydriving roll pins (#6) through pivot

pin holes.

4. Attach Floating Chains (#4) to hitch plate lugs at

positions marked (B1) with chain pins (#5).

5. Insertcotterpins(#2)throughchainpinholes and bend

one leg of each cotter pin to secure it in place.

Land Pride

Hitch Mounted Centered

1. Align hitch pivot pin bushings (#3) with cutter

mounting lug holes (A2).

2. Insert hitch pivot pins (#7) through mounting lug holes

(A2) and bushings (#3).

3. Secure pivotpins bydriving roll pins (#6) through pivot

pin holes.

4. Attach Floating Chains (#4) to hitch plate lugs at

position (B2) with chain pins (#5).

5. Insertcotterpins(#2)throughchainpinholes and bend

one leg of each cotter pin to secure it in place.

24548

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

14

Hitch Offset

Figure 2-1

1/07/09

Page 17

Land Pride

Section 2: Adjustments

Table of Contents

Height Adjustment Safety Chain

!

Always secure cutter deck in the up position with solid

supports or by locking the hydraulics before working around

or under a raised deck. Never work under equipment

supported by hydraulics. Hydraulics can drop equipment if

controls are actuated or if hydraulic lines burst. Either

situation can dropthe cutter instantly even when power to the

hydraulics is shut off.

Do not raise cutter higher than 16 1/2" offtheground.Raising

cutter higher can cause serious bodily injury and/or death.

Use safety limit chain to limit cutter height.

Do not tilt hitch plate to raise front of cutter higher than the

rear. Raising front of cutter can cause serious bodily injury

and/or death.

WARNING

!

DANGER

!

DANGER

Refer to Figure 2-2:

For safety, the cutter rear skid shoes should not be

raised higher than 16 1/2" off the ground (18" Maximum

cutting height).

NOTE: Two people may be required to install and

adjust the safety chain.

1. Raise cutter’s rear skid shoes slightly less than

16 1/2" off the ground.

2. Run height adjustment safety chain from under the

2" x 3" hitch tube to the Skid Steer lower hitch loop.

Thread chain through the hitch loop and back towards

the hitch plate. Connect quicklink coupler to a chain

loop as shown.

3. Raise cutter up until the safety chain is tight. Check

height of rear skid shoes.

4. If rear skidshoesare higher than 161/2"aboveground

level,lowercutter and makenecessary adjustmentsto

the safetychain to limit rear skid shoe height to

16 1/2" maximum.

5. Tighten quick link coupler nut to secure safety chain.

24586

Gauge Wheel

Ratchet Jack

Nominal Cutting Height

Bottom of Rear

Skid Shoes

Figure 2-2

Cutter Hitch Plate

Quick Link Coupler

Height Adjustment

Safety Chain

16 1/2"

Maximum Lift

Ground Level

Skid Steer

Lower Hitch Loop

1/07/09

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

15

Page 18

Table of Contents

Section 2: Adjustments

Deck Leveling with Optional Gauge Wheel

Refer to Figure 2-3:

!

Engage parking brake, disengage power to cutter, shut off

Skid Steer, remove key and ensure that all moving parts have

come to a complete stop before dismounting from the Skid

Steer.

DANGER

IMPORTANT: The bladesshould bepositioned to cut

material only at the front of the cutter. If the deck is

level or the rear of the cutter is lower than the front,

then the blades are subject to continuous material

flowresultingincuttingclumpsatthedischargechute,

horsepowerloss,high blade wear,and frequent blade

sharpening.

NOTE: Nominal Cutting Height is the distance

from bottom of cutter blade to ground level at the

front of the cutter. Subtract 1 1/2" from Nominal

Cutting Height to determine distance (A). Distance

(A) is measured from bottom of front skid shoes to

ground level.

Land Pride

1. Park Skid Steer with cutter on a level surface.

2. Adjust ratchet jackto raise gauge wheel up until it is

evenwith bottom of front skid shoes.

3. Use Skid Steer hydraulics to lower Skid Steer lift arms

and to tilt cutter hitch plate angle until bottom of skid

shoe at the front deck corner is dimension (A) off the

groundandtherear deckcorner isslightlyhigheroffthe

ground than the front deck corner.

4. Adjust ratchet jackto lower gauge wheel until it is at

ground level.

5. With gauge wheel at ground level,use Skid Steer

hydraulics to adjust cutter hitch plate angle until the

float chain sags.

!

CAUTION

Do Not over angle hitch plate forward. Over angling can

cause damage to deck, hitch and gauge wheel.

The Rotary Cutter should be operated with gauge wheel

on the ground, slack in float chain and deck rear slightly

higher off the ground than deck front. As the operator

travels over uneven terrain, the Skid Steer hitch plate tilt

angle and lift arm height may need some readjusting to

maintain correct deck positioning.

Float Chain should sag when gauge wheel is

resting on level ground. Adjust hitch plate

tilt angle to put a sag in the Float Chain.

Gauge Wheel

A"

Nominal CuttingHeight is the

distance from bottom of the

front leading cutting blade to

ground level.

Ratchet Jack

Ground Level

A" is 1 1/2" less than Nominal Cutting Height

and is the distance from bottom of Skid Shoe

at the front deck corner to ground level.

Nominal Cutting Height

Figure 2-3

Cutter Hitch Plate

Height Adjustment

Safety Chain

The rear deck corner should be raised

slightly higher above ground level

than the front deck corner.

24585

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

16

1/07/09

Page 19

Land Pride

Table of Contents

Section 2: Adjustments

Deck Leveling without Optional Gauge Wheel

Refer to Figure 2-4:

!

Engage parking brake, disengage power to the cutter, shut off

Skid Steer, remove key and ensure that all moving parts have

come to a complete stop before dismounting from the Skid

Steer.

DANGER

IMPORTANT: The bladesshouldbepositioned to cut

material only at the front of the cutter. If the deck is

level or the rear of the cutter is lower than the front,

then the blades are subject to continuous material

flowresultingincuttingclumpsatthedischargechute,

horsepowerloss,high blade wear,and frequent blade

sharpening.

NOTE: Nominal Cutting Height is the distance

from bottom of cutter blade to ground level at the

front of the cutter. Subtract 1 1/2" from Nominal

Cutting Height to determine distance (A). Distance

(A) is measured from bottom of front skid shoes to

ground level.

1. Park Skid Steer with cutter on a level surface.

2. Use Skid Steer hydraulics to lower Skid Steer lift arms

and to tilt cutter hitch plate angle until bottom of skid

shoe at the front deck corner is dimension (A) off the

ground and the rear deck corner is slightly higher than

the front deck corner.

The Rotary Cutter should be operated with float chain

tight to hold the front of the cutter at the correct cutting

height and lift arms set to hold the rear of the cutter

slightly higher off the ground than the front. As the

operatortravels over uneven terrain,the Skid Steer hitch

plate tilt angle and lift arm height will need readjusting

often to maintain correct deck positioning.

A"

Nominal CuttingHeight is the

distance from bottom of the

front leading cutting blade to

ground level.

Float Chain is kept tight

A" is 1 1/2" less than Nominal Cutting Height

and is the distance from bottom of Skid Shoe

at the front deck corner to ground level.

Cutter Hitch Plate

Height Adjustment

Safety Chain

Ground Level

The rear deck corner should be raised

slightly higher above ground level

than the front deck corner.

24591

Nominal Cutting Height

Figure 2-4

1/07/09

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

17

Page 20

Table of Contents

Section 3: Operating Procedures

Section 3: Operating Procedures

Operating Information

Hazard control and accident prevention are dependent

upon the awareness, concern, prudence and proper

training involved in the operation, transport,

maintenance and storage of the Rotary Cutter.

Therefore, it is absolutely essential that no one operates

the Rotary Cutter without first having read, fully

understood and become totally familiar with the

Operator’s Manual. Make sure the operator has paid

particular attention to:

• Important Safety Information, page 1

• Section 1: Assembly & Set-up, page 9

• Section 2: Adjustments, page 14

• Section 3: Operating Procedures, page 18

• Section 5: Maintenance & Lubrication, page 23

The following inspections should be performed before

operating your Skid Steer cutter.

Inspection Checklist

Land Pride

!

WARNING

Do not operate Rotary Cutter without an operator protective

door mounted to the cab and protective eye wear such as

safety glasses or goggles. Flying objects from the cutter can

cause serious injury to the body and eyes.

!

WARNING

The SC2660 Rotary Cutter is designed to cut grass and brush

up to 2” in diameter.Using this cutter for another type of work

can damage the drive components, deck and support frame.

!

WARNING

Do not traveltoo fast. The rougherthe terrain, the slower you

must travel. Always travel at a speed slow enough to be able

to adjust the deck height before running it into the ground.

Remember, sudden dropping of the front tires can slam the

deck into the ground. Also, travel slow enough to stop before

running or turning into obstacles ahead and on either side.

✔ Check Reference

Make Sure all guards and shields are in place

and secure.

Inspect Hydraulic hoses for wear, damage

and hydraulic leaks. Replace damaged and

worn hoses with genuine Land Pride parts.

Grease all fittings. Refer to “Lubrication”

Check the Rotary Cutter initially and periodically

for loose bolts & pins,Torque Values Chart.

!

Rotary Cutters have the ability to discharge objects at high

speeds. Therefore, the use of front & rear deck safety shields

is required! Keep all bystanders at least 100 yards away.

Flying objects from the cutter can cause serious injury or

death.

Do not cut after dark without working lights. The equipment

can be damaged from hitting objects not seen in the dark and

from being hit by vehicles not able to see the equipment.

Cutter deck can be slippery especially when wet. Always step

on the anti grip pads when possible. Never hurry. Make sure

you have secure footing and hand hold when walking on the

deck.

Do not become entangled in the hydraulic hoses. Tripping

over the hoses while entering or exiting the Skid Steer

operator station can cause serious injury to the body.

CAUTION

!

CAUTION

!

CAUTION

!

WARNING

page 1

page 3

page 26

Page 31

!

Do not cut on steep inclines. The Skid Steer could flip over

causing damage to the equipment, serious injury or death.

Do not use deck to lift, push or pull objects. This can damage

the deck, cause serious injury or death.

Never carry a person on the cutter. A person can fall and be

ran over causing serious injury or death.

Do not use deck as a working platform. The deck is not

properly designed or guarded for this use. Using deck as a

working platform can cause serious injury or death.

Do not use deck as a fan. Cutting blades are not properly

designed or guarded for this use. Using the deck as a fan can

cause serious injury or death.

Do not operator the cutter with cutting blades raised higher

than 18" off the ground.Alwaysusetheheightadjusting safety

chain to limit cutting height to 18" (16 1/2" skid shoe height).

Raising the cutter higher canthrowdebris at the operator and

cause serious injury or death.

Shields must be secured in place when operating to avoid

injury or death from entanglement in rotating drivelines.

DANGER

!

DANGER

!

DANGER

!

DANGER

!

DANGER

!

DANGER

!

DANGER

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

18

1/07/09

Page 21

Land Pride

Table of Contents

Section 3: Operating Procedures

!

Hydraulic fluid under pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin, it must be treated by a

doctor within a few hours or gangrene may result.

DANGER

IMPORTANT: Shut off all power, disengage

auxiliary hydraulics, set park brake and remove

ignition key any time the Rotary Cutter is not

operating properly or needs adjustment.

IMPORTANT: Avoidcatching the hydraulic hoses on

brush, post, stumps, and other protrusions that

could damage and/or break them.

Transporting

3. If included, adjustgauge wheel tosupport deckfrontat

thepreferredheight and tilt hitch plate toputslackinthe

float chains.

4. Start the machine and engage hydraulic motor .Allow

severalseconds forcutter blades to become aligned

properly. If deck continues to vibrate after several

seconds, stop motor and inspect blades.

5. It is important to maintain correct hydraulic motor

speed. Loss of motor speed will allow the blades to

hinge backand result in ragged, unevencutting.

6. Ground speed depends on two things: the density of

thematerial being cut and sizeofSkidSteer.Neverrun

fast enough to overload the Skid Steer and/or cutter.

7. This cutter was designed to cut grass and medium

brushcutting on gently sloping or slightly contoured

right-of-ways, pastures, set aside acres, and row

crop fields.

!

When traveling on public roads whether at nightor during the

day, use accessory light and devices for adequate warning to

operators of other vehicles. Comply with all federal, state and

local laws.

1. Be sure to reduce ground speed when turning; and,

2. Select a safeground trav elspeed that is 20 m.p.h. or

3. Decrease transport speed when travelingov erroughor

4. When transporting Skid Steer and Rotary Cutter on a

CAUTION

leave enough clearance so the Rotary Cutter does

not contact obstacles such as buildings, trees or

fences.

lesswhentransportingfromoneareatoanother.When

travelingon roadways ,transport in such a way that

faster moving vehicles may pass you safely.

hilly terrain.

trailer:

• Use towing vehicle and trailer of adequate

capacity.

• Always drive up a ramp with heavy end uphill.

• Engage SkidSteer park brake andremove ignition

switch key once it is loaded.

• Secure Skid Steer Loader and attachment using

tie-downs and chains.

Cutting Instructions

NOTE: Your cutter is equipped with free swinging

cutting blades to reduce shock loads to the cutter

when striking an obstacle.

1. Thoroughly inspect the area to be cut for debris and

unforeseen objects. Mark any potential hazards.

2. Set Skid Steer hydraulic lift arms and hitch angle to

position the deck front at the preferred cutting height

and the deck rear slightly higher.

DO NOT OPERATE WITH

SKID STEER FRONT WHEELS OFF THE GROUND

Figure 3-1

!

WARNING

Refer to Figure 3-1:

DO NOT OPERATE CUTTER OR NAVIGATE TURNS WITH

FRONT WHEELS OF SKID STEER OFF THE GROUND.

OPERATING IN ABOVE FASHION WILL CAUSE DAMAGE

TO DECK, HITCH AND GAUGE WHEEL.

General Operating Instructions

It is absolutely essential that you read and understand

boththe operator’s manual forthe Land Pride SC2660or

SC2672 Skid Steer Rotary Cutter and the operator’s

manual for the Skid Steer unit you intend to attach it to

before attempting tooperate or cut with this combination

of equipment. You must be able to read, comprehend

and adhere to all safety warnings and decals in order to

avoid personal injury, fatalities, injury to others, or costly

damage to property and equipment. We highly

recommend that you be a skilled and competent Skid

Steer operator prior to attaching and attempting to use

the SC2660 or SC2672Skid Steer Rotary Cutter.If there

is any part of the information above or safe operating

procedures you do not understand, please contact your

nearest authorized dealer for a full explanation and

training session if necessary.

1/07/09

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

19

Page 22

Section 3: Operating Procedures

Table of Contents

Land Pride

Skid Steer Operating Instructions

Assuming you have met all of the above requirements

and taken them seriously, it is time to take the next step

and that is accomplished by dressing appropriately for

thetask.Youwillneedtoputon protective eye wear such

as safety glasses, goggles, or a face shield. A hard hat,

steel toed safety shoes, gloves, and hearing protection

are also highly recommended. Never wear loose fitting

clothing and you may want to put on a respirator or filter

mask to avoid breathing in dust, pollen, or agriculturally

used toxins that may be present.

The next stepis a static or non-running pre-inspection of

the Skid Steer unit. You will want to make sure that the

Skid Steer is equipped with a fully functioning ROPS

(Roll Over Protection System) which does include seat

belts and an operator safety enclosure. The cab must

alsobe equipped withanoperator protective door, which

may have been supplied with the Skid Steer unit. Land

Pride does offer a protective door with the SC2660 and

SC2672if one is notalreadyprovided.If the Skid Steeris

to be operated on local roadways, it must be equipped

with appropriate Slow Moving Vehicle (SMV) and other

required lighting packages so as to make it compliant

with state and local department of transportation

requirements.Thecutterdrivemotor must be matched to

the output of the hydraulic capacity of the Skid Steer.

Failure to do thiscould result inserious over-speeding of

the cutting unit possibly resulting in serious injury,

fatalities or property damage. The universal quick-hitch

mount should be in good working order and latches

should be located to the open position. There should be

no evidence of hydraulic leaks in and around the

auxiliary hydraulic couplers. There must be a readily

accessible attaching point for the Rotary Cutter lift-limit

chain on the lower front portion of the chassis frame.

Finally make surethat all shields and safety features are

in place and fully functional.

The next step is to perform a running check of the Skid

Steer unit. As you get onto the Skid Steer and into the

operator’ compartment always use factory provided

hand-holds and don’t grab the steering or control levers

toeaseorstabilizeyourentry.Fasten your seat belt once

you are seatedand begin tomentally orient yourself with

the position of all controls, switches, pedals, levers, and

their related functions. Once you are sure that the park

brake is on, no people or animals are in close proximity,

all control levers, pedals and hydraulic systems are in

neutral position, go ahead and startthe engine. With the

enginenowrunningandthethrottleat approximately one

third, test all controls to make sure they are fully

functioning. If at any time there is an equipment failure,

shut the unit down and make immediate and full repairs.

Rotary Cutter Operating Instructions

Assuming all systems with the Skid Steer are “go” and

fully functioning, it is time to connect to the SC2660 or

SC2672 Rotary Cutter. This is done by maneuveringthe

Skid Steer mounting plate into position under the

universal quick mount hitch saddle. Once this is

accomplished and the mower is fully supported by the

Skid Steer lift arms, lower the mower to a point

approximately two inches above the ground. Turn the

engineoff,setthe parking brake, and climb out of theSkid

Steer. Lock the latch handles down to engage the hitch

pins. Make the appropriate hydraulic connections to the

auxiliary hydraulic outlet and case drain making sure to

keep connectors clean. Be sureto use proper fittings and

if connection is difficult, moving levers may help relieve

line pressure. (Note! Hydraulic flow direction on all skid

steers is not the same. Make sure hoses are connected

properly or blades will rotate at a much slower speed.)

Wipe away spilled or excess hydraulic oil and secure

Cordura sleeves to contain potential leaks. Connect the

height limiting safety chain to the chassis attaching point

and restrict cutting height to no more that eighteen

inches. This completes theattachment of thecutter to the

Skid Steer.

The next step is to complete a pre-operation check of the

cutter. Make sure all guards, safety shields, safety

chains, and deflectors are in place. All hardware must be

in place and appropriately tightened. Damaged, severely

worn or defective parts must be replaced prior to

operation. If your unit is equipped with the optional front

mounted gauge wheel, you will want to adjust it for

desired cutting height at this time.

You should always inspect the area where you intend to

cutfor debris and hazardslocated on the ground.Noone,

including people and animals, should be allowed within

100 yards of this cutter when in operation. If someone

does approach, shut the cutter down immediately. The

blades on this cutter should never be allowed to come in

contact with objects such as wire, cable, rope, or chains

that might become entangled. These types of entangled

objects can become extremely hazardous by rotating

outside of the cutter deck housing resulting in serious

injury or death. Always inspect the area before you mow.

The best mowing results will be achieved at speeds

between 2 mph and 5 mph as grounds and mowing

conditions dictate. If you are mowing in particularly tall or

dense brush, you may want to make two passes with the

first pass being at 18" and the second pass made as a

cross-cut at the desired cut height. If you are mowing

without the benefit of the front mounted gauge wheel in

the float position, you will probably need to slow down

significantly especially over uneven terrain or furrows.

Driving too fast over uneven ground will cause the unit to

undulate in a forward pitching motion. The best advice is

to drive slow but keep engine speed and blade tip speed

high. Once you get the feel of it you can increase speed

and productivity.

When you do need to stop, make sure you set the park

brake, shut the Skid Steer engine off, and allow time for

the blades to stop rotating before you climb down. With a

little practice we are confident you will soon achieve safe

andexcellentresultswithyournewLandPride SC2660 or

SC2672 Skid Steer Rotary Cutter.

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

20

1/07/09

Page 23

Land Pride

Table of Contents

Section 4: Optional Equipment

Section 4: Optional Equipment

Front Mounted Gauge Wheel

Refer to Figure 4-1:

The Front mounted gauge wheel will aid in floating the

cutter over uneven terrain making the operator’s job

easierand helps protect againstrunning the cutter frame

into the ground.

Gauge Wheel Assembly . . . . . . . . . . . . . . . 326-004A

24549

Gauge Wheel Assembly

Figure 4-1

Skid Shoe Bundles

Refer to Figure 4-2:

Thereare two skid shoebundlesavailable. The standard

skid shoe bundle is constructed of 1/4" x 2" flat bar and

theheavy skid shoebundleis constructed of 3/8"x 3" flat

bar.Theheavyskid shoes will wear longer andwithstand

more abuse.

Standard Skid Shoe Bundle. . . . . . . . . . . . .326-027A

Heavy Skid Shoe Bundle . . . . . . . . . . . . . . .326-028A

Motor and Hose Assembly

Refer to Figure 4-3:

There are three motor and hose assembly options to

meet your Skid Steerrequirements. All threeassemblies

are interchangeable and do not require adapter kits.

Compare your motor’s GPM rating located on an

attached decal with the GPM ratings below:

Low Volume Motor & Hoses. . . . . . . . . . 11 - 16 GPM

Medium Volume Motor & Hoses. . . . . . . 17 - 21 GPM

High Volume Motor & Hoses . . . . . . . . . 22 - 27 GPM

24588

Skid Shoe Bundle

Figure 4-2

If your cutter’s motor and hose assembly is not

compactible with your Skid Steer, you should replace it

with one of the following assemblies:

Low Volume Motor & Hoses Assy . . . . . . . 326-013A

Medium Volume Motor & Hoses Assy . . . . 326-014A

High Volume Motor & Hoses Assy. . . . . . . 326-015A

1/07/09

Motor and Hose Assembly

Figure 4-3

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

24587

21

Page 24

Table of Contents

Section 4: Optional Equipment

Extended Hose Kit

Refer to Figure 4-4:

Some Skid Steer hydraulic connections are located

farther away from the motor. Standard set-up includes

two 80" long hoses and one 82" long return hose. The

ExtendedHoseKitincludestwo116"longhosesandone

118" long return hose.

Extended Hose Kit . . . . . . . . . . . . . . . . . . . .326-016A

Land Pride

24589

Extended Hose Kit

Figure 4-4

Operator Protective Door

Refer to Figure 4-5:

The Skid Steer MUST be equipped with an operator

protective door for shielding against flying debri when

attachedtoaRotaryCutter. Land Pride offers a universal

shield that attaches to your Skid Steer’s hand hold with

twou-bolts. Some notching intheshield may be required

to fit your particular Skid Steer model. See “Operator

Protective Door (Optional)” on page 13 for additional

information.

Protective Door Kit. . . . . . . . . . . . . . . . . . . .326-024A

24609

Operator Protective Door

Figure 4-5

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

22

1/07/09

Page 25

Land Pride

Table of Contents

Section 5: Maintenance & Lubrication

Section 5: Maintenance & Lubrication

Maintenance

Proper servicing and adjustment is the keyto the long life

of any implement. Withcareful and systematic inspection,

you can avoid costly maintenance, time and repair.

After using your Rotary Cutter for several hours, checkall

bolts to be sure they are tight.

Replace any worn, damaged or illegible safety labels by

obtaining new labels from your Land Pride Dealer.

Cutter Blade Maintenance

!

Always disconnect hydraulic hoses fromthe Skid Steer before

servicing underside of deck.The motor can be engagedif Skid

Steer is started resulting in possible damage to the cutter,

bodily injury and/or death.

Always secure the cutter deck in the up position with solid

supports before servicing the underside. Never work under

equipment supported by hydraulics. Hydraulics can drop

equipment if controls are actuated or if hydraulic lines burst.

Either situation can dropthe cutter instantly even when power

to the hydraulics is shut off.

Always inspect cutting blades before each use. Make

certain they are properly installed and are in good

working condition. Replace any blade that is damaged,

worn, bent, or excessively nicked. Small nicks can be

ground out when sharpening.

Removecutting blades and sharpen or replace asfollows:

1. Align blade bolt with access hole in deck.

2. Placeskidsteerinpark and/or set brakes,shutengine

3. Always disconnect hydraulics from Skid Steer and

4. See Figure 5-1. Unscrew locknut (#6) to remove

5. Both blades should be sharpened at the same angle

DANGER

!

WARNING

IMPORTANT: Replacement blades should be

ordered in pairs. Order only genuine Land Pride

blades. Other blades may not meet specifications.

off and remove ignition key.

secure cutter deck in the up position with solid

supports before servicing underside of cutter.

cutting blade (#3). Blade bolt (#1) is keyed and will

not turn freely.

as the original cutting edge and must be replaced or

re-ground at the same time to maintain proper

balance in the cutting unit. The followingprecautions

should be taken when sharpening the blades:

a. Do not remove more material than necessary.

b. Do not heat and pound out a cutting edge.

c. Donot grind bladestoa razor edge. Leave a blunt

cutting edge approximately 1/16” thick.

d. Always grind the cutting edge so that the end of

the blade remains square to the cutting edge and

not rounded.

e. Do not sharpen the back side of the blade.

f. Both blades should weigh the same after

sharpening with not more than 1 1/2 oz.

difference.Unbalanced bladeswillcause excessive

vibration which can damage gearboxbearings and

create structural cracks.

6. Carefully check cutting edges of blades in relation to

blade carrier rotation to ensure correct blade

placement. Cutter blades must be installed with

cuttingedgeleadingin rotation and airfoil(lift) mustbe

oriented towards the top of the deck.

Refer to Figure 5-1:

IMPORTANT: Shim (#2) below may or may not be

required. If blade deflection is less than 3/4" without

a shim, then the shim is not used. However, a shim

is required if blade deflection is greater than 3/4".

IMPORTANT: Locknutscan loose their ability to lock

properly once removed. Therefore, always use a

used blade nut or plain nut in steps 7 & 8 below and

then replace used nut with new locknut in step 9.

7. Start by assembling blades without shim (#2). Insert

blade bolt (#1) through blade (#3), dish pan (#4) and

flatwasher(#5).Temporarily securebladewith a used

1 1/8"-12 nut. Draw nut up snug. Do not tighten.

3/4" maximum

blade deflection

when blade

bolts are tight

24590

Cutter Blade Assembly

Figure 5-1

8. Check blade deflection. If deflection is greater than

3/4", removeblade bolt and reassemble as before

except include shim (#2) when reassembling. Select

shim thickness based on deflection. The greater the

deflection, the thicker the shim.

9. Once blade deflection is correct, replace used nut

with new locknut (#6) and torque to 450 ft. lbs.

10. If replacing dishpan (#4), nut on gearbox output shaft

shouldbetorquedto 450 ft-lbs. minimum and secured

with a cotterpin installed through the nutand bolt and

both legs bent opposite directions around nut.

1/07/09

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

23

Page 26

Table of Contents

Section 5: Maintenance & Lubrication

Land Pride

Land Pride Cutter Blade Parts

Item Part No. Part Description

318-586A BLADE BOLT KIT (Contains #’s 1, 2, 5 & 6)

1 802-277C BLADE BOLT 1 1/8-12 x 3 7/16 WITH KEY

2 312-075D BLADE SPACER 16 GA. (.060")

2 312-082D BLADE SPACER 18 GA. (.048")

2 312-089D BLADE SPACER 20 GA. (.036")

2 312-808C BLADE SPACER 24 GA. (.024")

3 820-112C SC2660 CUTTER BLADE 1/2 x 4 x 25 CW

3 820-249C SC2672 CUTTER BLADE 1/2 x 4 x 29 CW

4 316-124H WELDMENT DISHPAN SC2660

4 312-811H WELDMENT DISHPAN SC2672

5 804-147C WASHER FLAT 1 HARD ASTMF436

6 803-170C NUT HEX TOP LOCK 1 1/8-12 PLATE

Skid Shoe Maintenance

!

WARNING

Excessive wear on skid shoes may cause inadequate operation

of cutter and create a safety hazard!

Skid shoes should be inspected at the beginning of each

cutting season and replaced when material thickness is

less than 1/8" atany point. Order onlygenuine Land Pride

parts from your local Land Pride Dealer.

Refer to Figure 5-2:

Replace skid shoes as follows:

1. Raise the Rotary Cutter 3" or more off the ground

andplacesupport blocksunderthecutter.Makesure

the support blocks are positioned so they will not

interfere with skid shoe installation.

2. Lowercutterontothesupport blocks,placeSkidSteer

in park, set park brakes, shut the Skid Steer off and

remove switch key.

3. Remove 3/8" hexlock nuts (#4), lock washers (#5),flat

washers (#6), 3/8” plow bolts (#3), three skid shoes

(#1) and one skid shoe (#2) from all fourdeck corners.

4. Plow bolts should becheckedforwearandreplaced if

necessary.

5. Install the new short skid shoe (#2) to the back left

deck corner as shown with 3/8”-16 x 1 1/4 GR5 plow

bolts (#2), flat washers (#6), lock washers (#5) and

3/8" hex lock nuts (#4). Torque lock nuts (#4) to

31 ft. lbs.

6. Install the long skid shoes (#1) to the remaining three

deckcornerswith3/8”-16X1 1/4 GR5plowbolts (#2),flat

washers(#6), lock washers(#5) and 3/8" hexlocknuts

(#4). Torque lock nuts (#4) to 31 ft. lbs.

7. Raise cutter up and remove support blocks.

Land Pride Standard Skid Shoe Bundle 326-027A

Item Part No. Part Description

1 312-602D SKID SHOE, 1/4" x 2"

2 326-276D DECK RUNNER LH REAR, 1/4" x 2"

3 802-466C PLOW 3/8-16X1 1/4 GR5

4 803-013C NUT LOCK 3/8-16 PLT

5 804-013C WASHER LOCK SPRING 3/8 PLT

6 804-012C WASHER FLAT 3/8 SAE PLT

Land Pride Heavy Skid Shoe Bundle 326-028A

Item Part No. Part Description

1 326-343D SKID SHOE HEAVY, 3/8" x 3"

2 326-344D SKID SHOE HEAVY SHORT, 3/8" x 3"

3 802-466C PLOW 3/8-16X1 1/4 GR5

4 803-013C NUT LOCK 3/8-16 PLT

5 804-013C WASHER LOCK SPRING 3/8 PLT

6 804-012C WASHER FLAT 3/8 SAE PLT

24546

SC2660 & SC2672 Skid Steer Rotary Cutter 326-025M

24

Skid Shoe Replacement

Figure 5-2

1/07/09

Page 27

Land Pride

Section 5: Maintenance & Lubrication

Table of Contents

Hydraulic Maintenance

!

DANGER

Hydraulic fluid under pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin, it must be treated by a

doctor within a few hours or gangrene may result.

One of the most important things you can do to prevent

hydraulic system problems is to ensure that your Skid

Steer reservoir remains free of dirt and contamination.

Use a clean cloth to wipe the hose ends before attaching

them to your Skid Steer. Replace the filter element for

your Skid Steer’s hydraulic system at the prescribed

intervals. These simple maintenances will go a long way

to prevent occurrence of hydraulic problems.

Storage

!