Land Pride Accu-Z Razor ZSR54, Accu-Z Razor ZSR60 Service Manual

Table of Contents

Zero Turn Mowers

ZSR54 & ZSR60 Accu-Z Razor

®

27800

357-388SM

Service Manual

© Copyright 2012 Printed

7/30/12

Table of Contents

Table of Contents

Section 1: Operator Controls . . . . . . . . . . .4

Steering Arm Removal . . . . . . . . . . . . . . . . . . . . . .4

Steering Arm Installation . . . . . . . . . . . . . . . . . . . .4

Control Arm and Lever Removal . . . . . . . . . . . . . . 5

Control Arm and Lever Installation . . . . . . . . . . . . .6

Park Brake Removal . . . . . . . . . . . . . . . . . . . . . . . 7

Park Brake Installation . . . . . . . . . . . . . . . . . . . . . . 8

Deck Lift Removal . . . . . . . . . . . . . . . . . . . . . . . . .9

Deck Lift Installation . . . . . . . . . . . . . . . . . . . . . . .10

Control Panel Removal . . . . . . . . . . . . . . . . . . . . 11

Control Panel Installation . . . . . . . . . . . . . . . . . . . 12

Section 2: Seat & Frame . . . . . . . . . . . . . .13

Seat and Latch Removal . . . . . . . . . . . . . . . . . . . 13

Seat and Latch Installation . . . . . . . . . . . . . . . . . 14

Floor Panel Removal . . . . . . . . . . . . . . . . . . . . . . 15

Floor Panel Installation . . . . . . . . . . . . . . . . . . . . 15

Engine Bumper Guard Removal . . . . . . . . . . . . . 16

Engine Bumper Guard Installation . . . . . . . . . . . . 16

Section 3: Mower Deck . . . . . . . . . . . . . . .17

Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Deck installation . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pulley and Blade Hub Removal . . . . . . . . . . . . . . 19

Pulley and Blade Hub Installation . . . . . . . . . . . . 19

Spindle Hub Rebuild . . . . . . . . . . . . . . . . . . . . . .20

Section 4: Electrical System . . . . . . . . . .22

Battery Assembly Removal . . . . . . . . . . . . . . . . . 22

Battery Assembly Installation . . . . . . . . . . . . . . . . 22

Wiring Harness Removal . . . . . . . . . . . . . . . . . . . 23

Wiring Harness Installation . . . . . . . . . . . . . . . . . 24

Main Harness Wiring Schematics . . . . . . . . . . . . 25

Engine Wiring Schematics . . . . . . . . . . . . . . . . . .26

Section 5: Fuel System . . . . . . . . . . . . . .27

Fuel Valve and Hose Removal . . . . . . . . . . . . . . . 27

Fuel Valve and Hose Installation . . . . . . . . . . . . .28

Fuel Tank Removal . . . . . . . . . . . . . . . . . . . . . . . 29

Fuel Tank Installation . . . . . . . . . . . . . . . . . . . . . . 30

Section 6: Wheels . . . . . . . . . . . . . . . . . . .31

Front Caster Wheel Removal . . . . . . . . . . . . . . . .31

Front Caster Wheel Installation . . . . . . . . . . . . . . 32

Front Axle Removal . . . . . . . . . . . . . . . . . . . . . . .33

Front Axle Installation . . . . . . . . . . . . . . . . . . . . . .34

Rear Drive Wheel Removal . . . . . . . . . . . . . . . . .35

Rear Drive Wheel Installation . . . . . . . . . . . . . . . .35

Section 7: Power Train . . . . . . . . . . . . . . . 36

Muffler Removal . . . . . . . . . . . . . . . . . . . . . . . . . .36

Muffler Installation . . . . . . . . . . . . . . . . . . . . . . . .36

Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . .37

Engine Installation . . . . . . . . . . . . . . . . . . . . . . . .38

Clutch Removal . . . . . . . . . . . . . . . . . . . . . . . . . .39

Clutch Installation . . . . . . . . . . . . . . . . . . . . . . . . .40

Transaxle Removal . . . . . . . . . . . . . . . . . . . . . . .41

Transaxle Installation . . . . . . . . . . . . . . . . . . . . . .43

Section 8: Adjustments . . . . . . . . . . . . . .46

Torque Requirements . . . . . . . . . . . . . . . . . . . . .46

Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Front Floating Axle

(ZSR Models Only) . . . . . . . . . . . . . . . . . . . . . . . .46

Steering Adjustments . . . . . . . . . . . . . . . . . . . . . .47

Lower Control Lever . . . . . . . . . . . . . . . . . . . .47

Upper Control Lever . . . . . . . . . . . . . . . . . . . .48

Seat Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .48

Ground Drive Belt Adjustment . . . . . . . . . . . . . . .49

Deck Drive Belt Adjustment . . . . . . . . . . . . . . . . .49

Deck Adjustments . . . . . . . . . . . . . . . . . . . . . . . .50

Deck Cutting Height And Leveling . . . . . . . . . .50

Deck Lift Assist Springs . . . . . . . . . . . . . . . . . .51

Anti-Scalp Rollers . . . . . . . . . . . . . . . . . . . . . .52

Cutting Height Settings . . . . . . . . . . . . . . . . . . . .52

Section 8: Maintenance & Lubrication . . 54

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . .54

Maintenance Locations . . . . . . . . . . . . . . . . . . . .56

Torque Requirements . . . . . . . . . . . . . . . . . . . . .58

© Copyright 2012 All rights Reserved

Land Pridepro videsthis publication “asis” without warrantyof any kind,eitherexpressed orimplied.While every precautionhas been takenin the preparationofthis manual, Land

Pride assumesno responsibility f orerrors oromissions .Neither isany liability assumedfor damagesresulting from theuse of theinformation containedherein.Land Pridereserves

the rightto reviseandimprove itsproducts as itsees fit. Thispublication describes thestate of thisproduct at thetime of itspublication, andmay not reflectthe product inthe future.

All otherbrands and product namesare trademarks or registeredtrademarksof their respectiveholders.

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

Land Pride isa registered trademark.

Printed in the United StatesofAmerica.

1/20/12

Table of Contents

Table of Contents

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . 59

Hydrostatic Drive System . . . . . . . . . . . . . . . . . . 60

Hydraulic Oil Level Check . . . . . . . . . . . . . . . . . . 60

Transaxle Oil and Filter Change . . . . . . . . . . . . . 60

Transaxle Purging Procedures . . . . . . . . . . . . . . 61

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Evaporative Emission Control System . . . . . . . . . 63

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Draining The Fuel Tank . . . . . . . . . . . . . . . . . . . . 63

Belt Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 64

Deck Drive Belt Removal & Installation . . . . . . 64

Ground Drive Belt Removal & Installation . . . . 64

Mower Blade Maintenance . . . . . . . . . . . . . . . . . 66

General Engine Maintenance . . . . . . . . . . . . . . . 68

Engine Oil and Oil Filter . . . . . . . . . . . . . . . . . . . . 68

Check Engine Oil . . . . . . . . . . . . . . . . . . . . . . 68

Change Engine Oil . . . . . . . . . . . . . . . . . . . . . 68

Engine Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Internal Type Air Filters . . . . . . . . . . . . . . . . . . 69

Canister Type Air Filters . . . . . . . . . . . . . . . . . 69

Air Filter Handling . . . . . . . . . . . . . . . . . . . . . . . . 70

End of Season & Long Term Storage . . . . . . . . . 71

New Season Preparation . . . . . . . . . . . . . . . . . . . 71

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . 72

Section 10: Troubleshooting . . . . . . . . . 74

Section 11: Appendix . . . . . . . . . . . . . . . 76

Engine Specifications . . . . . . . . . . . . . . . . . . . . . 76

Hydrostatic Transaxle Specifications . . . . . . . . . . 76

General Specifications . . . . . . . . . . . . . . . . . . . . . 76

ZSR54 & ZSR60 Zero Turn Mowers . . . . . . . . . . 78

Additional Torque Values . . . . . . . . . . . . . . . . . . 79

1/20/12

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

3

Table of Contents

Section 1: Operator Controls

Section 1: Operator Controls

Steering Arm Removal

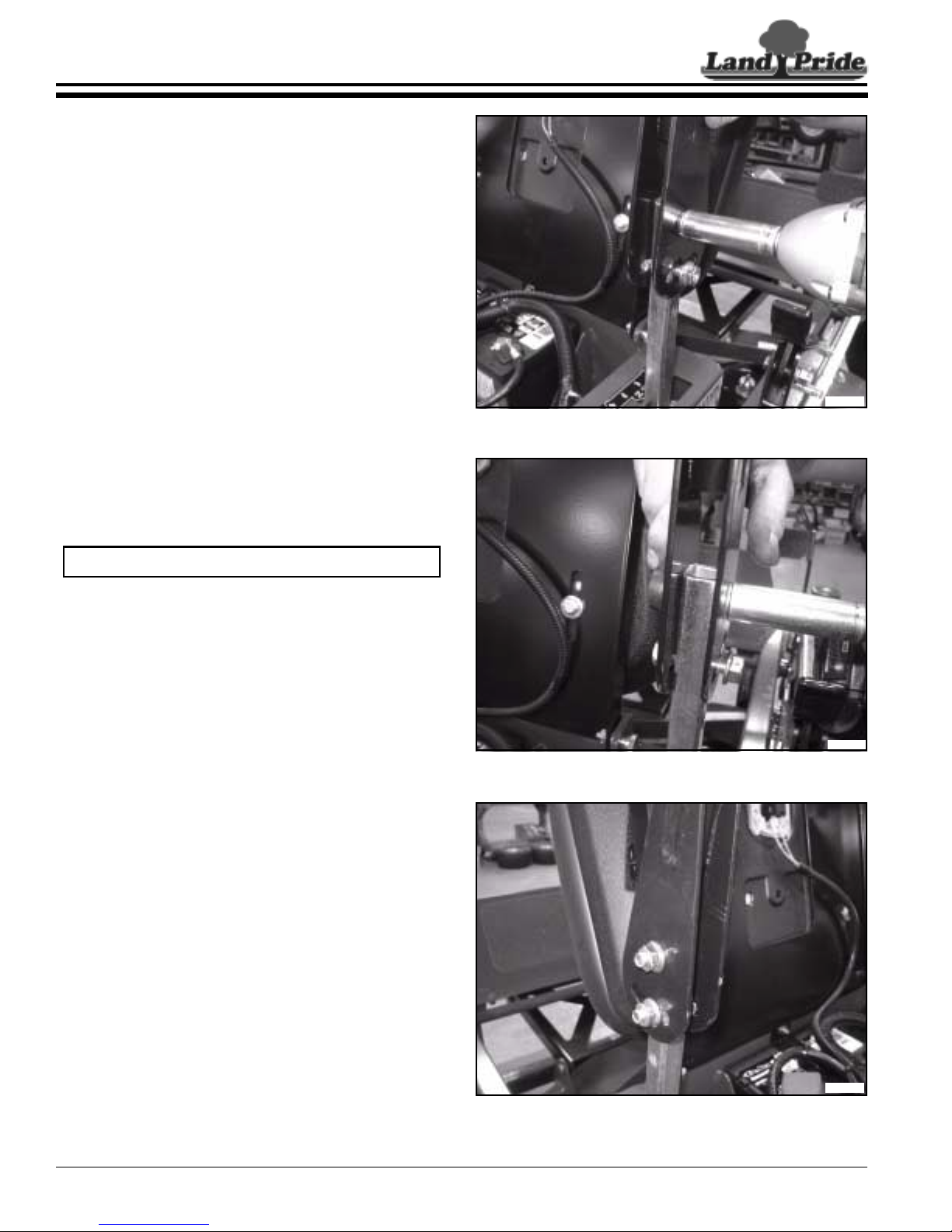

Refer to Figure 1-1:

1. Loosen and removetwo steering arm retaining bolts.

2. Slide steering arm up and off of the drive control

stub.

3. Repeat steps 1 through 2 for other side.

Steering Arm Installation

Refer to Figure 1-2:

1. Slide steer ing arm to desired height and install pivot

bolt and nut.

33678

Figure 1-1

NOTE: Do not tighten at this time.

2. Install bolt and nut in arm adjustment slot.

3. Adjust arms to desired angle for operation.

Refer to Figure 1-3:

4. Tighten all fasteners to standard torque. See chart

on page 79.

5. Repeat steps 1 through 4 for other side.

33679

Figure 1-2

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

4

33680

Figure 1-3

7/30/12

Table of Contents

Section 1: Operator Controls

Control Arm and Lever Removal

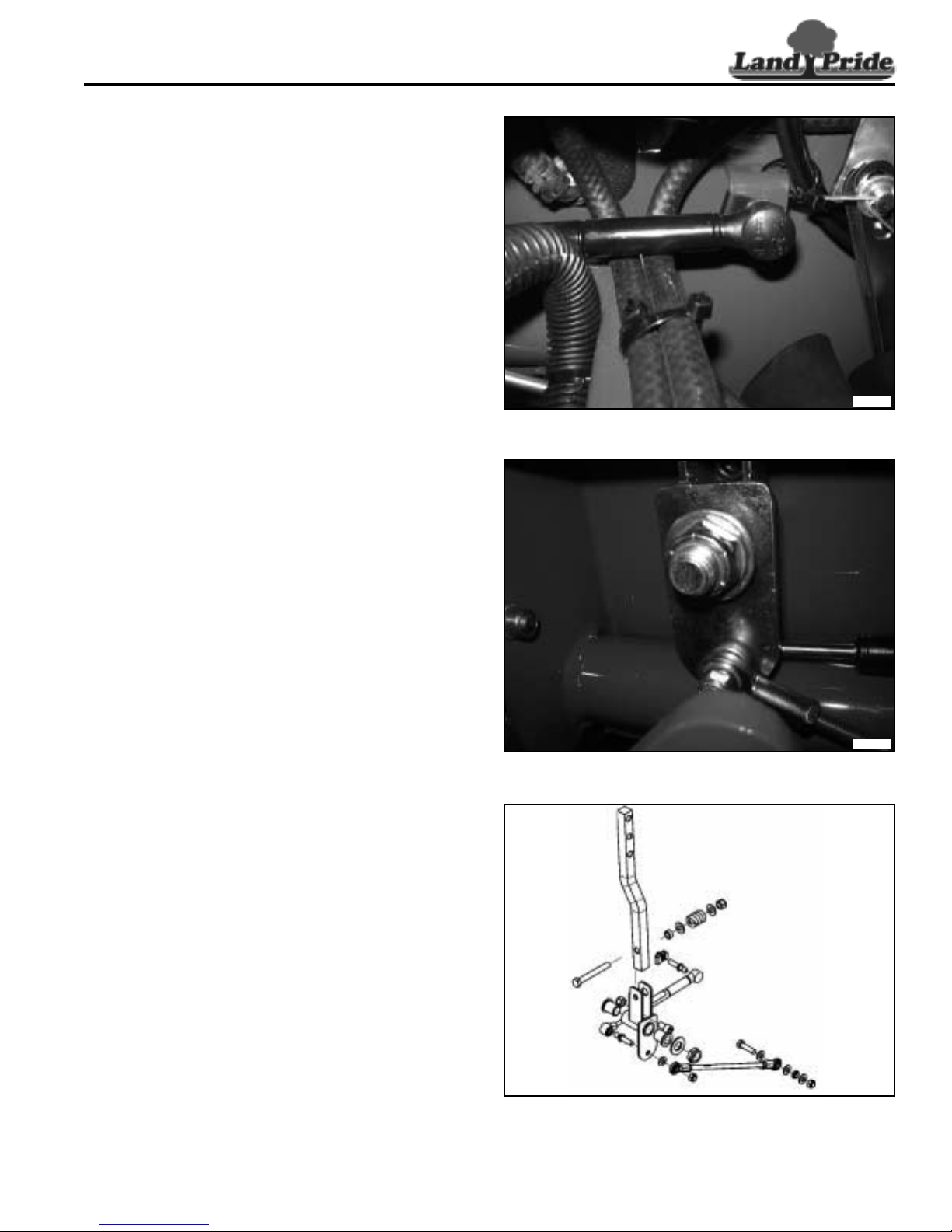

Refer to Figure 1-4:

1. Chock wheels to secure mower and prevent

movement while repairs are made.

2. Disconnect batter y to prevent accidental shock. See

“Battery Assembly Removal” on page 22.

3. Disconnect and remove seat pan assembly for easy

access.

4. Remove steering arm. See “Steering Arm

Removal” on page 4.

5. Unlock and remove retaining cap on the base end of

the control damper and remove from frame stud.

Refer to Figure 1-5:

6. Loosen and remove nut on the drive control rod

assembly and remove from steering lever.

7. Loosen and remove the steering lever retaining nut

and washer.

8. Remove steering lever bracket from frame mount

bolt. Ensure that the control arm is out in the brake

position and allow it to slide though the frame.

33681

Figure 1-4

Refer to Figure 1-6:

9. Unlock and remove retaining cap on the rod end of

the control damper and remove from the steering

lever stud.

10. Loosen and remove spring retaining nut and washer

from the control arm mount bolt.

11. Remove damper stud, pivot bushings, control arm

tension spring, and control arm from the steering

lever.

12. Repeat steps 4 through 11 for other side.

7/30/12

Figure 1-5

Figure 1-6

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

33682

33683

5

Table of Contents

Section 1: Operator Controls

Control Arm and Lever Installation

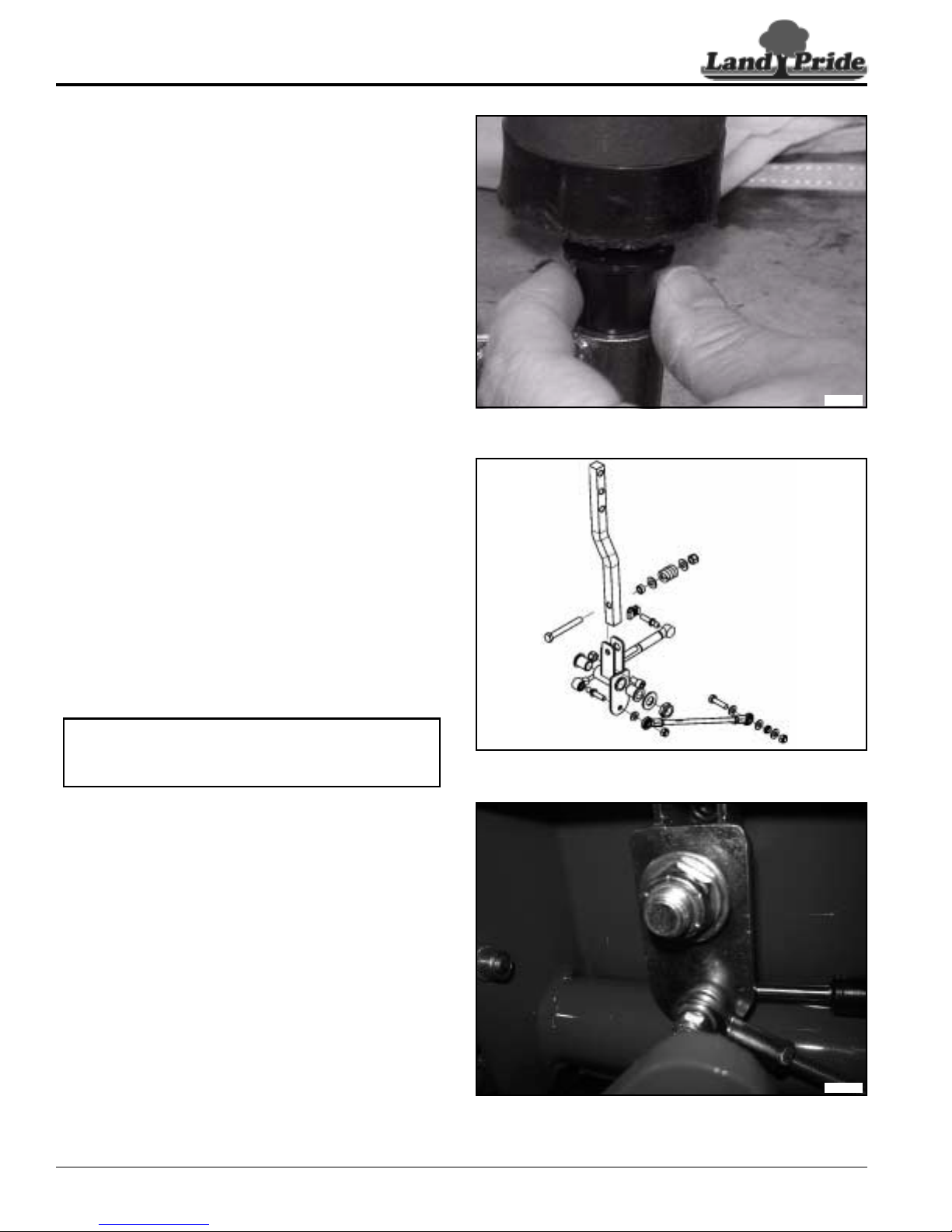

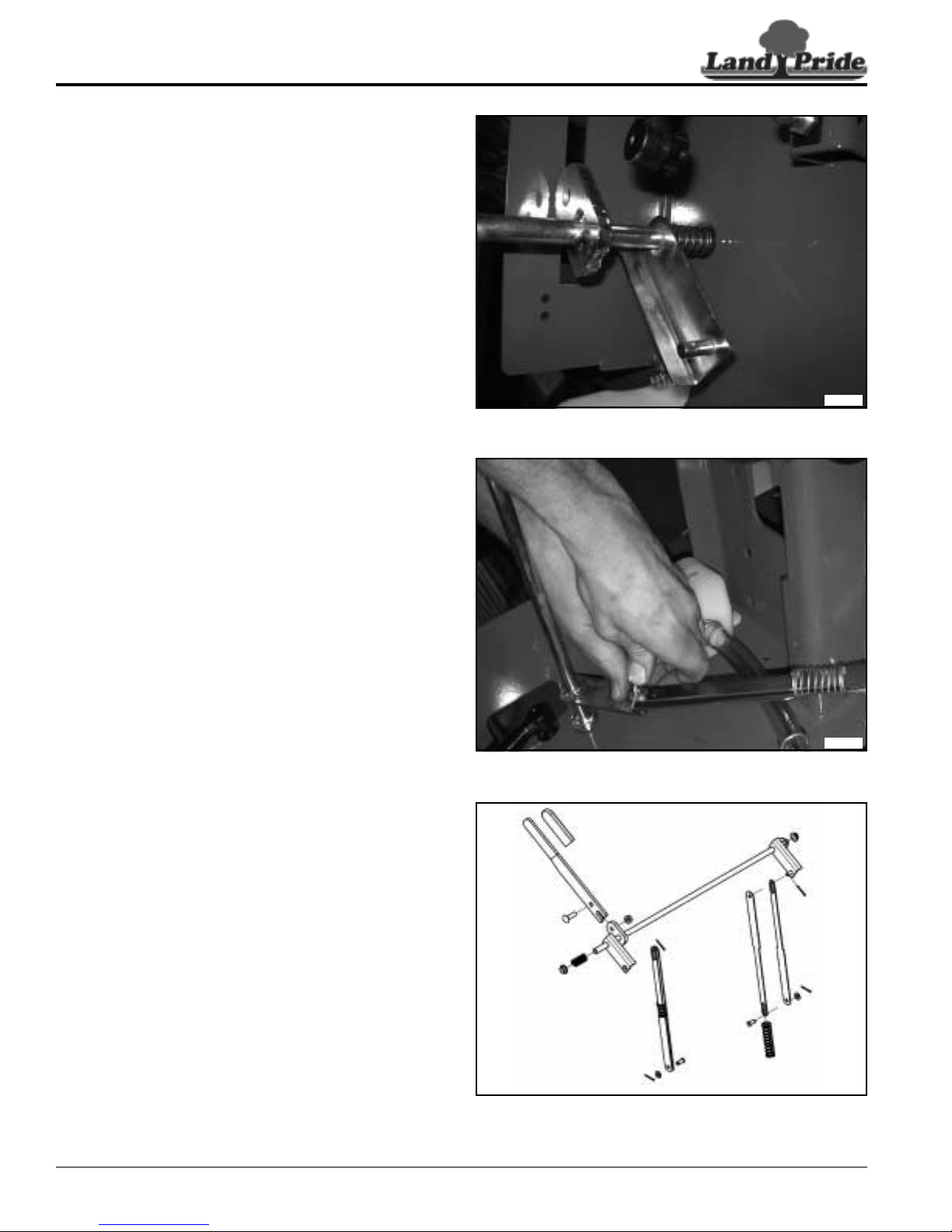

Refer to Figure 1-7:

1. Install flanged wear pivot bushings in both sides of

the control arm.

Refer to Figure 1-8:

2. Align and install the steering leveronthe control ar m

bolt.

3. Install the pivot washer, compression spring,

retaining washer and retaining lock nut.

4. Tightencompressionspringlocknut untilthreadsare

showing, may be adjusted to desired tension after

installation onto frame.

5. Install the damper stud into the rod end of the

damper and secure with retaining cap.

6. Insert threaded end of damper stud into the control

arm. The control rod retaining nut may be loosely

installed to aid in assembly.

33684

Figure 1-7

NOTE: Ensure correct alignment for left or right

hand side when inserting damper stud so that the

damper will be between frame and control arm.

Refer to Figure 1-9:

7. Push the control lever out into thebrakeposition and

insert though frame.

8. Align and install the control arm on the frame

mounting bolt, secure with retaining washerandlock

nut.

9. Tighten the steering arm retaining lock nut until tight,

then back off 1/8th of a turn to allow for free

movement of the steering arm.

10. Align and install the drive control rod assembly on

the threaded end of the control arm damper stud,

and secure with retaining lock nut.

11. Align and install base end of damper on frame stud

and secure with locking cap.

12. Install steering arm. See “Steering Arm

Installation” on page 4.

13. Repeat steps 1 though 12 for other side.

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

6

33683

Figure 1-8

33682

Figure 1-9

7/30/12

Table of Contents

Section 1: Operator Controls

Park Brake Removal

Refer to Figure 1-10:

1. Chock front wheels to secure mower and prevent

movement while repairs are made.

2. Disconnect batter y to prevent accidental shock. See

“Battery Assembly Removal” on page 22.

3. Raise and secure rear of mower and remove rear

wheels for easy access. See “Rear Drive Wheel

Removal” on page 35.

4. With park brake disengaged loosen and remove the

park brake handle retaining flanged lock nut.

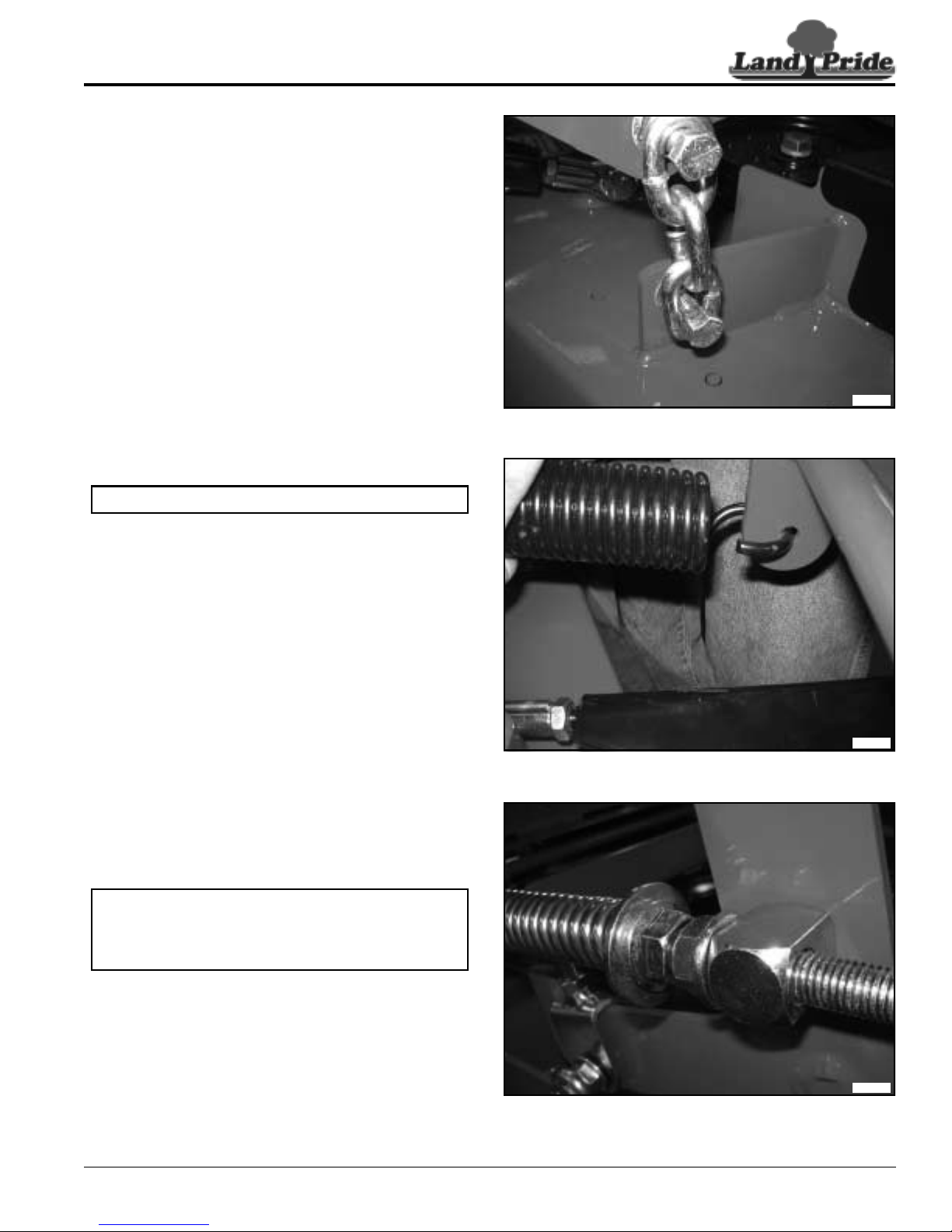

Refer to Figure 1-11:

5. Removethecarter pin and retaining washer from the

upper end of the brake link spring assemblies.

6. Disconnectthebrakelinkspringassemblies from the

park lever pivot assembly.

7. Pull the hair pin clip and retaining washer from the

lower end of the brake link spring assemblies.

8. Disconnectthebrakelinkspringassemblies from the

trans-axle brake control levers.

33685

Figure 1-10

Refer to Figure 1-12:

9. Remove the park lever pivot assembly by pushing

the assembly to the left and compressing the

compression spring. Pull the right side of the pivot

assembly from the pivot bushing on the right hand

side and pull it up and out of the unit.

7/30/12

Figure 1-11

Figure 1-12

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

33686

33687

7

Table of Contents

Section 1: Operator Controls

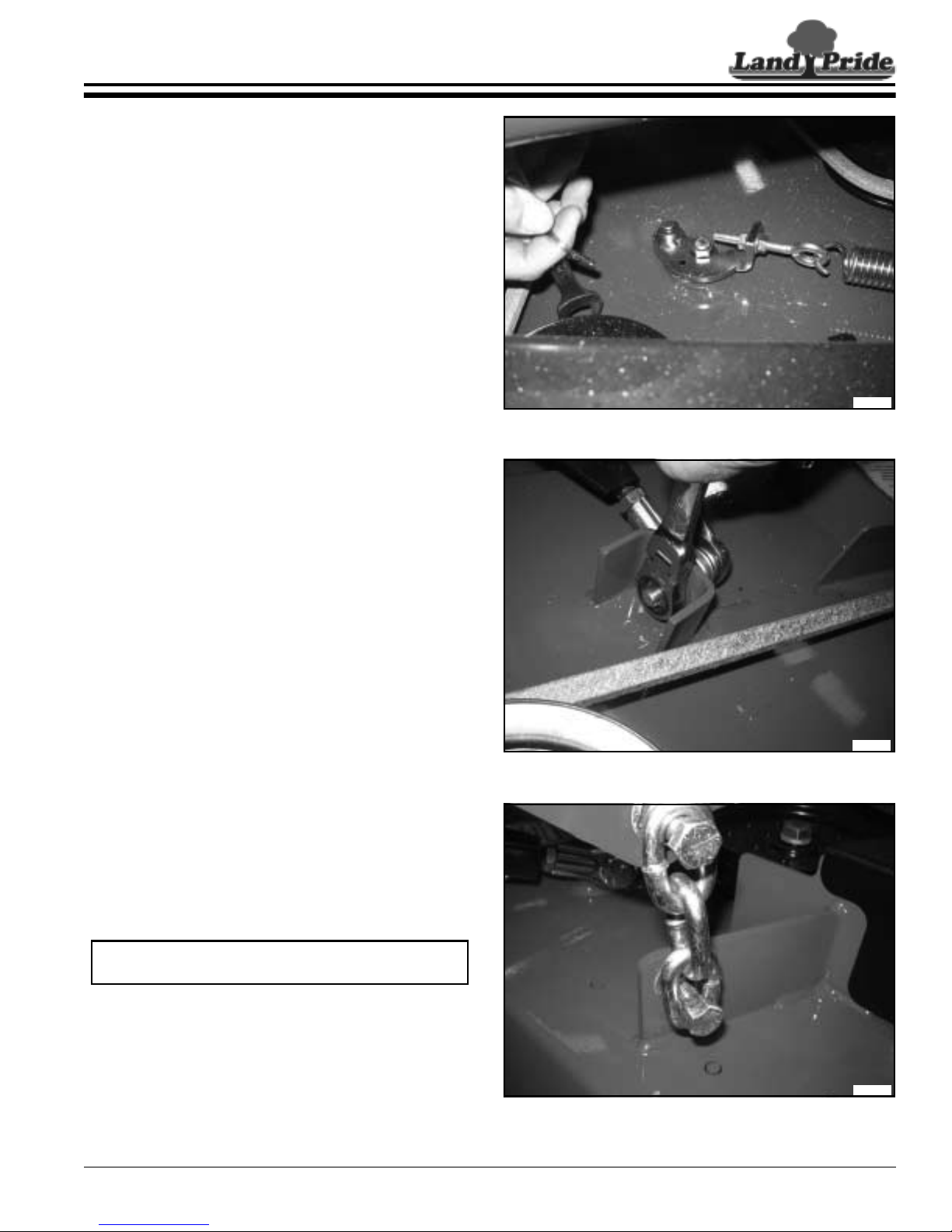

Park Brake Installation

Refer to Figure 1-13:

1. Align and insert the park lever pivot bushings in the

unit frame.

2. Install compression spring on the brake handle lug

end of the park lever pivot assembly.

3. Align and install the park lever pivot assembly into

the frame by starting with the left hand side and

compressing the spr ing. Install the r ight hand side of

the park lever pivot assembly into the frame and

allow the spring to push into place.

Refer to Figure 1-14:

4. Assemble the brake link spring assemblies by

inserting a brake link into each end of the spring.

5. Align and install the brake link spring assemblies

down to the trans-axle brake lever and attach to the

park lever pivot assembly.

6. Secure both brake link spr ing assembliesto the park

lever pivot assembly with retaining washers and

carter pins.

33687

Figure 1-13

Refer to Figure 1-15:

7. Attachthebottomofthebrakelinkspringassemblies

to the trans-axle brake control levers.

8. Secure both brake link spring assemblies to the

trans-axle brake control levers with retaining

washers and hair pin clips.

9. Align and install the park brake handle though the

frame and secure with carriage bolt and flanged lock

nut.

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

8

33688

Figure 1-14

33689

Figure 1-15

7/30/12

Table of Contents

Section 1: Operator Controls

Deck Lift Removal

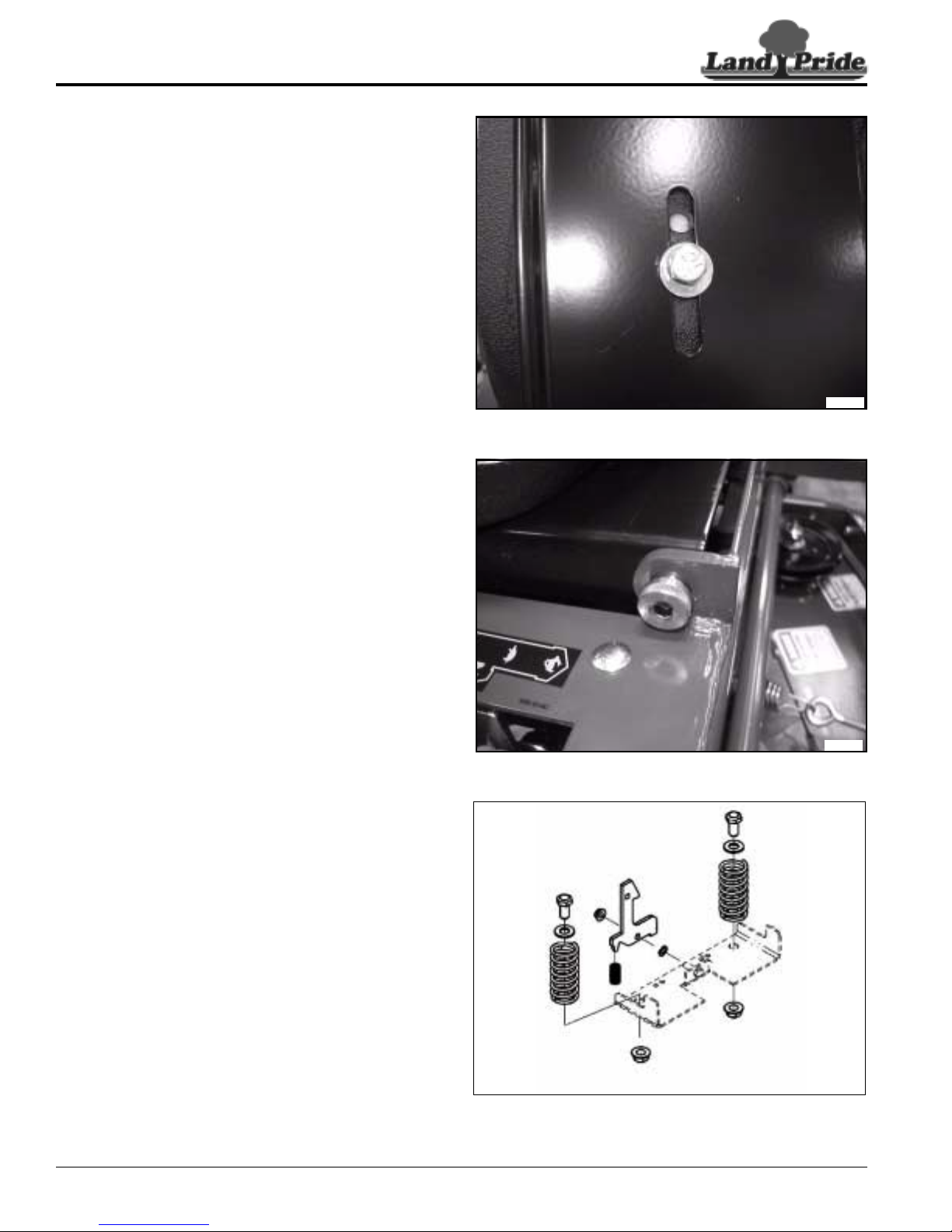

Refer to Figure 1-16:

1. Chock wheels to secure mower and prevent

movement while repairs are made.

2. Remove the deck height stop from the height gauge

bar.

3. Place blocks under the mower deck and lower the

deck until the deck is fully supported by the blocks.

Refer to Figure 1-17:

33690

Figure 1-16

NOTE: Ensure that the deck chains are all slack.

4. Remove the E-clip from the height gauge bar

trunnion that attaches the height gauge bar to the

foot lift peddle and remove the height gauge bar

trunnion from the foot lift peddle.

5. Slide the height gauge bar out of the frame channel.

The height pawl will not need to be removed for

removal of the height gauge bar.

6. Disconnect and remove the deck lift assist spring

from the deck lift pivot.

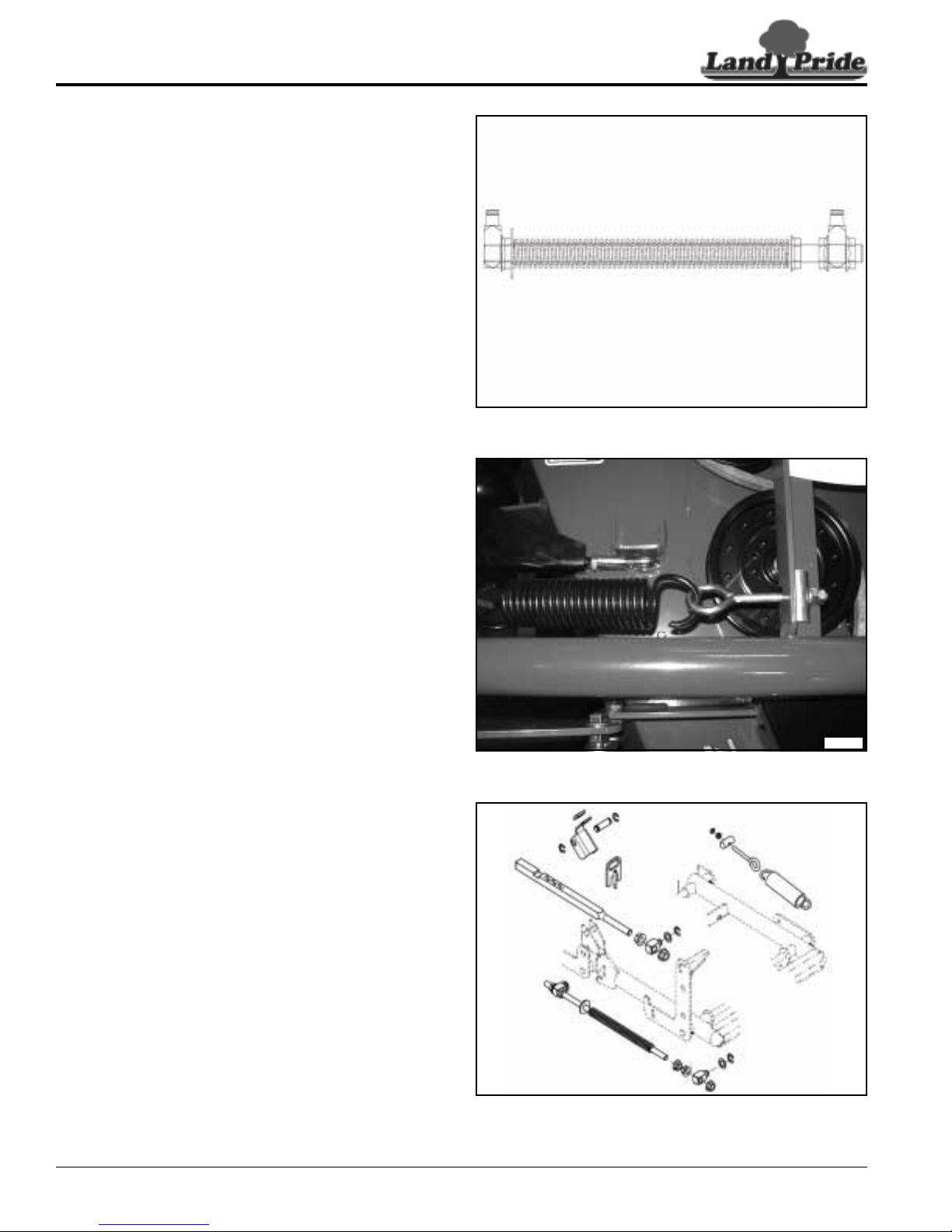

Refer to Figure 1-18:

7. Remove the E-clips from both the front and rear of

the lift spring assembly trunnions.

NOTE: Springsare under compression against the

frame stop and front jam nut on the lift spring

assembly and care should be taken when

removing.

33691

Figure 1-17

8. Remove lift spring tr unnion from the front deck lift

armandloosenthenutsandmovethetrunniontothe

end of the spring rod.

9. Compress the spring assembly back to loosen and

removethe lift spr ing trunnion from the back decklift

arm.

10. Allow spring on the lift spring assembly to

uncompress and remove the lift spring assembly

through the slot in the frame stop

7/30/12

Figure 1-18

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

33692

9

Table of Contents

Section 1: Operator Controls

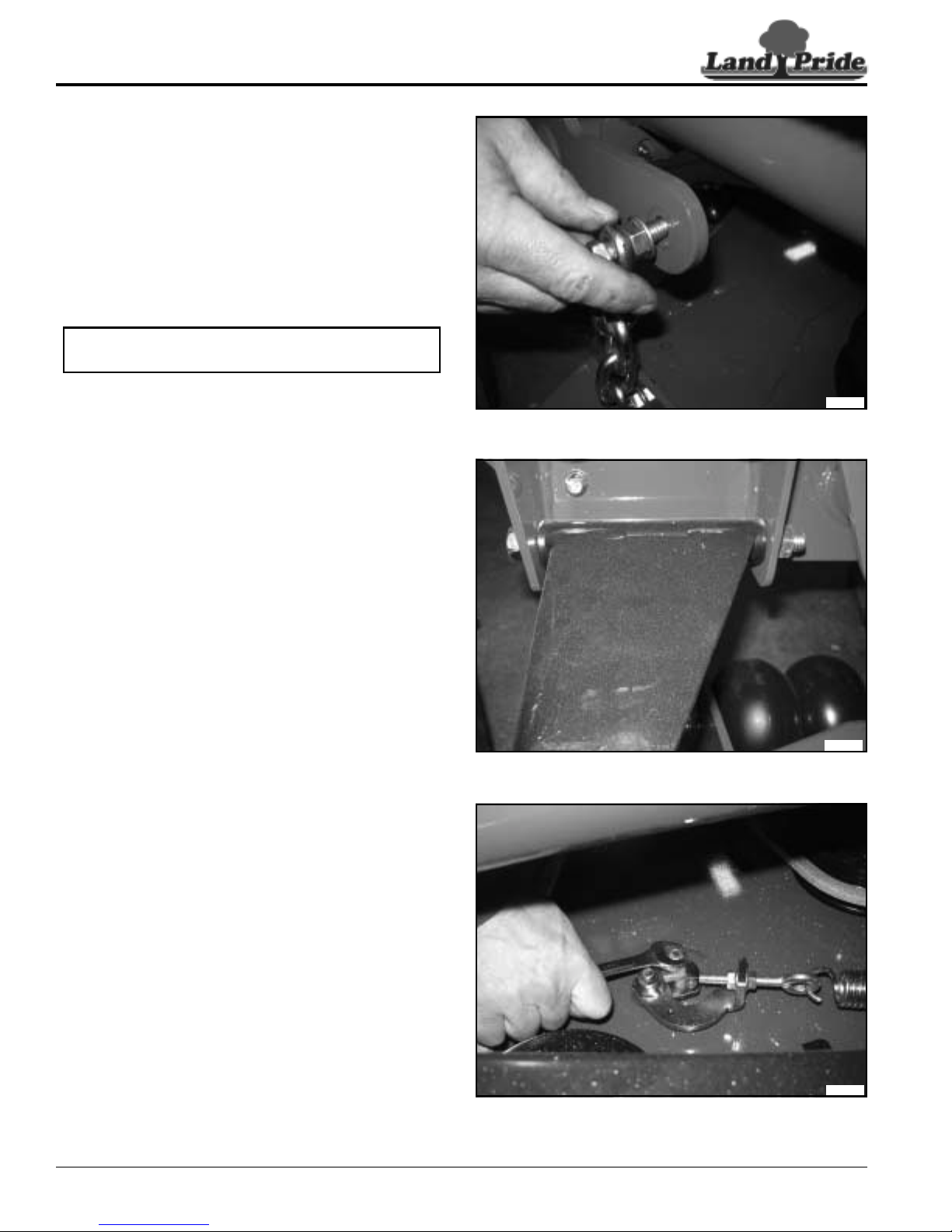

Deck Lift Installation

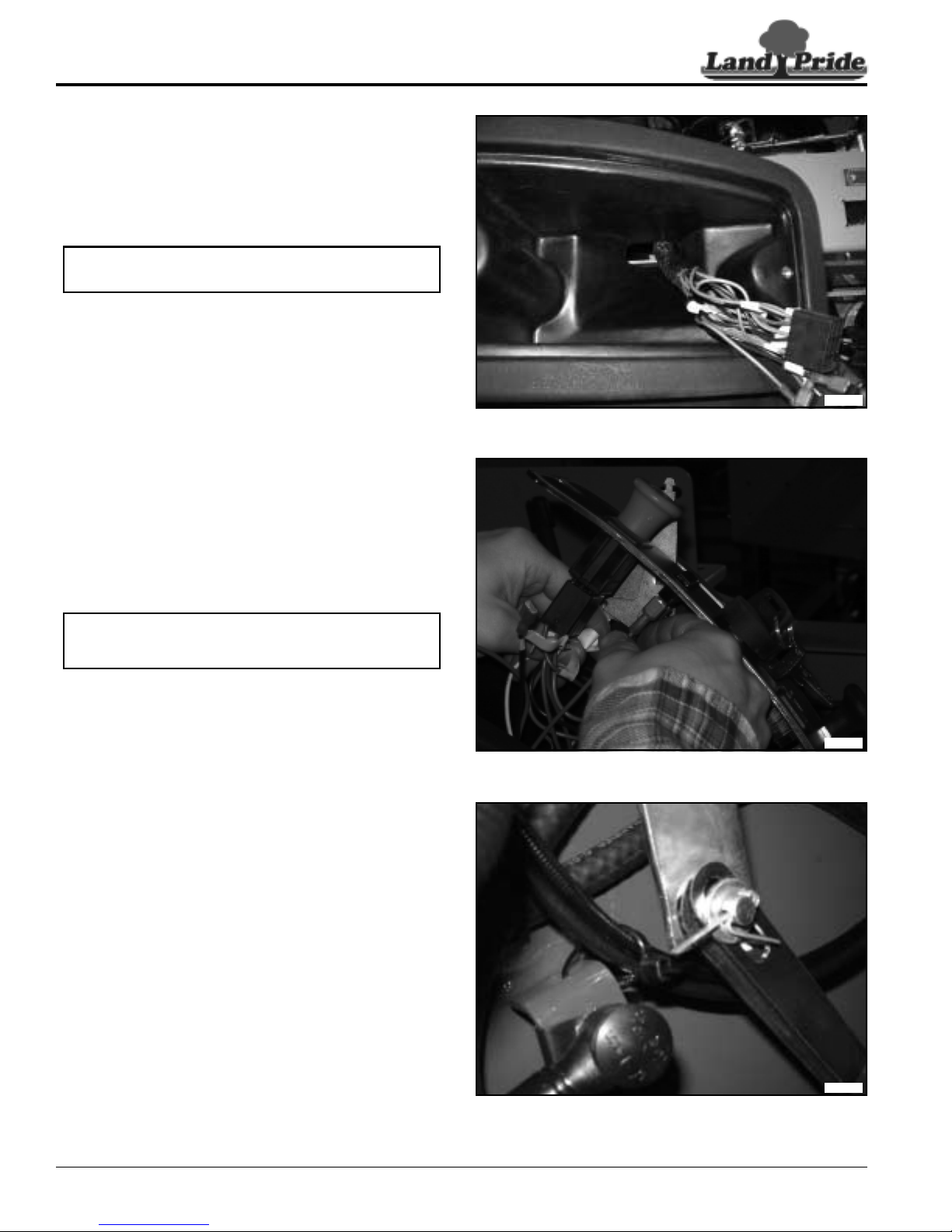

Refer to Figure 1-19:

1. Raise and block deck up to allow chains to be loose

during the installation of the lift spring assemblies.

2. Install jam nut with flange out on the threaded end of

the lift spring rod, allow enough room to install and

tighten the rear lift spring trunnion. Tighten jam nut

against the rear lift spring trunnion and tighten.

3. Install the spring stop washer and spring on to the

spring rod.

4. Install the spring compression flanged nut, jam nuts,

and the front lift spring trunnion loosely on the spring

rod.

Refer to Figure 1-20:

33693

Figure 1-19

5. Align the lift spring assembly with the spring stop

washer to the front of frame stop and insert the rod,

compressing the spring assembly to install the rear

lift spring trunnion in the rear deck lift arm. Secure

rear lift spring trunnion to the rear deck lift arm with

E-clip.

6. Tightentheliftspring compression nut and install the

front lift spring trunnion in the front deck lift arm.

Secure the front lift spr ing tr unnion to the front deck

lift arm with E-clip.

7. Tightenjamnutsagainstthe front lift spring trunnion.

The lift spring compression nut will be adjusted per

“Deck Lift Assist Springs” on page 51.

8. Align and install deck lift assist spr ing eye bolt in

frame and connect the spr ing to the deck lift pivot.

Refer to Figure 1-21:

9. Install jam nuts and the height gauge bar trunnion

loosely on the end of the height gauge bar.

10. Install the height gauge bar in the frame channel and

install the height gauge bar trunnion in the foot lift

peddle and secure with E-clip.

11. Attach the height pawl to the frame channel with the

height pawl pivot pin and secure with E-clips.

12. Install the deckheightstopandfollowtheadjustment

for “Deck Cutting Height And Leveling” on page

50.

33694

Figure 1-20

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

10

33695

Figure 1-21

7/30/12

Table of Contents

Section 1: Operator Controls

Control Panel Removal

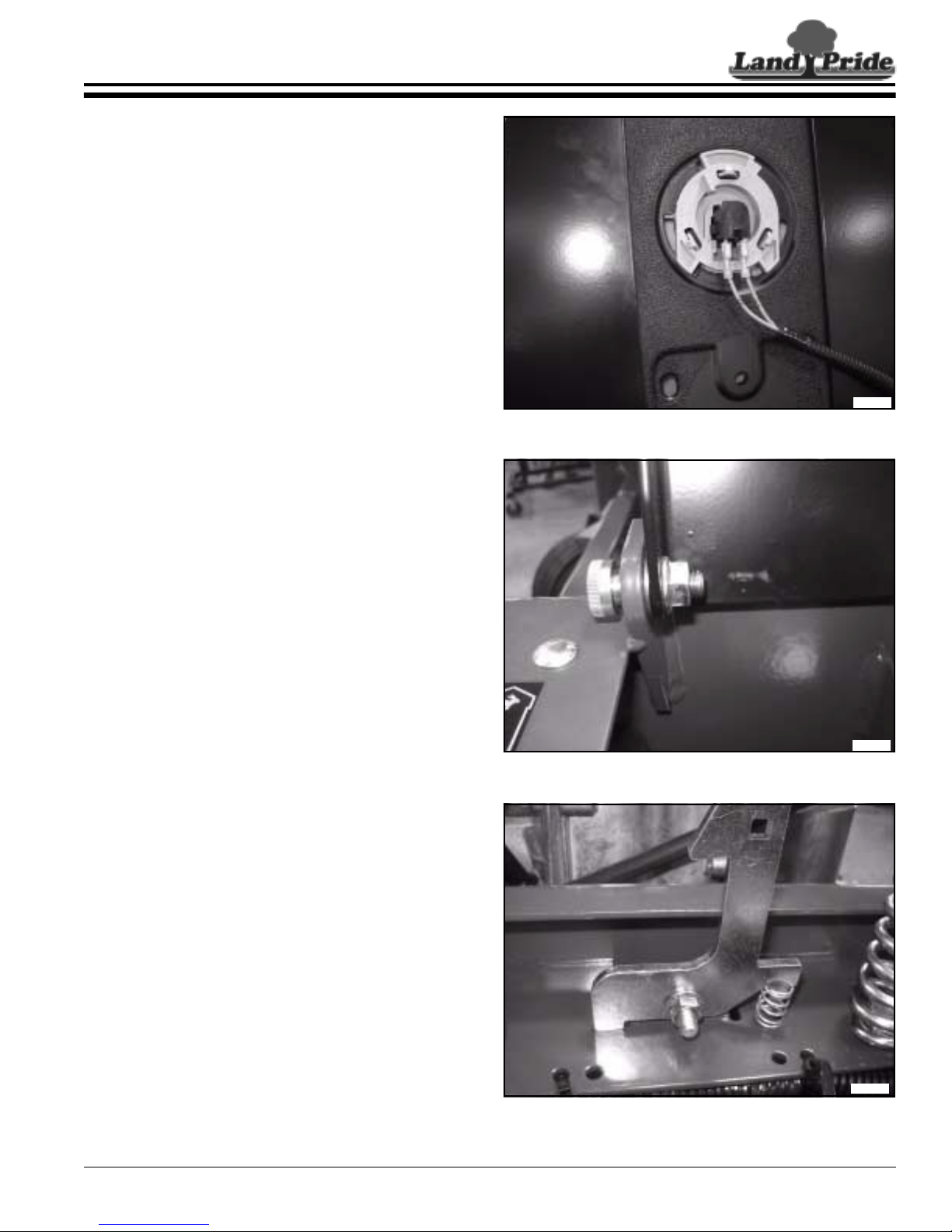

Refer to Figure 1-22:

1. Chock wheels to secure mower and prevent

movement while repairs are made.

2. Disconnect batter y to prevent accidental shock. See

“Battery Assembly Removal” on page 22.

3. Disconnect and remove seat for easy access.

4. Cut and remove plastic zip ties securing the throttle

and choke cables to the frame.

Refer to Figure 1-23:

5. Loosenengineclampsonboththethrottleand choke

cables. Mark each cable for reference.

6. Disconnect the throttle and choke cables from the

engine.

33685

Figure 1-22

NOTE: Picture is for reference only, cable

attachments will vary with engine model and type.

Refer to Figure 1-24:

7. Loosen and remove the cross head bolts on the

control panel.

8. Lift the control panel out of the fuel tank and

disconnect all electrical connections.

9. While removing the control panel, insure that the

throttle and choke cable do not become bound and

pull free of the opening in the bottom of the fuel tank.

33696

Figure 1-23

7/30/12

Figure 1-24

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

33697

11

Table of Contents

Section 1: Operator Controls

Control Panel Installation

Refer to Figure 1-25:

1. Start by routing the throttle and choke cable though

the top of the fuel tank and out the opening in the

bottom of the cavity in the fuel tank.

NOTE: Mark the ends of each cable to identify

when connecting to the engine.

2. Route the throttle cable and choke cable along the

frame and between the bumper and engine, do not

connect to the engine at this time.

33698

Figure 1-25

Refer to Figure 1-26:

3. Connect the electrical connectors to the control

panel. See the “Main Harness Wiring Schematics”

on page 25 of the manual for more information on

correct connections.

NOTE: Ensure that all connectors are spaced and

firmly connected.

4. Secure control panel to the fuel tank with cross head

bolts. Tighten bolts until snug against the control

panel.

Refer to Figure 1-27:

5. Connect the throttle and choke cable to engine as

per engine specifications, see engine manual for

more information on correct engine set up.

6. Attach the throttle and choke cable to the engine

clamps allowing for enough slack to adjust correctly.

7. Secure the throttle and choke cables to the frame

withplasticziptiestopreventthecablesfrom binding

or rubbing.

8. Test cable operation for binding or dragging of

cables.

33699

Figure 1-26

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

12

33685

Figure 1-27

7/30/12

Table of Contents

Section 2: Seat & Frame

Section 2: Seat & Frame

Seat and Latch Removal

Refer to Figure 2-1:

1. Chock wheels to secure mower and prevent

movement while repairs are made.

2. Disconnect batter y to prevent accidental shock. See

“Battery Assembly Removal” on page 22.

3. Unlatch seat pan and pull the seat assembly into the

upright forward position.

4. Disconnect the operator presence switch from the

wiring harness at the switch.

Refer to Figure 2-2:

5. Loosenandremovetheseatpanretainernutsonthe

left and right side of the seat pan assembly.

6. Support the seat pan assembly and remove both

retaining hex socket bolts, remove assembly.

7. Loosen and remove four seat retaining bolts and

remove pan from seat.

33700

Figure 2-1

Refer to Figure 2-3:

8. With a long socket inserted in spring assembly,

loosen and remove the seat spring retaining nut to

remove spring.

9. Loosen and remove the latch retaining nut.

10. Holding latch return spring, remove the latch lever

from the mounting bolt.

7/30/12

Figure 2-2

Figure 2-3

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

33701

33702

13

Table of Contents

Section 2: Seat & Frame

Seat and Latch Installation

Refer to Figure 2-4:

1. Align and install seat pan on seat with fourbolts,lock

washers and flat washers.

2. Center seat bolts on the seat pan slot to the middle

and tighten bolts.

Refer to Figure 2-5:

3. Align and install seat pan pivot bushings in frame

from the inside out.

4. Align and install seat pan assembly on unit with hex

socket bolts, raise and secure with flange nuts.

33703

Figure 2-4

Refer to Figure 2-6:

5. Insert washer and spr ing retaining bolt into the open

end of the seat springs.

6. Align and install the seat spring into frame and

secure with flanged lock nut.

7. Install the wavy spring washer on the seat latch

frame mount bolt.

8. Install the latch return spring onto the latch.

9. Align and install the latch on the seat latch frame bolt

while compressing the return spring.

10. Secure latch with the flanged lock nut, back nut off

1/8th of a turn.

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

14

33704

Figure 2-5

Figure 2-6

7/30/12

Table of Contents

Section 2: Seat & Frame

Floor Panel Removal

Refer to Figure 2-7:

1. Chock wheels to secure mower and prevent

movement while repairs are made.

2. Loosen and remove floor panel retaining bolts.

33706

Figure 2-7

Refer to Figure 2-8:

3. Pull forward on the front section of the floor panel to

disengage the slotted rear section of floor panel

mounting area.

Floor Panel Installation

Refer to Figure 2-9:

1. Align and install the slotted rear section of the floor

panel with the mower frame.

2. Align and install floor panel retaining bolts.

33707

Figure 2-8

7/30/12

Figure 2-9

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

33706

15

Table of Contents

Section 2: Seat & Frame

Engine Bumper Guard Removal

Refer to Figure 2-10:

1. Chock wheels to secure mower and prevent

movement while repairs are made.

2. Disconnect batter y to prevent accidental shock. See

“Battery Assembly Removal” on page 22.

NOTE: Ensure that mower is cooled before

performing any repair around the engine and

muffler to prevent accidental burning.

3. Cut and remove all plastic zip ties securing cables

and wires to the engine bumper guard.

4. Loosen and removethe locknuts from the Alan head

bolts on the lower bumper frame and remove bolts.

Refer to Figure 2-11:

5. Loosen and remove the locknuts on the engine

bumper guard bolts secured to the pedestal. Do not

remove bolts until the engine bumper guard is

removed from the unit.

6. With the lower engine bumper guard bolts removed

andthe nuts removedfrom the bolts on the pedestal,

lifttheenginebumperguardupatthefronttoremove

bolts and back to clear the engine muffler.

33708

Figure 2-10

Engine Bumper Guard Installation

Refer to Figure 2-11:.

NOTE: Never operate unit with out the rear engine

bumper guard installed to prevent accidental injury

or damage to the mower.

1. Assemble the engine bumper guard and tighten all

fasteners to standard torque. See “Torque Values

Chart” on page 79.

2. Align engine bumper guard over the muffler and

attachthefrontoftheguardtothepedestal base with

retaining bolts and lock nuts. Do not tighten until all

bolts have been installed.

Refer to Figure 2-12:

3. Insure all cables and wires are aligned inside of the

engine bumper guard and not pinched in between

the assembly and the frame.

4. Alignandinstallthelowerengine bumper guardbolts

thoughthe assembly and into the frame. Secure with

the flanged locknuts.

5. Tighten all the lower engine bumper guard bolts and

the two pedestal retaining bolts until the flanged lock

nuts are firmly secured to the main frame.

6. Withplasticziptiessecureall loose cablesandwires

to the engine bumper guard assembly.

33709

Figure 2-11

33710

Figure 2-12

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

16

7/30/12

Table of Contents

Section 3: Mower Deck

Section 3: Mower Deck

Deck Removal

Refer to Figure 3-1:

1. Chock wheels to secure mower and prevent

movement while repairs are made.

2. Remove the deck height stop from the height gauge

bar.

3. Placeblocksorpalletskid under the mower deckand

lower the deck until the deck is fully supported and

the deck chains are slack.

4. Raise floor panel to access the over center latch.

Loosen deck belt tension by pulling the securing pin

onthe overcenterlatch assembly and rotate counter

clockwise to disengage the latch. Remove belt from

the clutch.

Refer to Figure 3-2:

5. Remove the seat pan assembly from the mower for

ease of access. See “Seat and Latch Removal” on

page 13.

6. Loosen the nuts on the bolts for the deck interface

gimbals and remove the bolts from the deck strut

bracket.

7. Thedeckinterfacearmsmayberemovedorsecured

to prevent them from falling onto the deck dur ing

removal of the deck.

33711

Figure 3-1

Refer to Figure 3-3:

8. Loosen and remove the flanged nuts securing the

deck lift chains to the deck lift arms. Remove the

bolts from the deck lift chains and allow the chains to

drop down onto the mower deck.

NOTE: Lift chains do not need to be removed from

the deck for these repairs.

9. Removethedeck assemblyfromunderthemowerby

pulling it out from the side.

7/30/12

Figure 3-2

Figure 3-3

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

33712

33690

17

Table of Contents

Section 3: Mower Deck

Deck installation

Refer to Figure 3-4:

1. Slide the deck assembly under the mower and align

the deck so that the lift chains are under each of the

deck lift arms.

2. Raise the deck approximately 3 to 4 inches to allow

slack in the deck lift chains when installing.

3. Installthedeckliftarmchainboltsonthedeck chains

and secure with the inner flange nuts.

NOTE: Do not over tighten the chain on the bolt.

The chain should pivot easily on the bolt.

4. Attach the deck lift chains to the deck lift arms and

secure with the flanged nuts.

Refer to Figure 3-5:

5. If the deck interface arms were removedduring deck

removal, align and reinstall the deck interface arms

totheframewithpivotboltsandflangedlocknuts. Do

nottightenuntilthedeck interfacegimbalshavebeen

secured to the deck str ut bracket.

6. Align the deck interface arm gimbals to the inside of

the deck str ut bracket. Secure with bolts and

locknuts through the interface gimbals. Tighten strut

pivot bolt lock nuts.

Refer to Figure 3-6:

7. Install belt on the clutch insuring correct belt routing

as per the “Deck Drive Belt Removal &

Installation” on page 64.

8. Tighten belt by rotating the over center latch

assembly clockwise until the latch assembly

engages. Secure the over center latch with the latch

pin.

9. Remove blocks and adjust deck as per the “Deck

Adjustments” on page 50.

33713

Figure 3-4

33714

Figure 3-5

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

18

33715

Figure 3-6

7/30/12

Table of Contents

Section 3: Mower Deck

Pulley and Blade Hub Removal

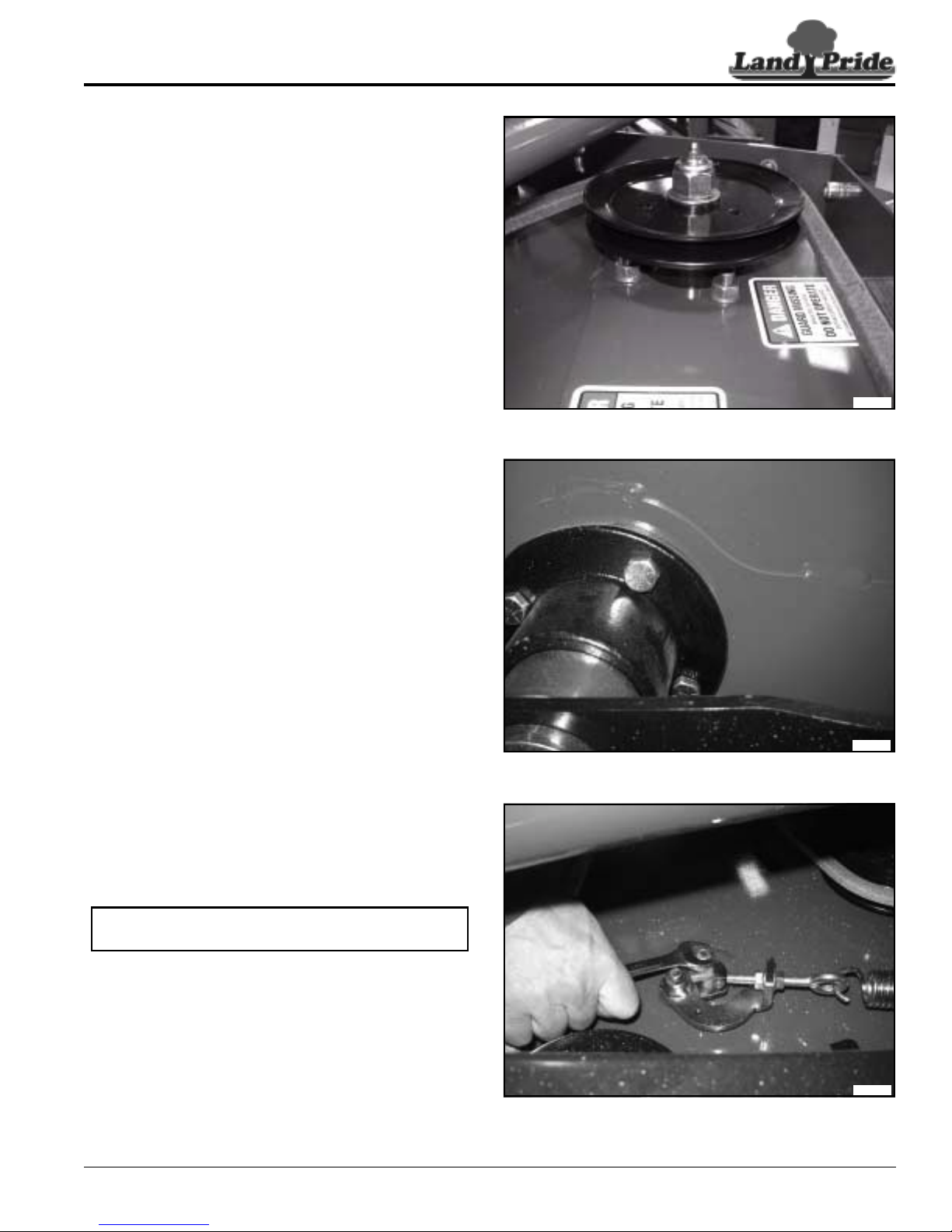

Refer to Figure 3-7:

1. Chock wheels to secure mower and prevent

movement while repairs are made.

2. Remove the floor panel to access the over center

latch. See “Floor Panel Removal” on page 15.

3. Loosen deck belt tension by pulling the securing pin

onthe overcenterlatch assembly and rotate counter

clockwise to disengage the latch. Remove belt from

the clutch.

4. Loosen and remove pulley retaining nut on spindle

assembly to be removed and remove pulley.

Refer to Figure 3-8:

5. Loosen and remove blade bolt from spindle

assembly to be removed and remove blade.

6. Loosen and remove the four spindle assembly

retaining nuts on top of the deck for the spindle

assembly to be removed. Pull the spindle assembly

out though the bottom of the mower deck.

33716

Figure 3-7

Pulley and Blade Hub Installation

Refer to Figure 3-9:

1. Insert spindlehubassemblythoughthebottom of the

deck and attach with bolts, lock washers, and nuts.

Tighten in a cross pattern until properly torqued.

2. Alignand install the drive pulley onto the spindle with

key and locknut. Tighten locknut to the correct

torque.

3. Install blade washer and blade onto the spindle

assembly and tighten bolt to approximately 45 ft/lbs.

NOTE: Do not over tighten blade bolt as this bolt

will tighten during operation of the mower.

4. Ensure correct belt routing per “Deck Drive Belt

Removal & Installation” on page 64.

5. Tighten belt by rotating the over center latch

assembly clockwise until the latch assembly

engages. Secure the over center latch with the latch

pin.

6. Perform belt tension adjustments as per instructions

on “Deck Drive Belt Adjustment” on page 49.

33717

Figure 3-8

33715

Figure 3-9

7/30/12

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

19

Table of Contents

Section 3: Mower Deck

Spindle Hub Rebuild

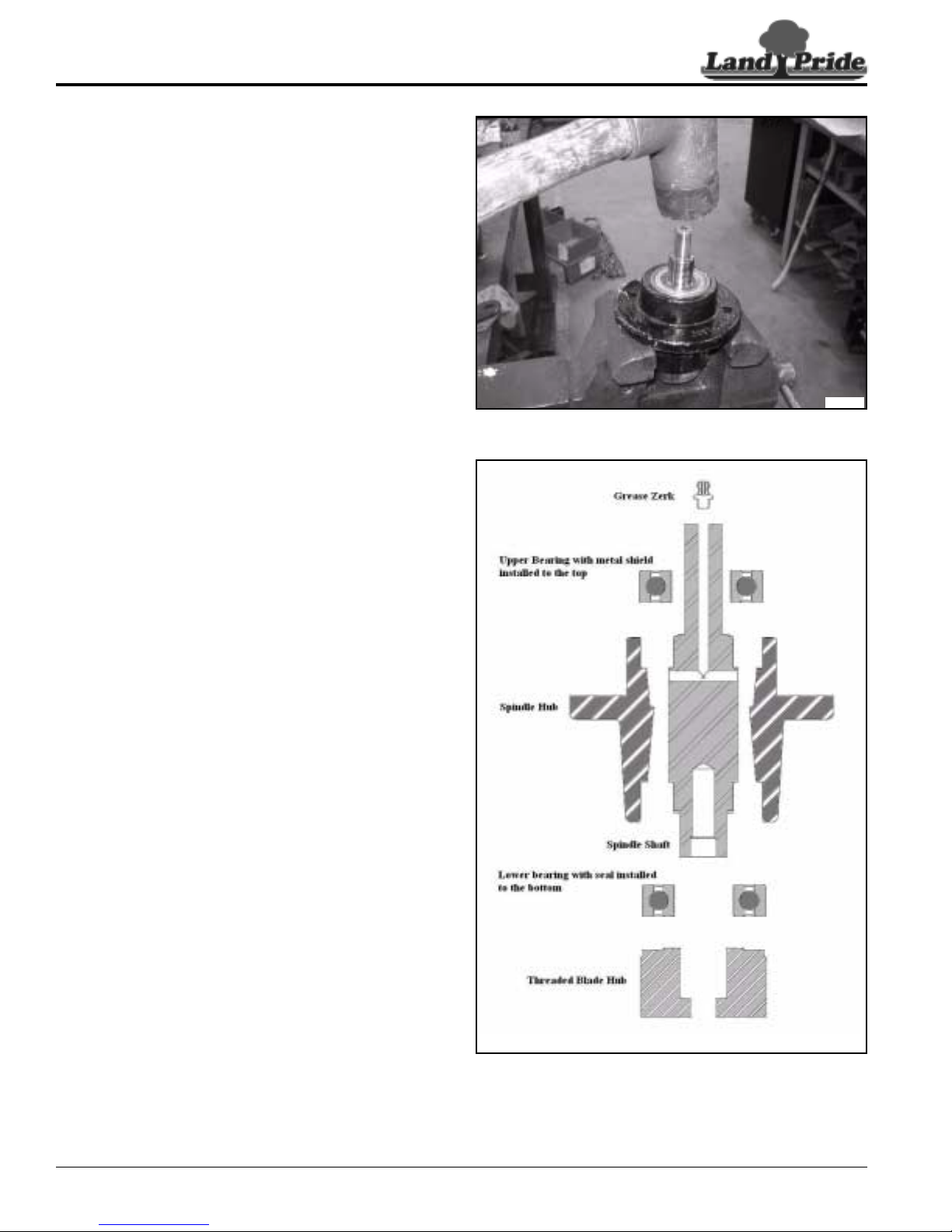

Refer to Figure 3-10:

1. Secure spindle hub assembly in vice with the lower

shaft and bearing clear of vise clamps.

2. With spindle pulley removed, loosen and removethe

grease zerk from the spindle.

3. Witharubbermallet,tapthespindle shaft to drivethe

spindle shaft, lower bearing, and blade hub from the

bottom of the spindle hub assembly.

Refer to Figure 3-11:

4. Loosenvice,turn the spindle hubassemblyoverand

re-secure in vice.

5. With a bearing removal tool or pipe, drive the upper

bearing out the top of the spindle hub.

6. Loosen vice and remove spindle hub.

7. Secure the spindle shaft with the lower bear ing and

blade hub attached in vice with the blade hub facing

upright. Pad shaft in vice with shop rag to prevent

scaring or damage to the spindle shaft.

8. Loosen and remove the blade hub from the spindle

shaft. This is a right hand thread, 1-14 class 2B

threaded shaft.

9. Remove the lower bearing from the spindle shaft. A

bearing puller may be required for removal.

10. Clean and replace spindle hub assembly parts as

needed.

11. Pre-grease or “pack” the bearing before assembly to

ensure adequate lubrication and for ease of

installation of the bearing into the spindle hub.

12. Secure the spindle shaft with the blade bolt facing

upright in vice. Pad the vice with shop rag to prevent

scaring or damage to the spindle shaft.

13. Install the bottom bearing onto the spindle shaft and

with a bearing set tool or small pipe ensure that the

bearing isfullyseatedagainstthespindleshaftlower

bearing stop.

33718

Figure 3-10

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

20

33719

Figure 3-11

7/30/12

Table of Contents

Section 3: Mower Deck

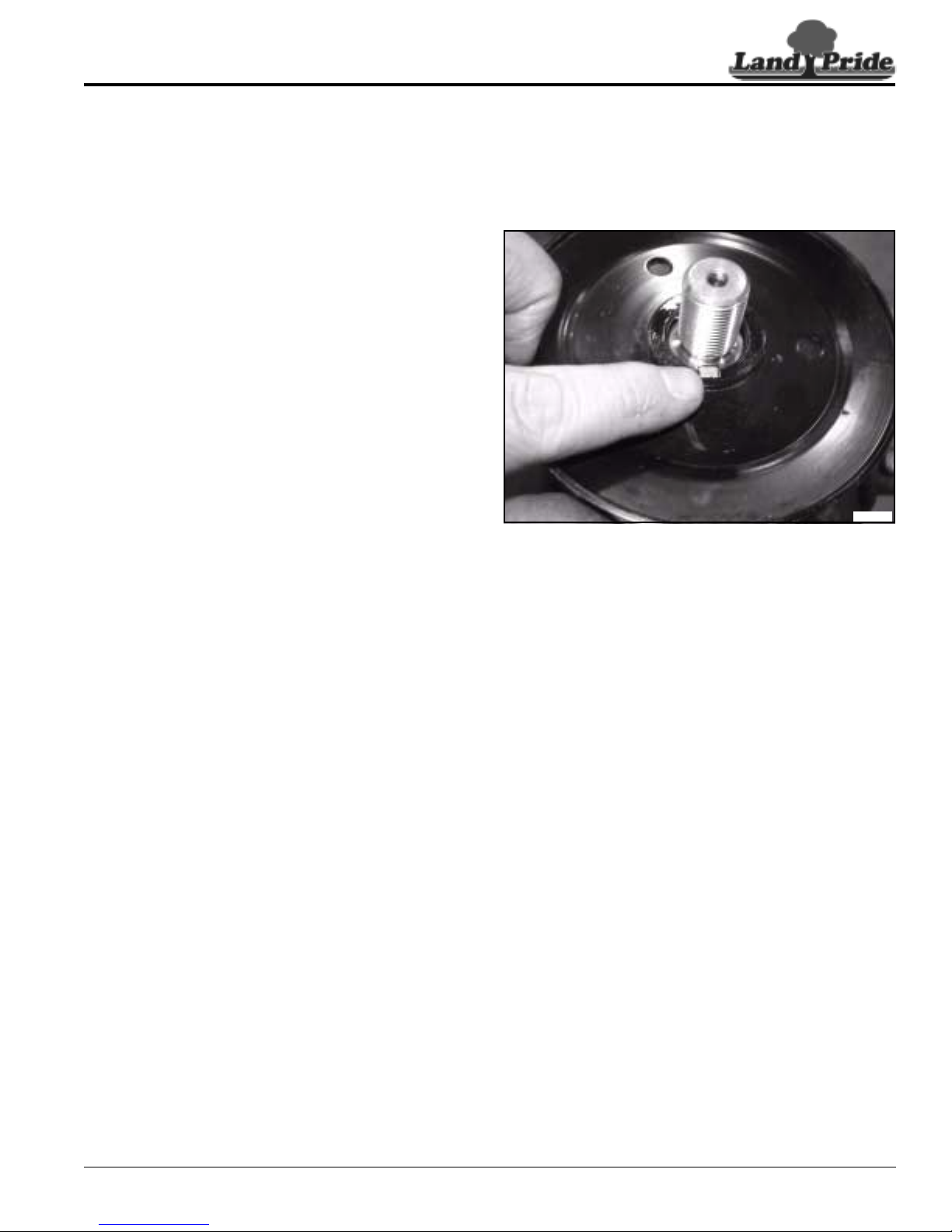

Refer to Figure 3-12:

14. Thread the blade hub onto the spindle shaft. Ensure

that the stepped bearing surface is facing the lower

bearing and tighten until firmly secured against the

lower bear ing.

15. Loosen and remove the spindle shaft from the vice

and set aside on a clean surface for installation in

spindle hub. Secure the spindle hub in vice with the

top side up.

16. Apply a light coat of grease to the upper spindle

shaft. Align and install the spindle shaft assembly

though the bottom the spindle hub assembly. With a

rubber mallet, tap the blade hub to fully seat the

lower bear ing into the spindle hub.

17. Loosen vice, turn thespindle hub assembly overand

re-secure in vice with the blade hub down and

against the vise clamps to prevent lower bearing

from being driven out during installation of the top

bearing.

18. With bearing set tool or pipe, install the top bearing

overthespindleshaft.Ensurethatthemetalshieldis

installed out, away from the spindle hub assembly,

and that the bearing isfully seated in the spindle hub.

19. Install grease zerk in the top of the spindle shaft and

tighten hand tight. Attach grease gun and fill the

spindle hub assembly until grease comes out the

purge hole on the upper bearing.

20. Remove spindle hub assembly from vice. If the

spindle hub is not going to be installed in mower,

install the spindle pulley and key onto the spindle.

33720

Figure 3-12

7/30/12

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

21

Table of Contents

Section 4: Electrical System

Section 4: Electrical System

Battery Assembly Removal

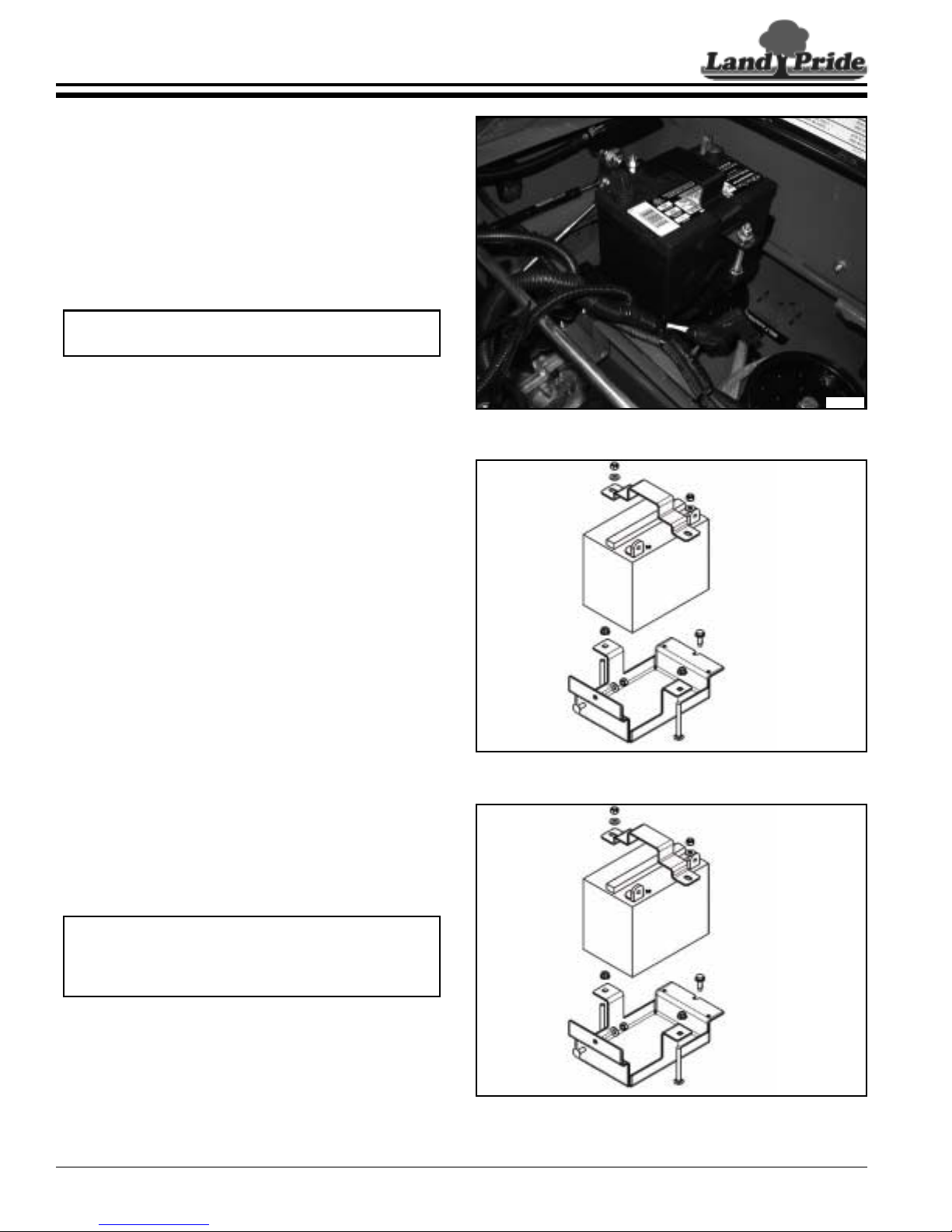

Refer to Figure 4-1:

1. Chock wheels to secure mower and prevent

movement while repairs are made.

2. For ease of access, remove the seat assembly. See

“Seat and Latch Removal” on page 13.

3. Loosen and disconnect the system battery cables

from the battery.

NOTE: Disconnect the ground cable before

removing the positive cable.

4. Loosen and remove the lock nuts on the battery hold

down bracket and remove the hold down bracket.

Refer to Figure 4-2:

5. Loosenandremovethejamnutfromthebatteryhold

down bracket bolts and remove the bolts from the

battery tray. Remove the battery from the battery

tray.

6. Loosen and remove the batter y tray retaining bolts

that connect the battery tray to unit frame.

7. Remove the batter y tray from the unit frame.

Battery Assembly Installation

Refer to Figure 4-3:

1. Align and install the battery tray in the unit frame.

2. Secure the battery tray with retaining bolts.

3. Install battery in the battery tray with terminals to the

left hand side of the unit.

4. Install the battery hold down bolts in the battery tray

and secure with flanged lock nuts.

5. Install the battery hold down strap over the battery

and secure with flanged lock nuts.

33721

Figure 4-1

33722

Figure 4-2

NOTE: Alwaysinstallthegroundsystemcableafter

the positive system cable to prevent accidental

shock or damage to the electronic components in

the mowers electrical system.

6. Attach the positive system cable to the positive

battery post.

7. 7. Attach the ground system cable to the negative

battery post. Check all wire connections and test for

system continuity.

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

22

33722

Figure 4-3

7/30/12

Table of Contents

Section 4: Electrical System

Wiring Harness Removal

Refer to Figure 4-4:

1. Chock wheels to secure mower and prevent

movement while repairs are made.

2. Disconnect batter y to prevent accidental shock. See

“Battery Assembly Removal” on page 22.

3. For ease of access, remove the seat assembly. See

“Seat and Latch Removal” on page 13.

4. Cut and remove all the plastic zip ties securing the

wiring harness to the frame.

Refer to Figure 4-5:

5. Remove control panel and disconnect it from wiring

harness. See ““Control Panel Removal” on page

11.

6. Disconnect the wiring harness from all brake, seat,

and neutral interlock switches.See ““Main Harness

Wiring Schematics” on page 25 for location of all

connectors.

7. Disconnecttheenginewiringharness connectorand

depress the retaining tabs on the main harness

connector and remove from mounting bracket.

8. Remove the main wiring harness from the unit.

33723

Figure 4-4

Refer to Figure 4-6:

9. Disconnect the engine wiring harness from the start

solenoid and the engine wiring. Mark each cable for

reference.

10. Remove engine wir ing harness from the unit.

NOTE: Pictures is for reference only, cable

attachments will vary with engine model and type.

7/30/12

Figure 4-5

Figure 4-6

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

33724

33725

23

Table of Contents

Section 4: Electrical System

Wiring Harness Installation

Refer to Figure 4-7:

1. Lay out the main wiring harness and check all the

connections for good crimps and that the plastic

shielding is secured.

2. Mark all ends of the main wiring harness to ensure

proper routing. Use the “Main Harness Wiring

Schematics” on page 25 for locations of all

connections.

3. Plug the engine wiring harness connector into the

mounting bracket. Route all the branches of the

wiring harness to the appropriate areas of the

mower. Ensure that the each of the branches of the

wiring harness are routed as close to the frame and

tie down points as possible.

Refer to Figure 4-8:

4. Connect the wiring harness to the brake, seat, and

neutral interlock switches. See “Main Harness

Wiring Schematics” on page 25 for locations of all

connectors.

5. Route the control cable though the bottom of the

fender and connect all the main wiring harness

connectors to the control panel.

33726

Figure 4-7

Refer to Figure 4-9:

6. Lay out the engine wiring harness and check all the

connections for good crimps and that the plastic

shielding is secured.

7. Mark all ends of the engine wiring harness to ensure

proper routing. Use the “Engine Wiring

Schematics” on page 26 for locations of all

connections.

8. Plug the engine wiring harness in to the start

solenoid and engine wiring.

9. Plug the engine wiring harness into the main wiring

harness connector.

10. Test and secure the main and engine wiring harness

to the frame and tie down points.

ZSR54 & ZSR60 Accu-Z Razor® Zero Turn Mowers 357-388SM

24

33699

Figure 4-8

33724

Figure 4-9

7/30/12

Loading...

Loading...