Page 1

Table of Contents

Gondo

4400EX Heavy Duty Off Road Utility Vehicle

21341

Cover illustration may show optional equipment not supplied with standard unit

720-051M

Operator’s Manual

Read the Operator’s manual entirely. When

you see this symbol, the subsequent

!

instructions andwarningsare serious - follow

without exception. Your life and the lives of

others depend on it!

© Copyright 2008 Printed

Cover photo may show optional equipment

not supplied with standard unit.

7/14/08

Page 2

Table of Contents

Section 1: Introduction . . . . . . . . . . . . . . . . . . . . . . 1

Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . 1

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Models Covered . . . . . . . . . . . . . . . . . . . . . . . . . 1

Getting Acquainted with your Gondo . . . . . . . . . 1

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 2

Serial Number Plate . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 2: Important Safety Information . . . . . . . . 3

Safety Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safe Operating Procedures . . . . . . . . . . . . . . . . . . 5

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section 3: Pre-Delivery and Check List . . . . . . . 12

Pre-Delivery Certificate . . . . . . . . . . . . . . . . . . . . 12

Vehicle Information . . . . . . . . . . . . . . . . . . . . . . 12

Dealer Service and Inspection List . . . . . . . . . . 12

Dealer Test Ride List . . . . . . . . . . . . . . . . . . . . 12

Dealer Delivery To Customer List . . . . . . . . . . . 13

Customer Acceptance List . . . . . . . . . . . . . . . . 13

Section 4: Operating Instructions . . . . . . . . . . . . 14

Operator Responsibilities . . . . . . . . . . . . . . . . . . . 14

Pre-Start Check List . . . . . . . . . . . . . . . . . . . . . 14

General Operation . . . . . . . . . . . . . . . . . . . . . . . . 14

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . 14

Dashboard Switches and Instruments . . . . . . . 14

Foot Operated Controls . . . . . . . . . . . . . . . . . . 15

Hand Operated Controls . . . . . . . . . . . . . . . . . . 16

Fuel Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Driving Conditions . . . . . . . . . . . . . . . . . . . . . . . . 17

Towing the Gondo . . . . . . . . . . . . . . . . . . . . . . . . 18

Traveling Tips From the Trail Masters . . . . . . . . . 19

Section 5: Options and Accessories . . . . . . . . . . 21

Gondo Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rear Cargo Box . . . . . . . . . . . . . . . . . . . . . . . . 21

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Gondo Accessories . . . . . . . . . . . . . . . . . . . . . . . 21

Section 6: Maintenance . . . . . . . . . . . . . . . . . . . . 22

General Maintenance . . . . . . . . . . . . . . . . . . . . . 22

Prepare Vehicle for Maintenance . . . . . . . . . . . . . 22

Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Wheel Lug Nuts . . . . . . . . . . . . . . . . . . . . . . . . 22

Engine Torques . . . . . . . . . . . . . . . . . . . . . . . . . 23

All Other Torques . . . . . . . . . . . . . . . . . . . . . . . 23

Tire Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 23

Jacking the Vehicle . . . . . . . . . . . . . . . . . . . . . . . 23

Shock Absorbers . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . 23

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Jump Starting the Battery . . . . . . . . . . . . . . . . . . . 24

Prepare Vehicle to Jump-Start . . . . . . . . . . . . . . 24

Connecting Jumper Cables . . . . . . . . . . . . . . . . 25

Disconnecting Jumper Cables . . . . . . . . . . . . . . 25

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Filling the Fuel Tank . . . . . . . . . . . . . . . . . . . . . . 26

Emptying the Fuel Tank . . . . . . . . . . . . . . . . . . . 26

Fuel Filter and Fuel Line Maintenance . . . . . . . 26

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . 26

General Information . . . . . . . . . . . . . . . . . . . . . . 26

High Altitude Carburetor Kit . . . . . . . . . . . . . . . . 27

Power Steering Belt . . . . . . . . . . . . . . . . . . . . . . . 27

Engine Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Air Filter Maintenance Schedule . . . . . . . . . . . . 28

Precleaner Foam Element . . . . . . . . . . . . . . . . . 28

Paper Element . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Spark Arrester . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Spark Arrester Maintenance Schedule . . . . . . . 29

Spark Arrester Maintenance Procedure . . . . . . 29

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . 29

Maintenance Schedule . . . . . . . . . . . . . . . . . . . 30

Section 7: Lubrication and Fluids . . . . . . . . . . . . 31

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Differential Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Transmission Fluid . . . . . . . . . . . . . . . . . . . . . . . . 34

Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Steering & Cargo Lift Cylinder Fluid . . . . . . . . . . . 35

Grease Type Lubrication . . . . . . . . . . . . . . . . . . . . 35

Driveline U-Joints . . . . . . . . . . . . . . . . . . . . . . . 35

Pillow Block Bearing . . . . . . . . . . . . . . . . . . . . . 36

Rotating Bearing Surfaces . . . . . . . . . . . . . . . . . 36

Section 8: Seasonal Storage . . . . . . . . . . . . . . . . . 37

Engine Preparation for Storage . . . . . . . . . . . . . 37

Vehicle Storage Preparation . . . . . . . . . . . . . . . 37

Vehicle Removal From Storage Preparation . . . 37

Section 9: Body Repair . . . . . . . . . . . . . . . . . . . . . 38

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Light Scuff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Scratch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Deep Gouge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Section 10: Specifications and Capacities . . . . . 40

Section 11: Troubleshooting . . . . . . . . . . . . . . . . . 41

Section 12: Appendix . . . . . . . . . . . . . . . . . . . . . . 45

Torque Values Chart . . . . . . . . . . . . . . . . . . . . . . . 45

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Land Pride Limited Warranty . . . . . . . . . . . . . . . . 47

© Copyright 2008 All rights Reserved

LandPride providesthis publication“as is”without warrantyof anykind, eitherexpressedor implied.While everyprecaution hasbeen takenin thepreparation ofthis manual,

Land Pride assumes no responsibility for errors or omissions. Neither is any liability assumedfor damages resulting from theuse of the information contained herein.Land

Pride reserves the right to revise and improve its products as it sees fit. This publication describes thestate of this product at the time of its publication, and may not reflect

the product in the future. The illustrations in this manual are not intended for safe and proper assembly or disassembly of equipment. The illustrations are intended for

ordering parts only.

Land Pride is a registered trademark.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

7/14/08

Page 3

Table of Contents

Section 1: Introduction

Section 1: Introduction

Land Pride welcomes you to its growing familyof new

productowners.Gondoseries trucks are heavy duty utility

vehicles that have been designed with care andbuilt by

skilled workers using quality materials. Proper set-up,

maintenance andsafe operating practiceswill help you

get years of satisfactory use from this vehicle.

Safety First

Land Pride is fully aware of the need for safe operating

procedures around all ofour equipment. We hope youwill

make a sincere effort to put safety above all other

priorities. The Gondo is designed and built for serious

work, recreation and enjoyment;however, improper and

irresponsible operation could resultin serious injury or

death. Sincethis is an off-road vehicle, operators will

seldom seethe road safety and warning signs they are

accustomed toseeing on highways andpublic streets.

This placesadditional responsibility on the driver to

operate thisvehicle well within thesafe operational limits

and capabilitiesof the unit.

This manual hasbeen prepared toinstruct you in thesafe

and responsible operationof yourGondo. Please read

andabide by all safetyalert information about this vehicle.

If you do not understand any part of this manual, contact

your local dealer for additionalinformation and

clarification. As the operator of this pieceof equipment,

you are in completecontrol. Only you can prevent an

accident fromhappening!

Using This Manual

Prior toany vehicle operation it isabsolutely essential

•

that youread and comprehend each sectionin this

manualtodevelopanunderstandingofyourvehicleand

safetypractices.Afterreviewingthismanual,storeitina

dry andeasily accessible place for futurereference.

• The Operator’s Section is designed to help familiarize

you withsafety, assembly, operation, adjustments,

troubleshooting andmaintenance. Read this manual

and followthe recommendations to help ensuresafe

and efficientoperation.

• The information contained within this manual was

current atthe time of printing. Someparts may change

slightly toassure you of the bestperformance.

• To order a newOperator’sorParts Manual contact your

authorized dealer.Manuals can also be downloaded,

free-of-charge fromour website at www.landpride.com

orprintedfromtheLandPride Service & Support Center

by yourdealer.

Terminology

Right-hand andleft-hand as used in thismanual are

determined by facing thedirection the vehicle will travel

while inuse unless otherwise stated.

Definitions

The following terms areused throughout this manual.

IMPORTANT: Aspecial pointof information relatedto

its preceding topic. Land Pride’s intention is that this

information should be read and noted before

continuing.

NOTE:Aspecialpoint of information that theoperator

must beaware of before continuing.

Application

Models Covered

4400EX

Getting Acquainted with your Gondo

The LandPride Gondo is an extreme utilityvehicle

designed exclusively for off-road use. It is not designed,

properly equipped, or licensed to be safely operatedon

public streets and highways. This 2200lb. payload hauler

is designed to carrytwo people inthecab and agenerous

amount ofcargo, gear, and supplies safely and

conveniently over extremely difficult or rough terrain.

The Gondofeatures centerarticulating power steering

coupled witha pivotinginteractive frame for unexcelled

terrain hugging capabilityand maximum traction.Traction

capabilitiesare evenfurther maximized with incorporation

of full-timeshaft driven four-wheeled drive. TheGondo is

poweredby the proven624cc 20hp Kohler Command Pro

Series Engine and a fully automotive 4 or 5 speed

synchromesh manualtransmission. Engaging the eightinchmanualclutchdeliverspowertotheautomotivegrade

front andrear open differentials.

TheGondoisequipped with highly dependable fourwheel

hydraulically activated automotivedrum type brakes. A

manual park brake isincluded as standard equipment.

Engine brakingis inherently available through the

standard transmissionwhen needed for traveling down

steepor slippery andtreacherous grades.Allfourtiresare

26x12-12 4-plyand are available with turf or bar type

tread.

The Gondoframe is tractor tough and constructed out of

welded and formed heavywalltubing that iscoatedwith a

durableblacksatin powder paint finish.A certifiedrollover

protection system(ROPS) with seat belts is standard

equipment. (Butmay beleft off by customer’s choosing.)

The consolebody and optional cab areconstructed of

extratough fiberglass withanattractivegel coat finish. The

high capacity cargobeds are madeofwelded and formed

heavygauge sheet metalfinishedwith black satin powder

7/14/08

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

1

Page 4

Section 1: Introduction

Table of Contents

paint. Customerscan choose either a 23 cu. ft. capacity

gondola stylebox oran 18 cu. ft. capacity tilt box witha

standard tailgate. Choosing the hydraulictilt option

makesboth boxescapableof hydraulically dumping their

full 1800lb. payload capacity by simple activation of a

leveron the operator’sconsole. A standardreceivertype

hitch comesas standard equipment and thisunit is

capable of up to2500 lbs. of towing capacity.

The operator’sstation is acab-forwardstyle console that

hingesforwardandhas aft suspensionover two coil-over

shocksprovidinga smoother rideandincreasedoperator

andpassenger comfort. Twocushioned high back bucket

seats are provided as standardequipment and seatbelts

are alsostandard forunits equipped with a ROPS. The

operators consoleis equipped with a standard hour

meter,voltmeter,12voltkeyedignition,andlightswitchto

activate the two standard halogen beam headlights.

Customers needingadditional protection from the

elements andsurrounding environment can also order

additional accessories such as cabs with safety glass

windshields, powered wipers, and soft sidedcab doors.

Snowplowsandlog skidders arealsoavailablefor added

versatility.

Whetheryouarehauling big game, farmingtools,hunting

and fishingcamp supplies, construction equipment,

livestock feed, military cargo, or fire fighting and rescue

equipment, the Gondo iscapableof getting you and your

cargothere and back over tough and extremeterrain and

in allkinds of weather.

Owner Assistance

The safety videoshould be viewedby the ownerand the

Warranty Registration card should be filled out bythe

dealer atthe time of purchase. The owner should also

receive a copy of the safety video upon purchasing the

vehicle as well as have participated ina short drivers

training coursewith the dealer. This information is

necessary to provide you with quality customer service.

Theparts onyourGondoHeavyDuty Utility Vehiclehave

been speciallydesigned and should only bereplaced

with genuineLand Pride parts.

If customer serviceor repairparts are requiredcontact a

Land Pridevehicle dealer. They have trained personnel,

genuine repairparts and equipmentspecially designed

to repairLand Pride products.

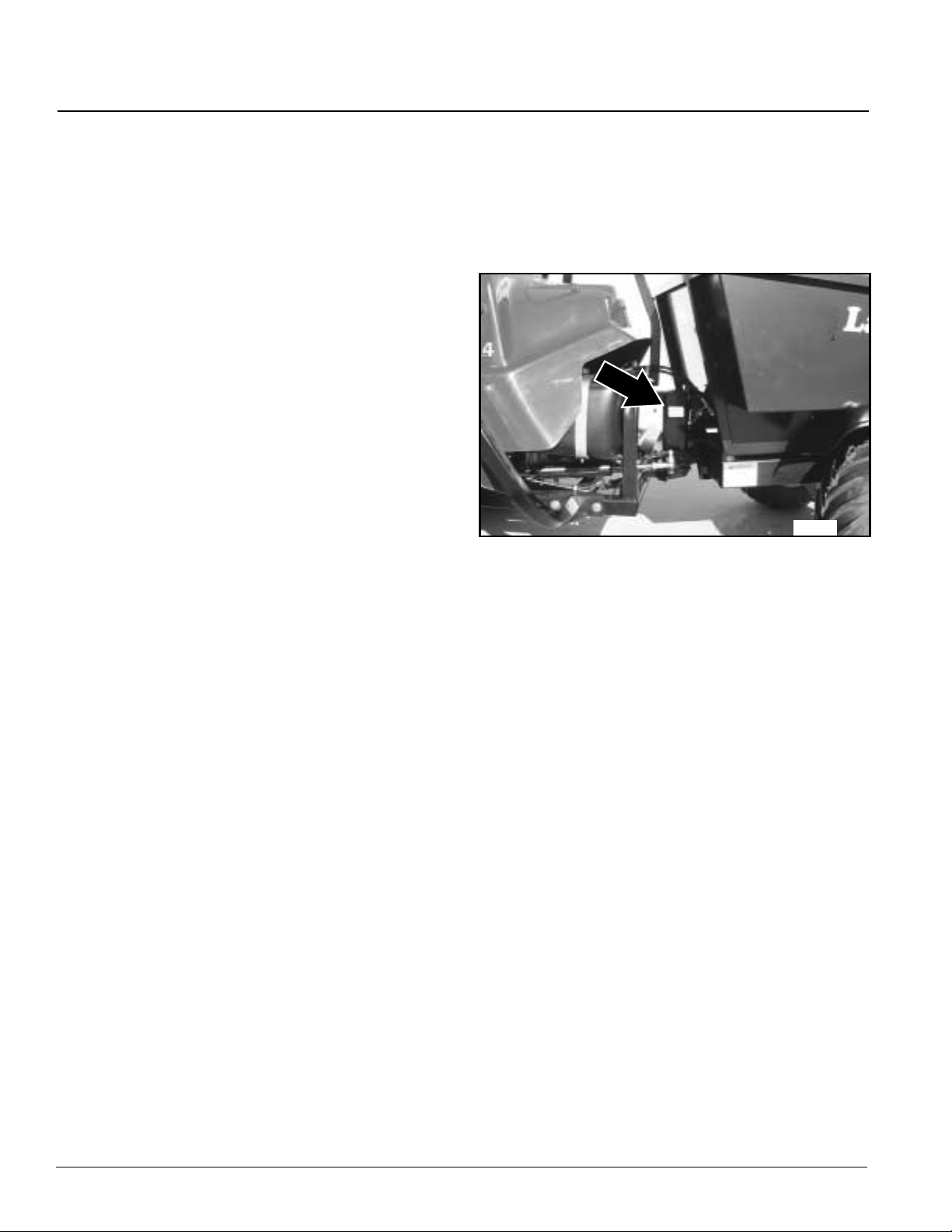

Serial Number Plate

Refer to Figure 1

Always use serial andmodel number when ordering

parts from your Land Pride dealer. The serial-number

plate islocated on the driver’s side on the center swivel

yoke as shown below.

21469

Serial Number Plate

Figure 1

Record your vehicle model number (4400EX) and serial

number here for quick reference:

Model Number:___________________________

Serial Number: ___________________________

YourLandPridedealerwantsyoutobesatisfiedwithyour

new vehicle. If you do not understand any part of this

manual orare not satisfied with the service received,

please take the following actions.

1. Discuss thematter with your dealership service

manager.Makesuretheyareawareof any problems

so they can assist you.

2. If you are still unsatisfied, seek out theowner or

general managerof the dealership.

3. For further assistancewrite to:

Product Support

Land Pride Service Department

1525 East North Street

P.O.Box 5060

Salina, Ks. 67402-5060

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

2

E-mail address

lpservicedept@landpride.com

7/14/08

Page 5

Table of Contents

Section 2: Important Safety Information

Section 2: Important Safety Information

Important: Read and understand all pages in this manual thoroughly before operating your v ehicle.

These are common practices that may or may not be applicable to the products described in

this manual.

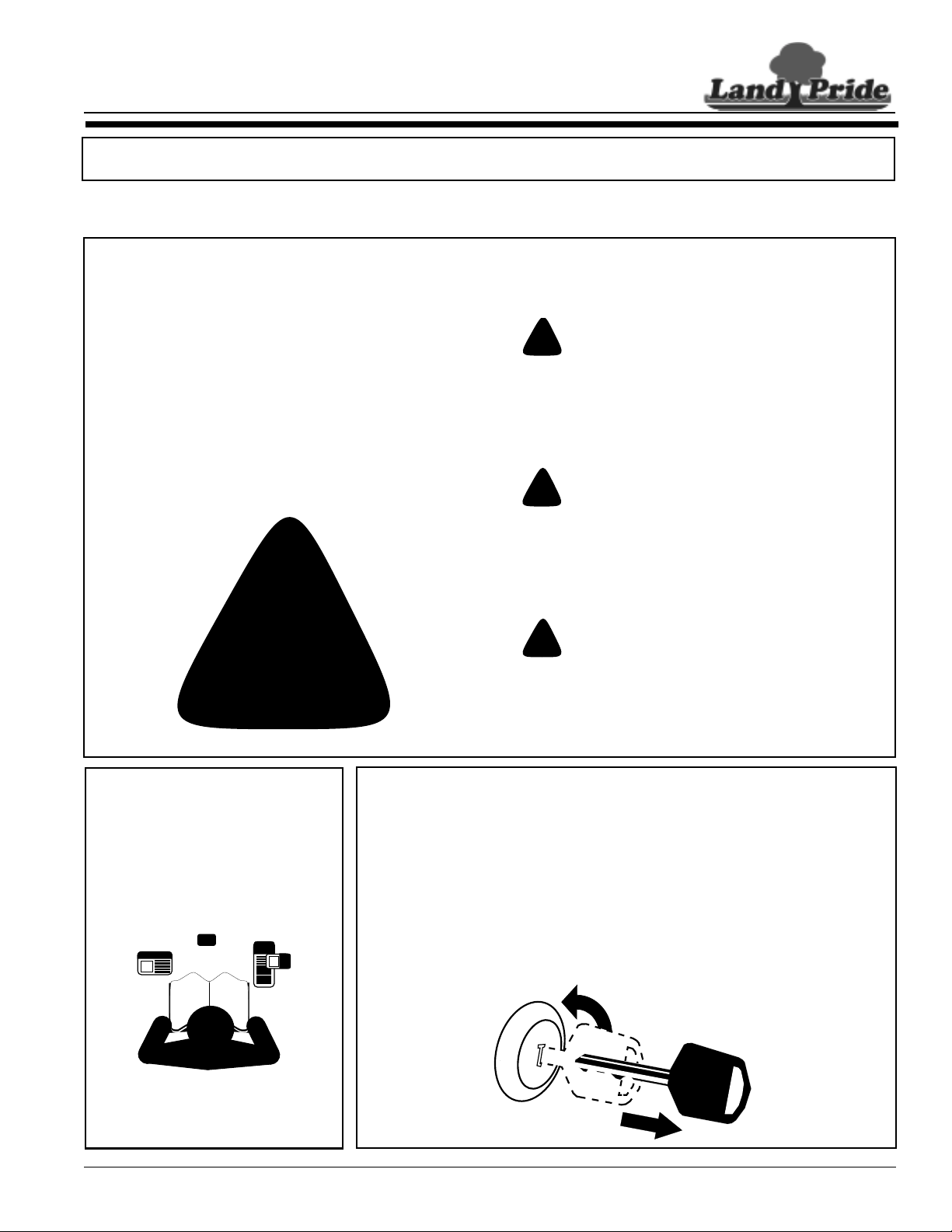

Safety Symbol

Look for the Safety symbol throughout this

manual.TheSAFETY ALERTSYMBOLindicates

there isa potential hazard to personalsafety

involved and extra safety precaution must be

taken. When you see this symbol, be alert and

carefully readthe message that followsit. In

additiontodesignandconfigurationof equipment,

hazard controland accident prevention are

dependent uponthe awareness, concern,

prudence and proper training of personnel

involved inthe operation,transport, maintenance

and storageof equipment.

!

Be Aware of Signal Words

Signal wordsdesignate a degree or level of

hazard seriousness.The signal words are:

!

DANGER

DANGERindicates animminentlyhazardous situation

which, if not avoided, will result in serious injury or

death. This signal word islimited to the most extreme

situations, typically for vehicle components that, for

functional purposes, cannot be guarded.

!

WARNING

WARNINGindicates a potentiallyhazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert

against unsafe practices.

!

CAUTION

CAUTIONindicates a potentiallyhazardoussituation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

For Your Protection

▲ Thoroughly read and understand

the “Safety Decal”section, readall

instructions noted on the decals.

7/14/08

Before Operating

▲ This Gondo Heavy Duty Utility

Vehicle is not to be driven on

public roads.

▲ Do not operate this vehicle under

the influence of alcohol or drugs.

▲ Always inspect the vehicle before

operating it. See "Pre-Start Check

List" on page 14.

OFF

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

▲ Do not operate this machine

unless all safety shields are in

place and all badlyworn, broken or

missing parts have been properly

replaced.

▲ Wear appropriate protective gear

and clothing such as safety

helmet, goggles, gloves, coveralls,

etc., when conditions warrant.

▲ No driver under age of 16.

3

Page 6

Table of Contents

Section 2: Important Safety Information

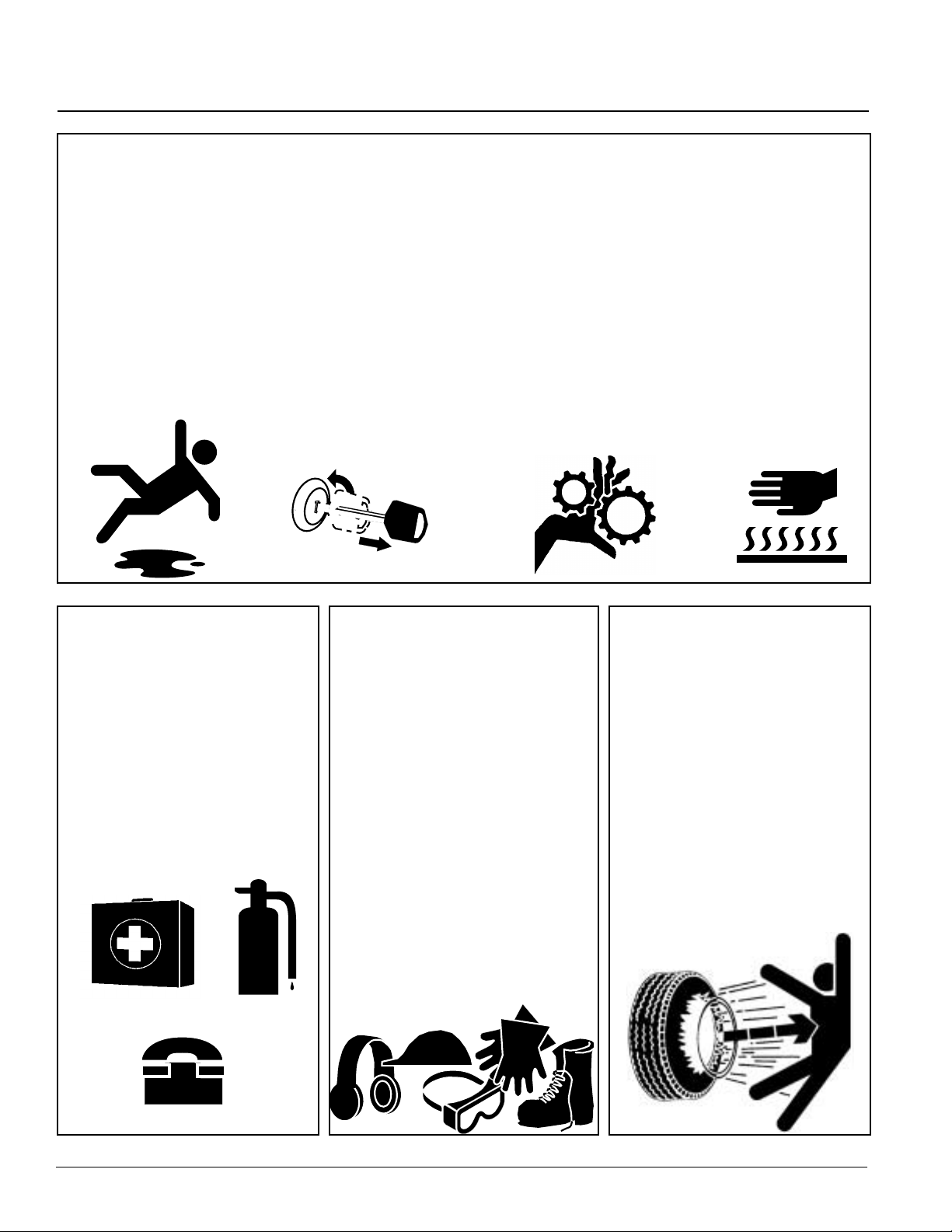

Practice Safe

Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment.Refertothis manual for

additional information.

▲ Work in a clean, dry area.

▲ Place the vehicle in neutral, set

parking brake, turn off engine and

remove key before performing

maintenance. Chock wheels if you

must perform maintenance on a

slope.

▲ Make sure all moving parts have

stopped and allsystempressure is

relieved.

▲ Allow the engine to cool

completely.

▲ Disconnect battery ground cable

(-) before servicing or adjusting

electrical systems or before

welding.

OFF

▲ Inspect all parts. Make sure parts

are ingood condition and installed

properly.

▲ Remove build-up of grease, oil or

debris.

▲ Remove all toolsand unusedparts

from the Gondo before operation.

Prepare for

Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire

extinguisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

Wear Pr otective

Equipment

▲ Wear protective clothing and

equipment.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to

loud noise can cause hearing

impairment or hearing loss, it is

best to wear suitable hearing

protection such as earmuffs or

earplugs.

▲ Because operating equipment

safely requires your full attention,

avoid wearing radio headphones

while operating machinery.

▲ It is the discretion of the operator

and passenger to wear Seat Belts

when available.

Tire Safety

Tire changingcan be dangerous

and should beperformed by trained

personnel usingcorrect tools and

equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough for you to stand to one

side–not in front of or over tire

assembly. Use a safety cage if

available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for weight

involved.

911

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

4

7/14/08

Page 7

Table of Contents

Section 2: Important Safety Information

Safe Operating Procedures

Thesafeoperationofanymachinery is a big concerntoall

consumers. Your Gondo has been designed with many

built-in safety features. However, no one should operate

this vehicle before carefullyreading this Operator’s

Manual. Alsoread all instructions noted onthe safety

decals.

!

WARNING

Mostaccidentswith off roadvehicles occur when travelingup,

down, or across the face of a slope. Refer to operation

instructions and safety video forproper operation procedures.

▲ Be familiar with all functions of this vehicle.

▲ Keep all bystanders away from this vehicle during

operation.

▲ Do not allow anyone to operate this vehicle who has not

fully read and comprehended this manual and who has

not been properly trained in the safe operation of this

vehicle.

▲ Do notoperatea vehicle with damagedordefectiveparts.

Repair all damages and defective parts before putting

vehicle back in to service.

▲ Do not allow anyone under 16 years of age to operate

this vehicle.

▲ Operator must always use both hands on the steering

wheel.

▲ A rider may, without knowing it, place his foot on the

accelerator pedal while bracing himself against a rough

ride. This makes it impossible to slow down the vehicle

until the passenger removes his foot from the pedal.

Inform the passenger to keep his foot off the accelerator

and always slow down before the ride gets rough.

▲ Operator and passenger are responsible for deciding if

their situation warrants using seat belts if so equipped.

▲ Do not use cargo bed as an additional passenger carrier.

▲ Do not use cargo bed as a working platform.

▲ The cargo power lift is designed to dump cargo only. Do

not use it to lift other objects.

▲ No riders allowed except in factory designed and

supplied seating and no more than one person in a seat.

Do not use cargo bed for carrying people. Maximum

vehicle occupancy including driver is 2.

▲ Operate vehicle from driver’s seat only.

▲ Do not leave vehicle unattended with engine running.

▲ Do not dismount a moving vehicle as serious injury or

death could occur.

▲ Always operate vehicle with all guards installed. Do not

leave pulleys, belts and other rotating components

exposed.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

▲ Do not wear clothing or other articles that hangs loosely.

Hanging clothing, long hair, jewelry etc. can catch in the

tires and other rotating objects.

▲ Keep hands, feet, long hair, clothing and jewelry away

from moving parts and obvious pinch points to avoid

getting caught.

▲ Some conditions may warrant extra safety gear to be

worn such as safety helmets and/or goggles.

▲ Keep hands, arms, feet and all bodily appendages safely

inside the confinesof the vehicle. Always be aware ofand

avoid tree limbs and brush that have a potential of hitting

and/or pokingindividuals riding the vehicle. Serious body

harm could result.

▲ Make sure area behind cargo box is clear of personnel

before operating the dump lever. Bodily harm can result

from being pinched between the cargo box and another

object or from a load dumping and/or rolling onto a

bystander.

▲ Do not touch engine, engine exhaust pipe and/or muffler

while they are hot.

▲ Use extreme caution when driving through dry grass,

brush and other fire hazard materials. Never stop or park

over combustible materials. Keep grass and brush from

collecting on and around engine and muffler parts.

▲ Battery fumes are explosive. A spark will ignite battery

fumes. Wear a face shield when charging or jumping a

battery. Follow all battery safety rules outlined in this

manual.

▲ Always disconnect the negative battery terminal before

making adjustments to the vehicle electrical system or

welding on this vehicle.

▲ Avoid battery acid spills. Do not get battery acid on eyes,

face, or other body parts. Flush eyes and other body

parts immediately with water for at least 15 minutes if

battery acid has gotten on them.

▲ Avoid pinch point hazards. Cargo bed, seat platform and

vehicle center pivot steering hinge creating pinch points.

▲ Do not stand, reach or allow any body part to enter

between the cab and cargo bed (articulating area) while

vehicle is running. This is an extremely high dangerous

pinch point area caused from turning the steering wheel.

▲ Always make certain the articulating area between the

cab and cargo bedis clear of personnelbeforeturning the

steering wheel.The steering wheel will turn the vehicleat

its articulation point whether the vehicle is running or not.

▲ Do not operate this vehicle on highways, public roads, or

where it may be a hazard to faster moving traffic.

▲ Never attempt wheelies, jumps, or other stunts. Never

drive recklessly. Always operate your vehicle at a safe

speed that will allow you to maintain control.

▲ Never modify any parts on the vehicle without

authorization. Unauthorized modifications will void

warranty to all parts directly and indirectly affected by the

modification.

7/14/08

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

5

Page 8

Table of Contents

Section 2: Important Safety Information

▲ Never use this vehicle for racing.This vehicle isdesigned

to achieveground speeds up to17mph.Any unauthorized

modifications intended to increase the ground speed of

this vehicle above 17mph mayresult in cancellation ofthe

vehicle warranty and may be in direct violation of laws

regulating current air quality standards.

▲ Avoid sudden stops, starts and turns.

▲ Be aware of cargo shifting when stopping or moving.

Make sure all cargo is properly secured and tied down.

Injury could result from loose cargo.

▲ Do not operate vehicle while drinking or under the

influence of alcohol or drugs.

▲ Always make sure vehicle pathway is clear of all objects

when backing up. Know location of persons around

vehicle and especially location of small children. Take

extra precautions when rear view is hindered by cargo.

▲ Do not exceed total payload capacity of this vehicle.

Over-loading can cause loss of control resulting in sever

injury or death.

▲ Always maintain proper tire inflation. See "Tire

Maintenance" on page 23.

▲ Do not pull a trailer or implement exceeding 2,500 lbs.

towing capacity and 250 lbs. tongue weight. Loss of

control may result.

▲ Do not attach an implement, trailer or other device to the

hitch that will produce negative tongue weight.

▲ Do not tow or pull the Gondo behind another vehicle

exceptto retrieve it ashort distancefrom an areawhere a

trailer won’t go. The Gondo should be loaded on a trailer

for towing. Follow all towing instructions in this manual

when towing the Gondo.

▲ Do not use the vehicle as an anchor device.

▲ Beware, tow ropes, cables and chains can break when

pulling anothervehicle or object causingserious injury or

death to anyone in line with the whipping action created

when they break. Never jerk when pulling, always ease

into a pull gently. Always stay clear of the tow line. Never

be in line with the tow line.

▲ Reduce speed and payload on hilly, rough, wet, slick or

unstable ground.

▲ Reduce speedwhenloaded with cargo. Heavy cargo load

takes longer to stop.

▲ Always make turns at aspeed that willmaintain control of

vehicle. Never make turns at full speed. Reduce speed

when turning empty and reduce speed even more when

turning loaded. Theheavierthe cargo load,theslower the

turn should be.

▲ The certified ROPS (Roll OverProtection System) serves

only as a protection device. Always avoid rollovers.

▲ Do not load ROPS with heavy equipment. Rollover could

result from such loading.

▲ Always park on level ground, stop engine, set park brake

and remove ignition key before leaving the vehicle. Chock

tires if condition warrants.

▲ Use extreme caution whencresting hillsor whenvisibility

is limited. Proceed slowly until you are sure trail

conditions immediately ahead are safe.

▲ Keep front wheels straight when cresting hills or going

over bumps.

▲ Do not stop, start suddenly or over accelerate on hills.

Loss of control and rollover could result.

▲ Use extreme caution when descending hills, running on

loose slippery surfaces, or when towing at maximum

capacity. Towing, braking and tractive capabilities are

greatly diminished.

▲ Do not operate vehicle on slopes over 15

▲ Avoid changing direction or making sharp steering

o

.

corrections on slopes or rollover may occur.

▲ If thisvehiclebegins to tipwhencrossing a slope,turn the

front wheels downhill to regain stability and control.

▲ When crossing a slope on soft terrain, turn the front

wheels slightly uphill and maintain a constant speed to

maintain a straight line of travel.

▲ When descendinghillsor slopes apply steadypressure to

the foot brake to avoid potential freewheeling orrunaway.

Do not shift vehicle out of gear. Take full advantage of

engine breaking.

▲ Never allow vehicle to coast or free wheel in neutral or

loss of control may result.

▲ If your vehicle loses power and stops on a hill,

immediately engage the foot brake. Press down on the

clutch and gently release brakes while backing slowly

down the hill maintaining a straight downhill line of travel.

Do not attemptto turn thevehiclesidewayson the hill ora

rollover could result.

▲ When traveling at night always use your headlights and

reduce speed according to visibility, trail and terrain

conditions.

▲ Avoid water crossings when possible and never cross a

body of waterwhere depth isunknown. Loss ofpowerwill

occur if engine becomessubmerged orwet.Unnecessary

crossing of streamsand waterwayserodes shore lineand

damages water-born habitat. If you must cross, do it at a

point where banks are not steep and proceed at a slow

and steady speed. Do not travel in water that is higher

than the floor board. Water higher than this can damage

the engine stalling the vehicle. However, intermittent

stream crossings where depth of water briefly comes into

contact with bottom of engine is acceptable. See "Going

Out on the Trail" Note 7 on page 19.

▲ Front bumper, brush guards and cargo box are not

designed as pusher bars. Do not attempt to push other

vehicles or implements or damage may result.

▲ When refuelinguse aULapprovednon-metalliccontainer

that has no screen or filter. Set the container on the

ground before fueling to eliminate staticdischarge and do

not use Methanol fuel.

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

6

7/14/08

Page 9

Table of Contents

Section 2: Important Safety Information

▲ Do not smoke or use electrical devices including cell

phones while refueling.

▲ Always checkwheel lug nuttorque values twohours after

initial operation and two hours after each tire repair and/

or replacement. Routinely check lug nut torque valves

every 100 hours of operation. See "Wheel Lug Nuts" on

page 22.

▲ Support this vehicle securely before working beneath.

Chock wheels to prevent vehicle from rolling.

▲ Do not inspect hydraulic leaks with bare hands. Always

use an object such as a stick to inspect for leaks. Serve

injury can occur from pressurized oil breaking through

skin.

▲ Do not operate the vehicle with hydraulic leaks, frayed or

kinked hoses. Repair or replace hydraulic leaks and

damaged hoses immediately.

Safety Decals

1. Your Gondo Heavy Duty Utility Vehicle comes equipped

with all safety decals in place. They were designed to help

you safely operate this vehicle and to serveas a reminder to

keep safety uppermostin your mind. Readand follow decal

directions.

2. Keep all safety decals clean and legible.

3. Replace all damaged or missing decals. Order new safety

decals through your Land Pride dealer.

4. Some newequipmentinstalledduringrepairrequiressafety

labels to be affixed to the replaced component as specified

by Land Pride. When ordering new parts or components,

also request corresponding safety decals.

5. Refer to this section forproper labelplacement. Installnew

decals as follows

a. Clean the area on whichthe decal is to be placed.

b. Spray soapy water on the surfacewhere thedecal isto

be placed.

c. Peel backing from decal. Press firmly on surface,

being careful not to causeair bubbles under decal.

d. Squeeze out air bubbles with the edge of acredit card.

818-543C

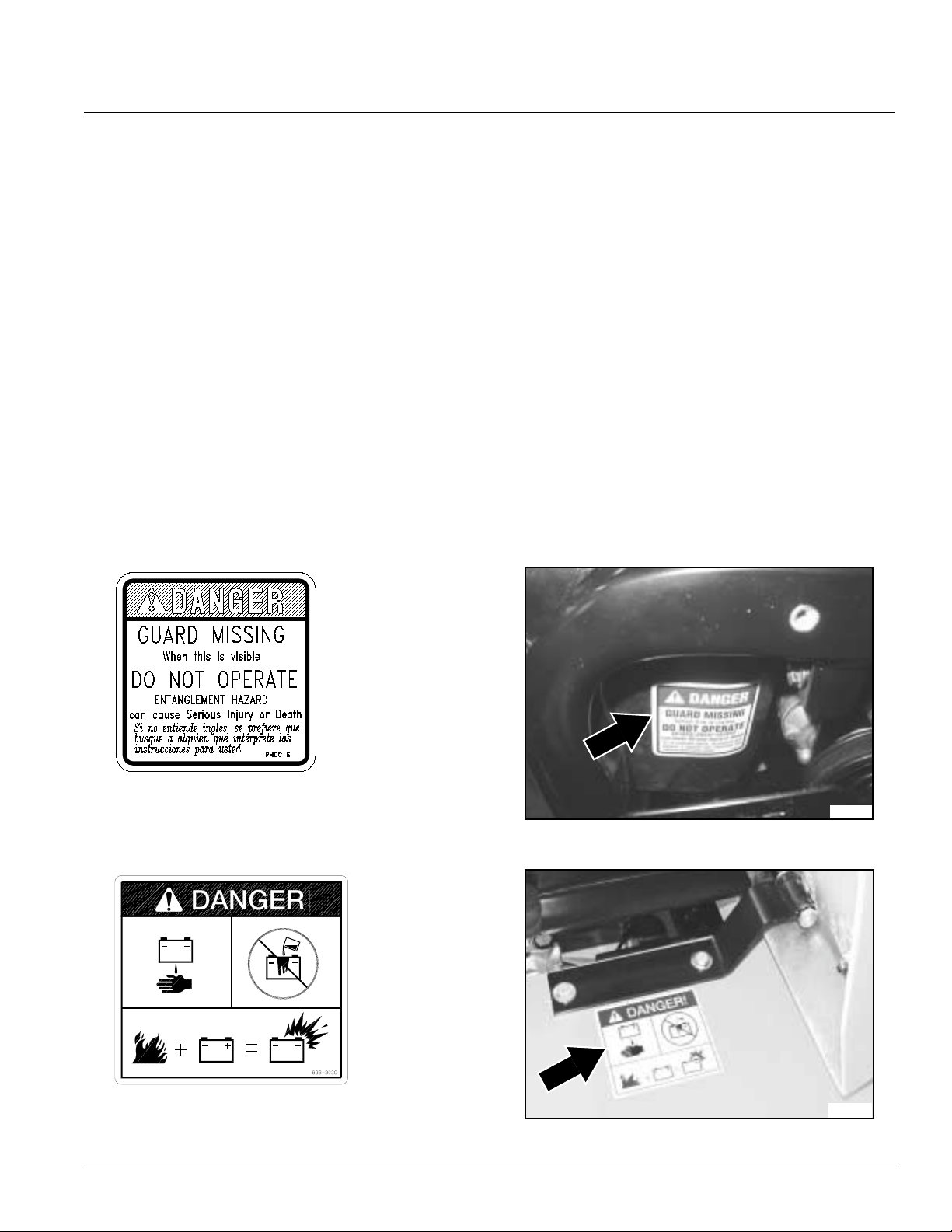

Danger: Guard Missing

838-303C

Danger: Battery

7/14/08

21434

21435

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

7

Page 10

Table of Contents

Section 2: Important Safety Information

838-492C

Caution: MaximumPowerSource

21440

838-629C

Warning: Pinch Point or Crushing Hazard

21443a21458

21443a21443a

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

8

21443b

7/14/08

Page 11

Table of Contents

Section 2: Important Safety Information

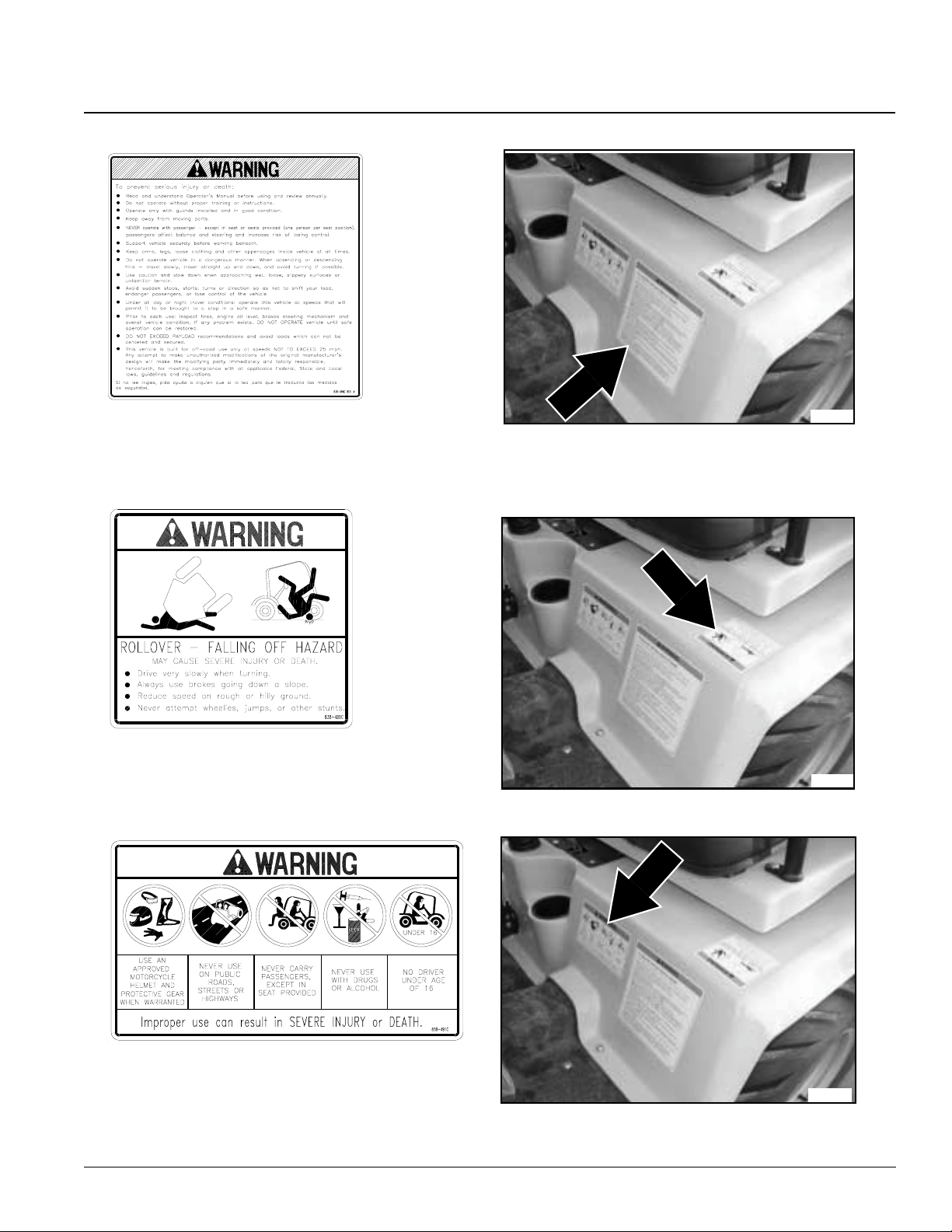

838-486C

Warning: General Utility Vehicle

838-489C

Warning: Rollover Hazard

21439

21439

838-491C

Warning: Improper Use

7/14/08

21439

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

9

Page 12

Table of Contents

Section 2: Important Safety Information

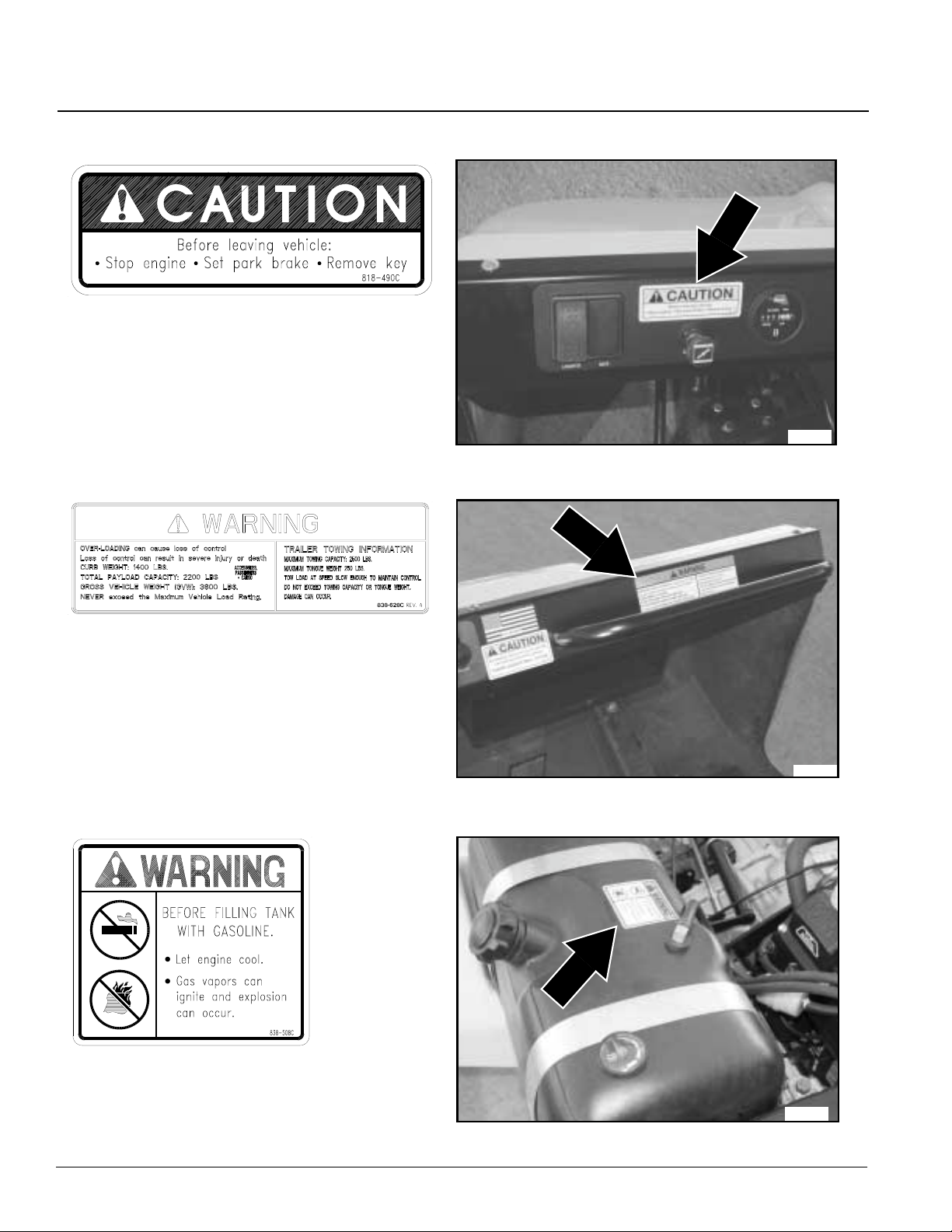

838-490C

Caution: StopEngine

21438

838-628C

Warning: Load Rating and

Trailer Towing Information

838-508C

Warning: Before Filling Tankwith Gasoline

21442

21441

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

10

7/14/08

Page 13

Table of Contents

Section 2: Important Safety Information

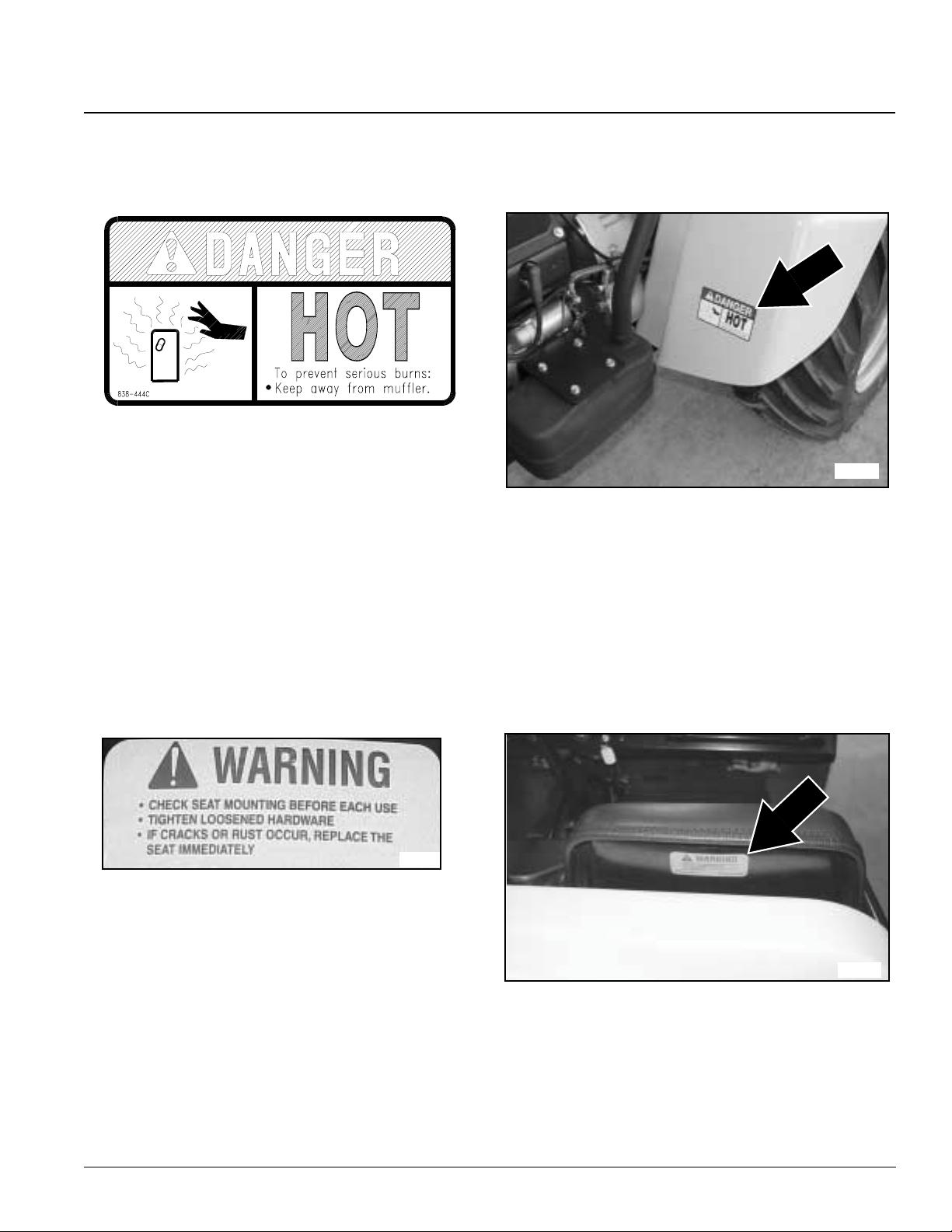

838-444C

Danger: Muffler hot

21436

Warning Label Included with Seat

Warning: Check Seat mounting

7/14/08

20971

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

21345

11

Page 14

Table of Contents

Section 3: Pre-Delivery and Check List

Section 3: Pre-Delivery and Check List

Each vehicle mustundergo a Pre-Delivery Inspection by the Dealer. Listed below is an exampleof the checklist that is

included withthe Warranty Registration that is to be submitted toLand Pride upon Retail Sale.The Pre-Delivery

Certificate and Warranty Registration must be submitted to Land Pride in order to activate thevehicle warranty.

Pre-Delivery Certificate

The dealeris required to complete LandPride’s

“Certificate of Heavy Duty Utility Vehicle Pre-Delivery”

form before customer maytake possession ofthe vehicle.

Theinformationmustbefilled in and check list checked off

or initialedby individuals performing the checks.

Dealership’s name, signatures of individuals filling in the

form, seller’s signature, customer’s signature and signing

datesarealsorequiredbeforetheformisreturned to Land

Pride. Below is a list of the information foundin the form

that isrequired to be completed andchecked off.

Vehicle Information

Model No. _________________

Date _________________

Serial No. _________________

Engine Serial No. _________________

Dealer Service and Inspection List

___Fully chargebattery. Check battery voltage to verify

that itis fully charged.

___Check tire pressure to make sure front tires have 15

psi andrear tires have 20psi.

___Make sure wheel lug bolts/nuts are tightened to 90

Newton meters/(65ft. lbs.).

___Check master cylinder to make sure it is filled.

___Checkengineoillevelat thedipstick. Add SAE 10W30

oil ifoil is below the full mark on the dipstick.

___Check engine for correct RPM. Setto factory

specification ifneeded. (See page 40)

___Check steering cylinder for tightness.

___Check choke control.It should moveand return freely.

___Step onfoot brake to make surethere is plenty of

pedal and thatbrakeshold pressure anddo not bleed

off. Add brake fluid and bleed brakes if required.

___Make sure seats and seatbelts areproperly fastened

to theframe if so equipped.

___Make sure all safety decalsare in place.

___Check headlights to make sure they are working and

are properly mounted.

___Inspect aircleaner element. Make certain it is clean

and inplace.

___Inspect thefuel tank to make sure it isproperly

installed andthat there are no leaks.

___Check fuel level to makesure thereis at least 1/8 ofa

tank ofgas prior to performing initialstarting

operations.

___Inspect fuellines to make sure they are properly

installed andthat there are no leaks.

___Check steering by executing a full lock to lock turn in

each direction.

___Checkparkbraketo make sure it will engage,holdand

release.

___Make sure neutral start feature is working by

depressing theclutch to start theunit.

___Check throttle control to make sure it movesand

returns freely.

___Check differential oil level atthe differentialoil plug.

Add 80/90gear lube if oil isbelow oilplug outlet.

___Checkoverallappearanceforcleanlinessandforbody

and moldingdamage.

Dealer Test Ride List

___Check engine for starting, accelerating,running and

idling smoothly.

___Check steering response. There shouldbe no free-

play.

___Checkforward,neutral and reverse shifting response.

Also check neutralstart response by depressing the

clutch tostart the vehicle.

___Check park braketo make sureit engages, holds and

disengages.

___Make sure rocker switches are all working.

___Make sure throttle is responsive andreturns freely.

___Make sure suspension ride is satisfactory and stable.

___Make sure there are no fuel or petroleum leaks.

___Make sure the foot brakehas afirm engagement and

that stoppingis straight.

___Make sure there are no bad rattles or vibrations.

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

12

7/14/08

Page 15

Table of Contents

Section 3: Pre-Delivery and Check List

Dealer Delivery To Customer List

___Warranty registration form is complete.

___Owner’s Manual has been delivered to and reviewed

by the customer.

___EngineManualhas been delivered to and reviewedby

the customer.

___Warranty Policy limits and requirementshave been

explained to the customer.

___Customer hasreviewed the safety video.

___Location andfunctions of vehicle controls have been

explained.

___Fuel transportation and storage procedures have

been explained.

___Fluid filland lubricationpoints have been located and

explained to the customer.

___Customer hascompleted the driving course.

___Information onthe safety decals have beenreviewed

with thecustomer.

Customer Acceptance List

Customerinitialsrequiredwhere acceptedassuccessfully

completed.

___Customer hasreviewed and understands Land Pride

warranty policy.

___Customer hasinspected the vehicle and it meets

customer’s satisfaction.

___Customerunderstandstheimportanceoffollowingthe

owner’smanual instructions.

___Customer hascompleted the Land Pride safety

training course.

7/14/08

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

13

Page 16

Section 4: Operating Instructions

Section 4: Operating Instructions

Operator Responsibilities

Table of Contents

!

WARNING

It is the operator’s responsibility to have read this manual

thoroughlyand to know how tooperatethis vehicle safely in all

situations. See "Section 2: Important Safety Information"

starting on page 3.

Pre-Start Check List

• Lubricate the vehicle as indicated in the Lubrication

portion of"Section 7: Lubrication and Fluids" on

page 31.

• Check tire pressure as indicated in the "Tire Inflation

Chart" onpage 23.

• Make sure wheel lug bolts/nutsare tightened to65ft. lbs.

• Allnuts,bolts,screwsandfastenersshouldbe checked.

Refer tothe Torque Value Chart in"Section 12:

Appendix" startingon page 45.

• Turn on headlights to make sure battery has a charge

and electricallighting circuit is working.

• Step on the foot brake and hold down to make sure it

canbeappliedwith plenty of pedalmovementremaining

and thatthe brakes hold without loosingpressure. Add

brake fluidas indicated in "Brake Fluid" on page 34.

Bleed brakesif required.

• Check parkbrake tomake sureit will engage, hold and

release.

• Check steering by executing a full lock to lock turn in

each direction.

• Check neutral start feature by depressing the clutchand

starting the vehicle. (Thevehicle shouldnotstart unless

the clutchis depressed.)

• Check engine oil level at the dipstick. Add oil as

indicated in "EngineOil" on page 31if oil isator below

the addmark on the dipstick. Donot overfill or plug

fouling willoccur.

• Check differential oil level atthe differentialoil plug.Add

gear lub as indicated in"Differential Oil"on page 33 if

oil isbelow oil plug outlet.

• Check fuel level to make sure there is at least 1/8 ofa

tankof gas prior toperforming initialstarting operations.

• Allow engine to warms up for 15 minutes or more to

reach operatingtemperature before checking to make

sure engineidle speed is set at1100 +/- 100 rpm and

that maximumengine static speed does notexceed

3800 rpm.Modifying or adjusting the carburetor to

increase vehicle speed above factory set

specificationis a safety violation and could result in

voiding the warranty.

General Operation

Starting the Engine

Followstarting procedures displayedatthe gearshift lever

and asnoted below.

!

DANGER

Avoid injury or death from entanglement in the rotating

components and pinch points. All shields must be in place and

secure when operating. Keep all persons away from rotating

components and pinch points.

1. Set park brake.

2. Place gearshiftin neutral. Depress clutch pedal.

Engine willnot start with clutch pedal out.

3. Apply choke fully when engine is cold.

4. Turn ignition key fully clockwiseand hold until engine

starts.

5. Release ignitionkey to run position and choke to

normal operating position immediately after engine

starts.

6. Turn ignition key counterclockwise to stop engine.

Operating a Gondo is likeoperating acar with a standard

transmission that hasfouror five speeds forward and one

reverse.Thekeyed 12volt electronic ignition with a neutral

start and clutch depressed feature makes for safe and

easy starting.

Braking isaccomplished bysimply depressing the

automotive style brake pedal located onthe floorboard.

This activates bothfront and rear automotive type

hydraulic drum brakes. Depress clutch and brake pedals

when comingto a complete stop. A lever action parking

brakeismountedonthefloor board between operator and

passenger seats. Push the lever forward tothe horizontal

position toengage the park brake and pull back to the

vertical position to release.

Raise cargo boxby pulling backand holding onthe dump

lever. Push forward on the lever and hold tolower the

cargo box. Stopcargo box movement by releasingthe

lever.

!

DANGER

Make sure area behind cargo box is clear of personnel before

operating the dump lever. Bodily harm can result from being

pinched between the cargo box and another object or from a

load dumping and/or rolling onto a bystander.

Dashboard Switches and Instruments

Refer to Figure 4-1A and Figure 4-1B onpage 15

#1 Light Switch: Turns on two sealed beamhead lights

when the switch key is on.Presstop of lightswitchto

turn on lights and bottomof switchto turn offlights.

#2 Auxiliary Switch Slot: A12 volton/off accessory

switchmay be installedat thislocation to operatean

auxiliary accessory such as a power winch.

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

14

7/14/08

Page 17

Section 4: Operating Instructions

Table of Contents

#3 Choke Switch: Used to increase fuel mixtureto help

start the engine when it is cold. Pull choke knobout

and holdto start a cold engine. Release knob after

engine hasstarted. Do not choke an engine that is

hot fromoperating. Engine flooding may result. To

avoid running the battery down, allow a flooded

engine toset 15 to 30 minutesbefore attempting to

restart it. Hold theaccelerator pedal all thewaydown

without applying the choke while starting a flooded

engine.

#4 Hour Meter: Indicates number of hours vehicle has

run to the nearest 1/10of an hour.

1 2

3

Figure 4-1A

4

21438

the dipstick and oil light stays on after the engine is

running.

NOTE:It is normalfortheoillighttocomeonwhenthe

ignitionswitchis turnedonandstayonuntiltheengine

is running.

#8 Power Plug Outlet: 12 volt accessories such as a

cell phoneor light can be connectedto this outlet.

Foot Operated Controls

Refer to Figure 4-2

#9 Accelerator Pedal: Changesengine rpm and

vehicleground speed. Pressdownontheaccelerator

pedal withyour foot to increase speed and let up on

the pedalto decrease speed.

IMPORTANT: Vehicleshouldnotmoveonlevelground

while engine is idling and brakes are not applied. See

your nearest Land Pride dealer if vehicle mov es .

!

WARNING

Always release clutch pedal slowly when starting and changing

gears. Sudden release of the pedal can damagethe power train

and jerk the vehicle injuring the operator and/or passenger.

#5 Volt Meter: Indicates battery ischarging. Check

battery if volt meter registers a charge that is lower

than normal. See yourauthorized Land Pride dealer

if battery is good and volt meter still register low

charge.

#6 IgnitionSwitch:Startsandshutsofftheengine. The

engine isoff when the switch key is in its vertical

position. See "Starting the Engine" on page 14 for

correct starting procedures.

5

21342

#7 Oil Light: Indicates low oil pressure if illuminated

while engine is running. Stopengine immediately if

light ison. Check oil level and add if low. See your

authorized Land Pridedealer if oil levelshows full on

6

7

Figure 4-1B

8

10

Figure 4-2

#10 Clutch Pedal: Stops transferof engine powerto the

transmission withoutstopping the engine from

running. Always changegears while holding the

clutchpedaldown.The clutch and brakemustalways

be appliedwhen bringing thevehicle toa complete

stop. See #11, Brake Pedal for stopping the vehicle.

IMPORTANT: Alwa ys press clutch pedal fully do wn.

Resting your foot on clutch pedal can cause clutch

plates to slip and shorten their life.

9

11

21343

7/14/08

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

15

Page 18

Table of Contents

Section 4: Operating Instructions

!

DANGER

Sudden hard braking pressure can throw occupants forward

causing body injury and death. Whenever possible, apply

pressure to the brake pedal gently and increase presser slowly

until desired braking force is achieved.

#11 Brake Pedal: Slows vehicle speed quickly and stops

vehicle.Slow vehicle speed quickly byremovingyour

foot from the acceleratorpedal and then apply

pressure tothe brakepedal. Apply clutch and brake

pedal before comingto a complete stop.

NOTE: Do not rest foot on brake pedal while driving

vehicleexceptwhenslowingorstopping. Pressure on

the brake pedalwill shorten life expectancy ofbrake

liners.

Hand Operated Controls

Refer to Figure 4-3

#12 Park Brake Lever: The park brake lever is located

onthe floor boardrightof the operator and should be

set atall times the vehicle is not inoperation. Push

the lever forward tothe horizontalposition to set the

brake.Releasethebrakebypullingbackon the lever

to the verticalposition. Do notdrivevehiclewith park

brake on.

The knob on the end of the handle maybe turned to

make minor adjustments to the braking capabilities.

Major adjustments should be made at either end of

the brake cable.

#13 Dump Lever: Dump lever activatesthe hydraulic

cylinder to raiseand lower thecargo box. Push lever

forward to raise cargo box. Pull leverback tolower

cargo box.

#14 Auxiliary Lever: Auxiliary leveris used to operate a

hydraulic cylinder on a front mountedsnow blade or

to operateequipment pulled by the Gondo.

Additional accessories must be purchased to make

hydraulic connections.

gear only after reaching sufficientspeed andengine

RPM. Continueshifting up to the next higher gear

until highest gear is reached. Shift down one or two

gears ifloss of engine power is noticed.

Alwaysplacegearshift in first gearwhendescending

a steepgrade under load to make use of the

additional brakingforce provided by the engine.

Knob

12

14

13

21344

Figure 4-3

15

Fuel Indicator

Refer to Figure 4-4

#16 Fuel Gauge: The fuel gauge,located on the gas tank,

displays approximately how much fuel you have in

thefuel tank. Alwayspark the vehicle on levelground

to getan accurate reading. The fueltank is empty

whenthe fuel gauge needlepointstoE and full when

the needle points to F.

IMPORTANT: Release dump lev erimmediately when

cargo box is fully up or down to e xtend hydraulic seal

life and to prevent overheating.

#15 Gear Shift Lever: Changes transmission gears from

neutral to one of the four forward speeds or reverse.

Alwaysstart engine with gear shift in neutral. Follow

theshiftpatternontheshiftleverto find yourselected

gear.

Always start infirst gear when under load or on an

incline. You may start in second gear if on the level

withnoloadand no incline. Shift up to the next higher

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

16

16

21441

Figure 4-4

7/14/08

Page 19

Section 4: Operating Instructions

Table of Contents

Steering

Refer to Figure 4-5

Steering: The vehiclesteers by pivoting aboutthe center

swivelyoke with the aid of a hydraulic cylinder.

IMPORTANT: Become familiar with the steering

capabilitiesof the Gondo beforeputtingthe vehicleinto

service. Be certain to practice steering going forward

and backing up as it has a different feel than normal

front wheel steered vehicles.

Center Swivel

Yoke

Power Steering

Hydraulic Cylinder

21346

Figure 4-5

Driving Conditions

Terrains vary creating different driving situations. The

following are circumstances you might encounter and

suggestions onhow to operate the Gondo safely. Always

approach eachnew situation with extremecaution until

you have become experienced in handling your vehicle.

We recommend for your safetyand the safety of others

that you allowonly operatorsexperienced in driving a

standardtransmission,understand all potentialdangersof

operatingthisvehicle,has studiedthis manual, viewedthe

video safety tapesupplied with this vehicle and has

received actual hands-on instructions from an

experienced operator.

Sandy Terrain

Tires withhigh air pressure perform better in loose sand.

Also,stayin low gear to avoidspinningthewheels.Always

maintainvehiclecontrol,don’tmakesharpturnsandavoid

hard brakingwhen possible.

Muddy Terrain

Better tractionis achieved by accelerating the vehicle

slowly to avoid spinning the wheels. Making sharp turns

and hardbraking can cause the vehicle to skid out of

control. Letup on the accelerator pedal and stop when

skidding outof control.

Clean off mud residue stuck to rotatingdriveshafts and to

the tiresas quickly as possible.Mud clinging to rotating

parts causes and imbalance that can damage vehicle

components.Alsocleanthebrakedrums of mud to reduce

premature brake wear.

Watery Terrain

Always determine the depth of water before driving

through it.Do not drive through water that ishigher than

the bottomof the floor board. Always enter the water

slowly and continue traveling slowly through the water to

minimizesplashing. The vehiclecould stall iftheelectrical

system getswet. Never allow water to get uparound the

engine.A wet engine is likelyto stallor becomedamaged.

Test the brakes for stoppingcapabilities oncethrough the

water.Allow the brakestodry beforeproceedingif braking

capabilities arereduced. Brakescan be dried faster by

driving the vehicleslowly on a levelsurfacewhile applying

light pressureto the brake pedal.

Snowy and icy Terrain

Like muddy terrain, accelerate the vehicle slowlyto avoid

spinning thewheels. Avoid making sharp turns andhard

braking. Letup on the accelerator pedal and stopwhen

skidding outof control. Always maintaina steady slow

speed allowing time to slow down and stop. Remember

slicksurfacesrequiremore time toslow down, make turns

and stops.

Uneven Terrain

The Gondo’s centerarticulating steering enables the four

driving wheels to maintain contact in various uneven

terrainsituations.Becauseof this, the vehicleiscapableof

maneuvering over rough surfaces, up and down steep

inclines. Avoid operatingon excessively steep hills and

especially onhills that are steeper than15 degrees.

Climbing Steep Hills

Alwaysapproach a steep hill straight on in 1st(lowgear)to

reduce enginestrain and minimize stalling. Continue

straightupthe hill in low gear moving rightorleftonly to go

around obstacles. Do not attempt to turn the vehicle

around during a steep climb. If thevehiclestalls or should

youdecide to stopthe climb,place vehicle inreverse gear

andbackdownthe hill slowly and as straight aspossibleto

a safe location. If needed,apply the brakes very lightly to

assist slowing downvehicle’sdescent. Hard braking can

cause totalloss of control and arollover situation. Don’t

depress theclutch while backing down except when

bringing the vehicle to a complete stop.

Maximum traction and control is achieved whiletraveling

upa steep incline in1st gearat thelowest possible speed.

Also traveling slowly allows more time to correct a

dangerous situation.

7/14/08

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

17

Page 20

Section 4: Operating Instructions

Table of Contents

Descending Steep Hills

!

WARNING

Do not descend a steep hill with rear cargo box removed.

Dangerous forward weight distribution is created.

Descend mosthills straight down in 1st gear.When

necessary, use steady pressure on the brakes without

locking them up. Hard braking can cause total loss of

control anda rollover situation.

Always consider ground conditions and load distributions

as outlinedbelow before descending a steep hill:

• Is the ground surface wet or dry? Wet surfaces can

result inloss of control and shouldnot be attempted.

• Is the groundsurface firmorloose? Loose surfaces can

result inloss of control and shouldnot be attempted.

• Is theterrain fairly even or is it eroded and uneven with

holes andboulders? Surfaces that are notfairly even

canresult in loss of controland shouldnot be attempted.

• Can the descent be made fairly straight or will you be

required toturn to a degree thatis approaching crosshill travelmaking the vehicle subject toimbalance and

turning over.

• Consider the vehicle’s center ofgravity. Isit frontheavy,

loaded highwith cargo and is therea passenger along

adding weight over the frontaxle? The rear axle should

have sufficientweight overit tocounter balanceweight

distributedoverthefrontaxle.A vehicle with poor center

of gravityis subject to flipping forwardend over end.

• Is the vehicle approaching maximum load rating

capacity. Is thevehicletotal loaded weightapproaching

maximum ratedgross weight? Too much weightcan

reduce operator’sability to brake and controlthe

vehicle.

• Is the vehicle towing a trailer and if so is the trailer

carryingaloadapproachinggrossweightoftheGondo?

Again,toomuchtrailer weight can reduce the operator’s

ability tobrake and control the vehicle.

Traverse Traveling on Steep Hills

Cross asteep slope only if noother alternative exists.

When crossing,consider ground conditions and load

distributions outlined in "DescendingSteep Hills" onpage

18. Make certain thatthe weighton the uphill side ofthe

vehicle is equal toor heavierthan the weight on the

downhill side of the vehicle. Crossin 1st gear and if your

vehicle starts to tip over,turn the vehicle down hillquickly

to regainstability and control.

Pulling Loads

The Gondois capable of pulling a load weighing many

times morethan its own weight. Because of thisit is

important thatyouknowthevehicle’scapabilityandhow to

operateitinawaythat willnotdamagethevehicleorinjure

yourself or others. Always consider the following:

• Does the loadexceed therecommendtowingcapacity?

Too muchweight will push the vehiclearound and

hinder itsstopping capabilities.

• Is the load front heavy placing too much weight on the

hitch?Excessive hitch weight will makethe front wheels

light onthe ground causing you toloose steering and

traction capabilities.

• What type ofterrainis the loadbeingpulled over? Isthe

groundsoft,wet,dry or inclined. Any of these can hinder

vehicle control.See "Descending Steep Hills" onpage

18 whenconsidering type of terrain.

When towing always start in1st gear and shift toa higher

gear onlyif thevehicle hassufficient power. Do not travel

ina gear that cannotcontrolthe load. Heavy loads should

be towed in1st or 2nd gear dependingon their ability to

hold theload backfrom pushing the vehicle when letting

up onthe accelerator pedal. Remember, the heavier the

load thelonger it takes forthe brakesto stop the vehicle.

Towing the Gondo

The Gondoshould be loaded on atrailer for towing.

However, it can be towed behind a tractor or another

vehicle for a short distanceto retrieve it from an area

where atrailer won’tgo.

IMPORTANT: Owner assumes all responsibility and

liability resulting from towing the Gondo.

IMPORTANT: Donot tow the Gondo atspeeds o ver 5

mph. Higher speeds may result in loss of control and

damage to the Gondo, vehicle towing the Gondo and

personnel.

Towing Without a Trailer

Thefollowingprecautions shouldbe followedwhentowing

the Gondobehind a tractor or another vehicle:

• Approved tow chain or rope must besecurely attached

to theGondo at a location thatwill not damage the

vehicle orcome loose from the vehicle.

• The gear selector must be placed in neutral position.

• The park brake must be off.

• Someone must be steering the vehicle while it is being

towed forit to track properly.

• Whenpossible, the engine should be running to operate

thepowersteering.Ifthe engine will not run,thesteering

will bevery heavy and will eventuallyquit as oil is bled

from itssteering sector.

• Do nottow the Gondo at speedsover 5 mph.Higher

speeds mayresult inloss of control and damage to the

Gondo, vehicletowing the Gondo and personnel.

• Donottowanothertrailerorvehiclebehind a Gondo that

is beingtowed.

• Do not tow the Gondo on roadways or across open

areas accessible witha trailer. Instead,load the vehicle

onto atrailer for towing.

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

18

7/14/08

Page 21

Section 4: Operating Instructions

Table of Contents

Towing Loaded on a Trailer

The Gondomay bedriven or winched onto a trailer.The

following precautions should be followedwhen loading

and towing the Gondo on a trailer:

• Always make certain loading ramps are capable of

supporting the Gondo’s weight, properly spaced forthe

Gondo wheels and secured tothe trailerbefore loading

the Gondo.

• Twopeopleshouldbepresentwhenloadingthevehicle.

One stands clearofthe Gondo ashe guides thevehicle

up theramps and onto the trailer.The other sits in the

Gondo andsteers the vehicle as itis being loaded.

• Drive or winch vehicle onto the trailer slowly to prevent

accidents.

• Once loaded, turnthe switchkeyoff, set parkbrake and

place transmissionin 1st gear.

• Properly secure the vehicleat itsfour cornersto thefour

corners ofthe trailer with tie downchains or other

approved tiedowns. Tie downs must bedesigned to

withstand forces inducedintothem during acceleration,

making turnsand applying brakes.

• Always tow at a speed where the driver is in control of

his vehicleat all times.

• Always allow enough traveling distance to slow down

and stop.The Gondo’s added weight tothe trailer will

require additionaltime and distance to slowdown.

• Slow down when turning to prevent loss of control and

rollovers.

• Do not allowanyone to ridein the Gondowhile towing it

on atrailer.

• Obey all state and local laws for towing. Traveling Tips From the Trail Masters

At LandPride we want you to get maximum working and

recreational enjoyment outof yourutility vehiclewhether

you are using oneof our All-Terrain Runaboutsor one of

our terrainhugging Gondo utility trucks. If your work

projectorrecreationaladventureis going to takeyouonan

extended ride deep into the wilderness orway out on the

prairie, you’ll needto seriously consider some ofthe

following tips from experienced pros about safety, gear,

clothing, suppliesand driving techniques.

Preparation and Planning

Do acomplete equipment check as follows:

1. Make sure youhaveplenty of fuel and oilto make the

trip and then some.

2. Make sure your tires have proper inflation, your lug

bolts are tightandthat you havea spare andthetools

to change, repairand inflate atire. Consider addinga

puncture sealantto your tires as a preventative

measure.

3. Check for any loose or missing parts and definitely

makethose needed repairsbeforegoinganywhere.It

is especiallyimportant that you checksteering,

braking, throttle, electrical and engine components

thoroughly.

Plan Your Route

1. Plan your route,destination and rendezvous points

before starting out.

2. Don’t goit alone if at allpossible. Takingsomeone

elsealongreducesthepotentialforloss of lifeormajor

injury to inclement weather,animal attacks, or

accidents. Besides, it’smore fun when you have

someone toshare the adventure with.

3. Obtain trailor area maps of your travel routes to and

from your destination. Communicate your travelplans

to responsible friends and or proper authorities. Plan

rendezvous points at conspicuouslandmarks along

yourroutejustincaseyourunintounexpectedtrouble

on thetrail.

4. Make sure you take a weather radio andtwo-way

communication devices such as cell phones or long

range-two way radios. It is also good to have ground

flares, a flare gun, a smoke canister, emergency

strobe light,a reflecting mirror, matchesfor asignal

fire anda compass.

Plan Your Gear

1. Check the shortand longrangeweather forecast and

take protective gear and clothing tocover all

contingencies. It doesn’t have to snow for you tofall

victim tohypothermia or exposure. Take or wear

appropriate eye and headprotection, gloves, boots, a

long sleeve shirt, longpants, a jacket, rain gear, dry

socks and a fullchange of dry clothing.

2. Plan your gear and gear up for the best and worst of

environmental conditions.

3. Packa first aid kit, sunblocker, lip balm, water, insect

repellent, personal medications, tarp or tent, flash

light, survival knife, binoculars, camera, tool kit, rope,

duct tape, tow strap, winch or come-along, eating,

utensils, cooking utensils and high energy trail food.

4. Tie and lash down your gear and supplies securely.

Keepthe bulk of the weight centered and mounted as

low as possible on the vehicle in order to maintain a

lowcenter of gravityforsafeand stable off-road travel.

Going Out on the Trail

1. Take it all in when hitting the trail but do it safely!

2. Make sure you brief your passenger on proper safety

procedures like keeping hands, arms, feet and other

bodily appendages inside the vehicle. Passengers

shouldonly be transportedinfactory supplied seating.

3. Operator and passenger are responsible for deciding

if their situation warrants using Seat Belts.

7/14/08

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

19

Page 22

Section 4: Operating Instructions

Table of Contents

4. Avoidoperating on excessively steep hills and

especially on hills that are steeper than 15 degrees.

Avoidcrossing slopes if possible and don’t make

sharp uphill steering corrections or a rollover could

result. If your vehicle starts to tip over on a slope turn

the front wheels quickly down hill to regain stability

andcontrol.The best waytoclimbmost hills is to drive

straight up while maintaining a steady ground speed

and constant engine rpm. The best way to descend

mosthillsisstraightdownwhile using steady pressure

on the brakes without locking them up. Locking up the

brakes in a steep downhill situation can result in loss

oftraction,steering and control. When you must cross

a slope on soft terrain, keep the front wheels turned

slightly uphill and maintain a constant speed and a

straight line of travel.

5. Driving too fast, being inattentive and turning too

sharplyonslipperysurfacescanresultin rolloversand

accidents almost quicker than any other ground

condition we know of. Snow cover, wet trails, loose

graveland frozen ground can all contribute to this

dangerous condition. In these conditions maintain

sharpfocusonthetrailahead. Don’t make sharp turns

and avoid the need for hard braking if at all possible.

Slow down and stop If you do start to slide.

6. Avoidpaved surfaces. Land Pride vehicles are

designed exclusively for off-road use only.We

understand that occasionally operators have to cross

publicroads or right of ways to gain access to work or

recreationsites,butdon’tgetinthewayof fastertraffic

and cross quickly and safely.

7. The Gondo is capable of crossing intermittent

streams where the depth of the water briefly comes

intocontactwiththebottomofthefloorboards,butyou

must keep these considerations in mind; You must

know how deep the water is and the strength of the

current. Cross where you have a gradual incline for

entry and exit and the bottomis fairly clean and free of

obstacles. Maintain a slow steady speed disturbing

the stream bed as little as possible. If you submerge

the engine, you will lose forward momentum and

power. If you submerge the engine or the whole

vehicle,donotattempttostart the vehiclebuttakeit to

your nearest dealer immediately. After intermittent

stream or shallow water crossings, dry out the brake

linings by slightly accelerating the engine rpm while

riding the brakes momentarily until full drive power

and braking are restored.

8. Backing up in an off-road situation might seem a

simplethingtodotoanovice,buthavingto back down

a hill is a very dangerous situation. If you are on level

ground always look behind you and back up slowly.If

you find yourself having to back down a hill, apply the

brakes very lightly. Hard braking can cause total loss

of control and a rollover situation. Try to back straight

down the hill without turning. Turning in this situation

can also cause a rollover.

9. Wheneverpossible, park your vehicle on a level

surface with the transmission in gear, set the park

brakeand remove the key. If you do have to park on a

hillside make to sure chock the rear wheels on the

downhill side to prevent a roll away. It’s a good idea to

keep your spare key stashed separately.

10. Never operate a vehicle under the influence of drugs

or alcohol. When you’re driving off-road vehicles you

need to keep your senses keen and capable of quick

reaction, sharp perception and good balance.

11. Workingorrecreationinthedeepwilderness or on the

prairies can be personally rewarding and very

enjoyable to those who truly love and understand

nature and the outdoors. Good judgement, maturity,

proper preparation and planning can turn these

adventuresinto great experiencesyou’ll talk about for

a lifetime. Share these adventures with young people

wheneveryou can and show them how to do it

properly. Don’t let anyone under 16 operate this

vehicle. They just aren’t mature and experienced

enough to take on the serious responsibility of

operating a vehicle in the off-road environment

without the benefit of an experienced adult with them.

Remember, the only one who can prevent and avoid

an accident is the operator in control and that’s you!

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

20

7/14/08

Page 23

Section 5: Options and Accessories

Section 5: Options and Accessories

Table of Contents

Gondo Options

There are several options Land Pride offers when

selecting your Gondo.

Rear Cargo Box

There are two styles of rear cargo boxesavailablefor you

Land Pride Gondo.

• Gondo style dump bed without tail gate

• Cargo style dump bed with tail gate

Tires

Refer to figure 5-1

There are two types of tires available for your Land Pride

Gondo.See figure 5-1. Both are 4-ply rated. The Bar Tire

withitschevronbarsisa good tire to choose when traction

is your first priority.This tire is a tough tire for going over

rough terrain. The Turf Tire is a good selection when one

wants to preserve the terrain being traveled over. Golf

courses, parks and other maintained areas make the Turf

Tire an excellent choice.

Gondo Accessories

A variety of accessory equipment has been designed to

complement your needs and make your Land Pride

Gondo a very functional and useful vehicle. See your

nearest Land Pride Dealer for all accessories available.

Accessories available are:

• Grab light

• Rear receiver type hitch

• Hydraulic bed lift

• Pup trailer with lug tires (without cargo box)

• CertifiedROPSwithseatbelts(ifnot originally equipped

with ROPS)

• Cab enclosure with soft doors and windshield wiper

• Front snow blade

• Log skidder

• Cold weather engine kit (Prevents carburetor icing)

7/14/08

Bar Tire

figure 5-1

Turf Tire

21387

4400EX Heavy Duty Off Road Utility Vehicle 720-051M

21

Page 24

Table of Contents

Section 6: Maintenance

Section 6: Maintenance

General Maintenance

!

WARNING

Read and observe all safety warnings in this manual and in the

engine service manual.

!

WARNING

Except when checking or changing components, always keep

protective shields on for safety as well as for cleanliness.

!

WARNING

Keep engine clean of oil, grease, trash and debris which can

cause engine overheating, fires and belt wear. Clean only after

the engine has completely cooled. Weargloves to protect hands

from cuts, puncture wounds and burns.

!

WARNING

DO NOT have engine running when servicing or making

adjustments to the vehicle. Shut engine off, place transmission

in gear, set park brake and remove ignition switch key for

maximum safety.

!

DANGER

Repairs or maintenance specifically requiring engine power

should be performed by trained personnel only. Transmission

gearshouldbesetinneutralwithtiresproperly chockedor with

drive tires properly supported off the floor. Enclosed areas

should be properly ventilated to prevent carbon monoxide

poisoning.

Some repairs require the assistance of a trained service

mechanic and should not be attempted by unskilled

personnel. Consult your Land Pride dealer when

assistance is needed.

Prepare V ehicle for Maintenance

Before servicing the vehicle the following procedure must

be followed to secure the vehicle:

1. Park vehicle on a level surface. Don’t work under or

around a vehicle parked on a steep incline.

2. Place gear selector in 1st or reverse.

3. Set park brake.