Land Pride BH2585 User Manual

Table of Contents

Backhoes

BH2585

20566

340-130M

Operator’s Manual

Read the Operator’s manual entirely. When

you see this symbol, the subsequent

instructions and warnings are serious - follow

!

without exception. Your life and the lives of

others depend on it!

© Copyright 2005 Printed

Cover photo may show optional equipment not supplied

with standard unit.

10/28/05

Table of Contents

Table of Contents

Land Pride

Information . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . .1

Introduction . . . . . . . . . . . . . . . . . . . . . . . .6

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . 6

Terminology: . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Definitions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . .6

Serial Number Plate . . . . . . . . . . . . . . . . . . . . . . . .6

Further Assistance . . . . . . . . . . . . . . . . . . . . . . . . .6

Backhoe Operation, Maintenance & Safety Tips . .7

Section 1 Assembly and Set-Up . . . . . . . . .8

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . .8

Skid Steer Requirements . . . . . . . . . . . . . . . . . . . . 8

Hydraulic System Requirements . . . . . . . . . . . . . .8

Select Hydraulic System . . . . . . . . . . . . . . . . . . . . 8

Tractor System . . . . . . . . . . . . . . . . . . . . . . . . .8

Power Beyond Hydraulic System . . . . . . . . . . .8

Power Beyond Hydraulic Systems . . . . . . . . . . . . . 8

Power Beyond and Closed Center Kit . . . . . . . . 8

Closed Center Hydraulic Systems . . . . . . . . . . . . .9

Power Beyond & Closed Center Kit . . . . . . . . . .9

Choose the Appropriate Hosing . . . . . . . . . . . . . . 10

Independent PTO Hydraulic Pump System . . . 10

For All Tractors . . . . . . . . . . . . . . . . . . . . . . . . . . 12

For John Deere Tractors . . . . . . . . . . . . . . . . . . . 12

Mounting The Backhoe . . . . . . . . . . . . . . . . . . . . 12

Lower Link Hitch Bracket Installation . . . . . . . 13

Backhoe Stabilizer Kit Installation . . . . . . . . . . 14

Seat Assembly . . . . . . . . . . . . . . . . . . . . . . . . 15

Bucket Installation . . . . . . . . . . . . . . . . . . . . . . 15

Skid Steer Hook-Up . . . . . . . . . . . . . . . . . . . . 15

Optional Equipment Assemblies . . . . . . . . . . . . . 16

Locking Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ripper Tooth . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 2 Operating Instructions . . . . . . . .17

Preparing For Operation . . . . . . . . . . . . . . . . . . .17

Preparing The Backhoe . . . . . . . . . . . . . . . . . .17

Preparing The Tractor . . . . . . . . . . . . . . . . . . .17

Operating The Backhoe . . . . . . . . . . . . . . . . . . . .17

Transporting The Backhoe . . . . . . . . . . . . . . . . . .17

Control Functions . . . . . . . . . . . . . . . . . . . . . . . . .18

Stabilizers . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Dipper Stick And Bucket . . . . . . . . . . . . . . . . .18

Digging Suggestions . . . . . . . . . . . . . . . . . . . . . .19

Observe the following cautions while digging. .19

Digging at the Correct Angle . . . . . . . . . . . . . . . .19

Dipper Stick & Boom Angle . . . . . . . . . . . . . . .19

Bucket Angle . . . . . . . . . . . . . . . . . . . . . . . . . .20

Section 3 Maintenance and Lubrication . . .21

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Bucket Tooth Replacement . . . . . . . . . . . . . . . . .21

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Bucket Pivot . . . . . . . . . . . . . . . . . . . . . . . . . .22

Bucket Pivot (End of Stick) . . . . . . . . . . . . . . .22

Bucket Cylinder Base End . . . . . . . . . . . . . . . .22

Dipper Stick Pivot . . . . . . . . . . . . . . . . . . . . . .22

Dipper Stick Cylinder Base End . . . . . . . . . . . .23

Boom Cylinder Rod End . . . . . . . . . . . . . . . . .23

Boom Pivots (Both Sides) . . . . . . . . . . . . . . . .23

Boom Pivot (Unerneath at end of Boom) . . . . .23

Boom Cylinder Base End . . . . . . . . . . . . . . . .24

Stabilizer Cylinder Rod End (Both Sides) . . . .24

Stabilizer Arms (Both Sides) . . . . . . . . . . . . . .24

Boom Swing Pivot . . . . . . . . . . . . . . . . . . . . . .24

Boom Swing Cylinder Rod End (Both Sides) . .25

Boom Swing Cylinder Base End . . . . . . . . . . .25

Section 4 Specifications and Capacities . .26

Section 5 Features and Benefits . . . . . . . .27

Section 6 Troubleshooting . . . . . . . . . . . . .28

Section 7 Appendix . . . . . . . . . . . . . . . . . .30

Torque Values Chart For Common Bolt Size . 30

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

© Copyright 2005 All rights Reserved

LandPrideprovidesthispublication “as is” withoutwarrantyofanykind,either expressed or implied.While every precaution hasbeen taken in thepreparationof this manual,

Land Pride assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Land

Pride reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect

the product in the future. The illustrations in this manual are not intended for safe and proper assembly or disassembly of equipment. The illustrations are intended for

ordering parts only.

Land Pride is registered trademark.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

10/28/05

Land Pride

▲

Table of Contents

Important Safety Information

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Safety at All Times

Thoroughly read and understand

the instructions given in this

manual before operation. Refer to

the “Safety Label” section, read

all instructions noted on them.

Do not allow anyone to operate

this equipment who has not fully

read and comprehended this

manual and who has not been

properly trained in the safe

operation of the equipment.

▲ Operator should be familiar with

all functions of the unit.

▲ Operate implement from the

driver’s seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Dismounting from a moving

tractor could cause serious injury

or death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet, and clothing

away from power-driven parts.

▲ Wear snug fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of

working area.

▲ Turning tractor too tight may

cause implement to ride up on

wheels. This could result in injury

or equipment damage.

Look For The Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and

extra safety precaution must be taken. When you

see this symbol, be alert and carefully read the

message that follows it. In addition to design and

!

configuration of equipment, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence and proper training

of personnel involved in the operation, transport,

maintenance and storage of equipment.

Be Aware of

Signal Words

A Signal word designates a degree or

level of hazard seriousness. The

signal words are:

!

DANGER

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for

functional purposes, cannot be

guarded.

For Your Protection

▲ Thoroughly read and understand

the “Safety Label” section, read all

instructions noted on them.

!

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may also

be used to alert against unsafe

practices.

!

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine, and

remove the key.

▲ Detach and store implements in a

area where children normally do

not play. Secure implement by

using blocks and supports.

10/28/05

OFF

REMO

VE

1

Table of Contents

Land Pride

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Use Safety

Lights and Devices

▲ Slow moving tractors, self-

propelled equipment, and towed

implements can create a hazard

when driven on public roads. They

are difficult to see, especially at

night.

▲ Flashing warning lights and turn

signals are recommended

whenever driving on public roads.

Transport

Machinery Safely

▲ Comply with state and local laws.

▲ Maximum transport speed for

implement is 20 mph. DO NOT

EXCEED.Never travel at a speed

which does not allow adequate

control of steering and stopping.

Some rough terrains require a

slower speed.

▲ Sudden breaking can cause a

towed load to swerve and upset.

Reduce speed if towed load is not

equipped with breaks.

▲ Use the following maximum

speed - tow load weight ratios as

a guideline:

▲ 20 mph when weight is less than

or equal to the weight of tractor.

▲ 10 mph when weight is double

the weight of tractor.

▲ IMPORTANT: Do not tow a load

that is more than double the

weight of tractor.

Transporting the Loader

and Attachment

▲ Always drive up the ramp with

heavy end uphill. Engage parking

brake.

▲ Secure loader and attachments

using tiedowns and chains. Use

towing vehicle and trailer of

adequate capacity.

Keep Riders

Off Machinery

▲ Riders obstruct the operator’s

view, they could be struck by

foreign objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

Tractors With Cabs

Tractors Equipped With

ROPS

▲ There should be sufficient

clearance for the operator when

mounted to a tractor with a cab or

that is equipped with ROPS.

▲ The ROPS may need to be

extended or flipped around to

obtain sufficient clearance.

2

10/28/05

Land Pride

Table of Contents

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment, refer to Operator’s

Manual for additional information.

▲ Work in a clean dry area.

▲ Lower the implement to the

ground, put tractor in park, turn off

engine, and remove key before

performing maintenance.

▲ Allow implement to cool

completely.

▲ Do not grease or oil implement

while it is in operation.

▲ Inspect all parts. Make sure parts

are in good condition & installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before

operation.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire

extinguisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Protective clothing and equipment

should be worn.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose fitting clothing.

▲ Prolonged exposureto loud noise

can cause hearing impairment or

hearing loss. Wear suitable

hearing protection such as

earmuffs or earplugs.

▲ Operating equipment safely

requires the full attention of the

operator. Avoid wearing radio

headphones while operating

machinery.

Avoid High

Pressure Fluids Hazard

▲ Escaping fluid under pressure can

penetratethe skin causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or

cardboard, NOTBODYPARTS, to

check for suspected leaks.

▲ Wear protective glovesand safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a

doctor immediately. Any fluid

injected into the skin must be

surgically removed within a few

hours or gangrene may result.

10/28/05

3

Important Safety Information

Table of Contents

Land Pride

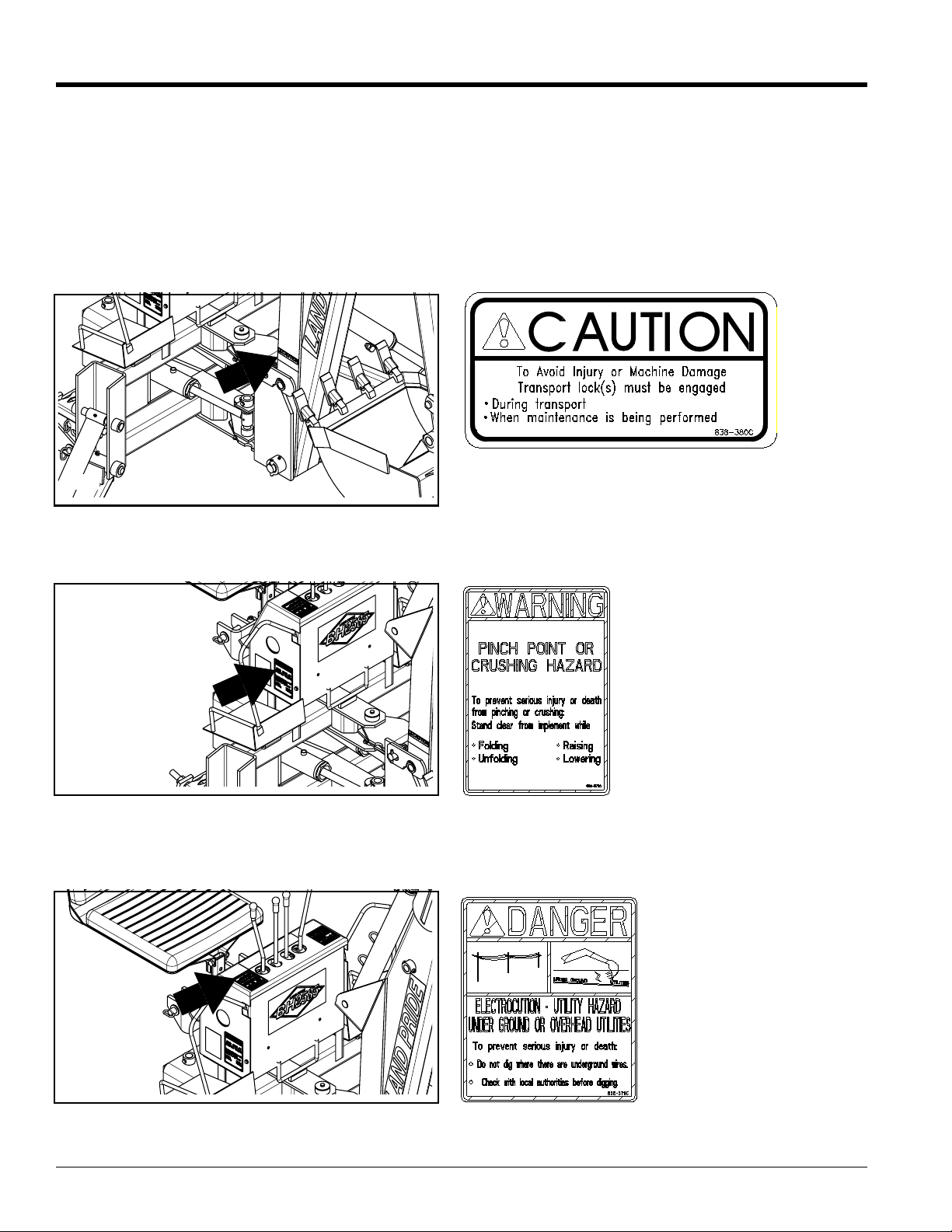

Safety Labels

Your Backhoe comes equipped with all safety labels in place.

They were designed to help you safely operate your Backhoe.

1. Read and follow label directions.

2. Keep all safety labels clean and legible.

3. Replace all damaged or missing labels.

4. Some new equipment installed during repair require safety

labels to be affixed to the replaced component as specified

20566

by Land Pride. When ordering new components make sure

the correct safety labels are included in the request. To

order new labels go to your Land Pride dealer.

5. Refer to this section for proper label placement.

To install new labels:

a. Clean the area the label is to be placed.

b. Peel backing from label. Press firmly on surface

being careful not to cause air bubbles under label.

838-380C

Caution: Lock For Transport

20566

20566

4

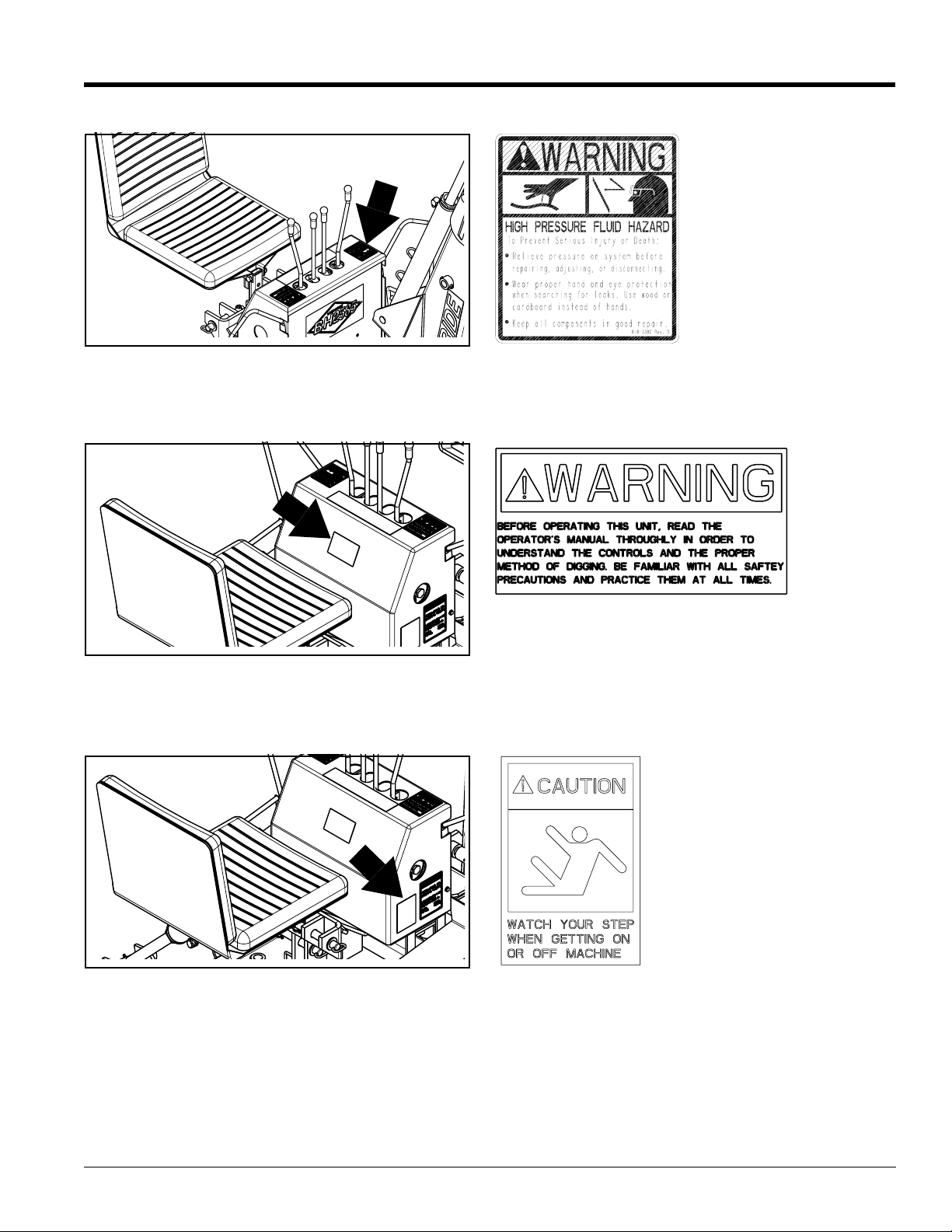

838-378C

Warning: Pinch or Crush Hazard

838-379C

Danger: Overhead/

Underground Utilities

10/28/05

Land Pride

Important Safety Information

Table of Contents

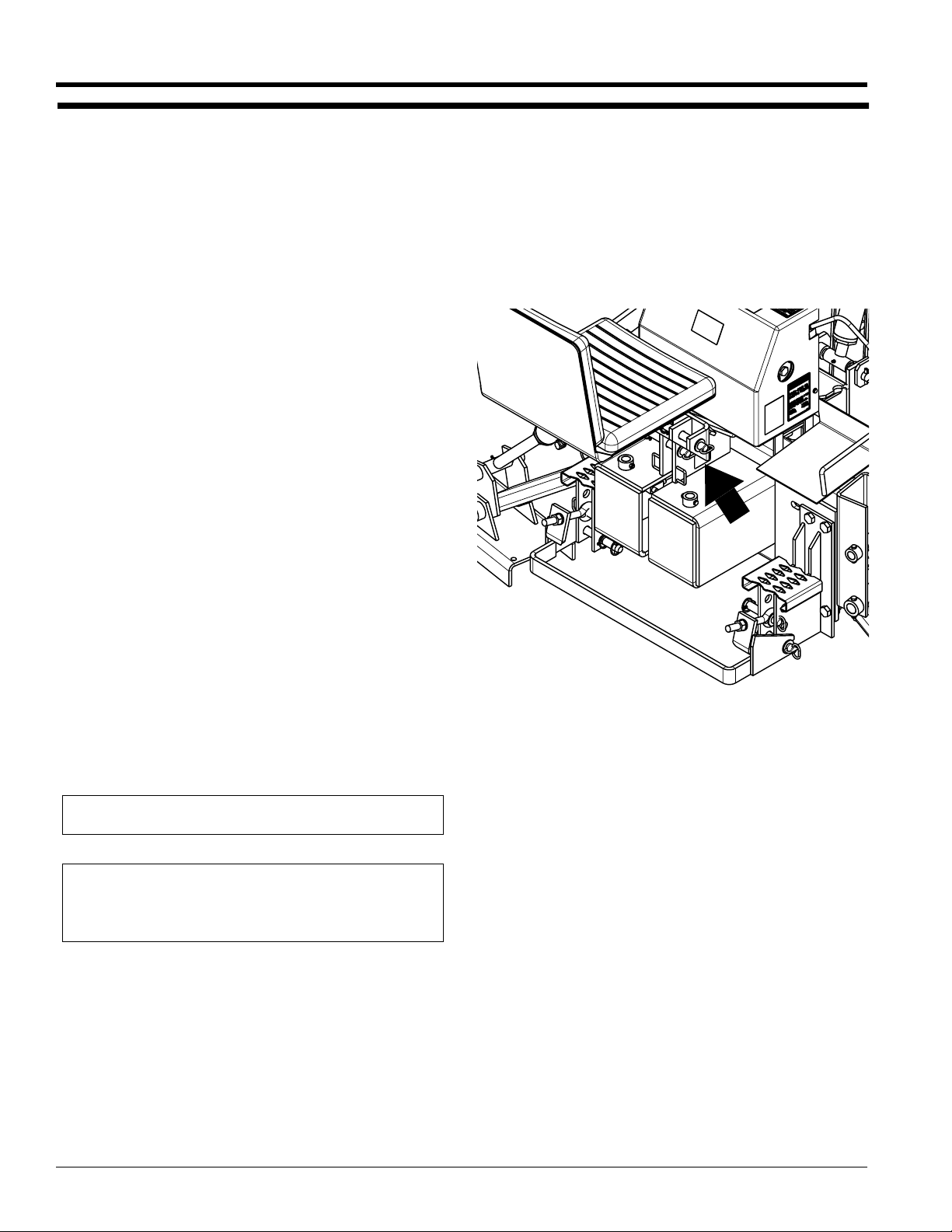

20566

20567

818-339C

Warning: High Pressure

839-933C

Warning: General

20567

10/28/05

839-932C

Caution: Watch your step

5

Introduction

Introduction

Table of Contents

Land Pride

Land Pride welcomes you to the growing family of new

product owners.

This Backhoe has been designed with care and built by

skilled workers using quality materials. Proper assembly,

maintenance, and safe operating practices will help you

get years of satisfactory use from the machine.

Application

The BH2585 Backhoe is the ideal tool for farms, drainage

ditches, nurseries, golf courses, utilities and cemeteries.

An unobstructed view of the work area, comfortable

positioningof thecontrols and walkthrough platformallow

for hours of fatigue free work. Stabilizer legs provide a

stance of 9’4" assuring more stability and safer

operational control. Optional rubber shoes can be added

to the stabilizer legs for working on concrete. Selected

skid steer loader mounting kits are available for added

versatility.See “Features and Benefits”, “Section 6” for

additional information.

Using This Manual

This Operator’s Manual is designed to help familiarize

•

you with safety, assembly, operation, adjustments,

troubleshooting, and maintenance. Read this manual

and follow the recommendations to help ensure safe

and efficient operation.

• The information contained within this manual was

current at the time of printing. Some parts may change

slightly to assure you of the best performance.

• To order a new Operator or Parts Manual contact your

authorized dealer. Manuals can also be downloaded,

free-of-charge from our website at www.landpride.com

or printed by your dealer from the Land Pride Service &

Support Center CD-Rom.

Terminology:

"Right " or "Left" as used in this manual is determined by

facing the direction the machine will operate while in use

unless otherwise stated.

Definitions:

NOTE:A special point of information that the operator

must be aware of before continuing.

IMPORTANT: A special point of inf ormation related to

its preceding topic. Land Pride’s intention is that this

information should be read and noted before

continuing.

Owner Assistance

The Warranty Registration card should be filled out by

the dealer at the time of purchase. This information is

necessary to provide you with quality customer service.

If customer service or repair parts are required contact a

LandPride dealer.A dealer hastrained personnel, repair

parts and equipment needed to service the implement.

The parts on your BH2585 Backhoe have been specially

designedand shouldonly bereplaced with genuineLand

Pride parts. Therefore, should your Backhoe require

replacement parts go to your Land Pride Dealer.

Serial Number Plate

For prompt service always use the serial number and

model number when ordering parts from your Land Pride

dealer.Be sureto includeyour serialand modelnumbers in

correspondence also. Refer to Figure 1 for the location of

your serial number plate.

20567

Serial Number Plate Location

Figure 1

Further Assistance

Your dealer wants you to be satisfied with your new

backhoe.If for any reason you do not understand any part

of this manual or are not satisfied with the service

received, the following actions are suggested:

1. Discussthe matter with your dealership service

managermaking sure he is aware of anyproblems you

mayhaveand that he has had the opportunity to assist

you.

2. If you are still not satisfied, seek out the owner or

general manager of the dealership, explain the

problem and request assistance.

3. For further assistance write to:

Land Pride

Service Department

P.O. Box 5060

Salina, KS 67402-5060

6

10/28/05

Land Pride

Introduction

Table of Contents

Backhoe Operation, Maintenance & Safety Tips

1. Your backhoe must be mounted only on a tractor

equipped with a Category 1 or 2 hitch or Skid Steer

Hitch. Failure to do so may result in serious injury.

2. When servicing the backhoe, make sure all moving

parts are on the ground.

3. To avoid injury from escaping pressurized hydraulic

fluid, move the control levers in all directions before

disconnecting any hoses, steel lines, or couplers.

4. Keep footpads clean to prevent feet from slipping

while mounting backhoe.

5. Do not transport your backhoe with the bucket fully

raised.

6. Be sure your tractor has sufficient front end weight to

operate and transport the backhoe.

7. When traveling on highwaysand roads, be sure the

boom and stabilizers are in the fully raised position

and transport lock is in the transport lock position.

8. When traveling on a road with your backhoe, use

proper safety lights and warning sign. Check local

regulations.

9. When traveling with your backhoe, do not make

sudden starts, stops or turn at high speeds. Do not

exceed safe speed limits on rough ground. Do not

make sudden starts when climbing grades.

10. Always wear protective headgear while operating

backhoe.

11. Be sure to lower the stabilizers to the ground before

operating the backhoe.

12. Lookoutfor overheadlowhanging wires. Donot touch

wires with any part of the backhoe.

13. Do not operate from any position other than the

backhoe’s operator’s seat.

14. Before swinging the backhoe for any reason, make

sure you have room to swing and that all persons are

clear of the backhoe.

15. Be extra careful when working on hillsides and close

to ditches or any place where danger of tipping or

sliding is possible.

16. Do not dig under the stabilizers or backhoe, as a

cave-in could occur.

17. Be sure you are not digging over underground wiring

or other underground obstructions.

18. Whendigging toeither side andclose tothe tractor,be

extremely careful that the backhoe does not contact

the stabilizers as serious damage could occur.

19. Do not attempt to raise the tractor off the ground or

movethe tractor forward or backward using the boom

or stabilizers.

20. When leaving the backhoe for any reason, lower the

bucketto the ground for safety.

21. Never leave the backhoe unattended with tractor

engine running.

22. To prevent injury during assembly,installation,

operation,adjustment, or removalof the backhoe, it is

recommended that gloves,safety glasses or face

shield, and safety toe shoes be worn.

23. Do not wear loose clothing while operating or working

near the backhoe. Keep hair and clothing away from

all moving parts of the backhoe.

24. Only the operator should be near the backhoe during

operation.Keepall others a minimum of fifty feetaway

from your work area.

25. Keep your work area clear of obstacles at all times.

26. Children should never be permitted to operate the

backhoe.

27. Do not attempt any repairs, maintenance, or

adjustments of your backhoe while it is in operation.

Always turn off your tractor before making repairs or

adjustments or performing maintenance procedures.

28. When the use of hand tools is required to perform any

part of assembly, installation, removal or adjustment

of the backhoe, be sure that the tools are designed

and recommended by the tool manufacturer for the

specific task in which they are being used.

29. Keepall bolts and nutstight. Replace any damaged or

worn parts such as hydraulichoses and fittings

immediately. Alwaysuse Land Pride replacement

parts.

30. Perform all maintenance procedures as

recommended.

31. Anytime hoses are disconnected from your backhoe,

cover all open ports with protective caps or plugs in

order to preventcontamination of the oil supply.

IMPORTANT: Make sure that there is sufficient

clearance forthe operatorif the backhoe is mounted to

a tractor with a cab or is equipped with a ROPS. The

ROPS may need to be extended or flipped around to

obtain sufficient clearance.

10/28/05

7

Section 1 Assembly and Set-Up

Section 1 Assembly and Set-Up

Table of Contents

Land Pride

Tractor Requirements

!

CAUTION!

Your backhoe must be mounted only on a tractor equipped with

a Category 1 or 2 hitch or Skid Steer Mounting. Failure to do

so may result in serious injury.

NOTE: In order to maintain steering control on your

tractor, ballast may need to be added to your tractor.

To determine whether or not to add the ballast, referto

your tractor’s operator’s manual.

Skid Steer Requirements

This Backhoe is designed to fit on Skid Steer Loaders

with a SAE lift capacity of 1200 lbs. and hydraulic

requirements of 11 GPM at 2200 psi minimum. Skid

Steer Hitches are available for specific Skid Loaders

from your Land Pride Dealer.

Hydraulic System Requirements

!

CAUTION!

The backhoe valve must be compatible with the hydraulic

system that will power it. Make sure that if you arepowering the

backhoe with an open center hydraulic system, the backhoe is

set for open center operation. If you are using a closed center

hydraulic system, the valve must be set for closed center

operation. If you are using a power beyond set-up, the valve

must be converted for this use. See the appropriate section of

this manual on how to convert your valve. If you do not know

how your valve is currently set-up, check with your Land Pride

dealer.

Select Hydraulic System

Tractor System

If an open center tractor hydraulic system is utilized,

attach the backhoe valve’s pressure hose to the tractor

pressure hydraulic outlet, and the backhoe valve return

hose to the tractor’s hydraulic oil sump or reservoir tank.

Power Beyond Hydraulic System

If you wish to run both a loader and a backhoe from the

same hydraulic system, make your connection as

illustrated in Figure 1-1. Also, refer to “Power Beyond

Hydraulic Systems” in the section below. Since there

are so many variations for this type of setup, we are

showing only a generalized hosing scheme. If you have

anyquestions concerning the specifics foryour situation,

please contact your dealer before attempting operation.

Power Beyond Hydraulic Systems

Power Beyond and Closed Center Kit

For power beyond applications, a Power Beyond and

Closed Center Kit # 340-084A must be purchased from

your Land Pride Dealer, then the following steps

performed:

1. Remove plug (#3) and install Power Beyond Sleeve

(#1) in port as shown in Figure 1-1.

2. Install a #8 O-Ring ell (Part # 839-882C) (#2) into

closed center sleeve (#1) opening. This converts it to

a power beyond sleeve.

3. Install a high pressure hose going to the inlet of

another valve (front loader valve). This hose is not

furnished.

4. The return hose must be connected to the tractor oil

sump.

Your backhoe cylinders have been filled with oil at the

factory. The oil in the unit is compatible with most tractor

manufacturers’oil. Donot move anycontrol leverson the

unit until after hydraulic connections to the tractor or the

independent hydraulic system have been made.

The Land Pride Backhoe has been designed to be

operated at a flow rate of 6-8 GPM.

Since many tractor systems exceed a flow rate specified

for your backhoe, the flow may have to be adjusted by

throttling the engine RPM down to obtain an acceptable

flow rate. By adjusting the flow rate correctly, you will

prevent sudden shock loads on the cylinders, pins,

hoses, seals, etc. This results in a smooth operation and

reduced maintenance costs and down time.

8

Power Beyond Hydraulic Systems

19616

Figure 1-1

10/28/05

Land Pride

Table of Contents

Section 1 Assembly and Set-Up

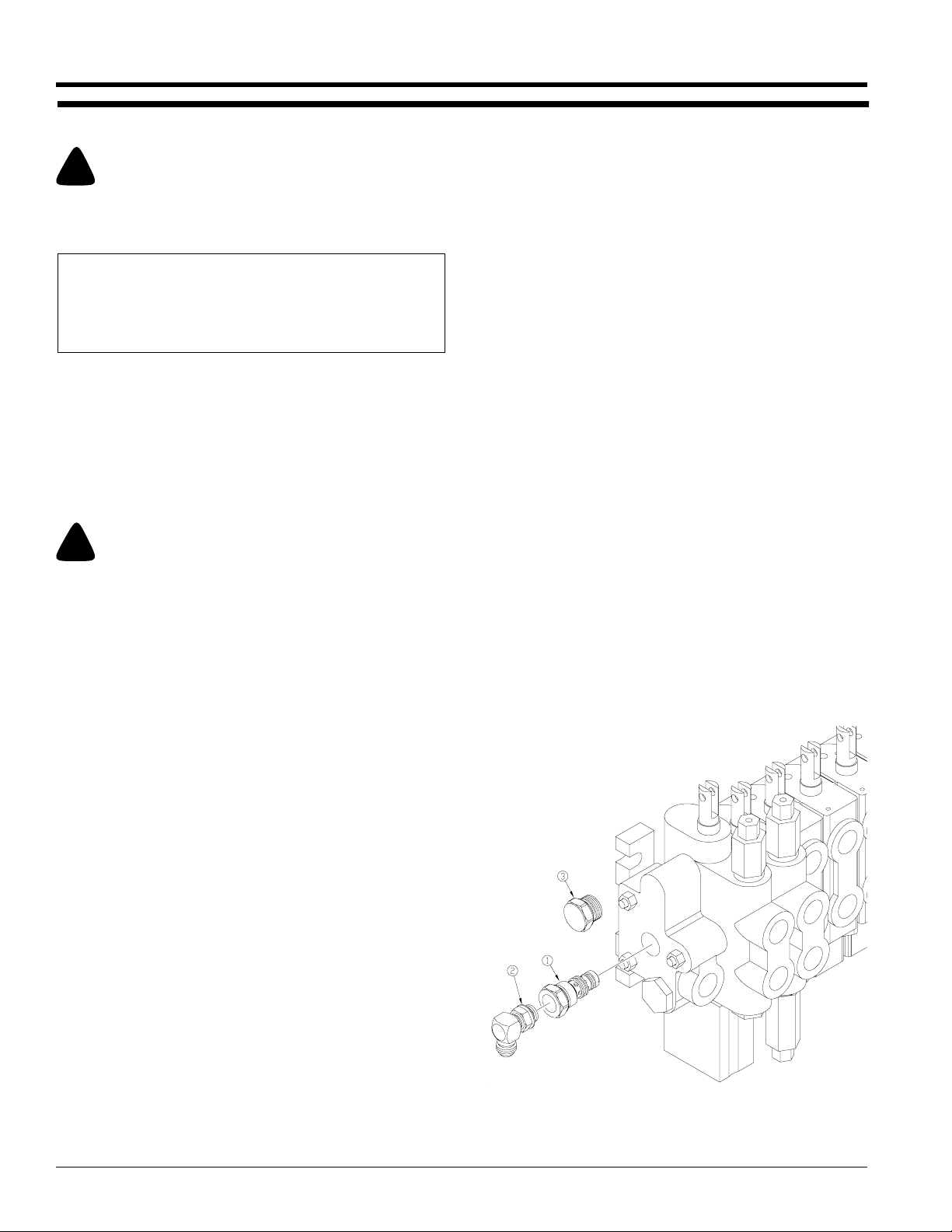

Closed Center Hydraulic Systems

Power Beyond & Closed Center Kit

!

CAUTION!

If you are going to use a closed center tractor hydraulic system

to power your Land Pride Backhoe, A Power Beyond and

Closed Center Kit must be purchased from your Land Pride

Dealer, then you must carefully follow the directions below.

Failure to do so may cause extensive damage to your tractor

and/or Land Pride Backhoe.

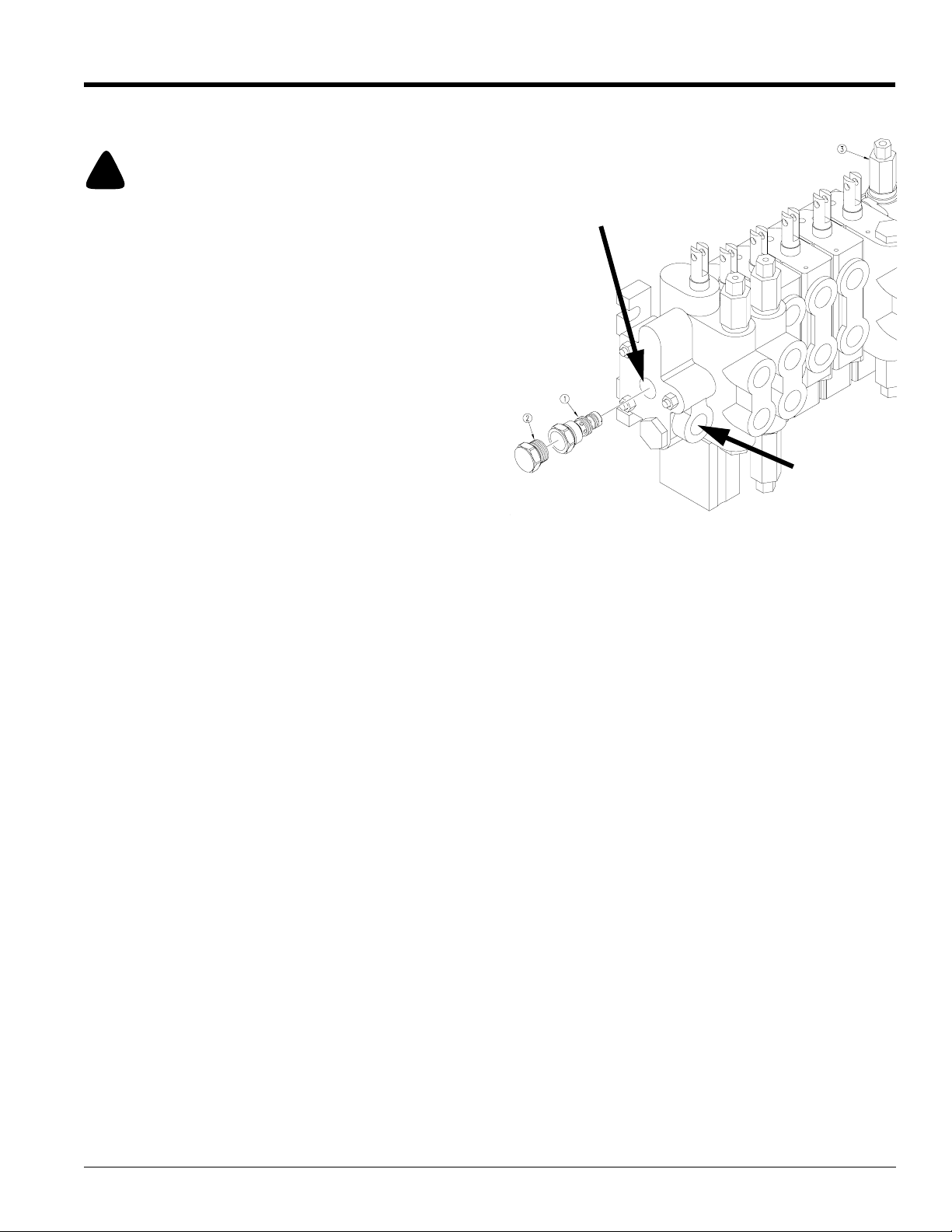

Refer to Figure 1-2:

1. Adjust Valve Bypass for Closed Center

Conversion only (Kit #340-084A).

a. Removethe covernut (#3) from the valvebypass.

This exposes a socket head screw.

b. Loosen locknut and turn socket head screw in

approximately four complete turns, then tighten

locknut.

c. Replace cover nut. Be sure to replace the washer

along with the cover nut as it acts as a gasket.

2. Installing the Closed Center Sleeve.

a. Return hose must be connected to the return

sectionof thevalveat point “A” andwith theother

end to the tractor.

b. Remove plug at point “B” and install the closed

center sleeve (#1). Use the plug (#2) that was

removed to plug the sleeve.

c. Connect return line to the adapterand return tooil

sump of the tractor.

B

A

19617

Closed Center Hydraulic Systems

Figure 1-2

This procedure converts the valve to a closed center

operation. If the valve is set for closed center operation,

it may be converted back to open center by reversing the

above procedure.

10/28/05

9

Loading...

Loading...